a

A

EDITION

=

=

==

EE:

PATENTED:

D367.528;

951,428.

2045812;

patents

UNITED

D371.144D371,194:

GERMANY:

2045814;

issued

and

STATES:

D.PB.

No.

2,045813;

pending.

U.

Patent

4,534,756;

CANADA:

EP

Patented/Brevete

P3482620.3;

JAPAN:

REA

S.

AND

P377821

1,743/42.

FOREIGN

5,096,385;

4,898,576,

1,219,497:1,279800:

1.8-08;

M9501997.9;

SWITZERLANO:

PATENTS

5,534,691;

5,542,826;

78.377:

M9,501,997.0;

78,376

M9501995.2;

+EP

0,121,931;

ISSUED

5,537,853;

5,563,347;

and

78,378.

FRANCE:

and

0,328,163;

M9501996.0.

0,328,162;

AND

PENDING.

5,568,912;

Brevet

GREAT

0,248,632;

5,575,632;

5,601,420;

No.

0,121,931; 0,431,310; 0,248,632;

BRITAIN:

122,210;

122,21

Patent

No.

land

5,603,613;

EP

0,121,931;

122,212.

5,609,576;

Other

D367,527;

951,426;

951,427

0,431,310;

US.

and

and

0,248,63;

foreign

This

document

possession

product

specific

This

Technical

does

described.

written

information,

Systems,

142466

ii

MAC“

10221

Signature

contains

not

proprietary

convey

Reproduction,

authorization

Service

please

Manual

call

Technical

Wateridge

Copyright © 1997

Edition™

Technical

any

rights

disclosure,

of

ALARIS

is

subject

Support

Circle,

ALARIS

Service

Manual

information

to

reproduce

Medical

to

change

at

(800)

San

Diego,

Medical

Systems,

of

ALARIS

its

or

use

other

Systems

without

854-77

CA

92121-1579,

Inc.

Medical

contents,

than

is

or

for

strictly

notification.

28

ext.

6003,

Attention:

All

Rights

Reserved.

Systems,

to

manufacture

the

intended

and

forbidden.

For

current

or

write

Technical

¡ts

receipt

or

sell

purpose

technical

ALARIS

Support.

Printed

in

or

any

without

Medical

the

U.S.A.

MEDICAL

SYSTEMS

Phone

Numbers

for

Reference

USA

For

Only

CUSTOMER

placing

TECHNICAL

(800)

For

technical,

QUALITY

(800)

(800)

an

order

checking

(619)

482-4822

for

status

458-6003

OR

854-7128,

troubleshooting

maintenance

ASSURANCE

854-7128

SERVICE

parts,

accessories,

of

an

order.

SUPPORT

EXT.

and

information.

EXT.

7812

etc.,

6003

preventive

and

CANADA

CUSTOMER

For

Western

For

all

CUSTOMER

For

Eastern

For

product

Only

complaints.

.

(800)513-2254

Canada

of

Canada

(800)

to

268-4457

Canada

place

to

SERVICE

to

place

SERVICE

place

orders.

complaints.

orders.

IVAC®

Signature

Edition™

Technical

Service

Manual

iti

WARRANTY

ALARIS

warrants

A.

B.

If

communicate

determine

repair

requiring

purchaser.

risk.

In

consequential

Systems

shall

warranty

loss

Systems

Medical

that:

Each

new

material

and

Directions

purchaser.

The

battery

under

by

any

no

normal

ALARIS

Medical

product

the

or

replacement

service

Loss

event

shall

product.

not

apply

shall

or

damage

product

IVAC®

For

and

requires

directly

appropriate

damages

to

not

arising

Systems,

Inc.,

Signature

workmanship

Use,

from

the

each

new

use

and

service

Systems

service

with

ALARIS

repair

will

be

should

or

ALARIS

This

any

which

be

returned

damage

in

Medical

in

connection

warranty

subsequent owner

apply

to,

and

in

connection

has

been:

(hereinafter

Edition™

under

date

accessory

Pump,

normal

of

delivery

are

for a period

to

the

original

during

the

applicable

Medical

facility.

carried

return

Systems

Except

out

at

promptly,

shipment

be

with

shall

apply

or

ALARIS

Medical

with

the

referred

to as

excluding

use

and

by

ALARIS

free

from

of

ninety

purchaser.

warranty

Systems

ALARIS

liable

the

solely

holder

headquarters

as

provided

Medical

properly

to

the

for

purchase

to

the

of

Systems

purchase

“ALARIS

the

battery,

service,

for

Medical

defects

(90)

in

days

period,

otherwise

Systems's

packaged

repair

any

facility shall

incidental,

or

use

original

the

product.

shall

not

or

use

Medical

is

free

the

period

Systems

material

from

and

the

the

(San

Diego,

in

this

expense.

and

postage

be

indirect

of

any

ALARIS

purchaser.

Furthermore,

be

responsible

of

any

ALARIS

Systems”)

from

defects

stated

to

the

original

in

workmanship

date

of

delivery

purchaser

CA)

warranty,

The

at

should

to

product

prepaid

purchaser's

or

Medical

This

warranty

this

for,

any

Medical

in

the

by

(a)

repaired

representative;

(b)

altered

by

in

products

(c)

subjected

lot

number

(d)

improperly

written

This

warranty

obligations

give

or

assume

use

of

ALARIS

EXPRESS

OR

See

packing

instructions

or

grant,

on

behalf

ALARIS

MEDICAL

OF

FITNESS

inserts

anyone

any

stability

to

misuse

altered,

way

other

so

or

reliability;

or

effaced

maintained

furnished

is

in

lieu

of

all

liabilities

directly

Medical

OR

of

or

indirectly,

of

ALARIS

Systems

SYSTEMS,

IMPLIED,

FOR A PARTICULAR

for

international

than

an

as

to

affect,

negligence

or

removed;

or

used

in

by

ALARIS

other

warranties,

ALARIS

Medical

the

Medical

Systems

products.

INC.,

INCLUDING

warranty,

authorized

in

ALARIS

or

accident,

ALARIS

Medical

or

any

manner

Medical

express

Systems,

authority

to

any

other

DISCLAIMS

ANY

WARRANTY

PURPOSE

if

applicable.

Medical

Systems

or

which

other

has

than

Systems.

or

implied,

and

ALARIS

any

representative

liability

ALL

OR

APPLICATION.

Systems

judgment,

had

the

in

accordance

and

of

Medical

in

connection

OTHER

OF

Systems

or

WARRANTIES,

MERCHANTABILITY

service

the

product

with

all

other

does

other

person

with

serial

the

not

to

the

sale

or

or

№

IVAC®

Signature

Edition™

Technical

Service

Manual

ALARIS

MEDICAL

SYSTEMS

List

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

of

Tables

1-1

1-2

1-3

1-4

2-1

2-2

2-3

3-1

4-1

4-2

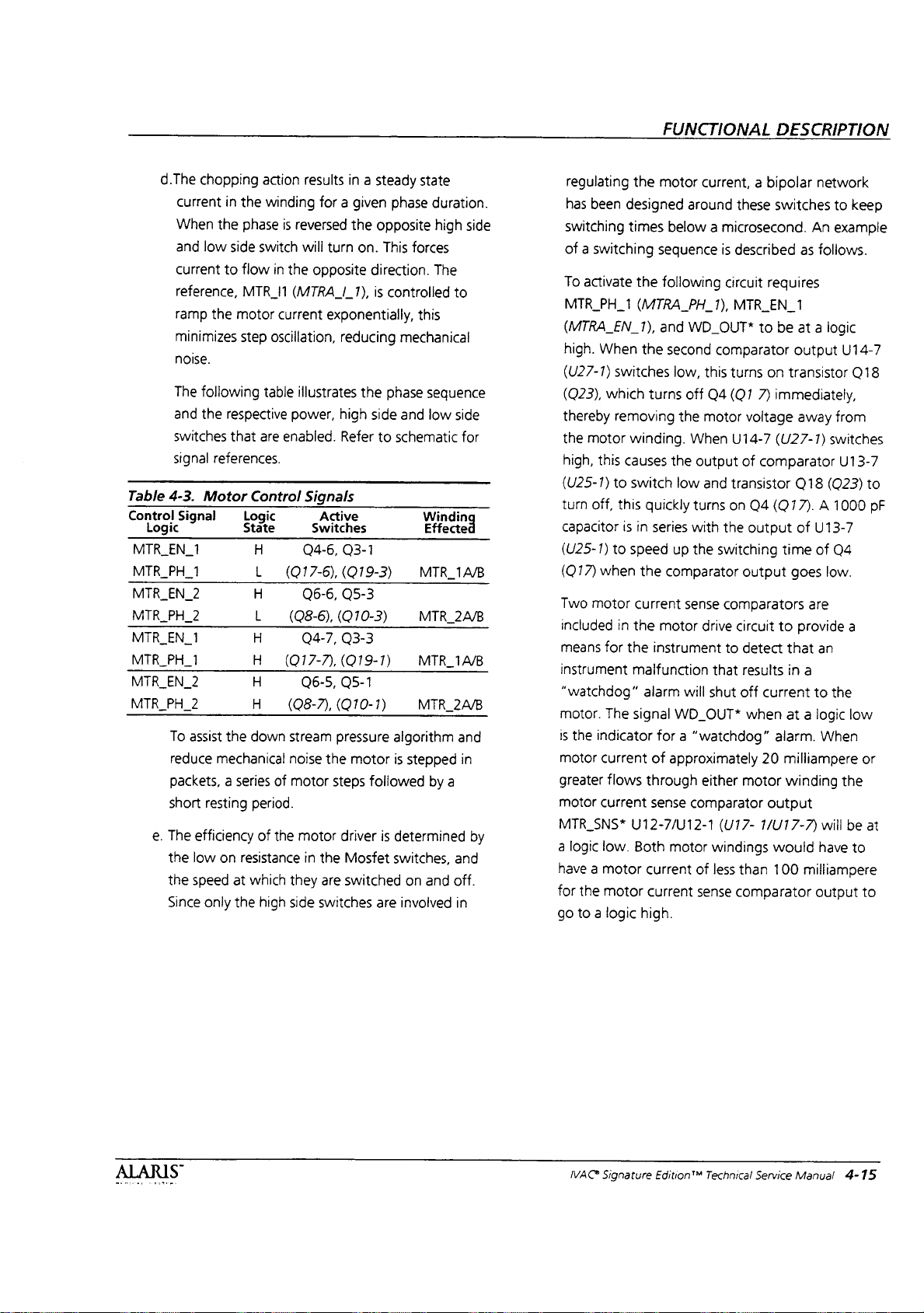

4-3

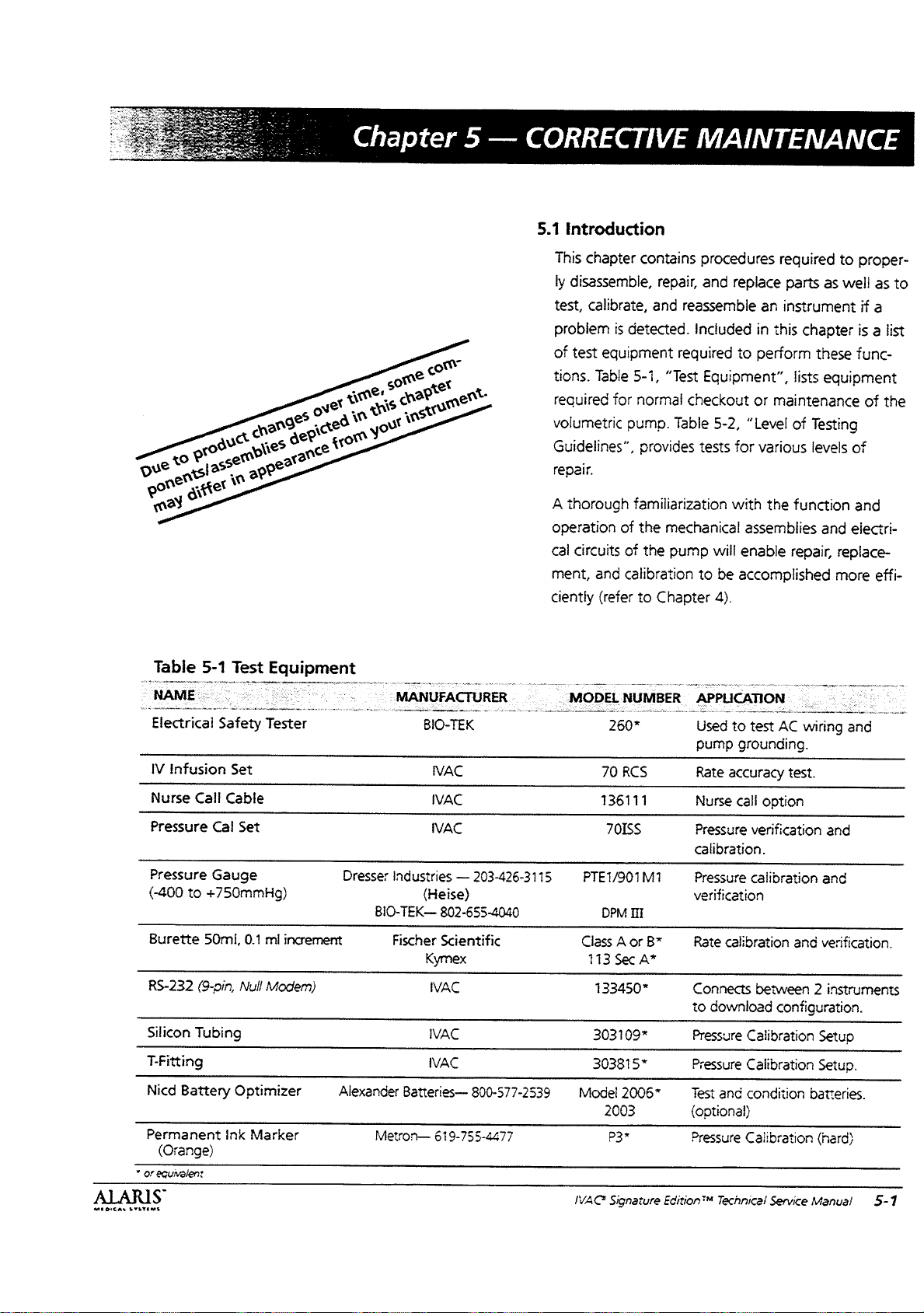

5-1

5-2

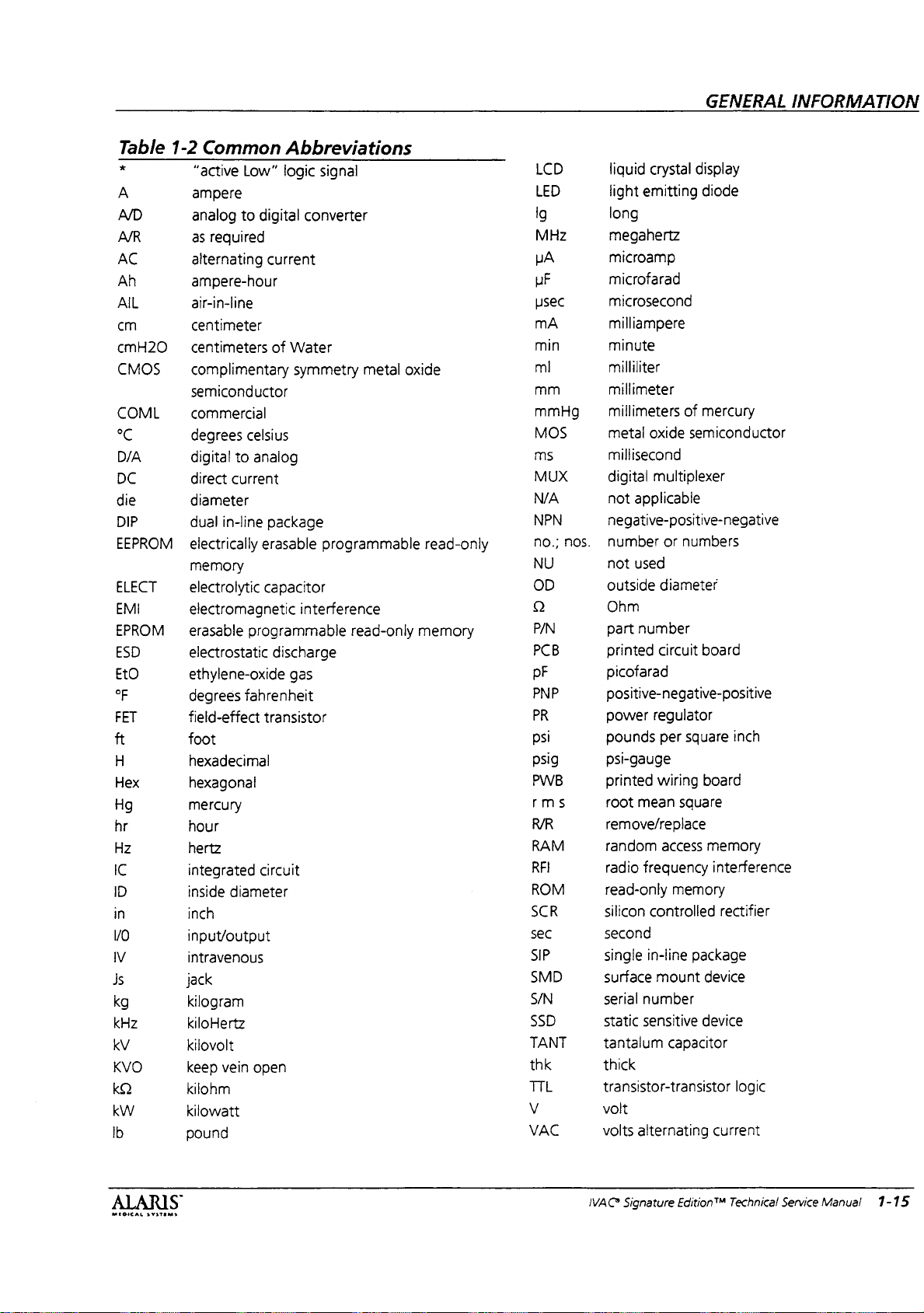

BatteyTripPoints

Common

Abbreviations

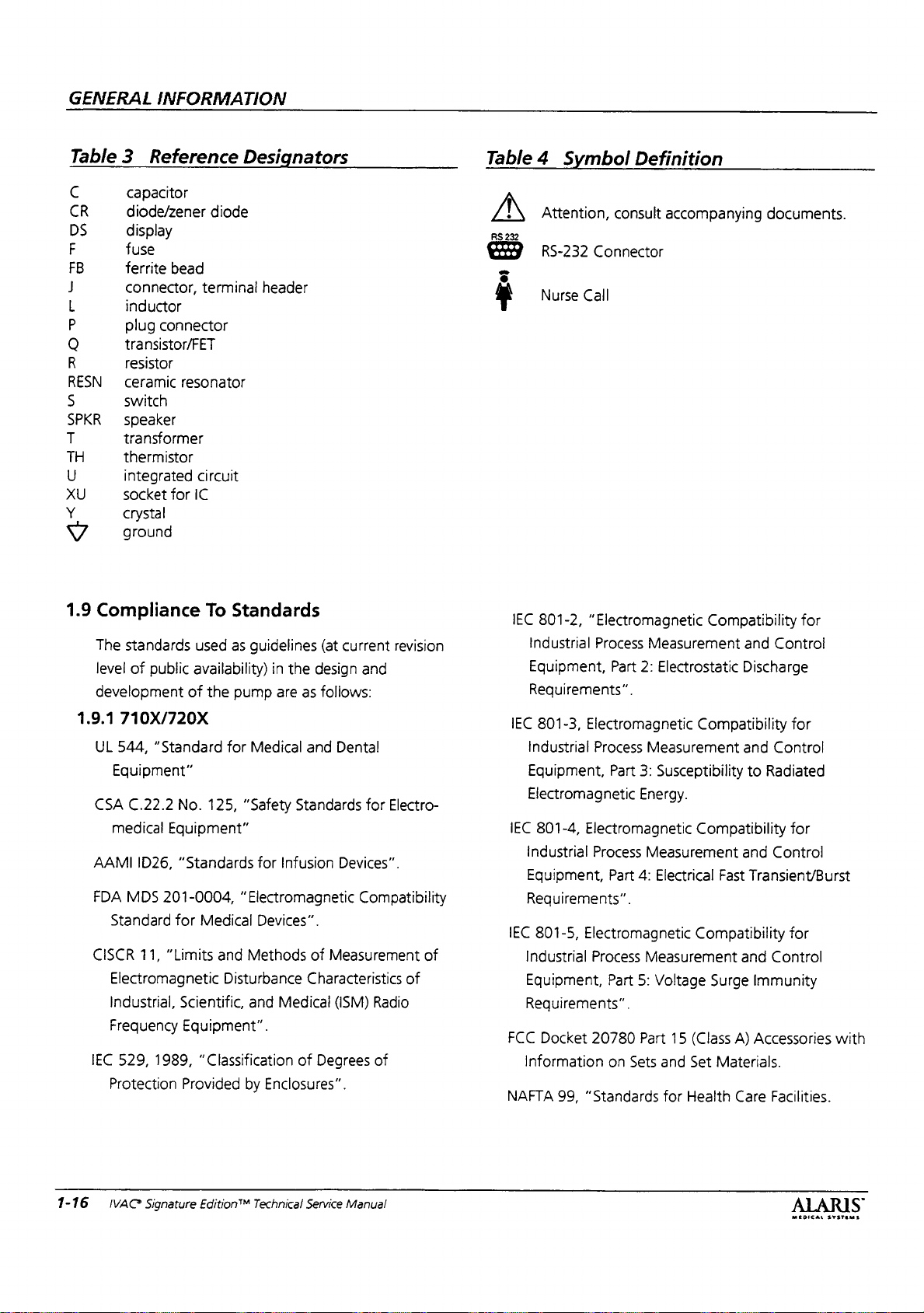

ReferenceDesignatol5

Symbol

Definition

Configuration

Druglist............................

Record

of

Configured

............................................

eman

.......................................................

Options

and

Defaults

........................

eme

Instruments

SN

Definition

Battery

Motor

Test

Level

of

Terms

Trip

Points

Control

Equipment

of

Testing

eee

Signals

............

ини

Guidelines

eee

000000000

eee

iii

00000

nene

лилии

KRKA

KRKA

ии

TABLE

E

PARA

mmm

лилии

ana

iii

ema

AE

PRA

PALA

Annan

OF

CONTENTS

mame

ama

anana

erreurs

eren

Ake

Pan

ent

n

ria

шине

té

1-6

1-15

1-16

1-16

2-2

2-7

2-17

3-7

4-3

4-8

4-15

5-1

5-25

Table

6-1

Table

6-2 Error

Table

6-3

Technical

Messages

Battery

Manager

Troubleshooting

Error

Codes

Guide

ae R KKK

nan

Ann

nh K AKA

iria

KE

KA

лишили

RA

AA

AA

PAA R AKA

eee

RA

AKA R LESS

ana

nooo

линии:

nat

anne

6-2

6-4

6-8

MEDICAL

SVITEMS

S

IVAC®

Signature

Edition"

Technical

Service

Manual

Xi

NOTE:

7200G

enable/disable

nore:

The

are

software

The

7101/7201

changes

and

from

7100F/7200F

only — added

real

time

software

Keypad

uses

event

clock.

symbols

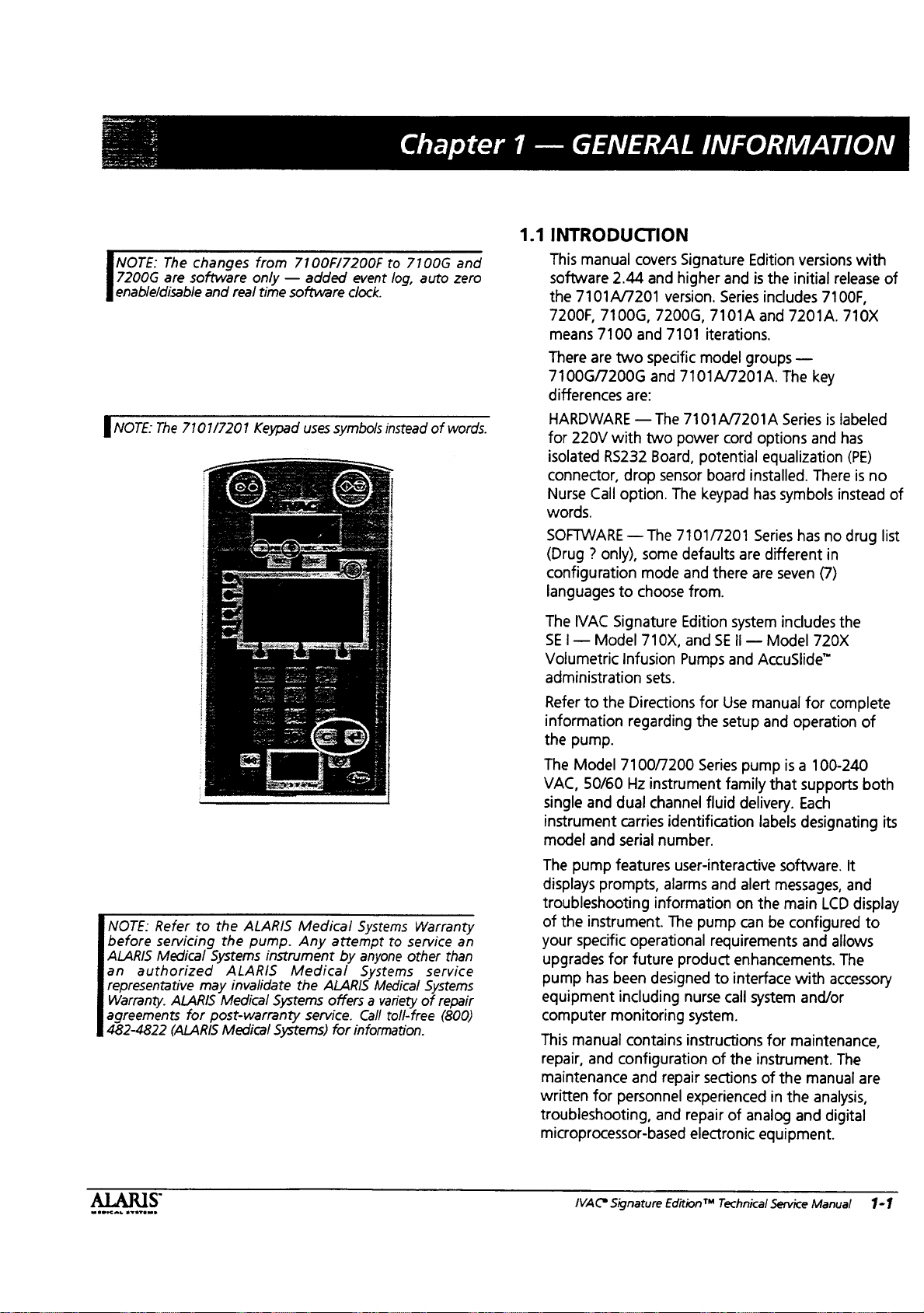

Chapter 1 —

to

7100G

log,

instead

auto

of

and

zero

words.

GENERAL

1.1

INTRODUCTION

This

manual

software

the

7101A/7201

7200F,

means

There

7100G/7200G

differences

E

7100

are

DO

covers

2.44

7100G,

two

are:

Signature

and

higher

version.

7200G,

and

7101

specific

and

7101A/7201A.

1

wo

power

INFORMATION

Edition

and

Series

7101A

iterations.

model

groups

cord

versions

is

the

initial

includes

and

7201A.

—

The

estica

release

7100F,

key

ana

710X

beled

with

of

NOTE:

before

ALARIS

an

representative

Warranty.

agreements

482-4822

Refer

servicing

Medical

authorized

ALARIS

for

(ALARIS

to

the

ALARIS

the

pump.

Systems

may

post-warranty

instrument

ALARIS

invalidate

Medical

Medical

Medical

Any

Medical

the

Systems

Systems)

ALARIS

offers a variety

service.

Systems

attempt

by

for

to

anyone

Systems

Medical

Call

toll-free

information.

Warranty

service

other

than

service

Systems

of

repair

(800)

an

isolated

connector,

Nurse

words.

SOFTWARE — The

(Drug ? only),

configuration

languages

The

SE | —

Volumetric

administration

Refer

information

the

The

VAC,

single

instrument

model

The

displays

troubleshooting

of

your

upgrades

pump

equipment

computer

This

repair,

maintenance

written

troubleshooting,

microprocessor-based

RS232

Call

IVAC

Signature

Model

to

the

pump.

Model

50/60

and

and

pump

prompts,

the

instrument.

specific

for

has

been

. .

monitoring

manual

and

for

Board,

drop

sensor

option.

to

The

7101/7201

some

defaults

mode

and

choose

from.

Edition

710X,

and

Infusion

Directions

regarding

7100/7200

Hz

dual

carries

serial

features

operational

future

including

contains

configuration

and

personnel

Pumps

sets.

instrument

channel

identification

number.

user-interactive

alarms

information

The

product

designed

,

nurse

system.

instructions

repair

experienced

and

repair

electronic

potential

board

keypad

there

equalization

installed.

has

Series

are

different

are

system

SE

li — Model

and

AccuSlide™

for

Use

manual

the

setup

and

Series

pump

family

that

fluid

delivery.

labels

and

alert

on

the

pump

can

be

requirements

enhancements.

to

interface

call

system

for

of

the

instrument.

sections

of

in

of

analog

equipment.

(PE)

There

symbols

seven

includes

has

instead

no

drug

in

(7)

the

720X

for

complete

operation

is a 100-240

supports

Each

designating

software.

messages,

main

configured

with

and/or

maintenance,

the

the

and

it

and

LCD

and

allows

The

accessory

The

manual

analysis,

digital

is

no

of

list

of

both

its

display

to

are

MEDICAL

AYATA

IVAC®

Signature

Edition®M

Technical

Service

Manual

1-1

GENERAL

INFORMATION

Specifications.

RATE

VOLUME

TO

VOLUME

BE

INFUSED

INFUSED

SYSTEM

DIMENSIONS:

RANGE:

RANGE:

RANGE:

KVO

RANGE:

ACCURACY

ALARMS:

0.1

to

0.1

to

0.1

to

0.1

to

0.0

to

0.1

to

+

5%*

*

Air

In

*

Battery

»

Channel

e

Computer

*

Flow

Width

Height

Depth)

Weight

Power

“without

999.9

ml/hr

in

0.1

270.0

ml/hr

in

0.1

9999.9

999.9

9999.9

20.0

ml

ml

ml

ml/hr

in

in

0.1

in

in

0.1

0.1

0.1

Line

Depleted

Malfunction + Key

Link

Failure + Latch

Sensor

Unplugged ο No

Cord

pole

clampwithout

ml/hr

ml/hr

mi

increments

ml

increments

ml

increments

ml/nr

e

Hold

e

Instrument

7100/7101

7.6

8.6

5.0

6.6

10ft/3

power

increments

increments

(primary)

(secondary)

increments

Time

Exceeded

Malfunction e Occlusion

Stuck

Open

Upstream

in/19.3

in/21.8

in/12.7

lbs./2.9

Flow

ст

cm

cm

kg

m

cord

(primary)

(secondary)

e

Occlusion

e

Primary

e

Set

Detected + Set

7200/7201

10.5

8.6

5.0

8.4 lbs/3.7

10ft/3

[el

Flow

Up

Time

Out

in/26.7

in/21.8

in/12.7

m

Downstream

Upstream

Detected

During

Exceeded

cm

cm

cm

kg

Secondary

ADMINISTRATION

POWER

MODE

GROUND

MAXIMUM

MAXIMUM

TIME

MAXIMUM

OCCLUSION

ENVIRONMENTAL

*

Testing

performed

IEC

1-2

601-2-24

IVAC

using

Signature

REQUIREMENTS:

OF

OPERATION

CURRENT

BOLUS

VOLUME

TO

ALARM

INFUSION

ALARM

CRITICAL

CONDITIONS:

per

proposed

IVAC

IV

sets.

Edition™

CASE:

SETS:

LEAKAGE:

BATTERY:

(ml)

(ml)

PRESSURE

PRESSURE

VOLUME:

standard

Technical

impact

Use

models

100-240V

Internal

resistant

only

IVAC

are

Power

defined

~,

Continuous

Risk

Current

Ground

Patient

(enclosure)

leakage

Rechargeable

Hydride,

pump

operating

12V,

will

on

operate

With a fully

will

be

retained

modes

Trending

At

At

16

12

Maximum

999.9

1.0

ml/hr:

1.0

mi/hr:

psi*

psi

+4psi,

ml/hr.

retain

information

incremental

Temperature

Relative

Atmospheric

Service

Humidity:

Manual

plastic

72

series

administration

on a separate

50/60

Hz,

0.6A

Source.

(normal/singie

leakage

current:

nickel

1.8AHr

less

cadmium.

(minimum)

for 4 hours

both

channels

charged,

special

not

new

for

at

least 6 months.

program

is

retained

0.5

ml:*

60

min*.;

adjustable*

battery

volume

Range:

Pressure:

sets.

card

included

-,

72VA

max — 3-wire

fauit

condition)

current:

than

Use

less

10/50

only

than

yA

IVAC

batteries.With a new,

nominal

at

100

simultaneously.

at

25°C,

volatile

Interrupted

settings

up

to

for 6 hours.

At

25

ml/hr: 0.5

At

25

ml/hr: 2 mint.

in

case

of

single

Operating

10°C

to

40°C

(50°F

to

104°F)

15

to

90%

Non-condensing

631

to

1031

mbar

All

disposable

with

this

Directions

grounded

100/500

(normal/single

Nickel

LA

Cadmium

fully

ml/hr

for a two

memory

secondary

six

hours.

Additionally,

mi*

point

failure

Storage/Transport

-40°C

(-40°F

Non-condensing

631

IV

set

and

IV

set

for

Use.

system.

(normal/single

fault)

or

charged

channel

Class 1 with

Nickel

battery,

instrument

fault)

Metal

configuration

or

advanced

Resistance

will

not

exceed

to

60°C

to

140°F)

5

to

95%

to

1031

mbar

accessory

the

information

operating

1.0

ml

©

ALARIS

MEDICAL

SYSTEMS

1.2

Expanded

Pump

Specifications

GENERAL

INFORMATION

Administration

When

used

gravity

Air-in-Line

Altitude:

Battery:

infusion:

Accuracy:

Case:

Fluid

Ingress

Rating:

Set:

for

Use

only

IVAC

Max.

Gravity

>4200

Operating

500

Recharge

+50%,

impact

Drip

ml/hr

Configured

50uL

100uL

200uL

500LL

Altitude:

charge/discharge

time

-0%

resistant

proof

iPX1

72

Series

Flow

Rate:

with

16

Threshold

-500

while

battery

plastic,

administration

gauge

catheter x 2.25”

Air

Volume

ft.(-150M)

cycles,

minimum

instrument

gauge

accuracy

flame

retardant

sets.

Detections

15uL - 85uL

35uL - 140uL

100uL - 235uL

275uL - 565uL

to

7,500

under

is

running,

is

Teflon

Range

ft.

(2285M)

nominal

4

hours

charging

to

95%

conditions

capacity

Ground

Parts

Programmable

Current

per

ml:

Features:

(Configuration)

These

features

by

qualified

Configuration

disconnected

and/or

can

service

from

battery

be

is

not

power.

Leakage:

customized

personnel.

lost

when

AC

power

(7100/7200)

Tested

equipment.

1150

steps

Air-in-line

Air-in-line

Audio:

<100

to

UL

Standard

to

deliver 1 ml

alarm

reset

feature:

Hi/Med/Lo

Communications:

Computer

Configuration

Display

Dose

Drug?

Drug

Dynamic

control:

language:

Rate

Calculation:

Access:

Specific

Access:

Monitoring™

Name: 4 bit

On/Off

pAmps.120Vrms

544

and

CSA

(Rate

threshold:

levels

Baud

Control,

50,

100,

On/Off

accessible

Rate,

Parity

Monitor,

alpha-numeric

Choice

of

two

On/Off

Short/Extended/Off

cal

or

C22.2

#191)

200,

or

Off

code

seven

(7100X/7200X

No.125

500

pi

for

medical

only)

and

dental

ALARIS

MEDICAL

SYSTEMS

IVAC*

Signature

Editiont“

Technical

Service

Manual

1-3

GENERAL

INFORMATION

Rate

Accuracy:

Mode:

Alert:

Hi

Resistance/Resistance/Pressure

On/Off

Restarts: 0 (Off),

Resistance

Resistance

Instrument

KVO

Loading

Panel

Preventive

Preventive

Maximum

Multi-Dose

Multi-Dose

Multi-Step

Transition

VTBI:

+5%

Display:

Trend

ID: 9 digits

rate:

0.1 - 20.0

Dose:

lock:

On/Off

maintenance

maintenance

rate:

Alert:

Mode:

Mode:

tone:

ON/OFF

typical

at

On/Off

0.1-

On/Off

(7101/7201

30”

1-9

On/Off

Graph:

mlfhr

interval

reminder:

999.9

On/Off

On/Off

On/Off

delivery

On/Off

ml/nr

or

flow

container

1-52

On/Off

sensor

Only

weeks

modification)

head

height

ΚΕΙ:

Temperature:

Volume

Warnings:

to Be

Infused

Range:

Tolerate > 10

Operating

0.1

0.1

0.1 to

0.1

to

0.1

to

0.1

to

e

Battery

e

Checking

e

Computer

e

Dose

e

Load

to

9999.9

to

999.9

999.9

9999.9

999.9

999.9

Complete

Dose

above

Low

V/m

30°C,

ml

in

ml

in

ml

in

0.1

ml

in

mi

per

m!

per

Line

Control

Complete

across

frequency

for

0.1

mi

0.1

ml

increments

ml

increments

0.1

ml

step

in

dose

in

Released

range

extended

increments

periods,

(secondary)

(loading

increments

0.1

ml

increments

0.1

mi

increments

e

e

e

e

will

(primary)

dose)

(dose

rate)

(multi-step)

(multi-dose)

Multi-Step

Resistance

Secondary

VTBI=

0

reduce

Complete

battery

Alert

Complete

life.

1-4

IVAC®

Signature

Edition®*

Technical

Service

Manual

ALARIS

MEDICAL

SYSTEMS

1.3

Battery

This

battery

on

how

the

the

the

detailed

The

Battery

processing

3.06)

performs

e

Controls

e

Provides a battery

e

Monitors

e

Controls

function)

e

Drives

ο

Includes a relative-time

The

processor

processor

which

data

Management

section

battery,

instrument,

main

battery

Battery

using

contains

management

the

Battery

controls

processor.

functional

management

Manager

circuits.

is a custom

the

the

voltage

the

the

Lower

Manager

via a serial

issues

then

responds

this

general

system.

Manager

the

and

provides

Refer

descriptions.

IC

and

The

programmed

following

battery

charger

status

and

instrument

LCD

communicates

data

commands

with

channel.

System

information

Included

monitors

power

various

Battery

functions:

temperature

Display

on/off

support

to

Chapter 4 for

system

consists

sensors

Manager

microcontrolier

“battery

power

source

(See

clock

channel.

to

status

The

the

Battery

information

on

is

information

and

maintains

for

the

functions

more

of

and

IC

(Rev.

gauge”

of

battery

4

(on/off

Figure

1-1)

with

the

main

Manager

the

rest

of

for

the

signal

that

main

and

The

battery

pack

temperature

Manager

The

thermostat

pack

to

monitor

also

which

temperature

temperature

battery

The

constant

Manager

regulates

charger

The

battery

charge,

a.

Fast

battery

by

use

current

turns

average

on

top-up

Charge:

is

more

than

or

self

charge

and

charge

less

unplugged

Ampere-seconds

current

fast

the

of

battery

value,

refer

for

is a continuous 1 Ampere.

charge

battery

charge

and

voltage

or

total

to

Battery

further

GENERAL

(10

to

18V)

has a built-in

sensor

gets

returns

discharge.

details.

which

allows

the

the

temperature

includes a temperature

opens

the

circuit

too

hot

and

closes

to

normal.

circuit

charges

of 1 ampere

the

charger

charge

off

with

cycle

charge,

Fast

charge

than 36°C, and

200

Ampere-seconds

for a day

of

self

is

detected

rises

7°C

is

at

least

declines

charge

Charge

whenever

on.

current

the

appropriate

consists

float

charge,

is

initiated

Leaving

would

cause

discharge.

when

above

its

30°C,

by

192mV

time

exceeds

Regulator

The

by

of

has

the

the

temperature

or

INFORMATION

Battery

of

the

battery.

limiting

if

the

battery

again

when

the

battery

Battery

turning

four

and

whenever

been

through

instrument

about

The

The end

temperature

when

below

3.2

section

with

the

Battery

Manager

the

duty

ratio.

modes;

hot

fast

charge.

the

discharged

actual

200

charge

of

a

of

at

start

the

its

peak

hours.

Also

(4.5.3)

the

a

1.3.1

Fan

The

internal

prolong

fan.

The

fan

“Fast”

time

1.3.2

Battery

The

battery

nickel-cadmium

hours

cycles).

MEDICAL

SYSTEMS

fan

is

used

battery

is

or

battery

life.

always

on

“Top-up”

temperature

and

Charging

is a ten

type

(with a minimum

for

It

is a ball

when

charge.

is

ceil

(1.2V

rated

of

500

cooling,

battery

The

over

mainly

bearing,

is

charging

fan

will

brushless

22°C.

go

Process

per

cell),

high

at

12

volts

and

charge/discharge

to

help

DC

with

on

any

capacity

1.8

amp-

b.

Top-Up

at

the

adding

battery

phase

for

0.9

At

that

charge

the

battery

spent

to

to

the

cool

down

instrument

IVAC

Charge:

end

of

the

last

and

balances

charges

seconds

time,

the

mode.

temperature

cool

180

minutes

time

will

Signature

The

top-up

the

fast

charge

few

percent

individual

at

an

average

every 5 seconds)

instrument

The

charger

will

exceeds

down

to

below

top-up

charge

exceeds 5 1/2

go

into

float

Edition™

Technical

charge

phase

of

charge

cell

rate

of

for

will

go

suspend

37°C.

37°C

hours,

charge

Service

phase

and

finishes

to

the

charges.

180

mA

180

minutes.

into

float

top-up

The

is

in

addition

time.

If

top-up

the

mode.

Manual

begins

This

(1A

if

time

1-5

GENERAL

c.

d.

>36°C

charges

seconds

of

43°C,

temperature

down

time.

the

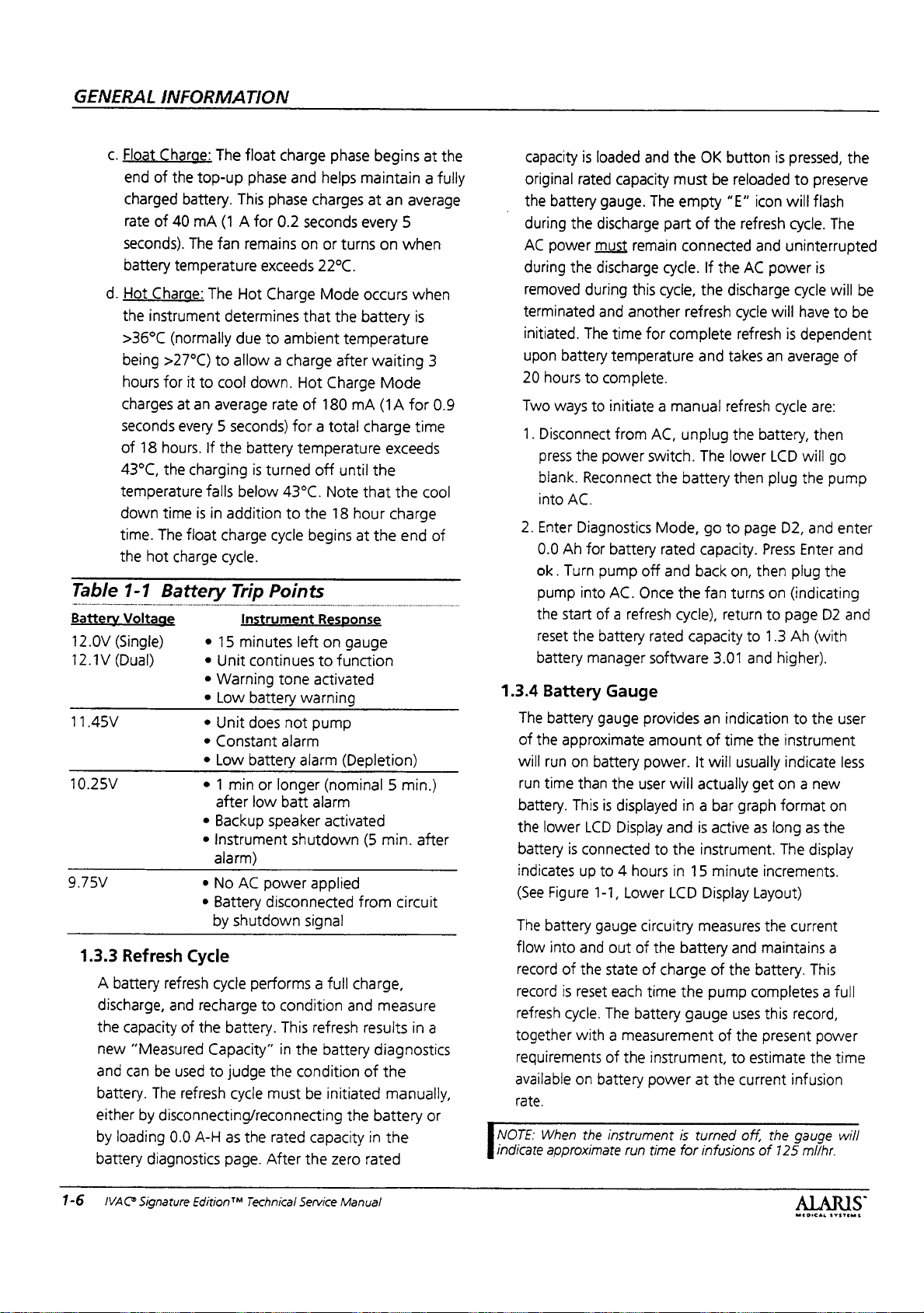

Table

Battery

12.0V

(Single)

12.1V

(Dual)

11.45V

10.25V

9.75V

1.3.3

A

battery

discharge,

the

new

and

battery.

either

by

loading

battery

INFORMATION

Float

Charge:

end

of

charged

rate

of

seconds).

battery

Hot

Charge:

the

instrument

being

>27°C)

hours

for

18

hours.

the

time

The

hot

1-1

Battery

Voltage

Refresh

refresh

capacity

“Measured

can

be

The

by

disconnecting/reconnecting

diagnostics

The

float

the

top-up

battery.

40

mA

The

temperature

This

(1 A for

fan

remains

The

Hot

phase

phase

exceeds

Charge

determines

(normally

it

at

due

to

allow a charge

to

cool

down.

an

average

to

every 5 seconds)

If

the

battery

charging

falls

is

float

charge

below

in

addition

charge

cycle.

is

turned

Trip

Instrument

e

15

minutes

e

Unit

continues

e

Warning

e

Low

battery

e

Unit

does

e

Constant

e

Low

battery

© 1 min

*

e

e

*

Cycle

and

recharge

of

the

used

refresh

0.0

A-H

Capacity”

to

or

after

low

Backup

speaker

Instrument

alarm)

No

AC

power

Battery

by

cycle

disconnected

shutdown

performs a full

to

battery.

judge

cycle

must

as

the

page.

After

charge

0.2

ambient

rate

43°C.

cycle

Points

tone

alarm

longer

batt

condition

This

in

the

rated

phase

and

helps

charges

seconds

on

or

turns

22°C.

Mode

that

the

temperature

after

Hot

Charge

of

180

mA

for a total

temperature

off

until

Note

to

the

18

hour

begins

left

at

Response

on

gauge

to

function

activated

warning

not

pump

alarm

(Depletion)

(nominal 5 min.)

alarm

activated

shutdown

applied

signal

charge,

and

refresh

the

battery

condition

be

initiated

the

capacity

the

zero

begins

at

the

maintain a fully

at

an

average

every

5

on

when

occurs

battery

when

is

waiting

3

Mode

(1A

for

0.9

charge

time

exceeds

the

that

the

cool

charge

the

end

of

(5

min.

after

from

circuit

measure

results

in

a

diagnostics

of

the

manually,

battery

in

or

the

rated

capacity

original

the

during

AC

power

during

removed

terminated

initiated.

upon

20

hours

Two

1.

Disconnect

press

blank.

into

2.

Enter

0.0

ok.

pump

the

reset

battery

1.3.4

Battery

The

battery

of

the

will

run

run

time

battery.

the

lower

battery

indicates

(See

Figure

The

battery

flow

record

record

refresh

together

reguirements

available

rate.

OTE:

When

indicate

approximate

is

loaded

rated

capacity

battery

the

must

the

during

The

battery

to

ways

to

the

gauge.

discharge

remain

discharge

this

and

another

time

temperature

complete.

initiate a manual

from

power

Reconnect

AC.

Diagnostics

Ah

for

battery

Turn

pump

off

into

AC.

Once

start

of a refresh

the

battery

manager

Gauge

gauge

approximate

on

battery

than

the

user

This

is

displayed

LCD

Dispiay

is

connected

up

to 4 hours

1-1,

Lower

gauge

circuitry

into

and

out

of

of

the state

is

reset

cycle.

with a measurement

on

the

of

each

The

battery

of

the

battery

instrument

run

and

the

OK

must

The

empty

part

of

connected

cycle.

If

cycle,

the

refresh

for

complete

and

AC,

unplug

switch.

the

battery

Mode,

rated

and

the

The

go

capacity.

back

fan

cycle),

rated

capacity

software

provides

amount

power.

It

will

actually

an

of

in a bar

and

is

to

the

instrument.

in

15

LCD

Display

measures

the

battery

charge

time

the

gauge

instrument,

power

time

at

is

turned

for

infusions

button

be

reloaded

“E”

icon

the

refresh

and

the

AC

power

discharge

cycle

will

refresh

takes

an

refresh

the

battery,

lower

LCD

then

plug

to

page

Press

on,

then

turns

on

return

to

to

1.3

3.01

and

indication

time

the

will

usuaily

get

graph

active

as

long

minute

increments.

Layout)

the

and

maintains

of

the

battery.

pump

completes a full

uses

this

of

the

present

to

estimate

the

current

off,

the

of

is

pressed,

to

will

cycle.

the

preserve

flash

The

uninterrupted

is

cycle

will

be

have

to

be

is

dependent

average

cycle

D2,

plug

(indicating

page

Ah

are:

then

will

go

the

pump

and

Enter

the

D2

(with

of

enter

and

and

higher).

to

the

user

instrument

indicate

less

on a new

format

The

on

as

the

display

current

a

This

record,

power

the

time

infusion

gauge

125

will

mifhr.

1-6

IVAC

Signature

Edition™

Technical

Service

Manual

1.3.5

Power

The

Battery

power

When

interprets

and

informing

pressed.

power

which

the

power

Battery

instrument.

If

watchdog

switch

turned

Manager.

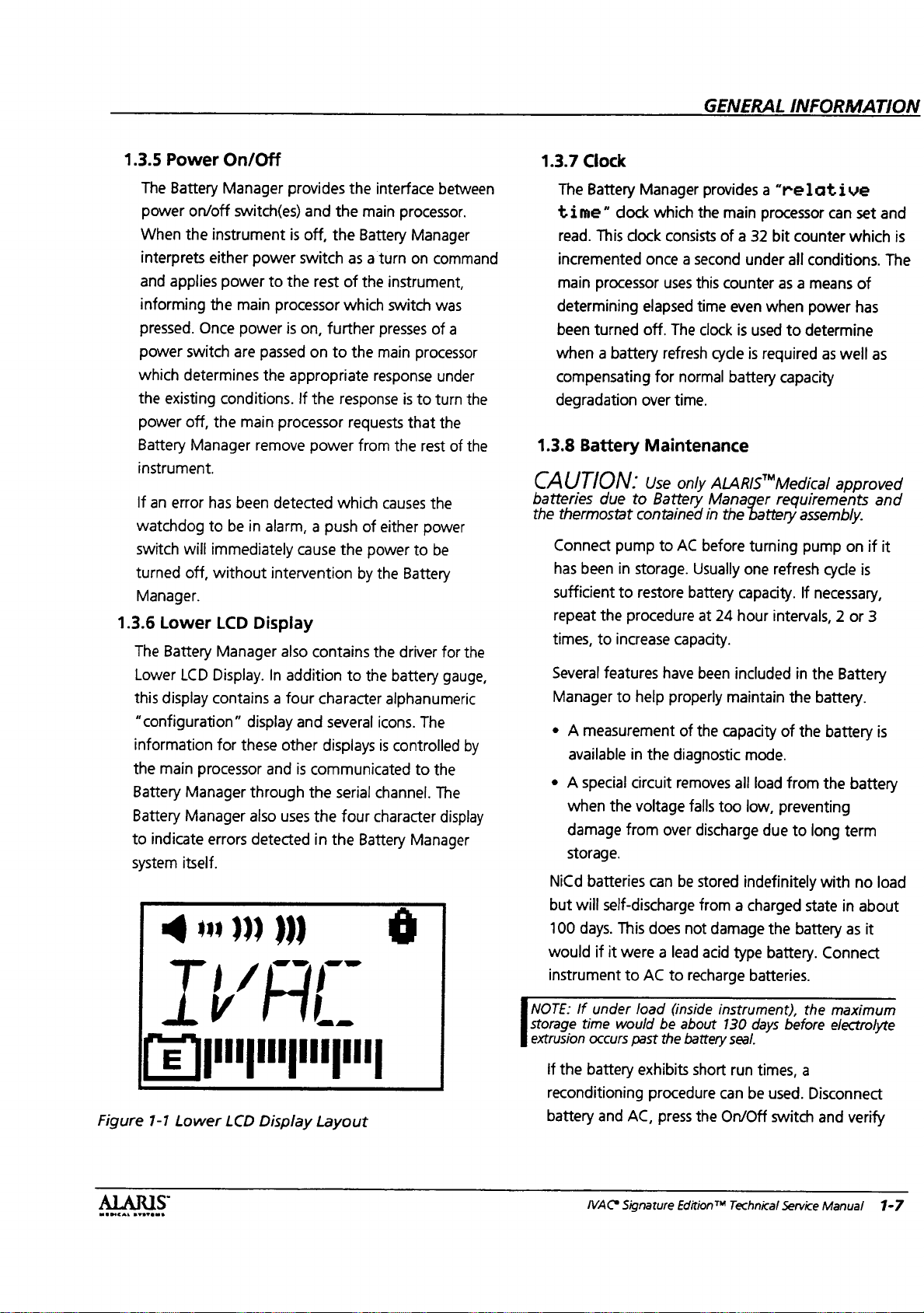

1.3.6

The

Lower

this

“configuration”

on/off

the

applies

switch

determines

existing

off,

Manager

an

error

will

off,

Lower

Battery

LCD

display

either

the

Once

has

to

information

the

main

processor

Battery

Battery

to

systern

Manager

Manager

indicate

errors

itself.

dm)

at

On/Off

Manager

switch(es)

instrument

power

main

power

are

conditions.

the

main

been

be

immediately

without

LCD

Manager

Display.

contains a four

for

these other

グイ

provides

and

is

off,

power

switch

to

the

processor

is

on,

passed

remove

in

on

the

appropriate

If

the

processor

power

detected

alarm, a push

cause

intervention

Display

also

In

addition

display

through

also

and

and

is

the

uses

detected

communicated

ガー

the

the

main

the

Battery

as a turn

rest

of

the

which

further

to

the

response

requests

from

which

of

the

power

by

contains

to

the

character

several

displays

serial

the

four

in

the

Battery

interface

between

processor.

Manager

on

command

instrument,

switch

was

presses

main

response

causes

either

the

the

icons.

is

channel.

character

of

a

processor

under

is

to

turn

that

the

the

rest

of

the

power

to

be

Battery

driver

for

battery

alphanumeric

gauge,

The

controlled

to

the

The

display

Manager

É

the

the

the

by

1.3.7

Clock

The

Battery

time”

read.

This

incremented

main

processor

determining

been

turned

when a battery

compensating

degradation

1.3.8

Battery

CAUTION:

batteries

the

times,

Several

Manager

e A measurement

e

NiCd

but

100

would

instrument

NOTE:

Storage

extrusion

due

thermostat

Connect

has

been

sufficient

repeat

the

to

features

available

A special

when

the

damage

storage.

batteries

will

self-discharge

days.

if

it

If

under

time

occurs

Manager

dock

which

clock

consists

once a second

uses

elapsed

off.

The

refresh

for

normal

over

time.

Maintenance

Use

only

to

Battery

contained

pump

to

AC

in

storage.

to

restore

procedure

increase

to

from

This

were a lead

to

would

capacity.

have

help

properly

in

the

diagnostic

circuit

removes

voltage

over

can

be

does

AC

to

load

(inside

be

past

the

of

not

about

battery

GENERAL

INFORMATION

provides a “relative

the

main

processor

of a 32

this

counter

time

clock

cycle

bit

under

even

when

is

used

is

required

battery

counter

all

conditions.

as a means

power

to

determine

capacity

ALARIS™Medical

Manager

in

the

before

Usually

battery

at

24

been

maintain

the

capacity

falls

too

discharge

stored

from a charged

damage

acid

recharge

instrument),

130

seal.

requirements

battery

assembly.

turning

one

capacity.

hour

included

pump

refresh

If

intervals, 2 or

in

the

of

the

mode.

all

load

from

low,

preventing

due

to

long

indefinitely

state

the

battery

type

battery.

batteries.

days

the

before

necessary,

the

battery.

can

set

which

of

has

as

well

as

approved

and

on

if

cycle

is

3

Battery

battery

the

with

Connect

is

battery

term

no

load

in

about

as

it

maximum

electrolyte

and

is

The

it

Figure

MEDICAL

1-1

Bvstenmi

S

Lower

LCD

Display

Layout

if

the

battery

reconditioning

battery

IVAC

and

AC,

Signature

exhibits

procedure

press

Edition™

short

can

the

On/Off

run

times,

be

used.

switch

Technical

Service

a

Disconnect

and

verify

Manual

1-7

GENERAL

lower

INFORMATION

LCD

instrument

Repeat

times

this

to

increase

conditioner.

CAUTION:

hospital

procedures,

battery

Corporation

1.4

there

protocol.

your

or

contact

(RBRC)

Nicd

Battery

All

batteries

they

are

guaranteed

specifications.

typically

result

Manufacturers

usually

specified

well

expressed

“ideal”

as

the

Manufacturer's

upcoming

November

An

ideal

battery

Ah)

year

1995).

charge

charged

constant

temperature.

charged

for

with a room

The

ideal

discharge

under a C/5

temperature

The

rated

capacity

discharge

discharged

0.9V

type

divided

at

for

at

least 5 hours.

has

different

instance, a battery

may

have

only

As

can

be

seen

are

many

battery

capacity.

goes

blank.

into

AC. A refresh

procedure

capacity

Dispose

of

Refer

to

state’s

EPA

Rechargeable

at

1-800-822-8837.

Capacity

have

specific

to

Deviations

in a reduction

of

nicd

in

Ah

charge

use

of a “new”

date

codes

(e.g.

date

cycle

starts

at

C/10

current

For

15

temperature

constant

discharging

360m-

for

instance, a 1.8Ah

hours

at

starts

current

is

then

by

5.

constant

capacities

rated

1.6Ah

at a 1600mA

from

the

conditions

The

following

Reconnect

at

24

or

or

recycle

your

the

cycle

will

hour

intervals, 2 or

use a battery

battery

institutions

guidelines

Battery

Information

conditions

meet

their

published

from

these

of

available

batteries

(Ampere-Hours),

and

(C

15

180mA

to a cell

Again, a 1.8Ah

Note

at

preceding

rate

capacities,

discharge

battery.

start

code

Battery

on

9/1 of

9611 = first

with a fully

is

the

rated

hours

while

battery

constant

of

23°C.

with a fully

load

charged

at

room

voltage

calculated

as

current

that a given

based

on

1.8Ah

at a 360mA

load.

ideal

which

can

affect

conditions

battery.

Plug

be

initiated.

following

operating

for

disposal

Recycling

under

which

conditions

capacity.

based

on

condition

the

week

discharged

capacity

at

the

ceil

and

the

conditions,

in

room

would

current

battery

of

0.9V.

time

to

would

not

reach

battery

load.

For

load

the

have

the

3

as

of

be

be

of

a

most

practical

this

instrument.

a.

TEMPERATURE

ambient

amount

of

decreased.

an

enclosed

about

90%

accept

the

at

instrument

temperatures

instrument

ways

the

the

battery

internal

battery

b.

CYCLE

and

fan)

temperature

LIFE

go

through

batteries

materials

The

way

the

assume

capacity

and

equivalent

cycles.

the

c.

PARTIAL

is

the

that a battery

at a rate

continually

These

runtime

DISCHARGE/RECHARGE - When a battery

partially

full

time,

capacities

different

then

times.

completed,

progressively

low

apparent

warning

that

The

require

The

reduce

history

and

the

mismatch

lowered

2-3

way

the

the

of

partial

impact

on

DURING

temperature

charge

At an

23°C.

itself

instrument

sees

that

ambient

battery

of

the

Since

case,

above

generates

include

and

turning

will

charge

they

room

limits

gets

AND

AGING - As

many

“wear

out”

in

used

to

construct

instrument

equivalent

reduce

to

30%

per

calculated

displayed

on

discharged,

differences

result

in

cells

If

the

full

the

cell

greater.

This

runtimes

alarms.

The

increases

capacity

full

is

discharge/charge

instrument

runtime

displayed

cycles.

battery

of

the

capacity

CHARGE - As

the

battery

battery

increases,

will

the

temperature

temporarily

it

would

the

batteries

will

be

exposed

accept

otherwise

are

temperature

heat.

Some

the

temperatures

forcing

off

the

too

high.

batteries

air

across

charger

get

charge/discharge

that

the

chemicals

the

cell

break

deals

with

this

will

continually

to

capacity

200

full

values

are

the

battery

then

charged

between

completing

charge

“mismatch”

is

viewed

and

premature

problem

for

not

permanent,

deals

with

based

reduce

30%

over 4 years

at a rate

discharge/charge

used

gauge.

for

individual

charge

sequence

becomes

by

the

low

is

cumulative

every

partial

cycles

to

this

is

on a limited

delivered

effective

the

accept

of

is

35°C,

only

internal

to

to

since

the

of

the

that

it

(an

when

the

older

cycles,

and

down.

is

to

to

reduce

less

than

cell

at

is

not

user

as

battery

in

cycle.

but

may

recover.

to

in

1-8

IVAC®

Signature

Edition"

Technical

Service

Manual

MEDICAL

SYSTEMS

GENERAL

INFORMATION

d.

CHARGE

hours

from

RATE - The

to

get

the

user's

to

provides a multiphase

in

about

80%

capacity

Fast

charge.

designed

individual

essentially

1.3.2

information.

completed,

and

the

Top-up

complete

turned

that

time.

e.

BATTERY

voltage

stops

operating

user

to

discharge

determined

a

battery

reach

the

are

not

before

series

with

actually

permanently

other

hand,

compensate

in

reduced

user

sees

and

alarms.

this

is

to

the

battery

assumed

battery.

the

minimum

all

these

The

to

finish

cells

rematching

for

Fast

Charge

If

then

cumulative

is a 3

hour

it

may

on

and

ALARM

is

the

voltage

plug

it

condition,

by

of

10

end

of

perfectly

others.

The

other

can

go

damages

increasing

for

runtimes

this

as

The

increase

is

not

capacity

The

battery

run

factors

to

the

off

into

0.9V/cell.

cells

into

imperfectiy

premature

way

into

ideal

charge

full

charge,

perspective.

which

The

charge

in

the

next

charge

the

charge

the

fully

charged

them.

and

Top-up

Top-up

the

capacity

charge,

be

over 5 hours

to

cell

mismatch

keep

charge

reduction

but

the

VOLTAGE - The

at

which

and

generates

AC

line.

As

the

end

of

Under

connected

discharge

matched

problem

cells

cell

with

at

so

some

occurs

can

go

below

reversa!,

the

particular

the

alarm

matched

available

low

the

instrument

the

alarm

voltage

damaged

to

gauge

time

below

left

and

that

is

intended

on

account.

rate

requires

is

undesirable

instrument

cycle

which

first 2 hours

phase,

Top-up,

and

to

bring

state,

Refer

to

Section

Charge

is

not

is

not

occurs.

the

elapsed

as

the

charger

battery

cool

battery

the

instrument

an

alarm

to

noted

in

the

discharge

perfect

in

9.0V.

conditions,

series

would

However,

will

reach

when a cell

0.9V

which

cell.

voltage

to

cells

capacity.

battery

warnings

deals

to

guarantee

reduce

printed

the

on

to

the

battery

results

after

is

all

reduced

time

during

alarm

tell

the

ideal

is

cells

0.9V

in

and

On

the

results

The

with

the

show

taking

15

to

is

NOTE:

In

different

different

the

added

5.3

Capacity

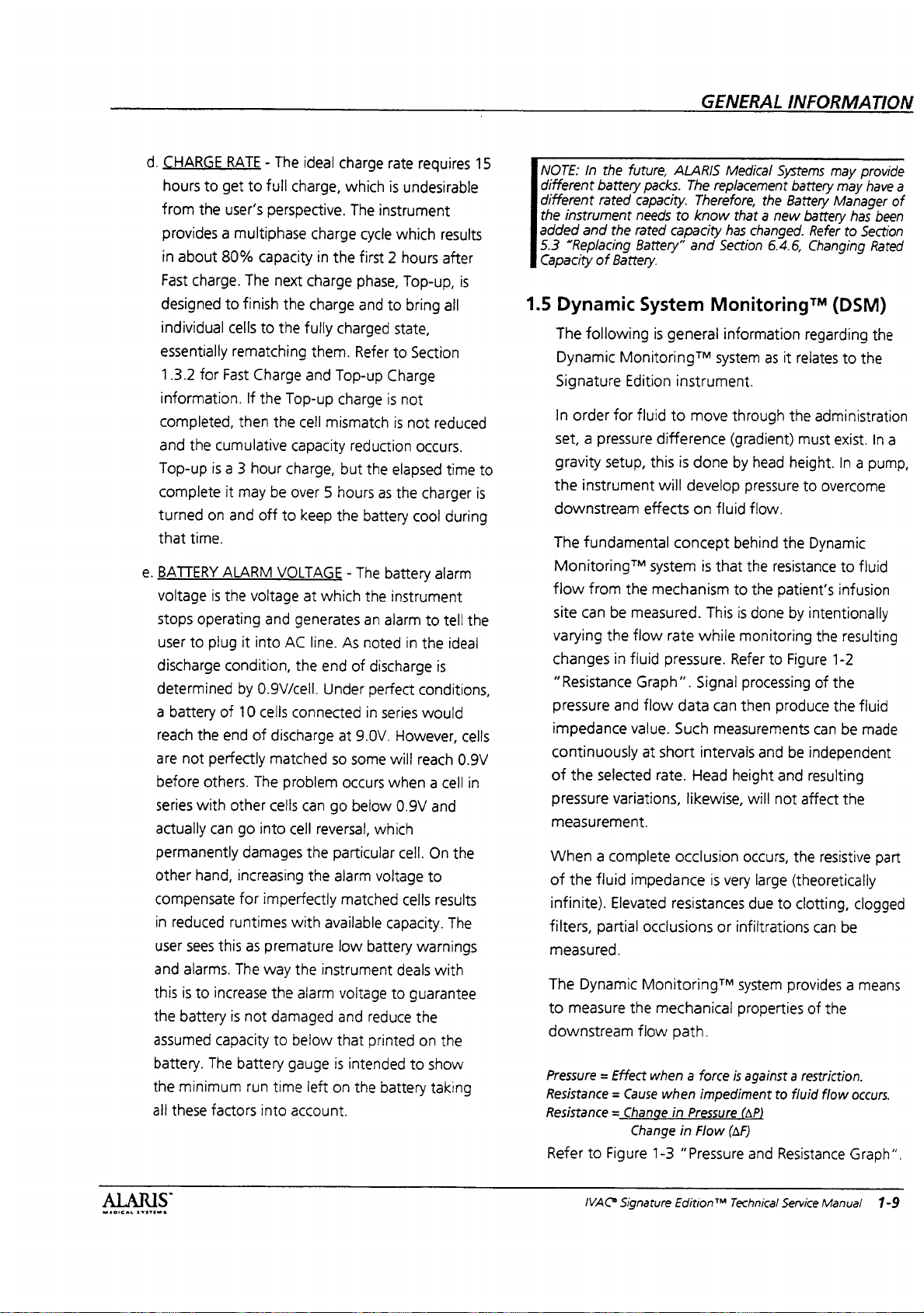

1.5

The

the

battery

rated

instrument

and

the

“Replacing

of

Battery.

Dynamic

following

Dynamic

Signature

In

order

for

set, a pressure

gravity

the

setup,

instrument

downstream

The

fundamental

Monitoring"“

flow

from

site

can

be

varying

changes

the

in

“Resistance

pressure

and

impedance

continuously

of

the

selected

pressure

variations,

measurement.

When a complete

of

the

fluid

infinite).

filters,

Elevated

partial

measured.

The

Dynamic

to

measure

downstream

Pressure = Effect

Resistance = Cause

Resistance = Change

Refer

to

Figure

future,

ALARIS

packs.

capacity.

needs

rated

Battery”

The

Therefore,

to

know

capacity

and

System

is

general

Monitoring™

Edition

the

fluid

the

instrument.

fluid

to

move

difference

this

is

done

will

develop

effects

on

concept

system

mechanism

measured.

flow

rate

while

pressure.

Graph”.

flow

value.

at

data

Such

short

rate.

Signal

Head

likewise,

occlusion

impedance

resistances

occlusions

Monitoring™

mechanical

flow

path.

when a force

when

in

Pressure

Change

in

1-3

“Pressure

Flow

intervals

impediment

Medical

replacement

has

Section

Systems

the

Battery

that a new

changed.

6.4.6,

battery

Monitoring™

information

system

fluid

is

that

This

can

measurements

is

or

as

it

through

the

(gradient)

by

head

height.

pressure

flow.

behind

to

the

resistance

the

is

done

the

patient's

by

monitoring

Refer

to

Figure

processing

then

produce

and

be

height

and

will

not

occurs,

very

the

large

(theoretically

due

to

infiltrations

system

provides a means

properties

is

against a restriction.

to

fluid

(AP)

(AF)

and

Resistance

may

provide

may

have

Manager

battery

has

to

Section

Rated

been

Refer

Changing

(DSM)

regarding

relates

administration

must

to

overcome

Dynamic

intentionally

the

of

can

independent

resulting

affect

resistive

clotting,

can

of

the

flow

the

to

the

exist.

In

In a pump,

to

fluid

infusion

resulting

1-2

the

the

fluid

be

made

the

part

clogged

be

occurs.

Graph”.

a

of

a

MEOICAL

SYSTEMS

IVAC

Signature

Edition™

Technical

Service

Manual

1-9

GENERAL

VFORMA

ION

Features

ES

presses

an

alarm

Ex

than

size

0%,

and

Resistance

or

line/site.

from 5 to

resistance

seconds

resistance

The

the

resistance

include:

Alarm

setting

impedance

pressure).

Detection: .omplete

Reduced r sance

effects

movement.

Faster

time

The

AutoRestartP|.

automatically

cleared

À

warning

occur

for

turned

of

off

restarts

The

restart

Run/Hold,

occurs.

When

infusion

depending

filters.

gradual

resistance

system

(pressure

suc

as

to

within

tone

up

to

(set

may

counter

if

the

Alert,

changes

The

Resistance

100%.

and

if

the

alert

will

and

is

based

on

changes,

occlusions.

alarms

head

neight

alarr=

at

TM

feature

con:

Je

the

-

f-check

ar

“Checking

40

:conds.

the

restarts

be

set

from 1 to

is

reset

-ump

or

is

<arted,

on

solution

provides

.n

the

It

allows

will

-rovide a tone

perce

it

resistance

mar

display

alarm

may

continue

aopropriately.

dynamic

not

by

minimizing

and

patient

low

rates.

allows

operation

period

Line”

The

feature

to

zero),

9.

whenever

channel

the

an

resistance

Alert

the

to

is

resistance

viscosity,

early

marker

nurse

exceeds

be

turned

monitor

system

absolute

artifact

the

pump

if

an

occlusion

(40

seconds).

message

can

be

or

the

number

the

Clinician

turned

off.

or

may

be

catheter/tubing

warning

of

can

to

every

off.

downstream

other

of

slow

the

IV

be

set

monitor

30

the

If

off,

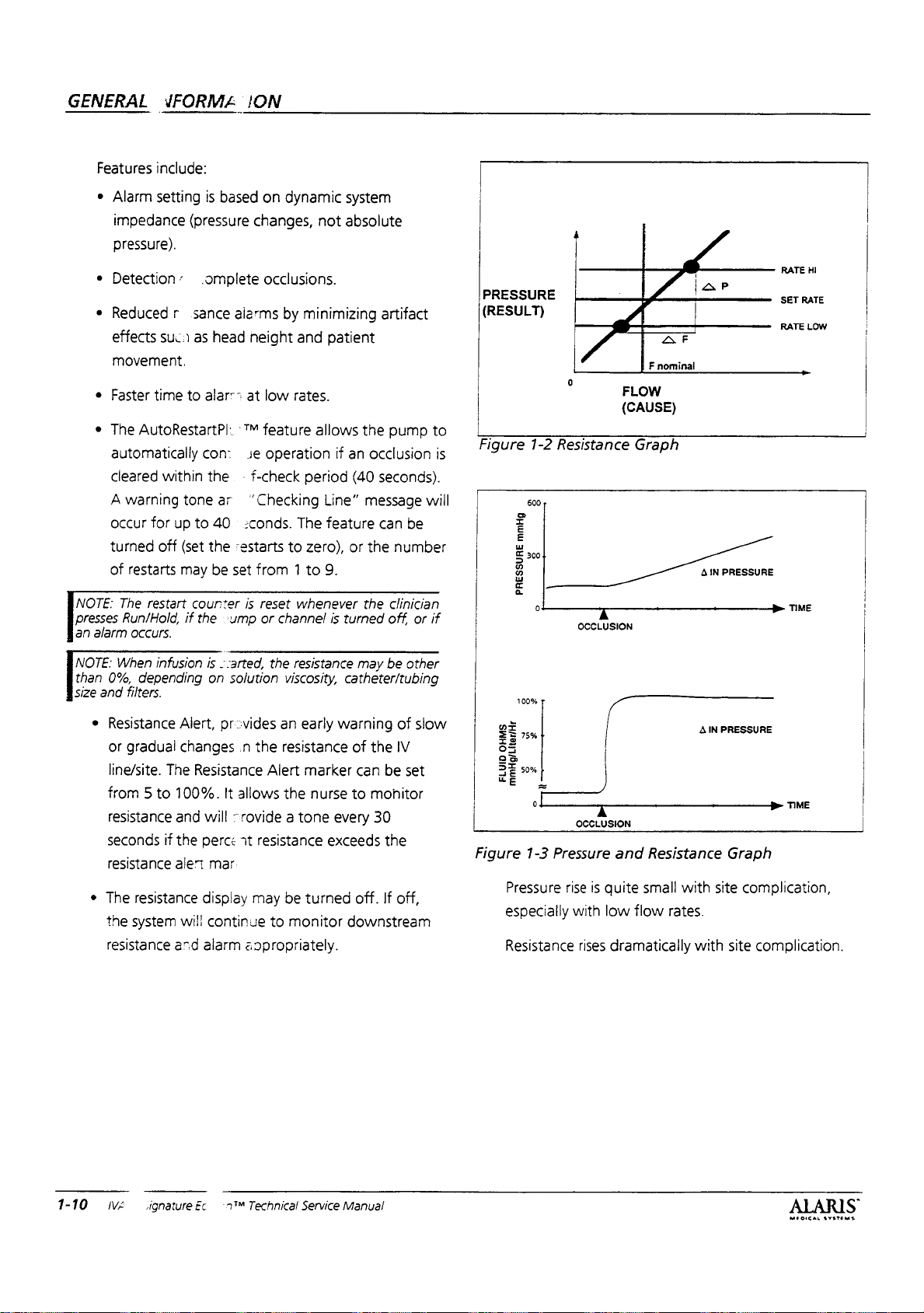

PRESSURE

(RESULT)

to

Figure

is

will

if

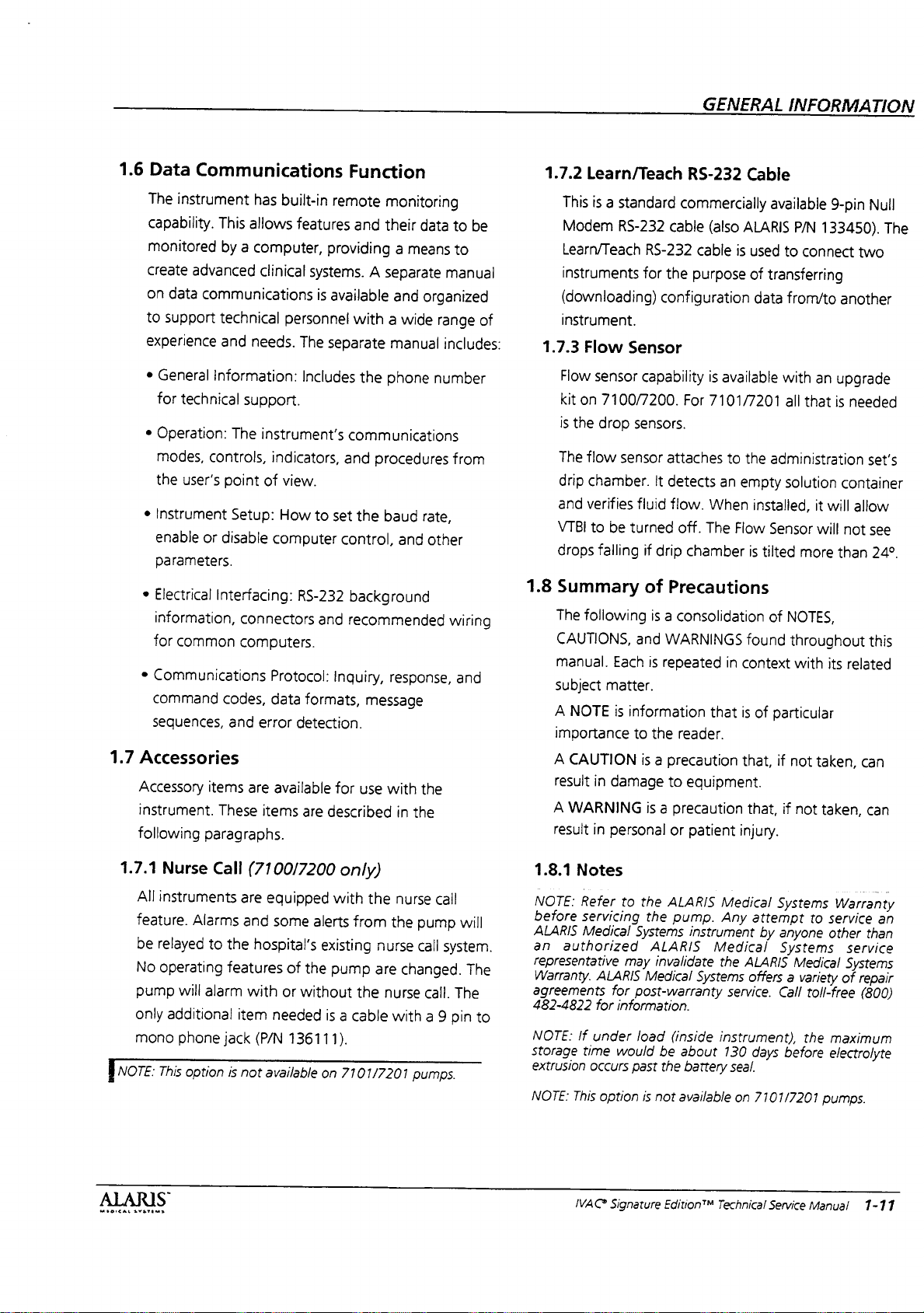

Figure

1-2

σι

©

mmHg

w

©

PRESSURE

ol

100%

ま

a

OHMS

FLUID

mmHg/Liter/Hr

o 2

1-3

Pressure

especially

Resistance

Resistance

o

o

OCCLUSION

OCCLUSION

Pressure

rise

is

with

rises

O

F

nominal

FLOW

(CAUSE)

Graph

I

|

pl

and

Resistance

quite

small

low

flow

rates.

dramatically

>

F

41N

A

with

with

P

PRESSURE

>

IN

PRESSURE

>

Graph

site

complication,

site

complication.

RATE

HI

SET

RATE

RATE

LOW

TIME

TIME

1-10

WA

signature

Ëc

nM

Technica!

Service

Manual

ALARIS

MEDICAL

SYSTEME

1.6

Data

The

capability.

monitored

create

on

data

to

support

experience

e

General

for

e

Operation:

modes,

the

e

Instrument

enable

parameters.

Communications

instrument

advanced

communications

technical

user's

or

has

This

allows

by

a

computer,

clinical

technical

and

needs.

Information:

support.

The

instrument's

controls,

point

indicators,

of

Setup:

disable

computer

built-in

remote

features

providing

systems.

is

available

personnel

The

separate

Includes

view.

How

to

set

control,

Function

monitoring

and

their

data

a

means

A

separate

and

organized

with

a

wide

manual

the

phone

communications

and

procedures

the

baud

rate,

and

other

to

be

to

manual

range

of

includes:

number

from

1.7.2

Learn/Teach

This

is a standard

Modem

RS-232

Learn/Teach

instruments

(downloading)

instrument.

1.7.3

Flow

Flow

sensor

kit

on

7100/7200.

drop

the

is

The

flow

chamber.

drip

and

verifies

VTBI

to

be

falling

drops

cable

RS-232

for

the

configuration

Sensor

capability

sensors.

sensor

attaches

It

detects

fluid

flow.

turned

drip

if

GENERAL

RS-232

commercially

cable

purpose

For

off.

chamber

Cable

(also

ALARIS

is

used

of

data

is

available

7101/7201

to

the

empty

an

When

installed,

The

Flow

is

tilted

INFORMATION

available

to

transferring

with

administration

Sensor

9-pin

P/N

133450).

connect

from/to

all

solution

an

that

it

will

another

upgrade

is

container

will

than

more

two

needed

set's

allow

not

Null

The

see

24°.

«

Electrical

information,

for

e

Communications

command

sequences,

1.7

Accessories

Accessory

instrument.

following

1.7.1

Nurse

All

instruments

feature.

be

relayed

No

operating

pump

only

mono

[νοτε:

This

Interfacing:

common

computers.

codes,

and

items

These

paragraphs.

Call

Alarms

to

the

features

will

alarm

additional

phone

option

item

jack

is

RS-232

connectors

Protocol:

data

formats,

error

detection.

are

available

items

are

(7100/7200

are

equipped

and

some

alerts

hospital's

of

the

with

or

without

needed

(P/N

136111).

not

available

background

and

recommended

Inquiry,

message

for

use

described

only)

with

the

from

existing

pump

are

the

is

a

cable

on

7101/7201

response,

with

the

in

the

nurse

the

pump

nurse

call

changed.

nurse

call.

with

a

pumps.

wiring

and

call

will

system.

The

The

9

pin

to

1.8

Summary

The

following

CAUTIONS,

manual.

subject

A

Each

matter.

NOTE

importance

A

CAUTION

result

in

damage

A

WARNING

result

in

personal

1.8.1

Notes

NOTE:

Refer

before

ALARIS

an

representative

Warranty.

agreements

482-4822

NOTE:

storage

extrusion

NOTE:

servicing

Medical

authorized

ALARIS

for

for

If

under

time

occurs

This

option

of

Precautions

is a consolidation

and

WARNINGS

is

repeated

is

information

to

the

reader.

is

a

precaution

to

equipment.

is

a

precaution

or

patient

to

the

ALARIS

the

pump.

Systems

may

post-warranty

information.

load

would

past

instrument

ALARIS

invalidate

Medical

(inside

about

be

battery

the

is

not

available

Systems

of

NOTES,

found

throughout

in

that

context

is

that,

that,

with

of

particular

if

not

if

not

injury.

Medical

Any

Medical Systems

the

service.

instrument),

130

seal.

Systems

attempt

by

ALARIS

offers a variety

days

on

7101/7201

to

anyone

Medical

Call

toll-free

the

before

this

its

related

taken,

can

taken,

can

Warranty

service

other

than

service

Systems

of

repair

(800)

maximum

electrolyte

pumps.

an

ALARIS

MUOICAL

SYSTEMS

IVAC

Signature

Edition™

Technical

Service

Manual

1-11

GENERAL

INFORMATION

“NOTE:

indicate

:

¿different

:

‘the

“added

„5.3

.

.NOTE:

‘presses

an

NOTE:

‘than

size

NOTE:

when

However,

be

record

NOTE:

for

defaults.

NOTE:

Rate

the

NOTE:

modes.

When

approximate

NOTE:

In

different

Capacity

battery

rated

instrument

and

“Replacing

of

The

Run/Hold,

alarm

occurs.

When

0%,

and

filters.

The

disconnected

lost.

If

before

ft

is

a

complete

Setting

will

lower

Maximum

The

the

instrument

run

the

future,

packs.

capacity.

needs

the

rated

capacity

Battery”

Battery.

restart

counter

if

the

infusion

depending

instruments

error

you

strongly

from

history

want

disconnecting

recommended

list

of

the

Maximum

the

KVO

Rate.

maximum

is

tumed

time

for

ALARIS

to

is

on

to

Medical

The

replacement

Therefore,

know

that a new

has

and

Section

is

reset

pump

or

channel

started,

configuration

and

defaults

the

solution

AC

power

infusion

save

this

power.

before

Rate

Rate.

The

rate

setting

off.

infusions

the

changed.

whenever

resistance

viscosity,

program

information