Alto Shaam VAE-30F Installation Manual

#8452/53/55 • 5/02

PRINTED IN U.S .A .

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 - 800.329.8744 U . S .A ./CANADA WEBSITE:

800.558.8744 U . S .A ./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

®

VENTILATOR HOOD

OPERATION & CARE MANUAL

VAE-55FS

VAE-30F

VPE-30F

MODELS: VPE-30F, VAE-30F, VAE-55F, -55FS

The Alto-Shaam fryer with ventilator hood has

been thoroughly tested and inspected to insure

only the highest quality unit is provided. When

you receive your unit, check for any possible

shipping damage and report it at once to the

delivering carrier. See Transportation Damage and

Claims section located in this manual.

The hood, complete with unattached items and

accessories, may be delivered in one or more

packages. Check to ensure that all items have

been received as standard with each unit.

Save all the information and instructions packed

inside the unit. Complete and return the

warranty card to the factory as soon as possible

to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by all

people using or installing this unit. Contact

your local Alto-Shaam distributor if you have

any questions concerning installation, operation,

and maintenance of this appliance.

NOTE: All claims for warranty must include the

full model number and serial number.

1. Carefully remove fryer with hood from the carton.

NOTE: Do not discard the carton and other

packaging material until you have

inspected the hood and fryer for

hidden damage and tested it for

proper operation.

2. Read all instructions in this manual carefully

before installation of this hood and fryer.

Read and understand all labels and diagrams

attached to the equipment.

DO NOT DISCARD THIS MANUAL. This

manual is considered to be part of the fryer

and should be retained by the owner or

manager of the business, or to the person

responsible for training fryer operators.

Additional manuals are available from your

Alto-Shaam distributor. This manual is to be

used in conjunction with the manual for the

fryer associated with a ventilator hood.

3. Remove all protective plastic film, packaging

materials and accessories from the hood and

fryer before the fryer is connected to

electrical power. Store accessories in a

convenient place for future use.

Operation and Care Manual #8452/53/55

PG.1

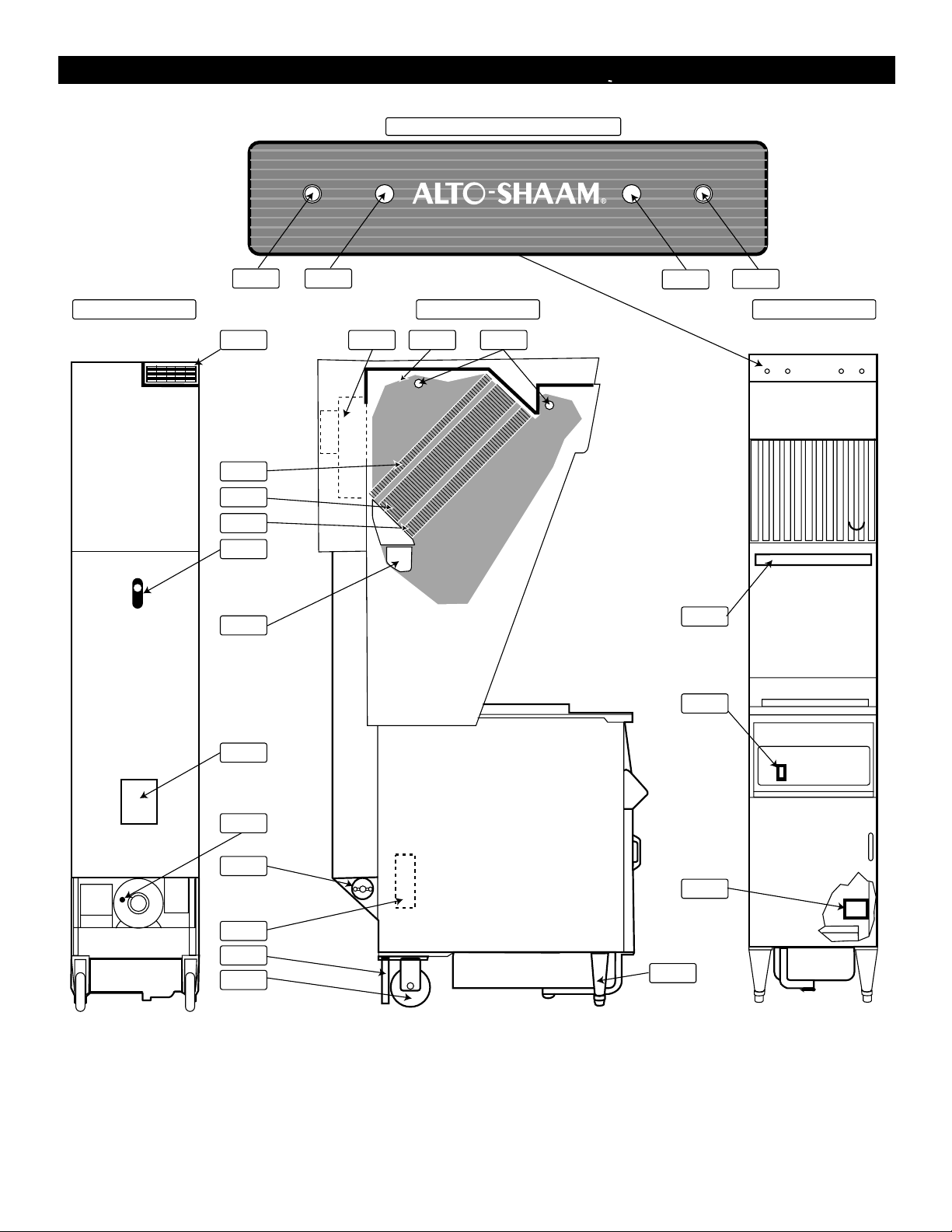

VENTILATOR HOOD & FRYER

DELIVERY

SPECIFICATION INFORMATION

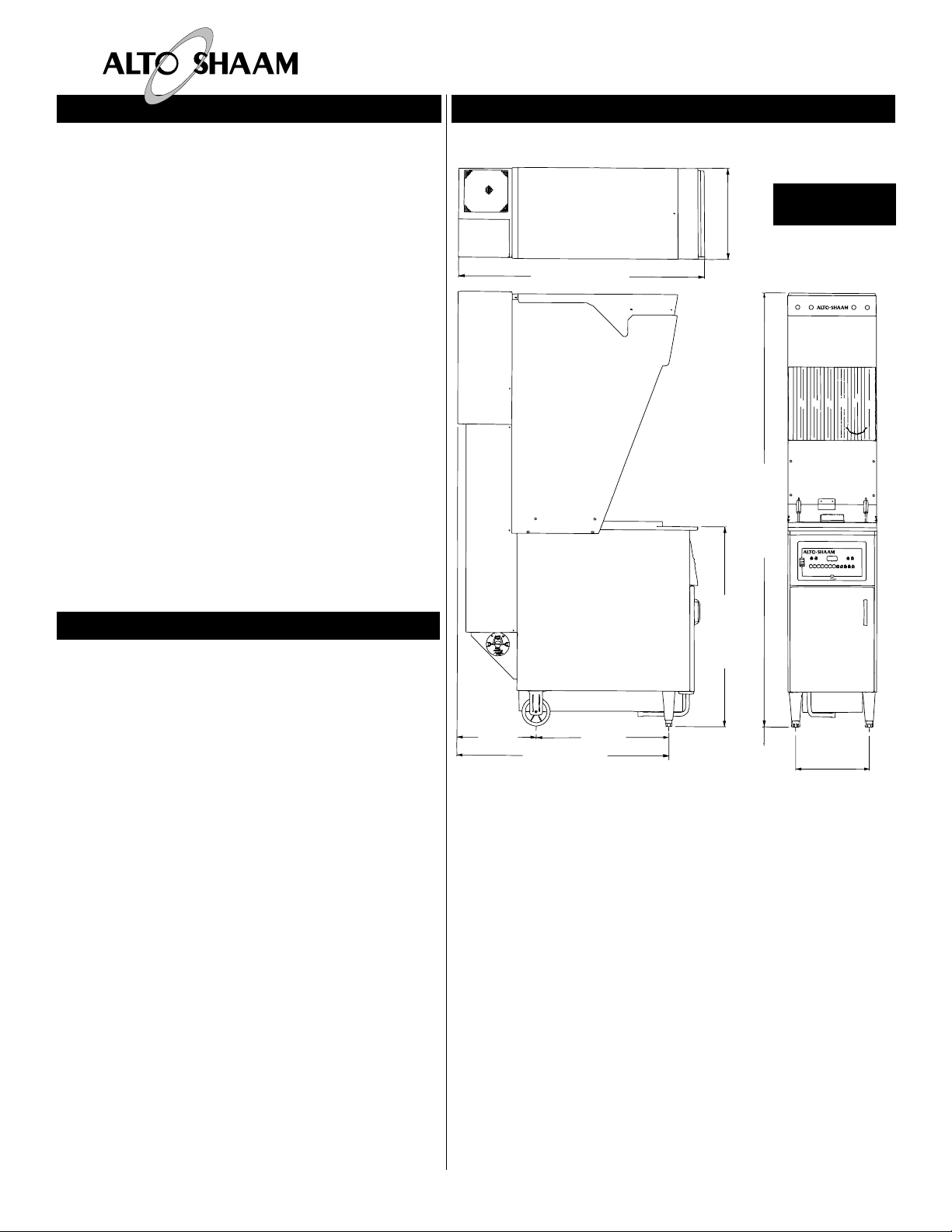

DIMENSIONS

®

NOTE: The ventilator hood is factory installed on the fryer.

Both appliances are shipped as a single unit.

The ventilator contains the following components:

1: Fire Suppression Agent Ansulex®R-102(HCS),

1.5 gallon (5,7 liters)

1: Fire Suppression Agent Tank

1: Fire Suppression System Charging Cartridge

1: Grease Receptacle

1: Stainless Steel Baffle Filter

1: Grease Vapor HEPA Filter

1: Odor Control Charcoal Filter*

*purchased separately as an option

1: literature package

UNPACKING

(401mm)

15-13/16"

43-11/16" (1110mm)

VENTILATOR

CHECK

POWER ON

FILTERS

76-3/8" (1940mm)

REPLACE

SERVICE

FILTER

REQUIRED

®

®

36"—(914mm)

14-1/16"

(356mm)

37-7/16" (950mm)

23-3/8"

(594mm)

13"

(330mm)

Operation and Care Manual #8452/53/55

PG.2

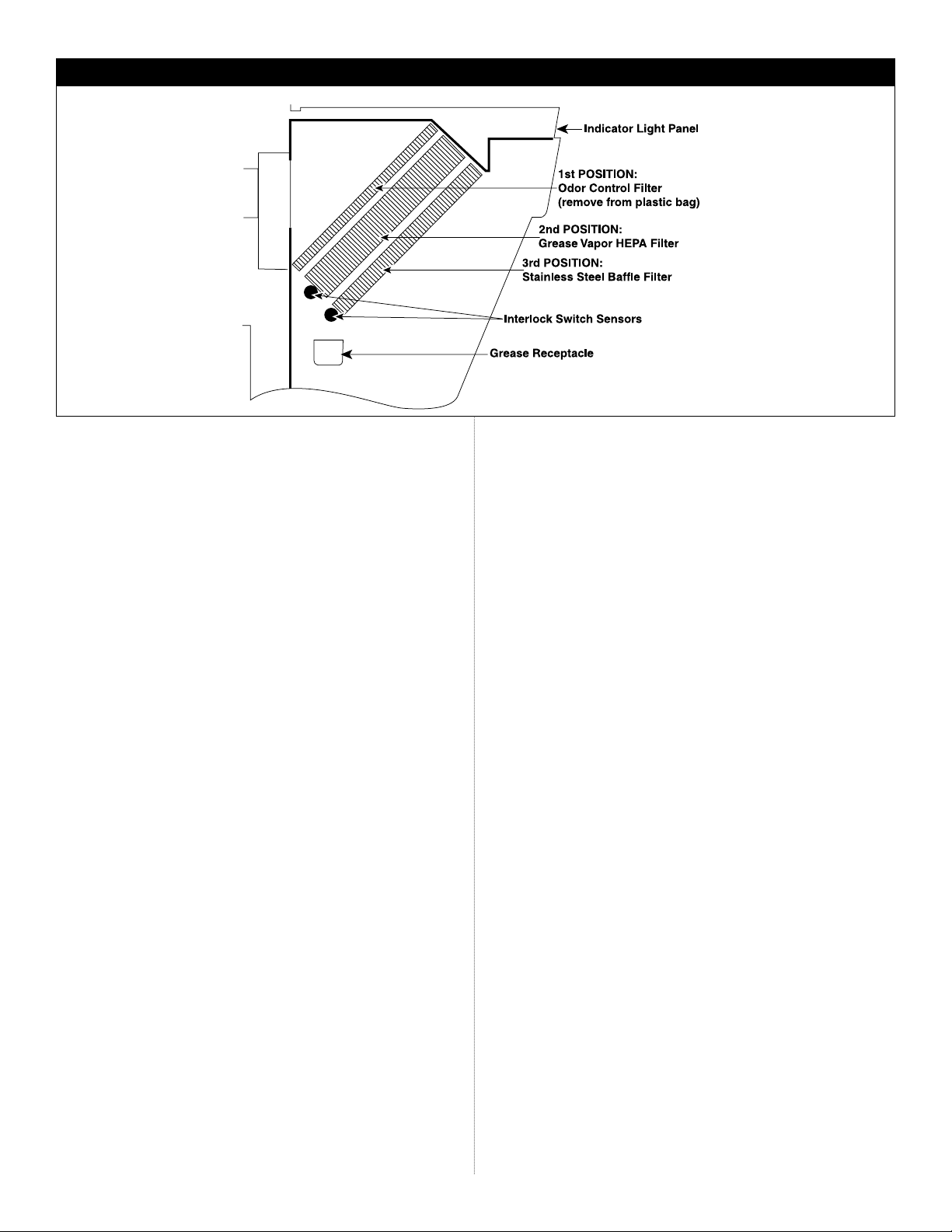

Knowledge of proper procedures is essential to the safe

operation of electrically energized equipment. In

accordance with generally accepted product safety labeling

guidelines for potential hazards, the following signal

words and symbols are used throughout this manual.

Used to indicate the presence of a hazard

which will cause severe personal injury,

death, or substantial property damage in

the event the statement is ignored.

Warning used to indicate the presence of a

hazard which can cause personal injury and

possibly death, or major property damage,

in the event the statement is ignored.

Caution is used to indicate the presence of a

hazard which will or can cause minor

personal injury or property damage in the

event the statement is ignored.

Used to indicate the presence of an

electrical hazard which will or can cause

personal injury or property damage in the

event the statement is ignored.

Note is used to notify personnel of

installation, operation, or maintenance

information which is important but not

hazard related.

HAZARD COMMUNICATION STANDARD (HCS)

The procedure in this manual may include the use of

chemical products. These chemical products will be

highlighted with bold face letters followed by the

abbreviation (HCS). See the

Hazard Communications

Standard

section of this manual for the appropriate

Material Safety Data Sheet(s).

1. This ventilator hood system is designed as part of a

deep fat fryer system. No other use of this product is

authorized or recommended.

2. This ventilator and attendant fryer are intended for

use in commercial establishments where all operators

are familiar with the appliance use, limitations, and

associated hazards. Operating instructions and

warnings must be read and understood by all

operators and users.

3. This ventilator hood system is designed to reduce odor

emissions, but will not completely eliminate cooking

odors. Air exchange at the installation site must

comply with the requirements of the local

jurisdictional authority. To ensure that odors do not

build up, recommended minimum air exchange is

400 cfm (11,3m

3

) into and out of the site.

4. This equipment is made in the USA and has American

size hardware.

5. Any trouble shooting guides, component views or

parts lists included in this manual are for general

reference only, and are intended for use by qualified

technical personnel.

6. This manual should be considered a permanent part of

this appliance. The manual with all supplied

instructions, diagrams, schematics, part breakdowns,

notices, and labels must remain with the appliance if it

is sold or moved to another location.

SAFETY PROCEDURES

PRECAUTIONS & GENERAL INFORMATION

1. Verify vertical clearances. Ventilator fryers require a

minimum of 96" (244cm) floor to overhead to allow for

adequate air circulation.

2. Verify that the ventilator hood assembly is properly

and securely assembled to the fryer before beginning

the installation procedure.

3. If a remote pull station is to be used, replace the rear

casters with fixed legs.

4. Adjust the fixed legs with a spirit level until the unit

is level front-to-back and side-to-side.

NOTE

EQUIPMENT SET-UP PRECAUTIONS

Since the fryer is electrically powered, only a licensed

electrician should be used to connect power to the unit.

1. Make certain this installation is in compliance with the

specifications listed in this manual, local code

requirements, and in accordance with the Standard for

Ventilation Control and Fire Protection of Commercial

Cooking Operations, NFPA-96 (current edition). These

requirements are the responsibility of the installer.

2. Certain codes require fryers to be restrained with a

tether or other restraint device. It is the responsibility

of the installer to check with the authority having

jurisdiction, in order to ascertain the applicability of

this requirement to this specific fryer installation. Any

restraint device must allow access to the back and

sides of the unit to provide service and maintenance

access, and must not interfere with the operation of

the fire suppression system.

3. Refer to the name plate on the front of the unit. The

electrical service power voltage and phase must match

the nameplate specifications and available electrical

service amperage must meet or exceed the

specifications listed. Wiring must be no less than 12

ga. solid copper wire, rated for at least 75°C.

ELECTRICAL SHOCK HAZARD

Electrical connections must be

made by a licensed electrician.

Electrical shock will cause death

or serious injury.

NOTE: Wire gauge, insulation type, and temperature

rating, as well as type, size, and construction of

conduit, must meet or exceed applicable

specifications of local codes of the National

Electrical Code.

4. Fryers are shipped from the factory wired for 3-phase

service. Refer to 3-phase wiring diagram included

with this fryer and verify that field wiring conforms

with this diagram.

NOTE: Fryers are field convertible to 1-phase. If single

phase operation is required, refer to the 3-phase to

1-phase instructions included with the fryer. Verify

that both internal wiring and field wiring conform

to the single-phase wiring diagram included.

IMPORTANT: Fryer Models VAE-55 and VAE-55FS units

MUST NOT BE CONVERTED TO SINGLE

PHASE OPERATION

. Conversion of these

units to single phase operation invalidates

the UL listing and voids the warranty.

Operation and Care Manual #8452/53/55

PG.3

INSTALLATION & ELECTRICAL INFORMATION

ELECTRICAL SPECIFICATIONS

The hood is wired into the fryer

to provide a single electrical connection.

MODEL VAC KW AMPS 1PH AMPS 3PH

VPE-30F

208 9.0 43.3 25 per line

240 9.0 37.5 22 per line

308-415 9.3 N/A 15-

L

1

, 13-L2 & L

3

VAE-30F 208 9.0 43.3 25 per line

240 9.0 37.5 21.7 per line

308-415 9.3 N/A

14.3-L1, 13-L

2,

& L

3

VAE-55F(S) 208 17.0 N/A 47.8 per line

240 17.0 N/A 41.0 per line

308-415 17.4 N/A 26-

L

1

, 24-L2 & L

3

FIRE HAZARD

The fire suppression

system must be installed,

activated, certified, and

maintained by an

authorized Ansul

®

technician. Do not

attempt to modify or bypass the fire

suppression system. An uncontrolled

fire can cause serious injury or death.

IMPORTANT

1.

The fire extinguisher system must

be set up and charged by an

authorized Ansul

®

technician.

2. The fryer is equipped with a

manual pull station at the lower

rear of the left side of the fryer.

The manual pull station must be in

a line of egress from the fryer. If

the fryer is installed in a location

where the factory installed manual

pull station is not accessible, an

additional remote pull station may

be required by local codes. Any

remote manual pull station must be

installed by an authorized Ansul

distributor in accordance with the

authority having jurisdiction.

BURN HAZARD • SPILLED OIL

The additional remote

pull station must

not be

installed on the front

and/or sides of the fryer,

forward of the ventilator side panels.

Discharge of the fire suppression

system into hot oil will cause hot foam to spill over the

frypot. Serious burns may result from this spillage. Injury

from slipping or falling could also result.

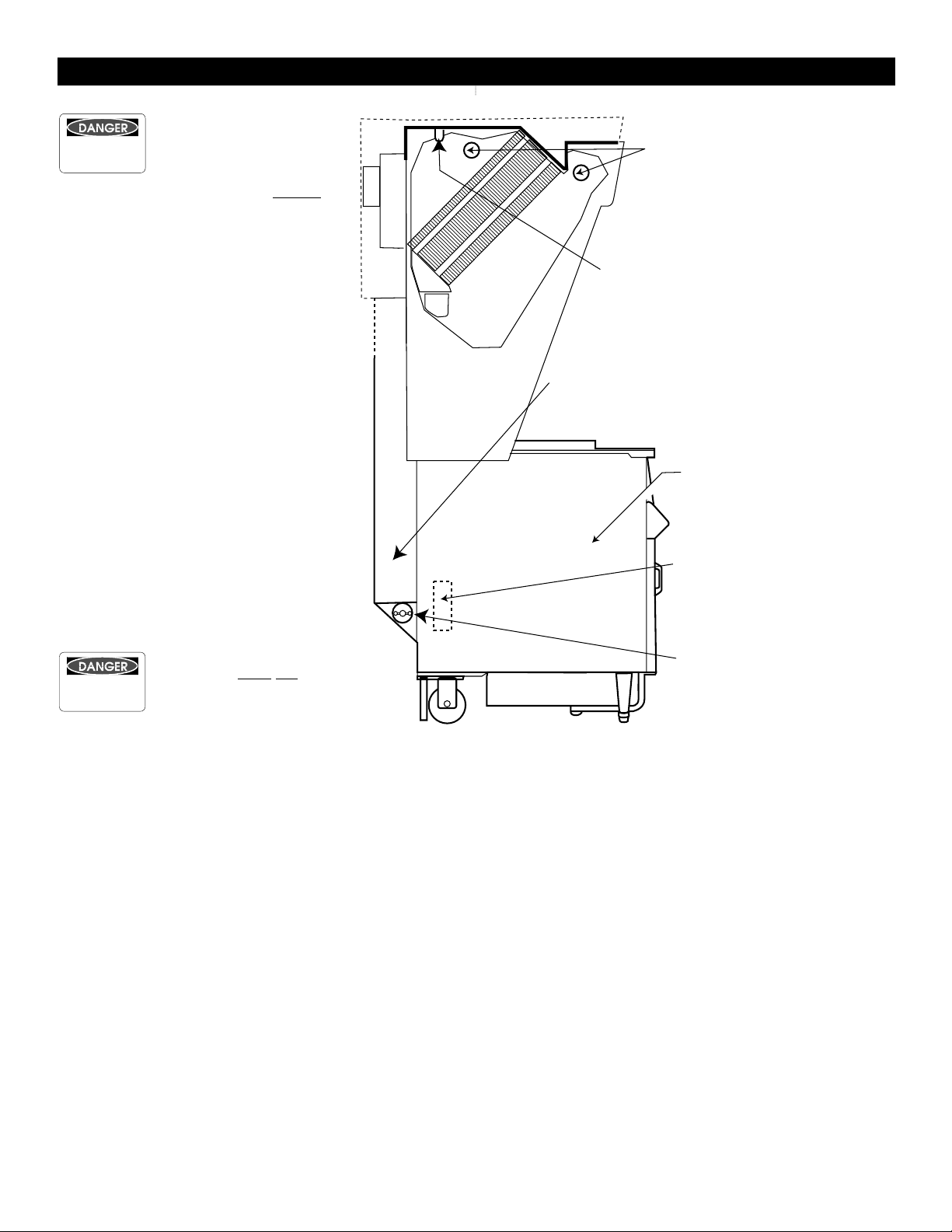

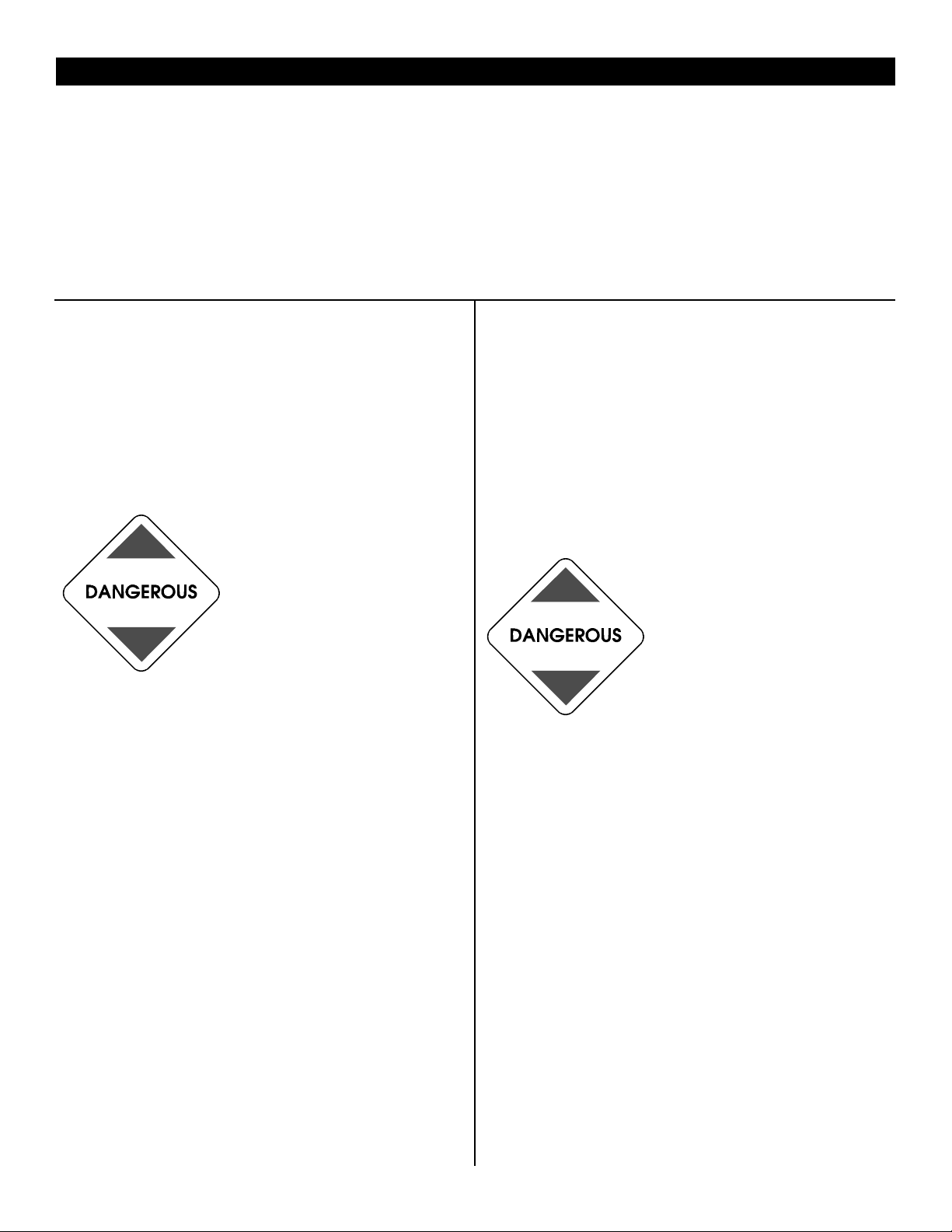

3. The fire suppression system is comprised of a

pressurized container of Ansulex

®

R-102 liquid fire

suppression media along with associated plumbing

and controls. The system utilizes two fusible links for

automatic actuation and a manual pull station for

manual actuation. Two nozzles are used to disperse

the dry chemical fire suppression media.

NOTE: If the fire suppression system is discharged, a

buzzer will sound continuously. The fryer will

remain inoperable until the fire suppression

system is serviced, recharged, and reset by an

authorized Ansul

®

distributor.

Charging the fire suppression system must be in

accordance with Ansul

®

Design, Installation, Recharge

and Maintenance Manual #418086.

4. When the fire suppression system discharges, the fryer

heating element(s) and controls are de-energized and

the fire suppression media is discharged. The fire

suppression media will form an emulsion designed to

both smother and cool the oil.

The primary 450°F (232°C) fusible link is located on the

frypot. This link will melt and discharge the fire

suppression system in the event both the temperature

control thermostat and the high limit control fail. The

secondary 280°F (138°C) fusible link is located in the filter

plenum and will protect against a fire in the plenum.

Melting of either link will discharge the fire suppression

media through both nozzles and cause a buzzer to sound.

NOTE: As an additional fire safety detection device, the

Alto-Shaam fryer includes a sensor located within

the frypot to continuously measure the

temperature of the oil. In the unlikely event of a

simultaneous failure of both the thermostat and

the high limit switch, the sensor will automatically

activate the fire suppression system at

approximately 100°F (38°C) below the oil

temperature ignition point.

Operation and Care Manual #8452/53/55

PG.4

FIRE SUPPRESSION SYSTEM INSTALLATION

FIRE SUPPRESSION AGENT

DISPENSING NOZZLE

(2 locations)

ALL MODELS REQUIRE A 280°F

(138°C) FUSIBLE LINK LOCATED

INSIDE HOOT BEHIND FILTERS

REMOVE HOUSING FOR ACCESS TO

FIRE SUPPRESSION SYSTEM. ACCESS

TO 450°F (232°C) FUSIBLE LINK ON VAE-55F(S)

REMOVE PANEL FOR ACCESS

TO FRYPOT. ACCESS TO 450°F

(232°C) FUSIBLE LINK ON VAE-30F

AND VPE-30F.

APPROXIMATE LOCATION

OF 450°F (232°C) FUSIBLE

LINK ON ALL MODELS.

MANUAL FIRE

SUPPRESSION

PULL STATION

ON ALL MODELS.

Operation and Care Manual #8452/53/55

PG.5

NOTE:

Items beginning with the letter "F" are components of the fryer.

Items beginning with the letter "V" are components of the ventilator.

FEATURES & OPERATING CONTROLS

INDICATOR LIGHT PANEL

V. 2

V.10

V.11

V.12

V.13

V.14

VENTILATOR

POWER ON

V. 3

CHECK

FILTERS

SIDE VIEW FRONT VIEWBACK VIEW

V. 6 V. 7 V.8

REPLACE

FILTER

SERVICE

REQUIRED

V. 4

V. 5

V.17

V.15

F.9

V.16

V. 7

F.19

F.20

V.17

F.1

F.18

F.21

Operation and Care Manual #8452/53/55

PG.6

F.1 FRYER POWER ON SWITCH

Pressing the fryer switch to the ON position

illuminates the ventilator power

ON light and

starts the blower. After approximately 10

seconds of operation in this condition,

sufficient air flow will be established to begin

fryer operation and the ventilator power

ON

indicator will remain lit.

V. 2 VENTILATOR POWER ON INDICATOR (GREEN)

Illuminates when the fryer power switch is ON

and adequate air flow has been established.

V.3 CHECK FILTERS INDICATOR (AMBER)

Illuminates when Odor Control filter or Grease

Vapor HEPA filter are missing or not properly

installed. When ON, the fryer heating elements

are de-activated and the fryer will not heat.

V.4 REPLACE FILTERS LIGHT (AMBER)

The "Replace Filter" light is directly tied to an air

flow diagnostic device which measures the air

pressure through the filter system. This light

will illuminate when the Grease Vapor filter and

the Odor Control filter accumulates a sufficient

amount of grease build-up to impede air flow.

This light is a clear indication to replace both

filters. Failure to replace these filters within

approximately one week from the date the

"Replace Filter" light illuminates will result in

the illumination of the "Service Required"

indicator. Once the "Service Required" light is

illuminated, the fryer will become inoperable

until both filters are replaced.

V.5 SERVICE REQUIRED LIGHT (RED)

This indicator will illuminate and the fryer will

be inoperable when there is insufficient

ventilator air flow due to grease laden filters.

V.6 VENTILATOR BLOWER

Provides air flow through the ventilator system.

V.7 FUSIBLE LINK LOCATIONS

Will melt at a predetermined set temperature to

activate the fire suppression system.

V.8 FIRE SUPPRESSION NOZZLE(S)

Disperses the fire suppression media.

FF.9.9OIL

OIL

FIL

FIL

TER PUMP

TER PUMP

MOTOR OVERLOAD RESET

MOTOR OVERLOAD RESET

Provides protection of the filter pump motor

when fryer is over temperature. When tripped,

allow the fryer to cool and reset manually by

pressing inward.

V.10 VENTILATOR EXHAUST COLLAR

Ventilator discharge outlet which includes a

fire damper with a fusible link which will

melt at a temperature of 165°F (74°C).

DO NOT BLOCK THIS OUTLET

V.11 ODOR CONTROL FILTER

V.12 GREASE VAPOR HEPA FILTER

V.13 STAINLESS STEEL BAFFLE FILTER

See Filters Installation section in this manual.

V.14 FIRE SUPPRESSION SYSTEM STATUS

INDICATOR

Indicates current status of the Ansul Fire

Suppression System (i.e., cocked or fired).

V.15 AUTOLIFT MOTOR ACCESS

On VAE model fryers equipped with an

automatic basket lift device.

V.16 MANUAL FIRE SUPPRESSION

PULL STATION

A remote fire suppression activation device

located on the lower left-hand portion of the

fryer body, at the back. This additional safety

feature can be activated manually if the

ANSEL auto-detection system fails in the

event of a fire.

V.17 GREASE RECEPTACLE

Catches grease and condensate dripping from

the Stainless Steel Baffle filter.

Always

replace the empty container in the fryer to

avoid condensate from splattering and

draining into the oil.

FF.18

.18

GREASE DRIP P

GREASE DRIP P

AN

AN

Collection point for grease and condensation

funneled through a drain at the top of the

fryer. The condensate receptacle should

emptied at regular intervals.

Always replace the empty container in the

fryer to avoid condensate from draining into

the oil filter pan.

F

F.19 STABILIZER

Prevents the unit from tipping backwards.

F

F.20 RIGID (REAR) CASTERS

Allows the unit to be easily positioned by

slightly lifting the front of the unit.

NOTE: If a manual fire suppression pull station is

furnished, both rear casters (F.20) must be

replaced with legs to deter movement of the

fryer.

Movement of an appliance which includes

a remote pull station will discharge the fire

suppression system media.

F

F.21 FIXED (FRONT) LEGS

FEATURES & OPERATING CONTROLS

Operation and Care Manual #8452/53/55

PG.7

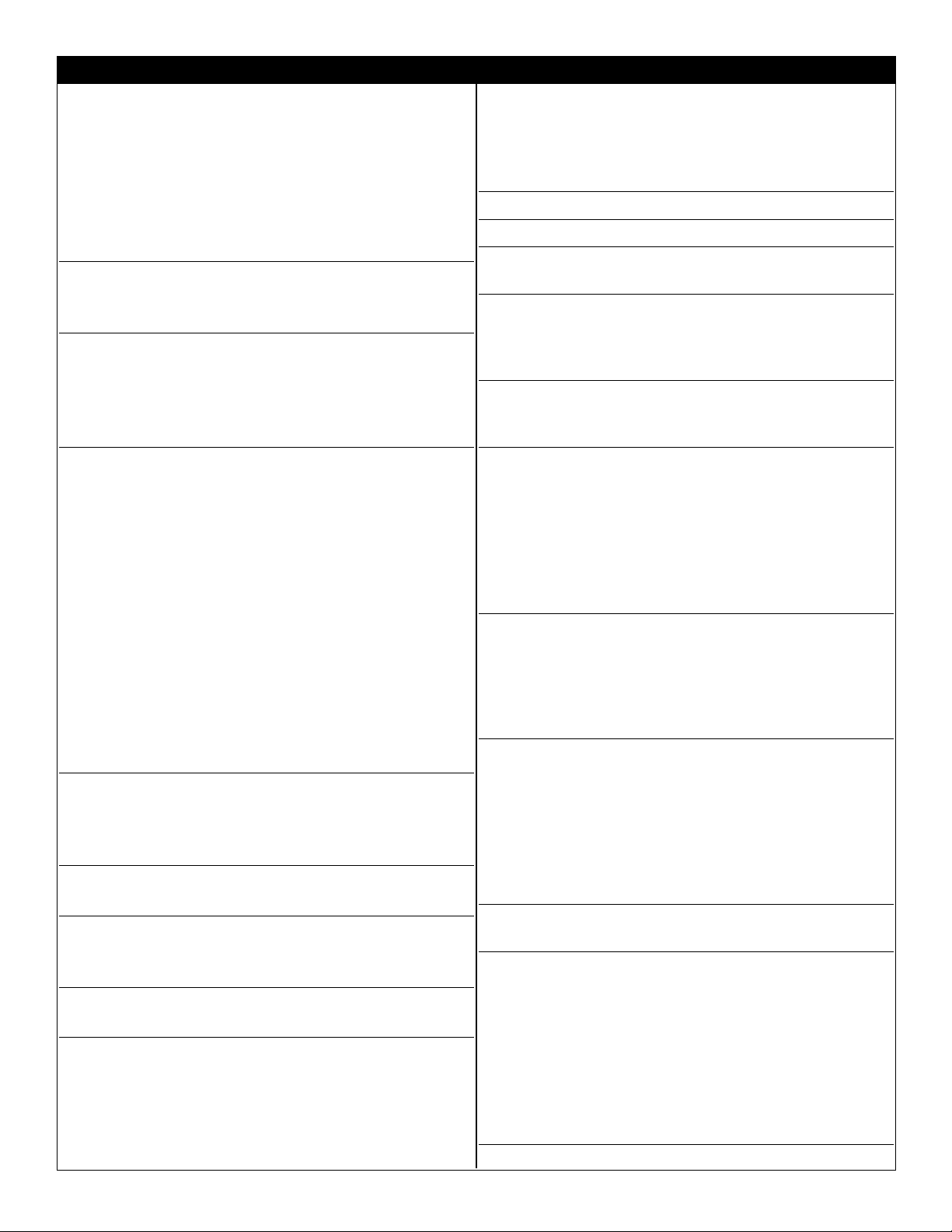

The fryer ventilation hood consists of a three-part

filtration system.

The carbon based, Odor Control Filter will reduce

odors to an acceptable level through the extraction of

airborne grease. While the use of this filter is

optional, utilization is strongly recommended when

frying on a regular basis This charcoal filter should

be lifted into place against the stainless steel flanges,

directly in front of the exhaust blower, and dropped

into the proper channel.

The

Grease Vapor HEPA Filter is a high-temperature

fiberglass medium, tightly woven to capture the

smallest particles of grease vapor as the air flows

through the exhaust system. This filter is one of two

individual filters directly interlocked with the fryer.

If this filter is not in place or not properly

positioned, the fryer will not operate. The Grease

Vapor HEPA filter should be lifted into place behind

the "Odor Control" filter and dropped into the

proper channel.

The two preceding filters are followed by the

Stainless Steel Baffle Filter which is designed to

extract larger grease particles as the air flows

through the system. This filter will also increase the

life of the Odor Control filter and the Grease Vapor

filter. Again, this filter is directly interlocked with

the fryer and if not in place nor properly positioned,

the fryer will not operate. When lifting this filter

into place, it is important to make certain it makes

contact with the electronic interlock switch which

activates the fryer. Unlike the other two filters, the

Stainless Steel Baffle filter is washable and should be

cleaned on a regular basis.

NOTE: When in proper position, the Grease Vapor

HEPA filter and the Stainless Steel Baffle

filter actuate magnetic reed switches. They

must be properly installed or the fryer

heating element(s) will not be energized.

1. Remove the protective plastic bag from the optional

charcoal, odor control filter before installing.

WARNING: Installing the filter without removing

the plastic bag will block the air flow.

This will cause the ventilator to shut

down 10 seconds after start-up and

the fryer will not heat.

2. Note the air flow direction arrow on each filter,

and verify that the arrow points toward the

plenum when the filter is installed. Install by

inserting the top of each filter into the top filter

support inside the hood assembly. Pivot the

bottom of each filter toward the rear of the hood

assembly and drop it into its respective bottom

filter support. Seat each filter firmly into the

bottom filter support.

ODOR CONTROL FILTER:

19-1/2" x 14" x 7/8"

(495mm x 356mm x 22mm)

GREASE VAPOR HEPA FILTER:

19-1/2" x 15-1/2" x 3-3/4"

(495mm x 394mm x 95mm)

STAINLESS STEEL BAFFLE FILTER:

19-1/2" x 15-1/2" x 1-5/8"

(495mm x 394mm x 41mm)

VENTILATION HOOD FILTERS

1. Install the grease receptacle (V.17) into the brackets

directly below the Stainless Steel Baffle filter.

NOTE: Operation of the fryer without replacing the

grease receptacle in the proper position will

cause accumulated fryer cooking grease and

condensation to drip directly into the frypot oil.

BURN HAZARD • HOT OIL SPLATTER

Do not operate unless grease

receptacle is installed. Moisture

will drip into hot oil in the

frypot causing hot oil splatter.

Serious injury will result from

contact with hot oil.

2. Install the drip pan (V.18) into the mounting

bracket behind the fryer door at the lower right

front of the fryer.

NOTE: Failure to install the grease drip pan will

allow grease, moisture, and other liquids

that accumulate on the fryer top panel to

drip onto the floor causing both a safety

hazard and a health hazard.

SLIPPING & FALLING HAZARD

• SPILLED OIL

Do not operate unless the drip pan

is installed. Oil will drip onto

the floor and falls will result.

Death or serious injury may result

from slipping and falling in spilled oil.

Operation and Care Manual #8452/53/55

PG.8

GREASE RECEPTACLE & GREASE DRIP PAN

Cooking vapors produced by frying, particularly pressure frying, will condense and accumulate on the

stainless steel surfaces of the hood. The ventless hood is designed to collect some of this condensation in a

grease receptacle located directly under the Stainless Steel Baffle filter. Additional accumulation is collected

at the top of the fryer and is funneled through a drain at the top of the fryer into a collection receptacle

located at the bottom of the unit. Both condensate receptacles should be emptied at regular intervals,

however, it is important to replace the empty containers in the fryer to avoid condensate from draining into

hot oil or the oil filter pan.

Loading...

Loading...