Page 1

IDH3

Technical Manual

DOCSIS® HMS Embedded Transponder

Effective: January 2010

Alpha Technologies

®

Page 2

Alpha Technologies

Power

®

2

745-420-B0-001 Rev. A

Page 3

IDH3

DOCSIS

®

HMS Embedded Transponder

Installation and Technical Manual

745-420-B0-001, Rev. A

Effective Date: January 2010

Copyright© 2010

Alpha Technologies, Inc.

A Member of the Alpha Group

Alpha denies responsibility for any damage or injury involving its enclosures, power supplies, generators,

batteries or other hardware, manufactured by Alpha or members of the Alpha Group, when used for an

unintended purpose, installed or operated in an unapproved manner, or improperly maintained.

Photographs and drawings contained in this manual are only for illustrative purposes. These photographs and

drawings may not exactly match your installation.

Review the written and illustrative information contained in this manual before proceeding. If there are

questions regarding the safe installation or operation of this product, please contact Alpha Technologies or

your nearest Alpha representative.

Contacting Alpha Technologies: www.alpha.com

OR

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

1-800-863-3930

For complete technical support, call

1-800-863-3364

745-420-B0-001 Rev. A

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

DOCSIS® is a Registered Trademark of CableLabs.

3

Page 4

Table of Contents

Safety Notes .......................................................................................................................... 6

1.0 Introduction to the DOCSIS® Transponder .................................................................7

1.1 System Overview ............................................................................................. 8

1.2 LED Indicators ............................................................................................... 10

2.0 Transponder Installation ............................................................................................11

2.1 Provisioning the Transponder .........................................................................11

2.1.1 Network Connectivity ...........................................................................11

2.1.2 Transponder Confi guration ................................................................. 12

2.2 Verifying Firmware Version and Device Address ...........................................13

2.3 Installing the Transponder Hardware .............................................................13

2.4 RF Connection ...............................................................................................15

2.5 Verifying Transponder Operation ................................................................... 15

3.0 Network/Element Management Software ................................................................. 16

3.1 Provisioning the SNMP Manager ...................................................................16

4.0 Using the Ethernet (Craft) Port ................................................................................. 17

4.1 IDH3 Web Interface ....................................................................................... 17

4.1.1 Overview ............................................................................................. 17

4.1.2 Status Page for Firmware Information ................................................ 21

4.1.3 Status Page for Connection Information .............................................22

4.1.4 Status Page for SNMP Event Log ....................................................... 23

4.1.5 HMS Power Supply Data Page ........................................................... 25

4.1.6 Generator Data Page .......................................................................... 25

5.0 Specifi cations............................................................................................................ 26

6.0 Acronym Defi nitions ..................................................................................................27

4

745-420-B0-001 Rev. A

Page 5

List of Figures

Fig. 1-1, IDH3 Transponder with EDSM ................................................................................ 7

Fig. 1-2, System Interconnection Diagram 1 ......................................................................... 8

Fig. 1-3, System Interconnection Diagram 2 ......................................................................... 9

Fig. 2-1, Attaching the PCB Standoff ................................................................................... 14

Fig. 2-2, Transponder Components ..................................................................................... 14

Fig. 2-3, RF Connection with Ground Block ........................................................................ 15

Fig. 4-1, Status Page for Firmware Information................................................................... 21

Fig. 4-2, Status Page for Connection Information ............................................................... 22

Fig. 4-3, Status Page for the SNMP Event Log ................................................................... 23

Fig. 4-4, HMS Power Supply Data Page ............................................................................. 24

Fig. 4-5, Generator Data Page ............................................................................................ 25

745-420-B0-001 Rev. A

5

Page 6

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any

questions regarding the safe installation or operation of the system, contact Alpha Technologies or the

nearest Alpha representative. Save this document for future reference.

To reduce the risk of injury or death and to ensure the continued safe operation of this product, the

following symbols have been placed throughout this manual. Where these symbols appear, use extra

care and attention.

The use of ATTENTION indicates specifi c regulatory/code requirements that may affect the placement of

equipment and /or installation procedures.

A NOTE provides additional information to help complete a specifi c task or procedure.

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING presents safety information to PREVENT INJURY OR DEATH to the technician

or user.

6

745-420-B0-001 Rev. A

Page 7

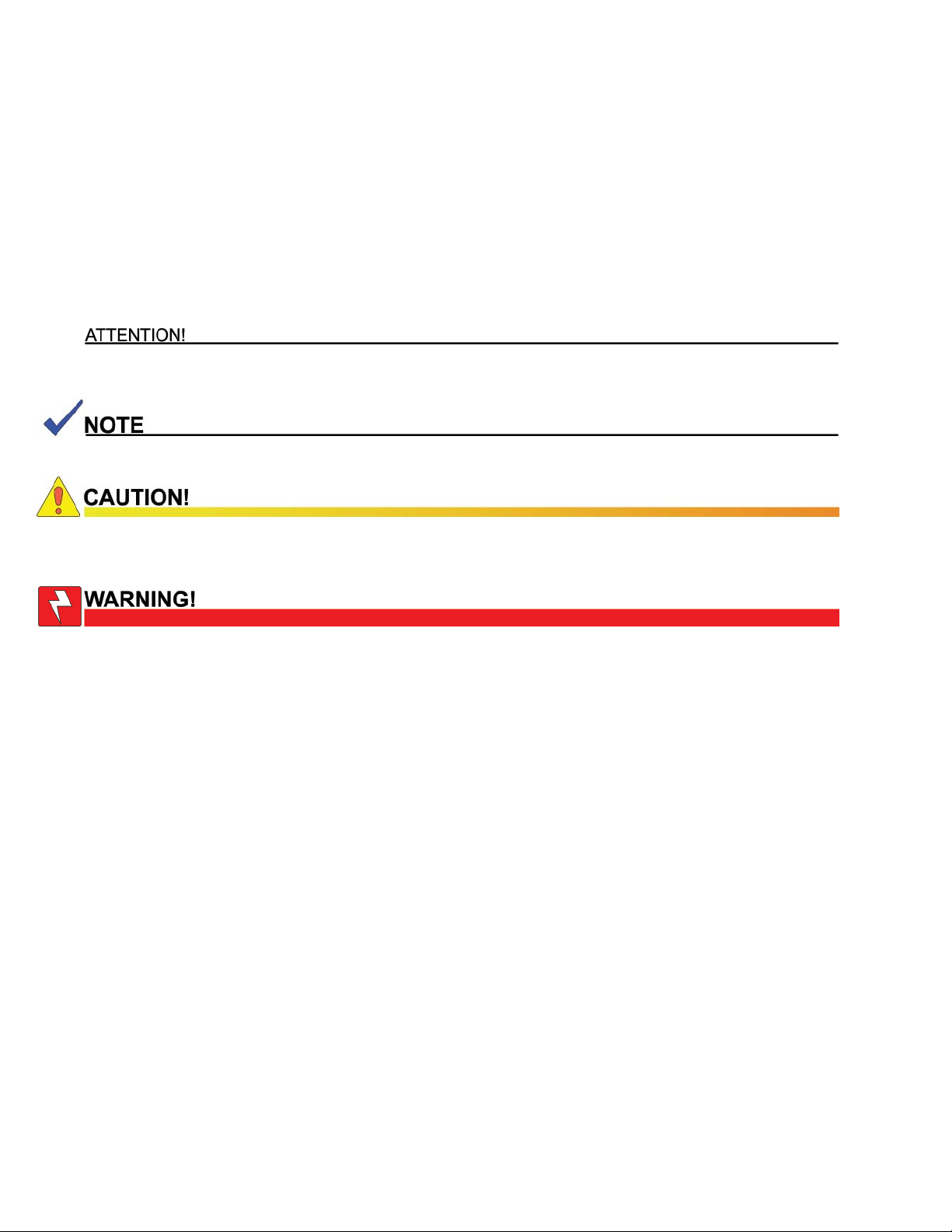

1.0 Introduction to the DOCSIS® Transponder

The IDH3 Transponder for the XM2 power supply manages network powering through existing cable

modem or high speed data infrastructure. A single transponder can monitor and manage multiple

power supplies, multiple strings of batteries, and one generator. The transponder transmits data

to a management system via the existing DOCSIS network. SNMP (Simple Network Management

Protocol) keeps bandwidth use to a minimum. Status monitoring data is compatible with ANSI/SCTE

HMS (Hybrid Management Sublayer) standards.

With optional VoIP test functionality, the power supply transponder becomes a powerful network

diagnostics tool. Contact Alpha Technologies for more information.

Outstanding Features:

• Uses existing headend DOCSIS CMTS equipment.

• Uses ANSI/SCTE HMS standards.

• Single transponder supports up to six power supplies, two battery strings, and one generator.

EDSM

DOCSIS HMS Embedded

IDH3 Transponder

Fig. 1-1, IDH3 Transponder with EDSM

745-420-B0-001 Rev. A

7

Page 8

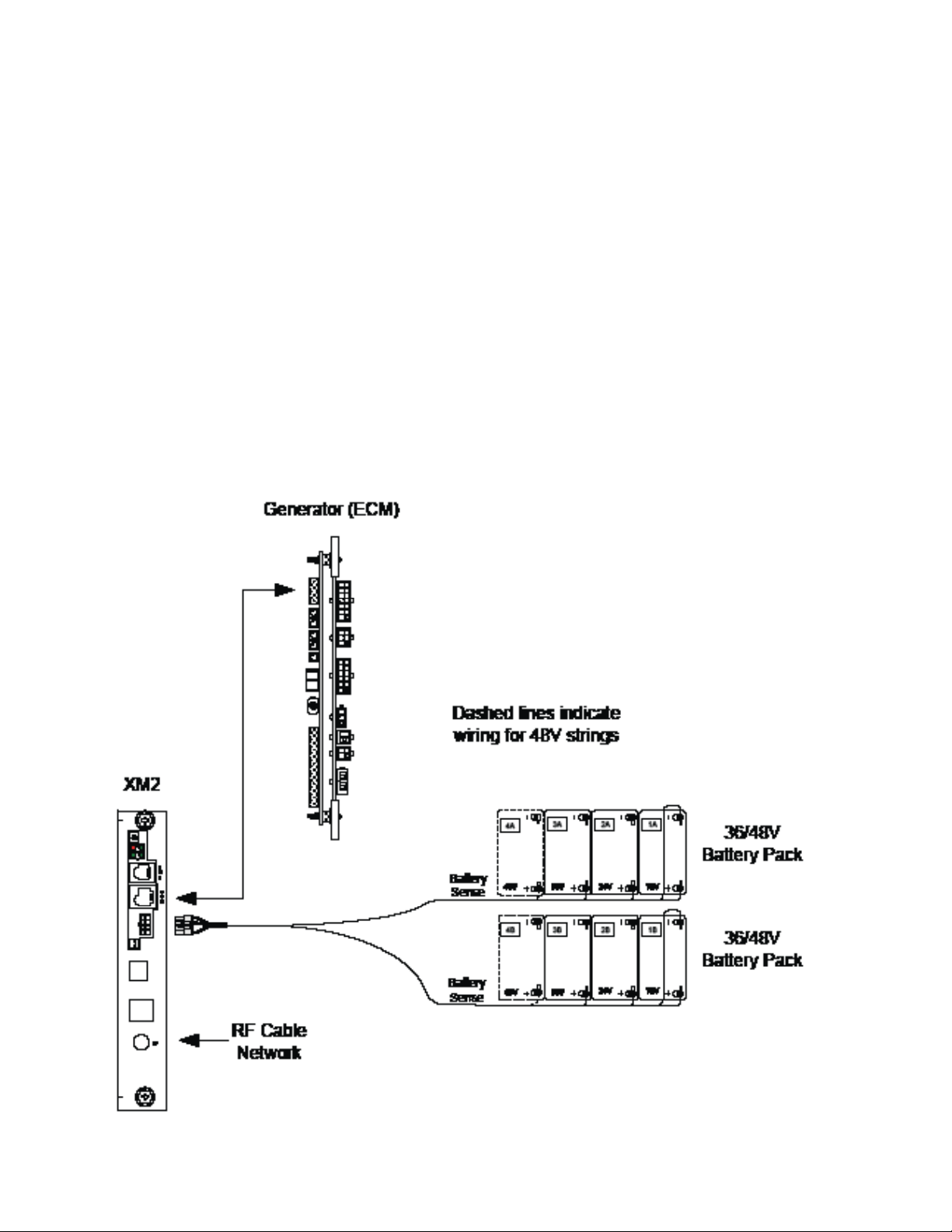

1.0 Introduction to the DOCSIS® Transponder, continued

1.1 System Overview

The IDH3 Transponder obtains data from the EDSM (Enhanced Digital Status Monitoring)

interface card through an XM2 Power Supply. The EDSM collects data directly from the

battery strings or from the AlphaBus Communications Network, depending on system

confi guration.

Equipment monitored (direct battery monitoring):

• An XM2 Power Supply

• One or two 36Vdc or 48Vdc battery strings

• One AlphaGen stationary generator system (if installed)

Battery Wire Sense

Harness

Fig. 1-2, System Interconnection Diagram 1

8

745-420-B0-001 Rev. A

Page 9

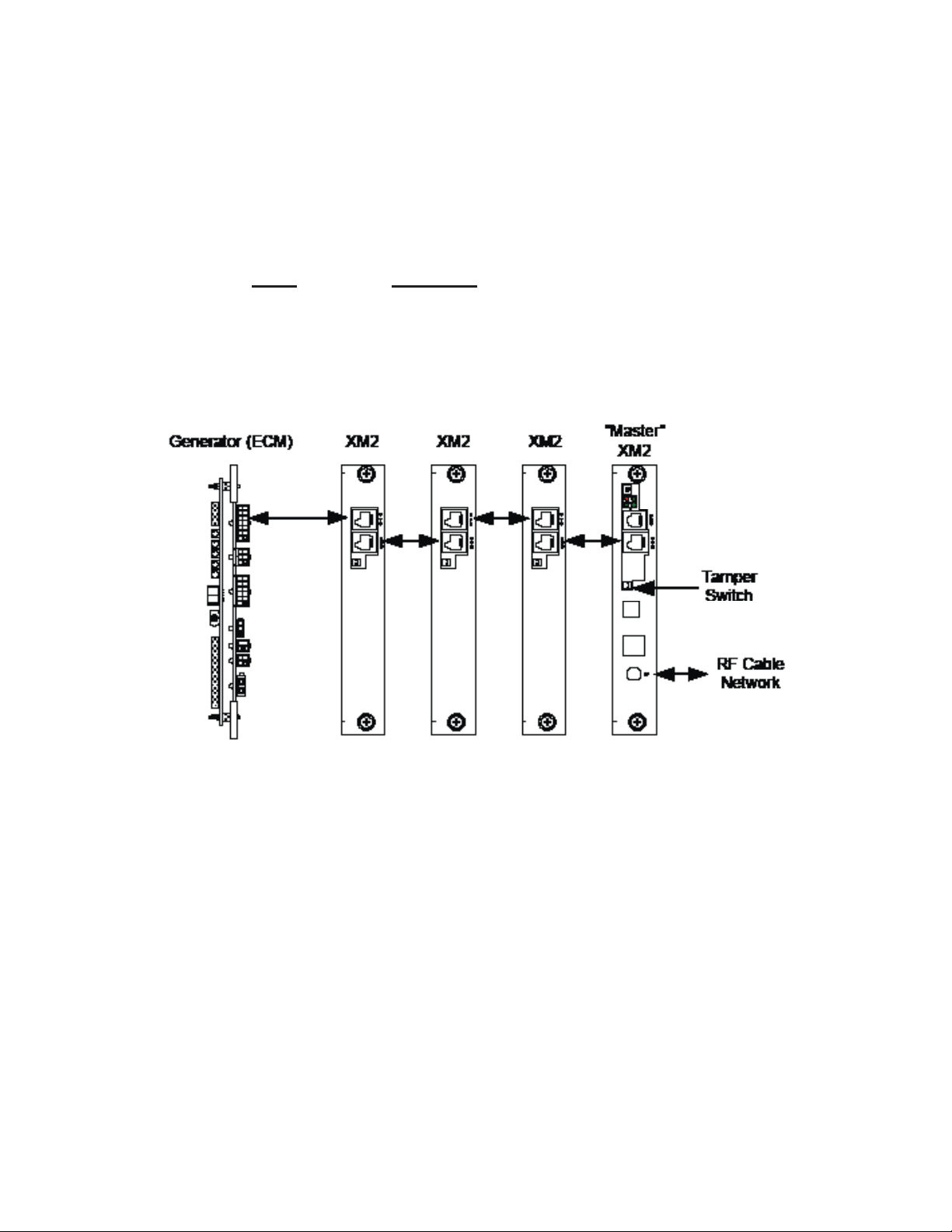

1.0 Introduction to the DOCSIS® Transponder, continued

1.1 System Overview, continued

Equipment monitored via the AlphaGuard™:

The AlphaGuard performs electrical compensation for differences in individual batteries in

the string. The unit can be confi gured to pass measurements from the battery string to a

status monitoring device (EDSM card, DOCSIS transponder, etc.) via an interface cable.

Model Description

AG-CMT-3SC AlphaGuard manages 3 batteries*

AG-CMT-4SC AlphaGuard manages 4 batteries*

* Includes 6’ battery cables

745-420-B0-001 Rev. A

Fig. 1-3, System Interconnection Diagram 2

9

Page 10

1.0 Introduction to the DOCSIS® Transponder, continued

1.2 LED Indicators

Communication State HMS RDY Tx Rx

Transponder Initializing OFF and ON OFF and ON OFF and ON OFF and ON

Searching for DOCSIS Downstream Channel OFF OFF and ON OFF OFF and ON

DOCSIS Channel Locked;

Establishing Upstream IP Connectivity

IP Connectivity Established; Registering with CMTS OFF OFF and ON ON ON

Registration Complete OFF and ON OFF and ON ON ON

OFF OFF and ON OFF and ON ON

10

745-420-B0-001 Rev. A

Page 11

2.0 Transponder Installation

Steps to a Successful Installation:

• Operator’s IT Department must allow the transponder’s Cable Modem (CM) to obtain an IP

address from the DHCP Server.

• Operator’s IT Department must provision the transponder, as described in the following section.

• Operator’s network security policies must allow SNMP traffi c to pass between transponder and

SNMP manager.

• Install the transponder and any related equipment in the power supply.

• Connect an RF drop.

• Verify proper operation.

2.1 Provisioning the Transponders in the Network

Before installing transponders, the transponders must be provisioned in the network for the

network to recognize, discover, and communicate with them when they are powered up. The

following graphic shows a typical network.

2.1.1 Network Connectivity

NOTE:

Some provisioning systems require that the transponder’s MAC address be added to the provisioning server

prior to installing the transponder to achieve full functionality.

Customers

Amplifier

Tap

DOCSIS Cable Modem

Configuration File

Power

Supply

PS

Fiber N ode

HFC

NETWORK

IDH3

Transponder

FIBER

CMTS

DOCSIS Cable Modem

Firmware Image Upgrade File

SNMP

Manager

IP

Network

Web Client

Time of Day Server

Provisioning Server

TFTP S er ver

745-420-B0-001 Rev. A

11

Page 12

2.0 Transponder Installation, continued

2.1 Provisioning the Transponder, continued

2.1.2 Transponder Confi guration

Many SNMP Management Applications require an SNMP Trap to be sent from the

transponder for self-discovery and for alarm notifi cations. An SNMP Trap destination

address can be specifi ed to the IDH3 through the DOCSIS confi guration fi les

docsDevNmAccessTable (RFC 2669).

12

745-420-B0-001 Rev. A

Page 13

2.0 Transponder Installation, continued

2.2 Verifying Firmware Version and Device Address

Before removing the Inverter Module (IM), verify the power supply fi rmware version and

device address are correct.

• IM fi rmware v3.00.0 is the minimum version compatible with the DOCSIS Embedded

Transponder.

• The power supply device address must not be set to zero, and no two power supplies

monitored by a single transponder may have the same address.

1. Press the Enter key on the inverter module twice to access the SETUP Menu.

2. Press the Down key until CODE VER is displayed.

3. Verify that the fi rmware code is 3.00.0 or higher.

4. Press the Down key twice until DEVICE ADDRESS is displayed.

5. If the address is correct (and not zero), skip to Step 10.

6. To change the address, press the Enter key to enter the Edit mode.

7. Press the Up or Down key until the desired address (between 1 and 7) is displayed.

Remember that each power supply on a single transponder must have a unique address.

8. Press the Enter key to load the new address.

9. Press the Enter key again to accept the new data.

10. Press ESC three times to return to the OPERATION NORMAL screen.

2.3 Installing the Transponder Hardware

The Embedded Transponder is static sensitive. An ESD wrist strap should be worn when installing

the transponder.

Tools Required: #1 Phillips Screwdriver

1. Move the XM2 Battery Breaker to the OFF position.

2. Unplug all connections to the front of the Inverter Module (battery cable, RTS, etc).

3. Loosen the thumbscrews holding the Inverter Module into the power supply. Slide the

Inverter Module out just enough to disconnect the ribbon cable. Now slide the Inverter

Module out of the power supply.

To reduce the risk of electric shock, completely remove the Inverter Module from the Power

Supply prior to installation.

745-420-B0-001 Rev. A

13

Page 14

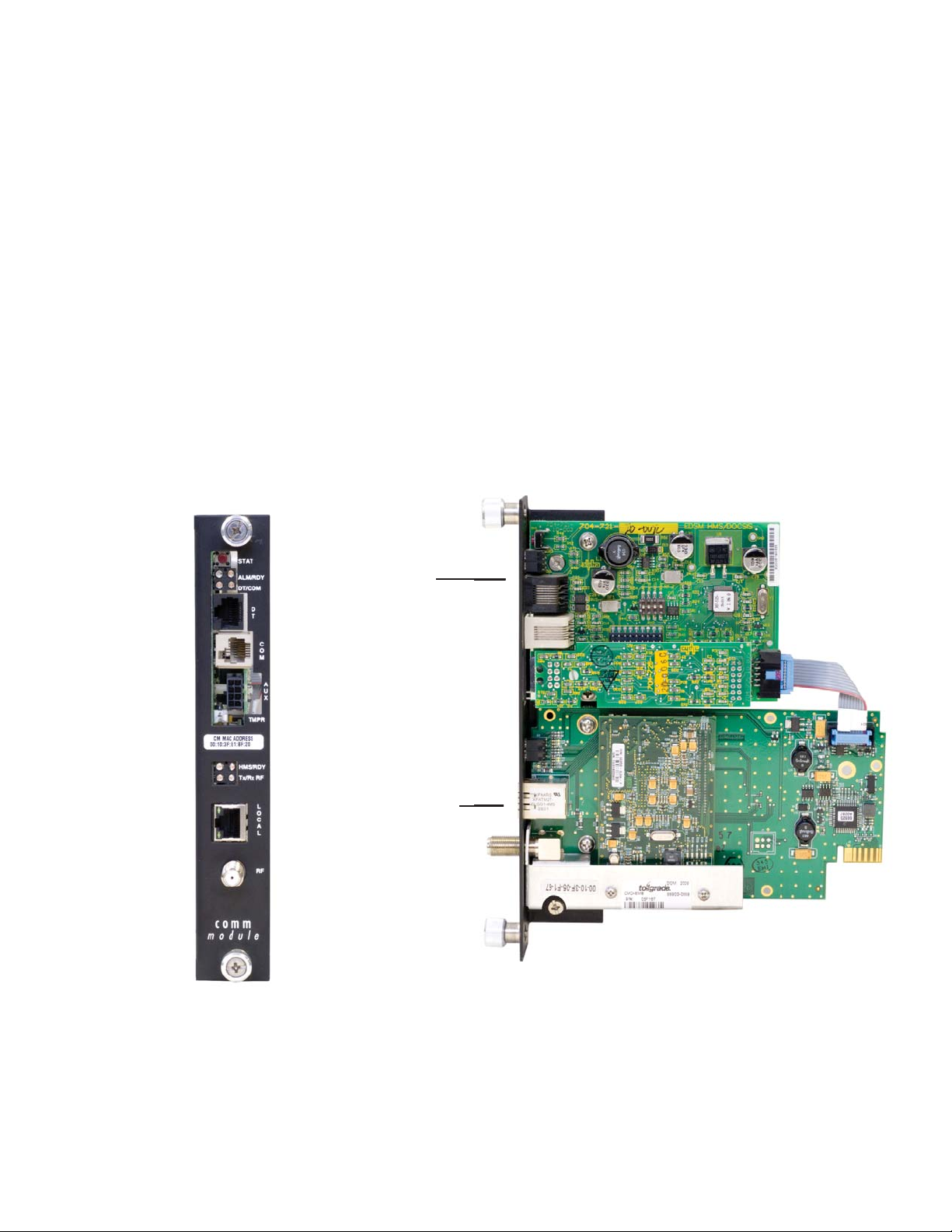

2.0 Transponder Installation, continued

2.3 Installing the Transponder Hardware, continued

4. Attach the new transponder ribbon cable supplied to the 10-pin connector on the

transponder. The connectors are keyed to prevent incorrect orientation.

5. Attach the plastic standoff to the transponder PC board as shown in Fig 2-1

6. Verify that the MAC address label is installed on the transponder. If the label is missing,

locate the label in the packaging and apply to the transponder as shown in Fig 2-2.

7. Place the transponder as shown in Fig 2-2 below. The RF connector must be inserted

through the front of the Comm Module bracket.

8. Press the standoff into the Inverter Module chassis.

9. Secure the transponder to the Comm Module Bracket with the two screws provided.

10. Connect the transponder ribbon cable to the EDSM. Note the 90o twist in the cable.

11. Reconnect the Inverter Module ribbon cable, and reinstall the Inverter Module into the

power supply.

12. Reconnect all the cables unplugged in Step 2 .

13. Move the Battery Breaker to the ON position.

Fig. 2-1, Attaching the PCB Standoff

IDH3 COMPONENTS

These two screws attach the transponder to the

1

Communications Module bracket.

2

Transponder ribbon cable connector

3

Location of PCB standoff

4

Transponder MAC address labels

Communications Module bracket (attaches to power

5

supply Inverter Module).

6

RF Connector

10-pin Connector

PCB Standoff

4

1

1

6

2

3

14

Fig. 2-2, Transponder Components

5

4

745-420-B0-001 Rev. A

Page 15

2.0 Transponder Installation, continued

2.4 RF Connection

Connect the RF drop to the RF connector on the transponder. The drop must have a properly

installed ground block in or on the power supply enclosure. Recommended forward RF level

is 0 dBmV.

RF Connection

Ground Surge

Protector

(User Provided)

RF Cable

to Headend

See Caution Below

Fig. 2-3, RF Connection with Ground Block

Alpha requires installing a grounded surge suppressor (Alpha P/N 162-028-10 or equivalent).

2.5 Verifying Transponder Operation

The LED behavior per the table below shows the status of LEDs during transponder

operation:

Communication State HMS RDY Tx Rx

Transponder Initializing OFF and ON OFF and ON OFF and ON OFF and ON

Searching for DOCSIS Downstream Channel OFF OFF and ON OFF OFF and ON

DOCSIS Channel Locked;

Establishing Upstream IP Connectivity

IP Connectivity Established; Registering with CMTS OFF OFF and ON ON ON

Registration Complete OFF and ON OFF and ON ON ON

OFF OFF and ON OFF and ON ON

745-420-B0-001 Rev. A

15

Page 16

3.0 Network/Element Management Software

3.1 Provisioning the SNMP Manager

The following MIB (Management Information Base) fi les are required for the SNMP Manager

to collect data from the transponders. These fi les can be found on the Society of Cable

Telecommunications (SCTE) web site www.scte.org. There are dependencies between MIB

fi les so they should be compiled in the following order listed below:

ANSI/SCTE 36 2002R2007 (formerly HMS 028), SCTE-ROOT Management Information

Base (MIB) Defi nitions

ANSI/SCTE 37 2008 (formerly HMS 072), Hybrid Fiber/Coax Outside Plant Status Monitoring

SCTE-HMS-ROOTS Management Information Base (MIB) Defi nition

ANSI/SCTE 38-1 2009 (formerly HMS 026), Hybrid Fiber/Coax Outside Plant Status

Monitoring SCTE-HMS-PROPERTY-MIB Management Information Base (MIB) Defi nition

ANSI/SCTE 38-2 2005 (formerly HMS 023), Hybrid Fiber/Coax Outside Plant Status

Monitoring SCTE-HMS-ALARMS-MIB Management Information Base (MIB) Defi nition

ANSI/SCTE 38-3 2008 (formerly HMS 024), Hybrid Fiber/Coax Outside Plant Status

Monitoring SCTE-HMS-COMMON-MIB Management Information Base (MIB) Defi nition

ANSI/SCTE 38-4 2006 (formerly HMS 027), Hybrid Fiber/Coax Outside Plant Status

Monitoring SCTE-HMS-PS-MIB Management Information Base (MIB) Defi nition

ANSI/SCTE 38-6 2006 (formerly HMS 033) Hybrid Fiber/Coax Outside Plant Status

Monitoring - SCTE-HMS-GEN-MIB Management Information Base (MIB) Defi nition

ANSI/SCTE 38-7 2008 (formerly HMS 050), Hybrid Fiber/Coax Outside Plant Status

Monitoring SCTE-HMS-Transponder-Interface-Bus(TIB)-MIB Management Information Base

(MIB) Defi nition

16

745-420-B0-001 Rev. A

Page 17

4.0 Using the Ethernet (Craft) Port

4.1 IDH3 Web Interface

4.1.1 Overview

A web interface is available on the IDH3 transponder. The default port for HTTP

traffi c is port 80, but can be confi gured to use other ports via the Tollgrade httpMgmt

MIB. HTTP port confi guration is available for the cable modem interface (via the

cable modem IP address) and the CPE interface (via the Local connection). The

Local connection’s IP address is 192.168.100.1, and may be easily accessed by

using a standard CAT5 patch cord between a computer and the ETHERNET port on

the front of the transponder.

The interface can be accessed by typing the cable modem IP address of the

transponder into your web browser. The interface includes status data for the cable

modem, the HMS transponder, High Speed Internet Access (HSIA) diagnostics, the

RF constellation page and equalizer page, and the MTA (Media Terminal Adapter) in

VoIP systems.

745-420-B0-001 Rev. A

17

Page 18

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.1 System Overview, continued

Depending on the network confi guration of the computer you are using to connect to

the IDH3 transponder, it may be necessary to set the network interface to a temporary static IP address. This will make itself known if you can’t bring up the fi rst web

page using 192.168.100.1. Here’s how to resolve that issue, and connect to the

transponder:

Click on the “start” button (lower left button on most Windows computers). When

the window pops up, right-click on “Network” (usually about half the way down the

second column).

Click on the bottom option, “Properties,” and right-click on the network interface you

are using. You’ll see a dialog box much like the one below; scroll down to the entry

“Internet Protocol (TCP/IP)” and then click on “Properties.”

18

745-420-B0-001 Rev. A

Page 19

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.1 System Overview, continued

You’ll see another dialog box, and enter the values as they appear in the diagram

below:

745-420-B0-001 Rev. A

Click on “OK” and try to connect to the transponder once again using 192.168.100.1

in your Web browser.

19

Page 20

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.1 System Overview, continued

NOTE:

The IDH3 web pages do not automatically refresh, so the user must manually reload each one to view the

most current data.

Confi guring the sysName and sysLocation OIDs

It is also possible to confi gure the sysName (1.3.6.1.2.1.1.5.0) and sysLocation

(1.3.6.1.2.1.1.6.0) OIDs from the web interface. This feature is password protected.

There are both Admin and User usernames and passwords. Both usernames (Admin

and User) have the authority to set sysName and sysLocation. The passwords can

be changed via the Broadcom httpMgmt MIB. The specifi c OIDs and default values

are shown below.

Table 5. OIDs for Usernames and Passwords for Web Interface Access

Parameter OID Default

httpAdminId 1.3.6.1.4.1.4413.2.2.2.1.1.3.1.0 edarglloT

httpAdminPassword 1.3.6.1.4.1.4413.2.2.2.1.1.3.2.0 aDm1n$TR8r

httpUserId 1.3.6.1.4.1.4413.2.2.2.1.1.3.3.0 Tollgrade

httpUserPassword 1.3.6.1.4.1.4413.2.2.2.1.1.3.4.0 Tollgrade

It is possible to change the port number for Web Access and to disable it entirely.

The table below lists the Parameters, OIDs, and default settings. Setting the Port

value to sero (0) will disable access to the HTTP server for the given interface. The

specifi c OIDs and their default values are listen in Table 6. The port must be open to

use all of the deatures described in the following sections.

Table 6. OIDs for Port Management

Parameter OID Default

httpCMMgmtPort 1.3.6.1.4.1.2082.5.5.1.1.1.0 80

httpCPEMgmtPort 1.3.6.1.4.1.2082.5.5.1.1.2.0 80

20

745-420-B0-001 Rev. A

Page 21

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.2 Status Page for Firmware Information

This homepage provides details on the fi rmware running in the cable modem and al-

lows navigation to other diagnostic information via the links provided..

745-420-B0-001 Rev. A

Fig. 4-1, Status Page for Firmware Information

21

Page 22

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.3 Status Page for Connection Information

This page provides detailed status information related to the current connection to the

CMTS.

22

Fig. 4-2, Status Page for Connection Information

745-420-B0-001 Rev. A

Page 23

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.4 Status Page for the SNMP Event Log

This page provides recent event log entries.

745-420-B0-001 Rev. A

Fig. 4-3, Status Page for the SNMP Event Log

23

Page 24

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.5 HMS Power Supply Data Page

This page displays HMS power supply, generator, and generic I/O data.

The coloring of an individual parameter indicates its alarm level as follows:

· Light grey: Parameter is not in alarm.

· Yellow: Parameter is in minor alarm.

· Red: Parameter is in major alarm.

24

Fig. 4-4, HMS Power Supply Data Page

745-420-B0-001 Rev. A

Page 25

4.0 Using the Ethernet (Craft) Port, continued

4.1 IDH3 Web Interface, continued

4.1.6 Generator Data Page

Click on the GEN8 link to see the Generator data page.

745-420-B0-001 Rev. A

Fig. 4-5, Generator Data Page

25

Page 26

5.0 Specifi cations

Power Supplies Supported: XM2-HP, XM2

DOCSIS Compatibility: DOCSIS 1.1, 2.0

Monitoring Protocol: SNMP v1

Devices Monitored:

Power Supply, Batteries and Generator

(compatible with ANSI/SCTE 25-3 2002,

formerly HMS 022)

Hardware

RF Cable Interface: F-connector, female, 75Ohm

Local Interface:

LED Indicators:

Ethernet interface for direct web page

access to diagnostic information.

Transponder Ready/RF Link Established

Transponder/CMTS Communications

Power Supply/Transponder

Communication

Environmental

Operating Temperature: -40 to 65°C / -40 to 149°F

Humidity: 10 to 90% non-condensing

EN50022 Class A and FCC Part 15

Emissions:

Class A

(Installed in power supply enclosure

system)

RF Transmit/Receive

Tx Frequency Range: 5 to 42MHz

Output Power: 8 to 58dBmV

Channel Bandwidth: 6MHz

Receive Center

Frequency Range:

Input Level: -15 to 15dBmV

91 to 857MHz (Standard, HRC, IRC

channels)

Power Supply Monitored Parameters

Major Alarm:

Minor Alarm:

Input Line Voltage: 90 to 270Vac 50/60Hz measured value

Output Voltage: 60/90Vac measured value

Output Current 1: 0 to 25A measured value

Output Current 2, 3, 4:

Output Power: Calculated, reported in AC Watts

UPS Status:

Enclosure Door: Open/Closed

Battery Voltage:

Battery Temperature: Measured, reported in Celsius

Remote Test Control: Start/Stop XM2 self test cycle

Logical (OR) of: test fail, battery fail, line

isolation alarm, output overload, inverter

over temperature, N+1 active, fuse fail

Logical (OR) of: temperature probe error,

AC line loss, N+1 error

0 to 25A measured value (if optional ports

installed)

AC line, Standby, Test in-process, Test

alarm

6 or 12V batteries, up to 4 battery strings

Individual battery voltages measured

reported to ±100mv resolution

Generator Monitored Parameters

Status: Engine off, running, alarm

Aggregate alarm consisting of: low oil

Generator Alarm:

Gas Hazard: OK, Alarm

Water Intrusion: OK, Alarm

Pad Shear: OK, Alarm

Enclosure Door: Open, Alarm

Ignition Battery Voltage: 10.2 to 15.5Vdc, 100mV resolution

Enclosure Temperature: -40 to 100°C / -40 to 212°F

Low Fuel: OK, Alarm

Remote Test: Start and Stop control input

pressure, engine over-temp, engine overspeed, crank limit, over voltage, low fuel,

water intrusion, pad shear, gas hazard,

test fail

26

745-420-B0-001 Rev. A

Page 27

6.0 Acronym Defi nitions

ANSI: American National Standards Institute

CM: Cable Modem

CMTS: Cable Modem Termination System

DHCP: Dynamic Host Confi guration Protocol

DOCSIS: Data Over Cable Service Interface Specifi cation

EDSM: Enhanced Digital Status Module

EMS: Element Management System

IT: Information Technology

MAC: Media Access Control

MIB: Management Information Base

NMS: Network Management System

QoS: Quality of Service

SCTE-HMS: Society of Cable Telecommunications Engineers-Hybrid Management Sublayer

SI: Serial Interface

SNMP: Simple Network Management Protocol

TFTP: Trivial File Transfer Protocol

TOD: Time of Day

UDP: User Datagram Protocol

VoIP: Voice over Internet Protocol

745-420-B0-001 Rev. A

27

Page 28

Page 29

Alpha Technologies

Power

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Web: www.alpha.com

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: +1 604 430 1476

Fax: +1 604 430 8908

Alpha Technologies

Europe Ltd.

Twyford House Thorley

Bishop's Stortford

Hertfordshire CM22 7PA

UNITED KINGDOM

Tel: +44 0 1279 501110

Fax: +44 1 279 659870

Alpha Technologies GmbH

Hansastrasse 8

D 91126 Schwabach

GERMANY

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec, Ltd

339 St. Andrews Street

Suite 101 Andrea Chambers

3307 Limassol

CYPRUS

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1 Offi ce 403

109028 Moscow

RUSSIA

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltic

S. Konarskio Street G.49-201

Vilnius LT-03123

LITHUANIA

Tel: +370 5 210 5291

Fax: +370 5 210 5292

Alpha Technologies

34, Grande Rue

Bétheny, F-51450

France

Phone: +33 32 64990 54

Fax: +33 67 54289 44

Copyright © 2010 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 745-420-B0-001 Rev. A.

Due to continuing product improvements, Alpha reserves the right to change specifi cations without notice.

Loading...

Loading...