Page 1

Part No. 060211-10, Rev.E

June 2007

OmniSwitch 9000 Series

Hardware Users Guide

www.alcatel-lucent.com

Page 2

This user guide documents OmniSwitch 9000 Series

hardware, including chassis and associated components.

The specifications described in this guide are subject to change without notice.

Copyright © 2007 by Alcatel-Lucent. All rights reserved. This document may not be reproduced in whole

or in part without the express written permission of Alcatel-Lucent.

®

Alcatel-Lucent

OmniSwitch

and the Alcatel-Lucent logo are registered trademarks of Alcatel-Lucent. Xylan®,

®

, OmniStack®, and Alcatel-Lucent OmniVista® are registered trademarks of Alcatel-Lucent.

OmniAccess™, Omni Switch/Router™, PolicyView™, RouterView™, SwitchManager™, VoiceView™,

WebView™, X-Cell™, X-Vision™, and the Xylan logo are trademarks of Alcatel-Lucent.

This OmniSwitch product contains components which may be covered by one or more of the following

U.S. Patents:

•U.S. Patent No. 6,339,830

•U.S. Patent No. 6,070,243

•U.S. Patent No. 6,061,368

•U.S. Patent No. 5,394,402

•U.S. Patent No. 6,047,024

•U.S. Patent No. 6,314,106

•U.S. Patent No. 6,542,507

•U.S. Patent No. 6,874,090

26801 West Agoura Road

Calabasas, CA 91301

(818) 880-3500 FAX (818) 880-3505

support@ind.alcatel.com

US Customer Support—(800) 995-2696

International Customer Support—(818) 878-4507

Internet—service.esd.alcatel-lucent.com

ii June 2007

Page 3

Contents

About This Guide .......................................................................................................... ix

Supported Platforms .......................................................................................................... ix

Who Should Read this Manual? ........................................................................................ix

When Should I Read this Manual? .....................................................................................x

What is in this Manual? ...................................................................................................... x

What is Not in this Manual? ............................................................................................... x

How is the Information Organized? ..................................................................................xi

Documentation Roadmap .................................................................................................. xi

Related Documentation ...................................................................................................xiii

User Manual CD .............................................................................................................xiv

Technical Support ........................................................................................................... xiv

Chapter 1 OmniSwitch 9000 Series ........................................................................................1-1

Application Example .......................................................................................................1-2

Availability Features .......................................................................................................1-3

Hardware Redundancy .............................................................................................1-3

Smart Continuous Switching ....................................................................................1-4

Software Rollback ....................................................................................................1-4

Hot Swapping ...........................................................................................................1-5

Hardware Monitoring ...............................................................................................1-5

Power Checking Sequence .......................................................................................1-6

Chapter 2 Chassis and Power Supplies ....................................................................................2-1

OmniSwitch 9800 ............................................................................................................2-2

OmniSwitch 9700 ............................................................................................................2-5

OmniSwitch 9600 ............................................................................................................2-8

Chassis Slot Numbering ................................................................................................2-11

Viewing Chassis Slot Information .........................................................................2-12

Mounting the Switch .....................................................................................................2-12

Power Supplies ..............................................................................................................2-16

600 Watt DC-to-DC Power Supply ........................................................................2-18

DC Power Supply Connection ...............................................................................2-19

Connecting the DC Cable Harness to the Chassis Power Supply ...................2-19

Connecting the DC Cable Harness to the DC Power Source ..........................2-19

Chassis Power Supply Module Support ........................................................................2-20

OmniSwitch 9000 Series Hardware Users Guide June 2007 iii

Page 4

Contents

Monitoring Chassis Power ............................................................................................2-21

Checking Chassis Power Before Adding a Module ...............................................2-21

Example 1: Adequate Power to Add a Module ...............................................2-22

Example 2: Inadequate Power to Add a Module .............................................2-23

Checking Chassis Power Before Shutting Off or Removing a Power Supply .......2-25

Example 1: Adequate Power to Remove a Power Supply ..............................2-25

Example 2: Inadequate Power to Remove a Power Supply ............................2-26

Adding a Power Supply ..........................................................................................2-26

Hot Swapping a Power Supply ...............................................................................2-26

Permanently Removing a Power Supply ................................................................2-26

Power Supply Redundancy ...........................................................................................2-27

Redundancy Defined ..............................................................................................2-27

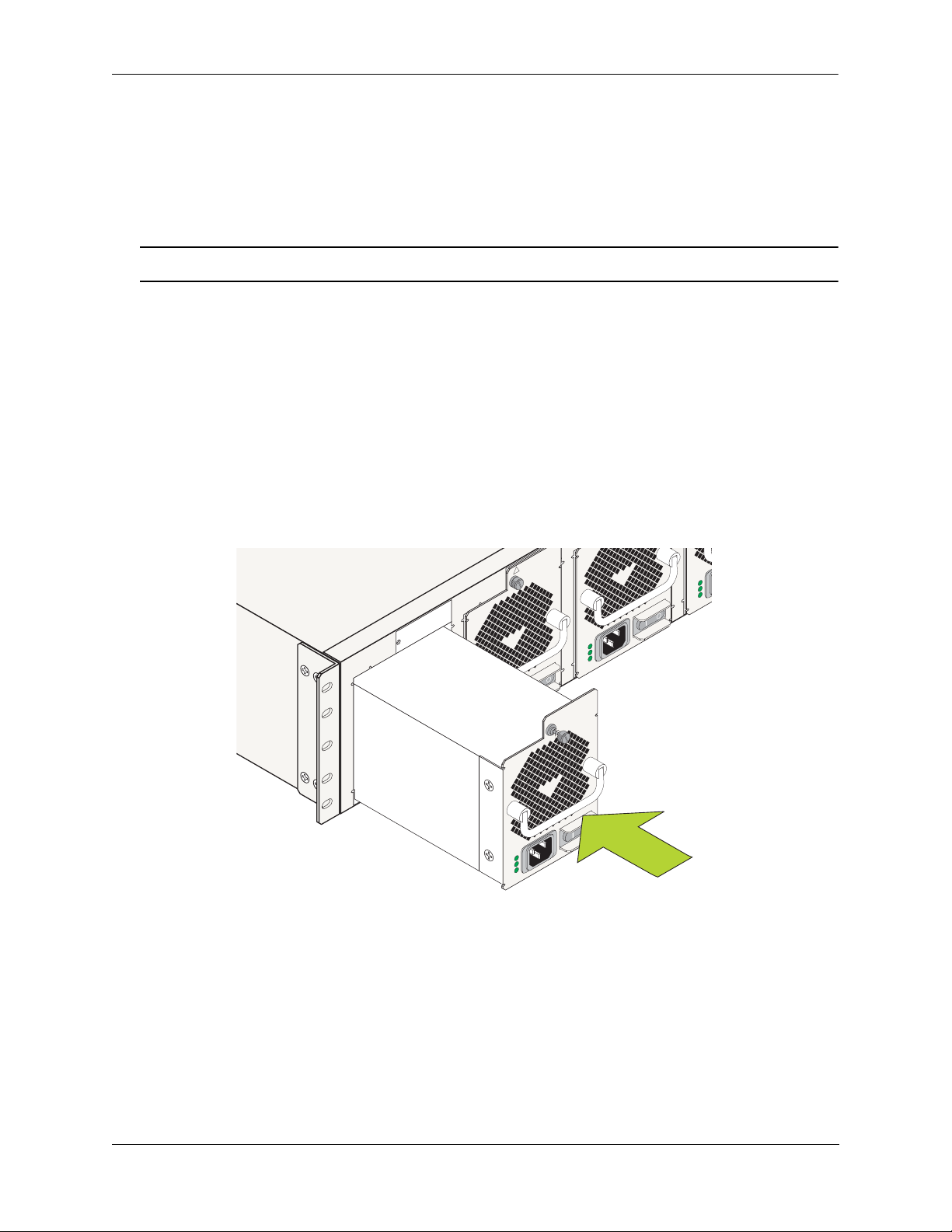

Installing a Power Supply .............................................................................................2-28

Removing a Power Supply .....................................................................................2-30

Power Cords ..................................................................................................................2-31

Redundant AC Circuit Recommendation ......................................................................2-32

Grounding the Chassis ...........................................................................................2-33

Temperature Management ............................................................................................2-33

Temperature Errors ..........................................................................................2-34

Chassis Fan Tray ...........................................................................................................2-35

Monitoring Fan Tray Status .............................................................................2-37

Fan Redundancy ..............................................................................................2-37

Hot Swapping the Fan Tray .............................................................................2-37

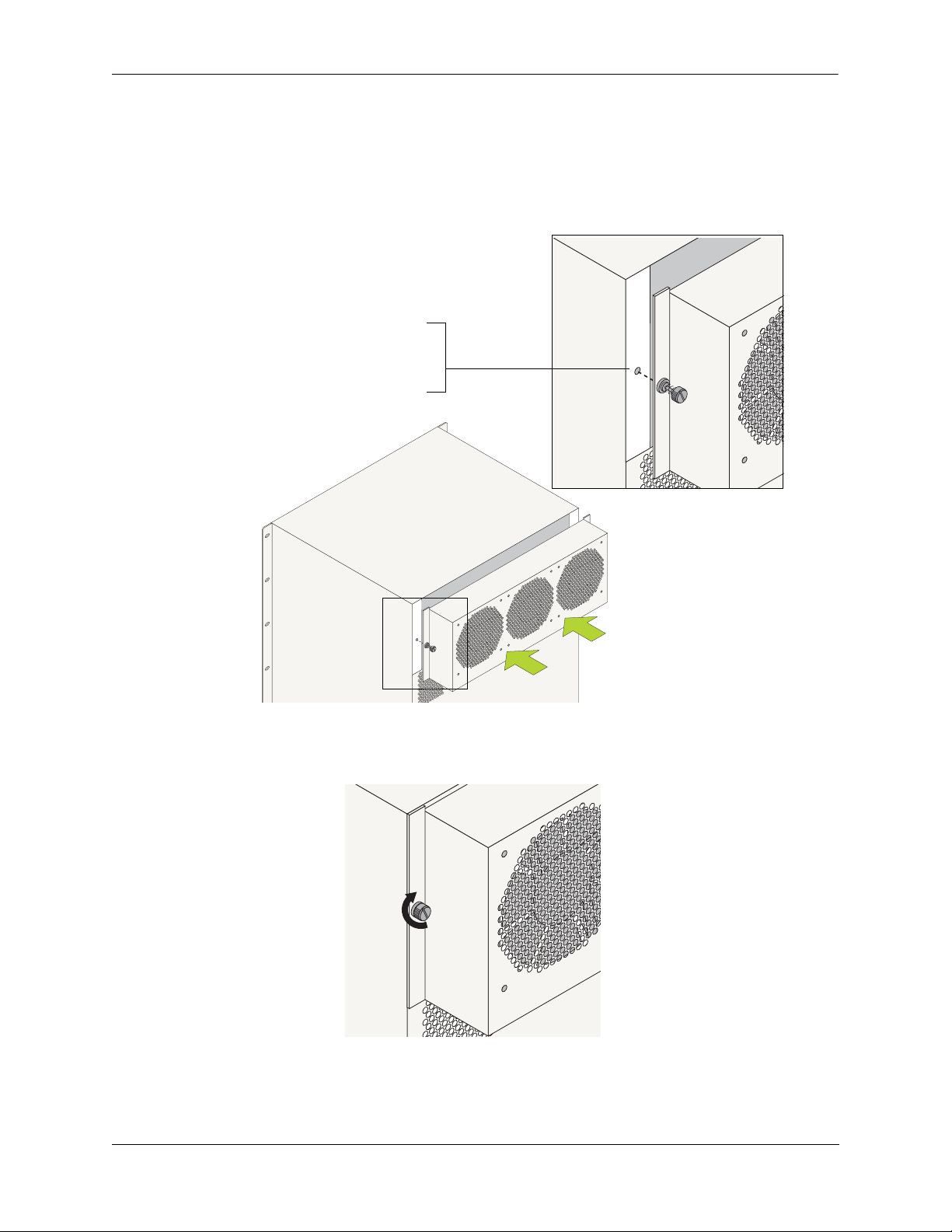

Removing the Fan Tray ...................................................................................2-38

Installing the New Fan Tray ............................................................................2-39

Chassis Airflow .............................................................................................................2-40

Power Supply Fans .................................................................................................2-43

Blank Cover Panels and Chassis Airflow ..............................................................2-44

Chapter 3 Installing and Managing Power over Ethernet (PoE) ......................................3-1

In This Chapter ................................................................................................................3-2

Power over Ethernet Specifications ................................................................................3-3

Power over Ethernet Overview .......................................................................................3-4

Power over Ethernet Components ...................................................................................3-6

OS-IP-SHELF PoE Power Shelf ..............................................................................3-6

510W/360W Power Supply ......................................................................................3-8

Power Shelf and PoE Port Guidelines .............................................................................3-9

Non-Redundant Power Supply Configurations ........................................................3-9

Redundant Power Supply Configurations ..............................................................3-10

Setting Up Power over Ethernet Hardware ...................................................................3-11

Basic Guidelines for Setting Up PoE Hardware ....................................................3-11

Positioning the Power Shelf ............................................................................3-11

Rack-Mounting the Power Shelf .....................................................................3-12

iv OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 5

Contents

Installing the Power Supplies .................................................................................3-15

Preparation .......................................................................................................3-15

Installation Steps .............................................................................................3-15

Removing the Power Supplies ...............................................................................3-17

Connecting the Power Shelf to the Chassis ............................................................3-19

Connecting the 360W/510W PoE Power Supply to the Chassis ...........................3-20

Power Shelf Slot Numbering ........................................................................................3-21

Viewing Power Shelf Status ..........................................................................................3-22

Configuring Power over Ethernet Parameters ...............................................................3-23

Power over Ethernet Defaults ................................................................................3-23

Understanding and Modifying the Default Settings ...............................................3-23

Setting the PoE Operational Status ..................................................................3-23

Configuring the Total Power Allocated to a Port ............................................3-24

Configuring the Total Power Allocated to a Slot ............................................3-24

Setting Port Priority Levels .............................................................................3-25

Setting PoE Redundancy Status ......................................................................3-26

Setting the Capacitor Detection Method .........................................................3-26

Understanding Priority Disconnect ...............................................................................3-27

Setting Priority Disconnect Status ..........................................................................3-27

Disabling Priority Disconnect .........................................................................3-27

Enabling Priority Disconnect ..........................................................................3-27

Priority Disconnect is Enabled; Same Priority Level on All PD Ports ...........3-28

Priority Disconnect is Enabled; Incoming PD Port has Highest

Priority Level ...................................................................................................3-29

Priority Disconnect is Enabled; Incoming PD Port has Lowest

Priority Level ...................................................................................................3-30

Priority Disconnect is Disabled .......................................................................3-31

Monitoring Power over Ethernet via the CLI ...............................................................3-32

Power over Ethernet Tutorial ........................................................................................3-34

Chapter 4 Chassis Management Module (CMM) ...................................................................4-1

CMM Slot Locations .......................................................................................................4-2

OS9700-CMM Versus OS9800-CMM ..............................................................4-2

CMM Front Panel ...........................................................................................................4-3

Ethernet Management Port (EMP) ...........................................................................4-5

Access to the EMP .............................................................................................4-6

EMP Cable Requirements .................................................................................4-6

Console Port .............................................................................................................4-6

Serial Connection to the Console Port ...............................................................4-6

Configuring X-ON/X-OFF Protocol ........................................................................4-8

CMM Redundancy ..........................................................................................................4-9

CMM Failover Sequence .........................................................................................4-9

Synchronizing the Primary and Secondary CMMs ................................................4-10

CMM Switching Fabric ..........................................................................................4-10

Hot Swapping CMM Modules ......................................................................................4-11

Module Presence Signalling ............................................................................4-11

Hot Swap Requirements .........................................................................................4-11

OmniSwitch 9000 Series Hardware Users Guide June 2007 v

Page 6

Contents

Managing CMM Modules .............................................................................................4-13

Reloading a CMM Module ....................................................................................4-13

Switching the Primary and Secondary Roles .........................................................4-13

Monitoring CMM Modules ...........................................................................................4-14

Front Panel LEDs ...................................................................................................4-14

Accessing General CMM Information ...................................................................4-14

CMM Hardware Information ..........................................................................4-14

Operating Status of CMM-Related Components ............................................4-15

CLI Commands Supported on Both the Primary and Secondary CMMs .......4-15

Chassis-Based MAC Address .......................................................................................4-17

Pinouts ...........................................................................................................................4-17

Chapter 5 Network Interface (NI) Modules ............................................................................5-1

In This Chapter ................................................................................................................5-1

GNI Modules ...................................................................................................................5-3

OS9-GNI-C24 Front Panel .......................................................................................5-4

OS9-GNI-P24 Front Panel .......................................................................................5-6

OS9-GNI-C20L Front Panel ....................................................................................5-8

OS9-GNI-C48T Front Panel ..................................................................................5-10

RJ-45 to RJ-45 Patch Panel .............................................................................5-12

MRJ-21to RJ-45 Cable ....................................................................................5-13

OS9-GNI-U24 Front Panel .....................................................................................5-14

5-15

XNI Modules .................................................................................................................5-16

OS9-XNI-U2 Front Panel .......................................................................................5-17

OS9-XNI-U6 Front Pane ........................................................................................5-19

Smart Continuous Switching .........................................................................................5-21

Module Priorities During Boot Sequence ........................................................5-21

Managing NI Modules ..................................................................................................5-21

Turning Power On or Off for a Specific NI Module .......................................5-21

Individual NI Reload .......................................................................................5-21

Monitoring NI Modules ................................................................................................5-22

Front Panel LEDs ............................................................................................5-22

Accessing General NI Information ..................................................................5-22

Hot Swapping NI Modules ............................................................................................5-23

Removing and Adding Modules ...................................................................................5-24

Using the Grounding Wrist Strap and Chassis Grounding Lug .............................5-24

Module Types and Slot Positions ...........................................................................5-25

Removing a Module ...............................................................................................5-25

Adding a Module ....................................................................................................5-27

Pinouts ...........................................................................................................................5-29

10/100 Mbps Ethernet Port – RJ-45 Pinout ..........................................................5-29

1 Gigabit Ethernet Port – RJ-45 Pinout .................................................................5-29

Handling Fiber and Fiber Optic Connectors .................................................................5-30

vi OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 7

Contents

Appendix A Regulatory Compliance and Safety Information ..............................................A-1

Declaration of Conformity: CE Mark ............................................................................A-1

Waste Electrical and Electronic Equipment (WEEE) Statement ............................A-1

China RoHS: Hazardous Substance Table .....................................................................A-2

Standards Compliance ....................................................................................................A-4

FCC Class A, Part 15 ..............................................................................................A-4

Canada Class A Statement ......................................................................................A-4

JATE ........................................................................................................................A-4

CISPR22 Class A warning ......................................................................................A-5

VCCI .......................................................................................................................A-5

Class A Warning for Taiwan and Other Chinese Markets ......................................A-5

Translated Safety Warnings ...........................................................................................A-6

Chassis Lifting Warning ...................................................................................A-6

Blank Panels Warning ......................................................................................A-6

Electrical Storm Warning .................................................................................A-6

Installation Warning .........................................................................................A-7

Invisible Laser Radiation Warning ...................................................................A-7

Lithium Battery Warning .................................................................................A-8

Operating Voltage Warning .............................................................................A-8

Power Disconnection Warning .........................................................................A-9

Proper Earthing Requirement Warning ............................................................A-9

Read Important Safety Information Warning .................................................A-10

Restricted Access Location Warning .............................................................A-10

Wrist Strap Warning .......................................................................................A-11

Instrucciones de seguridad en español .........................................................................A-12

Advertencia sobre el levantamiento del chasis ...............................................A-12

Advertencia de las tapaderas en blanco ..........................................................A-12

Advertencia en caso de tormenta eléctrica .....................................................A-12

Advertencia de instalación .............................................................................A-12

Advertencia de radiación láser invisible .........................................................A-12

Advertencia de la batería de litio ....................................................................A-12

Advertencia sobre la tensión de operación .....................................................A-12

Advertencia sobre la desconexión de la fuente ..............................................A-12

Advertencia sobre una apropiada conexión a tierra .......................................A-13

Leer “información importante de seguridad” .................................................A-13

Advertencia de acceso restringido ..................................................................A-13

Advertencia de pulsera antiestática ................................................................A-13

Clase de seguridad ..........................................................................................A-13

Advertencia de fuentes de poder ....................................................................A-13

Index ...................................................................................................................... Index-1

OmniSwitch 9000 Series Hardware Users Guide June 2007 vii

Page 8

Contents

viii OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 9

About This Guide

This OmniSwitch 9000 Series Hardware Users Guide describes your switch hardware components and

basic switch hardware procedures.

Supported Platforms

This information in this guide applies to the following products:

• OmniSwitch 9600

• OmniSwitch 9700

• OmniSwitch 9800

The OmniSwitch 9800 includes 18 slots for high performance 10/100/1000 Ethernet, Gigabit Ethernet, and

10 Gigabit Network Interface (NI) modules. The OmniSwitch 9700 includes 10 slots for high performance 10/100/1000 Ethernet, Gigabit Ethernet, and 10 Gigabit Network Interface (NI) modules. The

OmniSwitch 9600 includes 5 slots for high performance 10/100/1000 Ethernet, Gigabit Ethernet, and 10

Gigabit Network Interface (NI) modules.

Unsupported Platforms

The information in this guide does not apply to the following products:

• OmniSwitch (original version with no numeric model name)

• OmniSwitch 6600 Family

• OmniSwitch 6800 Series

• OmniSwitch 7700/7800

• OmniSwitch 8800

• Omni Switch/Router

• OmniStack

• OmniAccess

Who Should Read this Manual?

The audience for this users guide is network administrators and IT support personnel who need to configure, maintain, and monitor switches and routers in a live network. However, anyone wishing to gain

knowledge on the OmniSwitch 9000 Series hardware will benefit from the material in this guide.

OmniSwitch 9000 Series Hardware Users Guide June 2007 page ix

Page 10

When Should I Read this Manual? About This Guide

When Should I Read this Manual?

Read this guide as soon as you are ready to familiarize yourself with your switch hardware components.

You should have already stepped through the first login procedures and read the brief hardware overviews

in the OmniSwitch 9000 Series Getting Started Guide.

You should already be familiar with the very basics of the switch hardware, such as module LEDs and

module installation procedures. This manual will help you understand your switch hardware components

(chassis, cooling fans, power supplies, Network Interface modules, Chassis Management Modules) in

greater depth.

What is in this Manual?

This users guide includes the following hardware-related information:

• Descriptions of “Availability” features.

• Technical specifications for chassis, power supplies, Network Interface (NI) modules, and Chassis

Management Modules (CMMs).

• Power supply requirements.

• The dynamics of chassis airflow, including detailed illustrations of proper and improper airflow config-

urations.

• Hot swapping power supplies, fan trays, Network Interface (NI) modules, and Chassis Management

Modules (CMMs).

• Installation and removal procedures for power supplies, fan trays, Network Interface (NI) modules, and

Chassis Management Modules (CMMs).

• Detailed illustrations and LED descriptions for power supplies, Network Interface (NI) modules, and

Chassis Management Modules (CMMs).

• CMM redundancy.

• Hardware-related Command Line Interface (CLI) commands.

What is Not in this Manual?

The descriptive and procedural information in this manual focuses on switch hardware. It includes information on some CLI commands that pertain directly to hardware configuration, but it is not intended as a

software users guide. There are several OmniSwitch 9000 Series users guides that focus on switch software configuration. Consult those guides for detailed information and examples for configuring your

switch software to operate in a live network environment. See “Documentation Roadmap” on page -xi and

“Related Documentation” on page -xiii for further information on software configuration guides available

for your switch.

page x OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 11

About This Guide How is the Information Organized?

How is the Information Organized?

Each chapter in this guide focuses on a specific hardware component, such as the Chassis Management

Module (CMM), or a set of hardware components. All descriptive, technical specification, and procedural

information for a hardware component can be found in the chapter dedicated to that component.

Documentation Roadmap

The OmniSwitch 9000 Series user documentation suite was designed to supply you with information at

several critical junctures of the configuration process.The following section outlines a roadmap of the

manuals that will help you at each stage of the configuration process. Under each stage, we point you to

the manual or manuals that will be most helpful to you.

Stage 1: Using the Switch for the First Time

Pertinent Documentation: OmniSwitch 9000 Series Getting Started Guide

Release Notes

A hard-copy OmniSwitch 9000 Series Getting Started Guide is included with your switch; this guide

provides all the information you need to get your switch up and running the first time. It provides information on unpacking the switch, rack mounting the switch, installing NI modules, unlocking access control,

setting the switch’s IP address, and setting up a password. It also includes succinct overview information

on fundamental aspects of the switch, such as hardware LEDs, the software directory structure, CLI

conventions, and web-based management.

At this time you should also familiarize yourself with the Release Notes that accompanied your switch.

This document includes important information on feature limitations that are not included in other user

guides.

Stage 2: Gaining Familiarity with Basic Switch Functions

Pertinent Documentation: OmniSwitch 9000 Series Hardware Users Guide

OmniSwitch 6800/6850/9000 Switch Management Guide

Once you have your switch up and running, you will want to begin investigating basic aspects of its hardware and software. Information about switch hardware is provided in the OmniSwitch 9000 Series Hard-

ware Guide. This guide provide specifications, illustrations, and descriptions of all hardware components,

such as chassis, power supplies, Chassis Management Modules (CMMs), Network Interface (NI) modules,

and cooling fans. It also includes steps for common procedures, such as removing and installing switch

components.

The OmniSwitch 6800/6850/9000 Switch Management Guide is the primary users guide for the basic software features on a single switch. This guide contains information on the switch directory structure, basic

file and directory utilities, switch access security, SNMP, and web-based management. It is recommended

that you read this guide before connecting your switch to the network.

OmniSwitch 9000 Series Hardware Users Guide June 2007 page xi

Page 12

Documentation Roadmap About This Guide

Stage 3: Integrating the Switch Into a Network

Pertinent Documentation: OmniSwitch 6800/6850/9000 Network Configuration Guide

OmniSwitch 6800/6850/9000 Advanced Routing Configuration Guide

When you are ready to connect your switch to the network, you will need to learn how the OmniSwitch

implements fundamental software features, such as 802.1Q, VLANs, Spanning Tree, and network routing

protocols. The OmniSwitch 6800/6850/9000 Network Configuration Guide contains overview information, procedures, and examples on how standard networking technologies are configured in the

OmniSwitch 9000 Series.

The OmniSwitch 6800/6850/9000 Advanced Routing Configuration Guide includes configuration information for networks using advanced routing technologies (OSPF and BGP) and multicast routing protocols

(DVMRP and PIM-SM).

Anytime

The OmniSwitch CLI Reference Guide contains comprehensive information on all CLI commands

supported by the switch. This guide includes syntax, default, usage, example, related CLI command, and

CLI-to-MIB variable mapping information for all CLI commands supported by the switch. This guide can

be consulted anytime during the configuration process to find detailed and specific information on each

CLI command.

page xii OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 13

About This Guide Related Documentation

Related Documentation

The following are the titles and descriptions of all the OmniSwitch 9000 Series user manuals:

• OmniSwitch 9000 Series Getting Started Guide

Describes the hardware and software procedures for getting an OmniSwitch 9000 Series up and

running. Also provides information on fundamental aspects of OmniSwitch software architecture.

• OmniSwitch 9000 Series Hardware Users Guide

Complete technical specifications and procedures for all OmniSwitch 9000 Series chassis, power

supplies, fans, and Network Interface (NI) modules.

• OmniSwitch CLI Reference Guide

Complete reference to all CLI commands supported on the OmniSwitch 6800, 6850, and 9000.

Includes syntax definitions, default values, examples, usage guidelines and CLI-to-MIB variable

mappings.

• OmniSwitch 6800/6850/9000 Switch Management Guide

Includes procedures for readying an individual switch for integration into a network. Topics include

the software directory architecture, image rollback protections, authenticated switch access, managing

switch files, system configuration, using SNMP, and using web management software (WebView).

• OmniSwitch 6800/6850/9000 Network Configuration Guide

Includes network configuration procedures and descriptive information on all the major software

features and protocols included in the base software package. Chapters cover Layer 2 information

(Ethernet and VLAN configuration), Layer 3 information (routing protocols, such as RIP and IPX),

security options (authenticated VLANs), Quality of Service (QoS), link aggregation, and server load

balancing.

• OmniSwitch 6800/6850/9000 Advanced Routing Configuration Guide

Includes network configuration procedures and descriptive information on all the software features and

protocols included in the advanced routing software package. Chapters cover multicast routing

(DVMRP and PIM-SM), Open Shortest Path First (OSPF), and Border Gateway Protocol (BGP).

• OmniSwitch Transceivers Guide

Includes SFP and XFP transceiver specifications and product compatibility information.

• Technical Tips, Field Notices

Includes information published by Alcatel-Lucent’s Customer Support group.

• Release Notes

Includes critical Open Problem Reports, feature exceptions, and other important information on the

features supported in the current release and any limitations to their support.

OmniSwitch 9000 Series Hardware Users Guide June 2007 page xiii

Page 14

User Manual CD About This Guide

User Manual CD

All user guides for the OmniSwitch 9000 Series are included on the User Manual CD that accompanied

your switch. This CD also includes user guides for other Alcatel-Lucent data enterprise products. In addition, it contains a stand-alone version of the on-line help system that is embedded in the OmniVista

network management application.

Besides the OmniVista documentation, all documentation on the User Manual CD is in

requires the Adobe Acrobat Reader program for viewing. Acrobat Reader freeware is available at

www.adobe.com.

Note. In order to take advantage of the documentation CD’s global search feature, it is recommended that

you select the option for searching PDF files before downloading Acrobat Reader freeware.

To verify that you are using Acrobat Reader with the global search option, look for the following button in

the toolbar:

Note. When printing pages from the documentation PDFs, de-select Fit to Page if it is selected in your

print dialog. Otherwise pages may print with slightly smaller margins.

PDF format and

Technical Support

An Alcatel-Lucent service agreement brings your company the assurance of 7x24 no-excuses technical

support. You’ll also receive regular software updates to maintain and maximize your Alcatel-Lucent product’s features and functionality and on-site hardware replacement through our global network of highly

qualified service delivery partners. Additionally, with 24-hour-a-day access to Alcatel-Lucent’s Service

and Support web page, you’ll be able to view and update any case (open or closed) that you have reported

to Alcatel-Lucent’s technical support, open a new case or access helpful release notes, technical bulletins,

and manuals. For more information on Alcatel-Lucent’s Service Programs, see our web page at

service.esd.alcatel-lucent.com, call us at 1-800-995-2696, or email us at support@ind.alcatel.com.

page xiv OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 15

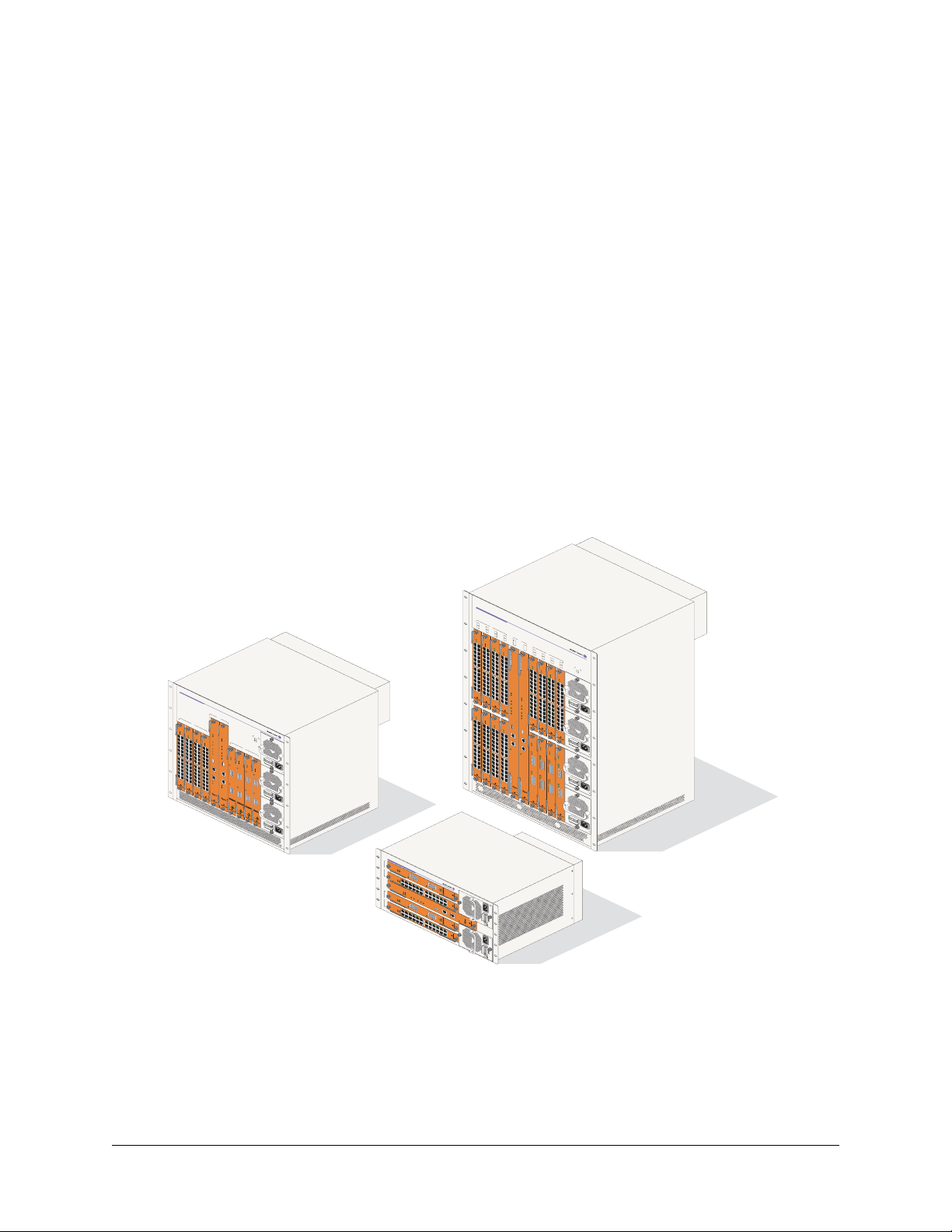

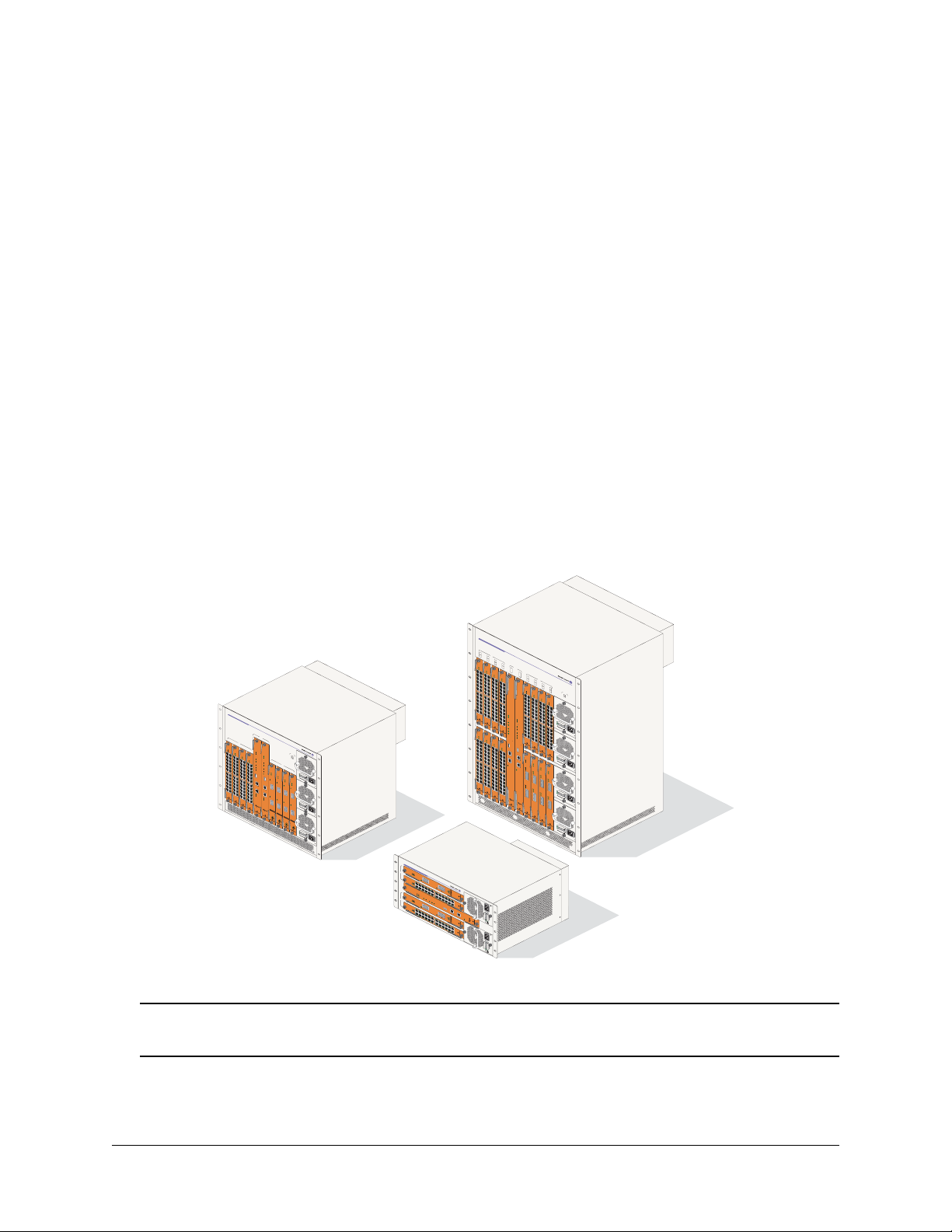

1 OmniSwitch 9000 Series

OmniSwitch 9000 switches offer high performance 10/100/1000 Ethernet, Gigabit Ethernet, and 10 Gigabit Ethernet capabilities, as well as embedded server load balancing for enterprise requirements. In this

release, these switches come in three chassis configurations—the 18-slot OmniSwitch 9800 (OS9800), the

10-slot OmniSwitch 9700 (OS9700), and the 5-slot OmniSwitch 9600 (OS9600).

Full duplex is supported on Gigabit Ethernet ports and 10-gigabit Ethernet ports.

Refer to the sections below for additional details on OS9000 switches.

OmniSwitch 9000 Series

The 18-slot OS9800 offers up to 768 Gigabit Ethernet ports and up to ninety-six 10-Gigabit Ethernet

ports.The 10-slot OS9700 offers up to 384 Gigabit Ethernet ports and up to fourty-eight10-gigabit Ethernet ports while the 5-slot OS9600 offers up to 192 Gigabit Ethernet ports and up to twenty-four 10-gigabit

Ethernet ports.

OmniSwitch 9700

1

OK1 OK1

OK2

22x20x18x16x14x12x10x8x6x4x

OmniSwitch 9800

1

NI

9

2

10

3

OS9-GNI-C24

11

4

OS9-GNI-C24

12

CMM

OK

1

OK

OS9-GNI-C24

2

A

A B

O

K

1

OK2

1x 3x 5x 7x 9x 11x

OS9-GNI-C24

A B

B

O

OS9800-CMM

K

1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

10x8x6x

13x 15x 17x 19x

14x12x

22x20x18x16x14x12x10x8x6x4x

20x18x16x

21x 23x

22x

OS9-GNI-C24

CMM

A

B

OS9600/OS9700-CMM

NI

2

OS9-GNI-C24

OS9600/OS9700-CMM

3

OS9-GNI-C24

4

OS9-GNI-C24

OK1

OK1

OS9-GNI-C24

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

OK1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x

OK1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x

22x20x18x16x14x12x10x8x6x4x

22x20x18x16x14x12x10x8x6x4x

23x

22x20x18x16x14x12x10x8x6x4x

23x

PWR

OK2

PS1

OK1

PS2

PS3

OK2

CON

TROL

5

FABRIC

CON

TROL

NI

6

TEMP

OS9-XNI-U2

FAB

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x

RIC

FAN

7

OS9-XNI-U2

T

EMP

PSU

FAN

8

AC

OS9-XNI-U2

USB

COSOLE/MDM

ETHERNET

LINK

ACT

23x

OK

OK1

DC OK

PSU

OVER

OK2

TEMP

OS9-XNI-U2

USB

OK1

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

OK2

LINK/AC

OK1

T

OK2

LINK/ACT

OK1

CONSOLE/MDM

OK2

LINK/ACT

1

LINK/ACT

1

ETHERNET

1

1

LINK/ACT

LINK

LINK/ACT

ACT

AC

OK

2

DC OK

LINK/ACT

OVER

TEMP

2

LI

NK/ACT

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

2

2

AC

OK

DC OK

OVER

T

EMP

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

OmniSwitch 9600

OS9-XNI-U2

1

NI

OS9-GNI-C24

2

LINK/ACT

OS9600/OS9700-CMM

CMM

LINK/ACT

OS9-XNI-U2

3

CONTROL

FABRIC

NI

TEMP

FAN

PSU

OS9-GNI-C24

4

LINK/ACT

LINK/ACT

OK1

OK2

A B

OK1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

10x8x6x

14x12x

20x18x16x14x12x10x8x6x4x

22x

22x20x18x16x

USB

COSOLE/MODEM

ETHERNET

LINK/ACT

5

A B

OK1

13

NI

OS9800-CMM

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

10x8x6x

14x12x

22x20x18x16x

OS9-GNI-C24

A B

OK1

OK2

1x 3x 5x 7x 9x 11x

4x

10x8x6x

13x 15x 17x 19x

14x12x

21x 23x

22x20x18x16x

6

A B

14

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

10x8x6x

14x12x

22x20x18x16x

OS9-GNI-C24

A B

OK

1

OK2

1x 3x 5x 7x 9x 11x

4x

10x8x6x

13x 15x 17x 19x

14x12x

21x 23x

22x20x18x16x

7

15

8

16

O

K

1

PWR

O

K2

A B

PS1

OK1

PS2

OK2

1x 3x 5x 7x 9x 11x

PS3

A B

PS4

OK1

O

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

K

2

4x

A B

O

K

1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

A B

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

10x8x6x

10x8x6x

OK1

OK2

10x8x6x

13x 15x 17x 19x

14x12x

OK1

AC

O

K

DC OK

OK2

CONTROL

FABRIC

TEMP

FAN

PSU

OS9-GNI-C24

U

S

B

CONSOLE/MODEM

A B

1x 3x 5x 7x 9x 11x

ETHERNET

LINK/ACT

13x 15x 17x 19x

21x 23x

OVER

TEMP

14x12x

100/

50

1

/6

15/25

CONTROL

FABRIC

TEMP

FAN

PSU

U

S

B

CONSOLE/MODEM

ETHERNET

LINK/ACT

0H

z,

8.

0

14x12x

V

0

/7.0/3.5

22x20x18x16x14x12x10x8x6x4x

A

20x18x16x

21x 23x

22x

22x20x18x16x

22x20x18x16x

OS9-XNI-U2OS9-GNI-C24

AC

O

K

D

C

O

K

O

V

ER

TEMP

OS9-XNI-U2OS9-GNI-C24

O

K1

100/115

50/

60

H

/

2

z

50V

,

8

OK

.

0/

OS9-XNI-U2OS9-GNI-C24

2

7

.0

/

3

.

5

A

OK1

OK2

OS9-XNI-U2OS9-GNI-C24

AC

OK

T

1

L

IN

O

K2

K

A

OK1

C

1

T

LINK

OK

2

TX

AC

1

T

LINK

R

X

TX

ACT

1

L

I

NK

RX

TX

1

R

ACT

X

TX

LI

N

K

AC

R

ACT

X

2

OK

DC OK

LI

N

K

OVER

TX

TEMP

AC

2

T

LINK

100/

RX

50/60Hz, 8.0

1

T

X

1

5/

2

50V

/

7

ACT

.0

/

2

3

.5

A

L

I

NK

RX

TX

2

R

X

T

X

RX

AC

OK

DC OK

O

VER

TEMP

1

0

5

0/115/250V

0

/

6

0H

z,

8.

0/7

.0/

3

.

5

A

OmniSwitch OS9600, OS9700, OS9800

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 1-1

Page 16

Application Example OmniSwitch 9000 Series

s

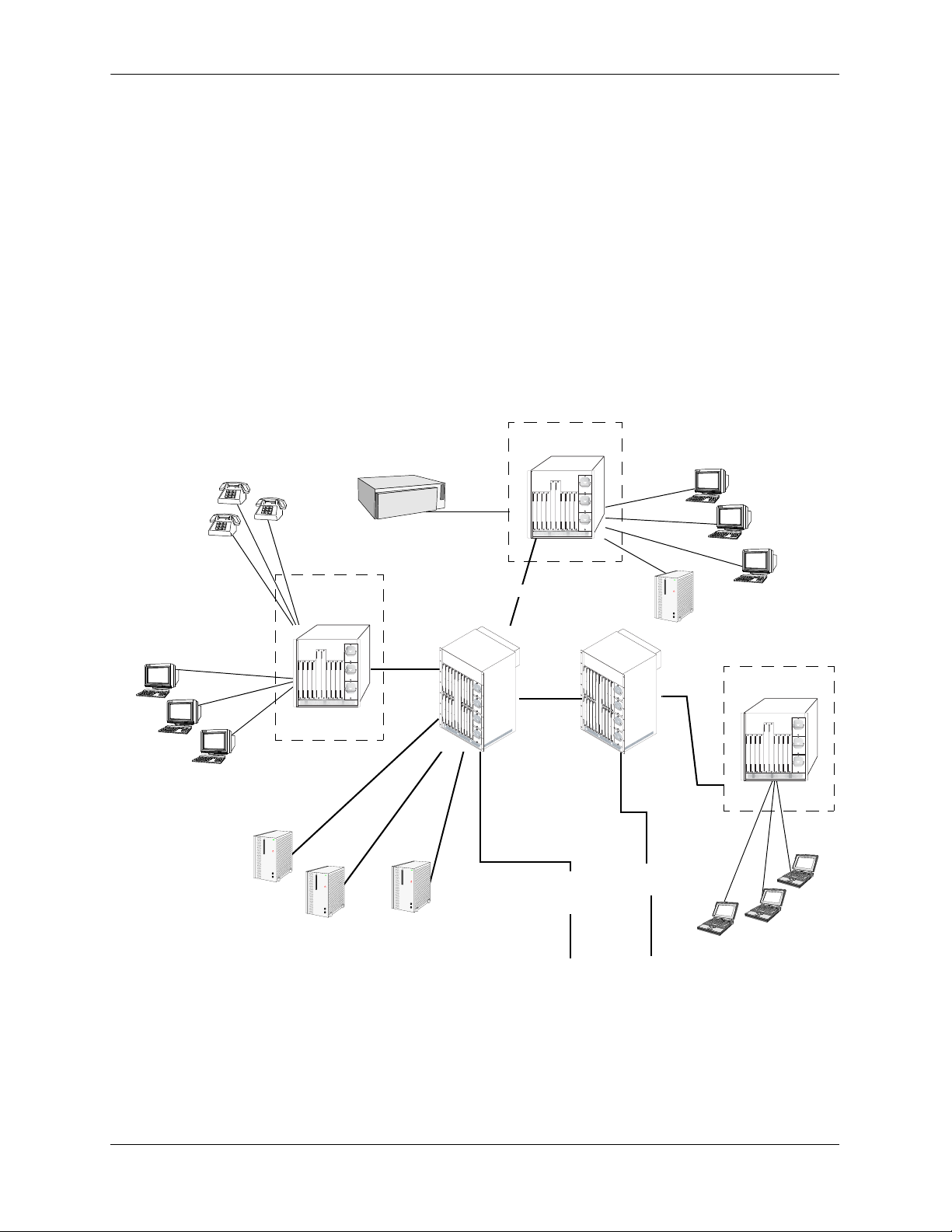

Application Example

The following application example shows one of the many ways OmniSwitch 9000 switches can be used

in an Enterprise network setting:

• Core Switch. In this example, an OS9800 is used as the core switch. Because the example network has

a high-speed Gigabit Ethernet or 10-gigabit Ethernet backbone, the Network Interface (NI) cards in the

chassis will be comprised mainly of Gigabit Ethernet or 10-gigabit Ethernet Network Interface (GNI,

XNI) modules. The core switch connects to wiring closet switches as well as the company server farm.

• Wiring Closet Switches. The switches in wiring closets 1, 2, and 3 must contain some GNI/XNI

modules in order to link to the Gigabit Ethernet/10-gigabit Ethernet core switch. However, in most

cases, these switches will largely be comprised of Gigabit Ethernet Network Interface (GNI) modules.

GNI modules support either 10/100/1000 (copper) or 100/1000 (fiber) Gigabit Ethernet connections.

These Ethernet ports connect to various network devices, such as workstations, IP phones, and servers.

Wiring Closet 2

IP Phones

10/100

OmniPCX

100BaseTX

Data

Wor ks ta ti on s

10/100

Data

Workstations

10/100

WebVi ew

Wiring Closet 1

Email

Server Farm

Oracle

Gigabit/

10-gigabit

Gigabit

OmniVista

Gigabit/10-gigabit

10-gigabit

Core

Switch

Gigabit

Gigabit

Ethernet

Ethernet

Backbone

Backbone

Server

Gigabit/10-gigabit

Gigabit

Gigabit

Ethernet

Ethernet

Backbone

Backbone

10/100

Web Vie w

Wiring Closet 3

Data

Workstation

page 1-2 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 17

OmniSwitch 9000 Series Availability Features

Availability Features

The switch provides a broad variety of Availability features. Availability features are hardware and

software-based safeguards that help prevent the loss of data flow in the unlikely event of a subsystem failure. In addition, some Availability features allow you to maintain or replace hardware components without powering off your switch or interrupting switch operations. Combined, these features provide added

resiliency and help ensure that your switch is consistently available for your day-to-day network operations.

Hardware-related Availability features include:

• Hardware Redundancy

• Smart Continuous Switching

• Software Rollback

• Hot Swapping

• Hardware Monitoring

• Power Checking Sequence

Information on software-related availability is provided in the OmniSwitch 6800/9000 Switch Management Guide and the OmniSwitch 6800/9000 Network Configuration Guide. Refer to the corresponding

feature chapter (e.g., VRRP).

Hardware Redundancy

Hardware redundancy refers to backup hardware components. If primary hardware components fail or go

offline for any reason, the redundant hardware automatically assumes the primary hardware functions (this

is also referred to as failover). The following components offer redundancy:

• Chassis Management Modules (CMMs)

• Power Supplies

• Fan Units

• MAC EEPROM

Note. Redundancy is a key Availability feature; it is recommended that you install redundant hardware

components in your switch whenever possible. However, CMM redundancy is not supported on the

OS9600 switch because it contains only one CMM slot.

For detailed information on CMM redundancy, refer to Chapter 4, “Chassis Management Module

(CMM).” For information on power supply and fan redundancy, refer to Chapter 2, “Chassis and Power

Supplies.”

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 1-3

Page 18

Availability Features OmniSwitch 9000 Series

Smart Continuous Switching

In redundant CMM configurations, the switch provides support for NIs during failover. In other words, if

the primary CMM fails or goes offline for any reason, NI modules will continue data transmission and

routing functions during the secondary CMM’s takeover process. This Availability feature is referred to as

Smart Continuous Switching.

Incoming Layer 2 packets will continue to be sent to the appropriate egress port during failover. Known

routes will also be supported. (Note, however, that the NI cannot learn new routes without CMM support.

Any new route information will be ignored.) Spanning Tree will continue handling BPDUs received on the

switch ports, as well as port link up and down states. The Spanning Tree topology will not be disrupted.

Note. Smart Continuous Switching is designed to maintain data flow only during CMM failover and is not

intended to support long-term data flow. If both the primary and secondary CMM modules go offline or

are removed from the chassis, switch operations (including all NI support) will be disabled. However,

smart continuous switching is not possible on the OS9600 switch because it contains only one CMM slot.

For more information on CMM redundancy and the failover process, refer to Chapter 4, “Chassis Manage-

ment Module (CMM).”

Software Rollback

Software rollback (also referred to as image rollback) essentially allows the switch to return to a prior “last

known good” version of software in the event of a system software problem. The CMM controls software

rollback through its resilient directory structure design (i.e., /flash/working and /flash/certified).

For detailed information on the software rollback feature, as well as the switch’s /flash/working and

/flash/certified directories, refer to the “Managing CMM Directory Contents” chapter in the Switch

Management Guide.

page 1-4 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 19

OmniSwitch 9000 Series Availability Features

Hot Swapping

Hot swapping refers to the action of adding, removing, or replacing certain hardware components without

powering off your switch and disrupting other components in the chassis. This feature greatly facilitates

hardware upgrades and maintenance and also allows you to easily replace components in the unlikely

event of hardware failure. The following hardware components can be hot swapped:

• Chassis Management Modules (CMMs)

• Gigabit Ethernet Network Interface modules (GNIs)

• 10-gigabit Ethernet Network Interface modules (XNIs)

• Power supplies

• Fan tray

Hot Swapping Non-Redundant Management Modules and Power Supplies. If there is only one CMM

or power supply installed in the chassis and either of these components is removed or replaced, all switch

functions will stop until a replacement is installed. However, hot swapping is not possible on the OS9600

switch because it contains only one CMM slot.

Hot Swapping NI Modules. It is recommended that you hot swap NIs of the same type

(e.g., OS9-GNI-C24) whenever possible. Otherwise, the network configuration may be adversely affected.

For information on hot swapping CMMs, refer to Chapter 4, “Chassis Management Module (CMM).”

For information on hot swapping NI modules, refer to Chapter 5, “Network Interface (NI) Modules.”

For information on hot swapping power supplies and the fan tray, refer to Chapter 2, “Chassis and Power

Supplies.”

Hardware Monitoring

Automatic Monitoring

Automatic monitoring refers to the switch’s built-in sensors that automatically monitor operations. The

majority of automatic monitoring is provided by the CMM. If an error is detected (e.g., over-threshold

temperature), the CMM immediately sends a trap to the user. The trap is displayed on the console in the

form of a text error message. (In the case of an over-threshold temperature condition, the CMM displays

an amber TEMP LED in addition to sending a trap.)

LEDs

LEDs, which provide visual status information, are provided on the CMM, NI, and power supply front

panels. LEDs are used to indicate conditions, such as hardware and software status, temperature errors,

link integrity, data flow, etc. For detailed LED descriptions, refer to the corresponding hardware component chapter (e.g., “Network Interface (NI) Modules”).

User-Driven Monitoring

User-driven hardware monitoring refers to CLI commands that are entered by the user in order to access

the current status of hardware components. The user enters “show” commands that output information to

the console. The Show commands for all the features are described in detail in the OmniSwitch CLI Refer-

ence Guide.

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 1-5

Page 20

Availability Features OmniSwitch 9000 Series

Power Checking Sequence

The power checking sequence is another built-in Availability feature. This feature helps regulate power in

the switch whenever the switch is booted or an NI module is installed in the chassis.

The sequence is a joint effort between the CMM, the NI modules, and the power supplies. During the boot

sequence, the primary CMM automatically compares the power consumption required by installed NIs

with the power available from the power supplies. If there is not adequate power to support all NIs, the

CMM will power on only the supported number of NIs, starting from the first NI slot position.

Important. During the power checking sequence, CMMs receive priority and are always powered on. NI

modules are then powered on sequentially by slot position. In other words, the NI in slot 1 is powered on,

then slot 2, then slot 3, etc. For information on slot positions, refer to Chapter 2, “Chassis and Power

Supplies.”

Installing a New NI into a Running Chassis

When an NI module is installed in the chassis, only a small portion of the circuitry is initially powered up.

The CMM immediately reads the incoming module’s ID and determines how much power the module will

require. If the number of power supplies installed in the chassis can provide sufficient power, the CMM

turns on the incoming module. If the number of installed power supplies cannot provide sufficient power,

the incoming NI will remain powered off.

page 1-6 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 21

2 Chassis and Power

Supplies

The OmniSwitch 9000 switches are available in three chassis configurations—the 18-slot OmniSwitch

9800 (OS9800), the 10-slot OmniSwitch 9700 (OS9700), and the 5-slot OmniSwitch 9600 (OS9600). This

chapter includes detailed information on each of these chassis types. The topics include:

• Technical specifications on page 2-7.

• Switch mounting information on page 2-12.

• Power supplies and power supply redundancy on page 2-16.

• Temperature management on page 2-33.

• Chassis fan tray on page 2-35.

• Monitoring the chassis components via the Command Line Interface (CLI) on page 2-21.

OmniSwitch 9800

1

NI

9

2

10

3

OS9-GNI-C24

11

4

OS9-GNI-C24

12

CMM

O

K1

O

OS9-GNI-C24

K

2

A

A B

O

K1

OK2

1x 3x 5x 7x 9x 11x

OS9-GNI-C24

A B

B

OK1

OS9800-CMM

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

5

4x

A B

OK1

13

NI

OS9800-CMM

O

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

6

K

4x

2

A B

14

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

7

4x

15

8

16

OK1

PWR

OK2

A B

10x8x6x

14x12x

O

K

1

O

22x20x18x16x

K

2

CONTROL

FABRIC

TEMP

FAN

PSU

OS9-GNI-C24

OS9-GNI-C24

U

S

B

U

A B

O

K

1

CONSOLE/MODEM

O

1x 3x 5x 7x 9x 11x

K2

A B

CONSOLE/MODEM

1x 3x 5x 7x 9x 11x

4x

ETHERNET

ETHERNET

10x8x6x

LINK/ACT

13x 15x 17x 19x

14x12x

13x 15x 17x 19x

21x 23x

22x20x18x16x

21x 23x

PS1

OK1

PS2

O

1x 3x 5x 7x 9x 11x

K2

PS3

A B

PS4

O

K1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

A B

OK1

O

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

K2

4x

A B

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

4x

10x8x6x

10x8x6x

10x8x6x

13x 15x 17x 19x

14x12x

OK1

AC

OK

D

C

OK

OK

2

O

V

ER

TEMP

14x12x

100/115/2

5

0

/6

0H

CONTROL

z

5

,

0V

8.

14x12x

0/7.

0/

3

.5

A

FABRIC

22x20x18x16x14x12x10x8x6x4x

20x18x16x

21x 23x

TEMP

22x

FAN

22x20x18x16x

PSU

22x20x18x16x

S

B

OS9-XNI-U2OS9-GNI-C24

AC

OK

DC OK

OVER

T

EM

P

OS9-XNI-U2OS9-GNI-C24

OK1

100/

50/

115/

6

0H

2

z

5

,

8.0

0V

O

K

OS9-XNI-U2OS9-GNI-C24

/

2

7.

0

/

3.

5

A

O

K1

OK2

OS9-XNI-U2OS9-GNI-C24

ACT

OK1

LI

OK2

N

K

LIN

K/ACT

A

OK1

CT

1

LINK

OK2

TX

ACT

1

LIN

K

RX

TX

ACT

1

LINK

RX

TX

1

R

ACT

X

T

X

LINK

AC

R

A

X

CT

2

OK

D

C

LIN

OK

K

O

V

T

E

X

R

TEMP

ACT

2

LI

NK

100/

RX

50/60

11

TX

5/

H

25

z, 8.0/7.0/3.5

0V

ACT

2

A

LINK

RX

TX

2

R

X

T

X

R

X

AC

O

K

DC

O

K

O

V

ER

TEMP

100/

5

0

115

/6

0

Hz,

/2

5

0

8.

V

0

/

7.

0/

3

.5

A

OmniSwitch 9700

1

OK1OK1

OK2

22x20x18x16x14x12x10x8x6x4x

10x8x6x

10x8x6x

13x 15x 17x 19x

14x12x

14x12x

22x20x18x16x14x12x10x8x6x4x

20x18x16x

21x 23x

22x

22x20x18x16x

OS9-GNI-C24

OS9-GNI-C24

O

CMM

A

B

OS9600/OS9700-CMM

NI

2

OS9-GNI-C24

OS9600/OS9700-CMM

3

OS9-GNI-C24

4

OS9-GNI-C24

OK1

O

K

1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

OK1

OK

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x

2

22x20x18x16x14x12x10x8x6x4x

22x20x18x16x14x12x10x8x6x4x

23x

PWR

OS9-GNI-C24

OK2

PS1

OK1

PS2

PS3

OK2

CON

TROL

OK1

5

FABRIC

O

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x

K

2

CON

TROL

NI

6

TEMP

OS9-XNI-U2

FAB

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x

RIC

FAN

7

OS9-XNI-U2

TEMP

PSU

FAN

8

AC

OS9-XNI-U2

OK

USB

OK1

DC OK

PSU

OVER

OK2

TEMP

OS9-XNI-U2

USB

OK1

100/115/250V

5

0

/

OK

6

0Hz, 8

2

.0

/7.0/3.5

L

I

COSOLE/MD

M

ETHERNET

LINK

22x20x18x16x14x12x10x8x6x4x

ACT

23x

23x

A

OK1

NK/ACT

OK

2

LINK/ACT

O

CONSOLE/

K1

OK2

MDM

L

I

NK/AC

1

T

L

INK

1

/

A

C

T

ETHERNET

1

1

LINK

/

ACT

LINK

LI

ACT

NK/A

C

T

AC

OK

2

DC OK

LI

N

K/ACT

OVER

TEMP

2

LINK/ACT

1

00/115

50

/

60H

/

250V

z

,

8.0

/

7

.0

/3.

2

5

A

2

AC

OK

DC OK

OVER

TEMP

10

50/60Hz, 8.0/7.0/3.5 A

0

/115/2

5

0V

OmniSwitch 9600

OS9-XNI-U2

1

NI

OS9-GNI-C24

2

LINK/ACT

OS9600/OS9700-CMM

CMM

OS9-XNI-U2

3

CONTROL

FABRIC

NI

TEMP

OS9-GNI-C24

4

LINK/ACT

K1

OK2

A B

OK1

O

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

K

2

A B

OK1

OK2

1x 3x 5x 7x 9x 11x

4x

4x

10x8x6x

10x8x6x

14x12x

13x 15x 17x 19x

14x12x

20x18x16x14x12x10x8x6x4x

22x

22x20x18x16x

21x 23x

22x20x18x16x

LINK/ACT

FAN

PSU

USB

COSOLE/MODEM

LINK/ACT

ETHERNET

LINK/ACT

OmniSwitch OS9600, OS9700, OS9800

Warning. Do NOT install white color OmniSwitch 7700/7800 CMMs or NI modules in an OmniSwitch

9000 Series chassis, or damage to the modules or chassis may occur.

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 2-1

Page 22

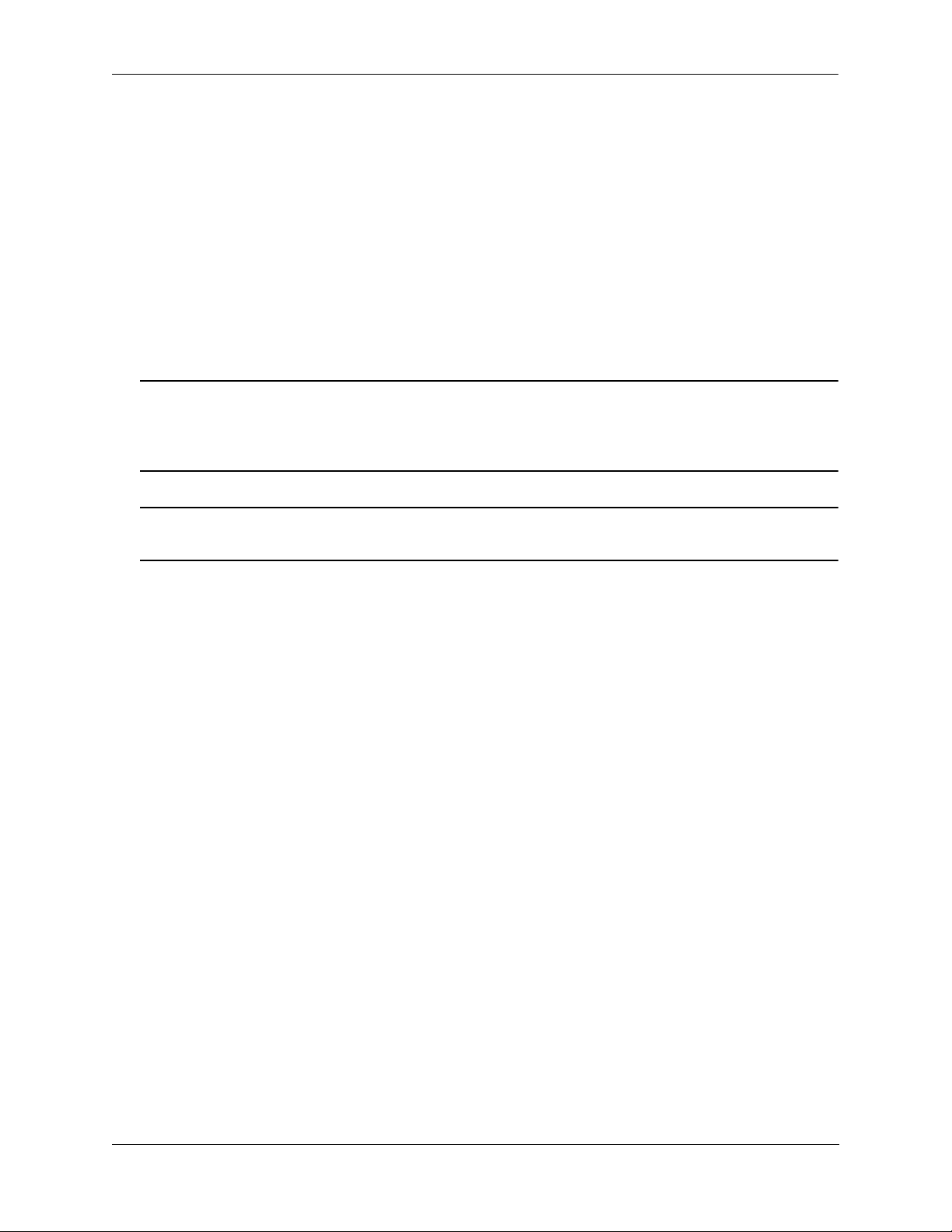

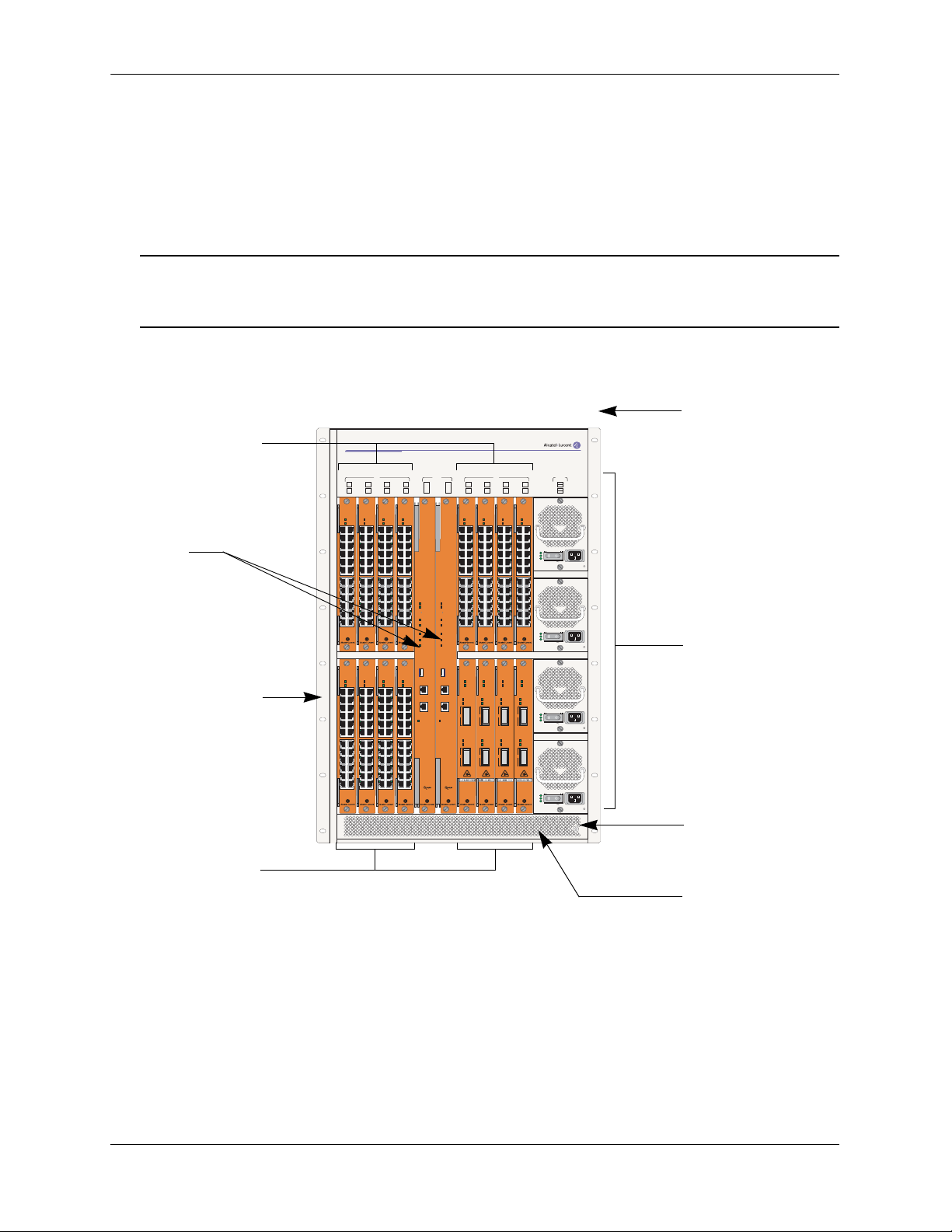

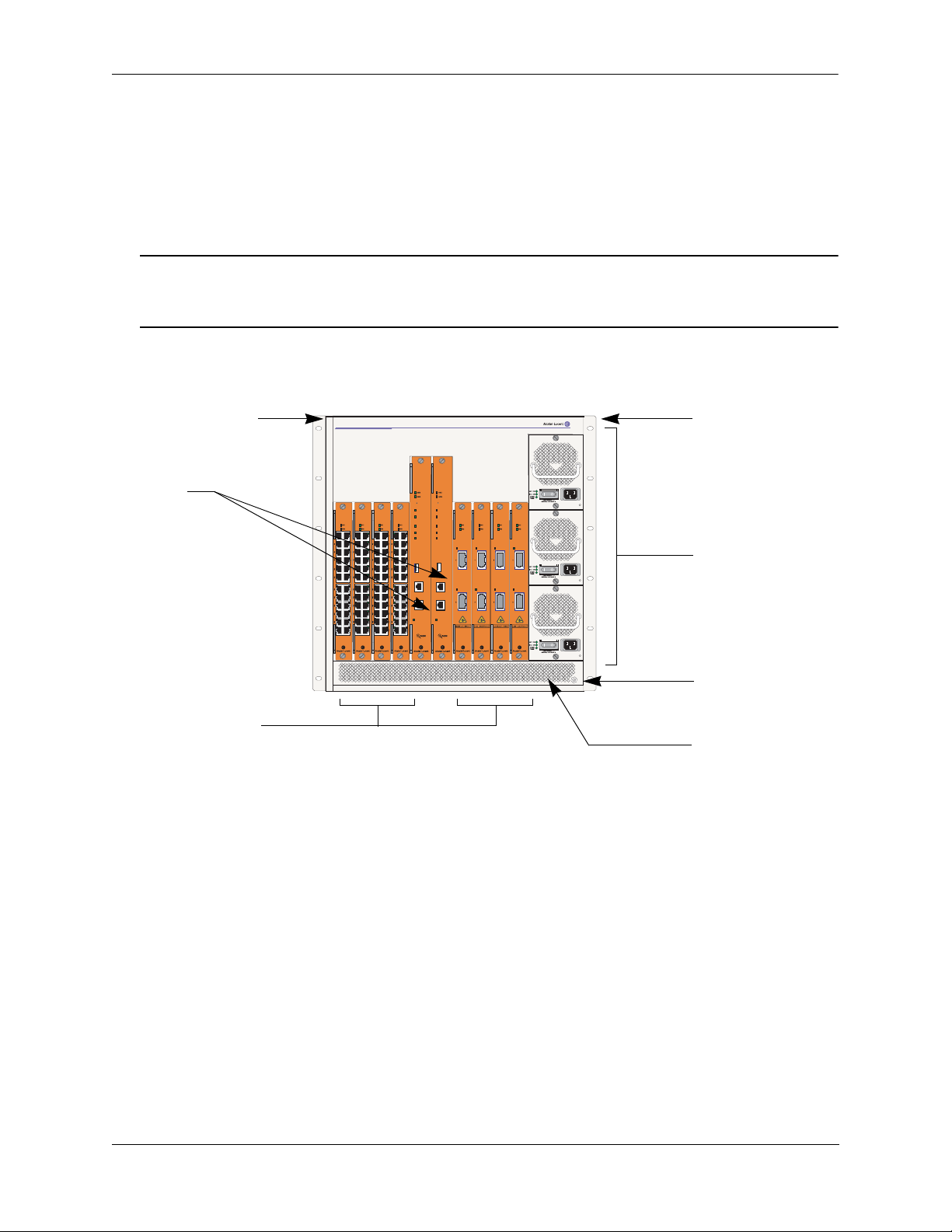

OmniSwitch 9800 Chassis and Power Supplies

OmniSwitch 9800

The OmniSwitch 9800 is a high performance switch offering 16 slots for Gigabit Ethernet and/or 10-Gigabit Ethernet Network Interface (NI) modules. An additional two slots are reserved for primary and redundant Chassis Management Modules (CMMs). The OmniSwitch 9800 supports a maximum of four power

supplies.

Note. Power supply requirements are based on the number of NIs installed in the chassis. Refer to

“Power Supplies” on page 2-16 for important information on power supplies and power supply

redundancy.

The following illustrations outline the major components of the OmniSwitch 9800 switch.

Front Rack Mount

Network Interface

(NI) Modules

CMMs

Front Rack Mount

Flange

OmniSwitch 9800

1 2 3 4

9 10 11 12

OS9-GNI-C24

OS9-GNI-C24

OK1

OK1

OK2

OK2

1x 3x 5x

1x 3x 5x

6x4x

6x4x

7x 9x 11x

7x 9x 11x

12x10x8x

12x10x8x

13x 15x 17x 19x 21x 23x

13x 15x 17x 19x 21x 23x

22x20x18x16x14x

22x20x18x16x14x

OS9-GNI-C24

OS9-GNI-C24

OK1

OK1

OK2

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

22x20x18x16x14x12x10x8x6x4x

22x20x18x16x14x12x10x8x6x4x

NI

6x4x

12x10x8x

22x20x18x16x14x

22x20x18x16x14x12x10x8x6x4x

OK1

OK2

OK1

OK2

OS9-GNI-C24

1x 3x 5x

7x 9x 11x

13x 15x 17x 19x 21x 23x

OS9-GNI-C24

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

6x4x

12x10x8x

22x20x18x16x14x

22x20x18x16x14x12x10x8x6x4x

OS9-GNI-C24

OK1

OK2

1x 3x 5x

7x 9x 11x

13x 15x 17x 19x 21x 23x

OS9-GNI-C24

OK1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

A B

OS9800-CMM

OK1

OK2

CONTROL

FABRIC

TEMP

FAN

PSU

USB

CONSOLE/MODEM CONSOLE/MODEM

ETHERNET

LINK/ACT

OK1

OK2

CONTROL

FABRIC

TEMP

FAN

PSU

USB

ETHERNET

LINK/ACT

5 6 7 8

13 14 15 16

OS9800-CMM

OS9-GNI-C24

OK1

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

22x20x18x16x14x12x10x8x6x4x

22x20x18x16x14x12x10x8x6x4x

OS9-XNI-U2

OK1

OK2

ACT

LINK

RX

1

1

TX

ACT

LINK

RX

2

2

TX

NICMM PWR

OS9-GNI-C24

OS9-GNI-C24

OS9-GNI-C24

OK1

OK1

OK1

OK2

OK2

OK2

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

22x20x18x16x14x12x10x8x6x4x

22x20x18x16x14x12x10x8x6x4x

OS9-XNI-U2

OS9-XNI-U2

OS9-XNI-U2

OK1

OK1

OK1

OK2

OK2

OK2

ACT

ACT

ACT

LINK

LINK

LINK

RX

RX

RX

1

1

TX

TX

TX

ACT

ACT

ACT

LINK

LINK

LINK

RX

RX

RX

2

2

TX

TX

TX

PS1

PS2

PS3

PS4

1x 3x 5x 7x 9x 11x 13x 15x 17x 19x 21x 23x

AC OK

DC OK

OVER

TEMP

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

AC OK

DC OK

OVER

TEMP

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

AC OK

DC OK

OVER

TEMP

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

AC OK

DC OK

OVER

TEMP

100/115/250V

50/60Hz, 8.0/7.0/3.5 A

Flange

Power Supplies

Grounding Lug

Network Interface

(NI) Modules

Air Intake Vent

OmniSwitch 9800 Front View

page 2-2 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 23

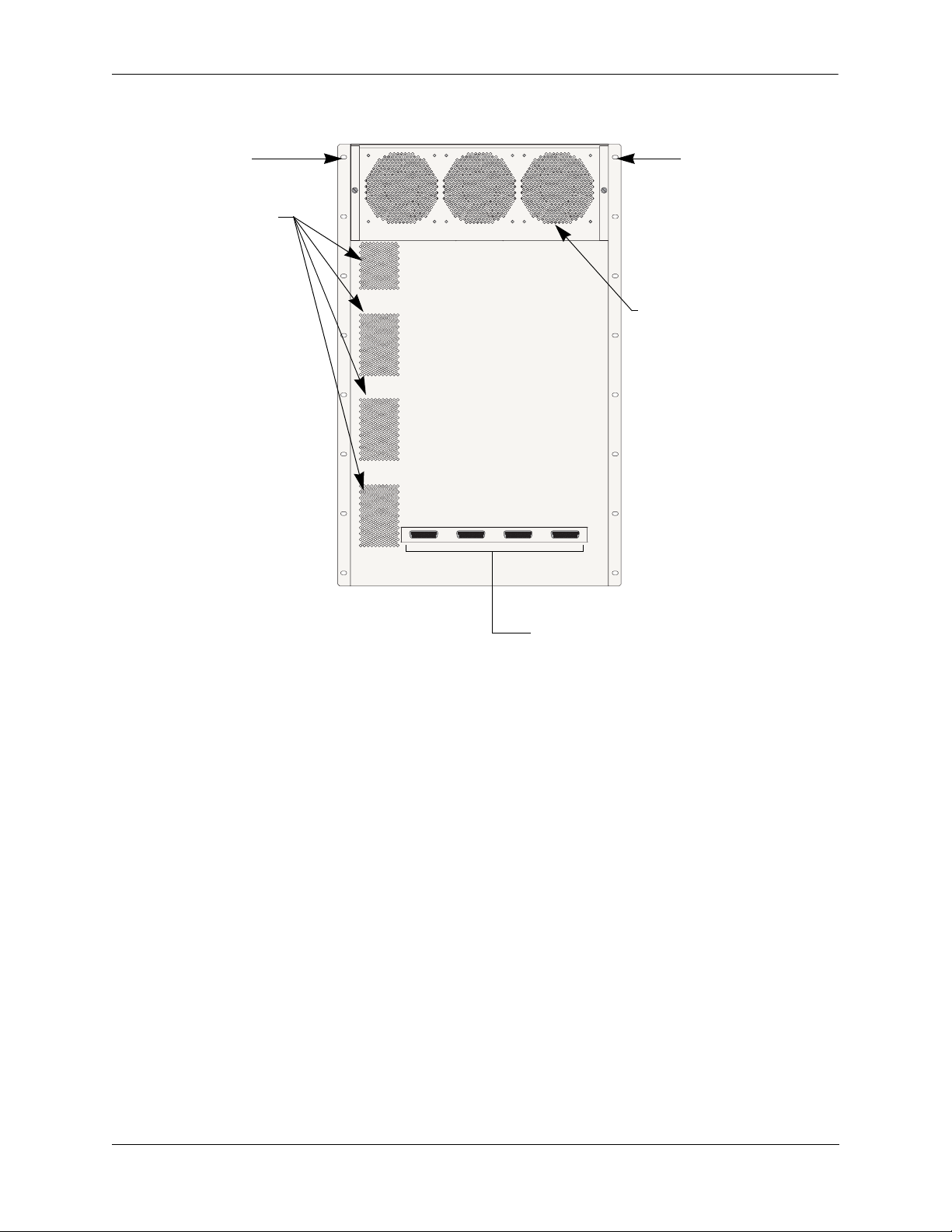

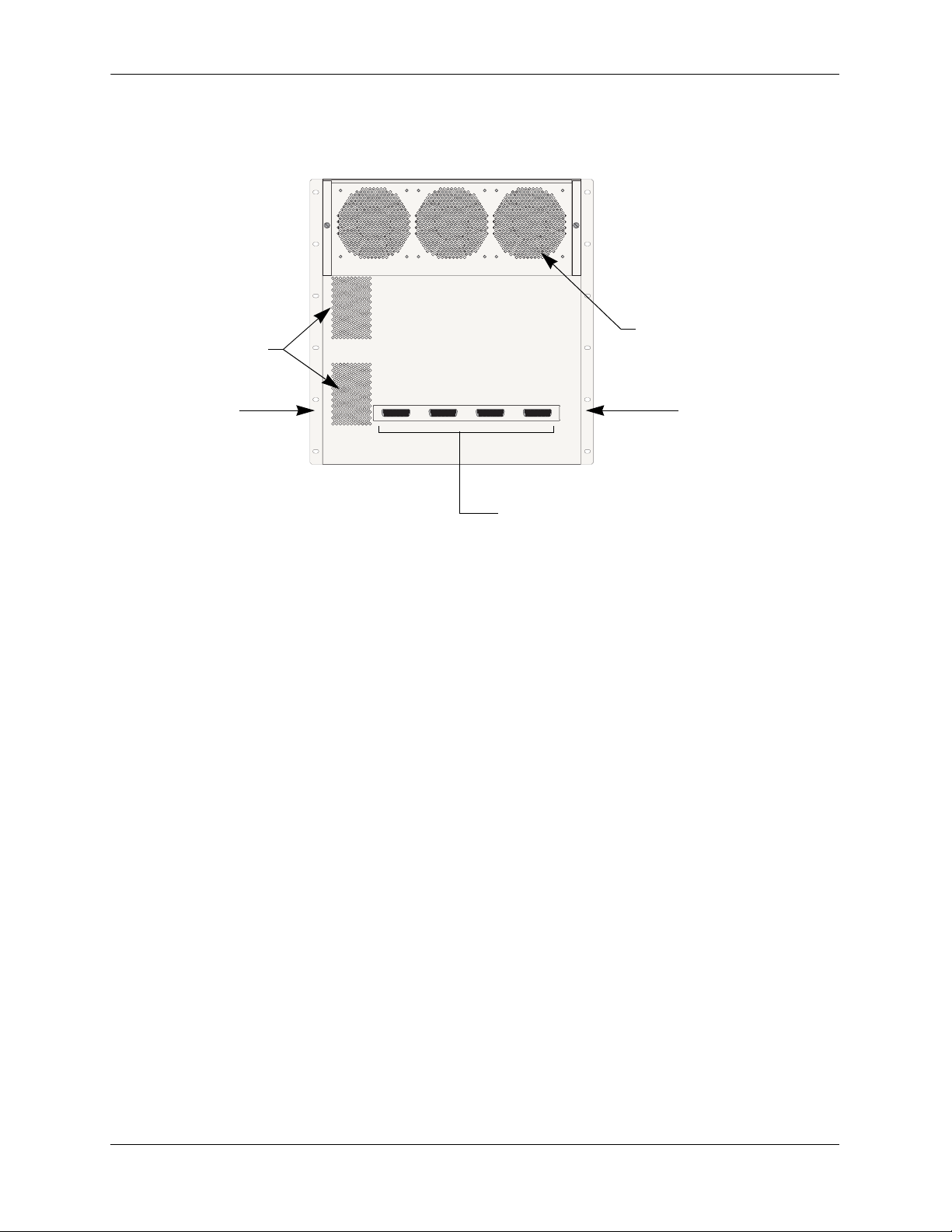

Chassis and Power Supplies OmniSwitch 9800

Front Rack Mount

Flange

Airflow Exhaust Vents

(for power supplies)

Front Rack Mount

Flange

Fan Tray (contains three fans)

for chassis temperature

control and airflow exhaust

Connectors for inline power supply.

OmniSwitch 9800 Back View

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 2-3

Page 24

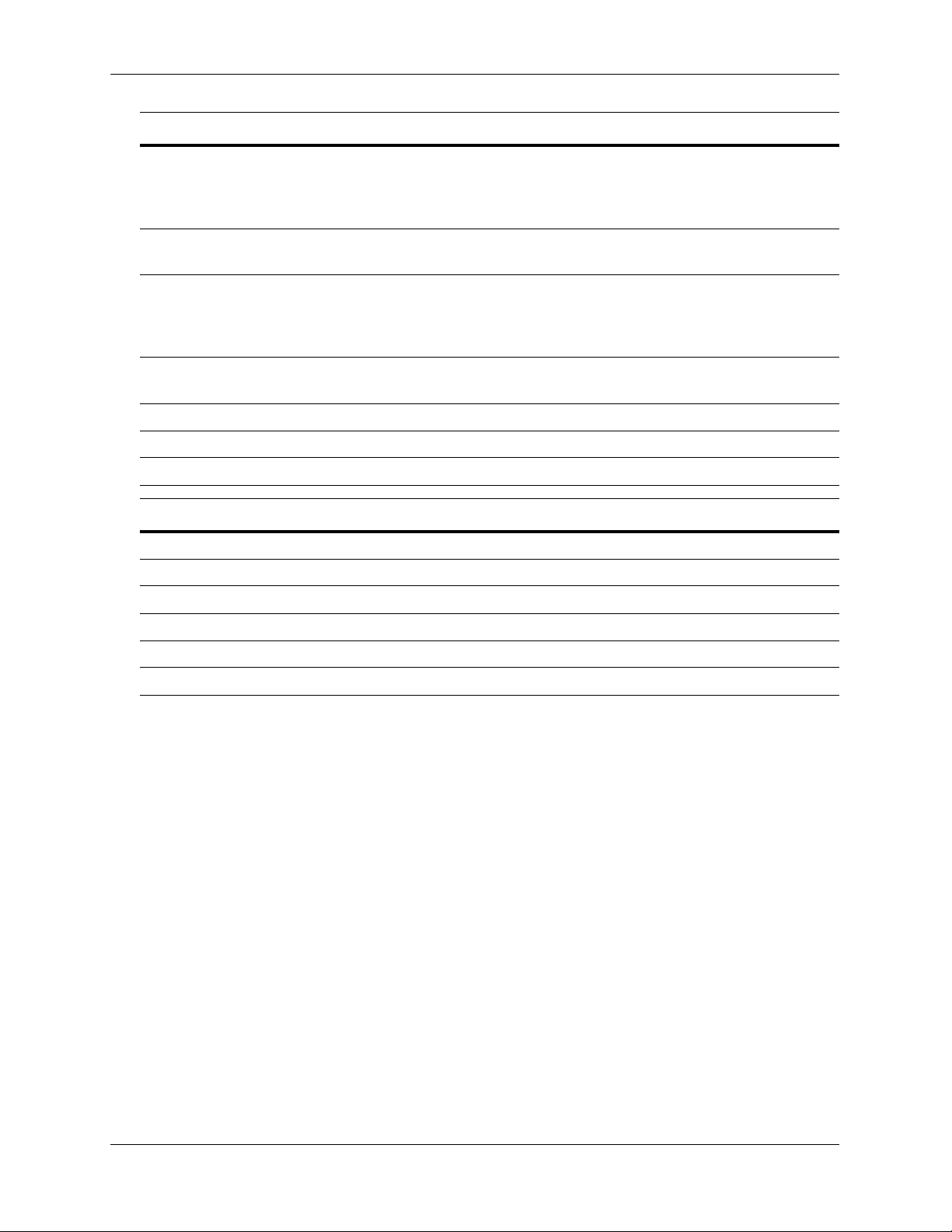

OmniSwitch 9800 Chassis and Power Supplies

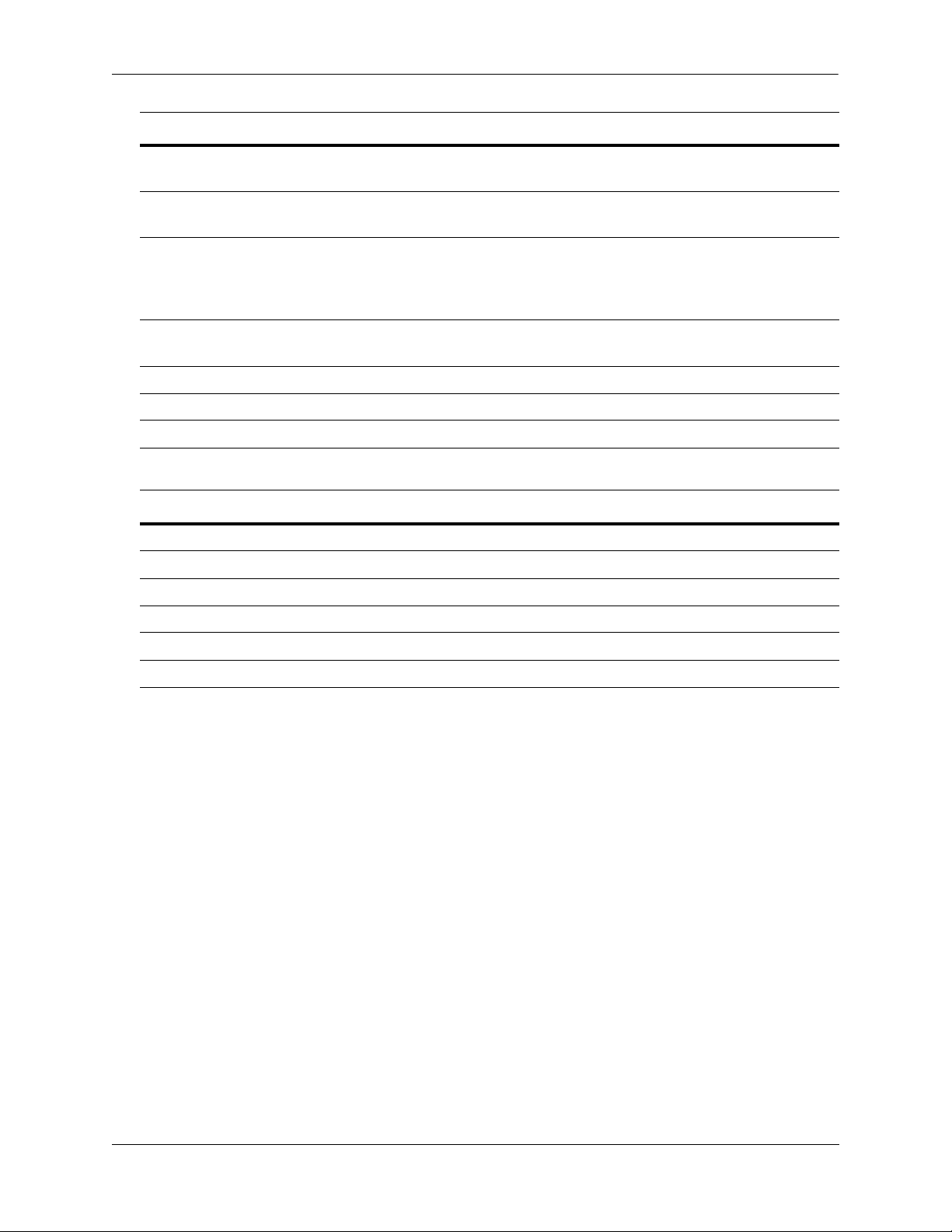

OmniSwitch 9800 Technical Specifications

Total 10/100/1000 copper Ethernet ports available

768 (Fully-populated with OS9-GNI-C48T modules. No other

NI module types installed.)

384 (Fully-populated with OS9-GNI-C24 and/or OS9-GNI-P24

modules. No other NI module types installed.)

Total 1000BaseSX Ethernet

ports available

Total 10-Gigabit Ethernet ports

available

384 (Fully-populated with OS9-GNI-U24 modules. No other

NI module types installed.)

32 (Fully-populated with OS9-XNI-U2 modules, with each

XNI containing two GBICs. No other NI modules installed.)

96 (Fully-populated with OS9-XNI-U6 modules, with each

XNI containing six GBICs. No other NI modules installed.)

Total slots available for network

16

interface (NI) modules

Total slots available for CMMs 2

Total bays for power supplies 4

Power 85 watts (approximate)

OmniSwitch 9800 Chassis Dimensions

Overall Width (including rack-mount flanges) 19 1/8 inches

Chassis Width (rack-mount flanges not included) 17 9/16 inches

Height 29 3/4 inches

Height (rack units) 17 RU

Overall Depth (including required fan tray) 17 5/16 inches

Chassis Depth (fan tray not included) 14 3/4 inches

page 2-4 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 25

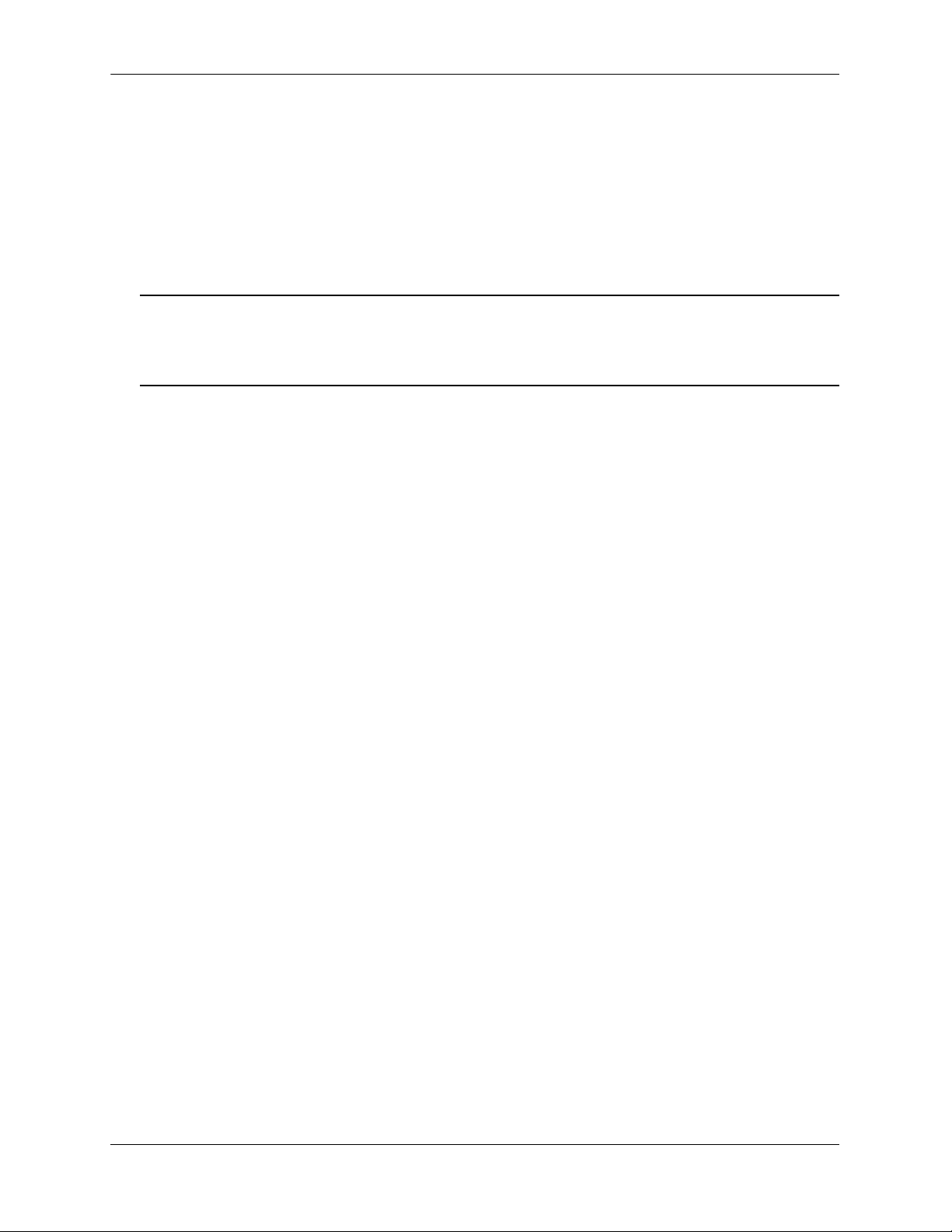

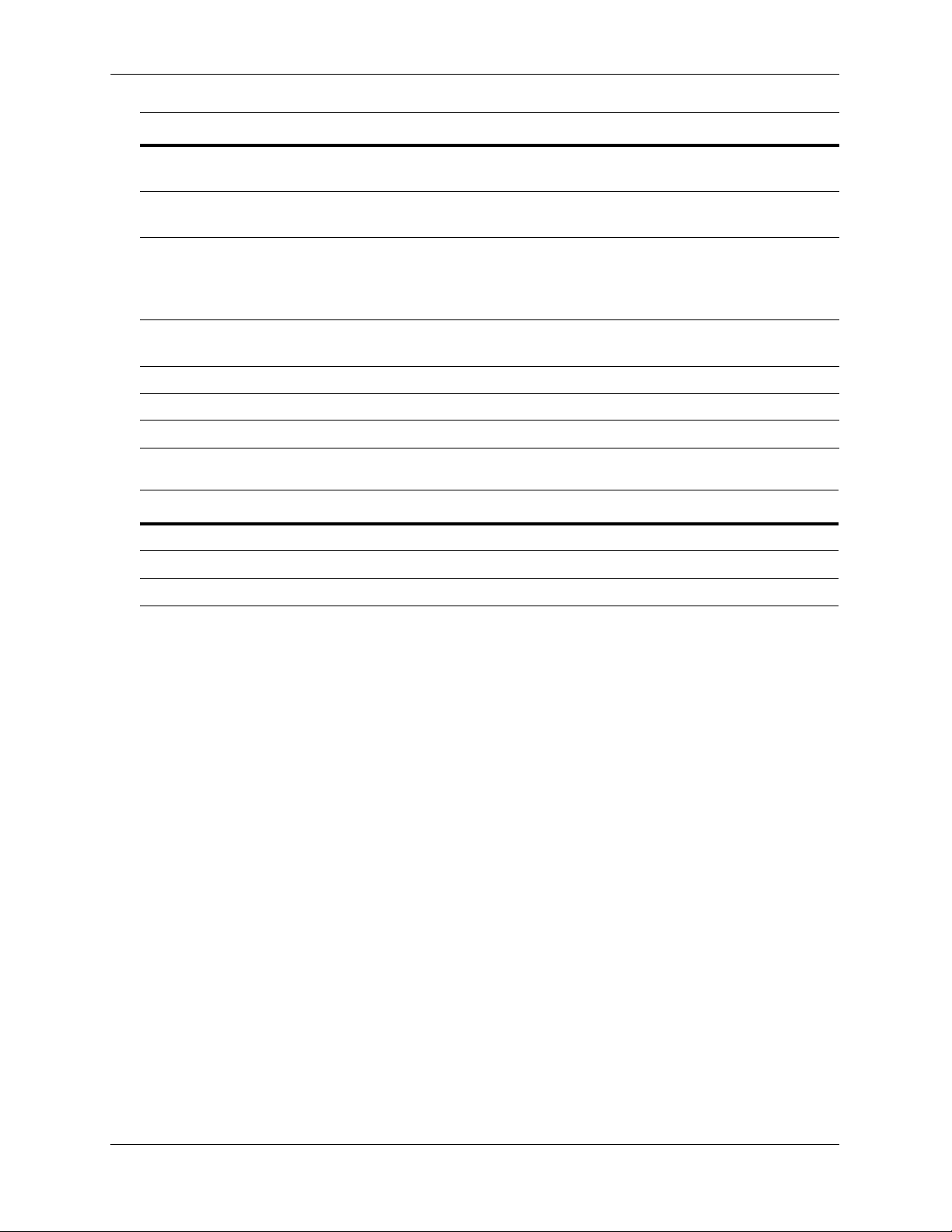

Chassis and Power Supplies OmniSwitch 9700

OmniSwitch 9700

The OmniSwitch 9700 is a high performance switch offering eight slots for Gigabit Ethernet and/or 10gigabit Ethernet Network Interface (NI) modules. Additional two slots are reserved for primary and redundant Chassis Management Modules (CMMs). The OmniSwitch 9700 supports a maximum of three power

supplies.

Note. Power supply requirements are based on the number of NIs installed in the chassis. Refer to

“Power Supplies” on page 2-16 for important information on power supplies and power supply redun-

dancy.

The following illustrations outline the major components of the OmniSwitch 9700 switch.

Front Rack Mount

CMMs

Network Interface

(NI) Modules

OmniSwitch 9700

OS9600/OS9700-CMM

OS9600/OS9700-CMM

OS9-GNI-C24

OS9-GNI-C24

OS9-GNI-C24

OS9-GNI-C24

COSOLE/MODEM

CONTROL

FABRIC

TEMP

FAN

PSU

USB

ETHERNET

LINK/ACT

CONTROL

FABRIC

TEMP

FAN

PSU

LINK/ACT LINK/ACT LINK/ACT LINK/ACT

USB

COSOLE/MODEM

LINK/ACT LINK/ACT LINK/ACT LINK/ACT

ETHERNET

LINK/ACT

OS9-XNI-U2

OS9-XNI-U2

OmniSwitch 9700 Front View

OS9-XNI-U2

Front Rack Mount

FlangeFlange

OS9-XNI-U2

Power Supplies

Grounding Lug

Air Intake Vent

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 2-5

Page 26

OmniSwitch 9700 Chassis and Power Supplies

Fan Tray (contains three fans)

Airflow Exhaust Vents

(for power supplies)

for chassis temperature

control and airflow exhaust

Front Rack Mount

Flange

Front Rack Mount

Flange

Connectors reserved for use with inline

power supply.

OmniSwitch 9700 Back View

page 2-6 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 27

Chassis and Power Supplies OmniSwitch 9700

OmniSwitch 9700 Technical Specifications

Total 10/100/1000 copper Ethernet ports available

Total 1000Base SX fiber Ethernet ports available

Total 10-Gigabit Ethernet ports

available

384 (Fully-populated with OS9-GNI-C24 and/or OS9-GNI-P24

modules. No other NI module types installed.)

192 (Fully-populated with OS9-GNI-U24 modules. No other

NI module types installed.)

16 (Fully-populated with OS9-XNI-U2 modules, with each

XNI containing two XFPs. No other NI modules installed.)

48 (Fully-populated with OS9-XNI-U6 modules, with each

XNI containing six XFPs. No other NI modules installed.)

Total slots for network interface

8

(NI) modules

Total slots for CMM 2

Total bays for power supplies 3

Power 50 W (approximate)

OmniSwitch 9700 Chassis Dimensions

Overall Width (including rack-mount flanges) 19 1/8 inches

Chassis Width (rack-mount flanges not included) 17 9/16 inches

Height 19 1/4 inches

Height (rack units) 11 RU

Overall Depth (including required fan tray) 17 5/16 inches

Chassis Depth (fan tray not included) 14 3/4 inches

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 2-7

Page 28

OmniSwitch 9600 Chassis and Power Supplies

OmniSwitch 9600

The OmniSwitch 9600 is a high performance switch offering four slots for Gigabit Ethernet and/or

10 gigabit Ethernet Network Interface (NI) modules. An additional one slot is reserved for the primary

Chassis Management Module (CMM). The OmniSwitch 9600 supports a maximum of two load sharing

power supplies on the front panel and there are optional power connectors, which consist of three DB-25

connectors mounted on the rear panel of the chassis for PoE applications. Either OS9-IP-SHELF or

360W/510W power supplies can be used. The first two connectors support OS9-IP-SHELF power supplies

and the third connector supports 360W/510W power supplies.

Note. Power supply requirements are based on the number of NIs installed in the chassis. Refer to

“Power Supplies” on page 2-16 for important information on power supplies and power supply redun-

dancy.

The following illustrations outline the major components of the OmniSwitch 9600 switch:

Front Rack

Mount

Flange

OmniSwitch 9600

CMM

NI

CMM

NI

Network

Interface (NI) Modules

OS9-XNI-U2

1

OS9-GNI-C24

2

OS9600/OS9700-CMM

OS9-XNI-U2

3

OS9-GNI-C24

4

OK1

OK2

LINK/ACT

OK1

OK2

OK1

OK2

CONTROL

FABRIC

OK1

OK2

LINK/ACT

OK1

OK2

LINK/ACT

TEMP

OVER

AC OK

DC OK

TEMP

FAN

PSU

USB

COSOLE/MODEM

LINK/ACT

ETHERNET

LINK/ACT

TEMP

OVER

AC OK

DC OK

Front RackMount Flange

Power Supplies

OmniSwitch 9600 Front View

page 2-8 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 29

Chassis and Power Supplies OmniSwitch 9600

Fan Tray (contains four fans)

Connectors reserved for use with inline

power supply.

for chassis temperature

control and airflow exhaust

Airflow

exhaust vents

(for power

supplies)

Front rack mount

flange

Front rack mount flange

OmniSwitch 9600 Back View

OmniSwitch 9000 Series Hardware Users Guide June 2007 page 2-9

Page 30

OmniSwitch 9600 Chassis and Power Supplies

OmniSwitch 9600 Technical Specifications

Total 10/100/1000 copper Ethernet ports available

Total 1000Base SX fiber Ethernet ports available

Total 10-Gigabit Ethernet ports

available

192 (Fully-populated with OS9-GNI-C24 and/or OS9-GNI-P24

modules. No other NI module types installed.)

96 (Fully-populated with OS9-GNI-U24 modules. No other NI

module types installed.)

8 (Fully-populated with OS9-XNI-U2 modules, with each XNI

containing two XFPs. No other NI modules installed.)

24 (Fully-populated with OS9-XNI-U6 modules, with each

XNI containing six XFPs. No other NI modules installed.)

Total slots for network interface

4

(NI) modules

Total slots for CMM 1

Total bays for power supplies 2

Power 50 W (approximate)

OmniSwitch 9600 Chassis Dimensions

Width 19 inches

Height 9.575 inches

Depth 14.432 inches

page 2-10 OmniSwitch 9000 Series Hardware Users Guide June 2007

Page 31

Chassis and Power Supplies Chassis Slot Numbering

Chassis Slot Numbering

The term slot refers to the position at which a CMM or NI module is installed in chassis. CMM slot positions are designated as Slot A and Slot B. On OS9800 switches, NI slot numbers range from 1 to 16. On

OS9700 switches, NI slot numbers range from 1 to 8. On OS9600 switches, NI slot numbers range from 1

to 4.

Note. The OS9600 contains only one CMM slot.

Power supply bays are also given specific slot numbers. On OS9800 switches, power supply slot numbers

are designated PS-1 through PS-4 from top to bottom. On OS9700 switches, power supply slot numbers

are designated PS-1 through PS-3 from top to bottom. On OS9600 switches, power supply slot numbers

are designated PS-1 and PS-2 from top to bottom.

OmniSwitch 9700

OmniSwitch 9800

NI NICMM PWR

1 2 3 4

9 10 11 12

A B

5 6 7 8

13 14 15 16

CMM

AB

NI NI

1234

PS1

PS2

PS3

PS4

5678

PWR

PS-1

PS1

PS2

PS3

PS-2

1

2

10

9

11

4

3

A

B

12

OS9800 (18-Slot Chassis)

5 6

7 8

13 141516

PS-1

PS-2

PS-3

PS-4

1

OmniSwitch 9600

1

NI

2

CMM

3

NI

4

4