Page 1

IVAC® Variable Pressure

Volumetric Pump

Models 571 & 572

Technical Service Manual

Page 2

This manual has been prepared for use by qualified service personnel only.

Card inal Health canno t accept any liabi lity for any breakdo wn or dete riorati on in

performance of parts or equipment resulting from unauthorised repair or modification.

Authorised EU Representive:

Cardinal Health*,

The Crescent,

Jays Close,

Basingstoke,

Hampshire

RG22 4BS,

United Kingdom

*Formerly ALARIS Medical UK Limited

IVAC® is a registered trademark of

Cardinal Health, Inc. or one of its subsidiaries

All other trademarks belong to their respective owners.

t

Cardinal Health**,

10221 Wateridge Circle,

San Diego, CA 92121,

USA.

** Formerly ALARIS Medical Systems, Inc.

© 1994 - 2008 Cardinal Health, Inc or one of its subsidiaries. All rights reserved.

IVAC® Volumetric Pump (Models 571 & 572) 2/104 1000SM00018 Issue 2

Page 3

Contents

Chapter 1 Introduction & Start Up 4

Chapter 2 Configuration & Calibration 13

Chapter 3 Routine Maintenance 22

Chapter 4 Troubleshooting 37

Chapter 5 Circuit Descriptions 43

Chapter 6 Spare Parts Replacement Procedures 47

Appendix A Specifications 83

Appendix B Spare Parts Listing 89

Appendix C Configured Options 97

Appendix D Disposal 99

Appendix E Service Contacts 101

Appendix F Document History 103

Page 4

Chapter 1

Introduction and Start Up

In this chapter

Introduction 5

General Precautions 6

Views of Models 571 and 572 6

Controls and Indicators 8

Loading the IV Infusion Set 9

Starting the Pump 9

Programming 10

Operating on Battery Power 10

Secondary Infusion (Model 572) 11

Flow Sensor 12

Pole Clamp Accessories 12

Page 5

Introduction and Start Up

Introduction

The IVAC® Volumetric Pump - Models 571 and 572 automatically regulates the infusion rate of IV solutions using a linear

peristaltic, volume displacement mechanism to regulate fluid flow at the prescribed rate. The pump can be operated with

a Flow Sensor and is compact and robust enough for most patient situations.

The IVAC® 571 Volumetric Pump operates in primary infusion mode only.

The IVAC® 572 Volumetric Pump has a primary and secondary infusion mode.

Product Familiarity

Ensure that you are fully familiar with the pump by carefully studying the Directions for Use (DFU) prior to operation and

prior to attempting any repairs or servicing. As part of continuous improvement, product enhancements and changes are

introduced from time to time.

Purpose of this Manual

This Technical Service Manual describes how to set up, test and maintain the following IVAC® Volumetric Pumps:

Model 571

Model 572

This manual is intended for use by personnel experienced in medical equipment testing and maintenance procedures .

Conventions Used in this Manual

BOLD Used for Display messages/values, self-test codes, controls and indicators referenced in this manual, for

example, CAL RATE, test code 11, ON/OFF switch.

'Single quotes' Used to indicate cross-references made to another section of this manual. For example, see

Chapter 2, 'Configuration and Calibration'.

underline Used to indicate a link to another section within this manual.

Italics Used to refer to other documents or manuals. For example, refer to the relevant Directions for Use

(DFU) for further information. Also used for emphasis, for example, ...if the gap still measures less

than...

Wherever this symbol is shown a Hints & Tips note is found. These notes provide useful advice or

information that may help to perform the task more effectively.

Wherever this symbol is shown a Toolbox note is found. These notes highlight an aspect of test

or maintenance that is important to know about. A typical example is drawing attention to a

software upgrade that you should check has been installed.

IVAC® Volumetric Pump (Models 571 & 572) 5/104 1000SM00018 Issue 2

Page 6

General Precautions

)6 #

Prior to using this pump, carefully read the Operating Precautions described in the Directions for Use

(DFU).

This pump contains static-sensitive components. Observe strict precautions for the protection of

static sensitive components when attempting to repair and service the pump.

An explosion hazard exists if the pump is used in the presence of flammable anaesthetics. Exercise

care to locate the pump away from any such hazardous sources.

Dangerous Voltage. An electrical shock hazard exists if the casing of the pump is opened or

removed. Refer all servicing to qualified service personnel.

This pump is protected against the effects of radio frequency emissions and is designed to be

M

fail safe if extremely high levels of interference are encountered. Should false alarm conditions

be encountered, either remove the source of the interference or regulate the infusion by another

appropriate means.

If the pump is dropped, subjected to excessive moisture, humidity or high temperature, or otherwise

suspected to have been damaged, remove it from service for inspection by qualified service

personnel.

Introduction and Start Up

When connected to an external power source, a three-wire (Live, Neutral, Earth) supply must be

used. If the integrity of the external protective conductor in the installation or its arrangement is in

d

doubt, the pump should be operated from the battery.

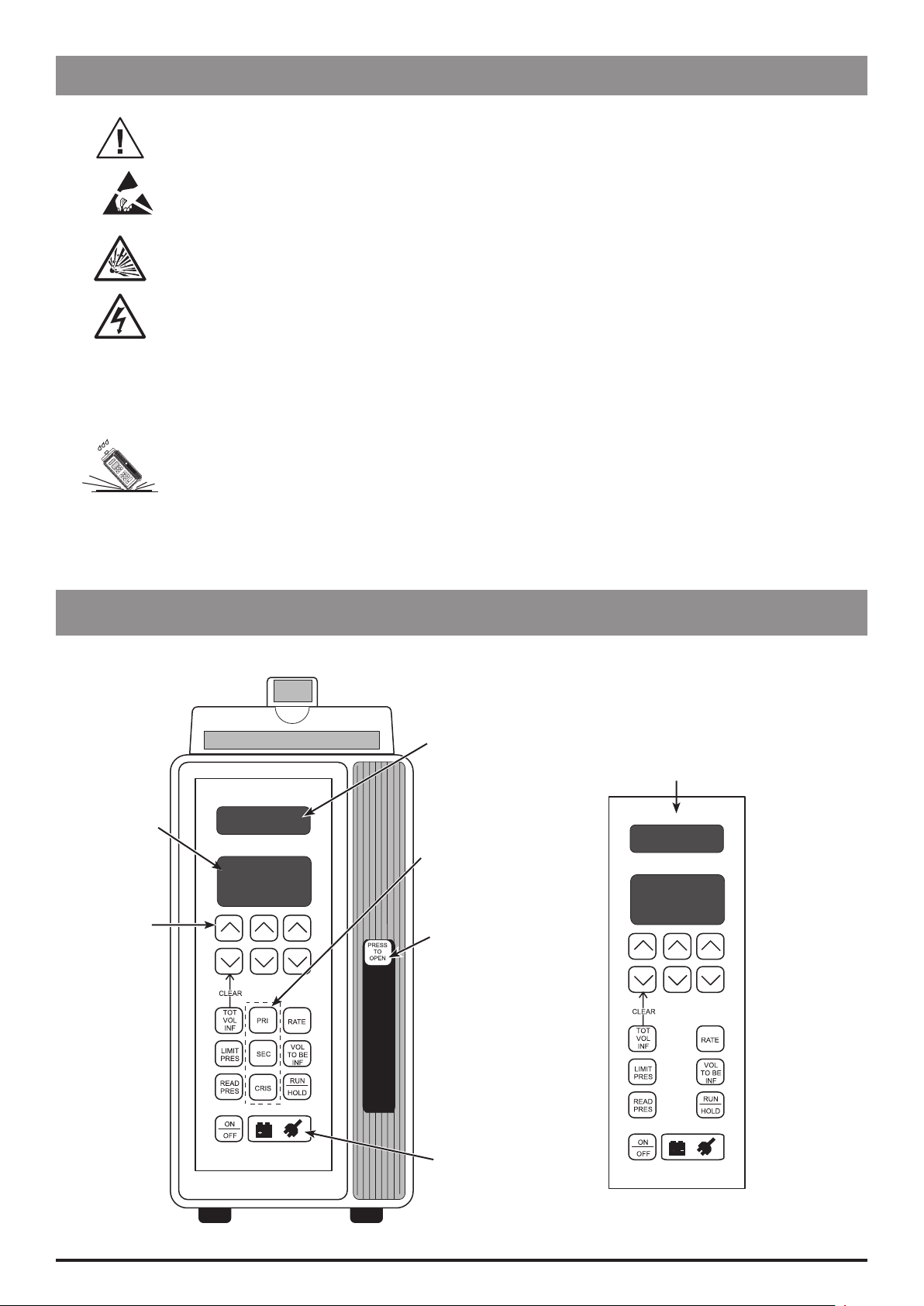

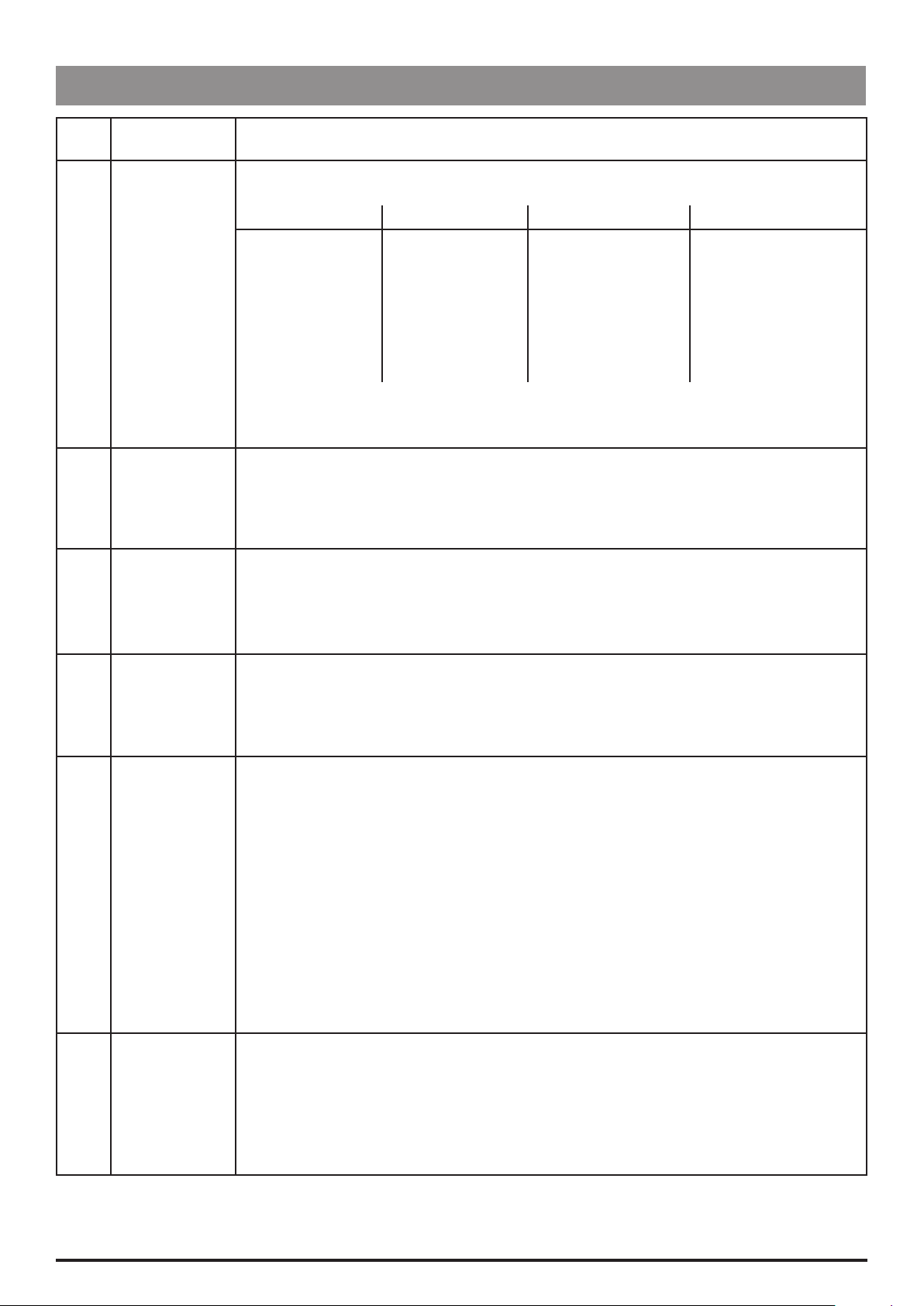

Views of Models 571 and 572

Front View

Numeric

Display

Switch Panel

(Model

572)

Information Display

Switch Panel

(Model 571)

Primary/Secondary/CRIS

Infusion Switches

(Model 572 only)

Door Latch

Battery and

AC power

Indicators

IVAC® Volumetric Pump (Models 571 & 572) 6/104 1000SM00018 Issue 2

Page 7

Introduction and Start Up

053(

4/

2%3%4

&,/7

3%.3/2

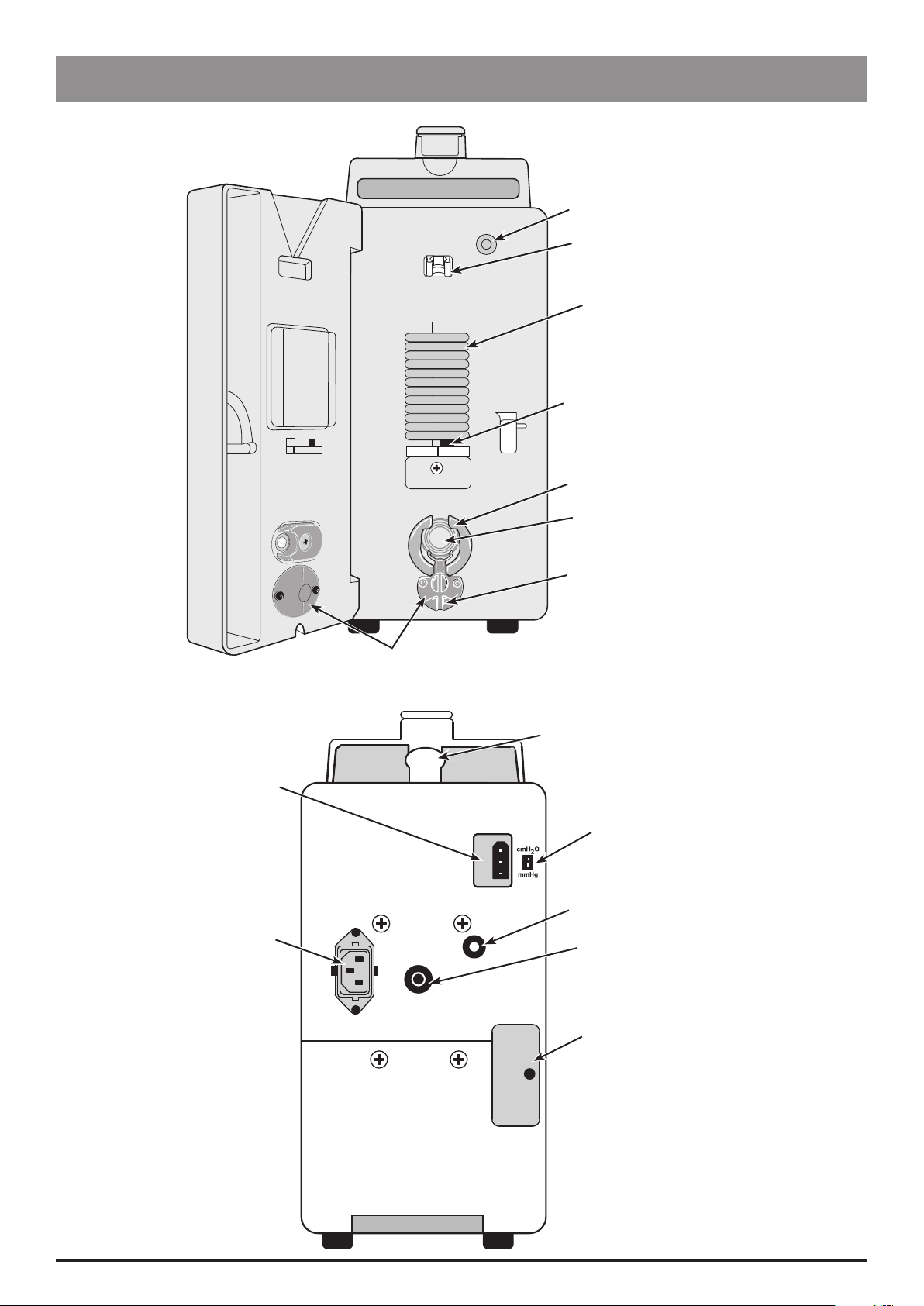

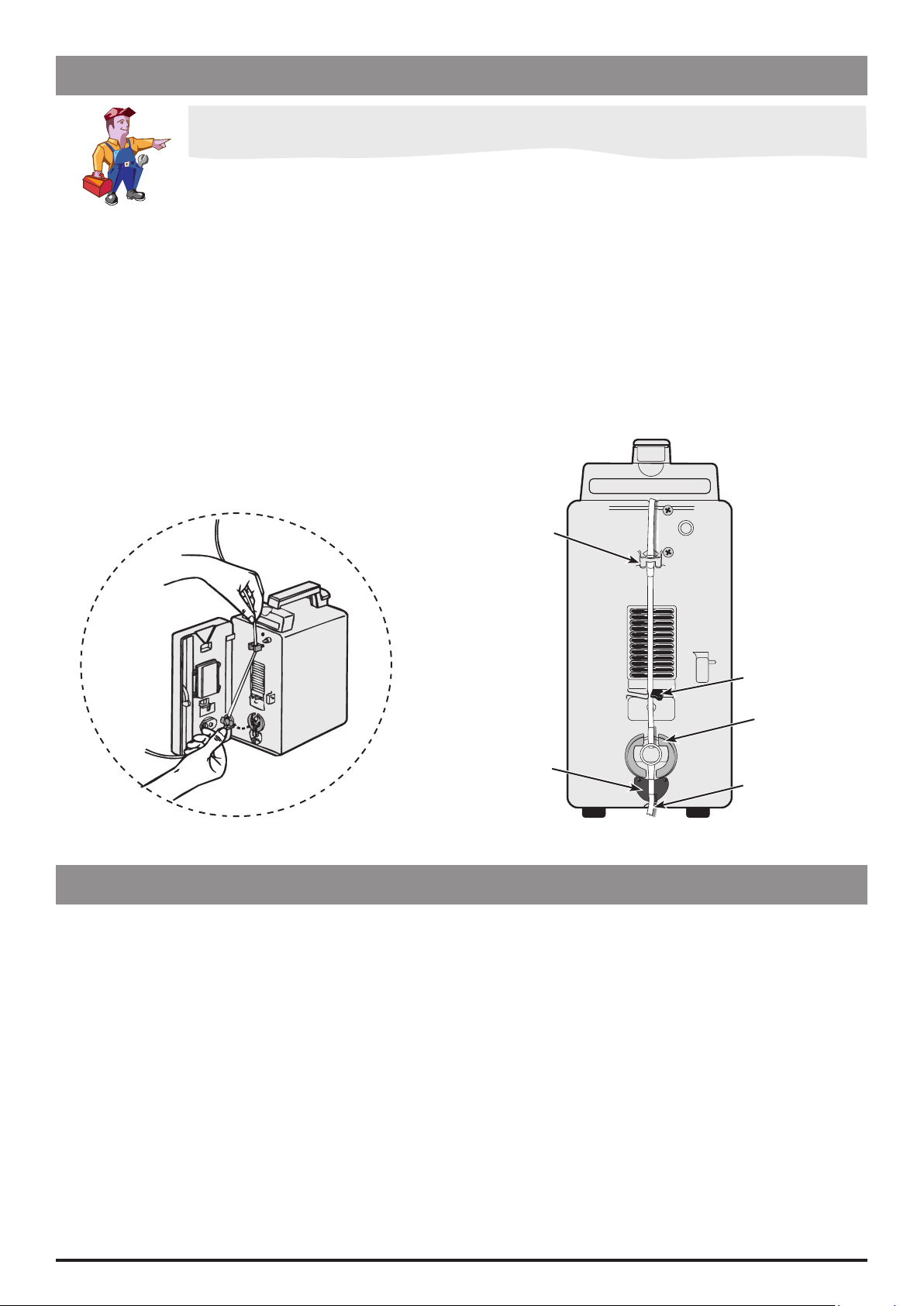

Views of Models 571 and 572 (continued)

Open Door View

Vacuum Plunger

Upper Tubing Retainer

Pumping Mechanism

Tubing Pincher

Pressure Sensing Disc

Retainer

Pressure Transducer

Rear View

Flow Sensor

Connector

AC Power

Connector

Lower Tubing Guide Posts

Air-In-Line Detector

Flow Sensor Storage

Pressure Unit

Selector Switch

PE Connector

Reset Switch

Test Connector

IVAC® Volumetric Pump (Models 571 & 572) 7/104 1000SM00018 Issue 2

Cover

Page 8

Introduction and Start Up

TOT

VOL

INF

TOT

VOL

INF

LIMIT

PRES

READ

PRES

PRI

SEC

CRIS

R A T E

VOL

TO BE

INF

RUN

HOLD

ON

OFF

053(

4/

2%3%4

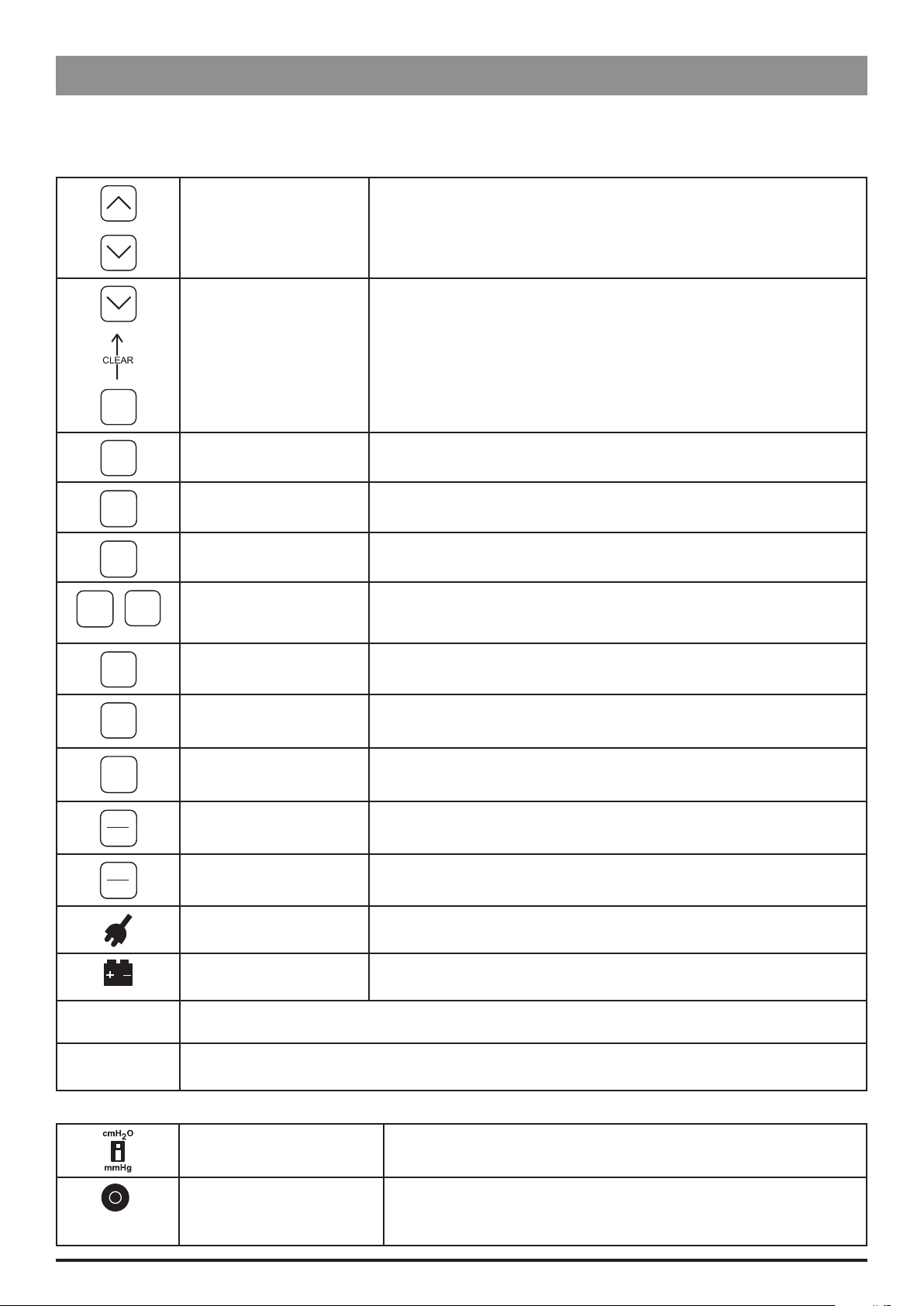

Controls and Indicators

Front Panel

The English switch panel controls and indicators are described below. For information on overlays in other languages,

refer to the relevant DFU. See also Appendix B, 'Spare Parts Listing' for switch panel part numbers.

Increases or decreases infusion rate and pressure and volume values. Three

UP/DOWN

columns for faster/slower increase or decrease:

Left = 100's, Centre = 10's, Right = units (or in micro mode Left = 10's,

Centre = units, Right = fractions).

CLEAR

TOTAL VOLUME INFUSED

PRESSURE LIMIT

READ PRESSURE

Clears total volume infused when both switches are held down together.

Displays total volume infused value (primary + secondary volume infused).

Sets the Information Display to continuously monitor volume infused.

Displays or changes the occlusion pressure alarm level limit.

Displays the IV infusion site pressure.

Sets the Information Display to continuously monitor infusion pressure.

(Model 572 only). Switches between PRIMARY and SECONDARY infusion

PRIMARY/SECONDARY

CRIS

modes. Allows displays of VTBI or rate setting of one mode while operating

in another.

On Model 572: only used in Self-test mode.

On Model 571: hidden switch, only used in Self-test mode.

RATE Changes the infusion rate.

VOLUME TO BE INFUSED

(VTBI)

Sets the value of Volume To Be Infused. Displays volume remaining to be

infused.

RUN/HOLD

Starts and stops pump infusion. Silences/cancels alarms and advances

start-up instruction messages.

ON/OFF Turns the pump on and off.

AC POWER INDICATOR

BATTERY INDICATOR

0

With a Flow Sensor in use, an illuminated ("0") in the Information Display window indicates a drop is

detected by the flow sensor in the drip chamber.

When illuminated, indicates the pump is connected to an AC power supply

and the battery is being charged.

Flashes to indicate the pump is operating on battery power.

Flashing Displays When the pump is operating on battery power, both Displays flash on/off.

Rear Panel

PRESSURE UNIT SELECTOR

SWITCH

RESET SWITCH Resets the circuit breaker.

Sets the displayed pressure units. Millimetres of mercury (mmHg) or

Centimeters of water (cmH20).

IVAC® Volumetric Pump (Models 571 & 572) 8/104 1000SM00018 Issue 2

Page 9

Introduction and Start Up

Loading the IV Infusion Set

Follow the Directions for Use supplied with the individual IV infusion set

Only use IVAC® "52" Series IV infusion sets

1. Prime the IV infusion set slowly ensuring all air is removed from the pressure disc then close the roller clamp.

2. Open the door.

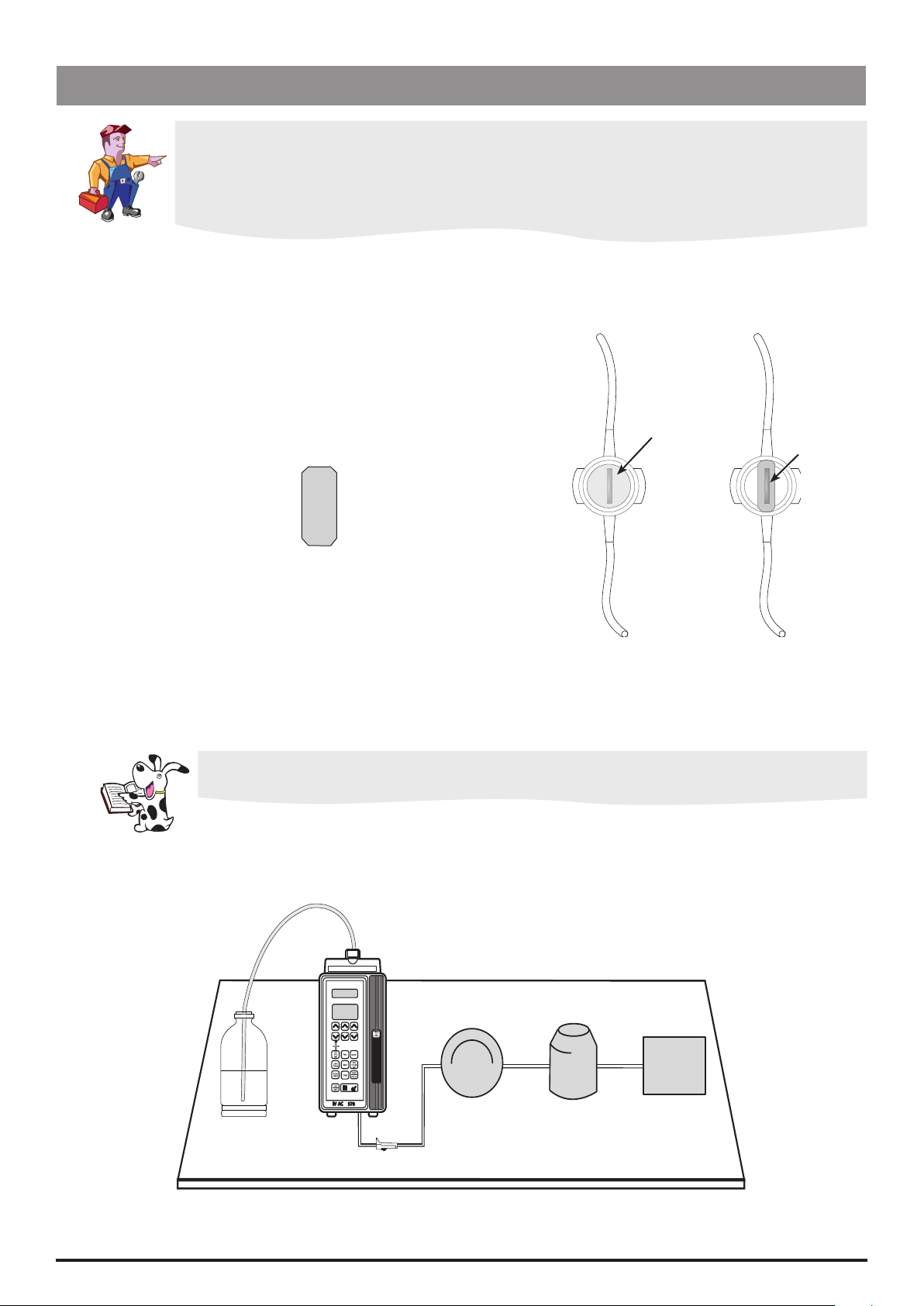

3. Load the primed IV infusion set (see Figures 1-1 and 1-2):

Insert the set tubing into the upper tubing retainer.

Grasp the pressure sensor disc tabs between thumb and forefinger with the flat side (membrane) toward the

pump

Hook the pressure sensor disc under the disc retainer then press up and in to properly seat the disc

Place the tubing between the lower tubing guide posts.

4. Close and latch the door.

5. Open the roller clamp. Check drip chamber to ensure no fluid flows.

6. Connect to test equipment as required.

Figure 1-1

Starting the Pump

Without Flow Sensor

1. Load the primed IV infusion set.

2. Press the

3. Use the UP/DOWN switches (JK) to set the rate.

4. Press the

5. Use the JK switches to set VTBI.

6. Press the

ON/OFF switch to power on the pump.

RUN/HOLD switch to confirm.

RUN/HOLD switch twice to start infusion.

Upper Tubing

Retainer

Tubing Pincher

Pressure Sensing

Disc Retainer

Air-In-Line

Detector

Lower Tubing

Guide Posts

Figure 1-2

With Flow Sensor

1. Load the primed IV infusion set.

2. Connect the flow sensor to the drip chamber

ensuring the flow sensor is plugged into the pump.

3. Press the

4. Use the UP/DOWN switches (JK) to set the rate.

5. Press the

6. Press

JK switches to set VTBI.

7. Press the

ON/OFF switch to power on the pump.

RUN/HOLD switch to confirm.

VOL TO BE INF (if required) then use the

RUN/HOLD switch twice to start infusion.

IVAC® Volumetric Pump (Models 571 & 572) 9/104 1000SM00018 Issue 2

Page 10

Programming

Introduction and Start Up

Changing the infusion rate

1. Press the RUN/HOLD switch to place the pump on hold.

2. Press the R AT E switch.

3. Use the JK switches to set the new rate.

4. Restart the pump at the new rate by pressing the

HOLD

switch.

RUN/

Clearing the total Volume Infused

1. Press the RUN/HOLD switch to place the pump on hold.

2. Press and hold the TOT VOL INF switch and the K

switch directly above simultaneously for 2 seconds until

display shows

3. Resume infusion by pressing the RUN/HOLD switch.

000.0.

Changing the Volume To Be Infused

1. Press the RUN/HOLD switch to place the pump on hold.

2. Press the VOL TO BE INF switch.

3. Set new volume by pressing the JK switches. OFF can

also be selected when a flow sensor is in use, see Notes

below.

4. Restart the pump by pressing the

Notes:

1) Without a flow sensor in use, a VTBI value must be entered,

otherwise, the pump will be unable to operate.

2) With a flow sensor in use, a VTBI value isn't required and

OFF can be selected if required.

RUN/HOLD switch.

Adjusting the maximum pressure limit

(Occlusion pressure alarm level)

1. Simultaneously press and hold the LIMIT PRES

switch whilst using the JK switches to adjust

the pressure limit.

2. Release the LIMIT PRES switch.

Note: Pressure value will be displayed in

cmH20 depending on unit selected. See 'Pressure

Unit Selector'.

mmHg or in

Reading the pressure

1. Press and hold the READ PRES switch. Wait at least

10 seconds to allow reading to stabilize.

Note: Pressure value will be displayed in

in cmH20 depending on unit selected. See 'Pressure

Unit Selector'.

mmHg or

Selecting alternating display of total

volume infused

1. Press and release the TOT VOL INF switch three

times within 2 seconds while the pump is infusing or

on hold.

On Model 572, the display will alternate between

primary or secondary infusion and total volume

infused.

On Model 571, the display will continuously

show the total volume infused.

Selecting alternating display of infusion

pressure

1. Press and release the READ PRES switch three times

within 2 seconds while the pump is infusing or on

hold.

On Model 572, the display will alternate between

primary or secondary infusion and infusion

pressure.

On Model 571, the display will continuously

show the infusion pressure.

Operating on Battery Power

The pump operates on battery power when it is disconnected from the AC power. The battery power indicator, the

Information and Numeric Displays will flash whenever the pump is on battery power. In the event of a power failure, the

pump will automatically continue to operate on battery power.

Two alarms indicate the condition of the pump's battery:

LOW BATT alternating with the selected volume or pressure status. This indicates that approximately 30 minutes of

operating time remains on battery power

LOW BATT (constant). This indicates that the battery is discharged. Connect the pump to an AC power supply to

recharge the battery.

Note: The pump's battery is designed for limited duration use. Wherever possible, the pump should be used connected

to an AC power supply. If the pump is to be taken out of service for an extended period, it is good practice to charge the

battery periodically to ensure full capacity.

IVAC® Volumetric Pump (Models 571 & 572) 10/104 1000SM00018 Issue 2

Page 11

Introduction and Start Up

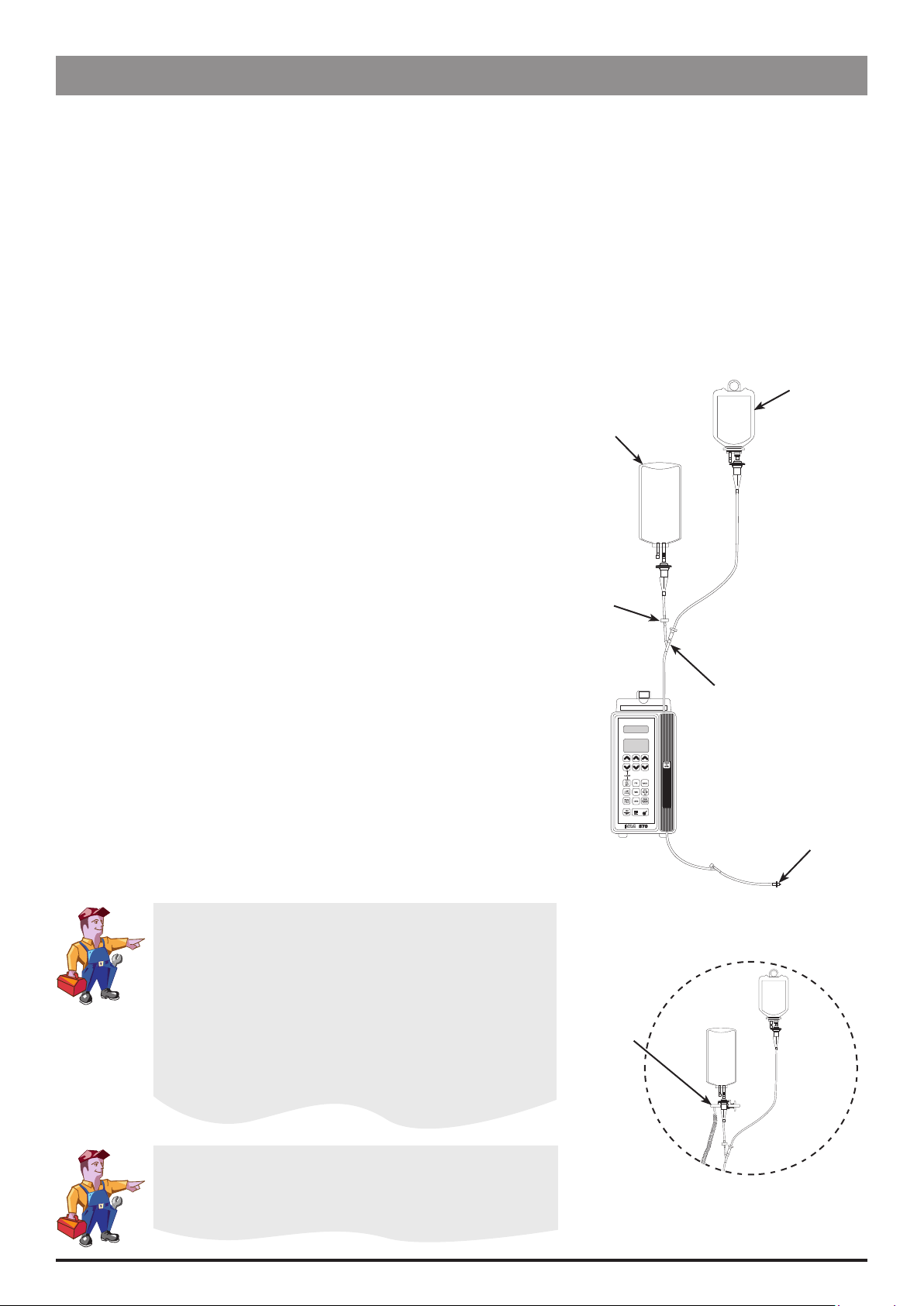

Secondary Infusion (Model 572)

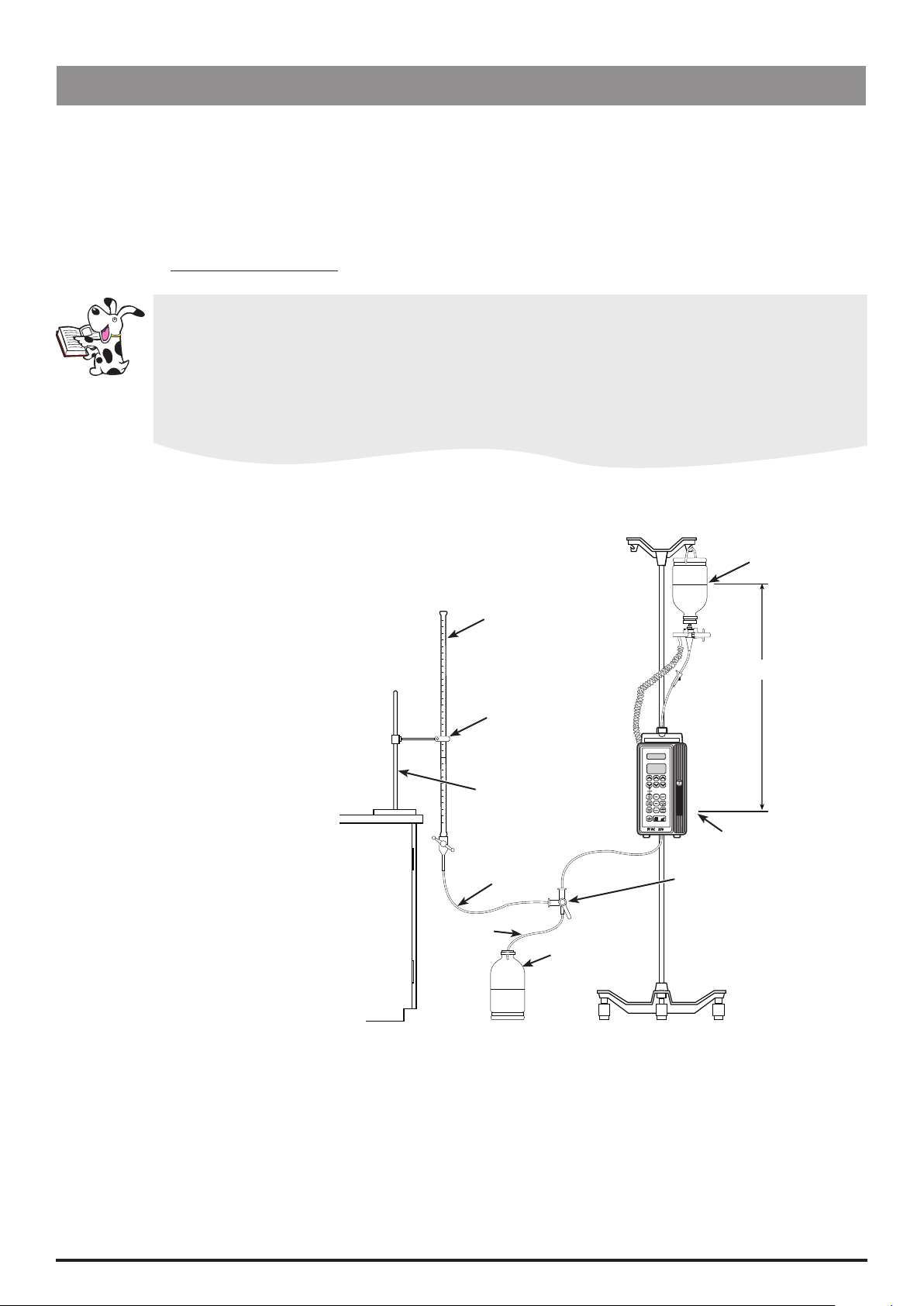

Introduction

This mode of operation supports automatic secondary infusions ("piggybacking") in the same pump channel. When

the secondary VTBI reaches zero, a transition tone will sound and the primary settings will automatically take effect.

Secondary mode can be used where a second, independent VTBI is required, and also when an automatic rate change is

required.

When the pump is programmed and delivering in the secondary mode, the primary infusion is temporarily stopped and

fluid is drawn from the secondary (higher) container. Delivery from the primary container resumes when the fluid level in

the secondary line is level with the fluid in the primary container.

Notes:

1) The primary fluid container must hang lower than the secondary fluid container to allow the secondary infusion to

run.

2) On completion of the secondary infusion the pump will automatically return to primary infusion.

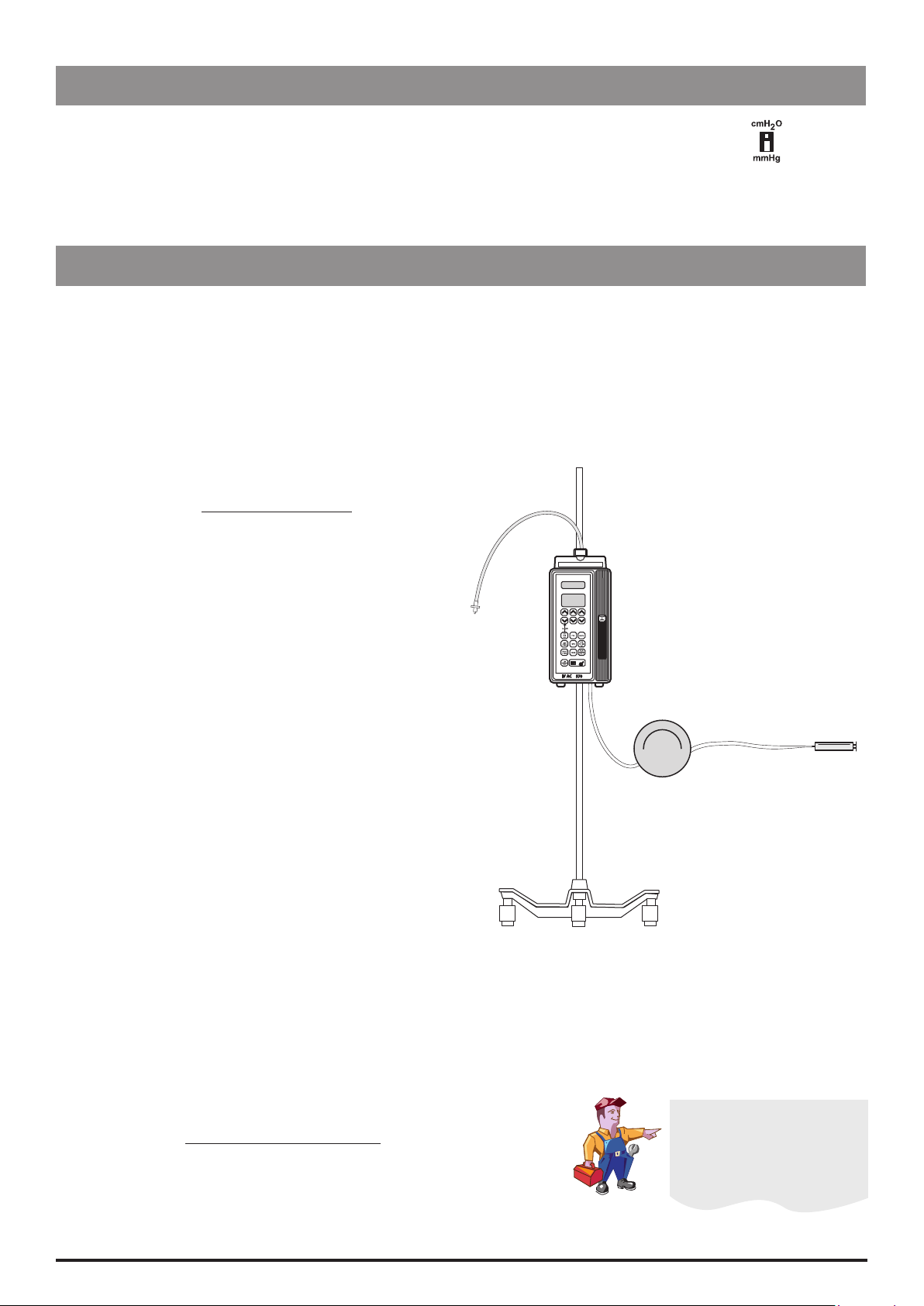

Secondary

Starting the Pump with Secondary Infusion

1. Load the primed set. See 'Loading the IV Infusion Set' earlier in this

chapter for instructions.

2. Prepare the secondary infusion using a secondary solution container

and the IVAC® "52" Series back check valve set; lower the primary

container. See Figure 1-3 below.

Prime the secondary IV infusion set in accordance with the set

Directions for Use

Attach a secondary IV infusion set to the upper Y-site of the

primary IV infusion set

3. Press the

up in PRIMARY mode.

4. Use the JK switches to set the primary rate.

5. Press

6. Set primary VTBI if required.

7. Press the SEC switch to place the pump into SECONDARY mode. The

pump will sound a four beep verification tone.

8. Use the JK switches to set the secondary rate.

9. Press the

10. Set secondary VTBI by using the JK switches.

11. Press

ON/OFF switch to power on the pump. Pump always starts

VOL TO BE INF if required.

VOL TO BE INF switch.

RUN/HOLD to start secondary infusion.

Primary

container

Back Check

valve

Y-Site

container

IV Infusion set

patient end

WARNING:

Secondary infusion applications using a back check

valve set must have a VTBI setting equal to the

volume in the secondary container; this will require

consideration of such variables as factory overfill,

medication additions, priming volume, etc.

Underestimating the volume will cause remaining

secondary solution to be infused at the primary rate;

overestimating will result in primary solution being

infused at the secondary rate.

When using a flow sensor it must be positioned on the

primary IV infusion set (as shown in Figure 1-4). Correct

placement of a flow sensor is essential for proper

operation.

Secondary Infusion Set Up

Flow

Sensor

Secondary Infusion Set Up

Figure 1-3

Figure 1-4

with Flow Sensor

IVAC® Volumetric Pump (Models 571 & 572) 11/104 1000SM00018 Issue 2

Page 12

Introduction and Start Up

Secondary Infusion (Model 572) continued

Additional Programming during Secondary Infusion

Verifying a value in one mode while operating in another

1. Press and release the appropriate (current) mode switch. For example, SEC.

2. Within two seconds press the switch representing the information to be displayed. For example, PRI.

Changing the infusion manually to primary mode

1. Press the RUN/HOLD switch to set pump on hold.

2. Press the PRI switch; pump sounds a three beep verification tone and goes into PRIMARY mode.

Flow Sensor

A flow sensor (part number 180) is used to detect an empty solution container. It is connected to the drip chamber and

when a drop is detected in the drip chamber an illuminated ("0") appears in the Information Display.

When not in use, the flow sensor can be stored on the pump handle.

Pole Clamp Accessories

The following pole clamp accessories allow the pump to be mounted on conventional IV poles:

Universal Pole Adapter (part number 6767)

Pole Adapter (part number 5767A)*

Pole Clamp Accessory (part number BC100A)*

* must be used in conjunction with each other.

Refer to Chapter 6, 'Spare Parts Replacement Procedures' for assembly information.

IVAC® Volumetric Pump (Models 571 & 572) 12/104 1000SM00018 Issue 2

Page 13

Chapter 2

Configuration & Calibration

In this chapter

Self-Test Mode 14

Mode Select Jumper 15

Configuration Settings 15

Selecting Pressure Units 17

Calibration Procedures 17

Page 14

Configuration & Calibration

Self-Test Mode

Self-test mode is used to access a number of configuration and test routines which are designed to test and verify many

of the pump functions, defaults and calibrations without requiring internal inspection. Configuration settings are also

accessed via self-test mode.

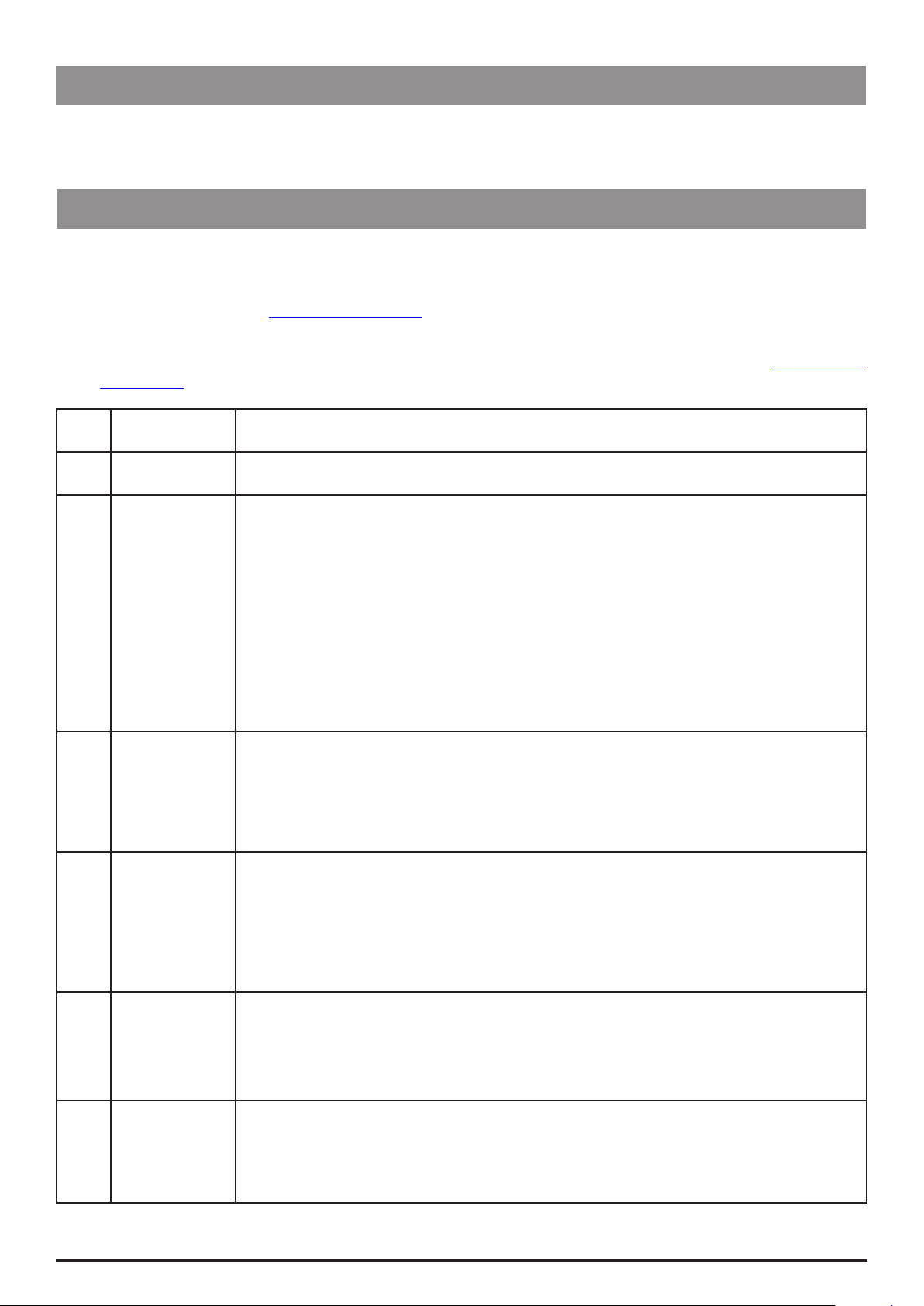

Each test is accessed by selecting a Test ID number as shown in the table below.

Test ID Description

001 Software Revision Display

002 Configuration Status Display

003 Flash Display Test

004 Segment Display Test

005 Sequence Display Test

006 EEPROM Test and Data Display

007 A/D Channels Test

008 Rate Calibration Display/Set

009 * Configuration Rate Display/Set

010 Maximum Rate Display/Set

011 * VTBI Configuration Display/Set

012 Pressure Display

013 Pressure Calibration Set

014 Maximum Occlusion Pressure Limit Display/Set

015 Default Occlusion Pressure Limit Display.Set

016 Alarm History Display/Clear

Entering Self-Test Mode

1. Press the RUN/HOLD and ON/OFF switches

simultaneously until the display turns on. Initially,

the current software revision level is displayed.

2. Press the RUN/HOLD switch. The Information

Display will read: TEST ID and the Numeric

Display will read: 002 which means the pump is

ready to start test 002.

Note: The display may bypass the display of the

software revision level and advance directly to

TEST ID 002, depending on how long the RUN/

HOLD switch is held down.

3. Use the

required.

J K switches to select the Test ID

The three columns of J K switches

allow faster/slower increments:

Left = 100's

Centre = 10's

Right = Units

017 Switch Test

018 AC Power Run Time Display/Reset

019 Battery Run Time Display/Reset

020 Secondary Mode Completion Tone Display/Set

021 Air-In-Line Test

022 I/O Port Test

023 Language Display/Set

024 CIM ID Display/Set

025 Alarm Tone Display/Set

026* AIL Alarm Threshold Display/Set

027 System Vacuum Display

028 Enter Operational Setup Mode

029 Burn-In Test

030 Not used

031* Infusion Mode Configuration Display/Set

* A mode select jumper (part number 132350) must be

used to change settings, see 'Mode Select Jumper' for

further details.

Test Execution

1. After selecting the Test ID number (see above),

press the RUN/HOLD switch to start the test.

2. To exit a test, press the

RUN/HOLD switch.

Exiting Self-Test Mode

Self-test mode can be exited at any time:

Turn the pump off by pressing the ON/OFF switch

OR

Select test 028 then press the RUN/HOLD switch

to enter the start-up mode of operation

IVAC® Volumetric Pump (Models 571 & 572) 14/104 1000SM00018 Issue 2

Page 15

Configuration & Calibration

Mode Select Jumper

In order to perform certain tests and to change any pump settings, a mode select jumper must be installed.

Procedure:

1. With the pump off, remove the test connector cover from the back of the rear case.

2. Connect the mode select jumper (part number 132350) to the test connector, orientating the jumper so that CR1 is at

the top.

3. Place the pump in self-test mode then select and carry out the test(s) as required.

4. When the test is complete, switch the pump off and remove the mode select jumper from the test connector.

5. Refit the test connector cover.

Configuration Settings

Enter Self-Test mode. See 'Entering Self-Test Mode' in previous section for instructions.

Note: For default settings refer to Appendix C 'Configured Options'.

Test ID Setting Action/Data Displayed

009

010

011

Rate Configuration

RATE CFG

Maximum Rate

MAX RATE

VTBI Configuration

VTBI CFG

Display and/or set the current rate range.

STANDARD = rate range of 001 to 999 ml/h

ALL RATE = rate range of 0.1 to 999.9 ml/h. Note: Use this setting where

fractional flow rates are required.

To change the setting:

Install the mode select jumper. See 'Mode Select Jumper'.

Press the CRIS (lower hidden switch on Model 571) and VOL TO BE INF

switches together and wait for a click.

Press the J unit (right column) switch to select STANDARD or the K unit

switch to select ALL RATE.

Display and/or set the maximum infusion rate.

999 = set to STANDARD rate configuration (ml/h). This rate cannot be changed.

0.1 and 999.9 = set to ALL RATE configuration (ml/h).

Note: Rate configuration is set in Test 009.

To change the maximum rate setting (for ALL RATE configuration):

Press and hold the PRI (upper hidden switch on Model 571) while using the

J K switches to adjust the value.

Display and/or set the Volume To Be Infused (VTBI) limit. VTBI limit ranges are:

MACRO = 1 to 9999 ml, MICRO = 0.1 to 999.9 ml.

If set to ALL RATE configuration (see Test 009), VTBI CFG can be set to MACRO

or MICRO.

If set to STANDARD rate configuration, VTBI CFG is set to MACRO and is not

adjustable.

To change the VTBI limit (for ALL RATE configuration):

Install the mode select jumper. See 'Mode Select Jumper'.

Press the CRIS (lower hidden switch on Model 571) and VOL TO BE INF

switches together and wait for a click.

Press the J unit switch to select MACRO or the K unit switch to select

MICRO.

Display and/or set the maximum occlusion pressure limit. Pressure values are

displayed in MMHG or CMH20 depending on the pressure units selected. See

'Selecting Pressure Units' for further information.

Maximum Occlusion

014

Pressure

MAXIMUM

IVAC® Volumetric Pump (Models 571 & 572) 15/104 1000SM00018 Issue 2

This pressure limit setting determines the upper limit of the pumps' variable

pressure range thereby fixing the upper limit when the LIMIT PRES switch is

used during normal operation.

To change the setting:

Press and hold the PRI (upper hidden switch on Model 571) while using the

J K switches to adjust the value.

Press the RUN/HOLD switch to save the new value.

Page 16

Configuration & Calibration

Configuration Settings (continued)

Test ID Setting Action/Data Displayed

Display and/or set the default pressure limit.

Pressure values are displayed in MMHG or CMH20 depending on the pressure

Default Occlusion

015

Pressure

DEFAULT

Secondary Mode

020

Completion Tone

(Model 572 only)

023 Language

units selected. See 'Selecting Pressure Units' for further information.

This setting determines the occlusion pressure limit at power up.

To change the setting:

Press and hold the PRI (upper hidden switch on Model 571) while using the

J K switches to adjust the value.

Press the RUN/HOLD switch to save the new value.

Display and/or set the audible tone that sounds when the SECONDARY infusion

finishes and switches to PRIMARY infusion.

1 CLICK = one-click tone

4 BEEPS = four-beeps tone

To change the setting:

Press the J unit switch to select 4 BEEPS or the K unit switch to select 1

CLICK

.

Display and/or set the language to be displayed. Languages are ENGLISH,

DUTCH, FRENCH, GERMAN, ITALIAN, SPANISH or SWEDISH.

To change this setting:

Press the J K unit switches to scroll through list and select language.

024

CIM ID

CIM ID

025 Alarm Tone

AIL Alarm Threshold

026

UL AIR

Setting is not in use. OFF = CIM not in use, 001 to 999 = CIM ID number

Important: Ensure the setting is OFF.

To change setting to OFF:

Press and hold the VOL TO BE INF switch while using the J K switches to

select OFF.

Press the RUN/HOLD switch to save the new setting.

Display and/or select the alarm tone volume level.

Approximate decibel volumes are:

HI TONE = 90 db

MED TONE = 80 db

LOW TONE = 70 db

To change the setting:

Press the J unit switch to select alarm tone.

WARNING: Take any necessary precautions against prolonged exposure to the

HI TONE alarm as this may result in hearing damage.

Display and/or set the air bubble length maximum value. This value is the

nominal air bubble threshold in microlitres used for air-in-line detection. Value

must be between 50 and 150 microlitres.

To change the setting:

Install the mode select jumper. See 'Mode Select Jumper'.

Press the CRIS (lower hidden switch on Model 571) and VOL TO BE INF

switches together and wait for a click.

Press the J K switches to enter the value (in 10 µl increments).

Display and/or set the pump infusion mode.

PRI ONLY = PRIMARY infusion mode only (Model 571).

SEC/CRIS = PRIMARY and SECONDARY infusions modes. (Model 572).

031

Infusion Mode

INFM CFG

To change the setting:

Install the mode select jumper. See 'Mode Select Jumper'.

Press the CRIS (hidden switch on Model 571) and VOL TO BE INF switches

together and wait for a click. Press the J unit switch to select PRI ONLY or

K unit switch to select SEC/CRIS.

the

Note: Model 571 must be set to PRI ONLY.

IVAC® Volumetric Pump (Models 571 & 572) 16/104 1000SM00018 Issue 2

Page 17

Configuration & Calibration

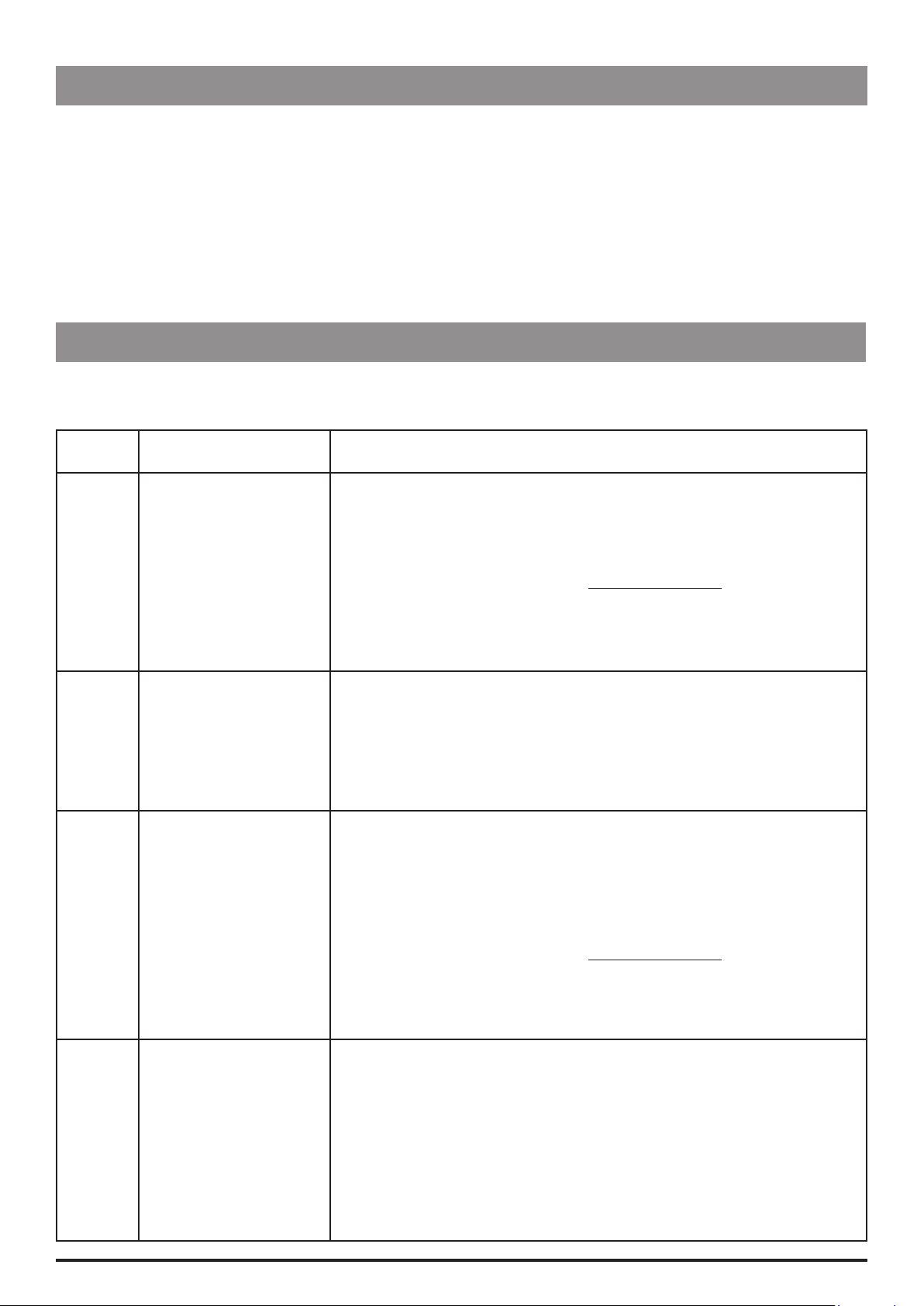

Selecting Pressure Units

The pressure units can be configured to be displayed as millimetres of mercury (mmHg) or

as centimeters of water (cmH20).

To select the pressure units:

Set the Pressure Unit Selector switch on the rear panel to the required position.

Pressure Unit

Selector Switch

Calibration Procedures

Vacuum System Calibration (Test 27)

Equipment required:

50ml syringe

Pressure gauge

"52" Series IV infusion set

Procedure:

1. Remove the battery cover from the pump to

allow access to the Accessory Interface Board.

See Chapter 6, 'Spare Parts Procedures' for

instructions.

2. Prepare a modified IV infusion set as follows:

Completely remove the clear membrane

cover from the white pressure sensing disc.

Ensure no membrane remains as this could

compromise the integrity of the vacuum

Attach the air-filled IV infusion set to the

syringe. Use the luer fitting on the distal end

of the set or cut approximately 1 inch (2.5

cm) off the distal end and press the tubing

firmly into the tip of the syringe. Ensure a

good seal is formed between the two devices

Splice a T-fitting into the IV infusion set

tubing approximately 1 foot (30 cm) up from

the syringe attachment. Connect the pressure

gauge to the T-fitting port

Push the syringe plunger in until it stops

3. Load the modified IV infusion set into the pump

and close the door. Ensure that the set tubing is

not kinked.

4. Enter self-test mode and select test 027. See 'Entering

Self-Test Mode' for instructions.

5. Press the RUN/HOLD switch to enter the Vacuum Display mode and display VAC MMHG.

6. Pull the syringe plunger out until the pressure gauge reads -95 mmHg and immediately clamp off tubing below the

pump to hold the vacuum stable.

7. Adjust the vacuum detect potentiometer R45 on the Accessory Interface Board until the numeric display on the

pump reads -95 ± 5 mmHg.

Note: R45 is the upper potentiometer on the Accessory Interface Board.

8. Perform the 'Vacuum Retention Verification' procedure as detailed in

Chapter 3, 'Routine Maintenance'.

Proximal

End of Set

Pressure

Gauge

Syringe

Do not adjust the lower

potentiometer, R4, this

is pre-adjusted during

manufacture.

IVAC® Volumetric Pump (Models 571 & 572) 17/104 1000SM00018 Issue 2

Page 18

Configuration & Calibration

6

Calibration Procedures (continued)

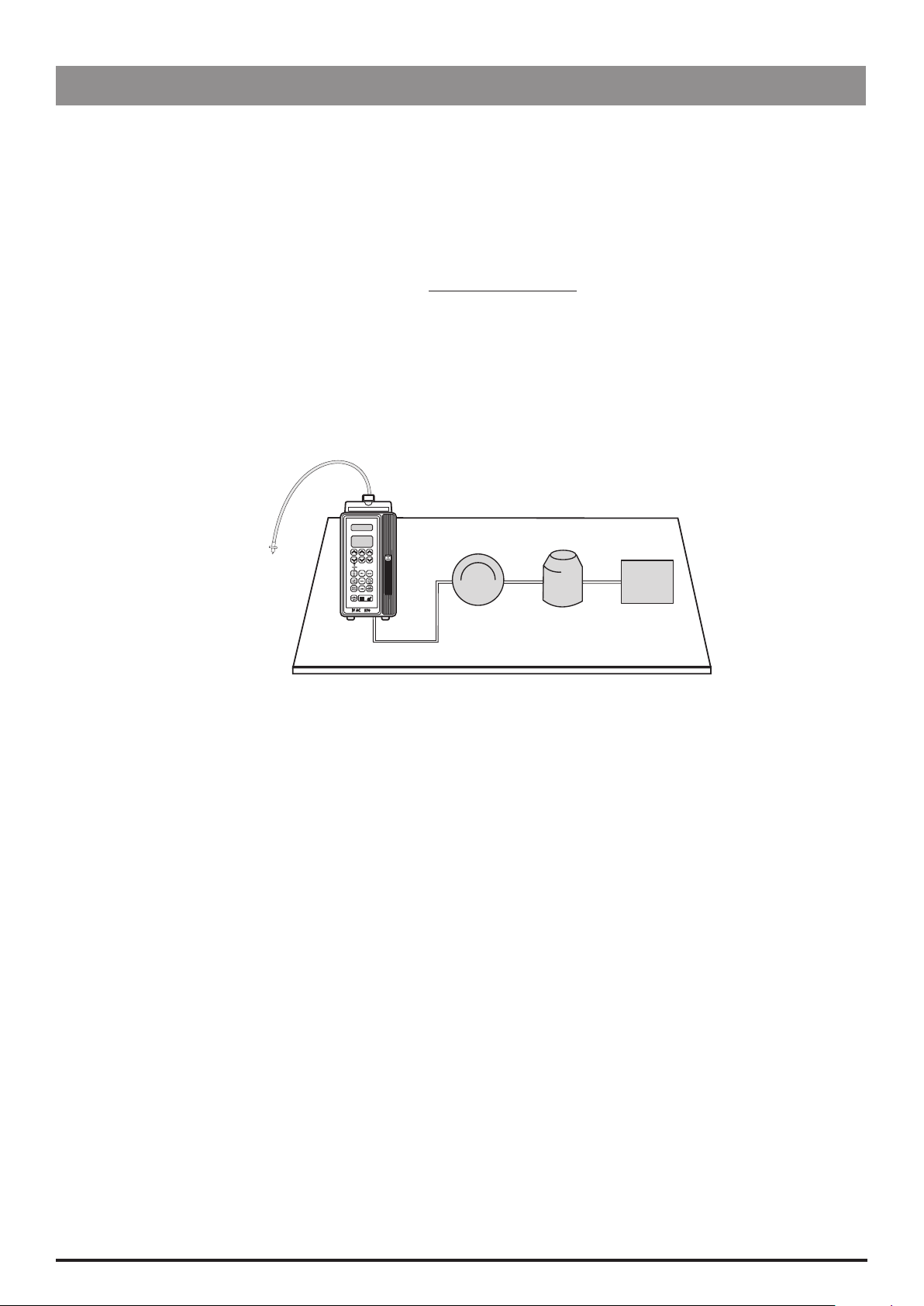

Dry Set Pressure Calibration (Test 13)

Equipment required:

Test jumper cable (142109)

Pressure gauge

"52" Series IV infusion set (dry set)

Procedure:

1. Remove the chassis from the body. See Chapter 6, 'Spare Parts Procedures' for instructions.

2. Attach the jumper of the test jumper cable between connector J7 on the Logic Board and connector P7 on the

Accessory Interface Board.

3. Connect the battery pack to the battery connector.

4. Set up equipment as shown below.

Note: Set the pressure unit selector switch (on the back panel of the pump) to the same units as the air pressure

source.

Proximal

End of Set

Pressure

Gauge

Reservoir

Air

Pressure Source

5. Enter self-test mode, press the RUN/HOLD switch and select test 12. Press the RUN/HOLD switch again to display the

pressure MMHG (or CMH20).

Ensure the pump is connected to the AC power supply for approximately 30 minutes before continuing with this

calibration.

6. Enter self-test mode, press the RUN/HOLD switch and select test 13. Press the RUN/HOLD switch again to display

PRES CAL.

7. With the door open and no set loaded, adjust the zero potentiometer (R20 on the Analog Board) so the pump reads

000 ±1 mmHg (or 000 ±1.4 cmH20).

8. Install an IV infusion set, close the door and apply a test pressure of 000 mmHg (000 cmH2O) to the distal end of the

set. Record the reading displayed as the PI offset value.

9. Apply a test pressure until the meter reads 400 mmHg (544 cmH2O) and adjust the span potentiometer (R23 on the

Analog Board) so the pump reads 400 mmHg ±2 (544 cmH20 ±10 ) plus the offset value, PI, recorded in the previous

Step.

10. Return the test pressure to 000 mmHg (000 cmH2O), bleed off any air from the IV infusion set then remove the IV

infusion set.

Note: If the set is removed when still under pressure may result in damage to the pressure sensing disc film.

11. Leave the door open and reverify that the pump reads 000 ±1 mmHg (000 ±1.4 cmH2O). If not, repeat the procedure

from Step 7, until no further adjustment of the zero and span potentiometers is required.

IVAC® Volumetric Pump (Models 571 & 572) 18/104 1000SM00018 Issue 2

Page 19

Configuration & Calibration

Calibration Procedures (continued)

Dry Set Pressure Calibration (Test 13) continued

12. Press the J unit and RATE switches simultaneously for a minimum of one second to set the 000 mmHg (000 cmH2O)

calibration point.

13. Reload the IV infusion set and apply test pressure until the meter reads 400 mmHg (544 cmH2O). When the pressure

reading is stable, press the TOT VOL INF and the

the 400 mmHg (544 cmH2O) calibration point.

Both Steps 12 and 13 must be performed to correctly set the calibration parameters. Performing

only one step will result in the message RECONFIG REQD when the pump returns to operation.

14. Press the RUN/HOLD switch to return to test 13 and turn the pump OFF. Remove the IV infusion set (first bleeding off

any pressure).

15. Disconnect the battery pack from the battery connector.

16. Remove the test jumper cable and reassemble the pump.

17. Perform the 'Dry Set Pressure Verification' procedure as detailed in Chapter 3, 'Routine Maintenance'.

J 100 switches simultaneously for a minimum of one second to set

IVAC® Volumetric Pump (Models 571 & 572) 19/104 1000SM00018 Issue 2

Page 20

Configuration & Calibration

Calibration Procedures (continued)

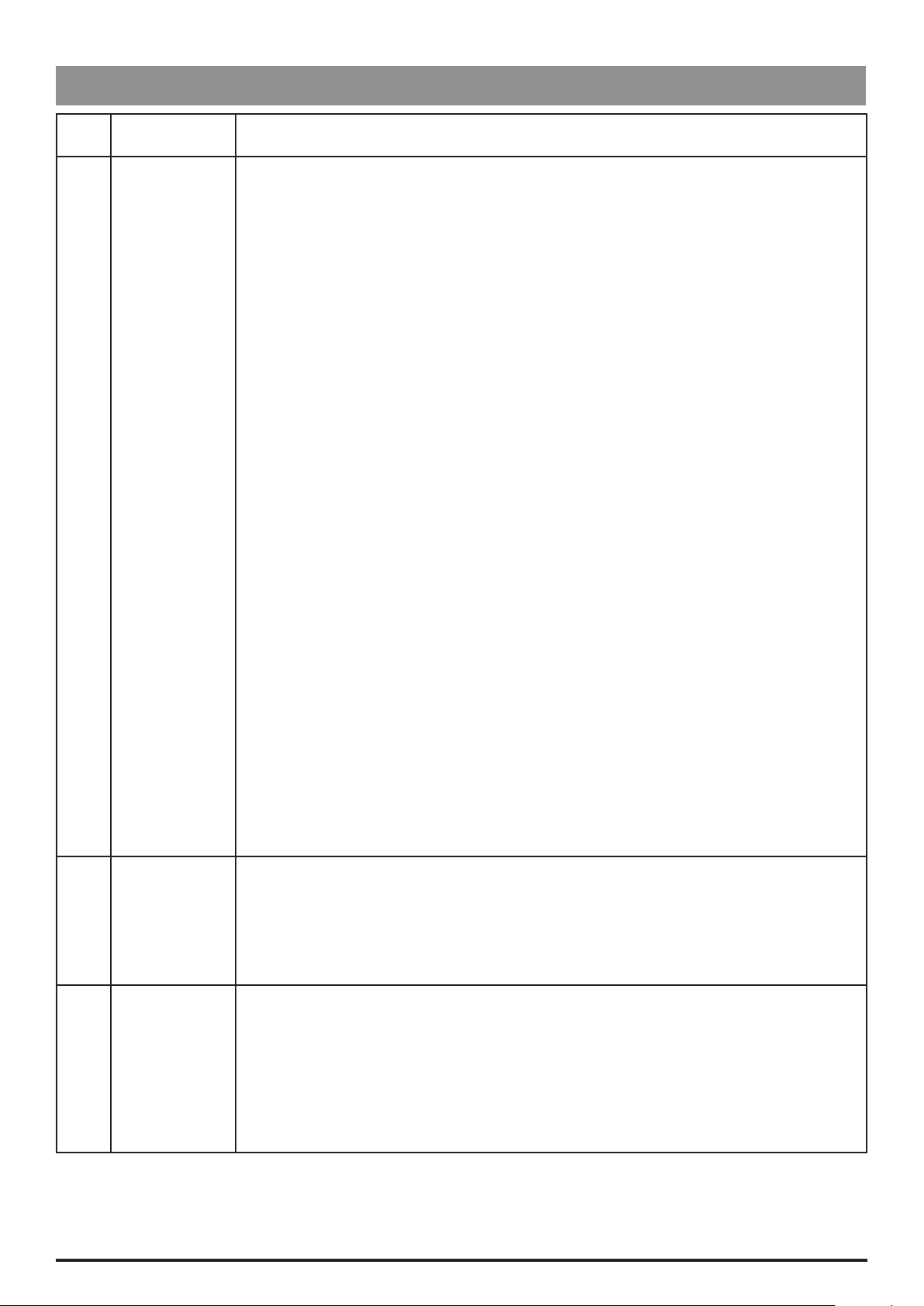

Rate Accuracy Calibration (Test 8)

There are two types of rate accuracy associated with the pump, these are System Rate Accuracy and Pump Rate Accuracy.

System Rate Accuracy is the rate accuracy of the pump when used with a standard "52" Series infusion set. Due to slight

variations in between sets, the system accuracy of the pump is ± 5%. Pump Rate Accuracy is the absolute rate accuracy of

an individual pump which can only be determined with the use of a characterised set.

The following procedure describes how to calibrate the Pump Rate Accuracy. For instructions on how to verify Pump Rate

Accuracy, see 'Rate Accuracy Verification' in Chapter 3, 'Routine Maintenance'.

Characterised Sets (part number 191806)

Must be used for rate accuracy calibration

Sets are labeled with a serial number, a nominal volume and an expiry date (180 days from the date

the set was characterised)

Handle sets with care at all times. Sets must not be pressurised. Prior to loading or removing from

the pump, manually open the auto-pinch-off mechanism. Do not stretch the set excessively

Record the number of times each set is used in a log book. A set must not be used for more than 20

rate runs.

Equipment required:

Characterized set (191806)

Stopwatch

Class A burette (50 ml) with 0.1 ml

graduations

Preparation:

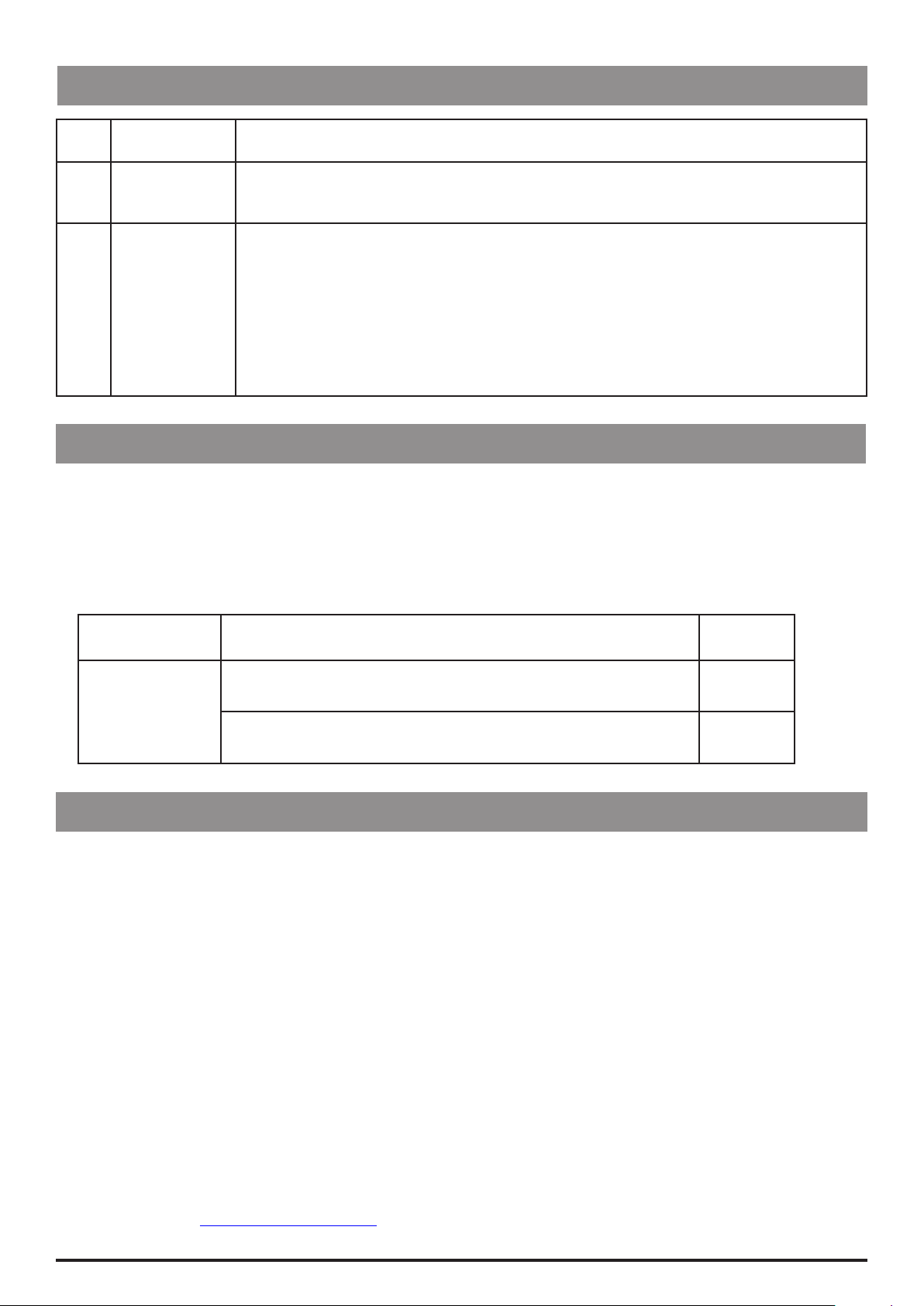

1. Set up the equipment as shown.

The vertical distance from the

fluid level of the container to

the pump pressure transducer

should be 34 ±4 inches

The burette zero line should

be within ± 2 inches from the

pump pressure transducer.

Verify that the inside of the

wall is free of droplets

Ensure fittings are secure and

there is no leakage through

the 3-way stopcock

Ensure that the air has been

purged from the characterised

set and all equipment

2. Close the set roller clamp.

3. Plug the pump into the AC mains

and turn the pump ON.

Table

or Bench

Equipment Stand

Set Tubing

Burette

Burette Clamp

Tubing

Used Fluid

Recptacle

Water Source

34 ± 4 inches (86 ± 10 cm)

Pressure Transducer

(level with)

Three-way

Stopcock

IVAC® Volumetric Pump (Models 571 & 572) 20/104 1000SM00018 Issue 2

Page 21

Configuration & Calibration

Calibration Procedures (continued)

Procedure:

1. Enter self-test mode, press the RUN/HOLD switch and select test 8. Press the RUN/HOLD switch again to display CAL

RATE.

2. Press and hold the PRI switch then use the JK switches to enter an initial rate calibration of 37. Press the ON/OFF

switch to turn the pump off.

Note: Ensure a characterised set is loaded and the burette is free of droplets.

3. Turn the pump ON and set the pump to Primary rate = 800 ml/h, VTBI = OFF, TOT VOL INF = 000.0 (or, if not using a

flow sensor, set the pump to Primary rate = 800 ml/h, VTBI = 100 ml, TOT VOL INF = 000.0).

4. Press the RUN/HOLD switch to start the pump and simultaneously start the stopwatch. Allow the pump to run for 3

minutes (180 seconds) then press the RUN/HOLD switch to put the pump on hold.

5. Verify that the volume in the burette is 40.0 ± 0.4 ml. If not, repeat the test.

If the percentage of error is greater than ± 1%, use the following formula to determine the new CAL RATE number:

Formula to determine new CAL RATE number

Final CAL RATE number =

(actual volume) -1 ) x 200

[

Example:

Final CAL RATE number =

[

Set the CAL RATE number to 41 in Test 8 while pressing the PRI switch.

6. Repeat the above calibration procedure until the actual volume is within ±1% of the expected volume indicated on

the characterised IV infusion set.

expected volume

actual burette volume = 40.8 ml

expected volume = 40.0 ml

initial CAL RATE number = 37

(40.8) -1 ) x 200

40.0

+ 37 = 41

]

+ initial number

]

IVAC® Volumetric Pump (Models 571 & 572) 21/104 1000SM00018 Issue 2

Page 22

Routine Maintenance

In this chapter

Routine Maintenance 23

Self-Test Functions 23

Chapter 3

Upgrading Software 26

Vacuum Retention Verification (Test 27) 26

Dry Set Pressure Verification (Test 12) 27

Functionality Checks 28

Auto-Pinch-Off (APO) Test 29

Mechanism Leak Test 30

Rate Accuracy Verification 32

Downstream Pressure Occlusion Test 33

Physical Inspection and Clean 34

Inspecting the Mechanism 35

Flow Sensor Check (where flow sensor is in use) 35

Performance Verification Procedure 36

Page 23

Routine Maintenance

Routine Maintenance

For routine maintenance, the following tests and procedures should be performed in addition to the tasks described in

the section 'Physical Inspection and Clean'.

Refer to the relevant DFU for the recommended routine maintenance period.

Self-Test Functions

The self-test functions are a series of test routines which are designed to test and verify many of the pump functions and

defaults without requiring internal inspection. These tests are accessed by entering Self-Test mode and selecting a Test ID

number as shown in the table below.

1. Enter Self-Test mode. See 'Entering Self-Test Mode' in Chapter 2 for instructions.

2. Proceed through the series of tests, referring to the table below for details of each test.

Note: For details of other tests such as the configurable options and calibration settings, see Chapter 2, 'Configuration

& Calibration'.

Test

ID

001

002

003 Display Flash Test

Test Action/Description

Software

Revision

Configuration

Status

Displays the current software revision level, e.g. REV 3.01.

Verifies whether or not the configuration data is valid.

CONFIG/VALID = configuration data is valid

OR,, where not valid, a message indicates which configuration is required to be set:

SET RATE CAL = see Test ID 008

SET RATE CONFIG = see Test ID 009

SET RATE MAX = see Test ID 010

SET VTBI CONFIG = see Test ID 011

SET PRES CAL = see Test ID 013

SET PRES MAX = see Test ID 014

SET PRES DEFAULT = see Test ID 015

SET AIR LIMIT = see Test ID 026

SET INF MODE CONFIG = see Test ID 031

Verify that the segments of both Displays light and the battery indicator flashes as follows:

Information Display: all positions show ******** alternating with 00000000.

Numeric Display: all positions show 8888 alternating with 0000. The two decimal points also

flash.

Battery indicator: flashes alternately on and off.

Verify that both Displays show various characters and the battery indicator flashes as follows:

Information Display: repeatedly cycles through the 64-character set (A to Z, 0 to 9 and ASCII

Display Segment

004

Test

Display

005

Sequence Test

EEPROM Test and

006

Display Data

IVAC® Volumetric Pump (Models 571 & 572) 23/104 1000SM00018 Issue 2

characters). All positions must show the same character at the same time.

Numeric Display: repeatedly cycles through numbers 0 to 9. All positions must show the same

character at the same time.

Battery indicator: flashes alternately on and off.

Verify that both Displays show numbers, one position at a time (and the battery indicator

flashes) as follows:

Information Display: numbers 0 to 7 appear sequentially, left to right.

Numeric Display: numbers 0 to 3 appear sequentially, left to right.

Battery indicator: flashes alternately on and off.

Verify that both Displays cycle through numeric sequences (and the battery indicator flashes)

as follows:

Information Display: ignore this 128-byte location reading.

Numeric Display: counts from 001 through 128.

Page 24

Routine Maintenance

Self-Test Functions (continued)

Test

ID

007

Test Action/Description

Verify the eight A/D channels (0 through 7) as follows, using the

each channel.

Note: The Information Display shows the Channel number being tested (0 through 7) and the

Numeric Display shows a value representing the analog input to the A/D convertor.

Channel 0 = Flow Sensor Test

Information Display: All positions show 0's, 00000000.

Numeric Display: Value must be greater than 195 (no obstruction in the light path), or less

than 185 (light path is obstructed).

Channel 1 = Drop Reference

Information Display: All positions show 1's, 11111111.

Numeric Display: Value must read 210 ± 8.

Channel 2 = Battery Monitor

Unplug the pump from AC power.

Information Display: All positions show 2's, 22222222.

Numeric Display: New battery reading must be greater than or equal to 140. A reading of less

A/D Converter

than 140 indicates a discharged or bad battery.

Test

Plug the pump into AC power.

J and K switches to select

012 Read Pressure

Read Alarm

016

History

Channel 3 = Pressure

Information Display: All positions show 3's, 33333333.

Numeric Display: value between 0 and 500.

Channel 4 = Flow Sensor Detect

Information Display: All positions show 4's, 44444444.

Numeric Display: Value less than 20 (flow sensor not plugged in) or more than 80 (flow sensor

plugged in).

Channel 5 = Vacuum Detect Signal

Information Display: All positions show 5's, 55555555.

Numeric Display: Value between 110 and 277 (with set installed).

Channel 6 = Not used. Ignore reading.

Channel 7 = Not used. Ignore reading.

Verify the pressure level reading sensed by pressure transducer. Note: To ensure a valid

reading, the pump should be powered on for at least 30 minutes prior to this test.

Information Display: CMH20 or MMHG (per pressure unit selection switch position on back

panel).

Numeric Display: Without set installed, shows value between -28 and +14 cmH20 or between

-20 and +10 mmHg.

Read the last 16 alarm or error messages (alarm stack).

The most recent alarm or error is always displayed first.

Information Display: All positions show *'s, ******** are displayed initially, followed by

repeated cycle of the last 16 alarm messages.

Numeric Display: Blank

To clear the alarm stack:

Press and hold the READ PRES switch and the J 100 switch for at least 2 seconds, until

the display shows ********.

IVAC® Volumetric Pump (Models 571 & 572) 24/104 1000SM00018 Issue 2

Page 25

Routine Maintenance

Self-Test Functions (continued)

Test

ID

Test Action/Description

017 Switch Test

Read Hours on

018

AC

Read Hours on

019

Battery

Information Display: Initially shows SWCH TEST. Press each switch and verify the

corresponding code is displayed:

Switch: Display code: Switch: Display code:

TOT VOL INF

PRI

RATE

LIMIT PRES

SEC

VTBI

READ PRES

TL V INF

PRI

RATE

LIMT PRS

SEC

VTBI

READ PRES

CRIS

J 100

K 100

J 10

K 10

J Unit

K Unit

CRIS

UP 100

DN 100

UP 10

DN 10

UP 1

DN 1

Notes:

1) The ON/OFF switch does not have a code.

2) The Numeric Display remains blank.

Read/clear the total number of hours that the pump has run on AC power.

Information Display: AC HRS

Numeric Display: Number of hours on AC power.

To reset the total AC power hours to 0000:

Press and hold the READ PRES switch and the J 10 switch for at least 2 seconds.

Read/clear the total number of hours that the pump has run on battery power.

Information Display: BATT HRS

Numeric Display: Number of hours on battery power.

To reset the total AC battery hours to 0000:

Press and hold the READ PRES switch and the J unit switch for at least 2 seconds.

021 Air-In-Line Test

022 I/O Port Test

System Vacuum

027

Test

Verify air-in-line sensor operation. To run test:

Load an air-filled or fluid-filled IV infusion set.

Information Display: 00000000 = fluid detected in IV infusion set and door is closed.

10000000 = air detected in IV infusion set or door is open.

Numeric Display: UAIL

Read data on the various input ports. Press the

J and K switches to select each port.

Information Display: Shows the 8 input port data bits in binary format.

Numeric Display: Indicates which port is being examined:

000 = display port, Display U7. 008 = switch port, Display U5. 016 = Logic U20. 048 = A/D end

of conversion, U22. 064 = Logic U21. 080 and 081 = parallel I/F ports. 096, 097, 098 and 099

= serial I/F ports. 128 = timer of Logic U14. 129 = Logic U23. 130 = Logic U24.

Key troubleshooting tests:

Port 016

bit 0 = rotation sensor 1

bit 1 = rotation sensor 2

bit 2 = set sensor

bit 3 = air-in-line sensor

Port 064

bit 7 = door sensor

Read the vacuum level being applied by the vacuum system when an IV infusion set is loaded

and the door is closed.

Information Display: VAC MMHG

Numeric Display: Current vacuum value that is generated to hold the pressure sensing disc in

place.

To run the test, following the instructions in 'Vacuum Retention Verification' later in this

chapter.

IVAC® Volumetric Pump (Models 571 & 572) 25/104 1000SM00018 Issue 2

Page 26

Routine Maintenance

Self-Test Functions (continued)

Test

ID

028

029 Burn-in Test

Test Action/Description

Enter

Operational

Setup Mode

The pump exits self-test mode and starts operational set up mode.

Allows pump to run (burn-in) without setting up an IV solution bag, fluid and drain.

Warning:

This test must only be run in a workshop environment for verification that internal failures have

been corrected. Full performance verification testing must then be carried out.

To run test: Load an air-filled IV infusion set and close the door. Enter self-test mode, select

test 029, press the RUN/HOLD switch then, within two seconds, press and hold the PRI and

CRIS switches together. Pump will start running at maximum rate and rate can be changed by

pressing the RATE switch and using the

J and K switches.

Upgrading Software

The latest version of software available for Model 571/572 is V3.01. Perform upgrades by acquiring the software upgrade

kits specified in the spare parts listing.

Equipment required:

Software upgrade kit

Software Upgrade Kits Available

Pump Model Part Number

145071

571/572

145070

KIT,UPGRD,REV 3.01,570

(EPROM only)

SERV ASSY,MEM,REV3.01,570(BOM)

(includes EPROM fitting and removal instructions)

Software

Version

3.01

3.01

Vacuum Retention Verification (Test 27)

The pump's vacuum system can be tested and verified by performing the following Vacuum Leak Test.

Procedure:

1. Enter self-test mode and select test 27. Press the RUN/HOLD switch to enter the Vacuum Display mode and display

VAC MMHG.

2. Load an IV infusion set and close the door.

3. Verify that the numeric display shows a reading of -250 or more negative.

4. Allow the reading to stabilise for 5 to 10 seconds, then record the value, for example, -337.

5. After 30 seconds, verify that the vacuum value has not decreased by more than 5, for example -332.

If the pump fails this test:

Check the following things, replacing and repeating the test as necessary:

Face of the pressure transducer

Replace the test IV infusion set

Y-clip, door latch pin, door latch

Pressure transducer/vacuum assembly

Perform the 'Vacuum System Calibration' procedure, see Chapter 2. for instructions.

IVAC® Volumetric Pump (Models 571 & 572) 26/104 1000SM00018 Issue 2

Page 27

Routine Maintenance

#

Dry Set Pressure Verification (Test 12)

When servicing the pump perform the following pressure calibration verification procedure.

Note: If the pump fails this test, perform the 'Dry Set Pressure Calibration' procedure. See Chapter 2. for instructions.

Procedure:

1. Connect the pump to the AC mains and set up the equipment as shown below..

Note: Set the pressure unit selector switch (on the back panel of the pump) to mmHg.

2. Enter self-test mode, press the RUN/HOLD switch and select test 12. Press the RUN/HOLD switch again to display the

pressure MMHG.

Allow the pump to warm up for approximately 30 minutes before continuing with this test.

Proximal

End of Set

Pressure

Gauge

Reservoir

Air

Pressure Source

3. Load an IV infusion set and close the door.

4. Apply a pressure of 000 mmHg and verify that the pump displays a reading of -20 to +10 mmHg.

When applying the 000 mmHg pressure, ensure the set has just been loaded. If necessary reload

the IV infusion set.

5. Apply a pressure of 400 mmHg and verify that the pumps displays a reading of 367 to 423 mmHg.

Do not allow the applied test pressure to exceed the intended pressure value by more than 50

mmHg. If this occurs, reload the IV infusion set and repeat test

The pressure read accuracy must be ±15 mmHg or ± 7%, whichever is greater

IVAC® Volumetric Pump (Models 571 & 572) 27/104 1000SM00018 Issue 2

Page 28

Functionality Checks

Alarms

Alarm Action

Routine Maintenance

LOAD SET

DOOR

AIL

FLOW SENSOR

BOTTLE CLAMP

(with Flow Sensor)

UPSTREAM

OCCLUSION

(without Flow Sensor)

Without an IV infusion set loaded, turn the pump ON, set rate to 125 ml/h then press the RUN/HOLD switch.

Verify that the LOAD SET message is displayed.

With the pump running, open the door. Verify that the pump stops, alarms and the message DOOR is

displayed. Verify that the automatic pinch-off clamp has stopped the flow by checking that no drops are

falling in the drip chamber.

Load a fluid-filled IV infusion set. Turn the pump ON, set rate to 125 ml/h then press the RUN/HOLD switch

to start infusing. Tilt the drip chamber of the set to induce air bubbles into the IV infusion set. Verify that

when the air bubble enters the pump, the pump alarms, stops and displays the message AIR IN LINE. Turn

the pump OFF and remove the test loop.

Load an empty, air-filled IV infusion set. Turn the pump ON then press the RUN/HOLD switch to start the

pump. The pump should not run; verify that the AIR IN LINE message is displayed. If the pump does run,

refer to Chapter 4, 'Troubleshooting'.

Block the light in the flow sensor (with a finger or other suitable object) to simulate a faulty flow sensor.

Press the RUN/HOLD switch to resume infusing. After a short time, verify that the pump stops, alarms and

the display message alternates between FLOW and SENSOR.

Press the RUN/HOLD switch to place the pump on hold. Hold the VOL TO BE INF switch and press the K

unit switch until OFF is displayed. Press the RUN/HOLD switch to start the infusion. After approximately one

minute, close the roller clamp. Verify that the pump stops running, the alarm tone sounds and the display

message alternates between BOTTLE and CLAMP.

Press the RUN/HOLD switch to place the pump on hold. Set VTBI to 60 ml by first pressing the VOL TO BE

INF switch then the

infusing. After approximately one minute, close the roller clamp to create an upstream occlusion.

Verify that the pump stops running, alarms and displays UPSTREAM OCCLUSION.

J K switches. Set rate to 900 ml/h then press the RUN/HOLD switch to start

TIME OUT

PRESSURE LIMIT

EXCEEDED

(DOWNSTREAM

PRESSURE

EXCEEDED)

Press the RUN/HOLD switch to place the pump on hold. Verify that the pump takes 2 minutes ±10 seconds

to alarm after the last switch has been pressed. TIME OUT is displayed, and the rate is still shown.

See 'Downstream Pressure Occlusion Test' procedure later in this chapter for instructions.

Battery Power Check and Operation Test

Before performing this test, it is recommended that the battery is charged to full capacity by

connecting the pump to AC mains for a minimum of 16 hours.

1. Remove power cord from the AC power socket.

2. Press the ON/OFF switch to turn the pump on. Verify that the battery indicator flashes on and off.

3. Set rate to 499 ml/h then press the RUN/HOLD switch to start the pump. Verify that the pumping indicator bar

appears on the Information Display and that it rotates rapidly.

4. (Optional) Verify that the pump continues to run for a minimum of 15 minutes without alarming LOW BATT.

5. Plug the power cord back in to AC power socket.

Flow Sensor Check

See 'Physical Inspection and Clean' for instructions.

IVAC® Volumetric Pump (Models 571 & 572) 28/104 1000SM00018 Issue 2

Page 29

Routine Maintenance

Auto-Pinch-Off (APO) Test

Procedure:

1. Set up equipment as shown below.

2. Prepare a modified set as follows:

Take an IV infusion set and cut the tubing a couple of inches below the drip chamber, discarding the drip chamber.

Connect the air pressure source to the freshly cut proximal end of tubing.

Insert the distal end of the modified set into a container of water.

3. Close the roller clamp. Adjust the air pressure to 10 psi.

4. Load the modified IV infusion set. Close the door then open the roller clamp.

5. Open the door and verify that (after an initial spurt of bubbles) no further bubbles are seen coming from the distal

end of the tubing into the water bottle.

If bubbles continue, replace the auto-pinch mechanism. Refer to Chapter 6, 'Spare Parts Replacement Procedures' for

instructions.

Water Bottle

Roller Clamp

Pressure

Gauge

Reservoir

Air

Pressure Source

IVAC® Volumetric Pump (Models 571 & 572) 29/104 1000SM00018 Issue 2

Page 30

Routine Maintenance

Mechanism Leak Test

When servicing the pump, the Mechanism Leak Test must be performed to verify the integrity of

the pumping mechanism.

Misalignment of the pumping mechanism can result in the pressure plate and the mechanism's cam

followers failing to pinch the IV infusion set tubing sufficiently, thereby allowing the pump to leak

fluid at low rates or when stopped.

Procedure:

1. Prepare a special Pressure Test Set as follows:

Take an IV infusion set and cut the tubing a couple of inches

below the drip chamber, discarding the drip chamber.

With a knife, carefully remove the membrane cover from the

white pressure sensing disc, see Figure 3-2. Ensure no membrane

(rough edges) remain—the surface of the pressure sensing disc

should be as flat as possible after the membrane is removed.

Cut out a piece of mylar to match the shape and size shown

below.

Cut away

membrane cover

Firmly press

mylar cap

over slot

Mylar Cap

Shape

Remove the adhesive backing and firmly press the mylar onto the

surface of the pressure sensing disc so that it covers the vertical

slot and is centered on the disc. See Figure 3-3

The distal end (bottom) end of the set may be cut to adapt it for

connecting to the air pressure source.

Figure 3-2

Figure 3-3

2. Load the special pressure test set, with 15.0 psi (775 mmHg) air pressure at the distal end, into the pump and close the

door.

Change the special Pressure Test Set after 20 uses, or if signs of wear are visible on the silicone

section or if any leak in the set is observed.

3. Run the top end of the pressure test set into the water bottle and below the water level (as shown below).

4. Open the pressure test roller clamp to pressurise the set.

Pressure

Water Bottle

Roller Clamp

IVAC® Volumetric Pump (Models 571 & 572) 30/104 1000SM00018 Issue 2

Gauge

Reservoir

Air

Pressure Source

Page 31

Routine Maintenance

Mechanism Leak Test continued

5. Verify that the pressure (that the transducer is seeing) is not greater than 300 mmHg when set is fully pressurised. To

do this read the pressure using test 12 (Enter self-test mode, press the RUN/HOLD switch and select test 12).

Warning: A pressure reading greater than 499 mmHg may result in damage to the transducer.

If a high pressure reading is noted, check the following:

The pressure sensing disc is positioned correctly.

The mylar cap is adhered tightly and correctly on the pressure sensing disc.

The height of the mylar cap matches the Myler Cap Shape shown above.

6. Connect the pump to the AC mains then turn the pump ON, entering self-test mode.

7. Press the RUN/HOLD switch and select the burn-in test 29, then within two seconds, simultaneously press and hold

the PRI switch and the CRIS switch.

Verify that the pump is running at 999 (or 999.9 ml/h).

8. Set the rate to 20 ml/h (or 20.0 ml/h) by simultaneously pressing the R AT E switch and the J K switches. Run the

pump for at least one minute. Verify that no bubbles are visible in the water bottle.

If air bubbles are visible in the water bottle, the pump fails the test.

If the pump fails the test, verify set up and repeat the test as required, otherwise, return the pump to the

manufacturer.

9. Turn the pump OFF.

10. Close the roller clamp slowly. Open the door to release any pressure trapped in the pressure test set and carefully

remove the set from the pump.

Note: Take care not to stretch the silicone segment of the set as correct segment length is critical to the mechanism's

pinch-off capabilities.

IVAC® Volumetric Pump (Models 571 & 572) 31/104 1000SM00018 Issue 2

Page 32

Routine Maintenance

Rate Accuracy Verification

There are two types of rate accuracy associated with the pump, these are System Rate Accuracy and Pump Rate Accuracy.

System Rate Accuracy is the rate accuracy of the pump when used with a standard "52" Series infusion set. Due to slight

variations in between sets, the system accuracy of the pump is ± 5%. Pump Rate Accuracy is the absolute rate accuracy of

an individual pump which can only be determined with the use of a characterised set.

The following procedure describes how to verify the Pump Rate Accuracy. For instructions on how to calibrate the Pump

Rate Accuracy, see 'Rate Accuracy Calibration' procedure in Chapter 2.

Equipment required:

Characterized set (191806)

Stopwatch

Class A burette (50 ml) with 0.1 ml graduations

Characterised Sets (part number 191806)

Must be used for rate accuracy calibration

Sets are labeled with a serial number, a nominal volume and an expiry date (180 days from the date

the set was characterised)

Handle sets with care at all times. Sets must not be pressurised. Prior to loading or removing from

the pump, manually open the auto-pinch-off mechanism. Do not stretch the set excessively

Record the number of times each set is used in a log book. A set must not be used for more than 20

rate runs.

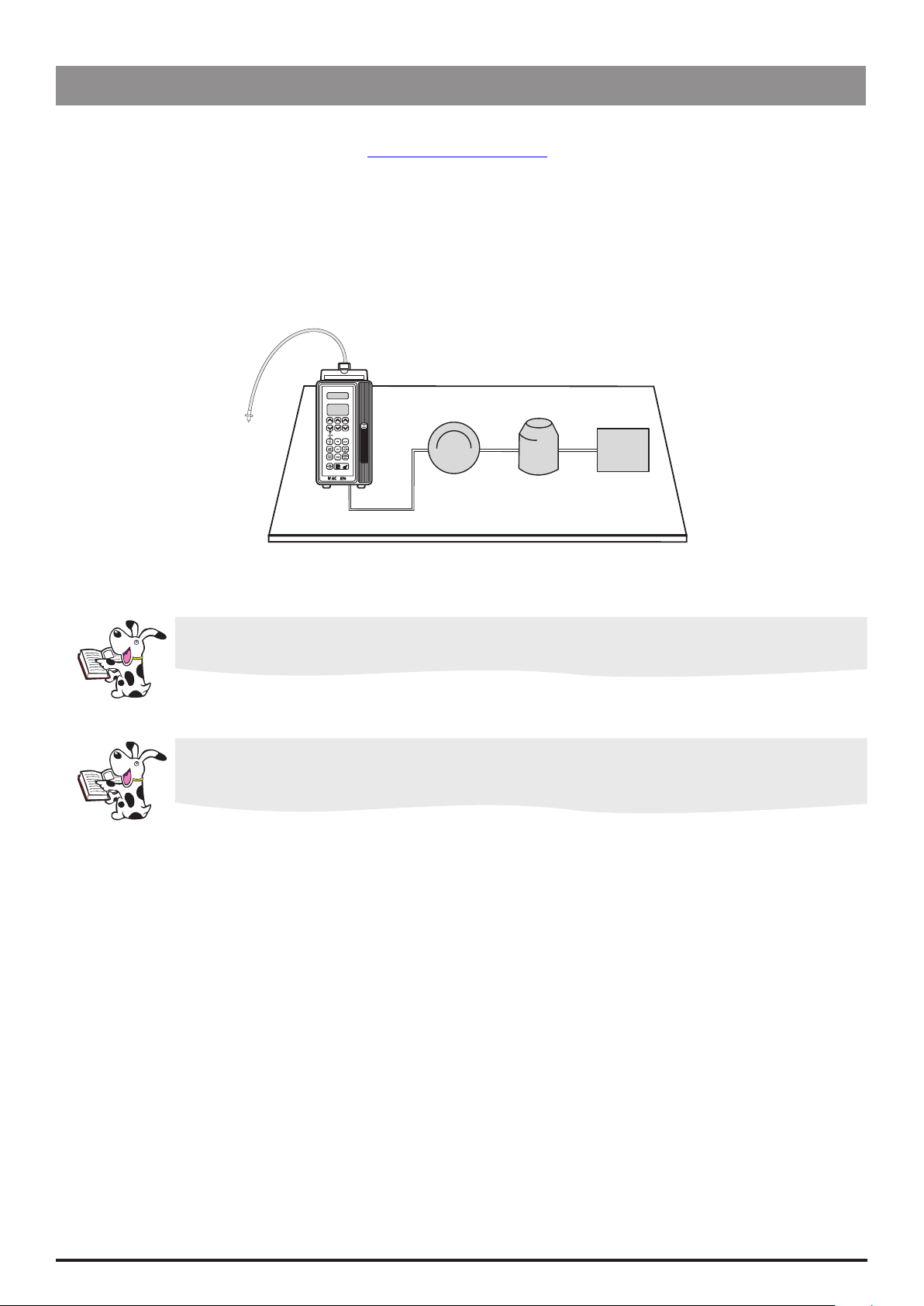

Preparation:

1. Set up the equipment as shown.

The vertical distance from the

fluid level of the container to

the pump pressure transducer

should be 34 ±4 inches

The burette zero line should

be within ± 2 inches from the

pump pressure transducer.

Verify that the inside of the

wall is free of droplets

Ensure fittings are secure and

there is no leakage through

the 3-way stopcock

Ensure that the air has been

purged from the characterised

set and all equipment

2. Close the set roller clamp.

3. Plug the pump into the AC mains

and turn the pump ON.

Table

or Bench

Equipment Stand

Set Tubing

Burette

Burette Clamp

Tubing

Used Fluid

Recptacle

Water Source

34 ± 4 inches (86 ± 10 cm)

Pressure Transducer

(level with)

Three-way

Stopcock

IVAC® Volumetric Pump (Models 571 & 572) 32/104 1000SM00018 Issue 2

Page 33

Routine Maintenance

Rate Accuracy Verification (continued)

Procedure:

1. Set the pump to Primary rate = 800 ml/h, VTBI = OFF, TOT VOL INF = 000.0 (or, if not using a flow sensor, set the pump

to Primary rate = 800 ml/h, VTBI = 100 ml, TOT VOL INF = 000.0).

2. With the pump displaying START PRIMARY or ON HOLD PRIMARY, press the RUN/HOLD switch to start the pump

and simultaneously start the stopwatch. Allow the pump to run for 180 seconds (3 minutes) ± 0.5 seconds then press

the RUN/HOLD switch to put the pump on hold.

3. Measure the volume in the burette and calculate the percentage of volume error using following formula:

Formula to calculate the percentage of volume error

% volume error =

x 100

n

Where:

b = volume in burette

n = nominal volume as indicated on the

characterised set

4. If the % volume error is ± 2% or less, the pump is within the correct specification. If not, repeat the test.

If the pump fails a second time, perform the 'Rate Accuracy Calibration' procedure. See Chapter 2 for instructions.

Downstream Pressure Occlusion Test

Procedure:

1. Connect an IV infusion set to a fluid container. Prime the set to ensure that air is completely

expelled.

2. Verify and, if necessary, adjust the DEFAULT pressure setting (test 015) and the MAXIMUM

(test 014) occlusion pressure setting to 500 mmHg.

3. Connect a fluid pressure gauge to the luer end of the set.

4. Turn the pump ON and set the pump to VTBI = 100 ml, Primary rate = 499 ml/h.

5. Connect the pump to the pressure gauge by closing the three-way stopcock. Start the pump

and allow it to run until it alarms DOWNSTREAM PRESSURE EXCEEDED.

6. Verify that the pressure gauge reads between 11.0 and 14.0 psi.

7. Open the stopcock to relieve the pressure.

If the pump fails to alarm as stated, perform the 'Dry Set Pressure Calibration' procedure.

See Chapter 2 for instructions.

b - n

Reservoir

Three-way

Fluid

Pressure

Gauge

IVAC® Volumetric Pump (Models 571 & 572) 33/104 1000SM00018 Issue 2

Stockcock

(or a Clamp)

Page 34

Routine Maintenance

Physical Inspection and Clean

To ensure the pump remains in good operating condition, it is important to keep it clean and carry out the routine

procedures described below.

Routinely clean the pump, especially if spillage has occurred.

Before cleaning always switch OFF and disconnect from the AC power supply. Never allow fluid to

enter the casing and avoid excess fluid build up on the pump.

Keep pump upright to prevent fluid entry around the pressure transducer.

Do not use aggressive cleaning agents as these may damage the exterior surface of the pump.

Do not steam autoclave, ethylene oxide sterilise or immerse this pump in any fluid.

Unplug the power cord from the AC wall outlet before cleaning. Do not allow fluids to enter the pump case.

Clean the exterior surfaces (the outer case top, bottom, sides; the switch panel, the front panel and inside the door)

with a cloth dampened with warm water, or a mild non-abrasive detergent (such as commercially available dish

cleaning liquid) mixed with water.

Note: Alcohol, ammonia, acetone, benzene, phosphoric acid, xylene and similar solvents can erode (wear away pit)

or otherwise damage the cam followers and other surfaces of the pump. The cam followers must be kept clean using

a solution of warm water and a mild non-abrasive detergent, and inspected for possible erosion according to the

procedure outlined on the following page, see 'Inspecting and Cleaning the Mechanism'.

Check that labels are flat, legible and fully adhered. Replace as necessary.

Inspect the case for loose or damaged components and replace if necessary.

Inspect the circuit breaker for damage.

Inspect the AC power supply plug and cable for damage.

Inspect the door assembly for damage. Check that the door pivots freely and latches securely.

Inspect the mechanism for fluid spill residue or foreign matter. Open the door and inspect the exposed cam followers,

the pressure plate and tubing pincher. Clean any surfaces where solution has accumulated.

(A) (B)

(B)

(C)

(A) (B) (C)

Pressure

Transducer

Clean crevices (A) using a soft-bristle brush,

such as a one-inch paint brush, dipped in the

mild detergent solution (see above). Pat dry

all moistened areas with a cloth then leave the

door open for at least 15 minutes to air-dry

crevices.

Manually actuate points (B) by pressing then

releasing each part to verify that it moves freely.

After cleaning is complete, if required and

where heavy spillage has required extensive

cleaning, lubricate the tubing pincher and the

sides of the mechanism (C) using a siliconebased grease.

See also 'Inspecting and Cleaning the

Mechanism' on the following page.

(A)

Do not use alcohol or alcohol-based

(A)

IVAC® Volumetric Pump (Models 571 & 572) 34/104 1000SM00018 Issue 2

cleaning agents on the surface of the

pressure transducer.

Page 35

Routine Maintenance

Physical Inspection and Clean (continued)

Inspecting and Cleaning the Mechanism

Open the door and inspect/clean the exposed cam followers, the pressure plate and tubing pincher.

Clean any surfaces where fluid spill residue is noted, referring to the cleaning instructions above for appropriate

cleaning method.

Check the Cam Followers for cleanliness and erosion:

Shine a flashlight into the cam followers. The followers should be clean and shiny. A dull appearance may indicate

erosion. If the followers appear to be dirty or are dull, clean per the following procedure.

Clean the Cam Followers:

Clean the surface of the cam followers using a cotton-tipped applicator dampened in a solution of warm soapy water

and a mild non-abrasive detergent (such as commercially available dish cleaning liquid). Rinse the cam followers with

a soft cloth or cotton-tipped applicator dampened in water then allow the cam followers to dry.

Check the Cam Followers for erosion after cleaning:

If, after cleaning the cam followers, they are still dull, replace the mechanism assembly per replacement instructions in

Chapter 6 of this manual, or return the pump to the manufacturer.

Verify that the Pressure Plate is not bent, cracked or deformed.

Verify that the Tubing Pincher opens and closes freely (without sticking).

If the pincher is sticking or is hard to actuate, remove the pincher cover and inspect for contamination or inadequate

lubrication. Remove assembly and clean if necessary. See Chapter 6, 'Spare Parts Replacement Procedures' for pincher

removal instructions.

If required, apply a coating of silicone lubricant to cavity in front panel. Refit the pincher, pincher spring and pincher

cover following the instructions in Chapter 6.

Flow Sensor Check (where flow sensor is in use)

Clean the flow sensor by wiping over with a cloth, lightly dampened with warm water and a

standard disinfectant/detergent solution. Ensure the connector does not get wet. Dry flow sensor

before use.

To aid cleaning of flow sensors which have been heavily soiled, contaminated or if the handles

operation is not free, the flow sensor may be immersed and soaked in clean soapy water.

Activating the spring mechanism of the sensor whilst immersed will assist in cleaning the inside of

the mechanism. After cleaning, the sensor should be allowed to dry fully prior to use.

CAUTION: the plug of the sensor should not be immersed as damage will occur.

Check that labels are flat, legible and fully adhered. Replace as necessary.

Check that lenses are clean and clear and show no sign of cracks.

Inspect the body of the flow sensor for damage.

Check that the sliding action of the flow sensor operates smoothly.

Inspect the cord and plug for damage.

IVAC® Volumetric Pump (Models 571 & 572) 35/104 1000SM00018 Issue 2

Page 36

Routine Maintenance

Performance Verification Procedure

Model / Serial Number: Service Order / Inventory Number:

Hospital Name / Reference: Software Version:

INSPECTION

CH3

Physical inspection and clean

Lubricate pincher cavity as required

UPDATES Recommended when serviced

Fit Strain Relief and Flexi Cable

Check all functions in self-test

Dry set pressure verification

Applied pressure = 0 mmHg Displayed pressure = -20 to +10 mmHg

SELF TEST

CH4

Applied pressure = 400 mmHg Displayed pressure = 367 to 423 mmHg

Vacuum retention verification

With door closed and set installed displayed pressure < -250 mmHg for 30 seconds

Alarms functionality check

LOAD SET, DOOR, AIL, FLOW SENSOR, VTBI, KVO, TIME OUT, UPSTREAM OCCLUSION, BOTTLE CLAMP,

INFUSING

CH3

DOWNSTREAM PRESSURE EXCEEDED, SET OUT

Ensure pump works on battery and AC mains

Check operation with and without a Flow Sensor

ON HOLD/OFF

CH3

APO test (10 psi with door open and closed)

(self-test 12) Use a dry set.

(self-test 27)

UPDATE REF:

CH6

Fitted

Not fitted / Not

Applicable

Rate accuracy test

Set pump infusing at 800 ml/h for 180 seconds ± 0 5 seconds

VERIFICATION

CH3

TESTS

Delivery = 38 to 42 ml

Downstream pressure exceeded test

_____________ ml

Pressure set to 500 mmHg

Pump occludes between 11 and 14 psi

_____________ psi

SETUP Set rate to zero (or lowest value possible), Clear Volume Infused and VTBI

Clear Error / Alarm / Battery logs (as required)

Alternatively attach printed test results

_____________ Ω

_____________ µA

_____________ µA

ELECTRICAL

SAFETY TESTS

Class I Type CF

Earth Resistance Test <= 0.2 Ω

Earth Leakage Current <= 500 µA

Enclosure Leakage Current <= 100 µA

Verification

Performed

By

CHX

indicates the chapter number in the Technical Service Manual (TSM) E.G.

_______________________________

Sign

_____________________________

Print

CH4

= Refer to TSM Chapter 4.

_______________________

Date

NOTE: The content of this Performance Verification procedure is accurate at the time of issue of this TSM and is based on PVP

100 Issue 2.

IVAC® Volumetric Pump (Models 571 & 572) 36/104 1000SM00018 Issue 2

Page 37

Troubleshooting

In this chapter

Introduction 38

Chapter 4

Error Messages 38

General Faults 42

Page 38

Troubleshooting

Introduction

Use this troubleshooting guide to help identify the cause of errors and faults which may occur as a result of damage

to the pump or failure of an internal component. The following tables list the error messages and general faults and

describe what action to take to resolve the problem. For information on alarm procedures and messages, refer to the

relevant DFU.

If the nature of the problem is unclear, enter self-test mode and step through the self-test functions

to check that the main functions of the pump are operating correctly. See Chapter 3, 'Routine

Maintenance' for details.

Test 016 READ ALARM HISTORY displays the sixteen most recent malfunction messages. To run test

016, enter self-test mode and select the test. See Chapter 3 for instructions.

Error Messages

Message Failure Action/Replace

AIR IN LINE Air in IV infusion set detected by air-in-line

sensor.

IV infusion set removed from air-in-line detector

or is not installed in lower tubing guides.

AIR IN LINE

non-flow sensor

operation

persistent

AIR IN LINE

BOTTLE CLAMP

flow sensor

operation only

CHECK DISC

non-flow sensor

operation only

COM LINE

only when pump

connected to a CIM

Air in IV infusion set detected by air-in-line

sensor.

Empty container; clamp closed, upstream

occlusion, flow sensor mispositioned, tubing/

bottle venting incorrect.

Air-in-line transmitter or receiver failure.

VCO or timer failure.

No fluid flow.

Empty container; clamp closed, upstream

occlusion, flow sensor mispositioned, tubing/

bottle venting incorrect.

Foreign matter lodged between pressure

transducer and pressure disc.

Pressure sensing disc improperly seated in

retainer.