Industrial Ni-Cd Batteries Standard Range

Technical Manual

Effective: October, 2009

Alpha Technologies

Alpha Technologies

Power

®

Alpha Ni-Cd Pocket Plate Battery

Technical Manual

EN-Alpha-TMSR-001

Effective Date: October, 2009

Copyright© 2009

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

Contacting Alpha Technologies: www.alpha.com

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

EN-ALPHA-TMSR-001 (10/09)

or

1-800-863-3930,

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

3

Table of Contents

1. 0 Alpha Ni-Cd Pocket Plate Cell ..................................................................................................................... 6

1.1 Features. ...................................................................................................................................................................................6

1.2 Venting System ..................................................................................................................................................................... 7

1.3 Electrode frame ....................................................................................................................................................................8

1.4 Separators .............................................................................................................................................................................. .8

1.5 Positive and negative electrode plate .........................................................................................................................8

1.6 Distance plate .......................................................................................................................................................................9

1.7 Cell cases .................................................................................................................................................................................9

1.8 Electrolyte ...............................................................................................................................................................................9

2. 0 Battery Range and Applications .......................................................................................................................................... 10

2.1 Battery ranges .................................................................................................................................................................... 10

2.2 Applications and choice of cell type ......................................................................................................................... 10

3.0 Electrochemistry of Ni-Cd Batteries .................................................................................................................................. 11

4. 0 Operating Features .................................................................................................................................................................... 12

4.1 Capacity .............................................................................................................................................................................. .12

4.2 Cell voltage .......................................................................................................................................................................... 12

4.3 Internal resistance ............................................................................................................................................................ 12

4.4 Impact of temperature on cell performance and available capacity .............................................................. 13

4.5 Impact of temperature on lifetime .............................................................................................................................. 14

4.6 Short-circuit values .......................................................................................................................................................... 14

4.7 Open circuit loss................................................................................................................................................................. 15

4.8 Cycling .................................................................................................................................................................................. 15

4.9 Water consumption and gas evolution ..................................................................................................................... 16

5.0 Battery Sizing. ............................................................................................................................................ 17

5.1 Voltage window ................................................................................................................................................................. 17

5.2 Load profi le ......................................................................................................................................................................... 17

5.3 Ambient temperature ...................................................................................................................................................... 17

5.4 Recharge time and state of charge ............................................................................................................................. 17

5.5 Aging ..................................................................................................................................................................................... 17

5.6 Floating effect - Voltage depression ........................................................................................................................... 18

6.0 Charging .................................................................................................................................................... 19

6.1 Constant voltage charge ................................................................................................................................................. 19

6.2 Charge acceptance .......................................................................................................................................................... 20

6.3 Charge effi ciency .............................................................................................................................................................. 21

6.4 Temperature infl uence ................................................................................................................................................... 22

6.5 Commissioning .................................................................................................................................................................. 22

4

EN-ALPHA-TMSR-001 (10/09)

Table of Contents

7.0 Installation and operating instructions .................................................................................................. 23

7.1 Receiving the battery ...................................................................................................................................................... 23

7.2 Storage ................................................................................................................................................................................. 23

7.2.1 Uncharged and unfi lled cells ...........................................................................................................................23

7.2.2 Charged and fi lled cells/discharged and fi lled cells ................................................................................ 23

7.3 Installation ............................................................................................................................................................................. 23

7.3.1 Location ................................................................................................................................................................... 23

7.3.2 Ventilation ............................................................................................................................................................... 23

7.3.3 Setting up ................................................................................................................................................................ 24

7.3.4 Electrolyte ............................................................................................................................................................... 24

7.3.5 Commissioning ..................................................................................................................................................... 25

7.3.5.1 Commissioning with constant current ............................................................................................ 25

7.3.5.2 Commissioning with constant voltage ............................................................................................ 26

7.4 Charging in operation ..................................................................................................................................................... 27

7.4.1 Continuous battery power supply (with occasional battery discharge) .......................................... 27

7.4.1.2 Two level charge ...................................................................................................................................... 27

7.4.1.3 Single level charge .................................................................................................................................. 27

7.4.2 Buffer operation ................................................................................................................................................... 27

7.5 Periodic Maintenance ...................................................................................................................................................... 27

7.5.1 Equalising charge ................................................................................................................................................. 27

7.5.2 Electrolyte check and topping up .................................................................................................................. 28

7.5.3 Replacing of electrolyte ..................................................................................................................................... 28

7.5.4 Electrolyte temperature ..................................................................................................................................... 28

7.6 Additional warning notes ............................................................................................................................................... 29

Figures, Graphs & Tables

Fig.1-1 Cutaway view of battery ................................................................................................................................... 6

Fig.1-2 Battery vents .........................................................................................................................................................7

Fig.1-3 Battery terminal cross-section ........................................................................................................................7

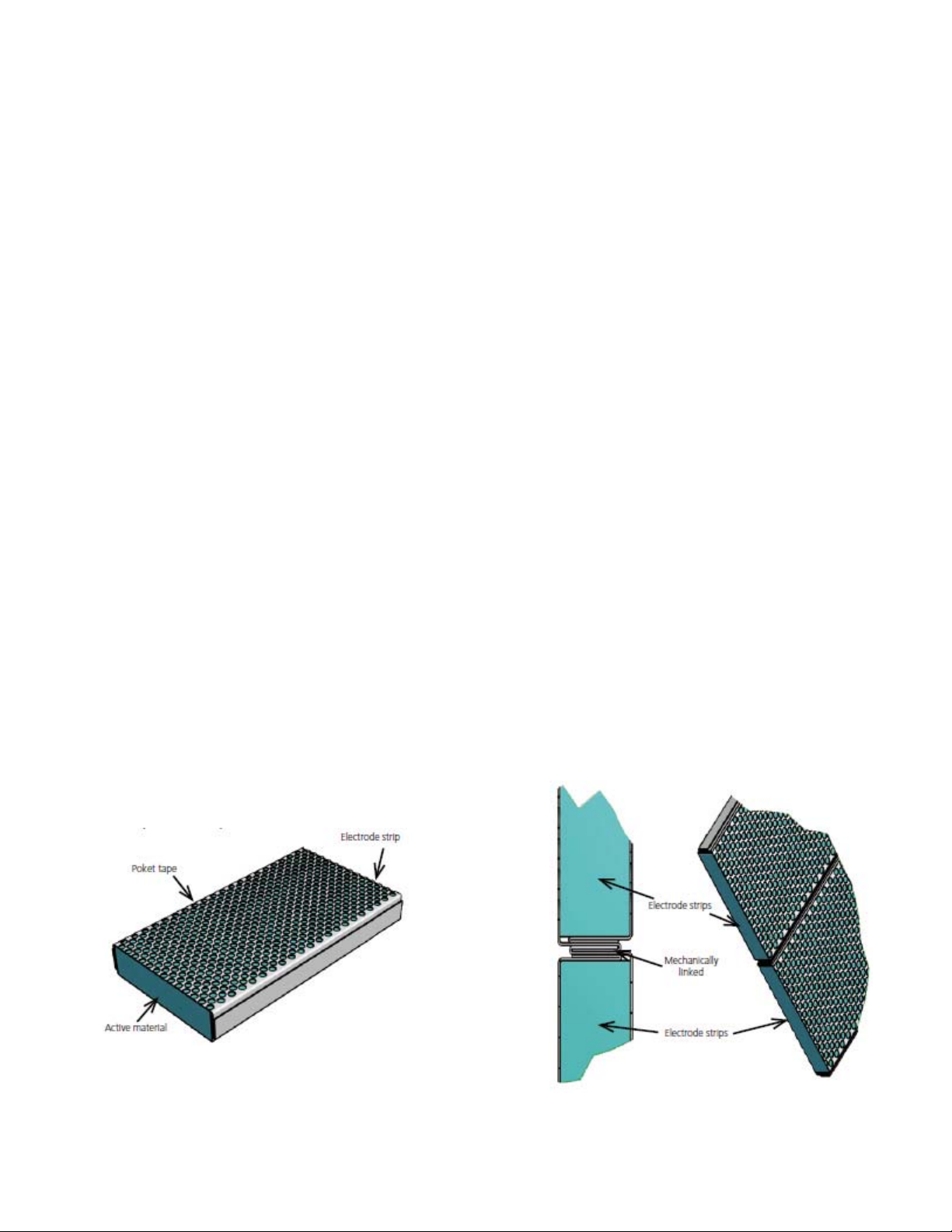

Fig.1-4 Components of the Electrode plates ...........................................................................................................8

Fig.1-5 Electrode plate linkage .....................................................................................................................................8

Fig.7-1 Terminal connection with Nuts ................................................................................................................... 24

Fig. 7-2 Terminal connection with Screws ..............................................................................................................24

Graph 4-1 NiCd-cell performance varation with temperature ............................................................................. 13

Graph 4-2 NiCd vs. Pb-acid battery lifetimes at 25°C .............................................................................................. 14

Graph 4-3 Self-discharge of NiCd-accumulators (fully charged) .........................................................................15

Graph 4-4 Cycle life vs. depth of discharge .................................................................................................................. 15

Graph 4-5 Relationship between water loss and charging voltages ................................................................. 16

Graph 5-1 Floating derating factor as a function of discharge time ..................................................................18

Graph 6-1 Time to reach state of charge (M-Range) ................................................................................................ 20

Graph 6-2 Time to reach state of charge (L-Range) .................................................................................................. 20

Graph 6-3 Time to reach state of charge (H-Range) ................................................................................................. 21

Graph 6-4 Temperature-corrected Float Voltage ....................................................................................................... 22

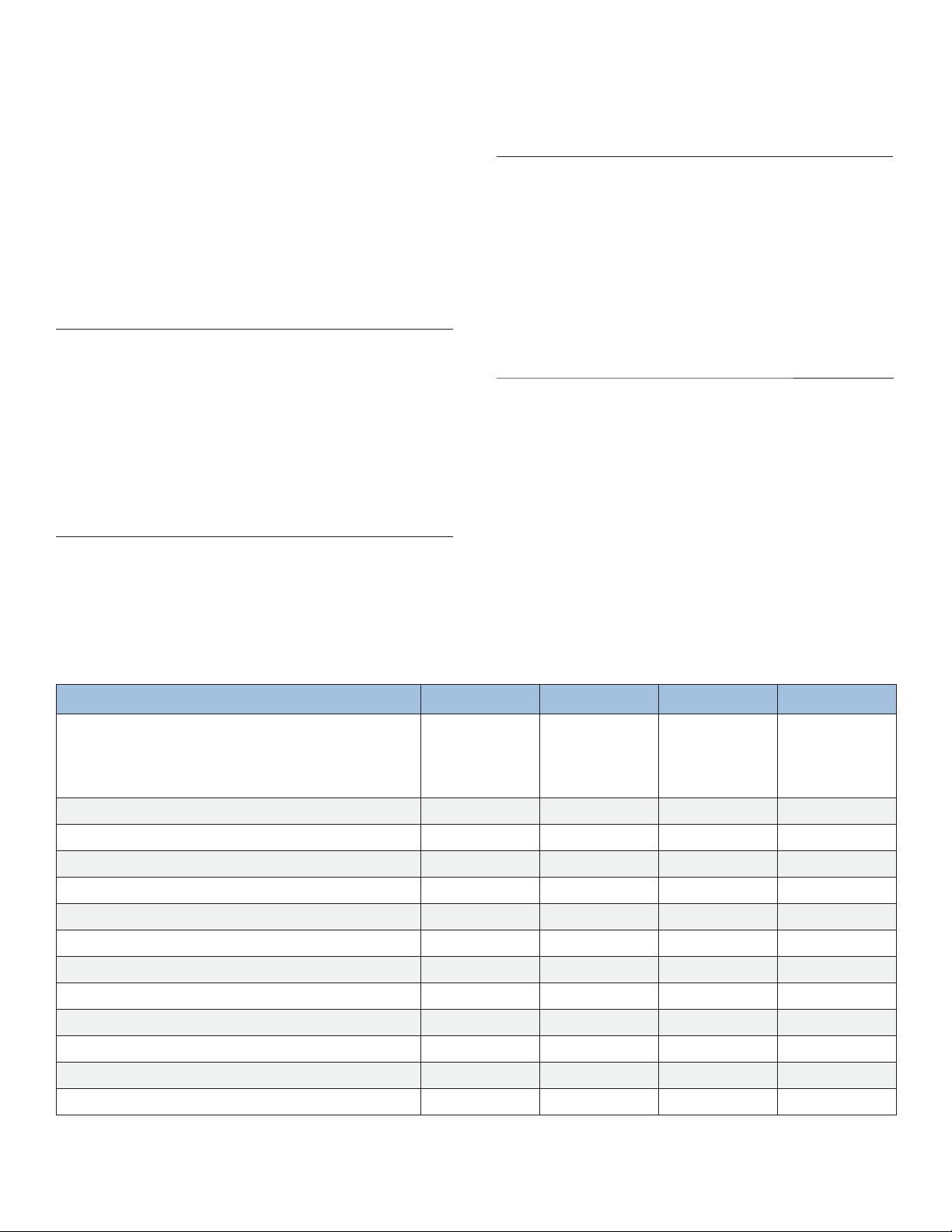

Table 2-1 Battery (cell type) selection matrix ............................................................................................................ 10

EN-ALPHA-TMSR-001 (10/09)

5

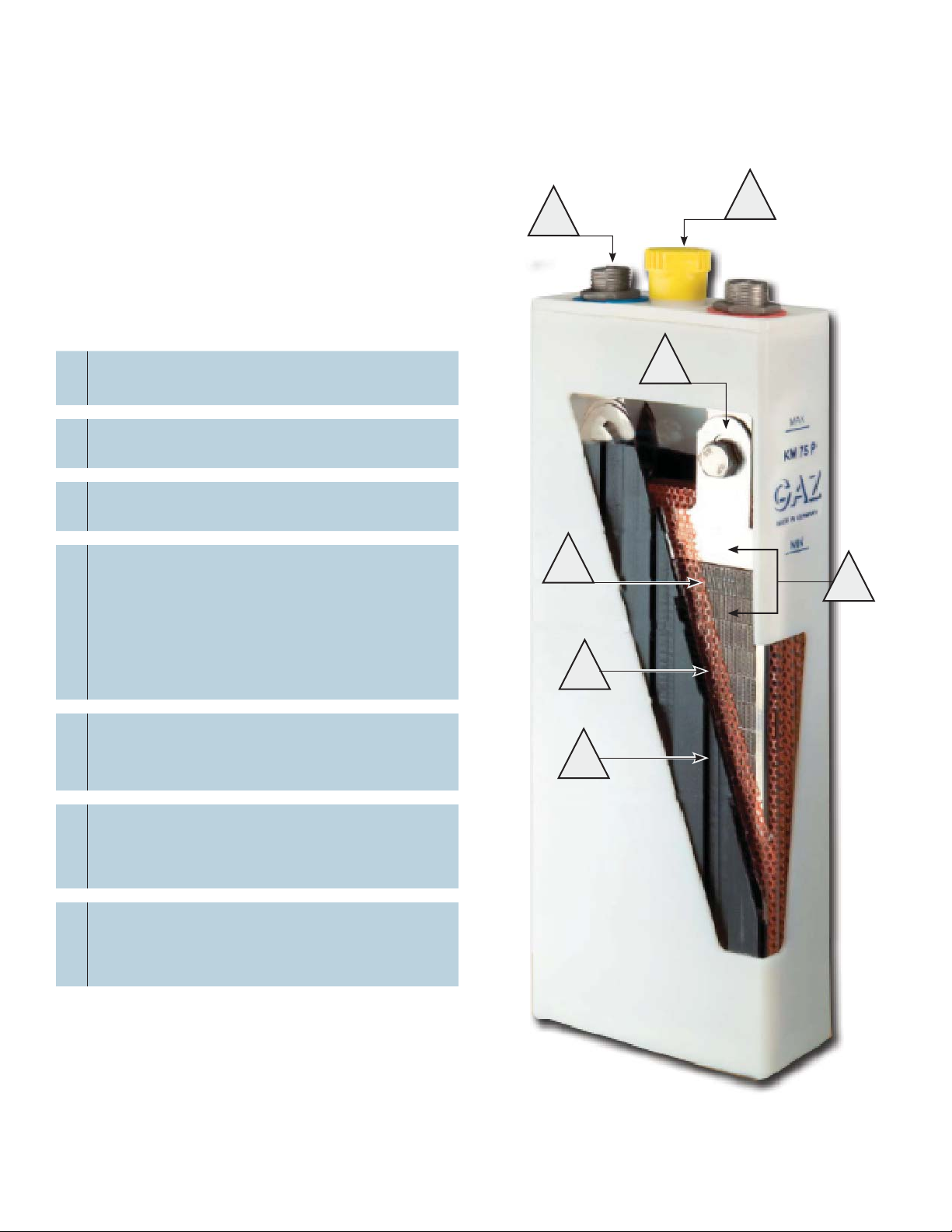

1.0 Alpha Ni-Cd pocket plate cell

1.1 Features

1

2

Low-pressure, fl ame-arresting vent; prevents

1

carbonate formation.

Safety terminal; Redundant leak protection

2

minimizes carbonate formation.

Electrode edge; connected to pole bolt via

3

hardware for high mechanical stability

Electrode frame; Comprised of electrode edge

and side bars. Seals the plates and serves as a

current collector Horizontal pockets; formed by

4

perforated steel strips containing the active material.

Corrugated, perforated plastic separator.

Insulates the plates and allows the free circulation

5

of electrolyte.

3

5

4

6

7

Fiber mat separator; special separator

insulates the plates and improves the internal

6

recombination.

Distance Plate; Prevents movement of the

7

electrode pack.

6

Fig.1-1 Cutaway view of battery

EN-ALPHA-TMSR-001 (10/09)

1.0 Alpha Ni-Cd pocket plate cell, continued

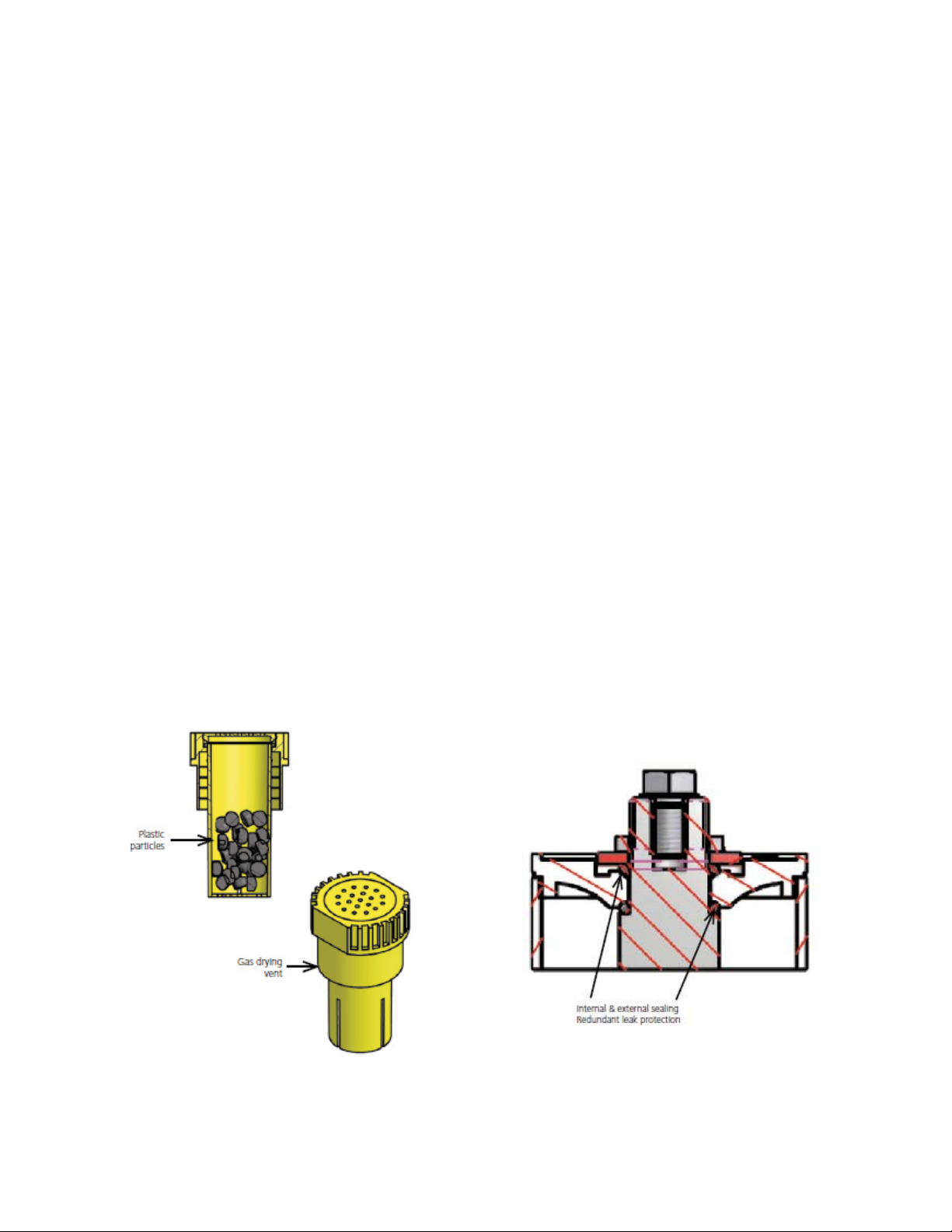

1.2 Venting System

Alpha batteries can be equipped with a normal fl ip-top vent or with a special gas drying as well as a fl ame

arresting vent.

The originated charging gases (hydrogen and oxygen), which occur during the charging process

of Ni-Cd batteries carry also small electrolyte drops of the electrolyte solution. This accellerates the decline of the

electrolyte level in comparison to the normal water decomposition during overcharging, resulting in more frequent

maintenance. Furthermore, a strong incrustation of the fi lling vents can be due to the creation of carbonate.

The use of the gas drying or fl ame arresting vents reduces the build-up of carbonate material. The vents

contain small plastic particles with a large surface area which capture the electrolyte drops. The capturing of the

electrolyte keeps it in the cell and prevents the build-up of carbonate.

The additional feature of the fl ame arresting vent is the microporous disc on the top. This feature results in a

diffused leakage of the charging gases. Moreover, high local concentrations can be prevented which fi nally leads

to a lower risk of fl ammability. According to IEC 60623 the total amount of entrained potassium hydroxide shall be

not more than 0.05 mg/ Ah during 2 hours overcharge. Alpha batteries with the special venting system improve

the required value many times over to 0.011 mg/ Ah during 2 hours overcharge.

A specially developed terminal design with redundant leak protection prevents any leakage of electrolyte. Depending on the cell range and type terminals are designed as female or male thread and polarity is colored marked.

Fig.1-2 Battery vents Fig.1-3 Battery terminal cross-section

EN-ALPHA-TMSR-001 (10/09)

7

1.0 Alpha Ni-Cd pocket plate cell, continued

1.3 Electrode frame

The electrode frame of Alpha Ni-Cd-batteries consists of a right and a left side bar as well as the electrode edge

which are connected by welding shaping the electrode frame. The electrode frame operates as a current collector

and also seals the electrode plates. This procedure leads to an electrode design with high mechanical robustness

but also ensures a reliable service for the complete lifetime of the battery.

1.4 Separators

The separation of the electrodes is ensured by a corrugated perforated plastic (M- and L-types) or plastic grid

separator (H-types). The plastic grid separator is used for high discharge types (H-types) in order to achieve a

superior cell performance caused by a lower internal resistance, which is very typical and necessary for their

high discharge currents. The separator also ensures a large space between the electrodes, which allows free

circulation of the electrolyte and a good dissipation of the gases generated during end of charging.

1.5 Positive and negative electrode plate

The nickel-cadmium cell is composed of the positive plates containing nickel hydroxide and the negative plates

containing cadmium hydroxide. The pockets formed from a nickel plated and perforated steel tape, the so-called

pocket tape, infold strips of the active material.

The electrode strips are mechanically linked together forming the electrode plate and cut to size appropriate to the

width based on the cell type and range.

The plates then are welded or mechanically linked to the plate frame (see point 3) forming the electrodes - the

heart of the battery - and assembled to the plate block.

The basis for the extemely long useful lifetime and the very good cycle life features of the Ni-Cd pocket plate

batteries are the special plate designs whose structural components are made of steel. This prevents the

possibility of gradually deterioration by corrosion and since the alkaline electrolyte does not react with steel the

substructure of the battery remains intact for the total lifetime of the battery. Very important and unique is the

enfolding of the electrochemical active masses in the perforated nickel plated steel pockets, so that the risk of

shedding or penetration of material is very small and consequently also the risk of structural damages and of soft

short circuits is well under control.

Fig.1-4 Components of the Electrode plates Fig.1-5Electrode plate linkage

8

EN-ALPHA-TMSR-001 (10/09)

1.0 Alpha Ni-Cd pocket plate cell, continued

1.6 Distance plate

The distance plate operates as an additional stabilization to prevent any movement of the electrodes. It is an

additional feature for applications where vibrations are possible.

1.7 Cell cases

The cell cases are made from a translucent polypropylene or polystyrene, which ensures a visual control of

the electrolyte level. The exeptional sturdy Alpha cell cases provide a satisfactory service for the total lifetime

of the battery but also will have a superior fi nish at every stage. The lid and the container are welded or glued

together forming an integrative compound. All Alpha Ni-Cd cells have got a single cell design that prevents in the

greatest possible extend any leakage of the cell cases since they are made by injection molding out of one piece.

Therefore, the weld or glueseams of the cell cases and the lids lies over the electrolyte level. The Alpha single

cell design eliminates completely the risk of faulty welded seams on the sides and on the bottom of the cell cases.

Caused by the single cell design an economical replacement of faulty cells is possible, viz only the faulty cell can

be replaced. A special fl ame retardent material (acc. to standard UL 94 V0) is also available, which admittedly

brings along some impaired properties. By using this material a visual check of the electrolyte is no longer

possible.

1.8 Electrolyte

The electrolyte used in Alpha Ni-Cd batteries is a solution of potassium hydroxide and lithium hydroxide that

is optimized to give the best combination of performance, energy effi ciency and a wide temperature range of

use. The concentration of the standard electrolyte allows operations between - 30 °C and + 50 °C. For special

operations within very low temperatures a special high density electrolyte can be used. It is an important property

of the Alpha battery, and indeed all nickel-cadmium batteries, that the electrolyte does not change during charge

and discharge. It retains its ability to transfer ions between the cell plates, irrespective of the charge level. In most

applications the electrolyte will retain its effectiveness for the life of the battery and will never need replacing.

However, under certain conditions, such as extended use in high temperature situations, the electrolyte can

become carbonated. If this occurs the battery performance can be improved by replacing the electrolyte (see

“Maintenance and Handling Instructions”).

EN-ALPHA-TMSR-001 (10/09)

9

2.0 Battery Range and Applications

2.1 Battery ranges

In order to enable Alpha to offer an appropriate

solution in accordance with the customer's

requirements and to have a choice for any battery

application existing on the market, Alpha Ni-Cd

batteries are designed in four different performance

ranges.

KL ...P

This Alpha cell type has been especially designed

for low rates of discharge over long periods, viz the

current is relatively low in comparison with the total

stored energy. The discharges can generally be

infrequent and the recommended discharge time for

the KL ...P range is 1 hour to 100 hours.

KM ...P TP

The Alpha M type has been especially designed

for "mixed loads" that include a mixture of high

and low rates of discharge. It is used for frequent

and infrequent discharges and the recommended

discharge time is 30 min to 120min.

KM ...PN NON-STOP

This Alpha cell type is a further developed M type,

which provides caused by a special perforation

higher discharge currents for special application up

to 1 hour. It is especially used for UPS and similar

applications and the recommended discharge time is

10 min to 60 min.

KH ...P TSP

The Alpha H type was designed especially for high

current discharging over short discharge periods. The

recommended discharge time for this cell range is 1 s

to 30 min

2.2 Applications and choice of cell type

Alpha Ni-Cd batteries cover a wide range of

applications and are used in almost every sector,

no matter if it is a private, industrial, commercial,

governmental or military one. The table on page 8 on

which some examples can be found represents only

a small overview in te extended fi eld of applications.

Therefore, it is to be understood as a precept and

general information.

Rate of Discharge

Cell Type

Intercity and Urban Transport

Substations and signalling

UPS

Offshore and onshore oil and petrochemical refi neries

Emergency lighting

Telecommunication

Photovoltaic

Diesel start

Ship equipment

Electricity, gas & water production and distribution

Emergency supply

Alarm equipment

Table 2-1 Battery (cell type) selection matrix as a function of application and rate of discharge

L OW MEDIUM MEDIUM (M/N) HIGH

KL ...P

KL ...

KM ...P

KM ...

TP ...

T ...

KM ...P/N

KH ...P

KM ...

TSP ...

TS ...

XXXX

XXXX

XXXX

XXXX

X

XX

X

X

XXXX

XXXX

XX X

X

10

EN-ALPHA-TMSR-001 (10/09)

Loading...

Loading...