Alpha INEX 100A STS User Manual

INEX 100A STS Module

and MBS+PDU

User Manual

019-061-B2

This page intentionally left blank.

Argus Technologies Ltd. Visit www.argus.ca

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233

Argus Technologies reserves the right to make changes to the products and information contained in this document without notice.

Copyright 2009 Argus Technologies Ltd. Argus

Printed in Canada.

®

is a registered trademark of Argus Technologies Ltd. All Rights Reserved.

INEX 100A STS Module and MBS+PDU

User Manual

019-061-B2

Applies to 019-061-10, 030-440-10, 020-438-10, and 018-593-1 0.

The following documents and drawings are included in this manual to provide the necessa ry information required for

installation, operation and fault diagnosis of the unit:

• Specifications: 019-061-B1

• Installation and Operation Instructions: 019-061-C0

• Service Centers: 048-693-10

Argus Technologies Ltd. 019-061-B2 Rev A WC

Printed in Canada. © 2009 Argus Technologies Ltd. ARGUS and INEX are registered trademarks of Argus Technologies Ltd. All Rights Reserved.

This page intentionally left blank.

Specifications for INEX 100A STS Module and MBS+PDU

DC Auxiliary Power Input

Operating Range: 40 to 60Vdc within rated limits

AC Input

Voltage Range: 110/115/120Vac: 89 to 138Vac

208/220/230/240Vac: 176 to 276Vac

Over Voltage Threshold: 276 / 138Vac

Under Voltage Threshold: 176 / 89Vac

Back-feed Protection: Comply with safety requirement

Redundant Power Supply Design: Startup by priority source or alternative

NOTE: the over/under voltage must be set by controller, if there is no additional setting, STS will adopt the widest range

to set over/under voltage in order to guarantee its performance, for 110/115/120Vac system, the range is 89Vac

(under voltage point) to 138Vac (over voltage point), for 208/220/230/240Vac system, the range is 176Vac (under

voltage point) to 276Vac (over voltage point). But once the STS is set by user, it will keep the setting whether a

controller exists or not, until such time that the STS is set by user again or next time the source connected to STS

is changed from 120V (110/115/120) to 230V (208/220/230/240) or 230V (208/220/230/240) to 120V

(110/115/120).

AC Output

Waveform: Sinusoidal

Nominal Output Voltage: Same as mains AC or the output of inverter modules

Permissible Frequency Area: Max. ±2.5% (synchronize area of inverter)

Transfer Time: Typical 1/4 cycle, DIN VDE 0558 Part 5; IEC 146-4

Rated Power: 100A for 120 / 230Vac

Operation Methods: Inverter priority / Mains priority

Over Load Capability: 1.2 x Inom ≥ 20s

1.6 x Inom ≥ 5s

3200A ≤ 10ms (Mains bypass)

Inom = 100A

Argus Technologies Ltd. 019-061-B1 Rev A WC

Printed in Canada. © 2009 Argus Technologies Ltd. ARGUS is a registered trademark of Argus Technologies Ltd. All Rights Reserved. Page 1 of 2

Specifications for INEX 100A STS Module and MBS+PDU Continued

Mechanical

STS Module: Dimensions: 88mm H x 218mm W x 270mm D

[3.5" H x 8.6" W x 10.6" D]

Weight: 2.1 kg (4.6 lb.)

STS Shelf: Dimensions: 88.1mm H x 483mm W x 330mm D

[3.5" H x 19" W x 13" D]

Weight: 7.0 kg (15.4 lb.)

Hot Swappable: STS hot swappable only available when MBS at Mains Bypass and

Inverter Bypass position

Mechanical Bypass Switch Requirement: The STS module used with a Mechanical Bypass Switch module shall

provide voltage free system maintenance. It should be interlocked with

the static switch module so that the static switch module cannot be

removed without the maintenance bypass being activated.

Force Cooling: Two fans

Alarm Relay: Dry contact alarm output

Environmental

Operating Temperature: -20 to +70°C (-4 to +158°F)

-20 to +50°C (-4 to +122°F) with full performance

Storage Temperature: -30 to +85°C (-22 to +185°F)

Operating Humidity: 0 to 95% relative, non-condensing

Heat Dissipation: Forced air cooling

Operating Altitude: 1500m (4922 feet)

Audible Noise: 55dB ETS 300 753 Class 3.1

Standards

Safety Compliance: EN 62040-1-1/IEC 62310-1/UL-1778

Certification: CE, UL

RoHS: Compliant

EMC: EN55022 Class B

MTBF: >200,000 hours as per Telcordia SR-332

The above information is valid at the time of publication. Consult factory for up-to-date ordering information. Specifications are subject to change without notice.

Argus Technologies Ltd. 019-061-B1 Rev A WC

Printed in Canada. © 2009 Argus Technologies Ltd. ARGUS is a registered trademark of Argus Technologies Ltd. All Rights Reserved. Page 2 of 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This section contains important instructions that should be followed during the installation and maintenance of

equipment and batteries. Please read all of the instructions before operating the equipment, and save this

manual for future reference.

The following safety symbols will be found throughout this manual, carefully read all information and abide by the

instructions:

DANGEROUS VOLTAGE

This symbol indicates a dangerous voltage

exists in this area of the product.

GAS HAZARD

This symbol indicates a gas hazard

exists in the area of vented batteries.

NO MATCHES OR OPEN FLAMES

This symbol indicates a fire or explosive hazard

exists in the area of the product.

The following levels of warning will be used with the above symbols:

DANGER: You WILL be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

WARNING: You CAN be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

CAUTION: You CAN be INJURED or equipment can be DAMAGED if instructions are not followed closely.

Before using the product, read all instructions and cautionary markings on the product and any equipment

connected to the product.

This unit is designed for indoor use only. Do not expose the product to rain or snow; install only in a clean, dry

environment.

CAUTION – To reduce the risk of fire hazard, do not cover or obstruct the ventilation openings. Do not install the

inverter in a zero-clearance compartment.

CAUTION – Unless otherwise noted, use of an attachment not recommended or sold by the product manufacturer

may result in a risk of fire, electric shock, or injury to persons.

CAUTION – Do not operate the product if it has received a sharp blow, it has been dropped, or otherwise

damaged in any way – return it to a qualified service center for repair.

CAUTION – Do not disassemble the product – call our qualified service centers for servici ng. Incorrect

reassembling may result in a risk of electrical shock or fire.

WARNING – The input and output voltages of the product are hazardous. Extreme caution should be maintained

when servicing or touching conductive components conne cted to the product.

Mechanical Safety

Power equipment can reach extreme temperatures under load.

Use caution around sheet metal components and sharp edges.

Electrical Safety

WARNING

To avoid a risk of fire and electric shock, make sure that existing wiring is in good condition and

that wire is not undersized. Do not operate the inverter with damaged or substandard wiring.

Before working with any live battery or power system, follow these precautions:

• Remove all metallic jewelry; e.g., watches, rings, metal rimmed glasses, necklaces.

• Wear safety glasses with side shields (and prescription lenses if necessary) at all times during installation.

• Use OSHA approved insulated hand tools.

Do not work alone under hazardous conditions.

Ensure no liquids or wet clothes contact internal components.

Battery Safety

Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

Never reverse DC+ and DC- to battery.

Keeps the battery away from heat sources including direct sunlight, open fires, microwave ovens and high-voltage

container. Temperatures over 60ºC may cause damage. Make sure the area around the battery is well ventilated.

Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all

metallic objects from hands and neck.

Use OSHA approved insulated hand tools. Do not rest tools on top of batteries.

Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Battery post terminals and related accessories contain lea d and lead compounds; wash hands

after handling (California Proposition 65).

If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters your eye,

immediately flood it with running cold water for at least twenty minutes and get medical attention immediately.

If you need to remove a battery, always remove the grounded terminal from the battery first. Make sure all

accessories are off so you don’t cause a spark.

WARNING

Follow battery manufacturer’s safety recommendations when working around battery systems.

WARNING

Do not smoke or present an open flame when batteries (especially vented batteries) are on

charge. Batteries vent hydrogen gas when on charge, which creates an explosion hazard.

Batteries are hazardous to the environment and should be disposed of safely at a recycling facility. Consult the

battery manufacturer for recommended local authorized recycl ers.

Wiring Requirements

Inverter is intended to be installed as part of a permanently grounded electrical per the National Electric Code

ANSI/NFPA 70 (current edition). This is the single point earth ground for the unit.

The ground on the inverter is marked with this symbol: G /

The AC voltage and current on the inverter is marked with this symbol: L / N

The DC voltage and current on the inverter is marked with this symbol:

TABLE OF CONTENTS

SECTION PAGE

1 INTRODUCTION .............................................................................................................................................................1

1.1 Scope of the Manual..................................................................................................................................... 1

1.2 Product Overview............................................................................................................... ...........................1

1.3 Illustration of Operation.................................................................................................................................2

1.4 STS Operating Principles.............................................................................................................................. 2

1.5 Voltage and Frequency Range.....................................................................................................................5

2 INSPECTION..................................................................................................................................................................6

2.1 Packing Materials..........................................................................................................................................6

2.2 Check for Damage........................................................................................................................................ 6

2.3 Handling and Storage ...................................................................................................................................7

3 INSTALLATION..............................................................................................................................................................8

3.1 Location......................................................................................................................................................... 8

3.2 Frame Assembly...........................................................................................................................................8

4 WIRING......................................................................................................................................................................10

4.1 Inverter Shelf Wiring With STS Chassis .....................................................................................................11

4.2 STS Shelf Wiring With MBS/PDU...............................................................................................................13

5 STS MODULE INSTALLATION......................................................................................................................................15

5.1 Installation Check........................................................................................................................................15

6 OPERATION................................................................................................................................................................16

6.1 MBS Position (0—Low, 1—High)................................................................................................................16

7 MAINT E NANCE AN D TROUBLESHOOTING...................................................................................................................... 18

7.1 Preventative Maintenance ..........................................................................................................................18

7.2 Troubleshooting Guide................................................................................................................................ 18

8 ARGUS CONVENTIONS................................................................................................................................................24

8.1 Numbering System......................................................................................................................................24

8.2 Acronyms and Definitions ...........................................................................................................................24

9 OUTLINE DRAWINGS...................................................................................................................................................25

This page intentionally left blank.

1 Introduction

1.1 Scope of the Manual

This instruction manual explains the features, installation, startup and maintenance of the INEX 100A STS

Module and MBS+PDU.

NOTE: Images contained in this document are for illustrative purposes only and may not exactly match your installation.

1.2 Product Overview

The STS (Static Transfer Switch) module increases system reliability by automatically switching between the

inverter output and the AC mains. By setting up the priority of operation mode, users can change the system

status of “on line mode” or “off line mode”. The on line mode will keep the input power provided by inverter line

and when inverter fails, the line will switch to AC utility line. In off line mode, the system power is always

connected to the AC utility line and will switch to inverter power line when AC utility fails. The transfer time is less

than 1/4 cycle which can avoid the power interruption. The reliable performance of the STS module can provide

the maximum protection to the connected telecommunication equipment against possible da mage caused by the

system power failure.

STS Module Features:

• Small footprint and weight

• Universal input range

• Hot-swap replacement in shelf (w/ MBS option)

• Back-feed protection

• Redundant fan design

• Fast transfer time, typically less than 1/4 cycle

• Low audible noise <55dBa

• No cross connect

• Optional maintenance bypass switch function

• Operation Priority Setup of transfer side by setting in Control Module

Figure 1–INEX 100A STS Module and MBS+PDU

Argus Technologies Ltd. 019-061-C0 Rev A WC

Printed in Canada. © 2009 Argus Technologies Ltd. ARGUS is a registered trademark of Argus Technologies Ltd. All Rights Reserved. Page 1 of 26

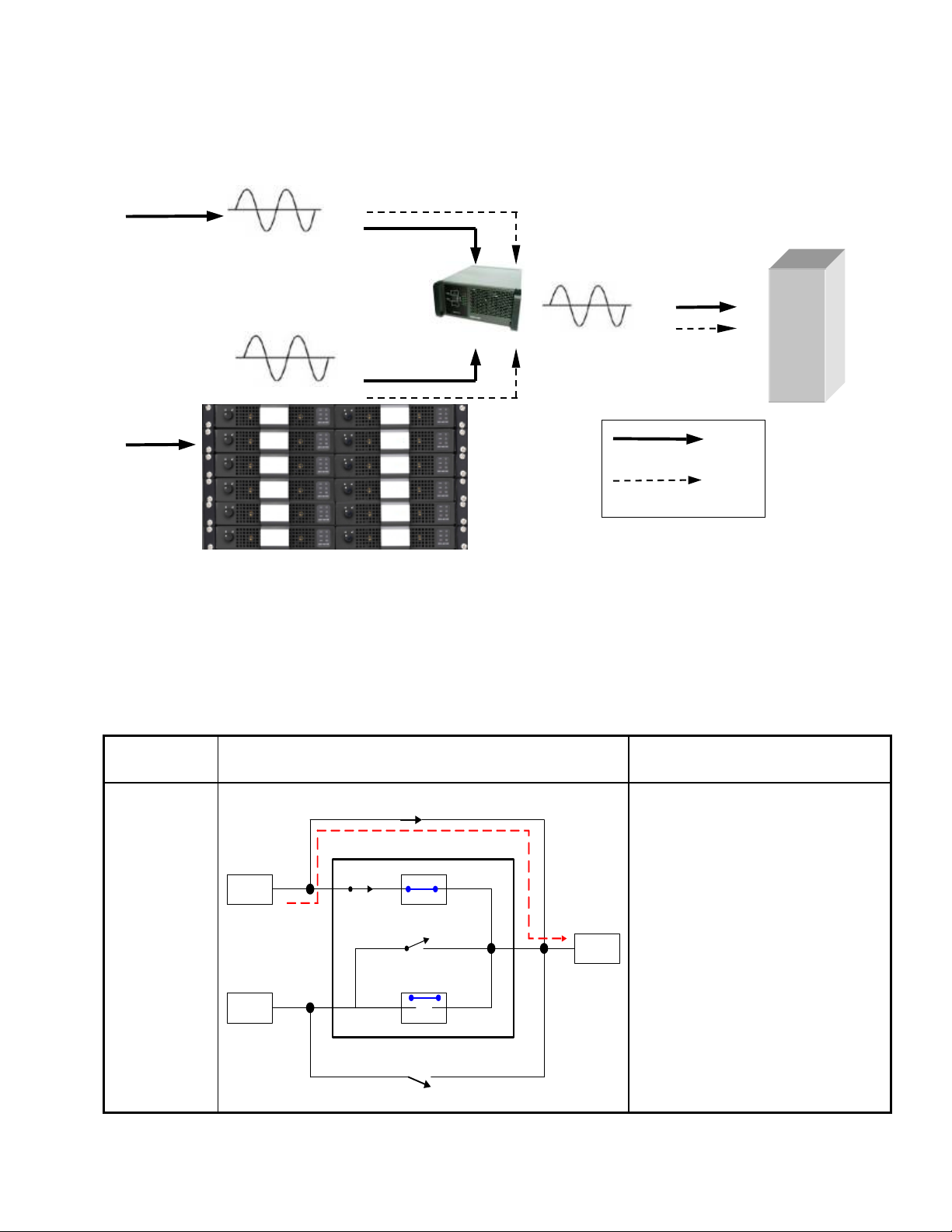

1.3 Illustration of Operation

STS-100 is designed to avoid operational disruptions of critical loads. This automatic static transfer switch (STS)

automatically transfers critical loads from the primary AC power source to an alternative AC power source in the

event of interruption or abnormal conditions.

Alternative AC Source

(UPS, generator, utility)

Sine Wave Output

STS Module

Inverter Output Voltage

Load

Power Line

Communication Line

Figure 2–STS-100 operation illustrated

STS-100 transfers the critical load between power sources in less than 1/4 cycle upon loss of sou r ce. The fast

transfer enables further redundancy in distribution, adding level of availability, flexibility and reliability to our

customer’s power infrastructure.

1.4 STS Operating Principles

MBS Status Schematic operating principle of STS Description

Mains

Mains

Bypass

(P1)

Inverter

MBS Main Contact1

Backfeed Relay

Bypass Relay

SCR1

SCR2

MBS Main Contact2

Load

Mains Bypass:

Load is powered through the

MBS by Mains AC

STS can be removed from the

system

MBS can only be switched

from P1 to P2 position

SCR2 open, SCR1 and Back-

feed Relay closed

Argus Technologies Ltd. 019-061-C0 Rev A WC

Printed in Canada. © 2009 Argus Technologies Ltd. ARGUS is a registered trademark of Argus Technologies Ltd. All Rights Reserved. Page 2 of 26

Loading...

Loading...