Page 1

SwitchBlade x8106

Layer 3+ Chassis Switch

AT-SBx81CFC960

Controller Fabric Card

AT-SBx8106 Chassis

AT-SBx81GT24 Ethernet Line Card

AT-SBx81GT40 Ethernet Line Card

AT-SBx81GP24 Ethernet PoE Line Card

AT-SBx81GS24a Ethernet SFP Line Card

AT-SBx81XS6 Ethernet SFP+ Line Card

AT-SBx81XS16 Ethernet SFP+ Line Card

AT-SBxPWRSYS1 AC and DC Power

Supplies

Installation Guide

AT-SBxPWRPOE1 AC Power Supply

613-001935 Rev. B

Page 2

Copyright © 2014 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis,

Inc.

Allied Telesis, AlliedWare Plus, VCStack Plus, and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated.

All other product names, company names, logos or other designations mentioned herein are trademarks or registered

trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document

without prior written notice. The information provided herein is subject to change without notice. In no event shall Allied

Telesis, Inc. be liable for any incidental, special, indirect, or consequential damages whatsoever, including but not limited

to lost profits, arising out of or related to this manual or the information contained herein, even if Allied Telesis, Inc. has

been advised of, known, or should have known, the possibility of such damages.

Page 3

Electrical Safety and Emissions Standards

This product meets the following standards.

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses , and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

European Union Restriction of the Use of Certain Hazardous Substances

(RoHS) in Electrical and Electronic Equipment

This Allied Telesis RoHS-compliant product conforms to the European Union Restriction of the Use of Certain Hazardous

Substances (RoHS) in Electrical and Electronic Equipment. Allied Telesis ensures RoHS conformance by requiring

supplier Declarations of Conformity, monitoring incoming materials, and maintaining manufacturing process controls.

EMI/RFI Emissions: FCC Class A, EN55022 Class A, EN61000-3-2, EN61000-3-3, CISPR Class A,

VCCI Class A, AS/NZS Class A

Warning: In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Immunity: EN55024

Electrical Safety: EN60950-1 (TUV), UL 60950-1 (

Safety Agency Approvals:

CULUS

, TUV, C-TICK, CE

CULUS

), EN60825

Laser Safety EN60825

3

Page 4

SwitchBlade x8106 Chassis Switch and AT-SBx81CFC960 Card Installation Guide

Translated Safety Statements

Important: The indicates that a translation of the safety statement is available in a PDF

document titled “Translated Safety Statements” on our web site at

http://www.alliedtelesis.com/support.

4

Page 5

Contents

Preface ............................................................................................................................................................15

Structure of the Installation Guide ....................................................................................................................16

Safety Symbols Used in this Document ...........................................................................................................17

Contacting Allied Telesis..................................................................................................................................18

Section I: Hardware Overview .................................................................................19

Chapter 1: Chassis and Power Supplies ..................... ................................................ ................................21

Introduction.......................................................................................................................................................22

AT-SBx8106 Chassis .......................................................................................................................................24

Slots for the Ethernet Line and Controller Cards..............................................................................................26

Slots for the Power Supplies ............................................................................................................................27

AT-SBxPWRSYS1 AC Power Supply .............. ... ... ... .................................................... ... .... ... ... ... ... ................28

LEDs ..........................................................................................................................................................28

AT-SBxPWRPOE1 Power Supply....................................................................................................................30

LEDs ..........................................................................................................................................................30

AT-SBxPWRSYS1 DC Power Supply ..............................................................................................................32

LEDs ..........................................................................................................................................................33

AT-SBxFAN06 Module.....................................................................................................................................34

LED............................................................................................................................................................34

Power Supply Interfaces (Opto-couplers).........................................................................................................35

LED............................................................................................................................................................35

Chapter 2: Ethernet Line Cards ............................. .................... ................... .................... ............................37

Ethernet Line Cards.......................... ... ... ... .... ... ................................................... .... ... ... ... ................................38

AT-SBx81GT24 Line Card................................................................................................................................39

LEDs ..........................................................................................................................................................39

AT-SBx81GT40 Line Card................................................................................................................................41

LEDs ..........................................................................................................................................................42

AT-SBx81GP24 PoE Line Card........................................................................................................................44

LEDs ..........................................................................................................................................................45

AT-SBx81GS24a SFP Line Card .....................................................................................................................47

LEDs ..........................................................................................................................................................47

AT-SBx81XS6 SFP+ Line Card........................................................................................................................49

LEDs ..........................................................................................................................................................49

AT-SBx81XS16 SFP+ Line Card......................................................................................................................51

LEDs ..........................................................................................................................................................51

10/100/1000Base-T Twisted Pair Ports............................................................................................................53

Connector Type............................. ... ... .... ................................................... ................................................53

Speed.........................................................................................................................................................53

Duplex Mode.................... ... ... .... ................................................... .... ... ... ... ................................................53

Maximum Distance.....................................................................................................................................53

Cable Requirements ..................................................................................................................................54

Automatic MDIX Detection............... ... .... ... ... ... ... .... ... ... ... .... ... ... ... .............................................................55

Port Pinouts................................... ... .................................................... ......................................................55

5

Page 6

Contents

Power over Ethernet on the AT-SBx81GP24 Line Card.................................................................................. 56

Powered Device Classes........................................................................................................................... 56

Power Budgeting....................................................................................................................................... 57

PoE Wiring................................................................................................................................................. 57

Chapter 3: AT-SBx81CFC960 Controller Fabric Card ................................................................................ 59

Hardware Components.................................................................................................................................... 60

Guidelines........................................................................................................................................................ 62

Dual Controller Cards ......... ... .... ... ... ... .... ... ... ... .................................................... ... ... .... ... ............................... 64

SYS Status LEDs............................................................................................................................................. 66

eco-friendly Button........................................................................................................................................... 68

SBx Linecard Status LEDs......... ... ... ... .... ................................................... .... ... ... ... ... .... ... ... ............................ 69

SFP+ Slots....................................................................................................................................................... 70

Console (RS-232) Port..................................................................................................................................... 72

Ethernet Management Port (NET MGMT) ....................................................................................................... 73

NET MGMT LED ....................................................................................................................................... 73

USB Port....................................................................... ... .... ... ... ... ...................................................................75

Reset Button .................................................................................................................................................... 76

AlliedWare Plus Software Releases for the Hardware Components ............................................................... 78

Section II: Installing the Chassis ............................................................................. 79

Chapter 4: Safety Precautions and Site Requirements ............................................................................. 81

Reviewing Safety Precautions ......................................................................................................................... 82

Selecting a Site for the SwitchBlade x8106 ..................................................................................................... 86

Installation Tools and Material ......................................................................................................................... 88

Chapter 5: Installing the Chassis in an Equipment Rack .......................................................................... 89

Required Tools and Material............................................................................................................................ 90

Preparing the Equipment Rack........................................................................................................................ 91

Unpacking the AT-SBx8106 Chassis............................................................................................................... 94

Removing the Rubber Feet.............................................................................................................................. 96

Adjusting the Equipment Rack Brackets.......................................................................................................... 98

Installing the Chassis in the Equipment Rack................................................................................................ 100

Removing the Shipping Brace ....................................................................................................................... 104

Installing the Chassis Grounding Wire........................................................................................................... 105

Chapter 6: Installing the Power Supplies .................................... ... .......................................................... 107

Protecting Against Electrostatic Discharge (ESD) ......................................................................................... 108

Installing the AT-SBxPWRSYS1 AC System Power Supply.......................................................................... 109

Installing the AT-SBxPWRPOE1 PoE Power Supply.....................................................................................115

Installing the AT-SBxPWRSYS1 DC System Power Supply.......................................................................... 121

Chapter 7: Installing the AT-SBx81CFC960 Controller and Ethernet Line Cards ................................. 127

Guidelines to Handling the Controller and Line Cards................................................................................... 128

Installing the AT-SBx81CFC960 Controller Fabric Card................................................................................ 130

Installing the Ethernet Line Cards.................................................................................................................. 136

Installing the Blank Slot Covers ..................................................................................................................... 140

Chapter 8: Installing the Transceivers and Cabling the Ports ................................................................ 143

Cabling Guidelines for the Twisted Pair Ports on the AT-SBx81GT24, AT-SBx81GP24, and

AT-SBx81GT40 Line Cards ........................................................................................................................... 144

Connecting Cables to the AT-SBx81GT40 Line Card............................................................................. 145

Guidelines to Installing SFP and SFP+ Transceivers .................................................................................... 147

Installing SFP Transceivers in the AT-SBx81GS24a Line Card .................................................................... 148

Installing SFP+ Transceivers in the AT-SBx81XS6 Line Card.......................................................................152

Installing AT-SP10TW Cables in the AT-SBx81XS6 Line Card..................................................................... 156

6

Page 7

SwitchBlade x8106 Chassis Switch and AT-SBx81CFC960 Card Installation Guide

Installing SFP+ Transceivers in the AT-SBx81XS16 Line Card .....................................................................159

Installing AT-SP10TW Cables in the AT-SBx81XS16 Line Card ...................................................................163

Cabling the NET MGMT Port on the AT-SBx81CFC960 Card.......................................................................165

Installing SFP+ Transceivers in the AT-SBx81CFC960 Card ........................................................................167

Chapter 9: Powering On the Chassis ........................................................................................................171

Verifying the Installation .................................................................................................................................172

Powering On the AT-SBxPWRSYS1 AC System Power Supply....................................................................173

Powering On the AT-SBxPWRPOE1 Power Supply ......................................................................................176

Powering On the AT-SBxPWRSYS1 DC System Power Supply ...................................................................179

Choosing a Method for Attaching the Grounding Wire.............................................................................181

Connecting the Grounding Wire with the Grounding Terminal.................................................................181

Connecting the Grounding Wire with Bare Wire ...................................................................................... 184

Choosing a Method for Attaching the Power Wires .................................................................................186

Connecting the DC Power Wires with the Straight Terminals..................................................................186

Connecting the DC Power Wires with the Right Angle Terminals............................................................195

Connecting Bare DC Power Wires... ... .................................................... ... ... .... ... ... ... .... ... ... ... ... ..............201

Monitoring the Initialization Process...............................................................................................................205

Using the LEDs to Monitor the Initialization Process ...............................................................................205

Using the Console Port to Monitor the Initialization Process ...................................................................205

Chapter 10: Verifying the Hardware Operations of the Chassis .............................................................209

Using the LEDs to Verify the Chassis.................. ... .................................................... ... ... .... ... ... ....................210

Using Local Management to Verify the Chassis.............................................................................................212

Starting a Local Management Session ....................................................................................................212

Entering the AlliedWare Plus Operating System Commands..................................................................213

Chapter 11: Troubleshooting .....................................................................................................................215

AT-SBxPWRSYS1 and AT-SBxPWRPOE1 AC Power Supplies ...................................................................216

AT-SBxPWRSYS1 DC Power Supply ............................................................................................................217

Ethernet Line Cards.......................... ... ... ... .... ... ................................................... .... ... ... ... ..............................219

Twisted Pair Ports ..........................................................................................................................................221

Power Over Ethernet......................................................................................................................................223

Fiber Optic or Twisted Pair Transceivers .......................................................................................................225

AT-SBx81CFC960 Controller Fabric Card .................................................... ... ... .... ... ... ... ..............................226

AT-SBxFAN06 Fan Module............................................................................................................................227

Local (Console) Management Session...........................................................................................................228

Power Supply Interfaces (Opto-couplers).......................................................................................................229

Chapter 12: Replacing Modules .................................................................................................................231

Replacing AT-SBxPWRSYS1 AC and AT-SBxPWRPOE1 Power Supplies ..................................................232

Replacing the AT-SBxPWRSYS1 DC Power Supply .....................................................................................237

Replacing Ethernet Line Cards......................... ... ... ... .... ... ... ... .... ... ... ... ......................................

Replacing the AT-SBx81CFC960 Controller Fabric Card ..............................................................................250

Replacing the AT-SBxFAN06 Fan Module.......... ... ........................................................................................253

Removing the AT-SBxFAN06 Fan Module ..............................................................................................253

Installing a New AT-SBxFAN06 Fan Module...........................................................................................256

Chapter 13: Upgrading the Controller Fabric Card ..................................................................................259

Before You Begin ...........................................................................................................................................260

Upgrading the Controller Fabric Card.............................................................................................................262

.....................248

Section III: Building a Stack with VCStack Plus .................................................267

Chapter 14: VCStack Plus Overview ......................... ... ... ... .... ... ... ... .... ... ....................................................269

Overview.........................................................................................................................................................270

Stack Trunk and Stacking Transceivers.........................................................................................................271

7

Page 8

Contents

Cabling Configurations for the Stacking Transceivers................................................... ... ... ... .... ... ................ 273

One Controller Card Per Chassis............................................................................................................ 273

Two Controller Cards Per Chassis.......................................................................................................... 274

VCStack Plus Feature License ...................................................................................................................... 276

Optional Feature Licenses............................................................................................................................. 277

Chassis ID Numbers...................................................................................................................................... 278

Priority Numbers ............................................................................................................................................ 279

Stacking Guidelines ....................................................................................................................................... 281

Chapter 15: Building a Stack ..................................................................................................................... 283

Before You Begin........................................................................................................................................... 284

Displaying the Management Software Version Number ................................................................................285

Activating the VCStack Plus Feature License................................................................................................ 287

Enabling the Stacking Feature....................................................................................................................... 289

Displaying the Feature Licenses.................................................................................................................... 291

Setting the ID Number ..... ... ... .... ... ... ... .... ... ... ... .................................................... ... ... .... ... ............................. 293

Setting the Priority Number............................................................................................................................ 297

Powering Off the Chassis .............................................................................................................................. 298

Configuring the Second Chassis.................................................................................................................... 299

Installing and Cabling the Stacking Transceivers ................................... ... .... ... ............................................. 300

Powering On the Stack .................................................................................................................................. 303

Controlling the Selection of the Initial Active Master Controller Card...... ... ... ... ... .... ... ... ... .... ... ... ... ... .......303

Powering On the Switches ......................................................................................................................304

Monitoring the Boot Up Sequence.................... ... ... ... .... ... ... ... .... ............................................................. 304

Verifying the Stack......................................................................................................................................... 307

Installing Optional Feature Licenses.............................................................................................................. 309

Troubleshooting the Stack ............................................................................................................................. 310

Appendix A: Technical Specifications ............................... ....................................................................... 313

Physical Specifications .................................................................................................................................. 313

Environmental Specifications..................... ... ... .... ... ... ... ... .... ... ... ... .... ... .......................................................... 315

Power Specifications...................................................................................................................................... 316

Safety and Electromagnetic Emissions Certifications.................................................................................... 318

Port Pinouts ........ ... .... ... ... ... .................................................... ....................................................................... 319

Fiber Optic Specifications of the AT-StackOP/0.3 and AT-StackOP/9.0 Transceivers.................................. 321

8

Page 9

Figures

Figure 1: AT-SBx8106 Chassis ........................................................................................................................................... 22

Figure 2: Power Supply Units.............................................................................................................................................. 22

Figure 3: Fan Module .......................................................................................................................................................... 23

Figure 4: Front View of the AT-SBx8106 Chassis............................................................................................................... 24

Figure 5: Rear View of the AT-SBx8106 Chassis................................................................................................................ 25

Figure 6: AT-SBx8106 Chassis with Line Cards, Controller Cards, and Power Supplies ................................................... 25

Figure 7: Ethernet Line and Controller Cards Slots............................................................................................................. 26

Figure 8: Power Supply Slots .............................................................................................................................................. 27

Figure 9: AT-SBxPWRSYS1 Power Supply ........................................................................................................................ 28

Figure 10: AT-SBxPWRPOE1 Power Supply...................................................................................................................... 30

Figure 11: AT-SBxPWRSYS1 DC Power Supply................................................................................................................ 32

Figure 12: AT-SBxFAN06 Module....................................................................................................................................... 34

Figure 13: Power Supply Interfaces (Opto-couplers)*......................................................................................................... 35

Figure 14: Ethernet Line Cards ........................................................................................................................................... 38

Figure 15: AT-SBx81GT24 Line Card.................................................................................................................................. 39

Figure 16: Port LEDs on the AT-SBx81GT24 Line Card..................................................................................................... 40

Figure 17: AT-SBx81GT40 Line Card.................................................................................................................................. 41

Figure 18: Port LEDs on an RJ Point 5 Cable Connector for the AT-SBx81GT40 Line Card ............................................. 42

Figure 19: Port LEDs on an RJ Point 5 Cable Connector for the AT-SBx81GT40 Line Card ...........................................

Figure 20: AT-SBx81GP24 PoE Line Card.......................................................................................................................... 44

Figure 21: Port LEDs on the AT-SBx81GP24 PoE Line Card............................................................................................. 45

Figure 22: AT-SBx81GS24a SFP Line Card ........................................................ ... ............................................................ 47

Figure 23: Port LEDs on the AT-SBx81GS24a SFP Line Card........................................................................................... 48

Figure 24: AT-SBx81XS6 Line Card.................................................................................................................................... 49

Figure 25: SFP+ Slot LEDs on the AT-SBx81XS6 Line Card.............................................................................................. 49

Figure 26: AT-SBx81XS16 Line Card.................................................................................................................................. 51

Figure 27: SFP+ Slot LEDS on the AT-SBx81XS16 Line Card........................................................................................... 52

Figure 28: AT-SBx81CFC960 Controller Fabric Card ......................................................................................................... 60

Figure 29: 100 - 125 VAC 125 V NEMA 5-20 Plug and Receptacle.................................................................................... 87

Figure 30: Reserving Vertical Rack Space.......................................................................................................................... 92

Figure 31: Rack Mounting Hole Locations........................................................................................................................... 93

Figure 32: Components of the AT-SBx8106 Chassis.......................................................................................................... 94

Figure 33: Components of the AT-SBx8106 Chassis (Continued) ...................................................................................... 95

Figure 34: Turning the Chassis Upside Down..................................................................................................................... 96

Figure 35: Removing the Rubber Feet ................................................................................................................................ 97

Figure 36: Rack Mounting Bracket Locations...................................................................................................................... 99

Figure 37: Rack Bracket Locations for Reverse Position of Chassis................................................................................... 99

Figure 38: Lifting the AT-SBx8106 Chassis into the Equipment Rack............................................................................... 101

Figure 39: Installing the Rack Mount Screws .................................................................................................... ................ 102

Figure 40: Tightening the Rack Mount Screws.................................................................................................................. 103

Figure 41: Removing the Shipping Brace.......................................................................................................................... 104

Figure 42: Stripping the Grounding Wire......................................................................................................... .................. 105

Figure 43: Removing the Grounding Lug........................................................................................................................... 105

Figure 44: Attaching the Grounding Wire to the Grounding Lug........................................................................................ 106

Figure 45: Installing the Grounding Lug and Wire............................................................................................................. 106

Figure 46: ESD Socket and Wrist Strap............................................................................................................................ 108

Figure 47: Power Supply Slots.......................................................................................................................................... 109

Figure 48: Removing the Blank Slot Cover from Power Supply Slot C ................................................................ ... .......... 110

Figure 49: Items Included with the AT-SBxPWRSYS1 Power Supply Module.................................................................. 111

.. 42

9

Page 10

List of Figures

Figure 50: Verifying the AT-SBxPWRSYS1 Power Supply.................................. ... ... ................................. ....................... 112

Figure 51: Unlocking the Handle on the AT-SBxPWRSYS1 Power Supply ................................................................... ... 112

Figure 52: Inserting the AT-SBxPWRSYS1 Power Supply................................................................................................ 113

Figure 53: Lowering the Handle on the AT-SBxPWRSYS1 Power Supply........................................................................ 114

Figure 54: Removing the Blank Slot Cover from Power Supply Slot A.............................................................................. 116

Figure 55: Items Included with the AT-SBxPWRPOE1 Power Supply Module.................................................................. 117

Figure 56: Verifying the AT-SBxPWRPOE1 PoE Power Supply ....................................................................................... 118

Figure 57: Unlocking the Handle on the AT-SBxPWRPOE1 Power Supply...................................................................... 118

Figure 58: Inserting the AT-SBxPWRPOE1 Power Supply............................................................................................... 119

Figure 59: Locking the Handle on the AT-SBxPWRPOE1 Power Supply ................................................................... ... ... 120

Figure 60: Removing the Blank Slot Cover from Power Supply Slot C.............................................................................. 122

Figure 61: Items Included with the AT-SBxPWRSYS1 DC Power Supply Module............................................................ 123

Figure 62: On/Off Switch on the AT-SBxPWRSYS1 DC Power Supply............................................................................ 124

Figure 63: Loosening the Handle Locking Screw on the AT-SBxPWRSYS1 DC Power Supply....................................... 124

Figure 64: Raising Handle on the AT-SBxPWRSYS1 DC Power Supply............................................................... ........... 125

Figure 65: Inserting the AT-SBxPWRSYS1 DC System Power Supply............................................................................. 125

Figure 66: Locking the Handle on the AT-SBxPWRSYS1 DC System Power Supply....................................................... 126

Figure 67: Aligning a Card in a Slot......................................................................................................... .......................... 129

Figure 68: Slots 5 and 6 for the AT-SBx81CFC960 Card.................................................................................................. 130

Figure 69: Items Included with the AT-SBx81CFC960 Controller Fabric Card............................................................... ... 131

Figure 70: Removing the AT-SBx81CFC960 Controller Fabric Card from the Anti-static Bag.......................................... 131

Figure 71: Removing the Battery Insulator ......................................................................................

Figure 72: Opening the Locking Handles on the AT-SBx81CFC960 Controller Fabric Card ............................................ 132

Figure 73: Aligning the AT-SBx81CFC960 Card in the Chassis Slot................................................................................. 133

Figure 74: Closing the Locking Levers on the AT-SBx81CFC960 Controller Fabric Card ................................................ 134

Figure 75: Tightening the Thumb Screws on the AT-SBx81CFC960 Card ........................................... ......................... ... 135

Figure 76: Slots 1 to 4 for the Ethernet Line Cards................................................................................................... ... ... ... 136

Figure 77: Removing an Ethernet Line Card from the Anti-static Bag................................................................. ... ........... 137

Figure 78: Aligning an Ethernet Line Card in a Chassis Slot.......................................................................................... ... 137

Figure 79: Seating an Ethernet Line Card on the Backplane Connector........................................................................... 138

Figure 80: Tightening the Thumb Screws on an Ethernet Line Card................................................................................. 139

Figure 81: Installing a Blank Slot Cover........................................................................................ ... .................................. 140

Figure 82: Tightening the Thumbscrews on a Blank Slot Cover........................................................................................ 140

Figure 83: RJ Point 5 Cable Connector for AT-SBx81GT40 Line Card............................................................................. 145

Figure 84: Connecting Cables to Ports on the AT-SBx81GT40 Line Card........................................................................ 146

Figure 85: Removing the Dust Cover from an SFP Slot in the AT-SBx81GS24a Line Card............................................. 148

Figure 86: Handle on SFP Transceiver................................................................................................................ .............. 149

Figure 87: Inserting the SFP Transceiver in the AT-SBx81GS24a Line Card................................................................... 149

Figure 88: Removing the Dust Cover from the SFP Transceiver in the AT-SBx81GS24a Line Card................................ 150

Figure 89: Verifying the Position of the Handle on the SFP Transceiver in the AT-SBx81GS24a Line Card.................... 150

Figure 90: Attaching a Fiber Optic Cable to an SFP Transceiver in the AT-SBx81GS24a Line Card............................... 151

Figure 91: Removing the Dust Cover from an SFP+ Slot in the AT-SBx81XS6 Line Card .............................................. . 152

Figure 92: Handle on SFP+ Transceiver .................................................................................................................. ......... 153

Figure 93: Installing an SFP+ Transceiver in the AT-SBx81XS6 Line Card...................................................................... 153

Figure 94: Removing the Dust Cover from an SFP+ Transceiver in the AT-SBx81XS6 Line Card................................... 154

Figure 95: Verifying the Position of the Handle on the SFP+ Transceiver in the AT-SBx81XS6 Line Card...................... 154

Figure 96: Attaching a Fiber Optic Cable to an SFP+ Transceiver in the AT-SBx81XS6 Line Card................ ... .............. 155

Figure 97: Removing the Dust Cover From an SFP+ Slot in the AT-SBx81XS6 Line Card..............................................

Figure 98: Release Tab on the AT-SP10TW Cable........................................................................................................... 157

Figure 99: Installing the AT-SP10TW Cable in the AT-SBx81XS6 Line Card ................................................................... 157

Figure 100: Removing the Dust Cover from a Transceiver Slot in the AT-SBx81XS16 Line Card.................................... 159

Figure 101: Installing a Transceiver in the AT-SBx81XS16 Line Card........................................................................ ... ... 160

Figure 102: Removing the Dust Cover from a Transceiver in the AT-SBx81XS16 Line Card........................................... 160

Figure 103: Verifying the Position of the Handle on the Transceiver in the AT-SBx81XS16 Line Card............................ 161

Figure 104: Attaching a Fiber Optic Cable to a Transceiver in the AT-SBx81XS16 Line Card ......................................... 162

Figure 105: Removing the Dust Cover From an SFP+ Slot on the AT-SBx81XS16 Line Card......................................... 163

Figure 106: Installing the AT-SP10TW Cable in the AT-SBx81XS16 Line Card ............................................................... 164

Figure 107: Removing a Dust Cover from an SFP+ Slot in the AT-SBx81CFC960 Controller Fabric Card........ ... ........... 167

Figure 108: Handle on an SFP+ Transceiver .................................................................................................................... 168

Figure 109: Installing an SFP+ Transceiver in the AT-SBx81CFC960 Controller Fabric Card......................... ... ... ........... 168

.................................. 132

156

10

Page 11

SwitchBlade x8106 Chassis Switch and AT-SBx81CFC960 Card Installation Guide

Figure 110: Removing the Dust Cover from an SFP+ Transceiver in the AT-SBx81CFC960 Controller Fab ri c Card ...... 169

Figure 111: Positioning the Handle on the Transceiver................................................................................................. .. .. 169

Figure 112: Attaching a Fiber Optic Cable to an SFP+ Transceiver in the AT-SBx81CFC960 Controller Fabric Card..... 170

Figure 113: AC Sockets on the Rear Panel of the AT-SBx8106 Chassis.......................................................................... 173

Figure 114: Connecting the AC Power Cord for the AT-SBxPWRSYS1 AC Power Supply.............................................. 174

Figure 115: Securing the Power Cord for the AT-SBxPWRSYS1 AC Power Supply to an Anchor................................... 175

Figure 116: Connecting the AC Power Cord for the AT-SBxPWRPOE1 Power Supply.................................................... 176

Figure 117: Securing the Power Cord for the AT-SBxPWRPOE1 Power Supply to an Anchor........................................ 177

Figure 118: Dress and Secure AC Power Cords............................................................................................................... 178

Figure 119: Components of the AT-SBxPWRSYS1 DC Power Supply............................................................................. 180

Figure 120: Grounding Wire Terminal ....................................................................................................... ........................ 181

Figure 121: Stripping the Stranded Grounding Wire.................................................................................. ... ..................... 181

Figure 122: Attaching the Stranded Grounding Wire to the Grounding Terminal.............................................................. 181

Figure 123: Removing the Nut and Washer from the Grounding Post .................................................................... .......... 182

Figure 124: Installing the Grounding Wire......................................................................................................................... 183

Figure 125: Stripping the solid or Stranded Grounding Wire............................................................................................. 184

Figure 126: Attaching the Bare Grounding Wire to the Grounding Post............................................................................ 184

Figure 127: Securing the Bare Grounding Wire to the Grounding Post............................................................................. 185

Figure 128: Power Wire Terminals............................................................................................................... ..................... 186

Figure 129: Stripping the Power Wires........................................................................................... .. ................................. 187

Figure 130: Attaching the Power Wires to the Straight Terminal Lugs.............................................................................. 187

Figure 131: On/Off Switch on the AT-SBxPWRSYS1 DC Power Supply.................................................................

Figure 132: Opening the Plastic Cover.............................................................................................................................. 189

Figure 133: Removing the Terminal Screws........................................................................................ .............................. 190

Figure 134: Connecting the Positive (+) Power Wire with a Straight Terminal.................................................................. 191

Figure 135: Connecting the Negative (-) Power Wire with a Straight Terminal................................................................. 192

Figure 136: Closing the Plastic Cover over the Terminal Connectors............................................................................... 193

Figure 137: Tightening the Handle Locking Screw.................................................................................... ... ... .................. 194

Figure 138: Stripping the Power Wires........................................................................................... .. ................................. 195

Figure 139: Attaching the Power Wires to the Right Angle Terminals............................................................... ................ 195

Figure 140: Removing the Plastic Cover......................................................................................................................... .. 196

Figure 141: Removing the Terminal Screws........................................................................................ .............................. 197

Figure 142: Connecting the Positive (+) Power Wire with a Right Angle Terminal............................................................ 198

Figure 143: Connecting the Negative (-) Power Wire with a Right Angle Terminal........................................................... 199

Figure 144: Tightening the Handle Locking Screw.................................................................................... ... ... .................. 200

Figure 145: Stripping Solid or Stranded DC Power Wires................................................................................................. 201

Figure 146: Connecting the Positive Lead Wire.............................................................................................................. .. 202

Figure 147: Connecting the Negative Lead Wire............................................................................................. .................. 203

Figure 148: Switch Initialization Messages........................................................................................................................ 206

Figure 149: Switch Initialization Messages (Continued)............................................................................ ... ... .................. 207

Figure 150: Connecting the Management Cable to the Console RS-232 Port.................................................................. 212

Figure 151: SHOW VERSION Command.......................................................................................................................... 213

Figure 152: SHOW CARD Command................................................................................................................................ 214

Figure 153: Disconnecting the AC Power Cord from the AC Socket on the Back Panel................................................... 232

Figure 154: Lifting the Locking Handle on the Power Supply............................................................................................ 233

Figure 155: Removing the Power Supply from the Chassis.............................................................................................. 234

Figure 156: Installing a Blank Power Supply Slot Cover ................................................................................................. .. 235

Figure 157: Lowering the Locking Handle on the Power Supply Slot Cover.........................................................

Figure 158: Loosening the Screw on the Locking Handle ............................................................................... .................. 237

Figure 159: Opening the Plastic Window on the Terminal Block..................................................................................... .. 238

Figure 160: Removing the Negative Lead Wire................................................................................................................. 239

Figure 161: Removing the Positive Lead Wire from the Terminal Block .......................................... ... ............................ .. 240

Figure 162: Reinstalling the Screws on the Positive and Negative Terminals............................................................... .. .. 241

Figure 163: Closing the Plastic Cover .................................................................................................................. ............. 242

Figure 164: Removing the Grounding Wire ............................................................................................ ... ... ..................... 243

Figure 165: Reinstalling the Nut and Washer on the Grounding Post............................................................................... 244

Figure 166: Lifting the Locking Handle and Removing the Power Supply......................................................................... 245

Figure 167: Installing a Blank Power Supply Slot Cover ................................................................................................. .. 246

Figure 168: Lowering the Locking Handle on the Power Supply Slot Cover..................................................................... 247

Figure 169: Loosening the Screw on the AT-SBxFAN06 Fan Module.............................................................................. 254

......... 188

............ 236

11

Page 12

List of Figures

Figure 170: Loosening the AT-SBxFAN06 Fan Module from the Backplane Connector.................................................. . 254

Figure 171: Withdrawing the AT-SBxFAN06 Fan Module 25 mm (1 in.) from the Chassis .............................. ................. 2 55

Figure 172: Removing the AT-SBxFAN06 Fan Module from the Chassis................................................................ ......... 256

Figure 173: Installing a New AT-SBxFAN06 Fan Module.................................................................................................. 257

Figure 174: Securing the AT-SBxFAN06 Fan Module on the Backplane Connector................................................... ...... 258

Figure 175: Tightening the Screw on the AT-SBxFAN06 Fan Module.............................................................................. 258

Figure 176: Cabling the Stacking Transceivers When Both Switches have One Controller Card..................................... 273

Figure 177: Cabling the Stacking Transceivers When Both Switches have Two Controller Cards................................... 274

Figure 178: Chassis ID Number in the Numbering Format.................................................................................. ... ........... 278

Figure 179: SHOW SYSTEM Command........................................................................................................................... 285

Figure 180: LICENSE Command................................................................................................................... .................... 288

Figure 181: LICENSE Command Message with Two Controller Cards............................................................................. 288

Figure 182: LICENSE Command Message with One Controller Card............................................................................... 288

Figure 183: STACK ENABLE Command Messages.......................................................................................................... 289

Figure 184: SHOW LICENSE BRIEF Command............................................................................................................... 291

Figure 185: SHOW STACK Command.............................................................................................................................. 293

Figure 186: STACK RENUMBER Command Messages................................................................................................... 294

Figure 187: SHOW STACK Command.............................................................................................................................. 296

Figure 188: Removing the Dust Cover from an SFP+ Slot on the AT-SBx81CFC960 Controller Fabric Card. ... ... .. ... ... ... 300

Figure 189: Handle on the AT-StackOP/0.3 and AT-StackOP/9.0 Transceivers............................................................... 300

Figure 190: Installing the AT-StackOP/0.3 or AT-StackOP/9.0 Transceiver............................................ ... ... .................... 301

Figure 191: Removing the Dust Cover from a Stacking Transceiver................................................................................. 301

Figure 192: Positioning the Handle on the Transceiver....................................................................................... .............. 302

Figure 193: Connecting a Fiber Optic Cable to a Stacking Transceiver............................................................................ 302

Figure 194: Initialization Messages for the Stack ................................................................................................... ........... 305

Figure 195: Initialization Messages for the Stack (Continued)....................................................................... ... ................. 306

Figure 196: SHOW STACK Command.............................................................................................................................. 307

Figure 197: Pin Numbers for RJ-45 and RJ Point 5 Ports (Front View).................................................................. ........... 319

12

Page 13

Tables

Table 1. AT-SBxPWRSYS1 Power Supply LEDs ...............................................................................................................28

Table 2. AT-SBxPWRPOE1 Power Supply LEDs ..............................................................................................................31

Table 3. LEDs on the AT-SBxPWRSYS1 DC Power Supply ..............................................................................................33

Table 4. AT-SBxFAN06 Module LED .................................................................................................................................34

Table 5. Power Supply Interface LED .................................................................................................................................36

Table 6. Port LEDs on the AT-SBx81GT24 Line Card .......................................................................................................40

Table 7. Port LEDs on the AT-SBx81GT40 Line Card .......................................................................................................43

Table 8. Port LEDs on the AT-SBx81GP24 PoE Line Card ...............................................................................................45

Table 9. Port LEDs on the AT-SBx81GS24a SFP Line Card .............................................................................................48

Table 10. SFP+ Slot LEDs on the AT-SBx81XS6 Line Card ..............................................................................................50

Table 11. SFP+ Slot LEDs on the AT-SBx81XS16 Line Card ............................................................................................52

Table 12. Twisted Pair Cable for the AT-SBx81GT24 and AT-SBx81GT40 Line Cards ....................................................54

Table 13. Twisted Pair Cable for the AT-SBx81GP24 Line Card .......................................................................................54

Table 14. IEEE802.3af and IEEE802.3at Powered Device Classes ..................................................................................56

Table 15. Maximum Number of Powered Devices .............................................................................................................57

Table 16. Components on the AT-SBx81CFC960 Controller Fabric Card .........................................................................60

Table 17. SYS (System) Status LEDs ................................................................................................................................66

Table 18. SBx Linecard Status LEDs .................................................................................................................................69

Table 19. LEDs for the SFP+ Slots on the AT-SBx81CFC960 Controller Card .................................................................71

Table 20. NET MGMT Port LED .........................................................................................................................................74

Table 21. AlliedWare Plus Operating System Releases for the Hardware Components ...................................................78

Table 22. Front Panel to Rack Rail Dimensions .................................................................................................................98

Table 23. Stacking Transceivers ......................................................................................................................................271

Table 24. Descriptions of the STACK ENABLE Command Messages .............................................................................289

Table 25. Descriptions of the STACK RENUMBER Command Messages ......................................................................295

Table 26. Product Dimensions ..........................................................................................................................................313

Table 27. Product Weights ...............................................................................................................................................313

Table 28. Environmental Specifications .......................................................................................

Table 29. Acoustic Noise Test Components .....................................................................................................................315

Table 30. AC Voltage and Frequency Requirements .......................................................................................................316

Table 31. DC Voltage Requirements ................................................................................................................................316

Table 32. Typical Power Savings in eco-friendly Mode ....................................................................................................316

Table 33. Maximum Power Consumption .........................................................................................................................316

Table 34. Maximum Power Efficiency ...............................................................................................................................317

Table 35. Heat Dissipation ...............................................................................................................................................317

Table 36. Available Power Over Ethernet with One PoE Power Supply ..........................................................................317

Table 37. Available Power Over Ethernet with Two PoE Power Supplies ........................................................................318

Table 38. PoE Mode on the AT-SBx81GP24 PoE Line Card ...........................................................................................318

Table 39. Safety and Electromagnetic Emissions ............................................................................................................318

Table 40. MDI Pin Signals (10Base-T or 100Base-TX) ....................................................................................................319

Table 41. MDI-X Pin Signals (10Base-T or 100Base-TX) ................................................................................................319

Table 42. 1000Base-T Connector Pinouts ........................................................................................................................320

Table 43. Fiber Optic Port Specifications for the AT-StackOP/0.3 Module ......................................................................321

Table 44. Fiber Optic Port Specifications for the AT-StackOP/9.0 Transceiver ...............................................................321

.....................................315

13

Page 14

List of Tables

14

Page 15

Preface

Note

This guide contains the hardware installation instructions for the Layer 3+

SwitchBlade x8106 Chassis Switch. The preface contains the following

sections:

“Structure of the Installation Guide” on page 16

“Safety Symbols Used in this Document” on page 17

“Contacting Allied Telesis” on page 18

This version of the installation guide applies to release 5.4.4 of the

AlliedWare Plus

Chassis Switch and AT-SBx81CFC960 Controller Fabric Card.

™ Operating System for the SwitchBlade x8106

15

Page 16

Preface

Structure of the Installation Guide

This guide has the following three sections:

Section I: Hardware Overview

The chapters in this section describe the hardware components of the

product, including the Ethernet line cards, AT-SBx81CFC960

Controller Fabric Card, and power supplies. You should start here if

you are unfamiliar with the switch. A basic understanding of the

hardware may help you avoid making mistakes during the installation

procedures.

Section II: Installing the Chassis

The chapters in this section contain the hardware installation

instructions for the device. They explain how to select a site, assemble

the hardware components, cable the ports, power on the unit, and

confirm the hardware operations of the various components. After

completing the instructions in this section, you may either begin to

configure the operating parameters and features of the chassis with

the commands in the command line interface of the AlliedW are Plus

operating systems, as described in the Software Reference for

SwitchBlade x8100 Series Switches, or proceed to Section III to build

a stack of two chassis with the VCStack Plus

™

™ feature.

Section III: Building a Stack with the VCStack Plus Feature

The chapters in this section describe the VCSt ack Plus feature and the

additional hardware and software components required to build a

stack. The section also contains step-by-step instructions on how to

configure the AlliedWare Plus operating systems on the switches for

the stacking feature. You should perform these instructions after you

have installed the two chassis of the st ack a t their respective sites and

confirmed their operations with the instructions in the chapters in

Section II of this guide. You might want to review the information in

Chapter 14, “VCStack Plus Overview” on page 269 prior to installing

the chassis to acquaint yourself with the feature and guidelines.

16

Page 17

SwitchBlade x8106 Chassis Switch and AT-SBx81CFC960 Card Installation Guide

Note

Caution

Warning

Warning

Warning

Safety Symbols Used in this Document

This document uses the following conventions.

Notes provide additional information.

Cautions inform you that performing or omitting a specific action may

result in equipment damage or loss of data.

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

Laser warnings inform you that an eye or skin hazard exists due to

the presence of a Class 1 laser device.

Fan warnings inform you of danger from hazardous moving fan

blades.

17

Page 18

Preface

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links

for the following services on this page:

24/7 Online Support — Enter our interactive support center to

USA and EMEA phone support — Select the phone number that

Hardware warranty information — Learn about Allied Telesis

Replacement Services — Submit a Return Merchandise

search for answers to your product questions in our knowledge

database, to check support tickets, to learn about RMAs, and to

contact Allied Telesis technical experts.

best fits your location and customer type.

warranties and register your product online.

Authorization (RMA) request via our interactive support center.

Documentation — View the most recent installation and user

guides, software release notes, white papers, and data sheets for

your products.

Software Downloads — Download the latest software releases for

your managed products.

For sales or corporate information, go to www.alliedtelesis.com/

purchase and select your region.

18

Page 19

Section I

Hardware Overview

This section contains the following chapters:

Chapter 1, “Chassis and Power Supplies” on page 21

Chapter 2, “Ethernet Line Cards” on page 37

Chapter 3, “AT-SBx81CFC960 Controller Fabric Card” on page 59

19

Page 20

20

Page 21

Chapter 1

Note

Chassis and Power Supplies

This chapter describes the Layer 3+ SwitchBlade x8106 Chassis Switch in

the following sections:

“Introduction” on page 22

“AT-SBx8106 Chassis” on page 24

“Slots for the Ethernet Line and Controller Cards” on page 26

“Slots for the Power Supplies” on page 27

“AT-SBxPWRSYS1 AC Power Supply” on page 28

“AT-SBxPWRPOE1 Power Supply” on page 30

“AT-SBxPWRSYS1 DC Power Supply” on page 32

“AT-SBxFAN06 Module” on page 34

“Power Supply Interfaces (Opto-couplers)” on page 35

This version of the installation guide applies to release 5.4.4 of the

AlliedWare Plus Operating System for the SwitchBlade x8106

Chassis Switch and AT-SBx81CFC960 Controller Fabric Card.

21

Page 22

Chapter 1: Chassis and Power Supplies

The chassis has slots for four

Ethernet line cards and two

controller cards, or five line

cards and one controller card.

The chassis also has slots for

two system power supplies and

two PoE+ power supplies.

AT-SBxPWRSYS1 AC Power Supply for

the Ethernet line cards, controller card,

and fan module.

AT-SBxPWRPOE1 AC Power Supply

with 1200 W PoE budget for the ports on

the AT-SBx81GP24 PoE Ethernet Line

Card.

AT-SBxPWRSYS1 DC Power Supply for

the Ethernet line cards, controller card,

and fan module.

Introduction

The SwitchBlade x8106 product is a modular Layer 3+ Ethernet switch.

The main components are the AT-SBx8106 Chassis, Ethernet line cards,

a controller card, system power supply, Power over Ethernet Plus (PoE+)

power supply, and fan module. The AT-SBx8106 Chassis is shown in

Figure 1.

Figure 1. AT-SBx8106 Chassis

Figure 2 illustrates the power supply modules.

Figure 2. Power Supply Units

22 Section I: Hardware Overview

Page 23

SwitchBlade x8106 Chassis Switch and AT-SBx81CFC960 Card Installation Guide

AT-SBxFAN06 Module Cooling

module for the chassis.

Figure 3 illustrates the fan module.

Figure 3. Fan Module

Section I: Hardware Overview 23

Page 24

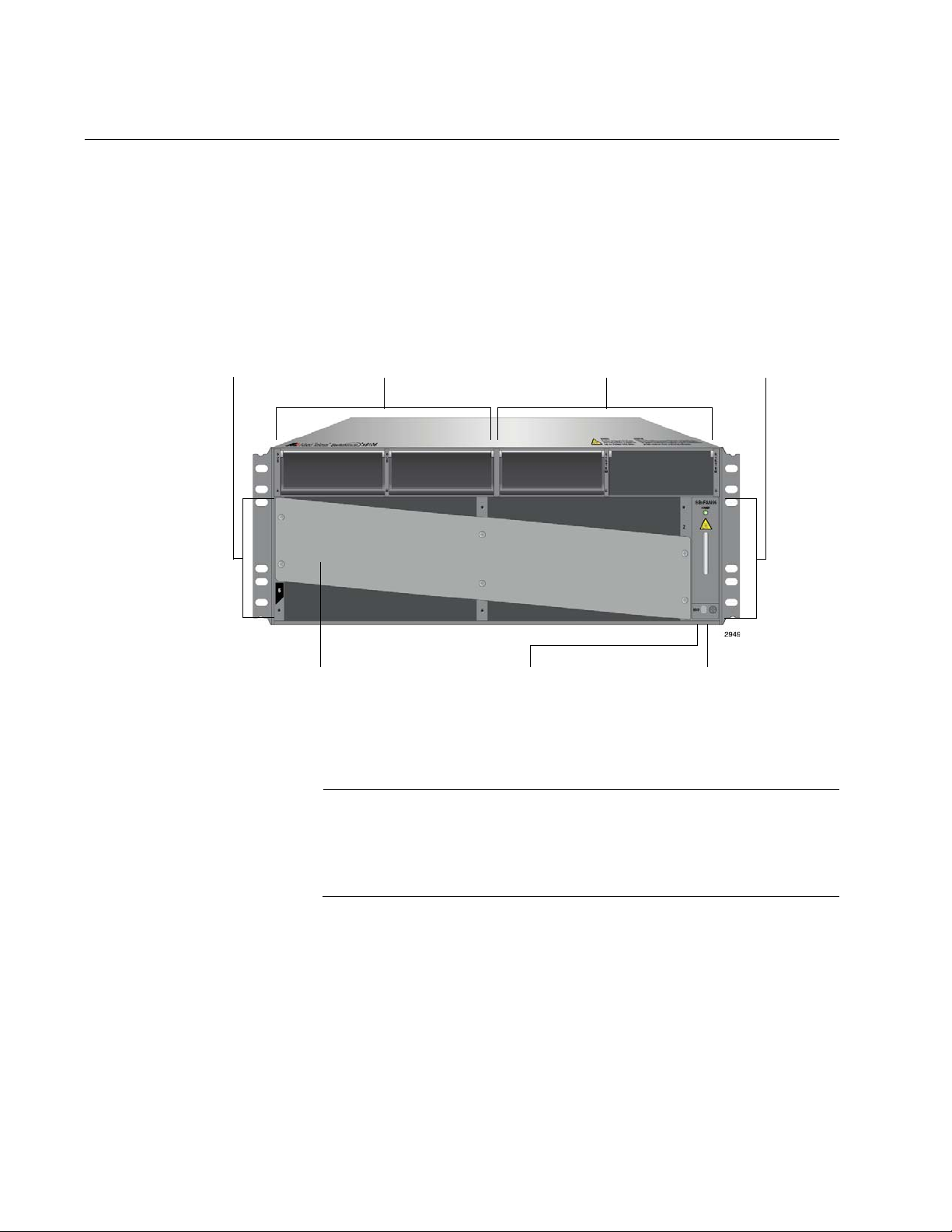

Chapter 1: Chassis and Power Supplies

Note

Shipping Brace

Slots for Ethernet

Line Cards and

Controller Cards

PoE Power

Supply Slots

System Power

Supply Slots

Slots for Ethernet

Line Cards and

Controller Cards

AT-SBxFAN06

Module

ESD Wrist

Strap Plug

AT-SBx8106 Chassis

The AT-SBx8106 Chassis is a 4RU unit with slots for four Ethernet line

cards and two AT-SBx81CFC960 Controller Cards, or five line cards and

one controller card. The chassis also has slots for two system power

supply modules and two PoE power supply modules. The chassis

components are identified in Figure 4 here and Figure 5 on page 25.

24 Section I: Hardware Overview

Figure 4. Front View of the AT-SBx8106 Chassis

Do not remove the shipping brace from the front of the chassis until

after the unit is installed in the equipment rack. You might bend the

chassis and cause misalignment of the slots and card guides if you

lift the chassis into the equipment rack without the shipping brace.

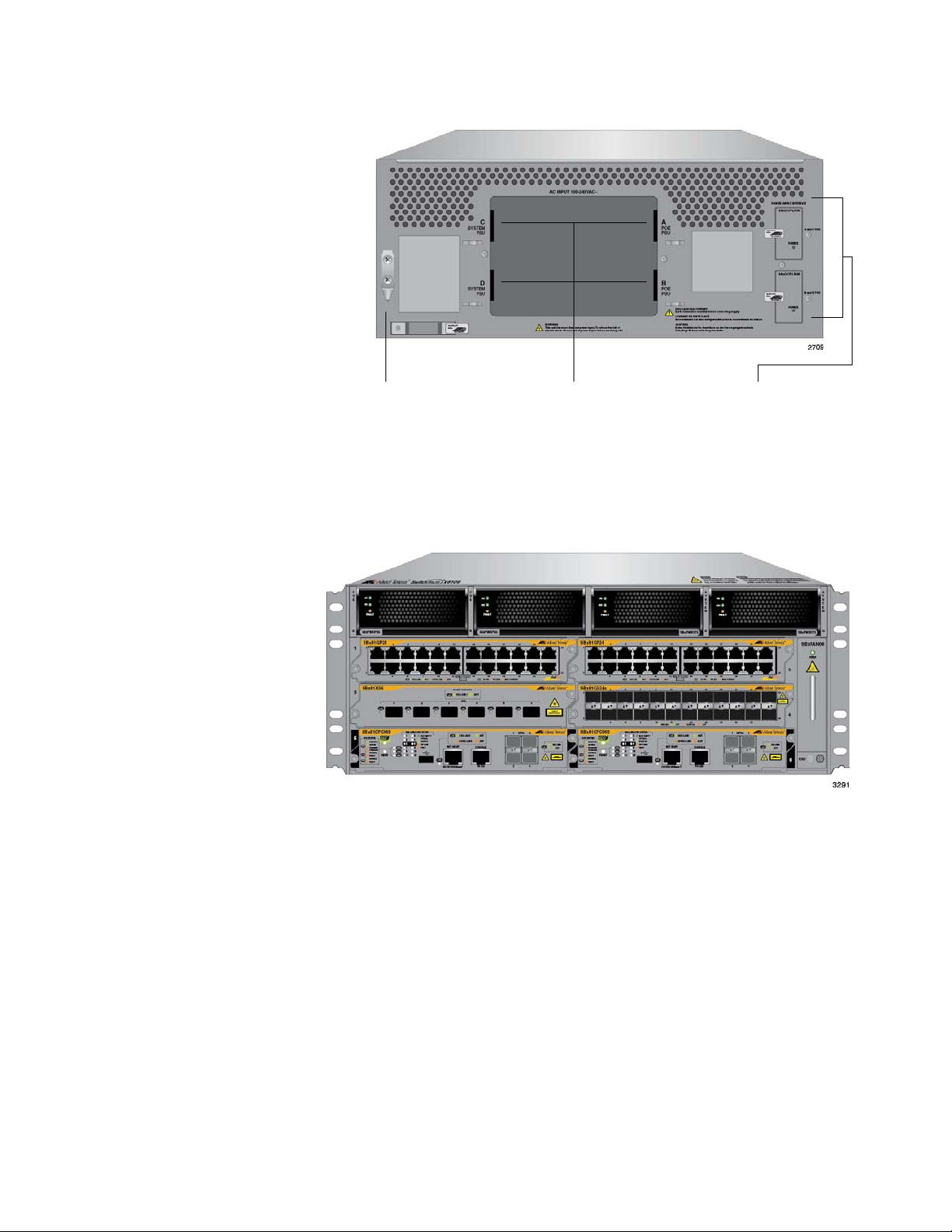

Page 25

SwitchBlade x8106 Chassis Switch and AT-SBx81CFC960 Card Installation Guide

Grounding

Lug

AC Power

Cord Sockets

Power Supply

Interfaces

(Opto-couplers)

Figure 5. Rear View of the AT-SBx8106 Chassis

Figure 6 is an example of a fully populated chassis.

Figure 6. AT-SBx8106 Chassis with Line Cards, Controller Cards, and

Power Supplies

Section I: Hardware Overview 25

Page 26

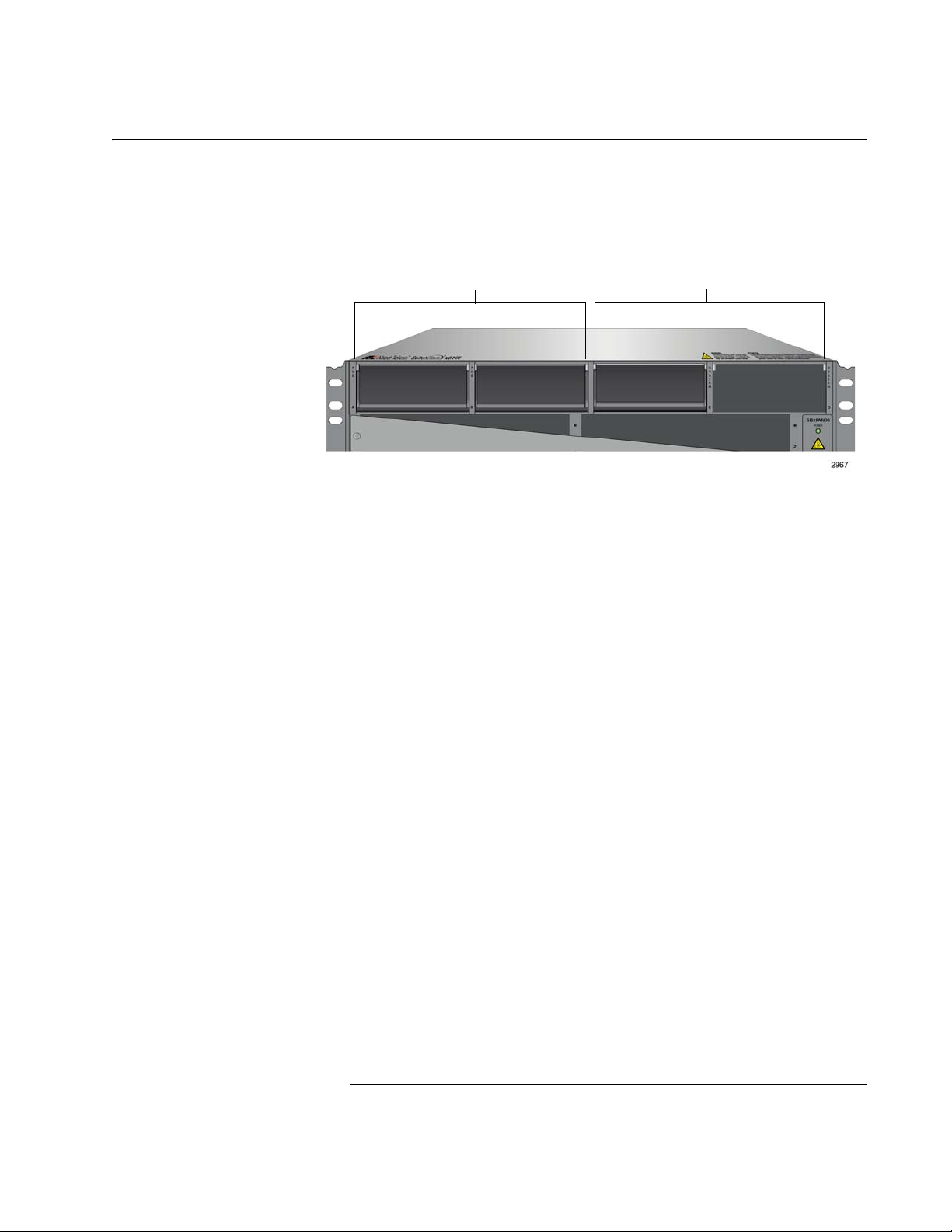

Chapter 1: Chassis and Power Supplies

Slot 1 - Line Card

Slot 3 - Line Card

Slot 5 - Controller

Slot 2 - Line Card

Slot 4 - Line Card

Slot 6 - Line Card

or Controller Card

Card

Slots for the Ethernet Line and Controller Cards

The chassis has slots for four Ethernet line cards and two ATSBx81CFC960 Controller Cards, or five line cards and one controller card.

The slot definitions are predefined and may not be changed. Figure 7

identifies the slots.

Figure 7. Ethernet Line and Controller Cards Slots

Slots 1 to 4 are for the Ethernet line cards. The cards may be installed in

any order or variety in the slots.

Slot 5 is for the AT-SBx81CFC960 Controller Fabric Card. The chassis

must have a controller card. The Ethernet line cards do not forward traffic

if the chassis does not have a controller card. The controller card stores

the management software and configuration settings for the Ethernet line

cards and controls the backplane in the chassis, which the line cards use

to forward network traffic to each other. The backplane has a bandwidth of

up to 80 Gbps for each line card slot when the chassis has one controller

card.

Slot 6 has a dual function. You may use it with an Ethernet line card to add

more ports to the chassis or a second controller card to add controller card

redundancy and to increase the bandwidth of the backplane. The chassis