Page 1

R

VISUAL PARKING ASSIST SENSOR

SYSTEM (VPASS)

VPX-B104R

• OWNER’S MANUAL

Please read before using this equipment.

• MODE D’EMPLOI

Veuillez lire avant d’utiliser cet appareil.

• MANUAL DE OPERACIÓN

Léalo antes de utilizar este equipo.

ALPINE ELECTRONICS MARKETING, INC.

1-1-8 Nishi Gotanda,

Shinagawa-ku,

Tokyo 141-0031, Japan

Phone 03-5496-8231

ALPINE ELECTRONICS OF AMERICA, INC.

19145 Gramercy Place, Torrance,

California 90501, U.S.A.

Phone 1-800-ALPINE-1 (1-800-257-4631)

ALPINE ELECTRONICS OF CANADA, INC.

777 Supertest Road, Toronto,

Ontario M3J 2M9, Canada

Phone 1-800-ALPINE-1 (1-800-257-4631)

ALPINE ELECTRONICS OF AUSTRALIA PTY. LTD.

161-165 Princes Highway, Hallam

Victoria 3803, Australia

Phone 03-8787-1200

ALPINE ELECTRONICS GmbH

Wilhelm-Wagenfeld-Str. 1-3,

80807 München, Germany

Phone 089-32 42 640

ALPINE ELECTRONICS OF U.K. LTD.

Alpine House

Fletchamstead Highway,

Coventry CV4 9TW, U.K.

Phone 0870-33 33 763

ALPINE ELECTRONICS FRANCE S.A.R.L.

(RCS PONTOISE B 338 101 280)

98, Rue de la Belle Etoile, Z.I. Paris Nord Il,

B.P. 50016, 95945 Roissy Charles de Gaulle

Cedex, France

Phone 01-48638989

Viale C. Colombo 8, 20090 Trezzano

ALPINE ELECTRONICS DE ESPAÑA, S.A.

Portal de Gamarra 36, Pabellón, 32

01013 Vitoria (Alava)-APDO 133, Spain

ALPINE ELECTRONICS (BENELUX) GmbH

ALPINE ITALIA S.p.A.

Sul Naviglio (MI), Italy

Phone 02-484781

Phone 945-283588

Leuvensesteenweg 510-B6,

1930 Zaventem, Belgium

Phone 02-725-13 15

EN

Page 2

Page 3

Contents

Operating Instructions

WARNING

DANGER ...........................................2

WARNING ........................................ 2

CAUTION .........................................3

NOTICE .............................................5

Sensor Operation

Introduction .......................................6

Important Information .....................6

How the Visual Parking Assist

Sensor System Works ....................6

Installation and Connections

Installation Diagram .........................7

1. Sedan ......................................................7

2. Pickup Truck ......................................... 7

Accessory Parts ..................................8

Component ................................................8

Installation Tool ........................................8

Wire Connection ...............................9

Painting Sensor Cover and

SensorUnit ...................................10

Sensor Assembly Painting Method ....... 10

Sensor Assembly ..............................11

Installation of Sensor ......................13

Installation of ECU .........................15

On-Screen Display Set Up .............15

Fish-eye Correction Menu ..................... 16

Parking Guide Line Adjustment ...........16

Diagnostic ................................................ 17

Setup Mode Structure Tree ............18

Function Test after Installation .....19

In Case of Difficulty ........................19

ENGLISH

1-EN

Page 4

Operating Instructions

WARNING

DANGER

This symbol means important instructions.

What to do in the case of an extremely critical

situation wherein someone may suffer grave

or mortal injury.

DO NOT PROCEED TO BACK UP YOUR VEHICLE WHILE

PEOPLE ARE IN YOUR VIEW OR THE CAMERA’S VIEW.

SERIOUS INJURY OR DEATH CAN RESULT.

WARNING

This symbol means important instructions.

Failure to heed them can result in serious

injury or death.

WHEN USING SYSTEM, THE DRIVER MUST VISUALLY

CHECK ACTUAL CONDITIONS AROUND THE VEHICLE.

MAKE SURE THERE ARE NO PERSONS OR ANIMALS

IN THE AREA IN WHICH YOU ARE MANEUVERING

OTHERWISE YOU COULD INJURE THEM.

A camera assists the driver by sending images to the screen

showing conditions in view of the camera. The camera uses

a wide-angle lens, therefore, there is a difference in distance

perspective between what is normally seen and what appears

on the screen. Also, the images shown by the rear view camera

are reversed, so as to appear the same as what is seen through

the rearview mirror.

The system may not perform to full capability due to

variables such as:

• weather conditions such as hard rain, snow, fog or mud

• extremely high or low temperatures near camera and/

orsensor

• slope of vehicle and/or roadway

• direct exposure to very bright light such as headlamp or

bright sunlight

• moving from very dark to very bright light and vice versa

such as in parking garages or tunnels

• extremely low light areas

• walls or objects that are located diagonally in relation to

the camera

• retracted mirrors that change camera viewing angle

• open doors or trunks

• changes to height of vehicle due to loading capacity or

hydraulic suspensions

• objects located at the corner of the vehicle

CHECK THAT THE CAMERA AND/OR SENSOR MOUNTING

IS ATTACHED SECURELY, AND THAT THE SCREWS ARE

TIGHT BEFORE DRIVING.

Failure to do so may result in an accident.

WHEN INSTALLING OR CHECKING A CAMERA AND/OR

SENSOR, DO SO AFTER PARKING THE CAR IN A LEVEL,

SAFE PLACE, TURNING OFF THE ENGINE, AND APPLYING

THE HAND BRAKE.

Failure to do so may result in an accident.

WHEN INSTALLING CAMERA AND/OR SENSOR, BE

SURE TO USE SPECIFIC VEHICLE C ALIBRATION KIT

OTHERWISE IT WILL NOT ACCURATELY DISPLAY

IMAGES.

Failure to do so may result in an accident.

MINIMIZE DISPLAY VIEWING WHILE DRIVING.

Viewing the display may distract the driver from looking

ahead of the vehicle and cause an accident.

DO NOT DISASSEMBLE OR ALTER.

Doing so may result in an accident, fire or electric shock.

KEEP SMALL OBJECTS SUCH AS BOLTS OR SCREWS OUT

OF THE REACH OF CHILDREN.

Swallowing them may result in serious injury. If swallowed,

consult a physician immediately.

USE THE CORRECT AMPERE RATING WHEN REPLACING

FUSES.

Failure to do so may result in fire or electric shock.

MAKE THE CORRECT CONNECTIONS.

When making connections to the vehicle’s electrical system,

be aware of the factory installed components (e.g. on-board

computer). Do not tap into these leads to provide power

for this unit. When connecting the device to the fuse box,

make sure the fuse for the intended circuit of the device has

the appropriate amperage. Failure to do so may result in fire

or damage to the unit and/or the vehicle. When in doubt,

consult your Alpine dealer.

BEFORE WIRING, DISCONNECT THE CABLE FROM THE

NEGATIVE BATTERY TERMINAL.

Failure to do so may result in electric shock or injury due to

electrical shorts.

DO NOT ROUTE ELECTRICAL CABLES NEAR HOT OR

MOVING PARTS.

Route the cables and wiring away from hot or moving parts,

and fix them securely to avoid heat/mechanical damage to

the cable insulation, which may result in a short circuit, fire

or electric shock.

DO NOT SPLICE INTO ELECTRICAL CABLES.

Never cut away cable insulation to supply power to other

equipment. Doing so will exceed the current carrying

capacity of the wire and result in fire or electric shock.

DO NOT INSTALL IN LOCATIONS WHICH MIGHT HINDER

VEHICLE OPERATION, SUCH AS THE STEERING WHEEL

OR SHIFT LEVER.

Doing so may obstruct forward vision or hamper movement

etc. and results in serious accident.

DO NOT DAMAGE PIPE OR WIRING WHEN DRILLING

HOLES.

When drilling holes in the chassis for installation, take

precautions so as not to contact, damage or obstruct pipes,

fuel lines, tanks or electrical wiring. Failure to take such

precautions may result in fire.

DO NOT USE BOLTS OR NUTS IN THE BRAKE OR

STEERING SYSTEMS TO MAKE GROUND CONNECTIONS.

Bolts or nuts used for the brake or steering systems (or any

other safety-related system), or tanks should NEVER be used

for installations or ground connections. Using such parts

could disable control of the vehicle and cause fire etc.

2-EN

Page 5

DO NOT ALLOW CABLES TO BECOME ENTANGLED IN

SURROUNDING OBJECTS.

Arrange wiring and cables in compliance with the manual

to prevent obstructions when driving. Cables or wiring that

obstruct or hang up on places such as the steering wheel, shift

lever, brake pedals, etc. can be extremely hazardous.

USE THIS PRODUCT FOR MOBILE 12V APPLICATIONS.

Use for other than its designed application may result in fire,

electric shock or other injury.

USE ONLY IN CARS WITH A 12 VOLT NEGATIVE GROUND.

(Check with your dealer if you are not sure.) Failure to do so

may result in fire, etc.

WHEN USING A DRILL TO MAKE A HOLE, TAKE

PRECAUTIONS SUCH AS WEARING GOGGLES SO

FRAGMENTS DO NOT GET INTO THE EYES.

Failure to do so may result in injury.

CALIBRATION REQUIRED.

Calibration may be required for adjusting parking guideline.

BE CAREFUL WHEN SETTING THE ALARM VOLUME.

Set the alarm volume to an audible level. If the alarm cannot

be heard due to the volume of the car radio, etc., it might

result in an accident.

CAUTION

This symbol means important instructions.

Failure to heed them can result in injury or

material property damage.

DO NOT AT TACH THE CAMERA AND/OR SENSOR

MOUNTING TO FLUOROC ARBON RESIN FINISHED CAR

BODIES OR GLASS.

Doing so could cause the strength of the mounting to

weaken, which could cause it to fall of and cause accidents,

injury, or damage to the car body.

DO NOT AT TACH THE CAMERA AND/OR SENSOR

MOUNTING TO ANY SURFACE WHERE THE ENTIRE

ADHESIVE SURFACE CANNOT BE APPLIED.

Doing so could cause the strength of the mounting to

weaken, which could cause it to fall of and cause accidents,

injury, or damage to the car body.

EXCEPT FOR THE CAMERA AND/OR SENSOR, DO NOT

ATTACH ANY PARTS TO AREAS WHICH WILL GET WET,

OR WHERE THERE IS A LOT OF HUMIDITY OR DUST.

Failure to do so may result in fire or damage.

USE SPECIFIED ACCESSORY PARTS AND INSTALL THEM

SECURELY.

Be sure to use only the specified accessory parts. Use of other

than designated parts may damage this unit internally or may

not securely install the unit in place. This may cause parts to

become loose resulting in hazards or product failure.

HAVE THE WIRING AND INSTALLATION DONE BY

EXPERTS.

The wiring and installation of this unit requires special

technical skill and experience. To ensure safety, always

contact the dealer where you purchased this product to

havethe work done.

ARRANGE THE WIRING SO IT IS NOT CRIMPED OR

PINCHED BY A SHARP METAL EDGE.

Route the cables and wiring away from moving parts (like

the seat rails) or sharp or pointed edges. This will prevent

crimping and damage to the wiring.

HALT USE IMMEDIATELY IF A PROBLEM APPEARS.

Failure to do so may cause personal injury or damage to the

product. Return it to your authorized Alpine dealer or the

nearest Alpine Service Center for repairing.

CHECK WIRING WHEN ATTACHING.

Double-check your wiring to ensure all connections are

correct and secure. Also, do not apply unnecessary force to

the harness. This can result in battery failure, performance

failure, connector damage, or wire breakage.

This system uses ultrasonic sensors to help sharpen the

driver’s detection of obstacles. It is used when parking in a

garage or a narrow passage. As such, this system does not

relieve the driver of the obligation to pay attention to his/

her driving, and the driver should exercise safe driving habits

without relying heavily on this system. The detection range

of the Visual Parking Assist Sensor System (VPASS system) is

restricted to the area around the bumper. When moving the

car either forward or backward, drive slowly and keep a safe

distance around the vehicle. To ensure the sensors function

accurately, never install accessories in close proximity to the

sensors.

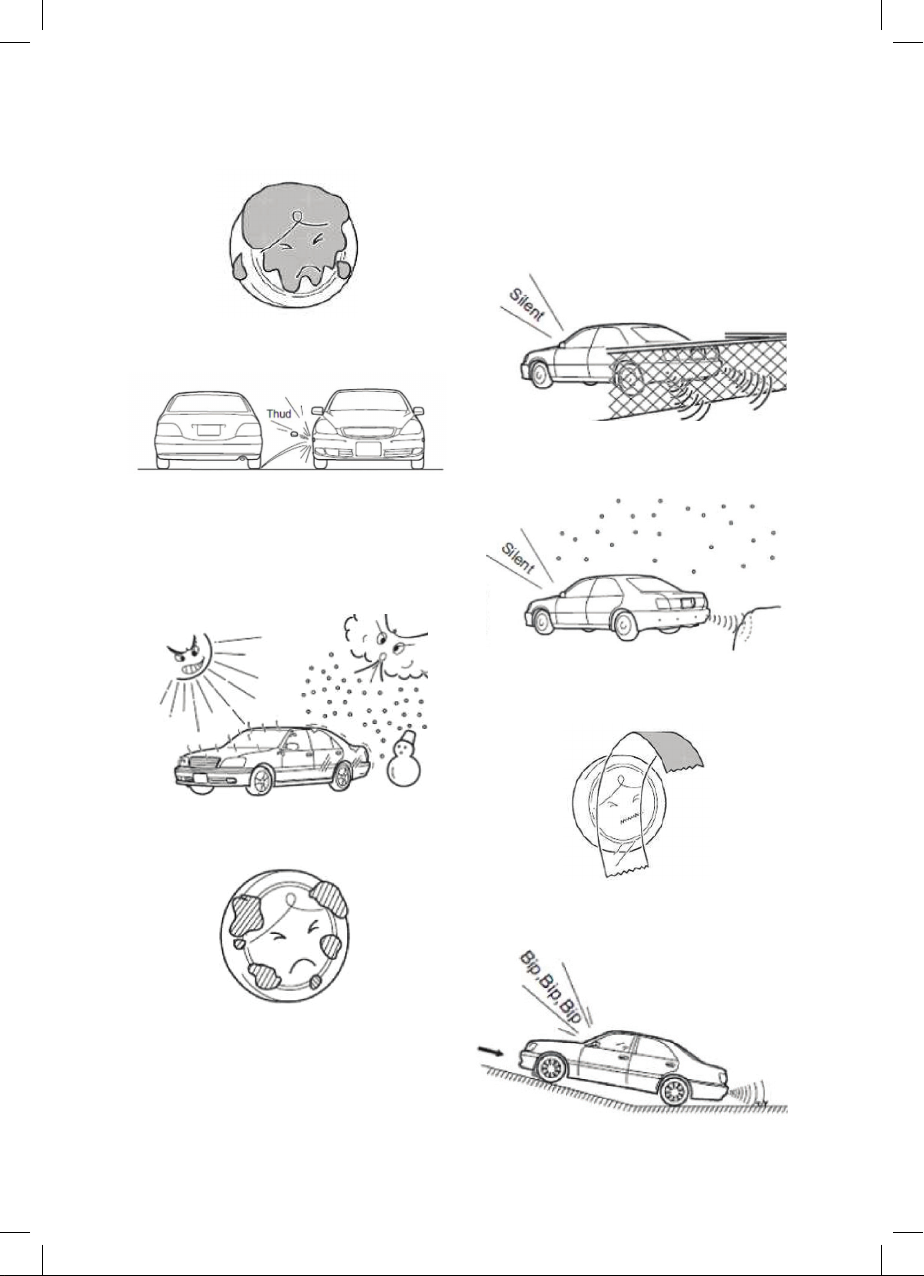

1 The detecting function might not

operate properly under the following

conditions:

• When the detection sensors become frozen. (Normal

function resumes after defrosting.)

3-EN

Page 6

• When the detection sensors are clogged with foreign matter

such as show, mud or icicles. (Normal function resumes

after removal.)

• When a detection sensor is subject to a strong impact.

2 The detecting range could decrease

under the following conditions:

• When the vehicle is parked for a long period of time in the

sunlight or in cold weather.

3 The Parking Corner Sensor might

not be able to detect the following

objects:

• Rope, wire, small-diameter pipes or objects made of these

materials, such as wire fences.

• Objects that absorb sound waves easily, such as fabrics or

other soft, absorbent materials.

• When a sensor is covered by something. (The function

resumes after removal.)

• When the detection sensors are clogged with mud, snow

or icicles.

4-EN

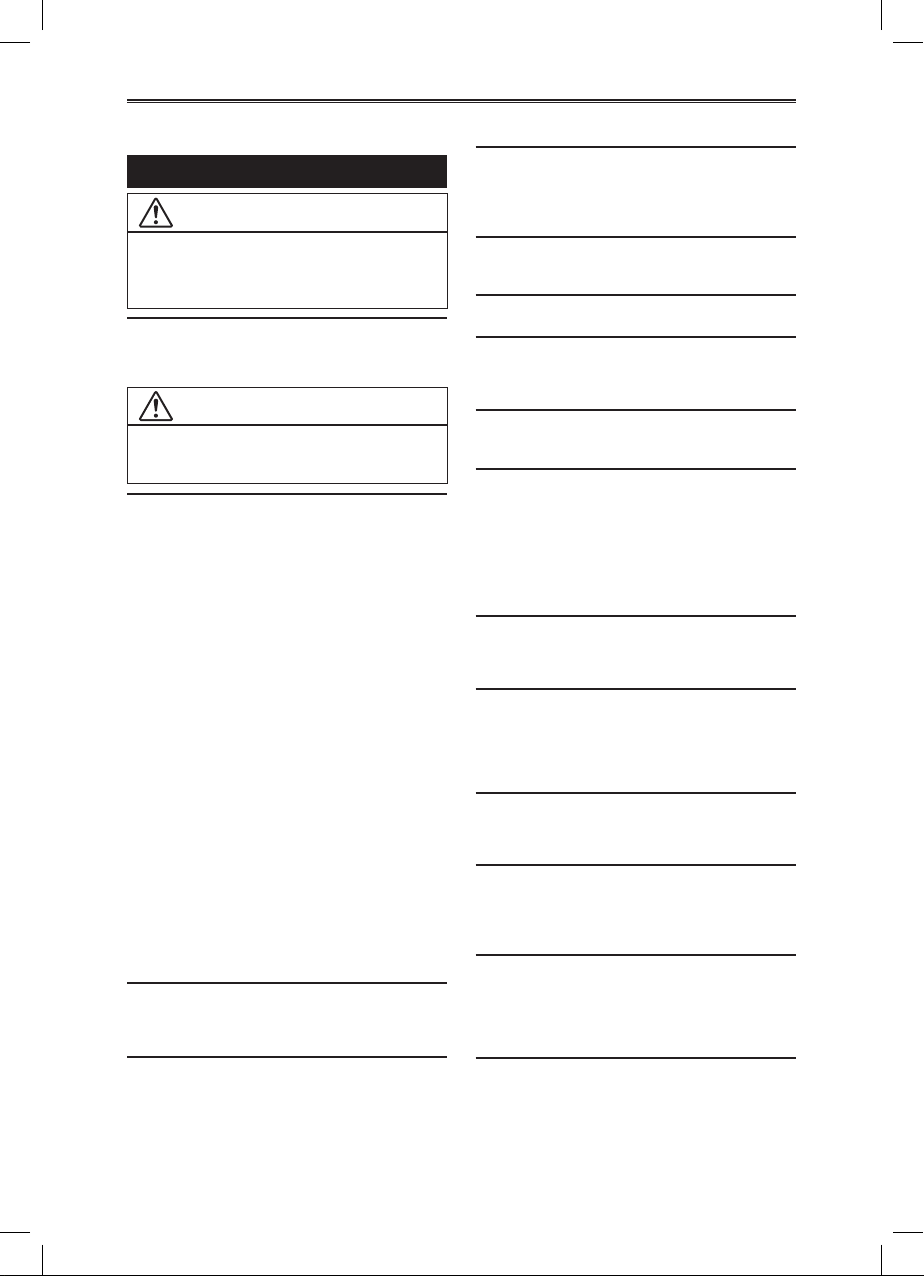

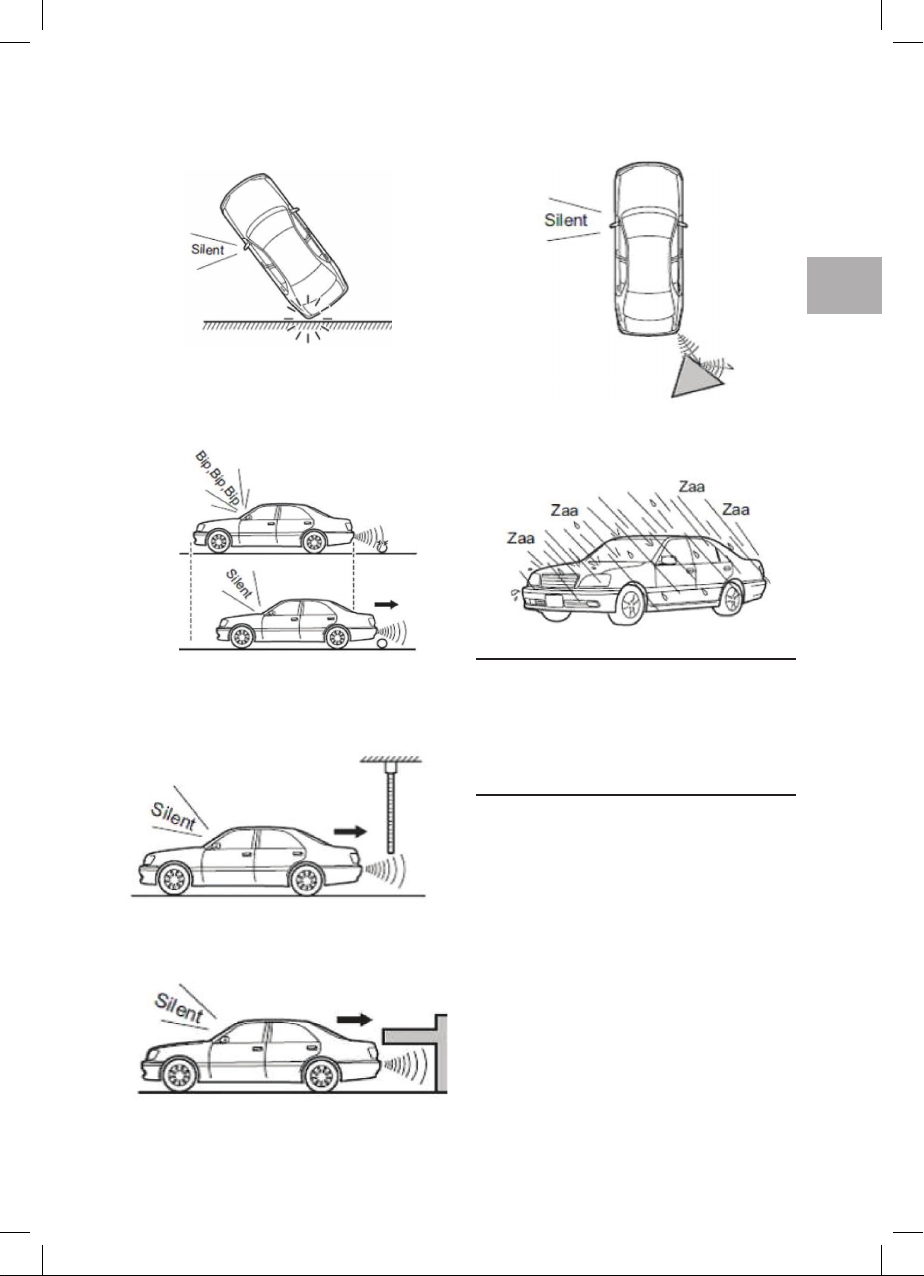

• When the vehicle is parked at extreme angles in relation to

surrounding objects.

Page 7

• When getting too close to an obstacle (< 0.7ft) as the

sensors might have a false detection; for example: no beep,

slow beep, fast beep or three fast beeps.

• Objects around the lower part of the bumper. Even if the

sensors detect a low object initially, when the vehicle is

driven closer to the object, the buzzer might suddenly stop

beeping.

Obstacles being lowered from above, such as a garage door.

• Non-reflecting objects that project at sharp or acute angles

in relation to the sensors.

• Heavy rain or a large amount of water (or splash) on the

sensors.

Caring for the Backup Sensors

1. Wipe the sensors clean with a clean cloth. Flush with lowpressure water if the sensors are clogged with mud or dirt.

2. Do not spray the sensors with high-pressure water, as

provided at a self-serve car wash.

Obstacles that project out high above the floor.

NOTICE

• When washing the vehicle, do not use an automatic car

washer, or high-pressure washer. Doing so could cause the

camera and/or object sensor to come off, damage to the

device cords, or may allow water to enter the camera and/

or object sensor.

• In some cases, to attach the device, a hole must be drilled

in the car body, requiring use of touch-up paint (retail

product) for rust-prevention, and should be prepared

beforehand.

• Route the cables and wiring away from hot or moving

parts, and fix them securely to avoid heat/mechanical

damage to the cable insulation, which may result in shortcircuit, fire or electric shock.

5-EN

Page 8

Sensor Operation

Introduction

Thank you for purchasing this Visual Parking

Assist Sensor System (VPASS system). Please read

this User’s Information Manual carefully before

using the VPASS system.

This Owners Manual contains important

information about the safe operation of the

VPASS system. We urge you to read this manual

carefully, and follow its recommendations to help

make your driving trouble-free and enjoyable.

Important Information

Before using the backup sensors, make sure

you read and understand the operation and

limitations of the system as discussed throughout

this manual.

The backup sensors make an audible sound

when they detect large stationary objects while

maneuvering the vehicle in reverse gear at low

speed. However, not all obstacles may be detected.

Even with backup sensors, the driver should

always look for obstacles near the vehicle and

make sure the path is clear when driving in

reverse gear.

Never rely solely on the backup sensors; always

look behind you before backing up. The sensors

may not always detect people or animals in the

path of your vehicle.

How the Visual Parking Assist

Sensor System Works

The system is ready for operation when the

ignition switch is turned ON and the shift lever is

moved to the reverse position.

The visual parking assist sensor system alerts

you with an audible signal and visual alert when

the rear bumper of your vehicle is approaching an

obstacle.

Sound On‐

screen

Message

Slow

No message GREEN Within

beep

Fast

CAUTION YELLOW Within

beep

Con-

WARNING RED Within

tinuous

beep

On‐

screen

Color

Distance

to

obstacle

3-6 ft

3-1.5 ft

0.7-1.5 ft

Display

Back Sensor

6-EN

Corner Sensor

Continuous beep (0.7 to 1.5 ft.)

Fast beep (3 to 1.5 ft.)

Slow beep (3 to 6 ft.)

Warning

Caution

Page 9

Installation and

Connections

For your protection, please pay extra attention to

the following symbols.

Installation Diagram

1. Sedan

Sensor

CAUTION

This symbol is intended to alert the user that

an accident, injury or vehicle damage may

occur if the instruction is not observed.

SUGGESTION

This symbol is intended to give the user a

better understanding for safer or easier use

ofthe system.

Camera

ECUBuzzerMonitor

• Buzzer can be installed anywhere within

10ft.(3 m).

• ECU MUST be installed inside vehicle.

• Sensor cable must be installed from left to right.

2. Pickup Truck

Parking

Sencor

Monitor

Buzzer

ECU

Camera

• Buzzer can be installed anywhere within

10ft.(3 m).

• ECU MUST be installed inside vehicle.

• Sensor cable must be installed from left to right.

• Optional extension cable (KWE-104PS) may be

required.

7-EN

Page 10

Accessory Parts

Check Accessory Parts.

x1

1 ECU

x1 x1

3 Setup Switch

Without "Grommet" Part

x1 x1

5 Main Harness 6 Sensor Cable

2 Sensor *4

Refer to Component section for detail.

4 Buzzer

Component

SUGGESTION

Please confirm the following sensor

components are not dirty or damaged.

Sensor Unit Box

x4

Sensor Unit Rubber Ring

Sensor Cap Box

x4

8-EN

x1 x1

7 Camera Cable

(3.5 m)

R

SYSTEM (VPASS)

VPX-B104R

• OWNER’S MANUAL

Please read before using this equipment.

• MODE D’EMPLOI

Veuillez lire avant d’utiliser cet appareil.

• MANUAL DE OPERACIÓN

Léalo antes de utilizar este equipo.

ALPINE ELECTRONICS OF AUSTRALIA PTY. LTD.

161-165 Princes Highway, Hallam

Victoria 3803, Australia

Phone 03-8787-1200

ALPINE ELECTRONICS GmbH

Wilhelm-Wagenfeld-Str. 1-3,

80807 München, Germany

Phone 089-32 42 640

ALPINE ELECTRONICS OF U.K. LTD.

Alpine House

Fletchamstead Highway,

Coventry CV4 9TW, U.K.

Phone 0870-33 33 763

ALPINE ELECTRONICS FRANCE S.A.R.L.

(RCS PONTOISE B 338 101 280)

98, Rue de la Belle Etoile, Z.I. Paris Nord Il,

B.P. 50016, 95945 Roissy Charles de Gaulle

Cedex, France

Phone 01-48638989

Viale C. Colombo 8, 20090 Trezzano

ALPINE ELECTRONICS DE ESPAÑA, S.A.

Portal de Gamarra 36, Pabellón, 32

01013 Vitoria (Alava)-APDO 133, Spain

ALPINE ELECTRONICS (BENELUX) GmbH

EN

ALPINE ITALIA S.p.A.

Sul Naviglio (MI), Italy

Phone 02-484781

Phone 945-283588

Leuvensesteenweg 510-B6,

1930 Zaventem, Belgium

Phone 02-725-13 15

x1

VISUAL PARKING ASSIST SENSOR

ALPINE ELECTRONICS MARKETING, INC.

1-1-8 Nishi Gotanda,

Shinagawa-ku,

Tokyo 141-0031, Japan

Phone 03-5496-8231

ALPINE ELECTRONICS OF AMERICA, INC.

19145 Gramercy Place, Torrance,

California 90501, U.S.A.

Phone 1-800-ALPINE-1 (1-800-257-4631)

ALPINE ELECTRONICS OF CANADA, INC.

777 Supertest Road, Toronto,

Ontario M3J 2M9, Canada

Phone 1-800-ALPINE-1 (1-800-257-4631)

9 Owner's and

Installation Manual

8 Extension Cable

(for Pick-Up Truck)

Registration

card

x1

0 Registration Card

Calibration

Paper

x2

x4

A Installation Paper B PS Guide Sticker

Tape

x2

x12

C Velcro Tape D Wire Tie

x4

E Mount Base

x4

0° Sensor Cap 6° Sensor Cap

x4

0° Spring Plate 6° Spring Plate

Installation Tool

15/16 inch (Ø 24 mm) drill bit is required.

x4

x4

Page 11

Wire Connection

ACC

Reverse

GND

Battery

(Red)

ACC

Buzzer

Setup Switch

Parking SensorsSensor Cable

Reverse

Buzzer

Sensor

Setup SW

(Black)

(Orange/White)

HCE-C104

Other Camera (RCA)

To Alpine Camera

To Alpine Video Monitor

To Other Video Monitor

Video in for HCE-C104 or other RCA video connection

Alpine Monitor

Alpine Monitor

Video in for HCE-C104 or other RCA video connection

Other Camera (RCA)

HCE-C104

To Alpine Camera

(Red)

(Orange/White)

(Black)

3.5 m

VPASS

10 m

For Sedan For Pickup Truck

HCE-C117D

M5 F5

F5 M6M6F6 M5

Note:

* Connect only one camera to the system using the Alpine Camera connector or RCA video in.

* Connect only one monitor to the system using the Alpine Video cable or RCA video out.

* Use the Alpine video cable (provided with system) to connect between the VPASS system and video monitor or between VPASS and Alpine camera

ACC

Reverse

GND

Buzzer

Setup SW

Sensor

System

To Other Video Monitor

To Alpine Video Monitor

HCE-C117D

F5 M6M6F6 M5

M5 F5

ACC

Reverse

Buzzer

Parking SensorsSensor Cable

10 m

Battery

3.5 m

Setup Switch

System

VPASS

9-EN

Page 12

Painting Sensor Cover and

Sensor Unit

Please follow the instructions in this manual for

painting and assembling, in order to get the best

performance.

CAUTION

• Use only the painting and assembling

methods detailed in this manual.

• Damages resulting from the failure to use the

methods detailed in this manual are not our

responsibility.

• Install sensors on the vehicle bumper after

painting and assembling.

• Please refer to the Installation Manual for

installing sensors on the vehicle bumper.

• Immediately clean the surface of the sensors

with a soft cloth if they contact any fuel, oil,

coolant, battery acid, sealants, adhesives, car

care products, or any other substance that

could cause damage.

Sensor Assembly Painting Method

1 Remove the sensor box cap.

3 Remove the spring plate from the

sensor cap box to avoid painting.

4 Remove the rubber ring from the

sensor unit box to avoid painting.

5 Evenly apply 2 or 3 base coats,allow

each coat to dry before recoating.

Note: Avoid painting the rubber ring around

the sensor.

6 Evenly apply 2 or 3 clear coats. For

temperatures under 60° F, allow each

coat to dry for 30minutes before

recoating.

7 When completely dried and hardened,

proceed to the sensor installation

instructions.

Coating Thickness Suggestion:

Base coat: (15 ~ 30 μm);

2 Check if any accessories are missing

and all accessories are aligning/

assembling properly.

10-EN

Clear coat: (25 ~ 30 μm)

CAUTION

• Limit the use of “Spray Paint” to apply the

coatings.

• Depending on the paint manufacturer, the

instructions for painting will vary.

• The sensor unit has been pre-painted with a

base coat, but additional coats are required.

• Before painting, make sure the box is free of

all oil and dust.

• Apply the coats from a distance of 0.5 to 0.8

ft, with a tilt of 45 degrees.

• Do not let the coating adhere to the terminal

and rubber during the time of painting.

• The sensor’s performance will be reduced if

the coating’s thickness is uneven.

Page 13

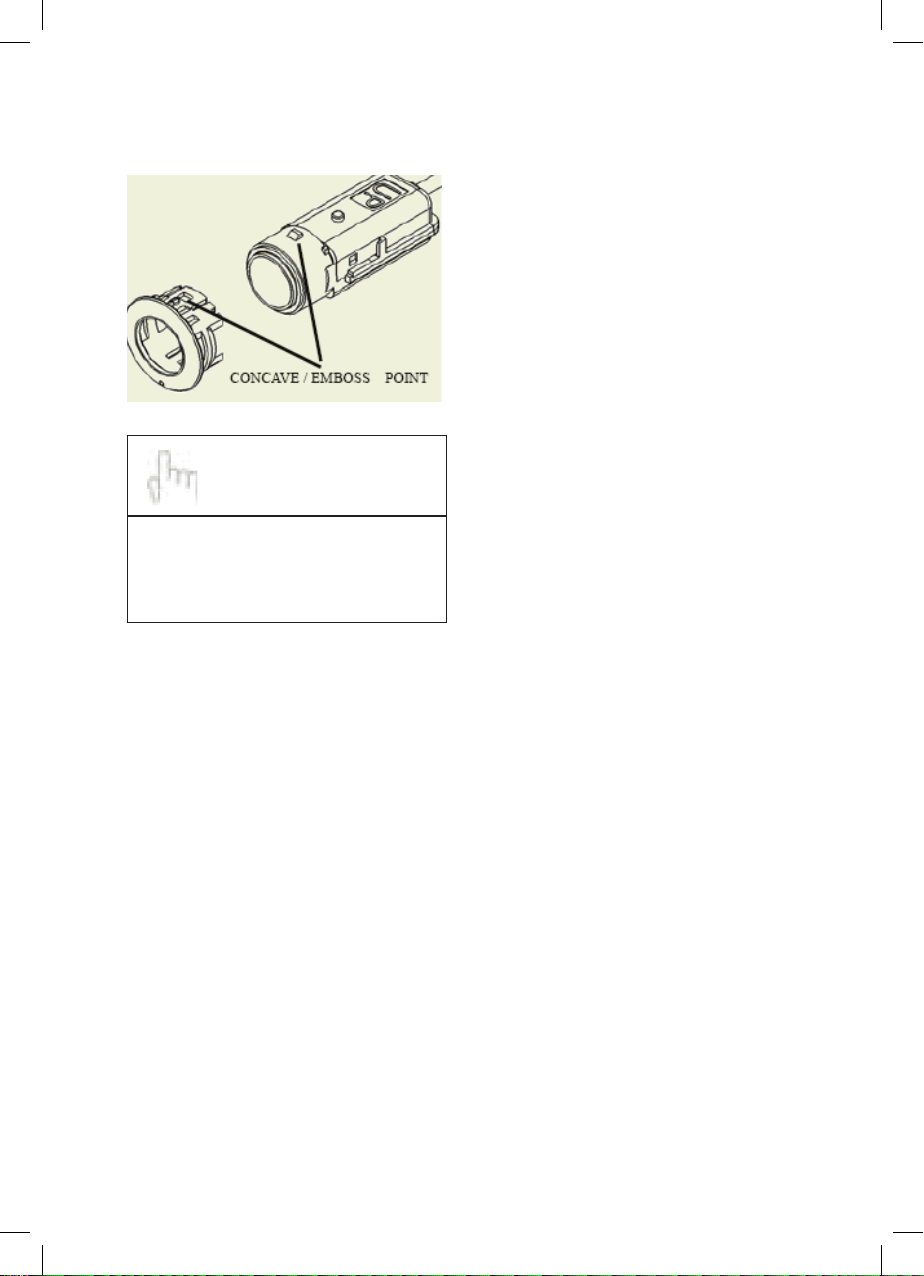

Sensor Assembly

1 Remove the cap from the sensor unit

after the paint is dry.

2 Install the sensor rubber into the

sensor unit.

CAUTION

The side of the sensor rubber with the 12

noticeable points must face the SENSOR UNIT.

CAUTION

• Do not damage the coating surface when

installing the rubber ring and sensor cap.

• Confirm the installation is not loose when

installing the rubber ring and sensor cap.

• Make sure the rubber ring is not deformed

when the sensor cap is installed into the

sensor unit.

• Use Superglue where the sensor cap and

sensor unit join, to increase security

(Use the superglue for plastic only)

Bumps

3 Install the sensor cap onto the sensor

unit.

4 Install the spring plate into the sensor

unit.

11-EN

Page 14

5 Install the sensor on the vehicle

bumper.

SUGGESTION

Refer to the Installation of Sensor for

installing sensors on the vehicle bumper.

Before installing sensors on the vehicle

bumper, make sure the painting process of

sensors has been finished.

12-EN

Page 15

Installation of Sensor

S1 S2 S3 S4

1.6 ft (Min)

0.4 ft (Min)

Equip the sensor with the 0° sensor cap and spring plate for a flat bumper.

Equip the sensor with the 6° sensor cap and spring plate for bumper with a slope.

1 Park the vehicle on a flat level surface.

1/3 Length 1/3 Length 1/3 Length

6 Divide the distance between 2 marked

2 Mark the bumper at 1.8 to 2.3 ft from

the ground as a horizontal guideline.

3 Mark the center of the vehicle bumper

with masking tape.

4 Select a smooth surface area on the

bumper along the horizontal guideline.

7 Check the size of the hole saw to

5 Mark the bumper 0.4 ft away from the

left and right corners of the bumper.

8 Drill a 15/16 inch hole at each of the

0.4 ft (Min)

points into three equal lengths. Mark

the points for sensors S2 and S3 so all

sensors are equally spaced.

match the diameter of the sensors

before drilling any holes.

points that you made in step 1 to 6.

13-EN

Page 16

9 Check behind the bumper to ensure

there is enough depth for sensor

installation.

10 Install the sensor vertically, with the

“UP” sign facing up.

11 Install the sensor into the hole and

mount firmly in the bumper.

13 Insert the plug into the socket.

12 Route the sensor cable.

14-EN

Page 17

Installation of ECU

Calibration sheet

1 Mount the ECU on a dry, protected

area inside the vehicle. For example,

behind the trunk panels or under the

seats.

2 Connect the red wire to the ACC (+),

the black wire to ground (-) of vehicle.

3 Connect reverse signal (+) to the

orange/white wire.

On-Screen Display Set Up

1 Align the calibration paper behind the

car, and up to the rear wheel. Align the

0 ft mark with the rear bumper.

Line up bumper with 0 ft

Calibration sheet

2 On screen color with distance obstacle:

RED (less than 1.5 ft), YELLOW

(1.5 - 3 ft), GREEN (3 - 6 ft).

3 Press the [ENT] and [+] buttons for

5seconds continuously to enter the

On-Screen Display set-up mode.

4 Each item in the [Setup mode] can be

selected by pressing the [+], [-] and

[ENT] buttons.

Following items can be adjusted in

Setup mode.

1. Fish-eye correction

2. Parking Guide Line

3. Diagnostic

4. Exit

15-EN

Page 18

Fish-eye Correction Menu

To go to Fish-eye correction menu, refer to

step 1 through 4 of On-Screen Display Set-up

section.

2 Use the [+] or [-] button to adjust the

top of Green line to match the back

edge of the calibration paper, 6ft

behind the rear bumper.

1 In the fish-eye correction menu, press

the [ENT] button to enter the fish-eye

correction sub-menu.

2 Each item in the [Fish-eye correction]

can be selected by pressing the [ENT].

Start with OFF, FEC 1 to 7 to avoid

screen distortion.

3 After Fish-eye Correction is completed,

return to the [Setup Mode] menu by

pressing the [ENT.]

1. Fish-eye Correction

Parking Guide Line Adjustment

To go to Parking Guide Line Adjustment,

refer to step 1 through 4 of On-Screen

Display Set-up section.

1 Select the “Line Length Adjustment”.

Press the [ENT] to enter.

3 Press the [ENT] to enter the sub-menu.

4 Select the “Line Width Adjustment”.

Press the [ENT] to enter.

5 Use the [+] or [-] button to adjust the

width to match the calibration paper.

6 Press the [ENT] to enter the sub-menu.

7 Select the “Line Slope Adjustment”.

Press the [ENT] to enter.

8 Use the [+] or [-] button to adjust the

slope to match the calibration paper.

9 Press the [ENT] to enter the sub-menu.

10 Select the “Line Ratio Adjustment”.

Press the [ENT] to enter.

11 Use the [+] or [-] button to adjust the line

ratio to match the calibration paper.

12 Press the [ENT] to enter the sub-menu.

13 Select the “Line Shift Adjustment”.

Press the [ENT] to enter.

14 Use the [+] or [-] button to adjust the

line shift to match the calibration

paper.

15 Press the [ENT] to enter the sub-menu.

16-EN

3 D U N L Q J * X L G H / L Q H

- /LQH/HQJWK$GMXVWPHQW

Page 19

Diagnostic

To go to Diagnostic menu, refer to step1

through 4 of On-Screen Display Set-up

section.

1 Select the “Diagnostic”. Press the [ENT]

to enter.

2 Select the “System status”. Press the

[ENT] to enter.

3 Use the [+] or [-] button to review the

“Firmware Version” and “Sensor Status”.

4 Press the [ENT] to enter the sub menu.

7 Press the [ENT] to enter the sub-menu.

Function Parameter

Fish - eye C o rrec t ion OFF

Lin e Le n gth 30

Lin e Sh i f t 44

System Status

Firmw a re Ver s ion

P10 0 2-0 8 -02

6 \ V W H P 6 W D W X V

6 H Q V R U 6 W D W X V

6

6 6 6

2. 2. 2. 2.

5 Select the “Function Parameter”. Press

the [ENT] to enter.

Function Parameter

Lin e Slo p e 60

Lin e Ra t io 0 5

8 Select the “RETURN”. Press the [ENT] to

enter the [Setup Mode].

9 Select the “Exit”. Press the [ENT] to exit.

6 Use the [+][-] button to review the

function parameter of Fish-eye

correction, Line Length, Line Width,

Line Shift, Line Slope and Line ratio.

17-EN

Page 20

Setup -Mode Structure Tree

Setup Mode Off

1. Fish-eye correction

2. Parking Guide Line

3. Diagnostic

4. Exit

FEC 1

FEC 2

FEC8

Return

2-1 Off

2-2 Line Length Adjustment

2-3 Line Slope Adjustment

2-4 Line Shift Adjustment

2-5 Line Ratio Adjustment

2-6 Return

3-1 System Status

3-2 Function Parameter

3-3 Return

Firmware Version

P1002-08-03

Battery Voltage 12.8V

Sensor Status

S1 :OK S2 :OK S3 :OK S4 :OK

Fish-eye correction 008

Line Length 005

Line Shift 058

Line Slpoe 045

Line Ratio 045

18-EN

Page 21

Function Test after

Installation

Turn on the vehicle's ignition switch and shift into

reverse. Use a flat board (2 x 2 ft) behind the car

to test the functions as described in the manual.

Refer to the troubleshooting guide if a problem

arises.

In Case of Difficulty

1. If a problem found with the sensor, the system

will make three short beeps, then silence for

one second. This audio signal occurs five times

and the following message is displayed for 5

seconds.

a) Check the cable connection to the sensor.

b) Check whether the sensor wires are plugged

into the ECU properly.

c) Check the sensor wires for damage.

SENSOR ERROR

NG OK OK OK

PLEASE CHECK SYSTEM.

2. Perform the following checks if the audible

signal does not sound when the vehicle is

approaching an obstacle.

a) Check whether the sensor surface is clean.

b) Check whether the sensor wires are plugged

into the ECU properly.

c) Check the sensor wires for damage.

• Ask an Alpine authorized dealer for advice if the

trouble persists.

3. Take your vehicle to an Alpine authorized

dealer if you encounter either of these problems:

a) The audible signal sounds continuously when

the shift lever is in the reverse position, and

the sensors are not frozen or clogged with

snow or mud.

b) The audible signal does not sound when the

shift lever is moved to the reverse position.

19-EN

Page 22

5KMG006334XA000X

Loading...

Loading...