Aktilite CL128 User manual

SERVICE MANUAL

Aktilite

Ver 1.

CL128

3

Photoc

Hoffsveien 48

NO-

0377 OSLO, Norway

Phone: +47 22 06 22 10

www.photocure.com

ure ASA

Service Manual Aktilite

SERVICE

MANUAL

Aktilite

Any kind of service should only be carried out by authorised personnel.

Refer

to the User Manual for further information regarding safety and precautions.

TABLE OF CONTENTS

1

ASSEMBLY OF AKTILITE

1.1 M

1.1.1 Tools needed for the assembly of lamp with fixed lamp head................................3

1.1.2

1.2 R

1.3 HO

1.4 L

1.5 G

1.6 P

1.6.1

1.6.2

1.7 H

1.8 H

1.9 L

1.9.1

1.9.2

1.9.3

1.10 S

1.11 L

1.11.1

1.11.2

1.12 P

1.12.1

1.12.2

1.13 L

ATERIAL/EQUIPMENT..................................................................................................

Tools need

EADY TESTED SYSTEM ELECTRONICS MODULE

USING TOP MODULE

IGHT MODULE

LUE LENSES .................................................................................................................

OSITIONING ARM MODUL

Fixed lamp head .....................................................................................................

Detachable lamp head............................................................................................

OUSING BOTTOM MODULE

OUSING BACK MODULE

AMP HEAD MODULE

Fixed lamp head ...................................................................................................10

Detachable lamp head..........................................................................................11

Disassemly and Assembly of the lamp

TOP BLOCK MODULE (TS1

AMP INCLUDING PARALL

Fixed lamp head (128

Detachable lamp head (128

ARALLEL ARM WITH LAM

Fixed lamp head (128

Detachable lamp head (128

ABELS PLACEMENT DESC

CL128 LAMP WITH PAR

ed for the assembly of lamp with detachable lamp head ......................

(128

-0-

610)

ASSEMBLY .............................................................

(128

-0-

750) ..........................................................................................

E

(128

-0-

400)

ASSEMBLY ......................................................

(128

-0-

820) .......................................................................

(128

-0-

810)

ASSEMBLY ..........................................................

(128

-0-

200)

ASSEMBLY..............................................................10

-0-

250)

ASSEMBLY ............................................................27

EL ARM ASSEMBLY...............................................................28

-0-

250)...............................................................................28

-0-

252)......................................................................29

P HEAD HOLDER UNIT A

-0-

210)...............................................................................31

-0-

212)......................................................................32

RIPTION ...............................................................................33

CL128

CL128

slide series............................................12

ALLEL ARM.....................

(128

-0-

439)

ASSEMBLY.....................

SSEMBLY ........................................31

3

3

3

4

5

6

6

7

7

8

9

9

2 REPLACING THE DC POW

3

ASSEMBLY OF AKTILITE

3.1 M

3.2

3.3

3.4

3.5 P

4

ERROR CO

Version 1.

ATERIAL/EQUIPMENT................................................................................................35

PS

ELECTRONICS MODULE

PS

HOUSING MODULE

PS

HOUSING MODULE

OWER SUPPLY

DES ..............................................................................................................40

3

(128

-0-

A

B

300)

(128

(128

ER PLUG.......................................................................34

CL128 POWER SUPPLY.............................................35

(128

-0-

330)

ASSEMBLY......................................................36

-0-

310)

ASSEMBLY..........................................................37

-0-

320)

ASSEMBLY..........................................................38

ASSEMBLY.......................................................................39

Page 2 of 41

This service manual is primarily meant for mechanical repairs

with fixed and deta

The electronic control board in the lamp head has to be programmed with the parameters

calibrated light module. If the electronic control board is faulty then the complete board is changed and

programmed with the original p

Device History Record for the lamp kept at the factory

mode can only be done by trained service personnel. The

and lenses.

If a power supply

Photocure. However, this has to be tested for leakage current,

test by qualified personnel.

1

1.1 Material/Equipment

Assembly of Aktilite CL128 Lamp with Parallel Arm

If a led diode is faulty then the complete

chable lamp head.

electronics board

Service Manual Aktilite

arameters for the light module. These

is faulty, a new tested power supply can be obtained from

CL128

and entering the device factory programming

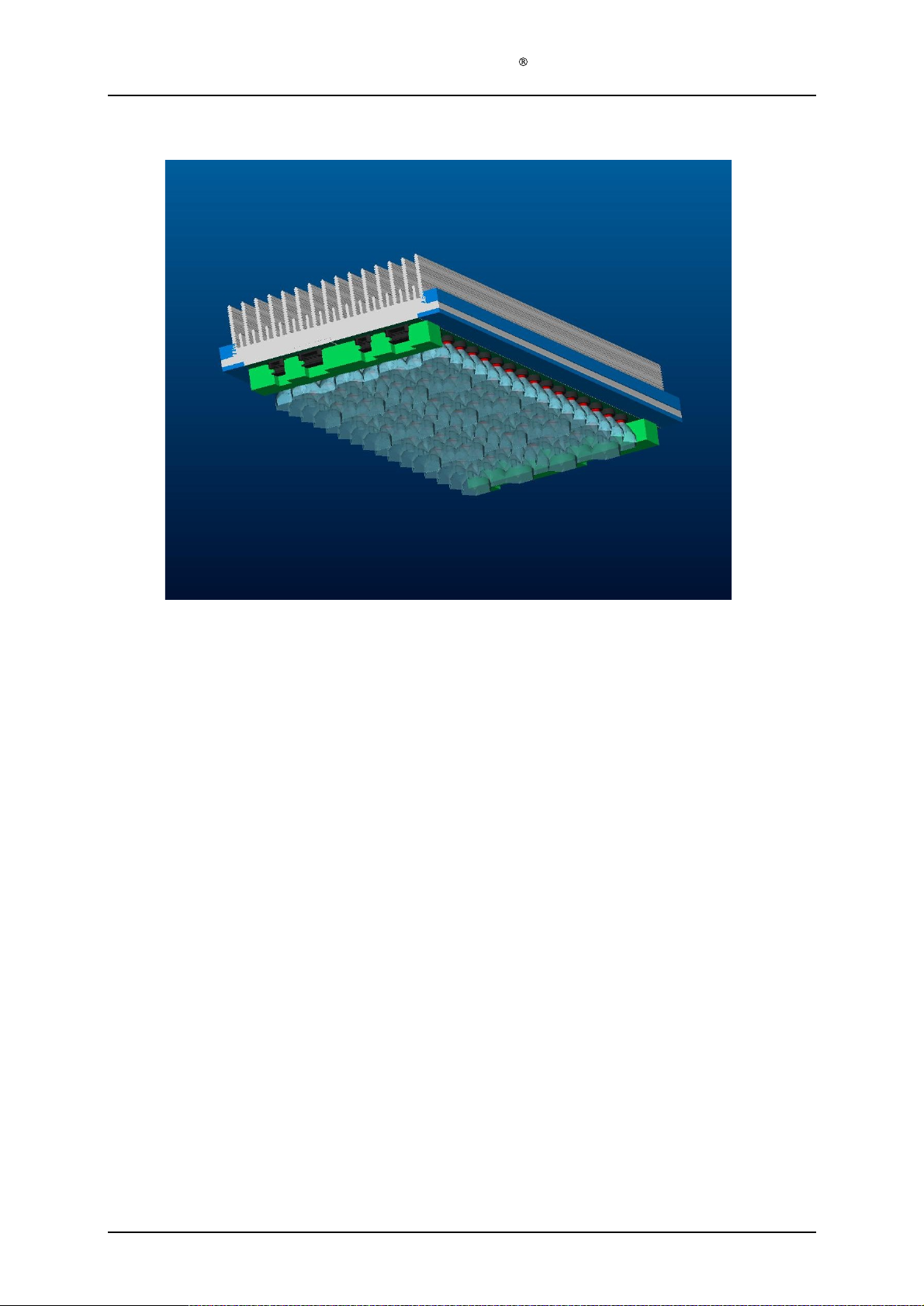

light module consist of led arra

light module

and covers both Aktilite

can

only

be retrieved from the

is changed.

eart

h continuity and withstanding voltage

CL128 lamps

to match

ys, heat sink

the

1.1.1 Tools needed for the assembly of lamp with fixed lamp head

Required tools

# of

items

1

1

1

1

1

1.1.2 Tools needed for the assembly of lamp with detachable lamp head

Required tools

# of

items

1

1

1

1

1

1

1

1

1

1

1

Description

Screwdriver,

Screwdriver, Pozidrive 2

Screwdriver, Torx

Screwdriver, Torx

Screwdriver, Torx T 20

Description

Screwdriver, Pozidrive 1

Screwdriver, Pozidrive 2

Screwdriver, Torx T 10

Screwdriver, Torx T 15

Screwdriver, Torx T 20

Allen key, 5mm

Press nut tool

Crimping tool LEMO DPC.91-701V

Locator male DCE.91.135.BVC

Locator female DCE.91.130.BVM

Ex

traction tool LEMO DCF.91.133.5LT

Pozidrive 1

T 7

T 10

Umbraco

Version 1.

3

Page 3 of 41

Service Manual Aktilite

1.2 Ready Tested System

Electronics

Module

CL128

(128

-0-

439

) assembly

Version 1.

3

Page 4 of 41

Service Manual Aktilite

1.3 Housing top module (128

Required items

Part #

128

-0-

978

1

128

-1-

637

1

128

-1-

932

5

128

-1-

626

1

128

-1-

628

1

128

-1-

931

4

128

-1-

636

1

# of items

CL128

-0-

610) assembly

Description

Housing top (mould

Housing top slide bearing

Screw

Housing right (moulded plastic)

Housing left (moulded plastic)

Screw

User interface (foil keyboard w/ta

Rubbing alcohol (fat free)

PT4x16 countersunk

PT4x25

ed plastic)

il)

Version 1.

Assembly description

Step 1)

Assemble the housing top slide bearing (128

the five countersunk PT4x16 screws (128

Step 2)

Assemble the housing left (128

(128

-0-

978) using the four PT4x25 screws (128

Step 3)

Clean the recessed area at the top of the housing top (128

alcohol

Step 4)

Glue the Key Touch panel (128

3

-1-

637) to the housing top (128

-1-

932).

-1-

628) and housing right (128

-1-

931).

-1-

636) to the housing top (128

-1-

626) to the housing top

-0-

978) using a cloth and rubbing

-0-

978).

-0-

978) using

Page 5 of 41

1.4 Ligh

t module (128

Service Manual Aktilite

-0-

750)

CL128

This light module comes as a ready

control electronics

the documentation f

comprehensive tests has to be done with spectrometer and radiometer so this can only

be done at the factory. The dose factor is a factor that is a combination of wavelength

and irradiance and will vary slightly from light modu

1.5 Glue lenses

If one of the lenses is loose they can be glued on to the substrate using

glue

.

and currents

ollowing

the specific light module. To determine the dose factor,

tested and

(set in factoring mode) has to be adjusted according to

calibrated part. The dose factor in the

le to light module.

Loctite 435

Version 1.

3

Page 6 of 41

Service Manual Aktilite

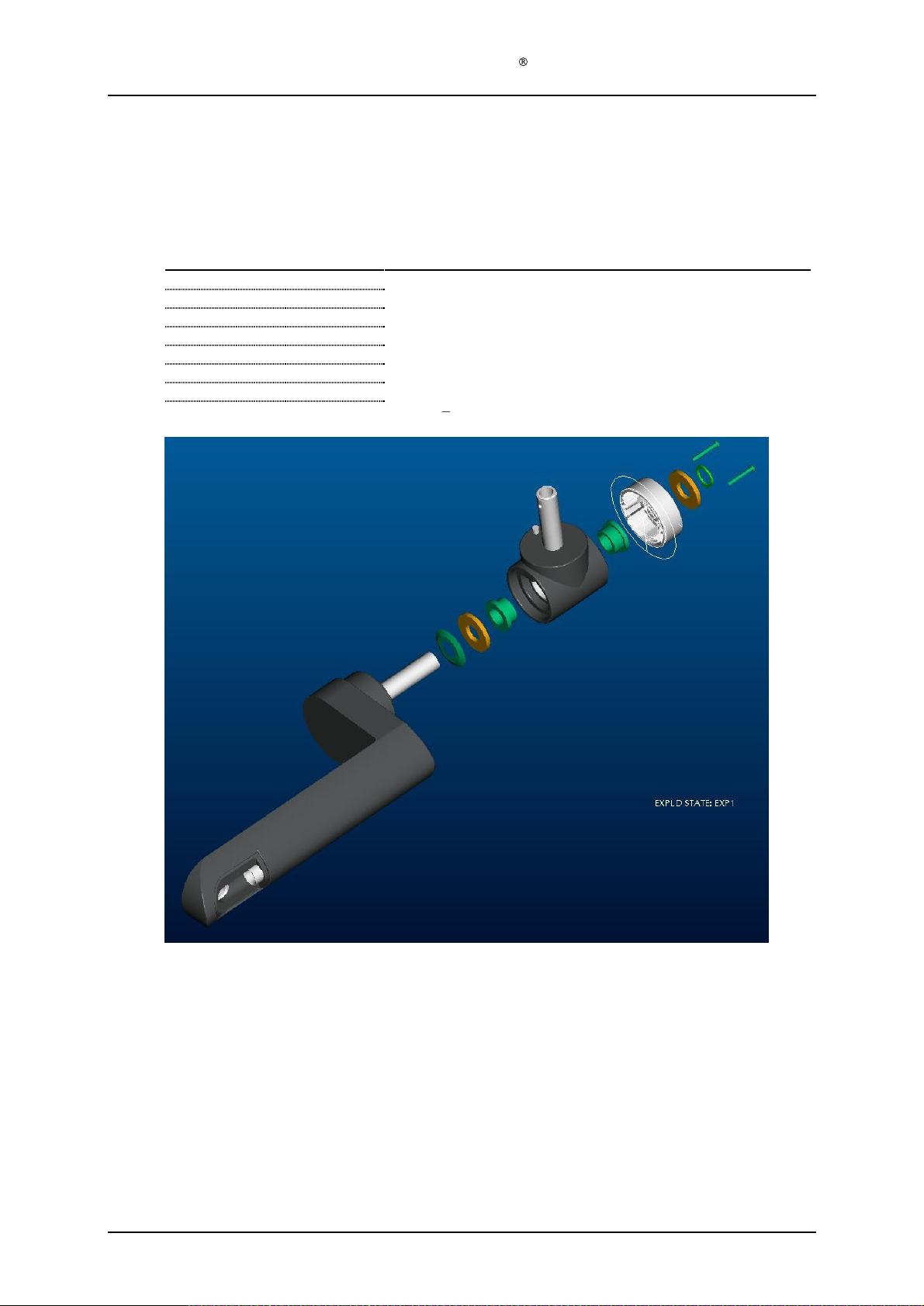

1.6 Positioning arm module (128

1.6.1

F

ixed lamp head

Required items

Part #

128

-0-437 1 T-piece (Moulded plastic)

128

-1-

910

2

128

-0-

428

1

128

-1-

914

2

128

-1-

912

1

128

-1-

916

1

128

-1-

424

1 T-

128

-1-

926

2

# of items

Description

Plastic bearing

Main arm (Moulded plastic)

Aluminium washer

Conical spring

Circlip

Screws PT3x25

CL128

-0-

400) assembly

s

s

piece cover (Moulded plastic)

Version 1.

Assem

Step 1)

Step 2)

Step 3)

Step 4)

Step 5)

Step 6)

3

bly description

Press the two plastic bearings (128

tool is necessary for this or a jig made by Kitron.)

Slide conical spring (128

end of the

Assemble one aluminium washer (128

already assembled plastic bearings (128

Compress the conical spring (128

the main arm (128

Assemble another aluminium washer (128

the Circlip is well located in the g

Assemble T-piece cover (128

conic spring (128

-1-

910) into the T-piece (128

-1-

912) onto aft tube of the main arm (128

-1-

912) goes towards the plastic of the main arm (128

-1-

914) and the T-piece (128

-1-

-1-

912) by

-1-

428). (This compression and holding can be done with one hand.)

roove.

-1-

424) using the two PT3x25 screws (128

910)).

holding the T-piece (128

-1-

914) and circlip (128

-0-437

). (Specially made

-0-

428), The pointed

-0-437

) (Including the

-1-437) tightly against

-1-

916). Make sure that

-1-

926).

-0-

428).

Page 7 of 41

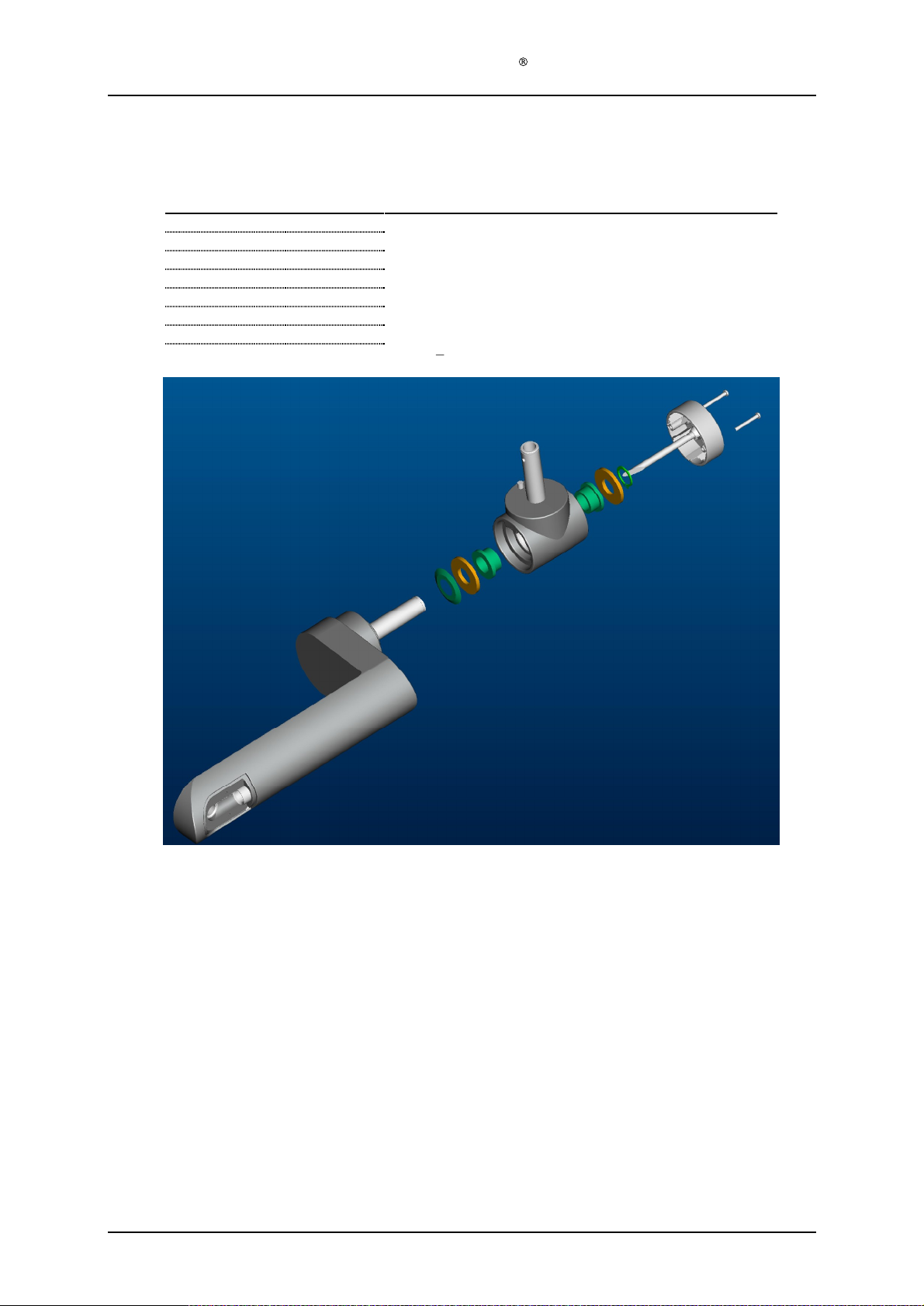

1.6.2

Deta

chable lamp head

Required Items

Part #

128

-0-

437

1 T-

128

-1-

910

2

128

-0-

428

1

128

-1-

914

2

128

-1-

912

1

128

-1-

916

1

128

-0-

988

1

128

-1-

926

2

Service Manual Aktilite

# of items

Description

piece (Moulded plastic)

Plastic bearing

Main arm (Moulded plastic)

Aluminium washer

Conical spring

Circlip

Cable from system electronics to lamp head connector

Screw

PT3x25

CL128

Version 1.

Assembly description

Step 1) Press the two plastic bearing

is necessary for this or a jig made by Kitron.)

Step 2) Broach the plastic bearings to Ø16,2mm after insertion in T-piece

Step 3) Slide conical spring (128

the conic spring (128

Step 4) Assemble one aluminium washer (128

already assembled plastic bearings (128

Step 5) Compress the conical

the main arm (128

Step 6) Assemble another aluminium washer (128

Circlip is

Step 7) Assemble power cable assembly (128

module (128

Step 8) Put in the cord and fasten the T-piece cover (128

988) using the two PT3x25

3

well located in the groove.

-0-

s (128

-1-

910) into the T-piece (128

-1-

912) onto aft tube of the main arm (128

-1-

912) goes towards the plastic of the main arm (128

-1-

914) and the T-piece (128

-1-

910)).

spring (128

-1-

428). (This compression and holding can be done with one hand.)

400).

-1-

912) by holding the T-piece (128

-0-

screws (128

-1-

914) and circlip (128

988) by inserting the cable thru the positioning arm

-1-

424) in the power cable assembly (128

-1-

926).

-0-

437). (Specially made tool

-0-

428), T

he pointed end of

-0-

428).

-0-

437) (Including the

-0-

437) tightly against

-1-

916). Make sure that the

Page 8 of 41

-0-

Service Manual Aktilite

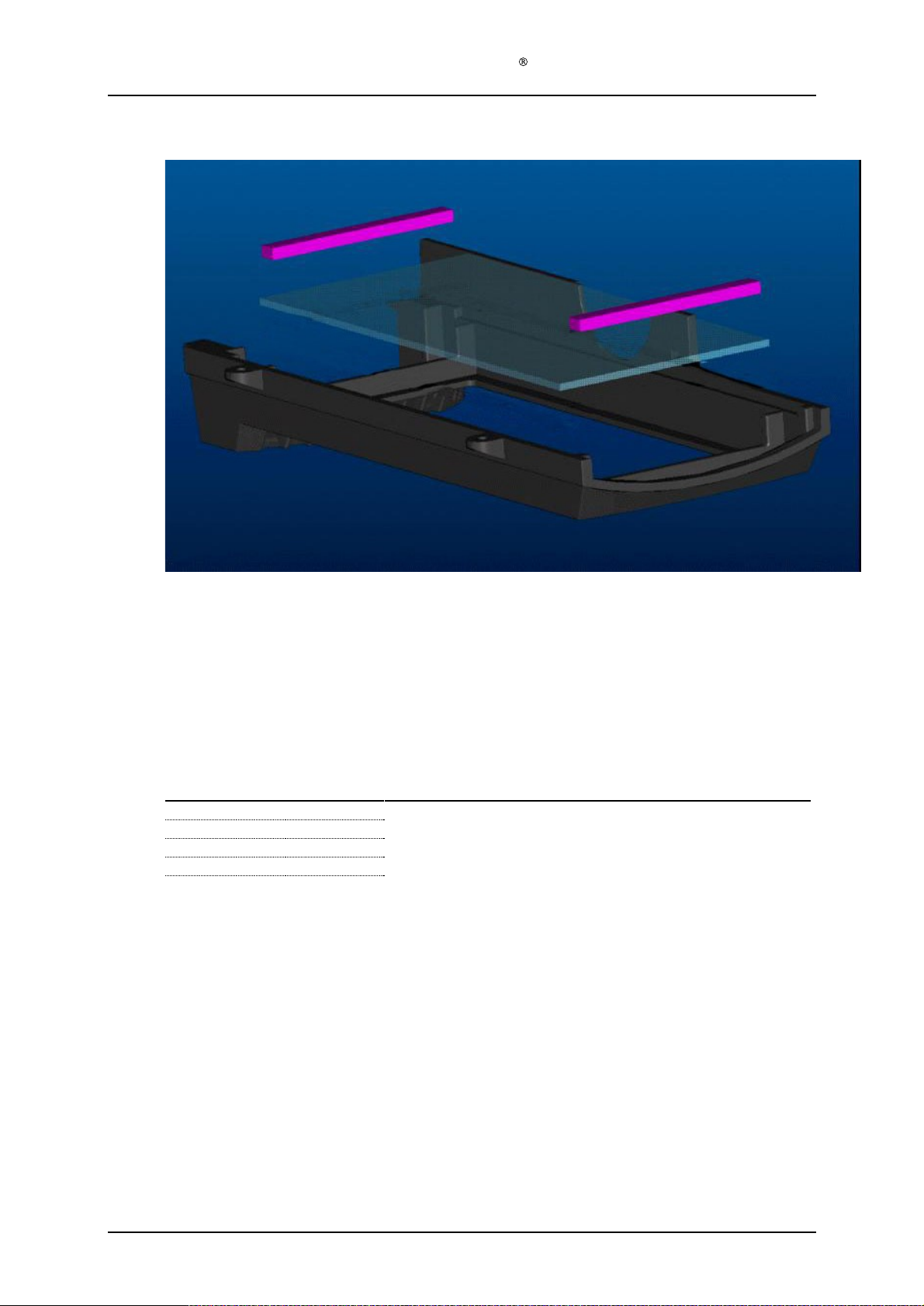

1.7 Housing bottom module (128

-0-

820)

CL128

The housing bottom c

Clean the glass if necessary before final assembly.

1.8 Housing back module (128

Required items

Part #

128

-1-

812

1

128

-1-

905

1

128

-1-

814

4

128

-1-

815

4

Assembly description

Step 1)

Place the fan (128

using the four M4x10 screws (128

must face upwards relative to the housing back (128

the top than at the bottom)

# of items

-1-

905) in the recess of the back housing (128

omes fully assembled as a s

-0-

810) assembly

Description

Housing back (Moulded plastic)

Fan

Screws M4x10 (DIN 7985)

Washer

s

-1-

814) and the four washers (128

-1-

pare part.

-1-

812) and mount the fan

812). (The housing back is wider at

-1-

815). The fan cable

Version 1.

3

Page 9 of 41

Service Manual Aktilite

1.9 Lamp head module (128

-

1.9.1

see slide series

F

ixed lamp head

Required items

Part #

128

-0-

610

128

-0-

400

128

-1-

914

128

-1-

912

128

-1-

916

128

-1-

202

128

-0-

810

128

-1-

928

128

-0-

439

128

-1-

921

128

-0-

750

128

-0-

820

128

-1-

929

128

-1-

890

128

-1-

923

128

-1-

945

inm Chapter 1.9.3

# of items

1

1

2

1

1

1

1

4

1

6

1

1

4

1

2

1

CL128

-0-

200) assembly

.

Description

Housing top module

Positioning arm module

Aluminium washer

Conic spring

Circlip

Power cable

Housing back module

Screws PT 4x30

System electronics module

Screws PT 2,5x8

Light module

Housing bottom module

Screws PT 4x10

Main arm mini cover (moulded plastic)

Screws PT 3x10

Ca

ble tension release

From PS to lamp head (fixed lamp head only)

s

(fixed lamp head only)

Assembly description

Step 1)

Assemble position arm module (128

the short axle of the main arm (128

Step 2)

Slide an alumi

aluminium washer (128

inside of the housing.

Step 3)

Compress the conical spring (128

easiest

done with a special made tool (see pictures)

securely in the groove.

Step 4)

Assemble power cable (128

(128

-0-

400). Leave exc

Step 5)

Position housing back module (128

0-

610). Do not assemble with screws yet.

Step 6)

Insert power cable (128

cable marked 2 is minus [-]), fan cable plug from housing back module (128

from the user interface of the housing top module 128

the system electronics module (128

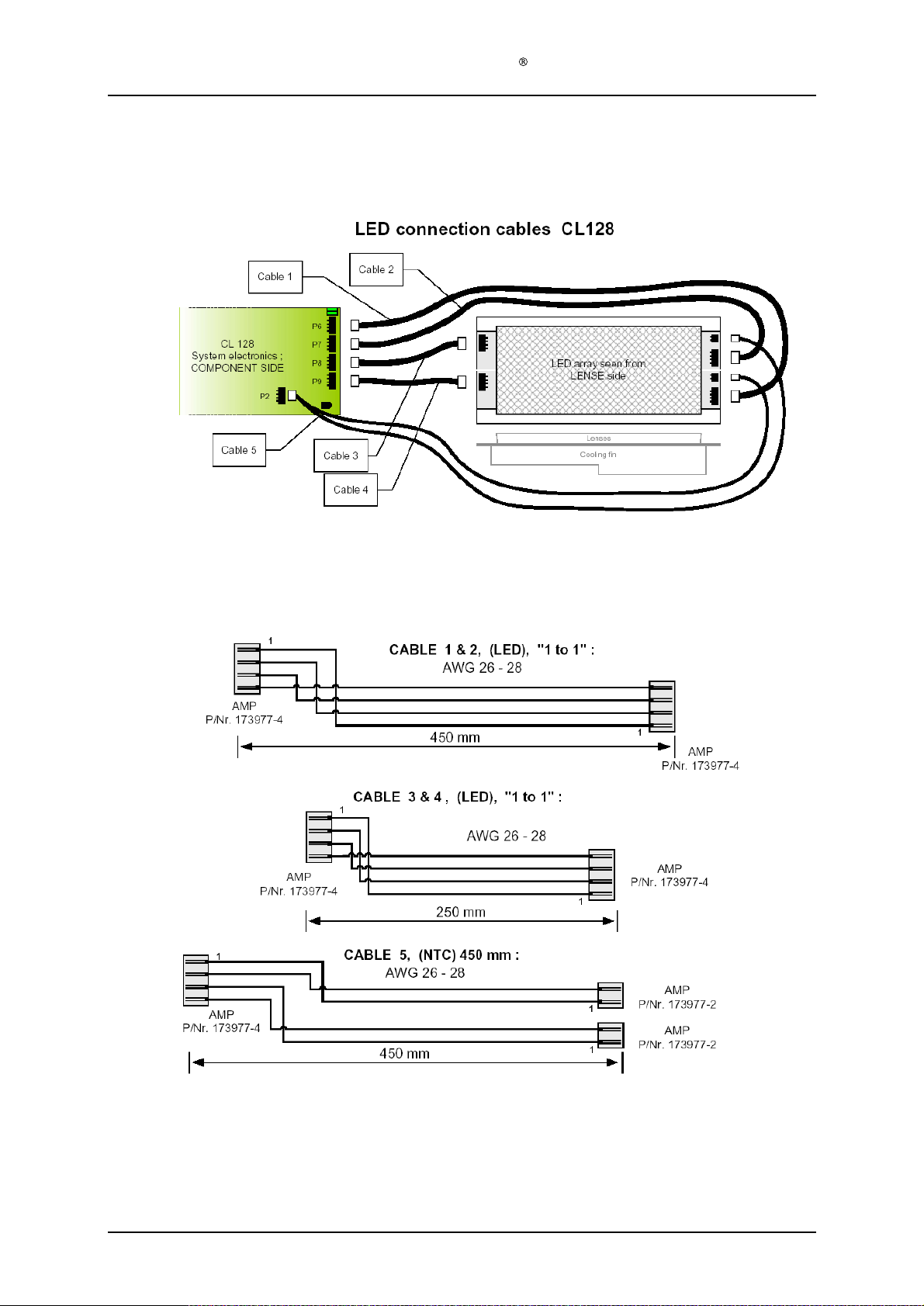

06.03.2002: "LED cables CL128, Rev. A".

Step 7)

Fasten the system electronics module (128

using the six PT 2,5x8 screws (128

302) from the lamp head.

Step 8)

Plug the six cables from the system electronics module (128

connectors on the LED-panels (128

Step 9)

Tidy the cables from the system electronics modul

four miniature cable holders (128

Step 10) Seat the light module (128

Step 11) Remove the protective foil from the protective window

module (128

Step 12) Assemble the housing bottom module (128

using the four PT 4x10 screws (128

Step 13) Fasten the housing back module (128

4x30 screws (128

Step 14) Assemble the main arm mini cover (128

using the two PT 3x10 screws (128

Step 15) Assemble the cable tension release (128

inserting it into the T-piece cover (128

nium washer (128

-1-

914) onto the short axle of the main arm (128

This is very important.

ess cable inside the lamp head to simplify assembly in a later step.

-1-

302) ends into appropriate rece

-0-

-0-

820).

-1-

928).

-0-

400) to housing top module (128

-0-

428) thru the housing top slide bearing (128

-1-

914), a conical spring (128

-1-

912) and assemble the circlip (128

. Make sure that the circlip is located

-1-

302) by inserting the cable thru the positioning arm module

-0-

810) at the back end of the housing top module (128

-0-

-0-

439

). Refer to cable spec from Kitron Development

-0-

439

) to the housing top module (128

-1-

921). And pull out the excess powe

-1-

762) of the light module (128

e (128

-1-

944) on the light module (128

750) properly in the housing top module (128

-0-

820) to the housing top module (128

-1-

929).

-0-

820) to the rest of the lamp head us

-1-

890) to the positioning arm module (128

-1-

923).

-1-

945) around the power cable (128

-1-

424) of the positioning arm module (128

-0-

610) by sliding

-1-

632).

-1-

912) and another

-0-

428) from the

-1-

916). This is

ptors (cable marked 1 is plus [+],

-0-

810) and tail

610 into appropriate connectors on

-0-

610)

r cable (128

-0-

439

) into the appropriate

-0-

750).

-0-

439) by inserting them thru the

-0-

750).

-0-

(128

-1-

826) of the housing bottom

ing the four PT

-1-

610).

-0-

-0-

302) and

-0-

-1-

610)

400)

400).

-

Version 1.

3

Page 10

of 41

Service Manual Aktilite

1.9.2 Detachable lamp head

Required items

Part #

128

-0-

610

1

128

-0-

400

1

128

-1-

914

2

128

-1-

912

1

128

-1-

916

1

128

-0-

810

1

128

-1-

928

4

128

-0-

439

1

128

-1-

921

6

128

-0-

750

1

128

-0-

820

1

128

-1-

929

4

128

-1-

890

1

128

-1-

923

2

# of items

CL128

Description

Housing top module

Positioning arm module

Aluminium washer

Conic spring

Circlip

Housing back module

Screw

System electronics module

Screw

Light module

Housing bottom module

Screw

Main arm mini cover (moulded plastic)

Screw

PT-K 40x30 WN 1452

PT 2,5x8

PT 4x10

PT 3x10

Assembly description

Step 1)

Assemble position arm module (128

the short axle of the main arm (128

Step 2)

Slide an aluminium washer (128

aluminium washer (128

inside of the housing.

Step 3)

Compress the

be done with a special made tool. Similar to a large pair of channel locks, but with custom

heads. Make sure that the circlip is located securely in the groove.

Step 4)

Position housing bac

0-

610). Do not assemble with screws yet.

Step 5)

Insert power cable (128

cable marked 2 is minus [-])

Step 6)

Fan cable plug from housin

the housing top module 128

system electronics module (128

Step 7)

Refer to PCU-010-128 for the connection of the cables going fro

board to the LED arrays..

Step 8)

Fasten the system electronics module (128

using the six PT 2,5x8 screws (128

302) from the lamp head.

Step 9)

Pl

ug the six cables from the system electronics module (128

connectors on the LED-panels (128

Step 10) Tidy the cables from the system electronics module (128

four miniature cable holders (128

Step 11) Seat the light module (128

Step 12) Remove the protective foil from the protective window (128

module (

Step 13) Assemble the housing bottom module (128

using the four PT 4x10 screws (128

Step 14) Fasten the housing back module (128

K 40x30 screws (128

Step 15) Assemble the main arm mini cover (128

using the two PT 3x10 screws (128

128

-1-

914) onto the short axle of the main arm (128

conical spring (128

k module (128

-0-

988) ends into appropriate receptors (cable marked 1 is plus [+],

g back module (128

-0-

-0-

-0-

820).

-1-

928)

.

-0-

400) to housing top module (128

-0-

428) thru the housing top slide bearing (128

-1-

914), a conical spring (128

-1-

912) and assemble the circlip (128

-0-

810) at the back end of the housing top module (128

-0-

810) and tail from the user interface of

610 shall be inserted into appropriate connectors on the

-0-

439

).

-0-

439

) to the housing top module (128

-1-

921). And pull out the excess power cable (128

-1-

762) of the light module (128

-0-

-1-

944) on the light module (128

750) properly in the housing top module (128

-0-

820) to the housing top module (128

-1-

929).

-0-

810) to the rest of the lamp head using the four PT

-1-

890) to the positioning arm module (128

-1-

923).

-0-

610) by sliding

-1-

-1-

912) and another

-0-

428), from the

-1-

916). This must

m the electronic control

-0-

-0-

439

) into the appropriate

-0-

750).

439

) by inserting them thru

-0-

750).

-0-

610).

-1-

826) of the housing bottom

-0-

632).

610)

-1-

610)

-0-

-

the

-

400)

Version 1.

3

Page 11

of 41

Service Manual Aktilite

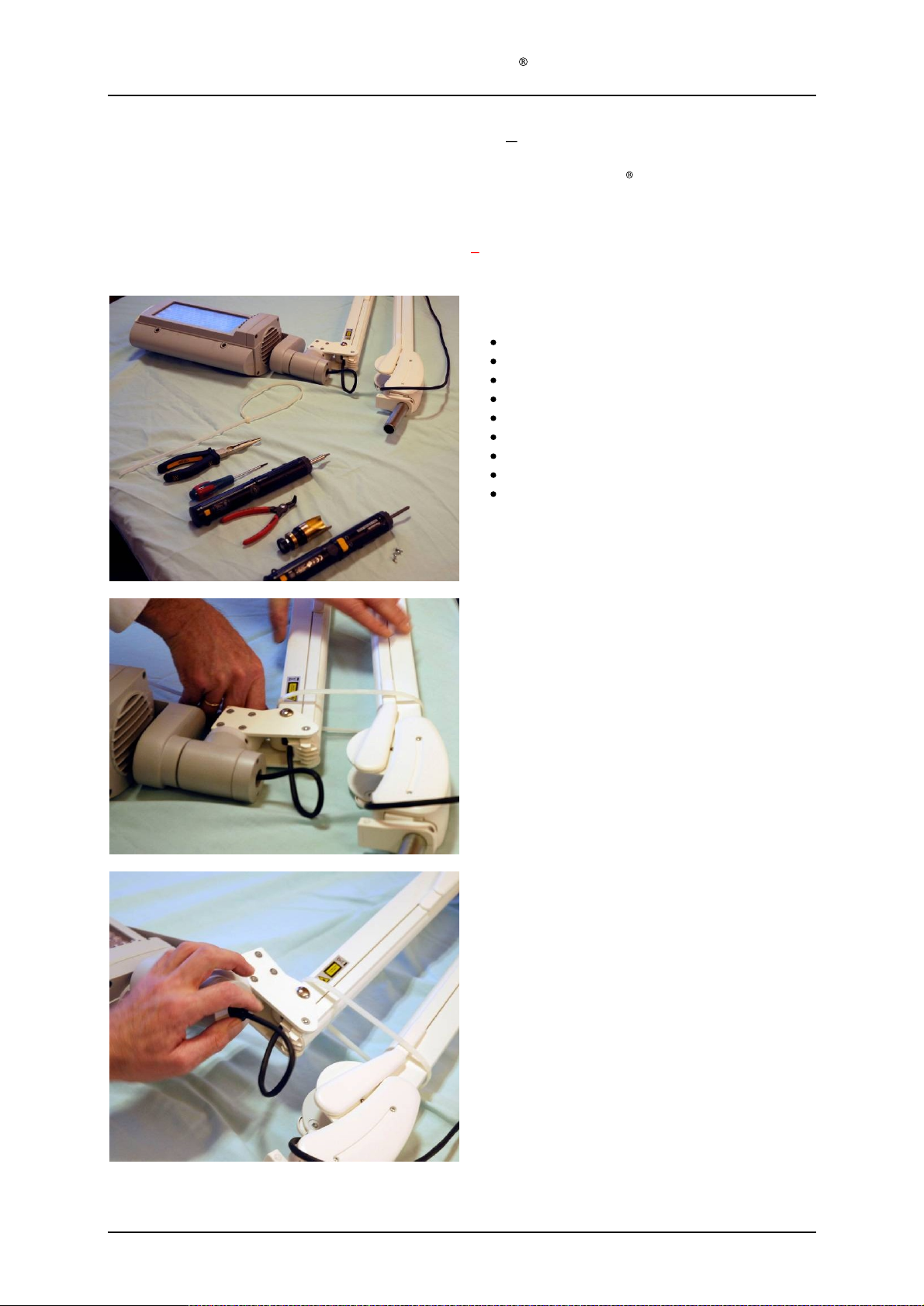

1.9.3 Disassemly and Assembly of

The lamp head module assembly slide series in this chapter is based on

head. However, there are only minor differences between lamp head module assembly for fixed and detachable

lamp head

Warning: The gas springs inside the arm is very powerful

. The below slide series is therefore common for both lamp head variations.

the lamp

therefore secure the arm with a strap

CL128

slide series

Required Tools

Nylon Strap length minimum 45 cm

Pair of telephone pliers

Circlip pliers for 16 mm circlip

Torx T7 screwdriver

Torx T10 screwdriver

Torx T20 screwdriver

Philips PH

Tool to compress the spring mechanism

Allen key (5mm)

the Aktilite

:

2 screwdriver

CL128 with fixed lamp

Step 1

Put on a strap or similar to secure the parallel arm.

Step 2

Step 2-5 is only necessary if you need to take off the

main arm, the housing or replace the cable.

Remove the

main arm using a pair of pliers

F

or lamps with deta

Disconnect the

plug and

lamp head holder locking screw using the

Allen key

strain relief (black) on the end of the

.

chable lamp head:

cable

plug

from the T-piece cover

detach

the lamp head by

.

removing

the

provided

Version 1.

3

Page 12

of 41

Service Manual Aktilite

Step 3

Step 2-5 is only necessary if you need to take off the

main arm, the housing or replace the cable.

Remove the strain relief.

Not applicable for lamps with detachable lamp

head

Step 4

Step 2-5 is only necessary if you need

main arm, the housing or replace the cable.

Remove the small cover on the main arm

T10 screwdriver

CL128

to take off the

using the

Step 5

Step 2-5 is only necessary if you need to take off the

main arm, the housing or replace the cable.

Feed a few cm

loop as shown.

of cord through the arm to make a

Version 1.

3

Page 13

of 41

Loading...

Loading...