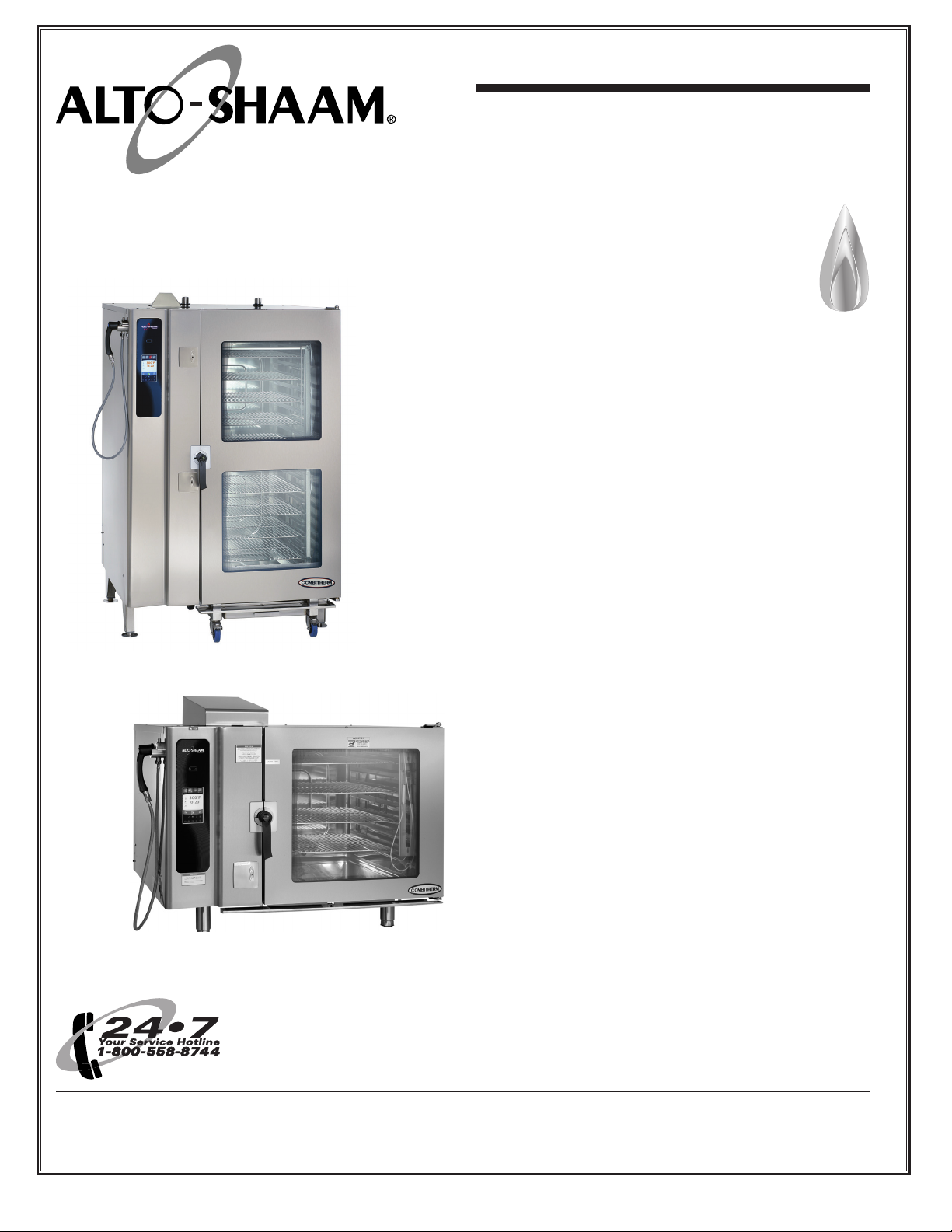

Alto-Shaam COMPITHERM 610ESG, COMPITHERM 1010ESG, COMPITHERM 1020ESG, COMPITHERM 714ESG, COMPITHERM 1218ESG User Manual

...

Combitherm®

Combination

Oven / Steamer

ES GAS

COMBITOUCH™

SERIES

6•10ESG

10•10ESG

7•14ESG

10•20ESG

12•18ESG

20•20ESG

• INSTALLATION

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744 USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WWW.ALTO-SHAAM.COM

PRINTED IN U.S.A.

MN-29246 • 10/10

Delivery .......................................................................... 1

Unpacking ..................................................................... 1

Safety Procedures and Precautions .............................. 2

Installation

Installation Codes and Standards ............................. 3

Ventilation Requirements ........................................... 3

Positioning on Site .................................................... 4

Positioning Requirements ......................................... 5

Stand Installation ...................................................... 5

Common Specications ............................................ 6

Specications, 6•10esG ............................................ 7

Specications, 10•10esG .......................................... 8

Specications, 7•14esG ........................................... 9

Specications, 10•20esG ........................................ 10

Specications, 12•18esG ........................................ 11

Specications, 20•20esG ........................................ 12

Electrical Connection ............................................... 13

Mobile Equipment Restraint ..................................... 14

Ventilation Requirements ......................................... 15

Gas Supply & Installation ......................................... 16

Gas Leak Testing ...................................................... 19

Gas Exhaust ............................................................. 19

Water Quality Requirements .................................... 20

Water Supply & Installation ...................................... 21

Water Valve .............................................................. 22

Water Drainage......................................................... 22

CombiTouch Checklist ............................................ 23

Error Codes ............................................................. 24

Warranty

Original Equipment Limited Warranty ...................... 30

Transportation Damage and Claims ......................... 31

i

DELIVERY

UNPACKING

This Alto-Shaam appliance has been

thoroughly tested and inspected to ensure only

the highest quality unit is provided. Upon

receipt, check for any possible shipping damage

and report it at once to the delivering carrier.

See Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered

in one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to ensure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood

by all people using or installing the equipment

model. Contact the Alto-Shaam Tech Team Service

Department if you have any questions concerning

installation, operation, or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

1. Carefully remove the

appliance from the

carton or crate.

®

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

Tech Team Service Department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

THE INFORMATION CONTAINED IN THIS

MANUAL IS IMPORTANT FOR THE PROPER

INSTALLATION OF THIS OVEN. PLEASE READ

CAREFULLY AND RETAIN FOR

FUTURE REFERENCE.

IMPROPER CONNECTION OF THIS APPLIANCE

WILL NULLIFY ALL WARRANTIES.

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 1.

CAUTION

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

LES INFORMATIONS CONTENUES DANS CE

MANUEL SONT IMPORTANTES POUR UNE

INSTALLATION CORRECTE DE CE FOUR.

PRIÈRE DE LE LIRE ATTENTIVEMENT ET DE

LE CONSERVER POUR POUVOIR S’Y RÉFÉRER

À L’AVENIR.

UN BRANCHEMENT INCORRECT DE

CET APPAREIL ANNULERA TOUTES LES

GARANTIES.

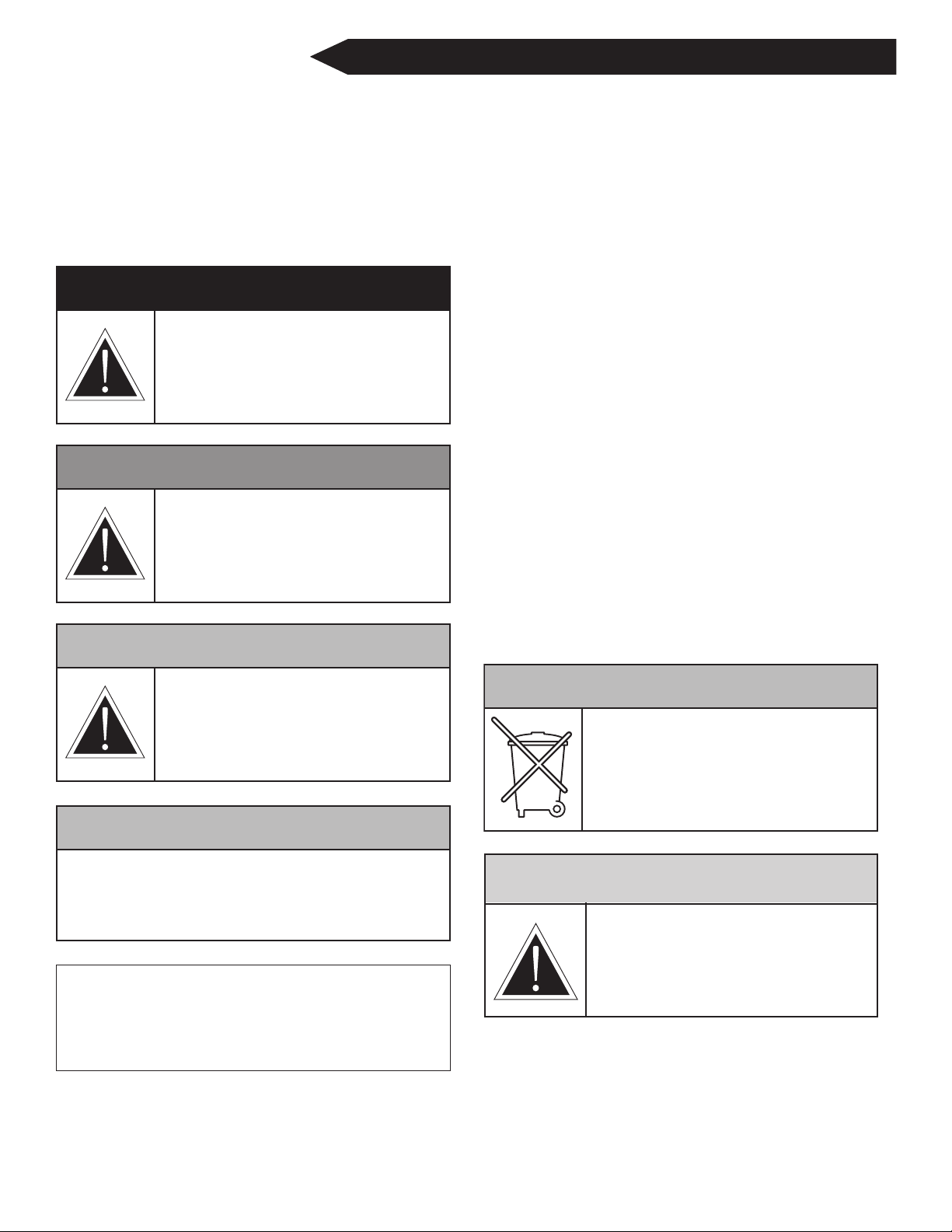

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

DANGER

Used to indicate the presence of

a hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

WARNING

Used to indicate the presence of

a hazard that CAN cause personal

injury, possible death, or major

property damage if the warning

included with this symbol is ignored.

1. This appliance is intended to cook, hold

or process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are

familiar with the purpose, limitations, and

associated hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

CAUTION

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

CAUTION

Used to indicate the presence of a hazard that

can or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

NOTE: Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

NOTE

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

CAUTION

WHEN WELDING ANY STAINLESS

STEEL COMPONENTS ON THIS

APPLIANCE, THE ELECTRONIC

CONTROL BOARDS MUST BE

ISOLATED FROM THE APPLIANCE.

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 2.

SITE INSTALLATION

INSTALLATION

DANGER

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

INSTALLATION CODES & STANDARDS

The following codes and standards are required for

installation of this oven:

AIR SUPPLY, ELECTRICAL CONNECTIONS,

WATER CONNECTIONS, AND WASTE WATER

DISCHARGE.

Installation must comply with local codes required

for gas appliances. In the absence of local codes,

installation must comply with the National Fuel

Gas Code, ANSI Z223.1 (latest edition). In Canada,

the appropriate code is the Natural Gas Installation

Code, CAN/CGA-B149.1 or the Propane Installation

Code, CAN/CGA-B. Adherence to code by a

qualified installer is essential for the following: Gas

Plumbing, Gas Appliance Installation, Commercial

Cooking Ventilation, Water and Plumbing, and

OSHA Regulations.

DANGER

AVERTISSEMENT : UNE INSTALLATION,

UN AJUSTEMENT, UNE ALTÉRATION,

UN SERVICE OU UN ENTRETIEN NON

CONFORME AUX NORMES PEUT CAUSER

DES DOMMAGES À LA PROPRIÉTÉ, DES

BLESSURES OU LA MORT.

LIRE ATTENTIVEMENT LES DIRECTIVES

D’OPÉRATION ET D’ENTRETIEN

AVANT DE FAIRE L’INSTALLATION, OU

L’ENTRETIEN DE CET ÉQUIPEMENT.

CAUTION

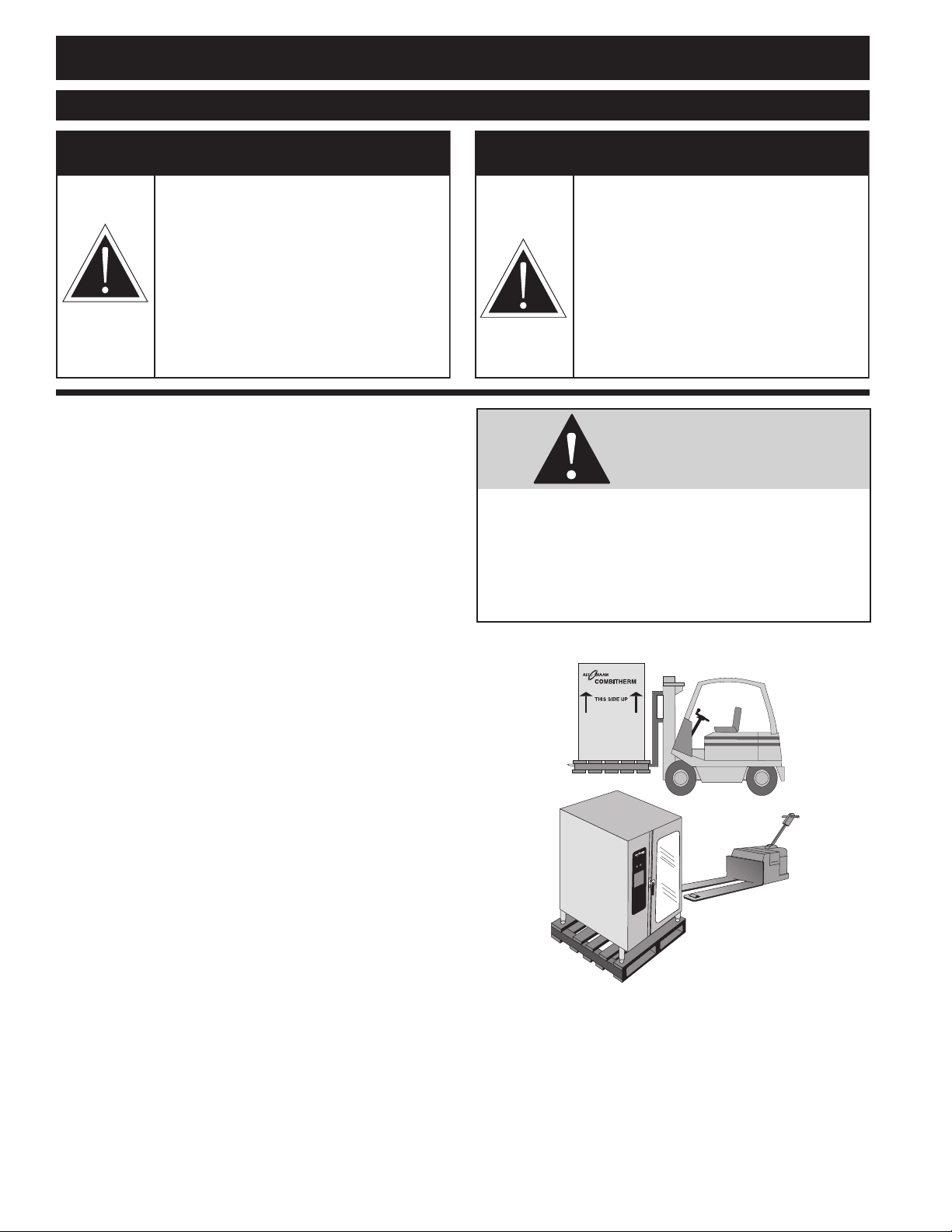

THE OVEN MUST REMAIN ON THE

PALLET WHILE BEING MOVED TO THE

INSTALLATION SITE BY FORK LIFT OR

PALLET LIFT TRUCK.

®

VENTILATION REQUIREMENTS

A steam ventilation hood is mandatory for the

operation of the oven. The ventilation hood must

be installed in accordance with local building codes

for the steam exhaust and must protrude 12-inches

to 20-inches (300 to 500mm) over the front side

of the oven. A grease filter must be located in the

protruding area of the hood. Grease filters should

be thoroughly cleaned on a regular basis following

manufacturer’s instruction. Ventilation hoods must

ensure an adequate amount of incoming air during

operation and must be operated whenever the

combination oven/steamer is used in order to avoid

the accumulation of condensation in the hood area.

See the section titled Gas Exhaust.

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 3.

NOTE: Note dimensions required for doorways

and aisles for access of the oven and pallet

to the installation site. Transport the oven

in an upright and level position only. Do

not tilt the oven.

INSTALLATION

SITE INSTALLATION

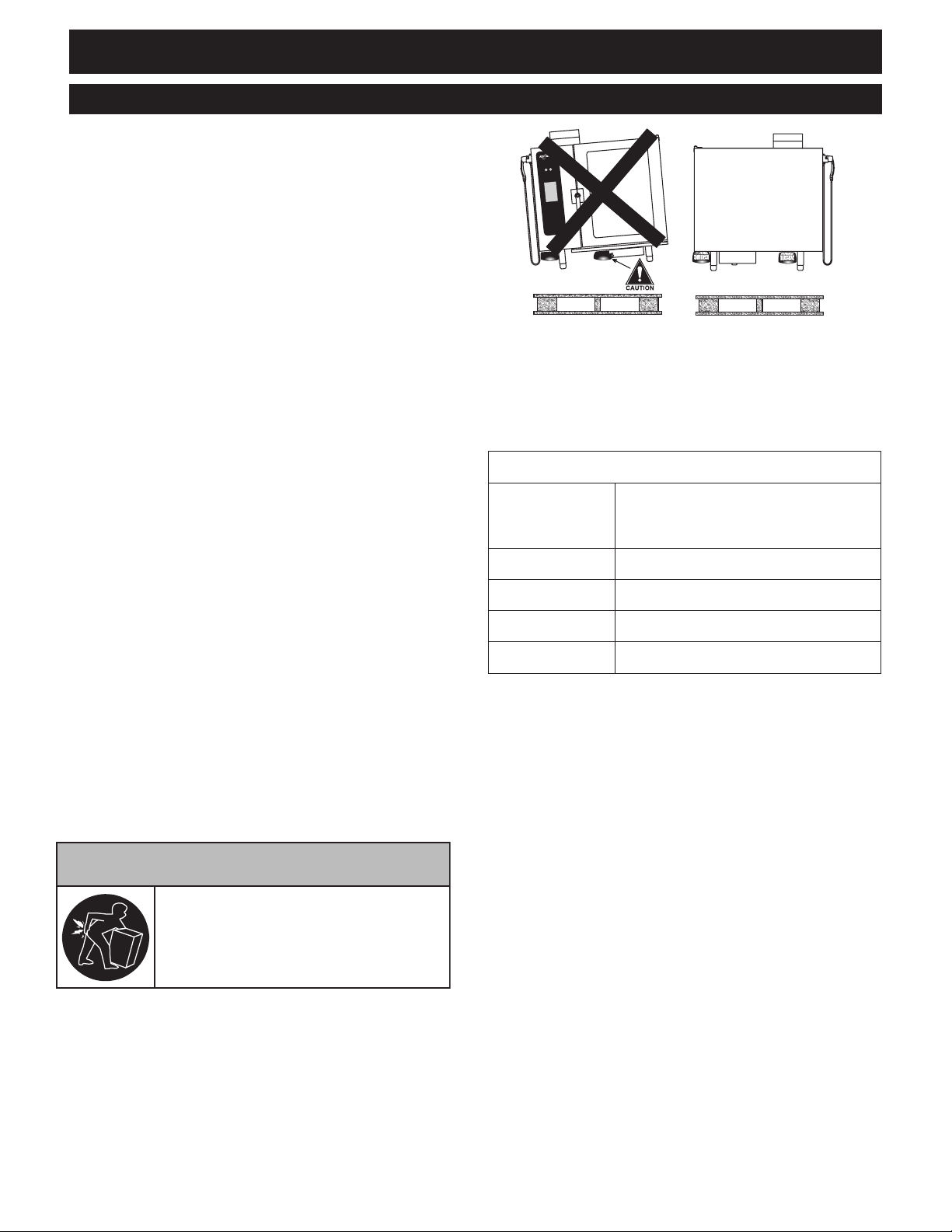

POSITIONING ON SITE

Lift the oven from the pallet with a fork lift or pallet

lift truck positioned at the front of the oven. For

damage protection, the use of two wooden boards,

placed between the bottom of the oven and the lifting

forks, is strongly recommended. To avoid damage,

position the lift forks to the left of the condenser

and right of the right leg as indicated in the diagram

above.

Stand the oven in a level position. Use the adjustable

feet to overcome an uneven floor and ensure that the

unit is level.

It is strongly recommended that table top models be

mounted on a factory supplied stand or a stand that

is stable, open, and level. Recommended height is

23-inches (584mm).

Adjust the height of floor models for smooth access

of the trolley or cart. When positioning the oven,

observe the minimum space allocation requirements

shown.

To insure proper operation, the installation of this

oven must be completed by qualified technicians in

accordance with the instructions provided in this

manual. Failure to follow the instructions provided

may result in damage to the oven, building, or cause

personal injury to personnel.

CAUTION

TO PREVENT PERSONAL INJURY,

NOTE: To avoid equipment damage, observe

attention label on oven for area to avoid

with lifting fork.

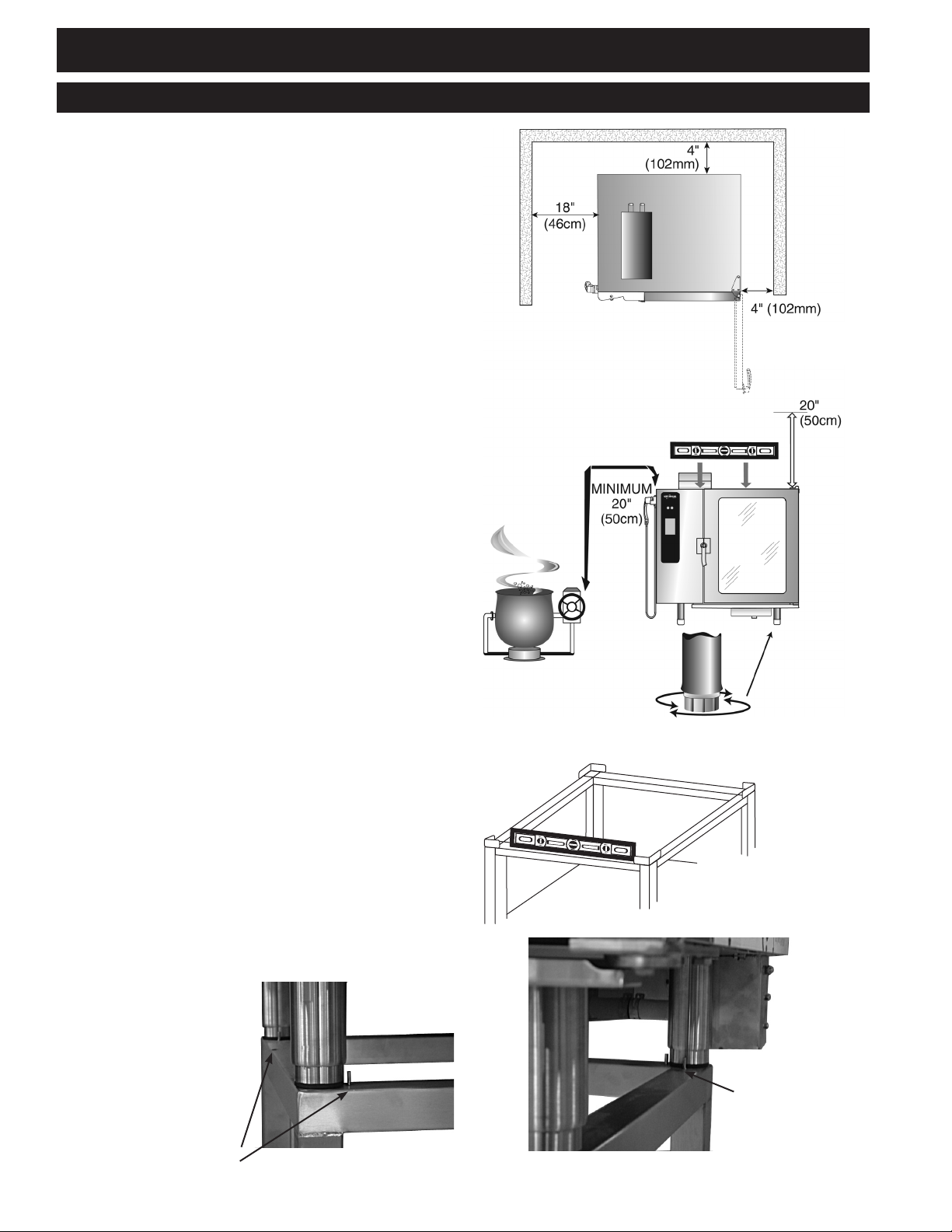

MINIMUM CLEARANCE REQUIREMENTS

LEFT SIDE 6” (152mm) MINIMUM

18” (457mm) SERVICE ACCESS RECOMMENDED

20” (508mm) FROM HEAT PRODUCING EQUIPMENT

RIGHT SIDE 4” (102mm)

BACK 4” (102mm) FOR PLUMBING

TOP 20” (508mm) FOR AIR MOVEMENT

BOTTOM 20” (508mm) FOR AIR MOVEMENT

NOTE: Additional clearance is needed for service

access. A minimum distance of 18-inches

is strongly recommended. If adequate

service clearance is not provided, it will be

necessary to disconnect the gas, water, and

drain to move the oven with a fork lift for

service access. Charges in connection with

inadequate service access is not covered

under warranty.

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 4.

INSTALLATION

SITE INSTALLATION

POSITIONING REQUIREMENTS

q In order to ensure proper ventilation, a minimum

distance of at least 6-inches (152mm) must be kept

from the control panels side (left) of the oven and

any adjoining surfaces.

NOTE: Additional clearance is needed for service

access. A minimum distance of 18-inches is strongly

recommended. If adequate service clearance is not

provided, it will be necessary to disconnect the gas,

water, and drain to move the oven with a fork lift for

service access. Charges in connection with inadequate

service access is not covered under warranty.

q Allow a minimum of 4-inches (102mm) from the

right side of the oven to allow the door to open to at

least a 90° angle. Fully opened, the door will extend

up to a 225° angle If the oven is furnished with the

retractable door option, allow a minimum clearance

of 6-1/2 inches (165mm).

RETRACTABLE DOOR

OPTION:

6-1/2” (165 mm)

q Allow a minimum clearance of 4-inches (102mm)

from the back of the oven for plumbing connections.

q Allow a 20-inch (500mm) clearance at the top of

the oven for free air movement and for the steam

vent(s) located at the top.

q Do not install the oven adjacent to heat producing

equipment such as fryers, broilers, etc. Heat

from such appliances may cause damage to the

controls of the Combitherm. Minimum clearance

recommended: 20-inches (500mm)

Place the Combitherm oven on a stable, noncombustible level horizontal surface. For countertop

models, the oven stand must be level. Level from frontto-back and side-to-side by means of the adjustable

legs. In addition, the overall height of the oven should

be positioned so the operating controls and shelves may

be conveniently reached from the front.

When placing a countertop

model on an oven

stand, position the oven

legs on the outside of

the positioning pins.

Positioning

Pins

Positioning

Pins

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 5.

INSTALLATION

COMMON SPECIFICATIONS

q CombiGuard™ BWS Blended Water System FI-28727

(INCLUDES 50 GALLON TANK, 1 MEMBRANE & 3 FILTERS)

q CombiGuard™ BWS Replacement Filter

Cartridge AMS-QT FI-29316

q CombiGuard™ BWS Replacement Filter

Cartridge SCLX2-Q FI-29317

q CombiGuard™ BWS Replacement Prefilter

Filter Cartridge CTO-Q FI-29318

CombiGuard™ Triple-Guard Water Filtration System

(INCLUDES 1 CARTRIDGE)

q 6•10, 10•10, 7•14 (CombiGuard™ 10) FI-23014

q 10•20, 12•18, 20•20 (CombiGuard™ 20) FI-28728

CombiGuard™ Triple-Guard Replacement Filter

q 6•10, 10•10, 7•14 (CombiGuard™ 10) FI-26356

q 10•20, 12•18, 20•20 (CombiGuard™ 20) FI-28744

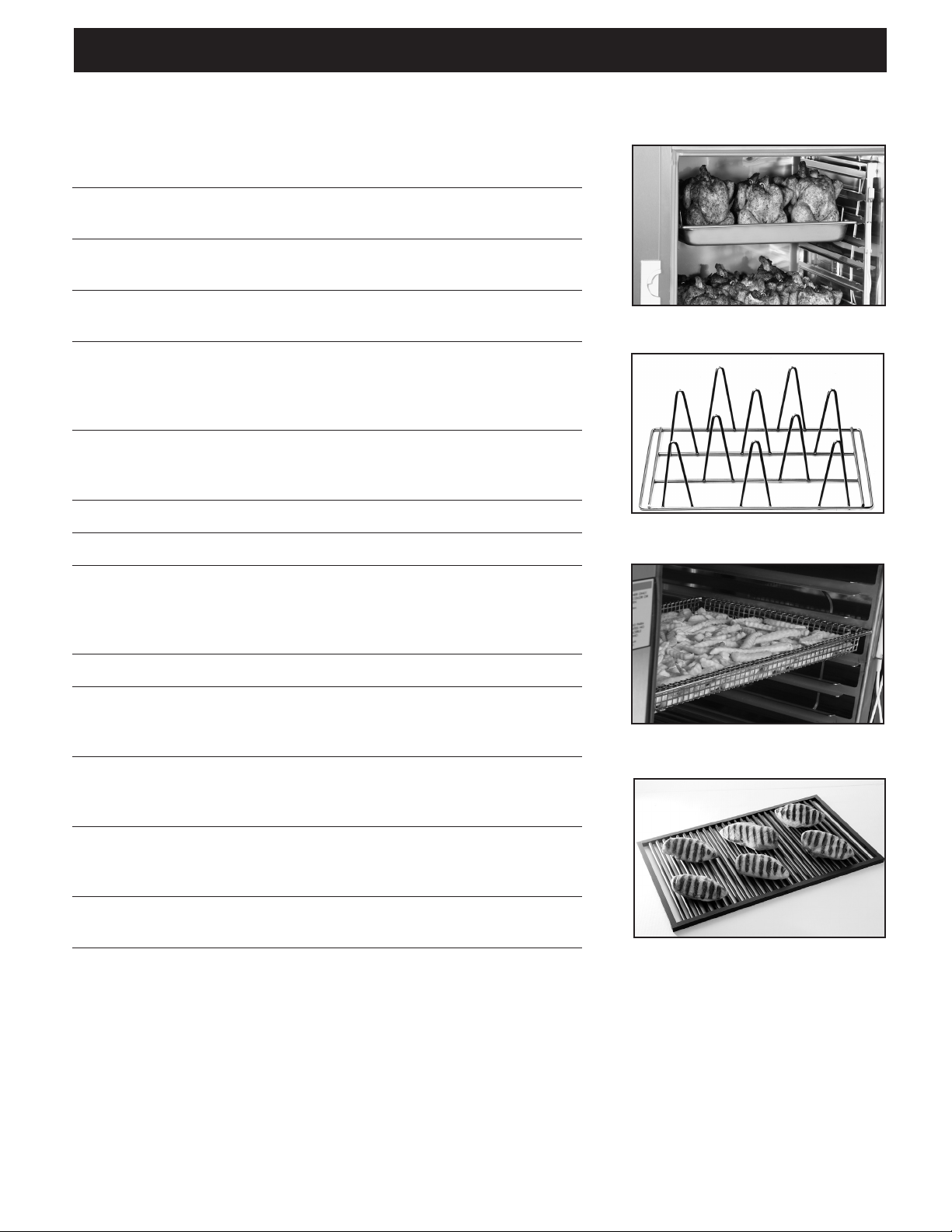

q Fry Basket, 12” X 20” (325mm x 530mm) BS-26730

q Grilling Grate, 12” X 20” (325mm x 530mm) SH-26731

Shelf, Stainless Steel Wire

q 6•10, 10•10 SH-2903

q 7•14, 12•18 SH-22584

q 10•20, 20•20 SH-22473

q Probe, Sous Vide PR-34747

q Combitherm Cleaning Liquid — CE-24750

SPECIALLY FORMULATED FOR COMBITHERM OVENS

➥ TWELVE (12) CONTAINERS/CASE, 1 QUART (C. 1 LITER) EACH

Six (6) Chicken Roasting Rack

(PAN NOT INCLUDED) SH-23000

Ten (10) Chicken Roasting Rack

SH-22634

Fry Basket BS-26730

q Combiclean™ Tablets — CE-28892

SPECIALLY FORMULATED FOR COMBITHERM OVENS

➥ 90 PACKETS EACH CONTAINER

q Scale Free™ CE-27889

(CITRUS BASED, NON-CORROSIVE DELIMING PRODUCT)

CASE = FOUR 4-LB BOTTLES; 4-LB BOTTLE MAKES 10 GALLONS

q Service Start-Up Check SPECIFY AS REQUIRED

AVAILABLE THROUGH AN ALTO-SHAAM FASTEAM CENTER

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 6.

Grilling Grate SH-26731

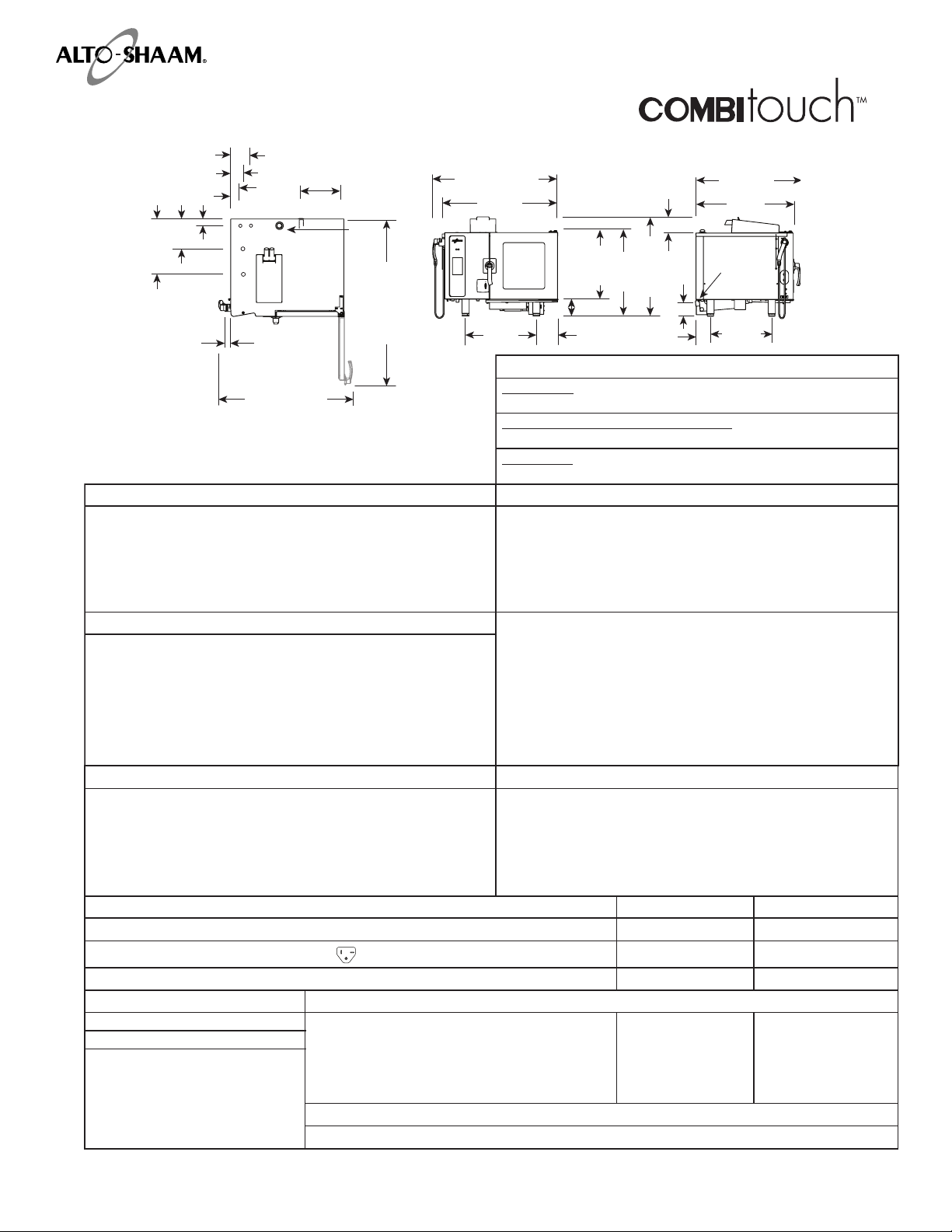

19-3/8"

(492mm)

"

(267mm)

10-9/16

2-3/8" (60mm)

B

A

C

D

5-11/16" (144mm)

4-1/2" (114mm)

2-15/16"

(74mm)

15-3/16"

(385mm)

Water Drain

(Back Side)

Steam

Vent

(Top)

42-1/16" (1068mm)

40-1/8"

(1018mm)

6-1/4"

(159mm)

6•10ESG

(140mm)

5" (125mm)

37" (939mm)

34-5/16"

(871mm)

Water Drain

(Bottom)

24-1/4"

(615mm)

30-1/2"

(774mm)

35-1/4"

(895mm)

5-9/16"

A = UNTREATED WATER

B = TREATED WATER

C = ELECTRICAL

D = GAS

2" (50mm)

47-5/16" (1201mm)

58-3/16" (1478mm)

25"

(635mm)

7-1/2"

(191mm)

DIMENSIONS: H x W x D

EXTERIOR:

35-1/4” x 42-1/16” x 37” (895mm x 1068mm x 939mm)

5-3/16"

(131mm)

21-11/16"

(550mm)

EXTERIOR WITH RECESSED DOOR:

35-1/4” x 46-1/16” x 37” (895mm x 1170mm x 939mm)

INTERIOR:

17-3/4” x 17-3/8” x 26-13/16” (450mm x 440mm x 680mm)

WATER REQUIREMENTS WATER QUALITY MINIMUM STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4” NPT*

ONE (1) UNTREATED WATER INLET: 3/4” NPT*

LINE PRESSURE: 30 to 90 psi 2.8 to 6.2 bar

* Can manifold off of

one 3/4” line.

WATER DRAIN: 1-1/2” CONNECTION WITH A 2” MINIMUM

AIR GAP INSTALLED AS CLOSE TO THE OVEN AS POSSIBLE

CLEARANCE REQUIREMENTS

LEFT 6” (152mm)

RECOMMENDED SERVICE ACCESS: 18” (457mm)

20” (508mm) FROM HEAT PRODUCING EQUIPMENT

RIGHT 4” (102mm) TOP: 20” (508mm) FOR AIR MOVEMENT

BACK 4” (102mm) BOTTOM: 5-1/8” (130mm) FOR LEGS

COUNTER-TOP INSTALLATIONS MUST MAINTAIN

CLEARANCE FROM COUNTER SURFACE

4” (102mm) MINIMUM

GAS REQUIREMENTS (TYPE MUST BE SPECIFIED ON ORDER)

CONNECTED ENERGY LOAD:

HOOK-UP:

MINIMUM CONNECTED PRESSURE:

45,000 Btu / hr Oven must be installed level.

NPT

3/4”

5.5” W.C. (Natural Gas)

9” W.C. (Propane)

MAXIMUM CONNECTED PRESSURE:

ELECTRICAL

(DEDICATED CIRCUIT REQUIRED) 6●10ESG 6●10ESG / sk

14” W.C.

USING A WATER SUPPLY NOT MEETING ALTO-SHAAM’S MINIMUM

WATER QUALITY STANDARDS WILL VOID THIS WARRANTY.

It is the responsibility of the purchaser to ensure that incoming water supply is

compliant with the specifi cations listed through adequate treatment measures.

Installation of the CombiGuard

this system may not address all water quality issues present.

Contaminant

Free Chlorine

Total Dissolved Solids (tds)

TM

Water Filtration System is recommended, but

Inlet Water Requirements (

Less than 0.1 ppm (mg/L)

Hardness

Chloride

Alkalinity

Less than 3 gpg (52 ppm)

Less than 30 ppm (mg/L)

7.0 to 8.5

pH

Less than 50 ppm (mg/L)

Less than 12 ppm (mg/L)

Silica

Less than 60 ppm

untreated water)

INSTALLATION REQUIREMENTS

Hood installation is required.

Water supply shut-off valve and back-flow preventer.

Alternate burner orifice is required for installation sites at

elevations of 2,000 feet (610m) above sea level.

VOLTAGE PHASE CYCLE/HZ AWG AMPS kW AMPS kW

110 – 120 1 50/60

OTHER VOLTAGES AVAILABLE: Range 200 – 415V – 1 or 3 ph, 50 or 60 Hz

NEMA 5-20P, 20A, 125V Plug, AWG 12 9.2 1.05 13.7 1.57

WEIGHT CAPACITY

NET 400 lb est (181 kg) FULL-SIZE PANS: 20” x 12” x 2-1/2” Six (6) Five (5)

SHIP 515 lb (233 kg) GN 1/1: 530 x 325 x 65mm Six (6) Five (5)

CRATE DIMENSIONS: (L x W x H)

45” x 53” x 45”

HALF-SIZE SHEET PANS:* 18” x 13” x 1” Six (6) Five (5)

ON WIRE SHELVES ONLY

(1143 x 1346 x 1143mm)

72 lb (33 kg) MAXIMUM

VOLUME MAXIMUM: 45 quarts (57 liters)

*ADDITIONAL WIRE SHELVES REQUIRED FOR MAXIMUM CAPACITY

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 7.

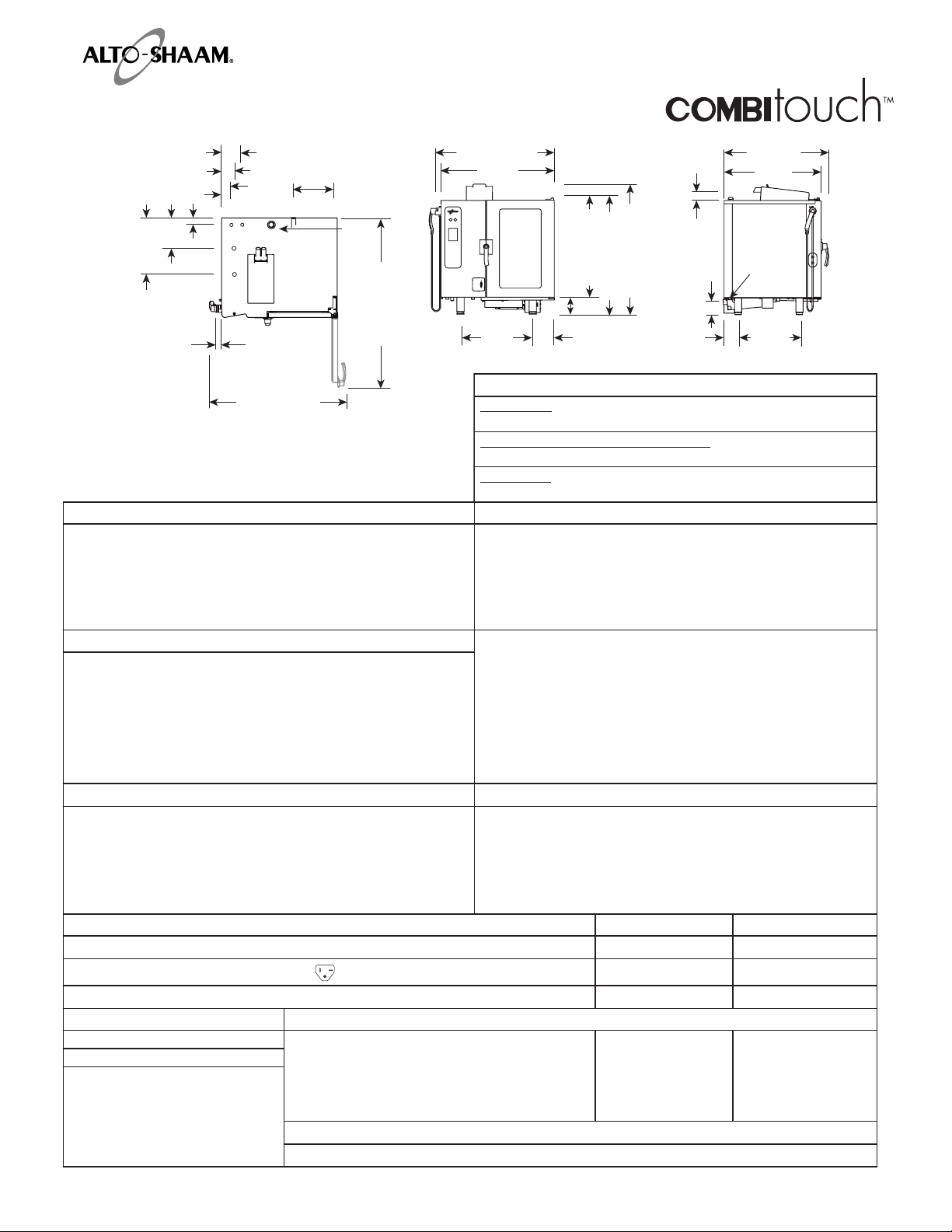

10•10ESG

(140mm)

5" (125mm)

37" (939mm)

34-5/16"

(871mm)

Water Drain

(Bottom)

21-11/16"

(550mm)

"

(267mm)

10-9/16

19-3/8"

(492mm)

A = UNTREATED WATER

B = TREATED WATER

C = ELECTRICAL

D = GAS

2-3/8" (60mm)

A

B

C

D

5-11/16" (144mm)

4-1/2" (114mm)

2-15/16"

(74mm)

2" (50mm)

15-3/16"

(385mm)

Water Drain

(Back Side)

Steam

Vent

(Top)

58-3/16" (1478mm)

42-1/16" (1068mm)

40-1/8"

(1018mm)

25"

(635mm)

33-7/8" (860mm)

6-1/4" (159mm)

40-1/8" (1019mm)

7-1/2"

(191mm)

5-9/16"

44-15/16" (1141mm)

5-3/16"

(131mm)

DIMENSIONS: H x W x D

47-5/16" (1201mm)

EXTERIOR:

44-15/16” x 42-1/16” x 37” (1141mm x 1068mm x 939mm)

EXTERIOR WITH RECESSED DOOR:

44-15/16” x 46-1/16” x 37” (1141mm x 1170mm x 939mm)

INTERIOR:

27-3/8” x 17-3/8” x 26-13/16” (695mm x 440mm x 680mm)

WATER REQUIREMENTS WATER QUALITY MINIMUM STANDARDS

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4” NPT*

ONE (1) UNTREATED WATER INLET: 3/4” NPT*

LINE PRESSURE: 30 to 90 psi 2.8 to 6.2 bar

* Can manifold off of

one 3/4” line.

WATER DRAIN: 1-1/2” CONNECTION WITH A 2” MINIMUM

AIR GAP INSTALLED AS CLOSE TO THE OVEN AS POSSIBLE

CLEARANCE REQUIREMENTS

LEFT 6” (152mm)

RECOMMENDED SERVICE ACCESS: 18” (457mm)

20” (508mm) FROM HEAT PRODUCING EQUIPMENT

RIGHT 4” (102mm) TOP: 20” (508mm) FOR AIR MOVEMENT

BACK 4” (102mm) BOTTOM: 5-1/8” (130mm) FOR LEGS

COUNTER-TOP INSTALLATIONS MUST MAINTAIN

CLEARANCE FROM COUNTER SURFACE

4” (102mm) MINIMUM

GAS REQUIREMENTS (TYPE MUST BE SPECIFIED ON ORDER)

CONNECTED ENERGY LOAD:

HOOK-UP:

MINIMUM CONNECTED PRESSURE:

68,000 Btu / hr Oven must be installed level.

NPT

3/4”

5.5” W.C. (Natural Gas)

9” W.C. (Propane)

MAXIMUM CONNECTED PRESSURE:

ELECTRICAL

(DEDICATED CIRCUIT REQUIRED) 10●10ESG 10●10ESG / sk

14” W.C.

USING A WATER SUPPLY NOT MEETING ALTO-SHAAM’S MINIMUM

WATER QUALITY STANDARDS WILL VOID THIS WARRANTY.

It is the responsibility of the purchaser to ensure that incoming water supply is

compliant with the specifi cations listed through adequate treatment measures.

Installation of the CombiGuard

this system may not address all water quality issues present.

Contaminant

Free Chlorine

Total Dissolved Solids (tds)

TM

Water Filtration System is recommended, but

Inlet Water Requirements (

Less than 0.1 ppm (mg/L)

Hardness

Chloride

Alkalinity

Less than 3 gpg (52 ppm)

Less than 30 ppm (mg/L)

7.0 to 8.5

pH

Less than 50 ppm (mg/L)

Less than 12 ppm (mg/L)

Silica

Less than 60 ppm

untreated water)

INSTALLATION REQUIREMENTS

Hood installation is required.

Water supply shut-off valve and back-flow preventer.

Alternate burner orifice is required for installation sites at

elevations of 2,000 feet (610m) above sea level.

VOLTAGE PHASE CYCLE/HZ AWG AMPS kW AMPS kW

110 – 120 1 50/60

OTHER VOLTAGES AVAILABLE: Range 200 – 415V – 1 or 3 ph, 50 or 60 Hz

NEMA 5-20P, 20A, 125V Plug, AWG 12 9.2 1.05 13.7 1.57

WEIGHT CAPACITY

NET 300 lb est (136 kg) FULL-SIZE PANS: 20” x 12” x 2-1/2” Ten (10) Nine (9)

SHIP 457 lb (207 kg) GN 1/1: 530 x 325 x 65mm Ten (10) Nine (9)

CRATE DIMENSIONS: (L x W x H) EST

45” x 53” x 48”

HALF-SIZE SHEET PANS:* 18” x 13” x 1” Ten (10) Nine (9)

ON WIRE SHELVES ONLY

(1143 x 1346 x 1219mm)

120 lb (54 kg) MAXIMUM

VOLUME MAXIMUM: 75 quarts (95 liters)

*ADDITIONAL WIRE SHELVES REQUIRED FOR MAXIMUM CAPACITY

COMBITOUCHTM ESG SERIES • GAS INSTALLATION MANUAL • 8.

Loading...

Loading...