Service

Electric Freestanding

BIG OVEN™

This manual covers general information

on Freestanding Electric BIG OVEN.

Refer to individual Technical Sheets

for information on specific models.

Service Manual for

Amana

®

This manual is to be used by qualified appliance

technicians only. Amana does not assume any

responsibility for property damage or personal

injury for improper service procedures done by an

unqualified person.

RS2320006

Revision 0

August 2001

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a qualified

service technician who is familiar with the safety procedures required in the repair and who is equipped with

the proper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE

INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Notices for Consumers and Servicers

!

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personal, dangerous

conditions (such as exposure to electrical shock) may result.

!

Amana will not be responsible for any injury or property damage from improper service procedures. If performing

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, consult your telephone book or the dealer from whom you purchased this product.

For further assistance, contact: 1 (800) 628-5782 first, if no answer call number listed below.

CONSUMER AFFAIRS DEPT. OR 1 (800) 843-0304

AMANA APPLIANCES CALL

AMANA, IOWA 52204

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

WARNING

CAUTION

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

RS2320006 Rev. 0 2

Table of Contents

Important Information ................................................. 2

Important Safety Information ...................................... 4

ALL APPLIANCES ............................................... 5

SURFACE COOKING UNITS .............................. 5

OVENS................................................................ 5

VENTILATION HOODS ....................................... 5

In Case of Fire ..................................................... 5

Precautions ......................................................... 5

General Information

Cooking Utensils.................................................. 6

Pan Bottom Test .................................................. 6

Oven Rack Placement ......................................... 7

Pan Placement .................................................... 7

Removing Oven Door .......................................... 7

Replacing Oven Door........................................... 7

Component Testing Information ................................. 8

Troubleshooting Procedures ...................................... 9

Disassembly Procedures

Oven Door Handle, Outer/Inner Glass, and

Door Hinges....................................................... 11

Reverse Procedure to Reassemble Oven Door.. 12

Oven Door Gasket ............................................. 12

Electronic Control .............................................. 12

Infinite Switch .................................................... 12

Indicator Light .................................................... 12

Maintop.............................................................. 13

Door Latch Motor, Plunger Light Switch, and

Latch Switch ...................................................... 13

Bake Element .................................................... 13

Broil Element ..................................................... 14

Sensor, Oven Control ........................................ 14

Oven Light and Oven Light Socket ..................... 14

Flue ................................................................... 14

Leveling Leg Bracket ......................................... 14

Front Frame and Oven Liner .............................. 14

Side Panel ......................................................... 14

Storage Drawer Removal................................... 15

Storage Drawer Tracks ...................................... 15

Power Cord........................................................ 15

Removing and Replacing Range ........................ 15

Appendix A

Installation Instructions .....................................A-2

Appendix B

Care and Cleaning ............................................B-2

Appendix C

Genesis Control ................................................C-2

Appendix D

Sigma Control...................................................D-2

3 RS2320006 Rev. 0

Important Safety Information

WARNING

!

To reduce the risk of the appliance tipping, it must be

secured by a properly installed anti-tip bracket(s). To

make sure bracket has been installed properly, remove

the storage drawer or decorative panel and look under

the range with a flashlight. Bracket(s) must be engaged

in the rear corner of the range.

• ALL RANGES CAN TIP

• INJURY TO PERSONS

COULD RESULT

• INSTALL ANTI-TIP

BRACKET(S) PACKED

WITH RANGE

• SEE INSTALLATION

INSTRUCTIONS

WARNING

!

To avoid personal injury, do not sit, stand or lean on

oven door or oven drawer.

WARNING

!

To avoid risk of electrical shock, personal injury, or

death, make sure your range has been properly

grounded and always disconnect it from main power

supply before any servicing.

WARNING

!

This appliance contains or produces a chemical or

chemicals which can cause death or serious illness

and which are known to the state of California to cause

cancer, birth defects or other reproductive harm. To

reduce the risk from substances in the fuel or from fuel

combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this booklet.

Do not store items of interest to children in cabinets

above a range or behind the backguard of a range.

Children climbing on the range to reach items could be

seriously injured.

CAUTION

!

To avoid risk of electrical shock, personal injury, death,

or property damage, verify wiring is correct, if

components were replaced. Verify proper complete

operation of unit after servicing.

DO NOT TOUCH SURFACE UNITS OR AREAS NEAR

UNITS—Surface units may be hot though they are dark

in color. Areas near surface units may become hot

enough to cause burns. During and after use, do not

touch, or let clothing touch or other flammable

materials contact surface units or areas near surface

units until they have had enough time to cool. These

areas include the rangetop and backguard.

DO NOT TOUCH HEATING ELEMENTS OR

INTERIOR SURFACES OF OVEN—Oven heating

elements may be hot though they are dark in color.

Interior surfaces of an oven may become hot enough

to cause burns. During and after use, do not touch, or

let clothing or other flammable materials touch heating

elements or interior surfaces of oven until they have

had enough time to cool. Other range surfaces that

may become hot enough to cause burns are the oven

door and oven.

WARNING

!

CAUTION

!

CAUTION

!

ALL APPLIANCES

1. Proper Installation—Be sure your appliance is properly

installed and grounded by a qualified technician.

2. Never Use Your Appliance for Warming or Heating the

Room.

3. Do Not Leave Children Alone—Children should not be

alone or unattended in the area where the appliance is

in use. They should never be allowed to sit or stand on

any part of the appliance.

4. Wear Appropriate Apparel—Loose fitting or hanging

garments should never be worn while using appliance.

5. User Servicing—Do not repair or replace any part of

the appliance unless specifically recommended in the

manual. All other servicing should be referred to a

qualified technician.

6. Storage in or on Appliance—Flammable materials

should not be stored in an oven or near surface units.

7. Do Not Use Water on Grease Fires—Smother fire or

flame, or use dry chemical or foam-type extinguisher.

8. Use Only Dry Potholders—Moist or damp potholders

on hot surfaces may result in burns from steam. Do

not let potholder touch elements. Do not use a towel

or other bulky cloth.

RS2320006 Rev. 0 4

Important Safety Information

SURFACE COOKING UNITS

1. Use Proper Pan Size—This appliance is equipped with

one or more surface units of different size. Select

utensils having flat bottoms large enough to cover the

surface unit heating element. The use of undersized

utensils will expose a portion of the heating element to

direct contact and may result in ignition of clothing.

Proper relationship of utensil to burner will also

improve efficiency.

2. Never Leave Surface Units Unattended—Boilover

causes smoking and greasy spillovers that may

ignite.

3. Make Sure Reflector Pans or Drip Bowls Are In

Place—Absence of these pans or bowls during

cooking may subject wiring or components

underneath to damage.

4. Protective Liners—Do not use aluminum foil to line

oven bottom. Improper installation of these liners may

result in a risk of electrical shock or fire.

5. Glazed Cooking Utensils—Do not use glass, ceramic,

earthware, or other glazed utensils. They can damage

smoothtop and can break due to sudden change in

temperature.

6. Utensil Handles Should be Turned Inward and Not

Extend Over Adjacent Surface Units—To reduce the

risk of burns, ignition of flammable materials, and

spillage due to unintentional contact with the utensil,

the handle of a utensil should be positioned so that it

is turned inward, and does not extend over adjacent

surface units.

7. Do Not Soak Removable Heating Elements—Heating

elements should never be immersed in water.

OVENS

1. Use Care When Opening Door—Let hot air or steam

escape before removing or replacing food.

2. Do Not Heat Unopened Food Containers—Buildup of

pressure may cause container to burst and result in

injury.

3. Keep Oven Vent Ducts Unobstructed.

4. Placement of Oven Racks—Always place oven racks

in desired location while oven is cool. If rack is

removed while oven is hot, do not let potholder contact

hot heating element in oven.

In Case of Fire

Fires can occur as a result of over cooking or excessive

grease. Though a fire is unlikely, if one occurs, proceed

as follows:

Surface Element Fire

1. Smother the fire with a nonflammable lid or baking

soda, or use a Class ABC or BC extinguisher. Not

water. Not salt. Not flour.

2. As soon as it is safe to do so, turn the surface

controls to “OFF”.

Oven Fires

1. If you see smoke from your oven, do not open oven

door.

2. Turn oven control to “OFF”.

3. As an added precaution, turn off power at main circuit

breaker or fuse box.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven. Do not

open oven door.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call an

authorized servicer before using range.

Precautions

• Do not cook food directly on range top surface, always

use cookware.

• Do not mix household cleaning products. Chemical

mixtures may interact with objectionable or even

hazardous results.

• Do not put plastic items on warm cooking areas. They

may stick and melt.

• Do not slide rough objects across range top surface.

Scratching or metal marking can result.

• Do not leave fat heating unless you remain nearby. Fat

can ignite if overheated by spilling onto hot surfaces.

• Do not allow pots to boil dry as this can cause damage

to cooking surface and pan.

• Do not use range top surface as a cutting board.

• Do not use range for storage or as a display counter.

VENTILATION HOODS

1. Clean Ventilation Hoods Frequently—Grease should

not be allowed to accumulate on hood or filter.

2. When flaming foods under hood, turn fan off. The fan, if

operating, may spread the flame.

5 RS2320006 Rev. 0

General Information

Cooking Utensils

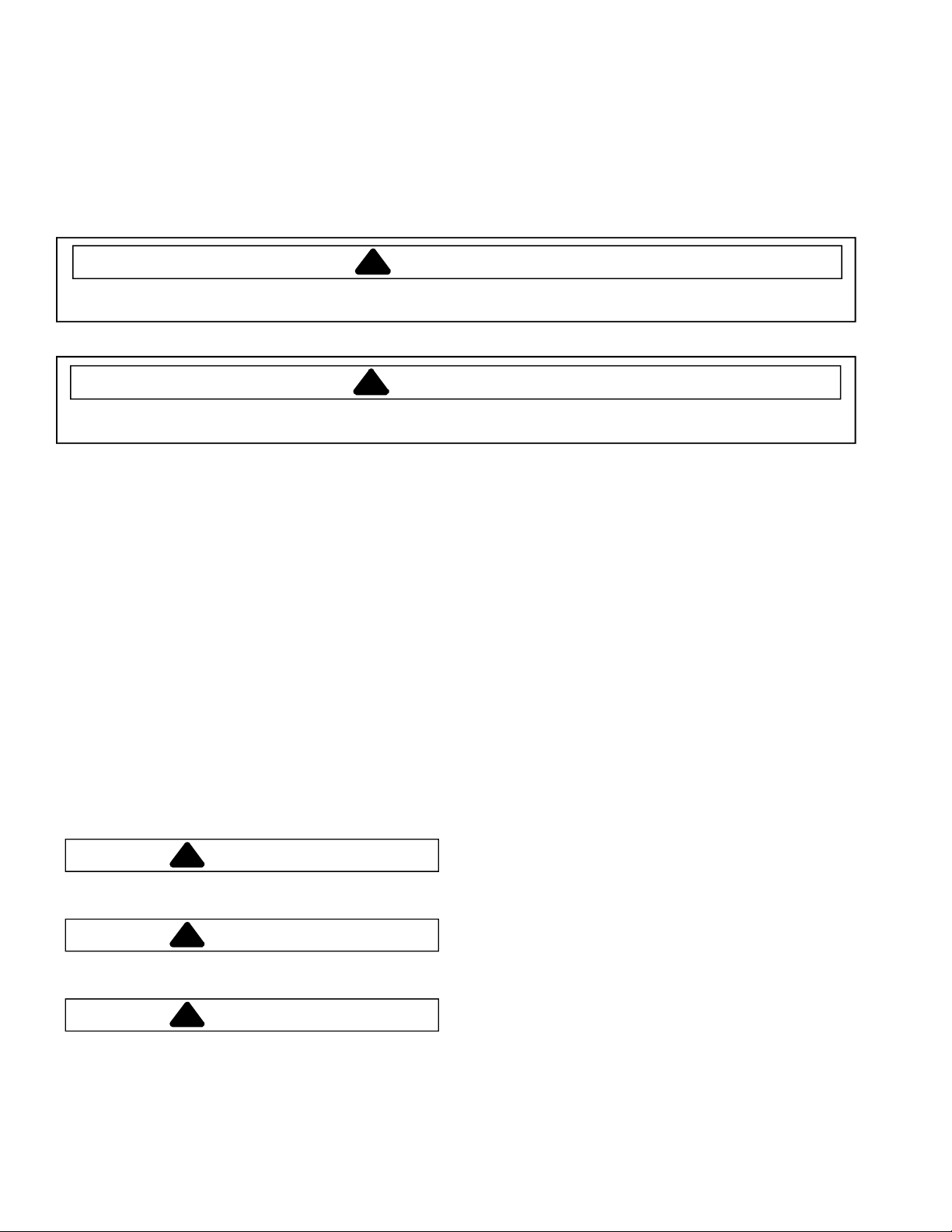

• Use proper pan size. Do not use a pan that has a

bottom smaller than element. Do not use utensils that

overhang element by more than 1 inch.

1"

Less than 1" overhang

2"

More than 1" overhang

• Use care when using glazed cooking utensils. Some

glass, earthenware, or other glazed utensils break due

to sudden temperature changes.

• Select utensils without broken or loose handles.

Handles should not be heavy enough to tilt pan.

• Select utensils with flat bottoms.

• Do not use a wok with a ring stand.

Do not use a wok with

a ring stand.

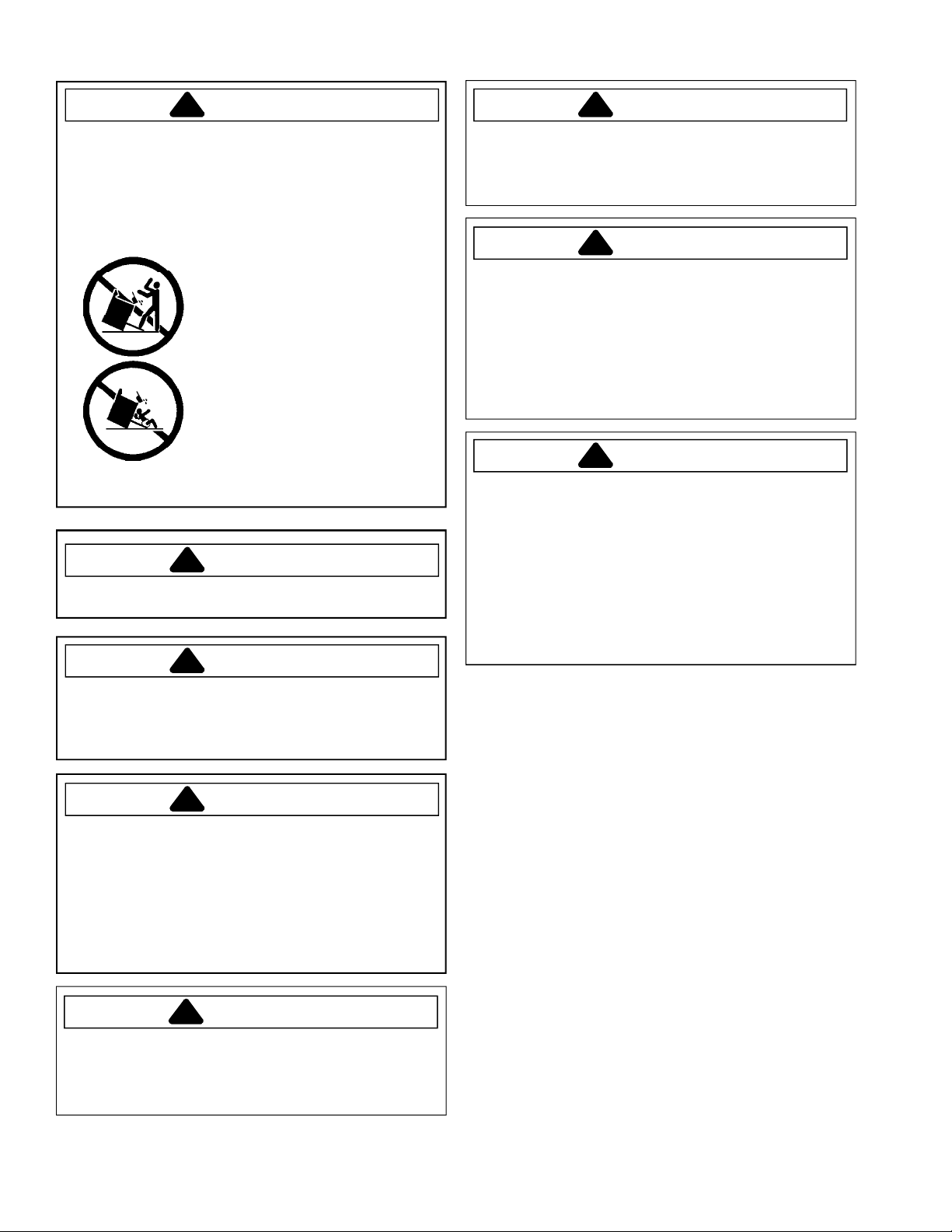

Utensil Material Characteristics

Type Temperature

Response

Aluminum Heats and

Cools Quickly

Cast Iron Heats and

Cools Slowly

Copper Tin

Lined

Enamelware Depends on

Ceramic

(Glass)

Stainless Steel

Heats and

Cools Quickly

Base Metal

Heats and

Cools Slowly

Heats and

Cools at

Moderate Rate

Uses

Frying, Braising,

Roasting

Low Heat

Cooking, Frying

Gourmet

Cooking, Wine

Sauces, Egg

Dishes

Low Heat

Cooking

Low Heat

Cooking

Soups, Sauces,

Vegetables,

General

Cooking

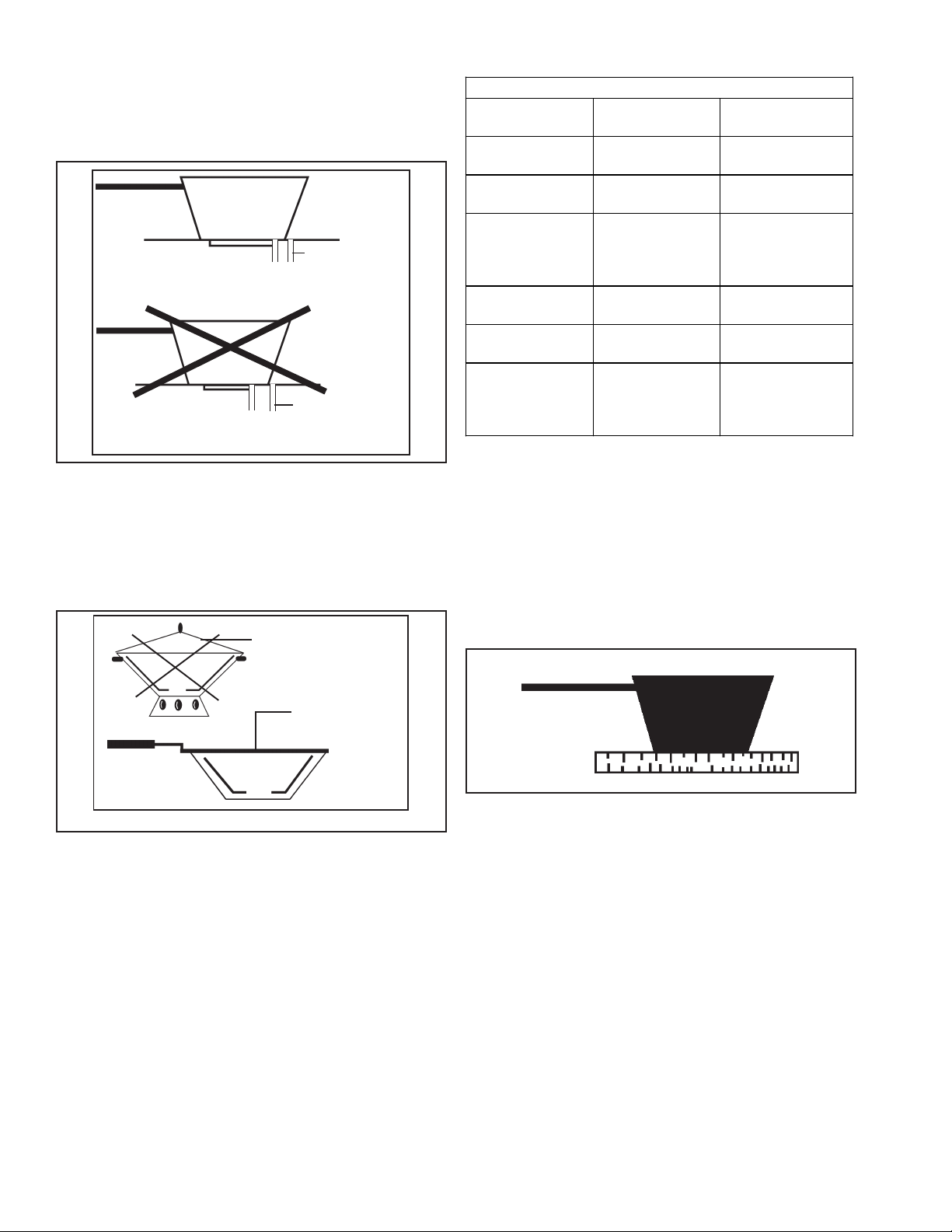

Pan Bottom Test

Determine if pan has a flat bottom. For best cooking

results, use a pan with a flat bottom.

1. Rotate a ruler along bottom of pan. If pan is not flat,

gaps between bottom of pan and edge of ruler occur.

2. A small groove or mark on a pan does not effect

cooking times. However, if a pan has a gap, formed

rings, or an uneven bottom, it does not cook

efficiently and in some cases may not boil water.

Use a flat

bottom wok.

RS2320006 Rev . 0 6

General Information

!

Follow these recommendations only as a guide for times

and temperature. Times, rack position, and temperatures

may vary depending on conditions and food type. For

best results, always check food at minimum time. When

roasting, choose rack position based on size of food

item.

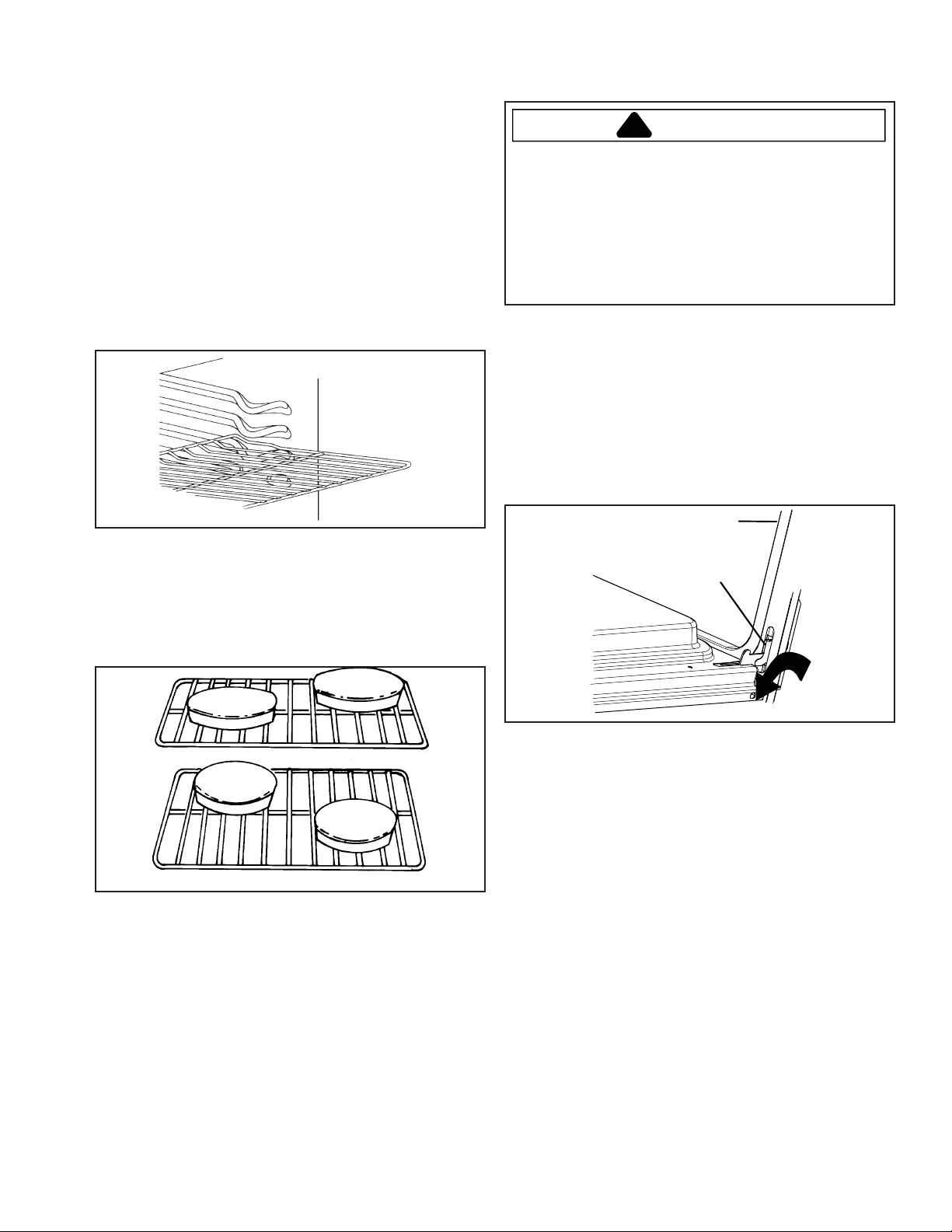

Oven Rack Placement

Position oven rack before turning on oven.

1. Pull rack forward to stop position.

2. Raise front edge of rack and pull until rack is out of

oven.

3. Place rack in new rack position.

• Curved edge of rack must be toward rear of oven.

Removing Oven Door

CAUTION

To avoid personal injury or property damage, handle

oven door with care.

• Door is heavy and can be damaged if dropped.

• Avoid placing hands in hinge area when door is

removed. Hinge can snap closed and pinch hands.

• Do not scratch or chip glass, or twist door. Glass

may break suddenly .

• Replace door glass if damaged.

1. Pull out or remove storage drawer to avoid damaging

finish.

2. Fully open oven door .

3. Push hinge locks down toward door frame, to the

unlocked position.

• This may require a flatblade screwdriver .

4. Firmly grasp both sides of top of oven door.

5. Close door to first stop position.

6. Lift door up until hinge arm is clear of the slot.

Oven Frame

Pan Placement

• Keep pans and baking sheets 2 inches from oven

walls.

• Stagger pans placed on different racks so one is not

directly over the other.

Hinge Lock

Oven

Door

Replacing Oven Door

1. Grasping door top firmly , seat indentation of hinge

arm into bottom edge of the hinge slot.

• Door should be at the first stop position angle.

2. Fully open oven door .

3. Push hinge locks up against the front frame of the

oven cavity to locked position.

4. Close oven door.

7 RS2320006 Rev . 0

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

Refer to Technical Sheet or Parts Manual for replacement components specifications.

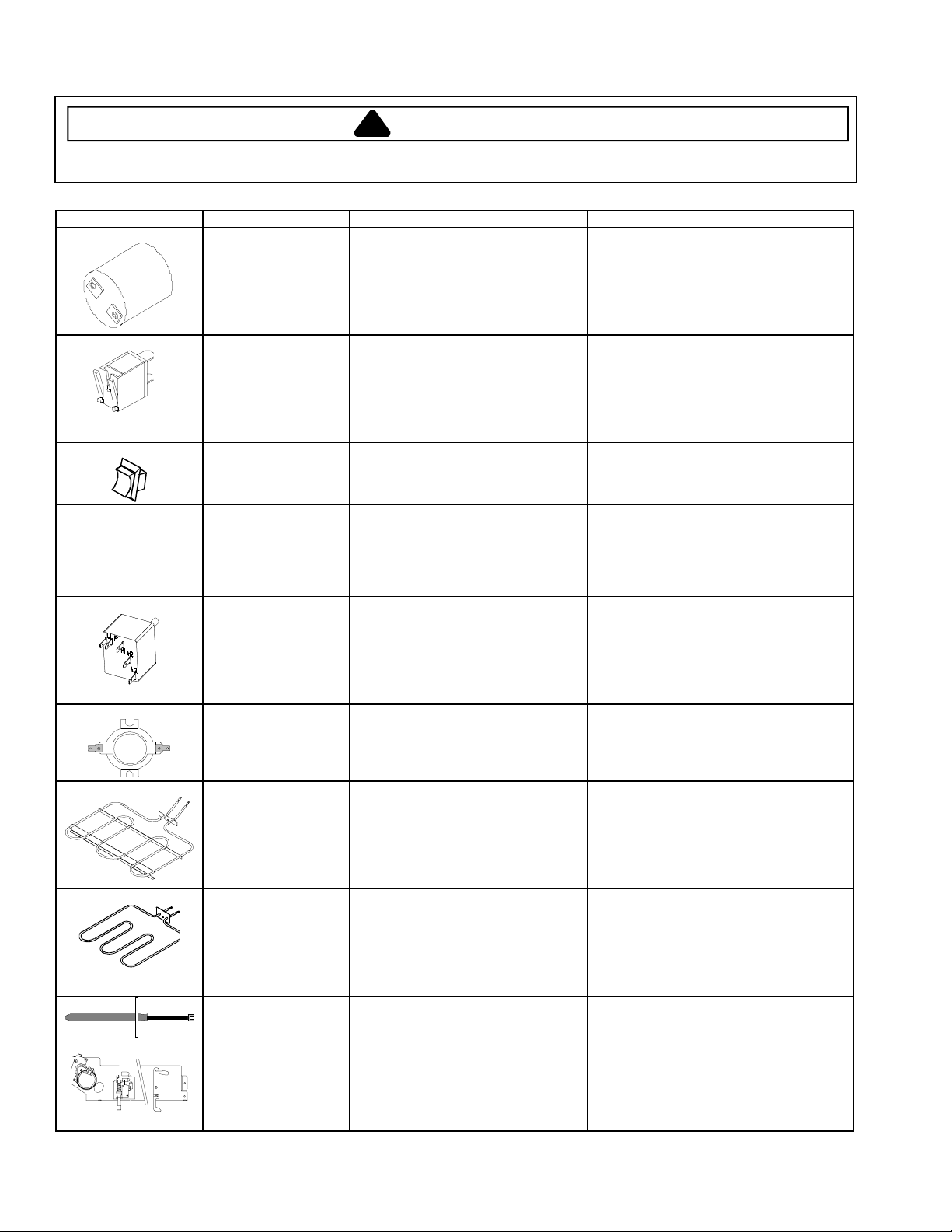

Illustration Component Test Procedure Results

Oven light socket Remove one wire from r eceptacle

and test resistance of terminals.

Indicates continuity with bulb sc rewed in.

Measure voltage at oven light...........

Oven indicator l ight

and

Surface indicat or light

Rocker switch Measure continuity of switch

Ribbon radiant

elements, limi ters are

not replaceable.

Infinite switch Remove wiring from terminals H1 and

Control limit Normally Closed

Bake element Disconnect wire leads to element and

Remove one lead from swi tch

terminal and measure resistance

across terminals.

Measure voltage at indicator light.....

positions:

Closed.............................................

Open...............................................

Remove one wire lead from element

and measure resistance of the

element.

Verify supply voltage ........................

H2. Connect Volt ohms meter to

H1 and H2.

Measure the following for voltages at

LO, MED, HI:

H1 to H2.........................................

Verify proper operat ion.

Closed............................................

Open..............................................

measure resistance of terminals.

120 VAC, see wiring diagram for terminal

identification.

If no voltage is pr esent at oven light,

check wiring or light switches.

Switch closed: 0

Switch open: Infinite resistance

If voltage is pr esent and light does not

operate. Replace l ight.

If no voltage is pr esent at indicator light

check wiring.

Continuity, if not replace.

Infinite, if not replace.

Continuity, if not replace.

1200W:44 to 49

1500W:36 to 40

2000W:26 to 30

2500W:20 to 23

240 VAC

LO 5% 95%

MED (4-5) 50% 50%

HI 100% 0%

240 VAC, if not replace switch.

Continuity

Infinite

If open at room temperat ure, replace.

Continuity, appr oximately 20 Ω,

if not replace.

Ω

Approximately

Ω

Approximately

Ω

Approximately

Ω

Approximately

Ω

Time On Time Off

Measure voltage at bake element.....

Broil element Disconnect wire leads to element and

Oven temperature

sensor

Auto latch assembly Motor switch

measure resistance of terminals.

Measure voltage at broil element......

Measure resistance.......................... Approximately 1100 Ω at room

Unlocked.....................................

Locked........................................

Door switch

Door closed.................................

Door open...................................

RS2320006 Rev. 0 8

240 VAC, see wiring diagram for terminal

identification.

If no voltage is pr esent at bake element

check wiring.

Continuity, appr oximately 19 Ω,

if not replace.

240 VAC, see wiring diagram for terminal

identification.

If no voltage is pr esent at broil element

check wiring.

temperature 75°F.

COM

N.O. continuity

−

COM

N.O. open

−

N.C. continuity

COM

−

COM

N.C. open

−

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

Problem Possible Cause Correction

Surface element does not heat

No bake operation

No broil operation

Oven light does not operate

Appliance not working

• Open element.....................................

• Loose wire connection or broken wire.

• Failed infinite switch............................

• Open bake element ............................

• Loose wire connection or broken wire.

• Open broil element .............................

• Loose wire connection or broken wire.

• Failed oven lamp ................................

• Failed light switch ...............................

• Failed wiring.......................................

• Failed light socket...............................

• Power outage ....................................

WARNING

• Check element for continuity,

replace if failed.

• Verify all connections are clean

and tight, replace broken wiring.

• Check infinite switch, replace if

failed.

• Check element for continuity,

replace if failed.

• Verify all connections are clean

and tight, replace broken wiring.

• Check element for continuity,

replace if failed.

• Verify all connections are clean

and tight, replace broken wiring.

• Check lamp and replace if

necessary.

• Check switch contacts.

• Check for broken and loose or

dirty connections.

• Check light socket for continuity.

• Make sure appliance is plugged

in. Verify that circuit breaker is

not tripped.

Frequent cycling of surface

element or warming zone

Oven not working

Clock and timer not working

• Normal...............................................

• Programming error.............................

• Power outage......................................

• Replace household fuse but do

not change fuse capacity.

• Element cycles to maintain

proper heat and to prevent

damage to smoothtop.

• Shut off power to oven for five

minutes by switching off circuit

breaker. Reset circuit breaker

and try oven again.

• Make sure appliance is plugged

in. Verify that circuit breaker is

not tripped. Replace household

fuse but do not change fuse

capacity.

• See appropriate control appendix

and if continues, contact service

department.

RS2320006 Rev. 0 9

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

WARNING

Problem Possible Cause Correction

Melted top door trim

Self-clean cycle not working

Oven door will not unlock

Oven not clean after a

self-clean cycle

• Miss-aligned door gasket ..................... • Replace door gasket.

• Check door hinges.

• Programming error...............................

• Oven is self-cleaning............................

• Oven still hot........................................

• Too much soil, grime left in oven..........

• Soot remains in oven after cycle...........

• Shut off power to oven for five

minutes by switching off circuit

breaker. Reset circuit breaker and

try oven again.

• Allow cycle to complete.

• Will not unlatch until a cooler

temperature has been reached.

Do not force door open, this will

void warranty. May blow cooler

air on latch area with a hair dryer

at cool setting to quicken

process.

• Wipe out and remove excess soil

prior to running self-clean cycle.

• Normal.

Locked light displayed

Display flashing

F-(numeric) display

Oven smokes the first few

times used

• Door locked..........................................

• Power failure reset clock...................... • Press CLOCK pad.

• Service code........................................

• Normal.................................................

• If oven is hot, allow to cool rather

than trying to force door latch

open.

• Shut off power to oven for one to

two minutes, by switching off

circuit breaker. Reset breaker.

• See appropriate control appendix

and if continues, contact service

department.

• Minor smoking is normal the first

few times the oven is used.

RS2320006 Rev. 0 10

Disassembly Procedures

WARNING

!

To avoid risk of electrical shock, personal injury or death;

disconnect power supply source before servicing, unless

testing requires it.

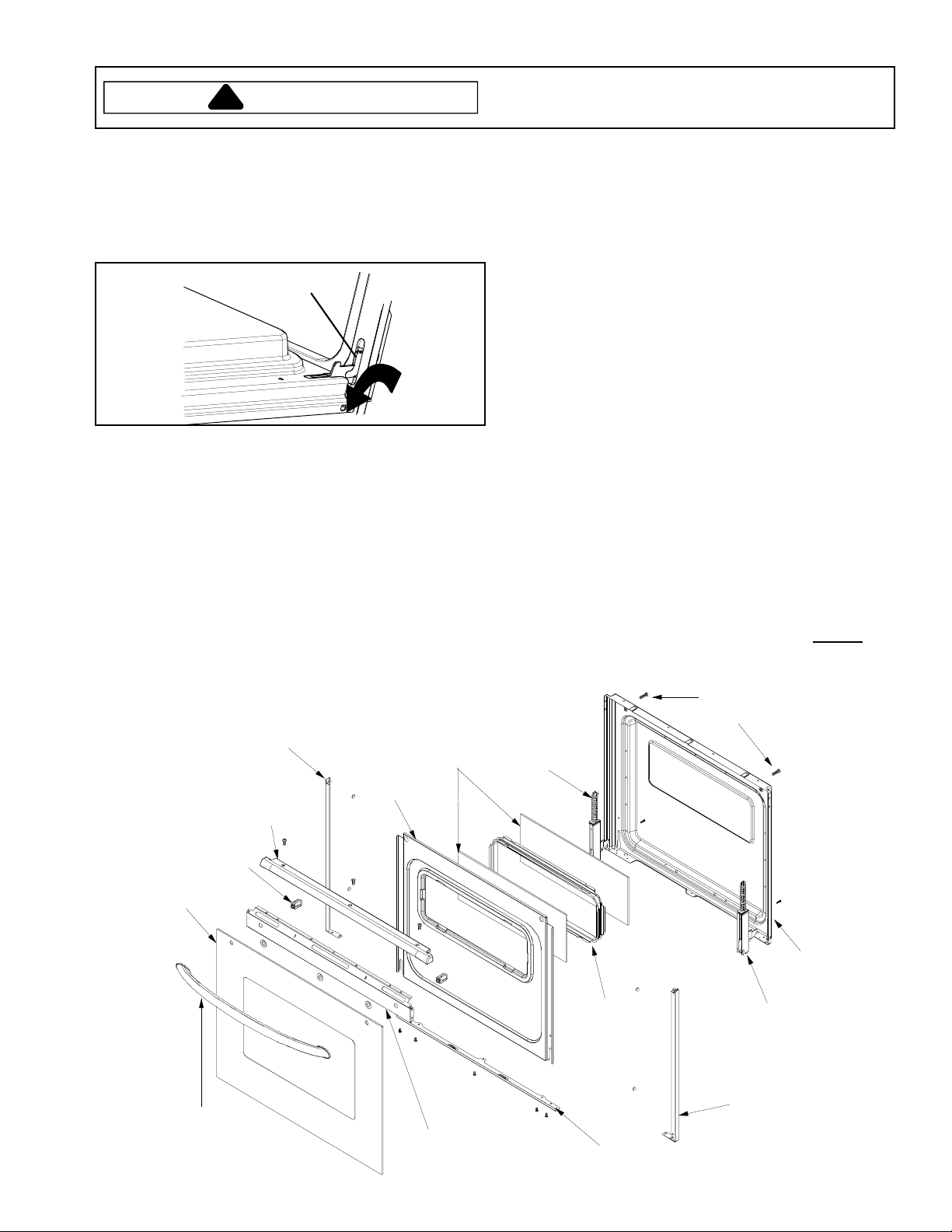

Oven Door Handle, Outer/Inner Glass, and

Door Hinges

1. Open or remove storage drawer to avoid damaging

finish.

2. Fully open the oven door, while open rotate both

hinge locking tabs into the LOCK position.

Hinge Lock

Oven

Door

3. Close oven door about all the way. The hinge locking

tabs will prevent the door closing completely.

4. Lift up equally on both sides of oven door. Hinges will

disengage from hinge receivers and oven door can

be removed.

5. Place oven door, with outer door glass facing

downward on a padded flat surface.

6. While supporting outer door glass, remove screws

securing left and right side the OVEN DOOR

HANDLE.

7. Again support outer door glass and turn door

assembly so outer door glass is facing upward and

remove outer oven door glass.

Side Door

Trim

Top Door

Trim

Heat

Shield

Window

Glass

NOTE: May need to loosen screws in bottom glass

retainer.

8. Remove screws and neoprene washer from the

bottom of OVEN DOOR HINGE and one screw

securing oven door hinge to the door assembly.

NOTE: Hinges are interchangeable.

9. Remove screws securing top of door trim. Lift up and

twist trim towards bottom of door to disengage plastic

finger tabs.

10.All outer perimeter door trim can now be removed.

11. After removing the OFFSET screws from left and

right door glass trim, access is gained to the door

glass heat shield.

12.Remove screws from each side and screws from top

of door glass heat shield. Note position of plastic door

handle supports remove same.

13.Lift out galvanized insulation retainer and fiberglass

insulation.

14.Remove the tempered glass panes individually as

well as the glass frame.

NOTE: Tempered glass panes do not have an inner or

outer side. Be careful of fingerprints before

reassembly.

NOTE: Position replacement hinges into LOCK

position by using channel lock pliers PRIOR to

installing oven door on range.

Door

Handle

Screw

Door

Hinge

Oven

Door

Window

Door

Handle

Bushing

Door Glass

Heat Shield

Oven

Door

Backer

Window

Frame

Glass Support

Door

Hinge

Side Door

Trim

11 RS2320006 Rev. 0

Disassembly Procedures

WARNING

!

To avoid risk of electrical shock, personal injury or death;

disconnect power supply source before servicing, unless

testing requires it.

Reverse Procedure to Reassemble Oven

Door

Position slot on oven door hinge arms into the hinge

receivers. When slot is engaged into the hinge

receivers, open the door just far enough to rotate both

hinge locking tabs to the UNLOCK position.

Oven Door Gasket

The braided fiberglass oven door gasket is clipped at

intervals in holes around the front of the oven liner then

inserted into a 3/8inch holes at the bottom.

A 6 1/2 inch gasket void at the bottom does not interfere

with sealing of oven to door.

1. Unclip original gasket from front frame and pullout

ends from 3/8inch holes.

2. Remove two knurled nuts securing oven bottom in

position. Remove oven bottom.

3. Divide oven gasket in half and insert center clip into

top center hole in the front frame. Proceed inserting

clips left and right.

4. Push gasket through the 3/8inch holes. From behind

the holes gently pull on the gasket ends to provide a

neat appearance. Then tuck the ends between cross

brace and front frame. Assure that gasket ends are

not visible through air intake slots. If so, reposition

prior to installing oven bottom and oven door.

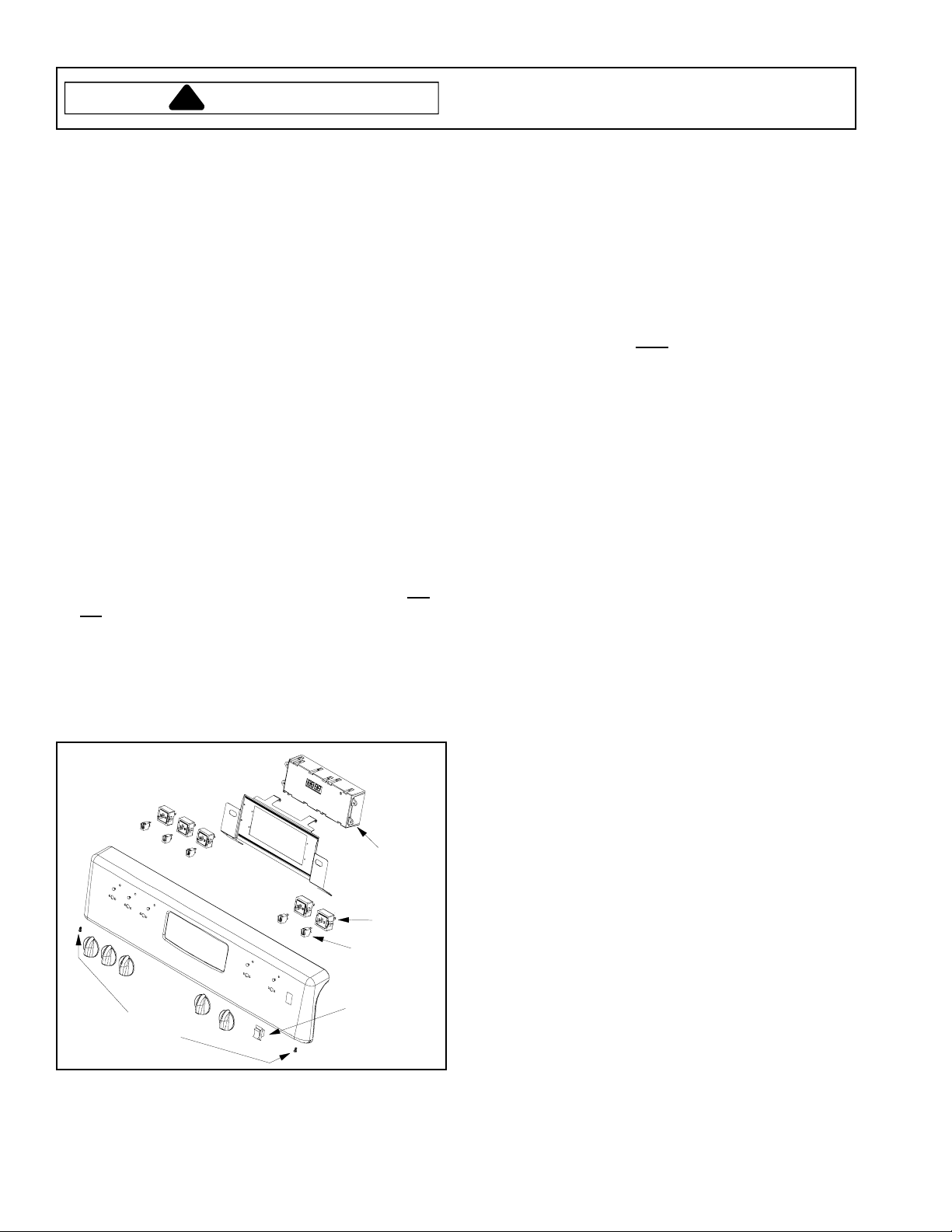

Electronic Control

1. Turn off electric supply to oven.

2. Using a stubby phillips screwdriver remove the

offset screws from the bottom front of control panel.

4. Place control panel on a protective padded surface

with the control down. Remove screws securing

electronic control to mounting bracket. There is

sufficient extra wire length to move electronic control

out of the way while installing new control. Transfer

electrical wires/connectors one at a time to new

control.

NOTE: When reinstalling control panel, be certain the

fiberfax insulation and its galvanized retainer is

above the flue cutout in control panel. Insulation

and retainer are NOT visible when correctly

positioned. Verify backguard heat shield (above

flue) is inside backguard panel and not visible

when installed.

5. Reverse procedure to reattach control panel to range.

Infinite Switch

1. Turn off power to unit.

2. Remove backguard, see "Electronic Control"

procedure.

3. Disconnect and label wire terminals.

4. Remove infinite switch knob from infinite switch.

5. Remove screws in front securing infinite switch.

6. Reverse procedure to reinstall.

Indicator Light

1. Turn off power to unit.

2. Remove backguard, see "Electronic Control"

procedure.

3. Disconnect and label wire terminals.

4. Slide indicator light sideways to release from indicator

light lens.

5. Reverse procedure to reinstall.

Clock

Infinite

switch

Indicator

light

Offset

screws

3. Rotate bottom of control panel outward, then lift up to

disengage top tabs.

RS2320006 Rev. 0 12

Rocker

switch

Disassembly Procedures

WARNING

!

To avoid risk of electrical shock, personal injury or death;

disconnect power supply source before servicing, unless

testing requires it.

Maintop

NOTE: Requires range to be moved out away from the

wall.

1. Turn power off to unit.

2. Slide range forward on slide guards.

NOTE: Usage of slide guards, prevents the unit from

damaging the floor.

3. Unplug the power cord.

4. Remove screws securing maintop to oven frame,

located in front, above the oven door.

5. Raise and support the maintop to gain access to wire

terminals.

6. Label and disconnect wire terminals from elements.

7. Remove screws securing elements support brackets

to the maintop. Type of brackets may vary.

NOTE: When removing elements from maintop mark or

label elements for reassembling.

Door Latch Motor, Plunger Light Switch,

and Latch Switch

1. Disconnect electrical supply to range.

2. Remove maintop, see Maintop procedure.

3. Remove screws in front and on right side securing

latch mechanism to range front frame and galvanized

insulation retainer.

4. Carefully maneuver assembly to the rear to clear door

catch and light switch plunger.

5. Move assembly to the left side then lift up on the right

side. After clearing the insulation retainer turn

assembly upside down to access screws securing

components to mounting plate.

6. Reverse procedures to reassemble.

NOTE: Latch motor, rod, and catch are not sold

separately.

Typical maintop assembly

8. Remove screws securing hinge to the maintop.

9. Remove maintop.

10.Reverse procedure to reinstall.

Bake Element

1. Turn off power to unit.

2. Remove all utensils and racks from oven cavity.

3. Remove oven door, see "Oven Door" procedure.

4. Remove screws securing oven bottom to the bottom of

the oven cavity.

5. Remove bake element cover.

Push downward on the front portion of the bake

element cover. This will raise the rear of the cover.

Grasp the back portion of the cover and slide

cover towards the rear of the oven cavity,

releasing the front portion of the cover from the

oven cavity.

Remove the cover from the oven cavity.

6. Remove screws securing bake element to the oven

cavity.

7. Pull element and wires into oven cavity.

NOTE: Pull bake element forward enough to disconnect

terminals on each element leg.

8. Disconnect terminals from each element leg.

9. Reverse procedure to reinstall bake element.

13 RS2320006 Rev. 0

Disassembly Procedures

WARNING

!

To avoid risk of electrical shock, personal injury or death;

disconnect power supply source before servicing, unless

testing requires it.

Broil Element

1. Turn off power to unit.

2. Remove screw securing broil element to rear of oven

wall.

3. Remove screws securing element hanging clip to

oven cavity.

4. Pull broil element forward enough to disconnect

terminals on each element leg.

5. Reverse procedure to reinstall broil element.

Sensor, Oven Control

1. Remove screws securing SENSOR to oven liner.

2. Gently pull wires forward to access the two pin

polarized disconnect plug.

3. Disconnect and reconnect new sensor.

4. Reverse procedure to reassemble.

NOTE: Verify disconnect terminal is behind the rear

insulation retainer.

Oven Light and Oven Light Socket

1. Disconnect electrical supply to oven.

5. Reverse procedures to reassemble.

Flue

NOTE: Requires removal of range.

NOTE: Self-clean cycle is highly recommended before

replacing flue. Ease of disassembly and

reassembly is much easier.

1. Disconnect electrical supply to range.

2. Using floor protection guides, slide range forward.

3. Remove backguard shield from rear of backguard.

4. Remove screws securing smoke eliminator located

inside, at top of oven cavity.

5. Pull flue out away from the range.

Replacing Flue

1. Place a thin but rugged piece of cardboard in the slot

where flue goes, this holds the insulation up and out

of the way for reassembly.

2. Align the smoke eliminator screen through oven and

secure with screws.

3. Reassemble in reverse order.

Leveling Leg Bracket

Remove screws securing bracket to chassis.

Front Frame and Oven Liner

Front Frame and Oven Liner are NOT field replaceable

on these units.

2. Wearing protective gloves unscrew the knurled

mason jar lens cover counterclockwise about 3/4

turn and remove. Unscrew old oven light bulb.

3. Remove screws securing oven light socket to the

oven cavity.

4. Pull oven light socket out through the front and

disconnect wire terminals from socket.

NOTE: Reposition fiberglass insulation around oven

light socket to eliminate possibility of heat

related problems.

Side Panel

1. Remove maintop, see Maintop procedure

steps 1 7.

2. Remove lower access panel, located on the rear of

unit.

3. Remove screws securing backguard bracket to side

panel.

4. Remove oven door from unit and slide oven drawer

outward to gain access to screws.

5. Remove screws securing side panel to oven chassis.

Screws are located on top, front, and back of unit.

6. Remove side panel by pulling outward on the back of

panel and sliding panel forward.

7. Reverse procedure to reassemble.

RS2320006 Rev. 0 14

Disassembly Procedures

WARNING

!

To avoid risk of electrical shock, personal injury or death;

disconnect power supply source before servicing, unless

testing requires it.

Storage Drawer Removal

1. Pull drawer out until it stops.

2. Grasp drawer sides near back of drawer and lift up

and out.

3. Reverse procedure to reinstall storage drawer.

Storage Drawer Tracks

1. Remove storage drawer from unit.

2. Remove bolt and nut securing track to the chassis

(located in the front of the unit).

3. Slide track backwards and then forward to remove

track.

Removing and Replacing Range

1. Disconnect power to range.

2. Slide range forward on slide guards.

NOTE: Usage of slide guards, prevents the unit from

damaging the floor.

3. Unplug range cord and place range aside.

4. Remove anti-tip bracket.

5. Install anti-tip bracket into new location using

instructions provided with bracket.

6. To reinstall range, follow instructions in Installation

section of this manual.

Power Cord

1. Slide unit outward to gain access to power cord.

2. Unplug power cord from receptacle.

3. Remove screw securing power cord to unit chassis.

4. Disconnect power cord.

5. Reverse procedure to reassemble.

NOTE: Power cord NOT supplied with unit.

15 RS2320006 Rev. 0

Disassembly Procedures

WARNING

!

This page intentionally left blank.

To avoid risk of electrical shock, personal injury or death;

disconnect power supply source before servicing, unless

testing requires it.

RS2320006 Rev. 0 16

Appendix A

A1 RS2320006 Rev. 0

Instructions

Electric Range

Installa tion

ImportantSave for local electrical inspectors use.

Keep instructions for future reference.

Be sure manual stays with range.

Read entire instruction before beginning installation.

Read Owners Manual for safe installation.

TM

Youll Need a Few

Things Before You Begin

3RZHU&RUG

ZLUHRUZLUH

DQG6WUDLQ5HOLHI

:UHQFK

1XW'ULYHU

RU6RFNHWV

6FUHZ

'ULYHUV

/HYHO

7DSH0HDVXUH

PREPARE TO

INSTALL RANGE

1

AND INSTALL

ANTI-TIP

BRACKET

Measure cabinet area and prepare

it according to illustrations in

Minimum Clearances to

Combustible Surfaces and Range

and Cabinet Dimensions section in

this manual.

Remove the packing materials and

locate the anti-tip bracket, screws,

plastic anchors and anti-tip bracket

installation instructions.

$QWLWLS

EUDFNHWFDQ

EHLQVWDOOHG

RQHLWKHU

VLGHRI

UDQJH

Anti-tip

Bracket

Installation

To reduce risk of range tipping,

secure range with a properly

installed anti-tip bracket. Refer to

anti-tip bracket installation

instructions. Do not proceed

with installation until this step

has been completed.

Once anti-tip bracket has been

installed, proceed to the next

step of the installation.

'ULOODQG'ULOO%LW

IRUZRRGIORRU

IRUFRQFUHWHIORRU

RS2320006 Rev. 0 A2

"

"

CONNECT

ELECTRICAL

2

CORD

To place electrical receptacle, see

Electrical Receptacle Location

diagram in this manual.

Range has been grounded at the factory to the center (nickel plated)

terminal of the terminal block in accordance with the National Electric Code.

When a separate ground is required by local code, disconnect the grounding

strap from the terminal block. Ground frame by connecting a grounding wire

to range frame using the grounding strap and screw, as shown below,

removed from the grounding strap.

$FFHVV

FRYHU

/

6WUDLQUHOLHI

QRWVXSSOLHGZLWKUDQJH

1HXWUDO

3-wire or 4-wire Plug Connection

Four-wire cord is required for mobile homes or where codes (Canada) do

not permit grounding through neutral.

1. Remove access cover from rear of range.

2. Use a strain relief (not supplied) and insert end of power cord (not

supplied) through power supply hole.

3. 4-wire Plug OnlyRemove the green ground screw from range back.

Remove both the hex nuts and the grounding strap from the center

terminal. Position grounding strap down and away from terminal block.

Replace 1 hex nut on the center terminal. Attach the power cord

ground wire (green or bare) and grounding strap to rear bulkhead using

ground screw.

4. Unscrew and use top hex nut to attach the power cord wires to the

terminal block as follows:

Red wire to L1 terminal.

Black wire to L2 terminal.

White wire to Neutral terminal.

5. Tighten all hex nuts and reinstall access cover removed in step 1.

ZLUH&RUG,QVWDOOHGZLUH&RUG,QVWDOOHG

1HXWUDO

/

/

5HG

:KLWH

%ODFN

Converting 3-Wire to 4-Wire Power Cord

1. Remove access cover from rear of range.

2. Remove bottom strain relief screw and retain for further use.

3. Remove hex nuts from terminal block and retain for further use.

4. Remove all 3-wire or cable leads from the terminal block and proceed to

remove the power cord from the range by pulling in a downward motion

so the cord is removed from strain relief.

5. To install the 4-wire cord, follow the 4-wire instructions shown above.

5HG

:KLWH

%ODFN

*URXQG

VFUHZ

/

*URXQG

VWUDS

*URXQG

ZLUH

A3 RS2320006 Rev. 0

POSITION AND

3

LEVEL RANGE

Place range near final position and

plug in. Then, slide range into final

position and adjust all legs (4) until

range is level side to side and front

to back.

Place a level on top oven rack or

on range top when leveling.

Leveling legs must extend ¼" to

engage anti-tip bracket.

Remove

Storage

Drawer and

Check Anti-tip

Bracket

After range is in position,

remove storage drawer or lower

panel and confirm anti-tip bracket is

engaged with range leveling leg.

To remove storage drawer

1. Slide drawer out until it stops.

2. Grasp drawer sides near back of

drawer.

3. Lift up and out. Reverse to

reinstall.

To avoid

damaging oven

door, do not lift or

move range by

oven door handle.

Glass can break.

Removal and Replacement of Range

1. Disconnect power to range.

2. Slide range forward.

3. Unplug range cord and place range aside.

4. Remove anti-tip bracket.

5. Install anti-tip bracket into new location using instructions provided

with bracket or see Anti-tip Bracket installation section in this

manual.

6. To reinstall range, follow instructions in this manual.

Questions?

See Owners Manual or call Amana

Consumer Affairs Department

1-800-843-0304

RS2320006 Rev. 0 A4

Installation Requirements

Consider Description

Before You Install

Location

Electrical Requirements

This range can be installed flush against right and left base cabinets, and rear

vertical wall. Range can also be installed flush against left or right vertical wall

extending above 36" standard countertop height.

Use dimensions shown in this manual to determine space needed for

installation.

Range must not be installed or stored in an area where it will be exposed to

water and/or weather. Range is heavy and must not be installed on soft flooring

such as cushioned vinyl or carpeting. If this type of flooring is present where the

range will sit, ¼" thick sheet of plywood or similar material should be placed

where the range will be installed.

Irregular Cabinet and Countertop Heights

Countertops such as ceramic tile tops cause cabinet and countertop to be higher

than 36". Follow instructions below when countertop is higher than 36".

1. Raise leveling legs to maximum height.

2. Measure from floor to rangetop. If the height of the range is less than height

of countertop, floor must be shimmed.

3. Shim floor using a piece of plywood same size as range opening. Secure

plywood to floor. Plywood must be as secure as original flooring.

4. Install anti-tip bracket and slide range into place.

Electrical Supply

Range needs a 3 or 4 wire 240 Volt AC, 40 amp, 60 Hertz, 1 Phase electrical

supply. Wiring system and grounding must conform with the latest edition of the

National Electric Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA

C22.1. Installation must conform to all local, municipal and state building codes,

and local utility regulations. Connect range to power supply with MAXIMUM

RATED VOLTAGE listed on the rating plate. Line voltage must not exceed rated

voltage.

Copper Wire

Terminal block is approved for copper wire connection only. If aluminum house

wiring is to be connected to the cooktop, use only connectors designed for

joining copper to aluminum and follow the manufacturer’s recommended

procedure closely. The following procedure is suggested:

1. Connect length of copper building wire to range terminal block with ring

terminals.

2. Splice copper wires to aluminum wiring using connectors that are design

certified by Underwriter’s Laboratories and recognized for joining copper to

aluminum. Follow the connector manufacturer’s recommended procedure.

3. Wire used, location and enclosure of splices must conform to local codes.

Pow er Cord

Power cord is not supplied with range. Power cord must be U.L. or C.S.A. listed

and meet NEC and Mobile Home Manufacturers Association Standards. Cord

must be rated at a minimum 250V—40 AMP, equipped with a plug configuration

in accordance with NEMA. Conductors must end with closed loop (ring)

terminals at the range.

• Three-conductor cord plug NEMA 10-50P allowed for residential in U.S.

• Four-conductor cord plug NEMA 14-50P required in Canada and for most

mobile home installations, but can be used for residential.

NOTE: Only a power cord suitable for use with ranges may be used.

For installation in a mobile home, or area where local codes (Canada)

do not permit grounding through the neutral terminal, a 4-wire cord

must be used.

A5 RS2320006 Rev. 0

Range and Cabinet Dimensions

Electrical Receptacle Location

Locate electrical receptacle in area with diagonal lines.

RS2320006 Rev. 0 A6

Important Safety Information

WARNING

!

To avoid risk of burns or fire by

reaching over elements, cabinet

storage space located above

range should be avoided. If

cabinet storage is provided,

install a range hood that projects

horizontally a minimum of 5"

beyond the cabinet bottom to

reduce the risk.

To avoid risk of the appliance tipping, it must be secured by a

properly installed anti-tip bracket. To make sure bracket has been

installed properly, remove the storage drawer or panel and look

under the range with a flashlight. Bracket must be engaged in the

rear corner of the range.

WARNING

!

ALL RANGES CAN TIP

INJURY TO PERSONS

COULD RESULT

WARNING

!

To avoid risk of electrical shock,

personal injury, or death, make

sure your range has been

properly grounded and always

disconnect it from main power

supply before servicing.

INSTALL ANTI-TIP

BRACKET(S) PACKED

WITH RANGE

SEE INSTALLATION

INSTRUCTIONS

Minimum Clearances to Combustible Surfaces

This range can be installed flush against right and left base

cabinets, and rear vertical wall. Range can also be installed

flush against left or right vertical wall extending above 36"

standard countertop height. The dimensions provided are

to be measured from the range itself, and not the

installation cutout for the range.

AMinimum of 30" between top of cooking surface and

bottom of an unprotected wood or metal cabinet.

OR

AMinimum of 24" between cooking surface and wood or

metal cabinet bottom protected by not less than ¼" thick

flame retardant millboard covered with not less than No. 28

MSG sheet steel, .015 inch thick stainless steel, .024 inch

thick aluminum, or .020 inch thick copper.

BMinimum of 30" of protected cabinets above the range

(refer to letter A)

CMinimum of 18" between top of countertop and bottom of

an unprotected wood or metal cabinet.

DMaximum depth of 13" for overcounter cabinets.

%

&

$

'

Part No. 36-32055801-0

Printed in U.S.A. 03/01

SAVE THESE INSTRUCTIONS

Ó 2001 Amana Appliances

Amana, Iowa 52204

A7 RS2320006 Rev. 0

This page intentionally left blank.

RS2320006 Rev. 0 A8

Appendix B

B1 RS2320006 Rev. 0

Care and Cleaning

CAUTION

!

To avoid personal injury or

property damage, handle oven

door with care.

Do not lift door by handle.

Remove storage drawer.

Door is heavy and can be

damaged if dropped.

Screwdriver can scrape or

chip range or oven finish.

Do not scratch or chip glass

or twist door. Glass may break

suddenly.

Replace door glass if damaged.

Cleaning Oven Door

Not all areas of the oven are cleaned

by the self-clean cycle. The oven

door, the gasket and area

surrounding the gasket will not be

cleaned effectively by the self-clean

cycle. DO NOT use spray cleaners

to clean the outside or inside of the

oven door.

Removing Oven Door

1. Fully open oven door.

2. Push hinge locks down toward door

frame, to the unlocked position.

This may require a flatblade

screwdriver.

3. Firmly grasp both sides of top of oven

door.

4. Close door to first stop position.

5. Lift door up until hinge arm is clear of

the slot.

2YHQ

'RRU

2YHQ)UDPH

+LQJH/RFN

Replacing Oven Door

1. Grasping door top firmly, seat indentation of hinge arm into bottom edge

of the hinge slot.

Door should be at the first stop position angle.

2. Fully open oven door.

3. Push hinge locks up against the front frame of the oven cavity to locked

position.

4. Close oven door.

Door Gasket

DO NOT clean the gasket. Do not

wet, rub, soak or use any type of

cleaning material to clean the oven

gasket. Any damage or defects

occurring from attempting to clean or

remove the gasket are not covered

by warranty.

To clean the area around the gasket

make sure oven is cool to the touch.

Using a cloth with a mild soap wipe

area needing to be cleaned. Avoid

gasket. Gasket should not be

removed while cleaning. Do not allow

water or cleaning solution to spill or

drip onto gasket.

Removing Storage

Drawer

1. Slide drawer out until it stops.

2. Remove stored items.

3. Grasp drawer sides near back of

drawer.

4. Lift up and out. Reverse to

reinstall.

RS2320006 Rev. 0 B2

Care and Cleaning

WARNING

!

To avoid risk of burns or electrical

shock:

disconnect electrical supply to

oven before changing light bulb.

before replacing light bulb make

sure oven and bulb are cool.

Do not operate oven without

bulb and cover in place.

CAUTION

!

To avoid risk of personal injury,

Wear gloves to protect hands

from accidental bulb breakage.

Replacing Oven Light

1. Disconnect electrical supply.

2. Remove oven door if desired.

3. While wearing protective gloves, unscrew counterclockwise the

light bulb cover located in rear of oven cavity.

Then turn light bulb counterclockwise to remove.

4. Replace light bulb with 120-volt, 40-watt appliance bulb.

Do not over tighten bulb or cover or they may be difficult to

remove later.

5. Replace light bulb cover and oven door before use.

6. Reconnect power supply.

To keep your smoothtop looking like new, Amana recommends routine cleaning. The following general instructions

for routine and tough spot cleaning are based on the performance of Amana recommended products. To order these

products, contact the Consumer Affairs department at 800-843-0304.

PART GENERAL DIRECTIONS

Broil element

Do not clean broil element. Any soil will burn off when element is heated.

Broiler pan and grid

Drain fat, cool pan and grid slightly. (Do not stand soiled pan and grid in oven to cool.) Sprinkle with soap. Fill

the pan with warm water. Let pan and grid stand for a few minutes

Control knobs

Pull off knobs. Wash gently with mild soap and water but do not soak. Dry and return knobs to oven, making

sure to match flat area on the knob to the flat area on the shaft.

Outside finish

Wash all glass with cloth dampened in soapy water. Rinse and polish with a dry cloth. If knobs are removed, do

not allow water to run down inside surface while cleaning.

Oven racks

Storage drawer

For heavy soil, place oven racks in large plastic bag with ammonia and water in cup. Seal tightly and allow to

stand overnight. Wash and rinse, dry thoroughly.

For heavy soil, clean by hand and rinse thoroughly. Remove drawer for ease in cleaning. Be sure drawer is dry

before replacing.

B3 RS2320006 Rev. 0

Care and Cleaning

Caring for the smoothtop

For routine cleaning, allow top to cool before cleansing. Wash surface with a dampened cloth and smoothtop cleaner

conditioner. Use another clean damp paper towel to wipe off the cleaner. Use a dry paper towel, buff the smoothtop

to make sure all the cleaner conditioner is removed. The smoothtop cleaner conditioner provides a thin layer of

protective polish that helps to prevent scratching. Do not use a harsh cleanser or steel wool pad. For specific

problems, see below.

PROBLEM CAUSE REMOVAL

Brown streaks

and specks

Blackened,

burnt on spots

Fine brown gray

lines, fine

scratches or

abrasions

Smearing or

streaking

Metal or

silver/gray

marks

Pitting or flaking

Hard water

spots

Cleaning with sponge or cloth containing

soiled detergent water.

Spatters or spillovers on a hot cooking area or

accidental melting of plastic like a bread bag.

Course particles, like salt, become embedded

in top if trapped under pan. Using abrasive

cleaning materials. Scratches from rough

ceramic, glass, or ceramic coated cookware.

Using too much smoothtop cleaner conditioner

or using a soiled dish cloth.

Sliding or scraping metal utensils across top. Remove marks before top is used again. If marks

Boilovers of sugar syrup on a hot smoothtop

can cause pitting if not removed immediately.

Condensation from cooking can cause

minerals found in water and acids in food to

drip onto smoothtop and cause gray deposits.

Spots are often so thin they appear to be in or

under smoothtop.

Normal cleansing (provided above).

Clean area with smoothtop cleaner conditioner

with clean damp paper towel, nonabrasive nylon

pad, or scouring brush.

If spot is not removed, on cool cooktop carefully

scrape area with a safety scraper held at a 30degree angle.

Fine scratches are not removable but can be

minimized by daily use of smoothtop cleaner

conditioner.

Follow label instructions carefully. See Routine

Cleaning, above.

are not removed by normal cleaning, use a safety

scraper at a 30° angle and cooktop cleaner

conditioner to carefully scrape off the mark.

Turn control to LOW setting. Wipe up excess spill

with dry cloth. Allow top to cool and carefully

scrape area with a safety scraper held at a 30degree angle.

Mix smoothtop cleaner conditioner with water and

apply thick paste to stained area. Scrub

vigorously. If stain is not removed, reapply cleaner

and repeat process

OR

make sure the surface is cool and put a small

amount of white vinegar on the spot and let it sit a

few minutes. Using a nonabrasive nylon pad,

gently rub the spot. Wipe off any excess with a

damp paper towel, then dry.

RS2320006 Rev. 0 B4

Care and Cleaning

Cleaning Stainless Steel

Damage to stainless steel finish due to improper use of cleaning

products, or using non-recommended cleaning products, is not

covered under warranty. For Amana recommended products, call

Consumer Affairs at 1(800) 843-0304 or online at www.amana.com.

Our stainless steel appliances have been factory finished for high shine

and luster. To maintain this quality appearance:

DO USE:DO NOT USE:

Can I use liquid

cleaners on my stainless

steel?

Just because a cleaner is a

liquid does not mean it is non-abrasive.

Many liquid cleansers designed to be

gentle on tile and smooth surfaces still

damage stainless steel. Cosmetic

damage from using non-recommended

products is not covered under warranty.

Citric Acid

Citric acid permanently

discolors stainless steel.

To prevent damage to

the finish of your stainless steel

appliance, do not allow these

substances to remain on the steel

finish:

Abrasive powders or liquids

Citrus based cleaners

Ammonia

Steel wool pads

Abrasive cloths

Oven cleansers

Acidic or vinegar based cleaners

Warm soapy water for routine

cleaning

Soft clean cloths to dry or polish

Stainless steel cleaner designed

for appliances such as Amana

Cleaning Polish and

Conditioner for Stainless Steel

(#31960801)

For best cleaning results

1. Wash surfaces with warm soapy water and a soft, clean cloth or

sponge.

2. Rinse surfaces with warm water. Dry surfaces with a soft, clean cloth.

DO NOT use the following harsh cleaners:

abrasive or acidic cleaners (ammonia, chlorine bleach, vinegar-based

product, etc.)

citrus-based cleaners

scouring pads (metal, textured plastic, etc.)

These items can scratch, discolor, or permanently tarnish surfaces.

3. Follow up rinsing by immediately drying with a soft, clean cloth. This will

avoid water spotting on stainless steel finish.

mustard

tomato juice

marinara sauce

citrus based sauces

citrus based products

Questions? Comments?

Concerns? Contact us!

www.amana.com

or call Consumer Affairs at

1-800-843-0304

B5 RS2320006 Rev. 0

This page intentionally left blank.

RS2320006 Rev. 0 B6

Appendix C

C–1 RS2320006 Rev. 0

Genesis Control Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

Mylar OverlayKRC

OVEN

TIMER

ON OFF

RECALL

OVEN TEMP

CLOCK

COOK

CLEAN

TIME

START

COOK

CLEAN

OVEN

LIGHT

CLEAN

BROIL

PREHEAT LOCKED

Illustration Component Test Procedure Results

J2

E5

E7

E3

E4

E2

E1

J1

Genesis electronic

range control

On power-up lock

light will blink for

approximately 25

seconds, while

control is verifying

lock latch position.

On power up, if

sensor has failed.

No F−Code will be

displayed.

No oven functions

will start.

PIN 1

Measure voltage at terminals

J2−E7 (L1) and E2 (NEU)................

Relay drive requirements

BakeBA to L2...............................

Broil BR to L2...............................

Bake...............................................

Broil................................................

Clean

Stage 1...........................................

Stage 2...........................................

Time (Adjustable) ...........................

Failure codes:

F1-Control malfunction .....................

F2-Oven over temperature ...............

F3-Oven temperature sensor

Open or Shorted..........................

F9-Door latch circuit malfunction ......

Temperature Calibration .................

120 VAC should be indicated, verifying

voltage to control.

240 VAC, if not replace control.

240 VAC, if not replace control.

75% bake element 25% broil element

100% broil element

Time controlled 60 minutes 100% broil

50% bake element and 50% broil element

2 hours minimum to 4 hours maximum

Verify voltage to control.

If no voltage is present, check wiring.

If voltage is present, replace control.

Check sensor resistance and wiring.

Replace control if sensor and wiring are

good.

Check sensor resistance and wiring.

Replace sensor, if wiring is good.

Check latch switch and associated wiring.

Turn oven control to OFF position.

Press and hold both slew pads for 5 sec.

Use slew pads to adjust temp setting.

After 5 sec. of no input the mode is exited.

OFF

WM

BAKE

PUSH TO TURN

RS2320006 Rev. 0 C−2

Genesis Control Programming Instructions

Setting Electronic Clock

The 12 hour clock does not display AM, PM or military time.

When power is connected or restored, display flashes until

RECALL OVEN TEMP/CLOCK pad is pressed or temperature

knob is turned.

1. Press RECALL OVEN TEMP/CLOCK pad.

2. Press appropriate slew pads until correct time-of-day

displays.

3. Time is locked in after 5 seconds of no adjustment.

Setting Minute Timer

The timer is a timer only. Electronic timer does not control

bake, broil or self-clean function. Timer can be set up to 11

hours and 59 minutes.

1. Press TIMER ON/OFF pad.

2. Press appropriate slew pads until desired amount of time

displays.

• Time increases in 1 minute and 10 minute increments.

• Timer begins counting down automatically after time is

entered.

• To view clock while timer counts down, press RECALL

OVEN TEMP/CLOCK pad. Timer will return after 3

seconds of no input.

3. Press and hold TIMER ON/OFF pad to cancel timer

signal.

• After time elapses, timer beeps a single, three second

tone.

Resetting and Canceling Timer

To reset the time when remaining time is displayed, press

TIMER ON/OFF pad, then appropriate slew pads until new

time displays. To cancel timer when remaining time is

displayed or when signal is beeping, press and hold TIMER

ON/OFF pad.

Baking

While oven is still cool, remove any stored items from the oven

cavity.

1. Place racks in desired position and close oven door.

2. Push and turn oven temperature knob to desired

temperature.

• Oven indicator light will turn on and stay on.

• Temperature is displayed in the clock area in 5°

increments.

• Temperature range is 170°F to 550°F

• Display will return to time of day after approximately 1

5 seconds.

• To recall oven temperature, press RECALL OVEN

TEMP/CLOCK pad.

3. PREHEAT light will turn on during the preheat cycle.

• PREHEAT light shuts off when oven has reached

desired temperature and oven beeps.

4. Open door carefully and place food in oven.

5. After cooking time elapses, remove food and turn oven

temperature knob to OFF.

Broiling

Broiling sears in natural juices and provides charbroiled flavor.

To broil, center food on broiling grid and pan and place on

proper rack in oven. Oven door must be fully closed.

Broiling does not require preheating so you can place food in

oven while it is still cool.

• Do not place aluminum foil over boiling pan, oven rack or

oven bottom.

1. Adjust oven racks to desired position.

2. Turn oven temperature knob to BROIL.

• Oven indicator light will turn on and remain on.

• BRL will display.

• Display will return to time of day approximately 15

seconds after broiling begins.

3. Close oven door.

• If oven door is ajar for more than 3 minutes, broil cycle

will stop.

• If broil cycle stops because the door was open too long,

close oven door and broil cycle will continue.

4. After broiling, remove food and turn oven temperature

knob to OFF.

Timed Baking

Set oven to cook for desired amount of time. Follow recipe

directions for preheating the oven.

1. Place food in oven.

2. Press COOK/CLEAN TIME pad.

3. Press appropriate slew pad until desired length of time is

displayed.

• Cook time can be set up to 11 hours and 59 minutes.

4. Push and turn the temperature control knob.

• Temperature displays in 5° increments starting at

170°F.

• Clock will return to time of day after approximately

15 seconds.

• To recall oven temperature, press RECALL OVEN

TEMP/CLOCK pad.

5. Oven will automatically begin to heat.

• To adjust cook time, press COOK/CLEAN TIME pad

twice while the remaining cook time is displayed. Cook

time can then be adjusted.

• When cooking time has elapsed an end of cycle signal

sounds and END will be displayed. Oven no longer

maintains cooking temperature after timed bake is

complete.

• Oven signal sounds 4 times, then once every 10

seconds until oven control knob is turned to OFF.

6. Turn knob to OFF to cancel baking.

Delayed Baking

Set oven to begin baking at a later time.

1. Place food in oven.

2. Press START COOK/CLEAN button.

• Default time displayed is current time of day.

3. Press appropriate slew pad until desired time displays.

• Start time can be set up to 11 hours and

59 minutes ahead of current time of day.

4. Press COOK/CLEAN TIME pad.

5. Press appropriate slew pad until desired cooking time

displays.

• 1 minute minimum cooking time.

• END will be displayed when cooking time has elapsed.

6. Push and turn oven temperature control knob to desired

temperature.

• Temperature displays in 5° increments starting at

170°F.

• Display will return to time of day after 5 seconds of no

input.

• START TIME and COOK TIME lights will remain on, but

OVEN ON light will not turn on until cooking begins.

C−3 RS2320006 Rev. 0

Genesis Control Programming Instructions

7. Oven will automatically begin to heat at selected start

time.

• OVEN ON light will turn on when oven begins to heat.

• To adjust cook time, press COOK/CLEAN TIME pad

twice while the remaining cook time is displayed. Cook

time can then be adjusted.

• When cooking time has elapsed an end of cycle signal

sounds and END will be displayed. Oven signal sounds

4 times, then once every 10 seconds until oven control

knob is turned to OFF. Knob must be turned to OFF

for oven to stop shut off.

8. Turn knob to OFF to cancel baking.

Self-Cleaning

Self-clean feature uses high oven temperature to clean oven

interior. For the oven to operate through a complete self-clean

cycle, the self-clean must be set when the oven is cool.

1. Prepare oven for self-cleaning. Oven bottom recess must

be checked for grease build up before beginning a

self-clean cycle.

2. Close door.

3. Push and turn oven temperature knob to CLEAN position.

• The default self-clean cycle length of 3 hours will

display.

4. Set cycle length for self-clean.

• Use slew pads to adjust time as necessary before oven

indicator light turns on.

• Clean cycle can be set from two to four hours in five

minute increments.

• Default setting for the cycle is three hours.

5. Self-clean begins.

• OVEN ON indicator light will be on and will remain on

until the end of the cycle.

• At the end of the self-clean cycle, the OVEN ON

indicator light will shut off.

• At the end of the self-clean cycle, the oven will stop

heating, however, oven will remain hot.

• The LOCKED indicator light will remain on until oven

reaches a cooler temperature. LOCKED light will flash

while door is unlocking, and then shut off when door

has unlocked. Oven cavity will be hot to the touch.

• DO NOT attempt to open door prior to LOCKED

indicator light shutting off. When oven is cool, turn oven

knob to OFF.

Interrupting the self-clean cycle

To stop a self-clean cycle that has already started follow these

steps. If an interruption occurs mid cycle, the oven will remain

locked, even though the cycle has stopped, until the oven

cavity has cooled to a lower temperature.

1. Turn oven temperature knob to OFF position.

2. When oven has cooled to a lower temperature, LOCKED

light turns off. Door can be unlocked.

• DO NOT force door. This can cause damage to the

latch.

Delayed Self-clean Cycle

Self-clean feature uses high oven temperature to clean oven

interior. Set oven to begin and end cleaning at later time.

Range control begins the self-clean at your specified start

time.

1. Prepare oven for self-cleaning. Oven bottom recess must

be checked for grease build up before beginning a

self-clean cycle.

2. Close door.

3. Press START COOK/CLEAN pad.

4. Set starting time for the cleaning cycle.

• Default time is current time of day.

• Start time can be set from current time to current time

plus 11 hours and 59 minutes.

5. Turn oven temperature knob to CLEAN.

• Default self-clean cycle length of 3 hours will display.

6. Set cycle length for self-clean.

• Use slew pads to adjust time as necessary.

• Clean cycle can be set from two to four hours in five

minute increments.

• Default setting for the cycle is three hours.

7. Self-clean cycle is set.

• Oven cannot be used until completion of the self-clean

cycle.

• Self-clean cycle will begin at selected start time.

• To view start time, press the START COOK/CLEAN

pad.

• OVEN ON indicator light will turn on when the self-clean

cycle begins and will remain on until the end of the

cycle.

• To view the clean cycle time, press the COOK/CLEAN

TIME pad.

• At the end of the self-clean cycle, OVEN ON indicator

light shuts off and the oven does not maintain the high

temperatures. Oven will still be hot, however.

• The LOCKED indicator light will remain on until oven

reaches a cooler temperature. LOCKED light will flash

while door is unlocking, and then shut off when door

has unlocked. Oven cavity will be hot to the touch.

• DO NOT attempt to open door prior to LOCKED

indicator light shutting off. Once oven is cool, turn oven

knob to OFF position.

Interrupting the self-clean cycle

To stop a self-clean cycle that has already started follow these

steps. If an interruption occurs mid cycle, the oven will remain

locked, even though the cycle has stopped, until the oven

cavity has cooled to a safe temperature.

1. Turn oven temperature knob to OFF position.

2. When oven has cooled to a lower temperature, LOCKED

light shuts off. Door can be unlocked.

• DO NOT force door. This can cause damage to the

latch.

RS2320006 Rev. 0 C−4

Appendix D

D–1 RS2320006 Rev. 0

Sigma Control Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires it.

Sigma Touchmatic electronic range control

Features

ERC Controlled

BAKE

BROIL

CLEAN

CLOCK

COOK

OVEN

LIGHT

VFD Display

12 Hour Clock

12 Hour Shutoff

Sabbath Mode (12 hour over ride)

Hour/Minute Timer ( 11:59)

Timed or Delay Bake to (11:59)

Variable Self Clean (2−4 hours)

Variable Broil

Broil interrupt door open over 3 minutes

Child Lockout

ERC - Sigma

Touchmatic electronic

range control

START

- No error. Initial factory setting.

F0-0

- Over temperature whil e

F1-1

cooking.

- Over temperature whil e

F1-3

cleaning.

- Cancel key input out of range.

F1-5

- Keyboard disconnected.

F1-7

- Shorted key.

F1-8

- Slave micro not functioning.

F1-9

- VCC/GND lift off.

F1-A

- Control not cal ibrated.

F1-C

- EEPROM data corruption.

F1-E

- Sensor or sensor circuit failure.

F3-1

- Auto latch will not lock.

F9-1

- Auto latch will not unlock.

F9-2

STOP

OVEN

CANCEL

TIMER

ON/OFF

1

4

2 3

5 6

7 8 9

0

Check sensor and wiring first, replac e

control if sens or is good.

Check sensor and wiring first, replac e

control if sens or is good.

Replace control.

Verify wire connections are tight and

replace control if failed.

Replace control.

Replace control.

Replace control.

Replace control.

Replace control.

Check wire connections and sensor.

Check wiring, mot or, and latch switc h.

Check wiring, mot or, and latch switc h.

RS2320006 Rev. 0 D2

Sigma Control Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless testing

requires it.

Illustration Component Test Procedure Results

ERC Controlled

ERC Controlled

ERC Controlled

ERC Controlled

Temperature

adjustment

(BAKE mode only)

Sabbath mode

(BAKE mode only)

Twelve hour off Control will automatically cancel any

Child lock out Press the 7 key and hold for 3

Press

Press in oven temperature of 500°F.

Immediately press and hold

until current offset appears in display,

approximately 3 seconds.

To decrease or increase oven

temperature. Press

negative or posit ive offset appears .

Oven can be adjusted from 35° to 35°. To avoid over adjusting oven

move temperature in 5° increments

each time.

Press

or press

previous offset setting.

Press

temperature and press

the

8

STAR symbol will flash and “Sab” is

displayed in the temp erature digits

area. The STAR will flash for 5

seconds until Sabbath mode initiates

and temperature displays. Pressing

CANCEL

mode and cancel the bake operation.

Sabbath mode can also be cancelled