Page 1

Important Safety,

Installation,

Operation andration and

Maintenance Instructions

Maintenance Instructions

Installation and Operation Manual

Spectra Series Battery Charger

Effective: March 2006

Page 2

Preliminary Operating Instructions 2 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 3

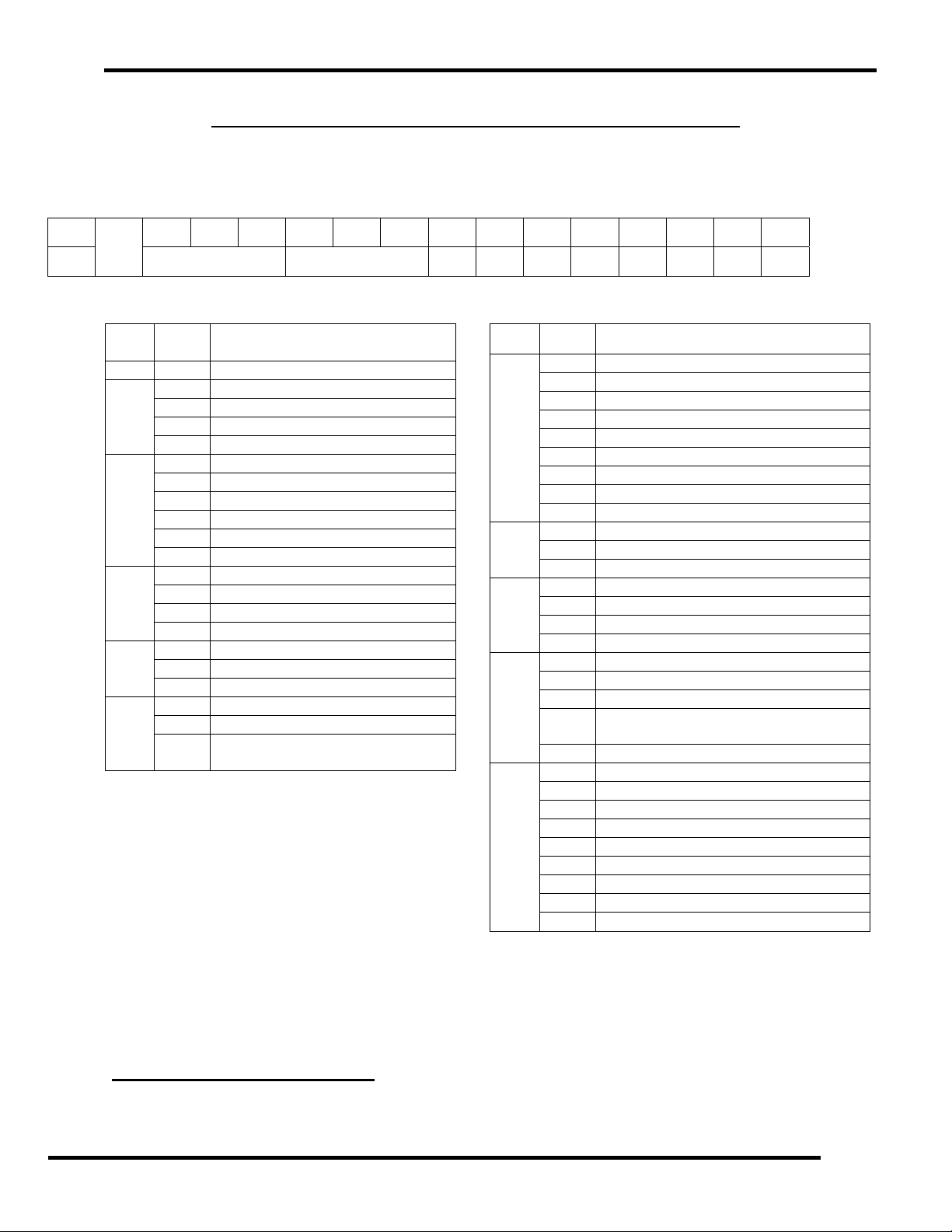

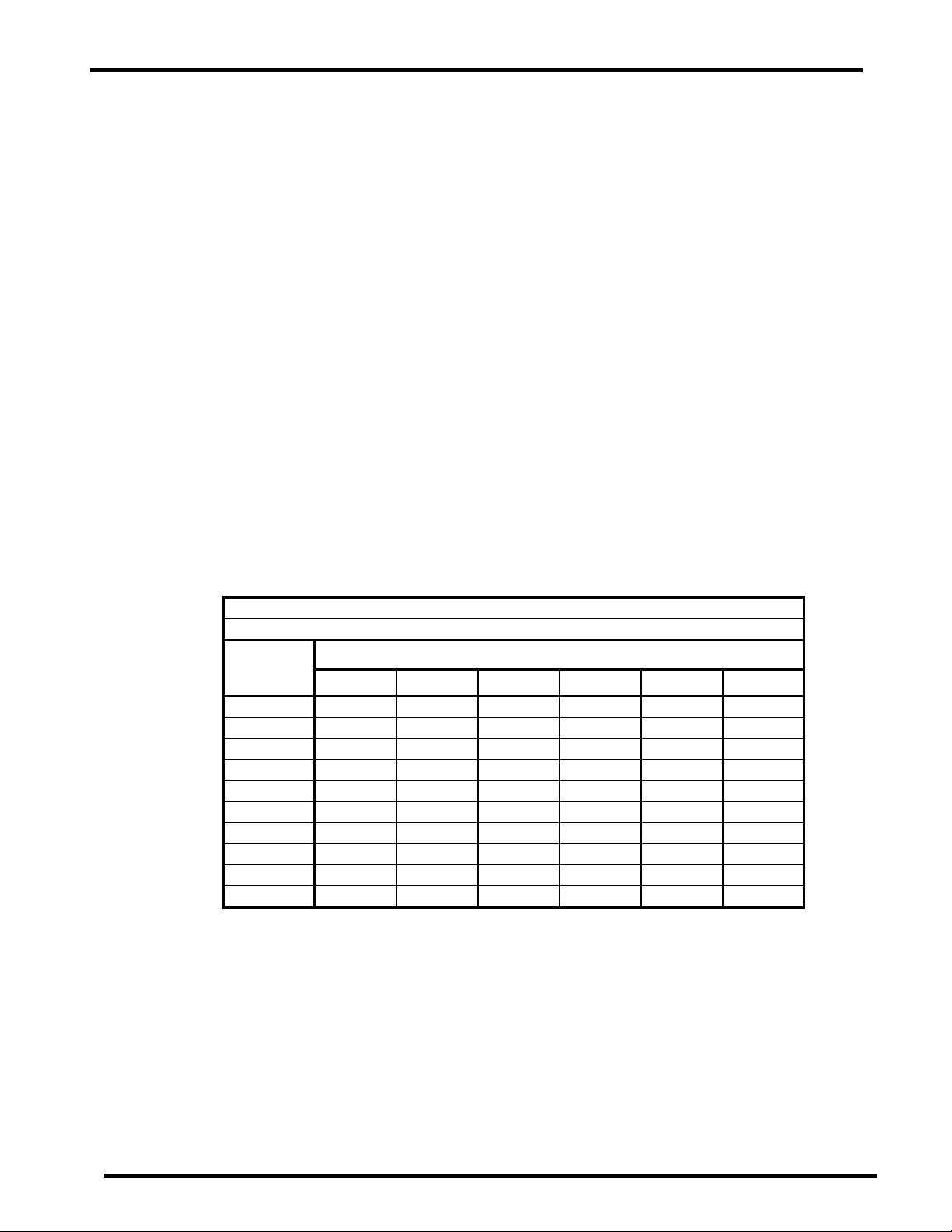

HOW TO READ THE ST MODEL NUMBER CONFIGURATION

The model number describes the options on the charger. Write the model number from the charger ratings specification label

in the spaces provided below. The descriptions shown below will confirm your charger’s configuration. If the charger options

are changed in the field, please make sure to tag the charger with a detailed description of the changes.

ST

A

If a space has no option selected, a zero must be inserted.

Box ST Description

A

B

C

D

E

F

Note:

* 130 Vdc; 50 Adc is not available in 120 Vac.

SAVE THIS MANUAL: Keep it in a location where it is available to anyone who may operate

B C D E F G H I J K

Box ST Description

1 1 Phase

Nominal DC Output Voltage

024 24 Vdc

048 48 Vdc

130 130 Vdc

Nominal DC Output Current

006 6 Adc

012 12 Adc

020 20 Adc

025 25 Adc

050 50 Adc *

Input Voltage

1 120

2 208 (not UL listed)

3 240

Filtering

0 Unfiltered

1 Filtered / Eliminator

Relays

0 No Relays

1 Individual Alarm Relay Contact

Board

or service the charger.

G

H

I

J

K

Remote Sensing

0 Not Supplied

1 Remote Control Panel

2 Remote Temperature Compensation

3 Remote DC Voltage Sensing

4 Lines 1 & 2

5 Lines 1 & 3

6 Lines 2 & 3

7 Lines 1, 2 & 3

Lightning Arrester

0 Not Supplied

1 Included

Charging

0 Not Supplied

1 Parallel Charging

2 Series Charging (Consult Factory)

Special Treatments

0 None

1 Fungus Proofing

2 Conformal Seal On Electronic PC

Board

3 Lines 1 & 2

Other Options

0 None

1 Lockable enclosure door

2 NEMA 4 enclosure

3 NEMA 12 enclosure

4 19” Rack flanges @ 6.0” from front

5 23” Rack flanges @ 6.0” from front

6 Lines 1 & 4

7 Lines 1 & 5

Preliminary Operating Instructions 3 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 4

TABLE OF CONTENTS

HOW TO READ THE ST MODEL NUMBER CONFIGURATION ....................................................................... 3

TABLE OF CONTENTS....................................................................................................................................... 4

IMPORTANT SAFETY INSTRUCTIONS............................................................................................................. 7

1. INTRODUCTION .............................................................................................................................................. 9

2. RECEIVING CHARGER................................................................................................................................... 9

3. STORING CHARGER...................................................................................................................................... 9

4. LOCATION FOR CHARGER INSTALLATION................................................................................................ 9

FIGURE 4.0: TABLE OF CHARGER ENCLOSURE SIZES.............................................................. 10

5. INSTALLATION OF CHARGER.................................................................................................................... 10

5.1 SHELF, COUNTERTOP OR FLOOR MOUNTING ............................................................................... 10

FIGURE 5.1: BOTTOM MOUNTING HOLE DIMENSIONS............................................................... 11

5.2 WALL MOUNTING ................................................................................................................................ 11

FIGURE 5.2-1: KEYHOLE DIMENSIONS.......................................................................................... 11

FIGURE 5.2-2: CHARGER WALL MOUNTING HOLES................................................................... 11

FIGURE 5.2-3: WALL ANCHOR DESIGN LOADS TABLE.............................................................. 12

5.3 RACK MOUNTING ................................................................................................................................ 12

FIGURE 5.3: ATTACHING RACK-MOUNTING BRACKETS............................................................ 12

6. AC ELECTRICAL SUPPLY ........................................................................................................................... 13

6.1 AC INPUT CONNECTIONS................................................................................................................... 13

FIGURE 6.1-1: RATINGS AND BREAKERS TABLE........................................................................ 13

FIGURE 6.1-2: AC AND DC WIRE HOOK UP................................................................................... 15

FIGURE 6.1-3: GROUND WIRE HOOK UP....................................................................................... 15

6.2 AC VOLTAGE JUMPER SETTINGS..................................................................................................... 15

FIGURE 6.2: AC VOLTAGE JUMPER POSITIONS.......................................................................... 16

6.3 AC AND DC CONNECTION LOCATIONS ........................................................................................... 16

FIGURE 6.3-1: S1 ENCLOSURE...................................................................................................... 16

FIGURE 6.3-2: S2 ENCLOSURE...................................................................................................... 17

FIGURE 6.3-3: S3 ENCLOSURE...................................................................................................... 18

7. DC OUTPUT................................................................................................................................................... 19

7.1 DC OUTPUT CONNECTIONS............................................................................................................... 19

FIGURE 7.1: VOLTAGE DROP PER 1 FT (305MM) OF WIRE TABLE ........................................... 19

8. REMOTE AND ALARM I/O RELAY OPTIONS............................................................................................. 19

8.1 REMOTE DC VOLTAGE SENSING...................................................................................................... 19

8.1.1 WIRING THE REMOTE DC VOLTAGE CABLE............................................................................. 20

FIGURE 8.1.1: CHARGER VOLTAGE SENSING WIRING DIAGRAM ............................................ 20

8.1.2 REMOVING REMOTE VOLTAGE SENSING CABLE.................................................................... 20

8.2 REMOTE TEMPERATURE SENSING CABLE..................................................................................... 20

8.2.1 REMOTE TEMPERATURE SENSING CABLE INSTALLATION................................................... 21

8.2.2 REMOVING TEMPERATURE SENSING CABLE.......................................................................... 21

8.3 OPTIONAL REMOTE CONTROL PANEL............................................................................................ 21

8.3.1 REMOTE CONTROL PANEL INSTALLATION.............................................................................. 21

8.4 ALARM I/O RELAY BOARD OUTPUT................................................................................................. 22

8.4.1 ALARM I/O RELAY BOARD OPERATION.................................................................................... 22

8.4.2 ALARM I/O FIELD INSTALLATION INSTRUCTIONS................................................................... 23

Preliminary Operating Instructions 4 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 5

8.4.3 WIRING THE ALARM I/O BOARD TO EXTERNAL CIRCUITS..................................................... 23

8.4.4 TESTING THE ALARM I/O RELAY BOARD AND EXTERNAL CIRCUITS .................................. 23

FIGURE 8.4.4-1: ALARM I/O RELAY BOARD MOUNTING............................................................. 24

FIGURE 8.4.4-2: ALARM I/O RELAY BOARD OUTPUT CONNECTIONS...................................... 24

9. CHARGER START UP SEQUENCE............................................................................................................. 25

9.1 CHECK DISPLAY AND LEDS .............................................................................................................. 25

9.2 CHARGER SETTINGS.......................................................................................................................... 25

9.3 AC & DC POWER UP............................................................................................................................ 25

9.4 RECONNECT DC & RE-CHECK........................................................................................................... 25

10. CIRCUIT BOARDS....................................................................................................................................... 25

10.1 SCR DRIVER BOARD......................................................................................................................... 25

FIGURE 10.1: SCR DRIVER BOARD................................................................................................ 26

10.1.1 BACKUP CHARGER POWER...................................................................................................... 26

10.1.2 SUMMARY ALARM BUZZER AND RELAY CONTACT CONNECTIONS.................................. 26

10.1.3 GFI JUMPER................................................................................................................................. 27

10.1.4 INTERNAL TEMPERATURE SENSOR........................................................................................ 27

10.1.5 OPTIONAL REMOTE TEMPERATURE SENSOR CONNECTOR............................................... 27

10.2 CONTROL BOARD FEATURES......................................................................................................... 27

FIGURE 10.2: CONTROL BOARD .................................................................................................... 27

10.2.1 LIQUID CRYSTAL DISPLAY (LCD)............................................................................................. 28

10.2.2 “HOLD TO EQUALIZE” BUTTON (LARGE SQUARE BUTTON)............................................... 28

10.2.3 ARROW BUTTONS....................................................................................................................... 28

10.2.4 GREEN “AC ON” LED.................................................................................................................. 28

10.2.5 GREEN “DC ON” LED.................................................................................................................. 28

10.2.6 YELLOW “FLOAT” LED............................................................................................................... 28

10.2.7 RED “EQUALIZE” LED ................................................................................................................ 28

10.2.8 BUTTON LOCKOUT JUMPER CONNECTOR............................................................................. 28

10.2.9 BEEPER ........................................................................................................................................ 28

11. CONTROL BOARD OPERATION ............................................................................................................... 28

11.1 DEFAULT DISPLAY MODES.............................................................................................................. 28

11.2 HOW TO VIEW OR CHANGE INFORMATION................................................................................... 29

11.3 CHARGER INFORMATION AND MENU DESCRIPTIONS................................................................ 30

11.3.1 DC VOLTAGE AND DC CURRENT.............................................................................................. 30

11.3.2 FAULT CODES AND FAULT LEDS............................................................................................. 30

11.3.3 DC SETTINGS............................................................................................................................... 32

11.3.4 ALARM SETTINGS....................................................................................................................... 33

11.3.5 EQLZ SETTINGS (EQUALIZE SETTINGS).................................................................................. 35

11.3.6 HRS RUN (HOURS RUN) ............................................................................................................. 36

11.3.7 INTEMP (INTERNAL TEMPERATURE)....................................................................................... 36

11.3.8 EXTEMP (EXTERNAL TEMPERATURE)..................................................................................... 36

11.3.9 CURRENT TIME............................................................................................................................ 36

11.3.10 PAUSE (CHARGER PAUSE) ..................................................................................................... 36

11.3.11 NEXT EQLZ (NEXT EQUALIZE CYCLE)................................................................................... 36

12. SPECIAL MENUS........................................................................................................................................ 36

12.1 SECURITY MENU ............................................................................................................................... 36

12.2 TECH MENU........................................................................................................................................ 37

12.2.1 RELAY START.............................................................................................................................. 37

12.2.2 LEDS ARE OFF............................................................................................................................. 37

12.2.3 DISP (DISPLAY VOLTAGE MODE)............................................................................................. 37

Preliminary Operating Instructions 5 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 6

13. CHARGER CONTROL BOARD QUICK GUIDE ......................................................................................... 37

14. MAINTENANCE........................................................................................................................................... 39

14.1 FUNCTIONAL TESTS......................................................................................................................... 39

14.2 PHYSICAL CLEANING....................................................................................................................... 39

14.3 CHECK AREA AROUND CHARGER................................................................................................. 40

14.4 VISUAL INSPECTION......................................................................................................................... 40

14.5 BATTERY CONDITION....................................................................................................................... 40

15. SERVICING THE CHARGER ...................................................................................................................... 40

15.1 TROUBLESHOOTING......................................................................................................................... 42

15.2 TESTING SCRS................................................................................................................................... 48

15.2.1 SCR1 SHORTED OR LEAKY....................................................................................................... 48

15.2.2 SCR1 OPEN .................................................................................................................................. 48

FIGURE 15.2.2-1: SCR1 TERMINAL DIAGRAM .............................................................................. 49

FIGURE 15.2.2-2: SCR1 TERMINAL DIAGRAM FOR 50A CHARGER........................................... 49

15.3 TRANSFORMER TESTING................................................................................................................. 50

FIGURE 15.3: TRANSFORMER AC VOLTAGES TABLE................................................................ 50

15.4 CHARGER ID TESTING...................................................................................................................... 51

FIGURE 15.4: TS1 ID TERMINAL STRIP RESISTORS TABLE....................................................... 51

16. ORDERING REPLACEMENT PARTS......................................................................................................... 51

17. FACTORY REPLACEMENT PARTS........................................................................................................... 52

18. CHARGER SCHEMATIC............................................................................................................................. 57

19. CHARGER SPECIFICATIONS .................................................................................................................... 58

Preliminary Operating Instructions 6 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 7

IMPORTANT SAFETY INSTRUCTIONS

1. SAVE THESE INSTRUCTIONS – This manual contains important safety and operating

instructions.

2. Before using battery charger, read all instructions and cautionary markings on battery

charger, battery, and product using battery.

LOOK FOR THIS SYMBOL TO POINT OUT SAFETY

PRECAUTIONS. IT MEANS: BE ALERT—YOUR SAFETY IS

3.

4.

5.

6.

7.

8.

9.

10.

11.

CAUTION: This charger is factory set to charge only lead-acid type rechargeable

batteries. Other types of batteries may burst causing personal injury and damage.

Before charging any other type of rechargeable battery, change the charger settings as

recommended by that battery manufacturer.

DANGER: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, CAREFULLY READ

AND FOLLOW THESE IMPORTANT SAFETY AND OPERATING INSTRUCTIONS BEFORE

INSTALLING OR OPERATING THE CHARGER.

INSTRUCTIONS IMPORTANTES CONCERNANT LA SECURITÉ.

DANGER: RISK OF ELECTRIC SHOCK. CAPACITORS STORE HAZARDOUS ENERGY.

DO NOT OPEN DOOR OR REMOVE PANELS UNTIL 5 MINUTES AFTER DISCONNECTING

ALL AC AND DC SUPPLY. THE CAPACITORS WILL HOLD A CHARGE FOR UP TO 5

MINUTES AND CAN CAUSE A SHOCK EVEN IF THE POWER HAS BEEN DISCONNECTED.

DANGER: TURN OFF EXTERNAL AC POWER AND DISCONNECT EXTERNAL DC

VOLTAGE BEFORE SERVICING CHARGER OR BEFORE CONNECTING OR

DISCONNECTING THE BATTERY TO PREVENT ARCING OR BURNING.

DANGER: RISK OF ELECTRIC SHOCK. DO NOT TOUCH UNINSULATED ELECTRICAL

PARTS, EITHER AC OR DC, WHILE THE POWER IS CONNECTED.

DANGER: RISQUE DE CHOCKS ÉLECTRIQUES. NE PAS TOUCHER LES PARTIES

NON ISOLÉES DU CONNECTEUR DE SORTI OU LES BORNES NON ISOLÉES DE

L’ACCUMULATEUR.

DANGER: TO PREVENT ELECTRICAL SHOCK, DO NOT TOUCH EITHER AC OR DC

UNINSULATED PARTS. MAKE SURE ALL ELECTRICAL CONNECTORS ARE IN GOOD

WORKING CONDITION. DO NOT USE CONNECTORS THAT ARE CRACKED, CORRODED

OR DO NOT MAKE ADEQUATE ELECTRICAL CONTACT. USE OF A DAMAGED OR

DEFECTIVE CONNECTOR MAY RESULT IN A RISK OF OVERHEATING OR ELECTRIC

SHOCK.

WARNING: HAZARD OF ELECTRIC SHOCK.

INVOLVED. IF YOU DO NOT FOLLOW THESE SAFETY

INSTRUCTIONS, INJURY OR PROPERTY DAMAGE CAN OCCUR.

Preliminary Operating Instructions 7 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 8

12. Lead-acid batteries generate explosive gases. To prevent arcing or burning near

batteries, do not disconnect DC charging cord from batteries when the charger is

operating. Switch the AC breaker and the DC breaker to the “off” position before

disconnecting the DC output cord from the batteries. Keep sparks, flame, and smoking

materials away from batteries.

13. Always shield eyes when working near batteries. Do not put wrenches or other metal

objects across battery terminal or battery top. Arcing or explosion of the battery can

result.

14. Batteries produce hydrogen gas, which can explode if ignited. Never smoke, use an open

flame, or create sparks near the battery. Ventilate the area when the battery is charging

in an enclosed place.

15. Lead-acid batteries contain sulfuric acid, which may cause burns. Do not get acid in

eyes, on skin, or clothing. If contact with the eyes occurs, flush immediately with clean

water for 15 minutes and obtain medical attention.

16. Only qualified personnel should program or service this equipment.

17. De-energize all AC and DC power connections before servicing this unit. If injury does

occur, apply standard treatment for electric shock and, if necessary, consult with a

physician.

18.

19.

20.

21. This charger is factory set to charge lead-acid batteries.

22. Do not operate the charger if it has received a sharp blow, been dropped, or otherwise

23. Do not disassemble the charger. Have the charger examined by a factory authorized

24. Make sure the battery system has the properly rated voltage for this charging system.

CAUTION: FOR INDOOR USE ONLY. THIS CHARGER IS NOT DESIGNED FOR

OUTDOOR USE. DO NOT EXPOSE THE CHARGER TO RAIN OR SNOW.

ATTENTION: NE PAS EXPOSER À LA PLUIE.

ATTENTION: UTILISER POUR CHARGER UNIQUEMENT LES ACCUMULATEURS AU

PLOMB À ELECTROLYTE LIQUIDE. D’AUTRES TYPES D’ACCUMULATEURS

POURRAIENT ÉCLATER ET CAUSER DES BLESSURES OU DOMMAGES. LES

CCUMULATEURS AU PLOMB À BOÎTIER ÉTANCHE, Y COMPRISE LES BATTERIES À

ÉLECTROLYTE GÉLIFÎE.

damaged. Have a factory authorized service technician examine and repair as needed.

service technician. Incorrect re-assembly of the charger may result in an explosion,

electric shock, or fire.

SAVE THESE INSTRUCTIONS

Preliminary Operating Instructions 8 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 9

1. INTRODUCTION

This single-phase battery charger is convection cooled, microprocessor controlled, and SCR regulated. The

charger has an “l-E” profile, which is high rate constant current (start region), and constant voltage (plateau

region). The plateau region is defined by one voltage point (knee) where the start region changes into the

plateau region. This plateau voltage point is called the “Float Voltage” and it is factory set at 2.25 volts per cell

for charging lead acid batteries.

The charger has an equalize feature used to perform an equalize charge of the battery. An equalize charge is

periodically used to change the voltage set point above the normal float voltage. This increases the gassing to

mix the electrolyte in a battery and charge all of the cells to a uniform level. The equalize charge voltage is

factory set to 2.32 volts per cell. Contact your battery manufacturer’s authorized service technician for

information on how often your batteries should be equalized.

CAUTION: This charger is factory set to charge only lead-acid type rechargeable batteries. Other

types of batteries may burst causing personal injury and damage. Before charging any other type of

rechargeable battery, change the charger settings as recommended by that battery manufacturer.

The charger settings can be changed by following the instructions in SECTION 11, “CONTROL BOARD

OPERATION”, of this manual.

2. RECEIVING CHARGER

Unpack the charger and examine it for possible shipping damage. If any damage is found, report it

immediately as a claim to the carrier.

3. STORING CHARGER

When the charger is stored prior to being installed and powered up, it should be stored upright, bolted to the

shipping pallet, and covered by the plastic wrap and shipping carton it was shipped in. This will help protect it

from dust and abrasion. It should be stored in an area where it is not likely to be damaged. Do not stack

anything on top of the charger.

It must be stored indoors in a clean and dry environment where the temperatures will not exceed a range of

32º F to 120ºF (0°C to 49°C).

The charger should not be stored more than two years before it is powered up. If the charger capacitors are

not powered up, they will lose their effectiveness over time and may need to be replaced.

4. LOCATION FOR CHARGER INSTALLATION

WARNING: DO NOT INSTALL THE CHARGER ON OR NEAR COMBUSTIBLES OR EXPLOSIVES.

INSTALL THE CHARGER ON A FIRE RESISTANT FOUNDATION OF STONE, BRICK, CONCRETE OR

GROUNDED METAL.

The charger should be located in a clean, cool, dry and well-ventilated area. To permit ample airflow for

convection cooling, allow 4” (102mm) minimum clearance on both the right and left sides of the charger. Allow

more space for cooling and convenience of service and maintenance if possible. Do not obstruct the airflow

space provided behind and underneath the charger.

Allow 36” (914mm) minimum clear space in front of the charger for ease of operation, maintenance and

service.

WARNING: DO NOT INSTALL THE CHARGER ABOVE OR NEAR THE BATTERIES. The batteries give

off hydrogen gas, which rises upward and can be explosive and also produce acid fumes, which may harm the

charger.

Do not install the charger in an area where conditions may be below freezing, above 105° Fahrenheit (40°C) or

above 95% relative humidity. These extreme temperatures will reduce the current capacity and possibly the

Preliminary Operating Instructions 9 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 10

service life of the charger. If the charger is to be operated at any of these temperature extremes, contact the

manufacturer to verify it will withstand these conditions, and perform at the needed capacity.

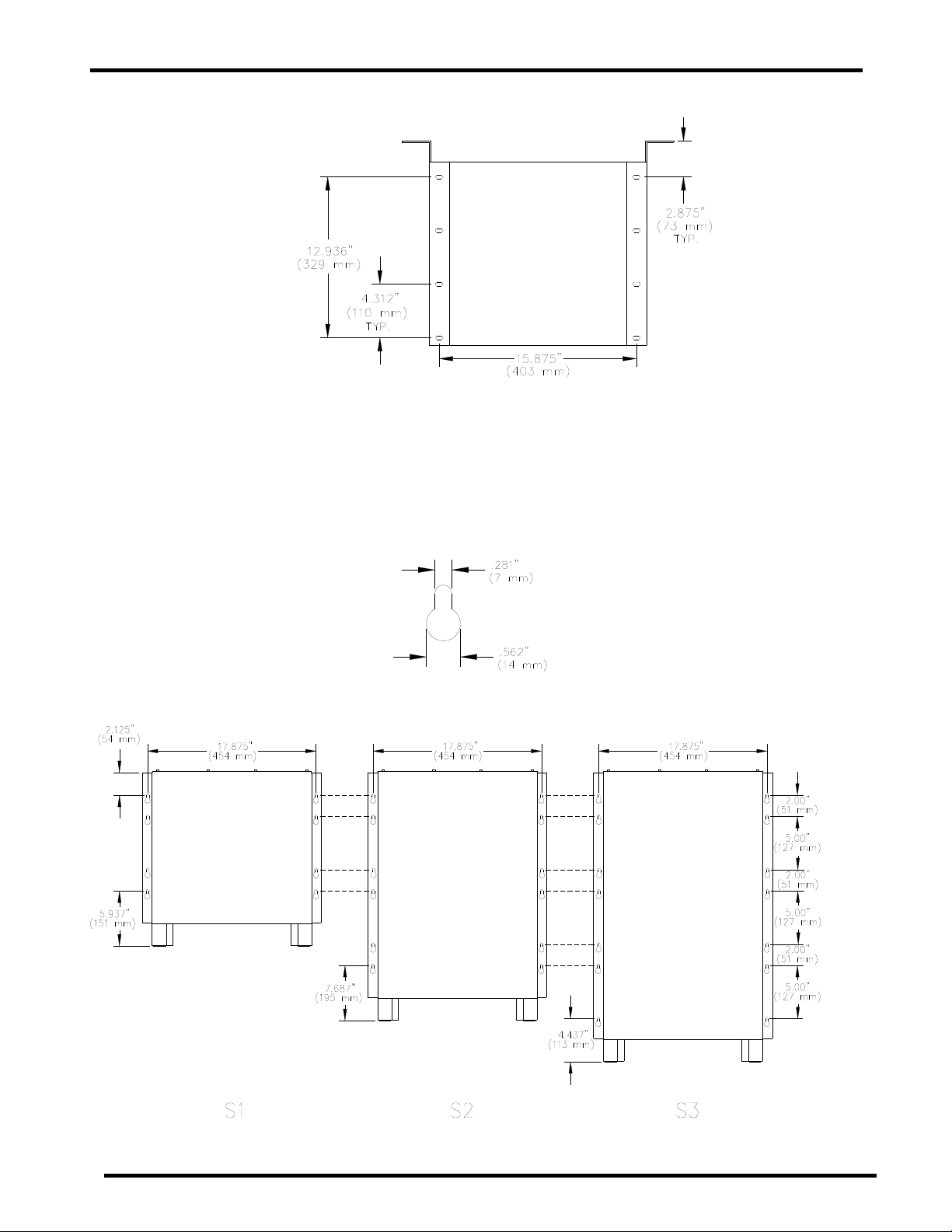

The overall outer dimensions of the S1, S2, and S3 charger enclosures are shown in FIGURE 4.0.

FIGURE 4.0: TABLE OF CHARGER ENCLOSURE SIZES

Overall

Enclosure

sizes

height in

modular

units

Overall height

in inches (mm)

Overall width

in inches (mm)

Overall depth in

inches (mm)

S1 10 U* 17.50 (445) 19.00 (483) 16.75 (425)

S2 15 U* 26.25 (667) 19.00 (483) 16.75 (425)

S3 20 U* 35.00 (889) 19.00 (483) 16.75 (425)

* A modular unit (U) is 1.75” (44mm) as defined by the

ELECTRONIC INDUSTRIES ASSOCIATION (EIA).

** Overall width is from the outer edges of mounting flanges, to correspond to a 19” (483mm) rack width.

5. INSTALLATION OF CHARGER

Proper installation is important to achieve good charger performance and to prevent damage to the charger

and batteries.

The S1, S2, and S3 enclosure sizes of the charger can be mounted on a shelf, countertop, floor, wall, or relay

rack.

Be sure to plan a clear routing for the conduit connections prior to mounting the charger. Looking at the front

of the charger, the conduit knockouts are provided on the right side, left side and bottom of the enclosure. See

SECTION 6.3. The AC input connections should enter at the left and the DC output connections at the right.

The alarm relay wiring, sensor wiring, and remote control wiring should enter at the right side through a

separate conduit knockout from the DC connections. The AC and DC wiring should be separated from each

other and from the other optional types of wiring, this is a UL requirement.

5.1 SHELF, COUNTERTOP OR FLOOR MOUNTING

The S1, S2 and S3 cabinets of the charger are shipped standard with a kit to install four cushioned feet.

These are designed to prevent marring of the mounting surface and to absorb vibration. The kit can be

found inside the charger cabinet in a small plastic bag. The kit consists of four round black rubber feet

and four mounting screws.

To install the feet, carefully lay the charger on its back onto a protective surface such as the shipping

carton collapsed flat. The four small .16” (4mm) diameter mounting holes can be found on the bottom

surface of the charger legs near the four corners of the charger. Place the mounting screw through the

recessed end of the foot. The screw head will be within the recess and the screw point will engage into

the mounting hole in the bottom of the charger. The screw is self-threading into the mounting hole.

Tighten each screw until it is snug but do not over compress the rubber.

Now, the charger can be rotated back to its upright position standing on the rubber feet. Be careful to lift

(do not slide) the charger into position.

Next, to avoid placing strain on the conduit and wiring, anchor the charger so it does not become

displaced. This can be done in either of two ways. The charger can be bolted down to the horizontalmounting surface that it is resting on or it can be bolted to the wall behind it.

To bolt to the horizontal mounting surface, the mounting bolts will attach through the four ½” (13mm)

diameter mounting bolt holes in the bottom surface of the charger legs that are nearest the corners of

the charger. The charger itself can be used as a template to mark the locations of the holes to be made

in the mounting surface or the bottom mounting hole dimensions in FIGURE 5.1 can be used to measure

the locations of the mounting bolt holes.

Preliminary Operating Instructions 10 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 11

FIGURE 5.1: BOTTOM MOUNTING HOLE DIMENSIONS

5.2 WALL MOUNTING

The S1, S2 and S3 cabinets have built-in wall mounting flanges at the rear. When these flanges are

mounted flush against the wall, they provide for a clear airflow space at the rear of the charger. This

space should not be reduced or obstructed in any way.

The mounting flanges each have a series of keyhole slots. These are designed to conveniently engage

a ¼” (6mm) diameter bolt. The mounting flange bolt hole patterns are shown in FIGURES 5.2-1 and

5.2-2.

FIGURE 5.2-1: KEYHOLE DIMENSIONS

FIGURE 5.2-2: CHARGER WALL MOUNTING HOLES

Preliminary Operating Instructions 11 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 12

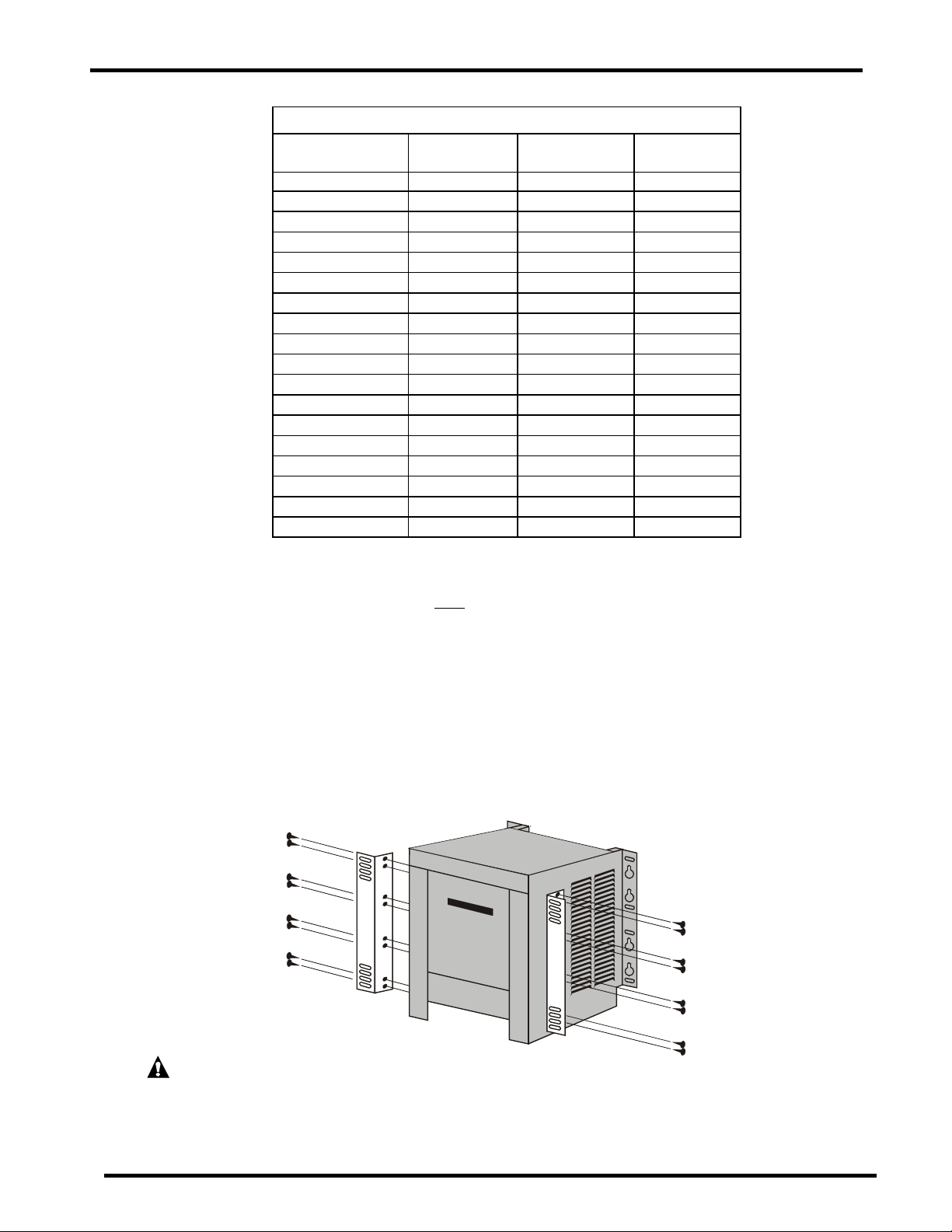

FIGURE 5.2-3: WALL ANCHOR DESIGN LOADS TABLE

Charger Type Enclosure size

Charger weight

lbs. (Kg)

Design load

lbs. (Kg)

24VDC 6A S1 70 (32) 350 (159)

24VDC 12A S1 75 (34) 375 (170)

24VDC 18A S1 85 (39) 425 (193)

24VDC 20A S1 85 (39) 425 (193)

24VDC 25A S1 90 (41) 450 (204)

24VDC 50A S3 190 (86) 950 (432)

48VDC 6A S1 75 (34) 375 (170)

48VDC 12A S1 90 (41) 450 (204)

48VDC 18A S1 110 (50) 550 (249)

48VDC 20A S1 110 (50) 550 (249)

48VDC 25A S1 115 (52) 575 (261)

48VDC 50A S3 222 (100) 1110 (500)

130VDC 6A S1 100 (45) 500 (227)

130VDC 12A S1 130 (59) 650 (295)

130VDC 18A S2 175 (79) 875 (397)

130VDC 20A S2 175 (79) 875 (397)

130VDC 25A S2 190 (86) 950 (432)

130VDC 50A S3 340 (154) 1700 (771)

FIGURE 5.2-3 shows the weight that the set of mounting bolts and their anchoring structure must

withstand for the various charger types. The “DESIGN LOAD” shows the “CHARGER WEIGHT” times a

safety factor of five (5). Be certain that both

the mounting structure and the bolts will, at a minimum,

support the “DESIGN LOAD”. Drywall or plaster will not be strong enough on its own, without proper

structural reinforcement.

5.3 RACK MOUNTING

The S1, S2 and S3 cabinets can be mounted to a standard EIA 19” (483mm) rack system using the

fasteners provided by the rack manufacturer. The rear mounting flanges are configured for an EIA 19”

(483mm) rack for a forward mounting arrangement. For a recessed mounting arrangement, optional

mounting brackets can be attached to the charger sides to fit either an EIA 19” (483mm) or a 23”

(584mm) rack. See FIGURE 5.3.

FIGURE 5.3: ATTACHING RACK-MOUNTING BRACKETS

CAUTION: TO ENSURE THE STRUCTURAL INTEGRITY OF THE RACK MOUNTING

BRACKETS, USE THE SIXTEEN #10 SELF-THREADING SCREWS PROVIDED IN THE KIT. USE

EIGHT SCREWS PER BRACKET AND TIGHTEN THEM UNTIL SNUG. DO NOT STRIP THE

THREADS.

Preliminary Operating Instructions 12 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 13

6. AC ELECTRICAL SUPPLY

The charger must be connected to a single-phase power source. All models can operate on an AC power

source input frequency of 50 or 60 +

3% Hertz. Check the label on the front of the charger or contact the

manufacturer for proper AC power source. The AC input voltage is pre-wired at the factory to 120, 208 or 240

(+10% / -12%) VAC and should not be changed.

NOTE: Field alteration of input voltage voids the charger’s UL Listing.

The AC input wiring must be sized and installed in compliance with the National Electric Code and all

applicable state and local codes and requirements. A qualified electrician must install the AC input wiring

system.

CAUTION: TO REDUCE THE RISK OF FIRE, USE ONLY CIRCUITS PROVIDED WITH BRANCH

CIRCUIT PROTECTION IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE, ANSI/NFPA 70.

6.1 AC INPUT CONNECTIONS

The standard charger is shipped with conduit knockouts and no AC power supply cord. A qualified

electrician must perform this AC input wiring work.

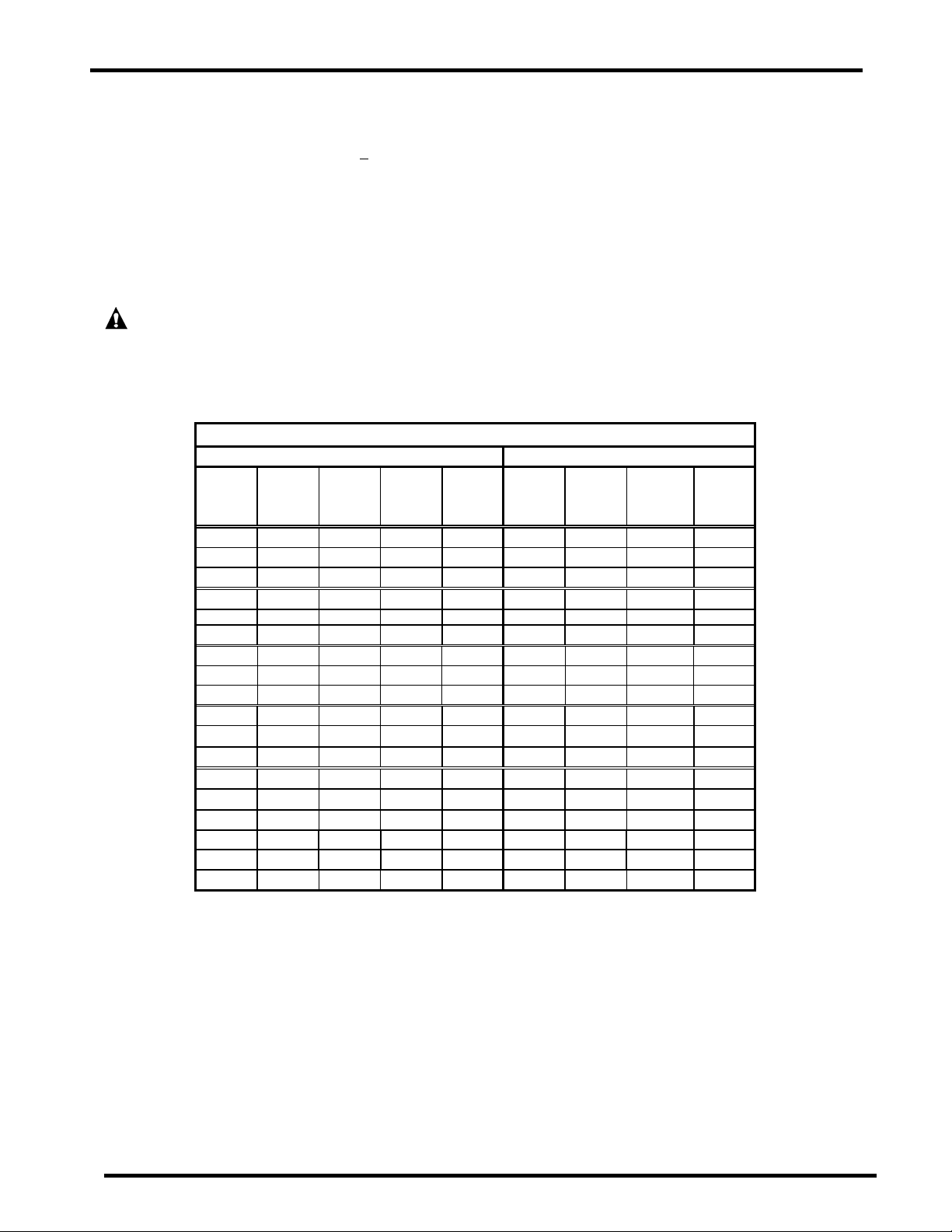

FIGURE 6.1-1: RATINGS AND BREAKERS TABLE

DC Output AC Input

Optional

Rated

DC

Volts

24 6 10 15 14 120 only 5 60 or 50 10

24 6 10 15 14 208 only 3 60 or 50 10

24 6 10 15 14 240 only 3 60 or 50 10

24 12 20 30 12 120 only 7 60 or 50 10

24 12 20 30 12 208 only 5 60 or 50 10

24 12 20 30 12 240 only 5 60 or 50 10

24 18 35 40 8 120 only 10 60 or 50 15

24 18 35 40 8 208 only 6 60 or 50 10

24 18 35 40 8 240 only 6 60 or 50 10

24 20 35 40 8 120 only 12 60 or 50 15

24 20 35 40 8 208 only 7 60 or 50 10

24 20 35 40 8 240 only 7 60 or 50 10

24 25 40 60 8 120 only 14 60 or 50 20

24 25 40 60 8 208 only 8 60 or 50 10

24 25 40 60 8 240 only 8 60 or 50 10

24 50 80 90 6 120 only 24 60 or 50 30

24 50 80 90 6 208 only 15 60 or 50 20

24 50 80 90 6 240 only 15 60 or 50 20

Notes: All input AC circuit breakers are of the “high inrush” type to prevent nuisance tripping during power-up.

Rated

DC

Amps

Rms.

DC

Amps

DC

Circuit

Breaker

Amps

Cable

Size

AWG

(Continued on next page)

Rated

AC Input

Volts

Rated

AC

Amps

AC

Frequency

Hz

AC

Circuit

Breaker

Amps

Preliminary Operating Instructions 13 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 14

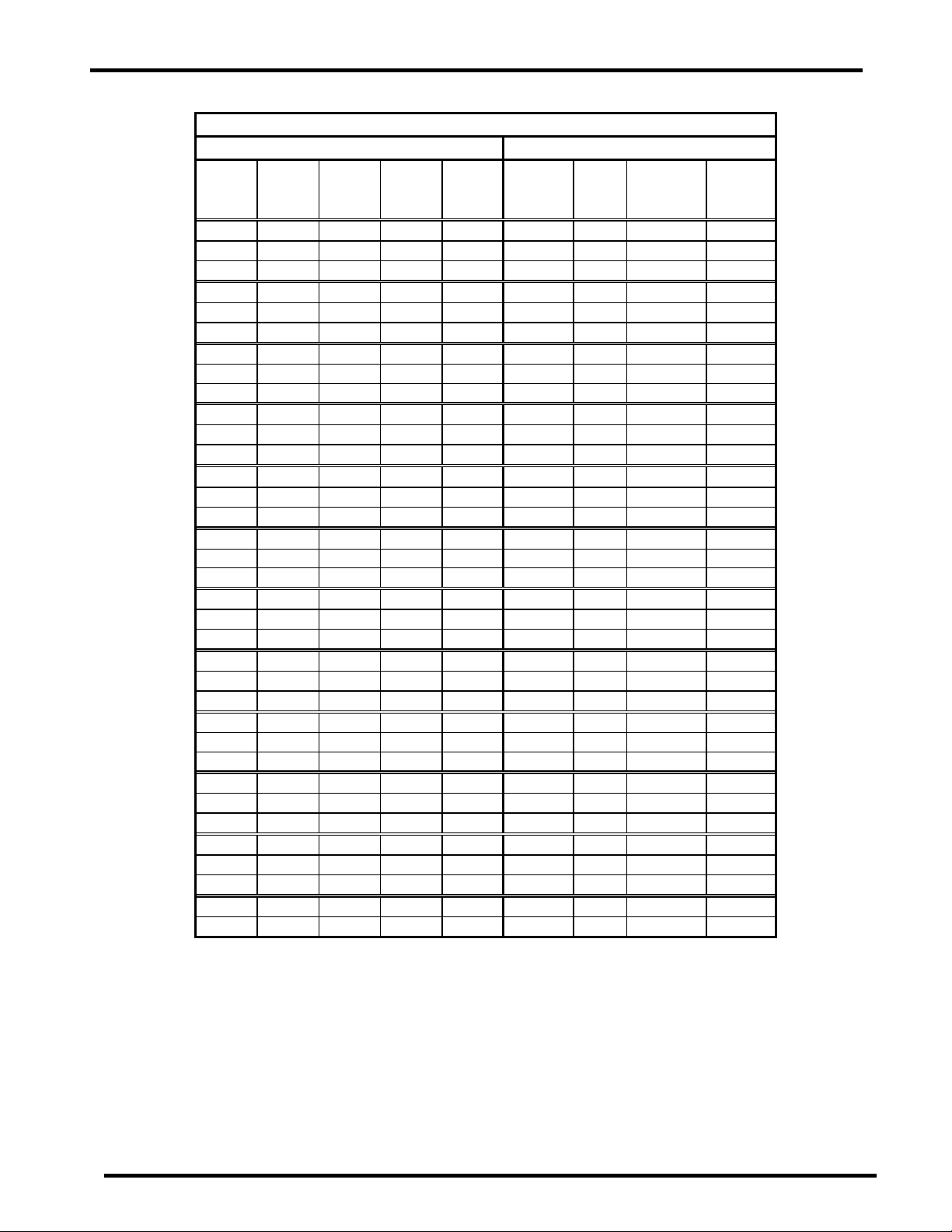

FIGURE 6.1-1: RATINGS AND BREAKERS TABLE

DC output AC input

Rated

DC

Volts

48 6 10 15 14 120 only 7 60 or 50 10

48 6 10 15 14 208 only 5 60 or 50 10

48 6 10 15 14 240 only 5 60 or 50 10

48 12 20 30 12 120 only 14 60 or 50 20

48 12 20 30 12 208 only 8 60 or 50 15

48 12 20 30 12 240 only 7 60 or 50 10

48 18 35 50 8 120 only 17 60 or 50 30

48 18 35 50 8 208 only 11 60 or 50 15

48 18 35 50 8 240 only 10 60 or 50 15

48 20 35 50 8 120 only 18 60 or 50 30

48 20 35 50 8 208 only 12 60 or 50 15

48 20 35 50 8 240 only 10 60 or 50 15

48 25 40 60 8 120 only 28 60 or 50 30

48 25 40 60 8 208 only 14 60 or 50 20

48 25 40 60 8 240 only 13 60 or 50 20

48 50 80 90 6 120 only 45 60 or 50 60

48 50 80 90 6 208 only 25 60 or 50 40

48 50 80 90 6 240 only 23 60 or 50 40

130 6 10 15 14 120 only 14 60 or 50 20

130 6 10 15 14 208 only 9 60 or 50 15

130 6 10 15 14 240 only 8 60 or 50 15

130 12 20 25 12 120 only 27 60 or 50 40

130 12 20 25 12 208 only 17 60 or 50 30

130 12 20 25 12 240 only 15 60 or 50 25

130 18 35 40 8 120 only 45 60 or 50 60

130 18 35 40 8 208 only 24 60 or 50 40

130 18 35 40 8 240 only 21 60 or 50 30

130 20 35 40 8 120 only 45 60 or 50 60

130 20 35 40 8 208 only 24 60 or 50 40

130 20 35 40 8 240 only 22 60 or 50 30

130 25 40 60 8 120 only 63 60 or 50 70

130 25 40 60 8 208 only 32 60 or 50 40

130 25 40 60 8 240 only 32 60 or 50 40

130 50 80 90 4 208 only 70 60 or 50 90

130 50 80 90 4 240 only 60 60 or 50 70

Notes: All input AC circuit breakers are of the “high inrush” type to prevent nuisance tripping during power-up.

Rated

DC

Amps

Rms.

DC

Amps

DC

Circuit

Breaker

Amps

Wiring and connections must meet the requirements of the National Electric Code, state and local codes

and requirements, and the requirements in this manual.

To connect the input AC voltage, route the AC conduit through the appropriate knockout hole. See

SECTION 6.3. Route the AC wiring to terminal lugs AC1 and AC2 located above the AC breaker as

shown in FIGURE 6.1-2. For proper connection, torque the AC1 and AC2 terminal strip screws to

18 inch pounds (2Nm), and the ground lug screw to 35 inch pounds (4Nm), see FIGURES 6.1-2

and 6.1-3.

Optional

Cable

Size

AWG

Rated

AC Input

Volts

Rated

AC

Amps

AC

Frequency

Hz

AC Circuit

Breaker

Amps

Preliminary Operating Instructions 14 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 15

WARNING: ALL AC AND DC CIRCUIT BREAKERS MUST BE IN THE “OFF” POSITION WH ILE

MAKING THE AC AND DC CONNECTIONS TO THE CHARGER.

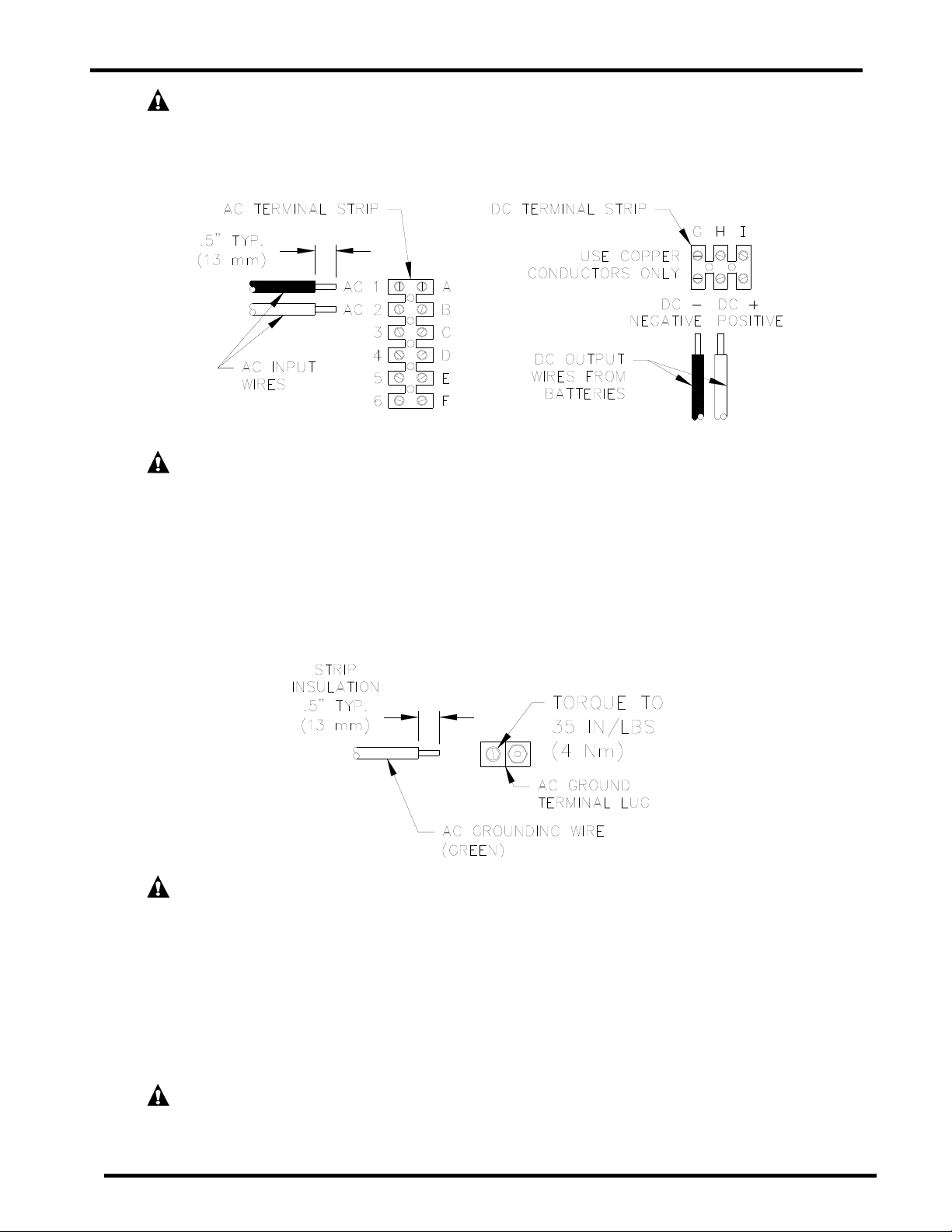

FIGURE 6.1-2: AC AND DC WIRE HOOK UP

WARNING: IMPROPERLY CONNECTED WIRING CAN CAUSE AN ELECTRICAL FIRE.

Connect the AC ground to the terminal lug located to the right of the AC breaker on the charger floor as

shown in FIGURE 6.1-3. In some models the AC ground lug is above the AC terminal strip on the innerpanel. See SECTION 6.3. For proper connection torque the screw to 35 inch pounds (4Nm).

FIGURE 6.1-3: GROUND WIRE HOOK UP

(Located on charger floor (S1,S2) or above terminal strip (S3))

WARNING: DO NOT OPERATE THE CHARGER WITHOUT PROPER GROUNDING.

IMPROPER GROUNDING MAY CAUSE AN ELECTRIC SHOCK, WHICH COULD RESULT IN INJURY

OR DEATH.

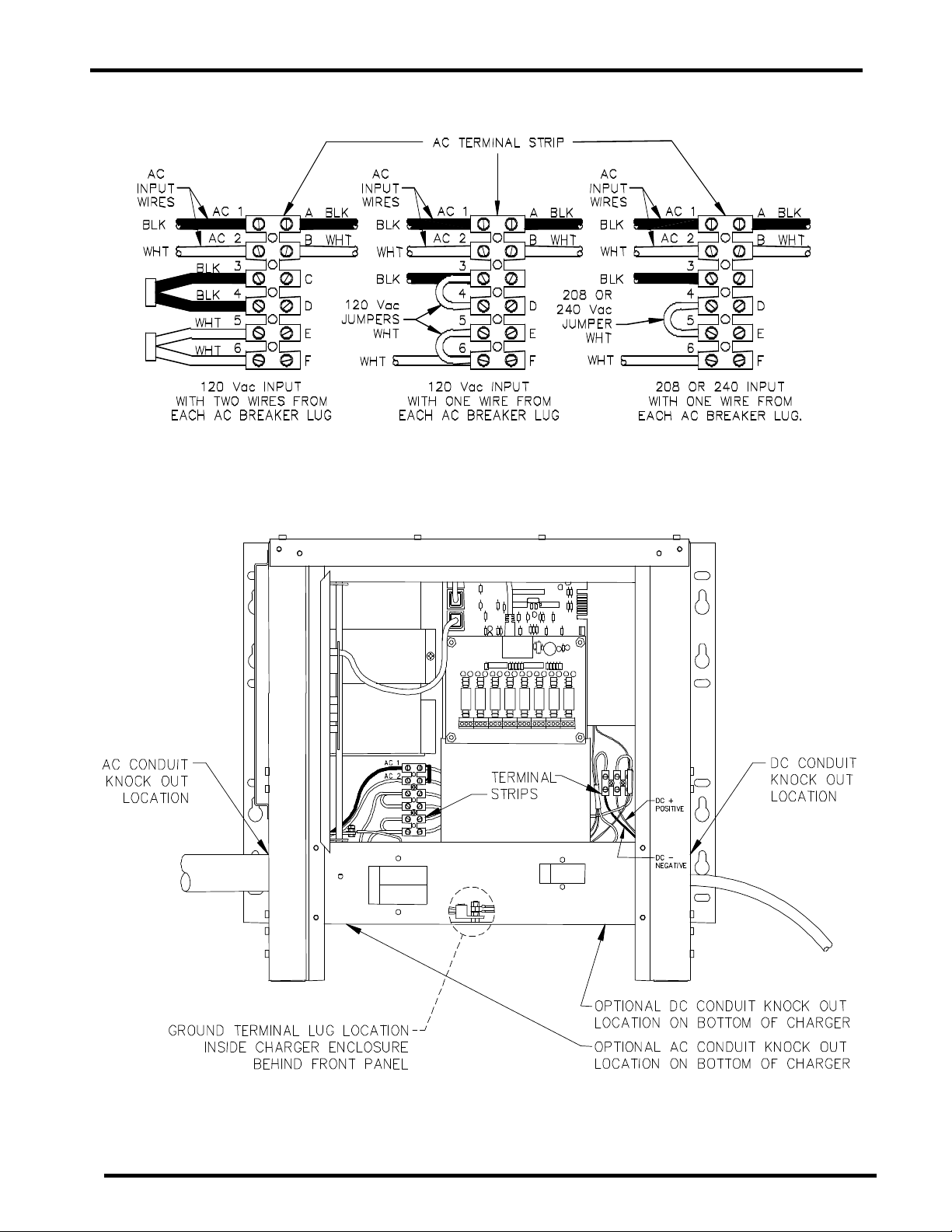

6.2 AC VOLTAGE JUMPER SETTINGS

Check the “AC VOLTS” box on the charger rating specification label to determine its AC Voltage setting.

The AC Voltage jumper settings and the AC Input Voltage of the charger cannot be changed. See

FIGURE 6.2 for AC Voltage Jumper Settings.

NOTE: Field alteration of AC voltage jumper settings voids charger’s UL listing.

WARNING: IMPROPER AC VOLTAGE JUMPER CONNECTION MAY CAUSE SEVERE

DAMAGE TO THE CHARGER AND BATTERY.

Preliminary Operating Instructions 15 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 16

FIGURE 6.2: AC VOLTAGE JUMPER POSITIONS

6.3 AC AND DC CONNECTION LOCATIONS

FIGURE 6.3-1: S1 ENCLOSURE

Preliminary Operating Instructions 16 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 17

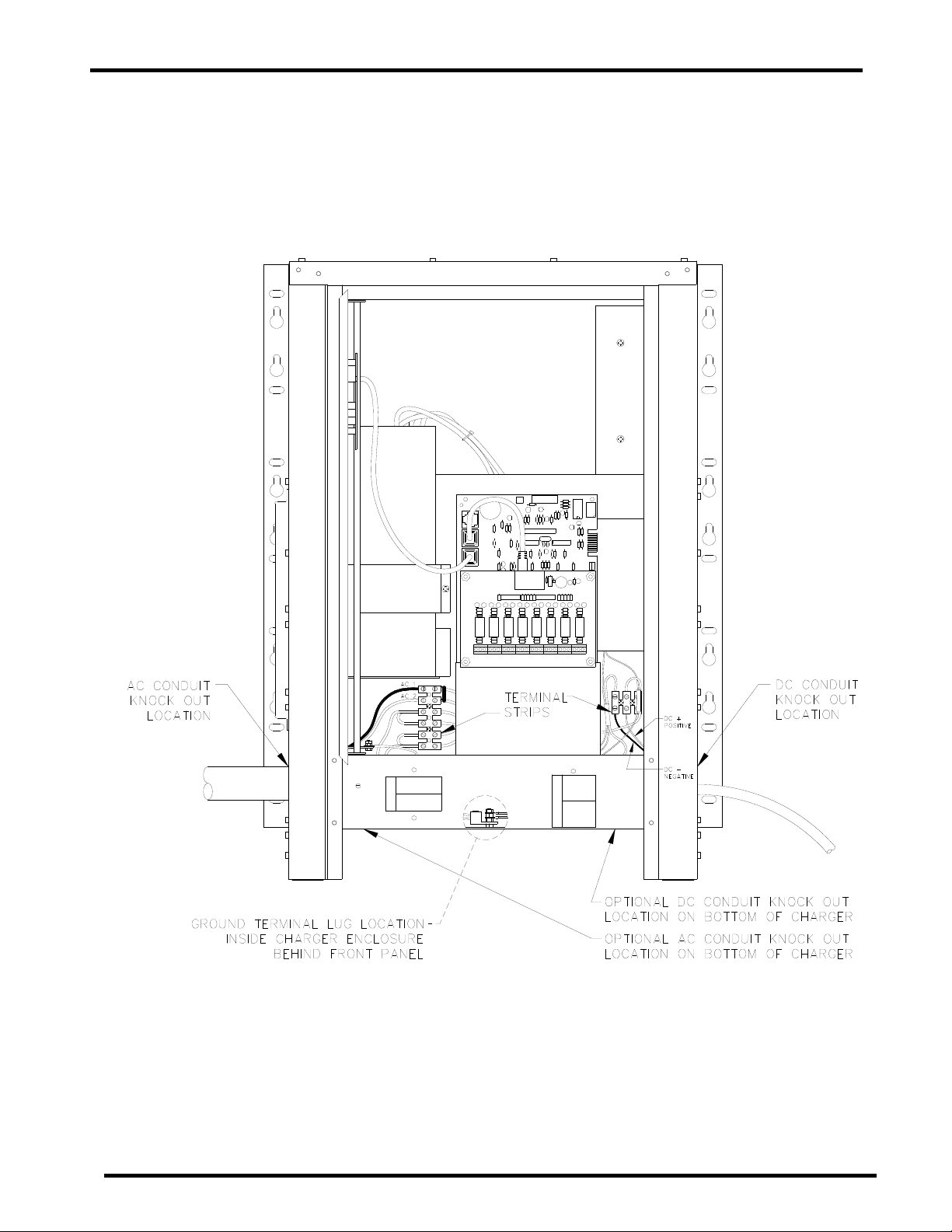

FIGURE 6.3-2: S2 ENCLOSURE

Preliminary Operating Instructions 17 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 18

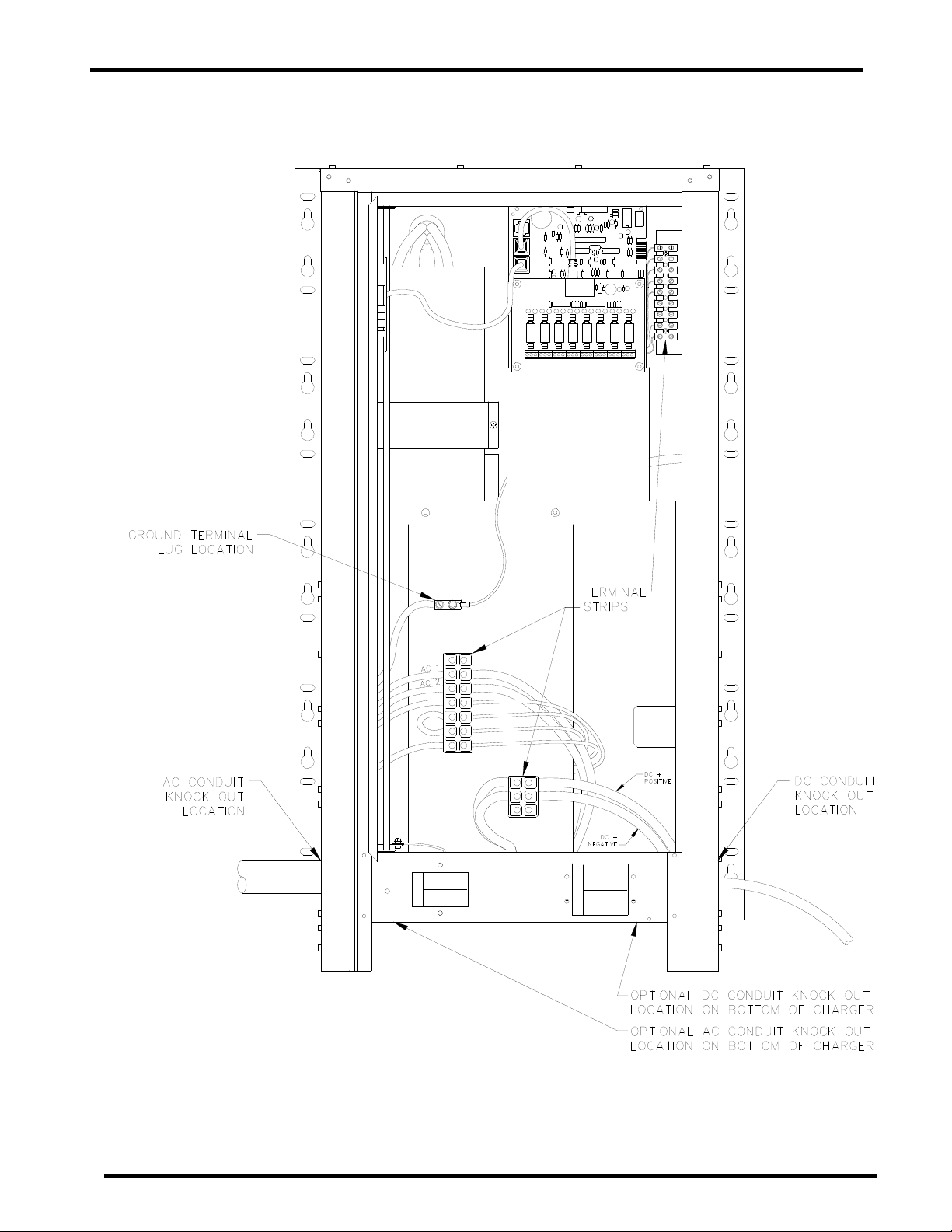

FIGURE 6.3-3: S3 ENCLOSURE

Preliminary Operating Instructions 18 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 19

7. DC OUTPUT

It is recommended that a DC disconnect switch or circuit breaker be used between the charger and the DC

bus. This device should have lockout capability to allow the charger to be disconnected from the DC bus when

connecting the charger during installation and maintenance.

7.1 DC OUTPUT CONNECTIONS

The standard charger is shipped with conduit knockouts and no DC output cable. Determine which

charger knockout to route the DC output cable through. See Section 6.3. Make sure to keep the DC

output cable isolated from the AC input cables and any other optional wiring.

To help in determining the proper size of cable to use for the DC output, FIGURE 7.1 lists the DC voltage

drop per one foot (305mm) of cable for the various Rated DC currents of the chargers and various wire

sizes. Take the appropriate number from FIGURE 7.1, and multiply it by the cable length needed to get

the approximate voltage drop from the charger to the battery or DC bus. FIGURE 7.1 values are

approximate values, the exact value can be measured after installation.

NOTE: If the total voltage drop of the DC output cable is greater than 1% of the charger voltage ( 0.24

VDC for a 24 VDC system, 0.48 VDC for a 48 VDC system, 1.3 VDC for a 130 VDC system) it is

recommended that the optional Remote DC Voltage Sensing cable be used.

To connect the DC output cable, route the conduit through the appropriate knockout hole. Route the DC

positive wire to terminal lug labeled DC POSITIVE and the DC negative wire to terminal lug labeled DC

NEGATIVE located above the DC breaker as shown in FIGURE 6.1-2. For proper connection, torque

the terminal strip screws to 18 inch pounds (2Nm). The charger will not operate in a reversed polarity

condition. The DC output circuit breaker is used to protect the silicon-controlled rectifiers (SCRs).

NOTE: DC circuit breaker may trip when switched on until capacitors are charged.

FIGURE 7.1: VOLTAGE DROP PER 1 FT (305mm) OF WIRE TABLE

For stranded copper wire at 68°F (20°C)

WIRE

SIZE

(AWG.)

16 0.0450 0.0900

14 0.0270 0.0540

12 0.0180 0.0360

10 0.0110 0.0220

8 0.0070 0.0140

6 0.0045 0.0090

4 0.0025 0.0050

2 0.0018 0.0036

1 0.0015 0.0030

0 0.0011 0.0022

6A 12A

RATED DC CURRENT, AMPERES

18A

0.1440

0.0864

0.0576

0.0352

0.0224

0.0144

0.0080

0.0058

0.0048

0.0035

20A 25A 50A

- - -

0.0945 - -

0.0630 0.0720 -

0.0385 0.0440 0.0880

0.0245 0.0280 0.0560

0.0158 0.0180 0.0360

0.0088 0.0100 0.0200

0.0063 0.0072 0.0144

0.0053 0.0060 0.0120

0.0039 0.0044 0.0088

8. REMOTE AND ALARM I/O RELAY OPTIONS

The Remote option allows the charger to be controlled and monitored remotely. The ALARM I/O relay board

allows the user to connect other devices to it to monitor various faults. The following sections go over function

and installation of these optional parts.

8.1 REMOTE DC VOLTAGE SENSING

This option will compensate for the voltage drop across the DC output cable due to the resistance and

current flowing through it. The remote voltage sensing cable can measure the DC voltage of batteries or

DC bus up to 30 ft. (9m) with the standard cable length. This can be extended with a longer cable. This

gives the charger display a more accurate voltage display. In order for the charger to function, the

connection to the DC bus must be secure and reliable.

Preliminary Operating Instructions 19 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 20

If the charger was shipped from the factory with the optional Remote Voltage Sensing cable, it will have

the sensing wires installed into the correct terminal strip and have the resistors moved to the correct

location. If this option is added later, installation instructions on how to wire it will be included.

8.1.1 WIRING THE REMOTE DC VOLTAGE CABLE

With both AC and DC de-energized follow the procedure below:

1. Place the RED and BLACK wires that are coiled up inside the charger through one of the spare

knockouts provided on the DC side of the enclosure. See SECTION 6.3. Do not place in the

same knockout as either the AC input or DC output wiring. Protect the wires to ensure the sharp

edges of the opening will not damage the wire. It is recommended to place a fuse in-line with the

cable near the battery connection in case the wires would get shorted together.

2. Securely con nect the RED wire to the POSITIVE of the battery or DC bus.

3. Securely con nect the BLACK wire to the NEGATIVE of the battery or DC bus.

4. Wire tie the cables so they can not be pulled loose.

5. After the charger is fully installed, connect the DC bus to the charger. Verify the voltage on the

display corresponds to the actual battery voltage. If so, the charger is ready for service.

For wiring diagram of this option, see FIGURE 8.1.1.

FIGURE 8.1.1: CHARGER VOLTAGE SENSING WIRING DIAGRAM

Torque all connections to 9 inch pounds (1Nm).

8.1.2 REMOVING REMOTE VOLTAGE SENSING CABLE

When removing Remote Voltage Sensing Cable both AC and DC will need to be de-energized.

Reference FIGURE 8.1.1 for proper placement of wires and R3 resistors.

8.2 REMOTE TEMPERATURE SENSING CABLE

This option will allow the charger to adjust the charging voltage to compensate for the temperature of the

batteries. The temperature of the battery will be closely monitored by the sensor and the float and

equalize voltages will be adjusted accordingly. The remote temperature sensing cable has a

temperature sensor that needs to be mounted to the battery post for accurate battery temperature

sensing.

Temperature compensation is based on a reference temperature of 77°F (25°C). The Temperature

compensation factor is - 2.5 mV (millivolts) per Cell per Degree F (- 4.5 mV per cell per Degree C). The

compensation factor is NEGATIVE because of the inverse relationship between the temperature and the

voltage (i.e. as the temperature increases the voltage should decrease).

Preliminary Operating Instructions 20 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 21

Note: When the remote temperature sensing cable is not installed, charging voltages can be

adjusted to compensate based on the internal temperature sensor, which is inside each charger

on the SCR driver board.

8.2.1 REMOTE TEMPERATURE SENSING CABLE INSTALLATION

A charger shipped from the factory will not have this option connected and temperature

compensation will be disabled. With both AC and DC de-energized, follow the procedure below:

1. The remote temperature sensing cable will be in the charger’s shipping carton. Carefully

unpack the cable from its bag and inspect for any cuts in the cable.

2. Place the 3-pin connector of the cable through one of the spare knockouts provided on the

DC side of the enclosure. See SECTION 6.3. Do not place in the same knockout as either

the AC input or DC output wiring. Protect the wire to prevent damage from the sharp edges

of the opening.

3. Connect the 3-pin connector to JP5. Secure the cable to prevent it from being pulled loose.

See FIGURE 10.1.

4. Secure the other end of the cable to a negative battery terminal post in the center of the

battery set.

5. After the installation is finished, connect DC voltage and verify that the display temperature

corresponds to the temperature of the battery. To view the external temperature, refer to

SECTION 11.3.8 of the manual.

6. Enable the Temperature Compensation by going to DC Settings then go to Temperature

Compensation. Default is disabled. Enable it to External (EX) by pressing right twice, refer

to SECTION 11.3.3 of the manual.

7. The charger is ready for service if the charger display shows the proper battery temperature.

8.2.2 REMOVING TEMPERATURE SENSING CABLE

With both AC and DC de-energized, remove connector from JP5. The charger will automatically

detect that there is no external temperature cable and return to temperature compensation

disabled.

8.3 OPTIONAL REMOTE CONTROL PANEL

This option will allow the charger to be controlled remotely from a distance of up to 50-ft. (15m); without

this option the charger would be controlled from the front door panel. Only one control panel can be

connected at a time. The Remote Control Panel is shipped with a 50-ft. (15m) communication cable with

plug-in connectors. The Remote Control Panel can be mounted to a 19-in. (483mm) relay rack or wall

mounted.

8.3.1 REMOTE CONTROL PANEL INSTALLATION

With both AC and DC de-energized, follow the procedure below:

1. If the Remote Control Panel was ordered with the charger as an option, it will be found

packed inside of the carton shipped with the charger. If it was ordered separately as a

service part kit, it will be packaged in its own carton. In either case, carefully unpack the

control panel assembly and inspect for any cuts in the cable or other damage.

2. It will be necessary to connect the remote control panel printed circuit board to the SCR

driver printed circuit board in the charger. If the remote control panel was ordered as a

service part option and the charger has a control board on the door then the Control printed

circuit board on the door will have to be disconnected before installing the Remote Control

Panel. Only one control printed circuit board can be electrically connected to the SCR Driver

board at a time.

3. Determine where and how the Remote Control Panel will be mounted. The Control Panel is

shipped from the factory with the communication cable entering the bottom of the case. If

preferred by the installer, the cable can be changed to enter the back of the case.

4. To change where the cable enters, remove the four nuts on the case cover to open the case.

Disconnect the cable from the control board, being careful to squeeze the retaining latch on

the cable connector before pulling on the connector. If the latch has been properly released,

Preliminary Operating Instructions 21 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 22

the connector will easily slide out of the socket. Carefully pull the cord and connector out

through the hole in the bottom of the cover. Reinstall the cable through the backside of the

larger hole in the back panel of the case. Reconnect the cable to either one of the connector

sockets on the control printed circuit board. Re-assemble the Remote Control Panel.

5. Carefully route the 50 ft. (15m) long communication cable to the charger making sure it is

protected from being pulled out of the Remote Control Panel or pinched.

6. Place the cable through one of the spare knockouts provided on the DC side of the

enclosure. See SECTION 6.3. Do not place in the same knockout as either the AC input or

DC output wiring. Protect the cable to ensure that the sharp edges of the knockout opening

will not damage the cable. Any excess communication cable can be coiled up and wire tied

out of the way.

7. The communication cable can be connected into any of the three RJ1, RJ2 or RJ3 connector

sockets on the charger SCR driver board. Do not connect more than one control board to the

SCR Driver board at the same time.

8. Reconnect the charger to either AC or DC and then verify that the Remote Control Panel is

functioning properly, (refer to SECTION 11). If both charger and remote control panel are

operating normally, they are ready for service.

Important: Proprietary communication protocol is used with the charger and control panel.

Equipment damage will occur if they are connected to Ethernet or any other network device or

port.

8.4 ALARM I/O RELAY BOARD OUTPUT

The optional ALARM I/O Relay board allows the user the use of “NO” (normally open) or “NC” (normally

closed) contacts with reference to “C” (common) to be connected to other equipment for fault detection.

The one GREEN LED and seven RED LEDs are used to signify when each individual relay coil has been

energized. The ALARM I/O Relay board receives its signal to energize the relays from the Charger

Control board.

8.4.1 ALARM I/O RELAY BOARD OPERATION

The GREEN LED (DS1) and J1 contacts are used to indicate the Auxiliary Summary Alarm fault

status. (See FIGURE 8.4.4-2) The GREEN LED will illuminate if the charger detects no faults.

Thirty seconds after any of the monitored faults have occurred, the J1 relay coil will be deenergized and the GREEN LED will go off.

C=COMMON NC=NORMALLY CLOSED NO=NORMALLY OPEN

The J1 terminal block contacts on the ALARM I/O relay board will switch at the same time as the

Summary Alarm terminal block contacts on the SCR Driver Board. With no faults the relay will be

energized and there will be continuity from “C” to “NC” and no continuity from “C” to “NO” on J1.

With a fault the relay coil will be de-energized and there will be continuity from “C” to “NO” and no

continuity from “C” to “NC”.

The seven RED LEDs and the J2 through J8 terminal block contacts on the ALARM I/O board are

used to indicate the seven individual fault conditions. Each relay will be energized and its

corresponding LED will illuminate when the SCR Driver board detects that fault. When there are

no faults, the relays will be de-energized and there will be continuity from “C” to “NC” and there

will be no continuity from “C” to “NO” on J2 through J8. With a fault, the appropriate relay coil will

be energized and there will be continuity from “C” to “NO” and no continuity from “C” to “NC”. The

appropriate LEDs will illuminate with each fault. See SECTION 11.3.4 for information on setting

up the charger faults. The ALARM I/O relay board terminal blocks and LED indicated fault

functions are shown in FIGURE 8.4.4-2.

Preliminary Operating Instructions 22 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 23

8.4.2 ALARM I/O FIELD INSTALLATION INSTRUCTIONS

The installation kit will come with the following components:

Qty. Part # Description

1 22845-XX* ALARM I/O Relay Board

1 31666 1 ft. (305mm) Communication cable

1 33456 Wiring Shield

4 32678 Spacers

4 03237 Nuts, 6-32

* - XX-Multiple options available, see SECTION 17 for proper option number.

Follow the instructions below to install the ALARM I/O Relay Board into the charger:

1. De-energize both AC and DC power from the charger.

2. To see how the ALARM I/O Relay board mounts to the SCR Driver Board and the cable

hookup, see FIGURE 8.4.4-1. (All RJ45 connector sockets are in parallel, so it will work with

the cable in any location.)

3. Install the four nylon spacers into the SCR Driver board on the inner panel of the charger.

4. Put the wiring shield on the bottom two nylon spacers.

5. Mount the ALARM I/O Relay board o n the four nylon spa ce rs a s shown.

6. Install the four nuts on the nylon spacers and tighten. (Do not over-tighten nuts or the nylon

spacers will strip.)

7. Connect the communication cable from the SCR Driver board RJ45 connector socket to the

ALARM I/O Relay board RJ45 connector socket.

8. Fold the wiring shield under the front of the charger base edge by the circuit breaker if

possible.

8.4.3 WIRING THE ALARM I/O BOARD TO EXTERNAL CIRCUITS

1. Route the wiring for your external circuits into the charger through one of the spare conduit

knockouts on the DC side of the enclosure. See SECTION 6.3. Make sure to isolate this

wiring from the charger AC input and DC output power wiring. The wiring shield is to help

isolate these wires from the other wires. Do not place in the same knockout as either the AC

input or DC output wiring.

2. Use #26-14 AWG wire stripped 0.25 in. (6mm) on the end going into the Individual Alarm

Terminal Blocks. Torque all connections to 5 inch pounds (.6Nm). All terminal blocks are

labeled in the non-alarm or fault condition.

3. Make sure to observe the Alarm Relay Contact Rating on FIGURE 8.4.4-2 when wiring into

external circuits.

4. Secure all wires with a strain relief in the conduit knockout so they will not to be pulled out of

unit. Protect the wires to ensure the sharp edges of the opening will not damage the wire.

5. Return power to the charge r.

8.4.4 TESTING THE ALARM I/O RELAY BOARD AND EXTERNAL CIRCUITS

1. It is recommended that a test be performed after installation to make sure everything works

as intended.

2. Go into the TEC H MENU on the charge r control board by pressing the RIGHT ARROW, then

LEFT ARROW buttons, and repeat this sequence 4 times while in the default display mode,

then enter the TECH MENU code which is set to “0001”. (For additional information on the

TECH MENU see SECTION 12.2.)

3. The first display in the TECH MENU is the control board version and date.

4. Press the DOWN ARROW button and you can get to the following menus: Relay Start, LEDs

are off, and Disp (Display voltage mode).

5. Go to the Relay Start Menu. This menu will only be available if the charger has an optional

ALARM I/O Relay Board that is functioning.

6. Press the RIGHT ARROW button at the “Relay Start” display. The ALARM I/O Relay Board

LEDs and Relay Contacts will go through a test cycle to verify they are working properly.

7. If you press the RIGHT ARROW button while the display shows “Relay Stop”, the test will

stop.

8. You can restart the test anytime the display shows “Relay Start”.

9. To exit the TECH MENU, press the LEFT ARROW button.

10. The charger is ready for service if all of these tests verify that it functions properly.

Preliminary Operating Instructions 23 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 24

FIGURE 8.4.4-1: ALARM I/O RELAY BOARD MOUNTING

FIGURE 8.4.4-2: ALARM I/O RELAY BOARD OUTPUT CONNECTIONS

Preliminary Operating Instructions 24 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 25

9. CHARGER START UP SEQUENCE

When all connections are made with the proper wire size, location and torque value, the charger is ready for

power up. Use the following steps to start up the charger.

9.1 CHECK DISPLAY AND LEDS

Switch the charger AC and DC breakers “OFF”, and disconnect the charger from the battery. Then,

reconnect the DC battery bus voltage to the charger. The Display and LEDs on the front of the charger

should power up and display the DC voltage that the charger senses on the DC terminal strip. If the

display does not show the proper DC voltages, disconnect charger from the DC battery bus and verify

connections and polarity again. (The charger requires at least 17 volts DC for the display to power up in

the 24 and 48-volt DC chargers and at least 100 volts DC in the 130-volt DC chargers.) If the Display or

LEDs do not power up correctly, even though connections were verified to be correct, see the

Troubleshooting section. Note: The back light of the LCD display will not be illuminated while the AC

breaker is off.

9.2 CHARGER SETTINGS

If the charger senses the proper voltage, you can go into the charger menus and customize the charger

settings. At this time, the summary alarm buzzer may sound because of various fault codes. If

necessary, disable the alarm buzzer or the fault condition while customizing the charger settings and

then enable them after the charger setup is complete.

9.3 AC & DC POWER UP

Disconnect the charger from the DC battery bus again with the switch or breaker. Apply the proper AC

voltage to the Charger AC terminal strip. Turn the AC Breaker “ON”. The charger Display should power

up with the display back light on, the “AC ON” LED should illuminate, now turn the DC breaker “ON”.

The charger will power up and slowly charge up the capacitor(s) in the charger to the proper float

voltage. The “DC ON” LED will illuminate.

9.4 RECONNECT DC & RE-CHECK

Connect the charger to the DC battery bus again with the switch or breaker. The charger will start

charging the battery at the appropriate voltage and current if everything is functioning properly. If you

experience any problems, go to the Troubleshooting section.

10. CIRCUIT BOARDS

The standard circuit boards are the SCR Driver Board and the Control Board. The optional circuit board is the

ALARM I/O Relay Board. Each of these three boards can be used universally in all charger models.

All three boards have RJ45 connector sockets to allow them to be easily connected or disconnected from each

other for service or to allow the use of an optional Remote Control Panel. The RJ45 connector sockets are all

connected in parallel so the cables can be plugged into any of the RJ45 receptacles on each board.

10.1 SCR DRIVER BOARD

The SCR Driver Board stores all of the important variables for the charger except for the time of an

equalize cycle. It determines what model the charger is, monitors the charger system for faults, and

sends information to the control board. It also provides the SCR gate drive pulses to control the charger

output and the proper supply voltages for the other two boards.

The following features are found on the SCR Driver Board. See FIGURE 10.1 for location of

components.

Preliminary Operating Instructions 25 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 26

FIGURE 10.1: SCR DRIVER BOARD

10.1.1 BACKUP CHARGER POWER

The SCR Driver Board is normally powered from the AC input power. However, if AC input power

is not present the SCR Driver Board will automatically switch to be powered from the DC batteries

as a backup power source. The SCR Driver Board includes a DC-to-DC converter that allows the

wide range of DC Battery voltage supplies to be converted to a usable 12 volt DC source. The

DC-to-DC converter has a fuse (F2) for over-current protection. This allows the charger to

monitor the charger information and provide the power supplies to the other circuit boards.

NOTE: It will not charge the batteries until AC power has returned.

10.1.2 SUMMARY ALARM BUZZER AND RELAY CONTACT CONNECTIONS

The Summary Alarm and Relay Contact Connections provide the user with two ways to monitor

for faults. See the Alarm Settings menu section for alarm setting information.

The Summary alarm buzzer and contacts will be enabled 30 seconds after the board detects a

fault code, reference FIGURE 10.1. Removing the JP3 jumper connector from pins 1 and 2 of

the JP3 connector can disable the summary alarm buzzer. When the jumper is connecting pins 1

and 2 (bottom two pins) the summary alarm buzzer is enabled. Removing the jumper from pins 1

and 2 disables the alarm buzzer. The jumper can be stored by installing it on pins 2 and 3 (top

two pins). Removing the fault code or disarming the fault code from the charger can be done

from the Alarm Settings Menu.

Preliminary Operating Instructions 26 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 27

The Summary Relay coil will also be de-energized after the board detects a fault for 30 seconds.

This will change the Relay Contact Connections on the JP2 terminal strip. With a fault the relay

coil will be de-energized and there will be continuity from “C” (common) to “NO” (normally open)

and no continuity from “C” to “NC” (normally closed). With no faults the relay will be energized

and there will be continuity from “C” (common) to “NC” (normally closed) and no continuity from

“C” to “NO” (normally open) on the JP2.

External wiring can be connected to the JP2 terminal block connections for external fault

detection. See SECTION 19 for information about the Alarm relay contact ratings.

10.1.3 GFI JUMPER

The GFI (Ground Fault Indicator) Jumper can be used to Enable (pins 2-3 of JP4) or Disable the

GFI faults. To disable the GFI, remove the Jumper from pins 2 and 3 of JP4 on the bottom edge

of the board. See the Alarm Settings menu SECTION, 11.3.4, for GFI setting information.

10.1.4 INTERNAL TEMPERATURE SENSOR

The Internal Temperature Sensor is located on the SCR Driver Board. It can be used for

monitoring the Charger temperature and also can be used for charger controlled temperature

compensation. See the DC Settings/Temp Comp SECTION, 11.3.3, for more information.

10.1.5 OPTIONAL REMOTE TEMPERATURE SENSOR CONNECTOR

The Optional Remote Temperature Connector is located on the SCR Driver Board. It allows the

optional Remote Temperature Sensor to be used to monitor battery temperature. It can also be

used for charger controlled temperature compensation based on the battery temperature. This is

the preferred method of temperature compensation because the battery voltage is adjusted

based on the battery temperature. See the DC Settings/Temp Comp SECTION, 11.3.3, for more

information.

10.2 CONTROL BOARD FEATURES

The charger control board has a 16-character alpha numeric Liquid Crystal Display (LCD), 5 Push

Buttons, 4 Light Emitting Diodes (LED’s), a button lockout jumper connector, and a beeper. These

features allow the operator to view the status of the charger functions and to change the charger

settings. Their operation is described in the following sections. See FIGURE 10.2 for Control Board

layout information.

FIGURE 10.2: CONTROL BOARD

Preliminary Operating Instructions 27 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 28

10.2.1 LIQUID CRYSTAL DISPLAY (LCD)

This is used to display DC Voltage and DC Current, fault identification, charger status information

and menu information.

10.2.2 “HOLD TO EQUALIZE” BUTTON (LARGE SQUARE BUTTON)

This is used to change from FLOAT mode to a manually started EQUALIZE mode. To manually

activate an EQUALIZE mode, push and hold about 6 seconds until the EQUALIZE LED

illuminates. The same button can be used to manually stop an equalize cycle and return to

FLOAT mode.

10.2.3 ARROW BUTTONS

The four Arrow buttons allow the user to go UP, DOWN, LEFT, and RIGHT in the menus. They

are used to view and change the different menus, display modes, and set point values.

10.2.4 GREEN “AC ON” LED

This LED will be illuminated whenever the charger has AC input power connected to it and the

AC circuit breaker is closed, (in the ON position).

10.2.5 GREEN “DC ON” LED

This LED will be illuminated whenever the DC circuit breaker is closed, (in the ON position) and

the charger detects DC voltage. This voltage can be the charger capacito r or b attery voltage.

10.2.6 YELLOW “FLOAT” LED

This LED will be illuminated whenever the charger has AC or DC voltage and it is in the FLOAT

mode.

10.2.7 RED “EQUALIZE” LED

This LED will be illuminated whenever the charger has AC or DC voltage and it is in an

EQUALIZE mode.

10.2.8 BUTTON LOCKOUT JUMPER CONNECTOR

This allows the buttons to be locked out for security purposes. The connector is located on the

top left edge of the control circuit board when looking at the back of the board. The buttons

enabled jumper position is located on the top two pins (pins 1-2) of the J2 connector. If the

jumper is removed or put on the bottom two pins of J2 (pins 2-3) of the connector, the buttons will

be disabled and not allow any changes. (Shown in FIGURE 10.2)

10.2.9 BEEPER

This is designed to beep each time a button is pushed, signifying a button press except when the

button lockout feature is being used. It also beeps when the charger changes charging modes,

and beeps a tune on control board initialization.

11. CONTROL BOARD OPERATION

The Control Board operation will be explained in the following sections. These sections will explain the various

display modes, how to view or change information, and menu descriptions.

11.1 DEFAULT DISPLAY MODES

The charger’s “DC Voltage and DC Current” values are continuously displayed when there are no fault

codes and the charger is in FLOAT mode.

If there are faults, the display will toggle between the “DC Voltage and DC Current” and the Fault codes.

If in Manual/Manual Equalize mode and an Equalize Charge is started, the display will toggle between

the “DC Voltage and DC Current”, any Fault Codes, and “Manual Eqlz” (manual equalize cycle).

In any other equalize mode, the display will toggle between the “DC Voltage and DC Current”, any Fault

Codes, and the number of hours left of the equalize charge.

Preliminary Operating Instructions 28 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 29

If the user is in any menu for longer than 60 seconds without pressing a button, the display mode will

return to the default display mode.

11.2 HOW TO VIEW OR CHANGE INFORMATION

The user can view and change charger settings easily. By using the UP ARROW or DOWN ARROW

buttons, the user can view the different charger information and menus that allow the user to change the

charger profile. In most cases there will be an ‘→’ to show that a value can be changed after the menu

description. The exception to this is the “Time” menu.

By pressing the DOWN ARROW button you can see the following menus or information:

Fault Codes, DC Settings, Alarm Settings, Eqlz Settings, Hrs Run, InTemp, ExTemp (if

unit has optional Remote Temperature Probe), Time of Day, Pause Time and Next Eqlz

Time. All of these will be explained in SECTION 11.3.

When the display has an ‘→’ after the menu description, the user can press the RIGHT ARROW button

to get into that menu or toggle between menu choices. The UP and DOWN ARROW buttons allow

values to be changed. After making the changes to the values that are underlined

the user must SAVE the change by pressing the RIGHT ARROW button until you get the ‘→’ again. In

most cases if the user backs out of changing a value by pressing the LEFT ARROW button, the value

will NOT be saved. The value will take affect only when the user presses the RIGHT ARROW button at

the last changeable value.

Example 1 – Changing Float Settings:

Example 1 explains how to change the Float settings for the charger

Press the DOWN ARROW button until you get to the following.

Press the RIGHT ARROW button and it will show you the charger type. Press the DOWN ARROW

button to get the following.

Press the RIGHT ARROW button to get the following.

Notice the arrow is gone and the 2 is underlined or the cursor is under it. The user can change the value

of the digit above the cursor by pressing the up and down arrow buttons. The up button increases to the

next higher digit and the down button decreases. Press the UP ARROW button to get the following.

Pressing the RIGHT ARROW button will move the cursor to the right to get the following.

The cursor has moved and again the value can be changed by pressing the up or down arrow button.

Press the DOWN ARROW button to get the following.

When the cursor is under the farthest right digit, if the user presses the RIGHT ARROW button, the

value shown will be saved and take affect. Press the RIGHT ARROW button to get the following.

“DC Settings →”

“Float 2.25V/C→”

“Float 2.2

“Float 2.3

“Float 2.35

“Float 2.30

5V/C”

5V/C”

V/C”

V/C”

or a cursor is present,

Preliminary Operating Instructions 29 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 30

“Float 2.30V/C→”

However, if the user pressed the LEFT ARROW button twice instead of the RIGHT ARROW button the

value will revert to the value before being changed like the following.

“Float 2.25V/C→”

Example 2 - Arming and Disarming Faults:

Example 2 explains how to toggle between arming and disarming fault codes and between many other

modes.

Press the DOWN ARROW button until you get the following.

Press the RIGHT ARROW button and it will show you the following.

Press the RIGHT ARROW button and it will show you the following.

The “AC Hi” alarm is now disarmed and will not be an active fault code. Press the RIGHT ARROW

button again and it will show you the following.

By pressing the RIGHT ARROW button in these types of menus you can see and change the different

charger profiles.

Press the UP or DOWN ARROW buttons when you have the selection you want and this will change to a

different Alarm setting.

By pressing the LEFT ARROW button you can get back to the following.

By pressing the LEFT ARROW button again you get back to the default menu.

Most of the Control Panel menus use one of the two example methods to make changes. The exception

to this is the GFI set point menu, which will be explained in SECTION 11.3.4.

“Alarm Settings →”

“AC Hi Armed→

“AC Hi Disarmed→

“AC Hi Armed→

“Alarm Settings →”

11.3 CHARGER INFORMATION AND MENU DESCRIPTIONS

11.3.1 DC VOLTAGE AND DC CURRENT

The Default Display is the DC Voltage and DC Current. It is updated every second. The last

character of the display changes every second to show the display is updating. Display Example:

(26.50V 20.00A –)

11.3.2 FAULT CODES AND FAULT LEDS

The display will show “No Faults” unless a fault has occurred. The following fault codes are

displayed on the display: Hi DC, Lo DC, EOD, GFI +, GFI - , Hi AC, Lo AC, HiLoc, and LoLoc.

The “AC ON” and “DC ON” LEDs can also be used as fault indicators.

Preliminary Operating Instructions 30 of 62 AIP SERVICE NUMBER 1-800-863-3364

Page 31

The SCR Driver Board in the charger has a Summary alarm and Relay contact that indicates

when any fault has occurred. The fault has to be active for 30 seconds before the summary

alarm and contact are activated.

The optional ALARM I/O Relay Board has LEDs and Relay contacts that can be used to indicate

the following fault codes: EOD, GFI (positive or negative), DC Fail, Lo DC, Hi DC, Lo AC, and Hi

AC. This board also has a Summary alarm and Relay contact, which indicates when any fault

has occurred. The fault has to be active for 30 seconds before the summary alarm and contact

are active.

FAULT CODE DEFINITIONS

Hi DC

This stands for High DC voltage. This fault occurs when the charger detects a DC voltage higher

than the value in the DC Hi set point location in the Alarm Settings menu.

Lo DC

This stands for Low DC voltage. This fault occurs when the charger detects a DC voltage lower

than the value in the DC Lo set point location in the Alarm Settings menu.

EOD

This stands for End of Discharge voltage. This fault occurs when the charger detects a DC

voltage lower than the value in the EOD set point location in the Alarm Settings menu.

GFI +

This stands for Ground Fault Indicator to the Positive Battery Terminal. This fault occurs when

the charger detects a leakage current from the battery positive to the charger ground of more

than the threshold value. The threshold value is set with a 10K-ohm resistor at the factory. The

GFI set points are set in the Alarm Settings menu.

GFI –

This stands for Ground Fault Indicator to the Negative Battery Terminal. This fault occurs when

the charger detects a leakage current from the battery negative to the charger ground of more

than the threshold value. The threshold value is set with a 10K-ohm resistor at the factory. The

GFI set points are set in the Alarm Settings menu.

HiLoc

This stands for High DC output voltage lockout. This fault occurs when the charger DC output

voltage exceeds the value in the HiLoc set point location in the Alarm Settings menu for more

than one minute or if the DC voltage varies above this value more than about three times in a

minute. This fault will lockout and not allow the charger to charge the batteries until the AC input

voltage is cycled off and then back on. Switching the AC breaker off and then on can do this.

The optional ALARM I/O Relay Board will indicate the “HiLoc” fault by actuating the “DC Hi”

contacts and LED if the “DC Hi” alarm is armed.

LoLoc

This stands for Low DC output voltage lockout. This fault occurs approximately 3 minutes after

the charger detects the DC output voltage drop below approximately 0.2 volts per cell or a near

short. This fault will lockout or not allow the charger to charge the batteries until the AC input

voltage is cycled off then back on or the battery voltage the charger detects increases above this

value.