Page 1

AT-9400Ts Series

Gigabit Ethernet

Switches

Basic Layer 3 AT-9424Ts

AT-9424Ts/XP

AT-9448Ts/XP

◆

AT-9400Ts Stack

Installation Guide

613-001191 Rev. B

Page 2

Copyright 2009 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names, company names, logos or

other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document without prior

written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesis, Inc. be liable for any

incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or related to this

manual or the information contained herein, even if Allied Telesis, Inc. has been advised of, known, or should have known, the possibility of

such damages.

Page 3

Electrical Safety and Emissions Standards

This product meets the following standards.

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses , and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

RFI Emissions FCC Class A, EN55022 Class A, EN61000-3-2, EN61000-3-3, VCCI

Class A, C-TICK, CE

Warning: In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

EMC (Immunity) EN55024

Electrical Safety EN60950 (TUV), UL 60950 (

CULUS

)

Laser Safety EN60825

3

Page 4

Translated Safety Statements

Important: The indicates that translations of the safety statement are available in the PDF

document “Translated Safety Statements” (613-000405) posted on the Allied Telesis website at

www.alliedtelesis.com.

4

Page 5

Contents

Preface ..................................................................................................................................................................................................................... 9

Product Documentation ...................................................................................................................................10

Where to Go First .............................................................................................................................................11

Starting a Management Session ......................................................................................................................11

Safety Symbols Used in this Document ...........................................................................................................12

Contacting Allied Telesis ..................................................................................................................................13

Online Support........................ ... ... .... .......................................... ................................................................13

Email and Telephone Support.......................................... ... ... .... ... .......................................... ...................13

Returning Products.....................................................................................................................................13

Sales or Corporate Information ..................................................................................................................13

Warranty.....................................................................................................................................................13

Management Software Updates.................................................................................................................13

Chapter 1

Overview ...............................................................................................................................................................................................................15

Switch Descriptions ...... .......................................... .......................................... ................................................16

AT-9424Ts Switch......................................................................................................................................16

AT-9424Ts/XP Switch ......... ................................................................................ .......................................17

AT-9448Ts/XP Switch ......... ................................................................................ .......................................18

10/100/1000Base-T Twisted Pair Ports ...........................................................................................................19

Connector Type................................ ... ... ... .... ... ....................................... ... ... ... ... .... ... ... ... ..........................19

Speed.........................................................................................................................................................19

Duplex Mode ................ ... .... .......................................... .......................................... ...................................19

Maximum Distance.....................................................................................................................................19

Cable Type.................................................................................................................................................20

Auto-MDI/MDI-X .........................................................................................................................................20

Port Pinouts...................................... ... ... ... ....................................... ... .... ... ... ... ... .... ... ................................20

SFP Transceiver Slots .....................................................................................................................................21

XFP Transceiver Slots .....................................................................................................................................22

Redundant Twisted Pair Ports .........................................................................................................................23

Compact Flash Card Slot .................................................................................................................................24

Port LEDs ........ ... ... .... ... ... ... ... ....................................... ... .... ... ... ... .... ... .............................................................25

10/100/1000Base-T Twisted Pair Port LEDs..............................................................................................25

Fiber Optic Port and Transceiver Slot LEDs...............................................................................................26

System LEDs ...................................................................................................................................................27

Stack LEDs ............................... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... .... ...................................28

AT-StackXG Stacking Module .. ... ... ... .......................................... .... ... ... ... .... ... ... ... ..........................................29

Terminal Port ...................................................................................................................................................30

AT-RPS3204 Redundant Power Supply ..........................................................................................................31

AC Power Connector .......................................................................................................................................32

Chapter 2

Installing the Hardware ...............................................................................................................................................................................33

Installation Overview ........................................................................................................................................34

Reviewing the Safety Precautions ...................................................................................................................36

5

Page 6

Contents

Planning the Installation of a Stack ..................................................................................................................38

Maximum Number of Switches in a Stack .................................... ... .... ... ... ... .... ................................................39

Unpacking a Switch ..........................................................................................................................................40

Installing the AT-StackXG Stacking Module .....................................................................................................41

Installing the Power Cord Retaining Clip (AC Switches Only) ..........................................................................44

Disconnecting the Network Cables ..................................................................................................................45

Installing the Switches in an Equipment Rack ..................................................................................................46

Labeling the Switches ........................... .... ... ... .......................................... .......................................................48

Chapter 3

Preparing the Switches .............................................................................................................................................................................. 49

Powering on a Switch .......................................................................................................................................50

Starting a Local Management Session .............................................................................................................52

Verifying the AT-S63 Version Number .............................................................................................................54

Updating the AT-S63 Management Software ............................ ...... ....... ...... ....... ...... ....... ...... ....... ...... .............55

Assigning the Static Module ID Number 1 to the Master Switch .................................. .... ... ... ... .... ... ... ... ..........56

Assigning Static Module ID Numbers to the Member Switches .......................................................................59

Chapter 4

Cabling and Powering on the Stack ...................................................................................................................................................61

Cabling the AT-StackXG Stacking Modules ................................. ....................................... .............................62

Powering On the Switches of the Stack ....................................................................... .... ... ... ... .... ...................65

Verifying the Installation ...................................................................................................................................67

Troubleshooting the Discovery Process ...........................................................................................................69

Chapter 5

Cabling the Network Ports ....................................................................................................................................................................... 71

Installing Optional Transceivers .......................................................................................................................72

Installing an SFP Transceiver.....................................................................................................................72

Installing an XFP Transceiver.....................................................................................................................74

Cabling the Twisted Pair and Fiber Optic Ports ...............................................................................................76

Chapter 6

Adding and Removing Switches .......................................................................................................................................................... 77

Replacing the Master Switch .............................. ................................. ................................ .............................78

Uploading the Active Configuration File......................................................................................................78

Removing the Current Master Switch.........................................................................................................79

Configuring the New Master Switch............................................................................................................84

Connecting the New Master Switch to the Stack........................................................................................86

Adding a New Member Switch ..................... ... ... .... .......................................... ... ... ... .......................................87

Replacing a Member Switch ............................... .... ... ... ... ... .... ..........................................................................89

Chapter 7

Troubleshooting ............................................................................................................................................................................................. 91

No Master Switch .............................................................................................................................................92

Power LED is Off ..............................................................................................................................................93

Twisted Pair Port Link LED is Off .....................................................................................................................94

Fiber Optic Port Link LED is Off ......................... .... ... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... .......................................95

Transceiver is Installed but the Status is “Not Present” ......................................................................

.............96

System Fault LED is Blinking ...........................................................................................................................97

System Fault LED is Steadily On .....................................................................................................................98

Cannot Establish a Local (Out-of-Band) Management Session .......................................................................99

Switch Functions Intermittently .................................. .......................................... ... ... ... .... ... ...........................100

6

Page 7

AT-9400Ts Stack Installation Guide

Appendix A

Technical Specifications ......................................................................................................................................................................... 101

Physical Specifications ..................................................................................................................................101

Environmental Specifications ................. .......................................... ... ... ... .... ... ... ... ... .....................................101

Power Specifications ......................................................................................................................................102

Certifications ..................................................................................................................................................102

RJ-45 Twisted Pair Port Pinouts ....................................................................................................................103

RJ-45 Style Serial Terminal Port Pinouts .......................................................................................................105

RPS 21-pin D-combo Port and Connector Pinouts ................ .......................................... ... ... .... ....................106

7

Page 8

Contents

8

Page 9

Preface

Note

This guide explains how to build an AT-9400Ts Stack of the AT-9424Ts,

AT-9424Ts/XP, and AT-9448Ts/XP Basic Layer 3 Gigabit Ethernet

Switches. This preface contains the following sections:

“Product Documentation” on page 10

“Where to Go First” on page 11

“Starting a Management Session” on page 11

“Safety Symbols Used in this Document” on page 12

“Contacting Allied Telesis” on page 13

For instructions on how to install the switches as stand-alone units,

refer to the AT-9400 Gigabit Ethernet Switch Installation Guide.

9

Page 10

Preface

Product Documentation

For overview information on the features of the AT-9400 Switches and the

AT-S63 Management Software, refer to:

AT-S63 Management Software Features Guide

(PN 613-001022)

For instructions on how to start a local or remote management session on

stand-alone AT-9400 Switches or AT-9400Ts Stacks, refer to:

Starting an AT-S63 Management Session Guide

(PN 613-001023)

For instructions on how to install or manage stand-alone AT-9400

Switches, refer to:

AT-9400 Gigabit Ethernet Switch Installation Guide

(PN 613-000987)

AT-S63 Management Software Menus User’s Guide

(PN 613-001025)

AT-S63 Management Software Command Line User’s Guide

(PN 613-001024)

AT-S63 Management Software Web Browser User’s Guide

(PN 613-001026)

For instructions on how to install or manage AT-9400Ts Stacks, refer to:

AT-9400Ts Stack Installation Guide

(PN 613-001191)

AT-S63 Management Software Command Line User’s Guide

(PN 613-001024)

AT-S63 Management Software Web Browser User’s Guide for

AT-9400Ts Stacks

(PN 613-001028)

The installation and user guides for all the Allied Telesis products are

available in portable document format (PDF) on our web site at

www.alliedtelesis.com. You can view the documents online or download

them onto a local workstation or server.

10

Page 11

Where to Go First

Allied Telesis recommends that you read Chapter 1, “Overview,” in the

AT-S63 Management Software Features Guide before you begin to

manage the switch for the first time. There you will find a variety of basic

information about the unit and the management software, like the two

levels of manager access levels and the different types of management

sessions. The AT-S63 Management Software Features Guide is also your

resource for background information on the features of the switch. You can

refer there for the relevant concepts and guidelines when configuring a

feature for the first time.

Starting a Management Session

For instructions on how to start a local or remote management session on

the AT-9400 Switch, refer to the Starting an AT-S63 Management Session

Guide.

AT-9400Ts Stack Installation Guide

11

Page 12

Preface

Safety Symbols Used in this Document

This document uses the safety symbols defined in Table 1.

Table 1. Safety Symbols

Symbol Meaning Description

Caution Performing or omitting a specific action may

result in equipment damage or loss of data.

Warning Performing or omitting a specific action may

result in electrical shock.

12

Page 13

AT-9400Ts Stack Installation Guide

Contacting Allied Telesis

This section provides Allied Telesis contact information for technical

support and for sales and corporate information.

Online Support You can request technical support online by accessing the Allied Telesis

Knowledge Base: www.alliedtelesis.com/support/kb.aspx. You can use

the Knowledge Base to submit questions to our technical support staff and

review answers to previously asked questions.

Email and

Telephone

Support

Returning

Products

Sales or

Corporate

Information

Warranty For hardware warranty information, refer to the Allied Telesis web site at

Management

Software Updates

For Technical Support via email or telephone, refer to the Allied Telesis

web site at www.alliedtelesis.com. Select your country from the list on

the web site and then select the appropriate tab.

Products for return or repair must first be assigned a return materials

authorization (RMA) number. A product sent to Allied Telesis without an

RMA number will be returned to the sender at the sender’s expense. For

instructions on how to obtain an RMA number, go to the Support section

on our web site at www.alliedtelesis.com.

You can contact Allied Telesis for sales or corporate information through

our web site at www.alliedtelesis.com.

www.alliedtelesis.com/support/warranty.

New releases of the management software for our managed products are

available from the following Internet sites:

Allied Telesis web site: www.alliedtelesis.com

Allied Telesis FTP server: ftp://ftp.alliedtelesis.com

If the FTP server prompts you to log on, enter “anonymous” as the user

name and your email address as the password.

13

Page 14

Preface

14

Page 15

Chapter 1

Note

Note

Overview

This guide explains how to install the AT-9424Ts, AT-9424Ts/XP and

AT-9448Ts/XP Gigabit Ethernet Switches as an AT-9400Ts Stack. This

chapter contains the following sections:

“Switch Descriptions” on page 16

“10/100/1000Base-T Twisted Pair Ports” on page 19

“SFP Transceiver Slots” on page 21

“XFP Transceiver Slots” on page 22

“Redundant Twisted Pair Ports” on page 23

“Compact Flash Card Slot” on page 24

“Port LEDs” on page 25

“System LEDs” on page 27

“Stack LEDs” on page 28

“AT-StackXG Stacking Module” on page 29

“Terminal Port” on page 30

“AT-RPS3204 Redundant Power Supply” on page 31

“AC Power Connector” on page 32

Allied Telesis recommends you read Chapter 1, “Overview,” and

Chapter 2, “AT-9400Ts Stacks,” in the AT-S63 Management

Software Features Guide before you begin to install the stack.

You should not begin the installation procedures in this guide until

you have read the Software Release Notes that are included with

the latest release of the AT-S63 Management Software. The Notes

list the features that AT-9400Ts Stacks support. Stacks may not be

suitable for all network environments because they do not support all

of the same features as stand-alone AT-9400 Switches. If your

network requirements include features that are not supported in a

stack, install the switches as stand-alone devices.

15

Page 16

Chapter 1: Overview

10/100/1000Base-T Ports

Port and SFP

RJ-45 Style Serial

Terminal Port

SFP Transceiver Slots

AC Power

Connector

RPS Connector

Slot LEDs

System

LEDs

1 3 5 7 9 11 13 15 17 19 21R 23R

2 4 6 8 1012 1416182022R24R

CLASS 1

LASER PRODUCT

AT-9424Ts

Gigabit Ethernet Switch

1 3 5 7 9 11 13 15 17 19 21R 23R

2 4 6 8 10 12 14 16 18 20 22R 24R

EJECT

TERMINAL

PORT

COMPACT FLASH

FAULT

RPS

MASTER

POWER

STATUS

SFP

21 22 23 24

L/A

D/C

D/C

L/AL/A

D/C

L/A

1000 LINK /

ACT

HDX /

COL

FDX

10/100 LINK / ACT

PORT ACTIVITY

STACK

PRES

MSTR

21

22

23

24

SFP

L/A

1

2

L/A

RPS INPUT

100-240VAC~

Expansion Slot

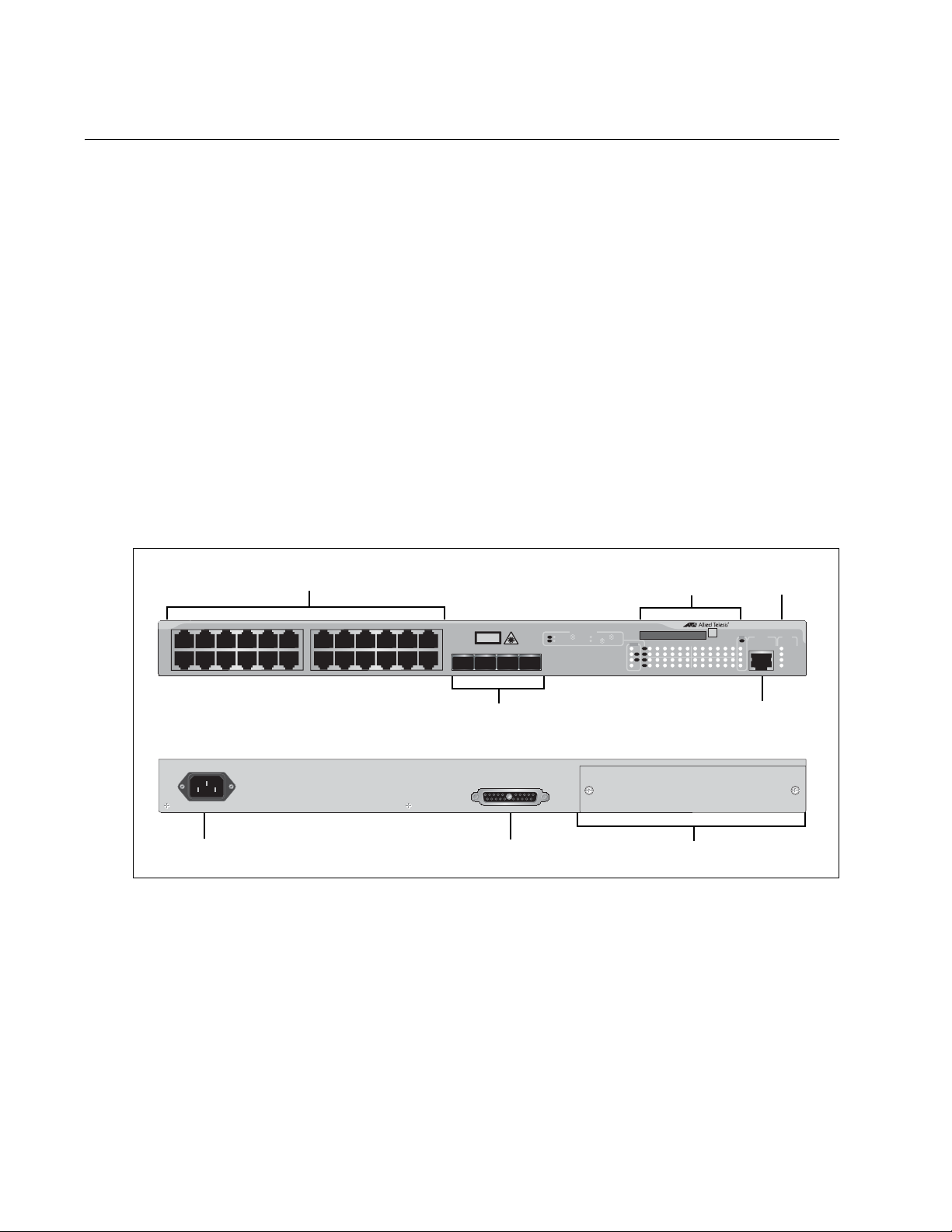

Switch Descriptions

The following sections describe the AT-9424Ts, AT-9424Ts/XP, and

AT-9448Ts/XP Gigabit Ethernet Switches.

AT-9424Ts

Switch

The AT-9424Ts Basic Layer 3 Switch has these hardware features:

24 10/100/1000Base-T ports

Four Gigabit Ethernet small form-factor pluggable (SFP) transceiver

slots

An RJ-45 style serial terminal port for local (out-of-band) management

Status LEDs for the ports, transceiver slots, and system

Redundant power supply connector

Compact flash card slot

Expansion slot for the AT-StackXG Stacking Module

Figure 1 shows the front and back panels of the AT-9424Ts switch.

16

Figure 1 AT-9424Ts Switch - Front and Back Panels

Page 17

AT-9400Ts Stack Installation Guide

10/100/1000Base-T Ports

Port and SFP

RJ-45 Style Serial

Terminal Port

SFP Slots

AC Power

Connector

RPS Connector

Slot LEDs

System

LEDs

1 3 5 7 9 11 13 15 17 19 21R 23R

2 4 6 8 1012 1416182022R24R

CLASS 1

LASER PRODUCT

AT-9424Ts/XP

Gigabit Ethernet Switch

1 3 5 7 9 11 13 15 17 19 21R 23R

2 4 6 8 10 12 14 16 18 20 22R 24R

EJECT

TERMINAL

PORT

COMPACT FLASH

FAULT

RPS

MASTER

POWER

STATUS

SFP

21 22 23 24

L/A

D/C

D/C

L/AL/A

D/C

L/A

1000 LINK /

ACT

HDX /

COL

FDX

10/100 LINK / ACT

PORT ACTIVITY

STACK

PRES

MSTR

21

22

23

24

SFP

L/A

1

2

L/A

L/A

25 26

XFP

XFP

XFP Slots

RPS INPUT

100-240VAC~

Expansion Slot

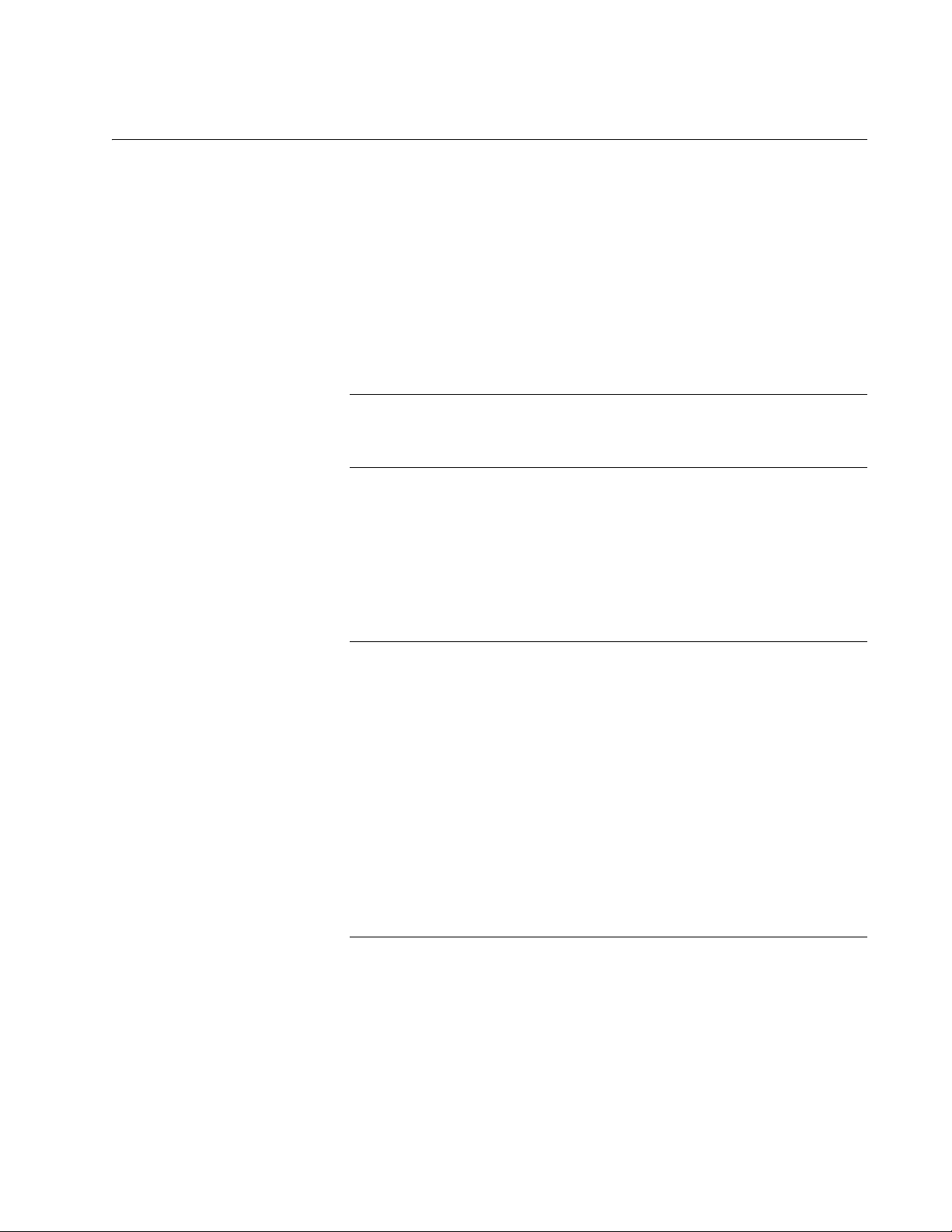

AT-9424Ts/XP

Switch

The AT-9424Ts/XP Basic Layer 3 Switch has these hardware features:

24 10/100/1000Base-T ports

Four Gigabit Ethernet small form-factor pluggable (SFP) transceiver

slots

Two 10 Gigabit Ethernet small form factor pluggable (XFP) tra nsceiver

slots

An RJ-45 style serial terminal port for local (out-of-band) management

Status LEDs for the ports, transceiver slots, and system

Redundant power supply connector

Compact flash card slot

Expansion slot for the AT-StackXG Stacking Module

Figure 2 shows the front and back panels of the AT-9424Ts/XP switch.

Figure 2 AT-9424Ts/XP Switch - Front and Back Panels

17

Page 18

Chapter 1: Overview

Port

LEDs

AC Power

Connector

RPS Connector

10/100/1000Base-T Ports

XFP Transceiver

RJ-45 Style Serial

Terminal Port

Slots and LEDs

System LEDs

AT-9448Ts/XP

STATUS

FAULT

MASTER

RPS

POWER

COMPACT FLASH

TERMINAL PORT

EJECT

49 50

15135791113 17 3331 473519 21 23 25 27 29 37 39 41 43 45

1000 LINK / ACT

10/100 LINK / ACT

FDX

HDX / COL

D/C

L/A

L/A D/C

CLASS 1

LASER PRODUCT

L/A

XFP XFP

LINK / ACT

STACK

PRES

L/A

L/A

34

4836 38 40 42 44 46

3216

2468 10 12 14 22 24 26 28 30

18

20

1

2

MSTR

Expansion Slot

Compact Flash

Card Slot

AT-9448Ts/XP

Switch

The AT-9448Ts/XP Basic Layer 3 Switch has the following hardware

features:

48 10/100/1000Base-T ports

Two 10 Gigabit Ethernet small form factor pluggable (XFP) tran sceiver

slots

An RJ-45 style serial terminal port for local (out-of-band) management

Status LEDs for the ports, transceiver slots, and system

Redundant power supply connector

Compact flash card slot

Expansion slot for the AT-StackXG Stacking Module

Figure 3 shows the front and back panels of the AT-9448Ts/XP switch.

100-240VAC~

18

RPS INPUT

Figure 3 AT-9448Ts/XP Switch - Front and Back Panels

Page 19

AT-9400Ts Stack Installation Guide

Note

Note

10/100/1000Base-T Twisted Pair Ports

This section describes the twisted pair ports on the switches.

Connector Type The ports have 8-pin RJ-45 connectors that use four pins at 10 or 100

Mbps and all eight pins at 1000 Mbps. For the pin assignments, refer to

“RJ-45 Twisted Pair Port Pinouts” on page 103.

Speed The ports can operate at 10, 100, or 1000 Mbps. The speeds can be set

automatically through Auto-Negotiation, the default setting, or manually

with the AT-S63 Management Software.

Twisted pair ports must use Auto -Negotiation to operate at 1000

Mbps. They cannot be manually set to 1000 Mbps.

Duplex Mode The twisted pair ports can operate at 10 or 100 Mbps in either half- or full-

duplex mode. (Ports that are operating at 1000 Mbps use only full-duplex

mode.) The twisted pair ports are IEEE 802.3u-compliant and can set the

duplex modes through Auto-Negotiation. You can disable AutoNegotiation on the switch ports and set the duplex modes manually

through the AT-S63 Management Software.

Maximum

Distance

Ports that are using Auto-Negotiation to set their duplex modes

should be connected to end nodes that are also using AutoNegotiation. Otherwise, duplex mode mismatches can occur.

Twisted pair ports that are using Auto-Negotiation default to halfduplex mode if they detect that the end nodes are not using AutoNegotiation. If the end nodes are operating at a fixed duplex mode of

full-duplex, the ports and the end nodes will operate at different

duplex modes, which can reduce network speed and efficiency.

To avoid a duplex mode mismatch when connecting an end node

with a fixed duplex mode of full-duplex to a switch port, use the

AT-S63 Management Software to disable Auto-Negotiation on the

port and to set the port speed and duplex mode manually.

The ports have a maximum operating distance of 100 meters (328 feet).

19

Page 20

Chapter 1: Overview

Cable Type Table 2 lists the cabling specifications for the 10/100/1000Base-T twisted

pair ports.

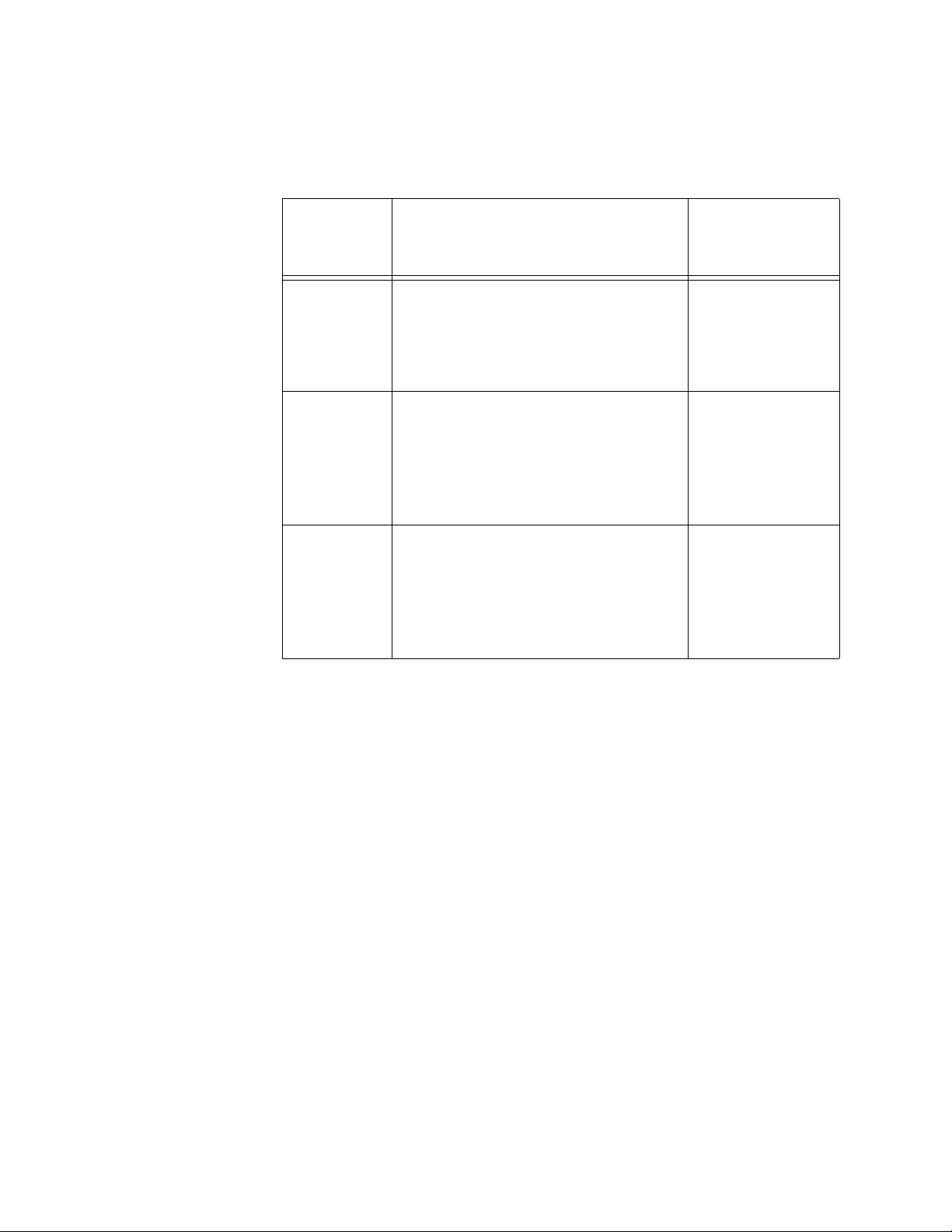

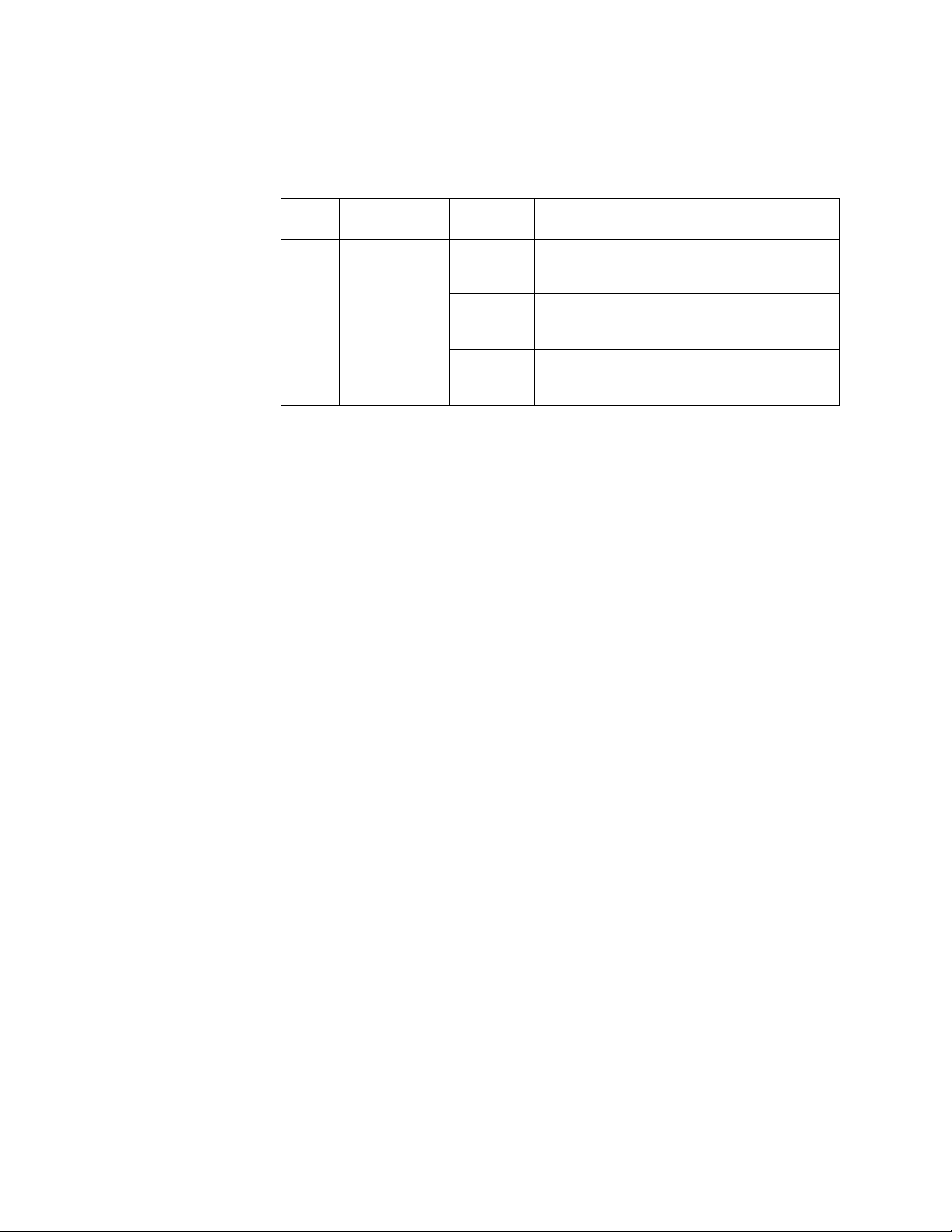

Table 2. Twisted Pair Cabling and Distances

Speed Cable Type

Maximum

Operating

Distance

Auto-MDI/

MDI-X

10 Mbps Standard TIA/EIA 568-B-compliant

Category 3 or better shielded or

unshielded cabling with 100 ohm

impedance and a frequency of 16

MHz.

100 Mbps Standard TIA/EIA 568-A-compliant

Category 5 or TIA/EIA 568-Bcompliant Enhanced Category 5 (Cat

5e) shielded or unshielded cabling

with 100 ohm impedance and a

frequency of 100 MHz.

1000 Mbps Standard TIA/EIA 568-A-compliant

Category 5 or TIA/EIA 568-Bcompliant Enhanced Category 5 (Cat

5e) shielded or unshielded cabling

with 100 ohm impedance and a

frequency of 100 MHz.

The twisted pair ports are IEEE 802ab-compliant and feature auto-MDI/

MDI-X. This feature, available when a port’s speed and duplex mode are

set through Auto-Negotiation, automatically configures a switch port to

MDI or MDI-X depending on the wiring configuration of the port on the end

node. This allows you to connect any network device to a port on the

switch using a straight-through twisted pair cable.

100 m (328 ft)

100 m (328 ft)

100 m (328 ft)

20

If Auto-Negotiation is disabled on a port and the speed and duplex mode

are set manually, the auto-MDI/MDI-X feature is also disabled and the

port’s wiring configuration defaults to the MDI-X setting. This setting can

be configured with the AT-S63 Management Software.

Port Pinouts Table 12 on page 103 has the port pinouts when the twisted pair ports are

operating at 10 or 100 Mbps in the MDI configuration. Table 13 on

page 103 has the port pinouts for the MDI-X configuration. Table 14 on

page 104 has the port pinouts for twisted pair ports that are operating at

1000 Mbps.

Page 21

SFP Transceiver Slots

Note

The AT-9424Ts and AT-9424Ts/XP Switches feature four slots for optional

Gigabit Ethernet SFP transceivers. You can use the transceivers to

connect the switches to network devices over large distances using fiber

optic cable. Figure 4 illustrates an SFP transceiver.

Each SFP slot is paired with a twisted pair port. A link on an SFP

transceiver takes priority in the event both an SFP transceiver and its

paired twisted pair port have established links to their respective end

nodes. For further information, refer to “Redundant Twisted Pair Ports” on

page 23.

AT-9400Ts Stack Installation Guide

Figure 4 SFP Transceiver

For the list of supported SFP transceivers, contact your Allied

Telesis sales representative.

21

Page 22

Chapter 1: Overview

Note

XFP Transceiver Slots

The AT-9424Ts/XP and AT-9448Ts/XP Switches have two slots for

optional XFP 10 Gigabit Ethernet transceivers that can be used to connect

high speed, 10 gigabit devices to the switches or to create high speed

backbone networks between the units. Figure 5 shows an example of an

XFP transceiver.

721

Figure 5 XFP Transceiver

For the list of supported XFP transceivers, contact your Allied

Telesis sales representative.

22

Page 23

Redundant Twisted Pair Ports

Note

The SFP slots 21 through 24 on the AT-9424Ts and AT-9424Ts/XP

Switches are paired with twisted pair ports 21R through 24R, respectively.

The “R” in the twisted pair port numbers on the front faceplates of the units

stands for “Redundant.” Here are the guidelines to using these ports and

slots:

Only one port in a pair -- the twisted pair port or the port on the

corresponding SFP module -- can be active at a time.

The twisted pair port is the active port when its SFP slot is empty, or

when an SFP module is installed but has not established a link to an

end node.

The twisted pair port automatically changes to the redundant status

mode when an SFP module establishes a link with an end node.

A twisted pair port automatically transitions back to the active status

when the link is lost on the SFP module.

AT-9400Ts Stack Installation Guide

In nearly all cases, a twisted pair port and an SFP module share the

same configuration settings, including port settings, VLAN

assignments, access control lists, and spanning tree.

An exception to the shared settings is port speed. If you disable Auto-

Negotiation on a twisted pair port and set the speed and duplex mode

manually, the speed reverts to Auto-Negotiation when an SFP module

establishes a link with an end node.

These guidelines do not apply to the XFP slots on the AT-9424T s/XP

and AT-9448Ts/XP Switches.

23

Page 24

Chapter 1: Overview

Note

Note

AT-9424Ts/XP

1 3 5 7 9 11 13 15 17 19 21R 23R

2 4 6 8 10 12 14 16 18 20 22R 24R

EJECT

TER

P

COMPACT FLASH

L/A

D/C

D/C

L/AL/A

COL

STACK

PRES

MSTR

21

22

23

24

SFP

L/A

1

2

L/A

26

XFP

Compact Flash Card Slot

The switches have slots for compact flash memory cards. You can use the

cards to store configuration files or the AT-S63 Management Software

image file. Compact flash memory cards can make it easier for you to

upgrade the files on a switch or transfer files between AT-9400 Switches.

Figure 6 Compact Flash Card Slot

A flash memory card is not required for normal operations of the

switch.

The only active compact flash card slot in a stack is on the master

switch. The slots on the member switches are deactivated and are

not accessible.

The AT-9400 Switches support only the AT-CF128A 128MB compact

flash card from Allied Telesis. Contact your Allied Telesis sales

representative for more information.

To insert a compact flash card, position it so that the manufacturer’s brand

label is facing up and press it into the slot until the button marked “Eject”

pops out.

To remove the compact flash card, press the button marked “Eject” until it

is pressed in completely and then remove the compact flash card.

For information on how to transfer files to and from a flash memory card,

refer to the AT-S63 Management Software User’s Guides.

24

Page 25

Port LEDs

AT-9400Ts Stack Installation Guide

The following sections describe the twisted pair and fiber optic port LEDs.

10/100/1000Base-

T Twisted Pair

Port LEDs

Each twisted pair port has two LEDs labeled L/A (link/activity) and D/C

(duplex mode/collisions). The L/A LED indicates the speed and activity on

a port. The D/C LED indicates the duplex mode (full- or half-duplex) and

the status of collisions on the port.

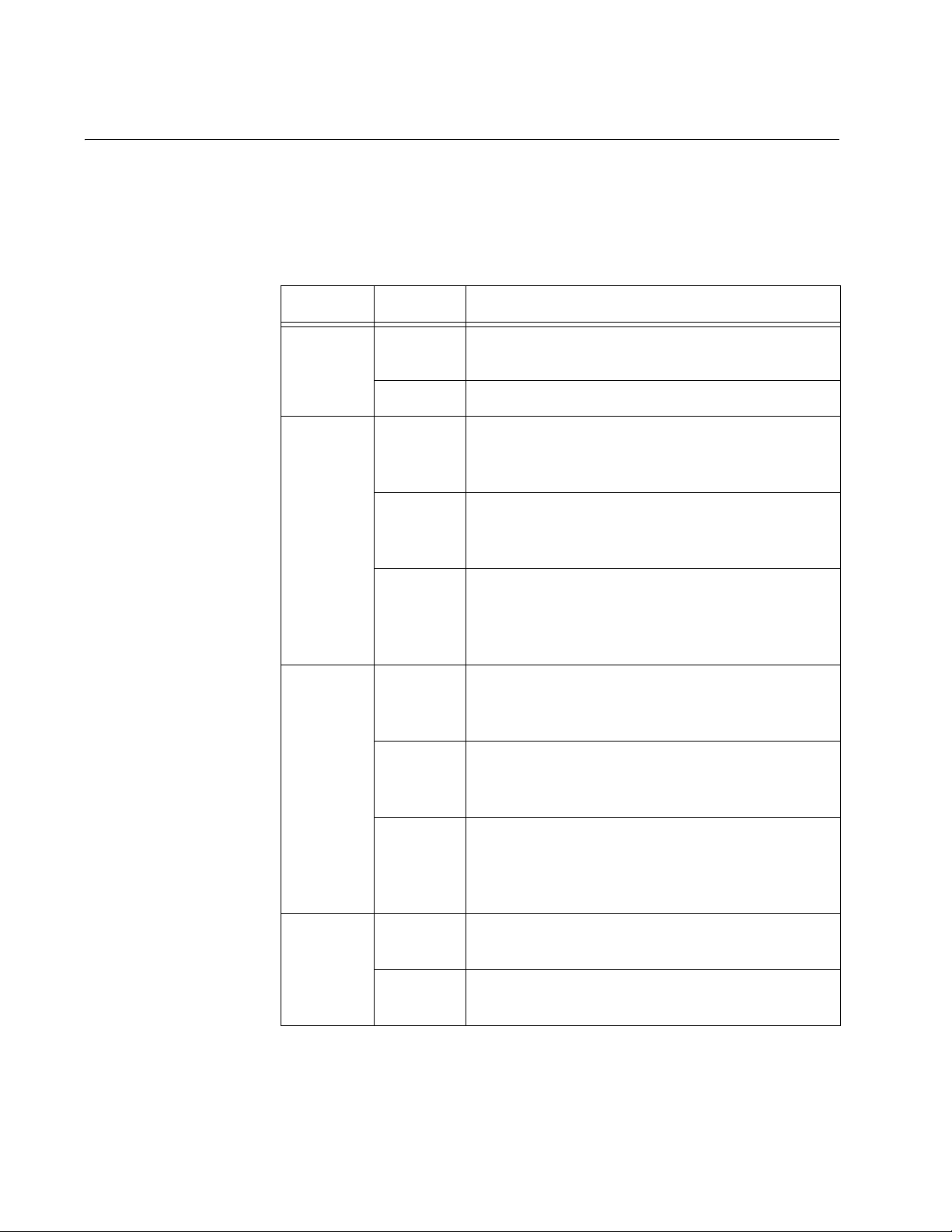

Table 3 describes the LEDs for the 10/100/1000Base-T twisted pair ports.

Table 3 Twisted Pair Port LEDs

LED Function State Description

L/A Link Status

and Activity

Off No link is established between the

port and the end node.

Solid

green

Flashing

green

Solid

amber

Flashing

amber

The port has established a link at

1000 Mbps.

Packets are being received or

transmitted at 1000 Mbps.

The port has established a link at 10

or 100 Mbps.

Packets are being received or

transmitted at 10 or 100 Mbps.

D/C Duplex

Mode and

Collisions

Green The port is operating in full-duplex

mode.

Amber The port is operating in half-duplex

mode. (Only when operating at 10 or

100 Mbps.)

Flashing

amber

Collisions are occurring on the port.

(Only when operating at 10 or 100

Mbps, half duplex mode.)

25

Page 26

Chapter 1: Overview

Fiber Optic Port

and Transceiver

Slot LEDs

Each 10 Gigabit Ethernet transceiver slot on the AT-9424Ts/XP and

AT-9448Ts/XP Switches has one LED, defined in Table 4.

Table 4 XFP Slot LED

LED Function State Description

L/A Link Status

and Activity

Off No link is established between the

port and the end node.

Solid

green

Flashing

green

The port has established a link at 10

Gbps.

Packets are being received or

transmitted at 10 Gbps.

26

Page 27

System LEDs

AT-9400Ts Stack Installation Guide

The system LEDs on the front panel display the general status information

described in Table 5.

Table 5 System LEDs

LED State Description

FAULT or

FLT

MASTER

or MSTR

RPS Off No optional redundant power supply is

Off Normal operation.

Solid

Red

Flashing

Red

Off The switch is not a member of an enhanced

Green The switch has an enhanced stacking status of

The switch or management software has

malfunctioned. (Refer to Chapter 7,

“Troubleshooting” on page 91 for instructions

on how to troubleshoot a problem.)

The switch is saving its configuration or is

downloading a new version of the AT-S63

Management Software.

stack or has an enhanced stacking status of

slave or unavailable.

The enhanced stacking feature is not related to

or supported on AT-9400Ts Stacks. For

information on enhanced stacking, refer to the

AT-S63 Management Software Features

Guide.

master.

connected to the switch.

POWER

or PWR

Green An optional redundant power supply is

physically connected to the switch and may be

powered on or off.

Off The switch is not receiving power.

Green The switch is receiving power.

27

Page 28

Chapter 1: Overview

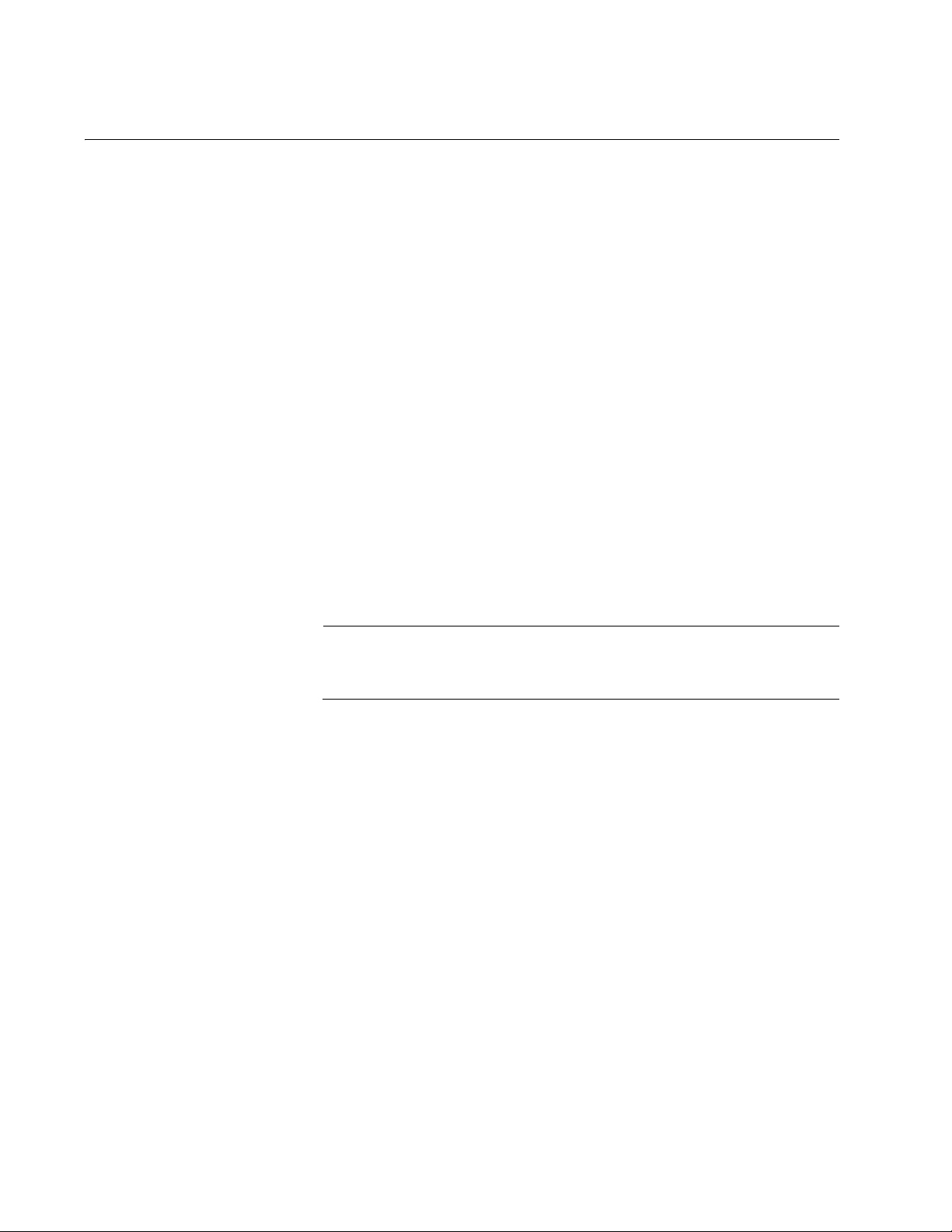

Stack LEDs

The Stack LEDs reflect the status of the two Stack ports on the

AT-StackXG Stacking Module. These LEDs remain off if the module is not

installed.

Table 6 Stack LEDs

LED State Description

MSTR Off The switch is not part of a stack or is a member

unit of a stack.

Green The switch is the master unit of a stack.

1 L/A Off Stack Port 1 has not established a link to a

stacking port on another AT-StackXG Stacking

Module.

Green Stack Port 1 has established a link to a

stacking port on another AT-StackXG Stacking

Module.

Flashing

Green

2 L/A Off Stack Port 2 has not established a link to a

Green Stack Port 2 has established a link to a

Flashing

Green

PRES Off The expansion slot for the AT-StackXG

Stack Port 1 has established a link to a

stacking port on another AT-StackXG Stacking

Module and is sending or receiving packet

traffic.

stacking port on another AT-StackXG Stacking

Module.

stacking port on another AT-StackXG Stacking

Module.

Stack Port 2 has established a link to a

stacking port on another AT-StackXG Stacking

Module and is sending or receiving packet

traffic.

Stacking Module is empty.

28

Green The AT-StackXG Stacking Module is installed

in the switch.

Page 29

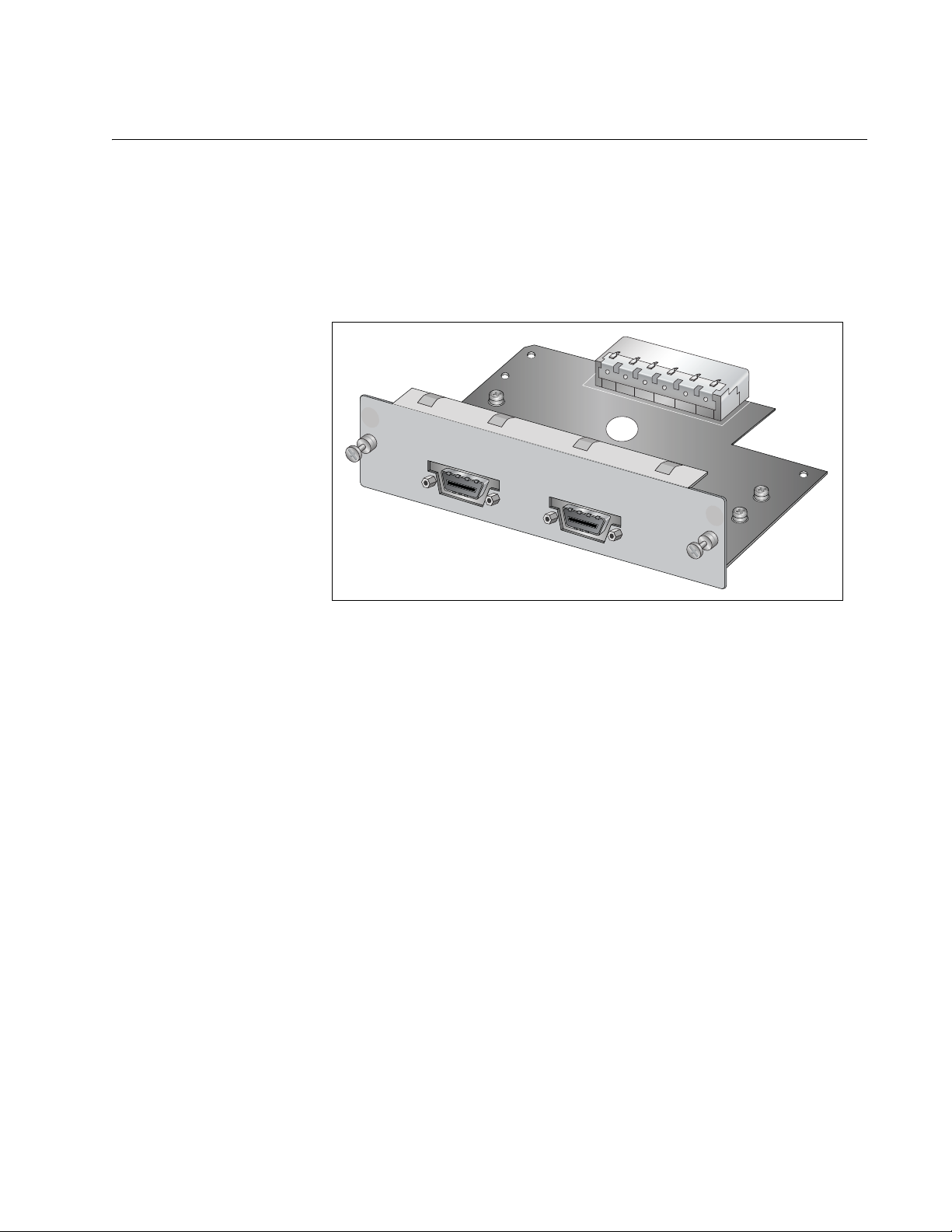

AT-StackXG Stacking Module

The AT-9424Ts, AT-9424Ts/XP, and AT-9448Ts/XP Switches have an

expansion slot on the back panels for the optional AT-StackXG Stacking

Module and its two full-duplex, 12-Gbps stacking ports. A switch must

have this module to be a part of a stack. The installation instructions are

found in “Installing the AT-StackXG Stacking Module” on page 41 and in

the installation guide that ships the module.

A

T

AT-StackXG

-LX44CPUCVR

Stack Port 1

AT-9400Ts Stack Installation Guide

Stac

k Port 2

Figure 7 AT-StackXG Stacking Module

1240

29

Page 30

Chapter 1: Overview

Note

Terminal Port

The terminal port is used to establish a local (out-of-band) management

session with the switch. You establish a local management session by

connecting a terminal or a personal computer with a terminal emulation

program to the port.

All local management sessions of a stack must be conducted through the

stack’s master switch. The master switch can be determined by viewing

the Stack MSTR LEDs on the front panels of the switches. The switch

whose LED is steady green is the master switch of a stack.

The terminal port has an RJ-45 style connector. An RJ-45 to RS-232

management cable is supplied with the switch.

The terminal port is set to the following specifications:

Default baud rate: 9600 bps (Range is 9600 to 115200 bps)

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

These settings are for a DEC VT100 or ANSI terminal, or an

equivalent terminal emulation program.

30

Page 31

AT-RPS3204 Redundant Power Supply

AT-PW

R3204

P

O

W

E

R

The RPS connector on the back panel of the switch connects to the

optional AT-RPS3204 redundant power supply unit, shown in Figure 8.

The unit can provide power to the switch in the event that the switch’s

internal power supply fails.

The AT-RPS3204 redundant external power supply features one

preinstalled AT-PWR3202 Power Module and three empty slots for

additional power modules. Each power module can support one switch.

When fully populated with AT-PWR3202 Power Modules, the

AT-RPS3204 unit can support up to four switches, simultaneously. For

information about installing an AT-RPS3204 unit, consult the

documentation that ships with the unit.

AT-9400Ts Stack Installation Guide

Figure 8 AT-RPS3204 Redundant Power Supply Unit

The pinouts for the redundant power supply’s 21-pin D-combo port and

connector are described in “RPS 21-pin D-combo Port and Connector

Pinouts” on page 106.

31

Page 32

Chapter 1: Overview

AC Power Connector

The AT-9400 Switch have a single AC power supply socket on the back

panel, which has autoswitch AC inputs. To power the switch on or off,

connect or disconnect the power cord.

Refer to “Technical Specifications” on page 101 for the input voltage

range.

Warning: Power cord is used as a disconnection device. To deenergize equipment, disconnect the power cord.

Warning: This unit might have more than one power cord. To

reduce the risk of electric shock, disconnect all power cords

before servicing the unit.

32

5

32

Page 33

Chapter 2

Installing the Hardware

This chapter contains an overview of the installation procedures for a stack

and the procedures for installing the hardware. The chapter contains the

following sections:

“Installation Overview” on page 34

“Reviewing the Safety Precautions” on page 36

“Planning the Installation of a Stack” on page 38

“Maximum Number of Switches in a Stack” on page 39

“Unpacking a Switch” on page 40

“Installing the AT-StackXG Stacking Module” on page 41

“Installing the Power Cord Retaining Clip (AC Switches Only)” on

page 44

“Disconnecting the Network Cables” on page 45

“Installing the Switches in an Equipment Rack” on page 46

“Labeling the Switches” on page 48

33

Page 34

Chapter 2: Installing the Hardware

Installation Overview

Table 7 lists the installation procedures for a stack of the AT-9424Ts,

AT-9424Ts/XP, and AT-9448Ts/XP Switches. The procedures, which are

divided into four chapters, should be performed in the order presented in

the table. Allied Telesis recommends that you print this table and place a

check mark beside the procedures as you complete them.

Chapter 2, “Installing the Hardware”

Table 7. Installation Procedures

Step Procedure

1 Refer to “Reviewing the Safety Precautions” on

page 36

2 Refer to “Planning the Installation of a Stack” on

page 38

3 Refer to “Maximum Number of Switches in a

St a ck” on page 39

4 Refer to “Unpacking a Switch” on page 40

5 Refer to “Installing the AT-StackXG Stacking

Module” on page 41

6 Refer to “Installing the Power Cord Retainin g Clip

(AC Switches Only)” on page 44

7 Refer to “Disconnecting the Network Cables” on

page 45

8 Refer to “Installing the Switches in an Equipment

Rack” on page 46

9 Refer to “Labeling the Switches” on page 48

Chapter 3, “Preparing the Switches”

10 Refer to “Powering on a Switch” on page 50

11 Refer to “Starting a Local Management Session”

on page 52

12 Refer to “Verifying the AT-S63 Version Number”

on page 54

34

13 Refer to “Updating the AT-S63 Management

Software” on page 55

14 Refer to “Assigning the St atic Module ID Numbe r

1 to the Master Switch” on page 56

Page 35

AT-9400Ts Stack Installation Guide

Table 7. Installation Procedures

Step Procedure

15 Refer to “Assigning Static Module ID Numbers to

the Member Switches” on page 59

Chapter 4, “Cabling and Powering on the Stack”

16 Refer to “Cabling the AT-StackXG Stacking

Modules” on page 62

17 Refer to “Powering On the Switches of the St ack”

on page 65

18 Refer to “Verifying the Installation” on page 67

19 Refer to “Troubleshooting the Discovery Process”

on page 69

Chapter 5, “Cabling the Network Ports”

20 Refer to “Installing Optional Transceivers” on

page 72

21 Refer to “Cabling the Twisted Pair and Fiber

Optic Ports” on page 76

35

Page 36

Chapter 2: Installing the Hardware

Note

Reviewing the Safety Precautions

Please review the following safety precautions before you begin to install

the switches or any of their components.

The indicates that a translation of the safety statement is

available in a PDF document titled “Translated Safety Statements”

(613-000405) posted on the Allied Telesis website at

www.alliedtelesis.com.

Warning: Class 1 Laser product.

Warning: Do not stare into the laser beam.

Warning: To prevent electric shock, do not remove the cover.

No user-serviceable parts inside. This unit contains hazardous

voltages and should only be opened by a trained and qualified

technician. To avoid the possibility of electric shock, disconnect

electric power to the product before connecting or disconnecting

4

5

the LAN cables.

Warning: Do not work on eq uipment or cables during periods of

lightning activity.

Warning: Power cord is used as a disconnection device. To deenergize equipment, disconnect the power cord.

Warning: Class I Equipment. This equipment must be earthed.

The power plug must be connected to a properly wired earth

ground socket outlet. An improperly wired socket outlet could

place hazardous voltages on accessible metal parts.

1

3

6

7

36

Pluggable Equipment. The socket outlet shall be installed near

9

8

10

the equipment and shall be easily accessible.

Caution: Air vents must not be blocked and must have free

access to the room ambient air for cooling.

Warning: Operating T emperature. This product is designed for a

maximum ambient temperature of 40° degrees C.

Page 37

AT-9400Ts Stack Installation Guide

All Countries: Install product in accordance with local and

National Electrical Codes.

Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect

that overloading of circuits might have on overcurrent protection

and supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this

concern.

Caution: Risk of explosion if battery is replaced by an incorrect

type. Replace only with the same or equivalent type

recommended by the manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

Attention: Le remplacement de la batterie par une batterie de

type incorrect peut provoquer un danger d’explosion. La

remplacer uniquement par une batterie du même type ou de

type équivalent recommandée par le constructeur. Les batteries

doivent être éliminées conformément aux instructions du

constructeur.

24

25

11

Warning: Mounting of the eq uipment in the rack shou ld be such

that a hazardous condition is not created due to uneven

28

39

33

41

40

mechanical loading.

Warning: This unit might have more than one power cord. To

reduce the risk of electric shock, disconnect all power cords

before servicing the unit.

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater

than the room ambient temperature. Therefore, consideration

should be given to installing the equipment in an environment

compatible with the manufacturer’s maximum rated ambient

temperature (Tmra).

Caution: Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the

equipment is not compromised.

Warning: Reliable earthing of rack-mounted equipment should

be maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuits

(e.g., use of power strips).

37

Page 38

Chapter 2: Installing the Hardware

Note

Planning the Installation of a Stack

Observe these requirements when planning the installation of the stack.

The switches of a stack should be installed in a standard 19-inch

equipment rack. Installing the switches on a table or desktop is not

recommended because it may create a hazardous work area.

The AT-9424Ts, AT-9424Ts/XP, and AT-9448Ts/XP Switches are the

only AT-9400 Switches that support the stacking feature.

Each switch must have the AT-StackXG Stacking Module.

Because of the 0.5 meter length of the AT-StackXG/.5 Stacking Cable,

the switches must be installed in the same equipment rack.

If the stack will include the optional AT-StackXG/1 Stacking Cable, the

distance between the top switch and the bottom switch of the stack

must not be greater than one meter.

Check to be sure the equipment rack is safely secured and will not tip

over. Devices in a rack should be installed starting at the bottom, with

the heavier devices near the bottom of the rack.

The power outlet for the switches should be located near the units and

be easily accessible.

The site should provide easy access to the ports on the front of the

switches. This will make it easy for you to connect and disconnect

cables, as well as view the system LEDs.

To allow proper cooling of the switches, air flow around the units and

through the cooling vents on the sides and rears should be

unrestricted.

Do not place objects on top of the switches.

Do not expose the switches to moisture or water.

Make sure the site is a dust-free environment.

Use dedicated power circuits or power conditioners to supply reliable

electrical power to the network devices.

38

Page 39

Maximum Number of Switches in a Stack

A stack can have up to eight 24-port AT-9424Ts and AT-9424Ts/XP

Switches, or up to four 48-port AT-9448Ts/XP Switches and four 24-port

switches, as shown in the following table.

The AT-9448Ts/XP Switch should not be used as the master switch of a

stack. A stack that has one or two AT-9448Ts/XP Switches should also

have at least one AT-9424Ts or AT-9424Ts/XP Switch to act as the

master switch. A stack that has three or four AT-9448Ts/XP Switches

should have at least two 24-port switches to act as the master switch and

the backup switch of the stack.

Table 8. Maximum Sizes of Stacks

Number of 24-Port AT-9424Ts and AT-9424Ts/XP Switches

AT-9400Ts Stack Installation Guide

Number of

48-Port

AT-9448Ts/XP

Switches

012345678

0

1

2

3

4

39

Page 40

Chapter 2: Installing the Hardware

Note

Unpacking a Switch

To unpack a switch, perform the following procedure:

1. Remove all the components from the shipping packages.

2. Place the switch on a level, secure surface.

3. Make sure the following components are included in your switch

Store the packaging material in a safe location. You must use the

original shipping material if you need to return the unit to Allied

Telesis.

package. If any item is missing or damaged, contact your Allied

Telesis sales representative for assistance.

One AT-9400 Gigabit Ethernet Switch

Two rack-mount brackets

Eight flathead Phillips rack-mount bracket screws

AC power cord (AC switches only; Americas, EU, Australia, and

UK only)

AC power cord retaining clip (AC switches only)

Management cable for local management

Documentation CD

40

Page 41

Installing the AT-StackXG Stacking Module

Note

Warning

This procedure contains the installation instructions for the AT-StackXG

Stacking Module. The module must be installed in all of the switches of the

stack. It is generally easier to install the module before a switch is mounted

in the equipment rack.

Although the stacking module can be hot-swapped, meaning that it

can be installed while the switch is powered on, Allied Telesis

recommends that the switches be powered off during the initial

installation of the stack.

The module can be damaged by static electricity. Be sure to observe

all standard electrostatic discharge (ESD) precautions, such as

wearing an antistatic wrist strap, to avoid damaging the device.

AT-9400Ts Stack Installation Guide

To install the AT-StackXG Stacking Module in the switch, perform the

following procedure:

1. Remove the blank panel from the expansion slot on the back panel of

the switch by loosening the two captive screws on the panel with a

cross-head screwdriver.

AT-LX44CPUCV

R

1241

Figure 9. Removing the Blank Panel from the Expansion Slot

41

Page 42

Chapter 2: Installing the Hardware

Note

Note

Note

Do not remove the blank panel from the chassis until you are ready

to install the module. An open slot allows dust to enter the unit and

reduces proper airflow and cooling in the chassis.

2. Unpack the AT-StackXG Stacking Module from its shipping package

and verify that the following items are included in the package:

One AT-StackXG Stacking Module

One AT-StackXG/.5 Stacking Cable

AT-StackXG Stacking Module Installation Guide

Warranty card

Store the packaging material in a safe location. You must use the

original shipping material if you need to return the unit to Allied

Telesis.

3. Align the edges of the module with the guides in the slot and carefully

slide the module into the chassis until it is flush with the back panel of

the chassis, as shown in Figure 10 on page 43. Light pressure may be

needed to seat the module on the connector on the back panel of the

chassis.

Do not force the module into place. Doing so may damage the

connector pins on the backplane inside the chassis. If there is

resistance, remove the module and reinsert it after verifying that the

edges of the card are properly aligned in the guides in the chassis’

expansion slot.

42

Page 43

AT-9400Ts Stack Installation Guide

A

T-LX44CPUCV

AT-StackXG

R

Stack Po

rt 1

Stack Po

rt 2

Figure 10. Installing the AT-StackXG Stacking Module

1242

4. Secure the module to the chassis by tightening the two captive screws

with a cross-head screwdriver. Refer to Figure 11.

-LX44CPUCV

A

T

AT-StackXG

R

Stack Po

r

t 1

Sta

ck Po

r

t 2

1243

Figure 11. Securing the AT-StackXG Stacking Module

5. Repeat this procedure to install an AT-StackXG Stacking Module in the

other switches of the stack.

You are now ready to install the power cord retaining clip, as explained in

the next procedure.

43

Page 44

Chapter 2: Installing the Hardware

100-240VAC

~

Installing the Power Cord Retaining Clip (AC Switches Only)

Perform the following procedure to install the power cord retaining clip on

the switches:

1. Locate the power cord retaining clip, shown in Figure 12.

Figure 12. Power Cord Retaining Clip

2. Install the clip on the AC power connector on the back panel of the

switch. With the “u” of the clip facing down, press the sides of the clip

toward the center and insert the short ends into the holes in the

retaining bracket, as shown in Figure 13.

100-240VAC

~

Figure 13. Inserting the Retaining Clip into the Retaining Bracket

If the switches of the stack were used as stand-alone units in your

network, go to the next procedure to remove the network cables.

Otherwise, go to “Installing the Switches in an Equipment Rack” on

page 46.

44

Page 45

Disconnecting the Network Cables

135

7

9

11

13

15 17

12

14

16 18

1

If the switches of the planned stack were used as stand-alone devices in

your network, label and disconnect all of the network cables from their

ports. You will reconnect the cables after the stack is created and after you

have reestablished the switches’ configuration settings. If you leave the

cables connected to the ports during the installation, loops might result in

your network topology and that could produce broadcast storms.

AT-9400Ts Stack Installation Guide

Figure 14. Removing the Network Cables from Stand-alone Switches

45

Page 46

Chapter 2: Installing the Hardware

Note

Installing the Switches in an Equipment Rack

Installing a stack on a table or desktop is not recommended

because it may create a hazardous work area.

Perform the following procedure to install the switches in a standard

19-inch rack:

1. Place the switch upside down on a level, secure surface.

2. Using a flat-head screwdriver, remove the snap-on plastic feet from

the bottom of the switch, as shown in Figure 15.

Figure 15. Removing the Feet

3. Turn the switch over.

4. Attach a rack-mount bracket to one side of the switch using four of the

screws that come with the switch, as shown in Figure 16.

Figure 16. Attaching Rack-Mount Brackets

46

Page 47

AT-9400Ts Stack Installation Guide

8LC

/S

P

Gigabit Ethe

r

net Sw

itc

h

F

A

U

LT

MAST

ER

RPS

P

O

WE

R

EJECT

ST

A

T

US

TERMINAL

PO

RT

L/A

5. Install the second rack-mount bracket on the other side of the switch

with the four remaining screws.

6. Mount the switch in a 19-inch rack using standard screws (not

provided), as shown in Figure 17.

Figure 17. Mounting the Switch in a Rack

After you have installed all the switches of the stack in the equipment ra ck,

you are ready to label the switches, as explained in the next procedure.

47

Page 48

Chapter 2: Installing the Hardware

135

246

COMPA

23 24

L/A

D/C

D/C

L/AL/A

D/C

L/A

1000 LINK /

ACT

HDX /

COL

FDX

10/100 LINK / ACT

PORT ACTIVITY

STACK

PRES

MSTR

L/A

1

2

Switch Number: 1

MAC Address:

00:0C:46:67:44:8B

135

246

COMPA

23 24

L/A

D/C

D/C

L/AL/A

D/C

L/A

1000 LINK /

ACT

HDX /

COL

FDX

10/100 LINK / ACT

PORT ACTIVITY

STACK

PRES

MSTR

L/A

1

2

Switch Number: 2

MAC Address:

00:0C:46:67:5E:11

135

246

COMPA

23 24

L/A

D/C

D/C

L/AL/A

D/C

L/A

1000 LINK /

ACT

HDX /

COL

FDX

10/100 LINK / ACT

PORT ACTIVITY

STACK

PRES

MSTR

L/A

1

2

Switch Number: 3

MAC Address:

00:0C:46:67:12:18

Labeling the Switches

Starting with the top or bottom switch of the stack, assign each unit a

number starting with 1 and affix labels with the numbers to their front

panels or adjacent to the units on the equipment rack. These numbers will

be their static module ID numbers, which you’ll assign later in “Assigning

the Static Module ID Number 1 to the Master Switch” on page 56 and

“Assigning Static Module ID Numbers to the Member Switches” on

page 59. The number has a range of 1 to 8. An example of a stack with

three switches is shown in Figure 18. When numbering the switches, note

the following:

The labels should also include the MAC addresses of the switches,

The switches can be numbered in any order, but they will be easier to

which are found on labels on the back panels. The switches will be

easier to identify and manage if the labels have both the stack ID

numbers and the MAC addresses.

identify and manage if they are numbered in sequence starting with

the top or bottom switch.

The switch assigned number 1 will be the master switch of the stack.

As explained in “Maximum Number of Switches in a Stack” on

page 39, the AT-9448Ts/XP Switch should not be used as the master

switch.

48

Figure 18. Labelling the Switches

After labeling the units, go to Chapter 3, “Preparing the Switches” on page

49.

Page 49

Chapter 3

Note

Preparing the Switches

The chapter contains the following procedures:

“Powering on a Switch” on page 50

“Starting a Local Management Session” on page 52

“Verifying the AT-S63 Version Number” on page 54

“Updating the AT-S63 Management Software” on page 55

“Assigning the Static Module ID Number 1 to the Master Switch” on

page 56

“Assigning Static Module ID Numbers to the Member Switches” on

page 59

The cables should not be connected to the AT-StackXG Modules

during the procedures in this chapter.

49

Page 50

Chapter 3: Preparing the Switches

100-240VAC

~

100-240VAC

~

Powering on a Switch

To power on a switch, perform the following procedure:

1. Position the power cord retaining clip in the up position, as shown in

Figure 19.

Figure 19. Power Cord Retaining Clip in the Up Position

2. Plug the power cord into the AC power connector on the back panel of

the unit (see Figure 20).

Warning: Power cord is used as a disconnection device. To de-

energize equipment, disconnect the power cord.

5

Warning: This unit might have more than one power cord. To

reduce the risk of electric shock, disconnect all power cords

before servicing the unit.

32

50

Figure 20. Connecting the AC Power Cord

Page 51

AT-9400Ts Stack Installation Guide

3. Connect the other end of the power cord to an appropriate AC power

outlet. For power specifications for the switch, refer to “Power

Specifications” on page 102.

Go to the next procedure to start a local management session on the unit.

51

Page 52

Chapter 3: Preparing the Switches

Note

AT-9408LC/SP

Gigabit Ethernet Switch

COMPACT FLASH

FAULT

MASTER

RPS

PO

WER

EJECT

STATUS

TERMINAL

PORT

464

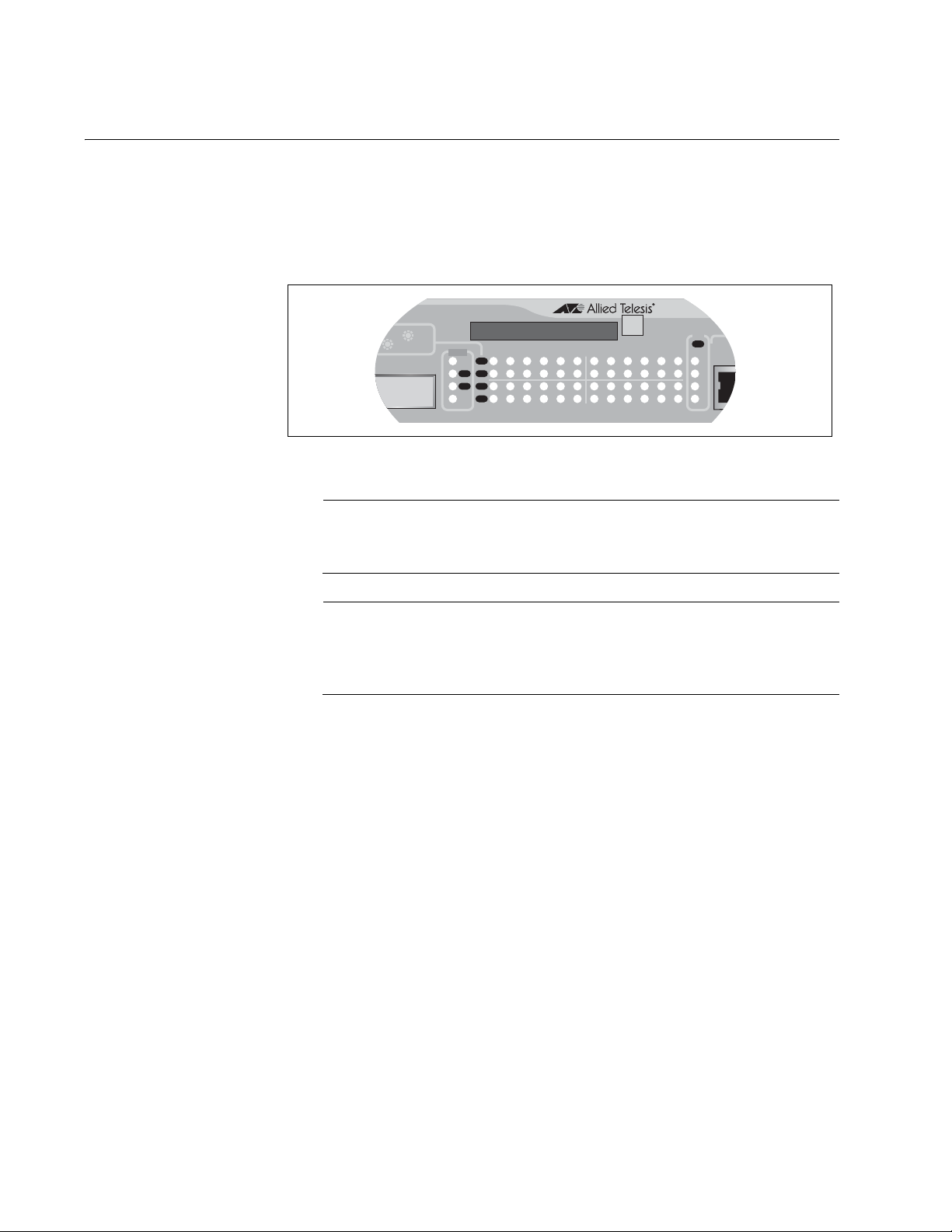

Starting a Local Management Session

To start a local management session on the unit, perform the following

procedure:

1. Connect the RJ-45 end of the management cable included with the

AT-9400 Switch to the Terminal Port on the front panel of the switch,

as shown in Figure 21.

52

Figure 21. Connecting the Management Cable to the RJ-45 Terminal Port

on the Switch

2. Connect the other end of the cable to an RS-232 port on a terminal or

a personal computer with a terminal emulation program.

3. Configure the terminal or terminal emulation program as follows:

Baud rate: Default is 9600 bps (Range is 9600 to 115200 bps)

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

The port settings are for a DEC VT100 or ANSI terminal, or an

equivalent terminal emulator program.

4. Press Enter.

You are prompted for a user name and password.

Page 53

AT-9400Ts Stack Installation Guide

5. If the switch is new, the user name is “manager” and the default

password is “friend“. If the switch was used as a stand-alone unit in

your network, enter the appropriate user name and password for

manager access. The user name and password are case sensitive.

Go to the next procedure to verify the version number of the AT-S63

Management Software on the unit.

53

Page 54

Chapter 3: Preparing the Switches

Allied Telesis Ethernet Switch AT-9424Ts/XP - AT-S63 v4.0.0

<No system name>

#

Verifying the AT-S63 Version Number

After you have logged on, the command line interface (CLI) prompt,

shown in Figure 22, is displayed.

Figure 22. Command Line Prompt

The version number of the AT-S63 Management Software on the switch is

displayed after “AT-S63.” In the example it‘s “V4.0.0.”

Note the following:

The management software must be version 3.0.0 or later.

All the switches of a stack must have the same version of the

management software.

If you need to upgrade the management software on the switch, go to the

next procedure. Otherwise, go to “Assigning the Static Module ID Number

1 to the Master Switch” on page 56 if you are configuring the master

switch of “Assigning Static Module ID Numbers to the Member Switches”

on page 59 if you are configuring a member switch.

54

Page 55

Updating the AT-S63 Management Software

Caution

If you need to upgrade the management software on the switch, perform

the instructions in this section. If the switch already has the correct version

of the management software, go to the next section.

These instructions use Xmodem to transfer the new management software

to the switch. If you prefer, you can download the file using TFTP. For

instructions, refer to the AT-S63 Management Software User’s Guides.

This procedure causes the switch to reset. The switch will not

forward traffic during the reset. If the unit is connected to a live

network, some network traffic will be lost.

This procedure assumes that you established a local management

session with the switch, as explained in the previous sections, and that

you have obtained the necessary management software from the Allied

Telesis web site and stored it on your workstation. For instructions on how

to obtain new management software, refer to “Management Software

Updates” on page 13.

AT-9400Ts Stack Installation Guide

To load new management software on the switch, perform the following

procedure:

1. Enter this command at the command prompt:

load method=xmodem destfile=appblock

2. At the confirmation prompt, enter “Y” for yes to continue with the

procedure or “N” for no to cancel the procedure.

This prompt is displayed;

Use Hyper Terminal’s Transfer/Send file option to

select Filename & Protocol

Note: Please select ‘1K Xmodem’ protocol for faster

download...

3. Use your Xmodem utility on your workstation to begin the file transfer.

After receiving the file, the switch writes it to flash memory and then

resets. The entire file transfer takes about seven minutes at 115200

bpi on the Terminal port.

55

Page 56

Chapter 3: Preparing the Switches

Note

Local MAC Addr :00:30:84:00:00:03

Standalone Mode ID :1

Stack Mode :AUTO

Stack ID :1

Stack Priority :16

Assigning the Static Module ID Number 1 to the Master Switch

This procedure explains how to assign the static module ID number 1 to

the master switch of the stack. If the switch will be a member switch, go to

the next procedure for instructions on how to assign it a stack ID number.

This procedure assumes that you have already established a local

management session with the device that is to be the master switch of the

stack. For instructions, refer to “Starting a Local Management Sessio n” on

page 52.

To assign the stack ID number 1 to the master switch, perform the

following procedure:

1. Enter the following command to view the switch’s current module ID

assignment:

show stack

If the switch displays the message “CLI Command Not Found or

Ambiguous,” the AT-S63 Management Software on the unit needs

to be updated. For instructions, refer to “Updating the AT-S63

Management Software” on page 55.

An example of the display is shown in Figure 23.

Figure 23. SHOW STACK Command

This command displays the following information:

Table 9. SHOW STACK Command

Field Description

Local MAC Addr The MAC address of the switch.

Standalone Mode ID The module ID number of the switch

when the device is not a part of a stack.

This parameter can be ignored.

56

Page 57

AT-9400Ts Stack Installation Guide

Note

Table 9. SHOW STACK Command

Field Description

Stack Mode The assignment method of the module ID

number. Auto means the number was

assigned dynamically by the

management software when the switch

was powered on. Static means the

number was assigned with the SET

STACK command.

Stack ID The switch’s current module ID number.

Stack Priority The switch’s current stack priority value,

used to control dynamic module ID

numbers.

When this command is performed on a stack, it includes a table that

lists the units of the stack. However, since the unit is not yet part of a

stack, the table is omitted.

2. Examine the Stack Mode and Stack ID fields. If the Stack Mode is

Static and the Stack ID is 1, no command is necessary. Go to step 8.

If the current setting of Stack Mode is Auto, enter this command to

change the switch’s dynamic module ID value to the static value of 1:

set stack moduleid=1 newmoduleid=1

If Stack Mode is Static and Stack ID is a value other than 1, enter the

following command, where n is the current value of Stack ID:

n

set stack moduleid=

newmoduleid=1

For example, if the current value of Stack ID is 4, the command would

be:

set stack moduleid=4 newmoduleid=1

If you are already familiar with the AT-S63 Management Software,

then you probably know about the SAVE CONFIGURATION

command, which is used to save your configuration changes in the

active boot configuration file. That command is not required in this

procedure because the SET STACK command automatically saves

the new module ID number in a hidden system file in the switch’s file

system.

57

Page 58

Chapter 3: Preparing the Switches

3. The new module ID number does not take affect until the switch is

reset. Reset the unit with this command:

restart reboot

4. Wait for the switch to reset and afterwards reestablish the

management session by logging in again.

5. Enter the following command again to verify the switch’s stack ID

assignment:

show stack

6. Verify that the Stack Mode is Static and the Stack ID is 1. If the values

are correct, go to the next step. Otherwise, repeat the procedure

starting with step 2.

7. Power off the switch.

Repeat the procedures in this chapter on the other switches of the stack.

Afterwards, go to the next chapter for instructions on how to cable and

power on the stack.

58

Page 59

AT-9400Ts Stack Installation Guide

Assigning Static Module ID Numbers to the Member Switches

This procedure is used to assign a static ID number to a member switch of

the stack. It must be performed on a switch before the cables are

connected to the AT-StackXG Stacking Module.