Page 1

Service

Top Load Washer

This Base Manual covers

new double front panel series,

Top Load Wash Machines.

Refer to individual Technical Sheet

for specific information on models.

Service Manual for

Amana

®

This manual is to be used by qualified appliance

technicians only. Amana does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

RS3100007

Revision 0

October 1999

Page 2

Table of Contents

Important Information ................................................... 3

Important Safety Information ........................................ 4

General Information

Proper Grounding and Polarization of

120 Volts Wall Outlets............................................ 5

Grounding Instructions.............................................. 5

General Operation Definition..................................... 6

Component Testing Information ................................... 7

Internal Motor Diagram and Schematic........................ 9

Troubleshooting Procedures

No hot water............................................................ 12

No cold water . ......................................................... 12

No warm water ........................................................ 12

Water fill does not stop at proper level.................... 13

Timer does not advance.......................................... 1 3

Motor does not operate. .......................................... 13

Washer smokes, overheats, and cycles on

protector or switch actuator kicks in and out........ 14

No agitation............................................................. 14

Constant agitation. .................................................. 14

Slow spin or no spin. ............................................... 15

Constant spin. ......................................................... 15

Washer stops in middle of cycle or quits after

a couple loads–intermittent. ................................. 15

Washer locks-up or binding. ................................... 16

Outer tub does not empty. ....................................... 16

Excessive vibration. ................................................ 16

Water leaking from outer tub................................... 16

Disassembly Procedures

Control Hood Assembly .......................................... 17

Control Hood End Panels........................................ 17

Electronic Control.................................................... 17

Timer....................................................................... 17

Temperature and Speed Switch .............................. 18

Pressure Switch ...................................................... 19

Rocker Switch ......................................................... 19

Graphic Panel ......................................................... 19

Loading Door .......................................................... 19

Agitator.................................................................... 20

Agitator, Drive Bell and Seal Assembly................... 20

Installing Drive Bell.................................................. 21

Service Access Panel ............................................. 22

Front Panel ............................................................. 22

Motor and Mounting Bracket ................................... 22

Pump and Belt Removal ......................................... 23

Reassembly of Pump and Belt................................ 23

Motor Disassembly ................................................. 24

Idler lever and Pulley............................................... 24

Motor Drive Belt ...................................................... 24

Motor Switch ........................................................... 24

Cabinet Top ............................................................. 25

Door Switch............................................................. 25

Mixing V alve............................................................ 25

Tub Cover and Gasket............................................ 26

Washtub and Balance Ring..................................... 26

Outer Tub................................................................ 26

Drive Pulley , Helix and Brake.................................. 27

Weldment and Bearing Assembly........................... 28

Transmission Assembly .......................................... 29

Upper Bearing Assembly ........................................ 29

Friction Ring ............................................................ 29

Appendix A

Installation Instructions (New Graphics).................A-2

Appendix B

Owner's Manual (New Graphics) ...........................B-2

Appendix C

Owner's Manual (Old Graphics).............................C-2

Amana Appliances Inc. • 2800 220thTrail • Amana, Iowa • 52204 • Printed in the U.S.A.

RS3100007 Rev . 0 2

Page 3

!

!

!

!

!

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a qualified

service technician who is familiar with the safety procedures required in the repair and who is equipped with the

proper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION

IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Notices for Consumers and Servicers

WARNING

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personnel, dangerous

conditions (such as exposure to electrical shock) may result.

CAUTION

Amana will not be responsible for any injury or property damage from improper service procedures. If performing

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER AFFAIRS DEPT. OR 1-319-622-5511 or (1-800-843-0304)

AMANA APPLIANCES, INC. CALL and ask for

AMANA, IOWA 52204 Consumer Affairs

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WA R N IN G

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION - Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

3 RS3100007 Rev . 0

Page 4

!

Important Safety Information

WARNING

To reduce the risk of fire, electric shock, serious injury

or death to persons when using your washer , follow

these basic precautions:

• Read all instructions before using the washer.

• Refer to the Grounding Instructions in the

Installation Manual for the proper grounding of the

washer.

• Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other flammable

or explosive substances as they give off vapors that

could ignite or explode.

• Do not add gasoline, dry-cleaning solvents, or other

flammable or explosive substances to the wash

water. These substances give off vapors that could

ignite or explode.

• Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. Hydrogen gas is

explosive. If the hot water system has not been

used for such a period, before using a washing

machine or combination washer-dryer, turn on all

hot water faucets and let the water flow from each

for several minutes. This will release any

accumulated hydrogen gas. The gas is flammable,

do not smoke or use an open flame during this time.

• Do not allow children to play on or in the washer.

Close supervision of children is necessary when the

washer is used near children. This is a safety rule

for all appliances.

• Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

• Do not reach into the washer if the wash tub is

moving.

• Do not install or store the washer where it will be

exposed to water and/or weather.

• Do not tamper with the controls.

• Do not repair or replace any part of the washer , or

attempt any servicing unless specifically

recommended in the User-Maintenance instructions

or in published user-repair instructions that you

understand and have the skills to carry out.

• To reduce the risk of an electric shock or fire, do not

use an extension cord or an adapter to connect the

washer to the electrical power source.

• Use your washer only for its intended purpose,

washing clothes.

• Always disconnect the washer from electrical supply

before attempting any service. Disconnect the

power cord by grasping the plug, not the cord.

• Install the washer according to the Installation

Instructions. All connections for water, drain,

electrical power and grounding must comply with

local codes and be made by licensed personnel

when required. Do not do it yourself unless you

know how!

• To reduce the risk of fire, clothes which have traces

of any flammable substances such as vegetable oil,

cooking oil, machine oil, flammable chemicals,

thinner , etc. or anything containing wax or chemicals

such as in mops and cleaning cloths, must not be

put into the washer . These flammable substances

may cause the fabric to catch on fire by itself.

• Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of

the fabric softener or product.

• Keep your washer in good condition. Bumping or

dropping the washer can damage safety features. If

this occurs, have your washer checked by a

qualified service person.

• Replace worn power cords and/or loose plugs.

• Be sure water connections have a shut-off valve and

that fill hose connections are tight. Close the shut-off

valves at the end of each wash day.

• Loading door must be closed any time the washer is

in operational fill, tumble, or spin. Do not attempt to

bypass the loading door switch by permitting the

washer to operate with the loading door open.

• Always read and follow manufacturer’s instructions

on packages of laundry and cleaning aids. Heed all

warnings or precautions. To reduce the risk of

poisoning or chemical burns, keep them out of the

reach of children at all times (preferably in a locked

cabinet).

• Always follow the fabric care instructions supplied by

the garment manufacturer .

• Never operate the washer with any guards and/or

panels removed.

• Do not operate the washer with missing or broken

parts.

• Do not bypass any safety devices.

• Failure to install, maintain, and/or operate this

washer according to the manufacturer’s instructions

may result in conditions which can produce bodily

injury and/or property damage.

NOTE: The Warning and Important Safety Instructions

appearing in this manual are not meant to cover

all possible conditions and situations that may

occur. Common sense, caution and care must

be exercised when installing, maintaining, or

operating the washer.

Always contact your dealer, distributor, service agent or

the manufacturer about any problems or conditions you

do not understand.

RS3100007 Rev . 0 4

Page 5

!

General Information

Model Identification

Thank you for purchasing this washer. Please read

these Installation Instructions thoroughly . This manual

provides proper maintenance information. Any

questions, call the Consumer Affairs Department at

1-800-843-0304 inside U.S.A. and 1-319-622-551 1

outside the U.S.A.

Complete registration card and promptly return. If

registration card is missing, call the Consumer Affairs

Department. Appliance can also be registered through

out website www.amana.com.

When contacting Amana Appliances, provide product

information. Product information is on the serial plate.

Record the following information.

Model Number: ___________________

Manufacturing Number: ___________________

S/N or Serial Number: ___________________

Date of Purchase: ___________________

Dealer's name and address: ___________________

___________________________________________

NOTE: Translation may sometimes cause variations in

meaning. In all cases where meaning varies, the

most accurate meaning will be the English

version of this document.

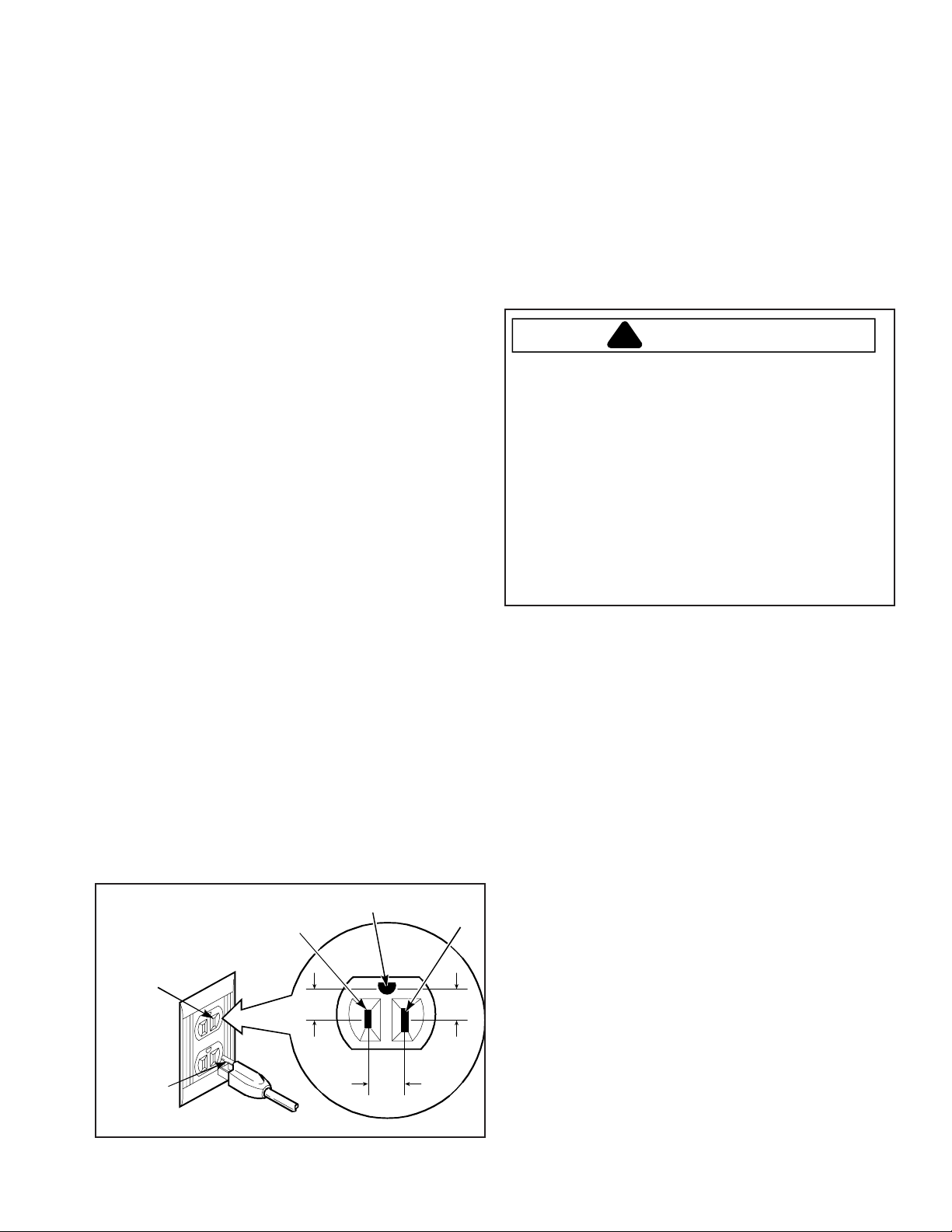

Proper Grounding and Polarization of

120 Volts Wall Outlets

For the safety of our customers and the service

technician ALL appliances have a three–prong power

cord and MUST be connected to a properly polarized

AND grounded wall outlet.

This information was written for those who do not

understand grounding and polarization of a wall outlet.

A 120 volt wall outlet must always be wired as shown

below.

Ground

L1

Neutral

Explanation

Polarization–This means that the larger slot must be

neutral and the small slot must be hot (live).

Mispolarized–The outlet is miswired so that the larger slot

is hot (live) and the smaller slot is neutral.

Grounded–This means the round hole connection is connected to earth ground through a connection to the main

power panel.

Ungrounded–The round hole connection is not complete

to earth ground and/or the main power panel.

Grounding Instructions

WARNING

• To avoid the risk of electrical shock or death, do

not alter the plug.

• Do not remove grounding prong when installing

grounded appliance in a home that does not have

three wire grounding receptacle. Under no

condition is grounding prong to be cut off or

removed. It is the personal responsibility of the

consumer to contact a qualified electrician and

have properly grounded three prong wall

receptacle installed in accordance with

appropriate electrical codes

• To avoid the risk of electrical shock or death, this

equipment must be grounded.

This equipment MUST be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the

electric current. This unit is equipped with a cord having

a grounding wire with a grounding plug. The plug must

be plugged into an outlet that is properly installed and

grounded.

Consult a qualified electrician or servicer if grounding

instructions are not completely understood, or if doubt

exists as to whether the equipment is properly

grounded.

Do not use an extension cord. If the product power cord

is too short, have a qualified electrician install a threeslot receptacle. This unit should be plugged into a

separate 60 hertz circuit with the electrical rating as

shown in the appropriate drawing. Models operate with a

120 supply voltage.

Neutral

side

Round

grounding

115±12

V.A.C.

115±12

V.A.C.

0

V.A.C.

prong

5 RS3100007 Rev. 0

Page 6

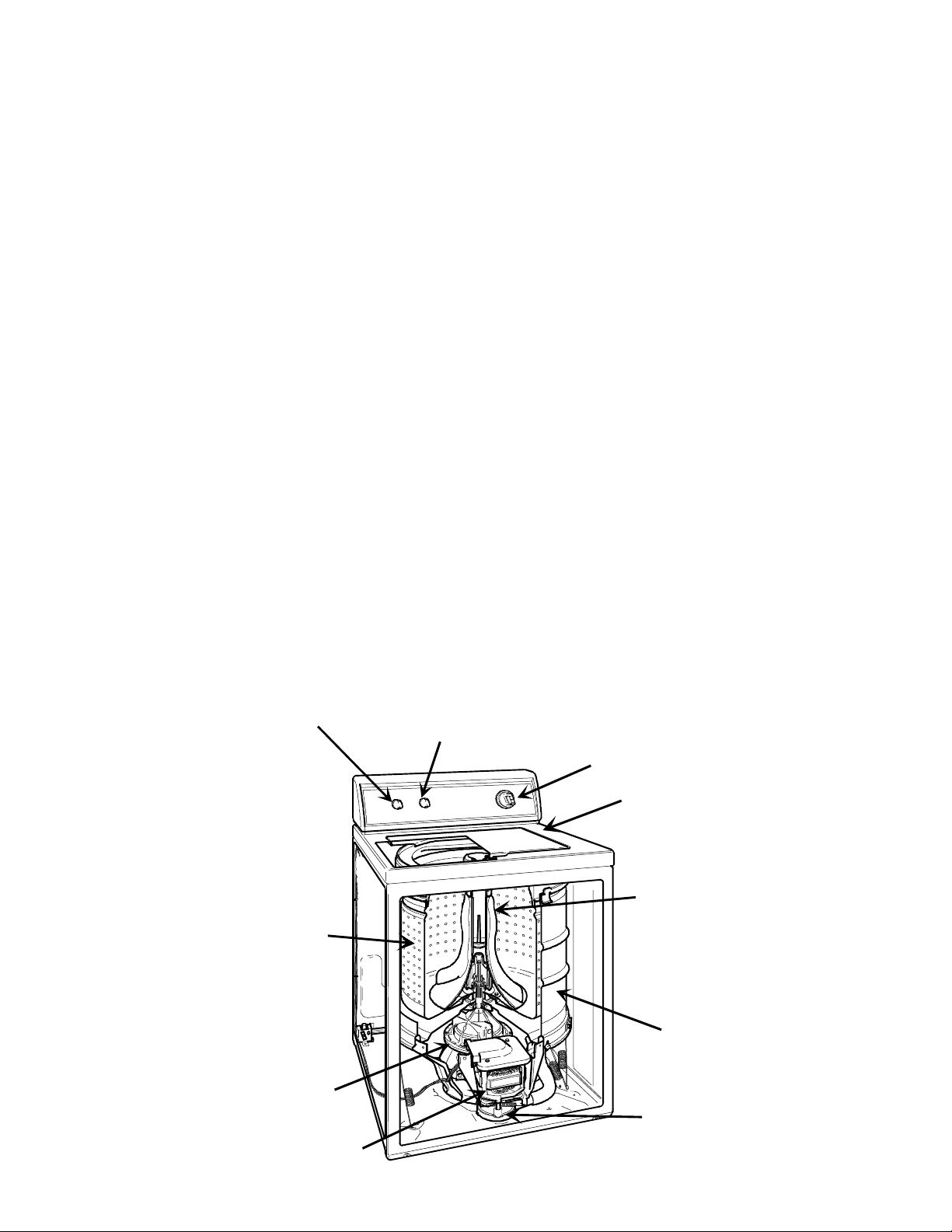

General Information

General Operation Definition

The cycle begins with a wash fill. The water temperature

is determined by the temperature selector. While water

fills the washtub, a column of air is trapped in the

pressure bulb and hose. Air pressure continues to

increase as the washtub fills with water until the

pressure is enough to activate the pressure switch.

Pressure switch then causes the wash fill to stop and

agitation to begin. However, the loading door must be

closed for the washer to agitate or spin.

The washer uses a reversing type motor, a special drive

belt and an idler assembly . Idler assembly applies

tension to the outside of the drive belt.

During agitation, the motor runs in a counterclockwise

direction. The spring tension on the idler pulley applies

tension required to reduce the slack on the drive belt

and maintain maximum belt to motor pulley contact.

This eliminates belt slippage and ensures an efficient

wash action, even with extra large loads.

The belt drives the transmission drive pulley in a

counterclockwise direction. The pulley drives the helix

which is attached to the input shaft of the transmission.

This causes the input shaft to turn inside of a roller

clutch which is pressed into the transmission cover.

This roller clutch acts as a bearing in a counterclockwise

direction allowing the transmission gears to operate.

The transmission’s rack and pinion gear design

produces a 210° agitation stroke at the output shaft of

the transmission which drives the agitator. The brake

assembly remains locked during the agitation mode

since no pressure is applied to it by the transmission

drive pulley .

Temperature

switch

Pressure

switch

After the wash agitation is completed, the timer

advances into the first spin. During spin, the motor

reverses turning in a clockwise direction to spin the

water out of the washtub. The combination of water,

washtub and load weight cause the drive belt tension on

the idler side of the belt to overtake the idler spring

pressure allowing the belt to slack on the opposite side.

This reduces the belt to pulley contact and allows

slipping between the belt and pulley .

As water is removed by the direct drive pump and the

momentum of the washtub increases, the idler spring

tension gradually overcomes the belt tension removing

the belt slack. This eventually increases the belt to

pulley contact until maximum spin speed is achieved.

The drive pulley turns clockwise riding up the ramps of

the helix, exerting pressure on the brake and forcing it to

release from brake pads. The helix drives the input shaft

of the transmission, and when the input shaft turns in a

clockwise direction the roller clutch locks onto the shaft

causing the entire transmission assembly to turn. None

of the gears in the transmission are operating at this

time. The hub of the washtub is attached to the

transmission tube and rotates with the transmission

assembly . The centrifugal force created by the spinning

washtub causes water to be extracted from the clothes.

Water is introduced during the first spin to “SPRAY” the

garments and remove suds from them. The initial spin is

followed by rinse agitation to rinse away any detergent

residue. The washer fills and then agitates like the wash

portion of the cycle. Following rinse agitation, a final spin

extracts the rinse water from the clothes preparing them

for the dryer .

Washtub

Transmission

Motor

RS3100007 Rev . 0 6

Timer

Mixing

valve

Agitator

Plastic

outer

tub

Pump

Page 7

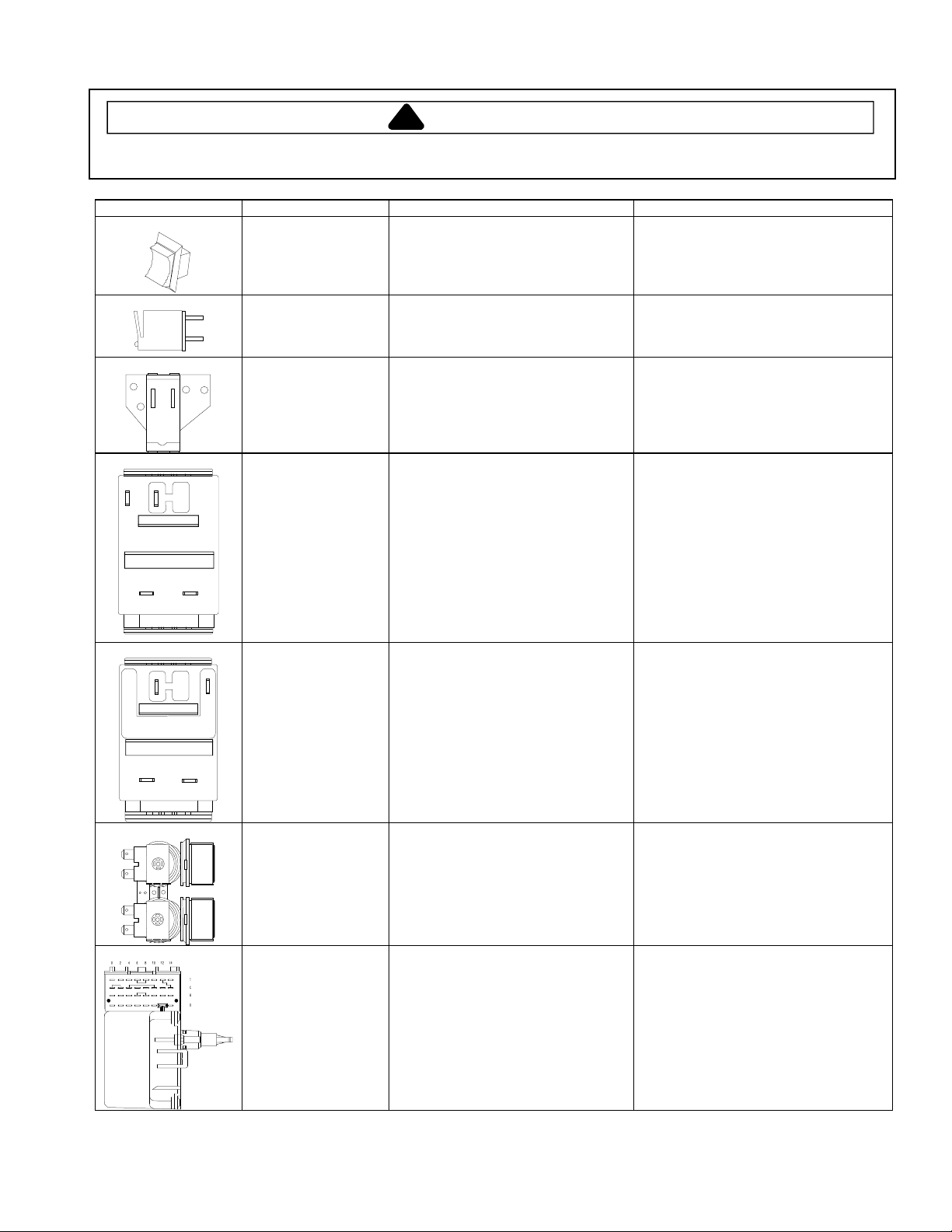

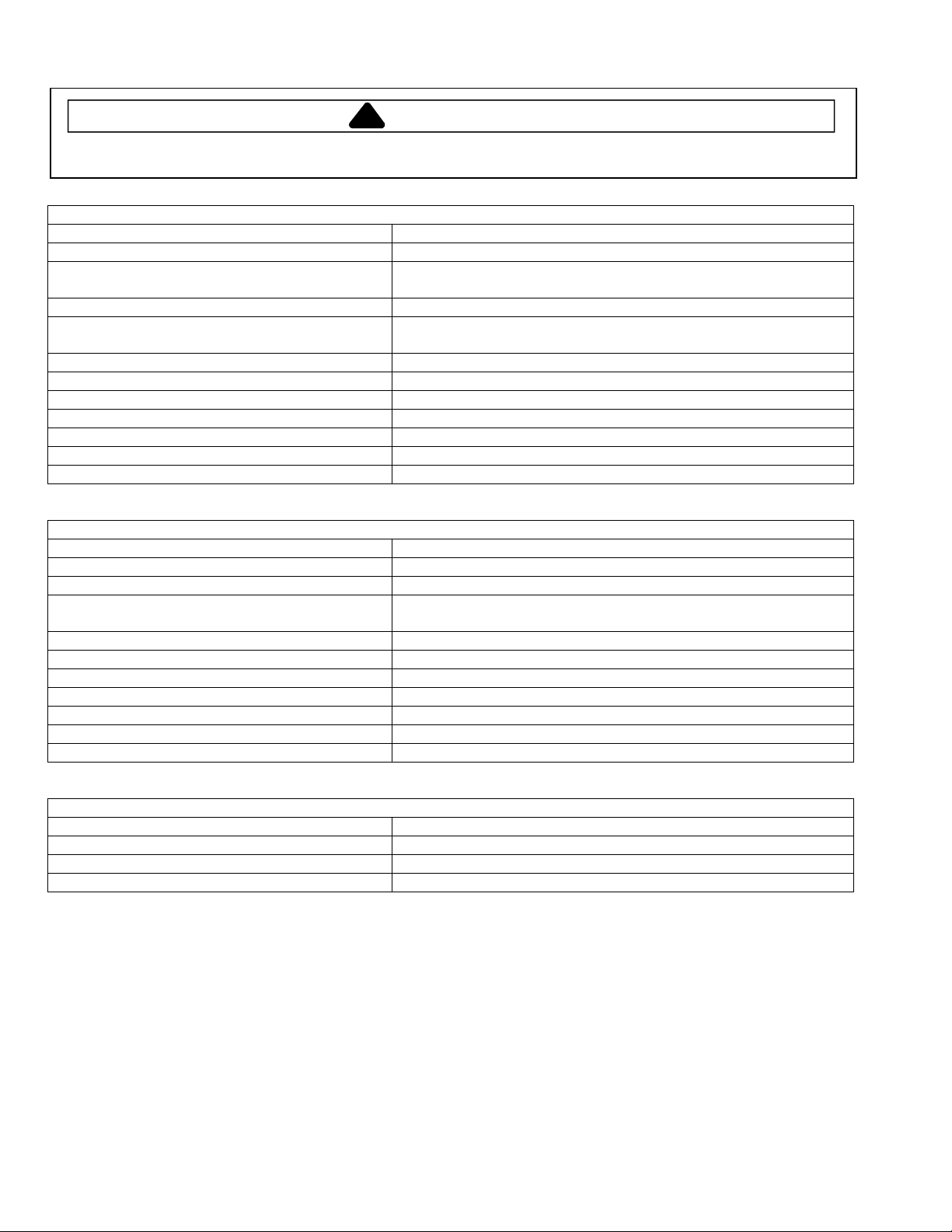

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Illustration Component Test Procedure Results

Rocker switch

(Extra Rinse)

Measure resistance of switch

positions:

Closed (ON position)

Open (OFF position)

Continuity >1

Infinite 1 M

Ω

Ω

Indicator light Measure voltage at indicator light. If line voltage is present and light does

Signal switch Measure resistance of the switch

Temperature switch Disconnect wires from component to

2

1

L2

L1

Speed switch Disconnect wires from component to

2

C

turned to LOUD position.

properly measure the resistance of the

component.

Place switch in the following positions

and measure across the terminals

below:

Hot / Cold L1-2

Warm / Warm L1-1, L1-2, L2-2

Warm / Cold L1-1, L1-2, 1-2

Cold / Cold L1-1

properly measure the resistance of the

component.

Place switch in the following positions

and measure across the terminals

shown below:

L2-1, L2-L1, 1-2

not work replace light.

If no voltage is present at indicator light

check wiring.

Nominal 1155 Ω ± 5%

>1

Ω

>1

Ω

>1

Ω

>1

Ω

L1

L2

Reg / Fast L1-C, L2-C

Reg /Slow L1-C, L2-2

Gentle / Fast L1-2, L2-C

Gentle / Slow L1-2, L2-2

Mixing valve Measure resistance of terminals on

each valve.

Resistance across each valve.

Timer Verify input and output voltage is

present.

>1

Ω

>1

Ω

>1

Ω

>1

Ω

Approximately 1000 Ω ± 10%

Refer to specific model Technical Sheet

for timing sequence chart and functional

description of the component.

RS3100007 Rev. 07

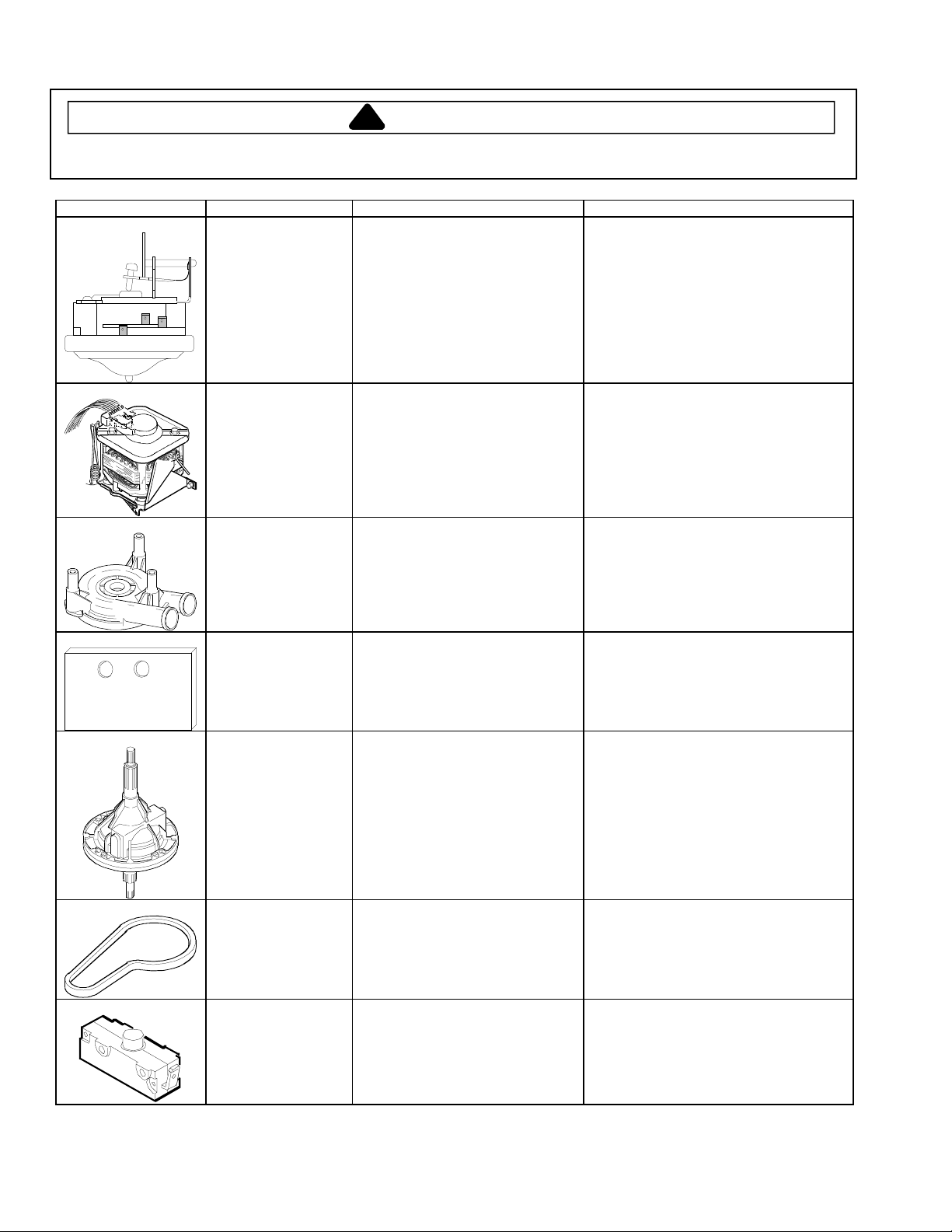

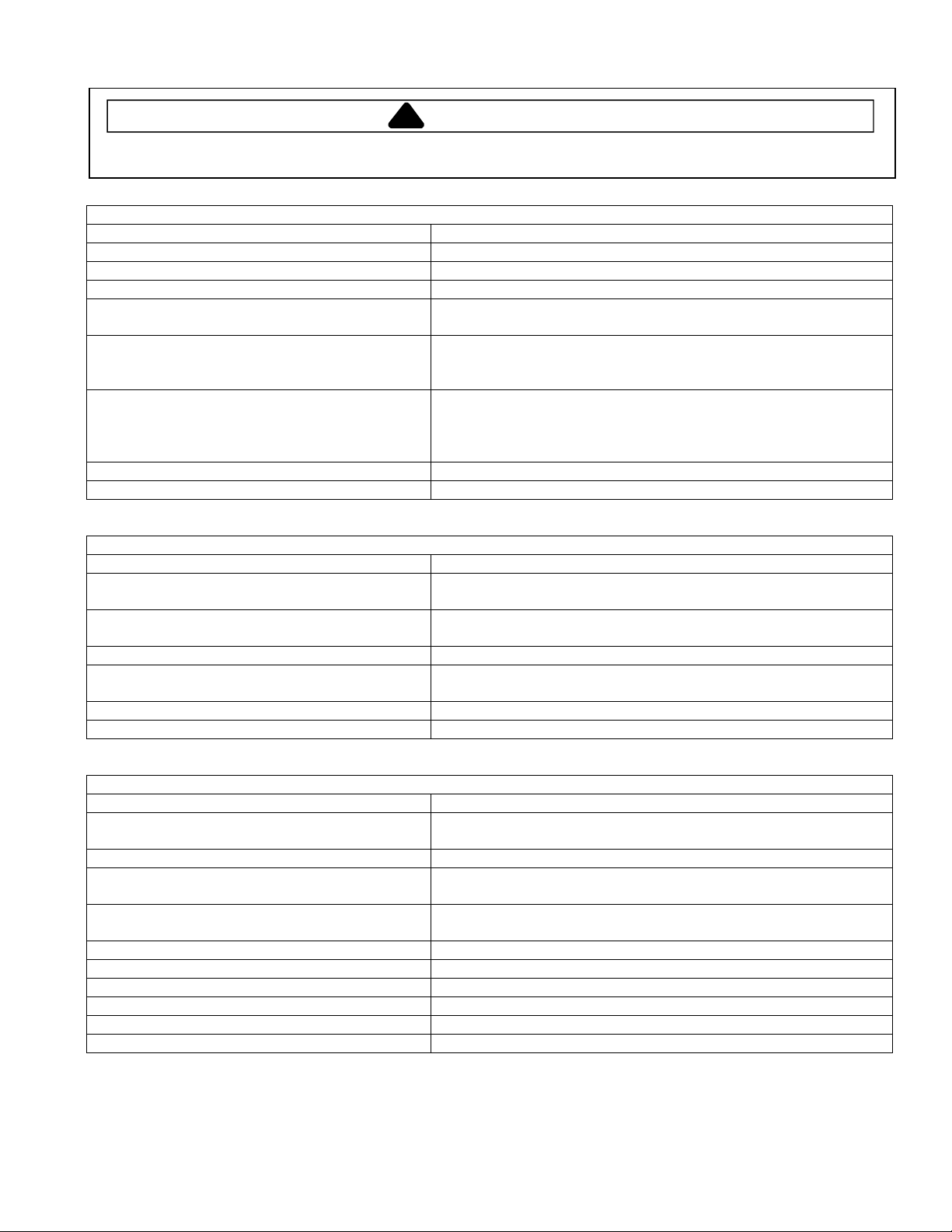

Page 8

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Illustration Component Test Procedure Results

Pressure switch Do not disconnect the pressure

2

1

3

hose from pressure switch to

perform measurements.

Measure resistance across the

following terminals on the pressure

switch:

Terminal 1 to 2

Terminal 1 to 3

Refer to wiring diagram/schematic for

correct contacts.

Continuity (no pressure)

Continuity (pressure)

Motor Three types of motors

Drain pump Verify drain pump is not clogged or

Brake pad If washtub does not stop spinning

Transmission

assembly

One speed

Two speed

Three speed

damaged.

within seven second after opening

loading door (no load).

If brake pads makes noises.

Two type of transmissions:

640 rpm

710 rpm

See following section “Internal Motor

Diagram and Schematic” for correct

wiring contacts.

Remove clog and verify proper operation.

Replace drain pump if damaged.

Replace all three brake pads.

Apply a thin layer of silicone on pads, see

Service Bulletin “ASQ−213−B“

Externally identical, must be identified by

part number.

If transmission locks-up during agitate cyle,

replace.

Drive belt Two type of drive belts:

Lid switch−SPST

640 rpm

710 rpm

There are two different types of

pulley sizes as well.

Disconnect wire terminals from

switch.

Test terminals with switch closed.

Test terminals with switch open.

RS3100007 Rev. 0 8

Refer to “Parts Manual”, to verify which

drive belt and pulley is required.

Continuity >1

Infinite 1 M

Ω

Ω

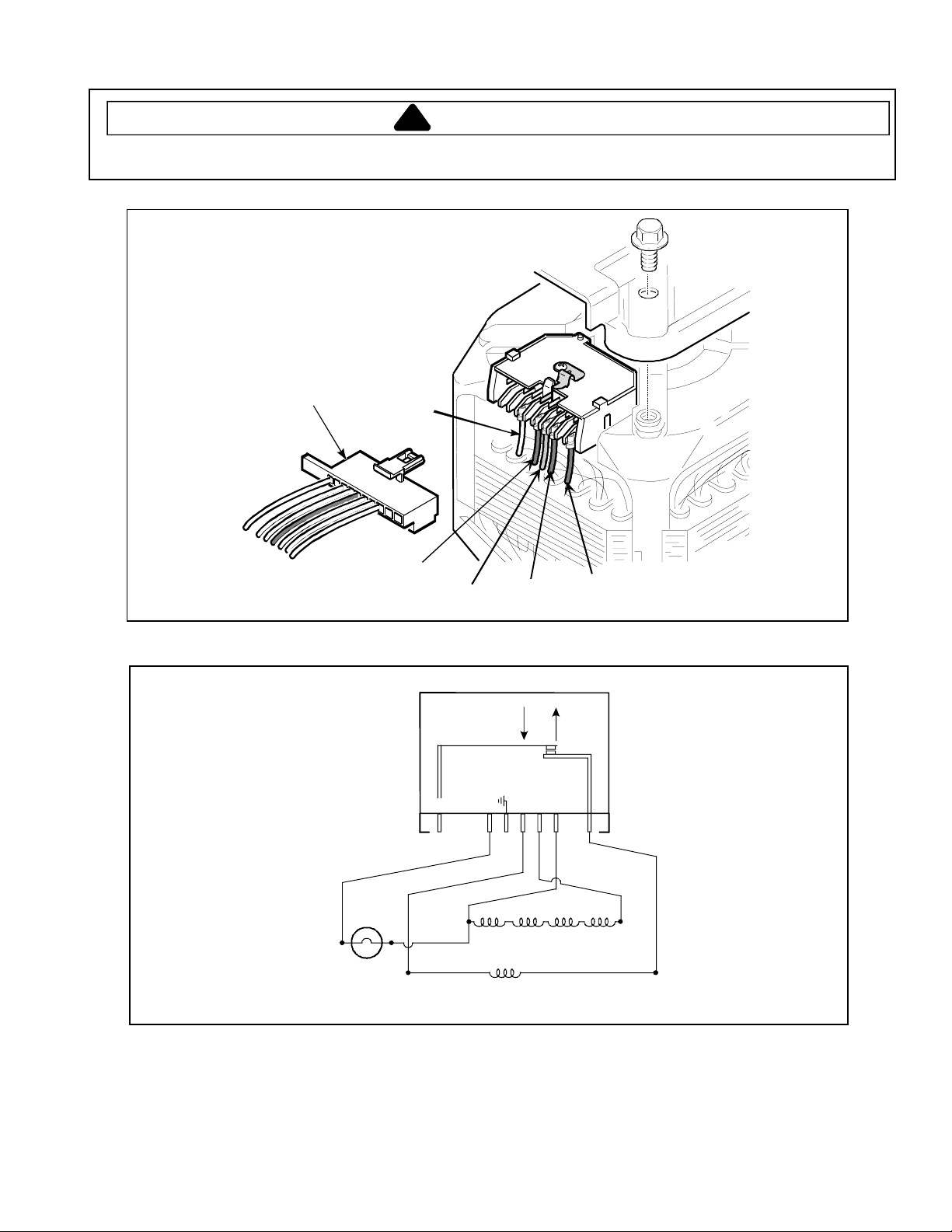

Page 9

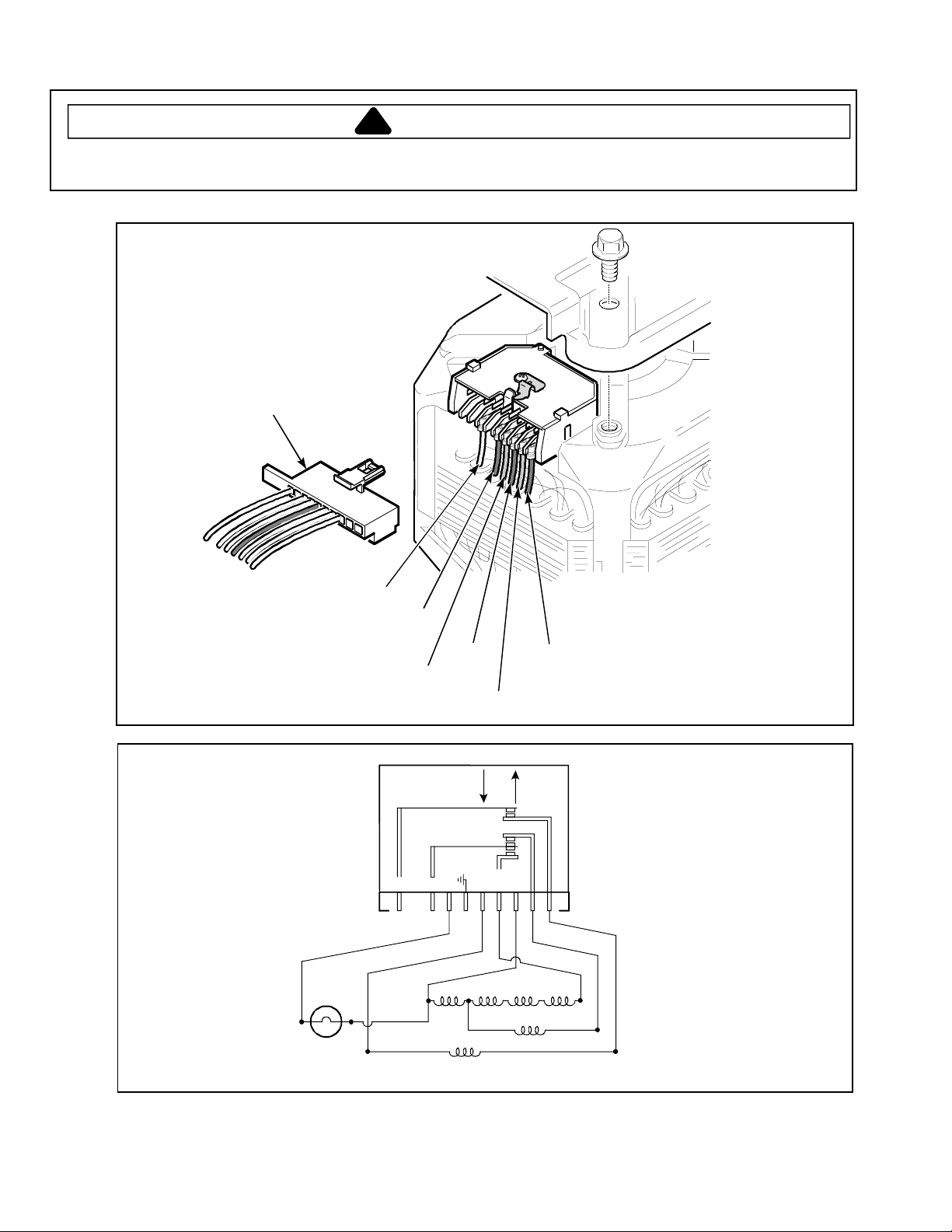

Internal Motor Diagram and Schematic

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Wire harness

connection

block

White

Brown

Blue

R

R

Yellow

G

W

P

BU

Y

R

BR

W

Red

RUN

START

Y

BU

BR

Red

White

Brown

Blue

Yellow

4P M

Yellow

Overload

protector

Aux.

Motor Assembly

(one speed motor)

RS3100007 Rev. 09

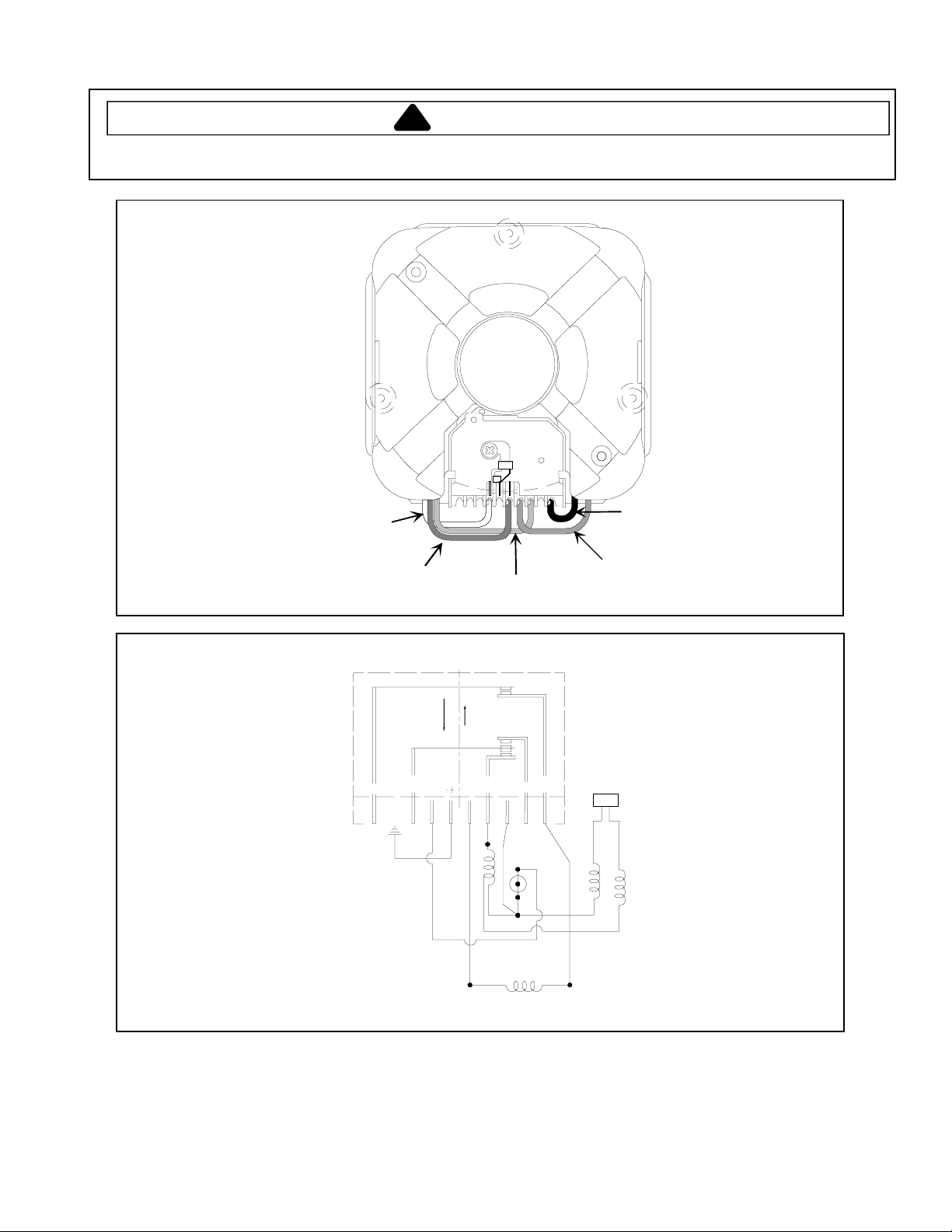

Page 10

Internal Motor Diagram and Schematic

!

T

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

Wire harness

connection

block

White

Brown

Blue

R

Yellow

Violet

STAR

P

BU

Y

BR

W

Red

RUN

R

P

White

Brown

Yellow

Overload

protector

Motor Assembly

(two speed motor)

RS3100007 Rev. 0 10

G

W

Yellow

Aux.

BR

Y

BU

4P M

6P M

Red

Violet

Blue

Page 11

Internal Motor Diagram and Schematic

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

G

W

W-BK

BU

Y

OR

R

BK

V

White

R

Yellow

OR

W

WHITE

White/Black

START

RUN

G

BU

Y

4P MAIN

YEL

Black

Blue

W-BK

BK

V

BLU

WHT

-BLK

BLK

PROT

W/OR

PLUG

W/V

8P MAIN

6P MAIN

AUX

Motor Assembly

(three speed motor)

RS3100007 Rev. 011

Page 12

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

1. No hot water.

Possible Cause Result

Hot water supply faucet is closed. Open faucet.

Water supply is cold. Check water heater

Verify hot water hose is connected to hot side of inlet valve.

Kinked hot water inlet hose. Straighten or replace hose.

Clogged mixing valve screens, or screens in

inlet hose closes to supply faucet.

Clogged pressure hose. Remove and clean or replace hose

Failed pressure switch. Test switch and replace if failed.

Failed temperature switch. Test switch and replace if failed.

Failed hot water side of mixing valve solenoid. Test solenoid and replace if failed.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

Disconnect inlet hose and clean or replace screen.

2. No cold water.

Possible Cause Result

Cold water supply faucet is closed. Open faucet.

Kinked hot water inlet hose. Straighten or replace hose.

Clogged mixing valve screens, or screens in

inlet hose closes to supply faucet.

Clogged pressure hose. Remove and clean or replace hose

Failed pressure switch. Test switch and replace if failed.

Failed temperature switch. Test switch and replace if failed.

Failed cold water side of mixing valve solenoid. Test solenoid and replace if failed.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

3. No warm water.

Possible Cause Result

No hot water.

No cold water.

Failed mixing valve. Test mixing valve and replace if failed.

Disconnect inlet hose and clean or replace screen.

No Hot Water

See “

No Cold Water

See “

” chart.

” chart.

RS3100007 Rev. 012

Page 13

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

4. Water fill does not stop at proper level.

Possible Cause Result

Failed pressure switch. Test switch and replace if failed.

Air leak in pressure hose Replace pressure hose.

Water in pressure hose. Blow air through hose to remove water.

Broken, weak, or missing mixing valve

armature spring.

Sediment on or under mixing valve diaphragm,

failed diaphragm, or armature binding in

armature guide.

A siphoning action started in washer will cause

water to be siphoned from washer during cycle.

Caused by drain hose being lower than washer

cabinet top.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

Replace mixing valve.

Replace mixing valve.

Install No. 526P3 Siphon Break Kit. Provide an air gap around

drain hose and drain receptacle. Install No. 36878 Standpipe

Adapter.

5. Timer does not advance.

Possible Cause Result

Timer is designed to pause during fill periods.

Some cycles have pause (delicate cycle).

Loading door is open. Close loading door. Loading door MUST be closed anytime the

Washer will not fill. Timer pauses until pressure switch is satisfied.

Verify washer is not siphoning during ri nse

cycle.

Failed timer. Test timer and replace if failed.

Broken, loose, shorted, or incorrect wiring. Refer to appropriate wiring diagram.

6. Motor does not operate.

Possible Cause Result

Power cord not plugged in, blown fuse or

tripped circuit breaker at circuit panel.

Loading door not closed or failed switch. Close door or test switch and replace if failed.

Motor overload protector has cycled. Wait two to three minutes for overload protector to reset. If

Binding in upper or lower motor bearings. Remove belt and determine if motor shaft will spin. Replace

Motor is dead, electrical power is present. Test motor switch and windings.

Motor start functions fail or motor only hums. Test motor start switch and start windings.

Timer improperly set. Reset timer or try another cycle.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

Allow completion of fill period.

washer is set to agitate or spin.

Install No. 526P3 Siphon Break Kit.

Verify electrical power is present at outlet and unit is plugged in.

There is no internal fuse in the washer.

overload protector cycles repeatedly, see following chart.

motor if shaft is locked up.

RS3100007 Rev. 0 13

Page 14

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

7. Washer smokes, overheats, and cycles on overload protector or switch actuator kicks in and out.

Possible Cause Result

Belt is tacky and does not allow proper

slipping.

Belt tension is too tight and does not allow

proper slipping.

Motor start functions fail. Test switch functions.

Bind in water pump. Replace pump.

Brake pads are binding. Free binding pads or replace pads.

Brake, transmission or motor have locked up

and will not turn.

Failed timer. Test timer and replace if failed.

Incorrect voltage. Contact local utility company, or have a qualified electrician

8. No agitation.

Possible Cause Result

Failed timer. Timer is designed to pause

(SOAK) during DELICATE cycle.

Failed pressure switch. Test switch and replace if failed.

Loose or broken drive belt. Adjust or replace drive belt.

Failed transmission assembly. Replace failed transmission assembly.

Sheared motor pulley roll pin. Remove drive motor and replace roll pin and any other damaged

Motor overload protector has cycled. Wait two to three minutes for overload protector to reset. If

Bind in water pump. Replace pump.

Loading door not closed or failed switch. Close door or test switch and replace if failed.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

Check belt and replace if failed.

Verify idler spring is properly connected.

Verify proper belt and pulley are inst alled.

Verify all components move freely. Correct binding component.

check power supply voltage.

Test timer and replace if failed.

components.

overload protector cycles repeatedly, see following chart.

9. Constant agitation.

Possible Cause Result

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Shorted or incorrect wiring. Refer to appropriate wiring diagram.

RS3100007 Rev. 014

Page 15

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

10. Slow spin or no spin.

Possible Cause Result

Some model washers, timer is programmed for

SLOW spin in DELICATE cycle regardless of

action switch setting.

Loading door not closed or failed switch. Close door or test switch and replace if failed.

Bind in water pump. Replace pump.

Loose or broken drive belt. Adjust or replace drive belt.

Oil on drive belt. Replace drive belt

Sheared motor pulley roll pin. Remove drive motor and replace roll pin and any other damaged

Motor overload protector has cycled. Wait two to three minutes for overload protector to reset. If

No clearance or stuck brake pads. Free sticky brake pads or replace brake pads.

Failed transmission assembly. Replace failed transmission assembly.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

Use a different cycle.

components.

overload protector cycles repeatedly, see following chart.

11. Constant spin.

Possible Cause Result

Washtub does not stop spinning within seven

seconds after loading door is open.

Excessive wear on brake pads, or missing

brake pads.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

12. Washer stops in middle of cycle or quits after a couple loads intermittent.

Possible Cause Result

Belt is tacky and does not allow proper

slipping.

Belt tension is too tight and does not allow

proper slipping.

Motor overload protector has cycled. Wait two to three minutes for overload protector to reset. If

Brake, transmission or motor have locked up

and will not turn.

Motor switch functions fail. Test switch functions.

Failed timer. Test timer and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

Replace brake pads.

Tighten Helix Bolt if loose.

Replace brake pads.

Check belt and replace if failed.

Verify idler spring is properly connected.

Verify proper belt and pulley are inst alled.

overload protector cycles repeatedly, see following chart.

Verify all components move freely. Correct binding component.

RS3100007 Rev. 0 15

Page 16

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

13. Washer locks-up or binding.

Possible Cause Result

Excessive drive belt tension. Replace drive belt and/or idler spring.

Bind in upper or lower bearing. Replace bearing.

Bind in water pump. Replace pump.

Bind in transmission. Replace transmission.

Brake pads are binding. Free binding pads or replace pads.

Incorrect voltage. Contact local utility company, or have a qualified electrician

check power supply voltage.

14. Outer tub does not empty.

Possible Cause Result

Kinked drain hose. Straighten drain hose.

Failed water pump. Replace water pump.

Obstruction in outer tub outlet hose. Remove obstruction.

15. Excessive vibration.

Possible Cause Result

Washer is not properly leveled. Adjust leveling legs for proper leveling.

Unbalance load in the tub. Stop washer, redistribute load and restart the washer.

Broken or disconnected centering springs. Connect or replace centering springs.

Washer is installed on weak, “spongy”,

carpeted or built-up floor.

Loose or damaged leveling legs. Tighten or replace leveling legs.

Damage base (wash was dropped). Replace base assembly.

Lubricant on pivot dome or broken friction ring. Remove lubricant and replace damage components.

Liquid filled balance ring leaking. Replace balance ring.

Shipping plug not removed. Remove shipping plug.

Rubber feet not installed. Install rubber feet.

16. Water leaking from outer tub.

Possible Cause Result

Water seal leaking on outer tub. Replace hub and seal kit assembly.

Hole in outer tub. Replace outer tub.

Pressure hose or accumulator leaking. Replace hose and/or accumulator.

Outer tub cover gasket leaking. Replace gasket.

Tub-to-pump hose leaking at clamp. Tighten hose clamp.

Obstruction in drain causing water to over f lo w

over tub cover.

Relocate washer, or support floor to eliminate weak or “spongy”

condition.

Remove obstruction in drain hose.

RS3100007 Rev. 016

Page 17

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

NOTE: When reference is made to directions (right or

left) in this manual, it is from operator’s position

facing front of washer.

NOTE: To avoid damaging or scratching the surface a

soft cloth should be placed over the top of the

unit.

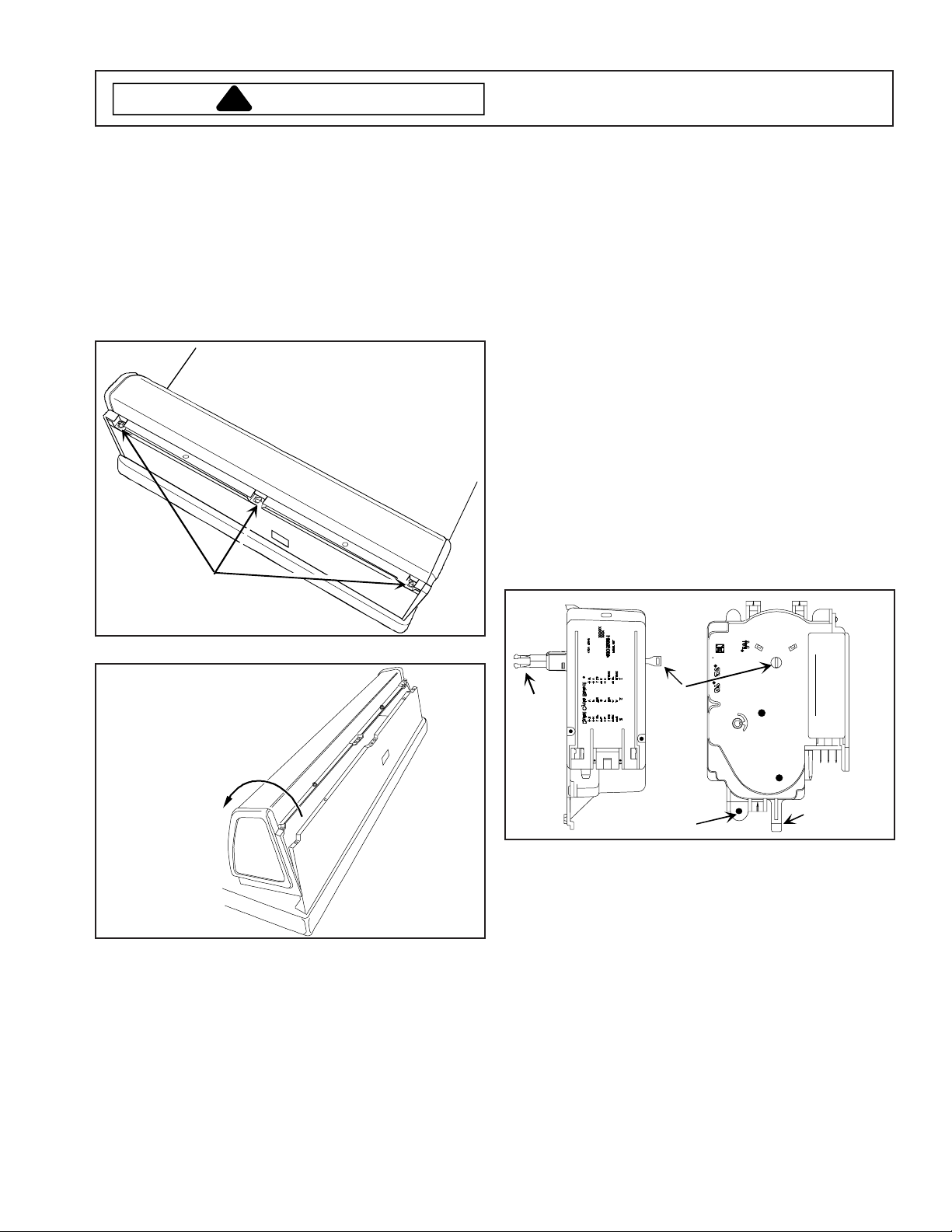

Control Hood Assembly

1. Remove screws securing control hood assembly to

control hood rear panel.

Hood

attaching

screws

2. Rotate hood assembly forward.

Electronic Control

1. Loosen control hood assembly, see “Control Hood

Assembly” procedure steps 1 through 3.

2. Disconnect wires from electronic control.

3. Remove screws securing electronic control to control

mounting plate.

4. Reverse procedure to reassemble.

NOTE: When removing or installing an electronic

control, handle control board by the edges to

prevent damaging control.

NOTE: See appropriate wiring diagram when rewiring

components.

Timer

1. Loosen control hood assembly, see “Control Hood

Assembly” procedure steps 1 and 2.

2. Remove timer knob from timer shaft by pulling black

plastic tab located on the back of timer outward to

release knob, then remove timer knob skirt.

NOTE: Slide a soft cloth under the knob skirt, wrapping

the entire skirt and pull gently away from the

control panel.

EMERSON

R

R

R

C

R

Knob

shaft

Black

plastic

tab

Pivot

hood

Securing

screw

Plastic tab

marked 1

forward

3. Remove screws securing timer to control hood

mounting plate.

4. Disconnect wire harness terminal plug from timer by

lifting locking tab and pulling terminal plug away from

3. Remove bottom of control hood from clips located on

cabinet top.

4. Disconnect wires from components and carefully

remove components from control hood assembly .

5. Reverse procedure to reassemble.

NOTE: See appropriate wiring diagram when rewiring

components.

timer.

5. Lift plastic tab marked 1 located above securing

screw and sliding timer to the side releasing tabs

securing timer to control hood mounting plate.

6. Reverse procedure to reassemble.

NOTE: To avoid an open circuit, DO NOT pull on

terminal block wires when removing blocks from

timer as this could damage wires or terminal

crimping.

Control Hood End Panels

• Remove screws securing end panels to control

mounting plate.

17 RS3100007 Rev . 0

Page 18

Disassembly Procedures

!

!

p

p

p

p

(

)

p

g

p

p

p

(rig

)

WARNING

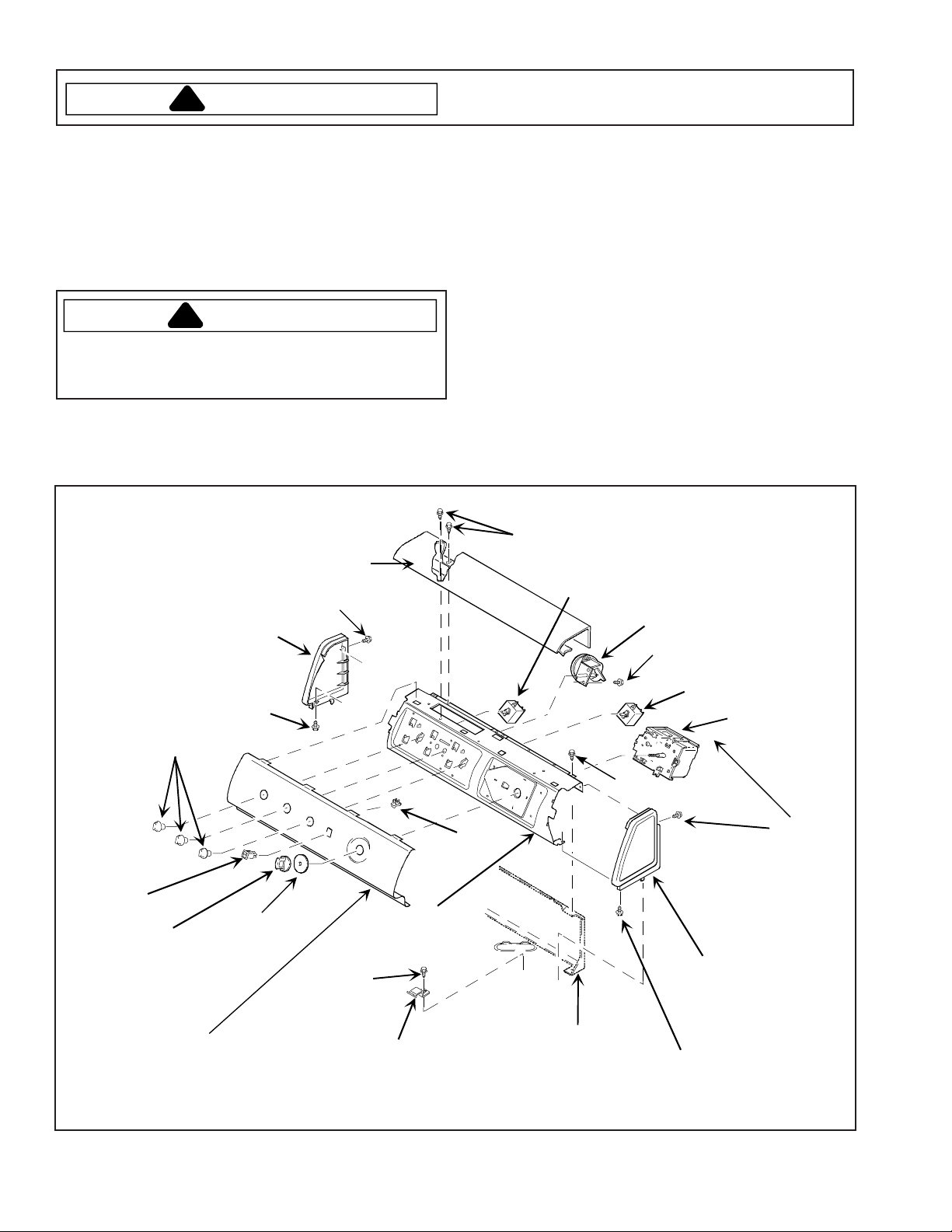

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Before attaching wire harness terminal blocks to timer,

verify all male terminals on timer are straight and are

capable of accepting terminals from wire harness

terminal blocks.

NOTE: When installing timer, verify timer is installed

correctly and is securely mounted to control

mounting plate.

CAUTION

To avoid risk of timer damage, do not allow timer to be

struck on the corners, edges of frame, or on timer

shaft.

To

cover

Screw

End

anel

left side

Screw

Control

knob

Temperature and Speed Switch

1. Loosen control hood assembly, see “Control Hood

Assembly” procedure steps 1 and 2.

2. Slide a soft cloth under the knob, wrapping the entire

knob and pull gently away from the control panel.

3. Disconnect wires from switch terminals.

4. From the front, press inward on black plastic tabs

next to the switch shaft and rotate switch to release

switch from control hood mounting plate.

5. Reverse procedure to reassemble.

NOTE: See appropriate wiring diagram when rewiring

components.

Screws

erature

Tem

switch

Pressure

switch

Screw

eed

S

switch

Timer

Rocker

switch

Timer

Timer

knob

Graphic

anel

RS3100007 Rev . 0 18

knob

skirt

Screw

Typical Control Panel Assembly

Ground

cli

Control

mountin

plate

Hold-down

cli

Control hood

rear

anel

Screw

Screw

End panel

ht side

Screw

Page 19

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Pressure Switch

1. Loosen control hood assembly, see “Control Hood

Assembly” procedure steps 1 and 2.

2. Disconnect wires and plastic hose from pressure

switch.

3. Remove screws securing pressure switch to control

hood mounting plate.

4. Reverse procedure to reassemble.

NOTE: See appropriate wiring diagram when rewiring

components.

NOTE: Before connecting hose to pressure switch,

blow air through pressure hose to remove any

condensation that may have accumulated in the

hose.

Rocker Switch

1. Loosen control hood assembly, see “Control Hood

Assembly” procedure steps 1 and 2.

2. Disconnect wire terminals from switch.

3. Squeeze plastic tabs located on top and bottom of

switch and push switch out through the front of

control panel.

4. Reverse procedure to reassemble.

Graphic Panel

1. Remove all knobs from switches.

2. Loosen control hood assembly, see “Control Hood

Assembly” procedure steps 1 and 2.

3. Disconnect wires from components and carefully

remove components from control hood assembly ,

see component removal procedure listed earlier .

4. Remove screws securing top cover to control

mounting plate and remove top cover .

5. Remove screws securing end panels (each side) and

remove end panels.

6. Remove grounding clip secured to metal tab on

graphic panel.

7. Bend tabs on graphic panel (located inside of control

hood) straight out towards the rear .

8. Remove graphic panel from front of control mounting

plate.

9. Reverse procedure to reassemble.

NOTE: See appropriate wiring diagram when rewiring

components.

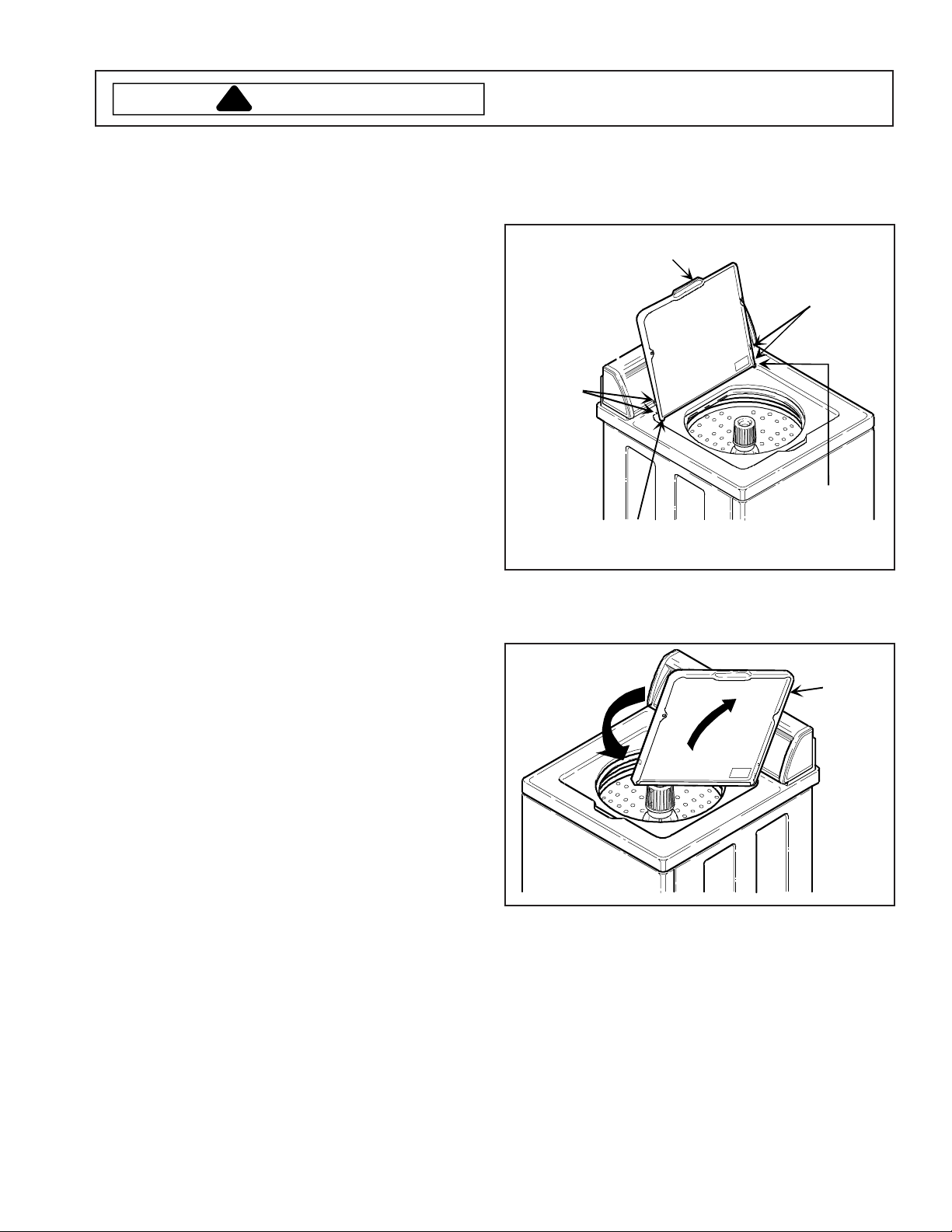

Loading Door

1. Open loading door .

2. Remove screws securing left hinge to door and

remove hinge.

Loading

door

Hinge

attaching

screws

Hinge

attaching

screws

Hinge

(right side)

Hinge

(left side)

3. Raise loading door to a vertical position, disengage

loading door from loading door clip by swing left side

of door toward front of washer.

Loading

door

4. Rotate loading door so door is upside down.

19 RS3100007 Rev . 0

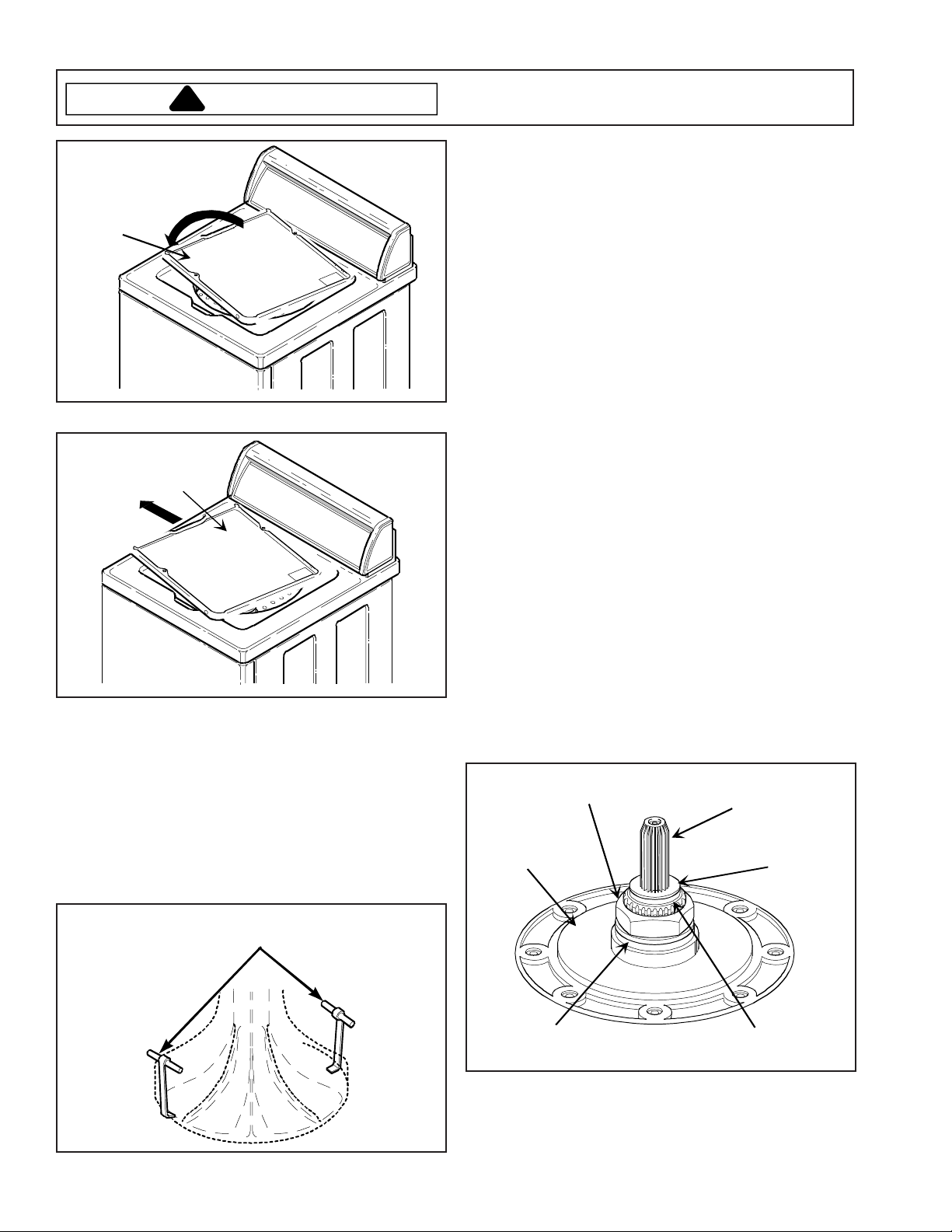

Page 20

Disassembly Procedures

!

WARNING

Loading

door

5. Maneuver loading door from washer cabinet top.

Loading

door

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

NOTE: Hooks must be positioned 180° from each other,

and must be placed under base of agitator near

agitator vane for greater stability . If hooks are

placed between the vane area, agitator damage

may occur .

3. Using a rocking motion (side-to-side) carefully lift

agitator up off drive bell.

4. To reassemble place agitator on top of drive bell.

Slowly rotate agitator until fingers on underside of

agitator line up with large slots on drive bell.

5. A sharp blow on top of agitator, with the palm of your

hand, will force agitator down onto drive bell,

allowing fingers on underside of agitator to lock

under bottom edge of drive bell.

NOTE: Do not push agitator onto drive bell any further

than necessary .

Agitator, Drive Bell and Seal Assembly

6. Remove screws securing right hinge and remove

loading door.

7. Reverse procedure to reassemble.

Agitator

1. Open loading door .

2. Remove agitator by placing hands under agitator lip

and pull upward, if agitator is stuck or stubborn use

two agitator hooks, No. 254P4P, under bottom edge

of agitator.

Agitator

hooks

NOTE: If water is present in washtub, remove water

before attempting to remove drive bell.

1. Remove agitator, see “Agitator” procedure.

2. Remove plug and 7/16" bolt from top of drive bell.

3. Using care pry drive bell upward of f transmission

shaft.

4. Remove old seal from hub assembly by:

a. Placing a flat bladed screwdriver between bottom

edge of seal and hub.

b. Using washtub bolts as a pry area, pop of f lower

seal bead.

c. Grasping bottom of seal and pulling straight up

freeing upper seal bead.

Hex

nut

Hub

assembly

Transmission

output sha ft

Washer

RS3100007 Rev . 0 20

Hub

shoulder

5. Clean all foreign material from seal mounting area of

hub assembly , bronze bearing and washer.

6. Lubricate new seal with liquid soap or soapy water to

aid in assembly of seal onto hub.

Bronze

bearing

Page 21

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

7. Apply a small amount of supplied grease,

No. 36765P, to inside sealing lips of seal.

Apply grease to

inside sealing lips

Hub

assembly

NOTE: DO NOT allow any lubricants to come in contact

with outside surface of seal

8. Apply remainder of supplied grease, No. 36765P, to

exposed surface of washer between transmission

output shaft and seal.

9. Place new drive bell seal onto hub and push into

position using large end of No. 293P4 Seal Tool.

NOTE: Using a small pocket mirror, check entire

circumference of bottom seal flange to verify

seal is pressed down against shoulder on hub;

there should be no gap!

10.Turn No. 293P4 Seal Tool upside-down and place

the small end over transmission output shaft and

onto the seal.

1 1.Push down on tool with a quick motion until it

bottoms out and the top of seal is fully seated.

Transmission

output shaft

Seal

293P4

Seal tool

Hub

assembly

Hub

shoulder

Bottom

seal flange

Top of

seal

Apply

36765P

grease

Installing Drive Bell

1. Position new drive bell over transmission output

shaft. Rotate drive bell until splines in drive bell line

up with splines on transmission output shaft.

2. Screw 7/16" bolt into transmission output shaft until it

bottoms out.

3. Using a wrench or socket, tighten bolt CLOCKWISE

to force drive bell down onto transmission shaft until

drive bell bottoms out on shaft.

NOTE: Tighten new shoulder screw between 60 to 80

inch-pounds.

4. Place new plug over hole in drive bell and firmly

press into place using the palm of your hand.

NOTE: It may be necessary to insert the end of a paper

clip or thin blade screwdriver along side of plug

as it is pressed into drive bell to release

entrapped air.

293P4

Seal tool

Hub

assembly

NOTE: When fully seated plug should not extend above

drive bell more than 1/8 inch (3.2 mm).

5. Place agitator on top of drive bell. Slowly rotate

agitator until fingers on underside of agitator line up

with large slots on drive bell.

6. A sharp blow on top of agitator , with the palm of your

hand, will force agitator down onto drive bell,

allowing fingers on underside of agitator to lock

under bottom edge of drive bell.

NOTE: Do not push agitator onto drive bell any further

than necessary.

21 RS3100007 Rev . 0

Page 22

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Service Access Panel

NOTE: Screws located at bottom edge of service

access panel do not have to be removed as the

holes in service access panel are slotted on

most models. Earlier models require removal of

bottom screws.

NOTE: Top edge of service access panel is held in

place by two spring clips located on bottom

flange of front panel.

1. Insert putty knife between service access panel top

and bottom edge of front panel (approximately three

inches in on each side).

2. Push in on putty knife and at the same time pull top

edge of service access panel away from front of

washer. Repeat for opposite side.

3. Lift service access panel upward off screws and set

panel aside.

4. Reverse procedure to reassemble.

Top front

panel

Brace

• Remove brace from front panel by swinging one end

towards bottom of front panel and remove brace.

Motor and Mounting Bracket

1. Remove service access panel, see “Service Access

Panel” procedure.

NOTE: There will always be some water that will remain

in outer tub, before removing hoses from pump,

hoses must be pinched off or drained to prevent

water spillage.

2. Loosen hose clamps and remove hoses from pump

assembly .

3. Unhook idler spring from clip on front of the motor

mounting bracket.

NOTE: Use care when releasing idler lever tension. If

idler spring is overstretched, washer operation

will be affected.

4. Reach in and around left side of motor and remove

belt off large drive pulley .

5. Disconnect wire harness from motor switch by

pressing down on locking tab on top of connection

block and at the same time, pull connection block

away from motor switch.

Switch attaching screws

Locking

tab

Service

access

panel

Front Panel

NOTE: Service access panel must be removed first to

remove front panel.

NOTE: Top edge of front panel is held in place by two

spring clips located on bottom flange of the

cabinet top.

1. Remove screws securing bottom of front panel.

2. Lift the bottom of front panel outward to release the

spring clips and set panel aside.

3. Reverse procedure to reassemble.

Panel Locators

• Remove screws securing panel locators to side

flanges of front panel.

Connecting

block

Motor

switch

RS3100007 Rev . 0 22

Page 23

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

6. Remove bolts securing motor and mounting bracket

to lower outer tub flange and to weldment assembly.

Motor mounting

attaching screws

Idler

sprin g

Belt

Pump

hoses

7. Lift complete assembly out of washer.

NOTE: Lay motor on its side. Observe belt

configuration around rear pump leg. Belt MUST

encircle rear pump leg when reassembling.

8. Reverse procedure to reassemble.

Pump and Belt Removal

1. Remove motor, see “Motor and Mounting Bracket”

procedure.

2. Remove screws securing pump assembly to motor.

Reassembly of Pump and Belt

NOTE: Install pump and belt together. Drive belt MUST

be replaced with belt No. 40053602 for one and

two speed models; or 40053601 for some two

speed models and three speed models (special

clutch-type belt) for proper washer operation.

Refer to Parts Manual for proper belt part

number.

1. Remove any corrosion or foreign material from motor

shaft.

2. Apply a thin film of No. 03637P lubricant to the end

and sides of motor shaft.

NOTE: This lubricant helps keep moisture out of the

hub area and prevents corrosion.

3. Align belt on motor pulley and tension pulley as

illustrated.

Pump

mounting screws

Rear

Pump

assembly

pump leg

(Must be located

between belt when

installing pump

assembly.)

Pump

legs

Motor shaft

(Clean shaft and apply

Motor

a thin film of lubricant

No. 03637P.)

embosses

Motor

emboss

Motor

assembly

4. Align pump impeller hub with motor shaft. Verify belt

encircles rear pump leg. Slide pump onto motor

shaft until legs touch the embosses on the motor

housing before securing.

NOTE: Tighten screws to 35 inch-pounds maximum.

DO NOT overtighten screws!

5. Install motor and pump assembly into washer , see

“Motor and Mounting Bracket” procedure.

NOTE: After installing motor and pump assembly in the

washer and all hoses have been secured, along

with reconnecting idler spring. Add at least one

quart of water to washtub to lubricate pump

seals. Running a pump without water will

damage the seals.

23 RS3100007 Rev . 0

Page 24

Disassembly Procedures

!

g

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Motor Disassembly

1. Remove nuts, steel washers, spacers and rubber

mounts securing motor to mounting bracket.

Motor

shield

Motor

switch

Motor

pully

Motor

mount

post

Motor

mount

Screw

Washer

Motor

mount

Motor

mount post

2. Lift motor off mounting bracket and remove

remaining rubber mounts and steel washers from

motor mounting studs.

NOTE: When installing motor on mounting bracket,

position motor with switch facing toward left side

of mounting bracket.

NOTE: When assembling motor to motor bracket, it is

extremely important to make sure the motor is

centered on isolator pads and all fasteners are

evenly torqued.

Screw

Motor

assembly

Roll

pin

Motor

mountin

bracket

Locknut

Screw

Locknut

Idler Lever and Pulley

1. Remove motor, see “Motor and Mounting Bracket”

procedure.

Idler spring

NOTE: Lay motor on its side. Observe belt

configuration around rear pump leg. Belt MUST

encircle rear pump leg when reassembling.

2. Remove nut, washer, and bolt securing idler lever

and pulley to motor mounting bracket.

3. Apply a light film of No. 03637P Lubricant to area of

idler lever that makes contact with motor mounting

bracket.

NOTE: DO NOT OVER LUBRICA T E! Excess lubricant

can be thrown into pivot dome area during

normal washer operation. Any lubricant on the

pivot dome, base or friction ring will affect

washer operation.

4. Reverse procedure to reassemble.

Motor Drive Pulley

1. Remove idler lever and pulley steps 1–3, see “Idler

Lever and Pulley” procedure.

2. Lay motor assembly on its side.

NOTE: To remove pulley, support motor shaft (to

prevent bending shaft) and drive out pulley roll

pin.

3. Reverse procedure to reassemble.

Motor Switch

1. Remove front panel, see “Front Panel” procedure.

2. Remove screws securing motor shield to motor.

3. Disconnect wire harness from motor switch. Press

down on locking tab connection block and at the

same time, pull connection block away from motor

switch.

CAUTION

To avoid risk of an open circuit, DO NOT pull on

terminal block wires when removing block from motor

switch as this could damage wires or connection

crimpings. Before attaching wire harness connection

block to motor switch, verify all male terminals on

motor switch are straight and are capable of accepting

terminals from wire harness connection block.

Motor shaft

(Clean shaft and apply

a thin film of lubricant

No. 03637P.)

Motor

assembly

RS3100007 Rev . 0 24

Page 25

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Switch attaching

screws

Locking

tab

Connection

block

4. Remove screw securing motor switch to motor and

remove switch.

5. Disconnect internal motor leads from motor switch

terminals.

NOTE: See appropriate wiring diagram when rewiring

components.

Motor

switch

Cabinet Top

1. Remove control hood assembly, see “Control Hood

Assembly” procedure.

2. Remove front panel, see “Front Panel” procedure.

3. Remove screws securing cabinet top.

4. Tape loading door closed.

5. Lift front of cabinet top slightly and pull forward to

disengage from rear hold-down brackets.

6. Pull cabinet top forward far enough to permit

disconnecting ground wires from top left rear corner

gusset of washer cabinet.

7. Disconnect wire terminals from door switch.

NOTE: See appropriate wiring diagram when rewiring

components.

8. Lift cabinet top of f washer and set along side the

washer cabinet on a protective padding.

NOTE: DO NOT lay cabinet top flat because it will

damage the door switch lever.

9. Reverse procedure to reassemble.

Door Switch

1. Remove front panel, see “Front Panel” procedure.

2. Remove screws securing cabinet top.

3. Tape loading door closed and lift cabinet top to a

vertical position by hinging it on the rear hinges.

NOTE: Cabinet top is self supporting, a small chain

may be used for additional support.

4. Disconnect wires from door switch.

5. Remove screw securing door switch assembly to

underside of cabinet top.

NOTE: See appropriate wiring diagram when rewiring

components.

6. Remove screws securing switch to switch holder.

7. Remove switch from switch holder.

8. Reverse procedure to reassemble.

Mixing Valve

1. Disconnect water inlet hoses.

2. Remove screw securing mixing valve bracket.

3. Pull mixing valve bracket and valve out the back of

washer.

4. Disconnect quick disconnect terminals from mixing

valve solenoid terminals.

NOTE: See appropriate wiring diagram when rewiring

components.

5. Reverse procedure to reassemble.

25 RS3100007 Rev . 0

Page 26

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Tub Cover and Gasket

1. There are eight tub cover hold-down tabs which snap

over the outer tub flange. Push downward on tub

cover, this will release the tension on the hold-down

tab on the tub cover. Pull out on the flap and at the

same time lift upward on cover to unsnap hold-down

tabs from outer tub flange. One by one, disengage

each of the eight hold-down tabs from outer tub

flange and remove cover.

2. Remove tub cover from outer tub and remove old

gasket from tub cover.

NOTE: When installing outer tub cover, always use a

new cover gasket.

NOTE: Clean and remove any foreign material in

gasket groove of outer tub cover and outer tub

flange.

3. Press gasket down into gasket groove of tub cover.

Avoid pressing gasket past ends of hold-down tabs.

NOTE: Care must be taken not to twist or bunch gasket

in any one area to avoid leaks after assembly .

4. Install gasket past ends of hold-down tabs to bottom

of gasket groove using semi-curled end of tub cover

gasket tool Part No. 273P4.

NOTE: Tub cover gasket tool, Part No. 273P4, is

designed to spread open hold-down tabs to

prevent tearing of gasket during installation.

5. Lower cover and press down firmly on top of

tub cover until tabs snap over edge of outer tub

flange.

6. Cross over to opposite side of tub cover and press

down firmly on top of hold-down tabs until tabs snap

over edge of outer tub flange. Continue with this

crisscross pattern, until tub cover is fully seated.

Visually check each tab area again to ensure cover

is seated.

Washtub and Balance Ring

1. Open loading door .

2. Remove agitator, see “Agitator” procedure.

3. Loosen cabinet top, see “Cabinet Top” procedure

steps 2 through 4.

4. Hinge cabinet top open to gain access.

5. Loosen and remove hose clamp and fill hose from

outer tub cover.

6. Remove tub cover, see “Tub Cover and Gasket”

procedure, steps 1 through 2.

7. Remove bolts and washers securing washtub to hub.

8. Lift washtub and balance ring out of outer tub.

NOTE: When removing washtub and balance ring, DO

NOT lift up on balance ring damage may occur.

Grasp top flange of washtub and remove from

outer tub.

9. Reverse procedure to reassemble.

NOTE: When installing washtub, verify lint filter is

between underside of washtub and hub.

Outer Tub

1. Remove agitator, see “Agitator” procedure.

2. Loosen cabinet top, see “Cabinet Top” procedure

steps 2 through 4.

3. Remove tub cover and gasket, see “Tub Cover and

Gasket” procedure.

4. Loosen and remove hose clamp securing pump hose

to pump. This will allow water to be drained from the

unit.

5. Remove washtub and balance ring, see “Washtub

and Balance Ring” procedure.

6. Remove large hex nut using No. 306P4 Hex Wrench.

Then remove spline insert from transmission tube.

NOTE: Use new spline insert each time the hex nut is

removed. DO NOT reuse the old insert as hex

nut may loosen during the washer operation.

7. Remove hub from splines on transmission shaft.

NOTE: It may be necessary to use a gear puller to

remove hub.

8. Remove old water seal from outer tub.

NOTE: Use care when removing old seal so as not to

damage tub flange.

NOTE: When reinstalling or replacing outer tub, always

install a new Hub and Seal Kit.

9. Using No. 289P4 Spring Hook Tool, unhook six

springs from lower edge of outer tub.

NOTE: When installing springs, verify spring hook is

fully seated in hole in tub skirt. Mark the word

“FRONT” on front side of outer tub so complete

tub module can be reinstalled in same position.

10.Grasp outer tub and lift complete tub module

assembly up and out of washer cabinet.

11.Turn outer tub upside-down and set on a protective

padding.

12.Loosen hose clamp and remove hose from bottom of

outer tub.

13.Loosen hose clamp and remove pressure hose from

pressure bulb.

RS3100007 Rev . 0 26

Page 27

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

14.Remove screws and lockwashers securing

counterweight and each support leg to outer tub

weldment. Lift transmission, weldment assembly and

counterweight off tub.

15.Remove screws securing outer tub bottom to plastic

outer tub.

16.Turn outer tub upright and remove pressure bulb and

grommet.

17.Reverse procedure to reassemble.

NOTE: When installing grommet into outer tub, thicker

lip of grommet must be installed to outside of

tub. Lubricate outer surface of large opening of

pressure bulb with liquid soap to aid when

assembling pressure bulb into grommet.

Drive Pulley, Helix and Brake

1. Remove outer tub, see Outer T ub” procedure,

steps 1 through 1 1.

2. Remove screw, washer and helix securing drive

pulley to input shaft and transmission assembly .

NOTE: On tall tub models, the weldment assembly

must be removed or loosened and raised

enough to get pulley off and on the input shaft.

3. Lift drive pulley up and of f input shaft of transmission

assembly .

NOTE: When reinstalling pulley, place a small amount

of No. 03200P Lubricant on top side of the drive

pulley that will be contacting large flat washers.

Lubricate helix ramps and bore with a small

amount of No. 03200P Lubricant.

DO NOT OVER LUBRICATE! Excess lubricant

can be thrown into pivot dome area during

normal washer operation. Any lubricant on pivot

dome, base or friction ring will affect washer

operation. This condition will persist until

lubricant is removed.

4. Remove bolts securing brake pads and brake

assembly to weldment assembly . Remove brake

assembly and pads off bottom of weldment

assembly .

NOTE: When reinstalling brake assembly, replace all

three brake pads. DO NOT replace worn pads

only . Apply a small amount of No. 26594P

Silicone Lubricant to both sides of each brake

pad where it will contact brake assembly.

DO NOT OVER LUBRICATE! Excess lubricant

can be thrown into pivot dome area during

normal washer operation. Any lubricant on pivot

dome, base or friction ring will affect washer

operation. This condition will persist until

lubricant is removed.

5. After brake is installed, put washer through the

following check to verify brake is operating properly .

a. Turn off electrical power to washer.

b. T urn drive pulley one complete revolution in

agitation directly , then push drive pulley up

against brake.

c. Check for a .030 (.76 mm) minimum gap between

drive pulley and helix ramp surfaces.

NOTE: If gap is less than .030 (.76 mm), brake may not

stop washtub from spinning in required seven

seconds because brake will not close properly.

d. Turn on electrical power to washer and start

washer in the final spin operation.

NOTE: After installing complete tub module in washer

and all hoses have been reconnected, add at

least one quart of water to washtub to lubricate

pump seals. Running a pump without water

will ruin the seals.

After washtub has been spinning for two

minutes, normal spin speed should be

427 ± 25 RPM SLOW speed and 640 ± 25 RPM

FAST speed on one and two speed models; or

473 ± 25 RPM on SLOW speed and

710 ± 25 RPM on FAST speed on some two

speed models and all three speed models.

Three speed models never spin on the lowest

speeds. If not, the cause could be dragging

brake pads. If problems occur with steps (c) or

(d), remove brake assembly and correct

problem.

27 RS3100007 Rev . 0

Page 28

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Weldment and Bearing Assembly

1. Remove outer tub, see Outer T ub” procedure,

steps 1 through 1 1.

2. Remove screw, washer and helix holding drive pulley

to input shaft and transmission assembly .

3. Lift drive pulley up and of f input shaft of transmission

assembly .

NOTE: When reinstalling pulley, place a small amount

of No. 03200P Lubricant on top side of the drive

pulley that will be contacting large flat washers.

Lubricate helix ramps and bore with a small

amount of No. 03200P Lubricant.

DO NOT OVER LUBRICATE! Excess lubricant

can be thrown into pivot dome area during

normal washer operation. Any lubricant on pivot

dome, hose or friction ring will affect washer

operation. This condition will persist until

lubricant is removed.

4. Remove bolts securing brake pads and brake

assembly to weldment assembly . Remove brake

assembly and pads off bottom of weldment

assembly .

NOTE: When reinstalling brake assembly, replace all

three brake pads. DO NOT replace worn pads

only . Apply a small amount of No. 265494P

Silicone Lubricant to both sides of each brake

pad where it will contact brake assembly .

DO NOT OVER LUBRICATE! Excess lubricant

can be thrown into pivot dome area during

normal washer operation. Any lubricant on pivot

dome, base or friction ring will offset washer

operation. This condition will persist until

lubricant is removed.

5. After brake is installed, put washer through the

following check to verify brake is operating properly .

a. Turn off electrical power to washer.

b. Turn drive pulley one complete revolution in

agitation direction, then push drive pulley up

against brake.

c. Check for a .030 (.76 mm) minimum gap between

drive pulley and helix ramp surfaces.

NOTE: If gap is less than .030 (.76 mm), brake may not

stop washtub from spinning in required seven

seconds because brake will not close properly .

d. Turn on electrical power to washer and start

washer in the final spin.

NOTE: After installing complete tub module in washer

and all hoses have been reconnected, add at

least a quart of water to washtub to lubricate

pump seals. Running a pump without water will

ruin the seals.

After washtub has been spinning for two

minutes, normal spin speed should be

427 ± 25 RPM SLOW speed and 640 ± 25 RPM

FAST speed on one and two speed models; or

473 ± 25 RPM on SLOW speed and

710 ± 25 RPM on FAST speed on some two

speed models and all three speed models.

Three speed models never spin on the lowest

speeds. If not, the cause could be dragging

brake pads. If problems occur with steps (c) or

(d), remove brake assembly and correct

problem.

6. Remove bolts securing counterweight and each

support leg to outer tub. Lift transmission, weldment

assembly and counterweight off tub.

NOTE: It may be necessary to tap lightly on the

weldment assembly to loosen it from

transmission tube.

Torque screws between 100 to 150 inchpounds.

7. Remove screws and washers securing

counterweight to leg on weldment assembly.

8. Reverse procedure to reassemble.

RS3100007 Rev . 0 28

Page 29

Disassembly Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before servicing.

Transmission Assembly

1. Remove outer tub, see Outer T ub” procedure,

steps 1 through 1 1.

2. Remove screws securing each support leg to outer

tub. Lift weldment assembly , and brake assembly off

transmission tube.

NOTE: It may be necessary to tap lightly on weldment

assembly to loosen it from transmission tube.

When installing lower bearing, weldment

assembly and brake assembly , apply No.

27604P Anti-Seize Compound to area of

transmission tube that will be contacting

bearing.

Do not overtighten screws as this could cause stripping

or damage. Torque screws between 100 to 150 inchpounds.

NOTE: When replacing or reinstalling transmission

assembly , it is important that No. 27604P

Anti-Seize Compound be applied to area of the

transmission tubes where they will be contacting

upper and lower bearings.

Carefully lower transmission through upper bearing. DO

NOT DROP OR LOWER TRANSMISSION ASSEMBLY

INTO POSITION TOO HARD. This can cause bearing to

move which will cause vibration, noise, wear or no spin.

Upper Bearing Assembly

1. Remove transmission assembly, see “Disassembly

of Transmission Assembly” procedure.

2. Remove screws securing each support leg to outer

tub.

3. Lift complete weldment assembly (with drive pulley,

brake assembly, lower bearing, and transmission

assembly attached) off outer tub.

NOTE: Do not overtighten screws as this could cause

stripping or damage.

4. Remove screws securing upper bearing and housing

to bottom of outer tub.

NOTE: Replace bearing and housing as an assembly.

When upper bearing assembly is reinstalled,

threads of cap screws must be secured with a

retaining compound.

Friction Ring

1. Remove outer tub, see “Outer T ub” procedure

steps 1 through 11.

2. Remove friction ring and replace with new friction

ring.

3. Reverse procedure to reassemble.

NOTE: When installing module springs, make sure

spring hooks are fully seated in the holes.

29 RS3100007 Rev . 0

Page 30

Appendix A

A–1 RS3100007 Rev . 0

Page 31

Installation

Instructions

Top Loading Washer

Keep instructions for future reference. Be sure manual stays with washer.

MOVE WASHER

1

TO FINAL AREA;

REMOVE

SHIPPING BRACE

& PLUG

Protect the floor when moving the

washer. W asher must be within 4 feet

of desired area before beginning

installation. Open washer lid and

remove installation parts from

shipping brace for use.

Reach through foam shipping

brace, grasp bottom of brace, and

pull up to remove.

CONNECT

2

WATER FILL

HOSES TO

WASHER

Tightly push one flat rubber

washer into one end of each

water fill hose and attach this end

of hose to washer. HOT and

COLD connections are identified

by letters H and C stamped into

washer cabinet and by HOT and

COLD printed on water fill hoses.

NOTE: Save shipping plug and

shipping brace; reinstall whenever

washer is moved more than 4 feet.

Do not lift or move washer without

shipping materials in place.