Page 1

S

S

S

e

e

e

r

r

r

C

C

C

v

v

v

o

o

o

i

c

i

c

i

c

l

o

l

l

e

e

e

o

o

r

r

r

M

M

M

T

T

T

a

a

a

V

V

V

n

n

n

u

u

u

a

a

a

l

l

l

Page 2

2

Model:

C

C

C

C

C

C

T

T

T

h

h

h

-

-

-

a

a

a

3

3

3

s

s

s

s

s

s

4

4

4

s

i

i

i

C

C

C

s

s

:

:

:

J

J

J

C

C

C

S

S

S

N

N

N

-

-

-

5

5

5

1

1

1

R

R

R

8

8

8

E

E

E

E

E

E

D

D

D

Model no.: CT-34CJ5RE.doc

version 1.0

Page 3

3

CONTENTS

SAFETY INSTRUCTIONS AND MAINTENANCE..........................................................................4

TECHNICAL SPECIFICATION...............................................................................................................................4

PRODUCT SAFETY NOTICE................................................................................................................................. 5

SAFETY SYMBOL DESCRIPTION........................................................................................................................ 7

MAINTENANCE ..................................................................................................................................................... 8

MECHANICA DISASSEMBLES......................................................................................................... 9

ADJUSTMENTS..................................................................................................................................11

SET-UP ADJUSTMENTS.......................................................................................................................................11

CIRCUIT ADJUSTMENTS.................................................................................................................................... 14

STRUCTURE AND CHASSIS FUNCTION DESCRIPTION.........................................................25

STRUCTION BLOCK DIAGRAM......................................................................................................................... 25

BLOCK DIAGRAM FOR SUPPLY VOLTAGE SYSTEM................................................................................... 26

CHASSIS DESCRIPTION...................................................................................................................................... 27

SERVICE DATA..................................................................................................................................28

TECHNICAL DATA OF KEY ICs......................................................................................................................... 28

SERVICE DATA OF KEY ICs............................................................................................................................... 51

APPENDIX............................................................................................54

CIRCUIT DIAGRAM

PARTS LIST

Please read this manual carefully before service.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 4

SERVICE SAFETY AND MAINTENANCE

WARNING:

BEFORE EXAMINING AND SERVICING

THIS CHASSIS READ CAREFULLY THE

FOLLOWING SAFETY

INSTRUCTIONS.

X-RAY RADIATION PRECAUTION

4

1. The EHT must be checked every time the TV is serviced to ensure that the CRT does

not emit X-ray radiation as result of excessive EHT voltage. The maximum EHT voltage

permissible in any operating circumstances must not exceed the rated value. When

checking the EHT, use the High Voltage Check procedure in this manual using an

accurate EHT voltmeter.

2. The only source of X-RAY radiation in this TV is the CRT. The TV minimizes X-RAY

radiation, which ensures safety during normal operation. To prevent X-ray radiation,

the replacement CRT must be identical to the original fitted as specified in the parts list.

3. Some components used in this TV have safety related characteristics preventing the

CRT from emitting X-ray radiation. For continued safety, replacement component

should be made after referring the PRODUCT SAFETY NOTICE below.

4. Service and adjustment of the TV may result in changes in the nominal EHT voltage of

the CRT anode. So ensure that the maximum EHT voltage does not exceed the rated

value after service and adjustment.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 5

5

SAFETY PRECAUTION

WARNING:

REFER SERVICING TO

QUALIFIED SERVICE

PERSONNEL ONLY.

1. The TV has a nominal working EHT voltage. Extreme caution should be exercised when

working on the TV with the back removed.

a. Do not attempt to service this TV if you are not conversant with the precautions

and procedures for working on high voltage equipment.

b. When handling or working on the CRT, always discharge the anode to the TV

chassis before removing the anode cap in case of electric shock.

c. The CRT, if broken, will violently expel glass fragments. Use shatterproof

goggles and take extreme care while handling.

d. Do not hold the CRT by the neck as this is a very dangerous practice.

2. It is essential that to maintain the safety of the customer all power cord forms be replaced

exactly as supplied from factory.

3. Voltage exists between the hot and cold ground when the TV is in operation. Install a

suitable isolating transformer of beyond rated overall power when servicing or connecting

any test equipment for the sake of safety.

4. When replacing ICs, use specific tools or a static-proof electric iron with small power (below

35W).

5. Do not use a magnetized screwdriver when tightening or loosing the deflection yoke

assembly to avoid electronic gun magnetized and decrement in convergence of the CRT.

6. When remounting the TV chassis, ensure that all guard devices, such as nonmetal control

buttons, switch, insulating sleeve, shielding cover, isolating resistors and capacitors,

are installed on the original place.

7. Replace blown fuses within the TV with the fuse specified in the parts list. 8. When

replacing wires or components to terminals or tags, wind the leads around the terminal

before soldering. When replacing safety components identified by the international

hazard symbols on the circuit diagram and parts list, it must be the company-approved

type and must be mounted as the original.

8. Keep wires away from high temperature components.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 6

PRODUCT SAFETY NOTICE

CAUTION:

FOR YOUR PROTECTION

THE FOLLOWING PRODUCT SAFETY NOTICE

SHOULD BE READ CAREFULLY BEFORE

OPERATING AND SERVICING THIS TV SET.

1. Many electrical and mechanical components in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection

and the X-ray radiation protection afforded by them cannot necessarily be obtained by

using replacements rated at higher voltages or wattage, etc. Components which have

these special safety characteristics in this manual and its supplements are identified by the

international hazard symbols on the circuit diagram and parts list. Before replacing any of

these components read the parts list in this manual carefully. Substitute replacement

components which do not have the same safety characteristics as specified in the parts list

may create X-ray radiation.

2. Do not slap or beat the cabinet or CRT, since this may result in fire or explosion.

3. Never allow the TV sharing a plug or socket with other large-power equipment. Doing so

may result in too large load, causing fire.

4. Do not allow anything to rest on or roll over the power cord. Protect the power cord from

being walked on, modified, cut or pinched, particularly at plugs.

5. Do not place any objects, especially heavy objects and lightings, on top of the TV set. Do

not install the TV near any heat sources such as radiators, heat registers, stove, or other

apparatus that produce heat.

6. Service personnel should observe the SAFETY INSTRUCTIONS in this manual during use

and servicing of this TV set. Otherwise, the resulted damage is not protected by the

manufacturer.

6

Model no.: CT-34CJ5RE.doc

version 1.0

Page 7

SAFETY SYMBOL DESCRIPTION

7

Model no.: CT-34CJ5RE.doc

version 1.0

Page 8

1. Place the TV set on a stable stand or base that is of adequate size and strength to

prevent it from being accidentally tipped over, pushed off, or pulled off. Do not

place the set near or over a radiator or heat register, or where it is exposed to direct

sunlight.

2. Do not install the TV set in a place exposed to rain, water, excessive dust,

mechanical vibrations or impacts.

3. Allow enough space (at least 10cm) between the TV and wall or enclosures for

proper ventilation.

4. Slots and openings in the cabinet should never be blocked by clothes or other

objects.

5. Please power off the TV set and disconnect it from the wall immediately if any

abnormal condition are met, such as bad smell, belching smoke, sparkling,

abnormal sound, no picture/sound/raster. Hold the plug firmly when disconnecting

the power cord.

6. Unplug the TV set from the wall outlet before cleaning or polishing it. Use a dry soft

cloth for cleaning the exterior of the TV set or CRT screen. Do not use liquid

cleaners or aerosol cleaners.

MAINTENANCE

8

Model no.: CT-34CJ5RE.doc

version 1.0

Page 9

MECHANICA DISASSEMBLIES

CABINET BACK REMOVAL

1. Refer to Figure 1, remove 7screws.

2. Pull off cabinet back and remove.

9

CHASSIS REMOVAL

1. Remove cabinet back.

2. Discharge the picture tube anode (2

grounding lead).

3. Disconnect Degaussing coil socket (KE). Picture tube socket, Deflection yoke connector

(KDY). Speaker connectors (KL and KR), and 2

4. Remove chassis completely by sliding it straight back.

nd

anode lead) to the dag coating (picture tube

nd

anode lead.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 10

10

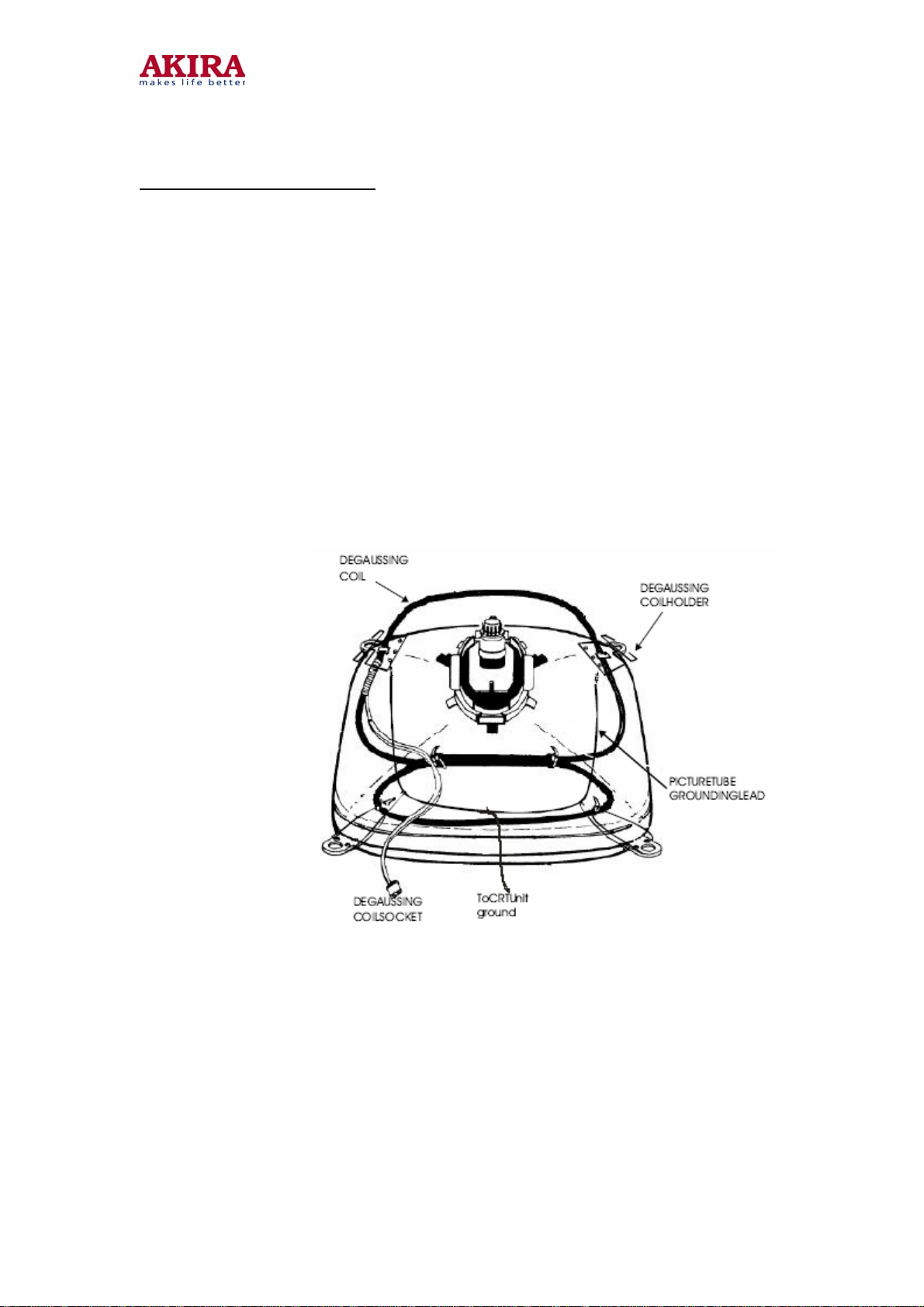

PICTURE TUBE REMOVAL

CAUTION: Do not disturb the deflection yoke or magnet assembly on the picture tube Neck.

Care must be taken to keep these assemblies intact, unless picture tube is being replaced.

Discharge the picture tube to the coating before handing the Tube.

1. Remove chassis, referring to Chassis Removal instructions.

2. Place cabinet front face down on the soft surface.

3. Remove the screw one ach corner of the picture tube and GENTLY lift the picture tube out

of the cabinet.

4. Install a replacement picture tube in reverse order.

5. Properly install the degaussing coil and picture tube grounding lead on the picture tube.

SeeFigure2.

Note: If the Picture Tube is being replaced, mount the Degaussing Coi l on the picture tube. See

following Figure1.Cabinet Back Removal

Model no.: CT-34CJ5RE.doc

version 1.0

Page 11

11

ADJUSTMENTS

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete realignment is required or a new

picture tube is installed.

Perform the adjustments in the following order:

1. Color purity

2. Convergence

3. White balance

Notes:

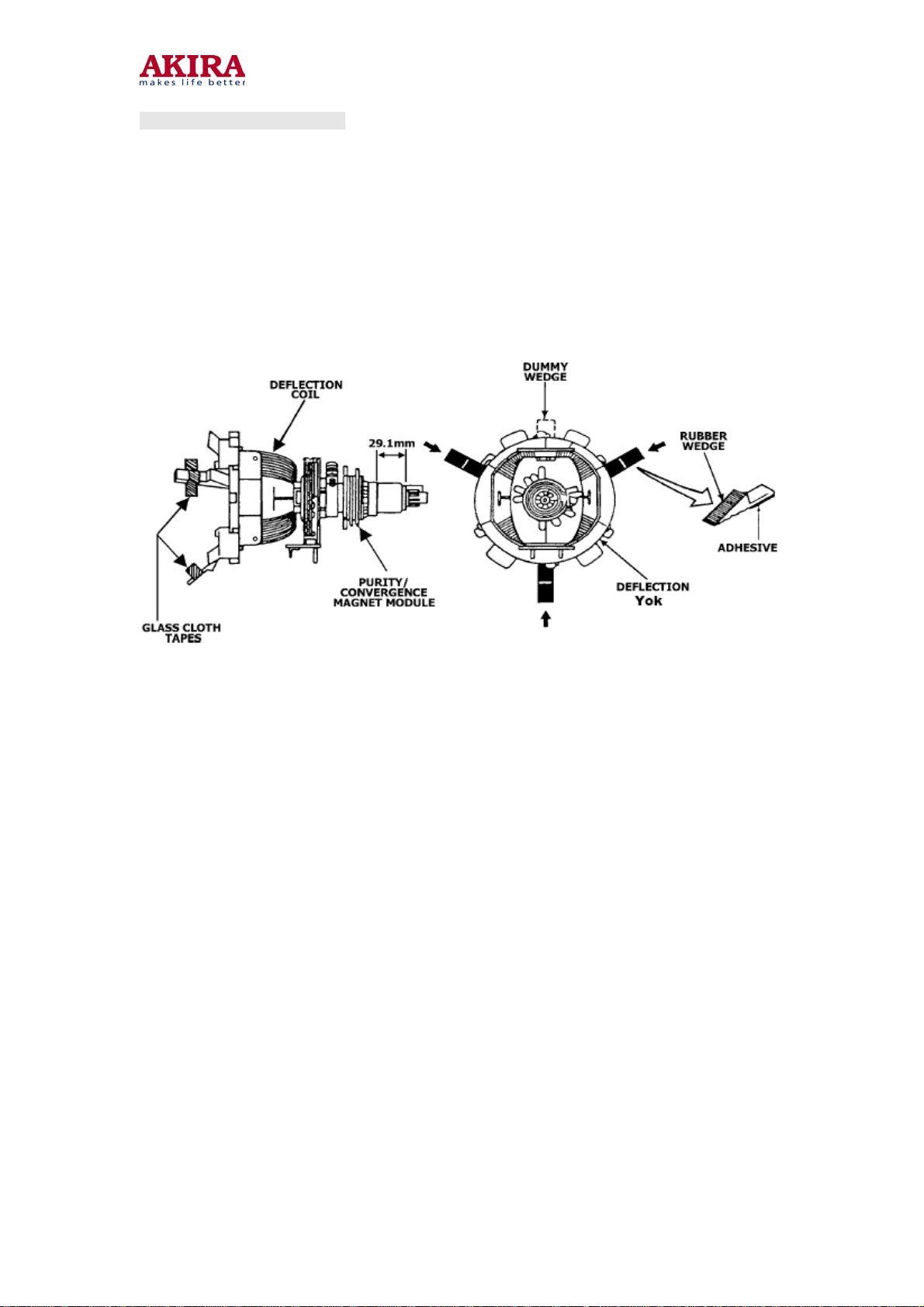

1. The purity/convergence magnet assembly and rubber wedges need mechanical ositioning.

Refer to Fig1, 2.

2. For some picture tubes, purity/ convergence adjustments are not required.

1. Color Purity Adjustment

Preparation:

Before starting this adjustment, adjust the vertical sync, horizontal sync, vertical amplitude and

focus.

1.1 Face the TV set north or south.

1.2 Connect the power plug into the wall outlet and turn on the main power switch of the TV set.

1.3 Operate the TV for at least 15 minutes.

1.4 Degauss the TV set using a specific degaussing coil.

1.5 Set the brightness and contrast to maximum.

1.6 Counter clockwise rotate the R /B low brightness potentiometers to the end and rotate

the green low brightness potentiometer to center.

1.7 Receive green raster pattern signals.

1.8 Loosen the clamp screw holding the deflection yoke assembly and slide it forward

or backward to display a vertical green zone on the screen. Rotate and spread the

tabs of the purity magnet around the neck of the CRT until the green zone is

located vertically at the center of the screen.

1.9 Slowly move the deflection yoke assembly forward or backward until a uniform

green screen is obtained.

1.10 Tighten the clamp screw of the assembly temporarily. Check purity of the red raster

and blue raster until purities of the three rasters meet the requirement.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 12

12

2. Convergence Adjustment

Preparation:

Before attempting any convergence adjustment, the TV should be operated for at least 15

minutes.

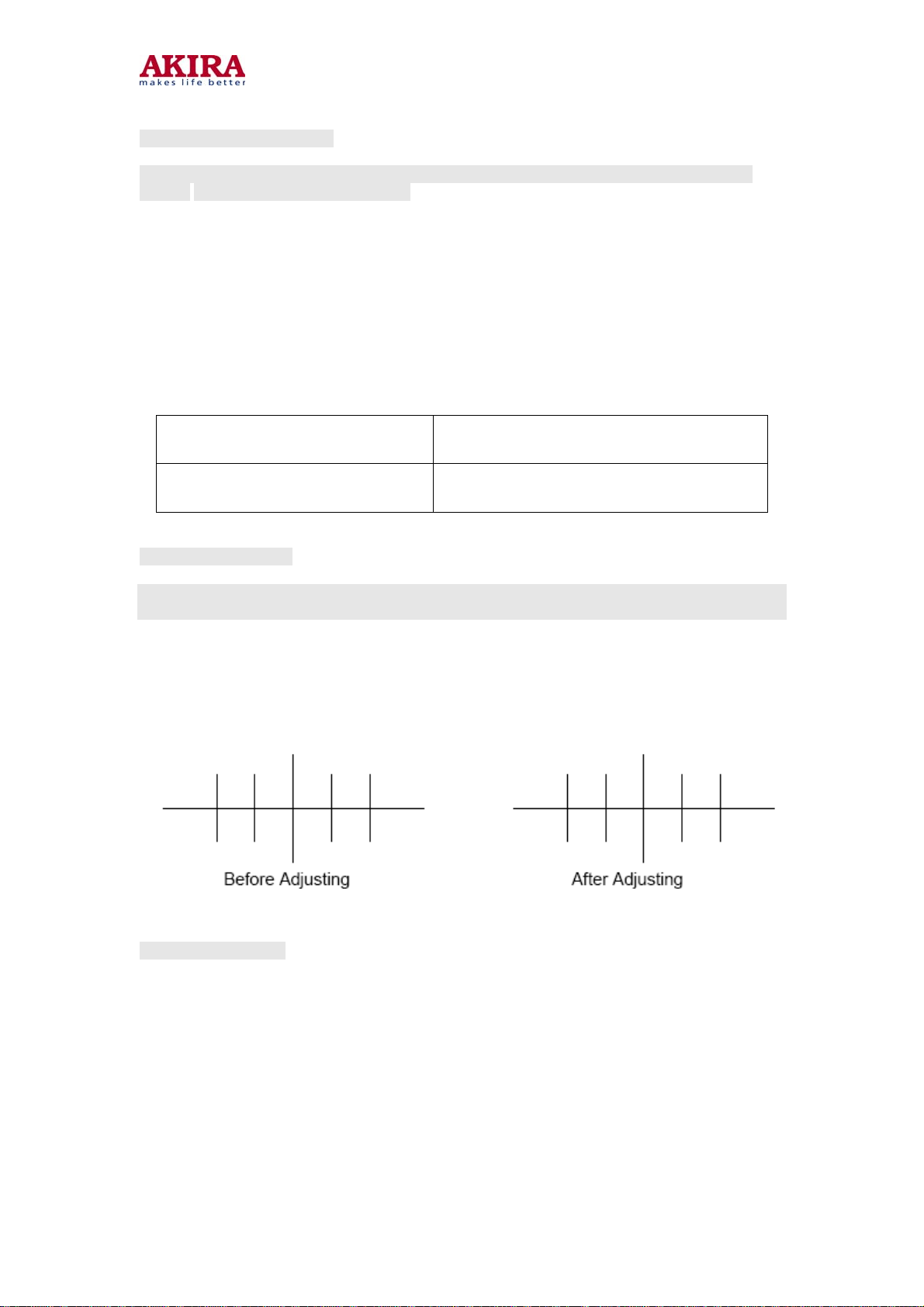

2.1 Center convergence adjustment

2.1.1 Receive dot pattern.

2.1.2 Adjust the brightness/contrast controls to obtain a sharp picture.

2.1.3 Adjust two tabs of the 4-pole magnet to change the angle between them and red and blue

vertical lines are superimposed each other on the center of the screen.

Fig. 1

2.1.4 Turn both tabs at the same time keeping the angle constant to superimpose red and blue

horizontal on the center of the screen.

2.1.5 Adjust two tabs of the 6-pole magnet to superimpose RED/BLUE line and green line.

2.1.6 Remember RED and BLUE movement. Repeat step 2.1.3 ~ 2.1.5 until optimal

convergence is obtained.

2.2 Circumference convergence adjustment

2.2.1 Loosen the clamp screw holding the deflection yoke assembly and allow it tilting.

2.2.2 Temporarily put the first wedge between the picture tube and deflection yoke assembly.

Move front of the deflection yoke up or down to obtain better convergence

in circumference. Push the mounted wedge in to fix the yoke temporarily.

2.2.3 Put the second wedge into bottom.

2.2.4 Move front of the deflection yoke to the left or right to obtain better convergence in

circumference.

2.2.5 Fix the deflection yoke position and put the third wedge in either upper space. Fasten the

deflection yoke assembly on the picture tube.

2.2.6 Detach the temporarily mounted wedge and put it in either upper space. Fasten the

deflection yoke assembly on the picture tube.

2.2.7 After fastening the three wedges, recheck overall convergence and ensure to get optimal

convergence. Tighten the lamp screw holding the deflection yoke assembly.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 13

3. White Balance Adjustment

Generally, white balance adjustment is made with professional equipment. It’s not practical to

get good white balance only through manual adjustment. For TVs with I

the bus data to adjust white balance.

²C bus control, change

13

Fig. 2

Model no.: CT-34CJ5RE.doc

version 1.0

Fig.3

Page 14

14

CIRCUIT ADJUSTMENTS

Preparation:

Circuit adjustments should be made only after completion of set-up adjustments. Circuit

adjustments can be performed using the adjustable components inside the TV set. For TVs with

2C bus control, first change the bus data.

I

1. Degaussing

A degaussing coil is built inside the TV set. Each time the TV is powered on, the

degaussing coil will automatically degauss the TV. If the TV is magnetized by external strong

magnetic field, causing color spot on the screen, use a specific degausser to demagnetize the

TV in the following ways. Otherwise, color distortion will be shown on the screen.

1.1 Power on the TV set and operate it for at least 15 minutes.

1.2 Receive red full-field pattern.

1.3 Power on the specific degausser and face it to the TV screen.

1.4 Turn on the degausser. Slowly move it around the screen and slowly take it away from

the TV.

1.5 Repeat the above steps until the TV is degaussed completely.

2. Confirmation and Adjustment for Voltage

Caution: +B voltage has close relation to high voltage. To prevent X-ray radiation, set +B

voltage to the rated value.

2.1 Power on the TV and receive Philips test pattern.

2.2 Check the resistors and coils for being burned. (If the fuse is burned out, do not power on

the TV again until the cause is found out.)

2.3 Measure voltages of test points with the digital voltmeter. Measure the CRT high voltage

with the high-voltage testing equipment and heater voltage with the high-frequency effective

voltmeter. The rated values are shown as below.

Table 2

Test Point Voltage (V) Test Point Voltage (V)

Negative of VD871

Positive of C879 5±0.5V

Positive of C882 9±0.5V

82V±5V in standby

134±1.5V in use

Positive of C414 5±0.5V

Positive of C412 9±0.5V

16±

Negative of VD872

1V

Positive of C117 32±1V

Negative of VD402A 12.5±1V

Negative of VD404

Heater 6.3+0.2\-0.3Vrms

Model no.: CT-34CJ5RE.doc

version 1.0

27±1.5V

Negative of VD873 16±1V

Negative of VD874 16±1V

Negative of VD403 190±5.0V

CRT anode

29.5KV±1.2KV (only for 29” CRTs)

30.5KV±1.2KV (only for 34” CRTs)

Page 15

15

3. High Voltage Inspection

Caution: No high voltage adjustment components inside the chassis. Please perform high

voltage inspection in the following ways.

3.1 Connect a precise static high voltmeter to the second anode (inside the high voltage cap)

of the CRT.

3.2 Plug in the supply socket (240V AC 50Hz) and turn on the TV. Set the brightness and

contrast to minimum (OµA).

3.3 The high voltage reading should be less than the limited EHT voltage.

3.4 Change the brightness from minimum to maximum, and ensure high voltage not beyond the

Nominal EHT voltage: 29.5±29.51.2KV Limited EHT voltage: 32KV (only for 29” CRTs)

Nominal EHT voltage: 30.5±1.2KV Limited EHT voltage: 35KV (only for 34” CRTs)

4. Focus Adjustment

Caution: Dangerously high voltages are present inside the TV. Extreme caution should be

exercised when working on the TV with the back removed.

4.1 After removing the back cover, look for the FBT on the main PCB. There should be a FCB

on the FBT.

4.2 Power on the TV and preheat it for 15 min.

4 .3 Receive a normal TV signal. Rotate knob of the FCB until you get a sharp picture.

Fig. 4

5. Safety Inspection

5.1 Inspection for insulation and voltage-resistant

Perform safety test for all naked metal of the TV. Supply high voltage of 3000V AC, 50Hz (limit

current of 10mA) between all naked metal and cold ground. Test every point for 3 sec. and

ensure no arcing and sparking.

5.2 Requirements for insulation resistance

Measure resistance between naked metal of the TV and feed end of the power cord to be

infinity with a DC-500 high resistance meter and insulation resistance between the naked metal

and degaussing coil to be over 20M

Model no.: CT-34CJ5RE.doc

version 1.0

Page 16

6. Service Mode

6.1 To enter the SERVICE mode

Set the volume to 0 by the remote control. Then press and hold the MUTE button

on the remote control and MENU button on the TV at the same time for over 2 seconds.

In the S mode, press the POWER button to quit the S mode.

S

16

( “S” is Red and other items are Yellow.)

Use the ↑ ⁄ ↓ bttons on the remote control to highlight an adjustment and the← ⁄ → buttons

to adjust it.

The POS+/-, ↑ ⁄ ↓ , 1~6, RECALL, VOL+/-, MUTE and POWER buttons on the remote control

function in the S mode, but 100+, 7, 8, 9 and 0 buttons not.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 17

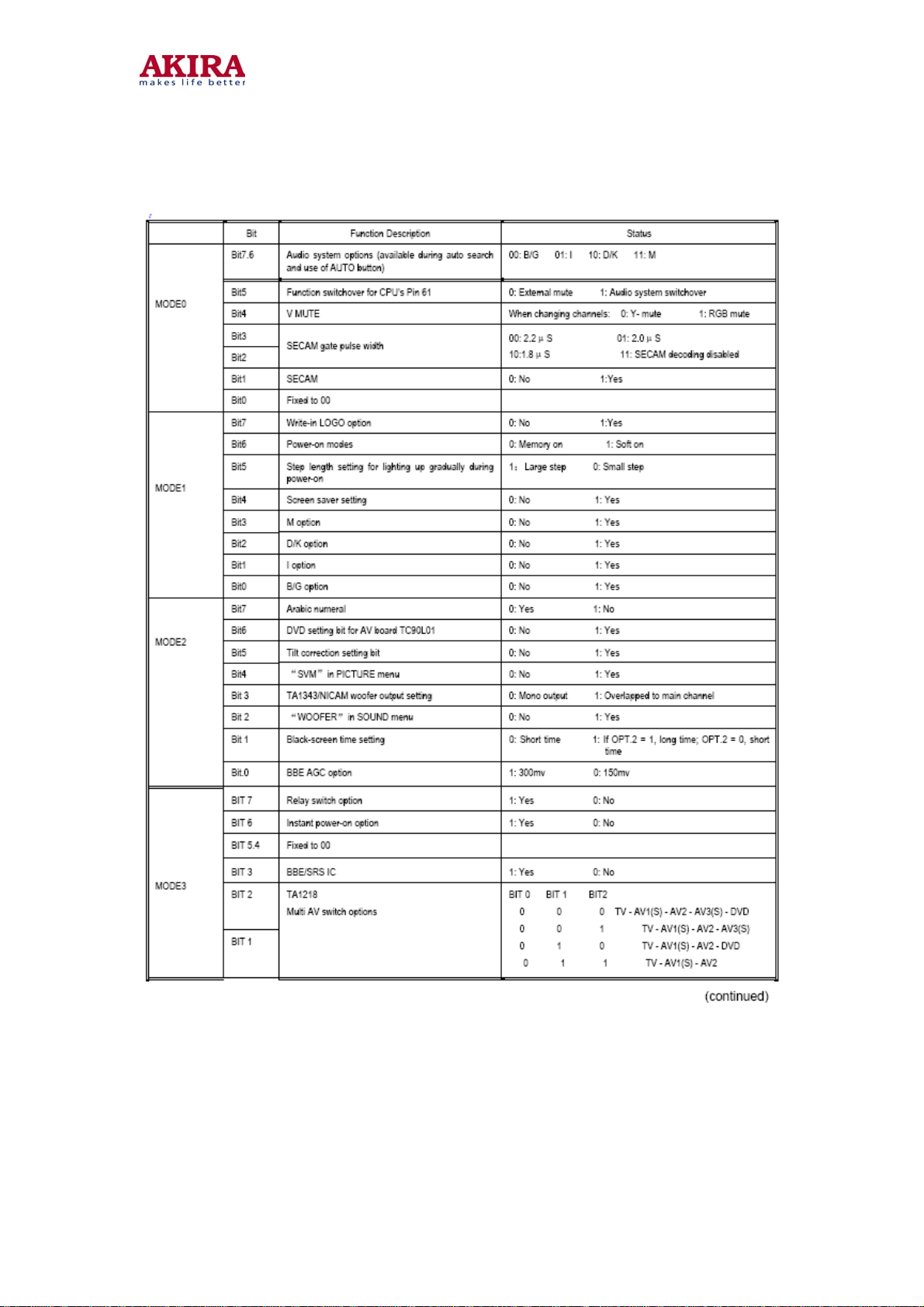

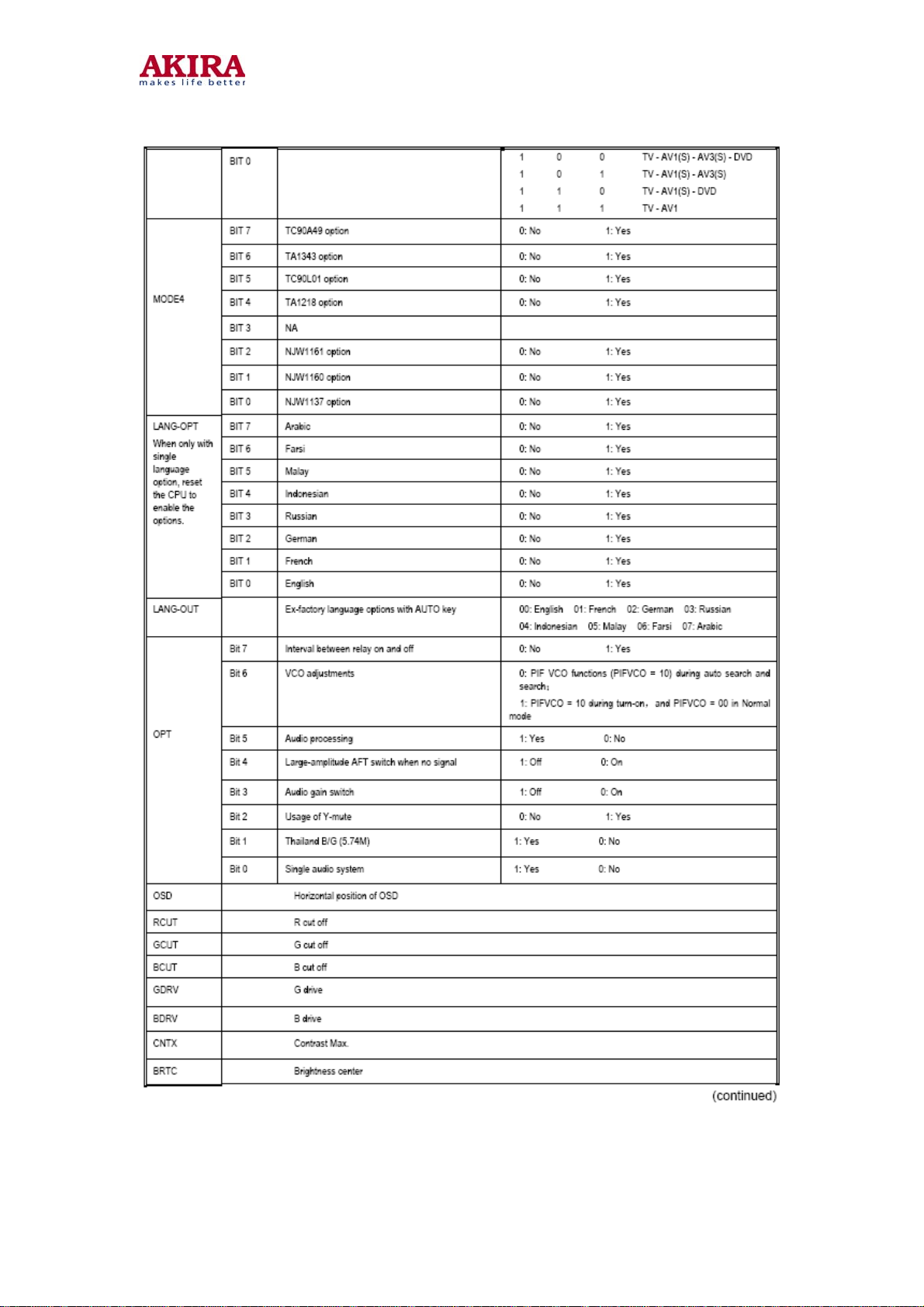

6.2 Adjustments for Service mode and design mode

Table 3

17

Model no.: CT-34CJ5RE.doc

version 1.0

Page 18

18

Model no.: CT-34CJ5RE.doc

version 1.0

Page 19

19

Model no.: CT-34CJ5RE.doc

version 1.0

Page 20

20

Model no.: CT-34CJ5RE.doc

version 1.0

Page 21

21

Model no.: CT-34CJ5RE.doc

version 1.0

Page 22

22

Model no.: CT-34CJ5RE.doc

version 1.0

Page 23

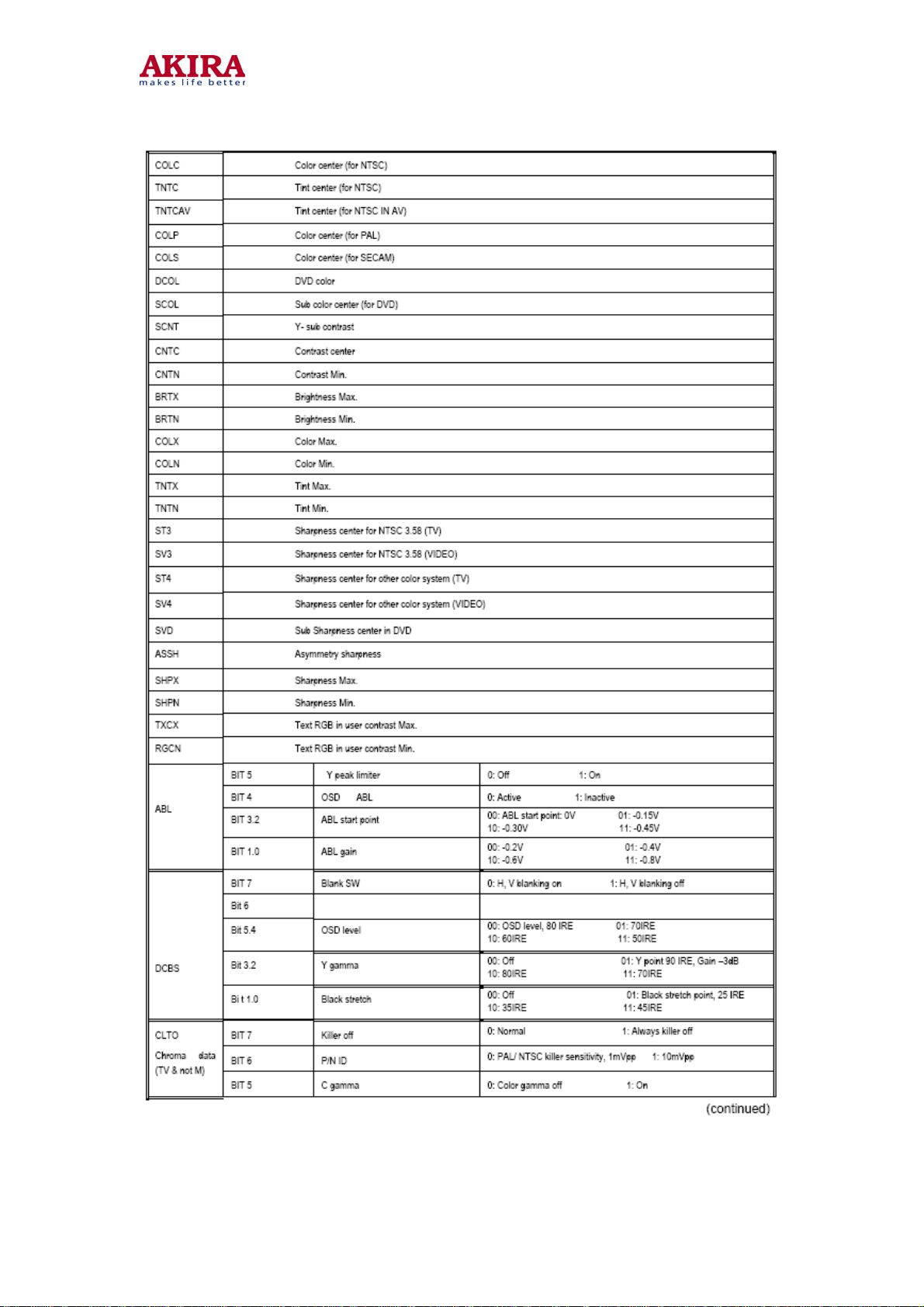

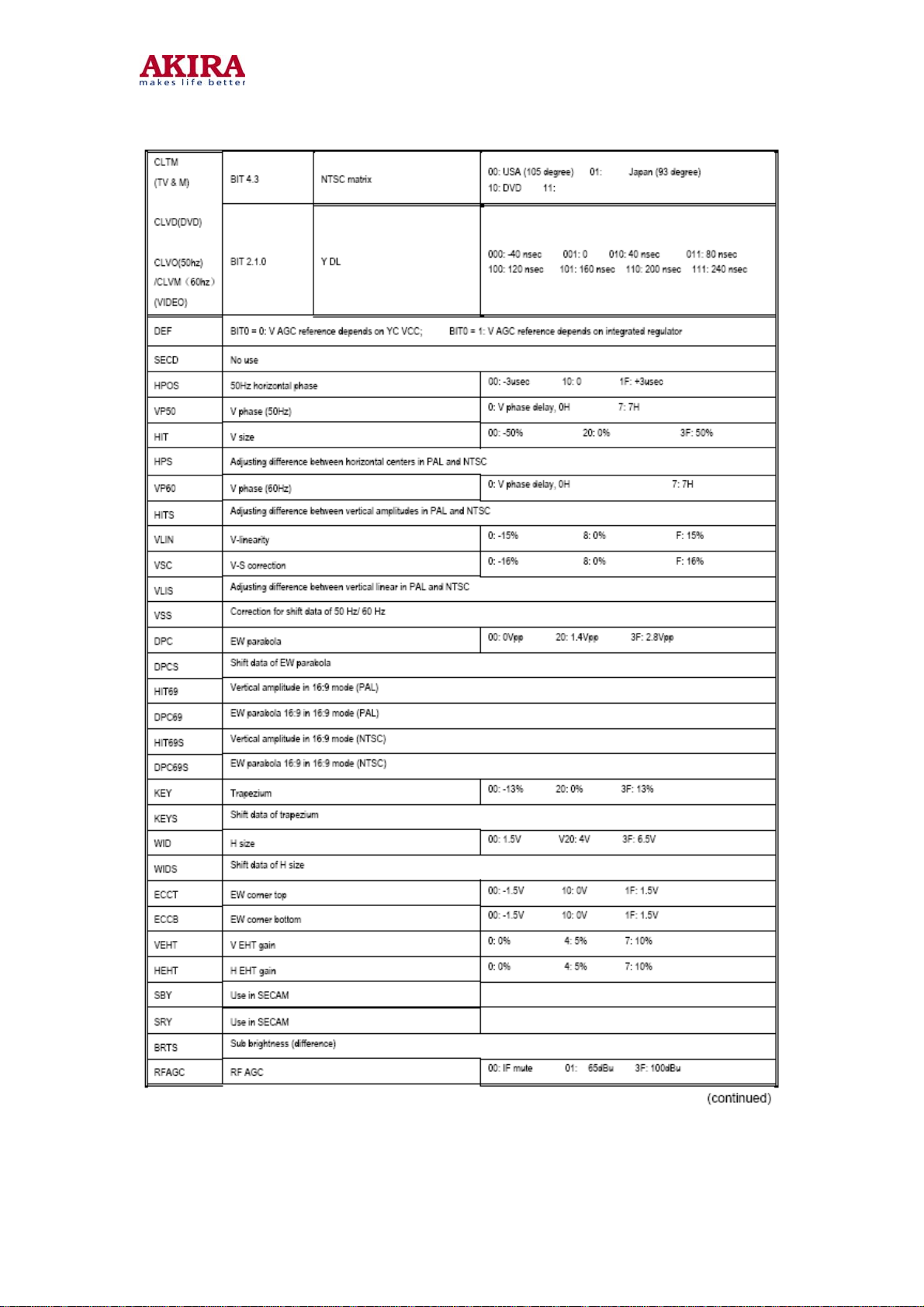

6.3 Adjustment and Bus date

23

Model no.: CT-34CJ5RE.doc

version 1.0

Page 24

24

Model no.: CT-34CJ5RE.doc

version 1.0

Page 25

25

STRUCTURE AND CHASSIS FUNCTION DESCRIPTION

1. STRUCTURE BLOCK DIAGRAM

Model no.: CT-34CJ5RE.doc

version 1.0

Page 26

2. BLOCK DIAGRAM FOR SUPPLY VOLTAGE SYSTEM

26

Model no.: CT-34CJ5RE.doc

version 1.0

Page 27

27

A

A

A

3. CHASSIS DESCRIPTION

General Description

CN-18ED chassis is applied in PF29158E. By use of Toshiba V/C/D -MCU 2IN1 IC for TV small

signal processing and bus control, the chassis enables TV tuning, adjustment, control and picture

correction, featur

compact circuit with fewer external components. The chassis, widely used in small and medium TVs,

provide

2 In 1 IC TMAP8827CSNG with function of E/W correction for PAL small signal processing

and bus control

EEPROM AT24C16 for data memory

s much more convenience for manufacturing and technical service. It includes:

ing high integration, highperformance -to -price ratio and high reliability and

LA78041

TDA8944J for audio power amplifying

Thick-film IC STR-G8656 for power circuit adjustment and control

AV control TC90L01N

The following features are available in the chassis:

Color systems: PAL NTSC SECAM

Sound systems: B/G D/K I M

236 programs preset

Multilingual on screen display

²C bus control

I

AV Stereo

Game

Biorhythm

Calendar inquiry

The chassis mainly uses the following ICs and assemblies.

for vertical output power amplifying

Table 5 Key ICs and Assemblies

No. Position Type Description

1 N230

2 N210 CH08T0605 (A8827CSNG5BK0 ) 2IN1 IC (Small signal processor + micro control (UOC))

3 N601 TA1343N

4 N603 TDA8944J Stereo audio power amplifier

5 N301 LA78041 Vertical scan output stage circuit

6 N801 STR-G8656 Switch-mode power supply control

7 N901 TC90L01N

8 A101 TDQ-5B4 M Tuner

Model no.: CT-34CJ5RE.doc

version 1.0

T24C016 EERPOM

udio processor

V switch

Page 28

28

SERVICE DATA

TECHNICAL DATA OF KEY ICs

1. TOSHIBA 2IN1 IC SERIES TMPA8827CMNG /CPNG/CSNG

MCU AND SIGNAL PROCESSOR FOR A PAL/NTSC/SECAM TV

The TMPA8827CMNG /CPNG /CSNG is an integrated circuit for a PAL/ NTSC/SECAM TV. A

MCU and a TV signal processor are integrated in a 64-pin shrink DIP package. The MCU

contains 8-bit CPU, ROM, RAM, I/O ports, timer/ counters, A/D converters, an on-screen

display controller, remote control interfaces, IIC bus interfaces and the Closed Caption decoder.

The TV signal processor contains PIF, SIF, Video, multi-standard chroma, Deflection, RGB

processors.

MROM: TMPA8827CMNG (ROM:32K)

TMPA8827CPNG (ROM:48K)

TMPA8827CSNG (ROM:64K)

OTP:TMPA8827SNG

Weight : 8.85g (typ.)

1) Features

MCU

High speed 8 bit CPU (TLCS-870/X series)

Instruction execution time:0.5 µ s (at 8MHz)

(TMPA8827CMNG)

32-Kbytes ROM, 2-Kbytes RAM

(TMPA8827CPNG)

48-Kbytes ROM,2-Kbytes RAM

(TMPA8827CSNG)

64-Kbytes ROM,2-Kbytes RAM

ROM correction

12 I/O ports

14bit PWM output 1 ch for a voltage

Synthesizer

7-bit PWM output 1 channel

8-bit A/D converter 3 ch for a touch key input

with Key ON wake-up CIRCUIT

Remote control signal preprocessor

Two 16-bit internal timer / counter 2 ch

Two 8-bit internal timer / counter 2 ch

Time base timer,watchdog timer

16 interrupt sources:external 5, internal 11

IIC bus interface (multi-master)

TV Processor

Model no.: CT-34CJ5RE.doc

version 1.0

Page 29

CCD Decorder

Digital data slicer for NTSC

OSD

Clcok generation for OSD display

Font ROM charaters:384 charaters

Charaters display:32 columns x 12 lines

Composition: 16 x 18 dots

Size of charaters: 3 (line by line)

Color of charaters: 8 (charaters by charater)

Display position:H 256/V 512 steps

Box function

Fringing, smoothing, Italic, underline

function

Conform to CCD REGULATION

Jitter elimination

IF

Intergrated PIF VCO aligned auto

Negative demodulation PIF

Multi-frequency SIF demodulator without external Tank-coil

Video

Integrated chroma traps

Chroma

Intergrated chroma BPFs

PAL / NTSC / SECAM demodulation

RGB / Base – Band

Intergrated 1 H base-band delay line

Base-band TINT control

Internal OSD interface

Half-tone and transparent for OSD

External YCbCr interface for DVD

RGB cut-off / drive controls by bus

ABCL (ABL and ACL combined)

Sync.

Integrated fH x 640 VCO

DC coupled vert. ramp output (single)

EW correction with EHT input

29

Model no.: CT-34CJ5RE.doc

version 1.0

Page 30

2) Block Diagram

30

Model no.: CT-34CJ5RE.doc

version 1.0

Fig. 8 Block Diagram

Page 31

31

3) Basic Structure

3.1) Internal Connections

TMPA8827 has two pieces of IC chip in one package, using Multi-Chip-Package (MCP)

technology. One is a micro controller (MCU) and the other one is a signal processor (SP) for a

color TV. There are some internal connections between these two ICs for handling below

signals.

Table 6 Signal Name Direction Description

No. Signal Name Direction Description

1 SCL M to S Internal IIC bus SCL

2 SDA Bi-direction Internal IIC bus SDA

3 OSD R M to S OSD signal connection

4 OSD G M to S OSD signal connection

5 OSD B M to S OSD signal connection

6 OSD Y/BL M to S OSD display control

7 OSD I, CS

OUT

8 C-Video S to M Composite video signal from internal video switch, for

9 C-Sync S to M Composite sync. signal from sync. Separator, for CCD

10 HD S to M Horizontal timing pulse regenerated from FBP, for OSD

11 VD S to M Vertical timing pulse from sync. Separator, for OSD

12 CLK M to S 8 MHz clock

13 AVDD M to S Reference voltage for C-Video interface

14 ADC S to M A/D converter monitoring RF-AGC, R-Y and B-Y

Functions of SP from MCU are controllable through the IIC bus of the internal connections.

3.2) Power Supply

TMPA8827 has some power supply and GND pins. Power supplies related MCU must be

applied at the first. Power supplies for H.VCC and TV D.VCC are the second with at least 100

ms delay after MCU power ON. The other power supplies are the last, which are recommended

to be supplied from a regulator circuit using FBP.

3.3) Crystal Resonator

solution requires two resonators at least, one for MCU and the other one for SP. An oscillation

clock with the crystal resonator of TMPA8827is supplied for MCU operation, PIF VCO

automatic alignment, alignment free AFT, chroma demodulation and horizontal oscillation. The

oscillation frequency is very important so that those of functions work properly, so that

designing the oscillation frequency

accurately is required. The spec of crystal is recommended to be within

fosc: 8 MHz +/-20 ppm

ftemp: 8 MHz +/-40 ppm (-20°C to +65°C)

While RESET of MCU is active, the MCU function stops. Hardware and software initialization

sequence including power supplies control is required, because status of any hardware after

the RESET period is unknown especially horizontal oscillator which is a very basic timing

generator of SP operation.

TMPA8827 requires only one crystal resonator, in stead that a conventional two-chip

M to S OSD half-tone control/Test pattern signal

CCD

Model no.: CT-34CJ5RE.doc

version 1.0

Page 32

4) Terminal Interface

MCU Block

32

Model no.: CT-34CJ5RE.doc

version 1.0

Page 33

33

Model no.: CT-34CJ5RE.doc

version 1.0

Page 34

34

Model no.: CT-34CJ5RE.doc

version 1.0

Page 35

35

Model no.: CT-34CJ5RE.doc

version 1.0

Page 36

36

2. AUDIO POWER AMPLIFIER TDA8944J

2 X 7 W STEREO BRIDGE TIED LOAD (BTL) AUDIO AMPLIFIER

1) General Description

The TDA8944J is a dualchannel audio power amplifier with an output power of 2 x 7 W at an 8Ω

load and a 12 V supply. The circuit contains two Bridge Tied Load (BTL) amplifiers with an

all-NPN output stage and standby/mute logic. The TDA8944J comes in a 17 -pin DIL -bent-SIL

(DBS) power package. The TDA8944J is printed-circuit board (PCB) compatible with all other

types in the TDA894x family. One PCB footprint accommodates both the mono and the stereo

products.

2) Features

Few external components

Fixed gain

Standby and mute mode

No on/off switching plops

Low standby current

High supply voltage ripple rejection

Outputs short-circuit protected to ground, supply and across the load

Thermally protected

Printed-circuit board compatible.

3) Blaock Diagram

Model no.: CT-34CJ5RE.doc

version 1.0

Page 37

4) Pinning Information

37

Model no.: CT-34CJ5RE.doc

version 1.0

Page 38

38

3. VERTICAL SCAN OUTPUT STAGE CIRCUIT LA78041

Both LA78040/LA78041 are vertical scan output stage power amplifiers. But there

is a little bit difference between the two amplifiers, that is, LA78040 has supply voltage of

24V and output current of 1.8AP-P while LA78041 has supply voltage of 30V and output

current of 2.2AP-P. LA78041 (N301)

Vertical Deflection Output Circuit

1) Features

Low power dissipation due to built-in pump-up circuit Vertical output circuit

Thermal protection circuit built in Excellent crossover characteristics DC coupling possible

2) Block Diagram

Package Type:TO-220-7H

Fig.12

Model no.: CT-34CJ5RE.doc

version 1.0

Fig.1 3 Block diagram

Page 39

39

4. EPROM AT24C04/08/ 16

1) Features

Low-voltage and Standard-voltage Operation

-2.7 (Vcc=2.7V to 5.5V)

-1.8 (Vcc=1.8V to 5.5V)

Internally Organized 128x8(1K), 256x8 (2K), 512x8 (4K), 1024x8 (8K) or 2048x8 (16K)

2-wire Serial Interface

Schmitt Trigger, Filtered Inputs for Noise Suppression Bi-directional Data Transfer Protocol

100kHz (1.8V, 2.5V, 2.7V) and 400 kHz (5V) Compatibility

Write Protect Pin for Hardware Data Protection

8-byte Page (1K, 2K), 16-byte Page (4K, 8K, 16K) Write Modes Partial Page Writes are allowed

Self-timed Write Cycle (10 ms max)

High-reliability

- Endurance: 1 Million Write Cycles

- Data Retention: 100 Years

Automotive Grade and Extended Temperature Devices Available

8-lead PDIP, 8 -lead JEDEC SOIC, 8 -lead MAP and 8 -lead TSSOP Package

2-wire

Serial EEPROM

AT24C01A 1K (128 x 8)

AT24C02 2K (256 x 8)

AT24C04 4K (512 x 8)

AT24C08 8K (1024 x 8)

AT24C16 6K (2048 x 8)

2) Description

The AT24C01A/02/04/08/16 provides 1024/2048/4096/8192/16384 bits of serial electrically

erasable and programmable read-only memory (EEPROM) organzed as 128/256/512/1024/2048

words of 8 bits each. The device is optimized for use in many industrial and commercial applications

where low-power and low-voltage operations are essential. The AT24C01A/02/04/08/16 is available

in space -saving 8 -pin PDIP, 8 -lead JEDEC SOIC, 8 -lead MAP and 8-lead TSSOP packages and

is accessed via a 2-wire serial interface. In addition, the entire family is available in 2.7V (2.7V to

5.5V) and 1.8V (1.8V to 5.5V) versions.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 40

3) Pin Configuration

40

Table 10

Fig. 14

Fig. 15

4) Pin Description

SERIAL CLOCK (SCL): The SCL input is used to positive edge clock data into each EEPROM

device and negative edge clock data out of each device.

SERIAL DATA (SDA): The SDA pin is bi-directional for serial data transfer. This pin is opendrain

driven and may be wired with any number of other open-drain or open-collector devices.

DEVICE / PAGE ADDRESSES (A2, A1, A0): The A2, A1 and A0 pins are device address inputs that

are hard wired for the AT24C01A and the AT24C02. As many as eight 1K/2K devices may be

addressed on a single bus system (device addressing is discussed in detail under the Device

Addressing section).

The AT24C04 uses the A2 and A1 inputs for hard wire addressing and a total of four 4K devices may

be addressed on a single bus system. The A0 pin is a no connect.

The AT24C08 only uses the A2 input for hardwire addressing and a total of two 8K devices may be

addressed on a single bus system. The A0 and A1 pins are no connects.

The AT24C16 does not use the device address pins, which limits the number of devices on a single

bus to one. The A0, A1 and A2 pins are no connects.

Model no.: CT-34CJ5RE.doc

version 1.0

Page 41

41

WRITE PROTECT (WP): The AT24C01A/02/04/16 has a Write Protect pin that provides

hardware data protection. The Write Protect pin allows normal read/write operations when

connected to ground (GND). When the Write Protect pin is connected to Vcc, the write

protection feature is enabled and operates as shown in the following table.

Table 11

WP Pin Part of the Array Protected

24C08

Status

At Vcc

At GND Normal Read/Write Operations

5) Memory Organization

AT24C01A, 1K SERIAL EEPROM: Internally organized with 16 pages of 8 bytes each, the 1K

requires a 7 -bit data word address for random word addressing.

AT24C02, 2K SERIAL EEPROM: Internally organized with 32 pages of 8 bytes each, the 2K

requires an 8 -bit data word address for random word addressing.

AT24C04, 4K SERIAL EEPROM: Internally organized with 32 pages of 16 bytes each, the 4K

requires a 9 -bit data word address for random word addressing.

AT24C08, 8K SERIAL EEPROM: Internally organized with 64 pages of 16 bytes each, the 8K

requires a 10 -bit data word address for random word addressing.

AT24C16,16K SERIAL EEPROM: Internally organized with 128 pages of 16 bytes each, the 16K

requires an 11-bit data word address for random word addressing.

6) Block Diagram

24C01A

Full (1K)

Array

24C02

Full (2K)

Array

24C04

Full (4K)

Array

Normal

Read/

Write

Operation

24C16

Upper

Half

(8K)

Array

Model no.: CT-34CJ5RE.doc

version 1.0

Fig.16 Block Digram

Page 42

5. SWITCH -MODE POWER SUPPLY IC STRG5653/G8656

1) General Description

The STRG5653/G8656 are part of the STRG5600/G8600 series thick-film ICs for switch-mode

power supply incorporating power MOSFET with a high-precise error amplifier. The ICs feature

fewer external components, small-size and standard power supply.

The series STR-G8600 use Chip on Chip technology with the same operation principle as

STR-G5600. Pin configuration, function and threshold of STR-G8600 are compatible with those of

STR-G5600.

42

Model no.: CT-34CJ5RE.doc

version 1.0

Page 43

6. TC9 0L01N

AUDIO / VIDEO SWITCHING IC FOR TVs

The TC90L01N is an audio/video switching IC

for TV sets. Conforming to I

it allows you to perform various switching

operations through the bus lines by using a

microcomputer. This IC has the functions of

audio mute, ALC (Auto Level Control), audio

volume and so on.

1) Features

²C bus control

· I

Video: 3-channel input abd 1-channel

outputs

(1 channels conforming to S system)

Audio: 3-channel inputs and 3-channel

outputs

Monitor Audio out

ALC (Auto Level Control)

Audio Volume by attenuator circuit

Audio mute

2 I/O ports

2C bus standards,

2) Pin Assignment

Fig. 18

43

Model no.: CT-34CJ5RE.doc

version 1.0

Fig.19 Pin Assignment

Page 44

3). Block Diagram

44

Model no.: CT-34CJ5RE.doc

version 1.0

Fig. 20 Block Diagram

Page 45

4) Pin Description

45

Model no.: CT-34CJ5RE.doc

version 1.0

Page 46

46

Model no.: CT-34CJ5RE.doc

version 1.0

Page 47

47

Model no.: CT-34CJ5RE.doc

version 1.0

Page 48

7. TA1343N

48

Model no.: CT-34CJ5RE.doc

version 1.0

Page 49

2) Block Diagram

49

Fig.21

Model no.: CT-34CJ5RE.doc

version 1.0

Page 50

3) Terminal Function

50

Table 14

Model no.: CT-34CJ5RE.doc

version 1.0

Page 51

SERVICE DATA OF KEY ICs

Table 15 Functions and Service Data of A8827CSNG5BK0 (N210)’s Pins

Pin No. 1 2 3 4 5 6 7 8

Voltage (V)

Resistance (KΩ)

Pin No. 9 10 11 12 13 14 15 16

Voltage (V)

Resistance (KΩ)

Pin No. 17 18 19 20 21 22 23 24

Voltage (V)

Resistance (KΩ)

Pin No. 25 26 27 28 29 30 31 32

Voltage (V)

Resistance (KΩ)

Pin No. 33 34 35 36 37 38 39 40

Voltage (V)

Resistance (KΩ)

Pin No. 41 42 43 44 45 46 47 48

Voltage (V)

Resistance (KΩ)

Pin No. 49 50 51 52 53 54 55 56

Voltage (V)

Resistance (KΩ)

Pin No. 57 58 59 60 61 62 63 64

Voltage (V)

Resistance (KΩ)

3.9 ~ 4.8 4.5~4.9 5 0 5 2.22 2 0

8.8 8.8 22 0 4.55 22.8 22.7 0

5 0 0 1.22 1.87 6.63 4.16 5

3.6 0 0 35.7 0.79 36.3 36.3 15.6

9 2 2.45 2.61 2.44 0 2.44 2.61

10 26 26 26 26 0 26 26

3.4 1.9 4.58 4.78 9.0 3.44 1.77 3.48

10.3 26 24.2 22.9 0.39 3.32 3.3 24.17

2.97 2.44 2.49 4.96 2.2 4.39 1.8 0

26 24.8 26 1.6 20 22.8 26 0

0.12 0.12 1.8 4.9 2.76 3.5 2.4 0

26 26 12.9 1.6 26 26 26 0

8.88 2 2 2 0 0 5 0.086

0.40 23.1 23.1 23.1 0 0 3.52 8.2

5 5 5 4.38 0 4.29 0.23 0.027

13.7 13.7 12 22.6 24.92 20.4 24.85 6.7

51

Model no.: CT-34CJ5RE.doc

version 1.0

Page 52

Table 16 Functions and Service Data of TDA8944J (N603)’s Pins

Digital Multimeter

Measure with

Pin

No.

1

Function Description

Negative Loudspeaker

Terminal

Ref.

Voltage

(V)

7.98 10 2.47

RED

probe while

grounding

Black probe

(KΩ)

2 Ground Channel 1 0 0 0

3 Supply Voltage Channel 1 15.79 7.17 1.7

Positive Loudspeaker

4

Terminal

7.84 11 2.44

5 Not Connected 0 ∞ ∞

6 Positive Input 1 7.85 16 3

7 Not Connected 0 ∞ ∞

8 Negative Input 1 7.85 15.7 3

9 Negative Input 2 7.64 15.7 3

Mode Selection Input

10

(standby, Mute, Operating)

0.21 18.6 2.89

Half Supply Voltage

11

Decoupling (Ripple

7.84 16.2 2.87

Rejection)

12 Positive Input 2 7.62 17 2.88

13 Not Connected 0 ∞ ∞

Negative Loudspeaker

14

Terminal 2

7.84 11 2.44

15 Ground Channel 2 0 0 0

16 Supply Voltage Channel 2 15.80 7.17 1.7

Positive Loudspeaker

17

Terminal 2

7.82 11 2.44

Table 17 Functions and Service Data of LA78041 (N301)’s Pins

GDM8145 Multimeter

Pin

No.

1

2 VCC 27.68 - 1.87

3

4 GND 0 0 0

5 Ver. OUTPUT 16.35 - 2.26

6

7

Function

Description

INVERTING

INPUT

PUMP UP

OUT

OUTPUT

STAGE Vcc

NON

INV.INPUT

Voltage of

Pin (V)

2.87 - 2.62

2.32 - 2.68

28.23

2.88 3.25 2.5

Measure with Red

probe while grouding

Ground Resistance (KΩ)

Measure with Black

probe while grouding

black probe

∞

Mearsure with

Black

probe while

grouding RED

probe (KΩ)

Red probe

2.35

52

Model no.: CT-34CJ5RE.doc

version 1.0

Page 53

53

Table 18 Functions and Service Data of AT24C16 (N230)’s Pins

Digital Multimeter

Pin

No.

1 Address Input 0 0 0

2 Address 0 0 0

3 Address 0 0 0

4

5 Clock Line 5 13.79 11.22

6 Data Line 5 13.70 13.13

7

8

Function

Description

Common

Ground

PW Write

Protect

Supply

Voltage

Ref.

Voltage

(V)

0 0 0

0 0 0

5 3.79 3.78

Table 19 Functions and Sevice Data of STR-G8656 (N801)’s Pins

Pin

No.

Functions Description

1 Drain Terminal 295 ∞ ∞

2 Source Terminal 0.024 0 0

3 Ground Terminal 0 0 0

4 Power Supply Terminal 32.1 ∞ 1.838

Overcurrent / Freback

5

Terminal

Measure with Red

probe while

Grounding Black

probe (KΩ)

Measure with Black probe

while grounding Red probe

(KΩ)

Digital Multimeter

Measure with

Ref. Voltage

(V)

Black probe (KΩ)

1.96 0.68 0.68

Red

Probe while

grounding

Measure with

Black

probe while

grounding

Red probe (KΩ)

Model no.: CT-34CJ5RE.doc

version 1.0

Page 54

54

APPENDIX

Model no.: CT-34CJ5RE.doc

version 1.0

Page 55

Speaker

Wired Connector XP205's A

Blue

Bla k

dRe

la kB c

Control Buttons Board Assembly

c

From Power Switch Assembly

XP803

XP804

XS901A

Remote Sensor PCB Assembly

Wired Connector AwD-02-700

Speaker

XPK01B

Wired Connector XP205's B

To Degaussing Coil

XP801

XS801

XP801

Wired Connector XS703A

XP200B

Wired Connector XP205

XP603

XP205

White

Black

eR d

Black

+

-

+

-

Power PCB Assembly

XP400

To Deflection Yoke

XP403

Wired connector XE01

XP200D

XP202

XP904

AV PCB Assembly

AD-04-480(V2)

XP201

XP903

XP908

XP901B

Screen Wire (Grey)

CRT's Ground Wire

(Soldered)

First soldered the focus wire,

then close the cover.

Wired connector AD-06-380

B

P903

Focus Wire (Red)

A2

A1

CRT RGB PCB assembly

P902A

Side-set AV PCB Assembly

Design

Examine

Standards

Approve

Tracing Width: A3

Page 56

This circuit diagram is only for reference, specifications are subject to change without reference.

Page 57

57

REPLACEMENT PARTS LIST

PART CODE PART NAME SPECIFICATION QTY LOCATION

56282105102 SPEAKER

BC602

562J1110080 SPEAKER

BC606

50640063030

C689A

DEGAUSSING COIL 1 XP804

54111A04650 POWER SWITCH KDC-A04(S) 1 SPB801

54111A04650 POWER SWITCH PS5E-A

54111A04650 POWER SWITCH KDC-A04-MU169

34" CRT 1

FRONT PANEL 1

883370288G001 POWER S JUC8.337.288-G001 1

883370289G006 FUNCTION KEY JUC8.337.289-G006 1

8864001550C LENS JUC8.640.155 1

820180263108L REMOTE CONTROLLER K18F-C108 1

87820111701C MAIN PCB JUC7.820.1117 1

51113100JU0 CARBON RES.

50620071680 CARBON RES.

51113470JU0 CARBON RES.

51113750JU0 CARBON RES.

51113101JU0 CARBON RES.

R204 R207 R212 R213 R222

R233 R238 R241 R243 R253

R255 R256 R258 R259 R263

51113151JU0 CARBON RES.

51113181JU0 CARBON RES.

51113221JU0 CARBON RES.

50620071630 CARBON RES.

51113391JU0 CARBON RES.

51113471JU0 CARBON RES.

50620071910 CARBON RES.

51113102JU0 CARBON RES.

R257 R410 R437 R879 R262

51113122JU0 CARBON RES.

50620073070 CARBON RES.

51113222JU0 CARBON RES.

51113332JU0 CARBON RES.

51113472JU0 CARBON RES.

R247 R610

50620071870 CARBON RES.

51113822JU0 CARBON RES.

51113103JU0 CARBON RES.

R327 R407 R409 R411 R608

R875 R876

51113123JU0 CARBON RES.

51113153JU0 CARBON RES.

51113223JU0 CARBON RES.

51113273JU0 CARBON RES.

50620071720 CARBON RES.

51113333JU0 CARBON RES.

50620071780 CARBON RES.

51113473JU0 CARBON RES.

51113513JU0 CARBON RES.

51113563JU0 CARBON RES.

50620072050 CARBON RES.

51113104JU0 CARBON RES.

50620071490 CARBON RES.

51113224JU0 CARBON RES.

50620071620 CARBON RES.

50620072030 CARBON RES.

51113105JU0 CARBON RES.

50620071270 CARBON RES.

50620071370 CARBON RES.

50620071290 CARBON RES.

50620101340 METAL OXIDE FILM RES.

50620101010 METAL OXIDE FILM RES.

50620101410 METAL OXIDE FILM RES.

50620101440 METAL OXIDE FILM RES.

50620101460 METAL OXIDE FILM RES.

50620100970 METAL OXIDE FILM RES.

50620101550 METAL OXIDE FILM RES.

YDT416-N-10W-8Ω

YDG52-A1-10W-8Ω

CD71-50V-1μFM

RT13-0.166W-10ΩJ

RT13-0.166W-27ΩJ

RT13-0.166W-47ΩJ

RT13-0.166W-75ΩJ

RT13-0.166W-100ΩJ

RT13-0.166W-150ΩJ

RT13-0.166W-180ΩJ

RT13-0.166W-220ΩJ

RT13-0.166W-240ΩJ

RT13-0.166W-390ΩJ

RT13-0.166W-470ΩJ

RT13-0.166W-560ΩJ

RT13-0.166W-1KΩJ

RT13-0.166W-1.2KΩJ

RT13-0.166W-2KΩJ

RT13-0.166W-2.2KΩJ

RT13-0.166W-3.3KΩJ

RT13-0.166W-4.7KΩJ

RT13-0.166W-5.6KΩJ

RT13-0.166W-8.2KΩJ

RT13-0.166W-10KΩJ

RT13-0.166W-12KΩJ

RT13-0.166W-15KΩJ

RT13-0.166W-22KΩJ

RT13-0.166W-27KΩJ

RT13-0.166W-30KΩJ

RT13-0.166W-33KΩJ

RT13-0.166W-39KΩJ

RT13-0.166W-47KΩJ

RT13-0.166W-51KΩJ

RT13-0.166W-56KΩJ

RT13-0.166W-82KΩJ

RT13-0.166W-100KΩJ

RT13-0.166W-150KΩJ

RT13-0.166W-220KΩJ

RT13-0.166W-240KΩJ

RT13-0.166W-820KΩJ

RT13-0.166W-1MΩJ

RT14-0.25W-220ΩJ

RT14-0.25W-680ΩJ

RT14-0.25W-3.3KΩJ

RY21-0.5W-1ΩJ

RY21-0.5W-8.2ΩJ

RY21-0.5W-270ΩJ

RY21-0.5W-3.9KΩJ

RY21-0.5W-4.7KΩJ

RY21-0.5W-820KΩJ

RY21-1W-18ΩJ

2 BC601

2 BC605

2 C688A

1 R136

1 R134

2 R245 R066

2 R605 R606

20 R103 R104 R122 R202 R203

1 R214

1 R140

3 R244 R607 R878

1 R415

1 R447

1 R249

4 R401 R402 R406 R415A

10 R101 R102 R232 R254 R256A

2 R130 R135

2 R611 R612

2 R242 R805

3 R210 R211 R405

7 R131 R222A R234 R236 R237

2 R322 R448

2 R248 R200

12 R118 R120 R224 R226 R231

2 R117 R320

5 R123 R449 R440A R680 R682

1 R114

1 R414

1 R218

2 R119 R239

1 R801

3 R615 R874 R877

1 R328

3 R121 R413 R423

1 R326

3 R115 R206 R252

1 R251

1 R217

1 R116

1 R446

1 R416

1 R418

1 R807

1 R434

2 R325 R330

1 R804

1 R205

1 R433

1 R806

1 R803

1 R441

Model no.: CT-34CJ5RE.doc

version 1.0

Page 58

58

PART CODE PART NAME SPECIFICATION QTY LOCATION

50620102510 METAL OXIDE FILM RES.

50620101790 METAL OXIDE FILM RES.

50620101680 METAL OXIDE FILM RES.

50620101710 METAL OXIDE FILM RES.

50620101980 METAL OXIDE FILM RES.

50620101960 METAL OXIDE FILM RES.

50620102000 METAL OXIDE FILM RES.

50620101760 METAL OXIDE FILM RES.

50620101860 METAL OXIDE FILM RES.

50620102120 METAL OXIDE FILM RES.

50620102040 METAL OXIDE FILM RES.

51515P27J70 FUSE RES.

51516P27J70 FUSE RES.

51224P10K60 FUSE RES.

51515P68J70 FUSE RES.

51527010J90 FUSE RES.

51CB5723725 THERMISTOR RES. B57237-S479-M 1 RT801

51CB5723725 THERMISTOR RES. 4.7D2-14LC

5251C200J10 CERAMIC CAP. CC1-63V-06C-C-20PFJ 2 C200 C201

5251C270J10 CERAMIC CAP. CC1-63V-06C-C-27PFJ 1 C242

5251C101J11 CERAMIC CAP. CC1-63V-08C-C-100PFJ 2 C244 C245

50640020640 CERAMIC CAP. CC1-63V-08C-SL-220PFJ 2 C115

50640022990 CERAMIC CAP. CC1-63V-10C-SL-330PFJ 1 C238

50640021950 CERAMIC CAP. CC1-63V-10C-SL-470PFJ 1 C801

52532102K10 CERAMIC CAP. CT1-63V-06C-2B4-1000PFK 4 C103 C124 C224 C260

52532152K10 CERAMIC CAP. CT1-63V-06C-2B4-1500PFK 6 C126 C620 C621 C622 C623

C803

52532472K11 CERAMIC CAP. CT1-63V-10C-2B4-4700PFK 3 C401 C613 C615

5253F103Z10 CERAMIC CAP. CT1-63V-08C-2F4-10NFZ 17 C121 C203 C220 C221 C228

C231 C236 C241 C243 C246

C258 C403 C412 C426 C815

C880 C881

50640022960 CERAMIC CAP.

52542221KV0 CERAMIC CAP. CT1-500V-06A-2B4-220PFK 3 C406 C407 C433

52542471KV0 CERAMIC CAP. CT1-500V-06A-2B4-470PFK 3 C873 C875 C877

50640021630 CERAMIC CAP. CT81-250VAC-2B4-470PFK-Y1 2 C811

50640063120 CERAMIC CAP. CD95-B2GA471KYHS C812

50640022190 CERAMIC CAP. CT7-250VAC-2B4-470PFK-Y1

52592471K20 CERAMIC CAP. CT81-2KV-10C-2B4-470PFK 1 C871

50640021930 CERAMIC CAP. CT81-2KV-14C-2B4-1000PFK 1 C804

5254E472P30 CERAMIC CAP. CT1-500V-12C-2E4-4700PFP 4 C806 C807 C808 C809

50640021700 CERAMIC CAP. CT81-400VAC-2E4-1000PFM-Y1 1 C830

5254F102M10 CERAMIC CAP. CD85-E2GA102MYHS

52572102M10 CERAMIC CAP. CT7-250VAC-2E4-1000PFM-YI

52367222J10 MYLAR CAPA. CL21X-50V-2200PFJ 1 C234

52367222J10 MYLAR CAPA. ECQB1H222JFW

50640011520 MYLAR CAPA. CL21X-50V-8200PFJ 1 C204

523A0682215 MYLAR CAPA. ECQB1H822JFW

52367103J10 MYLAR CAPA.

52367103J10 MYLAR CAPA. ECQV1H103JLW C214

52367123J10 MYLAR CAPA.

52367123J10 MYLAR CAPA. ECQV1H123JLW

52367223J10 MYLAR CAPA.

52367223J10 MYLAR CAPA. ECQV1H223JLW

52367104J10 MYLAR CAPA.

52367104J10 MYLAR CAPA. ECQV1H104JLW C113 C118 C119 C120 C210

C212 C213 C218 C233 C307

C609 C802A

52367104J10 MYLAR CAPA.

52367104J10 MYLAR CAPA. ECQV1H104JLW

52367224J10 MYLAR CAPA.

52367224J10 MYLAR CAPA. ECQV1H224JLW C608 C611 C612

52367474J10 MYLAR CAPA.

52367474J10 MYLAR CAPA. ECQV1H474JLW C404 C432

52369104J10 MYLAR CAPA.

52369104J10 MYLAR CAPA. ECQV1104JMW

52369224J10 MYLAR CAPA.

523A0122416 MYLAR CAPA. ECQE1224JFW

5241B473J80 POLYPROPYLENE CAP.

523A0247310 POLYPROPYLENE CAP. ECQE2473JF3

5241D433J90 POLYPROPYLENE CAP.

5241D433J90 POLYPROPYLENE CAP. ECQF4433JZH

50640011070 POLYPROPYLENE CAP.

5241D303JB0 POLYPROPYLENE CAP. ECWF4304JB7

5241F223J90 POLYPROPYLENE CAP.

5241F223J90 POLYPROPYLENE CAP. ECQF6223JZH

RY21-1W-1KΩJ

RY21-2W-1ΩJ

RY21-2W-0.12ΩJ

RY21-2W-0.39ΩJ

RY21-2W-4.7ΩJ

RY21-2W-330ΩJ

RY21-2W-47ΩJ

RY21-2W-15KΩJ

RY21-2W-220KΩJ

RY21-3W-15KΩJ

RY21-3W-15KΩJ

RF10-0.5W-0.27ΩJ

RF10-1W-0.27ΩJ

RF10-2W-0.1ΩK

RF10-0.5W-0.68ΩJ

RF11-2W-1ΩJ

CT1-63V-12C-2F4-0.022μFZ

CL21X-50V-0.01μFJ

CL21X-50V-0.012μFJ

CL21X-50V-0.022μFJ

CL21X-50V-0.1μFJ

CL21X-50V-0.1μFJ

CL21X-50V-0.22μFJ

CL21X-50V-0.47μFJ

CL21X-100V-0.1μFJ

CL21X-100V-0.22μFJ

CBB13-200V-0.047μFJ

CBB13-400V-0.043μFJ

CBB13-400V-0.3μFJ

CBB13-630V-0.022μFJ

1 R883

1 R380

1 R808

1 R601

1 R412

1 R329

1 R417

1 R442

1 R802

1 R444

1 R880

3 R427 R871 R872

1 R403

1 R870

1 R499

1 R431

1 C127

2 C208

1 C227

1 C252

13 C035

1 C216

4 C607

3 C206

1 C411

1 C302

1 C417

1 C429

1 C459

1 C420

Model no.: CT-34CJ5RE.doc

version 1.0

Page 59

59

PART CODE PART NAME SPECIFICATION QTY LOCATION

5248K222J90 POLYPROPYLENE CAP. CBB81-1.6KV-2200PFJ 1 C410

5248K222J90 POLYPROPYLENE CAP. ECWH16222JVY

526134P7M11 ELECTROLYTIC CAP.

52623010060 ELECTROLYTIC CAP.

C222 C240 C610

52613101M11 ELECTROLYTIC CAP.

52613221M11 ELECTROLYTIC CAP.

52613471M11 ELECTROLYTIC CAP.

52613102M11 ELECTROLYTIC CAP.

52614221M11 ELECTROLYTIC CAP.

52614471M11 ELECTROLYTIC CAP.

50640062160 ELECTROLYTIC CAP.

52614222M51 ELECTROLYTIC CAP.

52616471M11 ELECTROLYTIC CAP.

52616102M11 ELECTROLYTIC CAP.

52617P47M11 ELECTROLYTIC CAP.

52617010MV0 ELECTROLYTIC CAP.

50640062240 ELECTROLYTIC CAP.

52617470M11 ELECTROLYTIC CAP.

52617101M11 ELECTROLYTIC CAP.

50640062490 ELECTROLYTIC CAP.

52616101M11 ELECTROLYTIC CAP.

5268T331MA0 ELECTROLYTIC CAP.

50640062700 ELECTROLYTIC CAP.

50640061990 ELECTROLYTIC CAP.

526EC220M16 ELECTROLYTIC CAP.

50630061100 INDUCTOR

50630061150 INDUCTOR

50630061080 INDUCTOR

55632120K10 INDUCTOR

50630061170 INDUCTOR

55623560K30 INDUCTOR

50630061270 INDUCTOR

55650110K60 INDUCTOR

55572011085 INDUCTOR TEM2011 5 L404 L871 L873A L875 L876

50630061260 INDUCTOR

8475701320B INDUCTOR

8473900030B BCT-8(JUB4.739.003) 1 T402

61411075DU6 DIODE 2CK75D 9 VD203

61411075DT0 DIODE 1N4148 VD401A VD402 VD411 VD601 VD602

VD603 VD876 VD288

61216075045 DIODE IZ75 1 R317

50660092130 DIODE IZ75

617100210T0 DIODE BAV21 1 VD406

611120RU260 DIODE 2CZRU2 5 VD403 VD404 VD414 VD873 VD874

611120RU260 DIODE 2CZRU2 1 VD407

61112RU4ZB0 DIODE 2CZRU4Z 1 VD402A

61141010320 DIODE HER303 1 VD872

611173280B5 DIODE BY328 1 VD413

61118096D50 DIODE BYW96D 1 VD412

61138001Z45 DIODE ZEM01Z 1 VD304

61112188761 DIODE 2CZ1887 1 VD408

61100111046 DIODE AU01Z 3 VD802 VD803 VD804

61100103010 DIODE AK03 1 VD806

614145408E6 DIODE BY254 4 VD807

614145408E6 DIODE 1N5408 VD808 VD809 VD810

50660091490 DIODE RU4AM(LF-L1) 1 VD871

61118010215 DIODE MUR460

61212036AT5 DIODE W05Z3.6A 1 VD209

61212051BT5 DIODE W05Z5.1B 3 VD204

61212051BT5 GDZJ5.1B VD205 VD206

61212068BT5 DIODE W05Z6.8B 2 VD801 VD877

61212082BT5 DIODE W05Z8.2B 1 VD405

61212091BT5 DIODE W05Z9.1B 1 VD875

61212150CT5 DIODE W05Z15C 1 VD805

62210150YW0 AUDION 3CG1015-Y 5 V205

62210150YW0 AUDION 2SA1015-Y V400A

622101500T6 AUDION 2PA1015GR V401 V402 V603

62118150Y16 AUDION 3DG1815-Y 7 V103

62118150Y16 AUDION 2SC1815-Y/KTC3198-Y V201

50650030610 AUDION 2PC1815GR V204A V241 V251 V802 V803

621038820T0 AUDION 3DG388ATM 1 V101

621038820T0 AUDION 2SC388ATM

62118111296 AUDION KSC388C-Y

50650030820 AUDION 2SC388-Y

62426550YW5 AUDION 2SC2655-Y 1 V801

CD110X-16V-4.7μFM

CD110X-16V-10μFM

CD110X-16V-100μFM

CD110X-16V-220μFM

CD110X-16V-470μFM

CD110X-16V-1000μFM

CD110X-25V-220μFM

CD110X-25V-470μFM

CD110X-25V-1000μFM

CD110X-25V-2200μFM

CD110X-35V-470μFM

CD110X-35V-1000μFM

CD110X-50V-0.47μF

CD110X-50V-1μFM

CD110X-50V-10μFM

CD110X-50V-47μFM

CD110X-50V-100μFM

CDS-100V-10μFM

CD110X-35V-100μFM

CD293H-200V-330μFM

CD110X-250V-1μFM

CD110-250V-10μFM

CD288H-250V-22μFM(Φ10)

LGB0606-1μHK

LGB0606-4.7μHK

LGB0606-10μHK

LGB0606-12μHK

LGB0606-47μHK

LGB0606-56μHK

TLN3155D-100μHK

TLN2026-11μHK

TLN3063-500μHJ

JUB4.757.132$LGT-690μH

1 C225

8 C034 C122 C202 C215

3 C114 C229 C235

4 C207 C414 C416 C879

2 C230 C882

1 C402

1 C605

1 C878

2 C602 C876

1 C874

2 C306 C408

1 C305

5 C101 C102 C205 C223 C308

5 C209 C211 C226 C232 C304

2 C217 C633

1 C117

1 C802

1 C430

1 C303

1 C889

1 C431

1 C405

1 C409

1 L105

1 L243

5 L200 L202 L205 L206 L207

1 L204

2 L201 L203

1 L102

1 L872

1 L874

1 L401

1 L403

Model no.: CT-34CJ5RE.doc

version 1.0

Page 60

60

PART CODE PART NAME SPECIFICATION QTY LOCATION

62123830YT7 AUDION 2SC2383-Y 1 V404

62123830YT7 AUDION KSC2383-Y

62123830YT7 AUDION 2SC2383-Y

50390068590 I.C AT24C16A-10PI2.7 1 N230

50390068660 I.C AT24C16-10PI2.7

67109P62116 I.C HS817 1 N802

67109S81700 I.C TCET1106/TCET1103

50390020140 I.C H11A817A

66132501116 I.C PS2561A-1-V

67173882706 I.C CH08T0605/A8827CSNG5BK0(ON 1 N210

50390070940 I.C KA33V 1 VD101

67311574C30 I.C

67311574C30 I.C CW574CS

50950010430 CRYSTAL OSCILLATOR JA18AS-8MHZ 1 X201

828910001EB TDQ-5B4-M(JUB2.891.001-15) 1 A101

50570050080 CERAMIC TRAP FILTER XT5.5MB 1 Z243

5741455MB05 CERAMIC TRAP FILTER TPSRA5M50B00-B0

50570050110 CERAMIC TRAP FILTER XT6.0MB 1 Z245

5741460MB05 CERAMIC TRAP FILTER TPSRA6M00B00-B0

50570050120 CERAMIC TRAP FILTER XT6.5MB 1 Z241

5741465MB05 CERAMIC TRAP FILTER TPSRA6M50B00-B0

50570030200 SAW FILTER LBN38-96 1 Z101

51113101JU0 CARBON RES.

51113102JU0 CARBON RES.

51113103JU0 CARBON RES.

51113473JU0 CARBON RES.

51113104JU0 CARBON RES.

50640022980 CERAMIC CAP. CC1-63V-06C-C-39PFJ 1 C123

50640021960 CERAMIC CAP. CC1-63V-06C-C-82PFJ 1 C130

5251C101J11 CERAMIC CAP. CC1-63V-08C-C-100PFJ 1 C131

50630061150 INDUCTOR

55897679505 INDUCTOR TRF767950 1 L106

61411075DU6 DIODE 2CK75D 1 VD252

61411075DT0 DIODE 1N4148

62118150Y16 AUDION 3DG1815-Y 2 V102

62118150Y16 AUDION 2SC1815-Y/KTC3198-Y V254

50650030610 AUDION 2PC1815GR

50650030120 AUDION 2SC2878-A 1 V253

50650030910 AUDION 2SA562-Y 1 V252

62205624Y05 AUDION 3CG562Y

50650030870 AUDION 2SA562TM-Y

50650030910 AUDION 2SA562-Y

5741445MB25 CERAMIC TRAP FILTER TPSRA4M50B00-B0 1 Z242

50570050070 CERAMIC TRAP FILTER XT4.5MB

5251C270J10 CERAMIC CAP. CC1-63V-06C-C-27PFJ 1 C298

52367153J10 MYLAR CAPA.

55632270K10 INDUCTOR

51113101JU0 CARBON RES.

5251C200J10 CERAMIC CAP. CC1-63V-06C-C-20PFJ 2 C624 C625

5253F103Z10 CERAMIC CAP. CT1-63V-08C-2F4-10NFZ 3 C651 C652 C653

50640011520 MYLAR CAPA. CL21X-50V-8200PFJ 2 C641

523A0682215 MYLAR CAPA. ECQB1H822JFW C649

52367103J10 MYLAR CAPA.

52367103J10 MYLAR CAPA. ECQV1H103JLW

52367223J10 MYLAR CAPA.

52367223J10 MYLAR CAPA. ECQV1H223JLW

50640011410 MYLAR CAPA.

523A0127315 MYLAR CAPA. ECQV1H273JLW C650

52367333J10 MYLAR CAPA.

52367333J10 MYLAR CAPA. ECQV1H333JLW

52367393J10 MYLAR CAPA.

52367393J10 MYLAR CAPA. ECQV1H393JLW C657 C658

52367224J10 MYLAR CAPA.

52367224J10 MYLAR CAPA. ECQV1H224JLW

50640011440 MYLAR CAPA.

523A0147315 MYLAR CAPA. ECQV1H473JLW

526134P7M11 ELECTROLYTIC CAP.

52367393J10 MYLAR CAPA.

52367393J10 MYLAR CAPA. ECQV1H393JLW C655

52623010060 ELECTROLYTIC CAP.

52613101M11 ELECTROLYTIC CAP.

52617P47M11 ELECTROLYTIC CAP.

50630061080 INDUCTOR

67109134305 I.C TA1343N 1 N601

51113113J20 CARBON RES.

51113822J20 CARBON RES.

μPC574J

RT13-0.166W-100ΩJ

RT13-0.166W-1KΩJ

RT13-0.166W-10KΩJ

RT13-0.166W-47KΩJ

RT13-0.166W-100KΩJ

LGB0606-4.7μHK

CL21X-50V-0.015μFJ

LGB0606-27μHK

RT13-0.166W-100ΩJ

CL21X-50V-0.01μFJ

CL21X-50V-0.022μFJ

CL21X-50V-0.027μFJ

CL21X-50V-0.033μFJ

CL21X-50V-0.039μFJ

CL21X-50V-0.22μFJ

CL21X-50V-0.047μFJ

CD110X-16V-4.7μFM

CL21X-50V-0.039μFJ

CD110X-16V-10μFM

CD110X-16V-100μFM

CD110X-50V-0.47μF

LGB0606-10μHK

RT13-0.166W-11KΩJ

RT13-0.166W-8.2KΩJ

1 R227

1 R292

2 R228 R293

3 R100 R137 R291

2 R264 R265

1 L242

1 C299

1 L208

4 R641 R656 R657 R640

1 C656

1 C646

2 C640

1 C648

2

1 C645

1 C647

5 C638 C642 C643 C671 C672

1 C655

1 C673

1 C654

1 C644

1 L601

1 R321

1 R419

Model no.: CT-34CJ5RE.doc

version 1.0

Page 61

61

PART CODE PART NAME SPECIFICATION QTY LOCATION

50620101600 METAL OXIDE FILM RES.

50620102510 METAL OXIDE FILM RES.

50620101560 METAL OXIDE FILM RES.

5254FO00148 CERAMIC CAP. CT81-2KV-14C-2R4-1500PFK 1 C423

52592152K30 CERAMIC CAP. CT81-2KV-14C-2B4-1500PFK

52592152J30 CERAMIC CAP. CT81-2KV-14C-2B4-1500PFJ

5248K123HD0 POLYPROPYLENE CAP.

52A75815613 POLYPROPYLENE CAP.

5248K123JD0 POLYPROPYLENE CAP.

5248K123HD0 POLYPROPYLENE CAP. ECWH16123HV7

5248K123JD0 POLYPROPYLENE CAP. ECWH16123JV7

50640011070 POLYPROPYLENE CAP.

5241D303J10 POLYPROPYLENE CAP.

5241D303JB0 POLYPROPYLENE CAP. ECWF4304JBQ

8475600370B INDUCTOR HXT35A(JUB4.756.037) 1 L406

8475700520B INDUCTOR

8479901280B BSC73W1(JUB4.799.128) 1 T401

8479902290B BSC73W1(E)(JUB4.799.229)

50640061860 ELECTROLYTIC CAP.

8472601300B SW. TRANSFORMER BCK-24913L(JUB4.726.130) 1 T801

67110984405 I.C TDA8944J/N1 1

67113780415 I.C LA78041 1

50650030480 AUDION 2SC3852 1

63438520035 AUDION 3DA3852R

50390070690 I.C L7809CV 1

50390070690 I.C MC7809CT

50390070690 I.C CW7809CS

67241780556 I.C L7805CV 1

67241780556 I.C MC7805CT

67241780556 I.C KA7805TU

67241780556 I.C CW7805CS

67138865605 I.C STR-G8656 1

67241780556 I.C L7805CV 1

67241780556 I.C MC7805CT

67241780556 I.C KA7805TU

67241780556 I.C CW7805CS

50650020100 AUDION 3DD2253C 1 V405

8782006610C CRT PCB JUC7.820.661 1

50620071060 CARBON RES.

50620071100 CARBON RES.

50620071110 CARBON RES.

51113101JU0 CARBON RES.

50620071090 CARBON RES.

51113331JU0 CARBON RES.

51113471JU0 CARBON RES.

51113821JU0 CARBON RES.

50620072060 CARBON RES.

51113102JU0 CARBON RES.

51113122JU0 CARBON RES.

51113222JU0 CARBON RES.

51113332JU0 CARBON RES.

51113392JU0 CARBON RES.

51113472JU0 CARBON RES.

51113103JU0 CARBON RES.

50620071120 CARBON RES.

51224106J30 METALLIZED FILM RES.

50620071130 CARBON RES.

50620101190 METAL OXIDE FILM RES.

50620101200 METAL OXIDE FILM RES.

5251C101J11 CERAMIC CAP. CC1-63V-08C-C-100PFJ 1 C931

50640021950 CERAMIC CAP. CC1-63V-10C-SL-470PFJ 3 C904 C905 C907

52542472K30 CERAMIC CAP. CT1-500V-14C-2B4-4700PFK 1 C941

52532103K10 CERAMIC CAP. CT1-63V-16C-2B4-10NFK 1 C914

52594332K30 CERAMIC CAP. CT81-2KV-20C-2R4-3300PFK 1 C902

52617P47M11 ELECTROLYTIC CAP.

52613102M11 ELECTROLYTIC CAP.

52643100M10 ELECTROLYTIC CAP.

50640061990 ELECTROLYTIC CAP.

50630061030 INDUCTOR

50630061070 INDUCTOR

50630061020 INDUCTOR

50630061060 INDUCTOR

61112446060 DIODE 2CZ4406E 1 D911

61411075DT0 DIODE 1N4148 9 D901

61411075DU6 DIODE 2CK75D D903 D904 D905 D906 D907

D908 D909 D910

RY21-1W-3.3KΩJ

RY21-1W-1KΩJ

RY21-1W-1KΩJ

CBB81-1.6KV-0.012μFH

CBB81-1.6KV-0.012μFH

CBB81-1.6KV-0.012μFJ

CBB13-400V-0.3μFJ

CBB13-400V-0.3μFJ

LGT-150μH-K(JUB4.757.052)

CD293-450V-560μFM

RT13-0.166W-15ΩJ

RT13-0.166W-51ΩJ

RT13-0.166W-82ΩJ

RT13-0.166W-100ΩJ

RT13-0.166W-33ΩJ

RT13-0.166W-330ΩJ

RT13-0.166W-470ΩJ

RT13-0.166W-820ΩJ

RT13-0.166W-910ΩJ

RT13-0.166W-1KΩJ

RT13-0.166W-1.2KΩJ

RT13-0.166W-2.2KΩJ

RT13-0.166W-3.3KΩJ

RT13-0.166W-3.9KΩJ

RT13-0.166W-4.7KΩJ

RT13-0.166W-10KΩJ

RT14-0.25W-560ΩJ

RJ14-0.25W-10MΩJ

RT15-0.5W-1.2KΩJ

RY21-1W-100KΩJ

RY21-3W-7.5KΩJ

CD110X-50V-0.47μF

CD110X-16V-1000μFM

CD11C-16V-10μFM

CD110-250V-10μFM

LGB0606-4.7μHJ

LGB0606-10μHJ

LGB0606-39μHJ

LGB0606-100μHJ

1 R440

1 R317A

1 C419

1 C424

1 L402

1 C805

2 R905 R992

3 R916 R945 R946

3 R918 R924 R930

4 R915 R922 R929 R939

2 R933 R936

1 R934

4 R917 R925 R937 R980

4 R914 R921 R928 R981

1 R935

3 R912 R919 R926

2 R947 R977

2 R909 R941

1 R932

3 R942 R943 R944

1 R904

1 R940

3 R901 R902 R903

1 R948

1 R951

1 R949

3 R960 R961 R962

1 C910

2 C913 C912

1 C911

2 C909 C940

1 L910

1 L908

3 L905 L906 L907

3 L902 L903 L904

Model no.: CT-34CJ5RE.doc

version 1.0

Page 62

62

PART CODE PART NAME SPECIFICATION QTY LOCATION

61212051BT5 DIODE W05Z5.1B 1 D920

61112529G40 DIODE 2CZ5295G 1 D921

50650030610 AUDION 2PC1815GR 5 Q902

62118150Y16 AUDION 2SC1815-Y/KTC3198-Y Q904

62118150Y16 AUDION 3DG1815-Y Q906 Q910 Q920

637080422W5 AUDION BF422 1 Q921

637080422W5 AUDION 3DG422

637080422W5 AUDION BF422

62421200YW5 AUDION 2SC2120-Y 1 Q908

62421200YW5 AUDION 2SC2120-Y

50650030910 AUDION 2SA562-Y 1 Q907

62205624Y05 AUDION 3CG562Y

50650030870 AUDION 2SA562TM-Y

50650030910 AUDION 2SA562-Y

515162P2J70 FUSE RES.

53610230120 GZS CRT SOCKET GZS10-301-G2 1 V901A

53610230120 GZS CRT SOCKET GZS10-301-2

62118110514 AUDION 2SC4544 3

62118110514 AUDION 3DA4544

8782007161C1 POWER BOARD PCB JUC7.820.716-1 1

50620010490 GLASS GLAZED RES.

51725565J01 GLASS GLAZED RES.

50620040140 THERMISTOR RES. PTDCA1BF4R5Q200 1 RP801

5246Q224KB0 POLYPROPYLENE CAP.

523A0522445 MYLAR CAPA. ECQU2A224KLA

8475700950B INDUCTOR 150-F06T(JUB4.757.095) 1 TP801

84757003100 LINE FILTER LCL-F12(JU4.757.031) 1 TP802

50700010720 FUSE R/S/V50TT4AL250V 1 FP801

59818030040 FUSE 618004

8782005801V10 AV PCB JUC7.820.580-1 1

51113750JU0 CARBON RES.

50620071110 CARBON RES.

51113101JU0 CARBON RES.

R944 R946 R956 R957

R958 R967 R968 R998 W947

51113181JU0 CARBON RES.

51113471JU0 CARBON RES.

51113681JU0 CARBON RES.

51113102JU0 CARBON RES.

R942 R943 R945 R999A

51113222JU0 CARBON RES.

51113392JU0 CARBON RES.

51113472JU0 CARBON RES.

51113103JU0 CARBON RES.

51113123JU0 CARBON RES.

51113223JU0 CARBON RES.

51113473JU0 CARBON RES.

50620071970 CARBON RES.

51113104JU0 CARBON RES.

R914

50620071760 CARBON RES.

50620071900 CARBON RES.

51113105JU0 CARBON RES.

5251S181J10 CERAMIC CAP. CC1-63V-08C-SL-180PFJ 1 C915

52532152K10 CERAMIC CAP. CT1-63V-06C-2B4-1500PFK 1 C926

50640023020 CERAMIC CAP. CT1-63V-08C-2B4-2700PFK 1 C927

5253F103Z10 CERAMIC CAP. CT1-63V-08C-2F4-10NFZ 1 C909

52367104J10 MYLAR CAPA.

52367104J10 MYLAR CAPA. ECQV1H104JLW VD903

526132P2M10 ELECTROLYTIC CAP.

C925

52623010060 ELECTROLYTIC CAP.

C990

52613220M11 ELECTROLYTIC CAP.

52613330M10 ELECTROLYTIC CAP.

52613470M11 ELECTROLYTIC CAP.

52613101M11 ELECTROLYTIC CAP.

52613471M11 ELECTROLYTIC CAP.

52617010MV0 ELECTROLYTIC CAP.

61411075DT0 DIODE IN4148 2 VD901

61411075DU6 DIODE 2CK75D VD902

62118150Y16 AUDION 3DG1815-Y 6 Q903

62118150Y16 AUDION 2SC1815-Y/KTC3198-Y Q906

50650030610 AUDION 2PC1815GR Q907 Q908 Q913 Q915

62210150YW0 AUDION 3CG1015-Y 2 Q911

62210150YW0 AUDION 2SA1015-Y Q912

RF10-1W-2.2ΩJ

RI81-0.5W-5.6MΩJ

232224213565/VR37-0.5W-5.6MΩJ

CBB62-250VAC-0.22μFK

RT13-0.166W-75ΩJ

RT13-0.166W-82ΩJ

RT13-0.166W-100ΩJ

RT13-0.166W-180ΩJ

RT13-0.166W-470ΩJ

RT13-0.166W-680ΩJ

RT13-0.166W-1KΩJ

RT13-0.166W-2.2KΩJ

RT13-0.166W-3.9KΩJ

RT13-0.166W-4.7KΩJ

RT13-0.166W-10KΩJ

RT13-0.166W-12KΩJ

RT13-0.166W-22KΩJ

RT13-0.166W-47KΩJ

RT13-0.166W-68KΩJ

RT13-0.166W-100KΩJ

RT13-0.166W-390KΩJ

RT13-0.166W-560KΩJ

RT13-0.166W-1MΩJ

CL21X-50V-0.1μFJ

CD110-16V-2.2μFM

CD110X-16V-10μFM

CD110X-16V-22μFM

CD110-16V-33μFM

CD110X-16V-47μFM

CD110X-16V-100μFM

CD110X-16V-470μFM

CD110X-50V-1μFM

1 R920

1 RP802

2 CP801 CP803

4 R905 R907 R919 R920

2 R902 R903

13 R909 R935 R936 R940

1 R925

1 R950

1 R918

9 R908 R921 R938 R939 R941

4 R912 R915 R924 R955

2 R952 R953

2 R932 R933

1 R923

1 R951

2 R937 R992

5 R993 R994 R995 R996 R997

1 R949

6 R901 R904 R910 R911 R913

1 R948

1 R922

1 R991

2 C945

6 C917 C919 C920 C921 C923

6 C905 C908 C918 C922 C924

1 C962

1 C916

2 C913 C914

1 C910

1 C904

1 C911

Model no.: CT-34CJ5RE.doc

version 1.0

Page 63

63

PART CODE PART NAME SPECIFICATION QTY LOCATION

622101500T6 AUDION 2PA1015GR

67144900105 I.C TC90L01N 1 N901

53841023061 AV SOCKET AVW-23-6R-YUV 1 XP901

53841023060 AV SOCKET AVW-23-6R 1 XP902

53140312010 S-VIDEO SOCKET S-W-07K 1 XP905

8782013140C SIDE AV PCB JUC7.820.1314 1

53853313030 AV SOCKET AVL-13-3RA 1 XPK01

8782012110C FUNCTION KEY PCB JUC7.820.1211 1

51113512JU0 CARBON RES.

51C08013006 CARBON RES.

50620070880 CARBON RES.

51113183JU0 CARBON RES.

50620073010 CARBON RES.

54167605410 TOUCH SWITCH

S906

8782013150C IR RECEIVER PCB JUC7.820.1315 1

51113101JU0 CARBON RES.

51113471JU0 CARBON RES.

RP12A

51113222JU0 CARBON RES.

5253F103Z10 CERAMIC CAP. CT1-63V-08C-2F4-10NFZ 1 CP12

52613470M11 ELECTROLYTIC CAP.

61118005201 LED HFBA052MP(7.0) 2 VDP11A

VDP11B

67109138025 IR RECEIVER HRM380017 1 NP11A

67109138045 IR RECEIVER HS0038A2

67109138025 IR RECEIVER TSOP1238

67109138025 IR RECEIVER AT138A

The date are subject to change without prior notice

RT13-0.166W-5.1KΩJ

RT13-0.166W-7.5KΩJ

RT13-0.166W-11KΩJ

RT13-0.166W-18KΩJ

RT13-0.166W-36KΩJ

KA1W6×5-41

RT13-0.166W-100ΩJ

RT13-0.166W-470ΩJ

RT13-0.166W-2.2KΩJ

CD110X-16V-47μFM

1 RK91

1 RK92

1 RK94

1 RK95

1 RK96

6 S901 S902 S903 S904 S905

1 RP11

2 RP12

1 RP13

1 CP11

Model no.: CT-34CJ5RE.doc

version 1.0

Page 64

Loading...

Loading...