Page 1

link power

V

+10V

+

G

1516 13

opto

+-

SWITCH INPUTS

switch

G

+10V

2K2

opto

1214

+-+-+-+-

910

11

iDR-switch

24 IN 16 OUT SWITCH CONTROLLER

G 4321 G5678G 1211109 G13141516G 20191817 G21222324

VGVGVG +-+-+-

567+-8

+-+-+-

VG

123+-4

iDR-switch EXPANDER AP5141

100 - 240V~

47-63Hz ~ 15W MAX

WARNING

+10V DC max total 500mA

open collector

FUSE: T500mAL

next previous

OUT IN

DR-LINK

+24V DC, 200mA max

LOGIC OUTPUTS

+-+-+-

User Guide

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN. AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR. Made in the UK by ALLEN&HEATH LIMITED Complies with UL6500, CSA-E65, EN60065

The iDR-switch is an add-on control expander for the iDR-8 audio mix processor. It provides an additional 24 switch

closure control inputs and 16 logic control outputs in a 1U high rack or desk mount case. Up to three units can be

connected providing up to 72 additional switch and 48 additional logic controls. These can be custom wired by the

installer to allow external equipment to control pre-determined mixer functions, or the mixer to control external

equipment. Typical applications include room wall plates for local volume control and source selection, patch recall,

logic control, automatic control of room dividers, projection screens, media players, lamps and other equipment.

The inputs and outputs are opto-isolated to avoid problems with equipment interaction. Grounding the switch inputs

using simple contact closures triggers the programmed function. The logic outputs are open collector and can be

wired to use the internal reference voltage or an external power supply. These typically drive LED indicators, filament

bulbs, relays and circuit logic. Wiring the interface should be carried out by competent installation personnel. The

switch and output functions are easily programmed using the iDR System Manager software.

The iDR-8 communicates with the iDR-switch via the DR-Link port. This uses the proprietary Allen & Heath DR-Link

protocol. A standard 2 metre CAT5 STP cable is provided. However, you can use a cable up to 300 metres long

letting you position the unit closer to the local switch wiring. A pass through connection lets you network up to three

units by daisy chaining them.

Plan the system Before starting make sure you have planned how the

system is to work. Allocate the switch inputs and logic outputs and keep a log

of their intended function. Use the iDR System Manager software to configure

the system. Simulation windows are provided for you to try out your settings

without access to the units themselves. Refer to the Help file that comes with

the iDR System Manager software for details on how to assign the switch

inputs and logic outputs.

This product complies with the European Electromagnetic

Compatibility directives 89/336/EEC & 92/31/EEC and the

European Low Voltage Directives 73/23/EEC & 93/68/EEC.

NOTE: Do not remove the cover of the iDR-switch unit. There are no user

serviceable parts inside. Any changes or modifications to the equipment not

approved by Allen & Heath could void the compliance of the equipment and

therefore the users authority to operate it.

iDR-switch User Guide AP5141 Issue 2

Copyright © 2002 Allen & Heath Limited. All rights reserved

Whilst we believe the information in this guide to be reliable we do not assume

responsibility for inaccuracies. We also reserve the right to make changes in

the interest of further product development.

iDR-switch User Guide AP5141 1

Page 2

k

r

48mm

1.9"

44mm

1.7"

1U

iDR-switch

483mm

19"

link power

443mm

17.4"

iDR-switch

24 IN 16 OUT SWITCH CONTROLLER

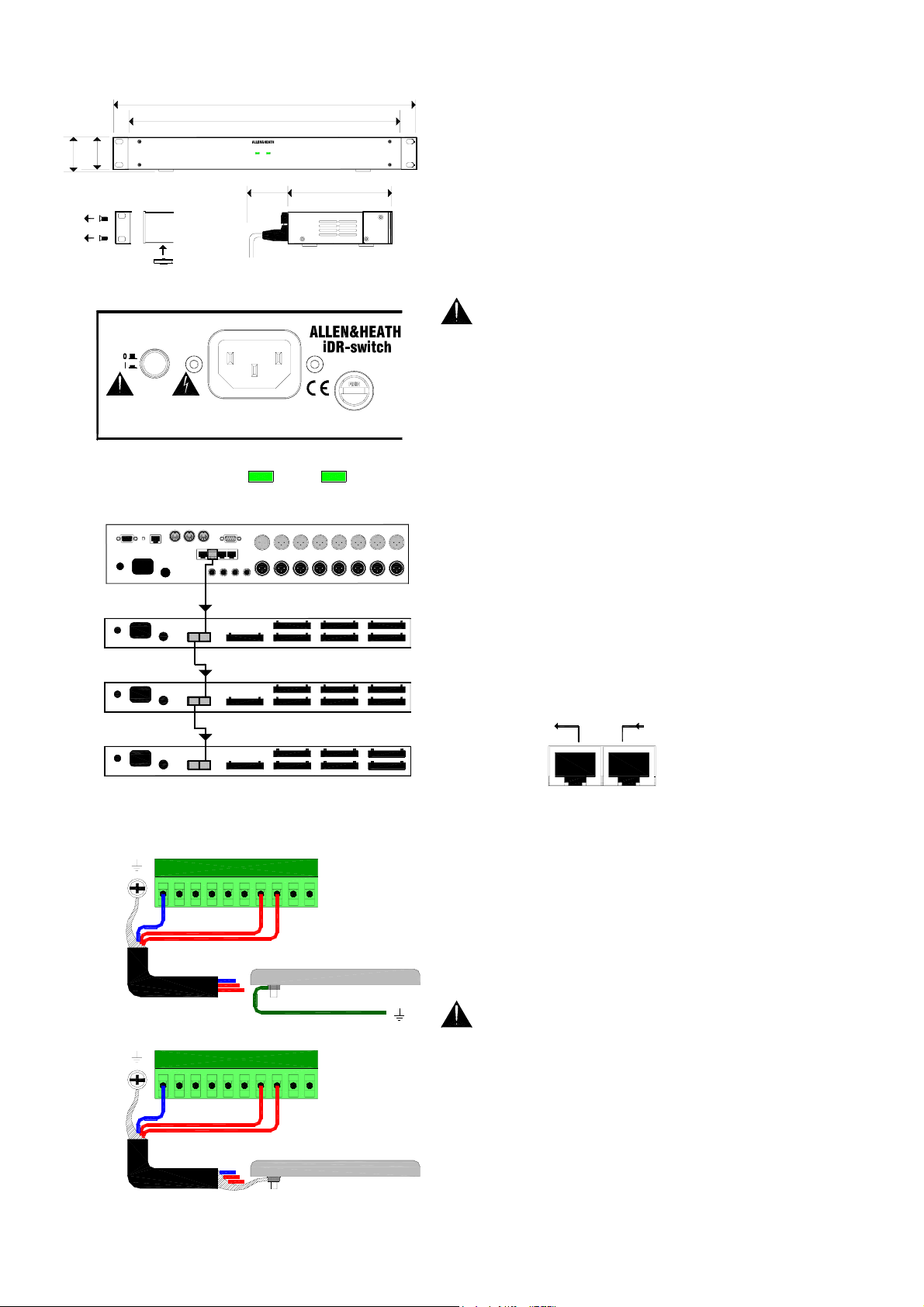

The iDR-switch can be rack mounted or free standing. There

are no user controls on the front panel. Allow a minimum of

65mm clearance behind the unit for the connectors and cables.

Ensure adequate ventilation to the side of and behind the unit.

Remove 2x rack ears

M3 Torx T10

Fit 4x feet

100 - 240V~

47-63Hz ~ 15W MAX

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN. AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

209mm

8.2"

65mm

2.6"

lin

DR-Link

SWITCH 1-24 OUT 1-16

SWITCH 25-48 OUT 17-32

SWITCH 49-72 OUT 33-48

144mm

5.7"

FUSE: T500mAL

powe

It is shipped with its rack ears fitted and its feet removed ready

to be mounted in a standard 19” equipment rack. 1U rack

space is required. For desk mount operation remove the two

rack ears using a Torx (star head) T10 screwdriver. Fit the four

plastic feet provided by pressing them into the underside.

Make sure you have read the Safety Instructions

Sheet AP3345 which comes with the unit. Check that your

local mains supply is compatible with that printed on the

rear panel of the unit. Ensure that the correct mains lead

with moulded plug and IEC connector has been supplied.

For your own safety and optimum performance make sure

the system is correctly grounded.

Turning the expander on or off Turn the unit on

by pressing the rear panel power ON/OFF switch. The power

LED lights up. The link LED lights if the DR-Link connection is

established with the iDR-8.

Connecting to the iDR-8 The iDR-8 communicates

with the iDR-switch using the DR-Link port. This serial

connection can be daisy chained through the 3 switch units as

shown, and then on to the iDR-in and iDR-out expanders if

fitted. Make sure you plug the DR-Link IN and OUT sockets

correctly. Use CAT5 STP cables with RJ45 connectors. Do not

use UTP cable. A standard 2 metre cable is provided with each

unit. You can use cables up to 300 metres long between units

for remote positioning. Ensure a good mains supply and solid

grounding to each unit.

next previous

OUT IN

DR-LINK

Connectors and grounding Pluggable Phoenix

G

METAL WALLPLATE

LOCAL EARTH BOND

G

METAL WALLPLATE

CHASSIS EARTH

type screw terminal connectors are used for connecting the

external switches and logic to the iDR-switch. Mating plugs

are provided with the unit. Make sure the wire ends are

carefully stripped and inserted into the terminals. Tighten the

screws using the correct slotted screwdriver. To ensure

interference-free operation use shielded cable. Connect the

shields to the chassis ground screw terminals provided next to

each connector. Fit the screws with the shake proof washers

provided.

For operator safety make sure that wall plates and

other control surfaces made from metal are correctly

bonded to ground (earth).

Strap the metal plate to the local ground at the wall box. For

ground isolation between the wall plate and equipment rack

connect the cable shield at the iDR-switch end only.

If a local ground is not available then use the cable shield to

connect the plate to the chassis of the iDR-switch unit as

shown. This is not necessary if the wall plate is made of nonconductive material such as plastic which insulates it from the

operator.

2 IDR-switch User Guide AP5141

Page 3

INPUTS

+10V

INTERNAL DR-switch CIRCUIT

(1 OF 8 SHOWN)

Important Note: The iDR-switch provides contact closure switch inputs and

open-collector logic outputs. How these are wired to external equipment is the

responsibility of the installer. Specification details are provided here for the iDR-switch

inputs and outputs. It is important that the installer is suitably qualified and familiar with

external control circuits to be able to work within the capabilities of the unit. Allen & Heath

do not assume responsibility for any damage done to the unit due to incorrect or faulty

connection to external equipment.

SWITCH

SWITCH

43215678GG

12 11 10 913141516GG

20 19 18 1721222324GG

2K2

OPTO

Using the switch closure inputs The input is

opto-coupled to isolate the iDR-switch from the connected

equipment. It is switched by linking its connector pin to the

ground (‘G’) pin. Use a contact closure such as a momentary

press switch to do this.

The input pin is fed from the internal +10V reference supply

through a 2k2 ohm resistor. Around 5mA maximum current

flows when connected to ground. Combined switch and cable

resistance should not exceed 1k ohm for the switch to activate.

Each 10way connector provides 8 switch inputs. Either pin 1 or

pin 10 ‘G’ may be used as the common switch ground. One

cable can feed this ground to a bank of switches. Two are

shown in the diagram here. Do not use the chassis ground

screw which is for cable shielding and safety earthing only.

For reliable operation we recommend the use of heavy duty

sealed switches.

INTERNAL DR-switch CIRCUIT

(1 OF 4 SHOWN)

+10V

V+-G+-+14 13+-15+-16

V+-G+-+10 9+-11+-12

V+-G+-+65+-7

+-8

+-3

+-4

V+-G+-+21

V-G+

V-G+

+10V DC

V-G+

OPTO

OPEN COLLECTOR

-+

SUITABLE RESIST OR

+10V DC

SUITABLE RESISTORS

LOW CURRENT 12V BULBS

+10V DC

LOW VOLTAGE RELAY

+

-

LED INDICATORS

TO EQUIPMENT

Using the logic outputs Each output is opto-

coupled to isolate the iDR-switch from the connected

equipment. It provides an open collector output with floating

collector (+pin) and emitter (-pin).

Each 10way connector provides 4 open collector pairs as well

as an internal +10V DC supply and ground pins. Do not use

the chassis ground screw which is for cable shielding and

safety grounding only.

The output may be used in many ways to satisfy a wide range

of interfacing applications. It is important that the installer has

a good working knowledge of open collector and interfacing

circuits. Incorrect application may result in damage to these

outputs.

The internal +10V supply may be used as the power source for

low current applications such as turning on LEDs, lamps and

small relays. One cable can feed the common supply or

ground to a bank of outputs.

Maximum current drawn from the +10V supply for all

outputs combined must not exceed 500mA. Care must be

taken in component choice to ensure each operates within

its specified capability.

For higher current or voltage applications an external DC

power supply may be used. This also provides total isolation

between the iDR-switch and external equipment.

Maximum external supply voltage must not exceed

+24V DC. Maximum current sink through any open

collector output must not exceed 200mA.

A few examples are shown in the diagram here. For further

advice contact Allen & Heath technical support.

200mA max

CURRENT SINK

DEVICE

GROUND

EXTERNAL POWER SUPPLY

+V (+24V DC max)

iDR-switch User Guide AP5141 3

Page 4

Remote controllers The iDR-switch is designed to be

used with a wide range of remote control devices including

custom wall plates and operator panels. Check out the Allen &

Heath range of PL wall plates and remote controllers. This

range is continually developing and it is likely that some may

be suitable for your application.

At the time of print of this user guide the PL-2 wall plate is

available for use with the iDR-switch. It has 4 switches and 4

3-colour LEDs which can be hard wired to the unit. It can be

fitted into a UK or US standard single wall box. For further

details visit the Allen & Heath web site.

iDR-switch

link power

iDR-switch

24 IN 16 OUT SWITCH CONTROLLER

Switch closures

Open-collector logic

Relays

Lamps

Connectors:

Pluggable Phoenix 10way terminal

Mating screw terminal plugs provided

Switch Inputs:

24x switch closure inputs

Opto-isolated via 2k2 from +10V

Switch closure connects pin to ground (5mA)

Switch cable resistance up to 1k ohm

Logic Outputs:

16x logic outputs

Opto-isolated open-collector

Floating collector (+) and emitter (-) pins

Internal 10V DC source (500mA total max)

External DC source (+24V 200mA each max)

Communication:

DR-link serial port using RJ45 connectors

Uses Allen & Heath DR-link protocol

2m CAT5 STP cable supplied, max 300m

Daisy chain up to 3 units

Configuration:

Configure with iDR System Manager

operating software

Separately configure switches and output

Latched, press, release, time of day action

Power Supply:

Universal mains input 100-240V.AC

Independent 10V supply for connections

500mA total available

Dimensions:

Rack 483 x 144 x 44 mm (1U)

19’’ x 5.7’’ x 1.7’’

Desk 443 x 144 x 48 mm

17.4’’ x 5.7’’ x 1.9’’

Allow 75mm 3’’ for connectors

Weight 2.2kg 5lbs

CHAIN

OUT INDR-LINK

DC REFERENCE

VOLTAGE

INTERNAL POWER

CONTROL

SWITCH 25-48 OUT 17-32

SWITCH 49-72 OUT 33-48

GROUND

+10V

2K2

OPTO-ISOLATED LOGIC OUTPUTS 1-16

+10V

V+-G13+-14+-15+-16

V+-G+-+14 13

G 20191817 G21222324

OPTO-ISOLATED SWITCH INPUTS 1-24

+-15

+

isolated

OPEN COLLECTOR

9-12 5-8 1-4

+10V DC INTERNAL POWER SUPPLY

LED INDICATORS

suitable resistors

+10V (or external supply)

RELAYS

200mA max

CURRENT SINK

SWITCH

9-16 1-8

+

-

DEVICE

SWITCH

LOW VOLTAGE

BULBS

LAMPS

MOTORS

EQUIPMENT

+V (+24V DC max)

EXTERNAL POWER SUPPLY

GROUND

4 IDR-switch User Guide AP5141

Loading...

Loading...