CONVECT-RITE

™

Air Cooled

III

Manual P/N 97394

Rev. K 10/23/2009

Convect-Rite™ III

Docking Stations

24 Meal Capacity (CR3D0XXX1)

30 Meal Capacity (CR3D1XXX1)

Used with

Convect-Rite™III Cart manual 98893

or

Convect-Rite™ Trans-Tray System manual 98871

U.S. Patent Number 7,025,121

INSTALLATION & SERVICE MANUAL

Copyright © 2004 Aladdin Temp-Rite

®

Changes may be made to the information in this document without notication.

MEAL

ENTER

MANUAL

MODE

AUTO

MODE

B

L

D

MANUAL

HOLD

MAN.

RETHERM

PM

PROGRAM

ALARM

SILENCE

CHILLING

RETHERM

EQUALIZE

HOLDING

DEFROST

R

3-18-03

CHILLING

Mode: (Green LED

illuminated) Cart is engaged.

After a 5 second delay, both the

hot side and cold side chambers

will be subjected to refrigeration

cooling to satisfy temperature

set points programmed into

the controller.

RETHERM

Mode: (Green LED illuminated)

The hot side chamber will receive

heating while the cold side chamber

will receive refrigeration cooling. This

cycle is used to rethermalize food on the

hot side of the cart. This mode can be

started using either the MANUAL RETHERM

key or pre-programmed meal times (AUTO

MODE). The timer will display the number of

remaining minutes in the retherm cycle and

Default Time

(Minutes)

Breakfast

Lunch &

Dinner

count down to zero.

24 Meal 30 Meal

38 45

48 55

IDLE

Mode: (Red AUTO MODE

or Red MANUAL MODE LED

illuminated) The Convect-Rite™

III system is powered up. No cart

is engaged. The alphanumeric

display shows the word

“Idle”.

EQUALIZE

Mode: (Green LED illuminated)

After the Convect-Rite III nishes the

RETHERM mode, it will automatically

move into the EQUALIZE mode (default

duration for the 24 meal dock is 10 minute,

for the 30 meal dock is 5 minute). During this

mode, the temperature set point for the hot

side chamber has a lower setting to allow for

temperature saturation throughout the cart.

The fans will continue to run to enhance

the saturation process. The cold side

chamber will continue to receive

refrigeration cooling.

ALARMS

An alarm can arise at any

point during the operation of the

Docking Station. A buzzer will sound

to indicate an alarm has been activated

and both the Red ALARM LED and the red

SILENCE LED will blink on and off. The

alphanumeric display will show which alarm

occurred. Press SILENCE key to silence

the alarm buzzer (the Red ALARM LED will

remain illuminated if the alarm condition

exists). The alarm will terminate once

the alarm condition is satised. See

the Owner’s Manual for all alarm

displays and descriptions.

Mode: (Red LED illuminated) The

HOLDING

HOLDING mode includes a sounding

alarm to indicate the rethermalization

process (RETHERM + EQUALIZE) is

complete. The cart can be removed at any

time. The temperature set point for the hot side

chamber has a lower setting than the EQUALIZE

mode. The fans will continue to run to enhance

the saturation process. The timer will display

the number of minutes held and count up to the

duration setting (default 10 minute duration,

max. hold 60 minute duration). Once the

programmed holding time is reached, all

heating and refrigeration will cease

operation and a second alarm will

sound continuously until the cart

is removed.

DEFROST

Mode: (Green LED illuminated)

If CHILLING mode continues for an

extended amount of time, the DEFROST

mode may be automatically activated.

During this mode, the refrigeration cooling

used during the CHILLING mode will turn off for

the programmed duration (default 10 minutes) of

the DEFROST mode. The fans will still operate.

This mode ensures the coils inside the dock do

not freeze while receiving extended periods of

refrigeration cooling in the CHILLING mode.

Once the DEFROST duration expires ,the

system will return to the CHILLING

mode. This mode will not activate

during the rethermalization

cycle.

CONVECT-RITE™ III Docking Stations

CONTENTS

I. INTRODUCTION 6

Convect-Rite™ III Docking Stations 6

II. RECEIVING INSPECTIONS 8

III. INSTALLATION INSTRUCTIONS 9

INTRODUCTION 10

INSTALLATION POLICIES 11

ELECTRIC POWER REQUIREMENTS 11

SELECTING THE OPERATING LOCATION 11

TEST BOOT 15

Installation & Service

Manual

SETTING AGAINST THE WALL 15

LIFTING THE UNIT OFF THE CASTERS 15

ADJUSTING THE SEAL & LATCHES 16

MOUNTING TO THE FLOOR 16

IV. PARTS LIST & ILLUSTRATION 22

24- Meal (CR3D0XXX1) 22

30- Meal (CR3D1XXX1) 26

V. OPERATION & PROGRAMMING 30

VI. PREVENTIVE MAINTENANCE 31

INTRODUCTION 31

OPERATOR’S TROUBLESHOOTING 33

TROUBLESHOOTING NOTES 33

SERVICING PROCEDURES 39

REPAIRING THE REFRIGERATION SYSTEM 42

PUMP DOWN 42

WIRING DIAGRAMS 44

VII. WARRANTY 52

CONVECT-RITE™ III Docking Stations

I. INTRODUCTION

Convect-Rite™ III Docking Stations

The Convect-Rite™ III Docking Stations are installed and electrically connected in the

ward pantry for a decentralized operation or grouped in one area for a centralized operation. Operation and programming of these units is shown in the Owners Manual. The

Convect-RiteTM III Docking Station is a dual cold and hot air-generator, which may be

used up to three times a day in the Auto mode:

•

To keep the meals at the recommended and safe temperature of

37/41°F (+3°C/+5°C) during stand-by periods prior to rethermalization.

•

To rethermalize starters, soups, hot desserts or main-courses in

approximately 50-60 minutes before service.

•

IMPORTANT NOTE: The food products in the cold section, should be at

maximum homogeneous 50°F (10°C) temperature when loaded inside the

cart, so that the Convect-RiteTM III System can keep them between 37

and 41°F (+3° and +5°C) at the end of the chill-down and rethermalization

cycle.

•

A minimum chill-down cycle of 50 minutes is recommended prior to

rethermalization to assure the lowest possible cold food temperatures.

Installation & Service

Manual

6

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

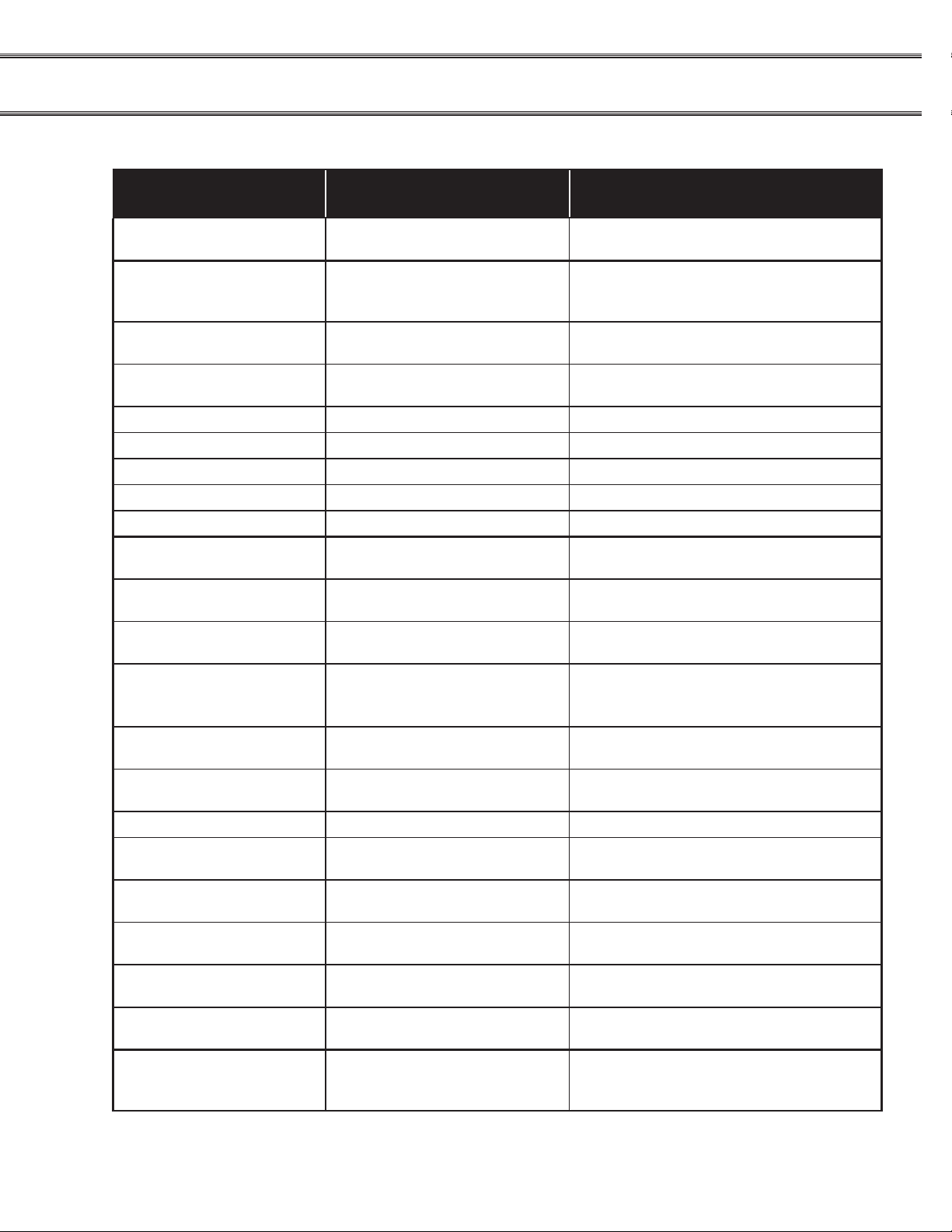

MODELS

This manual covers the standard models for the Convect-Rite™ III Docking Station that

accommodates 24 or 30 meals depending on the unit. Information for the ConvectRiteTM III System is listed in the table below. See below for dimensions.

TABLE 1-1

Tray Capacity, Dimensions, Weight, Electrical Data, & Heat Load Requirements

DIM CONVECT RITETM SYSTEM

A LENGTH/DEPTH

B WIDTH

C HEIGHT

MODELS

ALADDIN SALES CODE FOR

STANDARD MODELS

TRAY CAPACITY

TRAY SPACING

(OFF WALL FOR Docking Station)

WEIGHT

SHIPPING WEIGHT

Cart TURNING RADIUS n/a n/a

MAX HEAT EMISSIONS

@ 70oF AMBIENT

COOLING CAPACITY 6000 BTU/HR 7500 BTU/HR

ELECTRICAL REQUIREMENTS 208V - 3 Phase - 60 HZ / 4 Wire - 30 Amp

24 Meal 30 Meal

CR3D0XXX1 CR3D1XXX1

n/a n/a

32.56”

41.69”

77.63”

530 lb

550 lb

7900 BTU/HR 9900 BTU/HR

Docking Station

(82.7 cm)

(108.89 cm)

(197.18cm)

(240.4 kg)

(249.5kg)

(Hard wire connection required)

32.56”

41.69”

82.08”

573 lb

593 lb

(82.7 cm)

(108.89 cm)

(208.5 cm)

(259.9 kg)

(268.9 kg)

SPECIFICATIONS

CONVECT RITE™ III Docking Station

B

C

A

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

7

CONVECT-RITE™ III Docking Stations

#96712

MOCP

SERIAL / PRODUCT INFORMATION PLATES

During manufacture, Convect-Rite™ III Docking Stations are

assigned individual serial numbers. The serial number plate is

located on the top left hand side of the black plastic top cover. The

product information plate lists the model number, serial number,

voltage, power and wiring requirements, amount and kind of

refrigerant, pressure, and ETL listed mark. (See Figure 1-3)

Installation & Service

Manual

Figure 1-3

II. RECEIVING INSPECTIONS

Your Aladdin Convect-RiteTM III Docking Station is factory tested for performance and is free from

defects when shipped. The utmost care has been taken in packaging this product to protect against

damage in transit. All interior ttings have been secured to prevent damage.

You should carefully inspect your Convect RiteTM III components to assure that no damage has occurred in transit. If however, damage is detected, you should save all the packaging materials and

make note on the carriers Bill of Lading describing this shipment. A freight claim should be led

immediately. If damage is subsequently noted during or immediately after installation, contact the

respective carrier and le a freight claim. Under no condition may a damaged unit be returned to

Aladdin Temp-Rite without rst obtaining written permission (return authorization).

PACKAGING:

Your Convect RiteTM III Docking Station is packaged with care and shipped on dedicated carriers to

you from the factory.

IMPORTANT NOTE:

Aladdin Temp-Rite does not recommend laying the unit down on its front, side or back.

However, if you must, please be certain to allow the unit to remain in an upright position for 24 to 48

hours before attempting to place the unit into service, to assure that the compressor oils and refrigerant may settle.

ALADDIN DAMAGED GOODS POLICY

There are two types of damaged merchandise:

A. VISIBLE DAMAGE OR SHORTAGE

B. CONCEALED DAMAGE

8

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

A. VISIBLE DAMAGE OR SHORTAGE - (All claims should be reported within 10 business days)

1. Receiver should refuse the damaged portion of the shipment.

2. Receiver should sign the bill of lading indicating (delivery receipt) what merchandise is being

“refused due to damage” and have the driver initial the notation.

3. Receiver should note any shortages on the bill of lading (delivery receipt) in the same manner.

4. Receiver should contact Aladdin Customer Service at 1-800-888-8018 and alert them to the

situation.

B. CONCEALED DAMAGE- (All claims should be reported within 10 business days)

Any receiving operation should inspect for this type of damage.

IF PRODUCT IS DAMAGED

1. Receiver should hold the shipping container and its contents in the same condition as when the

damage was discovered insofar as possible and call the delivering carrier to arrange on site

inspection within 10 days of delivery.

2. Receiver should contact Aladdin Customer Service at 1-800-888-8018 for claims processing

after inspection has been completed.

III. INSTALLATION INSTRUCTIONS

IMPORTANT NOTE:

DO NOT INSTALL a Convect-RiteTM III Docking Station if damage is suspected.

INJURY & EQUIPMENT DAMAGE could result from improper installation of the Con-

vect-RiteTM III Docking Station or from installation of a unit damaged during shipment

or storage. Either of these conditions will void the equipment warranty.

! WARNING !

DO NOT move a Convect-RiteTM III Docking Station up a slope

greater than 10°.

DO NOT EVER tow a Convect-RiteTM III Docking Station

DO NOT push a Convect-RiteTM III Docking Station from the front

or back side

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

9

CONVECT-RITE™ III Docking Stations

! CAUTION !

Casters are ONLY intended for use during installation or service.

Unit MUST be positioned securely against a wall during operation!

INTRODUCTION

Install the Convect-RiteTM III Docking Station according to the policies and procedures

outlined in this manual. After selecting and preparing the Convect-Rite™ III Docking

Station operating location, the unit can be positioned and installed. When installation

is complete, perform all start-up checks to verify proper installation and operation.

This section is a guide for installation of the Convect-RiteTM III models identied

in the Introduction section of this manual. This guide is for use by qualied

professionals, and does not include all procedures and precautions in the common

domain of licensed plumbers, pipe tters, and electricians or experienced food

service equipment installers.

Installation & Service

Manual

This guide MUST be used in conjunction with professional experience and thorough

understanding of the local and national utility, construction & sanitation codes.

Before starting installation, the owner and the installer should read through

this chapter and thoroughly understand and agree upon:

• The installation policies of Aladdin Temp-Rite® as stated in Installation Policies

Section.

• An installation plan based on the Installation Instructions and Start-Up Check

List

10

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

INSTALLATION POLICIES

The Convect-RiteTM III Docking Station must be installed by qualied electrical, mechanical, or refrigeration personnel, working to all applicable national and local codes. Equipment installation must comply with the local and national codes.

All models of the Convect-RiteTM III Docking Station comply with the applicable standards

•

for manufacturers. Included among those certication agencies are: ETL Safety and ETL

Sanitation.

The Convect-RiteTM III Docking Station is certied for safe operation only when perma-

•

nently installed in accordance with local and/or national codes. Many local codes exist,

and it is the responsibility of the owner and installer to comply with these codes.

In no event shall Aladdin Temp-Rite assume any liability for damage or injury resulting

•

from installations which are not in strict compliance with the Installation, Instructions and

the codes cited above. Specically, Aladdin Temp-Rite will not assume any liability for

damage or injury resulting from improper installation of equipment, including but not limited to temporary or mobile installations.

ELECTRIC POWER REQUIREMENTS

Unit should be hard wired to electrical disconnect requirements specied which can also

be found on the product identication plate. The plate is secured to the top on the left hand

side as you look at the front of the unit as mentioned in serial/product information plate section. 208 volts / 3 phase / 30 amp circuit / 4 wire (3 hots & 1 ground)

SELECTING THE OPERATING LOCATION

For safe and efcient operation, observe the following criteria when selecting an operating

location for the Convect-Rite™ III Docking Station.

IMPORTANT NOTE:

The ooring directly under this unit must be made of non-combustible material and be capable of supporting the weight of this equipment.

1. Do not install these units in areas where combustibles are stored or may accumulate. The surrounding area must be clear of combustibles, including the

space under the unit.

2. A proper air supply for ventilation is critical to safe, efcient operation of the

Docking Station. The area around the Docking Station must have adequate

ventilation and the ambient temperature should never be above 85°F

(35°C).

3. Do not block the louvers or panels. Do not install any heat producing

equipment near the louvers of the unit. Ventilation occurs through open

slots on the dock’s right side and through louvers on the back of the dock.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

11

CONVECT-RITE™ III Docking Stations

R

FRONT DOOR SWING

30"

75 cm

R

REAR DOOR SWING

30"

75 cm

4. The dimension drawings in Figure 3-1 specify all dimensions and clearances

required for proper installation operation and service of the Convect-Rite™ III

Docking Station, covered in this manual. Maintain at least a 6” (15.2 cm) oper-

ating clearance between foot pedals of units, at least 10” (25.4 cm) between

foot pedal and sidewall, at least 18” above the unit, and at least a 5 3/4”

(14.6 cm) clearance at the back of the unit. The front and rear door swing

of the cart is 30” (750 cm).

5. The condensing unit and controller can be accessed by removing the black

plastic top cover. Removable side panels provide access for service of

various components; the right side for the cold side blowers and control panel

and the left side for the hot side motors. The back access panel permits

service to the cold side motors and expansion valves. Removing the left

side perforation panels allows access to the hot side heaters and blowers. A

minimum 6” (15.16 cm) clearance should be available on both sides of

the unit. For access to the back and side panels the Docking Station should

be lowered onto the casters and pulled away from the wall where it can be

turned 90°-180° for ease of service.

6. The location selected must be capable of supporting the operational weight

of the Convect-Rite™ III system including the weight of the Convect-Rite™

III cart loaded with trays, crockery, and food-products. See Table 1-1 for

equipment weights.

7. The oor surface under the unit must be level and continuous with the

ooring in front of the unit. The cart must roll smoothly to the Docking

Station for ease of operation and maintenance of the seal between the

Docking Station and the cart.

Installation & Service

Manual

12

Minimum

18” Clearance

(45.7 cm)

Minimum

Minimum

Clearance

10” (25.4 cm)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

clearance

between

foot pedals

6” (15.2 cm)

Minimum

5-3/4” Clearance

(14.6 cm)

Figure 3-1

WALL MOUNTING INSTRUCTIONS

IMPORTANT NOTE:

The wall directly behind the Docking Station must be able to support the average cart

Docking force of 550 lbs. Based on the condition of the support wall, a reinforcing

horizontal or vertical brace may be required at the upper and lower wall contact points, for

better stability. See gure below for details.

Support braces should be:

1) 2” x 6” X 3’

SPIB Southern pine wood or equivalent

2) 8” X 3’

10 Gauge 304 Stainless steel or equivalent

3) Use optional Aladdin wall mounting kit PN 98507

50” (127 cm)

13” (33 cm)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

13

CONVECT-RITE™ III Docking Stations

Dedicated electrical

disconnect or J-box

3/4" Liquidtight conduit

Installation & Service

Manual

INSPECTED FOR SHIPPING DAMAGE (see Section

CONNECT ELECTRICAL LINE

Electrical schematic diagrams can be found in Section VI. PREVENTIVE MAINTENANCE.

Connect the electrical cord to the electric connection box as described in Figure below.

Refer to Table 3-1 for amperage distribution

II. RECEIVING INSPECTION)

14

Table 3-1

Convect-Rite™ III Docking Station

208V / 3PH /4 WIRE/

(3 hot, 1 ground)/ 60

HZ

Product Total 9.3 kw MAX* 26 25 25 10 kw MAX* 28 27 27

*Actual duty load during rethermalization cycle is approximately 75% of maximum power

requirements.

24 Meal Unit (CR3D0XXX1) 30 Meal Unit (CR3D1XXX1)

Power

Watts

PH1

Amps

PH2

Amps

PH3

Amps

Power

Watts

PH1

Amps

PH2

Amps

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

PH3

Amps

TEST BOOT

With the unit still on all four casters, and after the hard wire connection

is complete, switch the breaker on for the unit and then turn on the

unit (the switch located on the upper right front of the unit). The unit

should boot up and the screen should display the time & “Idle”

(see gure to right) Turn the unit and breaker back off. If the unit

does not boot correctly check electrical connection. For further

information call Aladdin Tech Service 1 (800) 888-5426.

SETTING AGAINST THE WALL

Make adequate space and thoroughly clean the location before you begin the install.The Docking

Station has eight adjustable feet (four on the back & four on the bottom). When starting the

install process all eight feet should be completely seated. Gently push unit within 1/4” of the

wall. Loosen the 7/8” jam nuts on the back four feet. Adjust all four back feet close to the

wall but not touching it. Extend one foot at a time to touch the wall, trying to keep the unit

parallel to the wall as possible (due to wall inconsistency all four feet may be adjusted to

different lengths) NOTE: Recommend adjusting the top feet until the Docking Station sits at

a 5° angle away from the wall as a starting position.

LIFTING THE UNIT OFF THE CASTERS

NOTE: If feet are unevenly set the unit’s frame may be damaged by racking.

The Convect-Rite™ III Docking Station MUST BE LEVEL BOTH FRONT TO BACK AND SIDE TO

SIDE. Depending on oor condition reference gasket alignment between the cart and Docking Station to insure proper gasket seal for correct positioning.

Ensure that both caster locks point away from the wall, and are 90˚ to the wall in the locked

position.

The four feet on the base of the Docking Station are adjustable to achieve this. Be mindful

when setting the feet that:

• A Docking Station set too low can result in interference between the lower cart hinge and

the Docking Station interface channel.

• A Docking Station set out of level right-to-left can result in an insufcient seal between

the unit and the gaskets on the cart.

• A Docking Station set out of level front-to-back can result in an insufcient seal between

the unit and cart and possibly make mating the cart more

difcult.

Loosen the 7/8” jam nuts on the four bottom feet. Then adjust the

four feet close to the oor, but not touching it. Slowly continue to

extend each foot a turn at a time, until the top of the base is 7.1”

(see diagram) off the ground (the caster should be off the ground at

this point). However, due to oor inconsistency, all four feet may be

adjusted to different lengths

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

7.1”

15

CONVECT-RITE™ III Docking Stations

Mirco Switches

EXTENDING THE REAR FEET AGAINST THE WALL

NOTE: Shims should NOT be used.

Adjust back feet until they are tight against the wall. Check that the

feet are not bowed, skewed, or have less than 3 threads protruding

from rear brackets. If any of these conditions occur, the dock should

be lowered back on its casters and moved closer to the wall.

Installation & Service

Manual

ADJUSTING THE SEAL & LATCHES

Holding Screws

Roll a Convect Rite III Retherm Cart up to the

front of the Docking Station with the door open

on the non-handle end of the cart. NOTE: if

Docking Station is too low the cart will run

into the door support. If the cart does not hit

the door support, dock the cart to the unit.

Adjust any necessary feet until a uniform

compression seal is formed around the cart.

You many need to dock & undock the cart

several time to ensure a proper t.

If the cart does not depress the latches

when engaged to the dock, (see diagram for

location) the latches need to be adjusted. To adjust rst loosen the holding screws, adjust

the latch bolts so the switches are in contact with the cart. To move the switches forward,

turn the bolts clockwise. To move backward, turn counter clockwise. Tighten the holding

screws.

Latch Adjustment Bolts

Latches

MOUNTING TO THE FLOOR

16

The Docking Station should be secured to the oor with oor anchors that are included with

the unit.

Turn the feet out 45°, for better stability . Select a carbide drill bit equal to the

45°

leaving nut ush with end of anchor to protect threads. Drive anchor through the foot until

the washer is ush. Expand anchor by tightening

nut 3 to 5 turns past the hand tight position, or 25 ftlbs. torque.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

anchor diameter, 1/2”. Drill hole to desired depth suitable for the oor type. A

minimum embedment of 1-7/8” is required for concrete. Clean hole or continue

drilling additional depth to accommodate oor nish. Assemble washer and nut,

STARTUP CHECK LIST

This inspection checks for proper electrical wiring to the Convect-Rite™ III Docking Sta-

tion and veries basic operation of the unit.

IMPORTANT NOTE:

Equipment damage and faulty operation will result if electrical supply falls below requirements. This may be caused by other equipment on the same supply line. Supply a

dedicated electric service for each unit.

Refer to the appropriate dimension drawing and verify that the specied

●

clearances are met (Fig 3.1).

● Verify that the voltage supplied complies with the voltage requirements speci-

ed on the Product Identication Plate, located on top of the unit. Verify that

the wiring connections are correct for these voltage requirements.

●

Connect the Convect-Rite™ III Cart to the Convect-Rite™ III Docking Station

with both cart doors opened.

● Turn the unit power-switch to the on position. After an 5 second delay, fan-

motor rotation should start.

● Operate a complete cycle (make sure door opposite Docking Station is closed)

to check every function of the Convect-Rite™ III unit. Temperatures set points

for the cold and hot sections are pre-set at the factory. Both can be adjusted

to meet customer’s requirements. (Refer to Section V of the owners manual

programming instructions)

● Verify cold air blowing and hot air ventilation functions.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

17

CONVECT-RITE™ III Docking Stations

OPTIONAL WALL MOUNT (required for OSHPD where applicable)

BACK MOUNTING BRACKETS

Remove lower feet from dock.

Add the wall mounting bracket (98076) to the dock from the OSHPD

mounting kit PN 98674.

Wall Mounting Brackets

Remove Feet

Installation & Service

Manual

STANDARD UPPER MOUNTING ASSEMBLY

The following is for wall mounting of a 24 shelf unit, refer to Figure 3-2 for 30 shelf units.

Step 1: To secure top horizontal support channel assembly measure 49-13/16” from

nished oor to center of 1-5/8” channel (See Figure 3-2). Conrm 1⅝” x 1⅝” Unistrut

channel is level and fasten to vertical wall surface using appropriate fastening devices

for wall surface encountered to insure equipment stability.

Step 2: Next measure 6-5/8” from center of “Unistrut” channel down to center of lower

channel and fasten to wall surface as directed above.

This “Unistrut” assembly will serve as an attachment point for the wall mounting

hardware detailed in Figure 3-3.

Note: Utilize an 8’-0” span of “Unistrut” when mounting two Docking Stations adjacent

to one another, and maintain 15” spacing between units for serviceability.

Step 3: Assemble mounting hardware to support brackets located at the rear of

Docking Station and fasten to “Unistrut” support channel assembly previously described

and detailed in Figure 3-3.

Note: Fasten Floor Mounts only after unit has been adjusted for proper t and seal with

retherm cart.

OPTIONAL LOWER MOUNT:

18

If a lower mount assembly is utilized then the following instructions apply. The lower wall

mount is identical to the upper mounting assembly. Mount upper “Unistrut” channel 235/16 to center of channel and proceed as directed in step 2 above.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

POSITION & LEVEL THE CONVECT-RITE™ III Docking Station

1.

The Convect-Rite™ III Docking Station MUST BE LEVEL BOTH FRONT TO BACK AND

SIDE TO SIDE. Depending on oor condition reference gasket alignment between the cart

and Docking Station to insure proper gasket seal for correct positioning.

2.

The oor must be at and smooth.

3.

Make adequate space and thoroughly clean the location.

4.

Leave the minimum clearances (see Figure 3-1) on each side of the Docking Station for

better ventilation and access for technical service.

The unit must sit level on a level oor. The unit must be level both front-to-back and right-

to-left. The four lower Docking Station feet are adjustable to achieve this. Be mindful when

setting the feet that:

• A Docking Station set too low can result in interference between the lower cart hinge and

the Docking Station interface channel.

• A Docking Station set out of level right-to-left can result in an insufcient seal between

the unit and the gaskets on the cart.

• A Docking Station set out of level front-to-back can result in an insufcient seal between

the unit and cart and possibly make mating a cart more difcult.

Open the door of the Convect-RiteTM III Cart opposite the handles and mate the cart to the

Convect-RiteTM III Dock Station. Conrm that the cart gasket seals against the docking

Stations interface channel around its full perimeter. Make the proper adjustments to the

Docking Station if the mating is not correct. Once the Docking Station level is set, tighten

all wall 7/8” jam nut to nal torque settings. Once the Docking Station is secure, anchor the

unit to the oor with provided hardware. If cart does not latch properly adjust latch position

(see “Adjusting the latches”)

MOUNTING TO THE FLOOR

The dock should be secured to the oor with the oor mounting brackets.

Turn the feet out 45°, for better stability . Select a carbide drill bit equal to the

45°

leaving nut ush with end of anchor to protect threads. Drive anchor through the foot

until the washer is ush. Expand anchor by tightening nut 3 to 5 turns past the hand

tight position, or 25 ft-lbs. torque.

anchor diameter, 1/2”. Drill hole to desired depth suitable for the oor type. A

minimum embedment of 1-7/8” is required for concrete. Clean hole or continue

drilling additional depth to accommodate oor nish. Assemble washer and nut,

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

19

CONVECT-RITE™ III Docking Stations

1

2

3

4

5

6

7

Installation & Service

Manual

25-3/4”

Support channel 1-5/8” x 1-5/8”

(Unistrut)

25-3/4”

Center to Center of

mounting bracket

6-5/8” Center to Center

3-5/16”

Center to center

46-1/2” for 24 meal

50-3/4” for 30 meal

from center of upper

mounting plate to

nished oor.

20” from center of

mounting plate to

nished oor

OSHPD Mounting Kit Components

#

5/8”-11 jam nut 98627

1

5/8”-11x 6” full-thread stud 98626

2

Mounting plate for OSHPD 98672

3

3/8”-16 x 1-1/4” hex head bolt 39618

4

3/8” Belleville washer 97765

5

3/8”-16 channel nut 96332

6

Unistrut channel na

7*

*Item not supplied by ATR

Description PN

20

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

OPTIONAL WALL MOUNT REQUIRED FOR OSHPD

C

*

A

FIGURE 3-3

24 Unit 30 Unit

A 20” 20”

B 46-1/2” 50-3/4”

C 77-5/8” 82-1/16”

* From center of mounting plate to nished oor.

B

*

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

21

CONVECT-RITE™ III Docking Stations

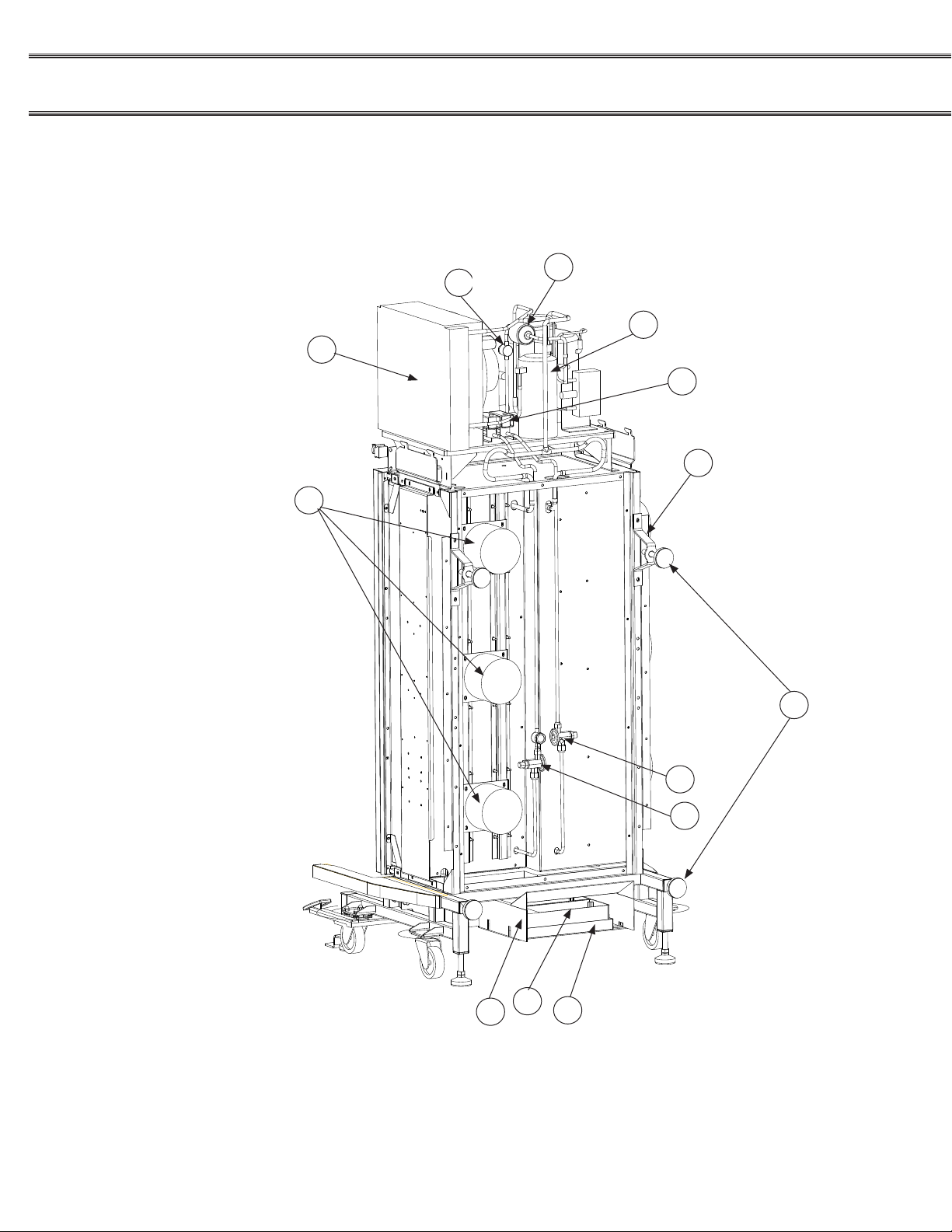

Installation & Service

IV. PARTS LIST & ILLUSTRATION

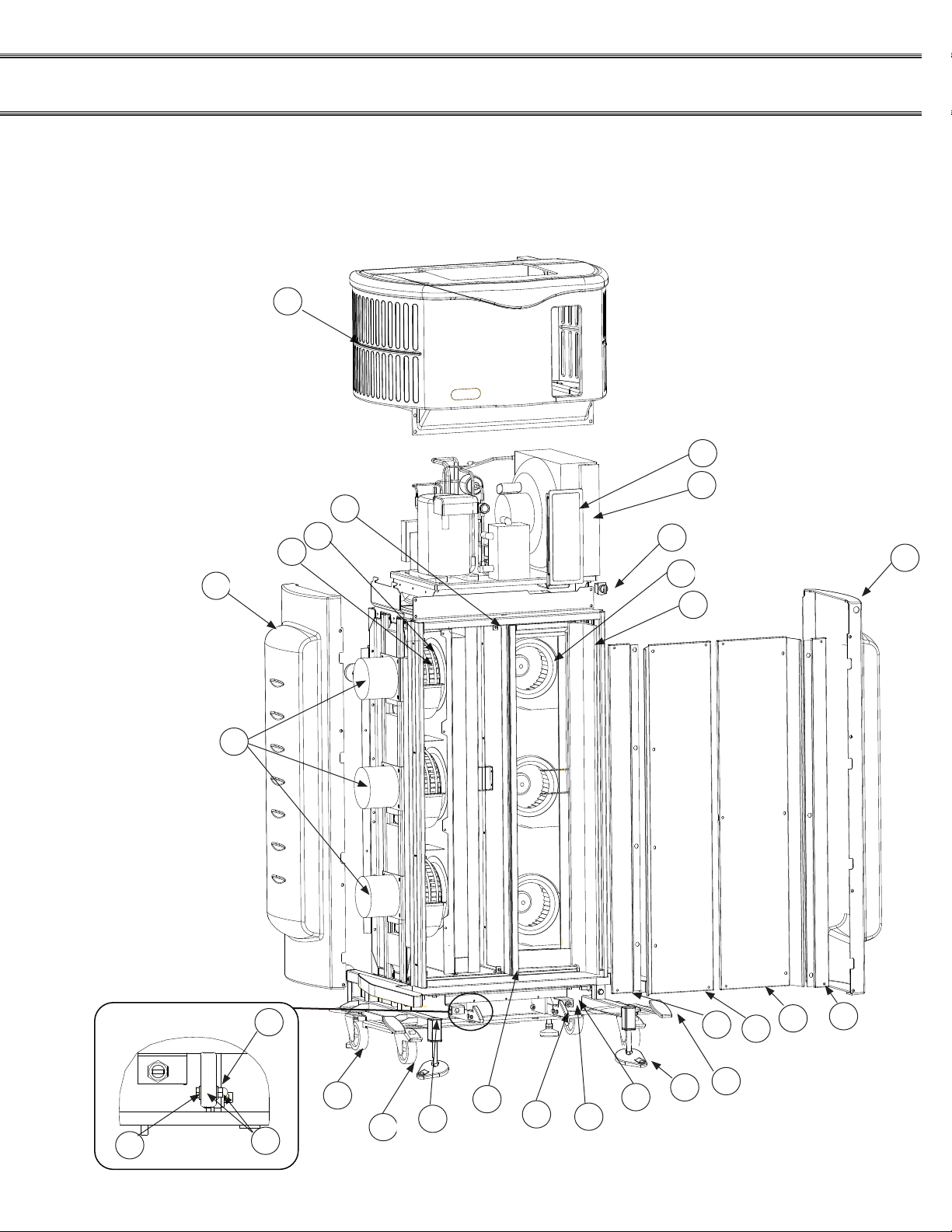

24- Meal (CR3D0XXX1)

Convect-Rite™ III Docking Station Parts List

(See Figures: 4-1 and 4-2)

Manual

ITEM# PART# DESCRIPTION

*1 98837 anchor, oor,1/2”,3/8”-16

*2 98774 compressor

3 96897 angle bracket

4 96734 blower wheel, cold side

5 96887 blower,wheel, hot side

6 96768 brass latch, foot pedal

7 98086 caster 4” swivel

8 98087 caster 4” swivel with brake

9 96783 clevis pin,3/8”,5/32” hole,1” lg

10 96996 condensing unit

11 96702 controller membrane ONLY, N7

12 96703 controller N7

13 96784 cotter pin,5/32” d,3/4”L

14 96717 cover,perf,cold,return

15 96713 cover,perf,cold,supply

16 96773 cover,perf,hot,return

17 96779 cover,perf,hot,supply

18 96758 dryer

19 96830 eps, vane,cold side

20 98191 evap pan bracket

21 98164 evap pan shroud

22 98117 evaporative pan assy

23 96816 extrusion, gasket,al,hold

24 na na

25 99763 foot pedal cover

26a 98838 foot, oor, tear drop

26b 98839 foot, back, round

*27 98189 gasket, interface

28 96742 heater coils for 8.5in dia blower

ITEM# PART# DESCRIPTION

*29 96688 heater gasket, silicone

*30 96811 housing eps

*31 96801 insulation, left hot side

*32 96889 insulation, lft fwd hot side

*33 96798 insulation, rear left cold side

*34 96800 insulation, rear mid cold side

*35 96799 insulation, rear right cold side

*36 96855 insulation, right cold side back

*37 96802 insulation, right cold side fwd

38 96728 motor, fan cold side and hot side

39 96898 receiver,copeland,577-0315-02

*40 96156 safe temp thermocouple (white wire)

41 96787 sensor nut,m14x1,260 brass

42 97751 side panel plastic(COLD)

43 97758 side panel plastic (HOT)

44 96759 site glass

45 96756 solenoid

46 96716 switch, on-off with light knob

47 96766 switch, limit, roller plunger, 9ft cable

*48 96792 thermocouple (right hand side of pair)

49 96785 thrust bearing,3/8” shft d, 3/4” od,1/8” t

50 98073 cap plastic

51 97754 top cover plastic

*52 98126 trim strip left & right side

*53 98348 trim strip top

54a 96993 valve, thermal expansion (cold)

54b 96993 valve,thermal expansion (hot)

55 98076 wall mount brackets

*56 98571 solenoid repair kit

22

The parts listed above are noted in Figures 4-1 and 4-2

Note: “*” Indicates items not shown in the diagram.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

24- Meal (CR3D0XXX1)

9

49

8

3

5

51

433813

23

41

6

47

24

14

15

16

17

42

11

12

19

46

25

28

7

4

50

26a

Convect-Rite™ III Docking Station Illustration

Figure 4-1

NOTE: Shown without evaporator on right side

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

23

CONVECT-RITE™ III Docking Stations

10

44

18

39

38

45

55

21

22

20

54a

54b

26b

24- Meal (CR3D0XXX1)

Convect-Rite™ III Docking Station Illustration

Installation & Service

Manual

24

Figure 4-2

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

TB1

F1-3

CR1

CR3

CR4

CR2

TR1

TH1

F4-5

CB1

CB2

28

30

11

12

10

9

18

17

1

2

3

4

25

31

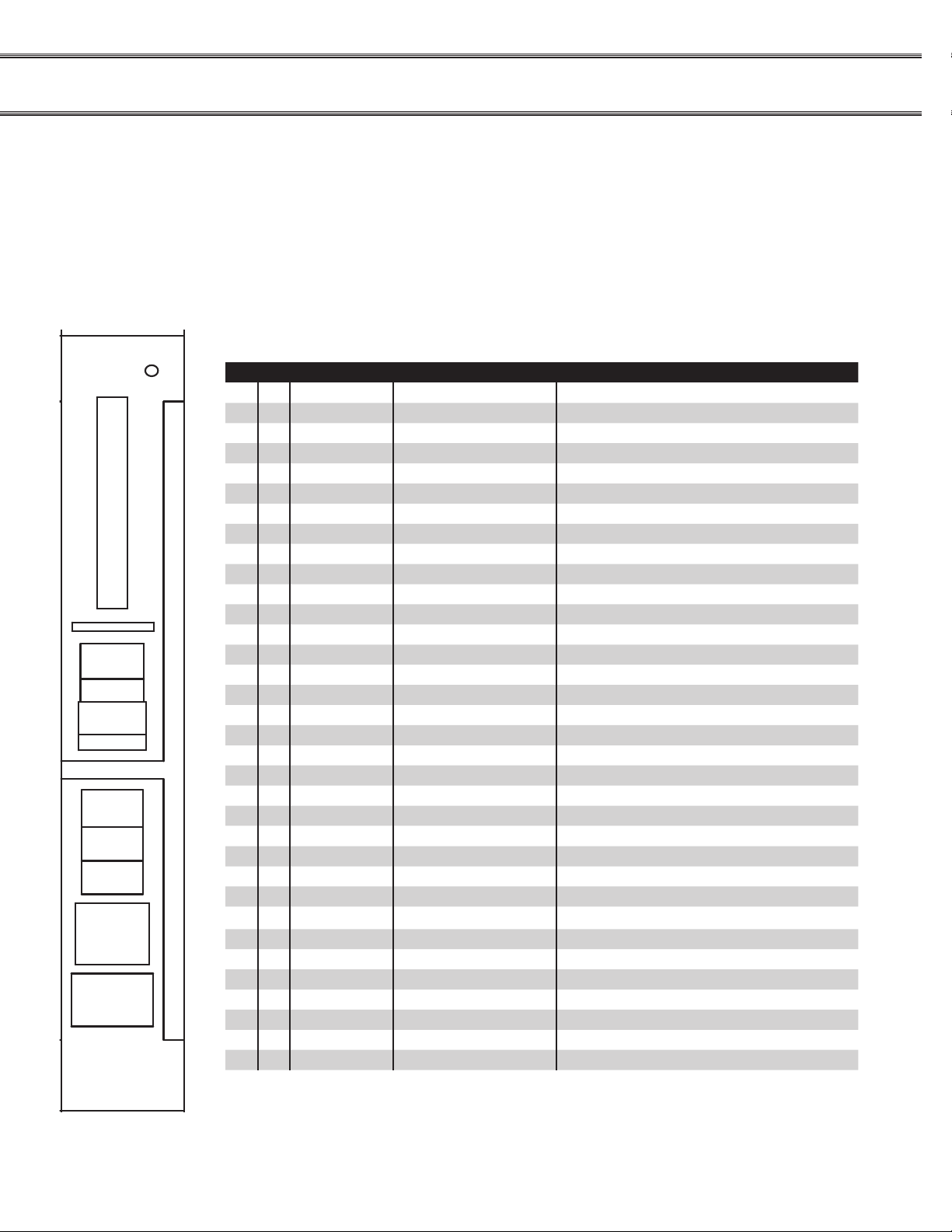

15

24- Meal (CR3D0XXX1)

Convect-Rite™ III Electrical Layout and Parts List

The electrical parts list below notes all “KEY” numbers in the control panel layout and illustrated in Figure 4-3.

KEY QTYSUPPLIER PART NUMBER DESCRIPTION

1 1 Aladdin 96910 Contactor,IEC 9 Amp,208 VAC,4 Pole

2 1 Aladdin 96940 Contactor,IEC 9 Amp,24 VAC,4 Pole

3 1 Aladdin 96911 Contactor,IEC 30 Amp,208 VAC,3 Pole

4 1 Aladdin 98231 Auxiliary Contact Block

*5 2 Aladdin 96913 Jumper,2 Pole

*6 3 Aladdin 96914 Jumper,3 Pole

*7 6 Aladdin 96915 End Anchor,DIN 35mm

*8 5 Aladdin 96916 End Barrier

9 1 Aladdin 96917 Fuse Block,Class CC,3 Pole,600 V,W/Indication

10 1 Aladdin 96918 Fuse Block,Class CC,2 Pole,600 V,W/Indication

11 1 Aladdin 96920 Supplementary Protector,15AMP,3 Pole

12 1 Aladdin 96919 Supplementary Protector, 4AMP,1 Pole

*13 30 Aladdin 96921 Terminal,30 Amp,Gray,600V,22-10 Awg

*14 12 Aladdin 96922 Terminal,30 Amp,Red,600V,22-10 Awg

15 1 Aladdin 96923 Transformer,208V/24V,63VA

*16 3 Aladdin 96924 Terminal,Grounding,22-12 Awg

17 2 Aladdin 96925 Fuse,600V,4 Amp,Class CC

18 3 Aladdin 96926 Fuse,600V,30 Amp,Class CC

*19 1 Allen Bradley 1492-SM6X12V1-10 Terminal Strip Marker,Vertical 1-10

*20 1 Allen Bradley 1492-SM6X12V11-20 Terminal Strip Marker,Vertical 11-20

*21 1 Allen Bradley 1492-SM6X12V21-30 Terminal Strip Marker,Vertical 21-30

*22 1 Allen Bradley 1492-SM6X12V31-40 Terminal Strip Marker,Vertical 31-40

*23 1 Allen Bradley 1492-SM6X12V41-50 Terminal Strip Marker,Vertical 41-50

*24 9 Thomas & Betts C10-10 Ring Terminal,Un-insulated,10-12 Awg,#10

25 1 Aladdin 96927 Contactor,E-Safe,3 Pole,20 Amp,24 Vac Control

25 1 Aladdin 99221 Contactor, E-Safe 2, For SN after J0017-1

*26 1 Molex 43025-1600 Housing,16 Pin Connector

*27 4 Molex 43030-0007 Pin,Femal,Molex

28 1 Square D PK9GTA Ground Bar

*29 1 Acco TS-35 Din Rail,Steel,7x35mm,(1) 12”,(1) 7”,(1) 6.5”

30 1 Aladdin 96928 Thermostat,15A,250V Contact, 200C Fixed SP

31 1 Quality Ind. Custom Panel

32 A/R Thomas & Betts T1XHDG Wire Duct,1 x 2” Gray

33 A/R Thomas & Betts T1CG Wire Duct Cover,1” Gray

Electrical Parts List

Figure 4-3

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

25

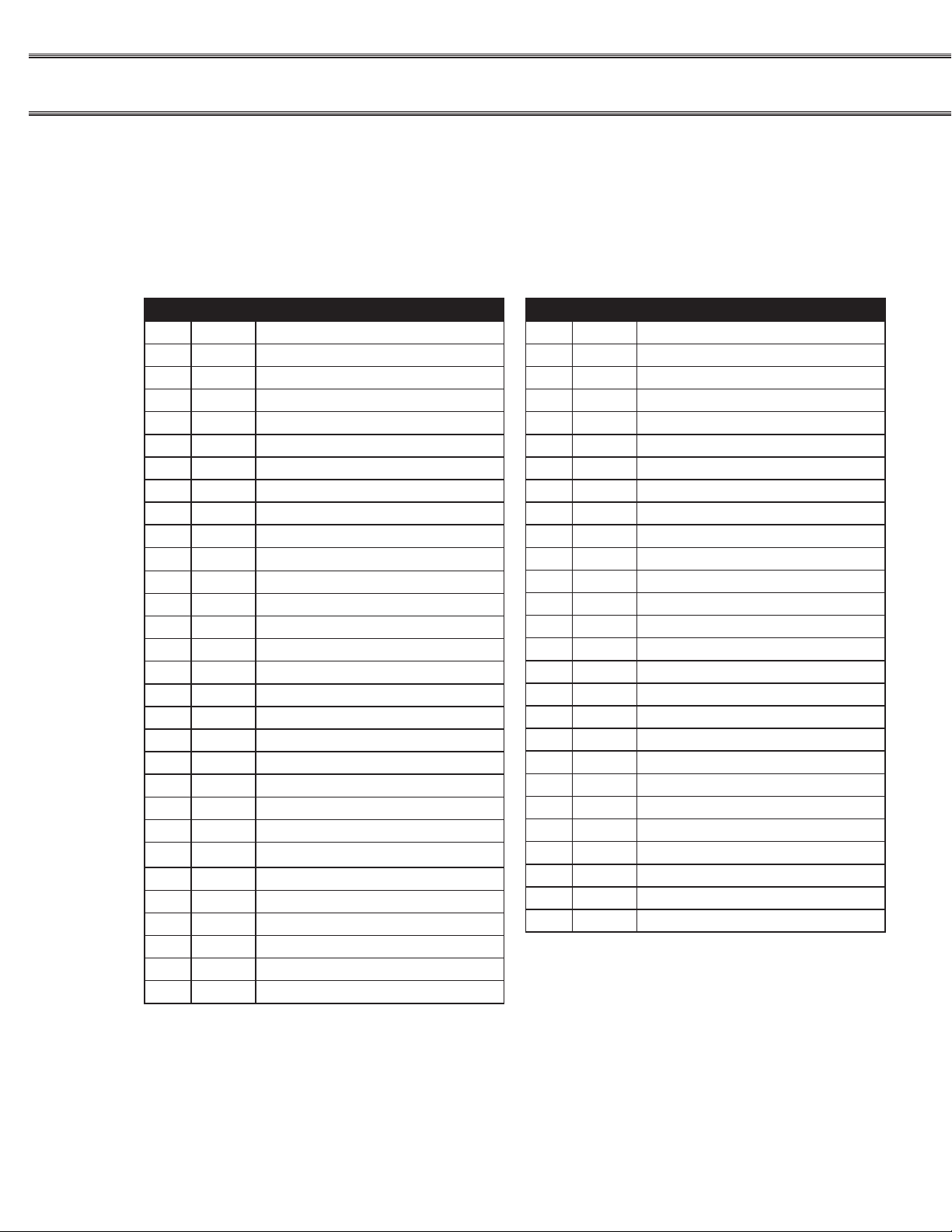

CONVECT-RITE™ III Docking Stations

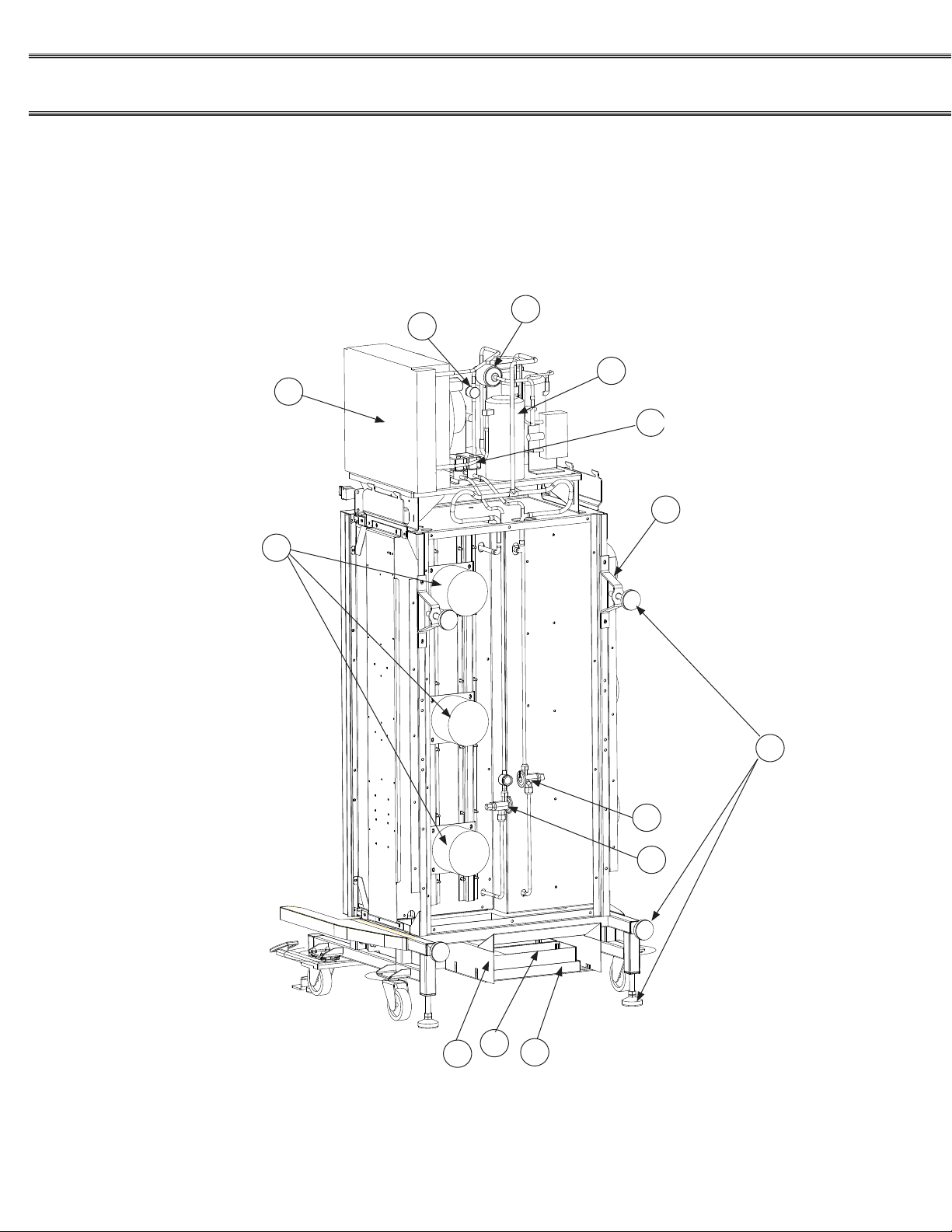

30- Meal (CR3D1XXX1)

Convect-Rite™ III Docking Station Parts List

(See Figures: 4-5 and 4-6)

Installation & Service

Manual

ITEM# PART# DESCRIPTION

*1 98837 anchor, oor,1/2”,3/8”-16

*2 98773 compressor

3 96897 angle bracket

4 96734 blower wheel, cold side

5 96887 blower,wheel, hot side,8.5” dia

6 96768 brass latch, foot pedal

7 98086 caster 4” swivel

8 98087 caster 4” swivel with brake

9 96783 clevis pin,3/8”,5/32” hole,1” lg

10 96943 condensing unit

11 96703 controller N7

12 96702 controller membrane only N7

13 96784 cotter pin,5/32” d,3/4”L

14 96955 cover,perf,cold,return

15 96954 cover,perf,cold,supply

16 96956 cover,perf,hot,return

17 96941 cover,perf,hot,supply

18 96758 dryer

19 96938 eps, vane,cold side

20 98191 evap pan bracket

21 98164 evap pan shroud

22 98117 evaporative pan assy

23 96974 extrusion, gasket,al,hold

24 na na

25 99763 foot pedal cover

26a 98838 foot, oor, tear drop shape

26b 98839 foot, back, round

*27 98190 gasket, interface

28 96742 heater coils for 8.5in dia blower

*29 96937 housing eps

ITEM# PART# DESCRIPTION

*30 96966 insulation, left hot side

*31 96972 insulation, lft fwd hot side

*32 96964 insulation, rear left cold side

*33 96965 insulation, rear mid cold side

*34 96963 insulation, rear right cold side

*35 96968 insulation, right cold side back

*36 96967 insulation, right cold side fwd

37 96728 motor, fan cold side and hot side

38 96898 receiver,copeland,577-0315-02

*39 96156 safe temp thermocouple (white wire)

40 96787 sensor nut,m14x1,260 brass

41 97764 side panel plastic (COLD)

42 97763 side panel plastic (HOT)

43 96759 site glass

44 96756 solenoid

45 96716 switch, on-off with light knob

46 96766 switch,limit,roller plunger,9ft cable

*47 96792 thermocouple (left hand side of pair)

48 96785 thrust bearing,3/8” shft d, 3/4” od,1/8”

49 98073 cap plastic

50 97754 top cover

*51 98127 trim strip left & right

*52 98348 trim strip top

53 97718 valve,thermal expansion (cold)

54 97719 valve,thermal expansion (hot)

55 98076 wall mount bracket

*56 98571 solenoid repair kit

The parts listed above are noted in Figures 4-5 and 4-6 and display the specic location of

each part.

Note: “*” Indicates items not shown in the diagram.

26

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

30- Meal (CR3D1XXX1)

9

835

13

23

6

24

14

15

16

17

111219

25

28

7

4

50

42

37

40

46

41

454849

Convect-Rite™ III Docking Station Illustration

Figure 4-1

NOTE: Shown without evaporator on right side

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

27

CONVECT-RITE™ III Docking Stations

10

18

26

21

22

20

43

38

44

54

37

53

55

30- Meal (CR3D1XXX1)

Convect-Rite™ III Docking Station Illustration

Installation & Service

Manual

28

Figure 4-6

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

TB1

F1-3

CR1

CR3

CR4

CR2

TR1

TH1

F4-5

CB1

CB2

28

30

11

12

10

9

18

17

1

2

3

4

25

31

15

30- Meal (CR3D1XXX1)

Convect-Rite™ III Electrical Layout and Parts List

The electrical parts list below notes all “KEY” numbers in the control panel layout and illustrated in Figure 3-3.

KEY QTY SUPPLIER PART NUMBER DESCRIPTION

1 1 Aladdin 96910 Contactor,IEC 9 Amp,208 VAC,4 Pole

2 1 Aladdin 96940 Contactor,IEC 9 Amp,24 VAC,4 Pole

3 1 Aladdin 96911 Contactor,IEC 30 Amp,208 VAC,3 Pole

4 1 Aladdin 98231 Auxiliary Contact Block

*5 2 Aladdin 96913 Jumper,2 Pole

*6 3 Aladdin 96914 Jumper,3 Pole

*7 6 Aladdin 96915 End Anchor,DIN 35mm

*8 5 Aladdin 96916 End Barrier

9 1 Aladdin 96917 Fuse Block,Class CC,3 Pole,600 V,W/Indication

10 1 Aladdin 96918 Fuse Block,Class CC,2 Pole,600 V,W/Indication

11 1 Aladdin 96920 Supplementary Protector,15AMP,3 Pole

12 1 Aladdin 96919 Supplementary Protector, 4AMP,1 Pole

*13 30 Aladdin 96921 Terminal,30 Amp,Gray,600V,22-10 Awg

*14 12 Aladdin 96922 Terminal,30 Amp,Red,600V,22-10 Awg

15 1 Aladdin 96923 Transformer,208V/24V,63VA

*16 3 Aladdin 96924 Terminal,Grounding,22-12 Awg

17 2 Aladdin 96925 Fuse,600V,4 Amp,Class CC

18 3 Aladdin 96926 Fuse,600V,30 Amp,Class CC

*19 1 Allen Bradley 1492-SM6X12V1-10 Terminal Strip Marker,Vertical 1-10

*20 1 Allen Bradley 1492-SM6X12V11-20 Terminal Strip Marker,Vertical 11-20

*21 1 Allen Bradley 1492-SM6X12V21-30 Terminal Strip Marker,Vertical 21-30

*22 1 Allen Bradley 1492-SM6X12V31-40 Terminal Strip Marker,Vertical 31-40

*23 1 Allen Bradley 1492-SM6X12V41-50 Terminal Strip Marker,Vertical 41-50

*24 9 Thomas & Betts C10-10 Ring Terminal,Un-insulated,10-12 Awg,#10

25 1 Aladdin 96927 Contactor,E-Safe,3 Pole,20 Amp,24 Vac Control

25 1 Aladdin 99221 Contactor, E-Safe 2, For SN after J0017-1

*26 1 Molex 43025-1600 Housing,16 Pin Connector

*27 4 Molex 43030-0007 Pin,Femal,Molex

28 1 Square D PK9GTA Ground Bar

*29 1 Acco TS-35 Din Rail,Steel,7x35mm,(1) 12",(1) 7",(1) 6.5"

30 1 Aladdin 96928 Thermostat,15A,250V Contact, 200C Fixed SP

31 1 Quality Ind. Custom Panel

32 A/R Thomas & Betts T1XHDG Wire Duct,1 x 2" Gray

33 A/R Thomas & Betts T1CG Wire Duct Cover,1" Gray

Electrical Parts List

Figure 4-7

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

29

CONVECT-RITE™ III Docking Stations

Safe-Temp Parts

Installation & Service

Manual

Description

Temperature transmitter (Hot & Cold side) 96151 99139

On/Off switch transmitter 96152 99135

Thermalcouple (Hot & Cold side) 96156 96156

Address label 98315 98315

NOTE: Digital transmitters have blue wire terminals

Analog

Digital

V. OPERATION & PROGRAMMING

The Convect-Rite™ III System is safe and easy to operate. The system uses the most

advanced rethermalization methods available. Please refer to the Owner’s Manual Operating

& Programing section for details on how to operate the Convect-Rite™ III System.

30

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

VI. PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE AND CLEANING

INTRODUCTION

Maintenance on the Convect-Rite™ III equipment must be performed on a regular basis

to keep the units operating properly. Follow the maintenance instructions in this chapter

and problems will be kept to a minimum. If problems do occur, refer to the Troubleshooting

Guide.

! WARNING !

DEATH, INJURY, OR EQUIPMENT DAMAGE may result from improper service

or maintenance practices. Always turn the main power switch or breaker on the

Docking Station switch to the OFF position on each unit before starting service,

maintenance or repairs.

Convect-Rite™ III Docking Station

Daily

• Clean the exterior of the unit only. As with any other piece of equipment containing

electrical components, it should be cleaned on a regular basis with a wet sponge.

Wipe it dry with a smooth cotton cloth. Avoid the use of abrasive products or chlorides. Do not spray Docking Station with hose or steam wand.

Monthly

• Check and adjust the Docking Station micro limit switches as required.

• Check and tighten all adjustment bolts both at the wall and on the oor.

Biannually

• Remove the black plastic top cover of the Docking Station. Vacuum the

condensing unit coil to remove dust and dirt.

! CAUTION !

Inside and outside front panel of the hot section of the Convect-Rite™ III Docking

Station stays hot for a short period of time after rethermalization; allow 15 minutes for

cool-down before cleaning.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

31

CONVECT-RITE™ III Docking Stations

Cleaning of plastic top and side panels:

NOTE: It is extremely important to read the following instructions for cleaning plastic

ancillary equipment.

• It is sufcient to wipe the plastic components of the Convect-Rite™ III Docking

Station with a soft cloth using warm water (Not to Exceed 140°F/60°C) to which

has been added diluted detergent; the detergent used must have a low alkaline

value and contain a very low percentage of caustic soda. The detergent must not

exceed the dilution rate recommended by the supplier.

• After cleaning these components, wipe down with a soft cloth using clear water.

• Make sure that all plastic components are thoroughly dried before using.

• Manufacturer accepts no responsibility if the above instructions are not strictly

adhered to.

Installation & Service

Manual

32

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

OPERATOR’S TROUBLESHOOTING GUIDE FOR OPERATIONAL SAFETY

! WARNING !

DEATH, INJURY, OR SHOCK can occur by touching electrical components

and wires inside the Docking Station when the main power switch is in the ON

position.

NEVER REMOVE THE PLASTIC TOP OR SERVICE ACCESS PANELS of

the Docking Station while main power switch is in the ON position. Allow only

authorized factory trained service representatives to perform service, maintenance and repairs that require the removal of any plastic top or service access

panels.

This troubleshooting guide includes a list of conditions that may be encountered during rou-

tine operation and maintenance. The rst column on the left describes these symptoms. The

second column in the middle lists the causes for the conditions listed in column one. The third

column on the right lists remedies and/or references for the conditions and causes in columns

one and two.

DO NOT TRY to correct the condition that requires an authorized service representative as

this may adversely affect the warranty coverage.

TROUBLESHOOTING NOTES

1. If problem is inside the Docking Station, call the Aladdin Temp-Rite® Service

Department at 1-800-888-5426. Aladdin will not pay for warranty repairs by

unauthorized repair centers.

2. Repairs to external wiring should be done by a Licensed Electrician.

3. Proper installation of the Convect-Rite™ III Docking Station is the responsibility of the owner or installer.

4. Repairs to external plumbing (if required) should be done by a Licensed mechanical contractor.

5. Repairs to compressor-condensing unit should be done by a Licensed

Refrigeration Engineer.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

33

CONVECT-RITE™ III Docking Stations

Condition is occurring

when: Condition/symptom: Solutions and things to check:

Leveling feet hit thresholds and

Moving the Docking Station

other oor imperfections. Raise feet to full up positions.

Installation & Service

Manual

Use ramp to roll dock over obstruction

Casters do not roll

Installing the Docking

Station.

Engaging the cart to the

Docking Station.

Loading trays Tray does not slide in slot

Shutting doors Doors on cart won’t close Tray not completely pushed in

Keeping cart door open Door not engaged in detent latch Push door completely to the side of the cart

Engaging cart to Docking

Station Cart doesn’t engage Check that dockside door is open

Leveling feet will not lower or

raise. Unlock 7/8” jam nut

Leveling feet will not reach wall

due to wall imperfections.

Wall CANNOT take Docking

force of 550 lbs.

Gap exist between cart and dock

when cart is engaged. Adjust appropriate feet to close gap

Cart does not depress one or

both switches

Docking Station rolls or creeps in

location over time. Check that dock is not resting on casters.

Check that lock is not depressed on either

front caster.

Adjust feet by turning 7/8” nut

Check that black tube caps are not in the

tube.

Securely fasten a 2”X8”X4’ wood board to

the wall to close gap between leveling feet

and wall.

Securely fasten a 2”X8”X4’ wood board to

the wall to distribute force.

Check that the dock is parallel to cart

interface.

Adjust one or both bolts that move latches

from front to back

Use oor mounting brackets to secure front

leveling feet.

Check that leveling feet have rubber grips.

Check that the tray is not warped or

damaged

Divider bar may be present

Check latch and door alignment

Check gasket t

(270°)

Check that door at hinge is completely

seated

Check that no debris is around detent latch

Check that dock is secured against the wall

Check that dock is level

34

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

Condition is occurring

when: Condition/symptom: Solutions and things to check:

Check that the optional safety doors on the

Docking Station are not closed

Check that the side of the cart with the

locking casters is facing away from the

dock

Check that the dock is at the appropriate

height for the cart

Check micro switch position (see section III

Chill Down

Cold holding overnight

Doesn’t show cart engaged

Cart engaged--compressor

hums, but does not start up

Cart engaged--compressor does

not hum and does not start up

Cart engaged but evaporator

fans do not turn on

Unit does not chill down (reach

programmed settings) in one

hour

Compressor does not cycle off in

one hour

A signicant amount of water

appears on oor the following

morning

for location)

Check “on/off” switch

Check safety switches

Check unit breaker in control panel

Check all wiring is properly seated

Check plug or junction box

Contact ATR technical service representative

Contact ATR technical service representative

Check component(s) electrical contractor

Check that cart doors are completely

closed

Make sure doors are adjusted to prevent

air leak around doors

Check that there is no air leak between

dock and cart

Initial temperature of food may be too high

Make sure ambient air temperature is less

than 85 degrees F.

Check that cart doors are completely

closed

Make sure doors are adjusted to prevent

air leak around doors

Check that there is no air leak between

dock and cart

Check condenser for proper spacing and

air ventilation

Check that water in evaporator drain tubes

drains into condensate pans

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

35

CONVECT-RITE™ III Docking Stations

Condition is occurring

when: Condition/symptom: Solutions and things to check:

Evaporator has frost exceeding

10% of coil

Rethermalization Cycle Does not start Retherm cycle

Retherm cycle is too long/short Check meal setting in program

Unit does not reach retherm temperature setting at end of cycle

and hot food temperature is NOT

acceptable

Heater element(s) do not get hot Check components) electrical contractor

Equalization Cycle Does not start Equalization

Equalization cycle is too long/

short

Installation & Service

Manual

Check the connection between the

condensate evaporating pans to insure it is

not clogged.

Check any air leaks between cart and dock

Check that evap pans are getting hot.

Check any air leaks around cart doors

Defrost occurrence and duration is not

often or long enough. Adjust as necessary

to eliminated condition.

Check any air leaks between cart and dock

Check any air leaks around cart doors

Check that automatic programmed start

time window has not passed

Check that controller is in automatic or

manual retherm mode

Check time AM-PM

Check time of meal settings

Wrong meal may have been selected in

manual mode

Cart was disengaged too soon or during

cycle

Slots in cart center panel may be missing

tray(s) or divider bar(s))

Check that all fans are turning

One or more heater elements may not be

functioning.

Check any air leaks between cart and dock

Check any air leaks around cart doors

Check that Equalization time is programmed

Adjust Equalization cycle temperature

setting(s) and duration(s)

36

Hold Cycle after Equalization Does not start Hold Check that Hold time is programmed

Adjust Hold cycle temperature setting(s)

Hold cycle is too long/short

and duration(s)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

Condition is occurring

when: Condition/symptom: Solutions and things to check:

Disengaging cart Cart will not disengage Depress either foot pedal release

Check cart caster locks

Hot food temperatures

Cold food temperatures

Dock continues to run when cart

is disengaged

Hot food temperatures not hot

enough after retherm and equalization

Hot food temperatures too hot

after retherm and equalization

Hot food temperatures have

more than 20°F difference from

tray to tray

Cold food temperatures not cold

enough after one hour of Chill

down cycle Check any air leaks between cart and dock

Check that micro switch is not sticking

closed

Check Retherm/Equalization cycle temperature setting(s) and duration(s)

Check any air leaks between cart and dock

Check any air leaks around cart doors

Slots in cart center panel may be missing

tray(s) or divider bar(s)

Inappropriate entrée dome, mug & soup

bowl may be in use

Check that all fans are turning

One or more heater elements may not be

functioning.

Wrong meal may have been selected in

Manual mode

Adjust temperature setting and tolerance

Wrong meal may have been selected in

Manual mode

Inappropriate entrée dome, mug & soup

bowl may be in use

Adjust Retherm/Equalization cycle temperature setting(s) and duration(s)

Food input temperature may have been too

high.

slots in cart center panel may be missing

tray(s) or divider bar(s)

Check that all fans are turning

Check for presence of air deectors inside

the supply plenum on the cart

One or more heater elements may not be

functioning.

Check any air leaks around cart doors

Check that all fans are turning

Check to see if compressor is running

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

37

CONVECT-RITE™ III Docking Stations

Condition is occurring

when: Condition/symptom: Solutions and things to check:

Installation & Service

Manual

Check to see if system is generating cold

air (possible refrigerant leak)

Adjust temperature setting and tolerance

Cold food temperatures have

more than 5°F difference from

tray to tray

Controller Display Improper temperature units Check program for proper unit - °C or °F

Check that all fans are turning

Check for presence of air deectors inside

the supply plenum on the cart

Slots in cart center panel may be missing

tray(s) or divider bar(s)

38

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

SERVICING PROCEDURES

FOR SERVICE ACCESS:

Adjust the four feet on the base of the Docking Station, lower the unit onto the casters.

Remove oor brackets. Pull unit away from the wall and turn 90°-180° for ease of

service.

MOTOR, HOT SIDE

1. See “FOR SERVICE ACCESS” then remove the bolts from the back ange, - slide the

cover back, slightly rotating it towards yourself; - pull the panel towards yourself. (Only

the back ange is bolted onto the frame; the front ange slides onto studs)

2. Disconnect wiring for the failed motor. (Time-saving tip: splice the wiring of new motor

into existing wiring)

3. Remove the perforated plates from the front of the unit and then remove the orice

plate. Mark the location of the blower on the shaft.

4. Remove the front part of the shroud, and then loosen the blower wheel mounted to the

shaft of the failed motor to easily slide it off.

5. Remove the motor mount bracket with the failed motor still mounted on it.

6. Replace the failed motor, and attach it to the motor mount bracket using (4) 10-32

nylock nuts and (4) #10 at washers with the capacitor mounted toward the left of the

bracket and back of the dock.

7. Place the motor mount bracket against the rails and locate it using (4) ¼-20 bolts and

(4) ¼” at washers. Center the motor shaft inside the housing hole and then tighten the

bolts down.

8. Attach the fan blower wheel to the shaft of the motor and slide down so it is set at the

depth on the shaft marked previously. Tighten setscrew on the “FLATS” of the shaft.

9. Reattach all removed components.

MOTOR, COLD SIDE

1. See “FOR SERVICE ACCESS”, slide forward, and oor, slide forward, and remove

back cover and right side panel.

2. Remove the right side panel: - remove the bolts from the back ange, -slide panel back,

slightly rotating it towards yourself; - pull panel towards yourself. (Only the back ange

is bolted onto the frame; the front ange slides onto studs)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

39

CONVECT-RITE™ III Docking Stations

3. Disconnect wiring for the failed motor. (Time-saving tip: splice the wiring of new motor

into existing wiring)

4. Remove the control panel, housing side cover and EPS vane.

5. Mark the location of the blower on the shaft and then loosen setscrew on the blower

wheel so it can slide off the shaft.

6. Remove the motor mount bracket with failed motor still mounted on it.

7. Replace the failed motor, and attach it to the motor mount bracket using 10-32 nylock

nuts and #10 at washers with the capacitor mounted towards the top of the bracket.

8. Place the motor mount bracket against the rails and locate it using (4) ¼-20 bolts and

(4) ¼” at washers. Center the motor shaft inside the housing hole and then tighten the

bolts down.

9. Attach the fan blower wheel to the shaft of the motor and slide down so it is set at the

depth on the shaft marked previously. Tighten setscrew on the “FLATS” of the shaft.

Installation & Service

Manual

10. Reattach all removed components

HEATERS

1. Remove left side panel: - remove the bolts from the back ange, -slide the panel back,

slightly rotating it towards yourself; - pull the panel towards yourself. (Only the back

ange is bolted onto the frame; the front ange slides onto studs)

2. Disconnect the wiring for the failed heater.

3. Remove the perforated plates from the front of the unit and then remove the orice

plate. Mark the location of the blower on the shaft.

4. Remove front part of the shroud, and then loosen the blower wheel mounted to the shaft

of the motor so you can easily slide it off.

5. Replace the failed heater and rectangular silicone insulator. Be careful to attach the

wires to the same terminal locations.

6. Attach the fan blower wheel to the shaft of the motor and slide down so it is set at a

depth on the shaft marked previously. Tighten setscrew on the “FLATS” of the shaft.

40

7. Reattach all removed components.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

GASKET

1. Remove damaged gasket.

2. Obtain a new gasket and install the corners or ends rst, and then continue towards

the center, spreading gasket uniformly so no buckling occurs.

LIMIT SWITCH

1. Remove right side panel: - remove the bolts from the back ange, -slide the panel back,

slightly rotating it towards yourself; - pull the panel towards yourself. (Only the back

ange is bolted onto the frame; the front ange slides onto studs)

2. Disconnect the limit switch wiring.

3. Remove protective brass nut from the front of failed limit switch.

4. Remove thin nut and pull failed switch out.

5. Obtain new limit switch and install it onto the base bracket. Locate and secure the

switch with thin nuts that come with the switch and tighten down completely with

protective brass nut. Make sure that new limit switch extends to the same level as

existing one.

6. Connect wiring and reattach all removed components

7. Dock cart to check engagement. Adjust the limit switch accordingly.

EVAPORATIVE PAN

1. Remove right side panel: - remove the bolts from the back ange, -slide the panel back,

slightly rotating it towards yourself; - pull the panel towards yourself. (Only the back

ange is bolted onto the frame; the front ange slides onto studs)

2. Disconnect failed evaporative pan wiring.

3. Remove evap pan bracket.

4. Replace the pans and install new pans, making sure that drain piping goes inside the

pans.

5. Replace evap pan bracket.

6. Connect wiring and reattach removed components.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

41

CONVECT-RITE™ III Docking Stations

REPAIRING THE REFRIGERATION SYSTEM

PUMP DOWN

1. Close the receiver outlet valve and operate the compressor until the suction pressure

gauge levels off to 3-5 psi.

2. Close the receiver valve and stop the compressor.

3. The system can now be opened for repair.

LEAK CHECKING

1. Once a repair has been made, pressurize and leak test the entire system including the

condensing unit, evaporator, and all connecting tubing, ttings, and brazed joints using

the intended operating refrigerant for leak testing.

Installation & Service

Manual

2. DO NOT USE OXYGEN OR COMBUSTIBLE GASES FOR LEAK TESTING.

3. A pressure equal to the low side test pressure marked on the unit nameplate is

recommended for leak testing.

4. Again, repair any leaks found.

EVACUATION

1. Connect a vacuum pump to both the low and high side evacuation valves with copper

tube or high vacuum tube (3/8” ID MIN.) and draw a deep vacuum of at least 1500

microns.

2. DO NOT USE THE MOTOR-COMPRESSOR TO PULL A VACUUM.

3. DO NOT OPERATE THE MOTOR-COMPRESSOR IN A VACUUM.

4. Break the vacuum with nitrogen.

5. Evacuate the system to hold at 500 microns and break the vacuum with refrigerant.

6. Remove the vacuum pump.

42

7. The system is now ready for charging.

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

CHARGING

1. Charge the system with the correct amount of refrigerant as listed on the data

nameplate on the right hand side of the unit.

2. DO NOT CHARGE THE UNIT BY THE SITE GLASS LOCATED ON THE

CONDENSING UNIT.

3. BE SURE NOT TO OVERCHARGE THE UNIT. AN OVERCHARGE MIGHT PERMIT

LIQUID REFRIGERANT TO ENTER THE MOTOR-COMPRESSOR AND DAMAGE

THE VALVES, RODS, PISTONS, ETC.

4. Make sure all are caps and valve caps are tight.

NORMAL OPERATING CONDITIONS FOR BOTH 24 AND 30 MEAL Docking Stations

These are the operating temperatures and pressures for both the 24 and 30 meal models

JUST BEFORE THE COMPRESSOR CYCLES OFF:

TEV Open Lo Pressure Lo Temp Super Heat Temp

Both 55-60psi 25-35°F 3-15°F

Cold Only 45-50psi 25-35°F 3-15°F

Hot Only 50-55psi 25-35°F 3-15°F

TEV Open Hi Pressure Hi Temp Subcooling

Both 250psi 90-100°F 5-10°F

Cold Only 240psi 90-100°F 5-10°F

Hot Only 245psi 90-100°F 5-10°F

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

43

CONVECT-RITE™ III Docking Stations

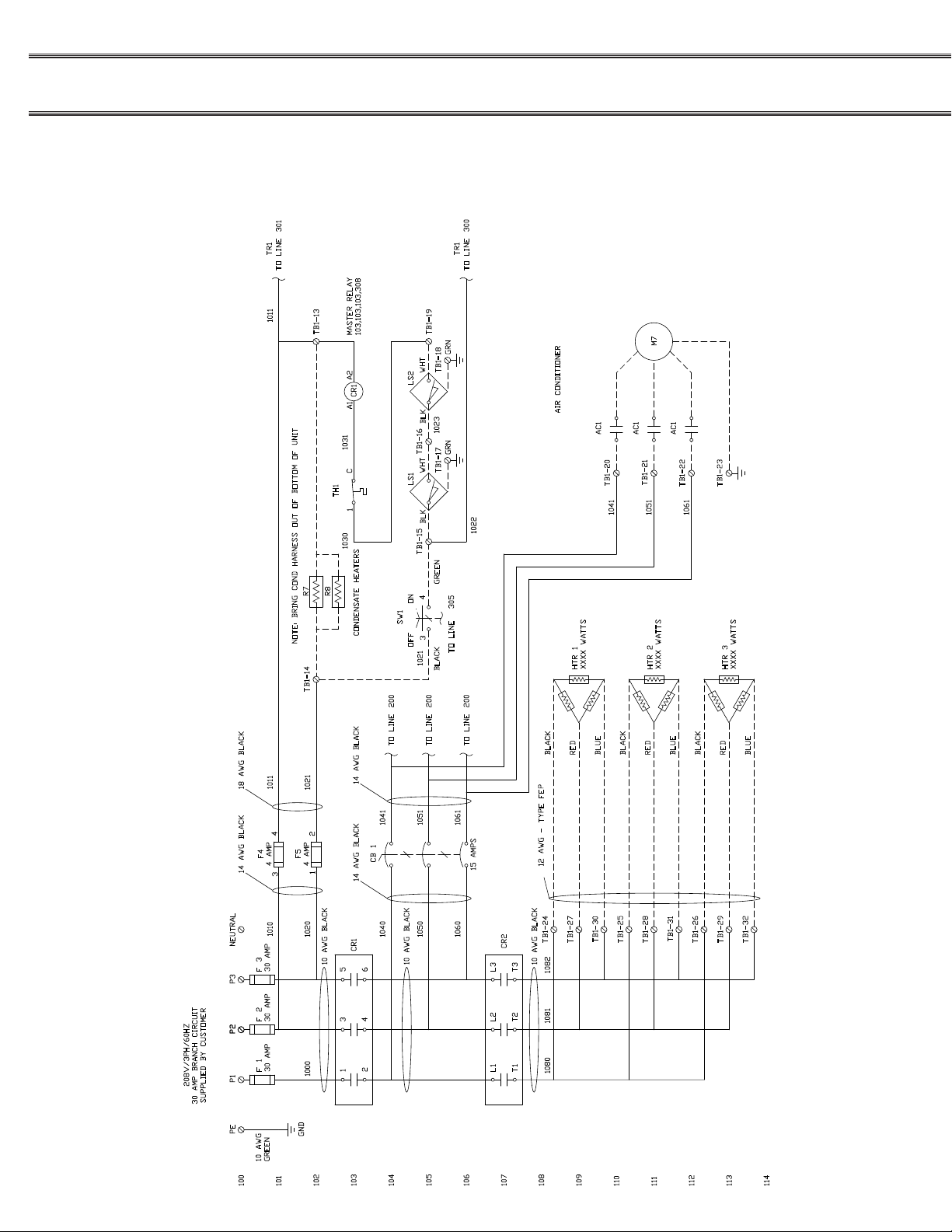

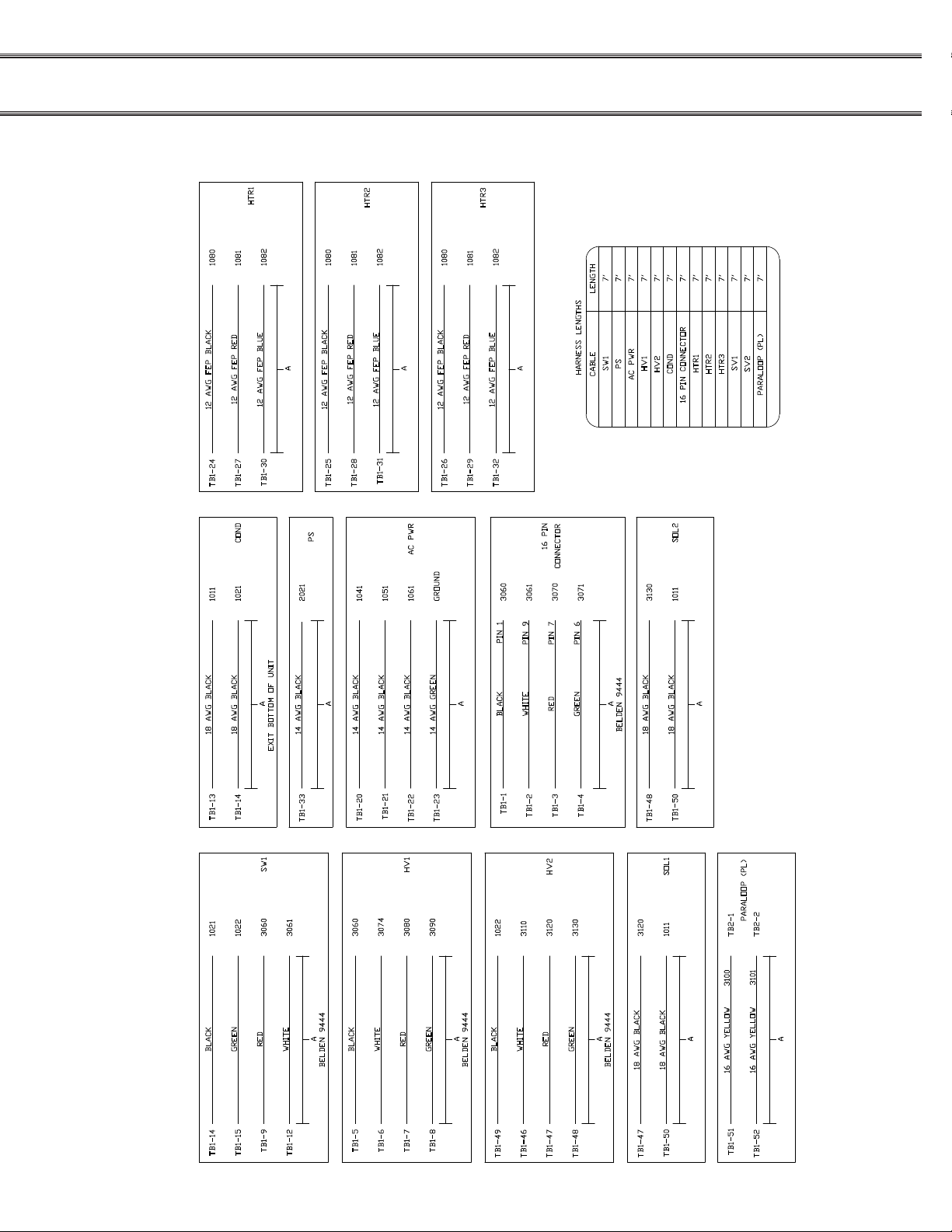

Wiring Diagrams

24 Meal (CR3D0XXX1)

Installation & Service

Manual

44

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

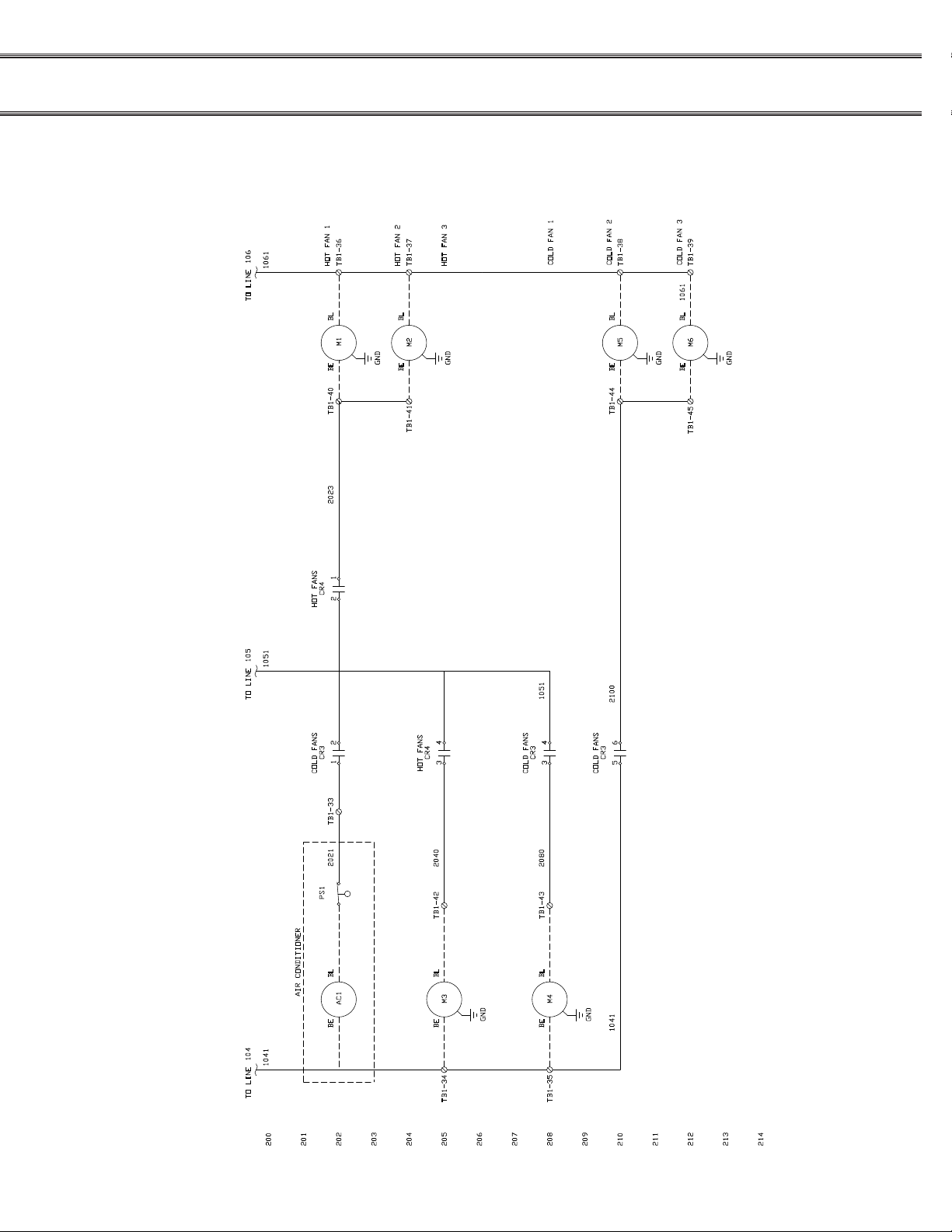

24 Meal (CR3D0XXX1)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

45

CONVECT-RITE™ III Docking Stations

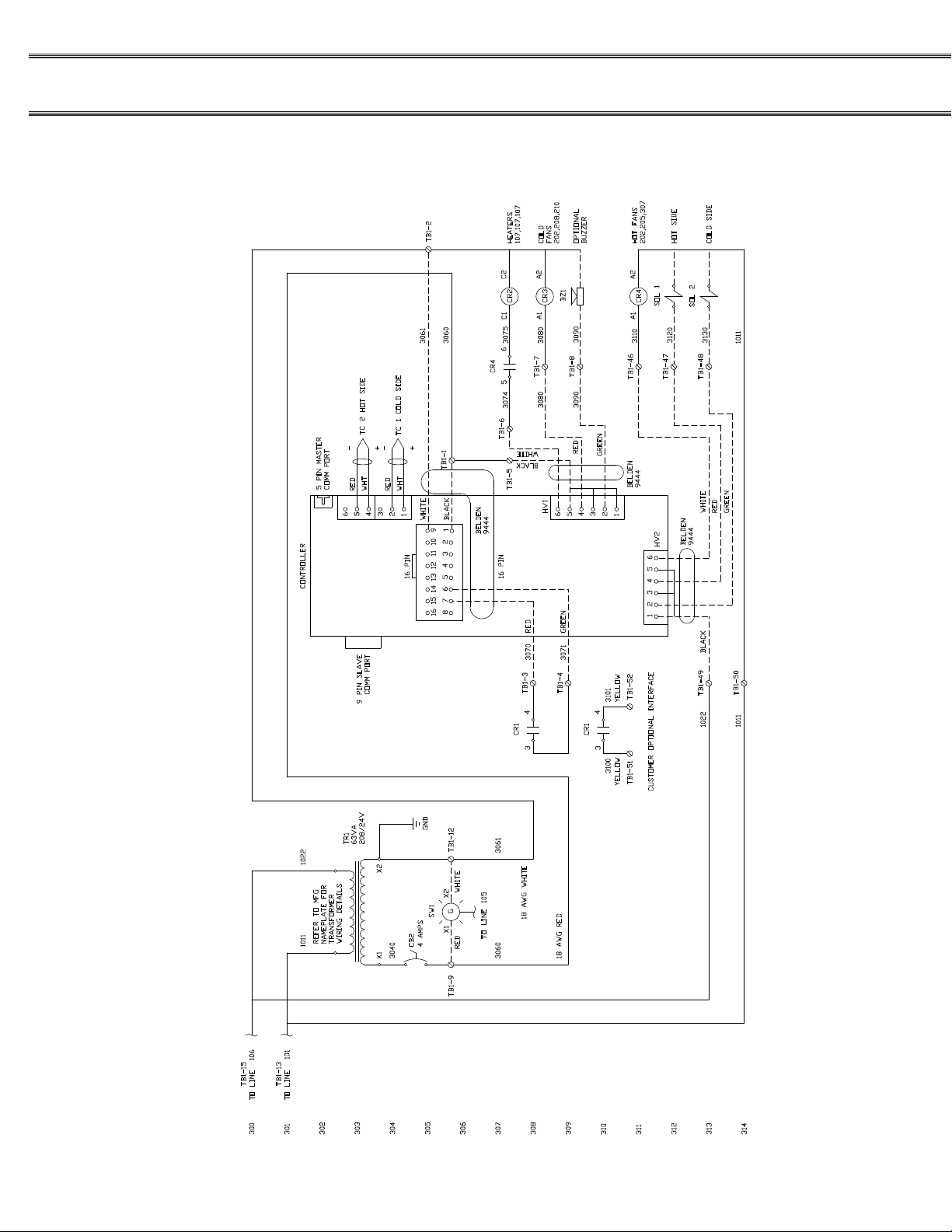

24 Meal (CR3D0XXX1)

Installation & Service

Manual

46

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

24 Meal (CR3D0XXX1)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

47

CONVECT-RITE™ III Docking Stations

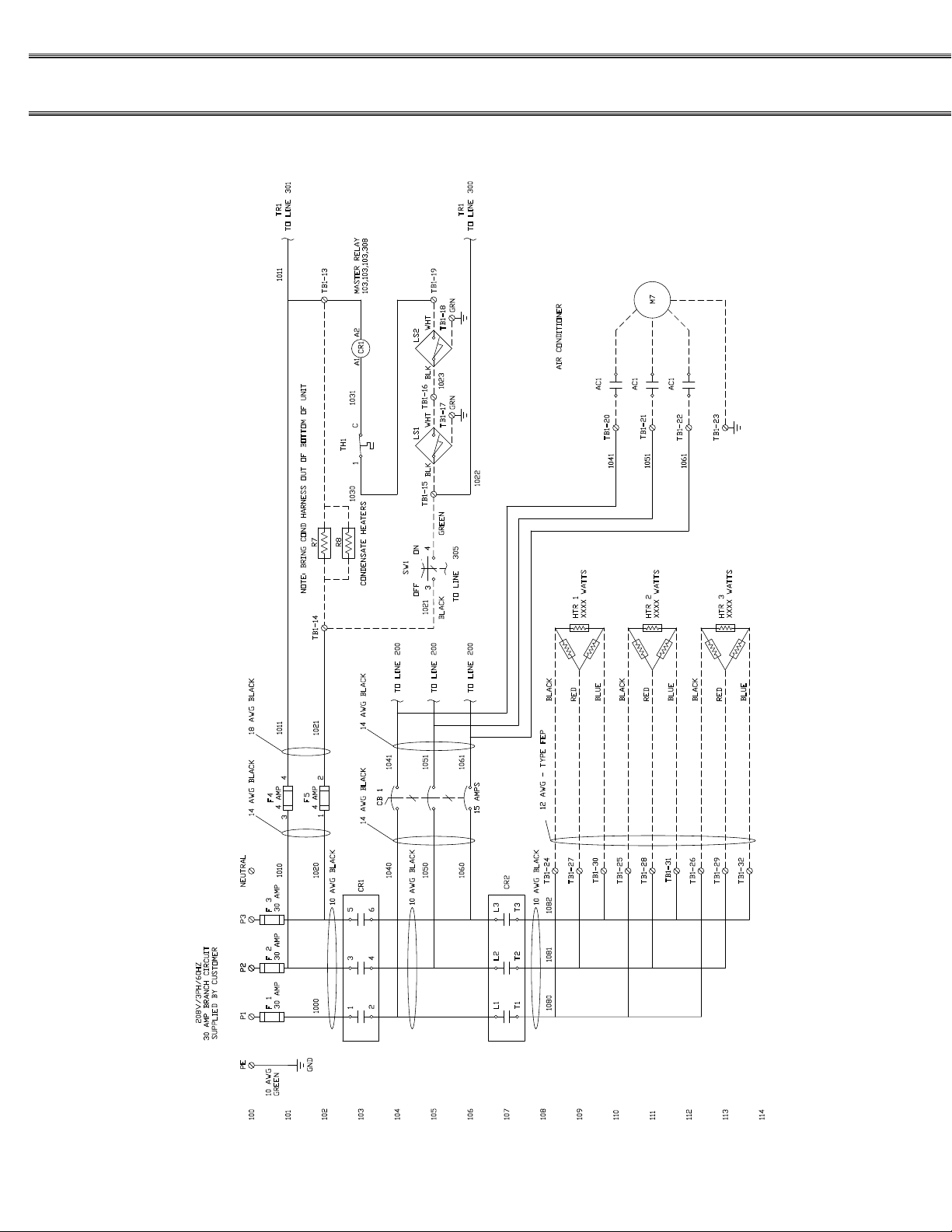

30 Meal (CR3D1XXX1)

Installation & Service

Manual

48

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

30 Meal (CR3D1XXX1)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

49

CONVECT-RITE™ III Docking Stations

30 Meal (CR3D1XXX1)

Installation & Service

Manual

50

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

30 Meal (CR3D1XXX1)

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

51

CONVECT-RITE™ III Docking Stations

Installation & Service

Manual

VII. WARRANTY

ALADDIN TEMP-RITE

EQUIPMENT

LIMITED WARRANTY

Effective March 24, 2004

Aladdin Temp-Rite (“ATR”) warrants to the original purchaser that the equipment listed below shall be free from defects

in material and workmanship under normal use for the applicable warranty term set forth below. ATR’s obligation under

this warranty is limited to the repair or replacement , at the sole option of ATR, of any part which upon inspection and

examination by ATR or its authorized agent is found to be defective. A written description detailing the nature of the claimed

defect, together with the equipment claimed to be defective if required by ATR, must be delivered to ATR or its authorized

agent within 30 days of discovery of the claimed defect (but in no event later than 30 days after the expiration of the

applicable warranty term).

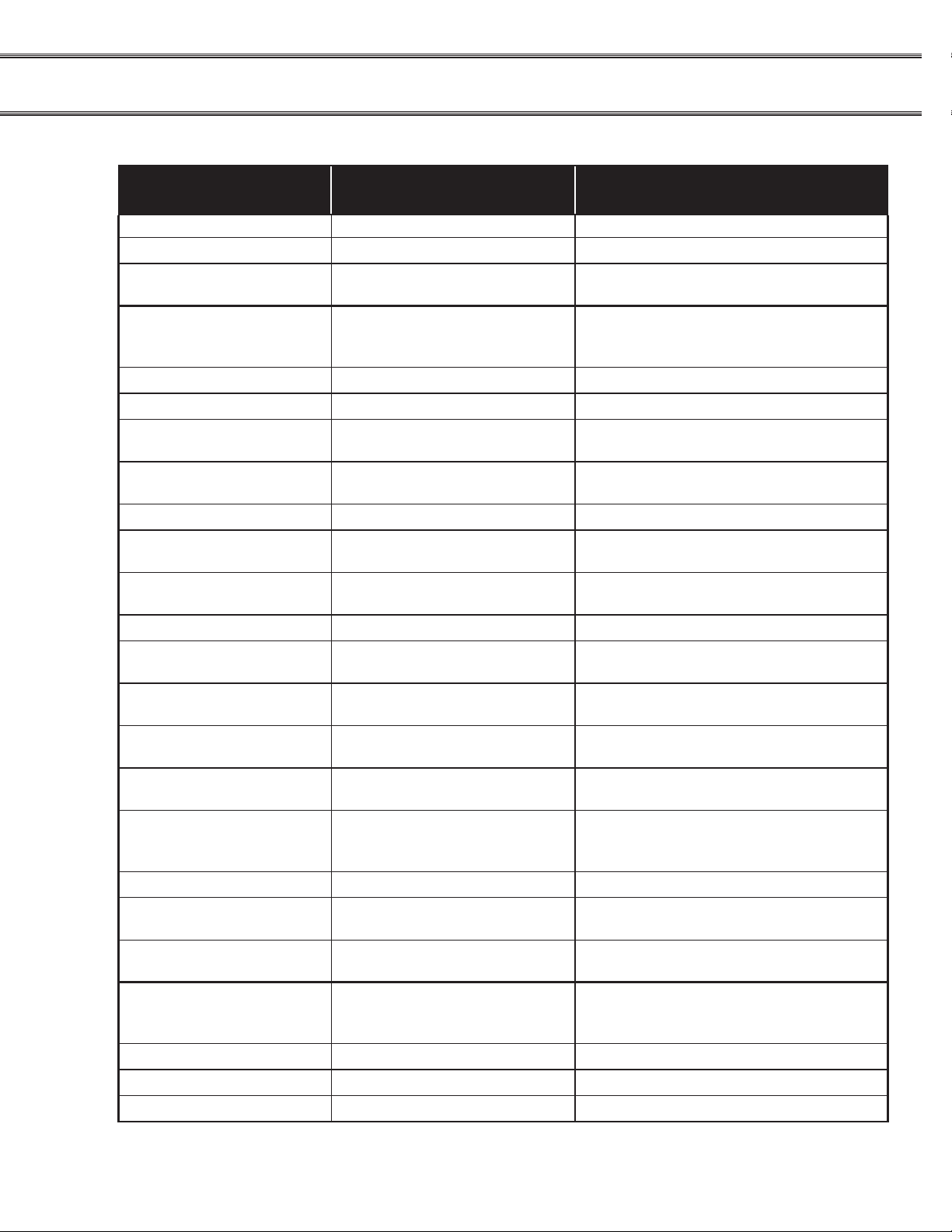

CONVECT-RITE™III

EQUIPMENT*

WARRANTY

TERMS*

COMPRESSOR

WARRANTY TERM*

PARTS ONLY**

PARTS LABOR

CONVECT-RITE™ III DOCKING STATION 1 Year 1 Year 5 Years

CONVECT-RITE™ III DOCKING STATION HEATING ELEMENTS

*The warranty term commences 30 days after the date of ATR’s invoice for the equipment. All our reusable crockery such

as: plates, dishes, bowls, covers are not included in our manufactures equipment warranty.

**The compressor warranty covers the compressor only and does not include any shipping charges, other transportation

costs, any external parts or electrical components, labor, refrigerants and taxes. Max 85°F Ambient operating environment.

THE WARRANTIES AND REPRESENTATIONS OF ATR CONTAINED HEREIN ARE EXPRESSLY IN LIEU OF, AND THE

BUYER WAIVES, ANY AND ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND ANY OTHER REMEDIES AGAINST ATR,

WHETHER BASED UPON CONTRACT, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE. ATR SHALL NOT BE

LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES OR ECONOMIC LOSS OF ANY NATURE (INCLUDING

WITHOUT LIMITATION LOSS OF REVENUES AND/OR PROFITS) THAT MAY BE CLAIMED TO RESULT FROM ANY

NEGLIGENCE OR BREACH OF WARRANTY OR CONTRACT BY ATR.

Exceptions and Exclusions

This warranty is issued only to the original purchaser, and is not transferable and applies only to the products installed

within the United States of America, its territories and Canada. During the term of any labor warranty, ATR will pay all

pre-approved shipping charges incurred in returning defective equipment to ATR and labor costs incurred in the removal

and reinstallation of such equipment. Contact ATR before returning any defective equipment or other wise performing any

warranty repairs. ATR assumes no liability for any work or repair performed without its prior approval. After the expiration

of any labor warranty, the original purchaser is responsible for all shipping charges incurred in returning defective equipment

to ATR and labor for removing and reinstalling such equipment. ATR shall not be responsible for the replacement of

expendable items like lamps and fuses or product failure resulting from normal wear and tear, improper installation, misuse,

sabotage, abuse, neglect, accident, unauthorized alterations to repair, or other factors beyond the control of ATR. Neither

this warranty, not the liability of ATR may be modied or extended by action of any agent, distributor or other person or by

custom or practice.

2 Years

1 Year na

CALL ATR TOLL FREE AT 1-800-888-5426 IF YOU HAVE ANY QUESTIONS ABOUT THIS WARRANTY OR YOUR ATR

PRODUCT.

52

FOR SERVICE CALL - ALADDIN TEMP-RITE® - Tech Service 1 (800) 888-5426

Loading...

Loading...