Alliance Laundry Systems SF135PV, SF250PV, UF135PV, UF250PV User Manual

Washer-Extractors

Cabinet Freestanding

Models SF135PV, SF250PV, SF250PV Tilt,

UF135PV, UF250PV and UF250PV Tilt

®

Output Indicators

Emergency Stop

Operating Instructions

1. Open Door

2. Load Articles

3. Close Door

4. Enter 2 Digit Wash Cycle

5. Press Start

NOTA: El manual en

español aparece después

del manual en inglés.

Emergency Stop

Operating Instructions

1. Open Door

2. Load Articles

3. Close Door

4. Enter 2 Digit Wash Cycle

5. Press Start

Output Indicators

Installation/Maintenance

R072I

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

R017I

Part No. F232102R3

January 2002

Table of

Contents

Safety.................................................................................................... 3

Key to Symbols..................................................................................... 4

Operator Safety..................................................................................... 6

Safe Operating Environment ................................................................ 6

Environmental Conditions............................................................... 6

Machine Location ............................................................................ 7

Input and Output Services................................................................ 7

AC Inverter Drive ............................................................................ 8

Misuse................................................................................................... 8

Installation........................................................................................... 9

Machine Overview................................................................................ 9

Emergency Stop Button................................................................... 9

Wet Clean Capable Features............................................................ 9

Delivery Inspection............................................................................... 10

Customer Service.................................................................................. 10

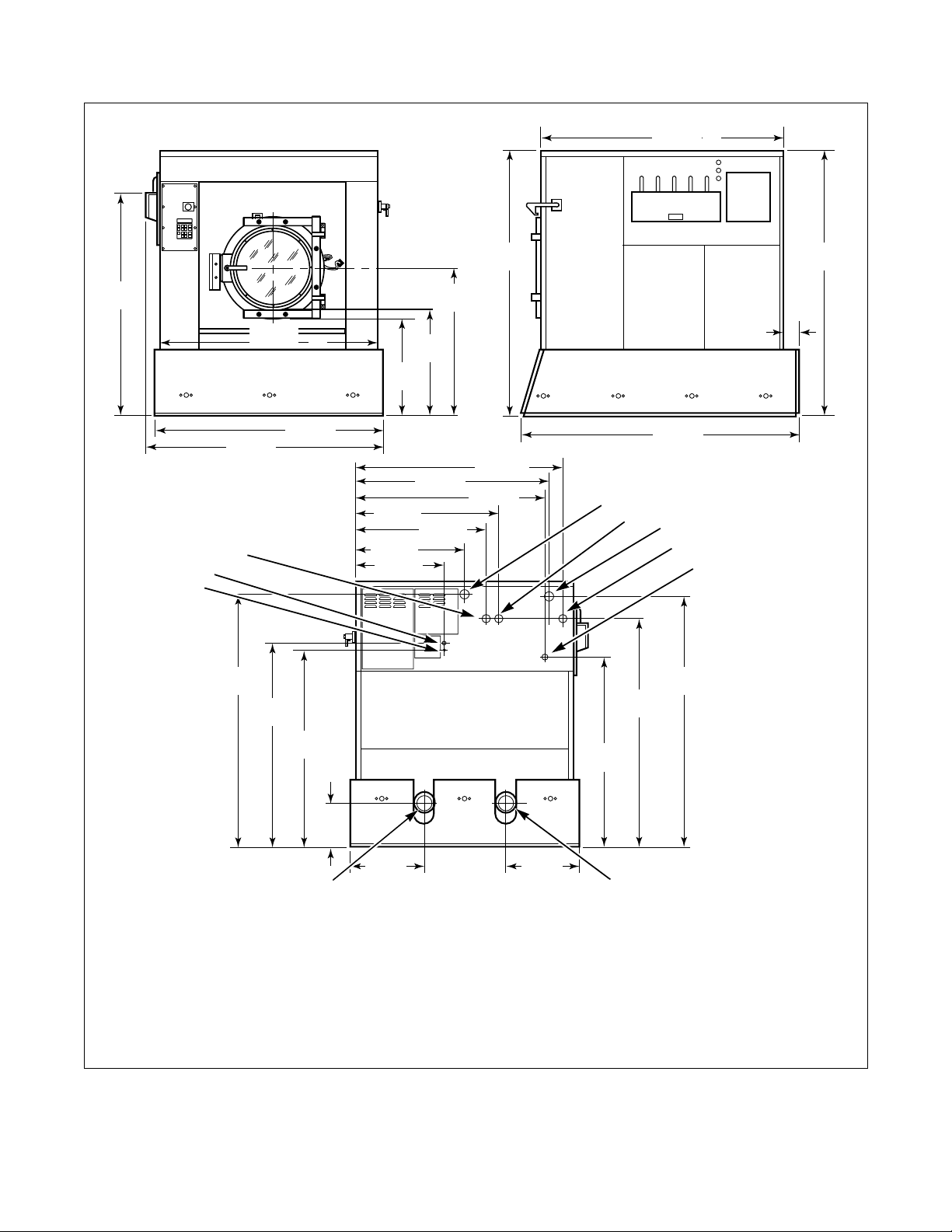

Machine Dimensions ............................................................................ 15

Dimensional Clearances................................................................... 15

Machine Foundation............................................................................. 21

Mechanical Installation – Standard Models ......................................... 22

Mounting Bolt Installation for Standard 135 Pound Capacity

and 250 Pound Capacity Machines................................................ 22

Mechanical Installation – Models with Tilt Option.............................. 25

Mounting Bolt Installation for 250 Pound Capacity Models

with Forward or Two-Way Tilt Option.......................................... 25

Drain Connection.................................................................................. 28

Water Connection................................................................................. 30

Electrical Installation............................................................................ 31

Power Cable/Plug Disconnect.......................................................... 32

Steam Requirements (Steam Heat Option Only).................................. 34

Air Requirements.................................................................................. 34

Chemical Injection Supply System....................................................... 35

Supply Compartments...................................................................... 36

Connecting External Liquid Supplies to the Washer-Extractor....... 36

Electrical Connections for Chemical Injection Supply Systems ..... 36

Control Function Test........................................................................... 38

Maintenance ........................................................................................ 39

Daily ..................................................................................................... 39

Beginning of Day............................................................................. 39

End of Day ....................................................................................... 40

Weekly.................................................................................................. 40

Monthly................................................................................................. 40

Quarterly............................................................................................... 42

Care of Stainless Steel.......................................................................... 42

Daily Preventive Maintenance Checklist.............................................. 43

Weekly Preventive Maintenance Checklist.......................................... 44

Monthly Preventive Maintenance Checklist......................................... 45

Quarterly Preventive Maintenance Checklist....................................... 46

Removal from Service ........................................................................ 47

Decommissioning ................................................................................. 47

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Safety

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

WARNING

Death or serious injury can result if

children become trapped in the machine.

Do not allow children to play on or around

this machine. Do not leave children

unattended while the machine door is

open.

SW001

DANGER

Anyone operating or servicing this machine must

follow the safety rules in this manual. Particular

attention must be paid to the CAUTION, WARNING,

and DANGER blocks which appear throughout the

manual.

The following warnings are general examples that

apply to this machine. Warnings specific to a particular

operation will appear in the manual with the

discussion of that operation.

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

CAUTION

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

SW020

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

3

Safety

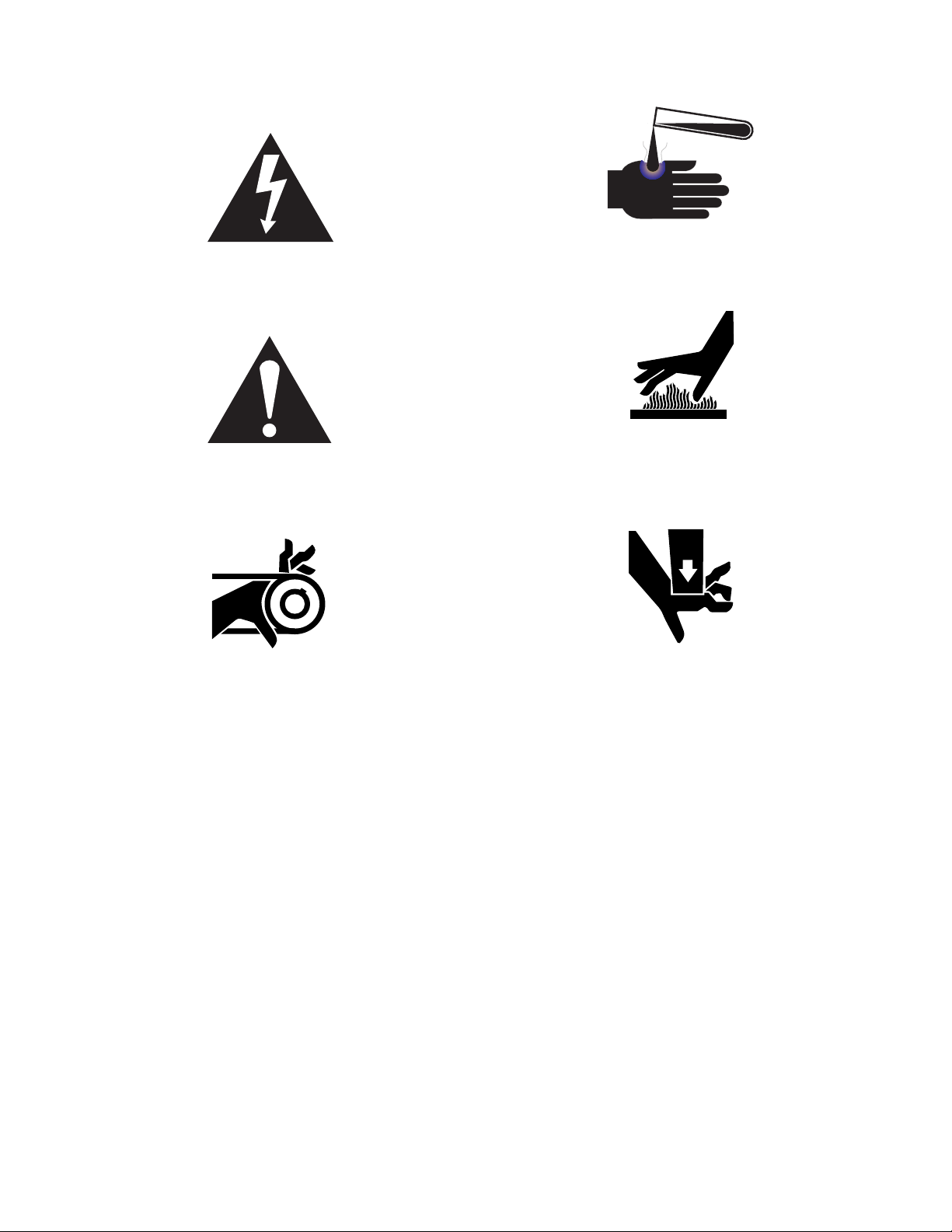

Key to Symbols

The lightning flash and arrowhead within the triangle

is a warning sign indicating the presence of dangerous

voltage.

The exclamation point within the triangle is a warning

sign indicating important instructions concerning the

machine and possibly dangerous conditions.

This warning symbol indicates the presence of possibly

dangerous chemicals. Proper precautions should be

taken when handling corrosive or caustic materials.

This warning symbol indicates the presence of hot

surfaces that could cause serious burns. Stainless steel

and steam lines can become extremely hot and should

not be touched.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms within the

machine. Guards should always be in place when the

machine is in operation.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving mechanical

parts can crush and/or sever body parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

DO NOT EXCEED

Safety

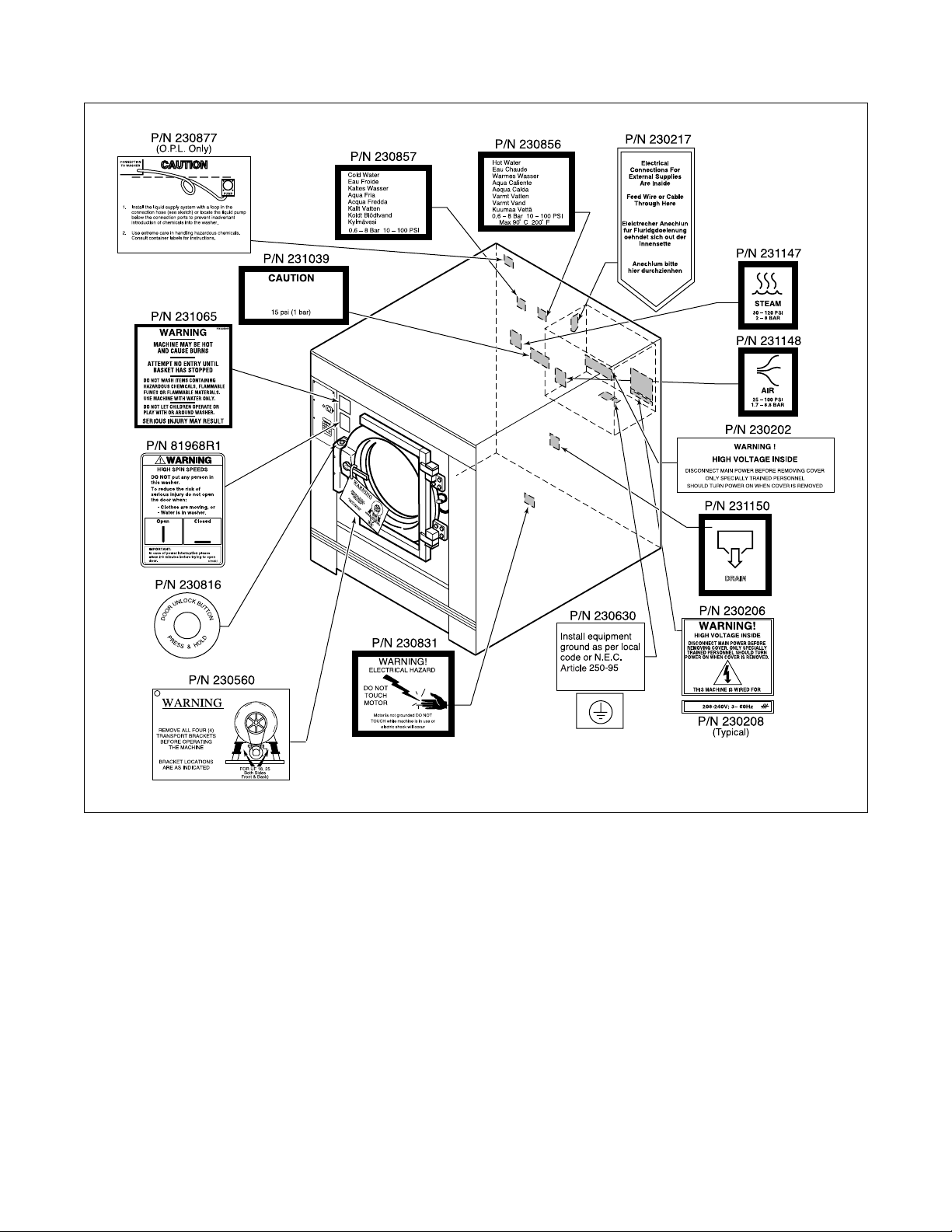

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals could

result in injury to the operator or service technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If questions

regarding safety arise, contact the factory immediately.

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

R066I

R066I

Figure 1

Use factory-authorized spare parts to avoid safety

hazards.

5

Safety

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW039

WARNING

Operator Safety

To ensure the safety of machine operators, the following

maintenance checks must be performed daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in the machine.

Safe Operating Environment

Safe operation requires an appropriate operating

environment for both the operator and the machine. If

questions regarding safety arise, contact the factory

immediately.

Environmental Conditions

● Ambient Temperature. Water in the machine will

freeze at temperatures of 32°F (0°C) or below.

Temperatures above 120°F (50°C) will result in

more frequent motor overheating and, in some

cases, malfunction or premature damage to solid

state devices that are used in some models.

Special cooling devices may be necessary.

Water pressure switches are affected by increases

and decreases in temperature. Every 25°F

(10°C) change in temperature will have a

1% effect on the water level.

● Humidity. Relative humidity above 90% may

cause the machine’s electronics or motors to

malfunction or may trip the ground fault

interrupter. Corrosion problems may occur on

some metal components in the machine.

If the relative humidity is below 30%, belts and

rubber hoses may eventually develop dry rot.

This condition can result in hose leaks, which

may cause safety hazards external to the machine

in conjunction with adjacent electrical

equipment.

● Ventilation. The need for make-up air openings

for such laundry room accessories as dryers,

ironers, or water heaters must be evaluated

periodically. Louvers, screens, or other

separating devices may reduce the available air

opening significantly.

● Radio Frequency Emissions. A filter is available

for machines in installations where floor space is

shared with equipment sensitive to radio

frequency emissions.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

● Elevation. If the machine is to be operated at

elevations of over 3280 ft. (1000 m) above sea

level, pay special attention to water levels and

electronic settings (particularly temperature) or

desired results may not be achieved.

F232102

Safety

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel

reducers, carbon tetrachloride, gasoline,

benzene, naptha, etc. Doing so could

result in serious personal injury and/or

damage to the machine.

SW002

DANGER

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any safety

devices.

SW019

CAUTION

● Chemicals. Keep stainless steel surfaces free of

chemical residues.

● Water Damage. Do not spray the machine with

water. Short circuiting and serious damage may

result. Repair immediately all seepage due to

worn or damaged gaskets, etc.

Machine Location

● Foundation. The concrete floor must be of

sufficient strength and thickness to handle the

floor loads generated by the high extract speeds

of the machine.

● Service/Maintenance Space. Provide sufficient

space to allow comfortable performance of

service procedures and routine preventive

maintenance.

● Steam Heat (Optional) Pressure. Best

performance will be realized if steam is provided

at a pressure of 30 – 80 psi (2.0 – 5.4 bar). Steam

pressure higher than 125 psi (8.5 bar) may result

in damage to steam components and may cause

personal injury.

For machines equipped with optional steam heat,

install piping in accordance with approved

commercial steam practices. Failure to install the

supplied steam filter may void the warranty.

● Compressed Air. For machines requiring

compressed air service, best performance will

be realized if air is provided at a pressure of

80 – 100 psi (5.4 – 6.7 bar).

● Drainage System. Provide drain lines or troughs

large enough to accommodate the total number of

gallons that could be dumped if all machines on

the site drained at the same time from the highest

attainable level. If troughs are used, they should

be covered to support light foot traffic.

● Pow er. For personal safety and for proper

operation, the machine must be grounded in

accordance with state and local codes. The

ground connection must be to a proven earth

ground, not to conduit or water pipes. Do not

use fuses in place of the circuit breaker. An easyaccess cutoff switch should also be provided.

This is especially important in connection with

machines equipped with an AC inverter drive.

Consult installation instructions for specific details.

Input and Output Services

● Wat er Pressure. Best performance will be

realized if water is provided at a pressure of

30 – 85 psi (2.0 – 5.7 bar). Although the machine

will function properly at lower pressure,

increased fill times will occur. Water pressure

higher than 100 psi (6.7 bar) may result in

damage to machine plumbing. Component

failure(s) and personal injury could result.

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

Always disconnect power and water supplies before

a service technician performs any service procedure.

Where applicable, steam and/or compressed air

supplies should also be disconnected before service

is performed.

7

Safety

AC Inverter Drive

Machines equipped with the AC inverter drive require

special attention with regard to the operating

environment.

● An especially dusty or linty environment will

require more frequent cleaning of the AC inverter

drive cooling fan filter and of the AC inverter

drive itself.

● Power line fluctuations from sources such as

uninterruptible power supplies (UPS) can

adversely affect machines equipped with the AC

inverter drive. Proper suppression devices should

be utilized on the incoming power to the machine

to avoid problems.

● A clean power supply free from voltage spikes

and surges is absolutely essential for machines

equipped with the AC inverter drive. Nonlinear

inconsistencies (peaks and valleys) in the power

supply can cause the AC inverter drive to

generate nuisance errors.

If voltage is above 230 Volt for 200 Volt

installations or above 440 Volt for 400 Volt

installations, a buckboost transformer is

recommended. If voltage is above 240 Volt or

480 Volt, a buckboost transformer is required.

Misuse

Never use this machine for any purpose other than

washing fabric.

● Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

● Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

● Never allow children to play on or around this

machine. Death or serious injury can result if

children become trapped in the machine. Do not

leave children unattended while the machine door

is open. These cautions apply to animals as well.

● Sufficient space to perform service procedures

and routine preventive maintenance is especially

important for machines equipped with the AC

inverter drive.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

This manual is designed as a guide to the installation

and maintenance of the 135 pound and 250 pound

capacity cabinet freestanding washer-extractors.

The manuals, installation instructions, and the wiring

diagrams which accompany the washer-extractor have

been included with the machine at no charge.

Additional copies are available at a nominal charge.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

Machine Overview

The design of the washer-extractor emphasizes

performance and long service life. The cylinder, shell,

and main body panels are fabricated of stainless steel.

The washer-extractor features the WE-6

microcomputer which offers 39 preprogrammed

cycles and programming versatility in the field.

The AC inverter drive control provides programmable

motor speeds using a single motor. This makes it

possible to achieve ultra-high extract speeds.

Two separate bearings support the cylinder on

135 pound and 250 pound models.

The cylinder is constructed with four lifters or ribs that

lift the laundry from the bath solution when the

cylinder rotates at slow speed and then allow it to

tumble back into the bath. This mechanical action

accomplishes the cleaning function. The cylinder is

perforated, allowing the water to drain from within

during the wash and extract steps.

The supply dispenser is located on the left side panel

of the washer-extractor. The supply dispenser

compartments are accessed by unlatching the supply

dispenser cover door. These compartments accept

powder or liquid supplies. Each compartment is

controlled independently by the WE-6 computer.

Electrical controls for the washer-extractor are housed

in three enclosures. The front control module is

located just behind the keypad and control panel. It

houses the WE-6 computer board, a fuse/relay board,

and other functional electrical components. The rear

control module houses the AC inverter drive and its

components.

A door-lock system prevents opening of the door when

water is in the washer-extractor. It also prevents

operation of the washer-extractor when the door is

open.

The doorbox contains the Hall-effect door-closed

sensor, door-open sensor, and the door-unlock

solenoid.

On 135 pound capacity models, water enters the

machine through electromechanical water valves. On

250 pound capacity models, water enters the machine

through pneumatic water valves on the rear of the

machine. (Pneumatic water valves are an option on

135 pound capacity models.)

Emergency Stop Button

On 135 pound capacity models, a red emergency stop

button is located on the right side of the washerextractor front. On 250 pound capacity models, the

emergency stop button is located on the left side. Push

the button to stop the machine.

Wet Clean Capable Features

The washer-extractor is equipped with the following

wet clean capable features: one-half wash speed for

gentle mechanical action during wash; eight supply

signals, providing normal laundering signals to

dispense detergents, bleaches, softeners, sours, etc.,

and also chemicals unique to wet clean processing.

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Installation

Delivery Inspection

Upon delivery, visually inspect crate, protective cover,

and unit for any visible shipping damage. If the crate,

protective cover, or unit are damaged or signs of

possible damage are evident, have the carrier note the

condition on the shipping papers before the shipping

receipt is signed, or advise the carrier of the condition

as soon as it is discovered.

Remove the crate and protective cover as soon after

delivery as possible. If any damage is discovered upon

removal of the crate and/or protective cover, advise the

carrier and file a written claim immediately.

Customer Service

If literature or replacement parts are required, contact

the source from whom the washer-extractor was

purchased or contact Alliance Laundry Systems LLC

at (920) 748-3950 for the name of the nearest

authorized parts distributor.

For technical assistance, call any of the following

numbers:

(850) 718-1025

(850) 718-1026

Marianna, Florida

(920) 748-3121

Ripon, Wisconsin

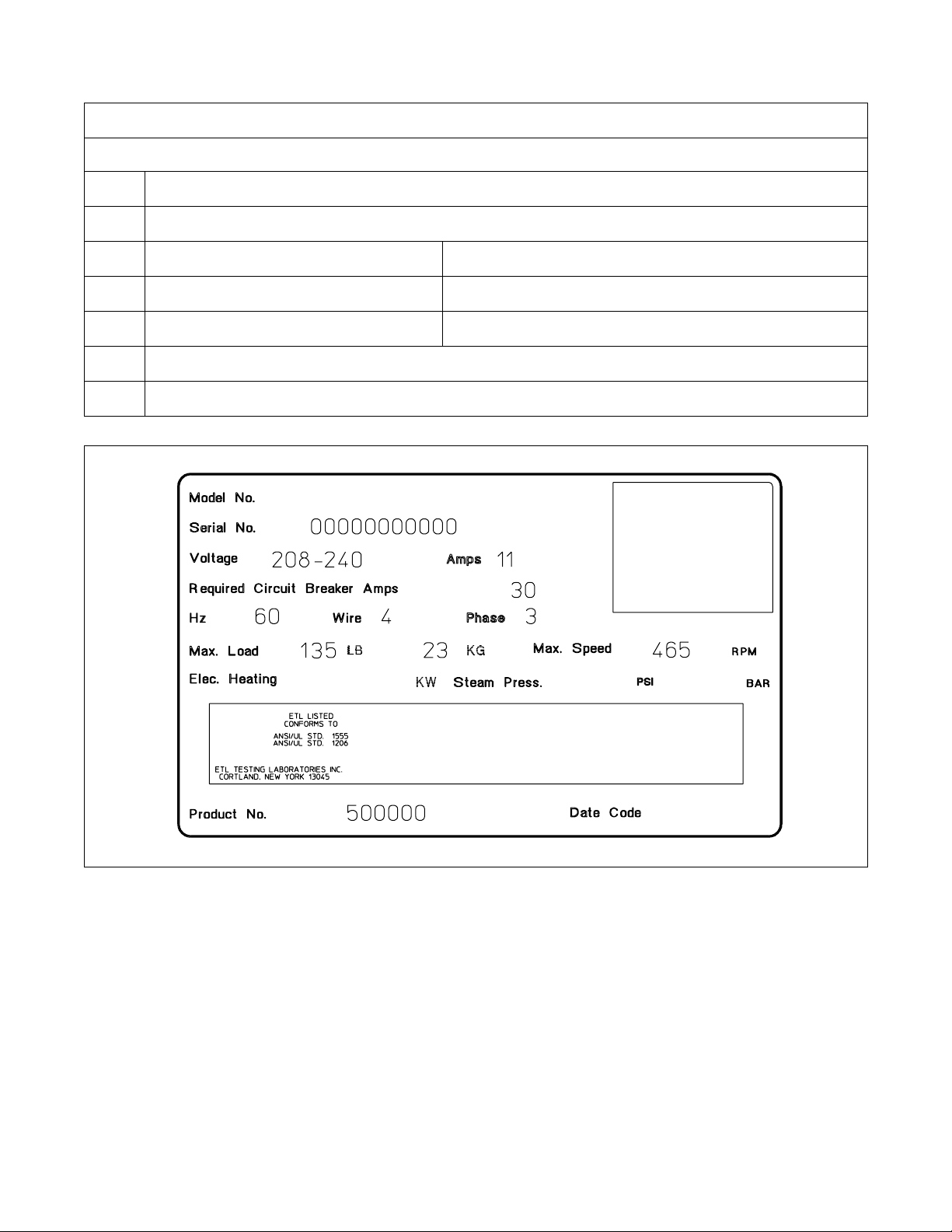

A record of each washer-extractor is on file with the

manufacturer. The serial number decal is located at the

rear of the washer-extractor. Figure 2 shows the

location of the serial number on the decal. Always

provide the washer-extractor’s serial number and

model number when ordering parts or when seeking

technical assistance.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Model Number Familiarization Guide

Sample Model Number: UF135PVQU20001

Installation

UF

135

P

V

Q

U2

0001

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight)

Type of Electrical Control P = WE-6 Computer

Washer-Extractor Speed Capabilities V = 7 Speeds

Electrical Characteristics Refer to Ta b l e 6.

Design Series

Option Identification (varies from machine to machine)

UF135PVQU20001

F232102

Figure 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

R073I

11

Installation

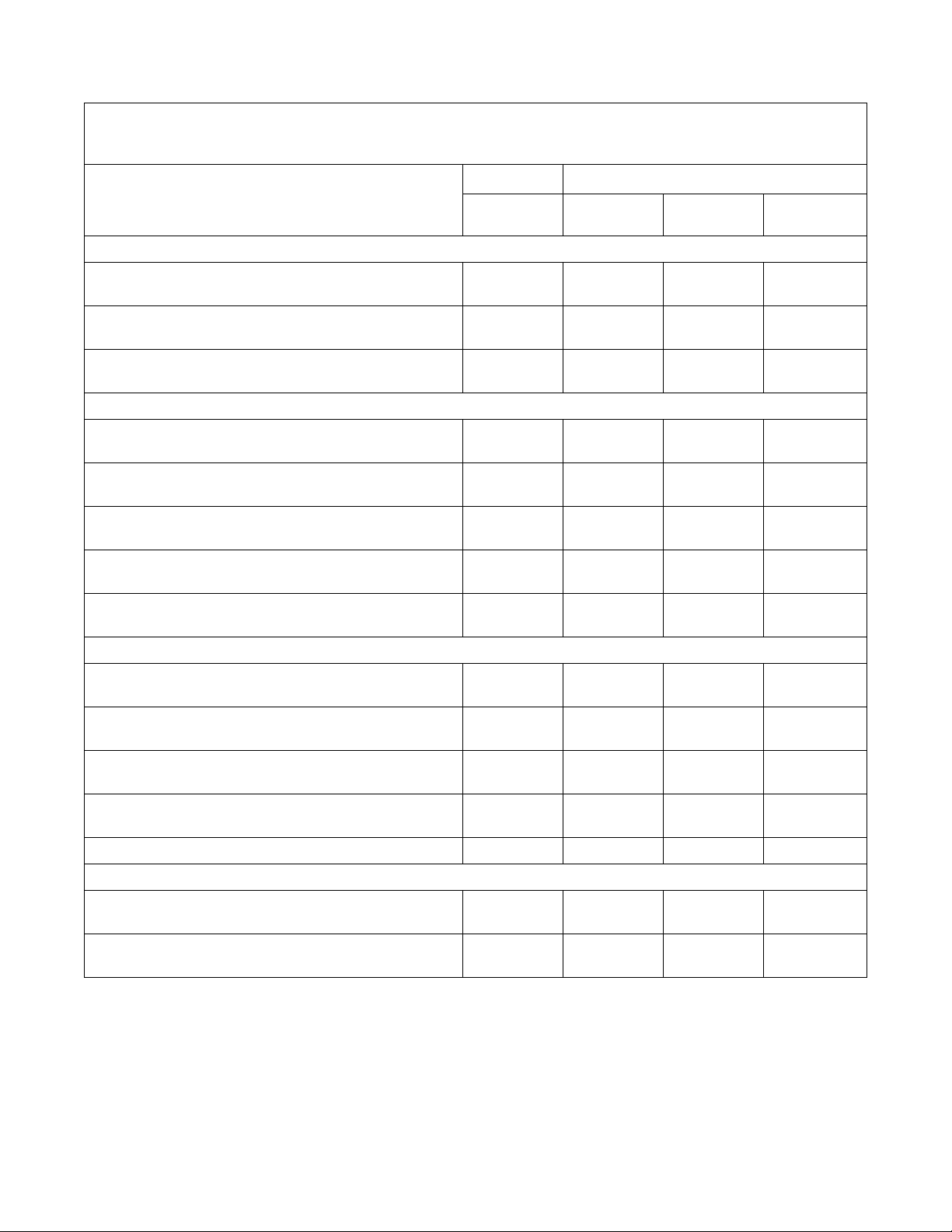

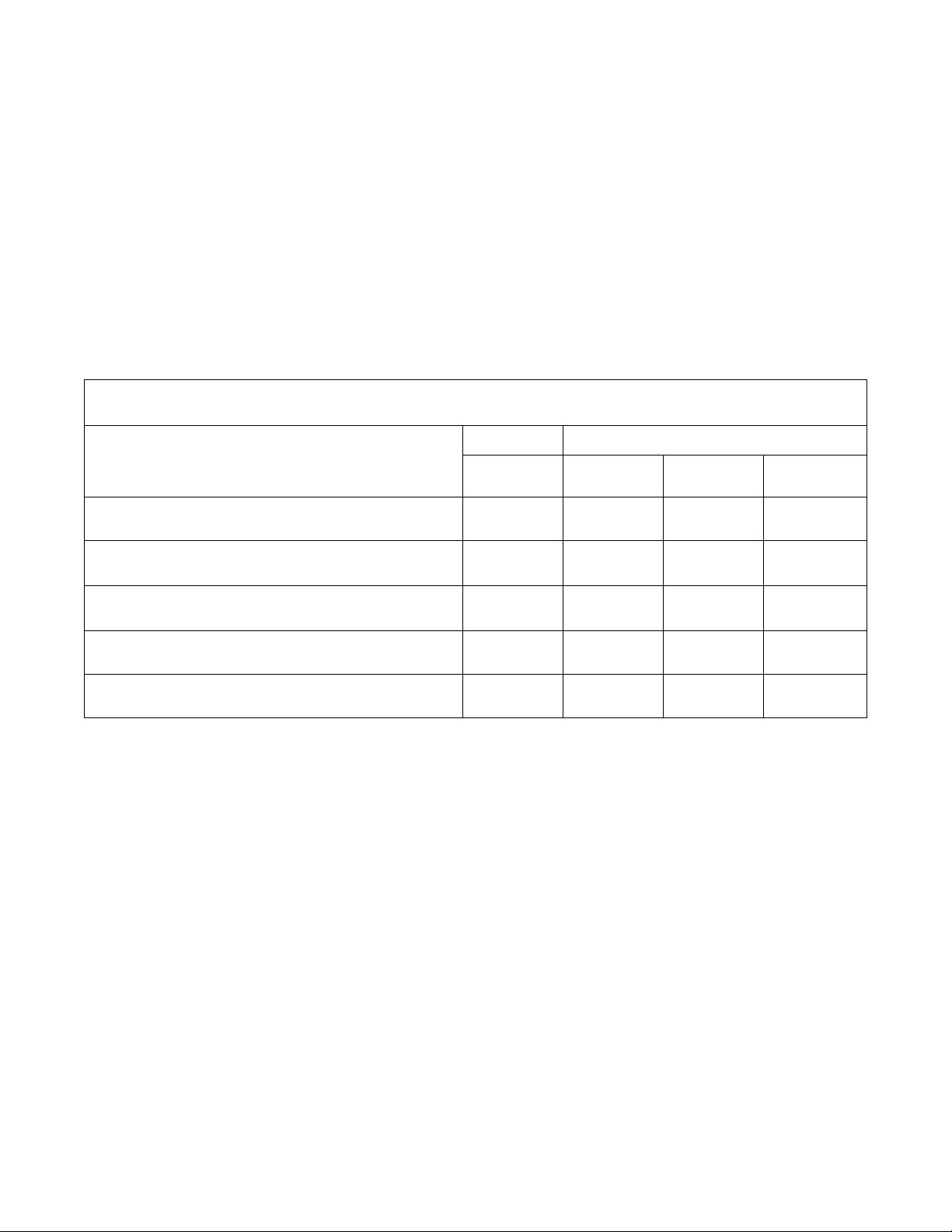

135 Pound and 250 Pound Capacity Models

Cabinet Freestanding

General Specifications

135 250

Standard Standard

Overall Dimensions

Overall width 71

in.

(1803 mm)

Overall height 75

in.

(1829 mm)

Overall depth 61

in.

(1550 mm)

Weight and Shipping Information

Net weight 4000 lbs.

(1818 kg)

Domestic shipping weight 4200 lbs.

(1909 kg)

Domestic shipping volume 253 ft

3

(7.1 m3)

Export shipping weight 4500 lbs.

(2045 kg)

Export shipping volume 291 ft

3

(8.1 m3)

Wash Cylinder Information

77.06 in.

(1957 mm)

82 in.

(2083 mm)

80.2 in.

(2040 mm)

7800 lbs.

(3545 kg)

8000 lbs.

(3636 kg)

3

406 ft

(11.4 m3)

8500 lbs.

(3860 kg)

3

454 ft

(12.7 m3)

Forward Tilt

Option

81 in.

(2057 mm)

88 in.

(2235 mm)

86.1 in.

(2190 mm)

8600 lbs.

(3909 kg)

8800 lbs.

(4000 kg)

3

406 ft

(11.4 m3)

9300 lbs.

(4227 kg)

3

454 ft

(12.7 m3)

Two-Way

Tilt Option

79.0 in.

(2006 mm)

88 in.

(2235 mm)

91 in.

(2311 mm)

9600 lbs.

(4364 kg)

9800 lbs.

(4445 kg)

3

406 ft

(11.4 m3)

10,300 lbs.

(4682 kg)

3

454 ft

(12.7 m3)

Cylinder diameter 43

Cylinder depth 25

Cylinder volume 21.0 ft

Perforation size 0.188

in.

(1092 mm)

in.

(635 mm)

3

(596 l)

in.

(4.77 mm)

52 in.

(1321 mm)

32 in.

(813 mm)

3

39.3 ft

(1114 l)

0.188 in.

(4.77 mm)

52 in.

(1321 mm)

32 in.

(813 mm)

3

39.3 ft

(1114 l)

0.188 in.

(4.77 mm)

52 in.

(1321 mm)

32 in.

(813 mm)

39.3 ft

(1114 l)

0.188 in.

(4.77 mm)

Perforation open area 23% 20% 20% 20%

Door Opening Information

Door opening size 23

Height of door bottom above floor 28.25

in.

(584 mm)

in.

(718 mm)

28.5 in.

(724 mm)

30.9 in.

(784 mm)

28.5 in.

(724 mm)

36.9 in.

(937 mm)

28.5 in.

(724 mm)

36.9 in.

(937 mm)

3

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

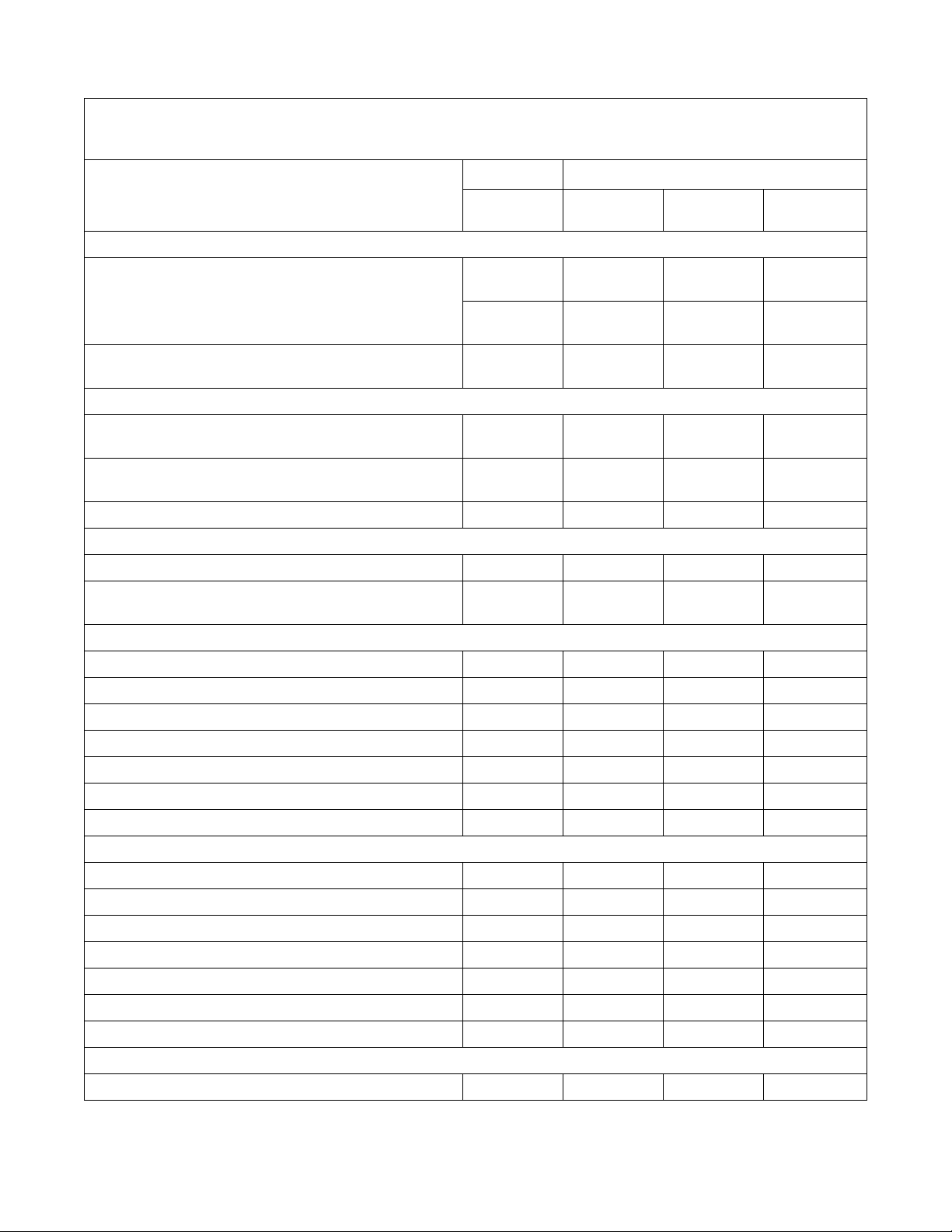

Installation

135 Pound and 250 Pound Capacity Models

Cabinet Freestanding

General Specifications (Continued)

135 250

Standard Standard

Water Consumption

Average water consumption per cycle HOT

153 gal

(579 l)

COLD

70 gal

(266 l)

Average hot water consumed per hour 220 gal

(833 l)

Power Consumption

Average power used per cycle

Average HVAC load

0.9 kW-hr

1500 BTU/hr

(kcal/hr)

Nominal sound emission

75 dBA 75 dBA 75 dBA 75 dBA

Drive Train Information

219 gal

(829 l)

105 gal

(399 l)

285 gal

(1079 l)

1.5 kW-hr

(Est.)

2200 BTU/hr

(kcal/hr)

Forward Tilt

Option

219 gal

(829 l)

105 gal

(399 l)

285 gal

(1079 l)

1.5 kW-hr

(Est.)

2200 BTU/hr

(kcal/hr)

Two-Way

Tilt Option

219 gal

(829 l)

105 gal

(399 l)

285 gal

(1079 l)

1.5 kW-hr

(Est.)

2200 BTU/hr

(kcal/hr)

Number of motors in drive train 1 1 1 1

Drive motor power

10 hp

(7.5 kW)

25 hp

(18.5 kW)

25 hp

(18.5 kW)

25 hp

(18.5 kW)

Cylinder Speeds

1/2 Wash/reverse speed 26 rpm 21 rpm 21 rpm 21 rpm

Wash/reverse speed 36 rpm 31 rpm 31 rpm 31 rpm

Distribution speed 62 rpm 54 rpm 54 rpm 54 rpm

Medium extract speed 170 rpm 140 rpm 140 rpm 140 rpm

High extract speed l 375 rpm 340 rpm 340 rpm 340 rpm

High extract speed 2 480 rpm 435 rpm 435 rpm 435 rpm

High extract speed 3 715 rpm 650 rpm 650 rpm 650 rpm

Centrifugal Force Data

1/2 Wash/reverse centrifugal force 0.412 Gs 0.325 Gs 0.325 Gs 0.325 Gs

Wash/reverse centrifugal force 0.790 Gs 0.708 Gs 0.708 Gs 0.708 Gs

Distribution centrifugal force 2.34 Gs 2.15 Gs 2.15 Gs 2.15 Gs

Medium extract centrifugal force 17.6 Gs 14.7 Gs 14.7 Gs 14.7 Gs

High extract 1 centrifugal force 85.8 Gs 85.3 Gs 85.3 Gs 85.3 Gs

High extract 2 centrifugal force 141 Gs 140 Gs 140 Gs 140 Gs

High extract 3 centrifugal force 312 Gs 312 Gs 312 Gs 312 Gs

Balance Detection

Vibration safety switch installed Standard Standard Standard Standard

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

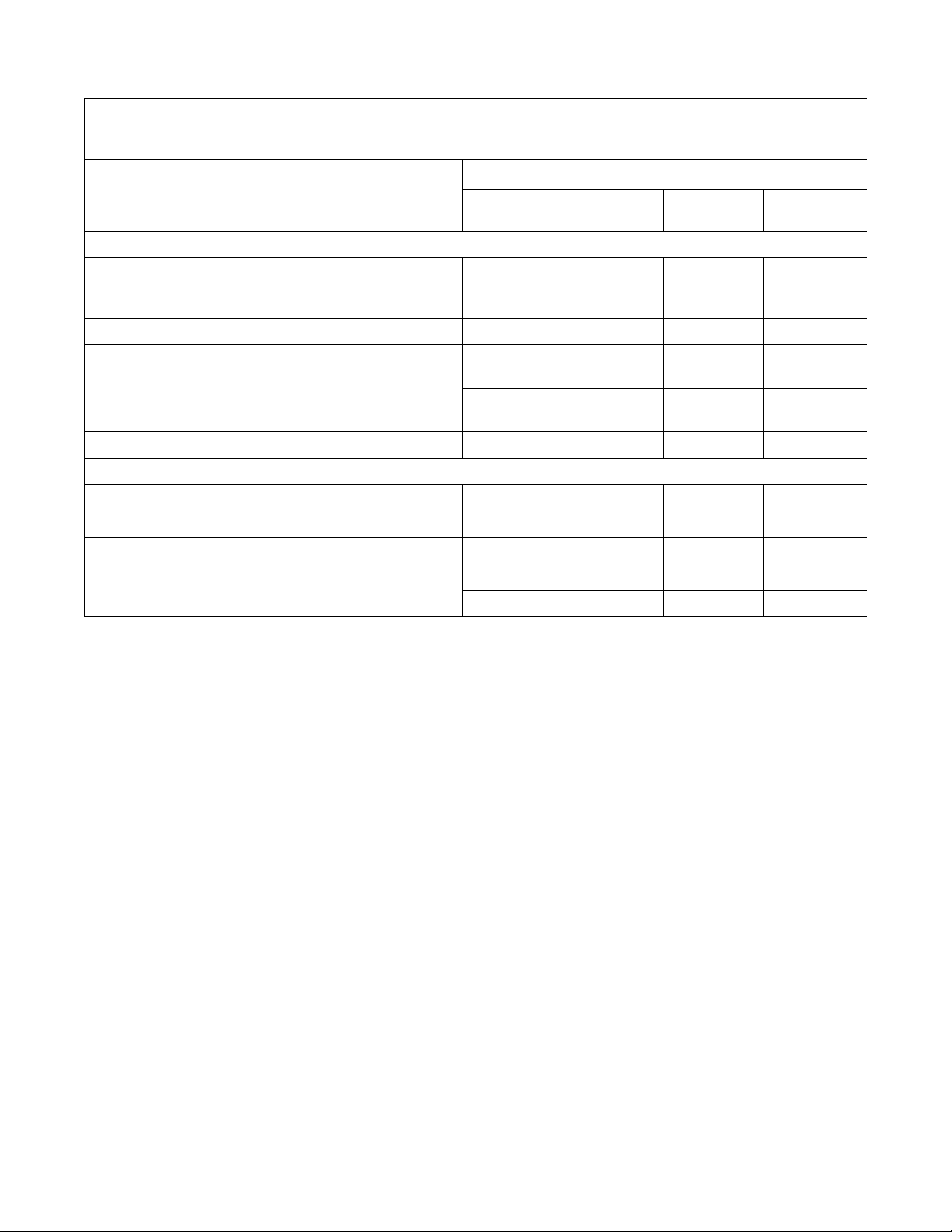

Installation

135 Pound and 250 Pound Capacity Models

Cabinet Freestanding

General Specifications (Continued)

135 250

Standard Standard

Forward Tilt

Option

Two-Way

Tilt Option

Direct Steam Heating (Optional)

Steam inlet connection size

in.

0.75

(DN19)

(19.05 mm)

1.0 in.

(DN25)

(25.4 mm)

1.0 in.

(DN25)

(25.4 mm)

1.0 in.

(DN25)

(25.4 mm)

Number of steam inlets 1 1 1 1

Steam required to raise bath temperature

10

°F

LOW 7.89 lbs.

(5.68 kg)

HIGH 10.2 lbs.

(7.36 kg)

12.75 lbs.

(9.18 kg)

17.6 lbs.

(12.6 kg)

12.75 lbs.

(9.18 kg)

17.6 lbs.

(12.6 kg)

12.75 lbs.

(9.18 kg)

17.6 lbs.

(12.6 kg)

Average steam use per cycle 5.28 BHP 8.8 BHP 8.8 BHP 8.8 BHP

Electric Heating (Optional)

Total electric heating capacity 45 kW N/A N/A N/A

Number of electrical heat elements 18 N/A N/A N/A

Electrical heat element size 2.5 kW N/A N/A N/A

Time required to raise bath temperature 10°F LOW 3.2 min N/A N/A N/A

HIGH 4.2 min N/A N/A N/A

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

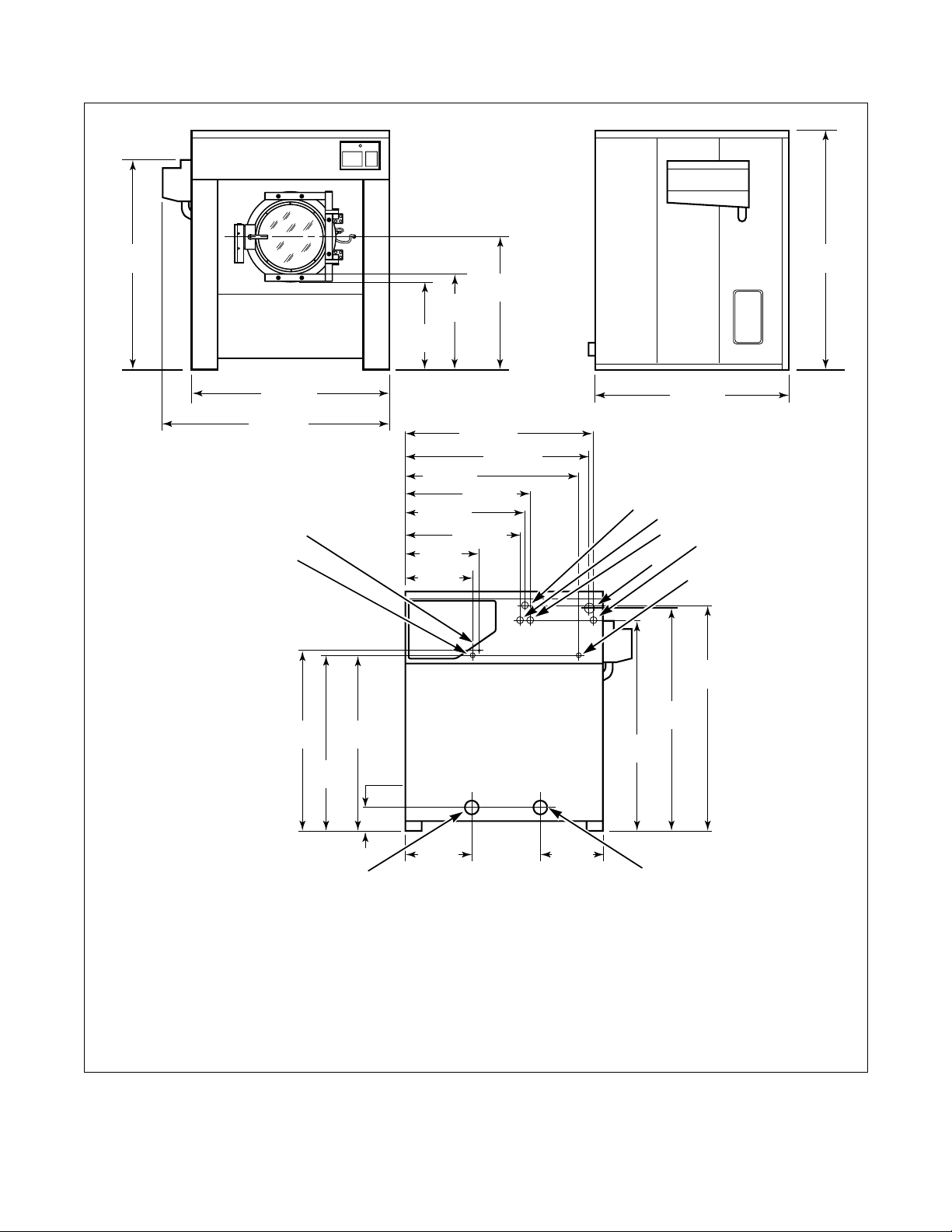

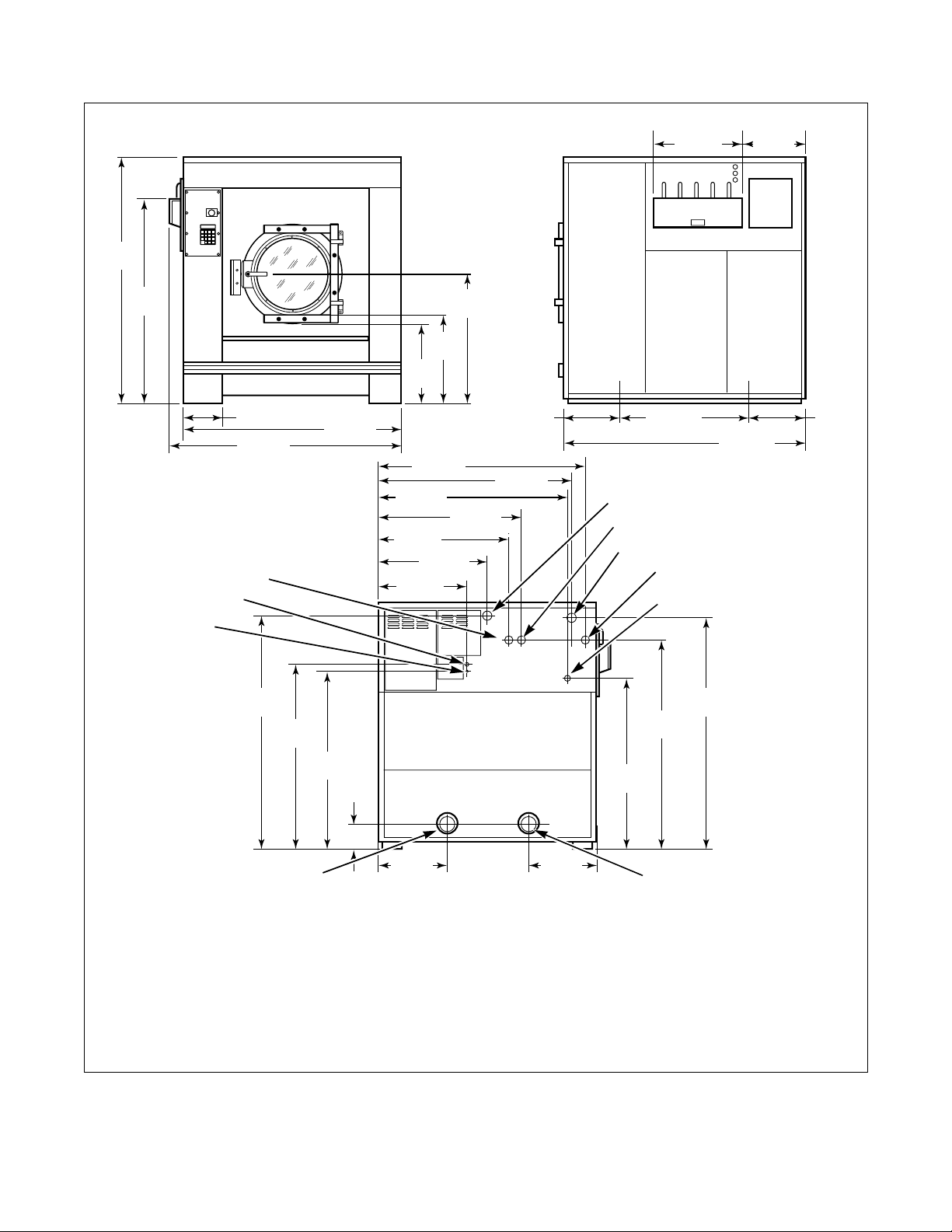

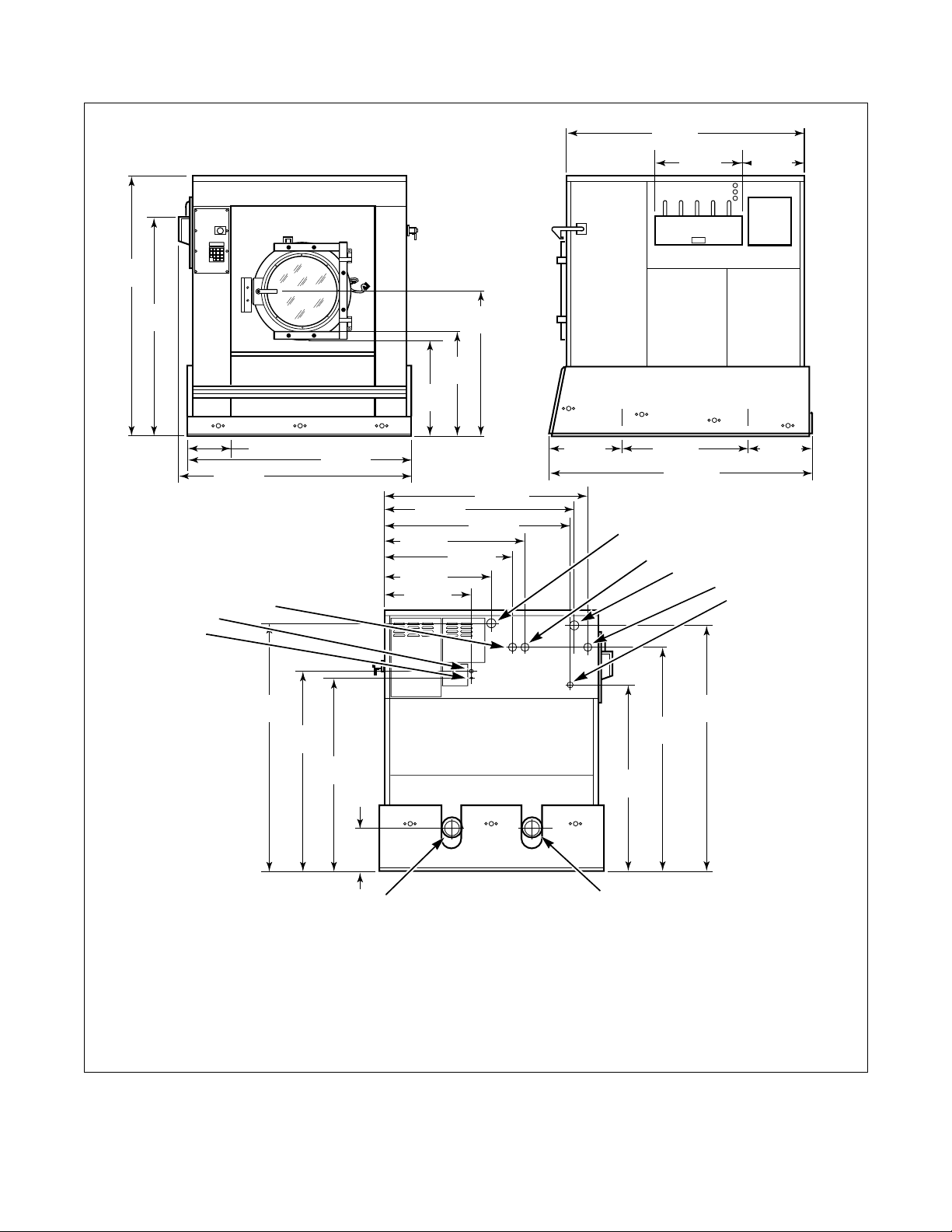

Machine Dimensions

Refer to Figure 3 for dimensions of the 135 pound

capacity model. Refer to Figure 4, Figure 5, and

Figure 6 for dimensions of the 250 pound capacity

models.

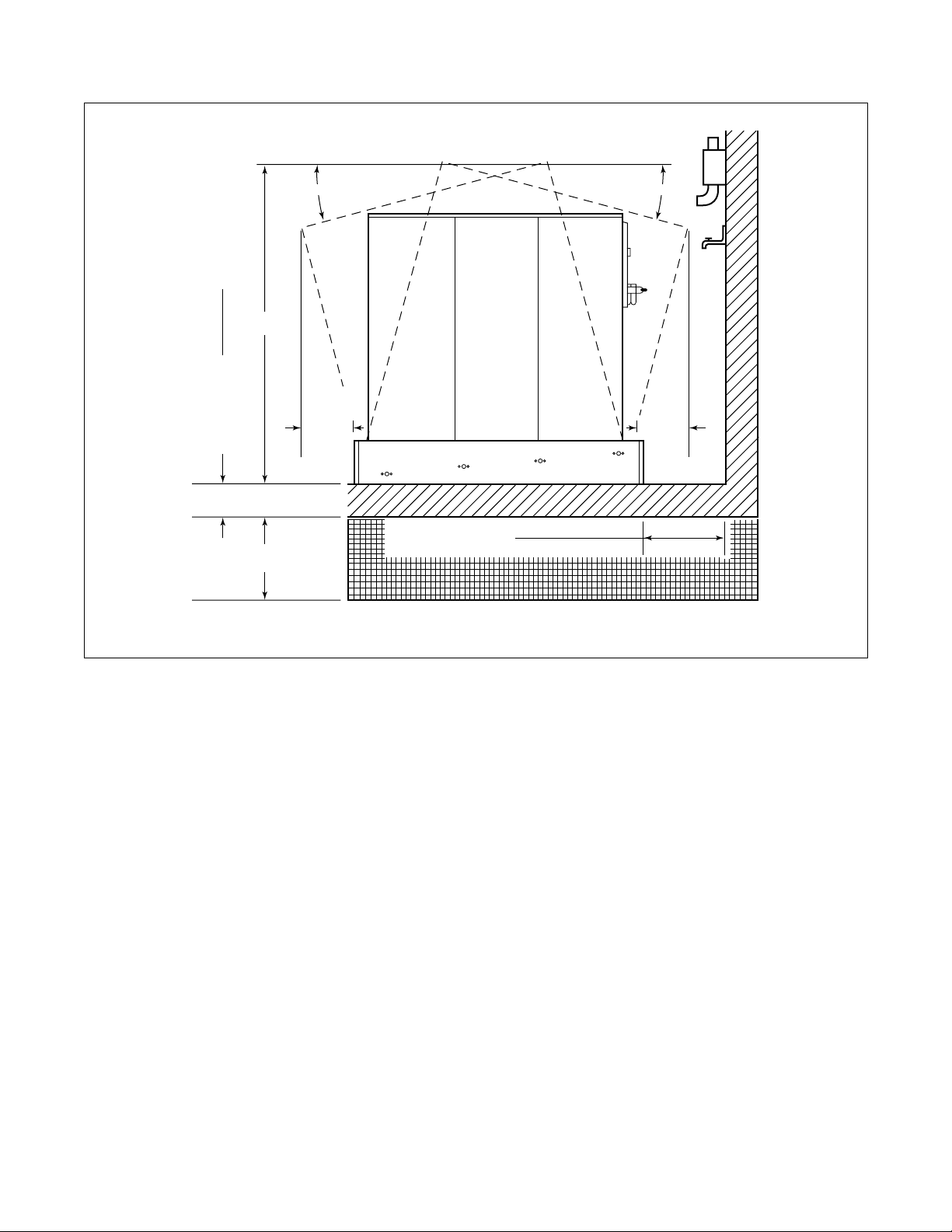

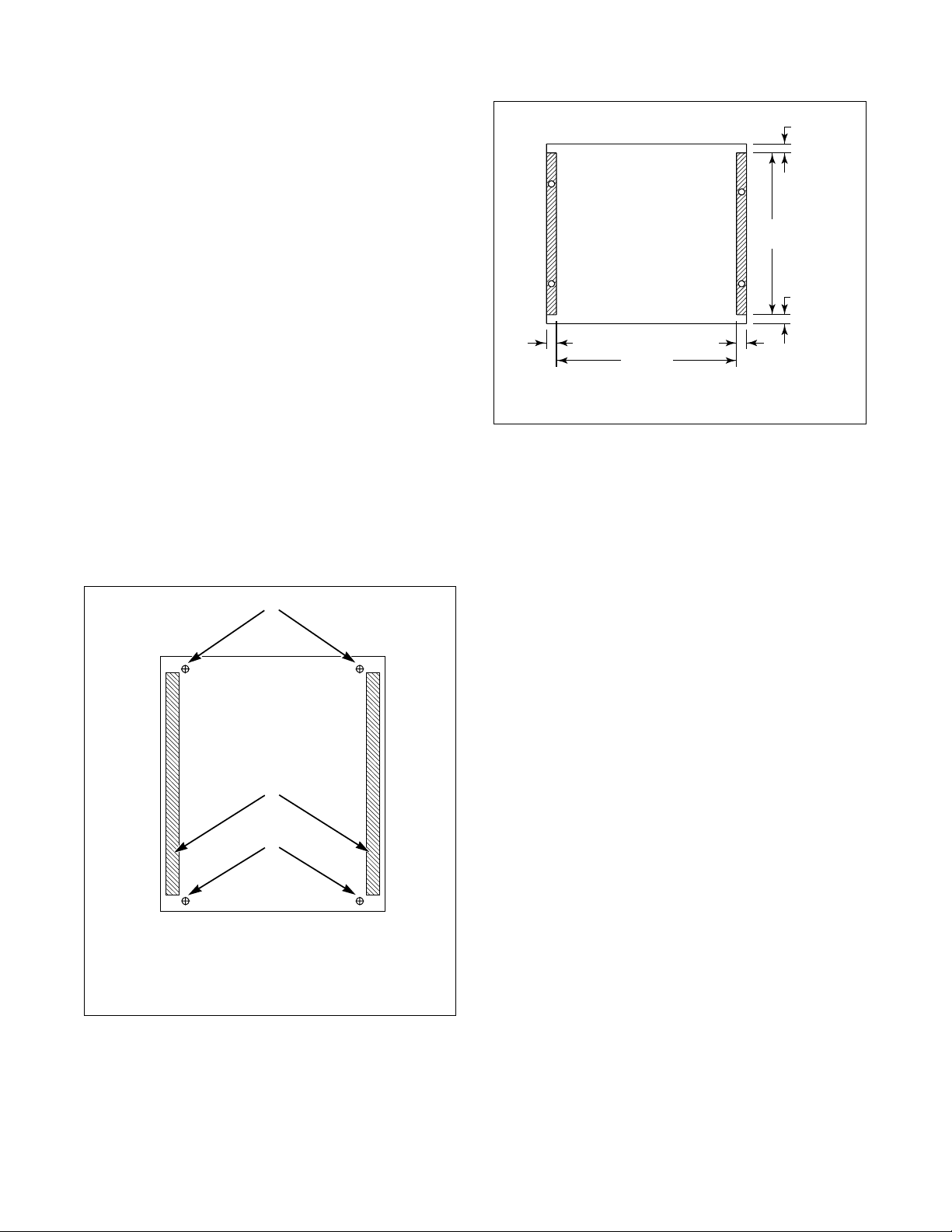

Dimensional Clearances

Table 1 below shows recommended minimum

clearances on all sides of the washer-extractor.

Washer-extractors equipped with the tilt option require

a minimum overhead clearance, as well. Refer to

Figure 7 for the minimum overhead clearance for the

250 pound capacity model with tilt option.

Cabinet Freestanding

Recommended Minimum Clearances

Minimum rear clearance 24

Minimum clearance between washer-extractor

and wall

Minimum clearance between washer-extractors

(side)

NOTE: The dimensions shown here are for

planning purposes only. They are approximate and

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or manufacturer.

We reserve the right to make changes at any time

without notice.

135 250

Standard Standard

in.

(610 mm)

18

in.

(457 mm)

in.

18

(457 mm)

24 in.

(610 mm)

18 in.

(457 mm)

18 in.

(457 mm)

Forward Tilt

Option

36 in.

(914 mm)

18 in.

(457 mm)

18 in.

(457 mm)

Two-Way

Tilt Option

36 in.

(914 mm)

18 in.

(457 mm)

18 in.

(457 mm)

Minimum front clearance 23

(584 mm)

Minimum overhead clearance 60.5

(1537 mm)

Table 1

in.

in.

36 in.

(914 mm)

88 in.

(2235 mm)

36 in.

(914 mm)

108 in.

(2743 mm)

36 in.

(914 mm)

108 in.

(2743 mm)

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Installation

65.5 in.

(1664 mm)

62 in.

(1575 mm)

71 in.

(1803 mm)

FRONT

6

75 in.

(1905 mm)

41.75 in.

(1060 mm)

30.25 in.

(768 mm)

28.25 in.

(718 mm)

61 in.

(1549 mm)

58.69 in.

(1491 mm)

57.31 in.

39.09 in.

(992 mm)

35.91 in.

(913 mm)

(1457 mm)

1

2

54.19 in.

(1376 mm)

37.5 in.

(952 mm)

7

23 in.

(584 mm)

20.81 in.

(529 mm)

8

9

SIDE

10

3

72 in.

(1829 mm)

71 in.

57.81 in.

(1468 mm)

(1435 mm)

56.5 in.

56.31 in.

(1430 mm)

6.75 in.

(171 mm)

5

20.5 in.

(521 mm)

REAR

20.06 in.

(509 mm)

67.5 in.

(1715 mm)

4

(1803 mm)

135 POUND CAPACITY MODELS

1 Recirculation Port 6 Main Power

2 Vent 7 External Signal Supply

3 Steam Inlet (Optional) 8 Extra Fill Valve

4 Standard Drain Outlet 9 Cold Water Inlet

5 Reuse Drain Outlet (Optional) 10 Hot Water Inlet

Figure 3

CFS209N

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

82 in.

(2083 mm)

(1740 mm)

68.5 in.

11.5 in.

(292 mm)

77.06 in.

(1957 mm)

10

9

FRONT

72 in.

(1829 mm)

32.63 in.

(829 mm)

30.88 in.

(784 mm)

68.69 in.

(1744 mm)

63.63 in.

(1615 mm)

43.19 in.

(1096 mm)

35.91 in.

(912 mm)

28 in.

(712 mm)

47.5 in.

(1207 mm)

47.19 in.

(1198 mm)

19 in.

(483 mm)

64.5 in.

(1639 mm)

28.38 in.

(721 mm)

40.69 in.

(1034 mm)

(559 mm)

80.19 in.

(2037 mm)

22 in.

19 in.

(483 mm)

SIDE

1

2

3

4

5

8

78.63 in.

(1997 mm)

62.38 in.

(1584 mm)

(1530 mm)

60.25 in.

7

8.63 in.

(218 mm)

22.5 in.

(572 mm)

22.5 in.

(572 mm)

59.91 in.

(1446 mm)

(1763 mm)

69.41 in.

6

77.19 in.

(1960 mm)

REAR

250 POUND CAPACITY MODELS

1 Recirculation Port 6 Standard Drain Outlet

2 Hot Water Inlet 7 Reuse Drain Outlet (Optional)

3 Vent 8 External Supply Signals

4 Cold Water Inlet 9 Main Power

5 Steam Inlet (Optional) 10 Extra Fill Valve (Optional)

CFS210N

F232102

Figure 4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Installation

88 in.

(2235 mm)

80.19 in.

(2037 mm)

28.38 in.

(721 mm)

22 in.

(559 mm)

74.41 in.

(1736 mm)

9

8

81 in.

(2057 mm)

(2149 mm)

13.5 in.

(343 mm)

10

84.63 in.

FRONT

68.38 in.

(1737 mm)

(1683 mm)

76 in.

(1930 mm)

66.25 in.

(981 mm)

36.88 in.

(936 mm)

64.5 in.

(1639 mm)

47.19 in.

(1198 mm)

35.91 in.

(912 mm)

28 in.

(712 mm)

(1359 mm)

38.91 in.

43.19 in.

(1096 mm)

53.5 in.

68.69 in.

(1744 mm)

63.63 in.

(1615 mm)

25.5 in.

(648 mm)

1

(1930 mm)

63.5 in.

(1613 mm)

40.69 in.

(1034 mm)

86.1 in.

(2190 mm)

2

3

76 in.

SIDE

83.5 in.

(2121 mm)

12.5 in.

(572 mm)

4

5

14.63 in.

(370 mm)

7

REAR

6

250 POUND CAPACITY MODELS WITH FORWARD TILT OPTION

1 Recirculation Port 6 Standard Drain Outlet

2 Hot Water Inlet 7 Reuse Drain Outlet (Optional)

3 Vent 8 External Supply Signals

4 Cold Water Inlet 9 Main Power

5 Steam Inlet (Optional) 10 Extra Fill Valve (Optional)

Figure 5

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFS211N

F232102

80.19 in.

(2037 mm)

Installation

Ref

74.41 in.

(1736 mm)

9

8

79.1 in.

(2010 mm)

10

84.63 in.

(2149 mm)

(1737 mm)

72 in.

(1829 mm)

FRONT

68.38 in.

66.25 in.

(1683 mm)

Ref

76.1 in.

(1933 mm)

36.88 in.

(936 mm)

47.19 in.

(1198 mm)

35.91 in.

(912 mm)

28 in.

(712 mm)

(1359 mm)

38.91 in.

(981 mm)

64.5 in.

(1639 mm)

43.19 in.

(1096 mm)

53.5 in.

88 in.

(2235 mm)

68.69 in.

(1744 mm)

63.63 in.

(1615 mm)

1

(1930 mm)

63.5 in.

(1613 mm)

2

76 in.

91 in.

(2311 mm)

3

4

83.5 in.

(2121 mm)

Ref

SIDE

5

4.25 in.

(108 mm)

87.9 in.

(2232 mm)

14.63 in.

(370 mm)

24.41 in.

(620 mm)

7

REAR

24.41 in.

(620 mm)

6

250 POUND CAPACITY MODELS WITH TWO-WAY TILT OPTION

1 Recirculation Port 6 Standard Drain Outlet

2 Hot Water Inlet 7 Reuse Drain Outlet (Optional)

3 Vent 8 External Supply Signals

4 Cold Water Inlet 9 Main Power

5 Steam Inlet (Optional) 10 Extra Fill Valve (Optional)

Figure 6

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFS212N

19

Installation

103.25 in.

(2622 mm)

MINIMUM

FLOOR THICKNESS

6 in. (152 mm)

18 in.(475 mm)

COMPACTED FILL DIRT

13°

13 in.

(330 mm)

36 in. (914 mm) RECOMMENDED

30 in. (762 mm) ALLOWABLE

13°

13 in.

(330 mm)

250 POUND CAPACITY MODELS WITH FORWARD AND TWO-WAY TILT OPTION

CFS219N

Figure 7

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

SW020

CAUTION

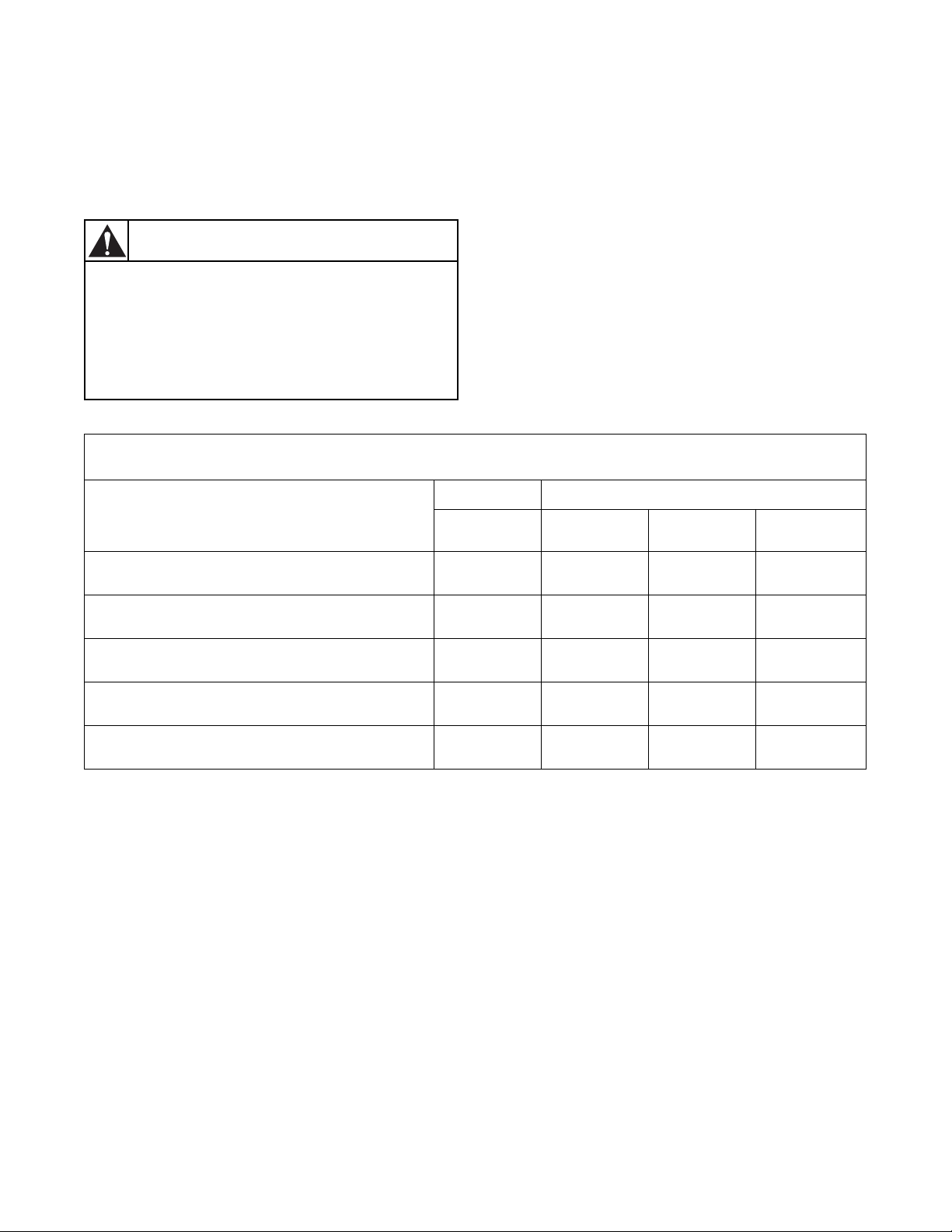

Machine Foundation

Thoroughness of detail must be stressed with all

foundation work to ensure a stable unit installation,

eliminating possibilities of excessive vibration during

extract.

Cabinet Freestanding

Floor Load Data

The washer-extractor must be placed on a smooth level

surface so that the entire base of the machine is

supported and rests on the mounting surface. (Do not

support the washer-extractor on only four points.)

NOTE: Do not mount the 250 pound capacity

washer-extractor on wooden floors, above ground

level, or over basements. Installation must be “slab

on grade” or equivalent.

The standard 135 pound capacity washer-extractors do

not require anchoring unless mandated by state or

local codes.

Static and dynamic loads on the floor or foundation are

shown in Table 2. Tab le 2 can be used as a reference

when designing floors and foundations.

135 250

Standard Standard

Forward Tilt

Option

Two-Way Tilt

Option

Static floor load 4916

Static pressure 187

Dynamic floor load 460

Maximum dynamic load 460

Dynamic pressure 17.8 lbs/ft

lbs.

(21.8 kN)

lbs/ft

(8.9 kN/m2)

lbs.

(2.05 kN)

lbs.

(2.05 kN)

(0.85 kN/m2)

Table 2

2

2

9354

lbs.

(41.5 kN)

lbs/ft

lbs.

lbs.

2

245

(11.7 kN/m2)

925

(4.12 kN)

925

(4.12 kN)

24.2 lbs/ft

(1.16 kN/m2)

2

10,154

lbs.

(45.1 kN)

lbs/ft

lbs.

lbs.

2

2

217

(10.4 kN/m2)

925

(4.12 kN)

925

(4.12 kN)

24.2 lbs/ft

(1.16 kN/m2)

11,154

lbs.

(49.5 kN)

lbs/ft

lbs.

lbs.

2

2

232

(11.1 kN/m2)

925

(4.12 kN)

925

(4.12 kN)

24.2 lbs/ft

(1.16 kN/m2)

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

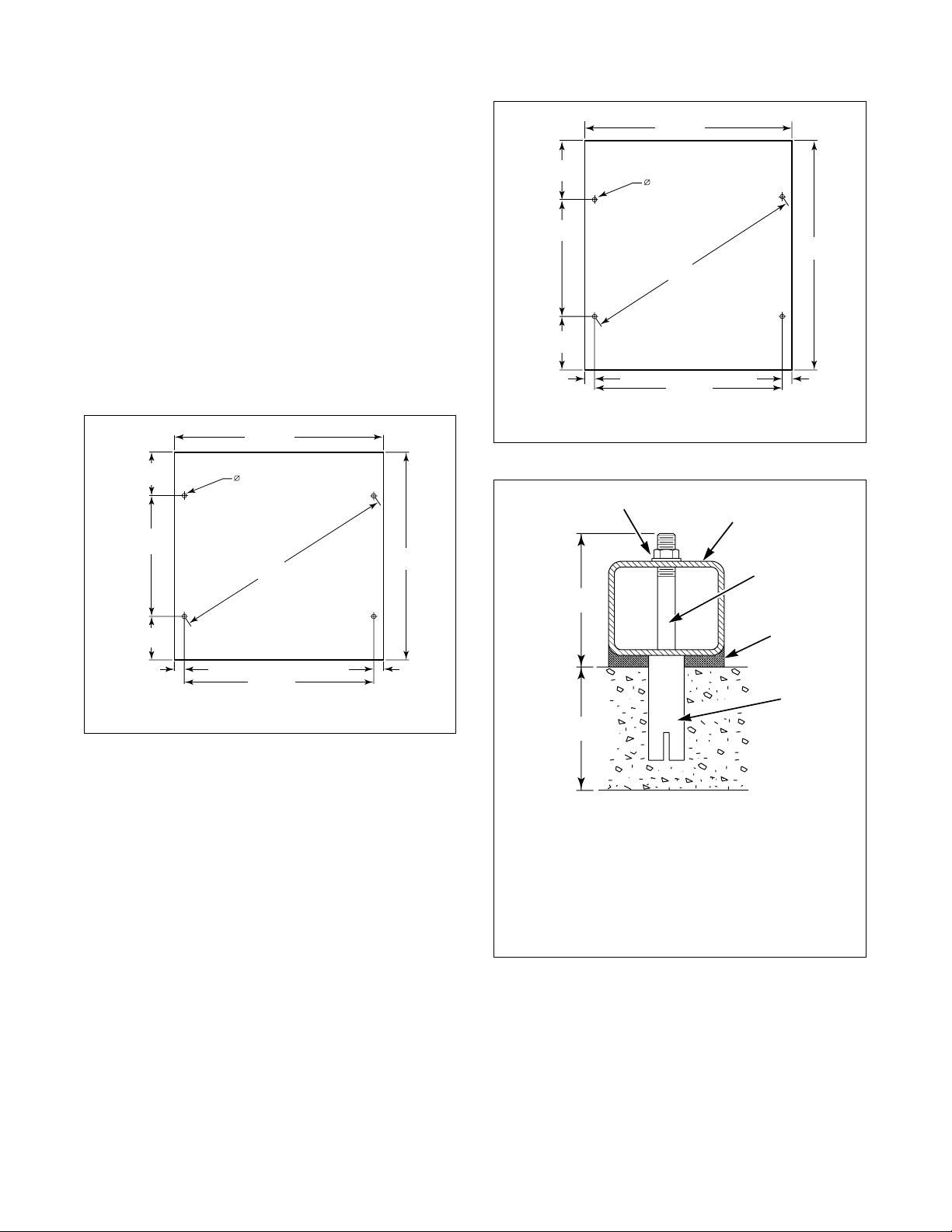

Installation

135

56 in.

(1422 mm)

3 in.

(76 mm)

3 in.

(76 mm)

66.63 in.

(1691 mm)

1.25 in.TYP

(32 mm)

62 in.

(1575 mm)

61 in.

(1549 mm)

12.81 in.

(324 mm)

36 in.

(914 mm)

12.31 in.

(311 mm)

Mechanical Installation – Standard

Models

Mounting Bolt Installation for Standard

135 Pound Capacity and 250 Pound

Capacity Machines

High-strength 3/4-16 x 10 in. machinery anchors should

be embedded in 3500 psi reinforced concrete that is a

minimum of 6 in. thick. Refer to Figure 8 for the

mounting bolt layout for standard 135 pound capacity

models. Refer to Figure 9 for the mounting bolt layout

for standard 250 pound capacity models. (The front of

the washer-extractor is the bottom of the diagram.)

Refer to Figure 10 for detailed information regarding

the machinery anchor bolt that should be used.

20 in.

(508 mm)

40.69 in.

(1034 mm)

19.5 in.

(495 mm)

3 in.

(76 mm)

1

72 in.

(1829 mm)

1.25 in. TYP

(32 mm)

77.5 in.

(1969 mm)

66 in.

(1676 mm)

250

Figure 9

3 in.

(76 mm)

2

80 in.

(2037 mm)

CFS214N

Figure 8

CFS213N

3

6 in.

(152 mm)

4

5

6 in.

MIN

(152 mm)

MOUNTING BOLT DETAIL – STANDARD MODELS

CFS215N

1 Locknut

2 Base Frame

3 3/4-16 x 10 in. Dia. Bolt

4 Grout

5 Anchor Bolt

Figure 10

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

After the anchor bolts are installed and the concrete

has cured, proceed as follows:

1. Place the washer-extractor adjacent to the

foundation. Do not attempt to move it by pushing

on the sides. Always insert a pry bar or other

device under the bottom of the frame of the

washer-extractor to move it.

2. Remove the wood skid by unscrewing the

carriage bolts holding it to the bottom frame of

the washer-extractor.

3. Place the washer-extractor carefully over the

anchor bolts. Never attempt to lift the machine by

the door handle or by pushing on the cover

panels.

4. Raise and level the washer-extractor 1/2 inch off

the floor on three points, using spacers such as

nut fasteners.

5. Fill the spaces between the washer-extractor base

and floor with a good quality non-shrinking

machinery grout to ensure a stable installation.

Refer to Figure 11 for grouting the 135 pound

capacity model. Refer to Figure 12 for grouting

the 250 pound capacity model.

1

4 in.

(102 mm)

71 in.

(1803 mm)

4 in.

(102 mm)

4 in.

(102 mm)

62 in.

(1575 mm)

4 in.

(102 mm)

250

CFS216N

Figure 12

6. Remove the spacers carefully, allowing the

washer-extractor to settle into the wet grout.

7. Position the mounting bolt washers and locknuts

on the anchor bolts and fingertighten locknuts to

washer-extractor base.

8. After the grout is completely dry, tighten the

locknuts by even increments – one after the

other – until all are tightened evenly and the

washer-extractor is fastened securely to the floor.

1 Bolt Holes

2 Frame Rails

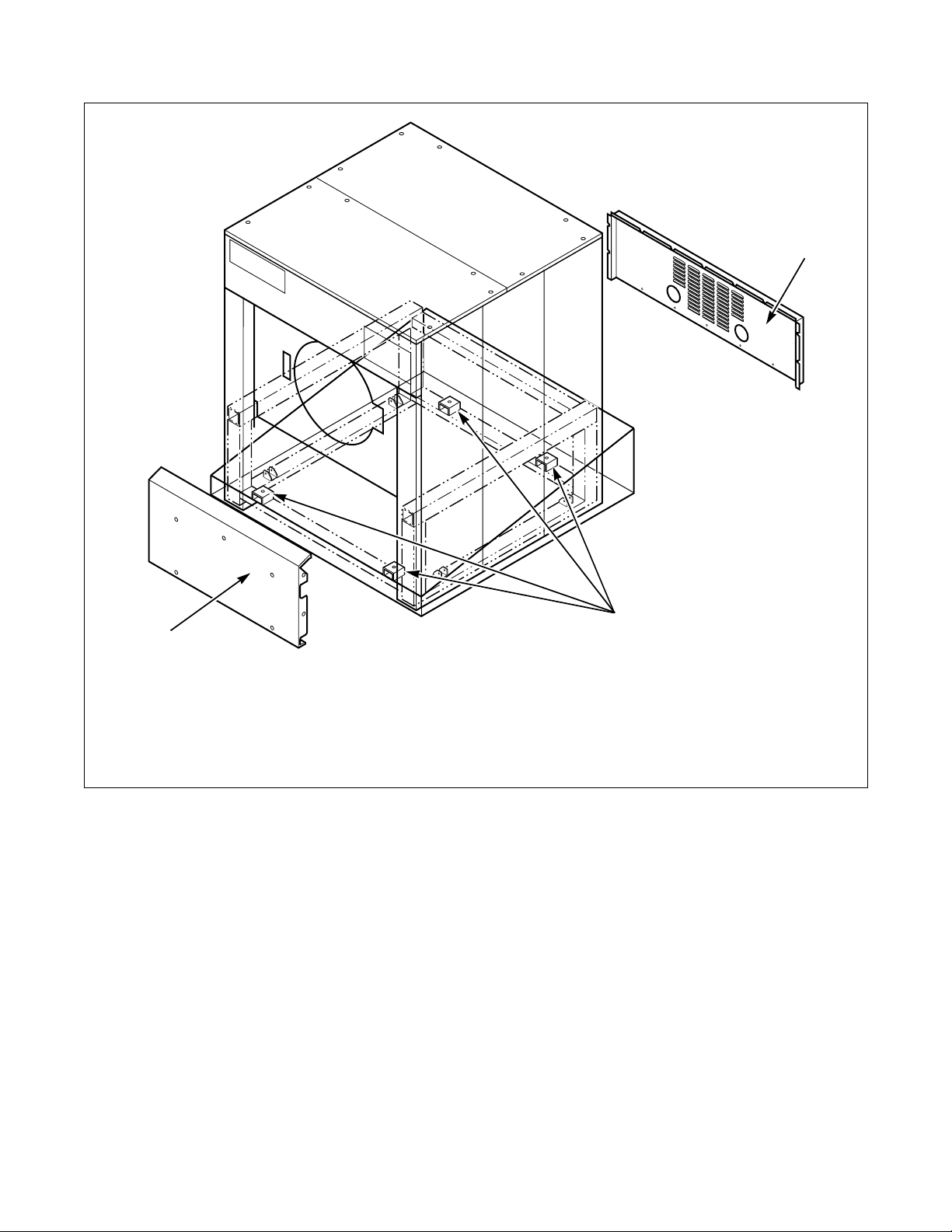

9. Remove the four red transport brackets used to

secure the washer-extractor during shipping.

Refer to Figure 13.

NOTE: Check and retighten the locknuts after five

to ten days of operation and every month

thereafter.

2

1

135

R007I

Figure 11

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

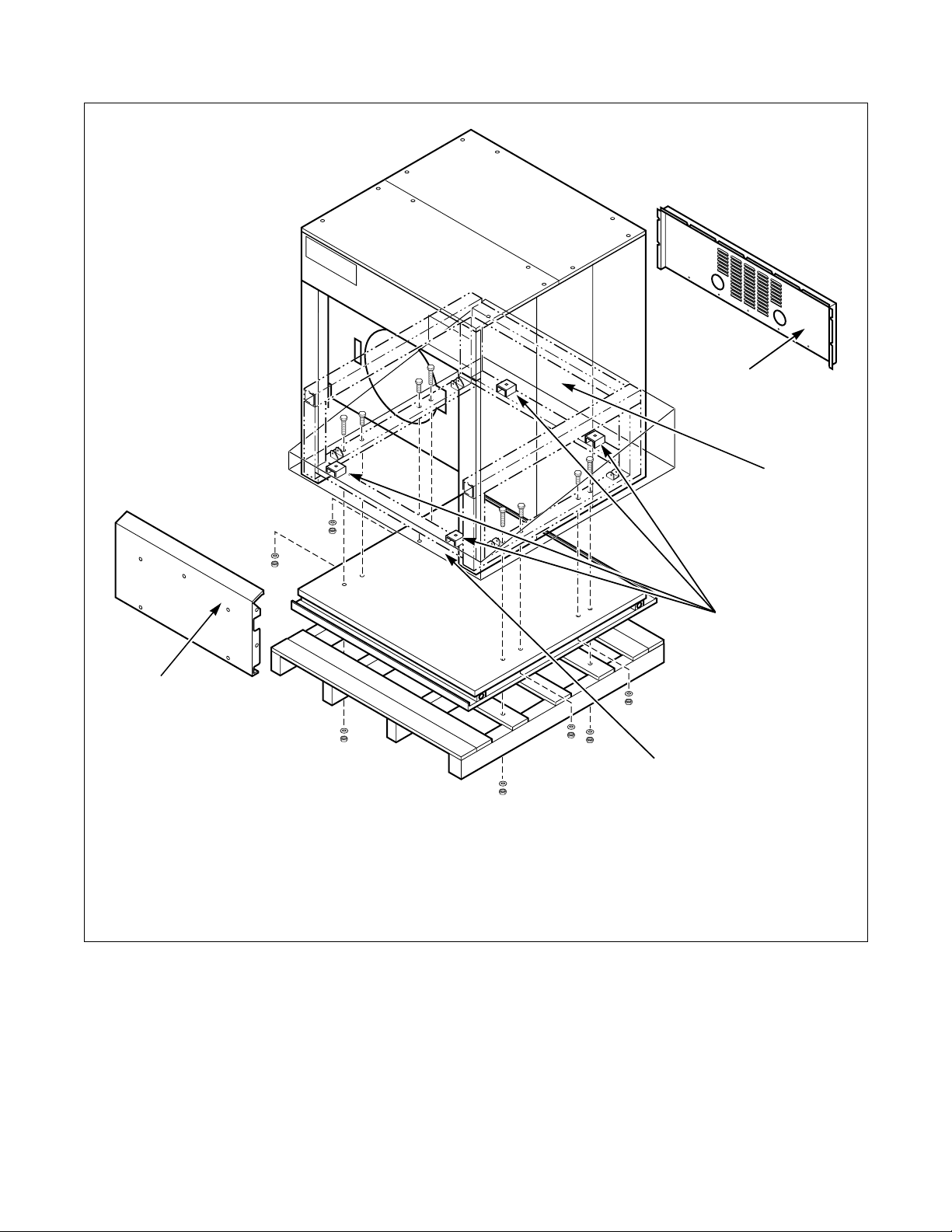

Installation

1

3

TYPICAL TRANSPORT BRACKET LOCATIONS

1 Rear Panel

2 Four (4) Transport Brackets

3 Front Panel

2

R036I

R036I

Figure 13

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

66 in.

(1676 mm)

5 in.

(127 mm)

5 in.

(127 mm)

24 in.

(610 mm)

26.31 in.

(668 mm)

77.5 in.

(1969 mm)

1.25 in.TYP

(32 mm)

76 in.

(1930 mm)

89 in.

(2261 mm)

40.69 in.

(1034 mm)

74 in.

(1880 mm)

91 in.

(2311 mm)

23 in.

(584 mm)

89 in.

(2261 mm)

8 in.

(203 mm)

25.31 in.

(643 mm)

24 in.

(610 mm)

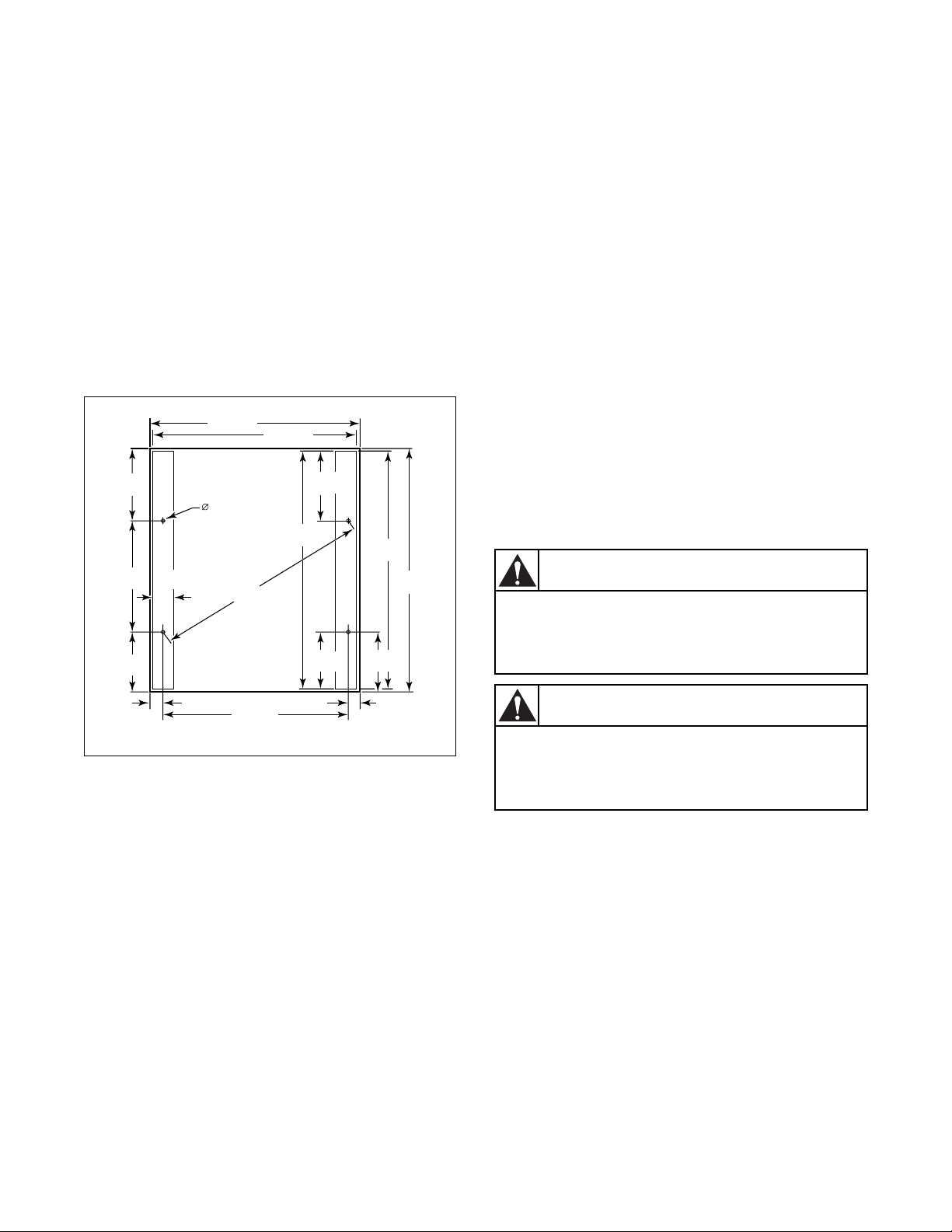

Mechanical Installation – Models

with Tilt Option

Mounting Bolt Installation for 250 Pound

Capacity Models with Forward or

Two-Way Tilt Option

NOTE: Models equipped with tilt option MUST be

anchored to the floor.

High-strength 1-16 x 10 inch machinery anchors

should be embedded in 3500 psi reinforced concrete

that is a minimum of 6 inch thick. Refer to Figure 14

for mounting bolt layout for 250 pound capacity

models with tilt option.

2. Remove all panels on the tilt mechanism.

Remove the top covers of the washer-extractor

to gain access to the lifting points. Remove the

front and rear side panels on each side of the

washer-extractor. This will give access to the

shipping fasteners that tie the skid, tilt

mechanism, and the washer-extractor together

for shipping.

3. The shipping fasteners consist of four (4) 15-inch

threaded rods. Remove nuts and washers from

both ends of each threaded rod and remove each

rod from the washer-extractor. Retain the nuts

and washers for use later in the installation

process.

4. Using the appropriate equipment, lift the washerextractor away from the tilt mechanism and the

skid and set aside. Remove the tilt mechanism

from the skid. Dispose of skid properly.

5. Place the tilt mechanism carefully over the

anchor bolts. Appropriate equipment is needed to

lift the tilt mechanism and keep it in a horizontal

position while moving it into position.

Figure 14

After the anchor bolts are installed and the concrete

has cured, proceed as follows:

1. Place the washer-extractor adjacent to the

foundation. Do not attempt to move it by pushing

on the sides. Due to the size and weight of the

250 model, appropriate equipment to lift and

move the washer-extractor must be available.

A rigging service is recommended.

CFS217N

DANGER

Damage to persons and property could

occur if the tilt mechanism is not kept in a

horizontal position.

W357

DANGER

Attempting to lift the tilt mechanism by

hand could result in personal injury and

damage to the tilt mechanism.

W358

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Installation

66 in.

(1676 mm)

5 in.

(127 mm)

5 in.

(127 mm)

24 in.

(610 mm)

40.69 in.

(1034 mm)

26.31 in.

(668 mm)

77.5 in.

(1969 mm)

1.25 in.TYP

(32 mm)

76 in.

(1930 mm)

89 in.

(2261 mm)

74 in.

(1880 mm)

91 in.

(2311 mm)

89 in.

(2261 mm)

23 in.

(584 mm)

24 in.

(610 mm)

25.31 in.

(643 mm)

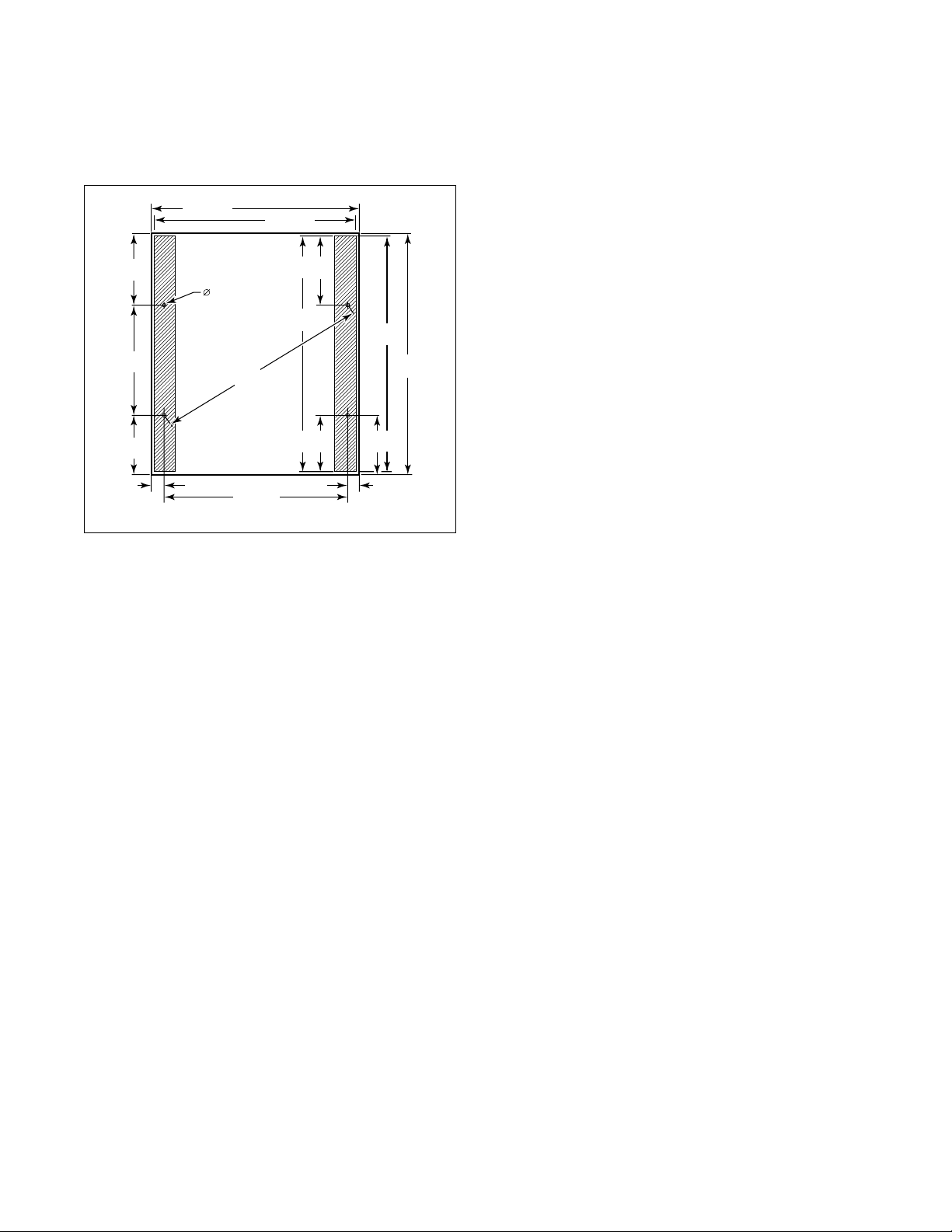

6. Fill the spaces between the tilt base and floor

with a good quality non-shrinking machinery

grout to ensure a stable installation. Refer to

Figure 15.

CFS218N

Figure 15

7. Remove the spacers carefully, allowing the tilt

mechanism to settle into the wet grout.

9. After the grout is completely dry, tighten the

locknuts by even increments – one after the

other – until all are tightened evenly and the tilt

mechanism is fastened securely to the floor.

10. Using the appropriate equipment, lift the washerextractor and place on top of the tilt mechanism

aligning the same four holes from which the

threaded rods were removed.

Four 1-1/4 x 6 inch GR-8 Hex Head screws (Part

No. 430478) are shipped in a plastic bag inside

the basket of the washer-extractor. Position one

of the washers (previously removed from the

threaded rod) under the head of one of the screws

and place the screw in one of the holes. Position

another washer on the screw and attach a nut

(retained from the removal of the threaded rods).

Repeat for all four holes. Then fasten tightly to

secure the washer-extractor to the tilt mechanism.

11. Remove the front and lower rear panels on the

washer-extractor. Then remove the four red

transport brackets used to secure the machine

during shipping. Refer to Figure 16.

12. Reinstall all previously removed panels prior to

start-up of the washer-extractor.

8. Position the mounting bolt washers and locknuts

on the anchor bolts and fingertighten locknuts to

the tilt base.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Installation

1

2

3

5

4

TYPICAL TRANSPORT BRACKET LOCATIONS – MODELS WITH TILT MECHANISM

1 Rear Panel 4 Front Panel of Tilt Mechanism

2 Rear Panel of Tilt Mechanism 5 Front Panel

3 Four (4) Transport Brackets

Figure 16

R024

R024

F232102

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Installation

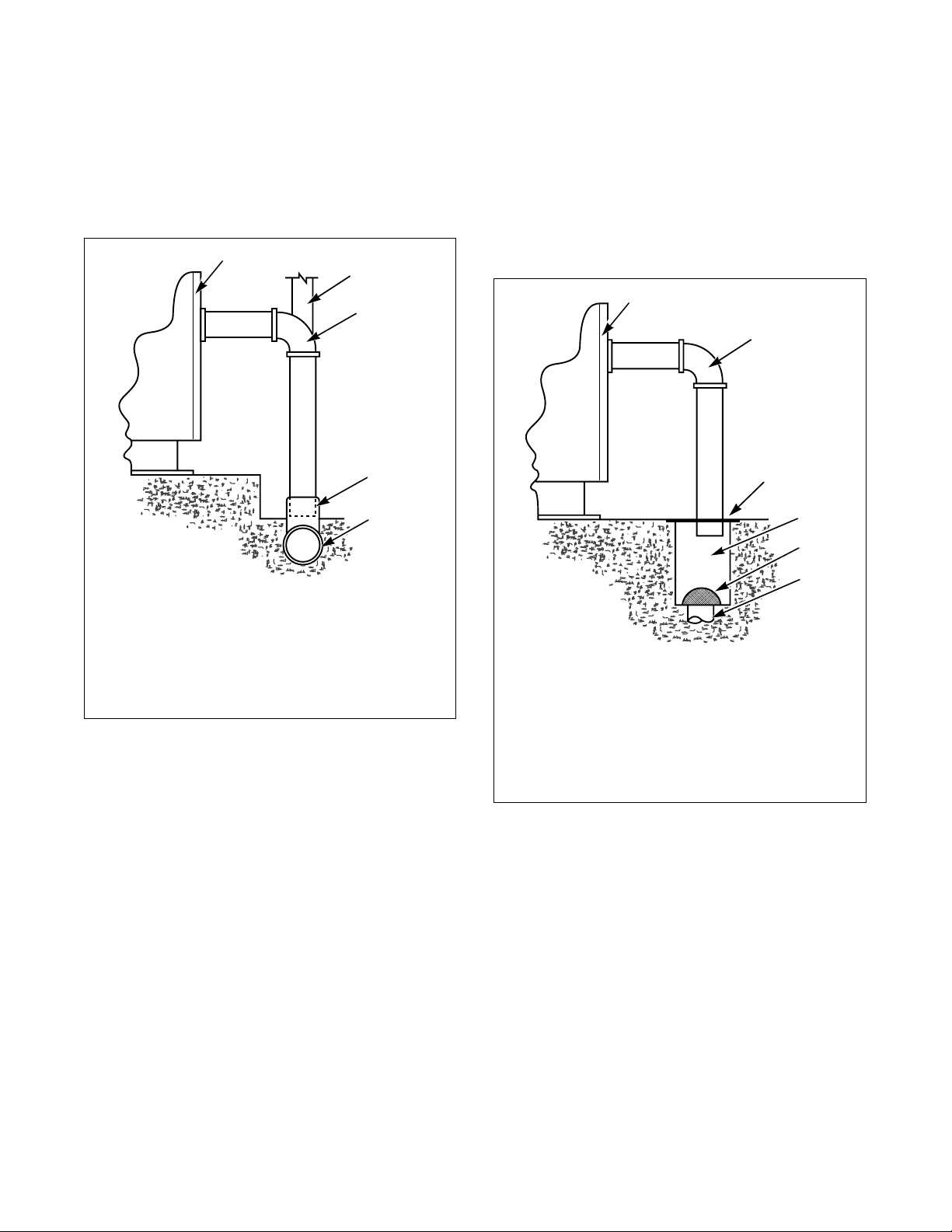

Drain Connection

A drain system of adequate capacity is essential to

washer-extractor performance. Ideally, the water

should empty through a vented pipe directly into a

sump or floor drain. Figure 17 and Figure 18 show

drain line and drain trough configurations.

1

2

3

4

5

Increasing the drain hose length, installing elbows, or

causing bends will decrease drain flow rate and

increase drain times, impairing washer-extractor

performance.

NOTE: Cabinet freestanding models equipped with

tilt option require flexible drain hose connection of

adequate length to allow for the tilting action of the

washer-extractor.

1

2

3

4

5

P037I

1 Rear of Machine

2 Vent

3 Drain Pipe

4 Waste Line Tee

5 Waste Line

Figure 17

A flexible connection must be made to a vented drain

system to prevent an air lock and to prevent siphoning.

If proper drain size is not available or practical, a surge

tank is required. A surge tank in conjunction with a

sump pump should be used when gravity drainage is

not possible, such as in below-ground-level

installations.

Before any deviation from specified installation

procedures is attempted, the customer or installer

should contact the distributor.

6

P046I

1 Rear of Machine

2 Drain Pipe

3 Steel Grate

4 Drain Trough

5 Strainer

6 Waste Line

Figure 18

Refer to Ta b le 3 for capacity-specific drain

information.

Installation of additional washer-extractors will

require proportionately larger drain connections. Refer

to Table 4.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232102

Loading...

Loading...