Page 1

INEX Inverter System

User Manual

014-114-B2

Page 2

This page intentionally left blank.

Argus Technologies Ltd. Visit www.argus.ca

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233

Argus Technologies reserves the right to make changes to the products and information contained in this document without notice.

Copyright 2008 Argus Technologies Ltd. Argus

Printed in Canada.

®

is a registered trademark of Argus Technologies Ltd. All Rights Reserved.

Page 3

INEX Inverter System

User Manual

014-114-B2

Applies to inverter modules 014-114-10, 014-115-10, 014-116-10, and 014-117-10.

The following documents and drawings are included in this manual to provide the necessa ry information required for

installation, operation and fault diagnosis of the unit:

• Specifications: 014-114-B1

• Installation and Operation Instructions: 014-114-C0

• Factory Service Information: 048-527-10

Argus Technologies Ltd. 014-114-B2 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved.

Page 4

Specifications for INEX Inverter System

Inverter Module Input

Nominal Voltage: 48Vdc

Operating Range: 40.5 to 58Vdc within rated limits

Under Voltage Warning Threshold: 45Vdc

Under Voltage Threshold: 40Vdc

Over Voltage Warning Threshold: 58Vdc

Over Voltage Threshold: 60Vdc

Isolation AC-DC: Reinforced isolation (Pri-Sec) 4242Vdc/1min

Inrush current: <2*Irated

Isolation DC-enclosure: 707Vdc (varistors and filter capacitor removed)/1min

Input Protection: Reverse polarity protection

Psophometric Noise Voltage: ≤1.0mV ITU-T O.41 (16.66 to 6000Hz)

Reflected Psophometric Noise Current: <1% according to YD/T 777-2006

Reflected Relative Band Width Current Noise: <10% (0-2MHz) according to YD/T 777-2006

Wide Band Noise: <1.0mV (psophometric, 25Hz to 5kHz)

<20mVrms (25Hz to 20kHz)

Peak to Peak Noise: <150mV up to 100MHz

Inverter Module Output

Power Capacity: 1000VA/800W,

1500VA/1200W

Waveform: Pure sine wave

Power Factor: 0.8

Nominal Output Voltage: 110/115/120Vac or 208/220/230/240Vac

Voltage Regulation: Max ±2%

Output Frequency: 50/60Hz

Frequency Variation: Max ±0.5%

Frequency Setting: Manually, field-selectable

Crest Factor: 3:1

T.H.D. (Current): <3% for linear load, <5% for non-linear load

Capacitive/Inductive Load: -0.8 to +0.8 without exceeding permissible distortion for resistive load

Efficiency: Min 88% at rated load for 48Vdc system

Argus Technologies Ltd. 014-114-B1 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 1 of 4

Page 5

Specifications for INEX Inverter System Continued

Current Limitation: Electronic current limitation at overloads and short circuits

Isolation AC-enclosure: Basic isolation (Pri-Gnd) 2121Vdc/1min

Surge Protection: EN61000-4-5, Telcordia GR-1089 CORE, ANSI/IEEE C62.41, STD 587-

1980

Dynamic Response: Better than ±10% according to IEC 62040-3 Class 1

Over Load Protection: 1.5*Inom >20s

1.25*Inom temperature controlled

Inom = 1000VA/output voltage

Short circuit current = 16A for INV-4810EA and 30A for INV-4810A

Load Sharing: <5%

Inverter Protection

Over Load: When load exceeds 150% of power capacity, inverter will shut down after

20 seconds, and diagnose as overload fault with red LED lit.

When load is 105~150%, inverter continuously delivers output power

with a yellow LED lit for warning.

Output Voltage Fault Detection: When the output RMS (root mean square) voltage is out of operating

voltage range, the inverter unit will diagnose as output voltage high or

low fault.

Inverter Output Short Circuit: When output RMS voltage is below 40VAC and output RMS current is

over 2A, the system will diagnose as inverter output short circuit fault

with red LED on.

Input Voltage Detection: When the DC input voltage is out of operating voltage range, the inverter

system will shut down and release visual and audio alarms.

Over Temperature: When inverte r intern al temperature rises over 100°C (212°F), the system

will diagnose as over temperature fault with red LED flicker.

Maximum Number of INEX Inverter Modules for Parallel Connection

Model With STS-050A Without STS-050A

INV-4810A (1000VA/120Vac) 6 12

INV-4810EA (1000VA/240Vac) 12 12

INV-4815A (1500VA/120Vac) 4 8

INV-4815EA (1500VA/240Vac) 8 12

Note: Static transfer switch (STS)

INEX Controller Module

DC Nominal Voltage: 48Vdc

DC Voltage Range: 30 to 70Vdc

Over Current Protection: 2A fuse

LCD Display: 3” backlit LCD screen with 4 lines by 16 characters

LED Indicators: Green/normal, yellow/warning, and red/fault

Argus Technologies Ltd. 014-114-B1 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 2 of 4

Page 6

Specifications for INEX Inverter System Continued

Function Keys: Esc for cancellation

Buzzer: Audio alarm when inverter, STS, or controller module operates

System Parameters: BaudRate – setting controller com port baud rate

INEX Static Transfer Switch Module

AC Input Voltage Range: 89 to 138Vac for 110/115/120Vac system

Over Voltage Threshold: Adjustable between

Under Voltage Threshold: Adjustable between

Redundant Power Supply Design: Startup power-on by priority source o r alternative

Nominal Output Voltage: Same as utility voltage or inverter output

Permissible Frequency Area: Max. ±2.5% (inverter synchronization)

Transfer Time: Typical 1/4 cycle

Rated Power: 50A

Operation Methods: Inverter priority/Mains priority (On-line/Off-line)

PgUp

PgDn

Enter

for cursor up movement

for cursor down movement

for selection of comment validation

abnormally. Esc key cancels audible alarm.

Keypad tones – setting keypad tones

Time & Date – setting current time and date

Setting Password – setting system password

Brightness – setting LCD brightness

Default – change current system parameters to default values

Bat Calib – calibration battery voltage

176 to 276Vac for 208/220/230/240Vac system

117 and 127Vac for 110Vac system, default is 121Vac

122 and 132Vac for 115Vac system, default is 127Vac

127 and 138Vac for 120Vac system, default is 132Vac

220 and 240Vac for 208Vac system, default is 229Vac

233 and 252Vac for 220Vac system, default is 242Vac

244 and 264Vac for 230Vac system, default is 253Vac

254 and 276Vac for 240Vac system, default is 264Vac

89 and 105Vac for 110Vac system, default is 99Vac

93 and 110Vac for 115Vac system, default is 104Vac

100 and 114Vac for 120Vac system, default is 108Vac

176 and 198Vac for 208Vac system, default is 187Vac

176 and 209Vac for 220Vac system, default is 198Vac

185 and 218.5Vac for 230Vac system, default is 207Vac

193 and 228Vac for 240Vac system, default is 216Vac

Argus Technologies Ltd. 014-114-B1 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 3 of 4

Page 7

Specifications for INEX Inverter System Continued

Mechanical

Inverter Module: Dimensions: 43.8mm H x 215mm W x 270mm D

STS Module: Dimensions: 43.8mm H x 215mm W x 270mm D

Controller Module: Dimensions: 43.8mm H x 87.9mm W x 277mm D

Interface Module: Dimensions: 43.8mm H x 129.5mm W x 79.7mm D

Inverter Shelf: Dimensions: 43.8mm H x 440mm W x 329.5mm D

Controller/Interface/STS Shelf: Dimensions: 43.8mm H x 440mm W x 329.5mm D

MBSDU Panel: Dimensions: 88mm H x 483mm W x 329.5mm D

Environmental

Operating Temperature: -20 to +70°C (-4 to +158°F)

Storage Temperature: -40 to +85° C (-40 to +185°F)

Humidity: 0 to 90% non-condensing

Heat Dissipation: Forced air cooling for inverter and STS modules

Operating Altitude: 1500m (4922 feet)

Audible Noise: 55dB ETS 300 753 Class 3.1

Standards

Inverter Module: EN 60950-1, UL-60950-1, IEC 60950-1, CSA C22.2 No. 60950-1

STS Module: EN62040-1-1, IEC 62310-1, CSA C22.2 No. 107.3, ANSI/UL 1778

Controller Module: EN 60950-1

Marking: cULus, CE, RoHS, C-Tick

The above information is valid at the time of publication. Consult factory for up-to-date ordering information. Specifications are subject to change without notice.

[1.7" H x 8.5" W x 10.6" D]

Weight: 2.5 kg (5.5 lb.)

[1.7" H x 8.5" W x 10.6" D]

Weight: 2.1 kg (4.6 lb.)

[1.7" H x 3.4" W x 10.8" D]

Weight: 0.5 kg (1.1 lb.)

[1.7" H x 5.1" W x 3.1" D]

Weight: 0.25 kg (0.55 lb.)

[1.7" H x 17.3" W x 13" D]

Weight: 2.7 kg (6 lb.)

[1.7" H x 17.3" W x 13" D]

Weight: 2.7 kg (6 lb.)

[3.5" H x 19" W x 13" D]

Weight: 7.0 kg (15.4 lb.)

-5 to +50°C (23 to +122°F) with full performance

Argus Technologies Ltd. 014-114-B1 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 4 of 4

Page 8

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

1. Please read this manual prior to use to become familiar with the product’s numerous features and operating

procedures. To obtain a maximum degree of safety, follow the sequences as outlined.

2. This manual provides warnings and special notes for the user:

a. Points that are vital to the proper operation of the product or the safety of the operator are

indicated by the heading: WARNING.

b. A notation that is in Bold or Italic typeface covers points that are important to the

performance or ease of use of the product.

3. Before using the product, read all instructions and cautionary markings on the product and any equipment

connected to the product.

4. Do not expose the product to rain or snow; install only in a clean, dry environment.

5. CAUTION – Unless otherwise noted, use of an attachment not recommended or sold by the product

manufacturer may result in a risk of fire, electric shock, or injury to persons.

6. CAUTION – Do not operate the product if it has received a sharp blow, it has been dropped, or otherwise

damaged in any way – return it to a qualified service center for repair.

7. CAUTION – Do not disassemble the product – call our qualified service centers for servicing. Incorrect

reassembling may result in a risk of electrical shock or fire.

8. WARNING – The input and output voltages of the product are hazardous. Extreme caution should be

maintained when servicing or touching conductive components connected to the product.

Page 9

TABLE OF CONTENTS

TU1UT TUINTRODUCTIONUT .............................................................................................................................................................1

TU1.1UT TUScope of the ManualUT ..................................................................................................................................... 1

TU1.2UT TUProduct OverviewUT .......................................................................................................................................... 1

TU1.3UT TUModel and Part NumbersUT .............................................................................................................................. 2

TU2UT TUINSPECTIONUT..................................................................................................................................................................3

TU2.1UT TUPacking MaterialsUT.......................................................................................................................................... 3

TU2.2UT TUCheck for DamageUT ........................................................................................................................................ 3

TU3UT TUSHELF INSTALLATIONUT ...................................................................................................................................................4

TU3.1UT TUInverter Shelf Preparation/MountingUT ............................................................................................................. 4

TU3.2UT TUController/Interface/STS Shelf Mounting/PreparationUT................................................................................... 6

TU3.3UT TUMBSDU Panel Mounting/PreparationUT ........................................................................................................... 7

TU4UT TUWIRING AND CONNECTIONSUT ..........................................................................................................................................8

TU4.1UT TUSafety PrecautionsUT ........................................................................................................................................ 8

TU4.2UT TUTools RequiredUT .............................................................................................................................................. 8

TU4.3UT TUWire SelectionUT ............................................................................................................................................... 8

TU4.4UT TUSingle Inverter Shelf SystemUT......................................................................................................................... 9

TU4.5UT TUMulti-Inverter Shelf SystemUT ......................................................................................................................... 11

TU4.6UT TUSTS/Controller ShelfUT ................................................................................................................................... 14

TU4.7UT TUController/Interface ShelfUT ............................................................................................................................ 15

TU4.8UT TUMBSDU PanelUT ............................................................................................................................................. 17

TU5UT TUMODULE INSTALLATION AND REMOVALUT .......................................................................................................................20

TU5.1UT TUInstallation and Removal of STS and Inverter ModulesUT.............................................................................. 20

TU5.2UT TUController Module ImplementationUT .............................................................................................................. 21

TU5.3UT TUInterface Module ImplementationUT................................................................................................................ 22

TU6UT TUOPERATIONUT................................................................................................................................................................23

TU6.1UT TUPre-Operation CheckUT .................................................................................................................................. 23

TU6.2UT TUStatus MonitoringUT ........................................................................................................................................ 23

TU6.3UT TUParameter SettingUT ....................................................................................................................................... 25

TU6.4UT TUModule Parameter SettingsUT ........................................................................................................................ 26

TU7UT TUDEFAULT VALUESUT ......................................................................................................................................................29

TU8UT TUMAINTENANCEUT ........................................................................................................................................................... 31

TU8.1UT TUInverter Fan ReplacementUT .......................................................................................................................... 31

TU8.2UT TUSTS Fan ReplacementUT................................................................................................................................32

TU8.3UT TUReplacement PartsUT...................................................................................................................................... 32

TU9UT TUTROUBLESHOOTINGUT....................................................................................................................................................33

TU10UT TUARGUS CONVENTIONSUT ................................................................................................................................................37

TU10.1UT TUNumbering SystemUT...................................................................................................................................... 37

TU10.2UT TUAcronyms and DefinitionsUT ........................................................................................................................... 37

TU11UT TUOUTLINE DRAWINGSUT...................................................................................................................................................38

TU11.1UT TUMechanical Dimensions of INEX Inverter ModuleUT ...................................................................................... 38

TU11.2UT TUMechanical Dimensions of INEX STS ModuleUT............................................................................................ 39

TU11.3UT TUMechanical Dimensions of INEX Controller ModuleUT ................................................................................... 40

i

Page 10

TU11.4UT TUMechanical Dimensions of INEX Interface ModuleUT..................................................................................... 41

TU11.5UT TUMechanical Dimensions of INEX Inverter ShelfUT .......................................................................................... 41

TU11.6UT TUMechanical Dimensions of INEX Controller/Interface/STS ShelfUT ............................................................... 42

TU11.7UT TUMechanical Dimensions of INEX MBSDU ShelfUT ......................................................................................... 43

ii

Page 11

1 Introduction

1.1 Scope of the Manual

This instruction manual explains the installation, interconnection, and operation of Argus Technologies’ INEX

Inverter System.

1.2 Product Overview

INEX inverter series is an integrated telecommunication AC power system, including inverter, static switch, LCD

controller, and interface modules. With versatile “building block” design and N+1 redundant configuration, INEX

inverter system facilitates complex telecommunication and industrial power demands.

INEX series DC to AC inverter module is available for 1000VA (800W) or 1500VA (1200W) to convert -48Vdc

input to 120Vac or 230Vac output at 50Hz or 60Hz. The inverter module is “hot swappable” meaning it can be

inserted or removed from the shelf without cutting power to or from the system.

A universal 19” shelf is designed to parallel connect and synchronize all INEX inverter models. With this shelf,

INEX series employs N+1 redundant configuration to output power maximum of 12kVA for 120Vac models and

18kVA for 230Vac models, and to operate in N+1 redundant mode for optimization. INEX “all master” dynamic

mechanisms automatically share and re-organize critical loads to further prevent interruption if one or more

inverter modules fail.

INEX selective static transfer switch (STS) provides automatic instantaneous load transfer, which further secures

uninterrupted operation of sensitive electronic equipment.

The INEX system controller, equipped with a DSP microprocessor, gives real-time system status through

comprehensive LCD/LED indication, and allows program settings through the display panel. A communication

interface module provides local or remote control and monitoring of the system.

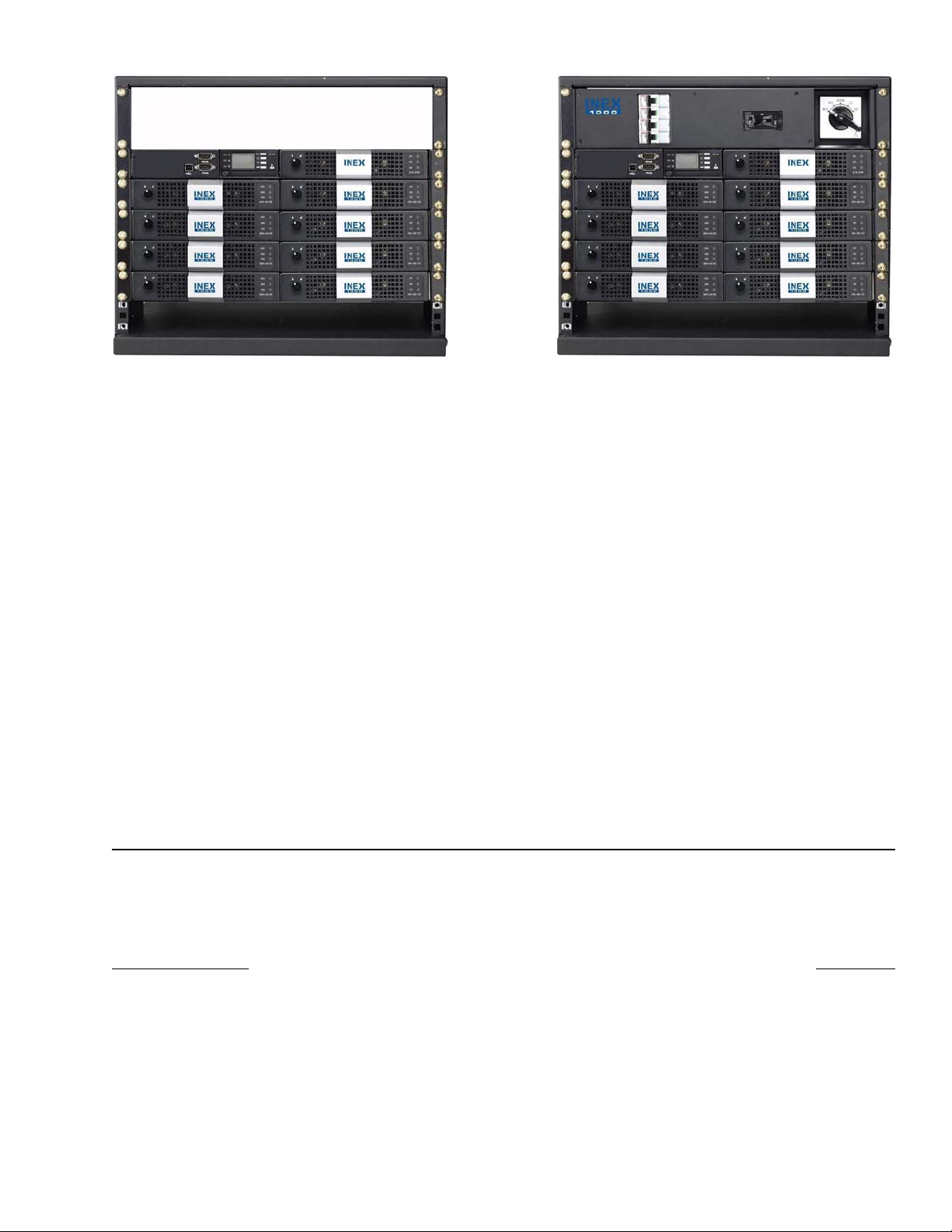

INEX Inverter system only

Illustrations only and may not match your installation.

INEX Inverter system with

control/metering

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 1 of 43

Page 12

INEX Inverter system with STS and

control/metering

Illustrations only and may not match your installation.

INEX Inverter system with STS,

control/metering, and MBS/distribution

INEX Inverter System features include:

• Pure sine wave output with low distortion

• Versatile module design allows a variety of configurations for different power needs

• Easily expands capacity up to 18kVA with N+1 redundancy

• “All master” dynamic mechanism eliminates single-point failure to optimize reliability

• Hot-pluggable connection allows module addition or removal without cutting power

• Ultimate high power density reducing space demand

• High efficiency (> 88%)

• Comprehensive LCD/LED display provides system status, and user-friendly panel eases program settings.

1.2.1 WinPower Software

WinPower is a power management software specifically designed to monitor and control the INEX inverter system

via a personal computer. It is available to download via the Argus website (www.argusdcpower.com).

To remotely monitor and control INEX inverters, connect the USB cable (A-B type) to the port on the front panel of

the interface module. Then follow instructions stated in the WinPower manual to properly install the software to a

personal computer physically connected to the INEX inverter system.

1.3 Model and Part Numbers

This product is available to order under the following part numbers:

UModel Number Description Part Number

INV-4810A 1000VA/800W inverter module (I/P: 48Vdc, O/P: 120Vac, 60Hz)......................014-114-10

INV-4810EA 1000VA/800W inverter module (I/P: 48Vdc, O/P: 230Vac, 50Hz)......................014-115-10

INV-4815A 1500VA/1200W inverter module (I/P: 48Vdc, O/P: 120Vac, 60Hz)....................014-116-10

INV-4815EA 1500VA/1200W inverter module (I/P: 48Vdc, O/P: 230Vac, 50Hz)....................014-117-10

MC-1000A Controller module................................................................................................018-593-10

STS-050A 50A static transfer switch module .......................................................................019-050-10

SMBSDU-50-2U-19AS Discontinued, see 020-424-10 ............................................................................S020-417-10S

MBSDU-50-2U-19-UA MBS+DU panel (maintenance bypass switch and NEMA AC distribution) ........020-422-10

MBSDU-50-2U-19A MBS+DU panel (maintenance bypass switch and IEC AC distribution).............020-424-10

INVSS-2EA-1U-19A Inverter shelf .......................................................................................................030-419-10

STSSS-I-1EA-1U-19A Controller/STS shelf (includes interface module IFC-1000NSA)........................030-420-10

MC-BLANK Controller blank plate ..........................................................................................614-616-10

IFC-BLANK Interface blank plate............................................................................................614-617-10

INV-BLANK Inverter/STS blank plate .....................................................................................614-618-10

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 2 of 43

Page 13

2 Inspection

2.1 Packing Materials

All Argus products are shipped in rugged, double walled boxes and suspended via solid inserts to minimize shock

that may occur during transportation. Packaging assemblies and methods are tested to International Safe Transit

Association standards.

Power systems are also packaged with Cortex. This plastic wrap contains a corrosive-inhibitor that protects the

product from corrosion for up to two years.

2.1.1 Returns for Service

Save the original shipping container. If the product needs to be returned for service, it should be packaged in its

original shipping container. If the original container is unavailable, make sure the product is packed with at least

three inches of shock-absorbing material to prevent shipping damage.

NOTE: Argus Technologies is not responsible for damage caused by the improper packaging of returned products.

2.2 Check for Damage

Prior to unpacking the product, note any damage to the shipping container. Unpack the product and inspect the

exterior for damage. If any damage is observed contact the carrier immediately.

Continue the inspection for any internal damage. In the unlikely event of internal damage, please inform the

carrier and contact Argus Technologies for advice on the impact of any damage.

Verify that you have all the necessary parts per your order for proper assembly.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 3 of 43

Page 14

3 Shelf Installation

This chapter is provided for qualified personnel to install the product.

3.1 Inverter Shelf Preparation/Mounting

The inverter shelf has been designed for flush or mid-mounting in a 19” relay rack. Mounting brackets are also

supplied for mounting in a 23” rack.

NOTE: The shelf shall be mounted in a clean and dry environment. Allow at least 1.75” of free space in front of the unit

for unrestricted cooling airflow.

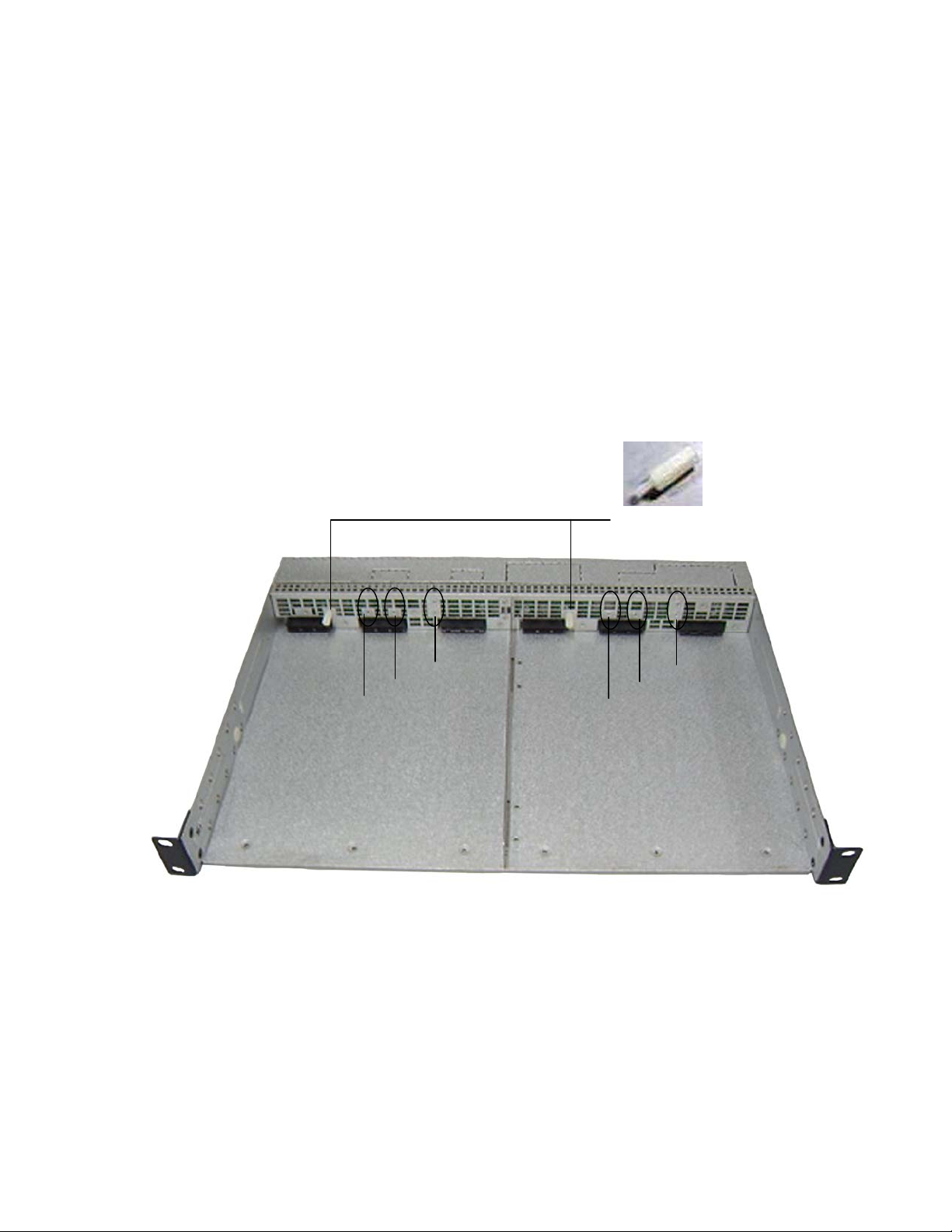

1. There are four holes right above three deck connectors of each inverter slot. Based on inverter model, insert

the supplied nylon guide pin to the corresponding hole:

• Position A for INV-4815A (as shown below)

• Position B for INV-4815EA

• Position C for INV-4810A

• Position D for INV-4810EA

Nylon guide pins shown in Position A

D

C

B

B

D

C

CAUTION

System will fail to operate normally when inverter modules of different specifications are inserted

into inverter shelves. Use supplied nylon guide pins for securing only inverter modules of the

same specifications.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 4 of 43

Page 15

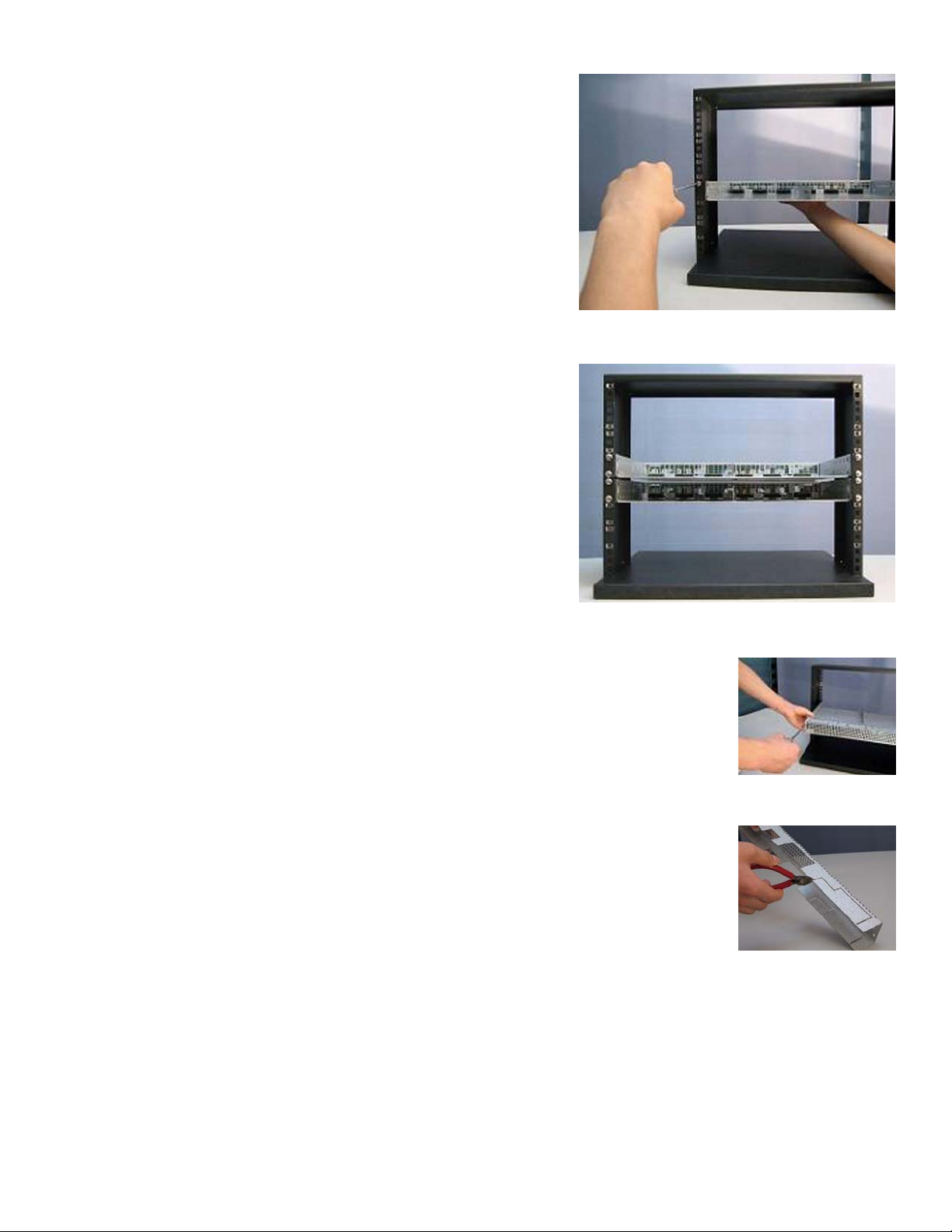

2. The shelf should be mounted to the rack using at least two

#12 – 24 x 1/2” screws in each bracket. Philips-type screws

and screwdriver should be used to eliminate the possibility of

slippage and scratching of the unit’s exterior. Washers (such

as internal tooth) or special screws that are designed to cut

through the painted surface should be used to ensure a good

chassis ground.

3. Put the inverter shelf into the equipment rack horizontally,

and align holes of mounting brackets and rack.

4. Each inverter shelf holds maximum two inverter modules.

Repeat the steps above to install the inverter shelves as

required.

5. All input and output connections are made through the knockouts, located in the top

and the bottom of the shelf rear cover, as well as both side panels.

Remove the rear cover to access the inverter shelf backplane and connectors.

6. Knockouts on top and bottom are for shelf inter-connections and supplementary wire

routing. To remove knockout, snip tabs, move plate up and down until tabs in back

snap apart.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 5 of 43

Page 16

3.2 Controller/Interface/STS Shelf Mounting/Preparation

The shelf has been designed for flush or mid-mounting in a 19” relay rack. Mounting brackets are also supplied

for mounting in a 23” rack.

NOTE: The shelf shall be mounted in a clean and dry environment. Allow at least 1.75” of free space in front of the unit

for unrestricted cooling airflow.

1. The shelf should be mounted to the rack using at least two #12

– 24 x 1/2” screws in each bracket. Philips-type screws and

screwdriver should be used to eliminate the possibility of

slippage and scratching of the unit’s exterior. Washers (such as

internal tooth) or special screws that are designed to cut

through the painted surface should be used to ensure a good

chassis ground.

2. Put the shelf into the equipment rack horizontally, and align

holes of mounting brackets and rack.

NOTE: Each INEX controller module or interface module allows maximum

control of 12 inverter units cascaded. It is recommended to have the

controller/interface/STS shelf installed on top of stacked inverter

shelves to ease inter-connections; however, it may be installed

below the inverter shelves if the MBSDU panel is not required.

All input and output connections are made through the knockouts, located in the top and the bottom of each of the

two rear covers, as well as both side panels. The cover on the right is for the controller/interface section, and the

cover on the left is for the STS section.

3. Remove the rear cover(s) to access the shelf backplane and

connectors.

4. Knockouts on top and bottom are for shelf inter-connections. To

remove knockout, snip tabs, move plate up and down until tabs

in back snap apart.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 6 of 43

Page 17

3.3 MBSDU Panel Mounting/Preparation

The panel has been designed for flush or mid-mounting in a 19” relay rack. Mounting brackets are also supplied

for mounting in a 23” rack.

NOTE: The panel shall be mounted in a clean and dry environment.

1. The panel should be mounted to the rack using at least two #12

– 24 x 1/2” screws in each bracket. Philips-type screws and

screwdriver should be used to eliminate the possibility of

slippage and scratching of the unit’s exterior. Washers (such as

internal tooth) or special screws that are designed to cut through

the painted surface should be used to ensure a good chassis

ground.

2. Put the panel into the equipment rack horizontally, and align

holes of mounting brackets and rack. The panel must be

mounted above the controller/interface/STS shelf.

3. All input and output connections are made through the knockouts, located in the bottom of the rear cover and

both side panels. To remove knockout, snip tabs, move plate up and down until tabs in back snap apart.

4. Remove the rear cover to access the backplane and connectors.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 7 of 43

Page 18

4 Wiring and Connections

This chapter provides notes on cable sizing and cabling details with respect to the Argus INEX 1000/1500 Inverter

System.

4.1 Safety Precautions

WARNING

Ensure all power sources are OFF during wiring. Disconnect battery cables from battery.

Before working with any battery or power system/distribution center, follow these precautions:

• Remove all metallic jewelry; e.g., watches, rings, metal rimmed glasses, necklaces.

• Wear safety glasses with side shields (and prescription lenses if necessary) at all times during installation.

The installer should follow all applicable local rules and regulations for electrical and battery installations; e.g.,

CSA, UL, CEC, NEC, OSHA, and local fire codes.

Use OSHA approved insulated hand tools.

4.2 Tools Required

Various tools are essential for product installation. Use this list as a guide:

• Slot head screwdrivers (blade sizes: 1/4”, 1/8”, 1/16”)

• Philips head screwdriver, #2 (tip size 3/16”)

• Digital voltmeter equipped with test leads

• Adjustable 48Vdc load (optional)

• Cutters and wire strippers

• Crimping tool (optional for large gauge wire)

• Anti-static wrist strap.

4.3 Wire Selection

The INEX inverter modules are designed to operate in parallel for higher output current. Two modules are

automatically connected in parallel in each shelf. Two or more inverter shelves can be further connected in

parallel for additional output power; this is done by connecting inputs (BAT-, BAT+) in parallel, and outputs (Line,

Neutral, Ground) in parallel. When paralleled, there is no master unit and each unit adjusts its own power level for

best power sharing. Please refer to the following wiring instructions for your needs.

When selecting wiring, consider the following factors:

• Current carrying capacity of the wire

• Maximum wire length needed

• Maximum ambient temperature.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 8 of 43

Page 19

NOTE: Use the following table as a guide only. Ensure that the installation complies with the specific wiring rules

applicable to your country or area of jurisdiction.

Shelf number of

2 x 1000VA

inverter

cascaded

#1 45.5A 18.2A 8.7A #8 AWG #14 AWG #16 AWG

#2 91.0A 36.4A 17.4A #4 AWG #10 AWG #14 AWG

#3 54.5A 26.1A #8 AWG #10 AWG

#4 72.7A 34.8A #6 AWG #10 AWG

#5 90.9A 43.5A #4 AWG #8 AWG

#6 109.1A 52.2A #3 AWG #8 AWG

Shelf number of

2 x 1500VA

inverter

cascaded

#1 68.2A 27.3A 13.0A #6 AWG #12 AWG #16 AWG

#2 136.4A 54.5A 26.1A #2 AWG #8 AWG #12 AWG

#3 81.8A 39.1A #6 AWG #10 AWG

#4 109.1A 52.2A #3 AWG #8 AWG

#5 136.4A 65.2A #2 AWG #6 AWG

#6 163.6A 78.3A #2 AWG #6 AWG

Input Current

Maximum

@ 40Vdc

Input Current

Maximum

@ 40Vdc

110Vac Output

Current Max.

110Vac Output

Current Max.

230Vac Output

Current Max.

230Vac Output

Current Max.

Minimum Size

of DC Input

Wire Max.

Minimum Size

of DC Input

Wire Max.

Min. Size of

110Vac Output

Wire Max.

Min. Size of

110Vac Output

Wire Max.

Min. Size of

230Vac Output

Wire Max.

Min. Size of

230Vac Output

Wire Max.

Table A–Recommended wire size versus current

Remarks: 1. Total Power Rating (VA, W) = No. of shelf × Inverter module power rating (VA, W) * 2

2. I/P current = Total power rating (W) ÷ 0.88 ÷ 40

3. O/P current = Total power rating (VA) ÷ AC voltage

4.4 Single Inverter Shelf System

1. In the inverter shelf package, you will find a jumper.

When only ONE inverter shelf is applied in the system, insert

the jumper to pins 1 and 2 of connector JP2:

2. Negative (BAT-) and positive (BAT+) DC input terminal studs are located in the left side of backplane. In

consideration of the power rating and distance from the battery, choose appropriate gauge wire using Table A

as well as local wiring rules.

NOTE: For inverter systems without a controller, open collector terminals are available on the inverter shelf backplane for

the inverter fail alarm. See details under point 9 of Section 4.5.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 9 of 43

Page 20

3. Thread battery cables through left-side panel knockout; put the hole lug at one end of each battery cable to

DC input stud.

4. Secure the connection with two supplied M5x12 cross hex-

washer type nickel screws and washers as shown:

CAUTION

Reverse polarity connections would damage the unit and is not cover by the warranty. Ensure

correct polarity (positive to positive, negative to negative) before completing connections

between battery and INEX inverter unit.

5. Install the other end of battery cables to battery or 48Vdc source.

WARNING

DC source voltage should be between 45V and 58V.

6. The three studs in the center of the backplane are AC output terminals. AC neutral, ground and line are

marked as UC3, UC4 and UC5, respectively. Check the AC output voltage. Using Table A, as well as local

wiring rules, choose appropriate gauge wire.

7. Thread AC neutral and line wires through left-side panel knock-out, put the hole lug at one end of each wire to

AC neutral and AC line studs.

8. Secure the connection with two supplied M5x12 cross hex-washer type nickel screws and washers as shown.

9. Install the other end of wires to the AC distribution or load.

10. AC Ground stud (UC4) is mainly for inter-connection with extra

shelves. To do system grounding, cover up the backplane with

the rear cover first, and screw the ground wire on the rear cover

with the supplied cross hex-washer type nickel screw as shown:

DANGER

To meet CEC/NEC requirements – to prevent fire, electric shock, improper operation of circuit

protection devices, as well as improper operation of the equipment – an electrical bond between

neutral and ground is required at the AC source or distribution point of an inverter system.

Ensure that the installation complies with the specific wiring rules applicable to your country or

area of jurisdiction.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 10 of 43

Page 21

4.5 Multi-Inverter Shelf System

CN20 and CN21 at the inverter shelf backplane are inter-parallel connectors for inverter synchronization. The

upper port is used to connect the inverter shelf above, and the lower port is used to connect the inverter shelf

below.

1. Use the flat communication cables provided to connect all

available inverter shelves:

2. Use the supplied bus bars for connecting the DC negative input (BAT-) studs of all available shelves together

with M5x12 cross hex-washer type nickel screws and washers. See Table A.

3. Similarly, connect DC positive input (BAT+) studs of all shelves together.

4. Do the same for AC neutral (UC3), AC ground (UC4) and AC line (UC5) studs individually:

NOTE: Spacers supplied are required on the last (bottom) shelf for AC bars.

CAUTION

Ensure that no jumper is inserted into JP2 connector of all connected inverter shelves.

5. Choose appropriate gauge wire with consideration for the total input current of the whole inverter system,

distance from the battery, and local wiring rules.

6. Thread two battery cables through left-side panel knockout, and attach one battery cable to one DC negative

input stud (BAT-) and the other to one DC positive input stud (BAT+).

CAUTION

Reverse polarity connections would damage the unit and is not cover by the warranty. Ensure

correct polarity (positive to positive, negative to negative) before completing connections

between battery and INEX inverter unit.

7. Secure the connection with two supplied cross hex-washer type nickel screws and washers as shown.

8. Install the battery cables to battery or 48Vdc source.

WARNING

DC source voltage should be between 45V and 58V.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 11 of 43

Page 22

9. For inverter systems without a controller, open collector terminals are available on the inverter shelf

backplane for the inverter fail alarm.

10. Check the AC output voltage. Using Table A, as well as local wiring rules, choose appropriate gauge wire.

11. Thread selected AC neutral and line wires through left-side panel knockout, and attach one cable to one AC

neutral (UC3) stud and the other to AC line (UC5) stud.

12. Secure the connection with two supplied M5x12 cross hex-washer type nickel screws and washers.

13. Install the other end of wires to the AC distribution or load.

To connect the INEX inverter with an Argus Cordex™ system controller (CXC), use the contacts of CN11 on the

INEX inverter shelf to connect to any available digital input on the CXC. See the following example:

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 12 of 43

Page 23

14. To do system grounding, cover up the backplane with the

rear cover first, and screw the ground wire on the rear cover

with the supplied cross hex-washer type nickel screw as

shown:

NOTE: INEX inverter modules allow maximum 12 units cascaded for expanding power capacity. The input current of

entire inverter system would exceed the current limit of available wires. When the total input cu rrent is over the

cable current limit, split DC connection to multiple groups by removing inter-connected BAT+ & BAT- bus b ars

between groups, and choose suitable wire size for each g roup. Input DC feed er breaker configured one per shelf

or optionally input breaker per two shelves maximum.

4.5.1 CASE STUDY – An inverter system with eight INV-4810A inverter modules (8kVA)

The total input current, 151.5A @ 48Vdc, can be halved by removing DC positive (BAT+) and DC negative (BAT-)

bus bars connected between shelves 2 and 3. DC connection is split into two groups (4kVA and 4kVA). After

selecting suitable wire for minimum transmission current of 75.8A, two pairs of battery cable are separately

connected to DC positive and negative studs of both groups as shown:

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 13 of 43

Page 24

4.6 STS/Controller Shelf

WARNING

Ensure all power sources are OFF during wiring. Disconnect battery cables from battery.

1. Follow wiring instructions to suit your installation.

CN1: Use shorting plug

for pins 1 to 4 when

MBS is not installed

CN2: SYNC port on the

controller/interface shelf

backplane

2. Locate the CN2 connector on the backplane of the STS shelf

and the CN7 connector on the backplane of the inverter

shelf. Connect these two connectors with the attached STS

signal cable as shown:

CN7: SYNC port on the

inverter shelf

backplane

3. Connect AC bus connectors of STS shelf to the AC bus of

the top level inverter shelf.

4. Then connect the AC bus connectors between inverter

shelves.

NOTE: Spacers supplied are required on the last (bottom) shelf for AC

bars.

5. Route both DC input wires through the wire hole on the left

side of the inverter shelf. Use the cross-pan type nickel

screws in accessory kit for fixing both DC input wires.

CAUTION

To connect AC output wires onto the system,

only one AC line and AC neutral are necessary to

be connected either from STS shelf or inverter

shelf.

6. For inverter shelf only or without STS module:

This page Next page

Connect AC LINE to the UC4 (AC-L OUT) connector of STS

shelf.

Connect AC NEUTRAL LINE onto UC3 (AC-N) connector of

STS shelf.

7. With STS module:

Connect AC LINE IN to UC5 and AC LINE OUT to UC4 of STS shelf. Connect AC NEUTRAL IN/OUT to UC3.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 14 of 43

Page 25

4.7 Controller/Interface Shelf

WARNING

Ensure all power sources are OFF during wiring. Disconnect battery cables from battery.

1. INEX controller and interface modules are powered from inverters. Securely plug one end of the supplied 3-

pin power cable to CN12 power jack on the controller/interface/STS shelf backplane, and the other end to

CN9 power jack on the inverter shelf backplane:

CN12: Power connector

of controller

CN9: Power connector

to controller

2. CN3 connector on the controller/interface shelf backplane, and CN8 connector on the inverter shelf backplane

are for data transferring between controller/interface modules and inverters. Use the supplied signal cable to

link the two connectors together as shown:

CN3: CAN COM port on

the controller/interface

shelf backplane

CN7 to CN11 relay alarm

contacts (1A rated)

[see below]

CN8: CAN COM port on

the inverter shelf

backplane

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 15 of 43

Page 26

3. Use #30 to 16AWG to connect dry contact terminal CN7 to CN11:

NOTE: To set the alarm mode of dry contact, refer to the next chapter.

4. Replace rear cover(s) once all connections have been

completed.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 16 of 43

Page 27

4.8 MBSDU Panel

1. Connect signal cables between MBSDU panel, STS and inverter shelves as shown:

2. Remove the shorting plug on CN1 and connect the 4-pin MBS cable to the CN1

connector on the backplane of the STS shelf.

#4 (AC I/P)

#1, #1, #2

3. Connect the 5 bus bars supplied with the MBSDU panel to the STS

backplane via the corresponding connectors of MBSDU panel as shown:

#3 (STS O/P)

DANGER

To meet CEC/NEC requirements – to prevent fire, electric shock, improper operation of circuit

protection devices, as well as improper operation of the equipment – an electrical bond between

neutral and ground is required at the AC source or distribution point of an inverter system.

Ensure that the installation complies with the specific wiring rules applicable to your country or

area of jurisdiction.

For INEX systems with a MBSDU, this can be facilitated by

installing a wire jumper between Neutral and Ground on the

terminal block labelled “output” on the back of the MBSDU

shown here:

4. Connect AC input to the terminal on the back left of

MBSDU panel according to the position of the labels as

shown.

Wire jumper should be sized

for the maximum capacity of

the system. Refer to Table A.

5. Connect AC output to the terminal (according to the

label) on the back right of MBSDU panel to external

distribution or load.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 17 of 43

Page 28

6. Replace rear cover(s) once all connections have been

completed.

7. Screw the system ground wire on the rear cover with the

supplied cross hex-washer type nickel screw.

CAUTION STS is not hot swap without MBS.

When installing STS module with MBS it is not necessary to turn off the system. However, the

incorrect install/removal action will damage the STS module frame because of the safety lock of

the MBS.

Proceed as follows: put switch at MBP or IBP position (Determined by mains and inverter output

status) as shown:

MBP position:

4.8.1 Position Status of MBS

The operation mode of STS is closely associated with the position of MBS. The MBS has two main connectors

and three assistant connectors. The signals generated by three assistant connectors are passed to DSP for

position status detection. There are five valid positions:

1. MBP –

UmUains UbUyUpUass

2. MSS – UmUains UsUtatic UsUwitch (for mains maintenance)

3. NORM –

4. ISS –

5. IBP –

UnormUal operation

UiUnverter UsUtatic UsUwitch (for inverter maintenance)

UiUnverter UbUyUpUass

STS will continuously detect the position of MBS in order to decide the transferring action between different

modes.

IBP position:

When the STS is powered on, it will judge whether the present position of MBS is valid. If the status is invalid,

STS will consider MBS not well connected, and it will not enter any types of operation mode until the detection

signal becomes normal.

If MBS is changed when STS runs at one of the five valid positions, and this change happens between two

adjacent positions, the STS will transfer to different mode based on current status. Otherwise, the STS will not

take any action.

For example, if MBS is set at P3, STS will take action when MBS is turned to P2 or P4.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 18 of 43

Page 29

NOTE: Be sure not to change MBS position immediately when STS is inserted into the rack, wait at least five seconds if

you want to change it. When you change its position you must confirm that you keep MBS at one position more

than one second in order for MCU of STS has enough time to detect MBS position via MBS auxiliary contacts

(CN1).

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 19 of 43

Page 30

5 Module Installation and Removal

5.1 Installation and Removal of STS and Inverter Modules

1. Install the inverter or STS module by sliding it into a pre-wired rack mount shelf until the faceplate is flush with

the mounting ears.

2. In order to prevent the inverter or STS module removal, turn the lock bolt counter-clockwise to LOCK position.

CAUTION

Parallel connection of inverter modules with different specifications would lead to serious

damage, and is not covered by the warranty. Use supplied nylon guide pins for securing only

inverter modules of the same specifications.

Inverter shelf holds only inverter modules; STS module will not fit in an inverter shelf.

3. Each inverter shelf holds maximum two inverter modules. Repeat previous steps to insert inverter module to

inverter shelf as required.

4. Inverter or STS module can be removed by pulling on the handle after turning the lock bolt to the UNLOCK

position. CAUTION: STS is not hot swap without MBS.

5. You can cover the excess cavity with an optional blank plate as follows:

The optional cover plate comes into two pieces: orthogonal silver metal piece and black coated cover plate.

6. After screwing the inner silver metal piece to the shelf bottom plate, use bolts on both sides to attach the

black metal cover to the inner silver piece.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 20 of 43

Page 31

7. If controller module and/or interface module is not required, you can cover the excess cavity of

controller/interface/STS shelf with optional blank plates. The optional blank plate comes into two pieces.

8. After screwing the inner silver metal piece to the shelf bottom plate, use bolts on both sides to attach the

black metal blank plate to the inner silver piece.

5.2 Controller Module Implementation

1. To install the controller module, slide it into the 2U-wide controller slot of the pre-wired

controller/interface/STS shelf until the faceplate is flush with the mounting ears. With the power on, the green

LED of the controller unit will light if everything functions correctly.

2. If an interface module is available, simply insert the interface module into the 3U-wide interface slot of the prewired controller/interface/STS shelf until the faceplate is flush with the mounting ears.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 21 of 43

Page 32

5.3 Interface Module Implementation

NOTE: IFC is pre-installed on the 030-420-10 shelf.

1. To install interface module, the rear cover must be removed.

2. Plug one end of the supplied flat cable to CN1 connector, and route the other end through the hole on the

controller/interface/STS shelf backplane as shown.

3. Cover up the controller/interface shelf backplane with the rear cover.

4. Pull the other end of flat cable to the front of INEX inverter system, and plug the cable to the cable socket on

the interface module PCB shown below:

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 22 of 43

Page 33

6 Operation

6.1 Pre-Operation Check

6.1.1 Inverter Operation Check

• Check the DC input polarity.

• Ensure the input voltage is in the standard range.

• Check wiring size based on local codes and the wiring table.

• Ensure the rear cover is securely installed for safety; preventing electrical shock.

• Ensure the ground wiring is properly connected on rear cover for safety; preventing electrical shock.

• Ensure the inverter module has been locked. The lock bolt should be in the lock position.

At power on, the inverter/STS unit enters into a self-diagnostic mode with POWER ON and WARNING LED

indicators blinking simultaneously. If everything functions correctly, the ON indicator will remain solid green, and

the power will be delivered to the AC output terminals.

6.1.2 STS Operation Check

• If installed, ensure the MBS is at “Normal” position.

• Ensure the rear cover is securely installed for safety; preventing electrical shock.

• Ensure the STS module has been locked. The lock bolt should be in the lock position.

6.1.3 Controller/Interface Operation Check

• Ensure the controller module is securely installed.

• Ensure the rear cover of controller/interface/STS shelf is securely installed.

• Ensure the interface module is securely installed and the wiring is properly connected.

6.1.4 MBS Operation Check

• The breakers are at ON position.

• The rear cover of MBS is securely installed.

6.2 Status Monitoring

When the controller module is properly installed with power on, the LCD screen will light by displaying “Waiting”

for self-diagnosis. Within a few seconds, STATUS and SETTING options will then show on the screen.

STATUS is classified into four sections: MODULE, CONTROLLER, BATTERY, and ALARM.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 23 of 43

Page 34

Heading Value

Address Inverter module location

Serial No Serial number of the selected inverter module

OPV Output voltage of the selected inverter module in Volts (V)

OPI Output current of the selected inverter module in Ampere (A)

OPF Output frequency of the selected inverter module in Hertz (Hz)

OPP Power capacity of the selected inverter module in Volt-Amperes (VA)

IPV DC input voltage of the inverter system in Volts (V)

Power Used Load level in percentage (%)

Heatsink Inverter system temperature in Celsius (ºC)

Ambient Temp. Inverter ambient temperature in Celsius (ºC)

Run time Inverter running time in hour (H)

Power Limited Power limited in percentage (%)

HW Rev Hardware version of the selected inverter module

SW Rev Software version of the selected inverter module

Table B–LCD display of inverter status

Heading Value

Address STS module location

Serial No Serial number of installed STS module

OPV Output voltage of STS module

OPI No display

OPF Output frequency of STS module

OPP No display

Mains AC Vol Voltage of AC connected to STS module

Main AC Freq Frequency of AC connected to STS module

INV AC Volt Voltage of Inverter AC connected to STS module

INV AC Freq Frequency of Inverter AC connected to STS module

MBS Position Current MBS position (IBP /ISS/Normal/MSS/MBP)

Running Mode STS current running mode (Inverter/mains/standby/power on)

Default Volt STS default output voltage (V)

Default Freq STS default output frequency (Hz)

Power Used Load level in percentage (%)

Temperature STS temperature in Celsius (ºC)

Run Time STS running time in hour (H)

Operation mode of STS module;

Priority Mode

HW Rev Hardware version of STS module

SW Rev Software version of STS module

ON = output from inverter, OFF = output from AC

STS, the default is ON

Table C–LCD display of STS status

Heading Value

Hardware Version Hardware version of controller module

Firmware Version Software version of controller module

Input Voltage DC input voltage of controller module in Volts (V)

Temperature Controller temperature in Celsius (ºC)

Table D–LCD display of controller status

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 24 of 43

Page 35

Main menu->Alarm->Active Alarm

Item Specification Remark

Inverter Serial number, Alarm name, Event time

STS Serial number, Alarm name, Event time

SMR (N/A) Serial number, Alarm name, Event time

6.3 Parameter Setting

INEX inverter system allows some parameters to be adjusted through the controller module.

For example:

Table E–LCD display of alarm log

1. Inv xxxxxxxxx

Fan Fault

yyyy-mm-dd

hh:mm:ss ▼

1. Use PgDn

2. A four-digit numeric password is required. Use PgUp

key and Enter key to select SETTING.

key to increase number, and PgDn key to decrease

number.

For example, press PgUp

key once for 1, twice for 2,

three times for 3, and so on.

3. Press Enter

to validate each digit of the

password once the desired number is selected.

The default password is 1234.

No setting modification can be executed if a wrong password is

entered.

SETTING section is divided into two categories: MODULE and SYSTEM.

Parameters of modules can be modified or adjusted under MODULE while system-related setups can be done

under SYSTEM. The following sections refer to detailed setup procedures.

NOTE: To activate system level changes, cycle the system power off then on again.

6.3.1 Password Setting

A new password can be set in SYSTEM option under SETTING.

1. Press Enter

key to enter SETTING PASSWORD menu for resetting the

password.

2. Use PgUp

3. Press Enter

key and PgDn key to select a number.

to validate each digit of the password once the desired number is

selected.

4. After the new four-digit password is input, the system will prompt the user to re-enter

the new password as confirmation. Input the new password again.

Once the password is successfully changed, DONE will appear on the screen.

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 25 of 43

Page 36

6.3.2 Inverter System Parameter Settings

Parameter Specification

BaudRate: Baud rate of COM port Selectable at 1) 2400bps, 2) 4800bps and 3) 9600bps

RS422 Addr: RS422 address RS422 communication protocol

Keypad tones: activation or de-activation

of audio alarm

Time&Date: Time and Date displayed on

LCD

Language English

Brightness: LCD brightness From 00~63 for adjusting LCD display contrast

Default: Reset Default value Press “Enter” for resetting the default value and “ESC” cancel the setting

Dry Connect: Dry contact setting Refer to Module Parameter Settings section: Dry Contact Setting

Bat Calib: battery voltage calibration xx.xxV

6.4 Module Parameter Settings

Parameter Setting Option

Output volt:

Inverter output voltage

Output Freq:

Inverter output frequency

OPV HL:

High loss of inverter output voltage

OPV LL:

Low loss of inverter output voltage

IPV LVSD:

Cut-off voltage of inverter input

Power Limited:

Inverter output power capacity

Fan Speed:

Fan speed level of inverter module

Inverter On/off:

Setting all/single inverter turn on or off

Selectable at 1) Enable and 2) Disable

Time: hh:mm:ss

Date: yyyy-mm-dd

Reset to Default Value (refer to Appendix A)

For regulating the battery voltage value of LCD display of controller after

operating for long period of time.

The adjustable range is from 20.01V to 69.99V

Table F–System parameter settings

For INV-4810EA/INV-4815EA, selectable at:

1) 208Vac 2) 220Vac 3) 230Vac 4) 240Vac

For INV-4810A/INV-4815A, selectable at:

1) 110Vac 2) 115Vac 3) 120Vac

Selectable at 1) 50Hz and 2) 60Hz

For Output volt = 208V, adjustable between 220V and 240V

For Output volt = 220V, adjustable between 233V and 252V

For Output volt = 230V, adjustable between 244V and 264V

For Output volt = 240V, adjustable between 254V and 276V

For Output volt = 110V, adjustable between 117V and 127V

For Output volt = 115V, adjustable between 122V and 132V

For Output volt = 120V, adjustable between 127V and 138V

For Output volt = 208V, adjustable between 1760V and 198V

For Output volt = 220V, adjustable between 176V and 209V

For Output volt = 230V, adjustable between 185V and 218V

For Output volt = 240V, adjustable between 193V and 228V

For Output volt = 110V, adjustable between 89V and 105V

For Output volt = 115V, adjustable between 93V and 110V

For Output volt = 120V, adjustable between 100V and 114V

Adjustable between 36V and 46V

Adjustable between 50% and 100%

Selectable at 1) Normal and 2) Full

1. All ->On/Off

2. Single

Serial No:

xxxxxxxxxx

On

Off

⊙

○

OFF

ON

I nv: X

Serial No:

xxxxxxxxx

⊙

ON

○

OFF

Single

↕

Enter

Table G–Inverter parameter settings

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 26 of 43

Page 37

Parameter Setting Option

AC HL: High loss of alternative AC input xxxV

AC LL: Low loss of alternative AC input xxxV

Inv HL: High loss of inverter AC input xxxV

Inv LL: Low loss of inverter AC input xxxV

Priority Selectable at 1) On line and 2) Off line

6.4.1 Fan Speed Control

Output current and NTC temperature decide the fan speed. The NTC temperature has the influential priority.

When the temperature is above 70ºC, the fan will work in full speed. However, when the temperature is less than

60ºC, the fan works according to the different load current. The fan has four levels of speed, the following tables

show the relation between fan speed and load current:

Load Detect Back Speed Duty

Load > 75% Speed1 100%

75% ≥ Load > 50% <=70% Speed2 2/3

50% ≥ Load > 25% <=45% Speed3 1/3

25% ≥ Load <=20% Speed4 0

Load Detect Back Speed Duty

Load > 75% Speed1 2/3

75% ≥ Load > 50% <=70% Speed2 1/3

50% ≥ Load > 25% <=45% Speed3 1/4

25% ≥ Load <=20% Speed4 0

Table H–STS parameter settings

Table I–One fan, rotate speed1

Table J–Two fans, rotate speed2

Relation between fan speed and load current:

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 27 of 43

Page 38

6.4.2 Alarm Settings

6.4.2.1 Clear Alarm History

In CLEAR menu, press Enter

for clearing all the alarm history.

6.4.2.2 Dry Contact Alarm Configuration A

Baud Rate

RS422 Addr

Keypad tones

Time&Date

Language

Settings

Module

►System

Password

Brightness

Default

► Dry connect

Bat Calib

Æ

DryCont: X↕

Alarm Type:XXX

Alarm No: X

xxxxxxxxxxx

Æ

Æ

⊙

INV

○STS

○Cont

○Smr

Alarm Type: INV

Alarm No: 1↕

Inv erter fault

Æ

1 2 2 3 4

1. From the SETTING menu, select SYSTEM.

2. Then select DRY CONNECT to choose number. Use PgUp

DRYCONT. Press Enter

to make selection.

D r y C o n t : 1

A l a r m T y p e : I N V

A l a r m NO: 02

I N v o v e r l o a d

3. To determine ALARM TYPE, select which module alarm group to assign to the dry contact.

Press Enter to make selection.

4. To select the alarm fault mode of the alarm type, enter ALARM NO. Press Enter to make

selection.

5. Press ESC to exit menu.

key and PgDn key to change

6.4.2.3 Dry Contact Alarm Configuration B

The alarm mode is programmed as follows:

No. Static Transfer Switch No. Inverter

01 Inverter unavailable 01 Inverter fault

02 Main unavailable 02 Inverter over load

03 Output overload 03 Inverter fan fault

04 Output short circuit 04 Power limit

05 K1 relay open 05 DC input abnormal

06 STS SCR1 short 06 Inverter low volt off

07 STS SCR2 short

08 Inverter bypass mode

09 Over temperature 01 DC input low

10 MBS position abnormal 02 Controller temperature high

11 STS fan lock 03 Controller EPROM fault

12 STS fault mode 04 DC input over

13 STS Eeprom fault 05 CAN bus off

No. Controller

Table K–Dry contact alarms

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 28 of 43

Page 39

7 Default Values

Setting Default Value

STS priority On-line

Mains high loss volt 138V

Mains low loss volt 100V

Inverter input high loss volt for STS 138V

Inverter input low loss volt for STS 100V

Inverter output high loss volt 138V

Inverter output low loss volt 100V

Inverter shutdown due to low input volt 40V

Inverter shutdown due to high input volt 60V

Inverter output volt 120V

Inverter output volt frequency 60Hz

Inverter output power limit 100%

Setting Default Value

STS priority On-line

Mains high loss volt 264V

Mains low loss volt 185V

Inverter input high loss volt for STS 264V

Inverter input low loss volt for STS 185V

Inverter output high loss volt 264V

Inverter output low loss volt 185V

Inverter shutdown due to low input volt 40V

Inverter shutdown due to high input volt 60V

Inverter output volt 230V

Inverter output volt frequency 50Hz

Table L–120Vac system factory defaults

Table M–230Vac system factory defaults

Setting Default Value

RS-232, RS-422, RS-485 communication baud rate 2400bps

RS-422 address 9999

Button tone On

LCD brightness value 45

Language English

Password 1234

Dry contact 1 Inverter overload

Dry contact 2 Inverter unavailable

Dry contact 3 Inverter fan fault

Dry contact 4 STS fan fault

Dry contact 5 Inverter power limit

Table N–System parameter factory defaults

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 29 of 43

Page 40

Alarm Type Alarm Name Level

Inverter fault Major Inverter fault

Inv over load Observe Inverter Over-loading

Inv fan fault Major Inverter Fan fault

Inv low volt off Major Inverter shut down due to low input voltage

Inv Bus High Critical Bus voltage over the maximal level

Inv Bus Low Critical Bus voltage under the minimal level

Inv BusSoft fail Critical Bus Soft Start Fail

Inv Output short Critical Inverter Output Short

Inverter

STS

Controller

Inv OPV Low Critical Inverter output voltage low

Inv OPV High Critical Inverter output voltage high

Inv Temp High Critical Inverter Temperature High

NegPow Protect Critical Inverter negative power protection

SynPulse fault Critical Sync Pulse Fault

Inv EPO Critical EPO

SoftStart fail Critical Inverter soft start fail

Eeprom fail Major Inverter EEPROM fault

Inv Temp High Critical Inverter temperature high

Inv unavailable Major Inverter unavailable

Main unavailable Major Mains unavailable

Output overload Major Output over load

OP Short circuit Critical Output short circuit

K1 Relay open Major Back-feed relay open

STS SCR1 short Critical SCR1 short circuit

STS SCR2 short Critical SCR2 short circuit

INV Bypass Mode Critical Inverter bypass mode

Over temperature Major STS temperature high

MBS Abnormal Critical MBS in abnormal position

STS Fan Lock Major STS fan fault

STS fault mode Critical STS running in fault mode

STS Eeprom Fault Major EEPROM fault

SPS Power Fail Critical Control power fail

OutPut Abnormal Critical STS output normal

Inv lost Critical Inverter lost

STS lost Critical STS lost

DC input low Critical Bat Volt Low

Cont temp high Critical Controller temperature High

Cont eeprom fail Major Controller EEPROM fault

DC input Over Critical Bat voltage high

CAN Bus Off Critical Controller CAN bus off

Remark

Table O–Alarm code factory defaults

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 30 of 43

Page 41

8 Maintenance

Although very little maintenance is required with INEX systems, routine checks and adjustments by qualified

service personnel are recommended to ensure optimum system performance.

The following table lists the maintenance procedures for this system. These procedures should be performed at

least twice a year.

WARNING: HIGH VOLTAGE AND SHOCK HAZA RD.

Use extreme care when working inside the shelf while the system is energized.

Do not make contact with live components or parts.

Circuit cards, including RAM chips, can be damaged by static electricity. Always wear a grounded

wrist strap when handling or installing circuit cards.

Procedure Date Completed

Clean ventilation openings

Inspect all system connections (re-torque as necessary)

Verify alarm/control settings

Verify alarm relay operation

Table P–Sample maintenance log

8.1 Inverter Fan Replacement

1. Unlock the inverter and slide the module 10 cm (4”) out of the shelf. Wait two minutes for module capacitors

to discharge.

2. Remove the six (6) screws that secure the front cover to the module.

3. Gently slide the front cover (with the fans) out of the module case.

4. Disconnect the fan power connectors (one per fan).

5. Note the direction of airflow and remove the fans from the assembly.

6. Install the replacement fans following the preceding steps in reverse order.

Fan power connectors

Screw hole (6 places)

for front panel

Fan screw (2 per fan)

Front cover w/fans

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 31 of 43

Page 42

8.2 STS Fan Replacement

1. Unlock the STS and slide the module 10 cm (4”) out of the shelf. Wait two minutes for module capacitors to

discharge.

2. Remove the six (6) screws that secure the front cover to the module.

3. Gently slide the front cover (with the fans) out of the module case.

4. Disconnect the fan power connectors (one per fan).

5. Note the direction of airflow and remove the fans from the assembly.

6. Install the replacement fans following the preceding steps in reverse order.

Screw hole (6 places)

for front panel

8.3 Replacement Parts

The INEX Inverter System offers a complete spare parts kit for each model number. Spare parts kits include the

power modules. Parts (those included in the spare parts kit) can be ordered individually or as a complete parts kit.

Fan power connector

(2 places)

Fan screw (2 per fan)

Front cover w/fans

To order an individual part, give the full description along with the complete model and part number.

UModel Number Description Part Number

INV-4810A 1000VA/800W inverter module (I/P: 48Vdc, O/P: 120Vac, 50/60Hz).................014-114-10

INV-4810EA 1000VA/800W inverter module (I/P: 48Vdc, O/P: 230Vac, 50/60Hz).................014-115-10

INV-4815A 1500VA/1200W inverter module (I/P: 48Vdc, O/P: 120Vac, 50/60Hz)...............014-116-10

INV-4815EA 1500VA/1200W inverter module (I/P: 48Vdc, O/P: 230Vac, 50/60Hz) ...............014-117-10

MC-1000A Controller module................................................................................................018-593-10

STS-050A 50A static transfer switch module .......................................................................019-050-10

Fan INEX inverter/STS module fan............................................................................500-419-10

Cover INEX inverter shelf rear cover .............................................................................614-844-10

Cover INEX STS shelf rear cover, large........................................................................614-845-10

Cover INEX STS shelf rear cover, small .......................................................................614-846-10

Argus Technologies Ltd. 014-114-C0 Rev D WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved. Page 32 of 43

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

Page 43

9 Troubleshooting

If the system fails to operate properly after having the installation and setup of the system thoroughly reexamined, use the following troubleshooting table to determine the probable cause(s) and solution(s) to resolve

error conditions. For unlisted error conditions, please contact your local dealer for technical assistance.

Error Condition Possible Cause Recommendation

Improper position of nylon guide pin.

Inverter module cannot

be properly inserted.

No AC output

and all LEDs off.

No AC output.

Both green and yellow

LEDs flicker.

No AC output.

Both yellow and red

LEDs are on.

No AC output.

Red LED is on.

Red LED blinks fast.

AC output exists with

yellow LED flickering.

AC output exists and