Amana NED7400WW Owner's Manual

ELECTRONIC

ELECTRIC DRYERS

Use & Care Guide

For questions about features, operation/performance,

parts, accessories, or service, call: 1-800-843-0304

or visit our website at...

ww.amana.com

w

Table of Contents................................................. 2

W10233410A

TABLE OF CONTENTS

DRYER SAFETY..............................................................................2

INSTALLATION INSTRUCTIONS ..................................................4

Tools and Parts ............................................................................ 4

Optional Pedestal......................................................................... 4

Location Requirements ...............................................................4

Electrical Requirements ............................................................... 6

Electrical Connection ................................................................... 8

Venting Requirements................................................................13

Plan Vent System .......................................................................14

Install Vent System.....................................................................15

Install Leveling Legs...................................................................16

Connect Vent..............................................................................16

Level Dryer .................................................................................16

Reverse Door Swing ..................................................................16

Close door and check that it latches securely.

Complete Installation .................................................................18

DRYER USE ..................................................................................19

Starting Your Dryer.....................................................................19

Stopping or Restarting Your Dryer ............................................20

Lock Controls .............................................................................20

.........................18

DRYER SAFETY

Drying and Cycle Tips ................................................................20

Status Lights...............................................................................20

Cycles .........................................................................................21

Modifiers.....................................................................................22

Options .......................................................................................22

Changing Cycles, Options, and Modifiers

Drying Rack Options ..................................................................22

DRYER CARE................................................................................24

Cleaning the Dryer Location.......................................................24

Cleaning the Lint Screen............................................................24

Cleaning the Dryer Interior .........................................................24

Removing Accumulated Lint......................................................24

Vacation and Moving Care.........................................................25

Changing the Drum Light ...........................................................25

TROUBLESHOOTING ..................................................................25

Dryer Operation ..........................................................................25

Dryer Results ..............................................................................26

ASSISTANCE OR SERVICE .........................................................27

WARRANTY ................................................................................. 28

.................................22

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

2

3

INSTALLATION INSTRUCTIONS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■ Flat-blade screwdriver

■ #2 Phillips screwdriver

■ Adjustable wrench that

opens to 1" (25.4 mm) or

hex-head socket wrench

(for adjusting dryer feet)

■ Wire stripper (for direct

wire installations)

■ Level

Parts supplied

Remove parts package from dryer drum. Check that all parts are

included.

NOTE: Do not use leveling legs if installing the dryer on a

pedestal.

■ Vent cl amps

■ Caulking gun and

compound (for installing

new exhaust vent)

■ Tin snips (new vent

installations)

■ ¼" nut driver or socket

wrench (recommended)

■ Tape measure

4 Leveling legs

Optional Pedestal

Are you placing the dryer on a pedestal? You have the option of

purchasing pedestals of different heights separately for this dryer.

You may select a 10" (254 mm) pedestal or a 15.5" (394 mm)

pedestal with a storage drawer. The pedestal will add to the total

height of the dryer for a total height of approximately

46" (1168 mm) or 51.5" (1308 mm), respectively.

For a garage installation, you wil

pedestal at least 9" (229 mm) above the floor. You will need to

e the 15.5" (394 mm) pedestal at least 3" (76 mm) above the

plac

fl

oor.

Optional pedestal (15.5" [394 mm] model shown)

To order, call the dealer from whom you purchased your dryer or

refer to the “Assistance or Service” section.

Pedestal Height Color Part Number

10" (

254 mm) White WHP1000SQ

394 mm) White XHP1550VW

15.5" (

l need to place the 10" (254 mm)

Parts needed

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

■ For close-clearance installations between 28.65" (728 mm)

and 34.15" (867 mm), see “Plan Vent System” section for

venting requirements.

34.15"

(867.4 mm)

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please refer to the “Assistance

or Service” section.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes

■ A UL listed 30-amp power supply cord, rated

■ A UL listed strain relief.

dryers. The kit should contain:

120/240 volt minimum. The cord should be type SRD

SRDT and be at least 4 ft (1.22 m) long. The wires that

connect to the

dryer must end in ring terminals or spade

terminals with upturned ends.

or

Stack Kit

Are you planning to stack your washer and dryer? To do so, you

will need to purchase a Stack Kit.

To order, call the dealer from whom you pur

chased your washer

or refer to the “Assistance or Service” section. Ask for Part

Number 8572546.

Location Requirements

You will need

■ A location that allows for proper exhaust installation. See

“Venting Requirements.”

■ A separate 30-amp circuit.

4

■ If you are using a power supply cord, a grounded electrical

outlet located within 2 ft (610 mm) of either side of the dryer.

See “Electrical Requirements.”

■ A sturdy floor to support the total dryer weight of 127 lbs

(57.6 kg). The combined weight of a companion appliance

should also be considered.

■ A level floor with a maximum slope of 1" (25 mm) under entire

dryer. (If slope is greater than 1" [25 mm], install Extended

Dryer Feet Kit, Part Number 279810.) Clothes may not tumble

properly and automatic sensor cycles may not operate

correctly if dryer is not level.

■ For a garage installation, you will need to place the dryer

at least 18" (460 mm) above the floor. If you are using a

pedesta

l, you will need 18" (460 mm) to the bottom of

the dryer.

Do not operate your dryer at temperatur

es below 45ºF (7ºC). At

lower temperatures, the dryer might not shut off at the end of an

auto cycle. Drying times can be extended.

The dryer must not be installed or st

ored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

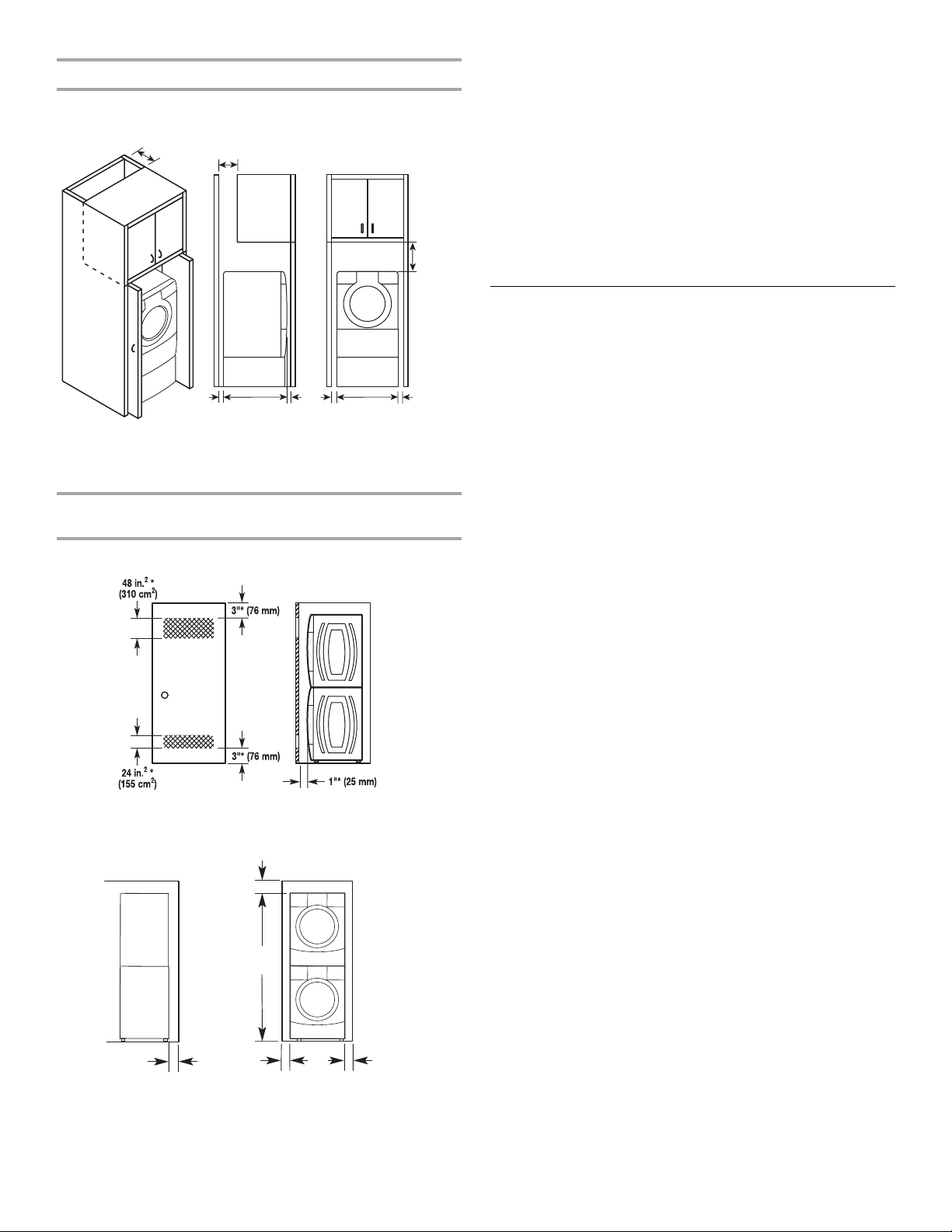

Installation clearances

The location must be large enough to allow the dryer door to

open fully.

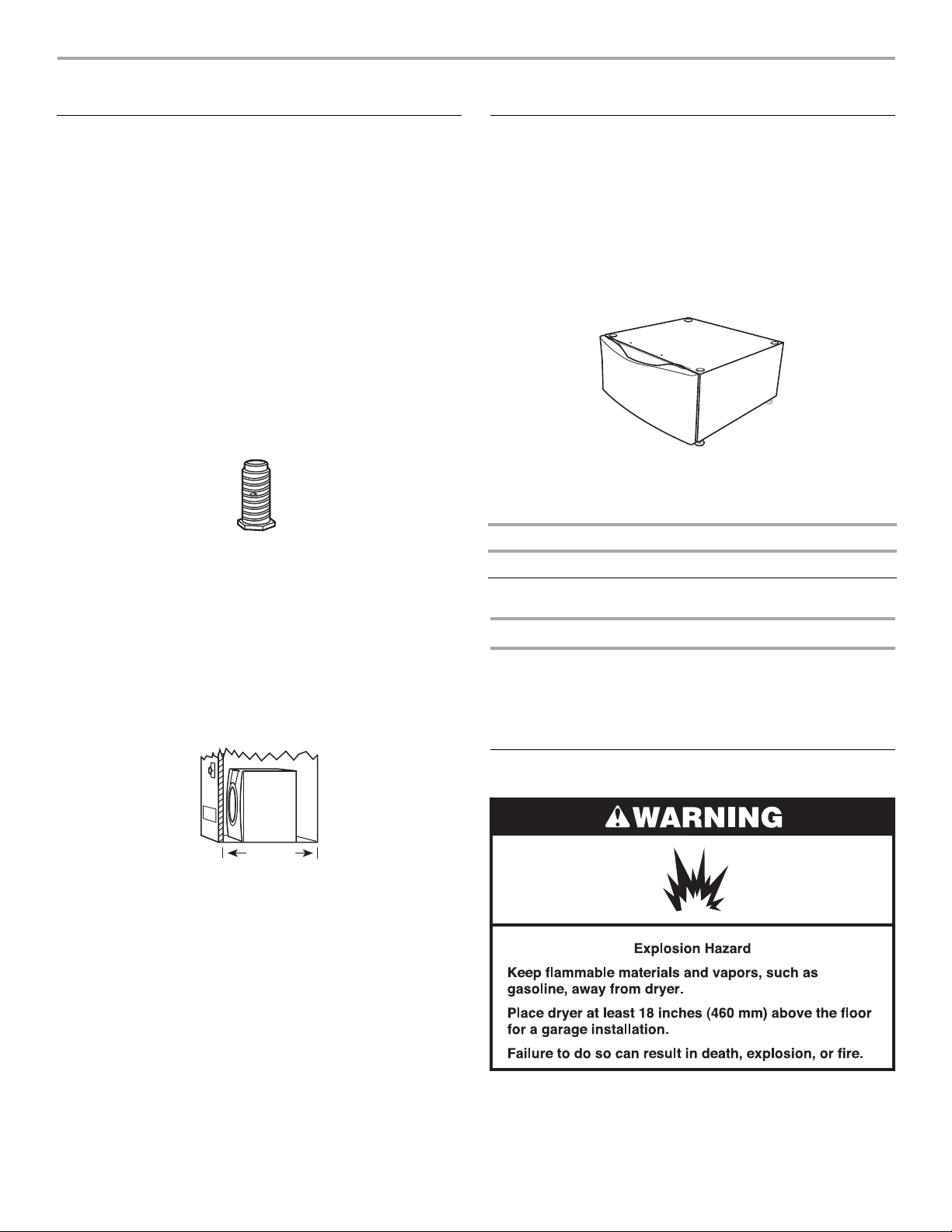

Dryer Dimensions

50"

(1283 mm)

36"

(914 mm)

Custom under

counter installation - Dryer only

36" min

(914 mm)

1"*

(25 mm)

27"

(686 mm)

1"*

(25 mm)

2"*

(50 mm)

*Required spacing

Closet installation - Dryer only

3"*

(76 mm)

3"*

(76 mm)

B

1"*

(25 mm)

14" max.*

(356 mm)

18" min.*

(457 mm)

28.65"

(728 mm)

A

5

"**

(127 mm)

2

48 in.

(310 cm

2

24 in.

(155 cm

*

2

)

*

2

)

A. Side view - closet or confined area

B. Closet door with vents

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed.

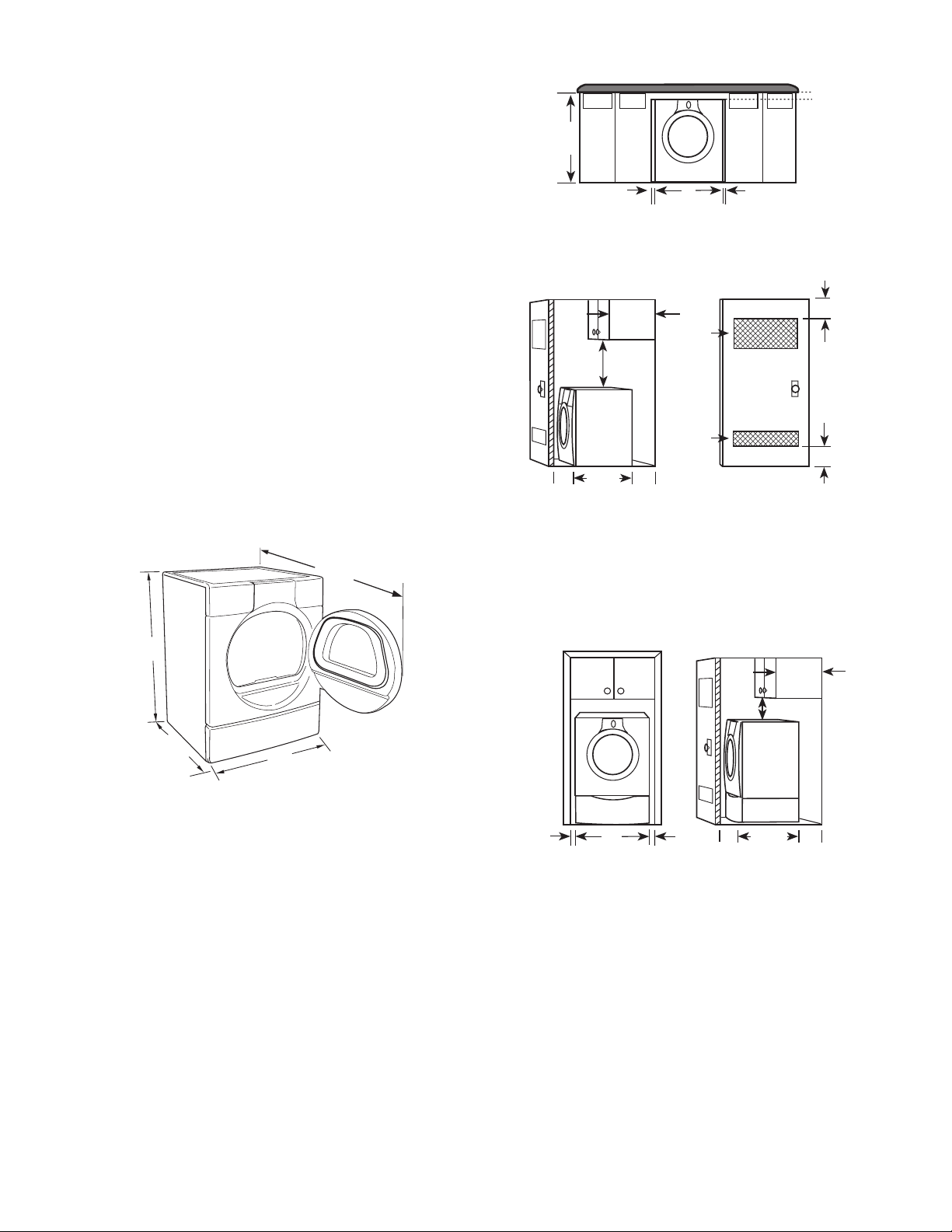

Recessed

or closet installation - Dryer on pedestal

14" max.

(356 mm)

18" min.*

(457 mm)

*28.65"

(728 mm)

27"

(686 mm)

*Most installations require a minimum 5" (127 mm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of 0" (0 mm)

cle

arance on the sides and rear. Recommended spacing should

be considered for the following reasons:

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

floor moldings.

■ Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

1"

(25 mm)

27"

(686 mm)

A

1"

(25 mm)

(25 mm)

1"*

28.65"

(728 mm)

B

5"**

(127 mm)

A. Recessed area

B. Side view - closet or confined area

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed.

5

Installation spacing for cabinet installation

■ For cabinet installation, with a door, minimum ventilation

openings in the top of the cabinet are required.

7"* (178 mm)

7"* (178 mm)

5"**

(127 mm)

28"

(728 mm)

1"*

(25 mm)

1"

(25 mm)

27"

(686 mm)

9"*

(229 mm)

1"

(25 mm)

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed.

Recommended installation spacing for recessed or closet installation, with stacked washer and dryer

The dimensions shown are for the recommended spacing.

*Required spacing

6"* (152 mm)

72"

(1829 mm)

5½"**

(140 mm)

1"

(25 mm)

27"

(686 mm)

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed.

1"

(25 mm)

Mobile home - additional installation requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Constru

ction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

■ Metal exhaust system hardware, which is available for

purchase from your dealer.

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

Electrical Requirements

It is your responsibility

■ To contact a qualified electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire supply

nection for homes built after 1996, dryer circuits involved

con

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

tional Fire Protection Association, One Batterymarch Park,

Na

Quincy, MA 02269.

■ To supply the required 3 or 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt

ectrical supply, if specified on the serial/rating plate) on a

el

separate 30-amp circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see “Optional 3-wire

connection” in the “Electrical Connection” section.

■ This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground wire is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground wire must be removed

from the external ground conductor screw (green screw), and

secured under the neutral terminal (center or white wire) of

the terminal block. When the neutral ground wire is secured

under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

■ A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas

wher

e local codes prohibit grounding through the neutral

conductors.

6

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes

■ A UL listed 30-amp power supply cord, rated

dryers. The kit should contain:

120/240 volt minimum. The cord should be type SRD

or

SRDT and be at least 4 ft (1.22 m) long. The wires that

connect to the

dryer must end in ring terminals or spade

terminals with upturned ends.

■ A UL listed strain relief.

If your outlet looks like this:

4-wire receptacle (14-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 4-wire power supply

cord, at least 4 ft (1.22 m) long, must have four 10-gauge copper

wires and match a 4-wire receptacle of NEMA Type 14-30R. The

ground wire (ground conductor) may be either green or bare. The

neutral conductor must be identified by a white cover.

If your outlet looks like this:

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 3-wire power supply

cord, at least 4 ft (1.22 m) long, must have three 10-gauge copper

wires and match a 3-wire receptacle of NEMA Type 10-30R.

If connecting by dir

Power supply cable must match p

ect wire:

ower supply (4-wire or 3-wire)

and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit. All

current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft (1.52 m) long.

7

Electrical Connection

Power Supply Cord

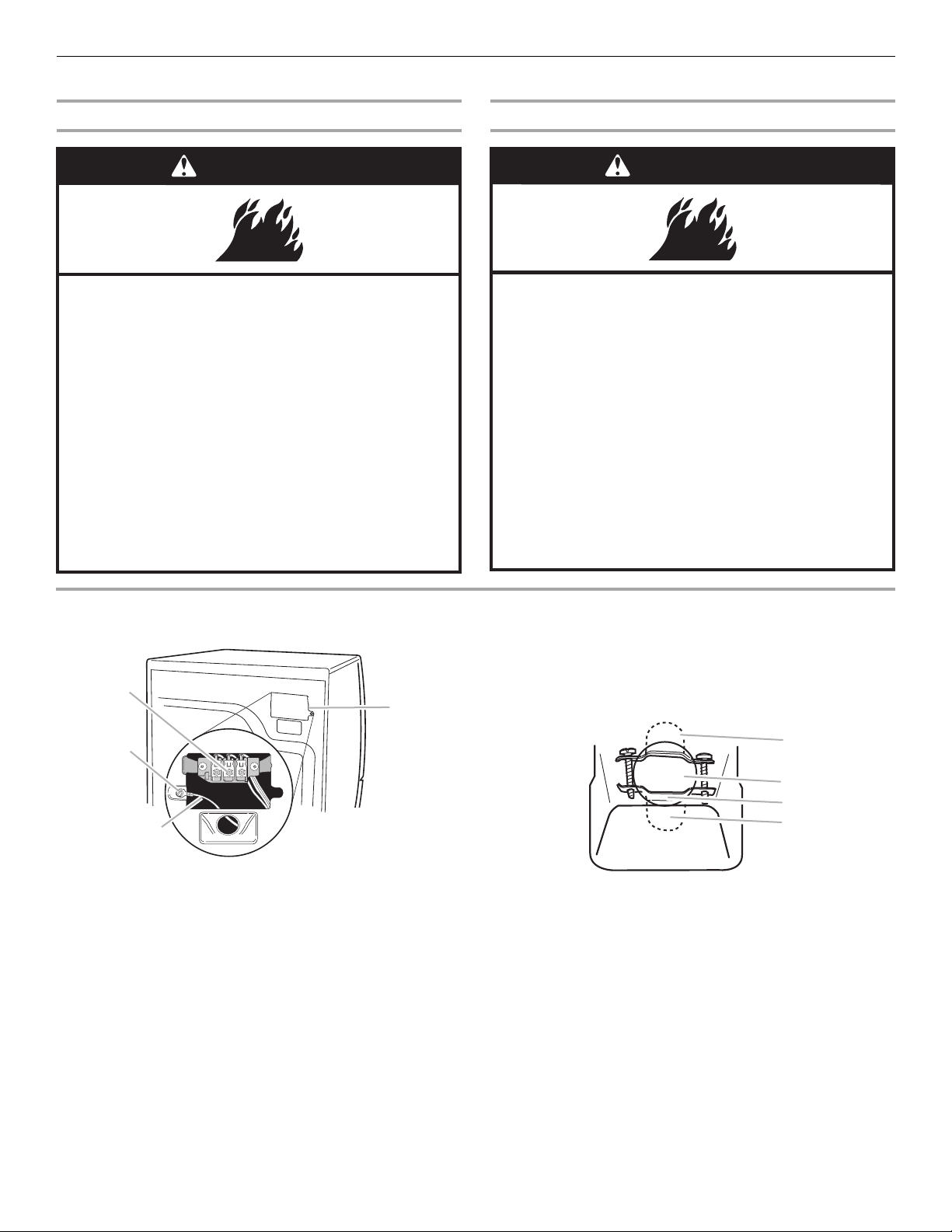

WARNING

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, re, or

electrical shock.

Direct Wire

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, re, or

electrical shock.

1. Disconnect power.

move the hold-down screw and terminal block cover.

2. Re

C

B

A

A. Neutral ground wire

B. External ground conductor scr

C. Center, silver-colored ter

D. Terminal block cover and hold-down screw

3. Install strain relief.

ew

minal block screw

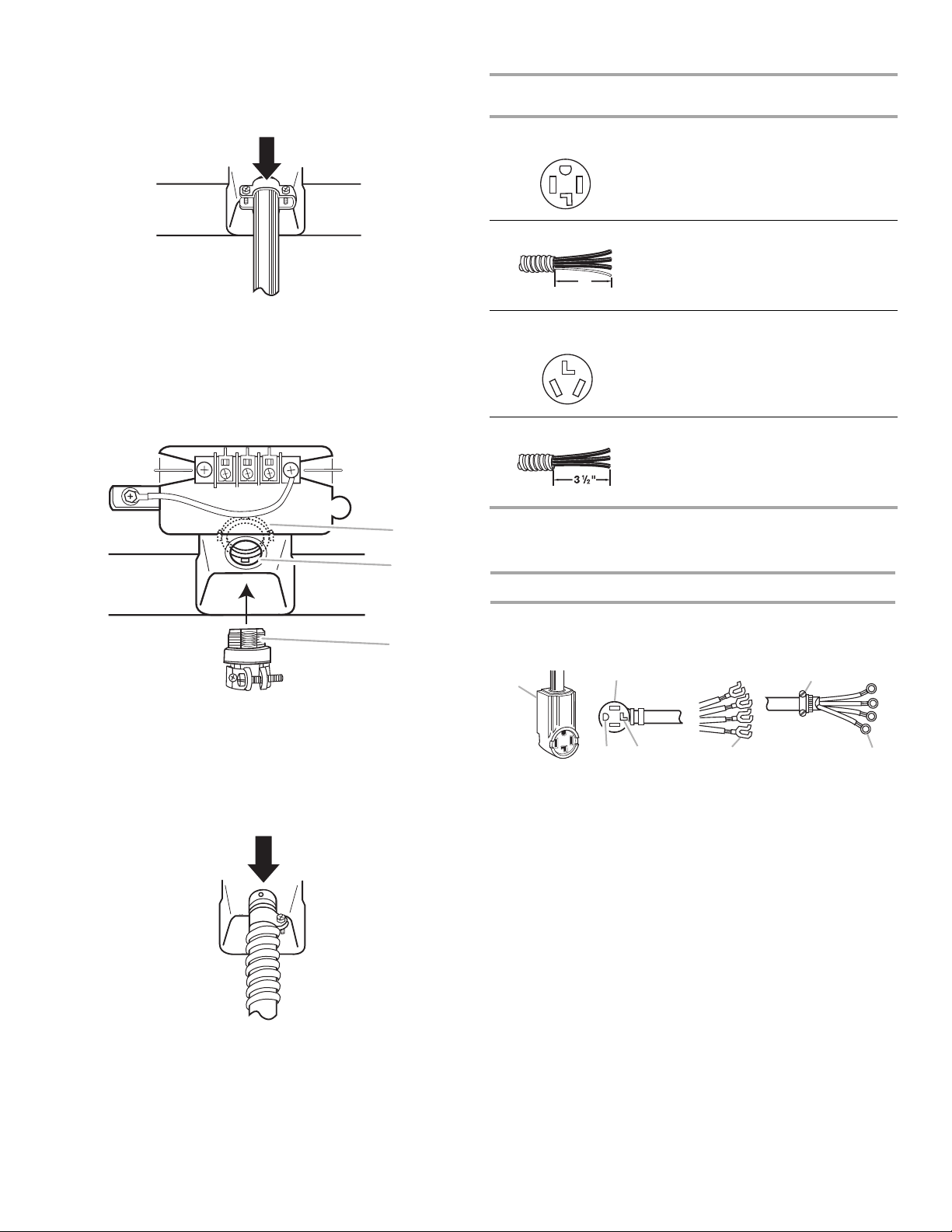

Style 1: Power supply cord strai

■ Remove the screws from a ¾" (19 mm) UL listed strain

relief (UL marking on strain relief). Put the tabs of the two

clamp sections into the hole below the terminal block

opening so that one tab is pointing up and the other is

pointing down, and hold in place. Tighten strain relief

D

screws enough to hold the two clamp sections together.

A. Strain relief tab pointing up

B. Hole below terminal block opening

C. Clamp section

D. Strain relief tab pointing down

n relief

A

B

C

D

8

■ Put power supply cord through the strain relief. Be sure

that the wire insulation on the power supply cord is inside

the strain relief. The strain relief should have a tight fit with

the dryer cabinet and be in a horizontal position. Do not

further tighten strain relief screws at this point.

Electrical Connection Options

If your home has: And yo

connecting to:

4-wire receptacle

(NEMA Type 14-30R)

A UL listed,

120/240-volt

minimum

30-amp, dryer

power supply

cord*

u will be

,

Go to Section

4-wire connection: Power supply cord

Style 2: Direct wire strain relief

■ Unscrew the removable conduit connector and any

screws from a ¾" (19 mm) UL listed strain relief (UL

marking on strain relief). Put the threaded section of the

strain relief through the hole below the terminal block

opening. Reaching inside the terminal block opening,

screw the removable conduit connector onto the strain

relief threads.

A

B

C

A. Removable conduit connector

B. Hole below terminal block opening

C. Strain relief threads

■ Put direct wire cable through the strain relief. The strain

relief should have a tight fit with the dryer cabinet and be

in a horizontal position. Tighten strain relief screw against

the direct wire cable.

4-wire direct

A fused

disconnect or

4-wire connection:

Direct Wire

circuit breaker

5"

(127 mm)

3-wire receptacle

(NEMA type 10-30R)

box*

A UL listed,

120/240-volt

minimum

,

3-wire connection:

Power supply cord

30-amp, dryer

power supply

cor

d*

3-wire direct

A fused

disconnect or

3-wire connection:

Direct Wire

circuit breaker

box*

(89 mm)

*If local codes do not permit the connection of a cabinet-ground

condu

ctor to the neutral wire, go to “Optional 3-wire

connection” section.

4-wire connection: Power supply cord

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

A

BF

D

C

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned ends

F. ¾" (19 mm) UL listed strain relief

G. Ring terminals

E

G

4. Now complete installation following instructions for your type of electrical connection:

4-wire (r

3-wire

ecommended)

(if 4-wire is not available)

1. Remove center, silver-colored terminal block screw.

9

Loading...

Loading...