Page 1

PSU not included in public version. Please see

distributor version.

ALLEN&HEATH

GL4000

Dual Function Audio Mixing Console

SERVICE MANUAL

PUBLICATION: AP2640

Page 2

INTRODUCTION

The information presented in this manual is intended for competent technical personnel to carry out service and product

support for the GL4000. It is assumed that the reader is familiar with the related electronic theory and audio terminology,

and is able to carry out basic servicing, fault-finding and repair of audio equipment of this type. Service personnel should

also be familiar with audio systems, mains earthing and power requirements, as well as handling precautions.

For further information on the operation and application of the GL4000 please refer to the USER GUIDE publication

AP2642 supplied with each console.

Whilst we believe the information in this manual to be reliable we do not assume responsibility for inaccuracies. We also

reserve the right to make changes in the interest of further product development.

SERVICE AND TECHNICAL SUPPORT

Under normal conditions the GL4000 does not require user maintenance or internal calibration. Any service work

required should be carried out by qualified technical personnel only.

We are able to offer further product support through our worldwide distribution network. To help us provide the most

efficient service please would you quote the console serial number in any communication regarding this product.

SAFETY WARNING !

Mains electricity is dangerous and can kill. Mains voltage is present within the console power

supply unit. Do not remove the top cover with mains connected. Do not carry out any work

within the unit while it is powered. High voltage components are insulated for safety but should

not be touched with power applied. The mains voltage setting is factory set and is indicated

on the rear panel. Check that this matches your local mains supply. Check your mains wiring

and earthing before switching on.

DO NOT REMOVE THE MAINS EARTH CONNECTION!

The console chassis is always connected to mains earth.

This manual is printed in four sections:

SECTION A provides all the technical information and service procedures. It also details how to order spare

parts for the GL4000 console and meterpod, the RPS11 power supply unit and the RPSD2

dual supply combiner/monitor. The contents of the GL4000 spares kits is also listed.

SECTION B contains the fitting instructions for the expander and add-on options.

SECTION C contains all the technical diagrams for the GL4000 console, the meterpod option and the

SYS-LINK option. Any technical bulletins are also in this section. Technical information for the

console power supply is given in Section D.

SECTION D contains all the technical diagrams and information for the console power supply unit . Spare

parts and assemblies for the power supply are listed in Section A.

SECTION E contains all the technical diagrams and information for the RPSD2 dual supply combiner/

monitor. Spare parts and assemblies for the RPSD2 are listed in Section A.

copyright © 2002 ALLEN & HEATH. All rights reserved

ALLEN & HEATH

2 L4DSM2

Publication ...................... AP2640 Issue 3

Page 3

CONTENTS

SECTION A

TECHNICAL DESCRIPTION ............................................................................................ 2

STANDARD CONSOLE FORMATS & OPTIONS ............................................................. 3

GL4000 DIMENSIONS FOR FLIGHTCASING .................................................................. 4

GL4000M DIMENSIONS FOR FLIGHTCASING ............................................................... 5

SPECIFICATION ............................................................................................................. 6

CONNECTIONS .............................................................................................................. 7

REMOVING A CHANNEL, GROUP, L/R, MONO or MASTER CIRCUIT BOARD ............. 8

REMOVING THE MICRO CIRCUIT BOARD ..................................................................... 9

REMOVING A CONNECTOR CIRCUIT BOARD .............................................................. 10

ASSIGNING AN INPUT CONNECTOR BOARD (CHANNEL MUTE ASSIGNMENT) ......... 11-12

INTERNAL LINK OPTIONS ............................................................................................. 13

ORDERING SPARE PARTS AND ASSEMBLIES ........................................................... 14-15

ORDERING A SPARES KIT ............................................................................................ 16-18

SECTION B

GL4000-8M/4SM EXPANDER FITTING INSTRUCTIONS .................................................

GL4000 SYS-LINK FITTING INSTRUCTIONS ..................................................................

GL4000 SYS-LINK APPLICATIONS NOTE ......................................................................

METERBRIDGE FITTING INSTRUCTIONS ......................................................................

SECTION C

TECHNICAL BULLETIN ................................................................................................... AHTB96010

FRONT PANEL LAYOUT ................................................................................................

REAR PANEL LAYOUT ..................................................................................................

BLOCK DIAGRAM - MONO / STEREO INPUT & TALKBACK .........................................

BLOCK DIAGRAM - GROUP / AUX / MATRIX / LR / MONO / 2 TRACK ..........................

BLOCK DIAGRAM - MUTE MICROPROCESSOR ...........................................................

INTERNAL LAYOUT ........................................................................................................

MONO INPUT PCB COMPONENT IDENT ....................................................................... AG2621

MONO INPUT PCB CIRCUIT DIAGRAM .......................................................................... C2621

MONO INPUT CONNECTOR PCB COMPONENT IDENT ................................................ AG2622

MONO INPUT CONNECTOR DIAGRAM sheet 1 ............................................................. C2622

MONO INPUT CONNECTOR DIAGRAM sheet 2 ............................................................. C2622

STEREO INPUT PCB COMPONENT IDENT ................................................................... AG2619

STEREO INPUT PCB CIRCUIT DIAGRAM ...................................................................... C2619

4 MONO 4 STEREO INPUT CONNECTOR PCB COMPONENT IDENT ........................... AG3122

4 MONO 4 STEREO INPUT CONNECTOR CIRCUIT DIAGRAM sheet 1 ......................... C3122

4 MONO 4 STEREO INPUT CONNECTOR CIRCUIT DIAGRAM sheet 2 ......................... C3122

STEREO INPUT CONNECTOR PCB COMPONENT IDENT ............................................ AG3123

STEREO INPUT CONNECTOR CIRCUIT DIAGRAM sheet 1 ........................................... C3123

STEREO INPUT CONNECTOR CIRCUIT DIAGRAM sheet 2 ........................................... C3123

4 STEREO 4 MONO INPUT CONNECTOR PCB COMPONENT IDENT ........................... AG2620

4 STEREO 4 MONO INPUT CONNECTOR DIAGRAM sheet 1 ........................................ C2620

4 STEREO 4 MONO INPUT CONNECTOR DIAGRAM sheet 2 ........................................ C2620

GROUP LEFT/RIGHT PCB COMPONENT IDENT ........................................................... AG2623

3L4DSM2

ALLEN & HEATH

Page 4

GROUP LEFT/RIGHT CIRCUIT DIAGRAM sheet 1 .......................................................... C2623

GROUP LEFT/RIGHT CIRCUIT DIAGRAM sheet 2 .......................................................... C2623

MASTER PCB COMPONENT IDENT .............................................................................. AG2626

MASTER CIRCUIT DIAGRAM sheet 1 ............................................................................. C2626

MASTER CIRCUIT DIAGRAM sheet 2 ............................................................................. C2626

MONO PCB COMPONENT IDENT .................................................................................. AG2625

MONO CIRCUIT DIAGRAM sheet 1 ................................................................................ C2625

MONO CIRCUIT DIAGRAM sheet 2 ................................................................................ C2625

MASTER CONNECTOR PCB COMPONENT IDENT ....................................................... AG2627

MASTER CONNECTOR DIAGRAM sheet 1 .................................................................... C2627

MASTER CONNECTOR DIAGRAM sheet 2 .................................................................... C2627

MPU & 3 DIGIT METER PCB COMPONENT IDENT ....................................................... AG2624+B

MPU CIRCUIT DIAGRAM ................................................................................................ C2624

MPU 3 DIGIT METER CIRCUIT DIAGRAM ...................................................................... C2624

SLAVE PCB COMPONENT IDENT ................................................................................. AG2628

SLAVE CIRCUIT DIAGRAM ............................................................................................ C2628

GL4000 METER PCB COMPONENT IDENT ................................................................... AG2092

GL4000 METER CIRCUIT DIAGRAM .............................................................................. C2092

GL4000M METER PCB COMPONENT IDENT ................................................................ AG3601

GL4000M METER CIRCUIT DIAGRAM ............................................................................ C3601

SYS-LINK PCB COMPONENT IDENT ............................................................................. AG2792

SYS-LINK CIRCUIT DIAGRAM sheet 1 ........................................................................... C2792

SYS-LINK CIRCUIT DIAGRAM sheet 2 ........................................................................... C2792

SYS-LINK WIRING ..... ......... ......... ......... .......................................................................... M002-211

CONSOLE POWER WIRING ..........................................................................................

SECTION D

TECHNICAL DESCRIPTION ............................................................................................ 2

FUSE RATING & MAINS VOLTAGE SETTING ............................................................... 3

SERVICE ACCESS ........................................................................................................

RPS11 ASSEMBLY & WIRING....................................................................................... M002-199A

RPS PCB COMPONENT IDENT ..................................................................................... AG0256

RPS11 CIRCUIT DIAGRAM ............................................................................................. C002-199

SECTION E

RPSD2 DUAL SUPPLY COMBINER / MONITOR ............................................................

RPSD2 FRONT & REAR PANEL LAYOUTS ...................................................................

RPSD2 SPECIFICATION ................................................................................................

RPSD2 INSTALLATION ...................................................................................................

RPSD2 PCB COMPONENT IDENT ................................................................................. AG2255

RPSD2 PCB CIRCUIT DIAGRAM sheet 1 ....................................................................... C2255

RPSD2 PCB CIRCUIT DIAGRAM sheet 2 ....................................................................... C2255

ALLEN & HEATH

4 L4DSM2

Page 5

SECTION A

SERVICE

PROCEDURES

CAUTION !

A

TO AVOID DAMAGE TO INTERNAL COMPONENTS BY

MISHANDLING AND/OR MISCONNECTION, ONLY

TECHNICALLY COMPETENT PERSONNEL SHOULD

ATTEMPT SERVICE WORK ON THIS CONSOLE.

L4DSM2

Section A - 1

ALLEN & HEATH

Page 6

TECHNICAL DESCRIPTION

The ALLEN & HEATH GL4000 is an 8 bus Front-of-House and 10 bus On-stage Monitor mixer. It can also be configured

for full 8 track, stereo and mono recording. Standard formats are 24, 32, 40 and 48 channels with optional SYS-LINK expander

system and RPSD-2 dual supply combiner / monitor.

CONSTRUCTION

All metal chassis with aluminium extrusions to provide rigidity along the console length. The front panels are non modular

with 8 channel input blocks and a master panel incorporating 8 groups, left, right, mono and master sections. The

connectors are rear panel mounted with input connectors mounted on circuit boards in blocks of 8. The connectors in

the master section are mounted on a single circuit board. The chassis base can easily be removed to gain service access.

The soft touch front armrest is incorporated into the front extrusion running along the length of the console.

THE CIRCUIT COMPONENTS

The GL4000 is manufactured using high performance industry standard linear op-amp, digital and discrete semiconductor

circuit devices. In particular the switches and potentiometers have proven to be durable and problem free. When operated

correctly the normal performance of the unit introduces no noticeable audio signal degradation.

AUDIO INPUTS AND OUTPUTS

All XLR connector inputs and outputs are balanced. All unbalanced connections are line level 3-pole ¼" jack sockets with

low impedance outputs and high impedance inputs. The channel mic and line inputs, and the L-R and Mono outputs are

electronically balanced (differential). The outputs can be used with unbalanced equipment by linking the -ve signal to

0V in the cable or input connector. All outputs are low impedance and thus capable of driving several high impedance

inputs simultaneously. All inputs and outputs are in phase except for the 2 track Return inputs.

THE PFL/AFL SYSTEM

The console stereo PFL (AFL) switches send pre- (post)-fade signals to the PFL (AFL) mix buses. These signals are

switched with 4053 CMOS gates located on the MASTER circuit board (PCB No: AG2626). The supply for the 4053 is ±7.5V

DC and is derived locally from the ±16V. The gates are switched when a PFL or AFL switch is selected.

EARTHING THE AUDIO SYSTEM

The console chassis is connected to mains earth via the DC power cable. FOR SAFETY REASONS NEVER

REMOVE THE EARTH WIRE FROM THE POWER SUPPLY UNIT MAINS PLUG. The console audio 0V

is connected to the console chassis. An additional chassis 0V terminal is located on the console rear panel for extra earth

bonding if required. Multiple earth paths cause earth (ground) loops which may result in audible hum and interference.

These may be avoided by making sure that there is only one path to earth from each piece of equipment, disconnecting

audio cable screens at one end if necessary.

INTERCONNECTIONS

Where possible use balanced connections for the CHANNEL inputs, AUX SENDs, L/R and MONO outputs to minimise

noise pick-up. Avoid running audio cables near to mains or lighting cables, thyristor dimmer units or power supplies etc.

These may cause audible hum and buzz. The use of low impedance sources significantly reduces interference pick-up.

Check the cables for correct wiring to avoid problems with phase reversal and unreliable connection. The GL4000 follows

the convention for XLR pin 2 and jack tip = signal hot (+).

Always use balanced cables when connecting to phantom powered microphones.

MAKE SURE THAT THE +48V SWITCHES ARE OFF WHEN THE CHANNEL

INPUT XLRs ARE CONNECTED TO NON-PHANTOM POWERED

MICROPHONES OR LINE SOURCES.

If ground loops cause problems, connect the cable screen at one end only. Balanced outputs may be connected to

unbalanced inputs and vice versa by linking the signal cold (-) to 0V ground.

ALLEN & HEATH

Section A - 2

L4DSM2

Page 7

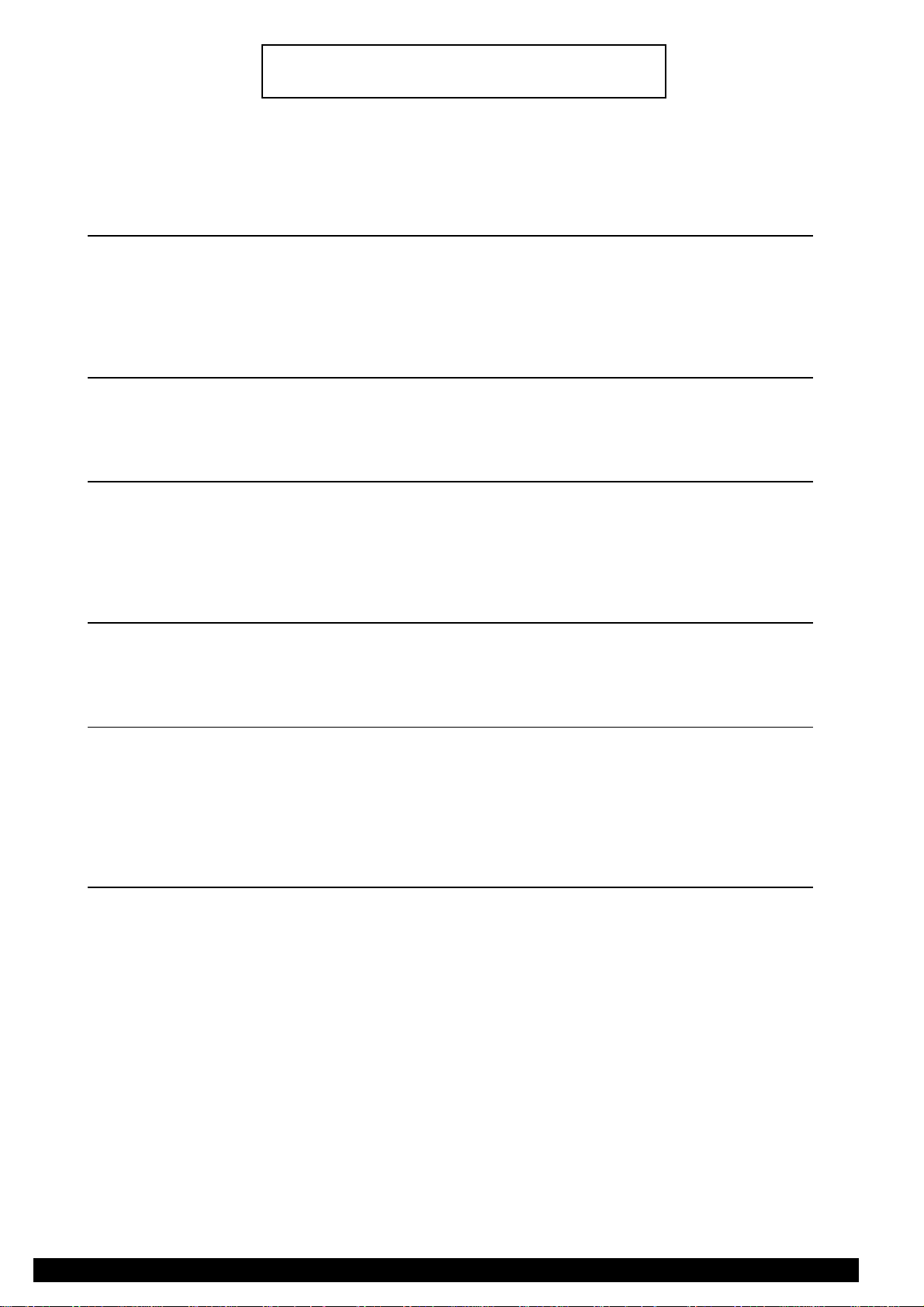

STANDARD CONSOLES

All consoles supplied with separate RPS11 rack mount power unit.

Optional RPSD dual supply combiner / monitor.

Optional VU meterpod and optional SYS-LINK expander system.

GL4000-824S

GL4000M-824n

GL4000-832S

GL4000M-832n

GL4000-840S

GL4000M-840n

CHANS

1-8

CHANS

1-8

M24 VU METERBRIDGE

CHANS

9-16

M32 VU METERBRIDGE

CHANS

9-16

M40 VU METERBRIDGE

MASTER

MASTER

CHANS

17-24

CHANS

17-24

CHANS

25-32

GL4000-848S

GL4000M-848n

GL4000-8M

CHANS

1-8

CHANS

1-8

MONO

CHANS

8x

CHANS

9-16

CHANS

9-16

CHANS

17-24

M48 VU METERBRIDGE

CHANS

17-24

MASTER

MASTER

GL4000-4SM

CHANS

25-32

CHANS

25-32

CHANS

33-40

CHANS

33-40

4x

MONO

4x

STEREO

CHANS

CHANS

41-48

L4DSM2

Section A - 3

ALLEN & HEATH

Page 8

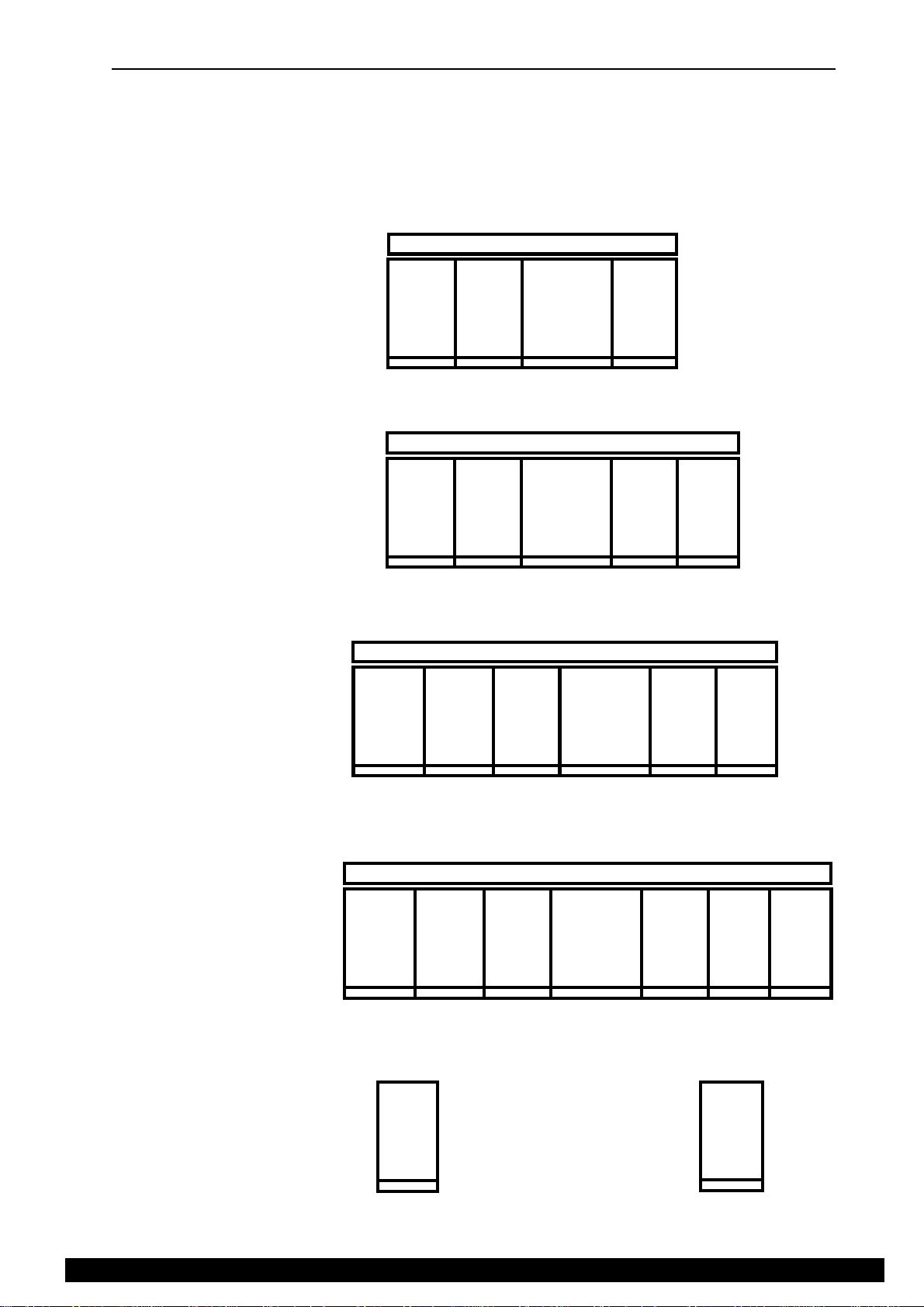

GL4000 DIMENSIONS (consoles up to serial number 403420)

The diagrams below give the dimensions for flightcasing the console and power supply unit.

418.7

413.4

401.3

158.3

167.1

14.2

482.6

465.1

367.6

57.2

132.5

2.0

167.1

115.2

100.0

64.7

The RPS11 is supplied with a 2m mains lead with a moulded mains plug and IEC socket. A3m DC output cable is also

supplied to connect the RPS11 to the GL4000.

MECHANICAL DETAILS

UNPACKED Width Depth Height Wt

GL4000-824 1166 748 197 43 kg

GL4000-832 1421 748 197 52 kg

GL4000-840 1676 748 197 61 kg

PACKED Width Depth Height Wt

GL4000-824 1702 900 390 76 kg

GL4000-832 1702 900 390 84 kg

GL4000-840 1950 900 390 92 kg

GL4000-848 1931 748 197 70 kg

GL4000-8M 255 748 197 9 kg

Meterpod 1154-1664 +56 +106

RPS11 483 (19") 232 135 (3U) 10 kg

RPSD2 483 (19") 180 45 (1U) 4.5kg

ALLEN & HEATH

Section A - 4

GL4000-848 2205 900 390 120 kg

GL4000-8M 480 830 260 12 kg

Meterpod 1290-1800 130 230 6-8 kg

RPS11 575 295 175 11 kg

RPSD2 570 340 75 6 kg

L4DSM2

Page 9

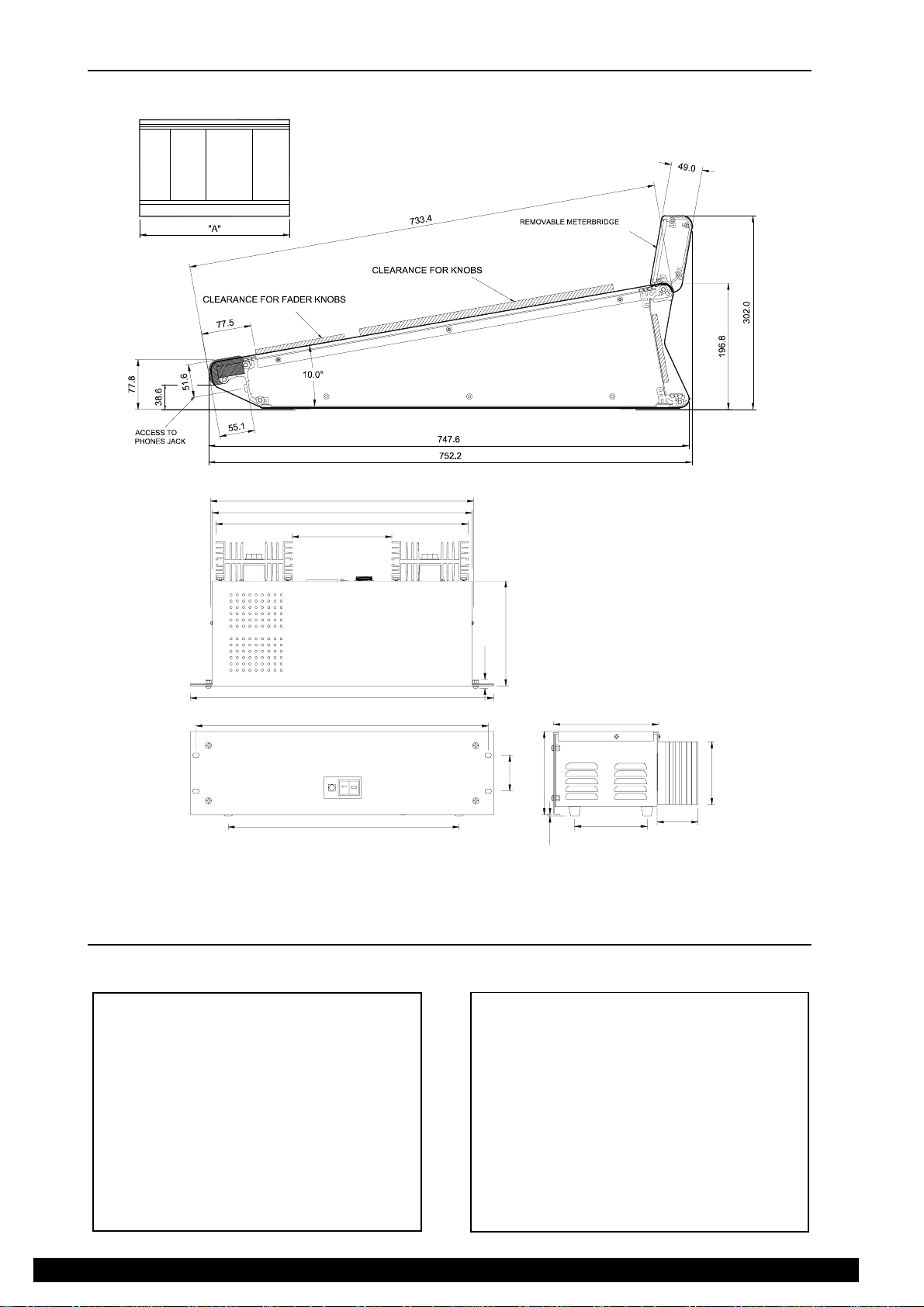

GL4000M DIMENSIONS (consoles from serial number 403421)

The diagrams below give the dimensions for flightcasing the console and power supply unit.

418.7

413.4

401.3

158.3

167.1

14.2

482.6

465.1

367.6

57.2

132.5

2.0

167.1

115.2

100.0

64.7

The RPS11 is supplied with a 2m mains lead with a moulded mains plug and IEC socket. A3m DC output cable is also supplied

to connect the RPS11 to the GL4000.

MECHANICAL DETAILS

UNPACKED Width Depth Height Wt

GL4000M-824 1166 748 285 47 kg

GL4000M-832 1421 748 285 57 kg

GL4000M-840 1676 748 285 67 kg

PACKED Width Depth Height Wt

GL4000M-824 1702 900 390 82 kg

GL4000M-832 1702 900 390 91 kg

GL4000M-840 1950 900 390 100 kg

GL4000M-848 1931 748 285 77 kg

GL4000-8M 255 748 285 9 kg

RPS11 483 (19") 232 135 (3U) 10 kg

RPSD2 483 (19") 180 45 (1U) 4.5kg

L4DSM2

GL4000M-848 1931 900 390 129 kg

GL4000-8M 480 830 260 12 kg

RPS11 575 295 175 11 kg

RPSD2 570 340 75 6 kg

Section A - 5

ALLEN & HEATH

Page 10

SPECIFICATIONS

0dBu = 0.775 Vrms Reference for high level equipment +4dBu =

1.23 V

0dBV = 1 Vrms Reference for low level equipment -10dBV = 310 mV

0VU meter reading = +4dBu at XLR outputs

Input Gain

Mic/Line Input ............................................ +6dB to +60dB variable

Mic/Line + Pad ............................................ -14dB to +40dB variable

Line Input ............................................ -14dB to +40dB variable

Stereo Line Input ........................................... off to +10dB variable

2-track Return ............................................ off to +10dB variable

Maximum Output Level

Main Outputs ............................................ +27dBu into load of >600 ohm

Jack Outputs ............................................ +21dBu into load of >2K ohm

Internal headroom ......................................... +21dB

Frequency Response

Measured 20Hz to 20kHz ref 1kHz

Mic to mix (+40dB) ....................................... +0/-0.5dB

Line to mix (0dB) ........................................... +0/-0.5dB

Distortion

THD + noise measured @ 1kHz +20dBu

Mic to mix (+40dB) ....................................... 0.006%

Line to mix (0dB) ........................................... 0.006%

Crosstalk

Referred to driven channel @ 1kHz

Channel to channel ....................................... > 100dB

Mute shutoff ............................................ > 85dB

Fader shutoff ............................................ > 90dB

Noise Performance

Measured rms 22Hz to 22kHz bandwidth

Mic EIN ............................................ -128dB 150 ohm source

Line pre-amp (0dB) ........................................ < -91dBu

Residual output noise .................................... < -98dBu (-102dB S/N)

Mix noise, nothing routed .............................. < -87dBu (-91dB S/N)

Mix noise, 24 channels routed ...................... < -81dBu (-85dB S/N)

Metering

Input meters ............................................ 4 segment LED (signal, 0, +6, peak)

Mix meters ............................................ 4 segment LED (signal, 0, +6, peak)

Output meters ............................................ 12 segment LED

LED meter response ..................................... peak reading

Peak indicators ............................................ on 5dB before clipping

Signal indicators ........................................... on -20dBu

VU meterpod ............................................ Illuminated VU moving coil meters

ALLEN & HEATH

Section A - 6

L4DSM2

Page 11

CONNECTIONS

INPUTS:

MIC/LINE IN .................. XLR ........................... pin 2 hot, 3 cold ........... balanced ......... 2 kohms .......... variable -60 to -6dBu

MIC/LINE IN +PAD ........ XLR ........................... pin 2 hot, 3 cold ........... balanced ......... 10 kohms ........variable -40 to +14dBu

LINE IN .......................... 1/4" JACK .................. tip hot, ring cold ........... balanced ......... 10 kohms ........ variable -40 to +14dBu

STEREO LINE IN .......... 1/4" JACK .................. tip hot, ring cold ........... balanced ......... 10 kohms ........ -10dBu or +14dBu

CHANNEL INSERTS ..... 1/4" JACK .................. tip hot, ring cold ........... balanced ......... 10 kohms ........ 0dBu

OUTPUT INSERT RET . 1/4" JACK .................. tip hot, ring cold ........... balanced ......... 10 kohms ........ -2dBu

2-TRACK INPUT ........... 1/4" JACK ......................................................... unbalanced ..... 10 kohms ........ variable -10dBV

OUTPUTS:

L, R, MONO OUT, ......... XLR ........................... pin 2 hot, 3 cold ........... balanced ......... 75 ohms .......... +4dBu

GROUP OUT, ................XLR ........................... pin 2 hot, 3 cold ........... balanced ......... 75 ohms .......... +4dBu

AUX OUT, ...................... XLR ........................... pin 2 hot, 3 cold ........... balanced ......... 75 ohms .......... +4dBu

MATRIX A, B, C, D ........ 1/4" JACK .................. tip hot, ring cold ........... impedence bal 50 ohms .......... +4dBu

DIRECT OUT ................. 1/4" JACK .................. tip hot, ring cold ........... impedence bal 50 ohms .......... 0dBu or variable

MONITOR ...................... 1/4" JACK .................. tip hot, .......................... unbalanced ..... 2 kohms .......... 0dBu variable

2-TRACK OUTPUTS .....1/4" JACK.................. tip hot, .......................... unbalanced ............................... 0dBu variable

HEADPHONES OUT ..... 1/4" JACK ................. tip L, ring R .................. for stereo headphones 8 to 400 ohms

( 2 SOCKETS) ............... 1/4" JACK ................. tip L, ring R .................. for stereo headphones 8 to 400 ohms

L4DSM2

GL4000 REAR PANEL CONNECTORS

Section A - 7

ALLEN & HEATH

Page 12

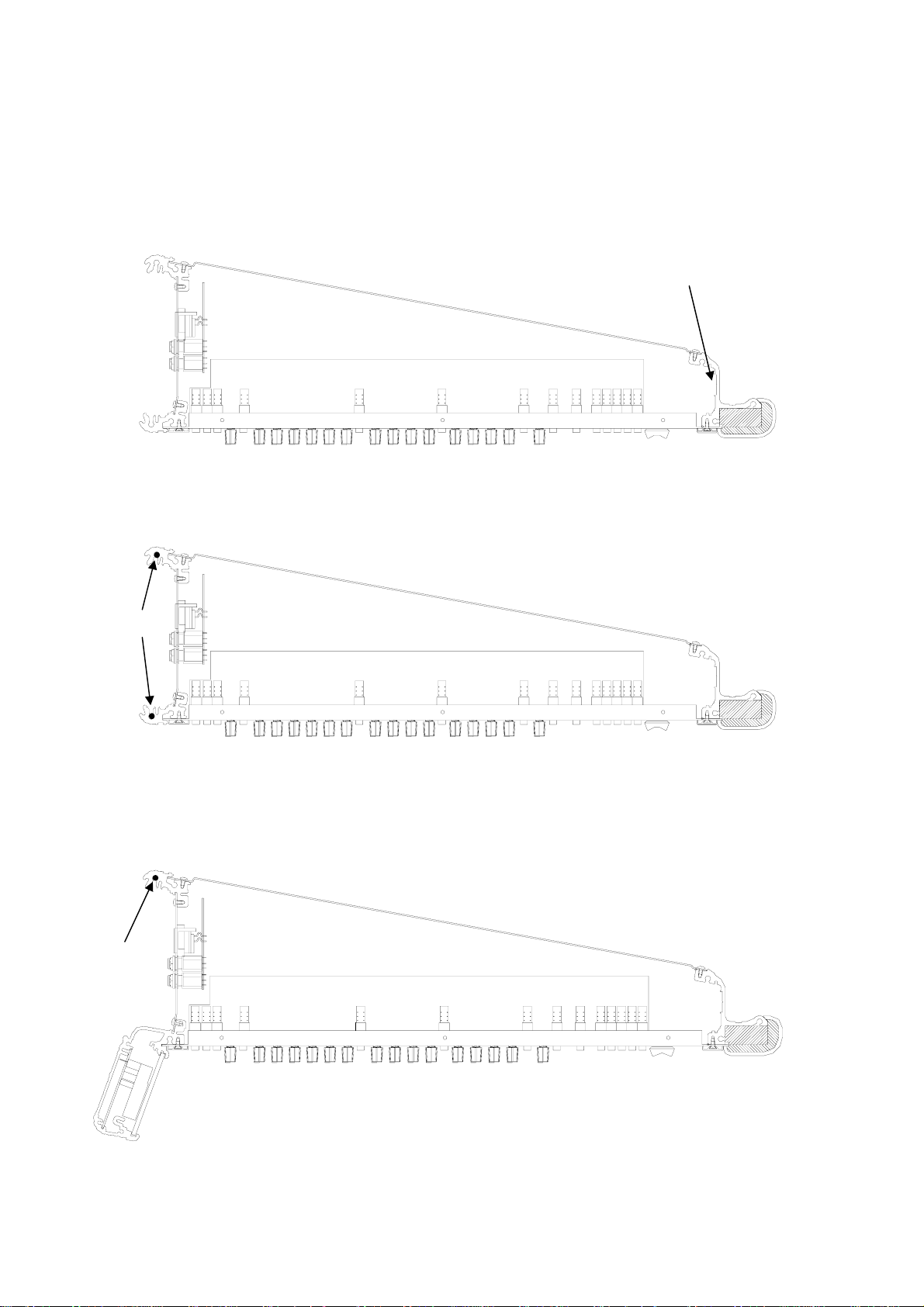

REMOVING A CHANNEL, GROUP, LEFT / RIGHT, MONO or MASTER

CIRCUIT BOARD ASSEMBLY

Before beginning any service work, remove all power to the console and disconnect any signal cables where necessary.

Service work is best carried out with the console inverted or positioned upright on its rear with the connectors removed.

Ensure adequate lighting and use the correct tools. Access to the CHANNEL, GROUP, LEFT/RIGHT, MONO or

MASTER circuit board is as follows:

1.) Before inverting the console, pull off the knobs and remove the pot nuts from the circuit assembly to be

removed. The switch caps can remain in place.

2.) With the console inverted or on its rear, remove the base and identify the circuit board to be removed.

3.) Disconnect the harness (A) plugged into the connectors mounted along the edge of the circuit boards..

4.) Carefully unplug the flat flexible cable (B) plugged into the circuit board asssembly to be removed.

WHEN REMOVING A CHANNEL CIRCUIT BOARD ASSEMBLY

Cut the Earth buss wire (G) on each side of the channel circuit board to be removed. Remember to resolder

the Earth buss wire (G) wire when channel circuit board has been replaced.

WHEN REMOVING A GROUP, LEFT/RIGHT or MONO CIRCUIT BOARD ASSEMBLY

The SLAVE circuit board assembly mounted across the GROUP, LEFT, RIGHT and MONO circuit board

assemblies in the master section of the console will have to be removed along with harness (D).

ALSO WHEN REMOVING THE RIGHT CIRCUIT BOARD ASSEMBLY

Harness (E) will have to be disconnected from the MONO circuit board along with harness (D).

ALSO WHEN REMOVING THE MONO CIRCUIT BOARD ASSEMBLY

Harness (E) and the flexible flat cable (F) will have to be disconnected from the MONO circuit board along

with harness (D). Take care not to stretch the DC power harness and fader wires still connected to the circuit

board assembly.

WHEN REMOVING THE MASTER CIRCUIT BOARD ASSEMBLY

The SLAVE circuit board assembly can remain in place, only harness (C) requires removal from both the

SLAVE and MASTER circuit board assemblies. The flexible flat cable, (F) and the green wire soldered onto

the trackside of the cicuit board will also need to be disconnected. Take care not to stretch the headphone

socket wires that are still connected.

5.) The circuit board can now be removed, take care not to stretch the fader wires that are still connected.

When all service work is complete, remove all debris such as solder, component legs and wire clippings from inside the

console and check your work carefully before reassembly. To refit the circuit assembly follow the above procedure in

reverse order. Make sure all harnesses are correctly aligned and plugged on. Test for correct operation.

B

B

CONSOLE REAR

E

D

C

SLAVE PCB

G

ALLEN & HEATH

F

A

CONSOLE FRONT

GL4000-824 inverted with the base cover removed.

Section A - 8

L4DSM2

Page 13

REMOVING THE MICRO CIRCUIT BOARD ASSEMBLY

Before beginning any service work remove all power to the console and disconnect any signal cables where necessary.

Service work is best carried out with the console inverted or positioned upright on its rear with the connectors removed.

Ensure adequate lighting and use the correct tools. Access to the MICRO circuit board is as follows:

1.) Working from the rear of the console, remove the screw (A) near to the CHASSIS GROUND terminal on the

rear connector panel.

2.) With the console inverted or on its rear, remove the base, identify the MICRO circuit board assembly and then

disconnect the ribbon harnesses plugged into the connectors mounted along the edge of the circuit board. Also

disconnect the flat flexible cable.

3.) The circuit board can now be removed by first squeezing the tops of the mounting pillars and lifting the circuit

board clear of the pillars. Then carefully manoeuvre the circuit board assembly into a suitable position to carry

out service work. Take care not to stretch the wires soldered onto the circuit board

When all service work is complete, remove all debris such as solder, component legs and wire clippings from inside the

console and check your work carefully before reassembly. To refit the MICRO circuit board assembly follow the above

procedure in reverse order. Make sure all harnesses are correctly aligned and plugged on. Test for correct operation.

rear panel view

MICRO PCB

Ù

A

CONSOLE REAR

L4DSM2

CONSOLE FRONT

GL4000-824 inverted with the base cover removed.

Section A - 9

ALLEN & HEATH

Page 14

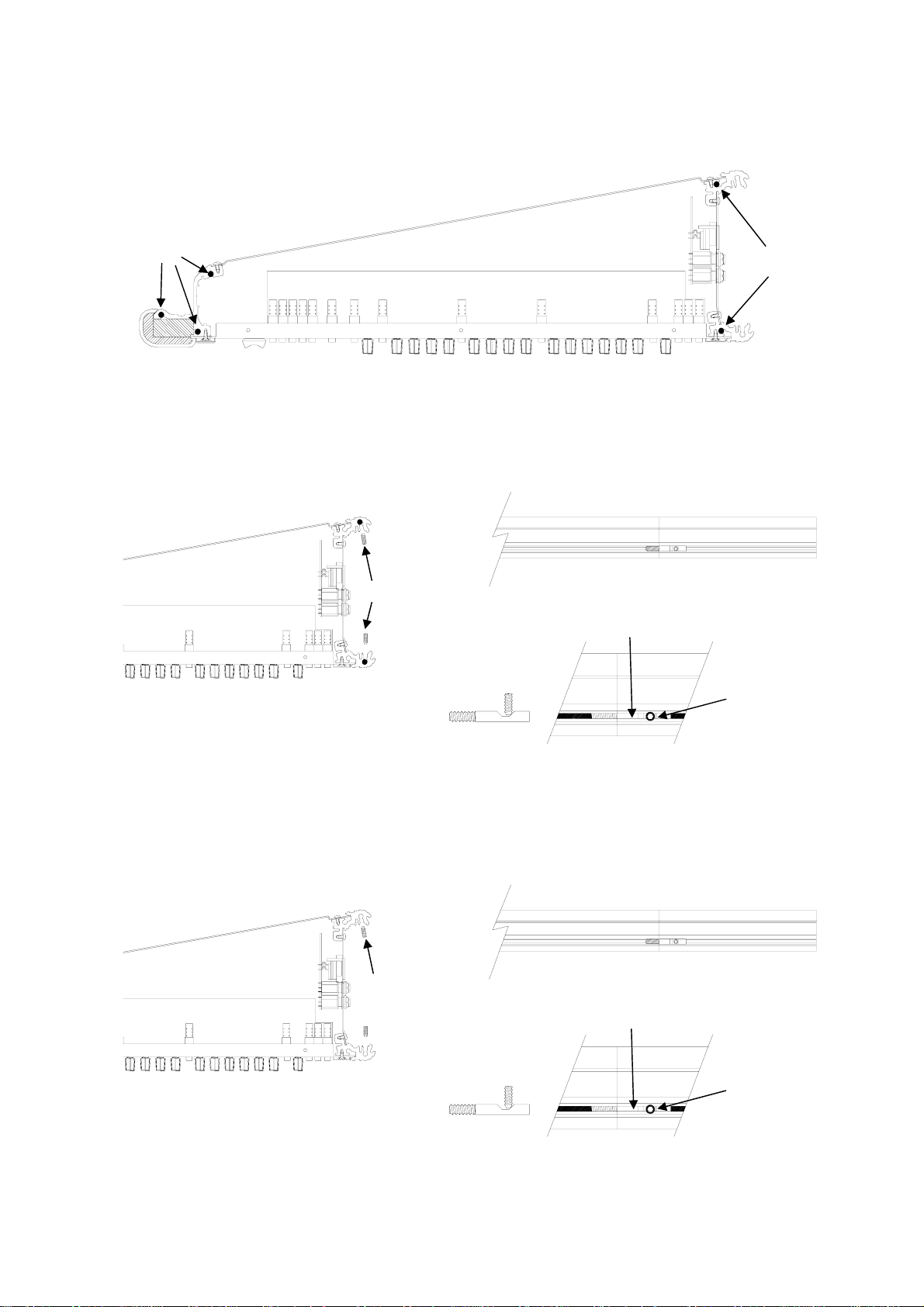

REMOVING A CONNECTOR CIRCUIT BOARD ASSEMBLY

Before beginning any service work, remove all power to the console and disconnect any signal cables where necessary.

Service work is best carried out with the console inverted on a clean work surface suitably covered to protect the console

cosmetics. Ensure adequate lighting and use the correct tools. Access to the connector circuit boards is as follows:

1.) With the console inverted, remove the base. Identify which connector board is to be removed and then

disconnect the flat flexible cables and ribbon harnesses to it.

2.) Working from the rear of the console remove the screws (A) fixing the XLR connectors to the panel but do

not remove the screws (B) fixing the panel to the chassis. Remove the 12mm hex jack nuts (C) with a suitable

tool.

3.) The circuit board assembly can now be removed from the rear panel.

NOTE: if removing a master connector circuit board assembly, unscrew the green earth wires connecting the

circuit board assembly to the chassis extrusion before lifting the circuit board clear.

When all service work is complete, remove all debris such as solder, component legs and wire clippings from inside the

console and check your work carefully before reassembly. To refit the connector circuit assembly follow the above

procedure in reverse order. Make sure all harnesses are correctly aligned and plugged on. Test for correct operation.

INPUT CONNECTOR

CIRCUIT BOARD

ASSEMBLY

MASTER CONNECTOR

CIRCUIT BOARD

ASSEMBLY

INPUT CONNECTOR

CIRCUIT BOARD

ASSEMBLY

INPUT CONNECTOR

CIRCUIT BOARD

ASSEMBLY

INPUT SECTION

ALLEN & HEATH

CONSOLE FRONT

GL4000-824 inverted with the base cover removed.

MASTER SECTION

GL4000 Rear Panel View.

Section A - 10

INPUT SECTION

B

C

C

C

C

A

A

B

L4DSM2

Page 15

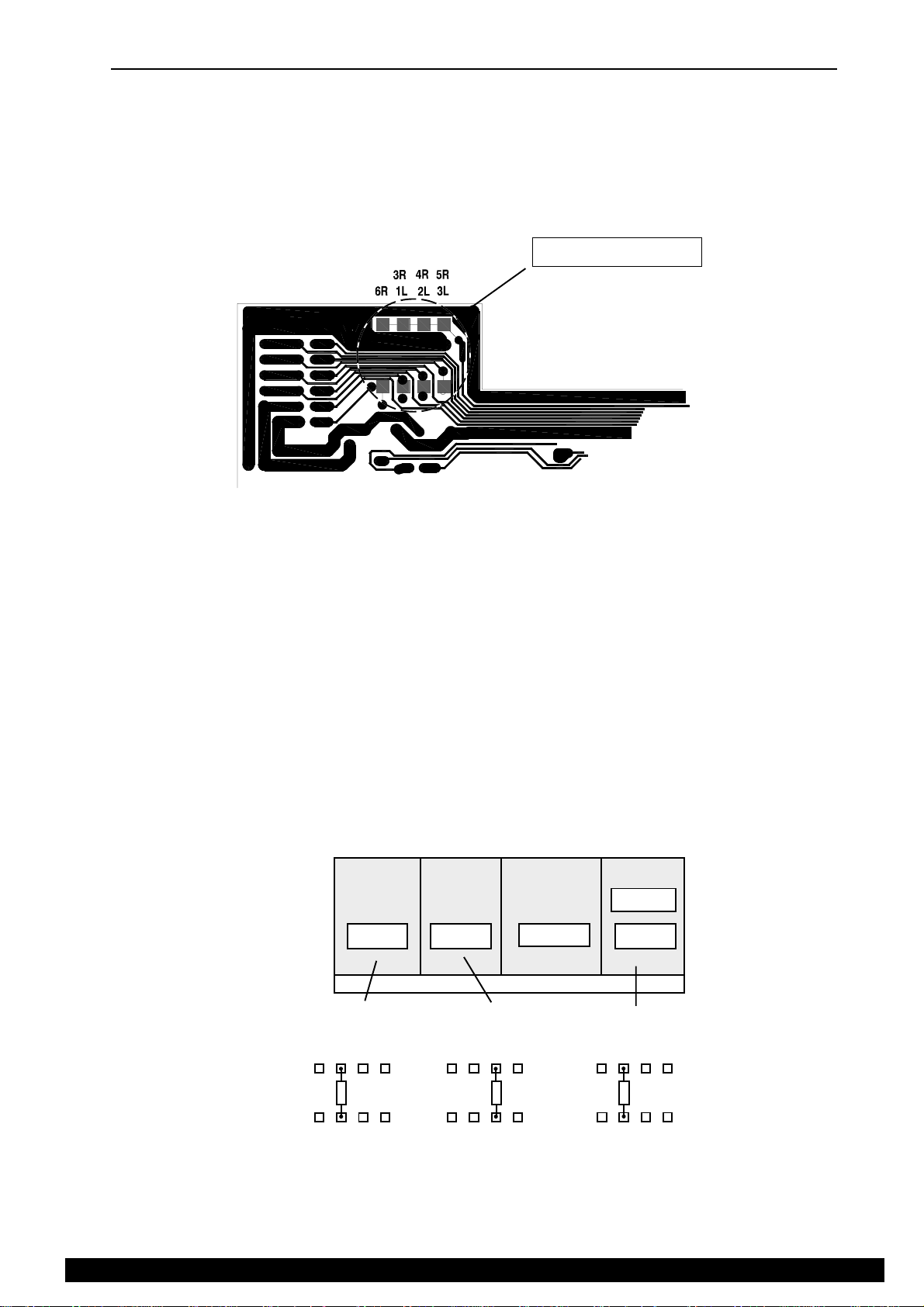

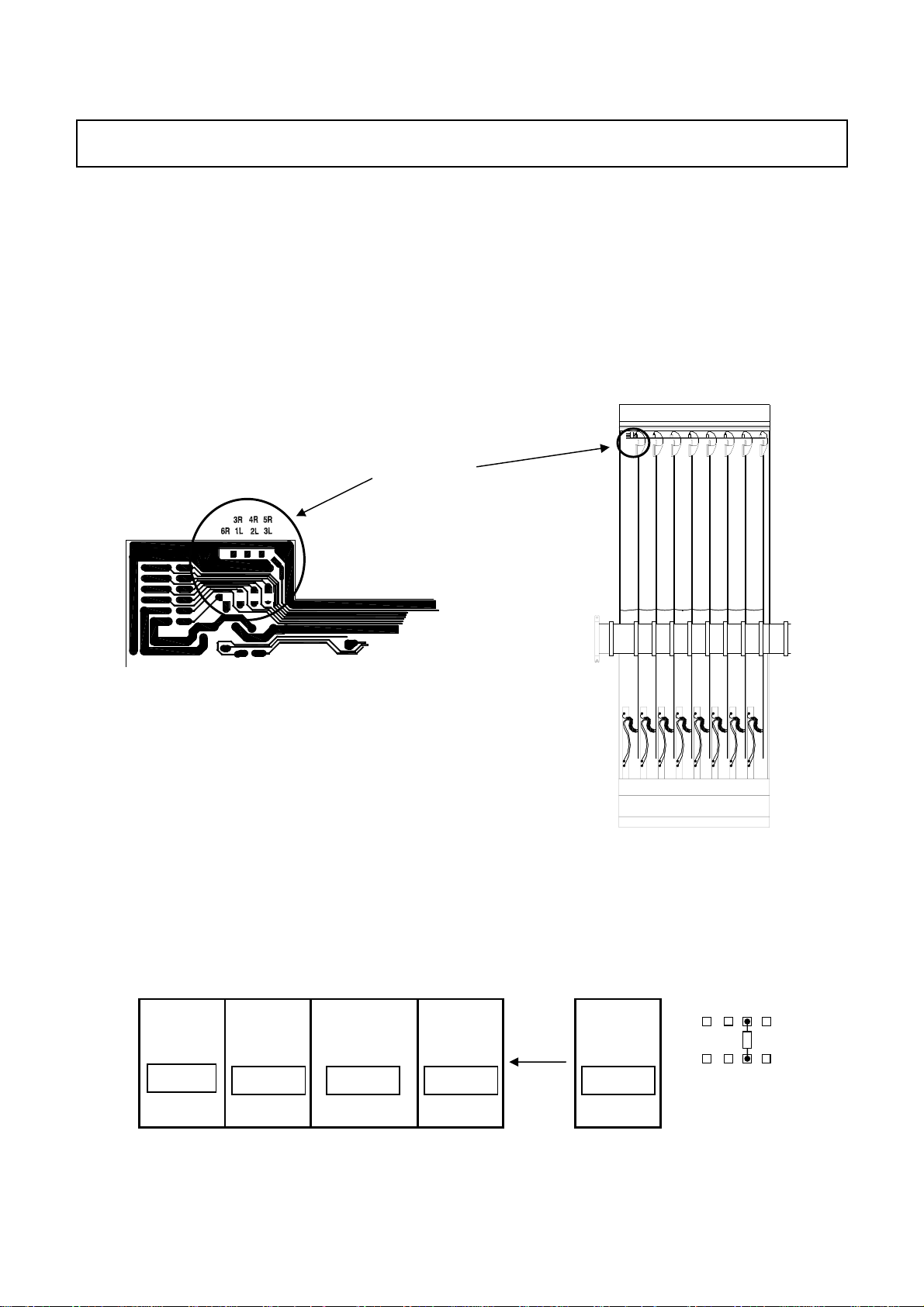

ASSIGNING AN INPUT CONNECTOR CIRCUIT BOARD ASSEMBLY

Before fitting a replacement input connector circuit board assembly, check the assignment of the channel mutes is

correct. If possible check the circuit board assembly with the one that has been removed.

The assignment links are zero ohm (0R) resistors and are located near to the ribbon harness connector on the input

connector board.

The channel mute assignment is set by soldering a 0R resistor into one of four locations. see below

Assignment links

Input connector

circuit board

track side view

The diagrams below show the channel mute link assignments for the input connector circuit board assemblies for each

console format.

Remember when adding an expander to the console the assignment of the links in the console may also require

reassigning. Refer to the expander fitting instructions (AP2794).

GL4000-824S

GL4000M-824n

(Stereo configurations differ)

stereo

6R

17 - 24

4R

3R

2L

1L

5R

3L

3R

1L

1 - 8

4R

2L

5R

3L

9 - 16

3R

6R6R

1L

4R

2L

MASTER

5R

3L

L4DSM2

Section A - 11

ALLEN & HEATH

Page 16

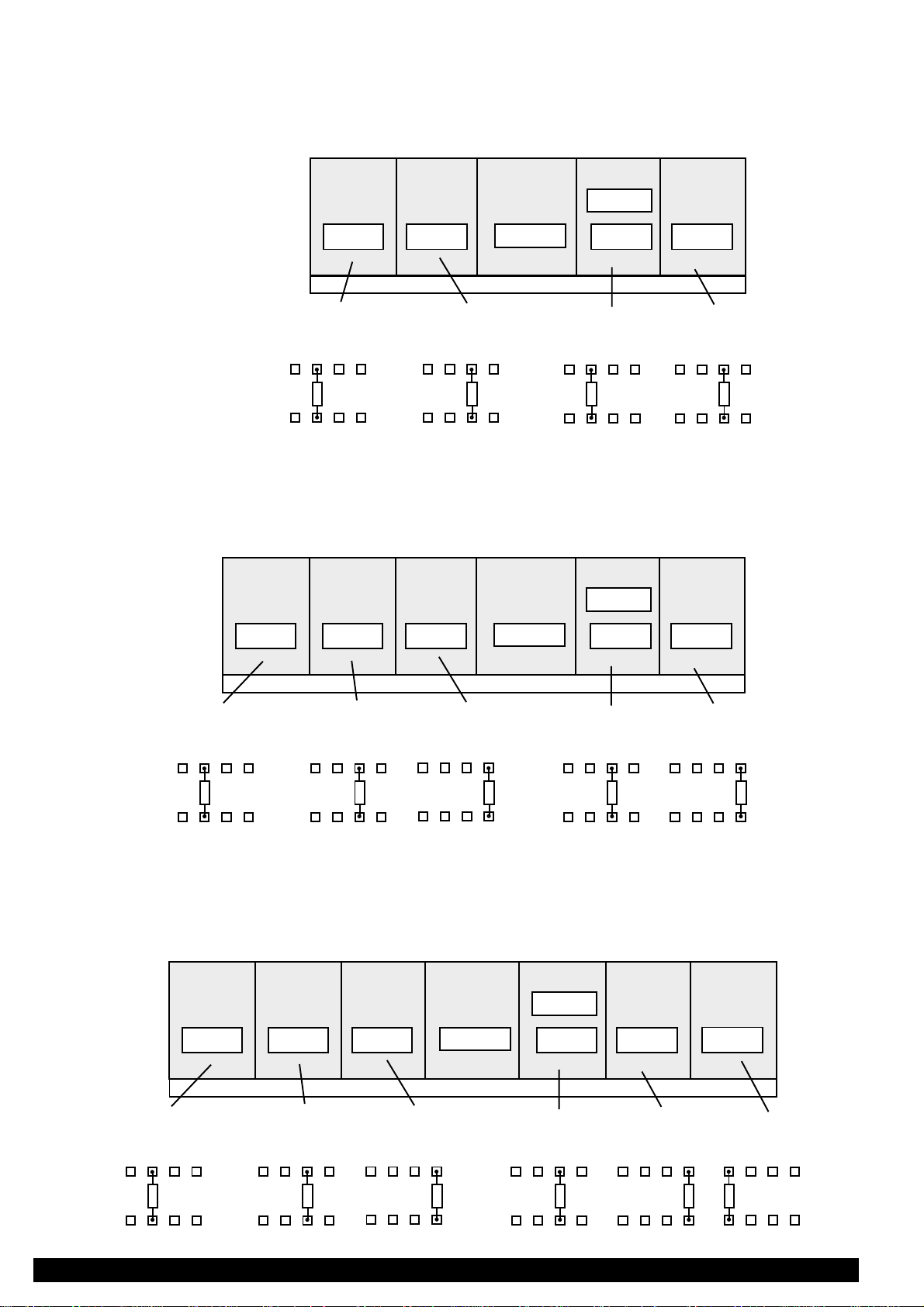

GL4000-832S

GL4000M-832n

(Stereo configurations differ)

stereo

GL4000-840S

GL4000M-840n

(Stereo configurations differ)

1 - 8

6R

3R

1L

1 - 8

4R

2L

9 - 16

5R

3L

9 - 16

3R

6R

1L

17 - 24

4R

2L

MASTER

5R

3L

MASTER

6R

17 - 24

4R

3R

2L

1L

stereo

25 - 32

5R

3L

25 - 32

3R

6R

1L

33 - 40

4R

2L

5R

3L

5R

4R

3R

6R

1L

2L

3L

GL4000-848S

GL4000M-848n

(Stereo configurations differ)

1 - 8

5R

4R

3R

6R

1L

2L

3L

9 -16

3R

1L

4R

2L

5R

3L

3R

1L

5R

4R

3L

2L

17 - 24

6R

3R

1L

6R

4R

2L

4R

3R

2L

1L

MASTER

5R

3L

5R

3L

6R

stereo

25 - 32

3R

4R

1L

2L6R

6R

5R

3L

3R

1L

4R

2L6R

6R

5R

3L

33 - 40

4R

3R

2L

1L

6R

5R

3L

3R

1L

5R

4R

3L

2L

41 - 48

3R

6R

1L

4R

2L

5R

3L

ALLEN & HEATH

Section A - 12

L4DSM2

Page 17

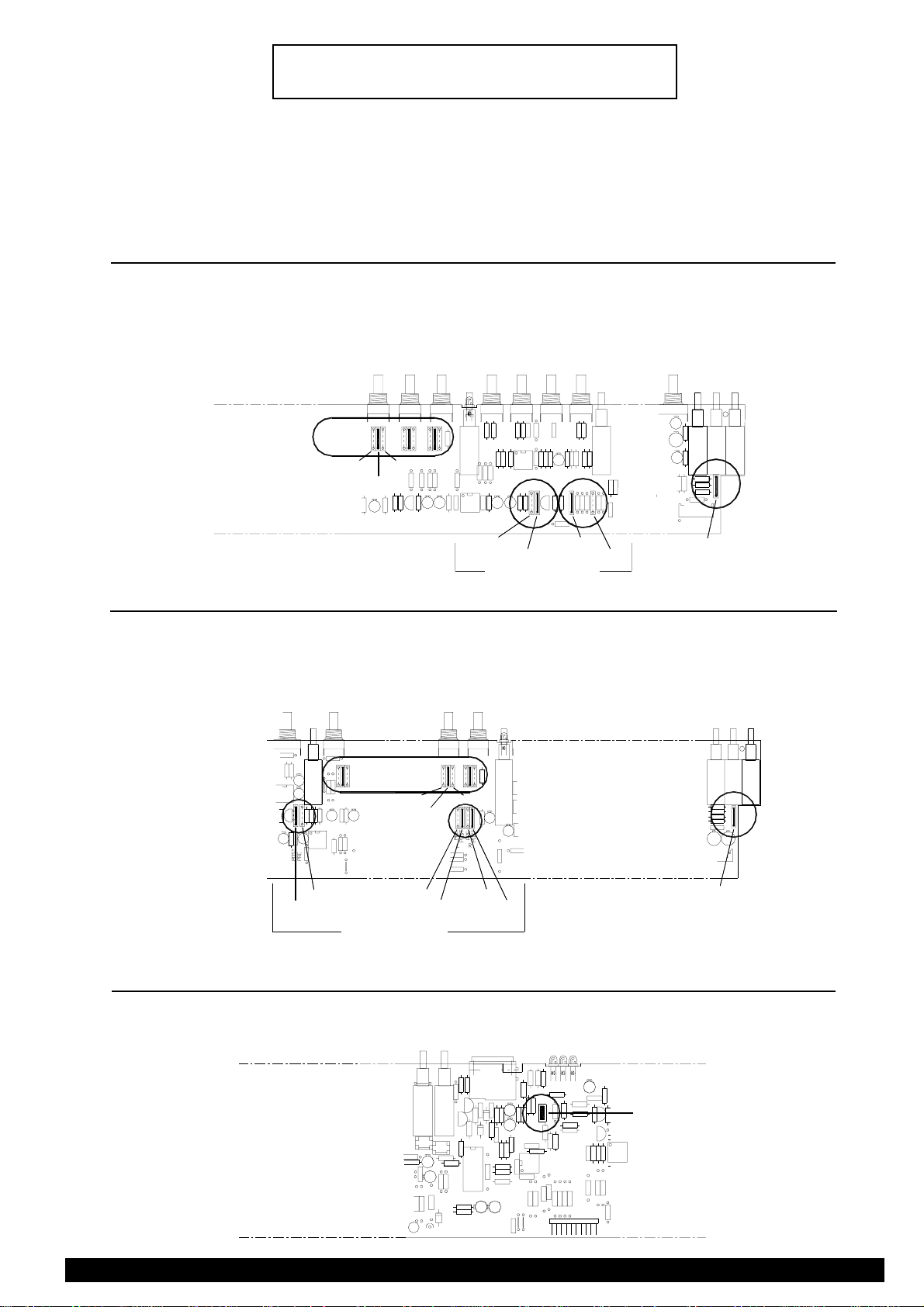

INTERNAL LINK OPTIONS

The GL4000 is configured to satisfy most of the applications that are likely be encountered. However, the following

internal link options are offered for those applications that may require alternative settings. These options require access

to the internal circuit assemblies and resoldering of circuit board links. This work should be carried out by technically

competent personnel. Further information is available in the separately available service manual and from your Allen

& Heath agent.

MONO CHANNEL

Set individual aux sends to be permanently pre-fader or post-fader rather than switched. Re-position wire links. Set the

pre-fade aux sends to be pre-EQ rather than post-EQ. Re-position a wire link. Set the pre-fade aux links to be pre-mute

rather than post-mute. Re-position a wire link. Disable +48V phantom power so that the panel switch has no effect. Cut

out the wire link.

AUX1AUX2AUX3

EQ

POST-FADE

PRE-FADE

SWITCHED

MONO INPUT

PRE-MUTE

POST-MUTE

PRE-FADE AUX OPTIONS

POST-EQ

PRE-EQ

+48V PHANTOM POWER

ENABLE

STEREO CHANNEL

Set individual aux sends to be permanently pre-fader or post-fader rather than switched. Re-position wire links. Set the

pre-fade aux sends to be pre-EQ rather than post-EQ. Re-position 2 wire links. Set the pre-fade aux links to be pre-mute

rather than post-mute. Re-position a wire link. Disable +48V phantom power so that the panel switch has no effect. Cut

out the wire link.

PRE-MUTE

POST-MUTE

POST-FADE

SWITCHED

PRE-EQ

POST-EQ

PRE-FADE AUX OPTIONS

AUX1AUX2

EQ

PRE-FADE

PRE-EQ

LR

POST-EQ

STEREO INPUT

+48V PHANTOM POWER

ENABLE

TALKBACK MIC +48V

Disable +48V phantom power from the TB mic input XLR. Remove a jumper link (fit on 1 pin to keep in console).

TB MIC IN

L4DSM2

TALKBACK

Section A - 13

TALKBACK MIC

PHANTOM POWER

+48V ENABLE

ALLEN & HEATH

Page 18

ORDERING SPARE PARTS

ORDERING A CONSOLE

To order a new console please specify the model number required. Refer to the section: Standard Consoles for more detail

MODEL DESCRIPTION ORDER CODE

GL4000M-824A/B/C/D 24 Input channels with integral meterbridge + Power Supply GL4000M-824n

GL4000M-832A/B/C/D/E 28 Input channels with integral meterbridge + Power Supply GL4000M-832n

GL4000M-840A/B/C/D 36 Input channels with integral meterbridge + Power Supply GL4000M-840n

GL4000M-848A/B/C/D/E/F 44 Input channels with integral meterbridge + Power Supply GL4000M-848n

ORDERING AN OPTION

To order an option please specify the model number required:

GL4000-M24 Meterpod to fit 24 channel console GL4000-M24

GL4000-M32 Meterpod to fit 32 channel console GL4000-M32

GL4000-M40 Meterpod to fit 40 channel console GL4000-M40

GL4000-M48 Meterpod to fit 48 channel console GL4000-M48

GL4000-8M 8 Mono Input channel expander GL4000-8M

GL4000-4SM 4 Mono + 4 Stereo Input channel expander GL4000-4SM

GL4000-SL1 GL4000 SYS-LINK kit GL4000-SL1

RPSD2 Dual supply Combiner / Monitor RPSD-2

MANUALS AND SUPPORT DOCUMENTATION

DESCRIPTION ORDER CODE

GL4000 Brochure AP2641

GL4000 User Guide AP2642

GL4000 Service Manual AP2640

GL4000 Meterpod Fitting Instructions AP2126

GL4000 SYS-LINK Fitting Instructions AP2786

GL4000 SYS-LINK Application Note AP2787

GL4000-8M / 4SM Fitting Instructions AP2794

RPS11 User / Installation Guide AP2725

RPSD-2 & RPSD User / Installation Guide AP2263

SOFTWARE EPROM

To order a replacement EPROM, please contact ALLEN & HEATH and notify us of your console serial number, its present

EPROM version and code number and reason for the replacement.

GL4000 software

SERVICE TOOLS

The tools required to service the GL4000 are standard to an electronics service workshop and are easily obtainable. The

following items are necessary for disassembly and service access:

ALLEN & HEATH

4mm Hexagon (Allen) key (M6 side trim) AT0033

1-point Crosshead screwdriver (M3, 4AB) AT0004

2-point Crosshead screwdriver (M4, 6AB) AT0004

11mm Nutdriver (potentiometer nuts, headphone socket nuts)

12mm Nutdriver (jack nuts)

Torx-headed screw drivers

Section A - 14

L4DSM2

Page 19

ORDERING AN ASSEMBLY

The following assemblies are supplied fully tested. Please note that several of these need to be assigned according to

their position in the console. This is done by soldering wire links or assignment pads. It is best to check the assignment

settings of the assembly you are replacing before removing it from the console. Please quote the description and order

code for the part required.

Printed circuit (PCB) assemblies:

Mono Input Connector IN-8M CONN PCB assembly* 002-161

Mono Input PCB assembly 002-160

Stereo Input Connector IN-4SM CONN PCB assembly* 002-196

Stereo Input PCB assembly 002-195

Group 1-4 PCB assembly*+ 002-162

Group 5-8 PCB assembly*+ 002-163

Left / Right PCB assembly*+ 002-197

Master PCB assembly 002-165

Master connector PCB assembly 002-166

Mono PCB assembly 002-164

Slave PCB assembly 002-167

MPU & 3 digit display PCB assembly 002-198

RPS11 PCB assembly 002-047

GL4000 Meterpod PCB assembly LEFT 002-039

GL4000 Meterpod PCB assembly RIGHT 002-040

GL4000M Meterpod PCB assembly LEFT 002-464

GL4000M Meterpod PCB assembly RIGHT 002-465

* Requires assignment + Quote Group Number, Left or Right

IDC connector harnesses:

GL4000-824/32/40 & 48 40 way Main harness AL2636

GL4000-824 & 832 16 way left hand harness AL2763

GL4000-840 & 848 16 way left hand harness AL2764

GL4000-816 & 824 16 way right hand harness AL2760

GL4000-832 & 840 16 way right hand harness AL2761

GL4000-848 16 way right hand harness AL2762

GL4000 (all formats) 16 way Master harness AL2759

GL4000 (all formats) 16 way Meter harness AL2733

GL4000 (all formats) 26 way MPU harness AL2732

THE CHASSIS TRIM

GL4000 (all formats) Left & Right Chassis side trims AA2089L/R

GL4000M (all formats) Left & Right Chassis side trims AA3584-L/R

Write-on strip 10' AK0327

GL4000-824 & 832 Ident strip CHAN 1-16 AK2637

GL4000-824 & 832 Ident strip CHAN 1-16 Rear AK3112

GL4000-840 & 848 Ident strip CHAN 1-24 AK2638

GL4000-840 & 848 Ident strip CHAN 1-24 Rear AK3113

GL4000-824 & 832 Ident strip GRP 1- CHAN 32 AK2639

GL4000-824 & 832 Ident strip GRP 1- CHAN 32 Rear AK3114

GL4000-840 & 848 Ident strip GRP 1- CHAN 40 AK2703

GL4000-840 & 848 Ident strip GRP 1- CHAN 40 Rear AK3115

GL4000-848 Ident strip CHAN 41-48 AK2704

GL4000-848 Ident strip CHAN 41-48 Rear AK3116

GL4000 Meterpod Left & Right Meterpod side trims AA2090L/R

L4DSM2

Section A - 15

ALLEN & HEATH

Page 20

ORDERING A SPARES KIT

It is recommended that the spares kit order code 002-177 is held and maintained by the service agent to enable in-field

service repairs to the GL4000 independent of the ALLEN & HEATH factory. If you are an existing ALLEN & HEATH

service agent who already stocks the spares kit for the ALLEN & HEATH GL4, you may already stock some of the common

parts. A TOP-UP kit 002-178 is available which provides just the parts unique to the GL4000 range. Commonly available

items such as resistors, capacitors, tools and soldering equipment are not included. The contents of the kit is listed below

and is supplied in a cabinet of drawers. Individual spare parts may be ordered. Please quote the description and order

code for the part required.

A - GL4000 STANDARD SPARES KIT

B - GL4 TO GL4000 TOP-UP KIT

AB

DESCRIPTION ORDER CODE QTY QTY

Fixings:

Screw 4AB x 5/16" Pan Pozi Black AB0057 10 Screw 4AB x 5/16" CSK Pozi Black AB0059 10 Screw 6B x 5/16" Pan Pozi Black AB2084 10 Screw 8B x 5/16" CSK Pozi Black AB2085 10 Screw 6B x 1/4" CSK Pozi zinc AB2083 10 Screw 6B x 3/8" CSK Pozi zinc AB2082 10 Screw M6 x 20mm CSK Allen Black AB0310 5 Screw M3 x 5mm CSK Pozi Black AB0070 10 Screw M3 x 8mm Pan Pozi Black AB0073 10 Screw M3 x 8mm CSK Pozi Black AB0074 5 Nylock Nut M3 AB0102 5 Fixing for D type connector AB2189 10 Joint Block AB0253 2 Plastic pillar snap-in AB2233 4 4

Knobs and caps:

Knob Yellow & Grey 11mm D AJ2079 10 Knob Dark Grey & Grey 11mm D AJ2078 10 Knob Green & Grey 11mm D AJ2077 10 Knob Blue & Grey 11mm D AJ2075 10 Knob Brown & Grey 11mm D AJ2080 10 Knob Red & Grey 11mm D AJ2074 10 Knob Pale blue & Grey 11mm D AJ2076 10 10

Fader Knob 11mm White+Black line Jungpoon* AJ2231 10 10

Fader Knob 11mm Red+White line Jungpoon* AJ2230 5 5

Fader Knob 11mm Yellow+Black line Jungpoon* AJ2232 5 5

Fader Knob 11mm Blue+White line Jungpoon* AJ2663 5 5

Fader Knob 11mm White+Black line Alps* AJ8078 10 Fader Knob 11mm Red+Black line Alps* AJ8079 5 Fader Knob 11mm Yellow+Black line Alps* AJ8080 5 Fader Knob 11mm Blue+Black line Alps* AJ8081 5 Button 5.5mm Square Grey AJ0363 10 Button 5.5mm Square Red AJ0364 10 Button 5.5mm Square White AJ0373 10 Button 10x5mm Rectangular Grey AJ0093 10 Button 10x5mm Rectangular White AJ0094 10 Button 10x5mm Rectangular Black AJ0096 5 Button large illuminated white AJ8107 10 10

* TO FIND OUT IF JUNGPOON OR ALPS K FADERS/FADER KNOBS CHECK CONSOLE SERIAL NUMBER WITH FACTORY

ALLEN & HEATH

Section A - 16

L4DSM2

Page 21

Faders, Potentiometers, switches, and connectors:

10KA fader 100mm Jungpoon* AI2665 5 5

10KA x 2 fader 100mm (stereo) Jungpoon* AI2664 2 2

10KA fader 100mm Alps K* AI8109 5 5

10KA x 2 fader 100mm (stereo) Alps K* AI8110 2 2

10KA fader 60mm AI8054 5 20KK (203K) AI8003 5 20KB x 2 (203B 14mm wide) AI8006 3 3

20KK x 2 (203K 14mm wide) AI8007 5 20KB (203B) centre click AI8004 5 20KB x 2 (203B 14mm wide) centre click AI8064 3 10KC x 2 (103C 14mm wide) AI0150 5 10KAC x 2 (103AC 14mm wide) AI8008 5 200KC x 2 (204C) AI8005 5 200KC x 2 (204C 14mm wide) AI8009 5 Pot Nut 9mm AB8050 10 Switch 2PCO Latching AL0162 5 Switch 2PCO Momentary AL0374 5 Switch 4PCO Latching AL0333 5 Switch 6PCO Latching AL0354 2 2

Jack Socket Vertical PCB Mount + Hex nut AL8082 5 Jack Socket Headphone AL0328 1 XLR 3 Pin Female Vertical PCB Mount AL8074 5 XLR 3 Pin Male Vertical PCB Mount AL8077 5 XLR 4 Pin Female Chassis Mount AL8104 - -

* TO FIND OUT IF JUNGPOON OR ALPS K FADERS/FADER KNOBS CHECK CONSOLE SERIAL NUMBER WITH FACTORY

LEDs and Semiconductors:

LED 5mm T1¾ Red AE0001 2 2

LED 3mm T1 Green AE0085 5 LED 3mm T1 Yellow AE0084 5 LED 3mm T1 Red AE0086 5 LED Bar 4way 2Gn+1Yel+1Rd AE2702 2 2

LED Bar 12way 8Gn+3Yel+1Rd AE2701 2 2

Transistor 2SB737 PNP AE8069 5 Transistor BC549 NPN AE0020 3 Transistor 2N4403 PNP AE0273 5 Transistor BC214 PNP AE0031 3 Transistor J111N FET AE0083 5 Transistor BC637 NPN AE0068 2 2

Transistor BC638 PNP AE0037 2 2

IC NE5532N Dual Op Amp AE0221 5 IC TL072CP Dual Op Amp AE0046 5 IC LM339N Quad Comparator AE0071 2 IC CMOS 4051B AE0118 1 IC CMOS 4053B AE0117 1 IC CMOS 4099B AE0238 1 IC CMOS 74HC259 AE2727 1 1

IC 6N136 Opto isolator AE0222 1 IC TTL 74LS373N AE0140 1 IC TTL 74LS138N AE0248 1 IC Regulator 7805 (+5V DC) AE0308 2 -

L4DSM2

Section A - 17

ALLEN & HEATH

Page 22

POWER SUPPLY:

Lamp Neon AL0200 2 Mains Fuse 20mm T3.15A (UK, EC) AL0464 5 Mains Fuse 20mm T5A (USA) AL2270 5 5

Mains Fuse 20mm T8A (DC) AL0487 5 5

Transformer 320VA AM2720 - Bridge Rectifier 25A 200V AE0239 1 Transistor MJ3001 AE0240 2 Transistor cover (inc. split washers) AK2767 2 2

Thyristor TIC126M AE0272 1 IC Adjustable Regulator 783 (+48V DC) AE0214 2 IC Regulator UA723CN (+/-16V DC) AE0056 2 Fuseholder 20mm Panel Mount AL0578 1 DC cable assembly (10pin plug to 10pin socket)002-223 - DC cable assembly (10pin plug to 5pin XLR) 002-225 - -

RPSD2:

Mains Fuse 20mm T8.0A AL0487 - Mains Filter IEC 10A AL2260 - Mains Outlet IEC 3 Pin AL2261 - Mains Switch Rocker 0-1 AL0587 - LED 5mm T1¾ Tri-colour AE2258 - Zener Diode BZX85 5V6 AE0012 - RPSD2 / RPSD Packing assembly 002-058 - RPSD DC Supply cable (8pin Cinch - 5pin XLR) 002-060 - RPSD2 DC Supply cable (8pin Cinch-10pin fem) 002-227 - IEC Mains Lead 3pin male to female AH2262 - -

METERPOD:

Preset 10K (calibrate) AC0250 - Meter VU+bulb AD3321 2 Bulb (VU meter) AD0013 5 Spacer PCB M3 AB0331 - Screw M6 x 12mm SKT Hex Black (Grub) AB2087 3 Screw M4 x 12mm CSK Hex Black AB2086 10 -

Miscellaneous:

GL4000M-824 Packing assembly 002-474 - GL4000M-832 Packing assembly 002-475 - GL4000M-840 Packing assembly 002-476 - GL4000M-848 Packing assembly 002-477 - Facia 3 digit display AA2726 - Flex cable 12 way 90mm AH2228 5 Flex socket 12 way 90deg AL2226 - Flex socket 12 way straight AL2227 - Ferrite Bead Axial AF0610 - -

ALLEN & HEATH

Section A - 18

L4DSM2

Page 23

SECTION B

FITTING

INSTRUCTIONS

CAUTION !

B

TO AVOID DAMAGE TO INTERNAL COMPONENTS BY

MISHANDLING AND/OR MISCONNECTION, ONLY

TECHNICALLY COMPETENT PERSONNEL SHOULD

ATTEMPT SERVICE WORK ON THIS CONSOLE.

L4DSM2

Section B - 1

ALLEN & HEATH

Page 24

GL4000 Expander

ALLEN&HEATH

Fitting instructions

The GL4000 expander options are designed to attach to either side of the GL4000 console depending on

console format. The expander can be fitted to consoles with the integral meterbridge as well as those consoles

that do not have the integral meterbridge. The expander modules allow a GL4000 console to be expanded up to

a maximum of 48 channels.

Please read the following instructions carefully before attempting to fit the module.

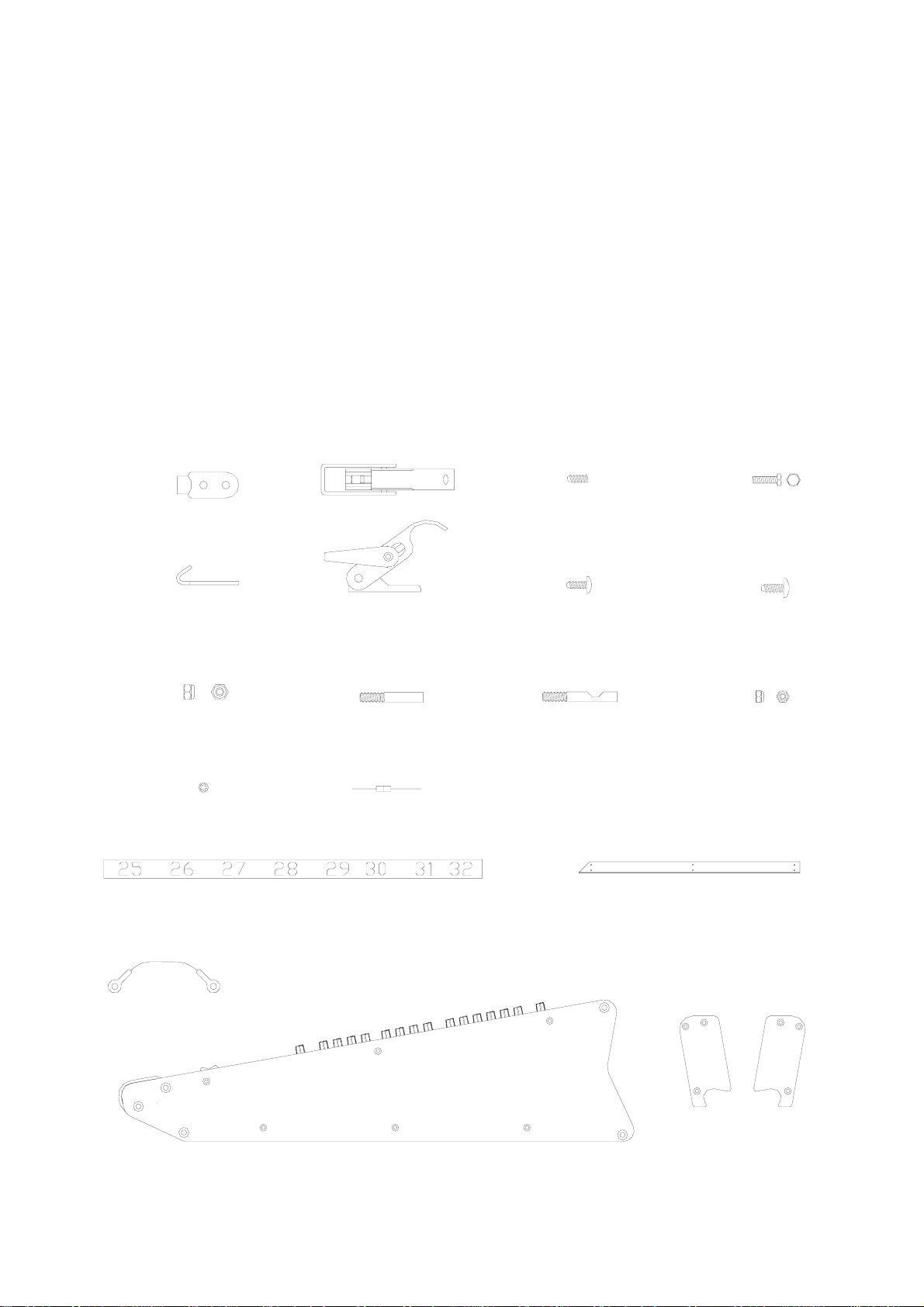

1. Check contents of pack to ensure all parts have been supplied.

A

CATCHPLATE

QUANTITY 1

PART NO. AB0336

G

NUT LOCK M4

QUANTITY 4

PART NO. AB0188

P

SHAKEPROOF WASHER

QUANTITY 3

PART NO. AB0244

IDENT STRIP

L

QUANTITY 1 SET

PART NO.s AK2637 AK2638 AK2639 AK2703 AK2704

AK3112 AK3113 AK3114 AK3115 AK3116

B

ADJUSTABLE FASTENER

QUANTITY 1

PART NO. AB0335

H

STUD M6X38.5

QUANTITY 5

PART NO. AB0325

Q

0R LINK

QUANTITY 5

PART NO. AC0335

C

SCREW M6X8 SKT HEX

QUANTITY 2

PART NO. AB2421

E

SCREW 6BX5/16

QUANTITY 40

PART NO. AB2810

J

STUD SLOTTED

QUANTITY 2

PART NO. AB2406

M

D

SCREW M3X6 HEX

QUANTITY 3

PART NO. AB2813

F

SCREW M4X10

QUANTITY 4

PART NO. AB0271

K

NUT LOCK M3

QUANTITY 3

PART NO. AB0102

BASE BRACKET

QUANTITY 1

PART NO. AA2191

EARTH STRAP

N

QUANTITY 1

PART NO. 002-237

EXPANDER WITH SIDE TRIMS

Allen & Heath AP2794 issue 3 1

SIDE PLATES

R

QUANTITY 1 PAIR

PART NO: AA3849L&R

Page 25

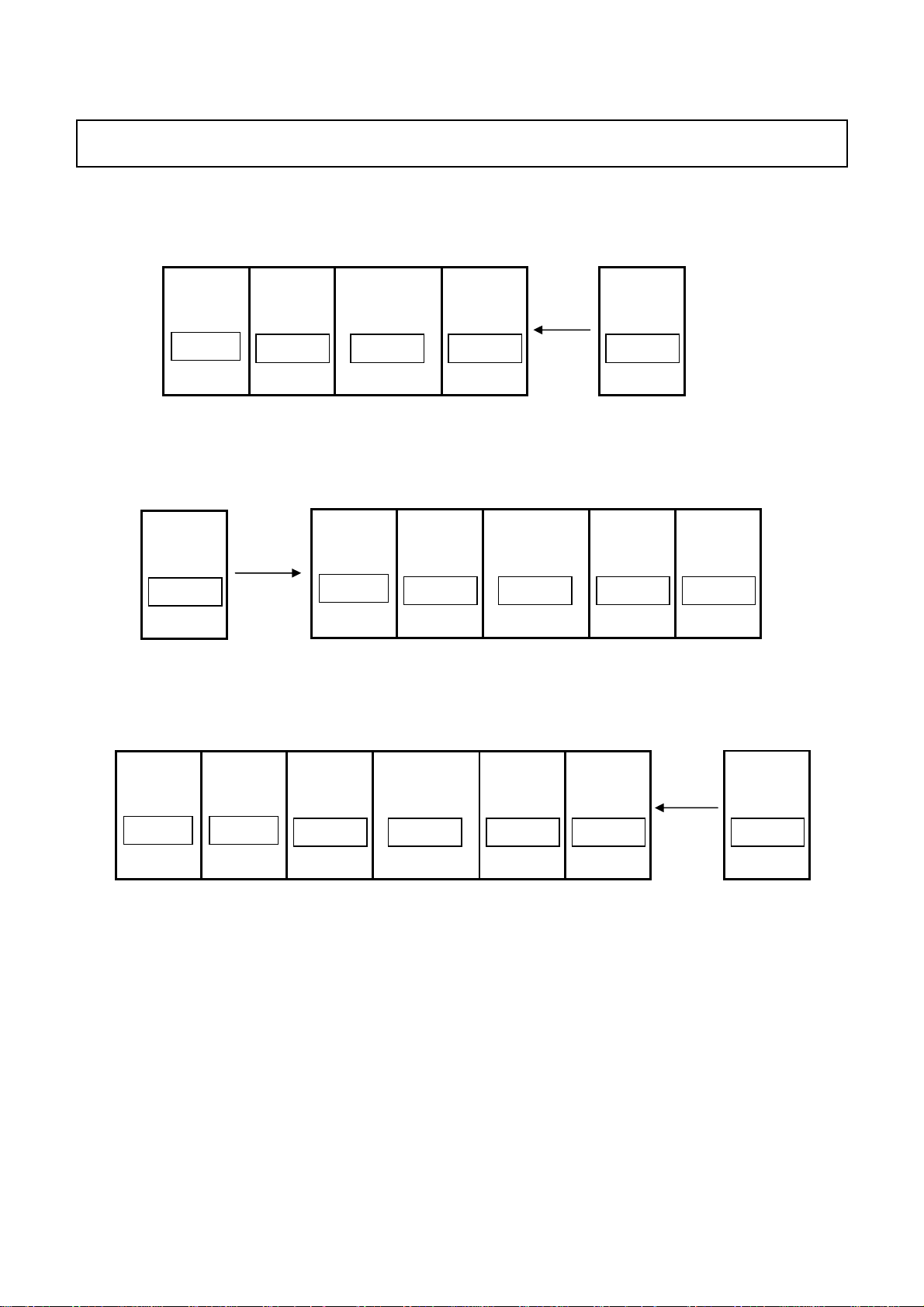

EXPANDER POSITIONING

2. The Expander unit must be fitted in the position shown in the diagrams below.

GL4000-824 + Expander

1 - 8

9 - 16 Master Expander 17 - 24

GL4000-832 + Expander

Expander

GL4000-840 + Expander

1 - 8

9 - 16 Master 25 - 32 17 - 24

1 - 8

9 - 16

17 - 24 Master 33 - 40 25 - 32

Expander

TOOLS REQUIRED:

The following tools are required to fit the expander module.

1x 2.5mm Hex key

1x 4mm Hex key

1x 1-point Pozi screwdriver

1x flat point screwdriver

1x long nose pliers

1x 5.5mm AF spanner

1x wire cutters

1x small tipped soldering iron and solder

Allen & Heath AP2794 issue 3 2

Page 26

INSTALLATION

Only technically competent personnel should attempt to fit the expander module.

Disconnect the Power Supply Unit and cables from the console before fitting the

expander module

3. Ensure you have a good work surface and clear area before starting work. Carefully invert the console and

remove the base panel by removing all screws along the edges of the base panel. Also remove the 3 screws

in the centre of the large base panel. Note; do not rest the console on the meterbridge.

4. Remove the side trim and bracket from the side of the console that is to have the expander fitted. Similarly;

remove the side trim and bracket from the side of the expander that is to be joined to the console.

Figure shows console to be expanded on right hand side

Allen & Heath AP2794 issue 3 3

Page 27

5. Attach the adjustable fastener ‘B’ to the inside of the front extrusion of the console and catchplate ‘A’ to the

inside of the expander using screws

‘F’ and nuts ‘G’. The mounting holes are located under the front

armrest of each unit and are pre-drilled for the adjustable fastener and catchplate. Make sure the movement

of the fastener lever does not interfere with the input channel circuit board assemblies.

Attach adjustable fastener ‘B’

‘

’

console

6. Screw the 2 slotted studs ‘J’ into the upper and lower rear extrusions of the console. Rotate the studs until

the flat is visible in the slots.

J

console

Console with integral meterbridge

6a. Screw the single slotted stud ‘J’ into the lower rear extrusion of the console. Rotate the stud until the flat is

visible in the slot.

J

Console with integral meterbridge

Allen & Heath AP2794 issue 3 4

Page 28

7. Screw the 5 plain studs

‘H’ into the extrusion holes of the expander as shown below.

H

8. Slide the expander module onto the 7 studs and close the adjustable fastener ‘B’ over the catchplate ‘A’,

see 5. The fastener can be adjusted to ensure a good join. Screw in the locking screws

tapped holes of the expander. Make sure the locking screws

expander

H

‘C’ into the pre-

‘C’ engages with the flat of the slotted studs

‘J’, see diagram below.

expander

console expander

C

C

C

J

Console with integral meterbridge

8a. Slide the expander module onto the 6 studs and close the adjustable fastener ‘B’ over the catchplate ‘A’,

see 5. The fastener can be adjusted to ensure a good join. Screw in the locking screw

tapped hole of the expander. Make sure the locking screw

see diagram below.

expander

‘C’ engages with the flat of the slotted stud ‘J’,

console expander

‘C’ into the pre

C

C

C

J

Allen & Heath AP2794 issue 3 5

Page 29

9. With the expander module and console securely clamped together, bolt the expander and console front

panels together using bolts

assembly nearest the panel flanges will have to be removed to gain access to the fixing holes.

10. Disconnect the main harness from the end input channel circuit board on the console. Connect the male

connector on the expander harness to the console main harness. Re-connect the end Input circuit board

with the extra connector on the expander harness.

11. The 16 way ribbon harness is factory fitted for attaching the expander onto the right hand side of the main

console as shown. Connect the 16 way ribbon harness in same way as the main harness.

If the expander is fitted on the left hand side then the 16 way ribbon harness will have to be repositioned

accordingly.

12. Connect the expander green wire back to the console main extrusion using screw

not connect the wire back to the expander extrusion.

13. Connect the short green wire strap ‘N’ across the join in the rear chassis extrusions of the console and

expander module using screws

16 way ribbon harness

(

see 11)

‘D’ and lock nuts ‘K’ with a 5.5mm spanner. The input channel circuit board

‘E’ and washer ‘P’. Do

‘E’ and washers ‘P’ .

N+E+P

(see 13)

D+K (see 9)

E+P (see 12)

main harness connected to expander harness.

(

see 10)

Console inverted and expanded on the right side.

Allen & Heath AP2794 issue 3 6

Page 30

EXPANDER ASSIGNMENT

14. Depending on whether the expander is positioned on the left or right hand side of the main console, one or

more of the input connector circuit boards (AG2622) will have to be assigned to enable the channel mutes to

function correctly.

For consoles that have the expander on the right hand side of the console (e.g. expanded GL4000-824S and

GL4000-840S consoles) only the expander requires assignment.

For consoles that have the expander on the left hand side (e.g. expanded GL4000-832S consoles), all of the

input connector circuit boards will have to have the existing assignment links removed and re-assigned.

Refer to the assignment diagrams below.

The assignment links are 0R resistors

input connector circuit board. Fitting the links in various positions determines the assignment for each block

of 8 input channel mutes.

Trackside view

Input connector circuit board

Link assignments for each input connector circuit board

To avoid having to remove the input connector circuit board, fit the links onto the track side of the circuit board

‘Q’, located next to the 16 way ribbon harness connector on the

Location of

assignment

links

GL4000-824 + Expander

1 - 8

Allen & Heath AP2794 issue 3 7

9 - 16 Master Expander17 - 24

3R 4R 5R

6R 1L 2L 3L

Page 31

GL4000-832 + Expander

Note: remove existing assignment links on all connector circuit boards before re-assignment.

Expander

1 - 8

9 - 16 Master 25 - 32 17 - 24

3R 4R 5R

6R 1L 2L 3L

3R 4R 5R

6R 1L 2L 3L

3R 4R 5R

6R 1L 2L 3L

3R 4R 5R

6R 1L 2L 3L

3R 4R 5R

6R 1L 2L 3L

GL4000-840 + Expander

1 - 8

9 - 16

17 - 24 Master 33 - 40 25 - 32 Expander

3R 4R 5R

6R 1L 2L 3L

Attaching the base panels

15. Attach the base panel joining bracket ‘M’ to the console base using screws ‘E’. Refit the base panels onto

the expanded console using screws

‘E’ .

Console with integral meterbridge.

Fit the meterbridge side plate ‘R’ using the screws from the original side trim.

Allen & Heath AP2794 issue 3 8

Page 32

NUMBER STRIP POSITIONING

16. Carefully turn the console the correct way up and fit the new number strips. A complete set of number strips

‘L’ is supplied with the Expander kit. The diagrams below show the combination of strips to be fitted to the

expanded consoles.

GL4000-824 + Expander

1 - 8

GL4000-832 + Expander

Expander

1 - 8

9 - 16 Master Expander17 - 24

MONO

9 - 16 Master 25 - 32 17 - 24

GL4000-840 + Expander

1 - 8

9 - 16

17 - 24 Master 33 - 40 25 - 32

MONO

Expander

41 4442 43 45 46 4847

Allen & Heath AP2794 issue 3 9

Page 33

TESTING THE CONSOLE

17. The fitting of the expander module is now complete. Before re-plugging the console, apply power and check

for correct operation e.g. mutes & PFL LEDs illuminate.

Please note; to prevent damage to the console chassis, the expanded console must be supported along

its entire length.

Should you experience any difficulties in fitting this module or have any queries regarding your GL4000 console

please contact your ALLEN & HEATH agent. Include the console serial number in any correspondence.

Allen & Heath AP2794 issue 3 10

Page 34

ALLEN&HEA ALLEN&HEA

ALLEN&HEA

ALLEN&HEA ALLEN&HEA

THTH

TH

THTH

GL4000

MIXING CONSOLE

SYS-LINK

EXPANDER OPTION

This option connects a GL4000 console as a channel expander to a

second console with just one or two interconnecting cables.

Kit GL4000-SL1 = SINGLE

Single option to install SYS-LINK to one GL4000 console to allow

interconnection to a second console already fitted with SYS-LINK.

Kit GL4000-SL2 = DUAL (2x GL4000-SL1)

Dual option to install SYS-LINK to two GL4000 consoles.

Interconnecting cables not supplied.

For information on using SYS-LINK please refer to APPLICATIONS NOTE AP2787

FITTING INSTRUCTIONS

Publication AP2786

Issue 2 July 01

Page 35

FITTING THE GL4000 SYS-LINK EXPANDER OPTION

CHECK THE CONTENTS :

nn

n

nn

GL4000-SL1

rear extrusion earth wire

Ribbon harness assembly supplied

pre-formed and connected to circuit

board assembly.

Rear panel D type

chassis connector

fixings already fitted.

4 x foam strips

8 x AB2189

fig. 1

Contents:

1x SYS-LINK circuit board assembly with interconnecting harness and mountings already fitted.

1x SYS-LINK ribbon harness assembly with D type chassis connector fixings already fitted.

1x SYS-LINK Fitting Instructions (AP2786)

1x SYS-LINK Application notes (AP2787)

4x self adhesive foam pads (AK0332)

TOOLS REQUIRED :

oo

o

oo

LONG NOSE

1pt & 2pt CROSS POINT

2

GL4000 SYS-LINK OPTION

ALLEN & HEATH

Page 36

Only technically competent personel should attempt to fit the SYS-LINK option.

Disconnect the Power Supply Unit and cables from the console before fitting

the expander module.

PRELIMINARY:

pp

p

pp

To fit the SYS-LINK option it is necessary to partially remove the INPUT CHANNEL circuit board assembly

next to the GROUP 1 circuit board to enable access to the SYS-LINK circuit board mounting holes. The

INPUT CONNECTOR circuit board assembly behind the SYS-LINK D type connector mounting holes on

the rear panel will also have to be removed. It is not necessary to remove any other circuit board assemblies

as access to the SYS-LINK connections can be made with a pair of long nose pliers.

REMOVE THE KNOB CAPS:

qq

q

qq

Pull off the knob caps and unscrew the nuts from the INPUT CHANNEL next to GROUP 1 channel. The

switch caps can remain in place.

Remove the optional Meterbridge if fitted.

REMOVE THE CONSOLE BASE :

rr

r

rr

Carefully invert the console and remove the base panel by removing all screws along the edges of the base

panel. Also remove the 3 screws in the centre of the largest panel

REMOVE THE INPUT CONNECTOR CIRCUIT BOARD ASSEMBLY:

ss

s

ss

The INPUT CONNECTOR circuit board assembly (A) directly behind the SYS-LINK connector mountings on

the rear panel must be removed to gain access to the SYS-LINK D type connector mounting holes.

Follow the procedure below:

1 Unscrew the 16 XLR mounting screws and remove the 32 jack socket nuts on the rear connector

panel.

2 Disconnect the 8 flexible flat cables (C) from the INPUT CHANNEL circuit board assemblies.

3 Disconnectd the ribbon harness (D)

4 Carefully remove the INPUT CONNECTOR circuit board assembly (A) and place to one side.

5 Now remove the SYS-LINK blanking plate.

C

Chan

24

D

B

A

Chan

1

ALLEN & HEATH

E

CONSOLE FRONT

GL4000-824 inverted with the base cover removed.

fig. 2

GL4000 SYS-LINK OPTION

3

Page 37

Refering to fig. 2, disconnect the MAIN HARNESS (E) plugged into the connectors mounted along the edge

tt

t

tt

of the circuit boards from INPUT CHANNEL 1 to GROUP 2.

The Input channel circuit board assembly next to GROUP 1 circuit board can now be removed and placed

uu

u

uu

on the adjacent Input channels. Take care not to stretch the fader wires that are still connected.

Remove the 8 screw fixings already partly screwed into the D type connectors on the SYS-LINK ribbon

vv

v

vv

harness assembly and place to one side.

Refering to fig. 3, fit the 4 self adhesive foam pads (F) in the positions indicated next to the front panel flange.

ww

w

ww

SYS-LINK HARNESS

INPUT CHANNEL

CIRCUIT BOARD

ASSEMBLY

F

CONSOLE FRONT

GL4000-824 inverted with the input connector circuit board assembly removed.

FITTING THE SYS-LINK RIBBON HARNESSES :

11

F

fig. 3

SYS-LINK

CIRCUIT

BOARD

F

F

Place the SYS-LINK circuit board assembly next to the GROUP 1 circuit board with the harness and ribbon

cables to the rear of the console. see fig. 3.

Slide the pre-formed SYS-LINK ribbon harnesses toward the back of the console and down the gap

between the Channel Input circuit boards and the back panel. Check the connectors are mounted into the

correct apertures on the rear panel.

Mount the 4 D type connectors using the 8 hex screws provided. see

4

GL4000 SYS-LINK OPTION

vv

v

vv

ALLEN & HEATH

Page 38

FITTING THE SYS-LINK HARNESS ASSEMBLY :

1 2

Refering to fig. 4, use a pair of long nosed pliers to fit the connectors onto GROUPS 1 - 8 and the LEFT

RIGHT and MONO circuit board assemblies in the following order:

GROUP 1 to GROUP 8, then LEFT, RIGHT and then finally the MONO circuit board assembly.

SYS-LINK ribbon harnesses

removed for clarity.

SYS-LINK CIRCUIT

BOARD ASSEMBLY

8x GROUP CIRCUIT BOARD ASSEMBLY

SYS-LINK WIRING HARNESS

LEFT CIRCUIT BOARD ASSEMBLY

RIGHT CIRCUIT BOARD ASSEMBLY

MONO CIRCUIT BOARD ASSEMBLY

ALLEN & HEATH

SYS-LINK harness circuit board interconnections

fig. 4

GL4000 SYS-LINK OPTION

5

Page 39

MOUNTING THE SYS-LINK CIRCUIT BOARD:

1 3

The SYS-LINK circuit board mounts onto the GROUP 1 circuit board using the 4 pillars already fitted to the

circuit board assembly. Two of the mounting pillars are fixed with screws (G) and two are 'snap-fit' (H).

H

G

G

H

fig. 5

To fit the SYS-LINK circuit board to the GROUP circuit board, unscrew the 2 screws already partly screwed

into the mounting pillars (G) and align all 4 pillars with the holes in the GROUP circuit board. Press the two

pillars (H) onto the GROUP circuit board assembly and fix the two pillars (G) with the screws provided.

Refit the INPUT CHANNEL circuit board assembly. Do not fit the channel nuts or knobs at this stage.

1 4

see

1 8

REFITTING THE INPUT CONNECTOR CIRCUIT BOARD ASSEMBLY

1 5

To refit the INPUT CONNECTOR circuit board into the console. Follow the procedure below refering to fig.

2:

1 Locate the circuit board assembly into the rear panel of the console.

2 Replace the 16 XLR mounting screws and the 32 jack socket nuts.

3 Reconnect the 8 flexible flat cables (C) into the sockets on the input channel circuit board assemblies

4 Plug on the ribbon harness (D).

Screw the SYS-LINK green earth wire onto the rear extrusion of the console with the screw and shakeproof

1 6

washer provided

1 7

Refering to fig. 2, re-fit the MAIN HARNESS (E) onto all circuit boards. Check the harnesses are correctly

aligned onto the circuit board connectors with pin 1 aligned with the red stripe of the ribbon harness.

1 8

REFITTING THE BASE :

Refit the base. Turn the console the correct way up and fit the pot nuts and knobs to the INPUT CHANNEL

replaced in

1 4

6

GL4000 SYS-LINK OPTION

ALLEN & HEATH

Page 40

1 9

PLUG ON THE INTERCONNECTING CABLES:

SYS-LINK connectors are female 25way D-type. Use 25way D-type male to male connector cables.

Connect pin one to pin one on all connectors. Connect shield (screen) to 0V. Standard cables are available

from electronic suppliers or computer shops. It is advised that the cable is a screened type less than 10

metres. Use professional quality locking connectors.

When connecting to equipment other than the GL Series link all unused audio inputs to 0V earth

at the SYS-LINK input.

2 0

TEST THE SYSTEM:

Test all SYS-LINK inputs and outputs for correct signal level and quality by probing the D-connector pins

or by interconnecting two consoles with SYS-LINK fitted. Test the PFL & AFL system for correct DC buss

switching.

The SYS-LINK circuit diagram and technical details are included for reference.

The SYS-LINK Applications Note AP2787 is included separately with these fitting instructions. Provide

this note to the user as applicable.

Please refer any queries to your Allen & Heath appointed service agent.

ALLEN & HEATH

GL4000 SYS-LINK OPTION

7

Page 41

ALLEN&HEA ALLEN&HEA

ALLEN&HEA

ALLEN&HEA ALLEN&HEA

THTH

TH

THTH

GL4000

MIXING CONSOLE

THE BENEFITS OF USING SYS-LINK

The GL4000 SYS-LINK option allows console to console interconnection by means of just one

or two cables. By connecting two GL4000 consoles together the number of input channels may

be increased. One console acts as a channel expander (slave) to the second (master). Up to 3

consoles may be 'daisy-chained' in this way. The system is also directly compatible with other

A&H consoles fitted with SYS-LINK.

Plugging consoles together using SYS-LINK connects the signals directly to the console busses

so avoiding the use of the main console outputs and channel inputs for the master / slave

connection. All the console channels are available to the user for input sources.

SYS-LINK CONNECTIONS

SYS-LINK connects all the console main busses including L, R, Mono, 8 Groups, 10 Aux sends,

and 4 matrices. The PFL & AFL systems are also interconnected such that operating PFL or

AFL on the slave console activates the master console monitor system. Operating PFL or AFL

on the master does not activate the slave monitor system which may be used for 'local'

monitoring if required. SYS-LINK connects the PFL & AFL audio mix and DC control buss.

SYS-LINK outputs are taken pre-fader so that the slave console output connectors may be used

for sub-mix or 'zone' feeds if required. All output signals are unbalanced, low impedance and

operate at a line level of -2dBu to prevent problems with audio interference and to maintain a

headroom of 23dB.

SYS-LINK inputs are unbalanced, operate line level at -2dBu and are high impedance to prevent

loading the connected source.

SYS-LINK is presented on two pairs of 25way female D-type connectors, one for the console

buss inputs and the other for the outputs. Several pins are provided for audio 0V earth.

USING SYS-LINK

Connect consoles using two standard 25way male to male D-type cables, available from

electronic suppliers or computer shops (25line male to male). It is advised that this cable is a

screened type if longer than 1 metre, no longer than 10 metres in total, and that professional

quality locking connectors are used. Connect all pins one to one with the screen to 0V.

Connect the slave console SYS-LINK output to the master console SYS-LINK input.

SYS-LINK may also be used to connect the GL4000 to other audio equipment. Make sure that

all unused inputs (except the PFL & AFL DC inputs) are linked to 0V earth at the SYS-LINK

input to prevent audible interference from connected audio signals. Connect line level signals

of around -2dBu. The GL4000 PFL & AFL systems may be activated by switching the PFL or

AFL DC inputs to 0V earth through a 15k ohm resistor.

For information on fitting SYS-LINK please refer to FITTING INSTRUCTIONS AP2786

SYS-LINK APPLICATIONS NOTE

Publication AP2787

Issue 2 July 01

Page 42

CONSOLE TO CONSOLE CONNECTION USING SYS-LINK

SYS-LINK connectors are 25way D-type female.

Use 25way D-type male to male connector cable.

Use screened cable, connect all pins.

0V0V0V0V0V0V0V

GRP5 out

GRP6 out

MONO out

AUX8 out

GRP7 out

GRP8 out

AUX7 out

AUX10 out

MTXB out

AUX9 out

MTXA out

OUT

Line level output at -2dBu

Unbalanced, in-phase

Low impedance <75 ohm

P/AFL DC output is open collector sink to 0V through 15k.

All outputs are pre-fader

MTXD out

0V

0V

MTXC out

B

0V0V0V0V0V0V0V

GRP5 in

GRP6 in

MONO in

AUX7 in

GRP7 in

GRP8 in

IN

AUX8 in

AUX10 in

MTXB in

AUX9 in

MTXA in

MTXD in

MTXC in

0V

0V

0V0V0V0V0V0V0V

LEFT out

GRP1 out

GRP2 out

RIGHT out

Line level input at -2dBu

Unbalanced, buffered in-phase

High impedance > 10k ohm

P/AFL DC input for pulldown to 0V through 15k resistor.

When connecting to equipment other than GL Series

link all unused audio inputs to 0V earth at the SYS-LINK

connector.

AUX2 out

AUX1 out

GRP3 out

GRP4 out

OUT

AUX4 out

AUX6 out

AFL out

PFL out

AUX3 out

AUX5 out

AFL DC

0V

0V0V0V0V0V0V0V

0V

LEFT in

PFL DC

A

GRP1 in

GRP2 in

RIGHT in

AUX1 in

GRP3 in

GRP4 in

IN

AUX2 in

AUX4 in

AUX6 in

AUX3 in

AUX5 in

AFL in

0V

PFL in

AFL DC

0V

PFL DC

IN B

MASTER GL4000

B to link GRP 5-8, AUX 7-10, MTX A-D

MASTER GL4000

IN A

IN A

B OUT

A OUT

SLAVE GL4000

A to link GRP 1-4, AUX 1-6, L, R, PFL & AFL

MULTI OUT

SLAVE GL2

2

GL4000 SYS-LINK APPLICATIONS NOTE AP2787 ALLEN & HEATH

Page 43

FITTING INSTRUCTIONS

METERBRIDGE FITTING INSTRUCTIONS

PFL/AFL ACTIVE

GL4000 meterbridge shown

The meterbridge has been designed to compliment the Allen & Heath GL series of Live consoles. Its purpose is to

monitor the programme signal at the console main outputs i.e; Groups 1 to 8, Left, Right and Mono. The meterbridge

is available in various sizes to fit each console size and runs full length.

Connecting the meterbridge to a console is very easy and only requires plugging in the meterbridge harness and

tightening the three "grub" screws in the lower lip of the meterbridge.

To fit the meterbridge:

1.) Carefully unpack the meterbridge and

fit it over the console rear extrusion (A)

as shown in fig 1. Make sure all of the

grub screws (B) are fully withdrawn

from the meterpod extrusion (C) before

fitting.

2.) Once the meterbridge is in place, tighten

the grub screws (B) to secure the

meterbridge in place.

3.) Plug in the meterbridge harness (D) into

the connector marked METERPOD

on the rear panel of the console. See fig.

2.

A

C

B

FIG. 1

D

FIG. 2

Please note; the PFL LED indicator illuminates when any PFL is selected with the PFL signal level displayed on

the MONO meter.

Manufactured in the UK by:

Allen & Heath Limited

Kernick Industrial Estate,

Penryn,

Cornwall. TR10 9LU.

tel: 44 (0) 870 755 6250

Publication AP2126 Issue 4

copyright © 2001 ALLEN & HEATH. All

rights reserved.

L3dSM

fax: 44 (0) 870 755 6251

http://www.allen-heath.com

Section A - 1

ALLEN & HEATH

Page 44

SECTION C

TECHNICAL

DIAGRAMS

CAUTION !

C

TO AVOID DAMAGE TO INTERNAL COMPONENTS BY

MISHANDLING AND/OR MISCONNECTION, ONLY

TECHNICALLY COMPETENT PERSONNEL SHOULD

ATTEMPT SERVICE WORK ON THIS CONSOLE.

L4DSM2

Section C - 1

ALLEN & HEATH

Page 45

Attention Service Departments

TECHNICAL BULLETIN

Ref.: AHTB96010 Issue No 1 Date 16/01/97 Page 1of: 1

Title: New fader specified for GL4000 Authorisation: CD

The following information applies to all GL4000 consoles after serial number 401300.

Origin of the change:

In accordance with Allen & Heath’s policy of continual product development, a new fader has been specified for

GL4000 consoles. The fader offers a custom taper that has been designed to match the needs of engineers using

the consoles in today’s live environment.

Details:

GL4000’s with serial numbers which precede the cut-off number stated above have been fitted with Jung Poon

faders. The order codes for these are:

AI2665 - Mono Fader

AI2664 - Stereo Fader

GL4000’s from Serial No 401300 onwards will be fitted with the Alps K-fader which has a special taper. The

numbers for these are as follows:

AI8109 - Mono Fader

AI8110 - Stereo Fader

Note that since the tapers of the two faders are different, it will be necessary to check that the correct fader is

ordered whenever replacements are needed. Otherwise, the channel gain will not correspond to the fader panel

silk-screen.

Please note however that the audio performance of the console will not be compromised by inadvertently fitting the

‘wrong’ fader type. The channel will perform equally well with either fader type.

ALLEN & HEATH

Section C - 2

L4DSM2

Page 46

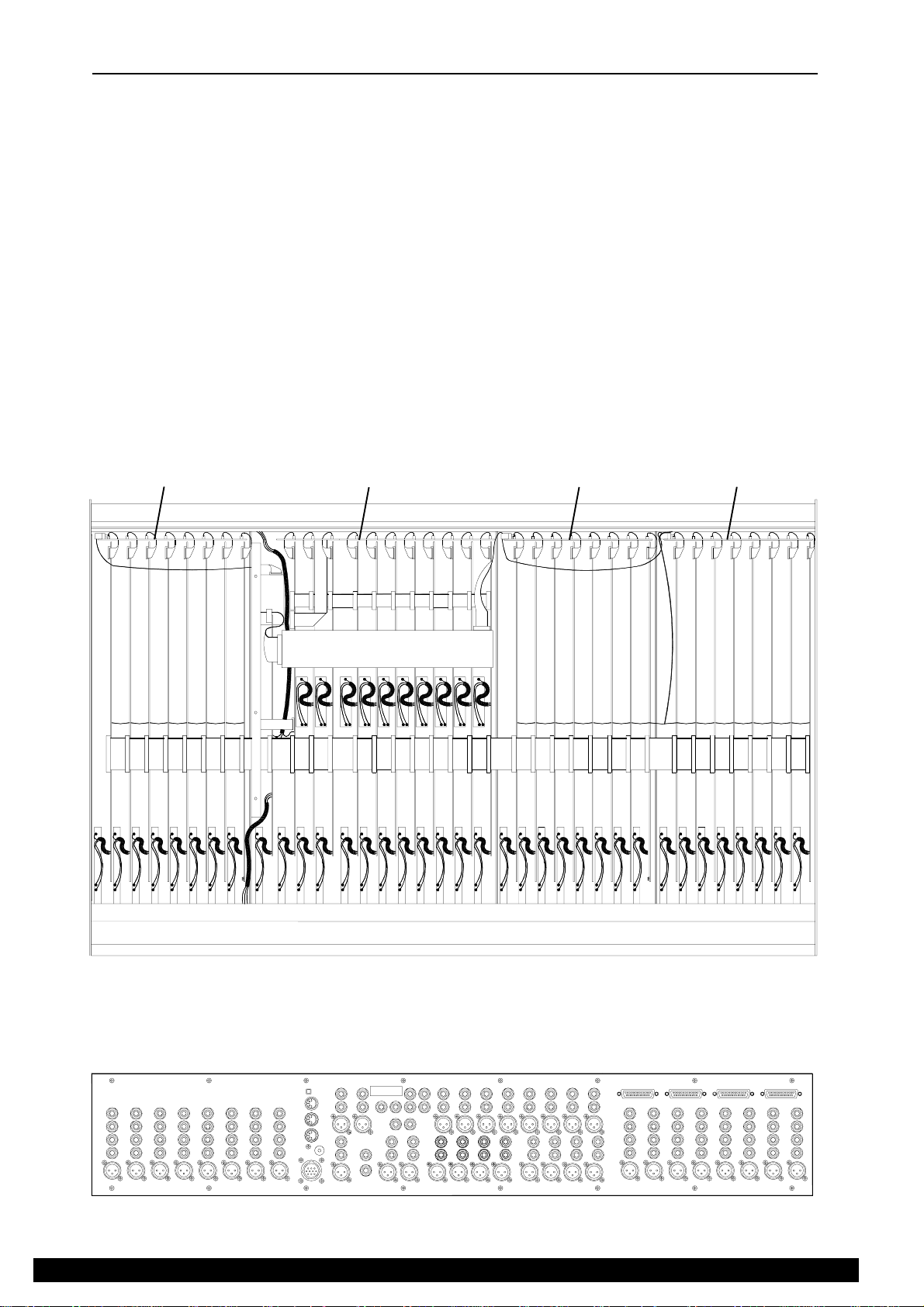

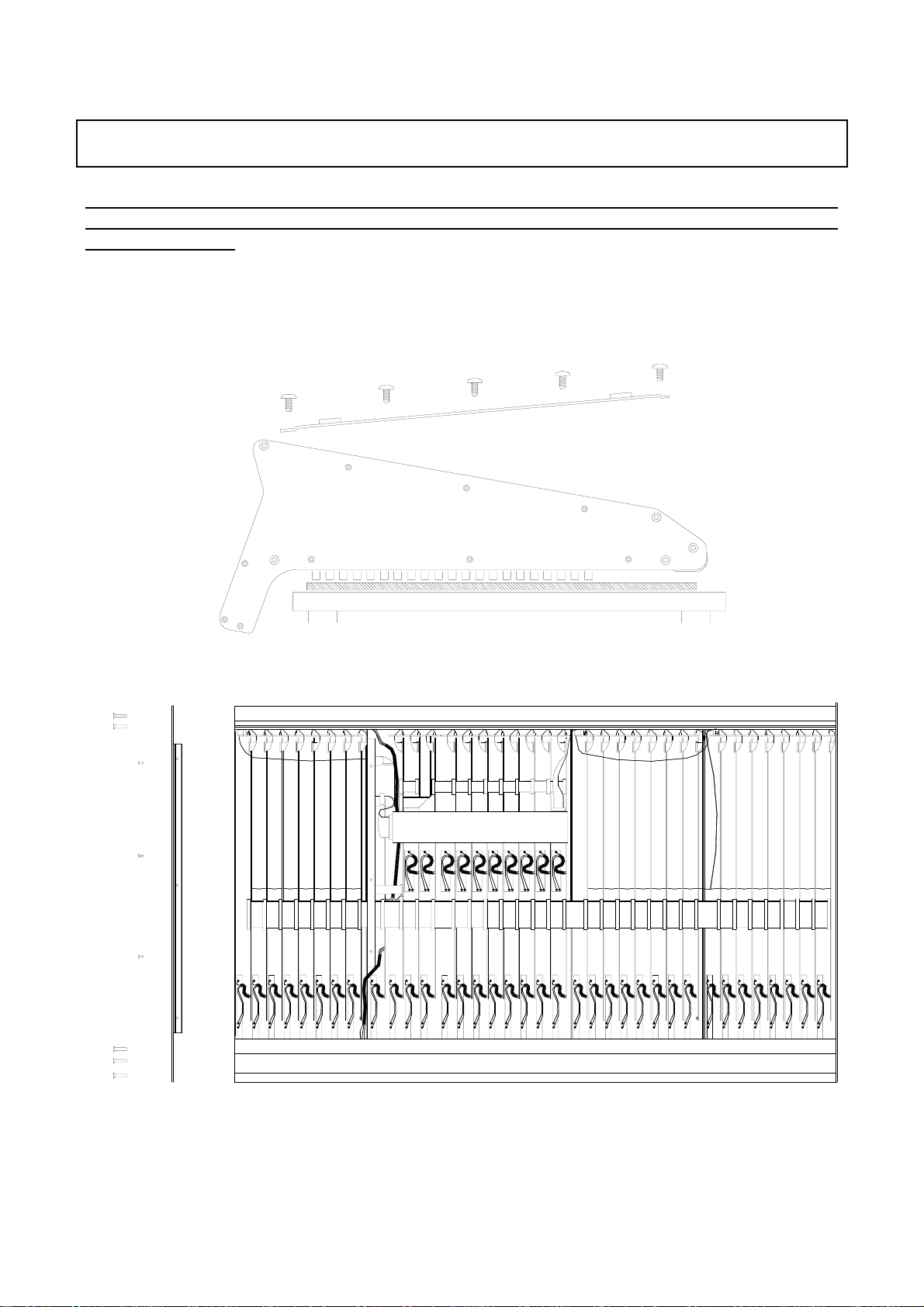

FRONT PANEL LAYOUT

L4DSM2

Section C - 3

ALLEN & HEATH

Page 47

REAR PANEL LAYOUT

INPUT SECTION

MASTER SECTION

STEREO

INPUT SECTION

MONO

Page 48

SHEET 1 OF 3

MONO / STEREO INPUT & TALKBACK

Page 49

GROUP / AUX / MATRIX / LR / MONO / 2 TRACK

SHEET 2 OF 3

Page 50

MUTE AUTOMATION

SHEET 3 OF 3

Page 51

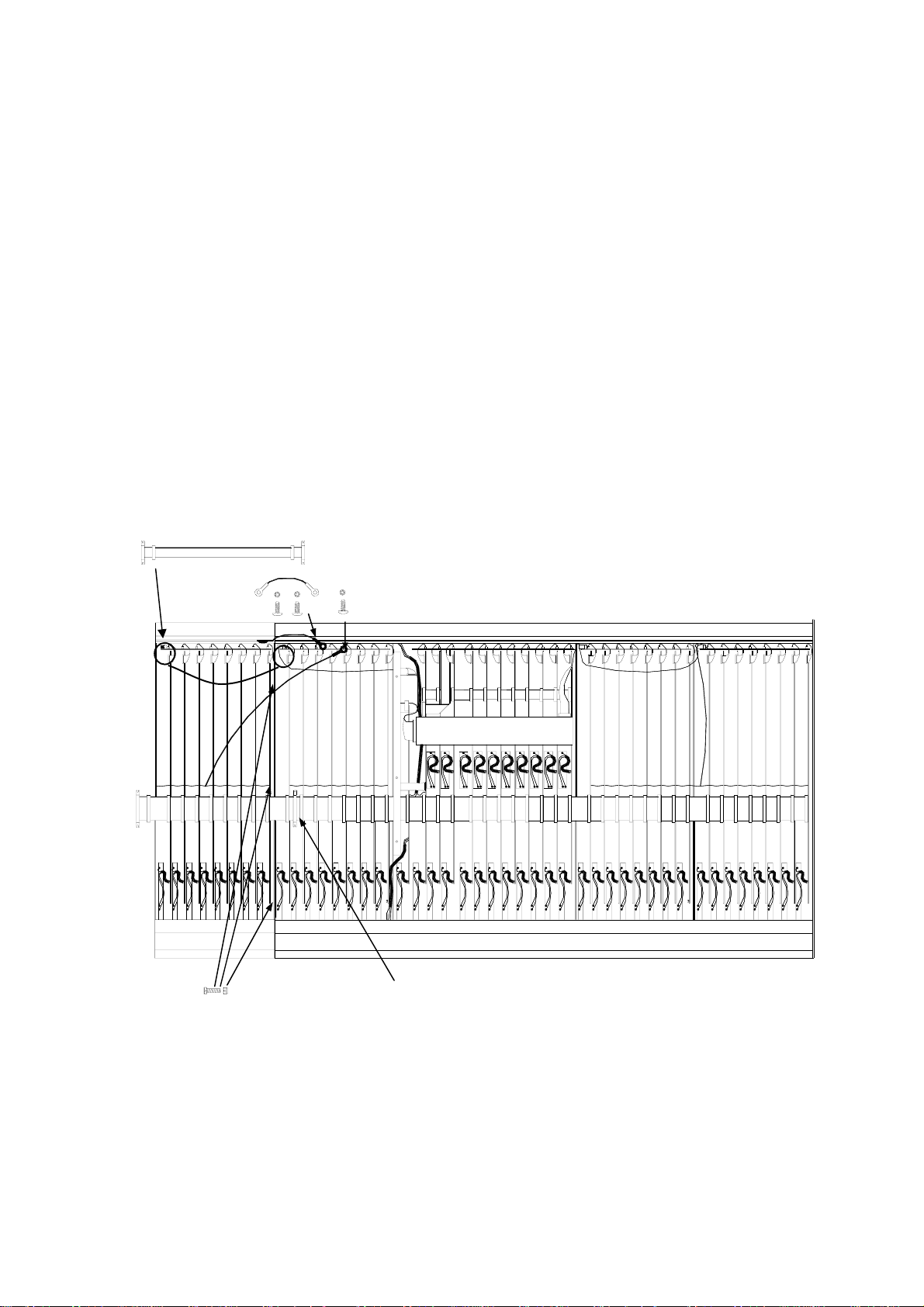

GL4000-824 INTERNAL LAYOUT

Console inverted with the base removed.

(x1)

HARNESS

1

8

16 WAY LEFT HAND

(x1)

INPUT CONNECTOR PCB

(x1)

HARNESS

16 WAY MASTER

(x1)

(x1)

SLAVE PCB

9

(x8)

INPUT PCB

16

(x8)

GROUP PCB

}

(x2)

L / R PCB

(x1)

MASTER CONNECTOR PCB

(x1)

HARNESS

16 WAY METER

(x1)

MICRO PCB

(x1)

16 WAY RIGHT