Page 1

iDR-8

Digital Audio Mix Processor

USER GUIDE

Hardware Configuration

For software configuration refer to the iDR System Manager Help file

Publication AP4530

Page 2

Limited One Year Warranty

This product is warranted to be free from defects in materials or workmanship for period of

one year from the date of purchase by the original owner.

To ensure a high level of performance and reliability for which this equipment has been

designed and manufactured, read this User Guide before operating.

In the event of a failure, notify and return the defective unit to ALLEN & HEATH Limited or

its authorised agent as soon as possible for repair under warranty subject to the following

conditions

Conditions Of Warranty

1. The equipment has been installed and operated in accordance with the instructions in

this User Guide.

2. The equipment has not been subject to misuse either intended or accidental, neglect,

or alteration other than as described in the User Guide or Service Manual, or approved

by ALLEN & HEATH.

3. Any necessary adjustment, alteration or repair has been carried out by ALLEN &

HEATH or its authorised agent.

4. The defective unit is to be returned carriage prepaid to ALLEN & HEATH or its

authorised agent with proof of purchase.

5. Units returned should be packed to avoid transit damage.

In certain territories the terms may vary. Check with your ALLEN & HEATH agent for any

additional warranty which may apply.

This product complies with the European Electromagnetic

Compatibility directives 89/336/EEC & 92/31/EEC and the

European Low Voltage Directives 73/23/EEC & 93/68/EEC.

This product has been tested to EN55103 Parts 1 & 2 1996 for use in

Environments E1, E2, E3, and E4 to demonstrate compliance with the

protection requirements in the European EMC directive 89/336/EEC. During

some tests the specified performance figures of the product were affected. This

is considered permissible and the product has been passed as acceptable for

its intended use.

Allen & Heath has a strict policy of ensuring all products are tested to the latest

safety and EMC standards. Customers requiring more information about EMC

and safety issues can contact Allen & Heath.

NOTE: Any changes or modifications to the equipment not approved by Allen

& Heath could void the compliance of the equipment and therefore the users

authority to operate it.

iDR-8 User Guide AP4530 Issue 3

Copyright © 2008 Allen & Heath Limited. All rights reserved

Whilst we believe the information in this guide to be reliable we do not assume

responsibility for inaccuracies. We also reserve the right to make changes in

the interest of further product development.

Allen & Heath Limited

Kernick Industrial Estate, Penryn, Cornwall, TR10 9LU, UK

http://www.allen-heath.com

2 IDR-8 User Guide

Page 3

Important Safety Instructions – Read First

Read instructions: Retain these safety and operating instructions for future reference. Heed all

warnings printed here and on the equipment. Follow the operating instructions

printed in this User Guide.

Do not open: There are no user serviceable parts inside. Refer any service work to

competent technical personnel only.

Power sources: Connect the unit to mains power only of the type described in this User Guide

and marked on the rear panel. The power source must provide a good ground

connection.

Power cord: Use the power cord with sealed mains plug appropriate for your local mains

supply as provided with the equipment. If the provided plug does not fit into

your outlet consult your service agent. Route the power cord so that it is not

likely to be walked on, stretched or pinched by items placed upon or against it.

Grounding: Do not defeat the grounding and polarisation means of the power cord plug.

Do not remove or tamper with the ground connection in the power cord.

Ventilation: Do not obstruct the ventilation slots or position the unit where the air flow

required for ventilation is impeded. If the unit is to be operated in a rack, plinth

or other furniture ensure that it is constructed to allow adequate ventilation.

Moisture: To reduce the risk of fire or electric shock do not expose the unit to rain or

moisture or use it in damp or wet conditions. Do not place containers of liquids

on it which might spill into any openings.

Heat: Do not locate the unit in a place subject to excessive heat or direct sunlight as

this could be a fire hazard. Locate the unit away from any equipment which

produces heat such as power supplies, power amplifiers and heaters.

Environment: Protect from excessive dirt, dust, heat and vibration when operating and

storing. Avoid tobacco ash, drinks spillage, and smoke, especially that

associated with smoke machines.

Handling: To prevent damage to the controls and cosmetics avoid placing heavy objects

on the equipment surfaces, scratching the surface with sharp objects, or rough

handling and vibration. Protect the controls from damage during transit. Use

adequate packing if you need to ship the unit. To avoid injury to yourself or

damage to the equipment take care when lifting, moving or carrying the unit.

Servicing: Switch off the equipment and unplug the power cord immediately if it is

exposed to moisture, spilled liquid, objects fallen into the openings, the power

cord or plug become damaged, during lightening storms, or if smoke, odour or

noise is noticed. Refer servicing to qualified technical personnel only.

Installation: Install the unit in accordance with the instructions printed in this User Guide.

Do not connect the output of power amplifiers directly to the unit. Use audio

connectors and plugs only for their intended purpose.

Important Mains Plug Wiring Instructions

The unit is supplied with a moulded mains plug fitted to the AC mains power

lead. Follow the instructions below if the mains plug has to be replaced.

The wire which is coloured Green/Yellow or Green must be connected to the

terminal in the plug which is marked with the letter E or with the Earth symbol.

This appliance must be earthed.

The wire which is coloured Blue or White must be connected to the terminal in

the plug which is marked with the letter N.

The wire which is coloured Brown or Black must be connected to the terminal

in the plug which is marked with the letter L.

iDR-8 User Guide 3

Page 4

Introduction

This user guide is intended for the technical engineer in charge of the installation and configuration of

the audio system. It is not intended for the day-to-day operator who should be provided with operating

instructions specific to the application by the installer. The function, application, installation and

technical details of the iDR hardware are described. It is kept short and to the point so that you can

quickly find the information you need. The Technical Specification at the rear of the guide provides a

complete and quick reference to the system parameters.

Please note : For details on the configuration of the DSP resources please refer to the Windows™

Help file which is part of the iDR System Manager software provided with the unit.

iDR is a growing system of components. Keep up to date with the latest additions and development by

referring to our web site http://www.allen-heath.com

configuration software, communication protocols, user guide, application notes and additional support

information can be downloaded.

For information on the status and availability of the features described in this user guide and any

changes and new additions please refer to the Release Notes which come with the current version of

operating software.

We are able to offer further product support through our world-wide network of approved dealers and

service agents. Our web site provides full company and product range information. To help us provide

the most efficient service please keep a record of the serial number, and date and place of purchase to

be quoted in any communication regarding this product.

. The latest version of the operating and system

The guide is structured for the technical user. The information

is displayed as follows:

Description Control, connector and system functions are

briefly described together with related technical specifications.

Information Where you see this symbol you will find an

explanation or background information on a particular topic.

Software Where you see this symbol you will find a

reference to the Allen & Heath iDR System Manager software

required to configure the unit.

Warnings For your own safety and to prevent damage

to equipment make sure you read and adhere to all warnings.

Model

Serial Number

Place of Purchase

Date of Purchase

4 IDR-8 User Guide

Page 5

Contents

Important Safety Instructions .......................................... 3

Welcome to the iDR-8 ..................................................... 6

Main Features.................................................................. 7

Front Panel Overview ...................................................... 8

Rear Panel Overview ....................................................... 9

System Processing Overview ....................................... 10

Getting Started - Check the Contents........................... 13

iDR System Manager Software ..................................... 13

Installing the iDR-8 ........................................................ 14

Earthing ......................................................................... 15

Connections and Cables............................................... 15

Backup Power Supplies ................................................ 15

Starting Offline with the Software.................................. 16

Turning the iDR-8 On and Off ....................................... 16

Checking the Operating Code Version......................... 17

Updating the iDR-8 Operating Code............................. 17

The iDR-8 Setup Menus ................................................ 18

Changing the Unit Name............................................... 19

Checking the Current Settings...................................... 19

Rebooting the iDR-8 ...................................................... 19

Getting Started – Checking the Hardware.................... 20

Communicating with the iDR-8 ..................................... 21

Communicating Using TCP/IP ...................................... 22

Connecting Direct to a PC ............................................ 23

Connecting to a Network .............................................. 23

Communicating Using a Dial-Up Connection............... 24

Connecting to a Modem Using RS232 ......................... 25

Connecting to a PC Using RS232................................. 25

Working with iDR System Manager .............................. 26

Setting the Time and Day Clock ................................... 26

Archiving and Loading Configurations ......................... 26

XLR Analogue Inputs and Outputs ............................... 27

Monitor Inputs and Outputs .......................................... 28

Adding iDR-in and iDR-out Audio Expanders............... 30

Linking iDR-8 Units........................................................ 32

Adding the iDR-switch Expander .................................. 34

MIDI, SysNet and PL-Anet Ports ...................................37

The iDR-8 Memory System ........................................... 38

Starting with Patches..................................................... 39

Technical Specification ................................................. 40

Factory Default Settings ................................................ 46

Template for Front Panel Label..................................... 47

iDR-8 User Guide 5

Page 6

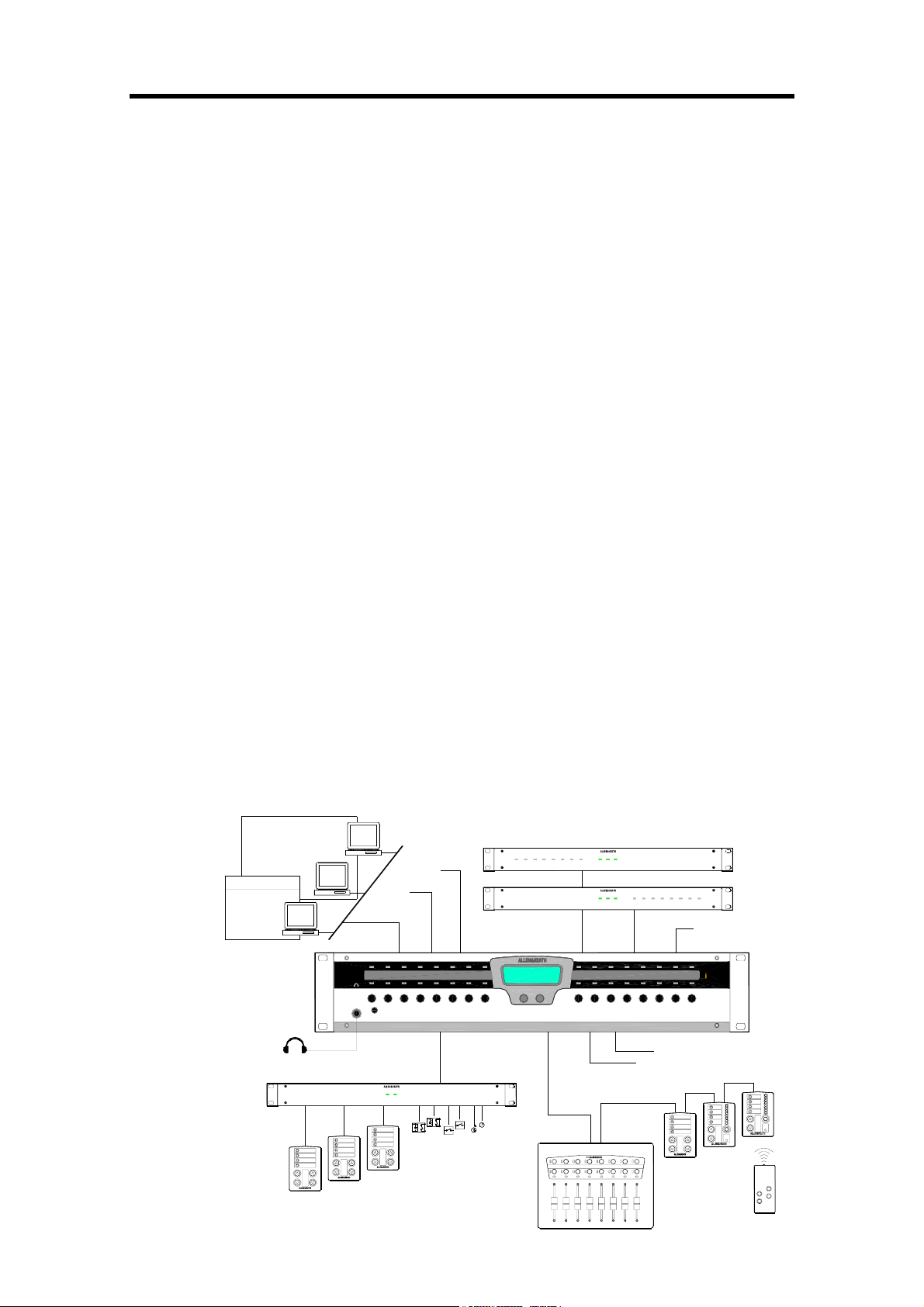

Welcome to the iDR-8

The Allen & Heath iDR system is a set of components whose hardware, control and signal processing

flexibility make it well suited to many installed, live sound and special project applications. The 2U

rack or desk mount iDR-8 is the main unit in the iDR system having all the DSP (digital signal

processing) power needed for 16 input and 16 output channels. It has 8 XLR analogue mic/line inputs

and 8 XLR analogue line outputs. You can add a further 8 inputs and/or 8 outputs bringing it up to a

maximum 16x16 matrix by plugging in the iDR-in and/or iDR-out audio expanders. The signal can be

routed at three key points: the input source patch bay, central matrix, and output source patch bay.

Although the iDR does not work with networked audio, the expanders can be located up to 250 metres

away so providing remote analogue audio inputs and outputs connected using CAT5 cables. You can

also daisy chain multiple iDR-8 units in a distributed system. The units are linked using an 8 channel

wide bus which plugs into the digital expander ports. Maximum matrix at any unit is 16x16 which

includes the interconnecting bus. Several iDR-8 units can be linked in this way, but you can have only

one iDR-in and one iDR-out expander per system. This is described later.

A stereo audio monitor is included. This has both input and output TRS jacks so that the monitor can

‘ripple through’ chained iDR units. It also feeds a front panel headphones socket for local monitoring

of any point in the audio signal path. The monitor can access the input and output channels so that

they can be used with the matrix. For example, you can achieve a 10x10 matrix from an unexpanded

iDR-8. A built-in signal/noise generator provides a further source which can be routed to the input

channels for test and line up purposes.

There are many operator control possibilities. You can configure the 16 front panel keys and 32 3colour LEDs, and use the DR-Link port to add up to 3 iDR-switch units for up to 72 additional switch

closure and 48 open-collector logic outputs. In addition you can choose two of the following: MIDI, the

Sys-Net serial port to interface with third party remote controllers, RS232 for modem communication,

and the PL-Anet serial port for running a network of Allen & Heath PL wall plates and controllers.

The iDR-8 features networked control. It is configured using the iDR System Manager software via an

Ethernet port either connected directly to the installer’s PC, or over a TCP/IP network. The PC control

can be password protected for security. Once configured it runs stand alone using its built-in iDR Unit

software with stored settings. iDR units can also be operated from networked PC workstations running

PL Client software configured as ‘virtual’ wall plates by the installer using PL Designer software. An

RS232 modem port lets the installer remotely interrogate units. A front panel RS232 port allows easy

operating code update.

The iDR system offers tremendous flexibility. The system set up is stored in patches. Up to 99 patches

can be programmed. You can decide which parameters are affected by each. To make best use of

this it is important that you plan your installation carefully before you start. You can try out, prepare

and archive different configurations offline before plugging in. Virtual panels and controllers are

displayed so you can simulate how it will work for real. You can program the unit name, clock and IP

address, and check diagnostic information and audio signal presence using the front panel menus

accessed by removing the face plate. You can also attach your custom label here so that it is

protected when the plate is refitted. For further information on the configuration of the unit please refer

to the Help files which come with the software.

iDR System Manager software

System configuration

PL Designer software

PL Client software

'Vitual' wall plates

iDR-switch

NETWORK

RS232

link power

MODEM

DR-Link

iDR-switch

24 IN 16 OUT SWITCH CONTROLLER

iDR-in

iDR-out

iDR-8

AUDIO EXPANDERS

powerlock link

lock link power

PL-Anet

MIDI

Sys-Net

iDR-in

AUDIO INPUT EXPANDER

iDR-out

AUDIO OUTPUT EXPANDER

AUDIO MONITOR

DR-8

AUDIO MIX PROCESSOR

Switch closures

Open-collector logic

REMOTE CONTROLLERS

Relays

Lamps

Infra-red

6 IDR-8 User Guide

Page 7

Main Features

• iDR-8 main processing unit 2U, 8 mic/line in, 8

line out audio mix processor with 16x16 channel

matrix. The heart of the iDR system, it features 2

24bit Motorola DSPs.

• Daisy chain iDR-8 units Any number may be

interconnected via the 8 channel digital bus using

CAT5 cable. Many possibilities for flexible sound

system solutions.

• iDR-in 1U, 8 mic/line input expander unit.

Expands the number of inputs to 16. Can be up

to 250 metres away for remote audio. Uses CAT5

digital link. One input expander per iDR system.

• iDR-out 1U, 8 line output expander unit.

Expands the number of outputs to 16. Can be up

to 250 metres away for remote audio. Uses CAT5

digital link. One output expander per iDR system.

• iDR-switch 1U add-on unit providing 24 contact

closure switch inputs and 16 open collector logic

outputs. Up to 3 units may be daisy chained for a

maximum 72 switch and 48 logic outputs. Each

unit can be separated by up to 250 metres.

Connects via the DR-Link serial port.

• PL wall plates and remotes The Allen & Heath

range of optional wall plates and controllers for

remote switch, rotary encoder, infra-red, fader,

LED indicator and logic output control. Connects

via the PL-Anet serial port.

• Desk top or 19” rack mounting Rubber feet and

removable rack ears provided.

• Universal mains power input automatically

detects worldwide voltage from 100V to 240V AC.

• Removable face plate for accessing front panel

setup menu system, RS232 connector and status

indicators. Also provides a protected custom

label facility.

• XLR mic/line inputs Electronically balanced, pin

2 hot, for microphone or line level equipment.

Soft control of gain, pad switch and 48V phantom

power. No internal adjustments needed.

• XLR line outputs Electronically balanced, pin 2

hot, 0dBu with +18dB headroom.

• Stereo audio monitor with front panel

headphones socket and rear panel TRS jacks.

Can monitor any point in the audio chain using

manual or mouse selection. Can be used with the

audio matrix as two additional channels, for

example providing a 10x10 matrix from an

unexpanded iDR-8.

• 16 Front panel soft keys can be assigned by the

installer as level, mute or patch recall with different

types of press action. Similar applies to the iDR-

switch functions.

• 32 Front panel 3-colour soft LEDs can be

assigned by the installer as signal meters, mute or

patch related indicators.

• Front panel LCD display A 16 character 2 line

LCD can display combinations of clock, patch

name, unit name and user defined text. This can

be linked to the patches.

• iDR System Manager software for system setup.

Once configured the PC can be removed and the

system operated stand alone.

• PL Designer and Client software for creation of

‘virtual’ wall plates and controllers that can be run

from networked PC workstations. Operator

control can be restricted by the installer.

• Powerful fixed architecture with full processing

on all 16 input and output channels. Familiar GUI

makes setup and control an easy task.

• 48kHz operation The iDR-8 has processing for a

full 16x16 matrix running at 48kHz. An upgrade to

96kHz may become available in the future.

• Patchbays and crosspoint matrix The input

source patchbay selects any physical input to any

input channel. The output patchbay selects any

output channel to any physical output. The 16x16

matrix allows independent level control at each

crosspoint.

• Channel stereo linking and grouping Input and

output channels can be linked for true stereo

operation, and grouped for master fader control.

• Configurations can be named, archived and

opened using PC files. These store the system

setup parameters such as communication

options, names, stereo linking, scheduled events

and set of patches.

• Patches Up to 99 patches can be created,

named and stored within the configuration file. A

patch can work with any number of selected

parameters including signal processing, soft key

and LED settings. This provides a unique

flexibility in setting up complex changes with

simple operator control.

• Time and day of week for display on the unit

LCD, and for scheduled event patch recalls using

the internal iDR-4 clock.

• Network port connects to a PC or network for

control using the iDR System Manager, PL Client

software, Telnet, TCP/IP, remote access etc.

• RS232 ports on front and rear for connection to

a PC for code update and to a modem for remote

system interrogation.

• SysNet port for control by third part touch

screens and other remote controllers.

• MIDI port IN, OUT and THRU sockets provided

for remote control using show controllers and

other MIDI equipment.

iDR-8 User Guide 7

• Naming Input channels, output channels, fader

groups and PL devices can be named.

• Channel processing Includes faders, mute,

polarity reverse, delay, parametric EQ, crossover

filters noise gates, compressors and limiters.

• Ducking, AMM and paging System functions

include a 16 priority level ducker, automatic mic

mixer and two independent pagers.

• Signal generator provides sine wave, white, pink

and band pass noise signals for system line up

and test.

Page 8

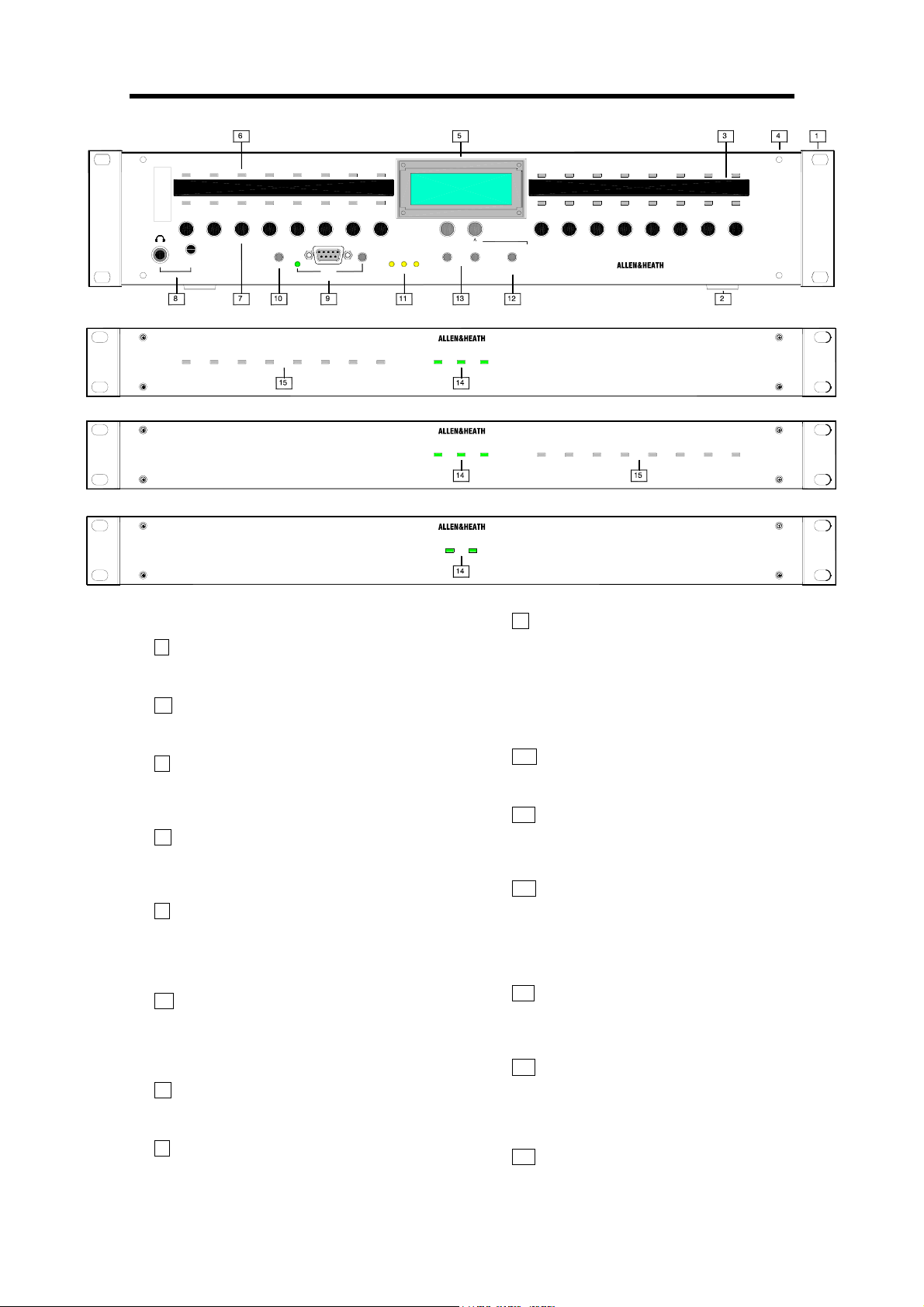

Front Panel Overview

L19L18L17 L20 L21 L22 L23 L24 L25L26L27L28L29

S4L4S5

CODE UPDATE

L5

active

For connection to PC com port

L3L2

S1

S2L1S3

LEVEL

TRIM

L7

S6L6S7

FRONT/REAR

RS232

L8

S8

ext

sync

lockslave 96k

Allen & Heath

Wed 13:44:08

Shown with face plate removed.

1 Rack ears Mount the unit into a standard 19”

equipment rack. Can be removed for stand alone

desk or shelf mounting.

2 Rubber feet Provided separately. Press

these into the base holes for stand alone desk or

shelf mounting.

3 Write-on label strip To mark up the soft key

and LED functions using a suitable marker pen or

adhesive label. A Windows™ Word template is

provided with the software.

4 Face plate fixing holes Fit the face plate

using the four M3 screws provided once the unit is

configured and labels fitted. A suitable 2mm hex

Allen key is supplied.

5 LCD display Displays system information on

a backlit 2x16 character LCD display. You can

configure this to display different combinations of

clock, patch name, unit name and user defined

text.

6 Soft LEDs 32 3-colour LED indicators

referred to as ‘soft’ because they can be assigned

by the installer as audio meters, mute or patch

related indicators. They can display red, green or

yellow.

7 Soft keys 16 momentary action switches

which can be assigned by the installer as level,

mute or patch recall.

8 Headphones output A front panel socket is

provided for stereo headphone monitoring. The

level trim can be adjusted using a flat bladed

screwdriver

<

scroll

<

ESC ENTER>MENU

powerlock link

lock link power

link power

L30 L31 L32

L10

L11

L12

L13

L14

L15

L16

hold for 2 seconds

audio monitor

patch select

day & clock

network setup

diagnostics

S9L9S10

S11

S12

S13

S14

S15

S16

Audio Mix Processor

DR-8

i

iDR-in

AUDIO INPUT EXPAND ER

iDR-out

AUDIO OUTPUT EXPANDER

iDR-switch

24 IN 16 OUT SWITCH CONTROLLER

9 Front panel RS232 port This is used for

code update from a PC via its RS232 COM port. It

can also be used for system configuration or

checking using iDR System Manager software but

the faster network port is recommended.

Pressing the FRONT/REAR switch selects either

the front or rear RS232 port. The active LED lights

when the port is available.

10 Code update switch Puts the unit into

code update mode ready to accept new operating

code from a PC. Status is shown on the LCD.

11 Status LEDs Both the slave and ext sync

lock LEDs light when the unit is correctly working

as a slave in a daisy chained iDR system. The 96k

LED is available for a possible future upgrade.

12 Menu key Press and hold this key for 2

seconds to access the setup menus. These let

you set up the clock, unit name, TCP/IP and PPP

communication parameters, select points in the

channel signal path to monitor, and check system

diagnostics.

13 scroll keys 4 keys are used to access the

setup menus and change parameter values. The

U and V keys are also used when the soft keys

are assigned as up/down level controls.

14 Expander status LEDs These display the

connection status. The link LED lights when

communication is established via the DR-Link

port. The lock LED lights when digital audio is

working correctly.

15 Expander soft LEDs Can be assigned as

audio meters, mutes or patch related indicators in

the same way as the main iDR unit.

8 IDR-8 User Guide

Page 9

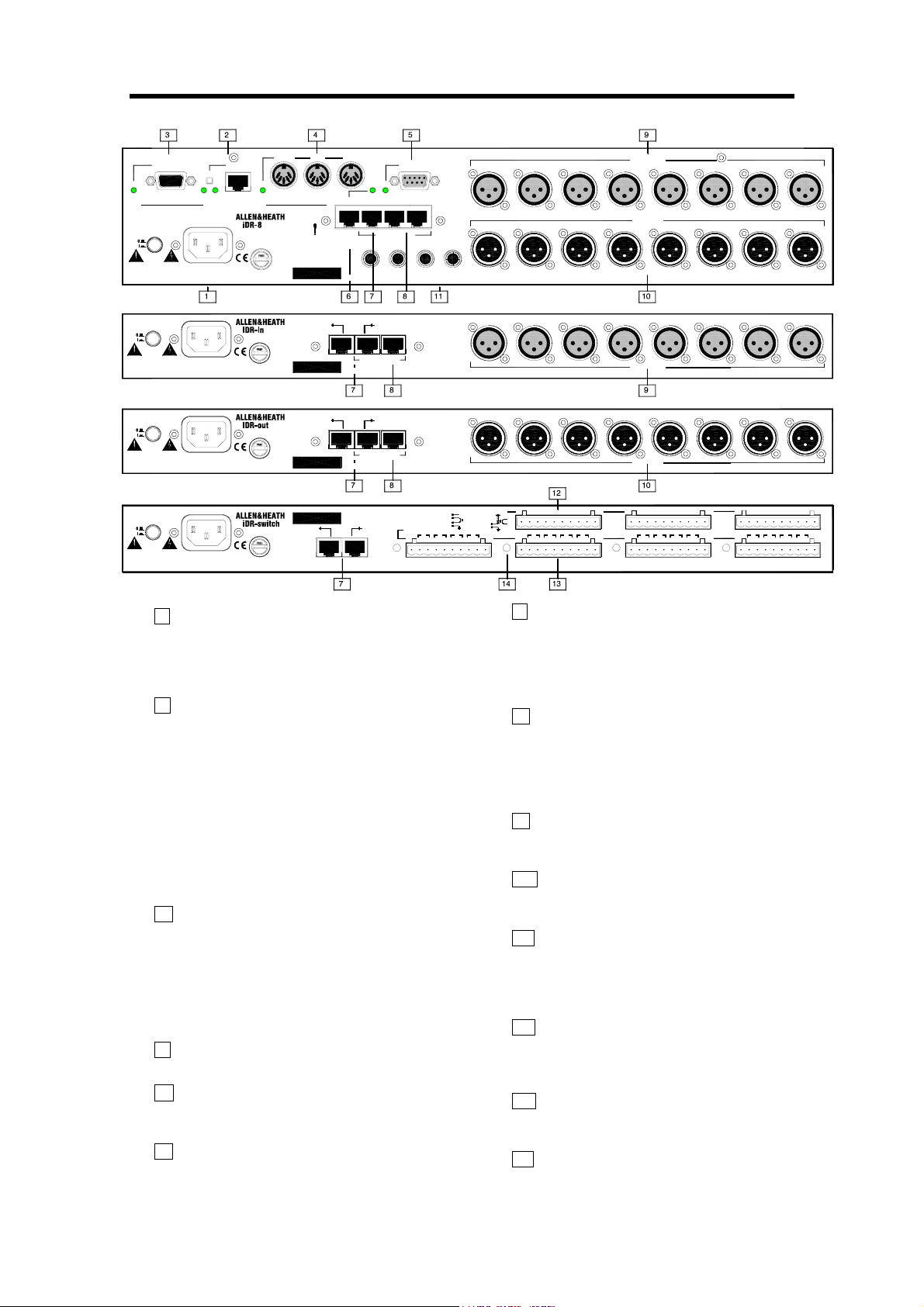

Rear Panel Overview

Use null-modem cable to connect to PC com port

RS232 (MODEM)

active

100 - 240V~

47-63Hz ~ 90W MAX

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN.

100 - 240V~

47-63Hz ~ 25W MAX

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN.

100 - 240V~

47-63Hz ~ 25W MAX

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

100 - 240V~

47-63Hz ~ 15W MAX

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN. AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR. Made in the UK by ALLE N&HEATH LIMITED Complies with UL6500, C SA-E65, EN60065

NETWORK

MDI/X

LINKTX

Refer to user guide for port select ion details

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

MIDI OUT

active

FUSE: T1.6AL

SERIAL NUMBER

FUSE: T500mAL

SERIAL NUMBER

FUSE: T500mAL

SERIAL NUMBER

FUSE: T500mAL

MIDI IN

THRU

PL-ANET

CAUTION 20V DC

TO AVOID DAMAGE ONLY CONNECT

COMPATIBLE REMOTE CONTROL

EQUIPMENT TO THE PL-ANET PORT.

Made in the UK by ALLEN&H EATH LIMITED

next

OUT

DR-LINK

Made in the UK by ALLEN&H EATH LIMITED

next

OUT

DR-LINK

Made in the UK by ALLEN&H EATH LIMITEDCAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN.

next previous

OUT IN

DR-LINK

active

active

DR-LINK

DIGITAL EXPANDER

MONITOR IN

R

previous

AUDIO OUT

IN

DIGITAL EXPANDER

previous

IN

AUDIO IN

DIGITAL EXPANDER

SYSNET PORT

AUDIO OUTAUDIO IN

MONITOR OUT

LR

Complies with UL6500, C SA-E65, EN60065

Complies with UL6500, C SA-E65, EN60065

Complies with UL6500, C SA-E65, EN60065

+10V DC max total 500mA

open collector

+24V DC, 200mA max

LOGIC OUTPUTS

1516 13

+-+-+-+-

L

+10V

V

+

opto

G

IN 8 IN 7 IN 5

OUT 8 OUT 7 OUT 5

IN 16 IN 15

OUT 16 OUT 15

SWITCH INPUTS

+10V

2K2

opto

switch

G

1214

+-+-+-+-

IN 6 IN 4

OUT 6 OUT 4

IN 14 IN 13 IN 11IN 12

OUT 14 OUT 13 OUT 11OUT 12 OUT 9

910

11

MIC/LINE INPUTS

LINE OUTPUTS

MIC/LINE INPUTS

LINE OUTPUTS

VGVGVG

+-+-+-

IN 3 IN 2 IN 1

OUT 3OUT 2OUT 1

IN 10

OUT 10

G 4321 G5678G 1211109 G13141516G 20191817 G21222324

567+-8

VG

+-+-+-

IN 9

123+-4

1 Mains input Use the IEC lead with moulded

mains plug suitable for your local mains voltage.

The protection fuse rating is marked on the rear

panel. The on/off switch is positioned on the rear

panel to prevent accidental operation.

2 Network port RJ45 socket for connection to

an Ethernet network or PC using UTP CAT5 cable.

This port is recommended for configuring the

system with iDR software. The MDI/X switch

selects network or direct to PC operation. The link

LED lights when communication is established.

The TX LED lights when data is communicated.

Note: The RS232, MIDI, SysNet and PL-Anet

control ports are not all available at the same time.

A combination of two is selected using iDR

System Manager. The associated active LED

lights when the port is available.

3 RS232 (MODEM) port This is used for

connection to a modem so that the unit can be

interrogated by a remote PC over a standard

telephone line. It can also be used for system

configuration using iDR System Manager software

but the faster network port is recommended.

Pressing the front panel switch selects either the

front or rear RS232 port.

4 MIDI port Standard opto-isolated MIDI port

with IN, THRU and OUT connectors.

5 SysNet port An RS232 serial port for

communication with third party remote controllers

running the Allen & Heath SysNet protocol.

6 PL-Anet port An RS485 serial port for

communication with a network of Allen & Heath

PL wall plates and remote controllers using CAT5

STP cable.

7 DR-Link port RJ45 socket for control of iDR

audio and logic expander units using CAT5 STP

cable. IN and OUT ports are provided on the

expander units so that the control can be daisy

chained through a system with more than one

expander.

8 Audio expander ports RJ45 sockets for

communicating 8 channel digital audio between

the iDR-8 and its expanders using CAT5 STP

cable. Two cables are required between the

expander and iDR-8, one for the audio, the other

for DR-Link control.

9 Mic/Line inputs Balanced XLR inputs for

microphone and line level sources. Adding the

iDR-in expands the iDR-8 to 16 inputs.

10 Audio outputs Balanced XLR line level

outputs with maximum +18dBu level. Adding the

iDR-out expands the iDR-8 to 16 outputs.

11 Monitor inputs and outputs Balanced TRS

jacks for L and R monitor inputs and outputs.

These provide a line level version of the front

panel stereo headphones output and can daisy

chain through multiple iDR units.

12 Switch closure inputs These are provided

on the iDR-switch. They can be hard wired from

remote wall plate and controller switches and

relays.

13 Open collector logic outputs These are

provided on the iDR-switch. They can be used to

control LEDs, lamps, relays and other devices.

14 Earth terminals These are provided to earth

(ground) the switch and logic output cable

shields.

iDR-8 User Guide 9

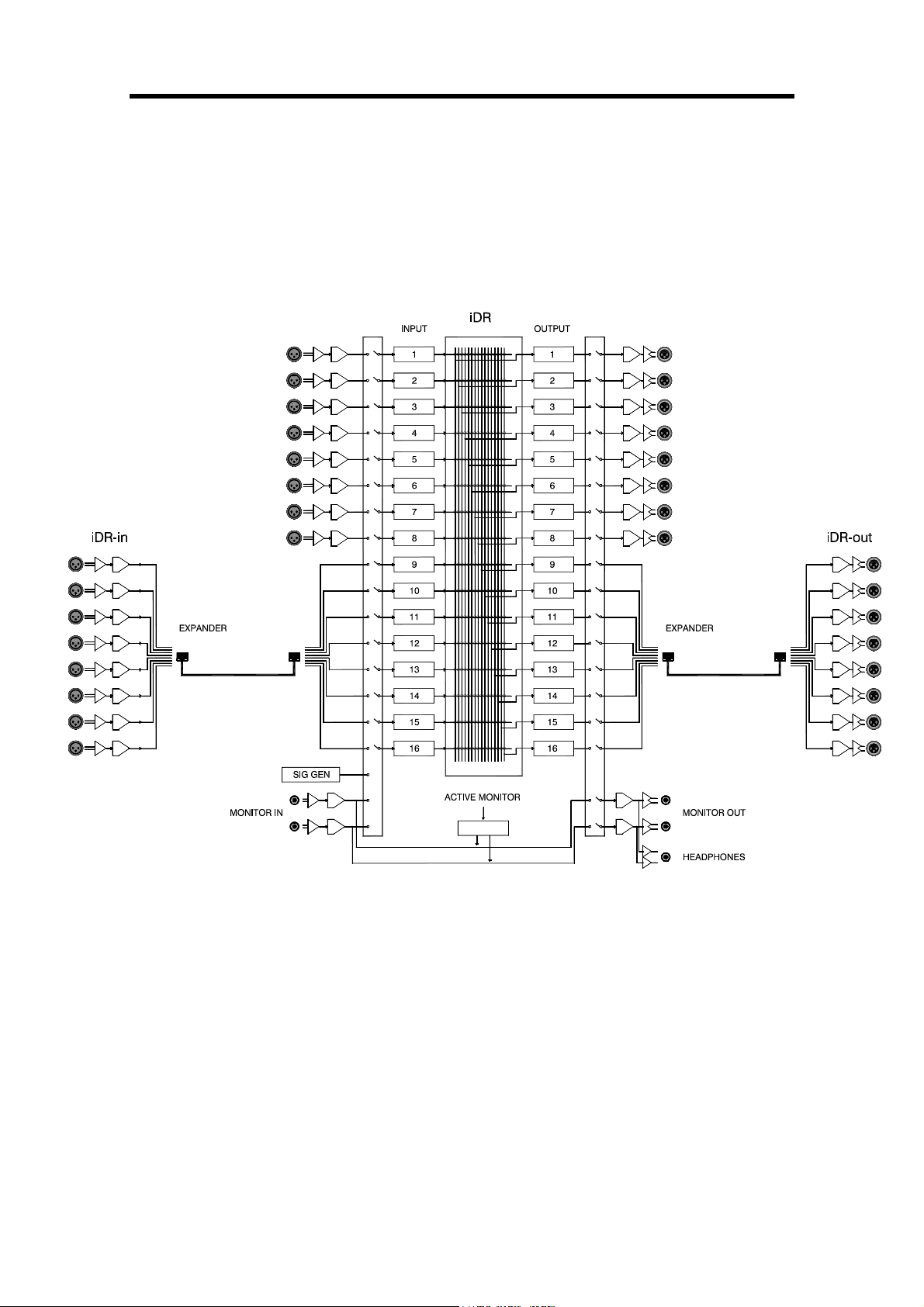

Page 10

System Processing Overview

The iDR-8 has 8 analogue inputs and 8 analogue outputs. However, it has the onboard DSP

processing for a full 16 input and 16 outputs. The extra 8 inputs and/or outputs are available when the

iDR-in and/or iDR-out audio expanders are added. Only one of each may be added. This means that

you can create an 8x8, 16x8, 8x16 or 16x16 system to suit your requirements. The stereo monitor input

and output can also be added into the matrix in a non-expanded iDR-8 to create a 10x10 system. iDR-

8 and iDR-4 units can be daisy chained together using the 8 channel wide digital expander bus to

create even more flexible systems with additional local inputs and outputs and a maximum 16x16

matrix.

The system architecture illustrating the expanded iDR is shown below:

10 IDR-8 User Guide

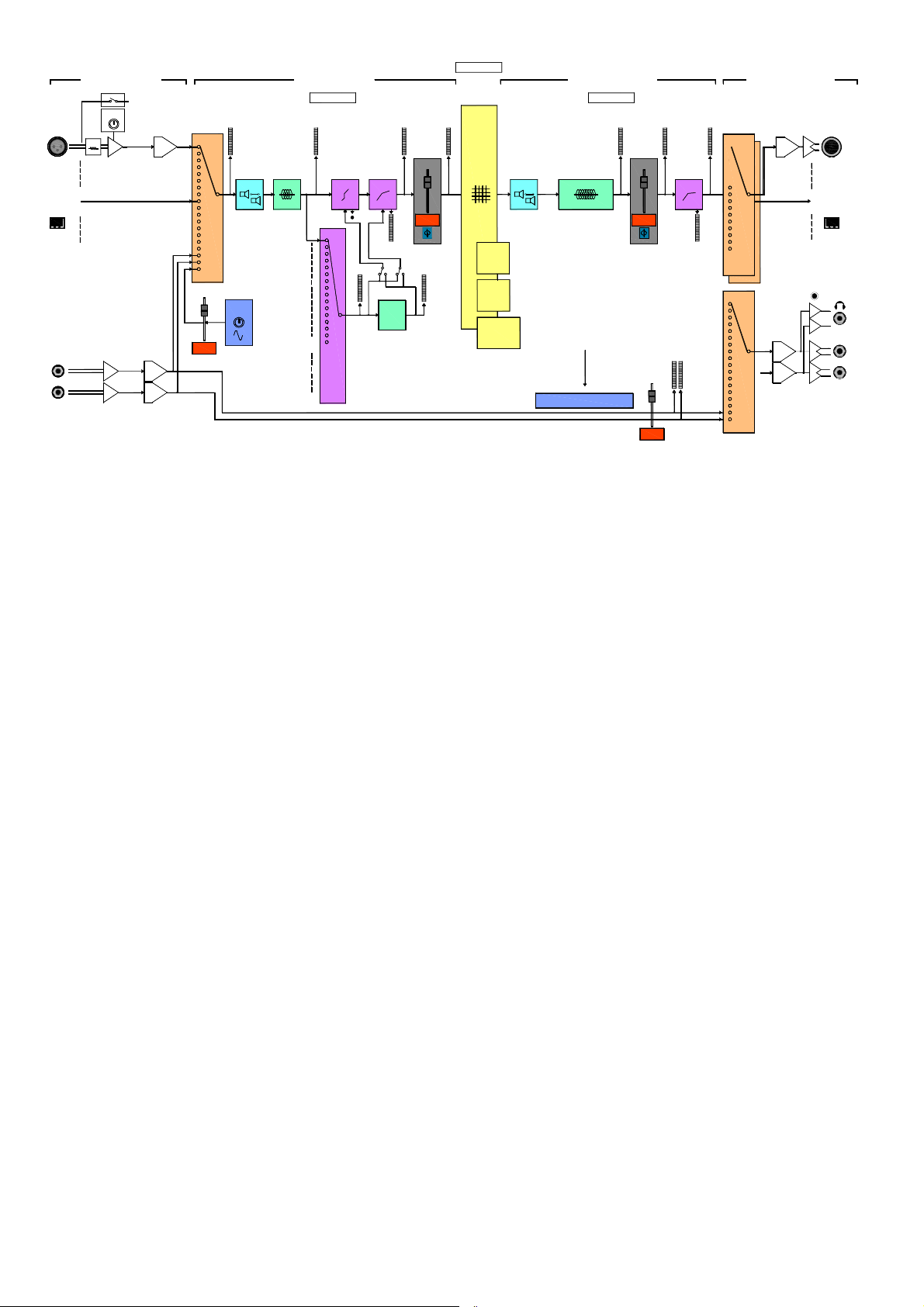

Page 11

PHYSICAL INPUTS INPUT CHANNELS

+48V

ANALOG

INPUT

EXPANDER

INPUT

MONITOR

INPUT

L

R

GAIN

LIMIT

PAD

+

-

1

8

9

16

+

-

+

-

ADC

ADC

ADC

SOURCE

FADER

MUTE

SILENCE

M M

DELAY

SIG GEN

FREQ

OSCILLATOR

PINK NOISE

WHITE NOISE

1/3 OCT BP

The channel architecture illustrating the processing blocks is shown above.

For detailed instructions on using these please refer to the Help file which

comes with the iDR System Manager software.

PEQ4

MONO

STEREO

1+2

15+16

iDR NAME

MIX

MATRIX

COMPGATE

GR

SIDECHAIN

FILTER

FADER

M

MUTE

PAGER

M

AMM

DUCKING

MM M

ACTIVE

SEL

1

16

OUTPUT CHANNELS

NAMENAME

MM

PEQ8DELAY

HF SHELF

LF SHELF

BELL

HF FILTER

LF FILTER

XOVER FILTER

M

ACTIVE MONITOR BUS

FADER

M

MUTE

FADER

LIMIT

GR

MUTE

PHYSICAL OUTPUTS

SOURCE

MM

SOURCE

DAC

PHONES TRIM

DAC

DAC

ANALOG

OUTPUT

1

8

EXPANDER

9

OUTPUT

16

MONITOR

OUTPUT

L

R

Physical inputs and outputs These are the

hardware audio connections including XLRs,

digital expanders, headphones and monitor.

Input and output channels These are

processing channels. The input channels can be

sourced from any physical input. The physical

outputs can be sourced from any output channel.

The input and output channels are interconnected

through the crosspoint matrix. They are routed to

and from the physical connections via the source

patchbays. The iDR-8 has enough processing

built in for 16 input and 16 output channels when

in 48kHz mode. The iDR-in and iDR-out

expanders simply convert between analogue

audio and the digital signals working with the iDR-

8 16x16 matrix.

Analogue inputs The iDR-8 and iDR-in each

have 8 analogue XLR inputs. These feed high

grade balanced mic preamp circuits. They accept

a wide range of microphone and line level signals.

Gain, pad and 48V phantom power switching are

controlled using the iDR System Manager

software so they can be part of the recallable

patch system. There are no trimmers or internal

adjustments needed.

Analogue outputs The iDR-8 and iDR-out each

have 8 analogue XLR line outputs. These are

balanced and can produce up to +18dBu

maximum signal level.

ADC and DAC converters These convert the

analogue signals into digital (ADC) and processed

digital signals into analogue (DAC). High grade

24bit converters are used.

Expander input and output 8 Channels of audio

are communicated between iDR units using these

RJ45 ports. The digital signals are fed to and from

the associated virtual patchbays. Routing the

signals through the patchbays in this way

provides the flexibility for common sources to be

networked between multiple iDR units using CAT5

cable.

Monitor inputs and outputs A front panel stereo

headphones output is provided. Balanced line

level L and R inputs and outputs are available on

the rear panel. The inputs feed the active monitor

bus and can also be routed into the source

patchbay. The outputs are fed from a patchbay

which gets its source from the active monitor bus

or any output channel. In this way these

connections can be used either as a monitor

system or as channels in their own right.

Signal generator Provides another selectable

source feeding the input channels through the

patchbay. Variable frequency sine wave, pink

noise, white noise or 1/3 octave band pass noise

can be selected. These can be used for system

line up and testing. The level is controlled using

the fader and mute function.

Source patchbays These connect the physical

inputs and outputs to the channels so providing a

flexible ‘virtual patchbay’ routing system. One

physical input can feed more than one input

channel. One output channel can feed more than

one physical output. Note that, as with any

physical patchbay, you cannot route two sources

into one channel, or two channels into one output.

Mix matrix This is the routing ‘heart’ of the

system fed by all 16 input channels, and feeding

all 16 output channels. It is known as a 16x16

crosspoint matrix. The signal can be switched or

have its level independently controlled at any

point. It is the matrix which provides the key to

independent multi-source zone routing and level

control.

iDR-8 User Guide 11

Page 12

Delay Each input and output channel provides

delay from 0 up to 340ms. It can be adjusted in

ms, metres or feet and has compensation for

temperature.

Metering Full metering is provided from all the

points marked with a meter bar in the diagram.

Sidechain level, gain reduction, and stereo

monitor meters are included.

PEQ The input channels each provide a 4 band

fully parametric equaliser, the output channels an

8 band equaliser. Compared with the graphic EQ

these are by far more powerful and accurate tools

for adjusting frequency response. Selectable

band types include HF shelf, LF shelf, bell, notch,

HPF, LPF and crossover filter type. Variable or

constant Q width can be used. The resulting

response is displayed on a frequency curve.

Gate The input channel noise gate is used to

turn the channel off when its level falls below a

preset ‘threshold’ level. This shuts off unwanted

noise such as ambient background pickup,

equipment hiss and hum and so on. It provides

threshold, depth, hold, attack and release

controls. The sidechain can be switched in for

frequency selective gating.

Compressor The input channel compressor

controls the dynamics of the signal. It can, for

example, help the intelligibility of the human voice

by reducing the gain of high levels and increasing

the gain of low levels, in effect squashing the

levels into a more manageable range. The

compressor provides threshold, ratio, hard/soft

knee, makeup gain, attack and release controls.

The sidechain can be switched in for frequency

selective compression such as de-essing or LF

contour.

Sidechain filter This input channel filter can be

switched into the gate and/or compressor so that

the dynamic response is tailored according to

frequency. For example, you can reduce the

‘pumping’ effect of a compressor by slightly

cutting the low frequencies in the sidechain, or

prevent false opening by triggering a noise gate

on the resonant frequency of an instrument using

a bell response sidechain filter. Full type and

parameter control is provided.

Pager Two independent paging systems are

provided. They are fully configurable with

selectable paging mic, zones affected, and

variable ducker depth. They can be triggered

from any soft switch and use any soft LED for

indication. The switch action can be momentary

or latching.

Ducking Any input can override any combination

of outputs with variable depth, threshold and

release. There are 16 assignable priority levels.

Ducking is useful for overriding background music

during announcements, recorded messages,

jukebox playback and so on.

AMM The automatic mic mixer is popular in

conference situations where several microphones

can contribute to the mix. Microphones are only

opened when they are being spoken into. The

overall gain is reduced as more microphones are

opened. The amount by which they are reduced

is known as the NOM (number of open mics)

setting. This maintains a more constant level and

helps stop feedback. The ambient level is the

sum of all the mic channels. Threshold adjusts

the point at which the microphone opens above

the ambient level.

Level sense switching The iDR logic outputs

can be switched when channel signal activity is

sensed. These could be used, for example, for

video broadcast of a conference to switch

between cameras when different microphones are

spoken into.

Naming Each input and output channel, input

and output fader group, PL device and patch

memory can be named for identification in the

system.

Limiter Each output channel includes a

protection limiter to control the maximum level

allowed at the outputs. This is typically used to

protect loudspeakers and control maximum SPL

listening levels. Threshold, attack and release can

be controlled.

Faders, mute and polarity The input and output

channels each provide a fader, mute switch and

polarity reverse. The fader offers +5dB boost

above the unity gain ‘0’ position. The matrix

provides variable level crosspoints with

independent fader control.

Groups and stereo linking Faders can be

grouped so that a master fader takes control of

assigned input or output faders. Channels can be

linked for stereo operation with single fader level

control and linked processing throughout the

audio path.

Active monitor bus Any point in the audio signal

path can be monitored. This is selected manually

or by moving the mouse over an active window.

The monitor can ‘ripple through’ several iDR units.

With no monitor point selected, the signal from the

previous iDR unit is passed through to the output.

This means that one monitor output can be used

to listen to any point in a multiple iDR system.

12 IDR-8 User Guide

Page 13

Getting Started - Check the Contents

Keep the product packing in case you need to ship the product

in the future. You should find the following components:

DR-8i Audio Mix Processor

DR-8

AUDIO MIX PROCESSOR

1x iDR-8 UNIT. This is packed with its face plate removed and

rack ears fitted. The ears can be removed for desk mounting.

1x iDR-8 FACE PLATE. Separately packed so that you can

start by configuring the unit using its front panel menu system.

4x SCREWS M3x12mm hex dome head. Part number AB4814.

Use these to secure the face plate to the unit.

1x ALLEN KEY 2mm hex. Part number AT4819. For fitting the

face plate screws.

4x RUBBER FEET. Part number AK0102. Press these into the

underside holes if you want to desk mount the unit.

1x IEC MAINS LEAD with moulded plug suitable for connection

to your local mains supply.

1x CAT5 UTP CABLE 2 metre RJ45. Part number AH4818.

Connects the unit to your PC or to a network.

1x RS232 CABLE. Part number AL3653. Connects the unit to

your PC for operating code update.

1x DOCUMENTATION PACK including Safety Sheet AP3345,

this user guide AP4530 and the Registration Card AP3594.

The iDR System Manager Software Available

The self-extracting file iDRnnn.exe is available

from the Allen & Heath web site. ‘nnn’ is the

version number. For example iDR300.exe is

version number V3.00. Once installed the

software provides:

IMPORTANT: Before installing check

the Allen & Heath web site to ensure you have

the latest version.

README FILE Read this before starting.

RELEASE NOTES This file contains important notes about the

related version of the software. Read before starting.

iDR SYSTEM MANAGER APPLICATION to configure and

control the iDR system using a PC running Windows™.

WINDOWS™ HELP FILE for the iDR System Manager

application.

iDR UNIT OPERATING CODE This is pre-installed in the iDR-8

unit. However, check that it is the latest version. Update the

code as described later if it is not.

HYPERTERMINAL .ht FILES for setting up communication

between the PC and iDR-8 for updating the operating code.

Files are provided for COM1, 2 and 3.

SYSNET, TELNET and MIDI PROTOCOLS pdf files explaining

how to use the SysNet and MIDI ports.

PL-Calculator, PL-Client and PL-Designer software for

configuring physical and virtual wall plates and controllers.

CONFIGURATION FILES Two .cfg files are provided, DEFAULT

and RESET. These give you a useful starting point.

LABEL TEMPLATE a Windows™ Word file for creating a

customised label to fit to the iDR-8 front panel. Use this to

identify the key and LED functions.

iDR-8 User Guide 13

Page 14

Installing the iDR-8

The iDR-8 and its expanders are supplied ready

for 19” rack mounting. For desk top or shelf

mounting remove the rack ears and fit the 4 pressin rubber feet provided. Use Torx (star head)

screwdrivers.

Fit the face plate once you have configured the

settings with the front panel menu system and

fitted any labels required to identify the key and

LED functions. The plate is packed separately.

Fit this using the 4 hex screws and the 2mm Allen

driver provided.

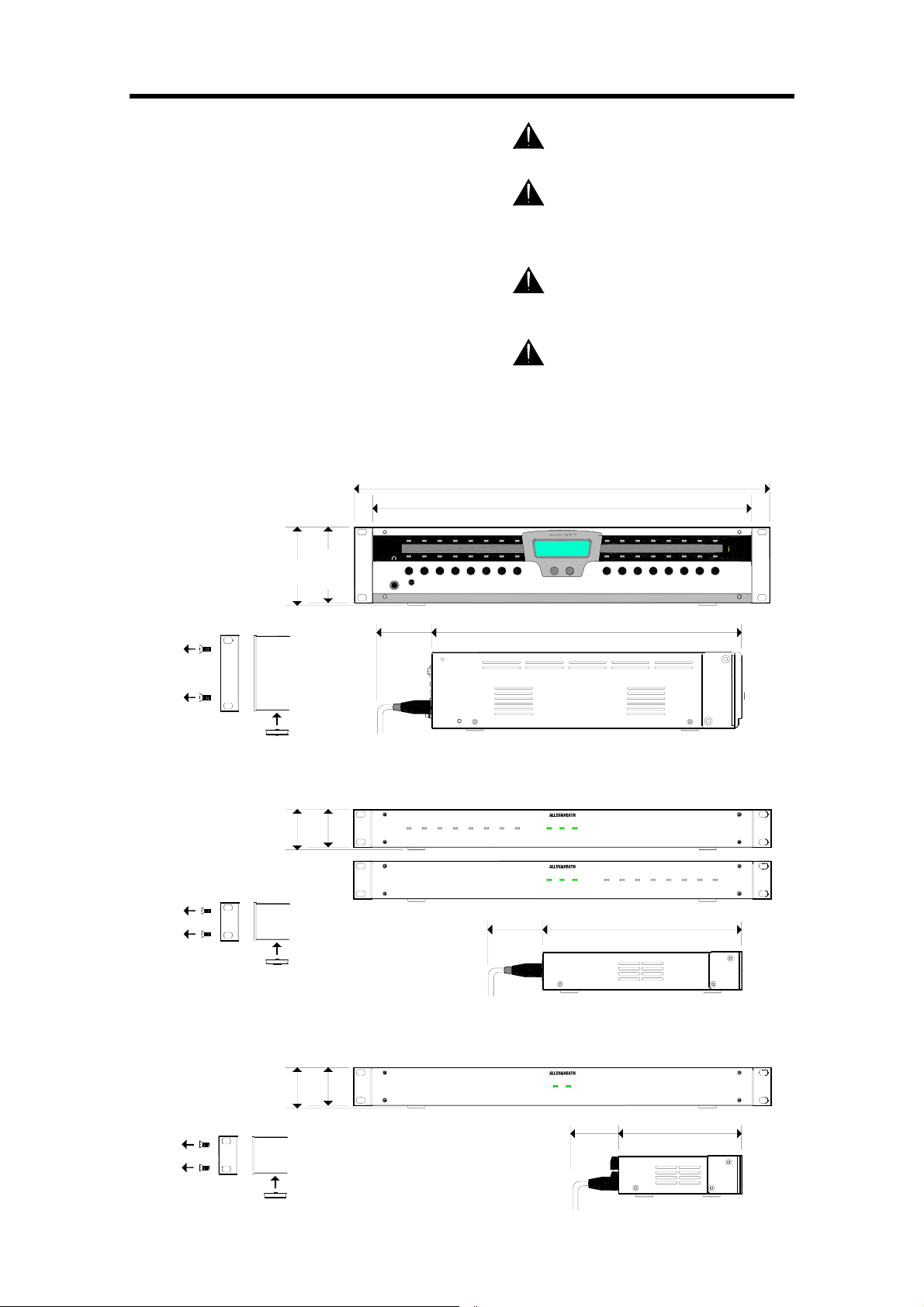

Allow adequate space behind the units for

plugging in the connectors. The dimensions are

shown below.

Plug the cables into their correct sockets. We

recommend that you colour code or label the

cables to avoid errors when replugging them in

the future.

iDR-8 MAIN UNIT

88mm

92mm

3.5"

3.6"

2U

Do not obstruct the side ventilation slots.

Ensure adequate air flow around the units.

Do not install the units directly above or

below heat or electromagnetic generating

equipment such as power supplies and

amplifiers.

To avoid damage to the internal

assemblies do not fit screws or drill through

the case metalwork.

Do not remove the cover of the iDR unit.

There are no user serviceable parts inside. All

configuration is carried out using the front

panel menus and iDR System Manager

software running on a PC

483mm

19"

443mm

17.4"

DR-8

AUDIO MIX PROCESSOR

Remove 2x rack ears

M4 Torx T20

Remove 2x rack ears

M3 Torx T10

Remove 2x rack ears

M3 Torx T10

Fit 4x feet

48mm

1.9"

Fit 4x feet

48mm

1.9"

Fit 4x feet

44mm

1.7"

1U

44mm

1.7"

1U

435mm

17.1"

75mm

3"

360mm

14.2"

iDR-in and iDR-out EXPANDERS

powerlock link

lock link power

307mm

232mm

12"

75mm

3"

iDR-switch EXPANDER

link power

209mm

8.2"

9.1"

144mm

5.7"

iDR-in

AUDIO INPUT EXPANDER

iDR-out

AUDIO OUTPUT EXPANDER

iDR-switch

24 IN 16 OUT SWITCH CONTROLLER

65mm

2.6"

14 IDR-8 User Guide

Page 15

Earthing

The connection to mains earth (ground) in an audio system is important for two reasons:

Safety - To protect the operator from a high voltage shock associated with the AC mains supply

feeding the system.

Audio Performance - To shield the audio signals from interference pickup and to minimise the effects

of ground loops which result in audible hum and buzz.

connected to mains earth so that exposed metal parts are prevented from

carrying high voltage which can injure or even kill the operator. The installation

engineer should check the continuity of the safety earth from all points in the

system including microphone bodies, cables, racks and equipment panels.

Earth is used to shield audio cables from external interference such as the hum fields associated with

power transformers, lighting dimmer buzz, and computer radiation. Problems arise when the signal

sees more than one path to mains earth. An earth loop results causing current to flow between the

different earth paths. This condition is usually detected as mains frequency audible hum or buzz. To

ensure safe and trouble-free operation we recommend the following:

Do not remove the earth connection from any iDR unit mains plug. The chassis of the unit is

connected to mains earth through the power cable to ensure your safety. Audio 0V is connected to the

chassis internally. If problems are encountered with earth loops use ‘ground lift’ switches or adaptors

on connected equipment accordingly, or disconnect the screens from interconnecting audio cables at

one end, usually at the destination.

Use a clean mains supply for the audio system. Ensure the audio mains supply is run separately

from lighting, motor, kitchen equipment and any other potentially noisy mains supplies. Use a mains

filter and surge protector for the audio supply if necessary. Take care to ensure good earthing in

distributed systems such as those with audio units linked over long distances.

WARNING: For safety it is important that all equipment earths are

Connections and Cables

Use professional quality cables and connectors and check for accurate wiring and reliable solder

joints.

Avoid running audio cables alongside mains, computer or lighting cables or near thyristor dimmer

and power supply units. If unavoidable, cross the cables at right angles or run them in separate

screened trunking to reduce the interference pickup.

Use low impedance sources such as 600Ω or less microphones to reduce susceptibility to

interference. The outputs of the iDR are designed to operate at very low impedance to minimise

interference problems.

Use balanced connections where possible as these provide further immunity by cancelling out

interference that may be picked up on long cable runs. To connect an unbalanced source to a

balanced Mic/Line input link the cold input (XLR pin3) to 0V earth (XLR pin1) at the unit. To connect a

balanced Line output to an unbalanced destination, link the cold output to 0V earth at the iDR unit.

Backup Power Supplies and Safety Standards

The iDR system is designed to conform to internationally accepted safety standards IEC60065 and

UL6500. It uses a built-in mains voltage power unit to supply the various internal power rails. It is

recommended that the iDR system be backed up using a UPS (uninterruptible power supply) in

installations where public safety is at risk. This is a requirement when an alarm or voice evacuation

system is integrated.

supply may be required. The standards may also apply to the grade of cable and

installation methods required.

iDR-8 User Guide 15

Check which safety standards apply to your installation. A backup UPS

Page 16

Starting Offline with iDR System Manager Software

You need to install the iDR System Manager software on your

PC. This requires Windows™ 95, 98, NT, ME, 2K or XP. We

recommend that you check the Allen & Heath web site for the

latest version. We are continually updating our software to add

new features or make improvements. Download the latest

version from our web site.

IMPORTANT: Do not install this software over a

previous version. The setup utility will install the iDR System

Manager into its own directory so that previous versions can be

retained. A previous version can be uninstalled using the

Windows™ Control Panel Add/Remove Programs application.

Run the self-extracting .exe file to install the software. Follow

the on-screen instructions. Make sure you read the Release

Notes before running the program. These may contain

important information about the new software version.

Start the iDR System Manager from the Start / Programs / Allen

& Heath menu. To open a new session click on the blue icon,

press Ctrl+N, or open the N

“Offline iDR-8” to start an offline session to get familiar with the

program before you connect the iDR-8 unit. Use the H

menu to learn more about how the software works. You can

archive your settings to load into the iDR-8 later.

ew item in the File menu. Select

elp

Turning the iDR-8 On and Off

100 - 240V~

47-63Hz ~ 90W MAX

FUSE: T1.6AL

WARNING

THIS APPARATUS MUST BE EARTHED.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION: RISK OF ELECTRIC SHOCK. DO NOT OPEN.

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

Please wait...

Allen & Heath

Wed 13:44:08

Make sure you have read the Important Safety

Instructions printed earlier. Also check that your local

mains supply is compatible with that printed on the rear

panel of the iDR-8. Ensure that the correct mains lead with

moulded plug and IEC connector has been supplied.

To avoid any unexpected audible clicks or thumps

always turn connected power amplifiers down or off before

switching the iDR-8 or any other signal equipment on or off.

Turn the unit on by pressing the rear panel power ON/OFF

switch. The LCD display lights up and the message ‘Please

wait…’ is displayed while the processor boots up. This is

followed by a ‘Recall..’ message if a power-up patch is active.

Finally, the normal display is shown.

Note that ‘normal’ display and control settings depend on the

last configuration loaded and whether a power-up patch has

been set.

Boot up time is normally around 10 seconds. However,

this can be up to 35 seconds if the front panel menu *5.1

DHCP Setup has been set to YES and the unit is not connected

to a DHCP network.

Parameters restored on power-up The iDR-8

remembers its unit name and address settings on power up.

IMPORTANT: The iDR does not recall

its last settings on power up. It initialises to

reset state or recalls a ‘power up’ patch if one

has been set. Read here >>>>>>>>>

16 IDR-8 User Guide

The clock is always running so the correct time and day is

retained. Configuration related parameters such as channel

names, stereo linking and scheduled events are restored.

Patch related parameters such as levels, EQ and soft control

settings are recalled only if a power-up patch containing them

has been set. If not, then all patch related parameters are reset

according to factory default. Further details are provided in the

section about Patches later in this user guide, and in the iDR

System Manager Help file.

Page 17

Checking the iDR-8 Operating Code Version

With the face plate removed, press and hold the ESC key to

A&H iDR V3.00

<

scroll

<

ESC ENTER

>

MENU

view the current version of operating code running in the unit.

Check that this code is the same version as the iDR System

Manager software you have installed on your PC. View this by

clicking on the software Help menu About item. If it is an older

version then carry out the code update procedure described

below. If you have several units connected over a network

make sure you check each for the correct version number.

We recommend that you check the Allen & Heath web site for

the latest version of software. Download and install this if it is

different to that already on your PC.

Updating the iDR-8 Operating Code

Operating code is held in non-volatile

memory within the iDR-8 unit. It is the

software which runs the unit once it is

configured.

IMPORTANT: Make sure all iDR units

to be controlled by the PC are running the

same version software as installed on the PC.

HyperTerminal settings If you prefer to

use an alternative terminal or

communications program, or you wish to

configure the HyperTerminal connection

manually, the required port settings are:

Baud Rate 115200

Data bits 8

Parity none

Stop Bits 1

Flow Control None

Protocol 1K Xmodem

DR Boot V1.00

Update.....

CODE UPDATE

active

RS232

For connection to PC com port

Boot code is the built-in software used

by the iDR-8 to manage its operating code.

It lets the unit communicate with your PC

when performing code updates. It is

permanently stored and cannot be updated

by the user.

FRONT/REAR

The front panel RS232 port is provided for updating the unit

operating code from a binary file on the PC. This is done using

the Windows™ HyperTerminal application which sends the file

to the iDR via the PC RS232 serial port. The file is provided

with the iDR System Manager software.

NOTE: The operating code can also be updated using the

iDR network port. This can only be done once communication

with the PC is established and iDR System Manager is running.

Select Upload New Program Code from the File menu.

RS232 Make sure your PC has the Windows™ HyperTerminal

application installed and an available COM1 or COM2 port.

Use a standard male to female RS232 lead such as the one

supplied with the unit. Do not use a null modem cable.

Refer to any Release Notes which may apply. We recommend

that you archive the current configuration before you start the

update if the iDR-8 has settings you wish to keep. Further

information is provided in the iDR System Manager Help file.

1 Start HyperTerminal From the Start / Programs / Allen &

Heath / iDR System Manager menu select the Update iDR Unit

Software (COMn) item. Select the COM1 or COM2 version as

appropriate for your PC. The HyperTerminal window is

opened.

2 Select the file to transfer From the Transfer menu select

the Send File item. Click on the Browse button. The file

named ‘iDR Unit Software V3_nn.bin’ is displayed. Make sure

the version number is the same as the one you want to load.

Open the file. The Send File window is opened ready to send

the file via the COM port. Do not do this until you have

prepared the iDR-8.

3 Prepare the iDR-8 With the face plate removed, plug one

end of the RS232 lead into the appropriate PC COM port. Plug

the other end into the iDR-8 front RS232 port. Press the

FRONT/REAR switch so that the green ACTIVE indicator next to

the port lights. Now press the CODE UPDATE switch. The

LCD displays the boot code version number and ‘Update...’.

4 Start the file transfer Click on the HyperTerminal Send

button. The transfer starts and a window displays information

and a progress bar. The LCD displays ‘Updating…’ progress

and then ‘Update Complete’. The process can take a few

minutes.

5 Restore normal operation Exit HyperTerminal. Deselect

the CODE UPDATE switch. The unit reboots automatically.

Deselect the FRONT/REAR switch if you want the rear RS232

port to become active. Press ESC to confirm that the correct

version of operating code has been loaded.

iDR-8 User Guide 17

Page 18

*8 Diagnostics

A&HA

*7 Monitoring

*6 PPP Setup

*5 Network Setup

*4 Unit Name

*3 Day of Week

*2 Clock

*1 Patch Select

REMOVE THESE SCREWS

PRESS AND HOLD FOR 2 SECONDS

PL-Anet Devs: nn

Locked: NO

Sync Slave: NO

Forced Mstr: NO

Audio Exp: None

Sampling: 48kHz

Num Connects: nn

*8.5 Comms Opt'n RS232 Sys-Net

*8.4 MAC Address 0004C4-000000

*8.3 Gateway 0. 0. 0. 0.

*8.2 Net Mask 255.255.255.0

*8.1 IP Address 192.168.0.2

*7.3 Point Source

*7.2 Channel Channel 1

*7.1 Ip/Op Input Channel

*6.4 Password

*6.3 Username

*6.2 Client IP

*6.1 Host IP

*5.4 Set Gateway

*5.3 Set Sub-Net

*5.2 Set IP Addr.

*5.1 DHCP Setup Use DHCP: NO

scroll character scroll character scroll character

i

DR iDRiDR

scroll day

DAY: Tuesday

scroll hours scroll minutes scroll seconds

TIME: 12

:44:41 TIME: 12:44:41 TIME: 12:44:41

scroll patches

01 Name

DR-8

AUDIO MIX PROCESSOR

The iDR-8 Setup Menus

*1 Patch Select Scroll through the available

patches and recall the one you want. This can be

useful for recalling test patches for system

checking without the need for connecting to a PC.

*2 Clock Change the time of the internal clock.

*3 Day of Week Change the day held in the

internal clock.

*4 Unit Name Give the unit a unique name so it

can be identified when connected to a PC or

network. This is important if you have more than

one iDR unit on the network.

*5 Network Setup This must be done before

connecting the unit to a PC or network using

TCP/IP. You can select automatic address

allocation by a DHCP server, or enter the IP

address and Subnet Mask manually.

*6 PPP Setup This must be done before

communicating with a modem or PC via RS232

using a dial-up connection. Enter the host and

client addresses, username and password.

*7 Monitoring Lets you select any point in any

Fader

Sidechain

Gate

Compressor

Eq

Delay

scroll channel

Output channel

scroll character scroll character scroll character

scroll character scroll character

i

DR iDR

scroll numbers scroll numbers scroll numbers scroll numbers

.168.0.2 192.168.0.2 192.168.0.2 192.168.0.2

192

scroll numbers scroll numbers scroll numbers scroll numbers

192

.168.0.1 192.168.0.1 192.168.0.1 192.168.0.1

scroll numbers scroll numbers scroll numbers scroll numbers

255

.255.255.0 255.255.255.0 255.255.255.0 255.255.255.0

scroll numbers scroll numbers scroll numbers scroll numbers

255

.255.255.0 255.255.255.0 255.255.255.0 255.255.255.0

scroll numbers scroll numbers scroll numbers scroll numbers

192

.168.0.1 192.168.0.1 192.168.0.1 192.168.0.1

Use DHCP: YES

channel for monitoring using the headphones and

rear panel monitor output. It is a convenient way

to check the audio signals without the need for a

PC and without affecting the normal operation of

the unit.

*8 Diagnostics Provides useful setup and status

information.

&HA&H

Max 16 characters

Max 16 characters

Max 16 characters

18 IDR-8 User Guide

Page 19

Accessing the iDR-8 Setup Menus

Before your PC can take control of the iDR-8 you need to set

up its unit name and communication settings. This is done

using a simple front panel menu system. Once communication

is established between the PC and iDR-8 you use the iDR

System Manager software to configure and control the unit.

*** Setup ***

*1 Patch Select

<

scroll

<

ESC ENTER

>

MENU

hold for 2 seconds

Setting the Unit Name

*** Setup ***

*4 Unit Name

audio monitor

patch select

day & clock

network setup

diagnostics

To access the menus If it is already fitted, first remove the

iDR-8 face plate by removing the 4 corner screws using the

2mm hex driver provided. This exposes the menu access keys.

Navigating the menus Press and hold the MENU key for 2

seconds until ‘***Setup***’ is displayed. Press the U and V

keys to scroll through the available menu options. Each menu

is numbered ‘*N.n’ where ‘N’ is the main menu number, and

‘n’ the sub menu. When you find the menu you want, press

ENTER. Press the U and V keys to change the value. Press

the Z ENTER and Y ESC keys to accept or decline the

changes and navigate through the sub menus. Always press

ENTER to save your changes. When you are finished, press

ESC to exit the menus.

The iDR-8 is identified to the PC or network by its unit name.

This name is displayed in the list of available units when you

open a new iDR System Manager session.

To change the unit name select menu item *4 Unit Name.

Scroll through each character using the Z ENTER and Y ESC

keys, and change the value using the U and V keys. The

name can have up to 16 characters.

Checking the Current Settings and Status

Select menu *8 Diagnostics. Scroll through the various sub

menus to view the current settings.

*** Setup ***

*8 Diagnostics

Menu *8.1, *8.2 and *8.3 display the last current IP address,

Subnet Mask and Gateway address if applicable. Make a note

of these if you need to restore them later. Note that the

address shown is likely to be temporary if the unit is working

with a DHCP server. Menu *8.4 displays the unique MAC

address belonging to the cpu card.

The ‘Num Connects’ item displays the number of connections

active via the NETWORK port. For example, an iDR-8

connected to a network with two PCs both running an active

session of iDR System Manager would report 2 connections. It

is a useful way of checking to see if the unit is being accessed.

The other information displayed includes which comms ports

are active, which audio expanders are connected, digital audio

sync status (locked, slave, forced master), and the number of

remote devices connected to the PL-Anet port.

Rebooting the iDR-8

It is necessary to reboot the iDR-8 if you make changes to the

network or PPP settings. You can do this two ways.

To avoid any unexpected audible clicks

or thumps always turn connected power

amplifiers down or off before switching the

iDR-8 or any other signal equipment on or off.

Power the unit off, then back on again, or

Press and then release the front panel CODE UPDATE switch.

This takes around a minute as the unit searches but does not

find update code. It reboots after the update search has timed

out. Note that the code is not updated in this case.

iDR-8 User Guide 19

Page 20

Getting Started – Checking the Hardware

The iDR-8 is supplied with its settings pre-configured so that you can turn it on and

immediately get audio passing through it. This can be useful when you are installing a unit

on site and need to carry out initial tests on the hardware before the custom configuration

software is loaded. This can be done without the need to connect your PC and run the iDR

System Manager software. When shipped, the iDR-8 is loaded with the DEFAULT

configuration. The iDR software provided with the unit also includes this configuration file

so that you can load it again later if you want to restore the default settings.

Signal Meters

Yellow

INPUT METERS 1-8

NOT USED

12345678

9 10111213141516

INPUT LEVEL UP/DOWN

INPUT METERS 9-16

+14dBu 4dB below clippingRed

0dBu normal level

OUTPUT METERS 1-8

Allen & Heath

Wed 13:44:08

< LEVEL >

NOT USED

12345678

OUTPUT LEVEL UP/DOWN

OUTPUT METERS 9-16

9 10111213141516

DR-8

AUDIO MIX PROCESSOR

iDR-in

AUDIO INPUT EXPANDER

iDR-out

AUDIO OUTPUT EXPANDER

The diagram above shows how the LCD, soft keys and soft

LEDs are assigned when you turn the unit on for the first time.

You can plug your test source such as a music CD into the XLR

inputs, and route the XLR outputs to your system amplifiers.

You should see the source signal displayed on the left hand

side soft LEDs. Note that the input preamp gains default to

0dBu line level sensitivity with pad selected and phantom

power off. To properly test microphone sources you need to

run iDR System Manager software and correctly set the gains.

Green

-24dBu signal present

Fader off

I/P1 LEV 0

Fader 0dB

I/P1 LEV 92

Fader +5dB

I/P1 LEV 100

The channel faders default to fully off. The soft keys are

assigned as level up/down selects to move the input and

output channel faders up and down. Press the soft key for the

channel you want. Now use the two middle keys to scroll the

volume up or down. These time out after 2 seconds of

inactivity. You should see the level displayed as a bar and

number on the LCD display.

To get audio to pass through the unit you need to raise both

the input fader and the required output fader. In this default

configuration all inputs are routed through the matrix to all

outputs. You can use one input to test each output by raising

the output levels in turn. Similarly, you can use one output to

test all input sources. The right hand side soft LEDs display

output signal level.

The levels can be adjusted from ‘0’ (off) to ‘100’ (+5dB boost).

To set the fader to its 0dB unity position raise the level bar until

it reads ‘92’. Note that all the channel processing such as

equalisers and compressors is set flat or out. If you set both

the input and output levels to ‘92’ then you should get 0dB

unity gain through the unit.

With the face plate removed you can use the Setup menus to

listen to selected points in the channels using the stereo

monitor and headphones outputs, adjust the time and day

setting, and enter the communication settings ready to connect

your PC.

For information on configuring the system run the iDR System

Manager software and refer to its Help file.

20 IDR-8 User Guide

Page 21

Communicating with the iDR-8

The iDR-8 is configured using a PC running the Allen & Heath

Windows™ iDR System Manager application.

You need to connect your PC to the iDR-8. To get them to

communicate you must first access the front panel Setup

menus and set up a few communications settings. You also

need to set up your PC to work with these settings.

The iDR-8 communicates using well established computer

communication methods. Full details are provided in the next

section. There are two ways to connect your PC to the iDR-8 :

Network Port

This uses a TCP/IP connection over Ethernet. You can connect

direct to the network port on your PC or via a network, using a

standard CAT5 network cable.

Your PC must have a network port or card fitted. Check that a

suitable port is available.

You need to set up a unique IP address for the iDR-8 unit

using the front panel Setup menus. You should check that

your PC uses its own unique but related IP address. This may

involve making changes to your PC LAN network settings. We

advise that you contact your network administrator or IT

manager if you are unsure how to do this.

The network connection is very fast and reliable and is

therefore recommended for configuring the iDR system.

RS232 COM Port

You can communicate with the iDR-8 via the COM1 or COM2

RS232 serial port on your PC.

NOTE: By the nature of RS232 serial communication, it is

much slower than the network connection. For this reason we

recommend that you use it only when absolutely necessary, or

when dialing up the unit using a modem via a telephone line to

remotely interrogate the iDR-8.

To do this you need to set up a PPP ‘dial-up connection’ on

your PC. This is similar to using your PC to dial into a remote

Internet server provider or a modem over a telephone line.

The iDR-8 has default PPP settings already set. You can use

these to create the dial up connection on your PC. If you prefer

or have reason to, you can change these using the front panel

Setup menus.

To work with the dial-up connection you must first have a

modem driver installed on your PC. If a suitable driver is not

already installed you need to add one using the Windows™

Phone and Modem Options item.

Once installed, you can create and name the dial-up

connection. It is held on your PC for future connection. Once

the connection is made you open up the iDR System Manager

and type in the Host IP Address set up on the iDR-8.

The type of RS232 cable you use depends on whether you are

connecting to the iDR-8 front or rear RS232 port, and whether

you are connecting to your PC or direct to a modem.

iDR-8 User Guide 21

Page 22

Communicating Using A TCP/IP Connection

The iDR-8 uses TCP/IP to communicate with a PC or

distributed network via a CAT5 Ethernet link. It can also

communicate over a dial-up connection using PPP via its

RS232 port. The faster Ethernet connection is recommended

for iDR configuration purposes. Note that the front panel

RS232 port is intended for operating code update. The rear

panel RS232 port is intended for remote interrogation of the

unit via a modem.

You can connect the iDR-8 directly to your PC using the

Ethernet connection. Alternatively you can plug into a network

so that any networked PC workstation running appropriate

Allen & Heath software can control it. You can have several

iDR-8 units plugged into the same network. This provides the

most flexible solution in today’s world of networked technology.

DR-8

AUDIO MIX PROCESSOR

Each iDR-8 unit must have its own unique IP address. It needs

to be related to the PC and network address ranges. It must be

within the range of addresses allowed on the Subnet. It must

not conflict with the addresses of other units plugged into the

network. It is also possible that the PC you use to configure

the iDR-8 is also used with a network at your place of work. If it

is served by a DHCP server then it is likely that it does not have

its own permanent IP address as this is leased by the server.

For these reasons it is very important that you take care when

choosing and setting up the IP addresses.

CAT5

TCP/IP

DIRECT

NETWORK

TCP/IP

DR-8

AUDIO MIX PROCESSOR

DR-8

AUDIO MIX PROCESSOR

Some networking terms explained:

LAN (Local Area Network), the physical

network that links many PCs and related devices

in the same building.

Ethernet, the most popular worldwide

network system. It is defined by the IEEE802.3

standard and implemented over twisted pair

cable.