Page 1

ALLEN&HEATH

iDR10

iLive System DSP MixRack

USER GUIDE

Publication AP6525

Page 2

Limited Two Year Warranty

This product has been manufactured in the UK by ALLEN & HEATH and

is warranted to be free from defects in materials or workmanship for a

period of two years from the date of purchase by the original owner.

To ensure a high level of performance and reliability for which this

equipment has been designed and manufactured, read this User Guide

before operating.

In the event of a failure, notify and return the defective unit to ALLEN &

HEATH or its authorised agent as soon as possible for repair under

warranty subject to the following conditions:

Conditions Of Warranty

1. The equipment has been installed and operated in accordance with

the instructions in this User Guide

2. The equipment has not been subject to misuse either intended or

accidental, neglect, or alteration other than as described in the User

Guide or Service Manual, or approved by ALLEN & HEATH.

3. Any necessary adjustment, alteration or repair has been carried out

by ALLEN & HEATH or its authorised agent.

4. The defective unit is to be returned carriage prepaid to ALLEN &

HEATH or its authorised agent with proof of purchase.

5. Units returned should be packed to avoid transit damage.

In certain territories the terms may vary. Check with your ALLEN &

HEATH agent for any additional warranty, which may apply.

This product complies with the European Electromagnetic

Compatibility directives 89/336/EEC & 92/31/EEC and the

European Low Voltage Directives 73/23/EEC & 93/68/EEC.

Any changes or modifications to the power supply unit not approved

by Allen & Heath could void the compliance of the product and

therefore the users authority to operate it.

iDR10 User Guide AP6525 Issue 1.

Copyright © 2008 Allen & Heath. All rights reserved

Manufactured in the United Kingdom by Allen & Heath Limited

Kernick Industrial Estate, Penryn, Cornwall, TR10 9LU, UK

http://www.allen-heath.com

2 iDR10 User Guide

Page 3

Important Safety Instructions

WARNINGS - Read the following before proceeding :

CAUTION

ATTENTION: RISQUE DE CHOC ELECTRIQUE – NE PAS OUVRIR

Read instructions: Retain these safety and operating instructions for future reference. Adhere to

all warnings printed here and on the equipment. Follow the operating

instructions printed in this User Guide.

Do not remove covers: Operate the equipment with its covers correctly fitted. Refer any service work

on the equipment to competent technical personnel only.

Power sources: Connect the equipment to a mains power supply only of the type described

in this User Guide and marked on the rear panel. Use only the power cord

with sealed mains plug appropriate for your local mains supply as provided

with the equipment. If the provided plug does not fit into your outlet consult

your service agent for assistance.

Power cord routing: Route the power cord so that it is not likely to be walked on, stretched or

pinched by items placed upon or against it.

Grounding: Do not defeat the grounding and polarisation means of the power cord plug.

Do not remove or tamper with the ground connection in the power cord.

WARNING: This equipment must be earthed.

Water and moisture: To reduce the risk of fire or electric shock do not expose the equipment to

rain or moisture or use it in damp or wet conditions. Do not place containers

of liquid on it which might spill into any openings.

Ventilation: Do not obstruct the ventilation slots or position the equipment where the air

flow required for ventilation is impeded. If the equipment is to be operated in

a flightcase ensure that it is constructed to allow adequate ventilation.

Heat and vibration: Do not locate the equipment in a place subject to excessive heat or direct

sunlight as this could be a fire hazard. Locate the equipment away from any

devices which produce heat or cause excessive vibration.

Servicing: Switch off the equipment and unplug the power cord immediately if it is

exposed to moisture, spilled liquid, objects fallen into the openings, the

power cord or plug become damaged, during lightening storms, or if smoke,

odour or noise is noticed. Refer servicing to qualified technical personnel

only.

Installation: Install the equipment in accordance with the instructions printed in this User

Guide. Use the equipment connections for their intended purpose only.

iDR10 User Guide 3

Page 4

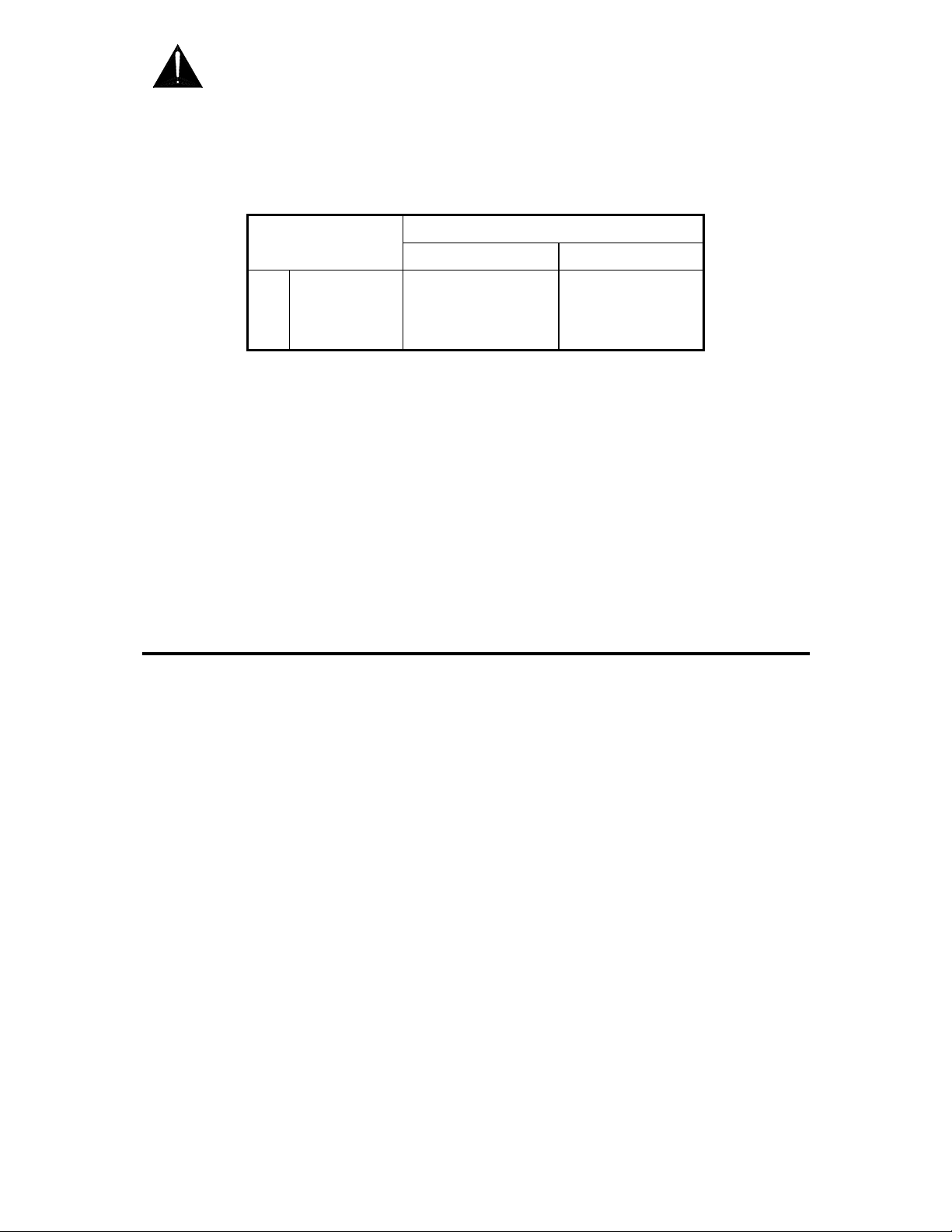

Important Mains plug wiring instructions.

The unit is supplied with a moulded mains plug fitted to the AC mains

power lead. Follow the instructions below if the mains plug has to be

replaced.

The wires in the mains lead are coloured in accordance with the

following code:

L LIVE BROWN BLACK

N NEUTRAL BLUE WHITE

E EARTH GND GREEN & YELLOW GREEN

The wire which is coloured Green and Yellow must be connected to

the terminal in the plug which is marked with the letter E or with the

Earth symbol. This appliance must be earthed.

The wire which is coloured Blue must be connected to the terminal in

the plug which is marked with the letter N.

The wire which is coloured Brown must be connected to the terminal

in the plug which is marked with the letter L.

Ensure that these colour codes are followed carefully in the event of

the plug being changed.

Precautions

TERMINAL

WIRE COLOUR

European USA/Canada

Damage : To prevent damage to the equipment cosmetics, avoid placing heavy

objects on the unit, scratching the surface with sharp objects,

subjecting the unit to rough handling and vibration.

Environment : Protect from excessive dirt, dust, heat and vibration when operating

and storing. Avoid tobacco ash, smoke, drinks spillage, and

exposure to rain and moisture. If the equipment becomes wet, switch

off and remove power immediately. Allow to dry out thoroughly

before using again.

Cleaning : Avoid the use of chemicals, abrasives or solvents. The equipment is

best cleaned with a soft brush and dry lint-free cloth. If the ventilation

grilles become blocked with dust use a vacuum cleaner to suck the

dirt out. Do not remove the cover to clean the unit.

Transporting : The equipment should be transported in the original packing or

purpose built flightcase to protect it from damage during transit.

or

Cables: Plan the location of the equipment so that the connecting cables are

not fully extended. Full extension of the cables can stress the

equipment and cables and may result in undesired performance.

Ensure that the cables are located such that they cannot be stood on

or tripped over.

Modules: Do not remove the modules from the unit while power is applied.

4 iDR10 User Guide

Page 5

Introduction

This is the user guide for the Allen & Heath iDR10 ‘MixRack’. We recommend that you

read this fully before starting. Included is information on installing, connecting and

operating the unit. Whilst we believe the information in this guide to be reliable we do

not assume responsibility for inaccuracies. We also reserve the right to make changes in

the interest of further product development.

We are able to offer further product support through our worldwide network of approved

dealers and service agents. You can also access our Web site (www.allen-heath.com)

for information on our company and its pedigree, our full product range and our design

philosophy. To help us provide the most efficient service please keep a record of your

unit serial number, and date and place of purchase to be quoted in any communication

regarding this product. The serial number is located on the rear panel.

For further information on using the iLive system please refer to:

iLive System Reference guide AP6526

iLive Getting Started Guide AP7260

Allen & Heath Resource CD AP4742

Allen & Heath web site www.allen-heath.com

Firmware Release Notes Downloadable from web site

Help file within system firmware

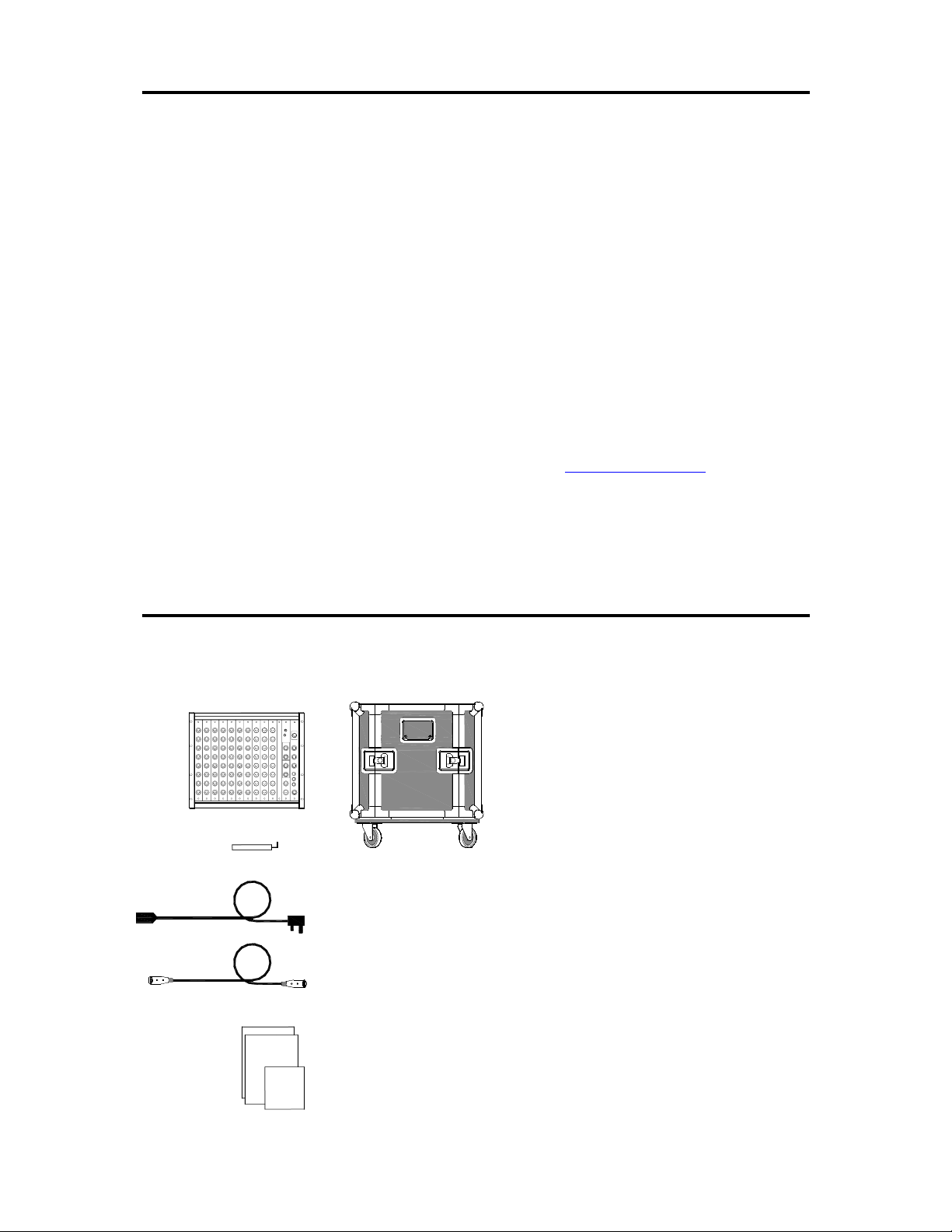

Check the packing contents

Retain the product packing should you need to ship the product in future. You should find the

following components:

ALLEN&HEATH iDR-64

MIX ENGINE

1x IEC MAINS LEAD with moulded plug. Check that the plug

is suitable for connection to your local mains supply.

iDR10/n where n = mains voltage 120 (USA), 220 (EU), 240

(UK)

1x CAT5 CABLE 1.8m RJ45 EtherCon connections.

Part number AH7001. Connects the iDR10 to the iLive

Surface or another MixRack. Note that the second cable

required is shipped with the iLive Surface.

DOCUMENTATION including the User Guide AP6525, Safety

Sheet AP3345, Registration Card AP3594, and sticker

AP4943.

1x iDR10 MixRack. Depending on the order

configuration, the MixRack is either shipped

in a carton or a touring grade, shock

mounted flightcase.

1x MODULE EXTRACTOR TOOL AA6869.

This is fitted in clips at the rear of the

flightcase or packed in the carton.

iDR10 User Guide 5

Page 6

Welcome to the iDR10 MixRack

The iDR10 is the heart of the iLive mixing system. It is called the ‘MixRack’ as it houses the iDR-64

DSP mix engine, the CPU module which manages and allows remote control of the mix functions,

and the RAB (remote audio) module which provides up to two audio networking interfaces (currently

both EtherSound). It is the mixer itself, configurable and controllable via Ethernet using an iLive

Surface or PC. It is called the iDR10 because it includes 10 additional slot positions to fit the required

combination of audio input and output modules. This means the MixRack may be positioned on

stage near its sources and controlled remotely from up to 100 metres away using a control surface

connected via a CAT5 cable. Local audio required at the mix position can be transported to and from

the MixRack via a second CAT5 cable, therefore doing away with the need for a bulky traditional

copper multicore snake. Audio may be further distributed around the venue using the EtherSound

audio networks. Systems may be linked for split FOH/Monitor/Recording applications using

EtherSound as a digital mic splitter.

The iDR10 features a 64 input x 32 mix bus architecture with full processing on all input and mix

channels. You do not need to allocate or share processing. The iDR-64 ‘Rack Extra’ module

provides enough DSP for all the channel processing to be available all the time, together with 8

stereo internal effects devices. Input processing includes high-pass filter, noise gate, parametric EQ,

compressor, limiter/de-esser and delay. Mix processing includes both parametric and graphic EQ,

compressor, limiter and delay. The module is called ‘RackExtra’ because it includes a virtual 8 slot

rack which can be loaded with up to 8 additional processors from a library of many emulations of

high quality effects devices. The effects can add an extra 8 ‘short returns’ complete with parametric

EQ bringing the total number of sources feeding the mix to 72.

The user has a choice of input and output modules to fit into the 10 available MixRack card slots.

The same module types may be loaded into the 4 slots available at the rear of the iLive surface.

Unused slots may have blanking plates fitted. Each module handles 8 signals, either inputs or

outputs. These modules may be fitted anywhere within the available MixRack and Surface card slots.

Choices currently available include analogue mic/line inputs, XLR line out, and digital inputs and

outputs with a variety of optional formats including SPDIF, optical, AES, ADAT and more.

The iDR10 does away with the need for cumbersome outboard processing and I/O racks letting you

configure a full spec mix system in a compact footprint comprising just the MixRack and Surface. If,

however, you wish to insert favourite outboard devices you can do this by configuring any number of

channel and mix inserts patched to sockets anywhere in the system. Virtual patchbays are provided

too letting you map any input source to any channel, and any output signal to any socket.

The RAB module provides a local headphones output, the networked audio options and digital clock

source if synchronisation with external devices is required. Up to 2 EtherSound network card options

may be fitted to transport audio to and from locations remote from the MixRack. ESA replaces the

traditional analogue multicore providing audio at the surface and distributed to other EtherSound

equipped break in/out boxes. ESB provides a digital mic splitter for FOH/Monitor systems, multitrack

recording and system expansion.

The CPU module allows TCP/IP over Ethernet control from network devices such as the iLive Surface

or PC running iLive application software. A 3-port switcher is built in for control from multiple devices

accessing the same network, for example both a Surface and a laptop. The module also allows

control via MIDI and PL-Anet for the Allen & Heath PL Series remote controllers.

The iDR10 is well equipped for the stage environment with a lamp socket for low lighting conditions,

LED status indicators for phantom power, mute and PAFL active, ideal for helping the stage tech find

the right socket. The MixRack may be shipped in a touring grade, shock mounted flight case, and be

configured to include two internal universal voltage power supply modules, one for redundant supply

backup. Full protection and thermal management is provided.

Sound quality has been one of the key objectives behind the design of the iLive system. The

architectural design and choice of components ensure a high performance, very low latency system.

DSP algorithms developed by Allen & Heath over many years have been tailored for the demands of

live sound. The iDR10 uses a top of the range preamp design and features very high headroom

throughout the signal path to cope with the busiest and most dynamic live mix.

Please take the time to read through the rest of this guide before starting. Also refer to the iLive

System Reference Guide which has more information of configuring and using the iLive system.

6 iDR10 User Guide

Page 7

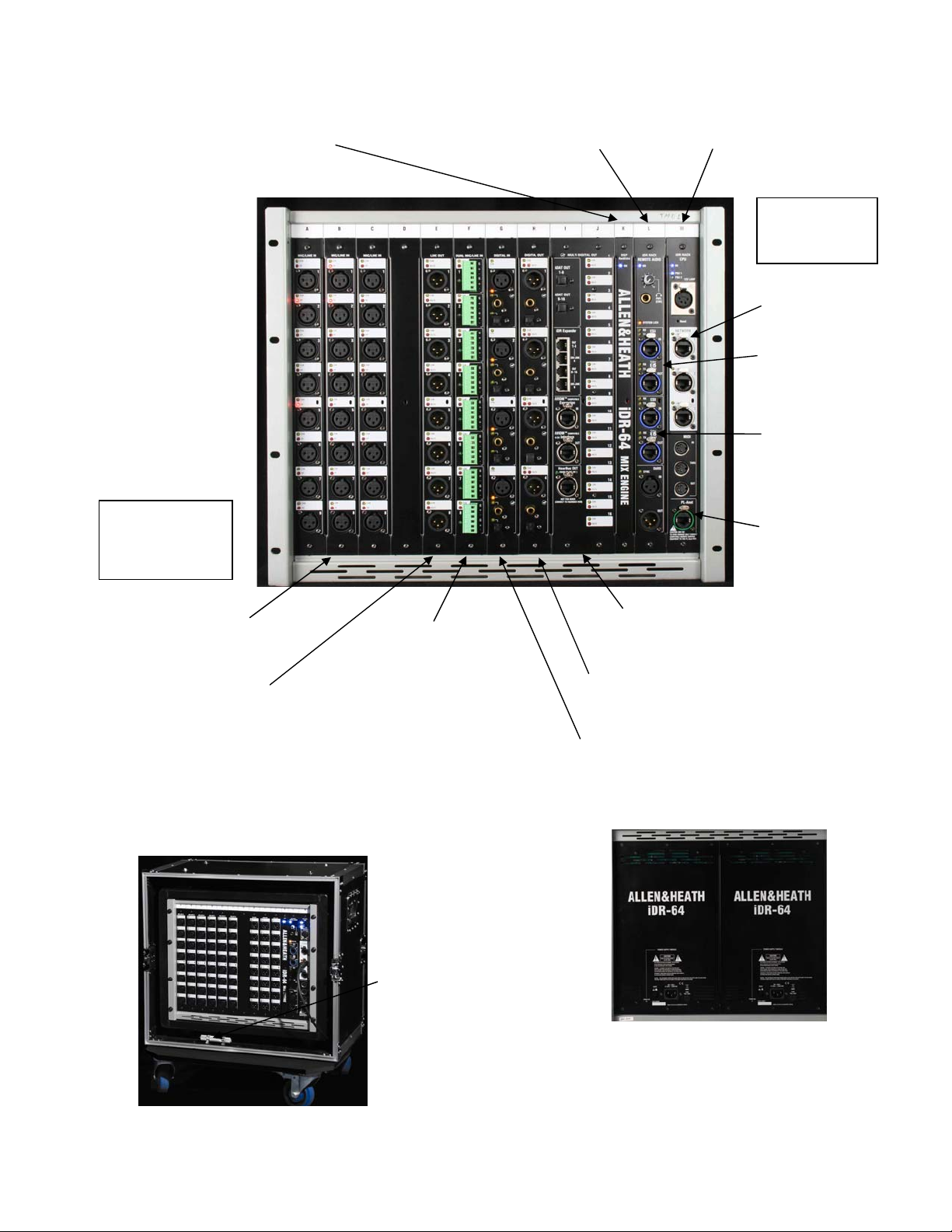

DSP ‘RackExtra’ module

The DSP mix engine, the heart

of the iLive mixing system.

64x32 mix architecture plus 8x

internal FX racks.

REMOTE AUDIO module

With system clock, headphones

and remote audio distribution. Fit

up to 2 audio network option

cards. EtherSound interface is

available here.

CPU module

Manages the MixRack

system and allows remote

control via Ethernet, MIDI

and PL-Anet. Also provides

iDR10

MixRack

Audio modules

10 slots available.

Slots A to J

MIC/LINE IN module

8x mic preamps with remote

gain control.

LINE OUT module

8x balanced line out sockets.

Note: You can choose any combination of input, output and blank

modules to load into the 10 available slots. The format above shows all

the options available at the time of print and is not representative of a

typical user setup. The photo below shows a popular configuration with

48 mic inputs and 24 line outputs loaded. Further inputs and outputs

would typically be available at the rear of the surface.

DUAL MIC/LINE IN module

Connect 16x inputs on screw

terminal plugs. 8x mic

preamps each with remote

selection of A and B inputs.

System

modules

Slots K, L, M

Ethernet switch

3x network ports.

ESA

EtherSound digital

snake. Surface

and break out/in

audio.

ESB

EtherSound digital

mic split, system

expansion, record.

PL-Anet

Connect to Allen &

Heath PL-Series

remote controllers.

MULTI DIGITAL OUT module

16x outputs in digital format. ADAT, Aviom,

HearBack, iDR Expander. Uses 2 slots.

DIGITAL OUT module

4x pairs of digital outputs simultaneously

available AES, SPDIF or OPTO.

DIGITAL IN module

4x pairs of digital inputs selectable

either AES, SPDIF or OPTO.

FLIGHT CASE

Touring grade case on

wheels. Shock mounted

rack. Front and rear

covers.

Module extractor tool

To help pull out modules if you

need to reconfigure the module

format.

Note: Do not remove or plug

in modules while power is

applied. The iLive system is not

‘hot pluggable’.

POWER SUPPLY module

Universal mains input. One

required. Fit second as redundant

supply backup.

iDR10 User Guide 7

Page 8

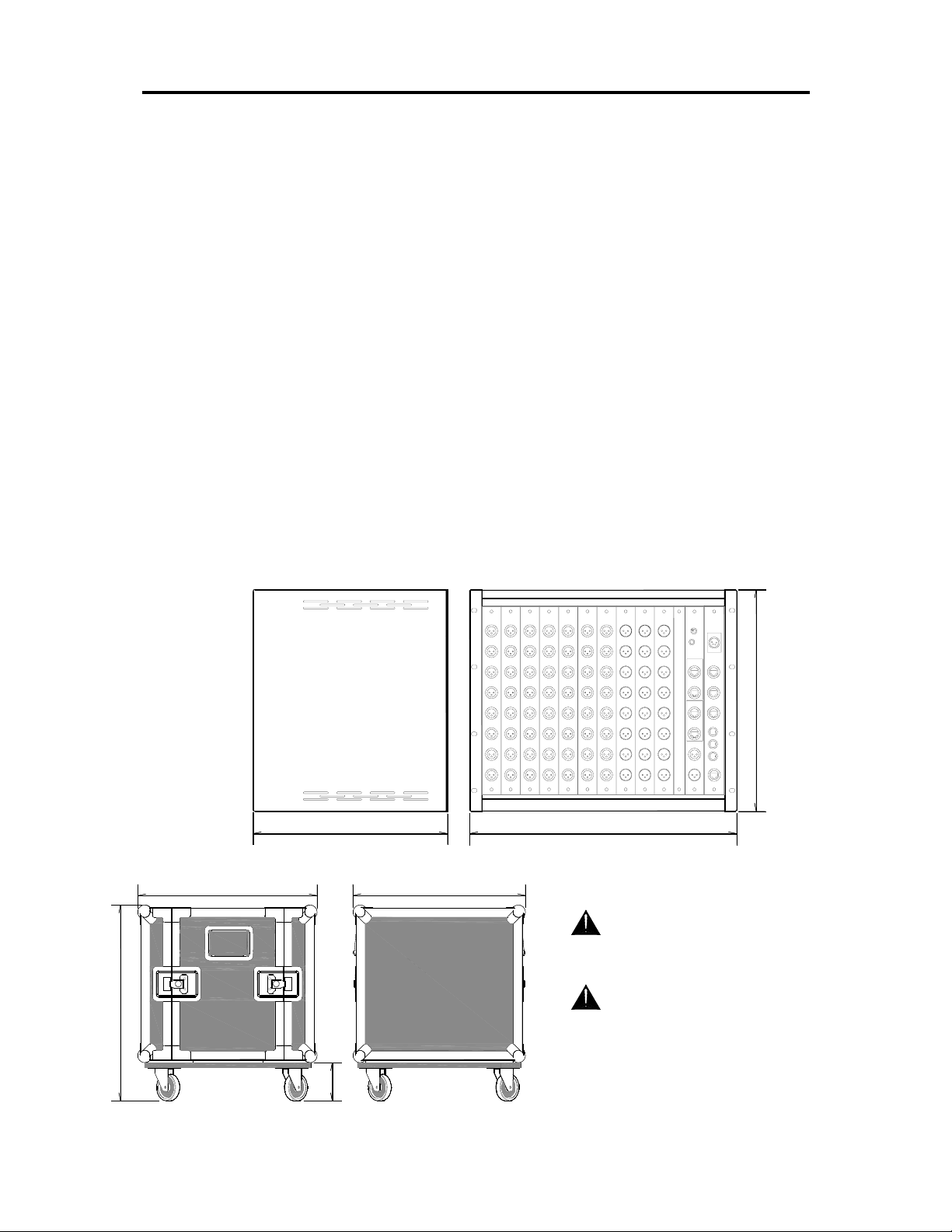

Installation

Free standing

The iDR10 can be operated as a freestanding unit for shelf or floor operation. Ensure adequate air

flow around the unit. It must not be covered in any way. Always stand the unit on a firm flat surface

away from any soft furnishings or carpet.

Rack mounting

The iDR10 is designed as a 19 inch rack mount unit and will occupy 9U of rack space. Ensure

natural convection of airflow around the unit by allowing good ventilation below, in front of and

behind the unit. Rack equipment known to produce a significant amount of heat should not be

mounted directly below the unit. Forced convection by means of a rack mounted fan-tray may be

desirable in situations where space is restricted and the ambient air temperature is high.

Flight casing

The iDR10 may be ordered with a suitable touring grade flight case. If you have a case made we

recommend that you use only a professional grade specification with shock mounted internal rack

frame. Ensure adequate ventilation in front of and behind the unit when it is powered. Make sure the

wheel locks are engaged when the unit is stationary.

Cables

Make sure the cables are not stretched in any way and are routed to avoid becoming kinked or

damaged. Allow enough service loop for access and removal of the unit. Ensure all connectors are

fully plugged in and locked.

Dimensions and weights

SIDE FRONT

669 mm / 26.34"

730 mm / 28.75"

142 mm / 5.6"

643 mm / 25.3"

HEATHALLEN

ALLEN&HEATH iDR-64

MIX ENGINE

482 mm / 19"350 mm / 13.8"

MIXRACK WEIGHT = 26kg / 57lb

Do not obstruct the ventilation

slots. Ensure adequate air flow

around the iDR10.

Ensure proper grounding. Do

not remove the IEC mains cord earth

(ground) connection.

400 mm / 15.75" 9U

MIXRACK IN FLIGHTCASE = 68kg / 150lb

MIXRACK IN CARTON = 27kg / 60lb

8 iDR10 User Guide

Page 9

Connecting the system

The iDR10 requires two main system connections, both using CAT5 cables. NETWORK connects a

remote controller such as the iLive Surface or a laptop. ESA connects audio to and from external

locations such as the Surface and EtherSound equipped break in/out boxes. The optional ESB port

can be used to connect audio between systems such as FOH/Monitor, broadcast or recording. iLive

systems are shipped with 1.8 metre UTP CAT5 cables fitted with EtherCon locking connectors as

standard. Allen & Heath can supply an 80 meter drum of approved cable (part number AH7000) if the

Surface is located remote from the MixRack. Two of these are required to connect control and audio

between the MixRack and the Surface. One is required to connect audio between the MixRack and

another remote rack.

Ethernet (control network) cable

A 3 port Ethernet switch is built into the CPU module allowing connection of more than one control

device, for example a Surface and a laptop. Cables up to 100 metres (330 feet) may be used. Plug

the CAT5 cable into any NETWORK port. Standard Ethernet hardware may be used to extend or

route this connection if required.

Note: Plug only one CAT5 cable to connect between the MixRack and Surface. You may plug this

into any one of the three network ports available. Do not connect a second cable for redundancy.

Third party systems are available to extend the connection or provide dual redundancy.

EtherSound (audio network) cable

Plug the MixRack ESA OUT to the Surface ESA IN to connect the PAFL, talkback and rear panel

input/output signals (ES channels 1 to 32) to and from the Surface. Plug the Surface ESA OUT to

external break in/out device ES IN to route signals to and from further locations if required (ES

channels 33 to 62). For information on using the optional ESB network refer to the panel descriptions

and application diagrams later in this user guide.

Note: Connect only one EtherSound cable between two devices. Do not connect both IN to OUT

and OUT to IN. The terminology ‘IN’ and ‘OUT’ refers to the clock master and not direction of audio.

Each EtherSound cable carries 64 channels of audio in both directions.

Note: The EtherSound standard is maintained and licensed by Digigram who recommend that only

the cable types and network components tested and approved for EtherSound are used. This is

most important to ensure reliability when using longer cable lengths approaching the 100 metre (330

feet) maximum. For further information on compatibility please refer to the EtherSound web site:

www.ethersound.com/technology/compatibility.php

.

NETWORK

CPU

RAB

CONTROL (ETHERNET)

AUDIO (ETHERSOUND)

ESA IN

Connect RACK ESA OUT to SURFACE ESA IN

NETWORK

ESA OUT

ESB OUT

ETHERSOUND MIC SPLIT / SYSTEM EXPAND

iDR10 User Guide 9

Page 10

Power up the system

Connect mains power

An IEC mains power cord with moulded plug suitable for

your territory is provided for each power supply module fitted

to the iDR10. Refer to your Allen & Heath agent if the

incorrect type has been provided. The iDR10 uses universal

voltage power supplies that accept world wide mains

sources from 100 to 240V.AC 47 to 63Hz. Make sure the IEC

plugs are pressed fully into their panel sockets and the

cables are clipped into the retaining clips to protect them

from accidental disconnection.

Note: To ensure operator safety, connect only to an

approved and properly grounded mains source. Do not

remove the ground connection in the mains cord.

Note: Read and understand the warnings in the safety

sheet supplied with the iDR10 and printed on the power unit

panel.

Note: It is good practice to connect both the MixRack and

the Surface to the same mains power ring or feed, and to use

a UPS (uninterruptible power supply) as a backup in critical

applications where there is any risk of mains or generator

power being interrupted.

MAINS FUSE - In the event of a fuse failure replace only

with the correct type and rating as indicated on the rear

panel. If the replacement fuse fails again, switch off and refer

to your Allen & Heath service agent.

ON/OFF switch - Press to toggle mains power on or off.

Booting up the system

Note: Always turn the MixRack on first, then the iLive Surface. Powering the

Surface up first may result in failure to connect or loss of EtherSound audio at the

surface. Power off the surface before turning off the MixRack.

1. Connect mains power.

2. Plug in the Control and Audio CAT5 cables.

3. Switch on the MixRack power.

4. Then switch on the Surface power.

While searching for the network connection between the MixRack and Surface after

power up, the NETWORK Lnk/Act indicator flashes at a slow rate for a few seconds.

Once connection is successfully made the indicator flashes at a steady fast rate. The

ES RX and TX indicators should flash at a steady fast rate soon after boot up.

The MixRack and Surface audio outputs are isolated from the connected equipment

during boot up using protection relays to prevent power up thumps. The connector

MUTE indicators light while the outputs are isolated. After around 15 seconds the

relays switch in and audio is presented to the outputs with the settings as they were

the last time the system was powered down.

The iLive system remembers its last settings on power up.

Note: For firmware versions up to 1.2 it is necessary to reboot the surface if the

network connection has become lost or its cable disconnected. To reboot the

surface switch its mains power off then on.

10 iDR10 User Guide

Page 11

Module options – Analogue inputs and outputs

MIC/LINE INPUT part M-MICIN-A

This is the main audio input module for the iLive

system. It provides 8x high performance analogue

input preamps for microphone and line level signals.

The front end gain, pad and phantom power are

remote controlled via the network connection from

the Surface or PC. The settings may be recalled as

part of the iLive system memories.

CHK Yellow indicator follows the PAFL function. It

lights when the channel it is associated with is

currently being PAFL’d at the surface or PC. This

provides a quick way to identify which sockets are

mapped to the channels, for example when the FOH

engineer wants to indicate to the stage tech which

connection to check.

Note: CHK will light whether the preamp is the main

channel source, insert return or mix external input for

the channel being PAFL’d. For example, four may

be lit if you PAFL a stereo input channel which has

an insert assigned.

PP Lights when phantom power voltage is detected

at the XLR input socket. This will light whether the

voltage is sourced internally from within the MixRack,

or externally via the cable plugged in.

INPUT XLR Balanced audio input with wide gain

range accepting signals from -65dBu to +30dBu.

Gain is remote controlled and has a 1dB resolution

and range of 80dB including 25dB pad. The

preamps feed the iLive mix engine through 24bit, low

noise, low latency converters. The preamp gain is

automatically set for +4dBu or -10dBV operating

level if assigned as an insert.

DUAL MIC/LINE INPUT part M-DUALIN-A

An 8 channel input module to connect up to 16

microphone or line level signals. As described

above but with remote controlled selection between

two inputs A or B per channel. Connection is via

screw terminal Phoenix plugs (supplied), ideal for

installed applications or where external stage boxes

are used. The green indicator lights when the B

input is selected.

Analogue LINE OUTPUT part M-LINEOUT-A

8x Balanced line level outputs operating at +4dBu

and with +22dBu maximum output. Any signal

whether a mix output, direct output, insert send or

MixRack input may be assigned to any socket.

CHK Lights when the socket is associated with a

channel currently being PAFL’d, whether an output

or insert send.

MUTE A red LED lights when the output is muted.

Note: The line outputs are relay switched to protect

speaker systems from power on/off thumps.

iDR10 User Guide 11

Page 12

Module options – Digital inputs and outputs

DIGITAL INPUT part M-DIGIN-A

This module provides 8 digital inputs arranged as

four pairs. Each offers a choice of digital format -

AES, SPDIF or optical (TOSLINK). For each pair,

one format is chosen and used at a time. The

selection is made using the iLive Surface or PC

application channel SEL function. One of 3 yellow

LED indicators lights to show which input format is

selected.

Blanking plugs are provided for unused optical

sockets to prevent interference and dust

contamination.

CHK Yellow indicator follows the PAFL function. It

lights when one or both channels of the input are

associated with the channel currently being PAFL’d

at the surface or PC. This provides a quick way to

identify which sockets are mapped to the channels,

for example when you want to quickly find which

sockets to plug your digital playback device into.

Note: CHK will light whether the input is the main

channel source, insert return or mix external input for

the channel or mix being PAFL’d. For example, three

may be lit if you PAFL a stereo input channel which

has an insert assigned.

DIGITAL OUTPUT part M-DIGOUT-A

Provides 8 digital outputs arranged as four pairs.

Each offers 3 digital output formats – AES, SPDIF

and optical (TOSLINK). All three formats are

available at the same time. For example, you could

record the same material via SPDIF and also AES to

two different recording devices at the same time.

Blanking plugs are provided to prevent dust

contamination and light spill from unused optical

sockets.

CHK Yellow indicator follows the PAFL function. It

lights when one or both channels of the output are

associated with the channel currently being PAFL’d

at the surface or PC. This provides a quick way to

identify which sockets are mapped to the channels,

for example when you want to quickly find which

sockets to feed your digital recording device.

Note: CHK will light whether the socket is the main

mix output or an insert send. For example, three

may be lit if you PAFL a stereo mix which has an

insert assigned.

MUTE A red LED lights when an output is muted.

12 iDR10 User Guide

Page 13

Module options – Digital outputs

DIGITAL MULTI OUT part M-MULTI-OUT-A

This module provides 16 outputs and therefore uses

two slots at the MixRack or Surface. Use the iLive

OUTPUTS patch bay to map any signal to any output

socket. The module presents these outputs

simultaneously to a variety of different multi-channel

digital formats:

ADAT There are two ADAT optical light pipe

outputs, each carrying 8 audio channels. Use these

to connect to ADAT equipped devices such as

multitrack recorders.

Note: One module allows up to 16 tracks of

recording. Fit two for 24 or 32 tracks. Note that you

can fit only one MULTI OUT module to the iLive

Surface in slots A and B. This provides up to 16

tracks at the surface. For multitrack recording up to

64 tracks consider using a PC fitted with the optional

Digigram LX6464ES EtherSound PCI card interfaced

to the MixRack via the ESB option. For more

information see www.digigram.com/products/

iDR Expander Two 8 channel proprietary iDR

expander ports are provided. Connect these to Allen

& Heath iDR output expander units (part of the iDR

installation range) for remote analogue balanced

XLR line outputs up to 300 metres (900 feet) away

using two CAT5 cables per unit. The DR-LINK cables

carry the control to these units.

AVIOM An Aviom compatible interface is provided

to feed the 16 channels of an Aviom personal

monitor mixing system, popular with many live

mixing installations such as houses of worship.

Connect OUT to the Aviom system using a CAT5

cable. IN allows expansion to add another 16

external signals to the feed. Signals may be

configured for mono or stereo operation within the

iLive operating system. For more information about

the Aviom system see web site www.aviom.com/

HearBus OUT The module also supports the Hear

Technologies Hear Back personal monitoring system

which distributes up to 8 signals using a single CAT5

cable. For more information see web site

www.heartechnologies.com/hb/hearbackintro.htm

CHK Yellow indicator follows the PAFL function. It

lights when the signal associated with the output is

currently being PAFL’d at the surface or PC. This

provides a quick way to check the socket patching,

for example to identify which signals are feeding

each channel of a personal monitoring system.

MUTE A red LED lights when the output is muted.

iDR10 User Guide 13

Page 14

Module options - System

iDR-64 RackExtra DSP

This is the DSP mix engine, the ‘brains’ of the iLive

system. The DSP (Digital Signal Processing)

handles the audio signal processing such as EQ,

dynamics, delays and mixing. The more recent

‘RackExtra’ version includes additional DSP to

handle up to 8 internal stereo effects ‘racks’. Older

systems with 2 effects may be upgraded to this

version by swapping out the iDR-64 DSP module.

Note: The DSP is in the MixRack not the Surface.

Audio in the Surface is converted to digital and

transported via EtherSound to the MixRack where it

is processed by the iDR-64 RackExtra module. The

surface cannot be used as a stand alone mixer

without the iDR10 or iDR0 rack which houses this

module.

REMOTE AUDIO (RAB) part M-RAB-B, C or D

Handles the audio clock, headphones signal and

interface for up to two digital audio networks.

HEADPHONES A built-in headphones amplifier

with volume control and ¼” output socket lets you

listen to the signal currently selected using the PAFL

function. This is the same signal presented to the

Surface headphones / local monitor system.

SYSTEM LOCK The yellow LED lights to indicate

digital audio sync lock. If it is not lit check that the

correct system Audio Clock Source is selected.

Setting audio clock source (Surface TouchScreen

MIXRACK / Mixer Pref / Audio Sync) If the iDR10 is

part of a single rack system, or the master in a linked

FOH/Monitor system then set the Clock Source to

‘Internal’. If it is the slave getting its channel preamp

sources via EtherSound network ESB then set it to

‘ESB’. If it is being synchronized to an external

DARS source then set it to ‘DARS’.

ESA and ESB audio network options - The iDR10

may be ordered with none, one or both EtherSound

option cards fitted:

Part M-RAB-B 1x ES (ESA)

Part M-RAB-C no ES

Part M-RAB-D 2x ES (ESA and ESB)

Use ESA to transport audio to and from the iLive

Surface and/or other EtherSound equipped devices

such as break out / break in boxes and speaker

controllers. Use ESB to transport audio between iDR

racks and other EtherSound equipped devices such

as the Digigram LX6464 PCI multitrack recording

card.

Note: With no ES option fitted you can still connect

the PAFL monitor and talkback signals to the iLive

Surface using analogue connections.

14 iDR10 User Guide

Page 15

Module options - System

Restore the factory default mapping of ESA if it has been previously changed for

other EtherSound applications using an external PC running the Auvitran ES Monitor

or similar software. This automatically reboots the iLive system, reconfiguring

(restoring) the current I/O setting assignments.

Set the system audio clock

source to Internal, ESB or

DARS sync input.

Note: Refer to the iLive

System Reference Guide for

more information on

EtherSound and how to

configure it.

Refer to the diagrams later in

this guide for applications

using EtherSound

NETWORK

CPU

RAB

ESA IN

Connect RACK ESA OUT to SURFACE ESA IN

ETHERSOUND MIC SPLIT / SYSTEM EXPAND

Surface

ESB IN

iDR10

NETWORK

ESA OUT

ESB OUT

iDR0

Setting the ESB Configuration (Surface

TouchScreen MIXRACK / Mixer Pref / Audio Sync)

This screen lets you configure the iDR10 to be the

ESB master or slave. If you are using ESB to provide

audio to another system then set it as MASTER. If

you are receiving the channel audio from another

system then set it as MASTER/SLAVE.

ES IN and OUT - Plug a single CAT5 cable to

connect audio between EtherSound equipped

devices. Plug into the OUT socket on whichever

device is the audio clock master or is in the chain

nearest to it. Plug into the IN socket on the slave

device. For example, plug iDR10 ESA OUT to

Surface ESA IN.

Correct EtherSound data traffic is indicated by the

steady flashing of both the RX and TX LEDs. If

neither or just one is flashing then check for correct

connection or a cable fault. The ES connection is

made as soon as the cable is plugged in.

Note: Only one cable is required to connect the

audio to and from the remote device. Connect OUT

on the master device to IN on the slave device. This

refers to the clock master, not audio direction. Do

not connect OUT to IN and IN to OUT using two

cables.

DARS IN and OUT - This lets you synchronize the

iDR10 audio clock to an external device, or

synchronize the external device to the iDR10 audio

clock using the AES Digital Audio Reference System.

iDR10 User Guide 15

Page 16

Module options - System

CPU module

Provides the control interface to the MixRack. This

module is identified as the ‘iDR RACK CPU’. It is not

interchangeable with the iLive Surface CPU module.

Power ON Blue LEDs display the power supply

status. One or two power supply modules may be

fitted to the MixRack. The second provides dual

supply redundancy.

12V LAMP Plug in a standard 4-pin XLR gooseneck

console lamp to illuminate the rack while plugging

up in a dark environment. We recommend you use

the Allen & Heath LEDlamp with long life white LED

bulbs and built-in dimmer.

NETWORK A 3 port Ethernet switch is built in. This

lets you connect several network devices to the

iDR10, for example an iLive Surface and a laptop

running the iLive application software. The yellow

Lnk/Act indicators flash to indicate network data

activity.

Note: Do not connect more than one network cable

between two devices. Attempting to connect a

second cable as a ‘redundant backup’ will result in

loss of control.

Note: When using firmware versions up to V1.2,

disconnection of the network cable or loss of

network connection requires a Surface reboot.

Reset A recessed switch lets you reset the network

address and settings to factory default. This is useful

if you are using a MixRack and a Surface with

unknown network addresses or which had different

addresses previously set. Resetting each networked

device (MixRack, Surface and TouchScreen) will

ensure the devices connect correctly. To reset the

settings, press and hold the switch in using a

pointed object while powering up the rack. Keep the

switch pressed for at least 10 seconds while the rack

boots. Default settings are:

IP address 192.168.1.1

Subnet mask 255.255.255.0

Gateway 192.168.1.254

MIDI IN, THRU and OUT - Standard MIDI interface

for external system control using MIDI messages.

For more information refer to the iLive Reference

Guide and firmware version release notes.

PL-Anet - Proprietary RS485 based control port for

connecting Allen & Heath PL Series remote

controllers such as wall plates, GPIO and

fader/encoder panels. For more information refer to

the iLive Reference Guide, PL Series guides and

firmware release notes.

16 iDR10 User Guide

Page 17

Using the iDR10

There are several ways the iDR10 can be used within an iLive system. It is one of many component

options that may be configured to satisfy a host of demanding audio mixing applications. We

recommend that you visit the Allen & Heath web site for information on the full range of iLive

components available. You can also download additional application drawings which illustrate the

versatility of iLive in satisfying many basic and advanced applications.

Refer also to the iLive Getting Started Guide AP7260 and the iLive System Reference Guide AP6526.

Further information on the latest features is available in the Release Notes which come with each

firmware release. Check our web site to download the latest version of iLive firmware.

The following pages illustrate some of the iDR10 applications. They are based on preconfigured

‘template’ Show memories which can be recalled from the Surface UTILITY / Configuration / Show

Manager screen. They give you a good starting point by configuring a recognisable classic

architecture and surface layout. You can edit these and name and store your customised

configurations as User Shows.

APPLICATION EXAMPLE - STANDARD SINGLE RACK SYSTEM

1

iLive

64 inputs, 32 mixes, 8 effects.

FOH_8fx_LRLoad Show

FOH

HEADPHONES and TALKBACK

NETWORK

ETHERNET

CAT5

ESA IN

ETHERSOUND

CAT5

2 x CAT5 cables to stage

iDR10

CONFIG

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

AUDIO CLOCK = INTERNAL

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

Set options using TOUCHSCREEN = MIXRACK / Mixer Pref / Audio Sync Networks

ABCDEFGHI J

A

B

DC

FOH LOCAL AUDIO

ALLEN&HEATH iDR-64

MIX ENGINE

STAGE INPUTS STAGE OUTPUTS

A1-G8 = I/P 1-56

H1-8 = AUX1-8

I1-2 = ST AUX1

I3-4 = I5-8 = MAIN1-4

J1-4 = MTX1-4

J5-6 = ST MTX1-2

A1-8 = CH 57-64

C1-2 = AUX7-8

C3-4 = ST AUX1

C5-8 = MAIN

D1-4 = MTX1-4

D5-8 = ST MTX1-2

NETWORK

ESA OUT

iDR10 User Guide 17

Page 18

APPLICATION EXAMPLE - FOH / MONITOR (Analogue mic splitter)

2

iLive

56 inputs FOH, 48 way split. Each engineer has gain control.

FOH

Each engineer has their own preamp (gain) control

FOH_8fx_LRLoad Show

HEADPHONES and TALKBACK

MONITORS

HEADPHONES / IEM

NETWORK

ETHERNET

CAT5

NETWORK

Set options usin g TOUCHSCREEN = MIXRACK / Mixer Pref / Audio Sync Networks

ESA IN

ESA IN

ETHERSOUND

CAT5

2 x CAT5 cables to stage

Load Show

A

B

DC

A

B

DC

MON_2fx_8m8st

LOCAL AUDIO

A1-8 = CH57-64

ENGINEER'S WEDGE

FOH LOCAL AUDIO

CAT5

A1-8 = CH 57-64

C1-2 = AUX7-8

C3-4 = ST AUX1

C5-8 = MAIN

D1-4 = MTX1-4

D5-8 = ST MTX1-2

AUDIO CLOCK = INTERNAL

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

iDR10

ABCDEFGHI J

MONITOR INPUTS

A1-F8 = I/P 1-48

MONITOR SPLIT FOH SPLIT

ALLEN&HEATH iDR-64

MIX ENGINE

MONITOR OUTPUTS

G1-8 = AUX1-8

H1-8 = ST AUX1-4

I1-8 = ST AUX5-8

J1-4 = MTX1-4

J5-6 = ST MTX1

J7-8 = PAFL OUT

NETWORK

ESA OUT

CONFIG

26x AUX = 8m 2st 2FX

8x MTX = 4m 2st

CONFIG

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

MIC SPLITTER

AUDIO CLOCK = INTERNAL

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

iDR10

ABCDEFGHI J

FOH INPUTS

A1-F8 = I/P 1-48

ALLEN&HEATH iDR-64

MIX ENGINE

FOH OUTPUTS

I1-2 = ST AUX1

I3-4 = I5-8 = MAIN1-4

J1-4 = MTX1-4

J5-6 = ST MTX1-2

NETWORK

ESA OUT

18 iDR10 User Guide

Page 19

APPLICATION EXAMPLE - FOH / MONITOR (Digital mic splitter)

3

iLive

56 inputs FOH, 48 way split. One engineer has gain control affecting both.

FOH_8fx_LRLoad Show

FOH

FOH engineer has control of preamp gain and phantom power

HEADPHONES and TALKBACK

MONITORS

FOH gain affects monitors but engineer has digital channel trims

NETWORK

ESA IN

NETWORK

ETHERNET

CAT5

ESA IN

ETHERSOUND

CAT5

2 x CAT5 cables to stage

Load Show

A

B

DC

A

B

DC

FOH LOCAL AUDIO

SLAVE_MON_8m8st

A1-8 = CH 57-64

C1-2 = AUX7-8

C3-4 = ST AUX1

C5-8 = MAIN

D1-4 = MTX1-4

D5-8 = ST MTX1-2

HEADPHONES / IEM

Set options using TOUCHSCREEN = MIXRACK / Mixer Pref / Audio Sync Networks

AUDIO CLOCK = ESB

ESB CONFIG = MASTER/SLAVE

CH SOURCE = ESB

iDR10

(SLAVE) (MASTER)

ABCDEFGHI J

CONFIG

26x AUX = 8m 2st 2FX

8x MTX = 4m 2st

MONITOR INPUTS

A-F = BLANK

CH1-56 = ESB

ALLEN&HEATH iDR-64

MIX ENGINE

MONITOR OUTPUTS

G1-8 = AUX1-8

H1-8 = ST AUX1-4

I1-8 = ST AUX5-8

J1-4 = MTX1-4

J5-6 = ST MTX1

J7-8 = PAFL OUT

NETWORK

ESA OUT

ESB IN

LOCAL AUDIO

A1-8 = CH57-64

ENGINEER'S WEDGE

AUDIO CLOCK = INTERNAL

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

iDR10

ABCDEFGHI J

CONFIG

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

FOH INPUTS

A1-G8 = I/P 1-56

CAT5

ALLEN&HEATH iDR-64

MIX ENGINE

FOH OUTPUTS

I1-2 = ST AUX1

I3-4 = I5-8 = MAIN1-4

J1-4 = MTX1-4

J5-6 = ST MTX1-2

NETWORK

ESA OUT

ESB OUT

iDR10 User Guide 19

Page 20

APPLICATION EXAMPLE - FOH / MONITOR (Digital mic splitter. No ESA at Monitor)

4

48 inputs FOH, 40 way split. One engineer has gain control affecting both.

FOH_8fx_LRLoad Show

iLive

FOH

FOH engineer has control of preamp gain and phantom power

HEADPHONES and TALKBACK

MONITORS

FOH gain affects monitors but engineer has digital channel trims

No ESA fitted. No audio in surface because the rack is local.

Surface PAFL monitor and TALKBACK use analogue connections to the rack.

XLR CABLES

NETWORK

NETWORK

ETHERNET

CAT5

LOCAL MON OUT

ESA IN

ETHERSOUND

CAT5

2 x CAT5 cables to stage

Load Show

PAFL IN

TALKBACK OUT (audio)

A

B

DC

A

B

DC

FOH LOCAL AUDIO

SLAVE_MON_8m8st

A1-8 = CH 57-64

C1-2 = AUX7-8

C3-4 = ST AUX1

C5-8 = MAIN

D1-4 = MTX1-4

D5-8 = ST MTX1-2

HEADPHONES / IEM

AUDIO CLOCK = ESB

ESB CONFIG = MASTER/SLAVE

CH SOURCE = ESB

iDR10

(SLAVE)

ABCDEFGHI J

LOCAL INPUTS MONITOR SENDS

F1-F8 = I/P 41-48

TB uses INPUT 48

ALLEN&HEATH iDR-64

MIX ENGINE

G1-8 = AUX1-8

H1-8 = ST AUX1-4

I1-8 = ST AUX5-8

J1-4 = MTX1-4

J5-6 = ST MTX1

J7-8 = PAFL OUT

ETHERNET

CAT5 CAT5

AUDIO CLOCK = INTERNAL

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

iDR10

(MASTER)

ESB IN

< DIGTAL MIC SPLITTER

ABCDEFGHI J

CONFIG

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

FOH INPUTS

A1-E8 = I/P 1-40

FOH OUTPUTS

I1-2 = ST AUX1

I3-4 = I5-8 = MAIN1-4

J1-4 = MTX1-4

J5-6 = ST MTX1-2

ALLEN&HEATH iDR-64

NETWORK

ESA OUT

MIX ENGINE

ESB OUT

20 iDR10 User Guide

Page 21

APPLICATION EXAMPLE - FOH / MONITOR (iDR0 at Monitors)

6

iLive

64 inputs FOH, 56 way split. FOH engineer has gain control.

FOH

FOH engineer has control of preamp gain and phantom power

FOH_8fx_LRLoad Show

HEADPHONES and TALKBACK

MONITORS

FOH gain affects monitors but engineer has digital channel trims

NETWORK

ESA IN

NETWORK

ETHERNET

CAT5

ESA IN

ETHERSOUND

CAT5

2 x CAT5 cables to stage

Load Show

SLAVE_MON_8m8st

A

B

DC

FOH LOCAL AUDIO

A1-8 = CH 57-64

D1-4 = MTX1-4

D5-8 = ST MTX1-2

HEADPHONES / IEM

iDR0 (SLAVE)

AUDIO CLOCK = ESB

ESB CONFIG = MASTER/SLAVE

CH SOURCE = GLOBAL ESB INPUT

A

B

DC

CAT5 CAT5

ENGINEER'S WEDGE

iDR10(MASTER)

CONFIG

26x AUX = 8m 2st 2FX

< MIC SPLITTER (MIXRACK I/P 1-56)

CONFIG

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

AUDIO CLOCK = INTERNAL

BCDEFGHI J

A

STAGE INPUTS FOH PA SENDS

A1-G8 = I/P 1-56

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

Set options using TOUCHSCREEN = MIXRACK / Mixer Pref / Audio Sync Networks

MONITOR AUDIO

A1-8 = CH57-64

B1-8 = AUX1-8

C1-8 = ST AUX1-4

D1-8 = ST AUX5-8

ALLEN&HEATH iDR-64

NETWORK

ESA OUT

MIX ENGINE

ESB OUT

I1-2 = ST AUX 1

I3-4 = I5-8 = MAIN1-4

J1-4 = MTX1-4

J5-8 = ST MTX1-2

iDR10 User Guide 21

Page 22

APPLICATION EXAMPLE - FOH / MONITOR (iDR0 at FOH)

7

64 inputs FOH, 56 way split. Monitor engineer has gain control.

iLive

HEADPHONES and TALKBACK

Set options using TOUCHSCREEN = MIXRACK / Mixer Pref / Audio Sync Networks

Monitor gain affects FOH but engineer has channel digital trims

FOH

NETWORK

ETHERNET

CONFIG

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

AUDIO CLOCK = ESB

ESA OUT

ESB CONFIG = MASTER/SLAVE

CH SOURCE = GLOBAL ESB INPUT

CAT5

ESB IN

Load Show

ESA IN

A

B

DC

ETHERSOUND

CAT5

Single CAT5 EtherSound cable to stage (no Ethernet connection)

iDR0

SLAVE_FOH_LR

(SLAVE)

FOH AUDIO

A1-8 = CH 57-64

C1-2 = AUX7-8

C3-4 = ST AUX1

C5-8 = MAIN1-4

D1-4 = MTX1-4

D5-8 = ST MTX1-2

MONITORS

HEADPHONES / IEM

iDR10

BCDEFGHI J

A

STAGE INPUTS

A1-G8 = I/P 1-56

(MASTER)

Load Show

MON_2fx_8m8st

Monitor engineer has control of preamp gain and phantom power

NETWORK

ETHERNET

CAT5

ALLEN&HEATH iDR-64

ESA OUT

MIX ENGINE

ESA IN

A

B

DC

ETHERSOUND

CAT5

ESB OUT

ENGINEER'S WEDGE

MIC SPLITTER (MIXRACK I/P 1-56) >

AUDIO CLOCK = INTERNAL

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

CONFIG

26x AUX = 8m 2st 2FX

8x MTX = 4m 2st

MONITOR OUTPUTS

A1-4 = MTX1-4

A5-8 = ST MTX1-2

B1-8 = AUX1-8

C1-8 = ST AUX1-4

D1-8 = ST AUX5-8

ETHERSOUND

CAT5

22 iDR10 User Guide

Page 23

APPLICATION EXAMPLE - FOH / MONITOR (iDR0 at FOH, No ESA on Monitor)

8

56 inputs FOH, 48 way split. No ESA on monitor system. Monitor engineer has gain control.

iLive

HEADPHONES and TALKBACK

Set options using TOUCHSCREEN = MIXRACK / Mixer Pref / Audio Sync Networks

FOH

8x GRP = 4m 2st

18x AUX = 8m 1st 8FX

MAIN = LR

8x MTX = 4m 2st

AUDIO CLOCK = ESB

Monitor gain affects FOH but engineer has channel digital trims

NETWORK

ETHERNET

CONFIG

ESA OUT

ESB CONFIG = MASTER/SLAVE

CH SOURCE = GLOBAL ESB INPUT

CAT5

ESB IN

Load Show

ESA IN

A

B

DC

ETHERSOUND

CAT5

Single CAT5 EtherSound cable to stage (no Ethernet connection)

iDR0

SLAVE_FOH_LR

(SLAVE)

FOH AUDIO

A1-8 = CH 57-64

C1-2 = AUX7-8

C3-4 = ST AUX1

C5-8 = MAIN1-4

D1-4 = MTX1-4

D5-8 = ST MTX1-2

MONITORS

HEADPHONES / IEM

(MASTER)

iDR10

ABCDEFGHI J

STAGE INPUTS MONITOR SENDS

A1-F8 = I/P 1-48

TB uses INPUT 48

Load Show MON_2fx_8m8st

Monitor engineer has control of preamp gain and phantom power

No ESA fitted. No audio in surface because the rack is local.

Surface PAFL monitor and TALKBACK use analogue connections to the rack.

PAFL IN

TALKBACK OUT (audio)

A

B

DC

ENGINEER'S WEDGE

MIC SPLITTER (MIXRACK I/P 1-48) >

AUDIO CLOCK = INTERNAL

XLR CABLES

NETWORK

ALLEN&HEATH iDR-64

MIX ENGINE

LOCAL MON OUT

ETHERNET

CAT5

ESB OUT

ESB CONFIG = MASTER

CH SOURCE = LOCAL INPUTS

G1-8 = AUX1-8

H1-8 = ST AUX1-4

I1-8 = ST AUX5-8

J1-4 = MTX1-4

J5-6 = ST MTX1

J7-8 = PAFL OUT

CONFIG

26x AUX = 8m 2st 2FX

8x MTX = 4m 2st

ETHERSOUND

CAT5

iDR10 User Guide 23

Page 24

24 iDR10 User Guide

Loading...

Loading...