Page 1

x930 Series

Gigabit Layer 3 Ethernet Switches

AT-x930-28GTX

AT-x930-28GPX

AT-x930-28GSTX

AT-x930-52GTX

AT-x930-52GPX

Installation Guide for Stand-alone

Switches

613-002100 Rev. C

Page 2

Copyright © 2015 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis, VCStack, and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names, company

names, logos or other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document without prior

written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesis, Inc. be liable for

any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or related

to this manual or the information contained herein, even if Allied Telesis, Inc. has been advised of, known, or should have known, the

possibility of such damages.

Page 3

Electrical Safety and Emissions Standards

Laser Safety EN60825

This product meets the following standards.

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses , and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

RFI Emissions: FCC Class A, EN55022 Class A, EN61000-3-2, EN61000-3-3, VCCI Class A,

C-TICK, CE

Warning: In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

EMC (Immunity): EN55024

Electrical Safety: EN60950-1 (TUV), UL 60950-1 (

CULUS

)

3

Page 4

Translated Safety Statements

Important: Safety statements that have the symbol are translated into multiple languages in the

Translated Safety Statements document at www.alliedtelesis.com/support.

4

Page 5

Contents

Preface ...............................................................................................................................................................................11

Document Conventions .......................................................................................................................................................12

Contacting Allied Telesis .....................................................................................................................................................13

Chapter 1: Overview ........................................................................................................................................................ 15

Models.................................................................................................................................................................................16

Features ..............................................................................................................................................................................17

x930 Models......... ... .. ...................................................................................................................................................17

10/100/1000 Mbps Twisted Pair Ports .........................................................................................................................17

Power Over Ethernet....................................................................................................................................................17

SFP Slots .....................................................................................................................................................................17

SFP+ Slots .......................................................................................................... ... ......................................................18

S1 and S2 Stacking Slots.............................................................................................................................................19

LEDs.............................................................................................................................................................................19

Optional Expansion Cards............................................................................................................................................19

Installation Options.......................................................................................................................................................19

MAC Address Table ...................................................................... ...............................................................................19

Management Software and Interfaces .........................................................................................................................20

Management Methods..................................................................................................................................................20

Power Supplies ............................................................................................................................................................20

Front and Back Panels........................................................................................................................................................21

Management Panel .............................................................................................................................................................24

Power Supplies....................................................................................................................................................................25

Guidelines ....................................................................................................................................................................27

10/100/1000Base-T Twisted Pair Ports...........................................................................................

Speed...........................................................................................................................................................................29

Duplex Mode................................................................................................................................................................29

Wiring Configuration.....................................................................................................................................................29

Maximum Distance.......................................................................................................................................................30

Cable Requirements.....................................................................................................................................................30

Port Pinouts........................................... ..................................... ..................................................................................30

Power Over Ethernet...........................................................................................................................................................31

PoE Standards.............................................................................................................................................................31

Powered Device Classes .............................................................................................................................................31

Cable Requirements.....................................................................................................................................................32

Power Budget...............................................................................................................................................................33

Port Prioritization..........................................................................................................................................................35

Wiring Implementation..................................................................................................................................................36

SFP Slots.............................................................................................................................................................................37

SFP+ Slots..................................................................... ... ...................................................................................................38

Stacking S1 and S2 SFP+ Slots..........................................................................................................................................39

Ethernet Management Port (NET MGMT) . ..........................................................................................................................40

NET MGMT LEDs ........................................................................................................................................................40

eco-friendly Button...............................................................................................................................................................41

LEDs....................................................................................................................................................................................42

LEDs for the Twisted Pair Ports...................................................................................................................................42

LEDs for the SFP Slots ................................................................................................................................................45

LEDs for the SFP+ Slots ..............................................................................................................................................46

LEDs for the Stacking Slots..........................................................................................................................................47

....................................29

5

Page 6

Contents

Switch ID LED ............................................................................................................................................................. 48

USB Port........................................... ................................................................... ... ............................................................ 50

Console Port....................................................................................................................................................................... 51

Optional Cards.................................................................................................................................................................... 52

AT-StackQS Card........................................................................................................................................................ 52

AT-x9EM/XT4 Card.....................................................................................................................................................53

Chapter 2: Beginning the Installation ............................................................................................................................55

Reviewing Safety Precautions............................................................................................................................................ 56

Choosing a Site for the Switch............................................................................................................................................61

Unpacking the Switch .........................................................................................................................................................62

Chapter 3: Installing the Power Supplies ......................................................................................................................65

Installing the Power Supplies..............................................................................................................................................66

Installing a Blank Power Supply Slot Cover........................................................................................................................72

Chapter 4: Installing the AT-x9EM/XT4 Card .................................................................................................................75

Guidelines........................................................................................................................................................................... 76

Installing the AT-x9EM/XT4 Card .......................................................................................................................................77

Chapter 5: Installing the Switch on a Table ...................................................................................................................87

Chapter 6: Installing the Switch in an Equipment Rack ...............................................................................................89

Required Items ....................................................... ............................................................................................................ 90

Installing the Switch in an Equipment Rack........................................................................................................................ 91

Chapter 7: Installing the Switch on a Wall .....................................................................................................................95

Switch Orientation on the Wall............................................................................................................................................96

Recommended Minimum Wall Area Dimensions................................................................................................................97

Plywood Base for a Wall with Wooden Studs..................................................................................................................... 99

Installation Guidelines....................................................................................................................................................... 101

Tools and Material..................................................................................................................................................... 101

Installing the Plywood Base....................................................................................................

Installing the Switch on the Plywood Base ....................................................................................................................... 104

Installing the Switch on a Concrete Wall........................................................................................................................... 107

.......................................... 103

Chapter 8: Wiring the DC Connector on the AT-PWR250-80 Power Supply ............................................................111

Chapter 9: Powering On the Switch .............................................................................................................................115

Powering On AC Power Supplies.....................................................................................................................................116

Powering On the AT-PWR250-80 DC Power Supply ....................................................................................................... 120

Monitoring the Initialization Processes..............................................................................................................................122

Chapter 10: Configuring the Switch for Stand-alone Operation ...............................................................................125

Determining the Status of the Switch................................................................................................................................126

Starting a Local Management Session.............................................................................................................................127

Disabling VCStack............................................... ..................................... ........................................................................ 129

Verifying Support for Hardware Options...........................................................................................................................132

Chapter 11: Cabling the Networking Ports ..................................................................................................................133

Cabling the Twisted Pair Ports.......................................................................................................................................... 134

Guidelines to Handling SFP or SFP+ Transceivers.......................................................................................................... 136

Installing SFP or SFP+ Transceivers................................................................................................................................ 137

Specifying Ports in the Command Line Interface for Stand-alone Switches..................................................................... 141

Chapter 12: Troubleshooting ........................................................................................................................................143

Appendix A: Technical Specifications .........................................................................................................................149

Physical Specifications ..................................................................................................................................................... 150

Environmental Specifications............................................................................................................................................ 152

Power Specifications......................................................................................................................................................... 153

Certifications.....................................................................................................................................................................155

RJ-45 Twisted Pair Port Pinouts.......................................................................................................................................156

RJ-45 Style Serial Console Port Pinouts.......................................................................................................................... 158

6

Page 7

Figures

Figure 1: Front Panels of the AT-x930-28GTX and AT-x930-28GPX Switches...................................................................21

Figure 2: Front Panels of the AT-x930-28GSTX, AT-x930-52GTX, and AT-x930-52GPX Switches....................................22

Figure 3: Back Panel............................................................................................................................................................23

Figure 4: Management Panel ...............................................................................................................................................24

Figure 5: AT-PWR150 and AT-PWR250 Power Supplies....................................................................................................25

Figure 6: AT-PWR250-80 Power Supply..............................................................................................................................26

Figure 7: AT-PWR800 Power Supply...................................................................................................................................26

Figure 8: AT-PWR1200 Power Supply.................................................................................................................................27

Figure 9: LEDs for the 10/100/1000Base-T Ports on the AT-x930-28GTX, AT-x930-28GSTX, and AT-x930-5 2GTX

Switches ...............................................................................................................................................................................42

Figure 10: LEDs for the 10/100/1000Base-T Ports on the AT-x930-28GPX and AT-x930-52GPX Switches ......................44

Figure 11: SFP Slot LEDs ....................................................................................................................................................45

Figure 12: SFP+ Slot LEDs ..................................................................................................................................................46

Figure 13: Switch ID LED.....................................................................................................................................................48

Figure 14: Switch ID LED.....................................................................................................................................................48

Figure 15: Switch ID LEDs in the Low Power Mode.............................................................................................................49

Figure 16: Optional AT-StackQS Card .................................................................................................................................52

Figure 17: Optional AT-x9EM/XT4 Card...............................................................................................................................53

Figure 18: Accessory Kit.......................................................................................................................................................62

Figure 19: Pre-installed Items...............................................................................................................................................63

Figure 20: Removing the AT-PNL250 Blank Panel ..............................................................................................................67

Figure 21: Power Supply Accessory Items...........................................................................................................................68

Figure 22: Installing a Power Supply ....................................................................................................................................69

Figure 23: Improper Installation of a Power Supply..............................................................................................................70

Figure 24: Tightening the Captive Screws on the Power Supply..........................................................................................70

Figure 25: Installing the Power Cord Retaining Clip............................................................................

Figure 26: Installing a Blank Panel on a Power Supply Slot.................................................................................................72

Figure 27: Tightening the Captive Screws on the Power Supply Blank Panel .....................................................................73

Figure 28: Loosening the Two Captive Screws on the AT-FAN09 Module ..........................................................................78

Figure 29: Removing the AT-FAN09 Module........................................................................................................................79

Figure 30: Loosening the Captive Screw on the AT-FAN09ADP Module.............................................................................80

Figure 31: Removing the AT-FAN09ADP Module................................................................................................................ 81

Figure 32: Removing the AT-x9EM/XT4 Card from the Anti-static Bag............................................... ... ..............................81

Figure 33: Aligning the AT-x9EM/XT4 Card in the Slot ........................................................................................................82

Figure 34: Seating the AT-x9EM/XT4 Card in the Switch.....................................................................................................83

Figure 35: Tightening the Captive Screw on the AT-x9EM/XT4 Card..................................................................................83

Figure 36: Aligning the AT-FAN09 Module in the Slot..........................................................................................................84

Figure 37: Tightening the Two Captive Screws on the AT-FAN09 Module..........................................................................85

Figure 38: Storing the AT-FAN09ADP Module in an Anti-static Bag............................................................ ........................85

Figure 39: Installing the Bumper Feet...................................................................................................................................87

Figure 40: Attaching the Equipment Rack Brackets.............................................................................................................92

Figure 41: Attaching the Equipment Rack Brackets (Continued) .........................................................................................93

Figure 42: Installing the Switch in an Equipment Rack.........................................................................................................94

Figure 43: Positions of the Switch on the Wall.....................................................................................................................96

Figure 44: Minimum Wall Area Dimensions with the Front Panel on the Left.......................................................................97

Figure 45: Minimum Wall Area Dimensions with the Front Panel on the Right....................................................................98

Figure 46: Switch on the Wall with a Plywood Base.............................................................................................................99

Figure 47: Steps to Installing the Switch with a Plywood Base ..........................................................................................100

Figure 48: Installing the Brackets to the Switch for Wall Installation ..................................................................................104

.................................71

7

Page 8

Figures

Figure 49: Mounting Holes..................................................................................................................................................105

Figure 50: Securing the Switch to the Plywood Base.........................................................................................................106

Figure 51: Marking the Locations of the Bracket Holes on a Concrete Wall............................................ ... ........................108

Figure 52: Installing the Switch on a Concrete Wall ...........................................................................................................109

Figure 53: On/Off Switch on AT-PWR250-80 Power Supply..............................................................................................112

Figure 54: DC Terminal Block.............................................................................................................................................112

Figure 55: Stripped Wire.....................................................................................................................................................113

Figure 56: Connecting the Ground Wire to the DC Terminal Block ................................................................. ...................113

Figure 57: Raising the Power Cord Retaining Clip .............................................................................................................117

Figure 58: Connecting the AC Power Cord.........................................................................................................................118

Figure 59: Lowering the Power Cord Retaining Clip...........................................................................................................119

Figure 60: On/Off Switch on the AT-PWR250-80 DC Power Supply..................................................................................120

Figure 61: Switch Initialization Messages...........................................................................................................................122

Figure 62: Switch Initialization Messages (Continued) .......................................................................................................123

Figure 63: Switch Initialization Messages (Continued) .......................................................................................................124

Figure 64: Connecting the Management Cable to the Console Port ..................................................................................127

Figure 65: User Exec Mode Prompt....................................................................................................................................129

Figure 66: SHOW STACK Command.................................................................................................................................129

Figure 67: Moving to the Global Configuration Mode.........................................................................................................130

Figure 68: Confirmation Prompt for the NO STACK ENABLE Command..........................................................................130

Figure 69: Disabling VCStack.............................................................................................................................................131

Figure 70: Returning to the Privileged Exec Mode .............................................................................................................131

Figure 71: Saving the Changes with the WRITE Command...............................................................................................131

Figure 72: Removing the Dust Plug from an SFP Slot.............................................................................

Figure 73: Installing an SFP Transceiver............................................................................................................................138

Figure 74: Removing the Dust Cover from an SFP or SFP+ Transceiver..........................................................................138

Figure 75: Positioning the SFP or SFP+ Handle in the Upright Position ............................................................................139

Figure 76: Connecting a Fiber Optic Cable to an SFP or SFP+ Transceiver ........................................................ .............140

Figure 77: PORT Parameter in the Command Line Interface.............................................................................................141

Figure 78: RJ-45 Socket Pin Layout (Front View)...............................................................................................................156

...........................137

8

Page 9

Tables

Table 1: Models and Basic Features ...................................................................................................................................16

Table 2: Twisted Pair Cable for the 10/100/1000Base-T Ports ...........................................................................................30

Table 3: IEEE Powered Device Classes ..............................................................................................................................32

Table 4: Twisted Pair Cable Requirements for the 10/100/1000Base-T Ports at 10 or 100Mbps .......................................32

Table 5: Twisted Pair Cable Requirements for the 10/100/1000Base-T Ports at 1000Mbps ..............................................33

Table 6: Power Supply Budgets of the Power Supplies ......................................................................................................33

Table 7: Power Budgets of the AT-PWR800 Power Supply ................................................................................................34

Table 8: Power Budgets of the AT-PWR1200 Power Supply ..............................................................................................35

Table 9: NET MGMT Port LED ............................................................................................................................................40

Table 10: LEDs on the 10/100/1000Base-T Ports on the AT-x930-28GTX, AT -x930-28GSTX, and AT-x930-52GTX

Switches ..............................................................................................................................................................................43

Table 11: LEDs on the 10/100/1000Base-T Ports on the AT-x930-28GPX and AT-x930-52GPX Switches .......................44

Table 12: SFP Slot LEDs on the AT-x930-28GSTX Switch .................................................................................................46

Table 13: SFP+ Slot LEDs ...................................................................................................................................................47

Table 14: Stacking Slot LEDs ..............................................................................................................................................47

Table 15: AT-StackQS Card LEDs ......................................................................................................................................52

Table 16: Twisted Pair Cable for the AT-x9EM/XT4 Card ...................................................................................................53

Table 17: AT-x9EM/XT4 Card LEDs ....................................................................................................................................54

Table 18: Accessory Items Included with the Power Supplies ............................................................................................68

Table 19: PORT Parameter Format ................................................................................................................................... 141

Table 20: Product Dimensions ...........................................................................................................................................150

Table 21: Product Weights ................................................................................................................................................150

Table 22: Ventilation Requirements ................................................................................................................................... 151

Table 23: Environmental Specifications .............................................................................................................................152

Table 24: Maximum Power Consumption with the AT-PWR150, AT-PWR250 or AT-PWR250-80 Power Supply ...........153

Table 25: Maximum Power Consumption with the AT-PWR800 Power Supply ................................................................ 153

Table 26: Maximum Power Consumption with the AT-PWR1200 Power Supply ..........................................................

Table 27: Input Voltages ....................................................................................................................................................154

Table 28: Product Certifications .........................................................................................................................................155

Table 29: Pin Signals for 10 and 100 Mbps .......................................................................................................................156

Table 30: Pin Signals for 1000 Mbps .................................................................................................................................156

Table 31: RJ-45 Style Serial Console Port Pin Signals .....................................................................................................158

.... 153

9

Page 10

Tables

10

Page 11

Preface

Note

This guide contains the installation instructions for the x930 Series of

Layer 3, Gigabit Ethernet switches. This preface contains the following

sections:

“Document Conventions” on page 12

“Contacting Allied Telesis” on page 13

This guide explains how to install the switches as stand-alone units.

For instructions on how to build a stack with Virtual Chassis Sta cking

(VCStack

Chassis Stacking.

™), refer to the x930 Series Installation Guide for Virtual

11

Page 12

Preface

Note

Caution

Warning

Document Conventions

This document uses the following conventions:

Notes provide additional information.

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

12

Page 13

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links for

the following services on this page:

24/7 Online Support — Enter our interactive support center to

search for answers to your product questions in our knowledge

database, to check support tickets, to learn about RMAs, and to

contact Allied Telesis technical experts.

USA and EMEA phone support — Select the phone number that

best fits your location and customer type.

Hardware warranty information — Learn about Allied Telesis

warranties and register your product online.

Replacement Services — Submit a Return Merchandise

Authorization (RMA) request via our interactive support center.

x930 Series Installation Guide for Stand-alone Switches

Documentation — View the most recent installation and user

guides, software release notes, white papers, and data sheets for

your products.

Software Downloads — Download the latest software releases for

your managed products.

For sales or corporate information, go to www.alliedtelesis.com/

purchase and select your region.

13

Page 14

Preface

14

Page 15

Chapter 1

Note

Overview

This chapter contains the following sections:

“Models” on page 16

“Features” on page 17

“Front and Back Panels” on page 21

“Management Panel” on page 24

“Power Supplies” on page 25

“10/100/1000Base-T Twisted Pair Ports” on page 29

“Power Over Ethernet” on page 31

“SFP Slots” on page 37

“SFP+ Slots” on page 38

“Stacking S1 and S2 SFP+ Slots” on page 39

“Ethernet Management Port (NET MGMT)” on page 40

“eco-friendly Button” on page 41

“LEDs” on page 42

“USB Port” on page 50

“Console Port” on page 51

“Optional Cards” on page 52

This guide explains how to install the switches as stand-alone units.

For instructions on how to build a stack with Virtual Chassis Stacki ng

(VCStack

™), refer to the x930 Series Installation Guide for Virtual

Chassis Stacking.

15

Page 16

Chapter 1: Overview

Models

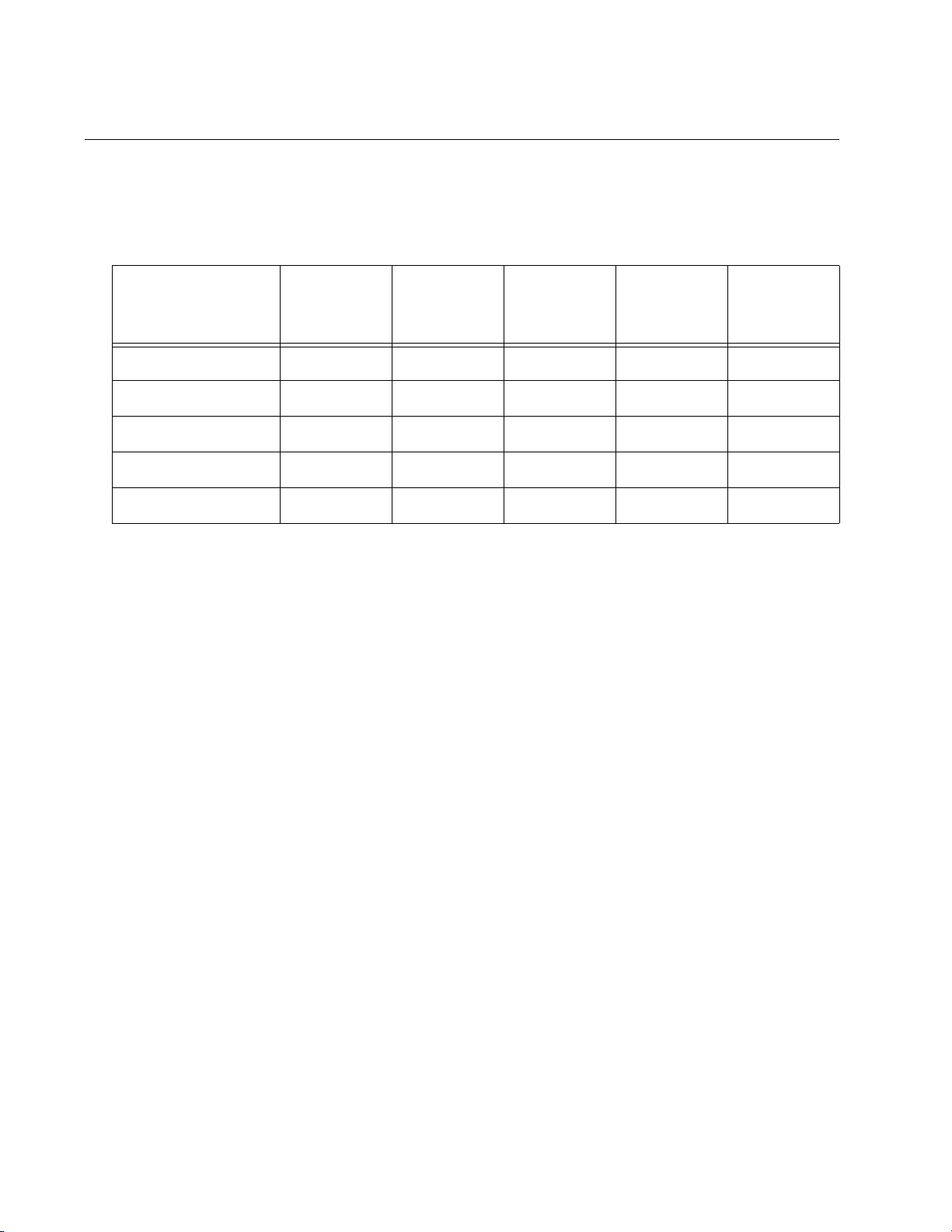

Table 1 lists the models and basic features of the x930 Series of stackable

Gigabit Layer 3 switches.

Table 1. Models and Basic Features

10/100/1000

Model

AT-x930-28GTX 24 0 4 No Yes

AT-x930-28GPX 24 0 4 Yes Yes

AT-x930-28GSTX 24 24 4 No Yes

AT-x930-52GTX 48 0 4 No Yes

AT-x930-52GPX 48 0 4 Yes Yes

Base-T

Ports

SFP Slots SFP+ Slots PoE+ VCStack

Additional information is listed here:

The switches do not come with power supplies. The power

supplies must be ordered separately. For more information, refer

to “Power Supplies” on page 25.

The power budgets of the AT-x930-28GPX and AT-x930-52GPX

Switches for PoE+ powered devices depend on the number and

types of power supplies installed in the units. For more information,

refer to “Power Budget” on page 33.

You may use the VCStack feature to stack the switches with either

the S1 and S2 ports, which come standard with the units, or with

the optional AT-StackQS card. For more information, refer to the

x930 Series Installation Guide for Virtual Chassis Stacking.

The twisted pair ports and SFP slots on AT-x930-28GSTX Switch

are paired together. Only one port or slot in a pair is operational at

a time. For more information, refer to “SFP Slots” on page 37.

16

Page 17

Features

x930 Models Here are the switches in the x930 Series:

x930 Series Installation Guide for Stand-alone Switches

Here are the switches and their features:

AT-x930-28GTX

AT-x930-28GPX

AT-x930-28GSTX

AT-x930-52GTX

AT-x930-52GPX

10/100/1000

Mbps Twisted

Pair Ports

Power Over

Ethernet

Here are the basic features of the 10/100/1000 Mbps twisted pair ports:

24 or 48 ports per switch

10Base-T, 100Base-TX, and 1000Base-T compliant

IEEE 802.3u Auto-Negotiation compliant

Auto-MDI/MDIX

100 meters (328 feet) maximum operating distance

IEEE 802.3x flow control in 10/100Base-TX full-duplex mode

IEEE 802.3x backpressure in 10/100Base-TX half-duplex mode

IEEE 802.3ab 1000Base-T

Jumbo frames up to 13KB

RJ-45 connectors

Here are the basic features of Power over Ethernet (PoE) on the twisted

pair ports on the AT-x930-28GPX and AT-x930-52GPX Switches:

Supported on ports 1 to 24 on the AT-x930-28GPX Switch and

ports 1 to 48 on the AT-x930-52GPX Switch

Supports PoE (15.4 watts maximum) and PoE+ (30 watts

maximum) powered devices

Supports powered device classes 0 to 4

Port prioritization

Mode A wiring

SFP Slots Here are the basic features of the twenty four SFP slots on the AT-x930-

28GSTX Switch:

Supports 100Base-FX, 1000Base-T, and 1000Base-SX/LX SFP

transceivers

17

Page 18

Chapter 1: Overview

Note

Note

Note

Note

Note

SFP+ Slots Here are the basic features of the four SFP+ slots on the switches:

Supports single-port BiDi 100Base-FX and 1000Base-LX SFP

transceivers

Supports 1000Base-ZX SFP transceivers

The SFP slots and twisted pair ports on the AT-x930-28GSTX

Switch are paired together. Only one slot or port in a pair is active at

a time. For more information, refer to “SFP Slots” on page 37.

SFP transceivers must be purchased separately. For a list of

supported transceivers, contact your Allied Telesis distributor or

reseller.

Supports 10Gbps, 10GBase-SR/LR fiber optic transceivers

Supports 10Gbps AT-SP10TW direct connect twinax cables with

SFP+ transceiver-style connectors

Supports 1000Base-SX/LX SFP transceivers

Supports single-port BiDi 1000Base-LX SFP transceivers

Supports 1000Base-ZX SFP transceivers

The SFP+ slots do not support 100Mbps 100Base-FX transceivers.

The slots support full-duplex mode only. They do not support halfduplex mode.

SFP and SFP+ transceivers must be purchased separately. For a

list of supported transceivers, contact your Allied Telesis distributor

or reseller.

18

Page 19

x930 Series Installation Guide for Stand-alone Switches

Note

SFP+ slots 27/S1 and 28/S2 on the 28-port switches and slots 51/S1

and 52/S2 on the 52-port switches are initially configured as stacking

slots for the VCStack feature. If you plan to use the switch as a

stand-alone unit, you may disable the VCStack feature and use the

slots with standard SFP or SFP+ transceivers. The configuration

instructions are provided later in this guide, in Chapter 10,

“Configuring the Switch for Stand-alone Operation” on page 125.

S1 and S2

Stacking Slots

LEDs Here are the port LEDs:

Optional

Expansion Cards

SFP+ slots 27/S1 and 28/S2 on the 28-port switches and slots 51/S1 and

52/S2 on the 52-port switches can be used with the VCStack feature to

build a stack of up to eight switches. For instructions on the VCStack

feature, refer to the x930 Series Installation Guide for Virtual Chassis

Stacking.

Link/activity and duplex mode LEDs for the twisted pair ports on

non-PoE switches

Link/activity and PoE status LEDs for the twisted pair ports on PoE

switches

Link/activity LEDs for SFP and SFP+ slots

Stack ID number LED

eco-friendly button turns off the LEDs to conserve electricity

Here are optional expansion cards:

AT-StackQS Card - Contains two transceiver slots for building a

VCStack of up to eight switches. For more information, refer to the

x930 Series Installation Guide for Virtual Chassis Stacking.

Installation

Options

MAC Address

Table

AT-x9EM/XT4 Card - Contains four twisted pair ports that operate

at 1Gbps or 10Gbps.

Here are the installation options for the switches:

19-inch equipment rack

Desk or tabletop

Wall

Here are the basic features of the MAC address tables of the switches:

Storage capacity of 61,440 dynamic and static entries

Automatic learning and aging

19

Page 20

Chapter 1: Overview

Management

Software and

Interfaces

Management

Methods

Here are the management software and interfaces:

AlliedWare Plus Management Software

Command line interface

Web browser interface

Here are the methods for managing the switches:

Local management through the Console port

Remote Telnet and Secure Shell management

Remote HTTP and HTTPS web browser management

SNMPv1, v2c, and v3

Power Supplies Here are the power supplies:

AT-PWR150

AT-PWR250

AT-PWR250-80

AT-PWR800

AT-PWR1200

20

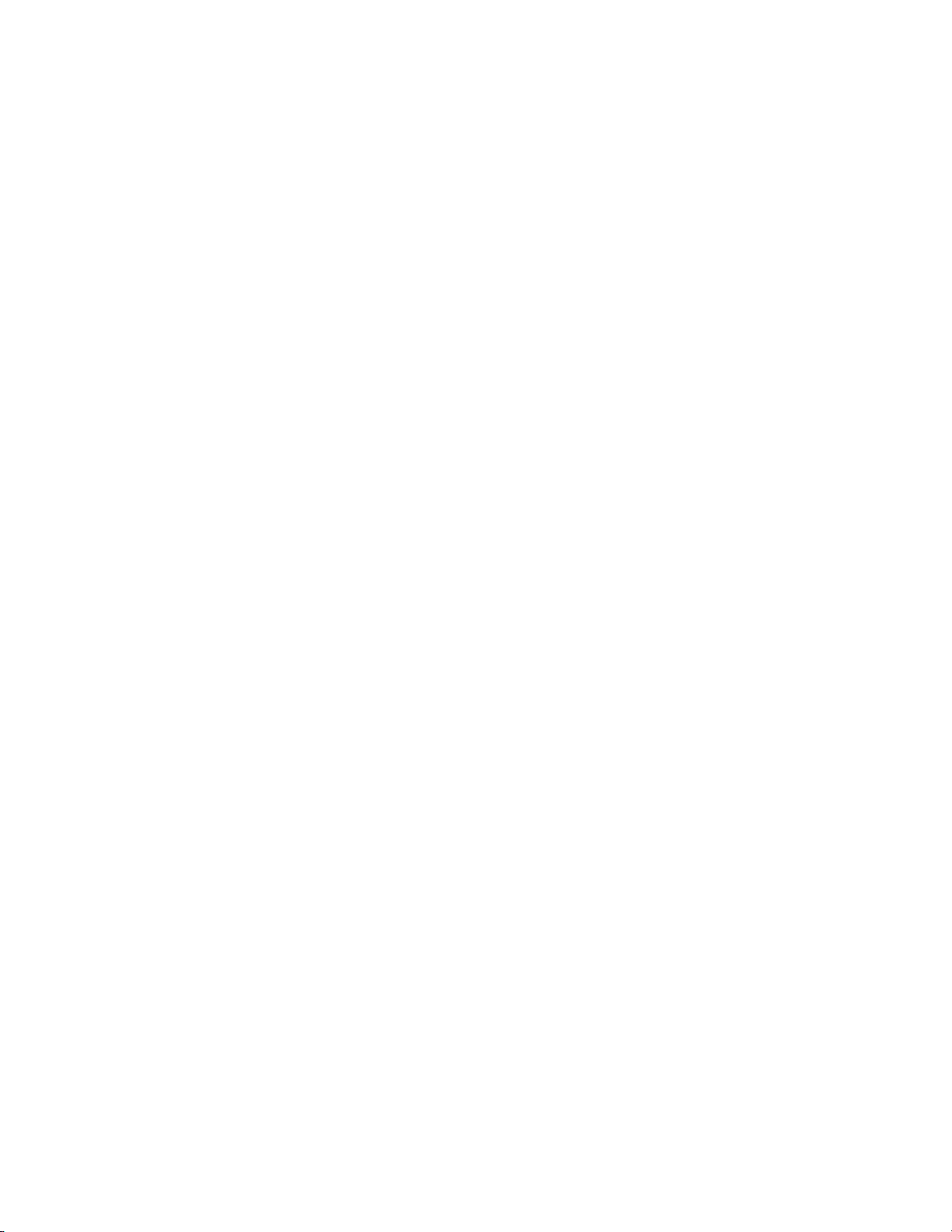

Page 21

Front and Back Panels

AT-x930-28GPX

AT-x930-28GTX

10/100/1000Base-T Ports

SFP+ Slots

Management

Panel

SFP+ or

Stacking Slots

SFP+ Slots

Management

Panel

SFP+ or

Stacking Slots

10/100/1000Base-T Ports

with PoE+

The front panels of the x930 Series switches are shown in Figure 1 and

Figure 2 on page 22.

x930 Series Installation Guide for Stand-alone Switches

Figure 1. Front Panels of the AT-x930-28GTX and AT-x930-28GPX

Switches

21

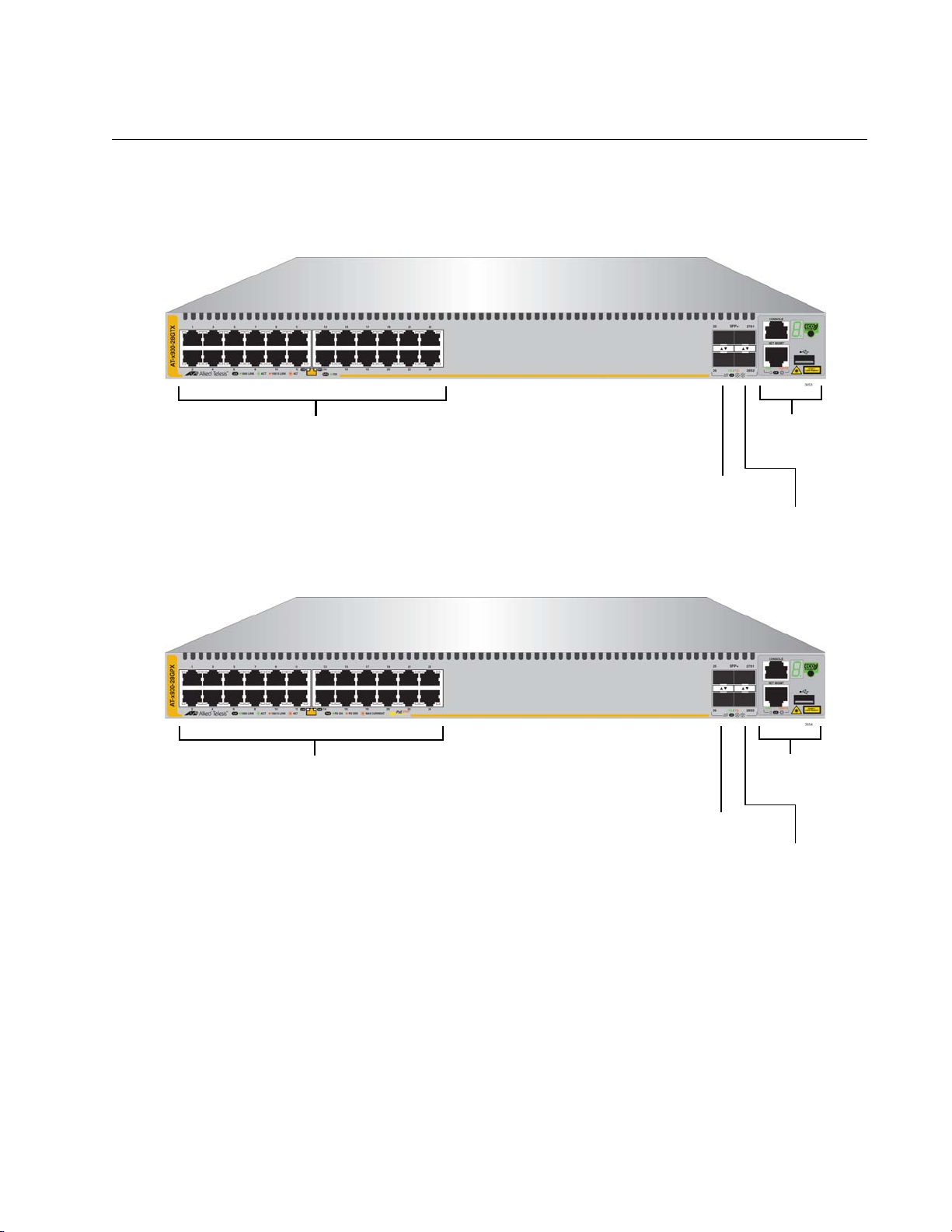

Page 22

Chapter 1: Overview

AT-x930-52GPX

AT-x930-52GTX

SFP+ Slots

Management

Panel

SFP+ or

Stacking Slots

10/100/1000Base-T Ports

SFP+ Slots

Management

Panel

SFP+ or

Stacking Slots

10/100/1000Base-T Ports

with PoE+

AT-x930-28GSTX

SFP+ Slots

Management

Panel

SFP+ or

Stacking Slots

10/100/1000Base-T Ports

SFP Slots

22

Figure 2. Front Panels of the AT-x930-28GSTX, AT-x930-52GTX, and AT-

x930-52GPX Switches

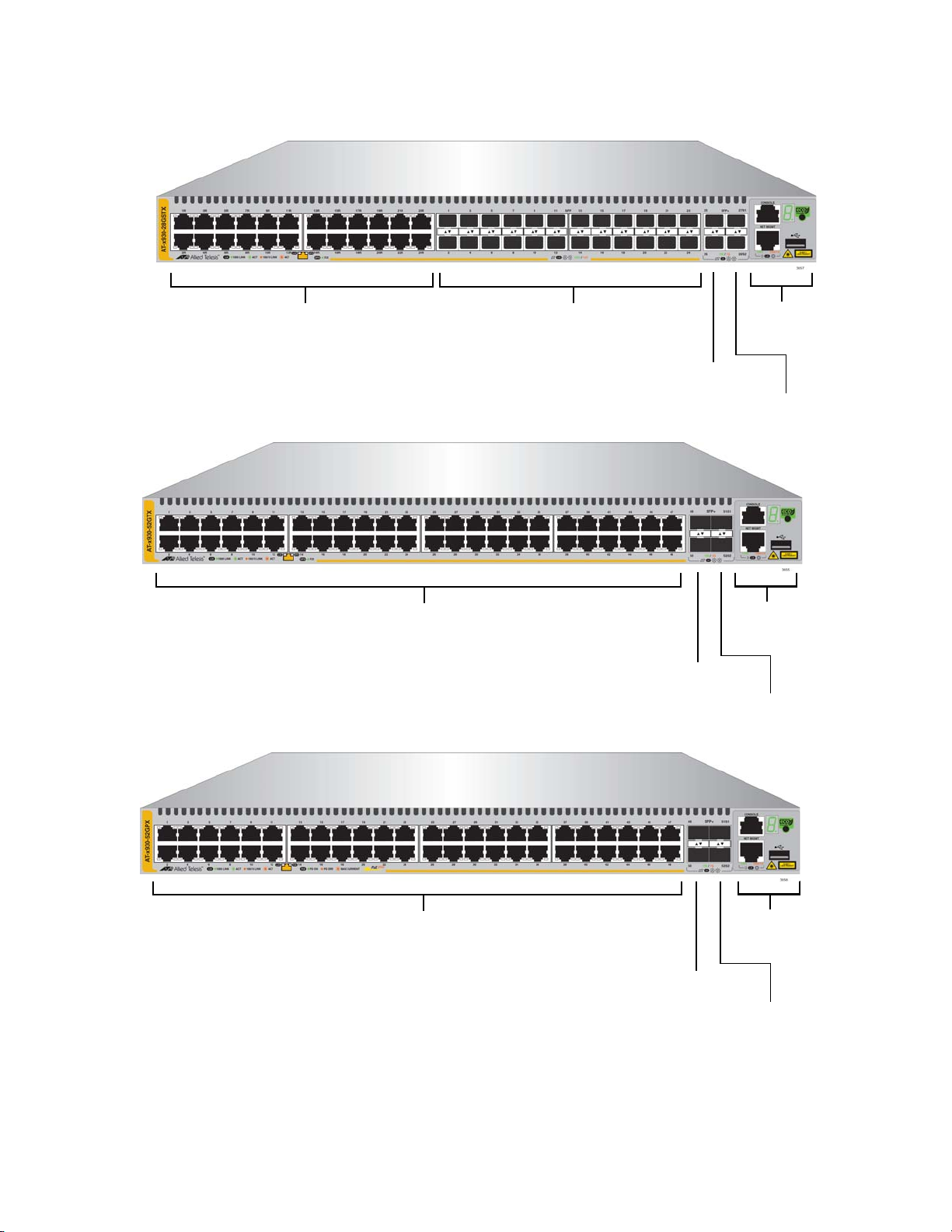

Page 23

x930 Series Installation Guide for Stand-alone Switches

AT-FAN09

Fan Module

Power Supply Slot B

Power Supply Slot A

AT-FAN09ADP

Module

with AT-PNL250 Blank Panel

Figure 3 shows the back panel. The back panel is the same on all of the

switches.

Figure 3. Back Panel

23

Page 24

Chapter 1: Overview

Console

eco-friendly

Button

Switch

Port

ID LED

Management

USB Port

Network Management Port

Management Panel

Figure 4 identifies the components in the management panel on the x930

Series switches.

24

Figure 4. Management Panel

Page 25

Power Supplies

x930 Series Installation Guide for Stand-alone Switches

There are five power supply models for the x930 Series switches. The

models are listed here:

AT-PWR150

AT-PWR250

AT-PWR250-80

AT-PWR800

AT-PWR1200

The top three models are primarily intended for the non-PoE AT-x93028GTX, AT-x930-28GSTX, and AT-x930-52GTX Switches. The bottom

two power supplies are for the PoE AT-x930-28GPX and AT-x930-52GPX

Switches.

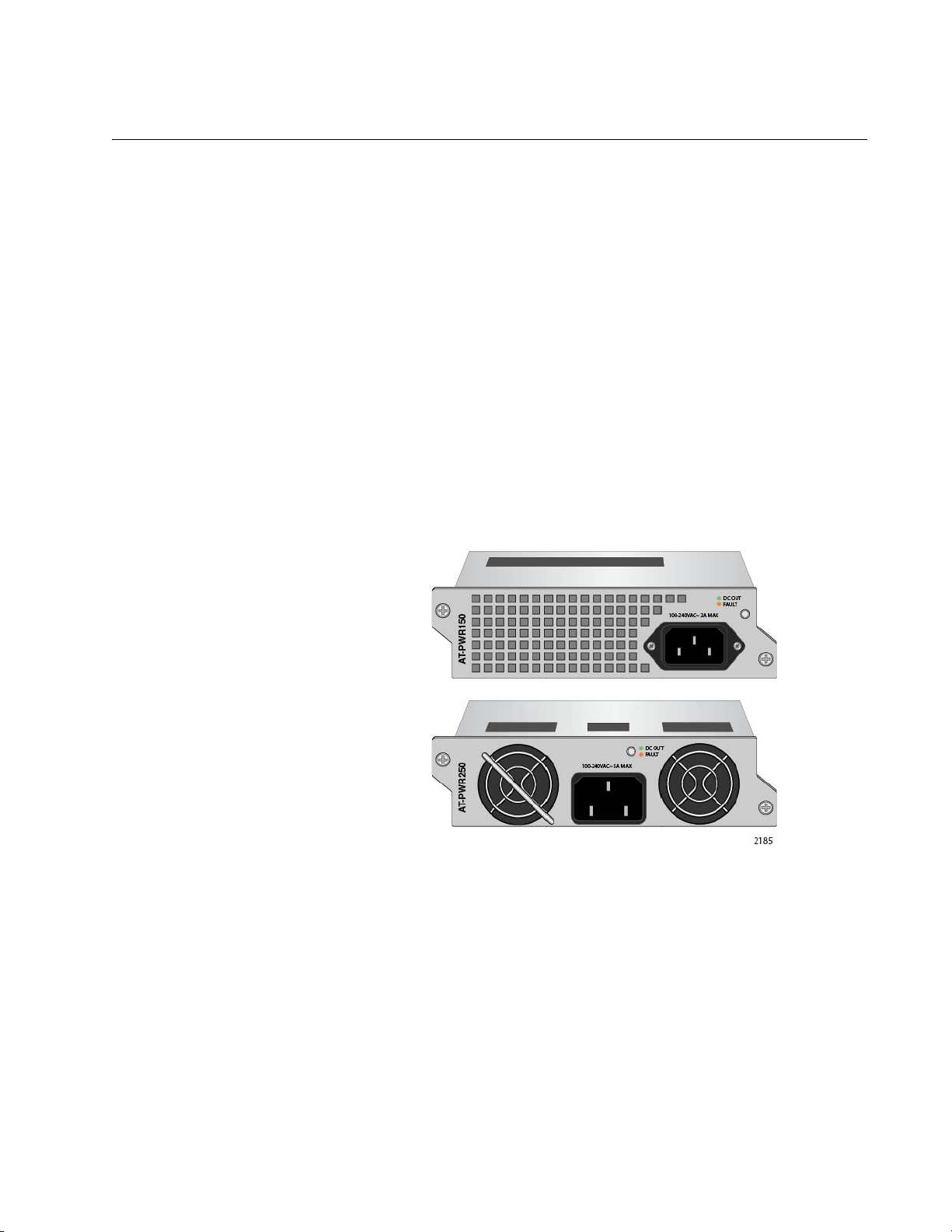

Figure 5 illustrates the AT-PWR150 and AT-PWR250 Power Supplies.

The two power supplies are functionally identical.

Figure 5. AT-PWR150 and AT-PWR250 Power Supplies

The two power supplies are primarily designed for the non-PoE switches

and have these operating characteristics:

The power supplies provide system power, but no PoE power.

A single power supply can power an entire non-PoE switch.

Installing two power supplies in a switch adds power redundancy.

The power supplies are not recommended for the PoE AT-x930-

28GPX and AT-x930-52GPX Switches because they do not have

power for PoE devices. You may install them into PoE switches,

but the switches will not be able to support PoE powered devices.

25

Page 26

Chapter 1: Overview

The AT-PWR250-80 DC Power Supply illustrated in Figure 6 has the

same operating characteristics as the AT-PWR150 and AT-PWR250

Power Supplies. It, too, is intended for the non-PoE switches because it

can supply system power, but no PoE power. The only difference is that

this power supply has a DC wiring connector instead of an AC connector,

for DC wiring environments.

Figure 6. AT-PWR250-80 Power Supply

Figure 7 illustrates the AT-PWR800 Power Supply.This power supply is

primarily intended for the PoE AT-x930-28GPX and AT-x930-52GPX

Switches. It provides both system power to the switch as well as up to 380

watts of PoE power for the powered devices connected to the network

ports.

26

Figure 7. AT-PWR800 Power Supply

A PoE switch with one AT-PWR800 Power Supply has the following power

characteristics:

Full system power

380 watts of PoE power

A switch with two AT-PWR800 Power Supplies has these power

characteristics:

Full system power and redundant system power

Either 740 watts of PoE power or 380 watts of active PoE power

and 380 watts of redundant PoE power.

You may install the AT-PWR800 Power Supply in the non-PoE AT-x93028GTX and AT-x930-52GTX Switches. But because the switches do not

support PoE, the power supply will provide system power but no PoE

power.

Page 27

x930 Series Installation Guide for Stand-alone Switches

The AT-PWR1200 Power Supply is shown in Figure 8. It is similar to the

AT-PWR800 Power Supply in that it is intended for the PoE AT-x93028GPX and AT-x930-52GPX Switches because it provides both system

power and power for PoE devices. The difference between them is the

amount of PoE power. The AT-PWR1200 Power Supply can provide up to

740 watts compared to 380 watts for the AT-PWR800 Power Supply.

Figure 8. AT-PWR1200 Power Supply

A PoE switch with one AT-PWR1200 Power Supply has the following

power characteristics:

Full system power

740 watts of power for PoE devices

A switch with two AT-PWR1200 Power Supplies has these power

characteristics:

Full system power and redundant system power

Either 1440 watts of PoE power or 740 watts of active PoE power

and 740 watts of redundant PoE power.

Guidelines Please review the following guidelines concerning power supplies:

The x930 Series Switches do not come with power supplies. The

power supplies must be ordered separately.

If you install two power supplies in the switch, they must both be

the same model. For example, you may install two AT-PWR800

Power Supplies or two AT-PWR1200 Power Supplies in a switch.

You may not install two different power supply models in the

switch.

The non-PoE AT-x930-28GTX AT-x930-28GSTX, and AT-x930-

52GTX Switches require only one power supply for full operations.

Installing a second power supply adds power redundancy, which

protects against interruptions to network operations in the event

one power supply loses power or fails. Power redundancy is

available only when both AC or DC connectors on the switch are

connected to power sources.

27

Page 28

Chapter 1: Overview

Warning

Warning

Note

The PoE AT-x930-28GPX and AT-x930-52GPX Switches also

require only one power supply for network operations, excluding

PoE. The switches can continue to operate even if one power

supply fails or loses power.

The second power supply in the PoE switches either increases the

amount of power for PoE or adds PoE redundancy. For further

information, refer to “Power Budget” on page 33.

The DC wires for the AT-PWR250-80 DC Power Supply should be

routed from a DC load center containing appropriate overcurrent

branch protection for each DC feed, as required by the cognizant

local electrical authority.

Refer to “Technical Specifications” on page 149 for the input voltage

ranges.

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. E3

This unit might have more than one power cord. To reduce the risk

of electric shock, disconnect all power cords before servicing the

unit. E30

The AT-PWR150, AT-PWR250, AT-PWR800, and AT-PWR1200

Power Supplies are powered on or off by connecting or

disconnecting the power cords. The AT-PWR250-80 Power Supply

is powered on or off with its On/Off power switch or by deactivating

the DC circuit.

28

Page 29

x930 Series Installation Guide for Stand-alone Switches

Note

Note

10/100/1000Base-T Twisted Pair Ports

The twisted pair ports on the switches are described in this section.

Speed The ports can operate at 10, 100, or 1000 Mbps. The speeds may be set

manually using the management software or automatically with AutoNegotiation (IEEE 802.3u), the default setting.

The ports must be set to Auto-Negotiation to function at 1000 Mbps

and are not compatible with devices that are not IEEE 802.3u

compliant.

Duplex Mode The twisted pair ports can operate in either half- or full-duplex mode. The

duplex mode of a port, like port speed, may be set manually using the

management software or automatically with Auto-Negotiation (IEEE

802.3u), the default setting.

Wiring

Configuration

The speed and duplex mode settings of a port may be set independently

of each other. For example, a port may be configured such that its speed

is set manually while its duplex mode is established through AutoNegotiation.

A switch port should not use Auto-Negotiation to set its duplex mode

if it is connected to a network device that does not support AutoNegotiation for 10 or 100 Mbps operation and has a fixed duplex

mode of full-duplex. Otherwise, a duplex-mode mismatch may occur

in which a switch port and a network device operate at different

duplex modes. The duplex modes of switch ports that are connected

to network devices that do not support Auto-Negotiation should be

set manually through the management software.

The wiring configuration of a port operating at 10 or 100 Mbps can be MDI

or MDI-X. The wiring configurations of a switch port and a network device

connected with straight-through twisted pair cabling have to be opposite,

such that one device is using MDI and the other MDI-X. For instance, a

switch port has to be set to MDI-X if it is connected to a network device set

to MDI.

You may set the wiring configurations of the ports manually or let the

switch configure them automatically with auto-MDI/MDI-X (IEEE 802.3abcompliant). This feature enables the switch to automatically negotiate with

network devices to establish their proper settings.

29

Page 30

Chapter 1: Overview

Note

The MDI and MDI-X settings do not apply when ports are operating at

1000 Mbps.

Maximum

Distance

Cable

Requirements

The ports have a maximum operating distance of 100 meters (328 feet).

The cable requirements of the ports are given in Table 2.

Table 2. Twisted Pair Cable for the 10/100/1000Base-T Ports

Cable Type 10Mbps 100Mbps 1000Mbps

Standard TIA/EIA 568-Bcompliant Category 3 shielded

or unshielded cabling with 100

ohm impedance and a

frequency of 16 MHz.

Standard TIA/EIA 568-Acompliant Category 5 or TIA/

EIA 568-B-compliant Enhanced

Category 5 (Cat 5e) shielded or

unshielded cabling with 100

ohm impedance and a

frequency of 100 MHz.

Yes Yes No

Yes Yes Yes

Standard TIA/EIA 568-Bcompliant Category 6 or 6a

shielded cabling.

For the cable requirements for the ports on the AT-x930-28GPX and

AT-x930-52GPX Switches for PoE devices, refer to Table 4 on

page 32.

Yes Yes Yes

Port Pinouts Refer to Table 29 on page 156 and Table 30 on page 156 for the port

pinouts of the 10/100/1000Base-T twisted pair ports.

30

Page 31

Power Over Ethernet

The AT-x930-28GPX and AT-x930-52GPX Switches feature Power over

Ethernet (PoE) on the 10/100/1000Base-T ports. PoE is used to supply

power to network devices over the same twisted pair cables that carry the

network traffic.

The main advantage of PoE is that it can make it easier to install a

network. The selection of a location for a network device is often limited by

whether there is a power source nearby. This often limits equipment

placement or requires the added time and cost of having additional

electrical sources installed. But with PoE, you can install PoE-compatible

devices wherever they are needed without having to worry about whether

there are power sources nearby.

A device that provides PoE to other network devices is referred to as

power sourcing equipment (PSE). The AT-x930-28GPX and AT-x93052GPX Switches act as PSE units by adding DC power to the network

cable, thus functioning as a central power source for other network

devices.

x930 Series Installation Guide for Stand-alone Switches

Devices that receive their power from a PSE are called powered devices

(PD). Examples include wireless access points, IP telephones, webcams,

and even other Ethernet switches.

The switch automatically determines whether or not a device connected to

a port is a powered device. Ports that are connected to network nodes that

are not powered devices (that is, devices that receive their power from

another power source) function as regular Ethernet ports, without PoE.

The PoE feature remains activated on the ports but no power is delivered

to the devices.

PoE Standards The AT-x930-28GPX and AT-x930-52GPX Switches support these PoE

standards:

PoE (IEEE 802.3af): This standard provides up to 15.4 watts at the

switch port to support powered devices that require up to 12.95

watts.

PoE+ (IEEE 802.3at): This standard provides up to 30.0 watts at

the switch port to support powered devices that require up to 25.5

watts.

Powered Device

Classes

Powered devices are grouped into the five classes listed in Table 3 on

page 32. The classes are based on the amount of power the devices

require. The switches support all five classes.

31

Page 32

Chapter 1: Overview

Table 3. IEEE Powered Device Classes

Maximum Power

Class

0 15.4W 0.44W to 12.95W

1 4.0W 0.44W to 3.84W

2 7.0W 3.84W to 6.49W

3 15.4W 6.49W to 12.95W

4 30.0W 12.95W to 25.5W

Output from a Switch

Port

PD Power Range

Cable

Requirements

Table 4. Twisted Pair Cable Requirements for the 10/100/1000Base-T Ports at 10 or 100Mbps

Cable Type

Standard TIA/EIA 568-Bcompliant Category 3 shielded

or unshielded cabling with 100

ohm impedance and a

frequency of 16 MHz.

Standard TIA/EIA 568-Acompliant Category 5 shielded

or unshielded cabling with 100

ohm impedance and a

frequency of 100 MHz.

Standard TIA/EIA 568-Bcompliant Enhanced Category

5 (Cat 5e) shielded or

unshielded cabling with 100

ohm impedance and a

frequency of 100 MHz.

The cable requirements for ports operating at 10 or 100Mbps are given in

Table 4.

10Mbps 100Mbps

Non-

PoE

Yes Yes No Yes Yes No

Yes Yes No Yes Yes No

Yes Yes Yes Yes Yes Yes

PoE PoE+

Non-

PoE

PoE PoE+

32

Standard TIA/EIA 568-Bcompliant Category 6 or 6a

shielded cabling.

Yes Yes Yes Yes Yes Yes

Page 33

x930 Series Installation Guide for Stand-alone Switches

The cable requirements for ports operating at 1000Mbps are given in

Table 5.

Table 5. Twisted Pair Cable Requirements for the 10/100/1000Base-T

Ports at 1000Mbps

1000Mbps

Cable Type

Standard TIA/EIA 568-B-compliant

Non-

PoE

PoE PoE+

No No No

Category 3 shielded or unshielded

cabling with 100 ohm impedance and a

frequency of 16 MHz.

Standard TIA/EIA 568-A-compliant

Yes Yes No

Category 5 shielded or unshielded

cabling with 100 ohm impedance and a

frequency of 100 MHz.

Standard TIA/EIA 568-B-compliant

Yes Yes Yes

Enhanced Category 5 (Cat 5e) shielded

or unshielded cabling with 100 ohm

impedance and a frequency of 100 MHz.

Standard TIA/EIA 568-B-compliant

Yes Yes Yes

Category 6 or 6a shielded cabling.

Power Budget The power budget is the maximum amount of power the switch can supply

to the powered devices on its ports. The higher the budget, the more PoE

devices the switch can support at one time.

The power budgets of the AT-x930-28GPX and AT-x930-52GPX Switches

depend on several factors. The first is the power supply model. The po wer

budgets of the five power supplies are listed in Table 6.

Table 6. Power Supply Budgets of the Power Supplies

Power Supply Power Budget for PoE Devices

AT-PWR150 0 watts

AT-PWR250 0 watts

AT-PWR250-80 0 watts

AT-PWR800 380 watts

AT-PWR1200 740 watts

33

Page 34

Chapter 1: Overview

Note

The AT-PWR250 and AT-PWR250-80 Power Supplies are intended

for the non-PoE AT-x930-28GTX, AT-x930-28GSTX, and AT-x93052GTX Switches. They are not intended for the AT-x930-28GPX

and AT-x930-52GPX Switches because they do not provide power

for PoE + devices. You may install them in the PoE+ switches, but

the switches will not support PoE devices.

Another factor that determines the power budget of the switch is the

number of PoE power supplies in the device. The power budget of a PoE

switch that has only one PoE power supply is equal to the budget of the

power supply. For example, a switch that has one AT-PWR1200 Power

Supply has a power budget of 740W for powered devices.

A PoE switch with two AT-PWR800 or AT-PWR1200 Power Supplies has

either redundant PoE power or nearly double the power budget. This is

controlled by the power boost feature, which has a status of either enabled

or disabled. When the power boost feature is enabled, a PoE switch with

two power supplies actively uses the PoE power from both supplies to

increase its available power budget. When the feature is disabled, the

switch uses the PoE power of only one of its power supplies and keeps the

other in reserve in case the primary power supply should fail or lose

power.

As an example, assume that a PoE switch has one AT-PWR1200 Power

Supply, which has a power budget of 740W for powered devices. Thus,

the switch would have a total power budget of 740W. Now assume the

switch has two AT-PWR1200 Power Supplies. When the power boost

mode is enabled, the switch uses the PoE power from both supplies, for a

total power budget of 1440W. When the power boost mode is disabled,

the switch has an active PoE power of 740W and a redundant budget of

the same amount. The switch activates the redundant power budget only if

the power supply providing the active power budget fails or loses power.

Table 7 lists the power budgets for the switch with one or two AT-PWR800

Power Supplies and the power boost mode.

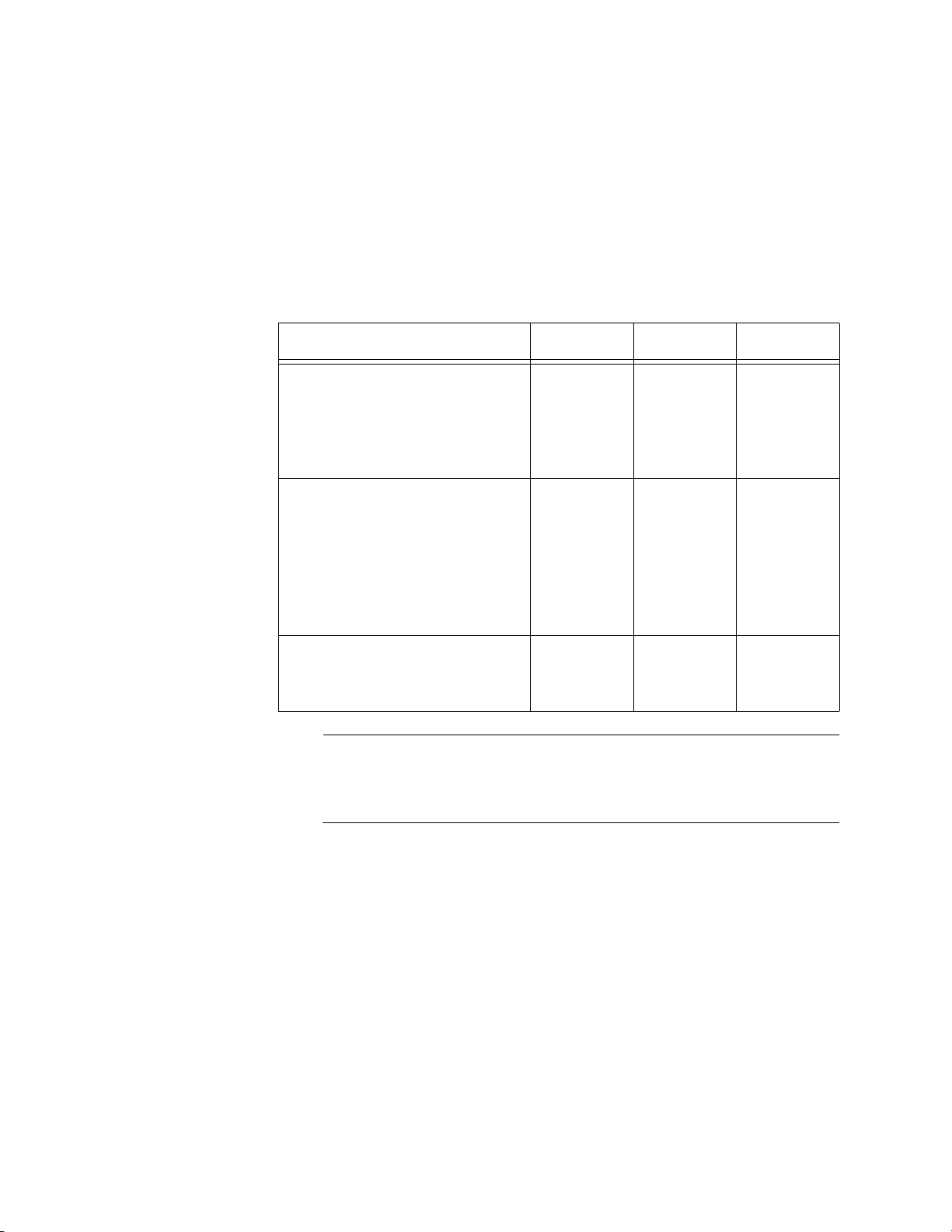

Table 7. Power Budgets of the AT-PWR800 Power Supply

Number of

Power

Supplies in the

State of Power

Boost

Power Budget

of the Switch

Redundant

Power

Switch

One NA 380 watts 0 watts

Two Enabled 740 watts 0 watts

Two Disabled 380 watts 380 watts

34

Page 35

x930 Series Installation Guide for Stand-alone Switches

Table 8 lists the power budgets for the switch with one or two ATPWR1200 Power Supplies and the power boost mode.

Table 8. Power Budgets of the AT-PWR1200 Power Supply

Number of

Power

Supplies in the

State of Power

Boost

Power Budget

of the Switch

Redundant

Power

Switch

One NA 740 watts 0 watts

Two Enabled 1440 watts 0 watts

Two Disabled 740 watts 740 watts

The maximum number of PoE devices the switch can support at one time

is determined by its power budget and the power requirements of the

devices. The switch can supply power to all of the devices as long as the

their total power requirements is less than its power budget. If the switch

determines that the power requirements of the devices exceed its power

budget, it denies power to one or more ports using a mechanism referred

to as port prioritization.

Port

Prioritization

To determine whether the power requirements of the PoE devices you

plan to connect to the switch exceed its power budget, refer to their

documentation for their power requirements and add the requirements

together. The switch should be able to power all of the devices

simultaneously as long as the total is below its power budget. If the total

exceeds the available power budget, you should consider reducing the

number of PoE devices so that all of the devices receive power.

Otherwise, the switch powers a subset of the devices, based on port

prioritization.

The switch can handle different power requirements on different ports.

This enables you to connect different classes of PoE equipment to the

ports on the switch.

If the power requirements of the powered devices exceed the switch’s

power budget, the switch denies power to some ports based on a system

called port prioritization. You may use this mechanism to ensure that

powered devices critical to the operations of your network are given

preferential treatment by the switch in the distribution of power should the

demands of the devices exceed the available capacity.

There are three priority levels:

Critical

High

Low

35

Page 36

Chapter 1: Overview

Ports set to the Critical level, the highest priority level, are guaranteed

power before any of the ports assigned to the other two priority levels.

Ports assigned to the other priority levels receive power only if all the

Critical ports are receiving power. Ports that are connected to your most

critical powered devices should be assigned to this level. If there is not

enough power to support all the ports set to the Critical priority level,

power is provided to the ports based on port number, in ascending order.

The High level is the second highest level. Ports set to this level receive

power only if all the ports set to the Critical level are already receiving

power. If there is not enough power to support all of the ports set to the

High priority level, power is provided to the ports based on port number, in

ascending order.

The lowest priority level is Low. This is the default setting. Ports set to this

level only receive power if all of the ports assigned to the other two levels

are already receiving power. As with the other levels, if there is not enough

power to support all of the ports set to the Low priority level, power is

provided to the ports based on port number, in ascending order.

Wiring

Implementation

Power allocation is dynamic. Ports supplying power to powered devices

may cease power transmission if the switch’s power budget is at

maximum usage and new powered devices, connected to ports with

higher priorities, become active.

The IEEE 802.3af standard defines two methods for the delivery of DC

power over twisted pair cable by a switch to the powered devices. These

methods, known as modes A and B, identify the wires within the cable that

carry the DC power from the switch to a powered device.

Twisted pair cabling typically consists of eight wires. With 10Base-T and

100Base-TX devices, the wires connected to pins 1, 2, 3, and 6 on the RJ45 connectors carry the network traffic while the wires connected to pins 4,

5, 7, and 8 are unused. With 1000Base-T devices, all eight wires are used

to carry network data.

It takes four wires to deliver DC power to a powered device. With Mode A,

the power is delivered on pins 1, 2, 3, and 6. These are the same pins in

10Base-T and 100Base-TX devices that carry the network data. With

mode B, the power is provided over the spare wires.

The ports on the AT-x930-28GPX and AT-x930-52GPX Switches deliver

the power using pins 1, 2, 3, and 6, which corresponds to mode A in the

IEEE 802.3af standard. Powered devices that comply with the IEEE

802.3af standard are required to support both power delivery methods.

Legacy devices that do not comply with the standard will work with the

switch if they are powered on pins 1, 2, 3, and 6.

36

Page 37

SFP Slots

x930 Series Installation Guide for Stand-alone Switches

The twenty four SFP slots on the AT-x930-28GSTX Switch support the

following types of transceivers:

100Base-FX, 1000Base-T, and 1000Base-SX/LX SFP transceivers

Single-port BiDi 100Base-FX and 1000Base-LX SFP transceivers

1000Base-ZX SFP transceivers

The slots are paired with the twenty four 10/100/1000Base-T twisted pair

ports. SFP slot 1 is paired with twisted pair port 1R, slot 2 with twisted pair

port 2R, and so on. Only one slot or port in a pair can be active at a time.

For example, if you install an SFP transceiver in slot 3 and connect it to an

active network device, the switch deactivates twisted pair port 3R.

Please review the following guidelines for using the SFP slots on the ATx930-28GSTX Switch:

Each SFP slot is paired with a twisted pair port.

You may not change the pairings of the ports and slots.

Only one port or slot in a pair can be active at a time.

The twisted pair port is the default active port of a pair.

An SFP slot automatically becomes active when you install and

connect an SFP transceiver to an active network device.

The switch automatically reactivates the twisted pair port of a pair

when the transceiver in the corresponding SFP slot loses its link to

a remote network device. For example, the switch reactivates

twisted pair port 4R if you disconnect the fiber optic cable from a

transceiver in slot 4.

The letter “R” in the numbering of the twisted pair ports on the front

of the switch refers to the “redundant” function of the ports. The

twisted pair ports are only available when their corresponding SFP

slots are empty or the SFP transceivers have not established links

with network devices.

37

Page 38

Chapter 1: Overview

Note

Note

Note

Note

SFP+ Slots

The four SFP+ slots on the switches support the following types of SFP

1000Mbps and SFP+ 10Gbps transceivers:

1000Base-SX/LX SFP transceivers

Single-port BiDi 1000Base-LX SFP transceivers

1000Base-ZX SFP transceivers

10Gbps, 10GBase-SR/LR fiber optic transceivers

10Gbps AT-SP10TW direct connect twinax cables with SFP+

transceiver-style connectors

You may use the slots and transceivers to connect switches to other

network devices over large distances, build high-speed backbone

networks between network devices, or connect high-speed devices, such

as servers, to your network.

The switches support a variety of short or long distance SFP or SFP+

modules. For a list of supported modules, contact your Allied Telesis

representative or visit our web site.

The SFP+ slots do not support 100Mbps 100Base-FX transceivers.

The slots support full-duplex mode only.They do not support halfduplex mode.

SFP and SFP+ transceivers must be purchased separately.

SFP+ slots 27/S1 and 28/S2 on the AT-x930-28GTX, AT-x93028GSTX, and AT-x930-28GPX Switches and slots 51/S1 and 52/S2

on the AT-x930-52GTX and AT-x930-52GPX Switches are initially

configured as stacking slots for the VCStack feature. If you intend to

use the switch as a stand-alone unit, you must disable the VCStack

feature before you can use the slots with standard SFP or SFP+

transceivers. The configuration instructions are provided later in this

guide, in Chapter 10, “Configuring the Switch for Stand-alone

Operation” on page 125.

38

Page 39

Stacking S1 and S2 SFP+ Slots

Note

Note

As explained in the previous section, you may use the four SFP+ slots on

the front panel of the switch with SFP 1000Mbps or SFP+ 10Gbps

transceivers to add high speed links from the switch to other network

devices. However, SFP+ slots 27/S1 and 28/S2 on the 28-port switches

and slots 51/S1 and 52/S2 on the 52-port switches have an additional

function. They can also be used with SFP+ transceivers and the VCStack

feature to build a stack of up to eight switches. The switches of a VCStack

act as a single virtual unit. They synchronize their actions so that switching

operations, like spanning tree protocols, virtual LANs, and static port

trunks, span across all of the units and ports. The two main advantages of

stacks are listed here:

You can manage multiple units simultaneously, which can simplify

network management.

You have more flexibility in how you configure some of the

features. For instance, a static port trunk on a stand-alone switch

has to consist of ports from the same switch. In contrast, a static

trunk on a stack may consist of ports from different switches in the

same stack.

x930 Series Installation Guide for Stand-alone Switches

SFP+ slots 27/S1 and 28/S2 on the 28-port switches and slots 51/S1

and 52/S2 on the 48-port switches are initially configured as stacking

slots for the VCStack feature. If you intend to use the switch as a

stand-alone unit, you must disable the VCStack feature before you

can use the slots with standard SFP or SFP+ transceivers. The