Page 1

SERVICE MANUAL

Model:

LCT2715

Safety Instructions

Production specification.

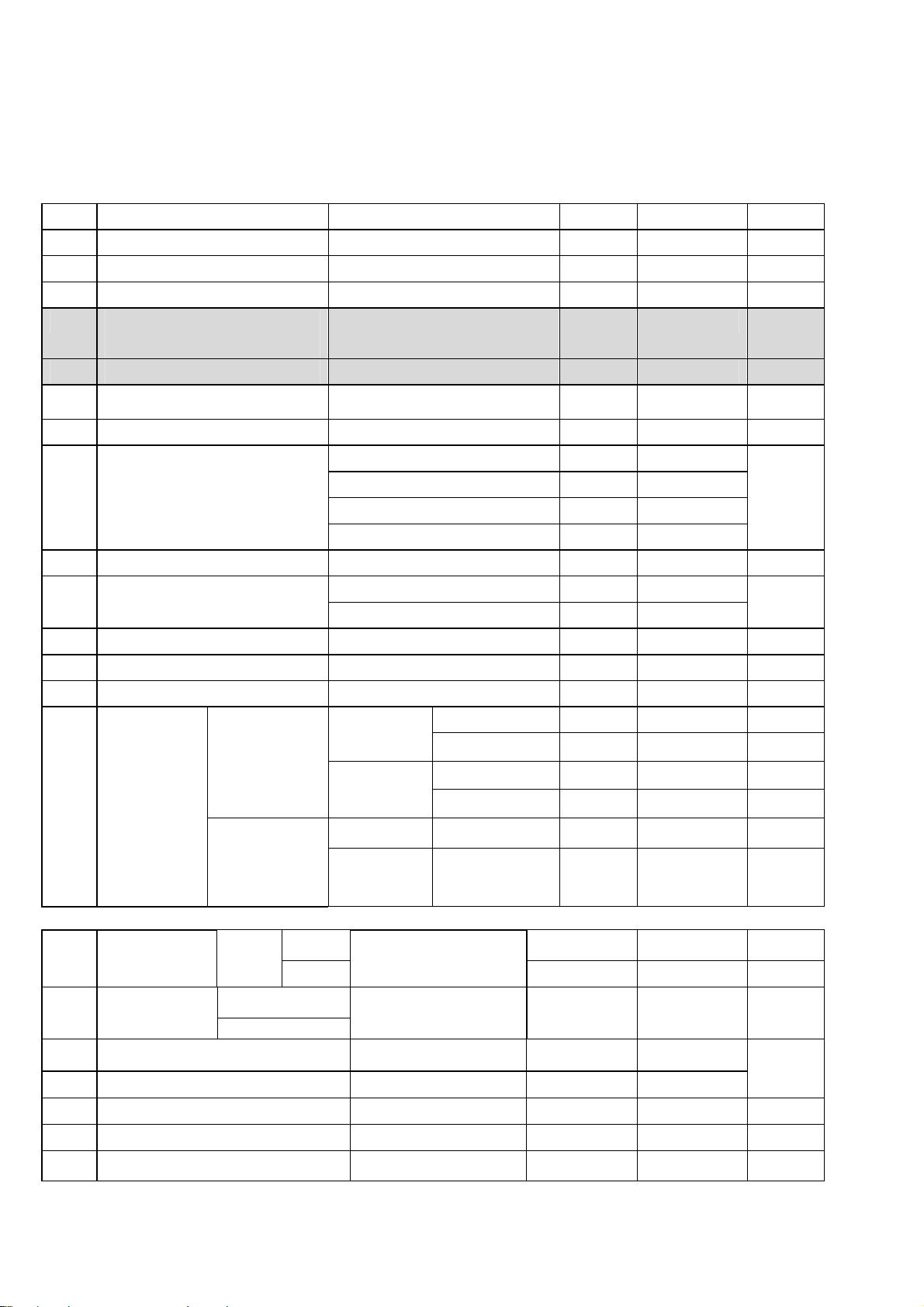

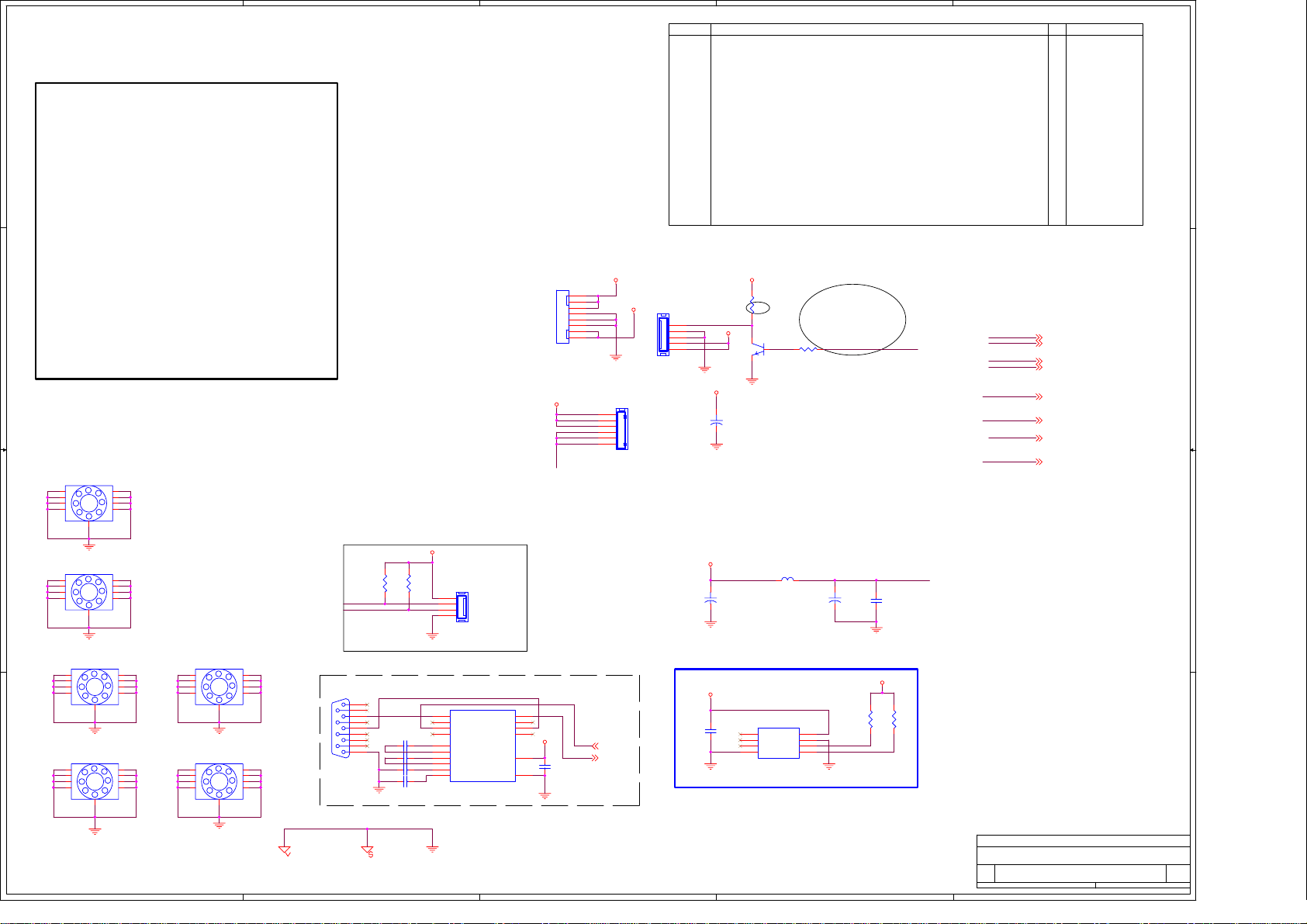

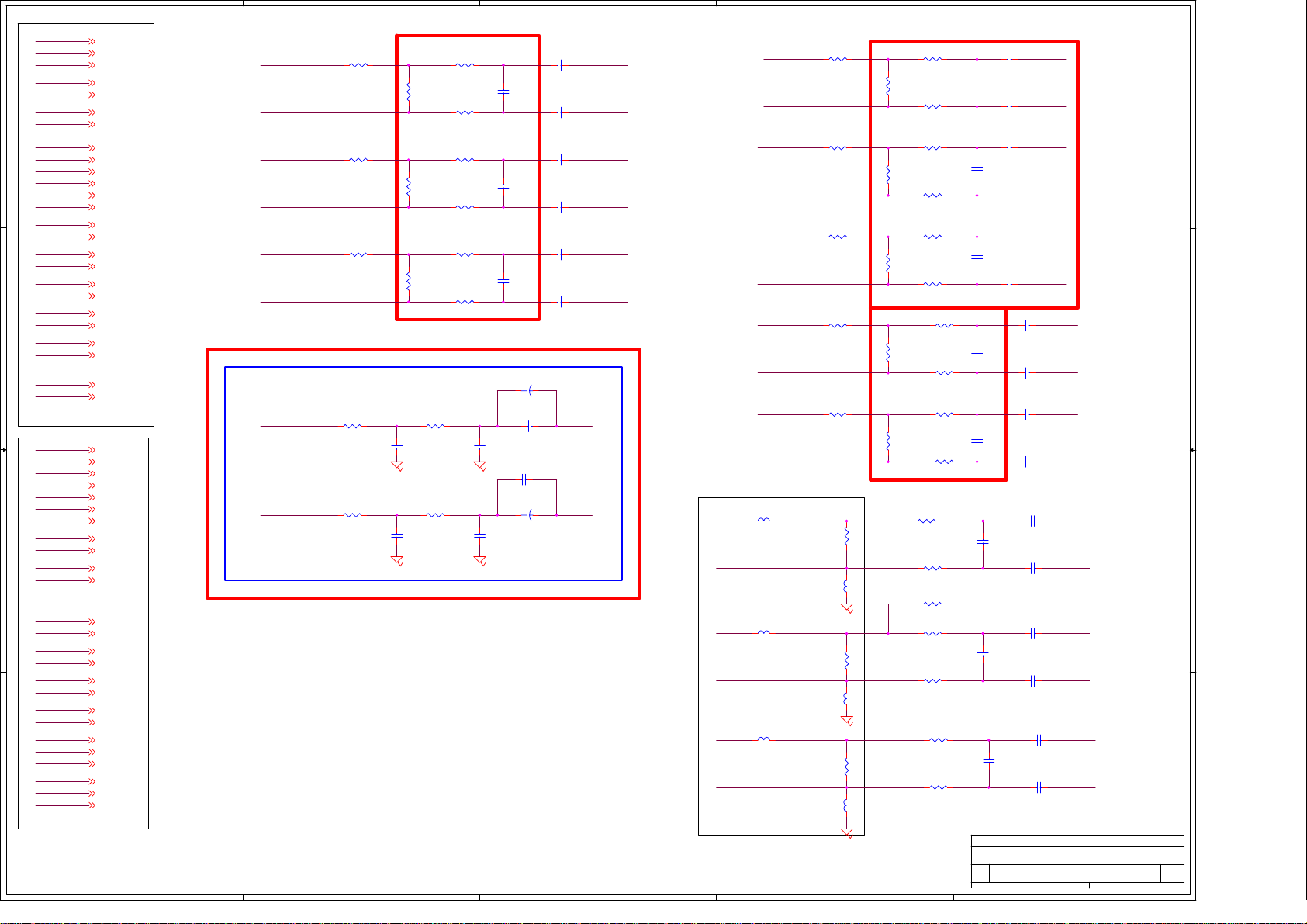

Block Diagram

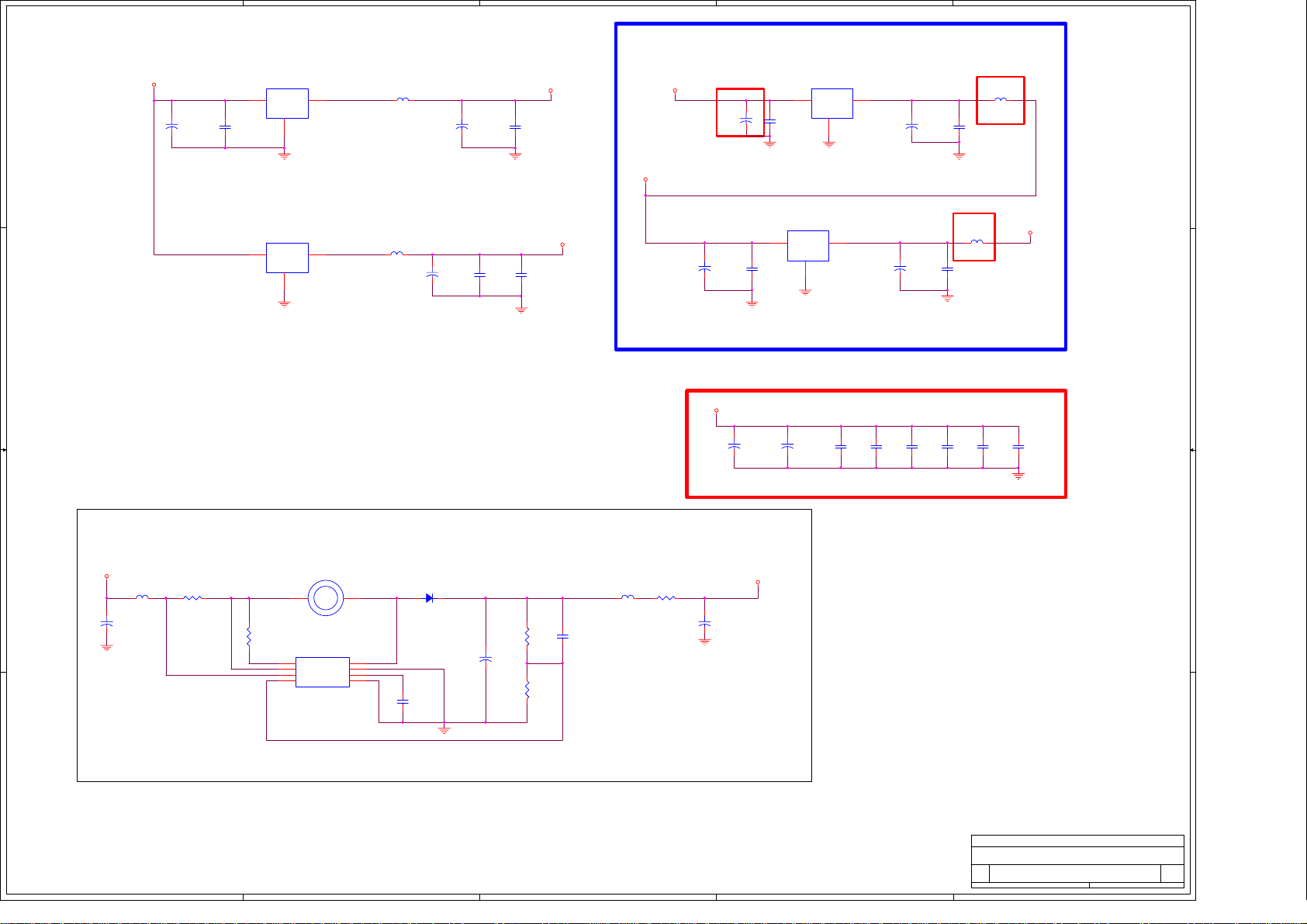

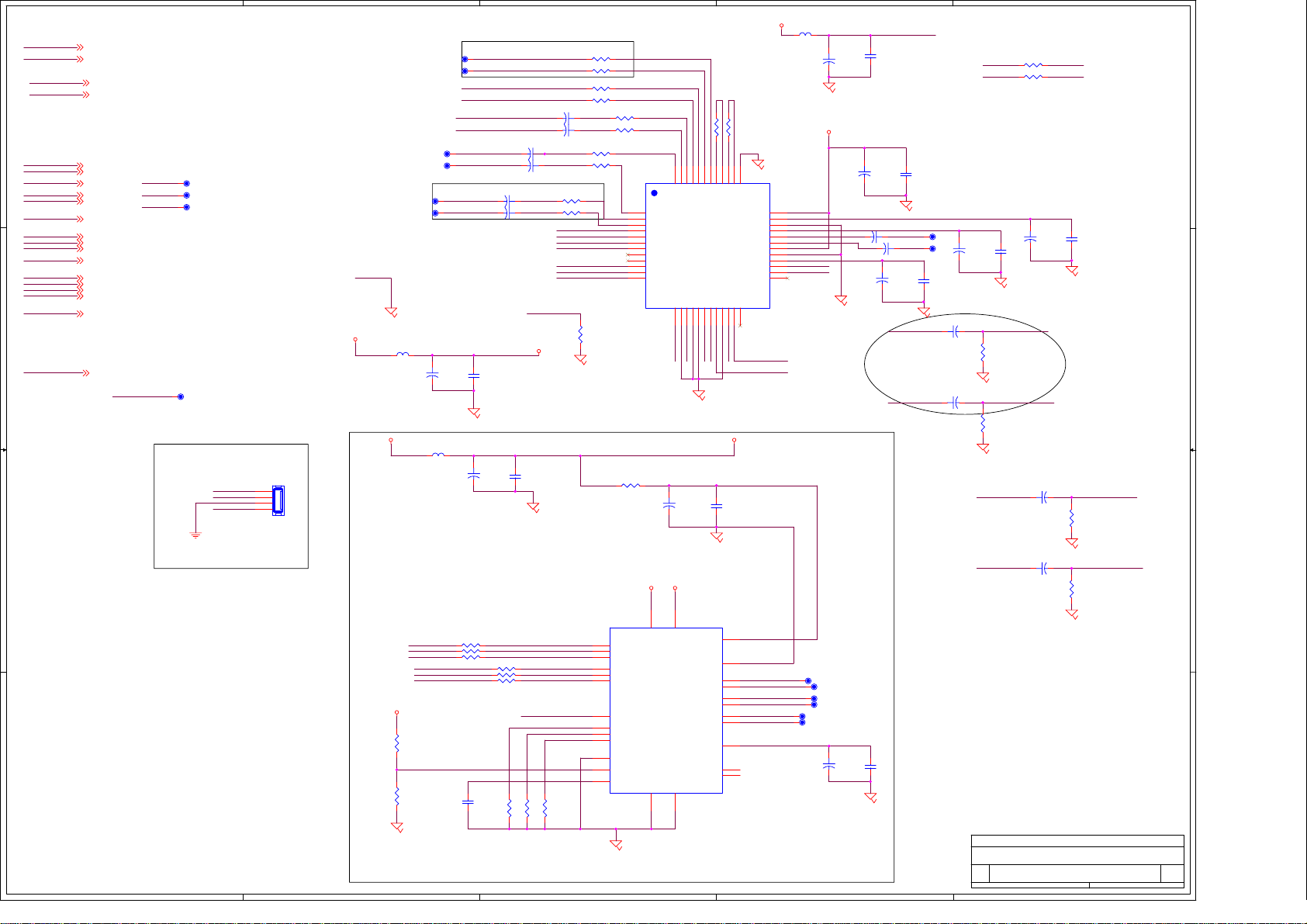

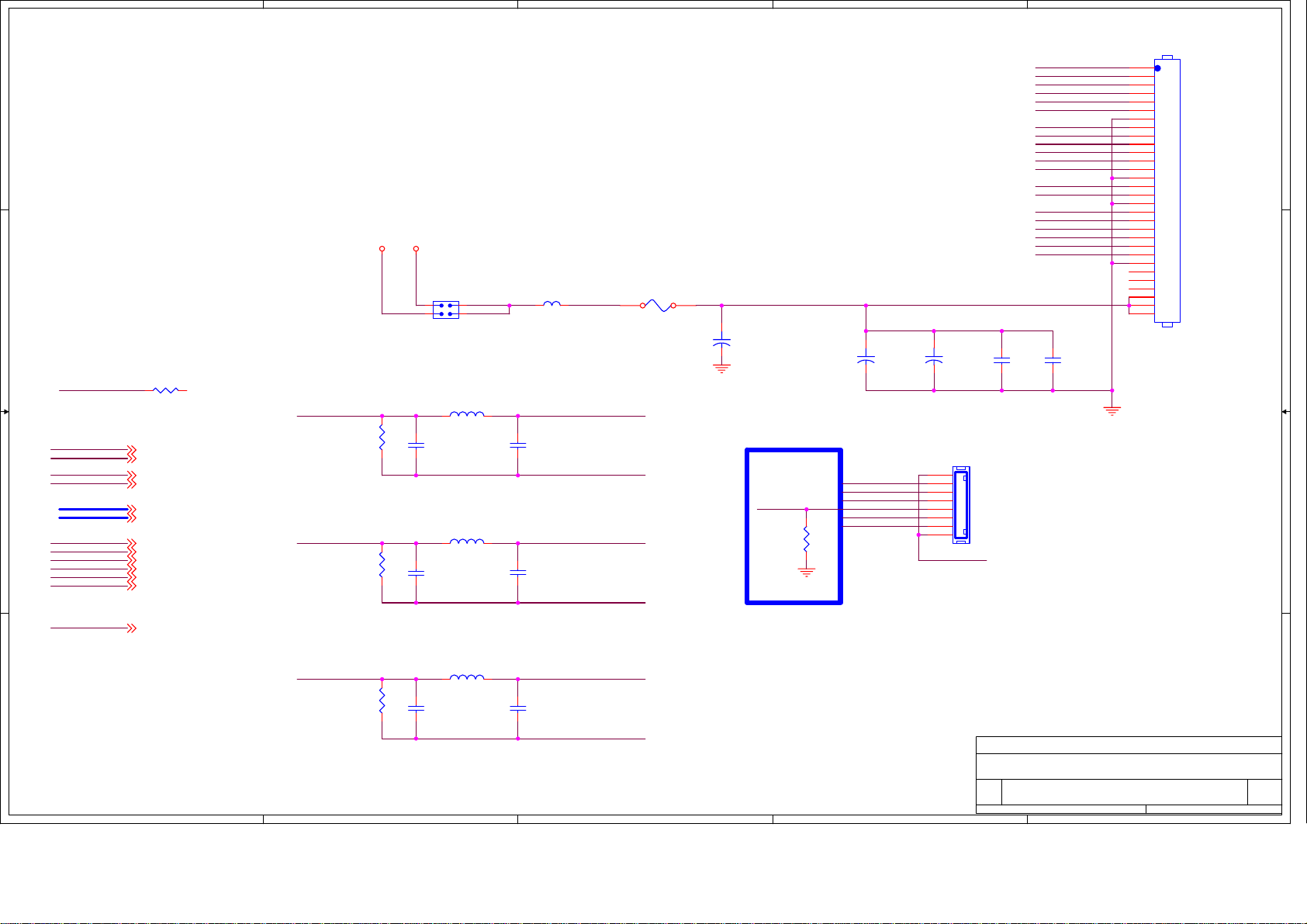

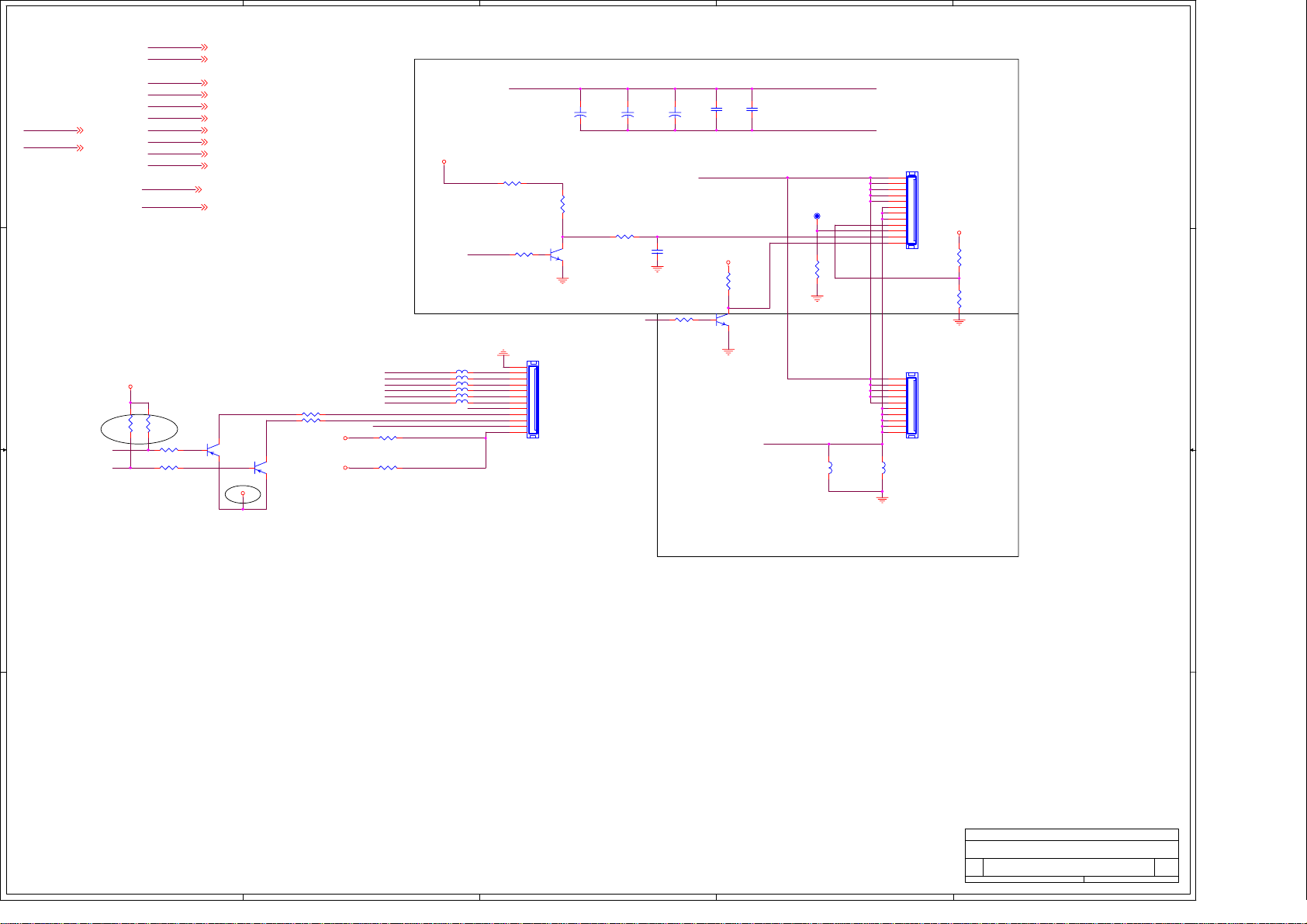

Circuit Diagram

Disassembly

Pin Descriptions

LCD Panel specification

Exploded View Diagram

Spare parts list

V-chip password and software upgrade

This manual is the latest at the time of printing, and does not

include the modification which may be made after the printing,

by the constant improvement of product.

Page 2

I. Safety Instru ctions

CAUTION

RISK OF ELECTRIC SHOCK

DO NO T OPEN

The l ightning fla sh w ith arro whead symb ol,

within an equilateral triangle, is intended to alert

the user to the presence of uninsulated “dangerous

voltage” within the product’ s enclosure that may

be of sufficient magnitude to constitute a risk of

electric shock to persons.

CAUTIO N: TO REDUCE THE RISK OF ELECTRIC

SHO CK, DO NOT REMOVE COVER (OR BACK). NO

USER-SERVI CEABLE PART S INSIDE. REFER

SERVICING TO QUALIFI ED SERVICE PERSONNEL

O NLY.

PRECAUTIONS DURING SERVICING

1. In a ddition to safety, other parts and assemblies are

speci fied for conformance with such regulations as

those applyi ng to spurious radiation. These must

also be replaced only with specified replacements.

Exampl es: RF converters, tuner units, antenna

selection switches, RF cables, noise-blocking

capacitors, noise-bl ocking filters, etc.

2. Use sp ecified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Do uble insulated wires

3) Hig h voltage leads

3. Use specified i nsulating materials for hazardous

live pa rts. Note especially:

1) In sulating Tape

2) PVC tubing

3) Spa cers (insulating barriers)

4) Insulating sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side compo nents

(tran sformers, power cords, n oise blocking

capacitors, e tc.), wrap ends of wires securely about

the te rminals before soldering.

5. Make sure that w ires do not contact heat generating

parts (he at sinks, oxide metal film resistors, fusible

resistors, etc.)

6. Check if replace d wires do not contact sharply edged

or po inted parts.

7. Make sure that foreign objects (screws, solder

drop lets, etc.) do not remain insi de the set.

MAKE YOUR CONTRIBUTION TO PROTECT THE

ENVIR ONMENT

Used batteries with the ISO symbol

for recycling a s well as small

accumu lators (rechargeable batteries), mini-batteries

(cell s) and starter batteries should not be thrown

into the garbage can.

Please leave them at an appropriate depot.

The excla mation po int wi thin a n equilateral

tri angle is intended to a lert th e user to the

presence of important operating and maintenance

(servici n g) instr u ct i o n s i n th e liter a tu re

accompanying the appliance.

W ARNING:

Before servicing this TV receiver, read the X-RAY

RADIATION PRECAUTION, SAFETY INSTRUCTION

and PRODUCT SAFETY NOTICE.

X-RA Y RADIATION PRECAUTION

1. Excessively high can prod uce potentially hazardous

X-RAY RADIATION. T o avoid such hazards, the high

volta ge must not exceed the specified limit. The

normal va lue of the high voltage of this TV receiver

is 2 7 KV at zero bean current (minimum brightness).

The high voltage must not exceed 30 KV under any

circu mstances. Each time when a re ceiver requires

servici ng, the high voltage should be checked. The

readi ng of the high voltage is re commended to be

reco rded as a part of the service record, It is

important to u se an accurate and reliable high

voltage meter.

2. The only source of X-RAY RADIATION in this TV

receiver is the picture tube. For con tinued X-RAY

RADIATION protectio n, the replacement tube must be

exactly the sa me type as specified in th e parts list.

3. Some parts in this TV receiver have special safety

related characteristics fo r X-RADIATION protection.

For continued safety, the parts replacement should

be under taken only afte r referring the PRODUCT

SAFETY NOTICE.

SAFETY IN STRUCTION

The se rvice should not be attempted by anyone

unfamiliar with the ne cessary instructions on this TV

receiver. The fo llowing are the necessary instructions

to be ob served before servicing.

1. An isolation transformer shoul d be connected in the

power li ne between the receiver and the AC line

when a service is performed on the primary of the

conve rter transformer of the set.

2. Comply wi th all caution and safety related provided

on th e back of the cabinet, inside the cabinet, on the

chassis or p icture tube.

3. T o avoid a shock hazard, always discharge the

pictu re tube's anode to the chassis g round before

removi ng the anode cap.

- 2 -

Page 3

4. Completely discharge the high potential voltage of the

picture tube before handli ng. The picture tube is a

vacuum and if bro ken, the glass will explode.

5. When rep lacing a MAIN PCB in the cabinet, always

be certai n that all protective are installed properly

such as control knobs, adjustment co vers or shields,

barri ers, isolation resistor networks etc.

6. When se rvicing is required, observe the original lead

dressing. Extra precau tion should be given to assure

correct lead dressing in the high voltage area.

7. Keep wires away from high voltage or high te mpera

ture components.

8. Befo re returning the set to the customer, al ways

perform an AC leaka ge current check on the exposed

meta llic parts of the cabinet, such as anten nas,

termin als, screwheads, metal overlay, control shafts,

etc., to be sure the set is safe to operate without

danger of electrica l shock. Plug the AC line cord

directly to the AC outlet (do not use a line isolation

transformer d uring this check). Use an AC voltmeter

havin g 5K ohms volt sensitivity or more in the

following manner.

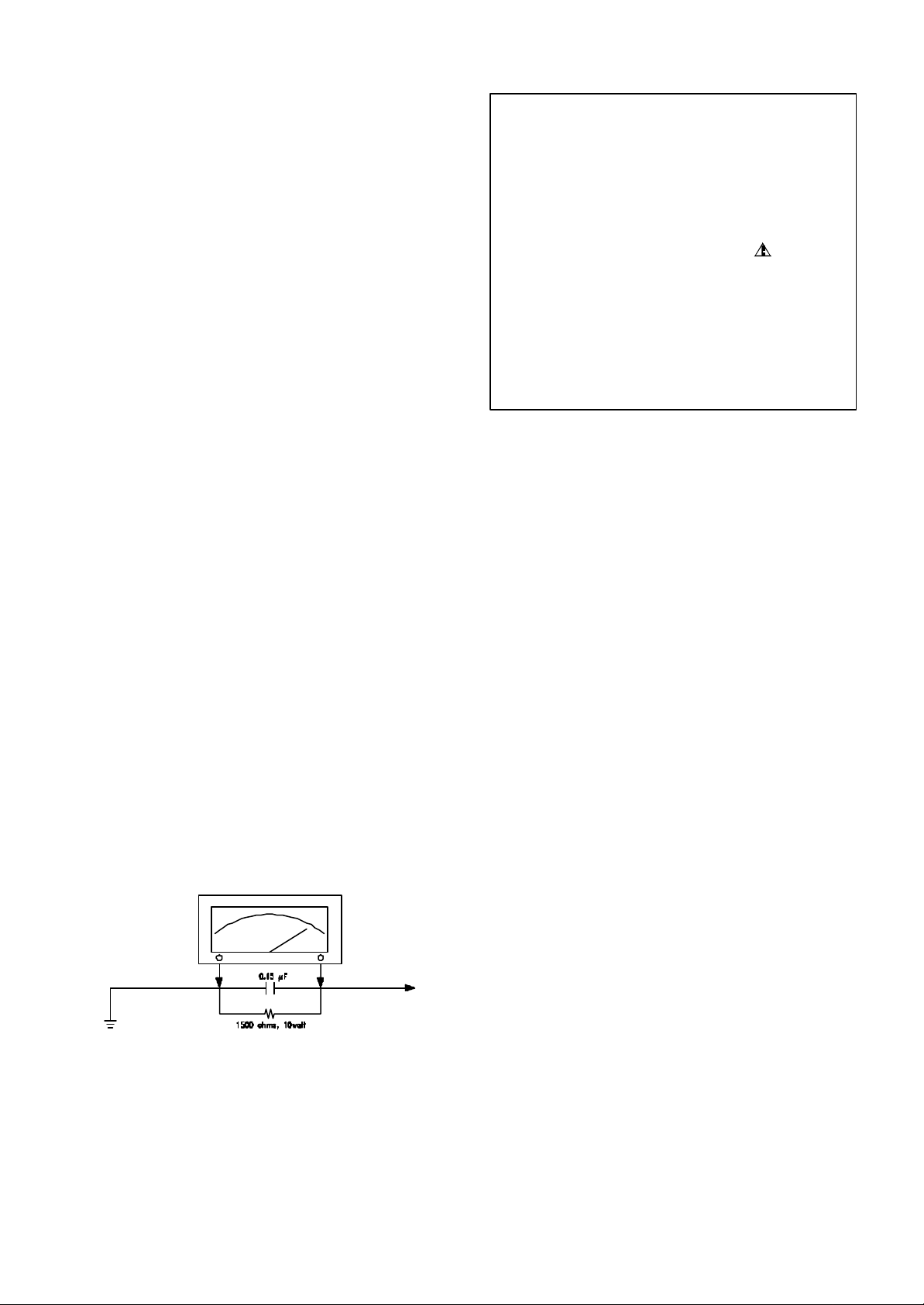

Conne ct a 1.5K ohm 10 watt resistor paralleled by a

0.15µF AC type capacitor, between a good earth

ground (water pipe, conductor etc.,) and the exposed

metallic parts, one at a time.

Measure the AC vol tage across the combination of

the 1 .5K ohm resistor and 0.15 uF capacitor. Reverse

the AC p lug at the AC outlet and repeat the AC

volta ge measurements for each exposed metallic

part.

The me asured voltage must not exceed 0.3V RMS.

This correspo nds to 0.5mA AC. Any value exceeding

this limit constitutes a potential shock hazard and

must be corrected immediately.

The resistance measurement should be done

betwe en accessible exposed metal parts and power

cord plug prongs with the power switch "ON". The

resi stance should be more than 6M ohms.

PRODUCT SA FETY NOTICE

Many e lectrical and mechanical parts in this TV

receiver have special safety-related characteristics.

These characteristics are offer passed unnoticed by

visual spection and the protection afforded by them

cannot necessari ly be obtained by using replacement

compon ents rates for a higher voltage, wattage, etc.

The replacemen t parts which have these special

safety characteristics are identified by marks on

the schematic diagram and on the parts list.

Before replacin g any of these components, read the

parts list in thi s manual carefully. The use of

substitute re placement parts which do not have the

same safety characteristics as specified in the parts

list may cre ate shock, fire, X-RAY RADIATION or

other h azards.

Good earth ground

such as the water

pipe, conductor,

etc.

AC Leak age Current Check

AC VOLTMETER

Place this probe

on eac h e xpos ed metallic

part

- 3 -

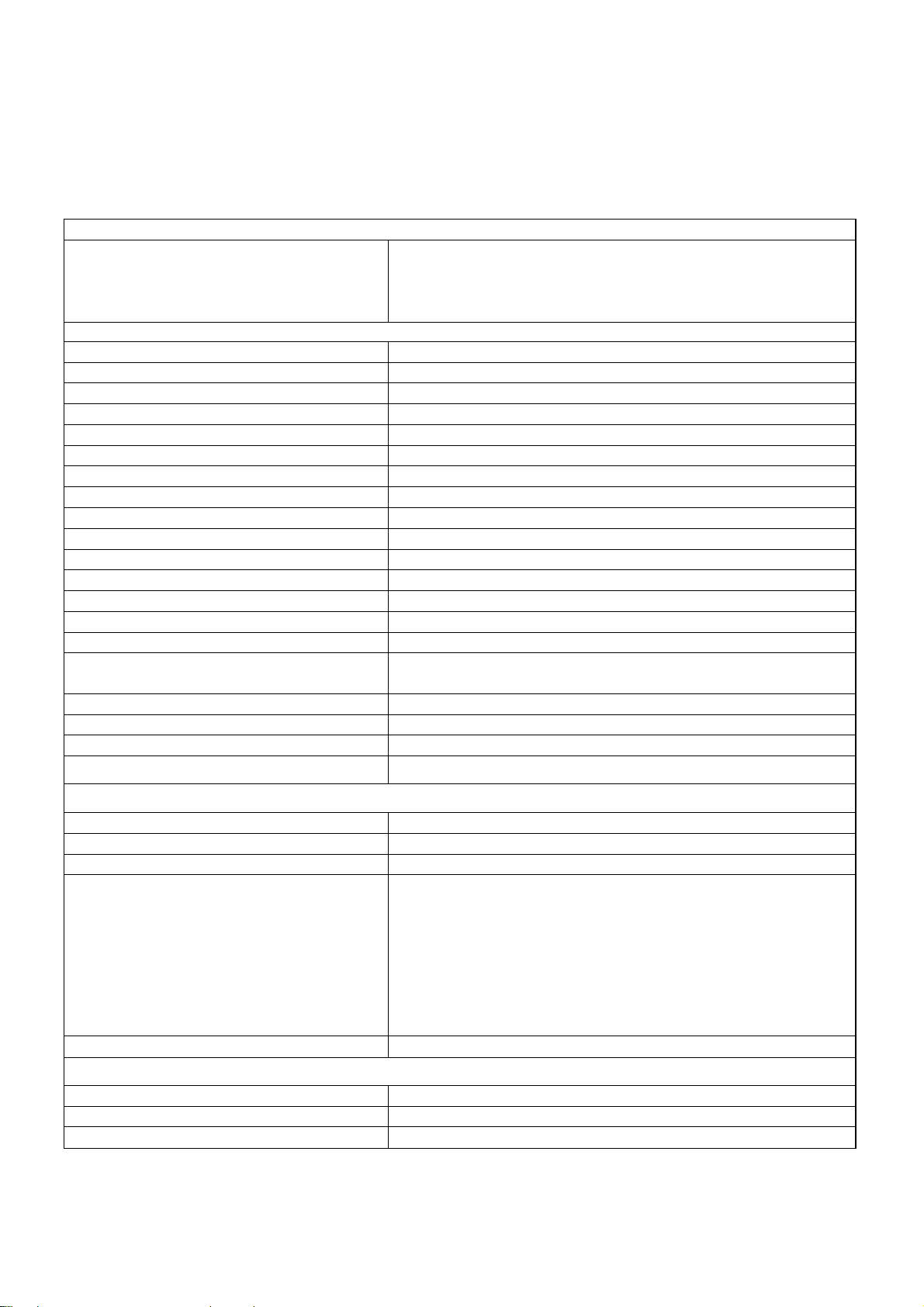

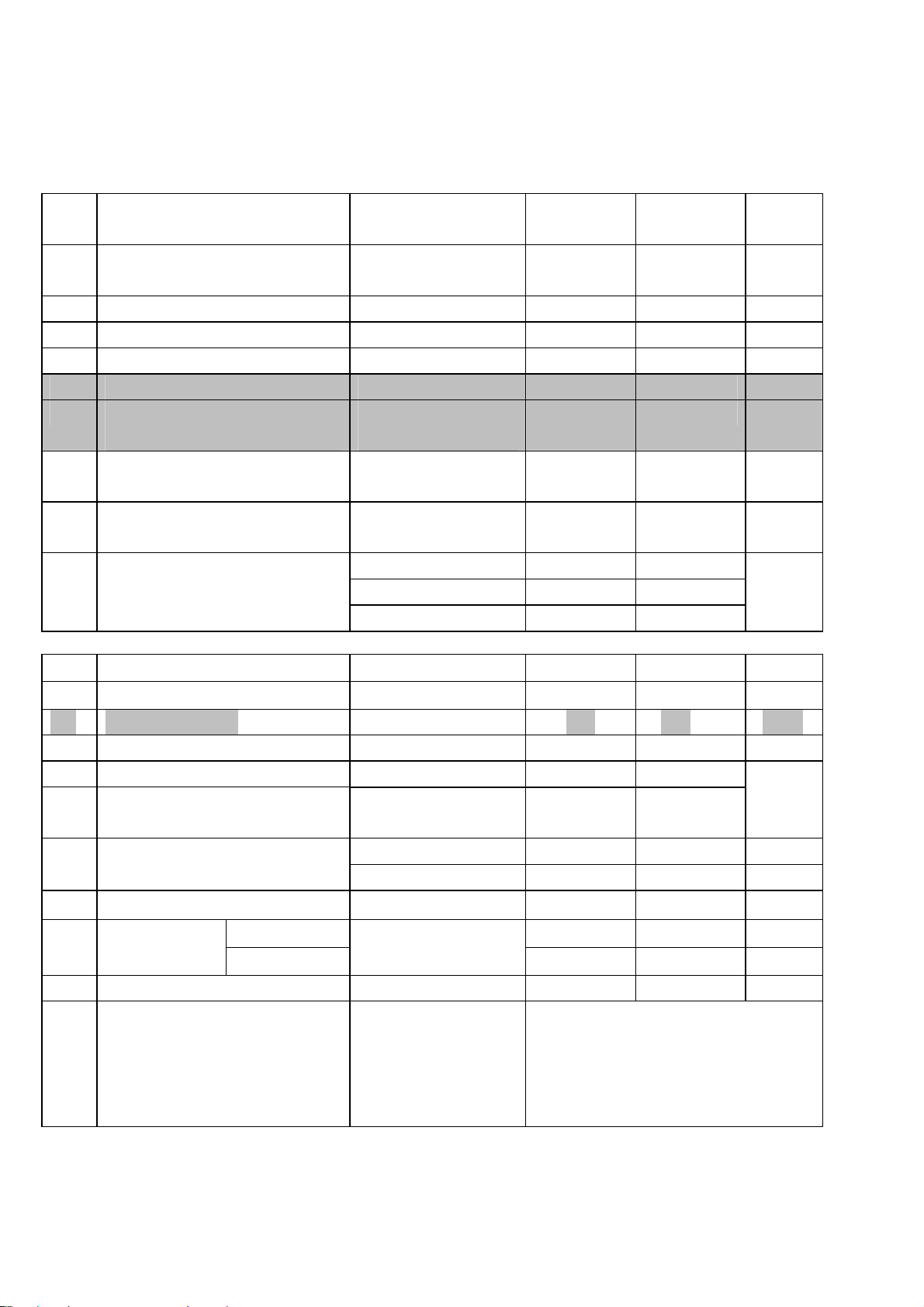

Page 4

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Product Specification

Reference No. : LC27HAB002

Revision : 0

Date : 2005.08.1

Page : P.1 of 8

Model No. : LC27HAB

Customer Model No. : LCT2715

Design Code : LC27HABCUSXM1-A01

BOM No. : LC27HABCUSXM1-A01

Artwork Ass'y No. : 580-L26ABHM-TU02L

Description : AKAL LCD TV 26” NTSC AC100V-240 V AC USA

Checked By: Electronic Engineer

Mechanical Engineer

Approved By: Engineering Manager

Approved By: PM Department Head

DOC Rev

NO.

0 Initial Release

The Latest Revision Details DATE

Page 5

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 2 of 8

General Description

1. Main features

Production Description

Panel Supplier and Model

Chips Solution

Market

1.1 VIDEO SECTION

Display size 27”/16:9

Display Resolution 1366 X 768

Pixel Pitch

Peak Brightness 550(nits)

Contract Ratio 1000:1, Typical (1/100 White Window, Dark Room)

View Angle Hor. And Vert. ≥170 degree

Color Deeps 16.7M Color (R / G/ B each 256 Scales)

PC Resolution Supporting VGA, SVGA, XGA,WXGA

HDTV Compatible 480p / 720p / 1080i

Progressive Scanning Yes

Film Mode Pull Down Yes

“GAMMA” Correction Yes

Color Temperature Control Yes

Comb Filter Yes

Second De-interlace for Sub picture No

Wide Mode

TV System NTSC M

Dual Tuner System No

AV Input Color System PAL /NTSC

PIP Basic mode (video on graphic mode,resolution≥1024×768)

AKAL LCD TV 27” NTSC AC100V-240VAC USA

CHIMEI V270B1-L01

MK8205

USA

0.1460mm×0.4365mm

Full,Fill Aspect Ratio,Nonliner,LB to 16:9,

LB subtitles to 16:9 or Anamorphic

1.2 AUDIO SECTION

Audio Output Power 6W×2 Max.(8 ohm)

Sound Effect NO

Tone Control Yes

1.3 Input Terminals

1.4 Output Terminals Audio Output (RCA ; L&R Type) ×1

1.5 Others

Closed Caption / V-Chip Yes

Teletext No

OSD Language English, FranÇais, Español

D-Sub 15 Pin Type(

D-Sub 9 Pin (RS-233 Input ) ×1

Component Video-YPbPr/YCbCr ×2 RCA Terminals

S-Video Input (Mini Din 4Pin) ×1

Video Input RCA Terminals

Y / Pb / Pr, Y / Cb / Cr (RCA Type) ×2

Stereo Audio Input for YPbPr / YCbCr x 2

Analog-RGB Input ) ×1

(3.5mm Phone Type) ×1

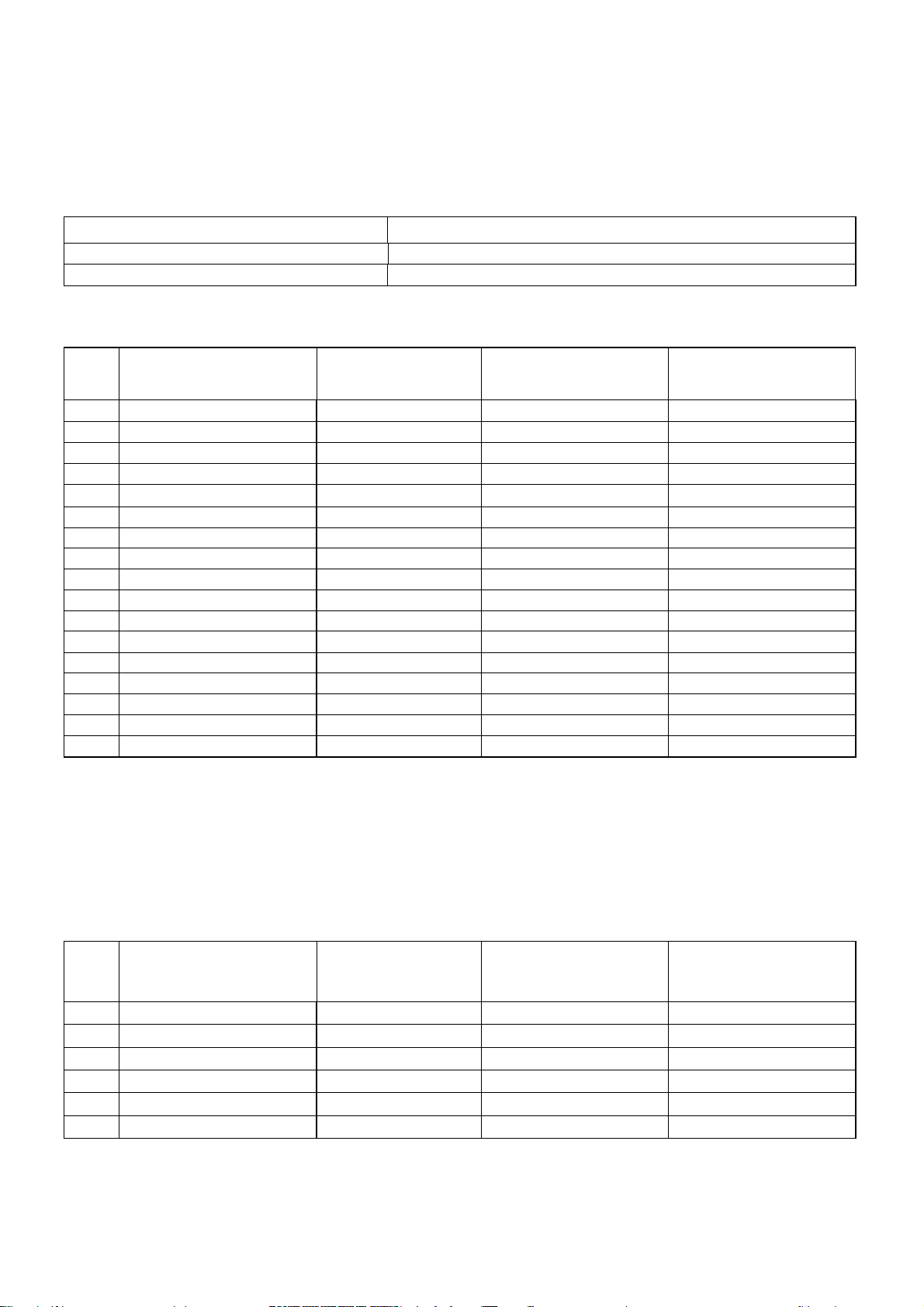

Page 6

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 3 of 8

Stereo Decode

Power Rating AC 100-240V, 50/60Hz

Power Consumption 200W

1.6 Support the Signal Mode

This machine can support the different from VGA signal mode in 19 kinds

No Resolution

1) 640×480 31.50 60.00 25.18

2) 640×480 35.00 67.00 30.24

3) 640×480 37.50 75.00 31.50

4) 640×480 37.86 72.81 31.50

5)

6) 800×600 35.16 56.25 36.00

7) 800×600 37.90 60.32 40.00

8) 800×600 46.90 75.00 49.50

9) 800×600 48.08 72.19 50.00

10) 832×624 49.00 75.00 57.27

11) 1024×768 48.40 60.00 65.00

12) 1024×768 56.50 70.00 75.00

13) 1024×768 60.00 75.00 78.75

14) 1152×864 63.86 70.02 94.51

15) 1152×864 67.52 75.02 108.03

16) 1280×960 60.02 60.02 108.04

17) 1280×1024 64.00 60.01 108.00

MTS with SAP

Horizontal

Frequency(Hz)

720×400

31.47 70.08 28.32

Vertical

Frequency(KHz)

Dot Clock

Frequency(MHz)

1.7 HDTV Mode (YPbPr)

No Resolution

1) 480i 15.734 59.94 13.50

2)

3)

4)

5)

6)

480p(720×480)

576p(720×576)

720p(1280×720)

720p(1280×720)

1080i(1920×1080)

Horizontal

Frequency(KHz)

31.468 59.94 27.00

31.25 50.00 27.00

37.50 50.00 74.25

45.00 60.00 74.25

33.75 60.00 74.25

Vertical

Frequency(Hz)

Dot Clock

Frequency(MHz)

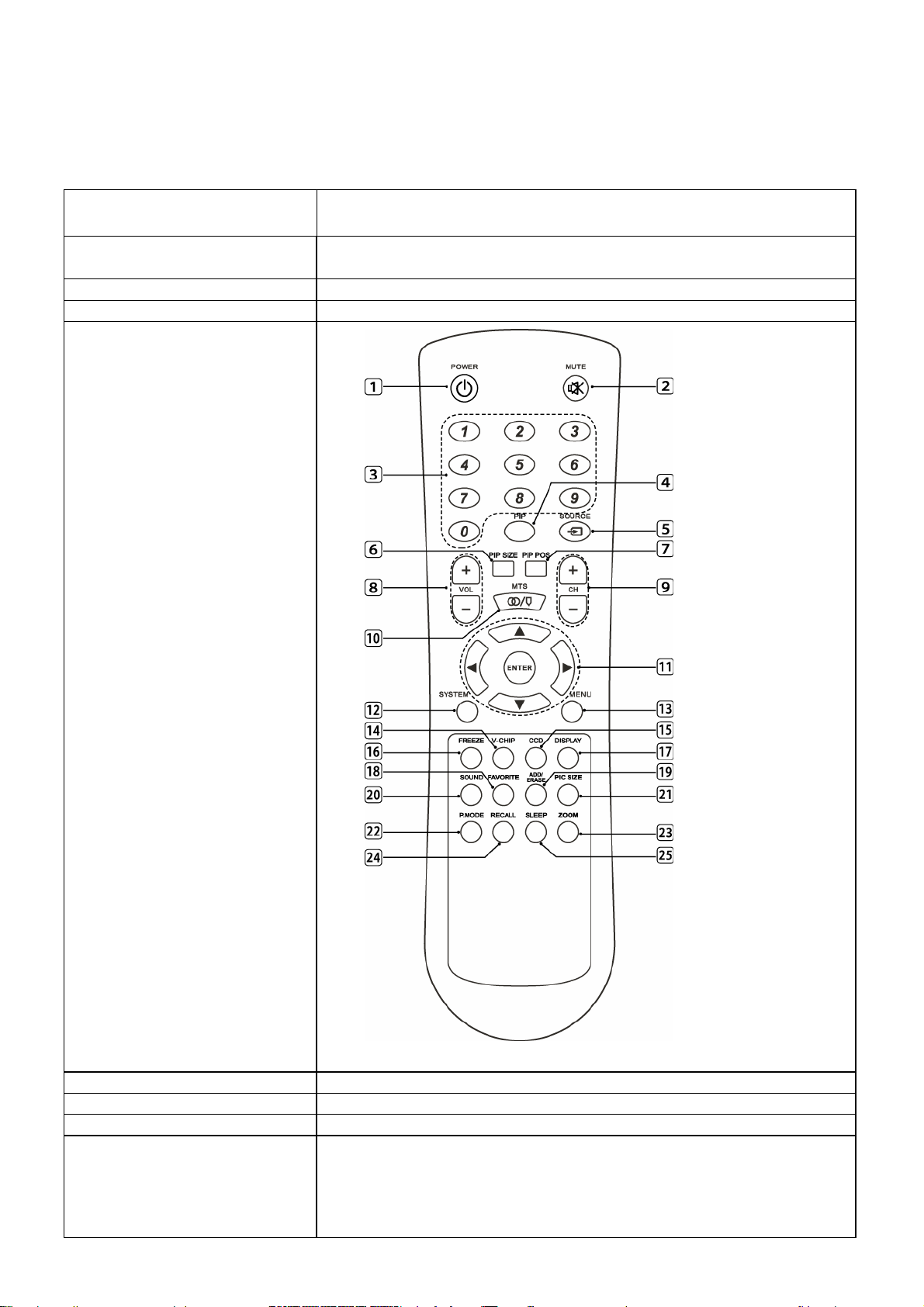

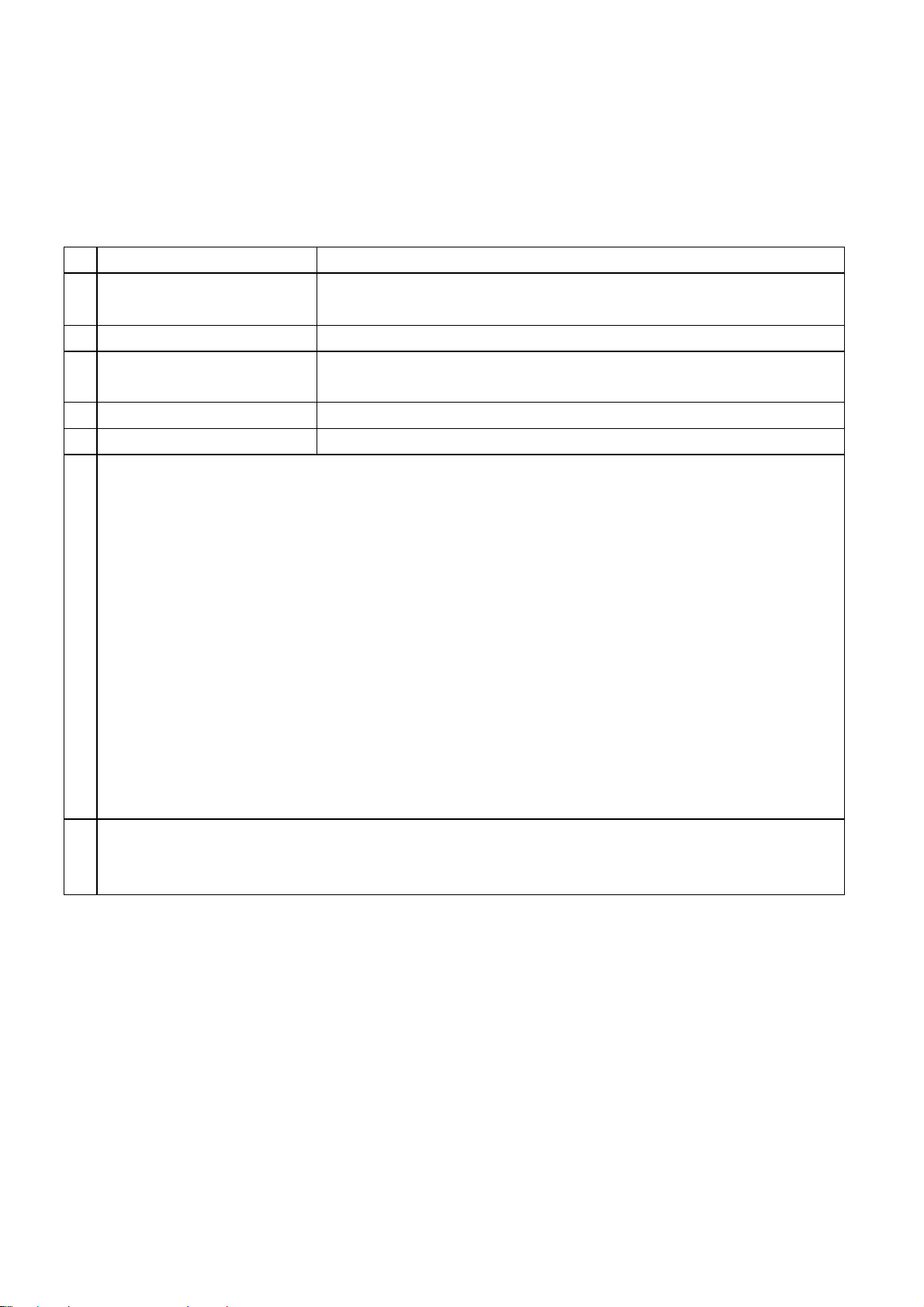

Page 7

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 4 of 8

2. LCD local control button

3. Led indicators :

4. OSD language

5. OSD Full on screen display

6. Remote control unit

Customer Remote

Code: 609F(NEC)

1 POWER button

2 MUTE button

3 0-9 DIGITAL button

4 PIP button

SOURCE

5

6 PIP SIZE button

7 PIP POS button

8 VOL +/- button

9 CH +/- button

10 MTS button

11 UP/DOWN,LEFT/RIGHT

ENTER buttons

12 SYSTEM button

13 MENU button

14 V-CHIP button

15 CCD button

16 FREEZE button

17 DISPLAY

18 FAVORITE button

19 ADD/ERASE buttons

20 SOUND button

21 PIC SIZE button

22 P.MODE button

23 ZOOM button

24 RECALL button

SLEEP button

25

button

buttons

Main power : push switch

Channel +/- volume up/down menu input. standby : soft touch

Power on: Green

Standby: Red

English, FranÇais, Español

7. Safety standard UL/FCC/cUL

8. EMC standard 15 Parts of the FCC rules,CLASS B

9. Performance standard LCD-TV Standard

10. Accessories Battery 2pcs

User Manual 1pcs

AC Cable 1pcs

Remote Control 1pcs

The Accessories box 1pcs

E7501-051001

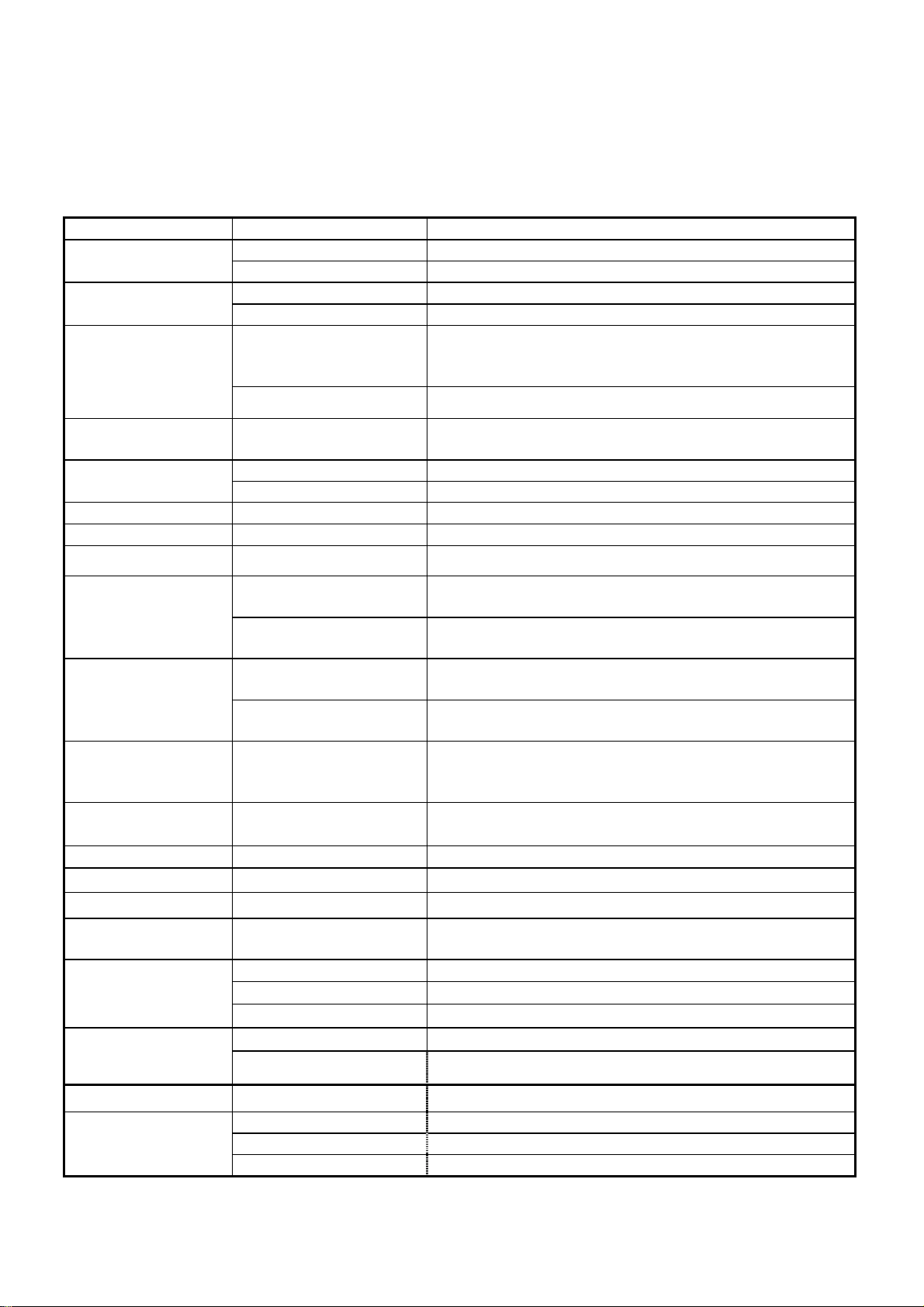

Page 8

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 5 of 8

Technical Data

1. Chassis MICO

TV AC 100-240 V, 50/60Hz 2. Power supply

Remote controller Battery 3V (UM-4/R03/AAA×2)

RF input NTSC M 3. TV system

Video input PAL/NTSC 3.58/NTSC 4.43

4. Receiving channels

TV

CATV 1~125CH

VHF-L : 2~6CH

VHF-H : 7~13CH

UHF : 14~69CH

5. Intermediate

frequencies

6. Sca nn in g H or iz o ntal (Hz ) 15625/15750

7. AC plug UL Plug

8. Panel V270B1-L01

9. Speaker Internal 8 ohm 10W (max) ×2

10.Operating

temperature

Accept picture/sound

11. Operating relative

humidity

Accept picture/sound

12. Electrical &

optical

specification

13. Circuit diagram

drawing No.

15. Cabinet

16. Cabinet color

17. Packing 1 set per

18. Container stuffing

method

19. Dimension (mm) LCD-TV

(No packing)

Remote control unit

20. Net weight LCD-TV 14.1Kg (with Stand) approx.

Remote controller 70g (approx.)

Picture 45.75MHz

Ver ti ca l ( Hz ) 50/60

Fulfill all specifications

reproduction

Fulfill all specifications 45% ~ 75%

reproduction

See the attachment 1.

RD/05/P/LC26HAB/CSI/02 REV: 01

15°C ~ 30°C

5°C ~ 33°C

20% ~ 80%

LC26HAB

883(W) × 468(H) × 110(D)mm (w/o Stand)

883(W) × 523(H) × 250(D)mm (with Stand)

183(L) × 53(W) ×28(T)mm

21. Cell Defect Subject to Panel supplier specification

Page 9

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 6 of 8

Attachment 1:Electrical & Optical Specification

No. Items Instruction Typical Limit Unit

1 Video sensitivity For 30dB S/N 44 ≤51 dBuV

2 FM sound sensitivity For 30dB S/N 21 ≤35 dBuV

3 Color sensitivity For RF transmission 37 ≤40 dBuV

4 CCD sensitivity

5 Minimum NICAM threshold Without crackline noise N/A N/A dBuV

6 Stereo Channel Separation BTSC. 18 ≥15 dB

TV screen refreshes 40 times

number of mistakes≤8

43 ≤50 dBuV

AGC static characteristic

7

8 Selectivity Adjacent sound carrier 30 ≥28

Below adjacent sound carrier 30 ≥30 dB

Adjacent picture carrier 45 ≥40

Up adjacent picture carrier 40 ≥30

9 IF rejection 55 ≥45 dB

10 Image rejection VHF 57 ≥45 dB

UHF 55 ≥40

11 AFT pull-in range ±1.0 ≥⏐±1.0⏐ MHz

12 Chroma sync pull-in range ±500 ≥⏐±200⏐ Hz

13 Color killer function -11 ≤-10 dB

14 Resolution

Video

Accept. Picture/Sound repr. 90

RF

Vertical

Horizontal

Vertical 400 ≥400 Lines

PAL 300 ≥300 Lines Horizontal

NTSC 260 ≥240 Lines

PAL 410 ≥400 Lines

NTSC 320 ≥300 Lines

450 ≥450 Lines

≥90

dBuV

White

Coordination

16 View

Angle(Lo/3)

17 Overscan Cross hatch signal 96 94~98 %

Horizontal

Vertical

XW 0.295 0.295±0.02 15 Color

W

Y

Full Pattern

0.300 0.300±0.02

170

≥170

Degree

18 Picture position In all direction ±2 ≤⏐±3⏐ mm

19 H sync pull-in range ±400 ≥⏐±200⏐ Hz

20 V sync pull-in range 6 ≥6 Hz

21 Audio frequency response ±3dB ref. to 1KHz 0.15~12 0.2~12 KHz

Page 10

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 7 of 8

22

Max Audio Output Power 7×2 ≥5.0×2 W

23 Audio output power

10% THD

24 THD Po=0.5W 0.5 ≤3 %

25 Signal to buzz ratio coeighting 50 ≥30 dB

26 Minimum volume hum coeighting 6 ≤10 mVrms

27 Maximum woofer output power N/A N/A W

28 Woofer audio frequency

response

29 Tone low frequency 100Hz ref. to 1KHz

30 Tone high frequency 10KHz ref. to 1KHz

31 Balance Center 0 ≤⏐±2⏐

Max. 3 >2 dB

Min. -35 ≤-30

32 Video input level 1.0 1±0.3 Vpp

1KHz 10% THD 6×2

±3dB ref. to 15Hz AV

mode

AV mode

AV mode

N/A N/A Hz

±8 ≥⏐±3⏐ dB

±8 ≥⏐±3⏐ dB

≥4.0×2 W

33 Audio input level*(1) 1.0 * 0.5±0.3 Vrms

34 Video output level N/A N/A Vrms

35 Audio output level*(2) 0.3 * 0.5±0.3 Vrms

36 AV Audio input max. level 2 ≤2 Vrms

37 AV Audio output L/R

Separation

39 IR receiving distance 0 Degree 7 ≥6 m

IR receiving

angle

41 Dielectric strength DC 3KV 1min. 5 ≤10 mArms

42 The vibration noise from

electromagnetic devices in LCD-

TV set

left/right 60 ≥45 Degree40

Up/down

35 ≥30 dB

Operating 200 ≤200 W 38 Power consumpution

Stand by 3 ≤5 W

5m

The distance between

the tester and the

LCD-TV set is four

times as many as the

screen height

20 ≥15 Degree

No obvious vibration noise can be

heard

Page 11

KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTRE

Reference No : LC27HAB001

Revision : 0

Date : 2005.8.1

Page : P. 8of 8

Test Condition

All tests shall be performed under the following conditions unless otherwise specified

1 Picture Modulation 87.5%

2 Sound Modulation

3 Picture to Sound Ratio 10dB

4 Sound Artificial Load

Resistor

Video signal

5

6 Audio signal 1KHz sine wave 0.5Vrms

7 Other conditions:

A. Switch LCD-TV on and let it warm up for more than 30 minutes.

Viewing distance: 3H (H: Panel High) in front of LCD, about 2M.

Ambient light: ≤0.1 cd/ m

B. Brightness, Contrast, Saturation, Tint, sharpness set at normal.

C. Connect RMS volt meter to speaker terminals and adjust the LCD volume to get 500mW RMS

power at each terminals.

D. With image sticking protection of LCD module. The luminance will descend by time on a same

still screen and rapidly go down in 5 minutes, when measuring the color tracking and luminance

of a same still screen, be sure to accomplish the measurement in one minute to ensure its

accuracy.

E. Due to the structure of LCD module. The extra-high-bright same screen should not hold over 5

minutes for fear of branding on the panel.

F. RF test point: Video output.

27KHz Dev. For DK/I/BG

15KHz Dev. For M/N

8 ohm

Stair and Special

2

8 Note:

*(1) Now this project cannot fit the limited spec. the typical audio input level is 1.0 Vrms,

*(2) The audio out level is controlled by the volume level, the range is from 0 to 0.5Vrms.

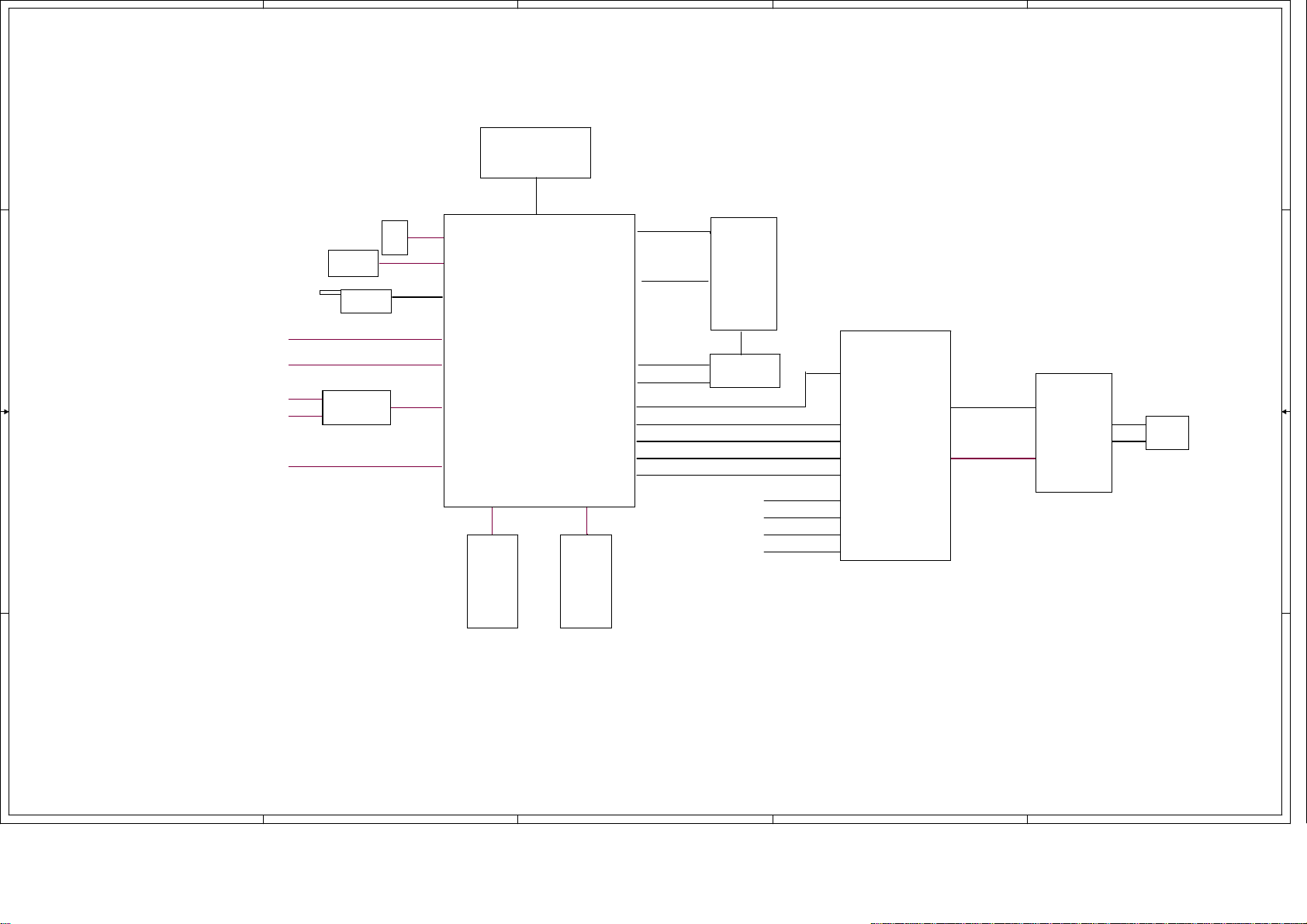

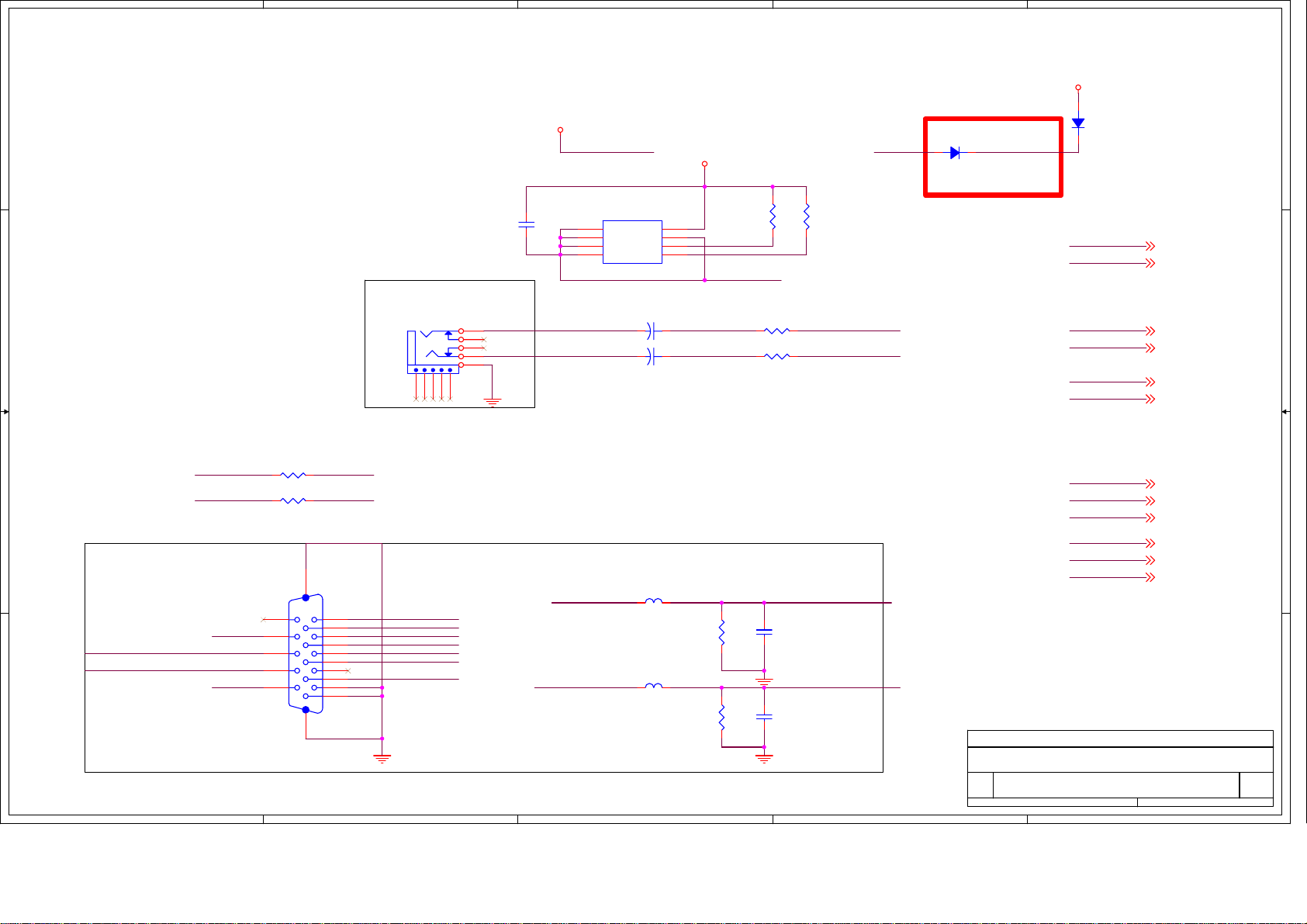

Page 12

A

4 4

B

C

D

E

Flash

IR

Keypad

TV

3 3

Tuner

LVDS SIGNAL

LVDS SIGNAL

LVDS PANEL

AV1

S_Video

Y1PbPr

Y2PbPr

VGA

MUX

YPbPr

MT8205

GPIO

GPIO

AOSDATA1

DACBCLK

DACMCLK

DACLRC

DOUT

Backlight

WM8776

COD_VOUTR

COD_VOUTL

Audio Board

Speaker

VGA_L/R

2 2

S1_AV1_L/R

Y1PbPr_L/R

Y2PbPr_L/R

DDR1 DDR2

1 1

A

B

C

D

E

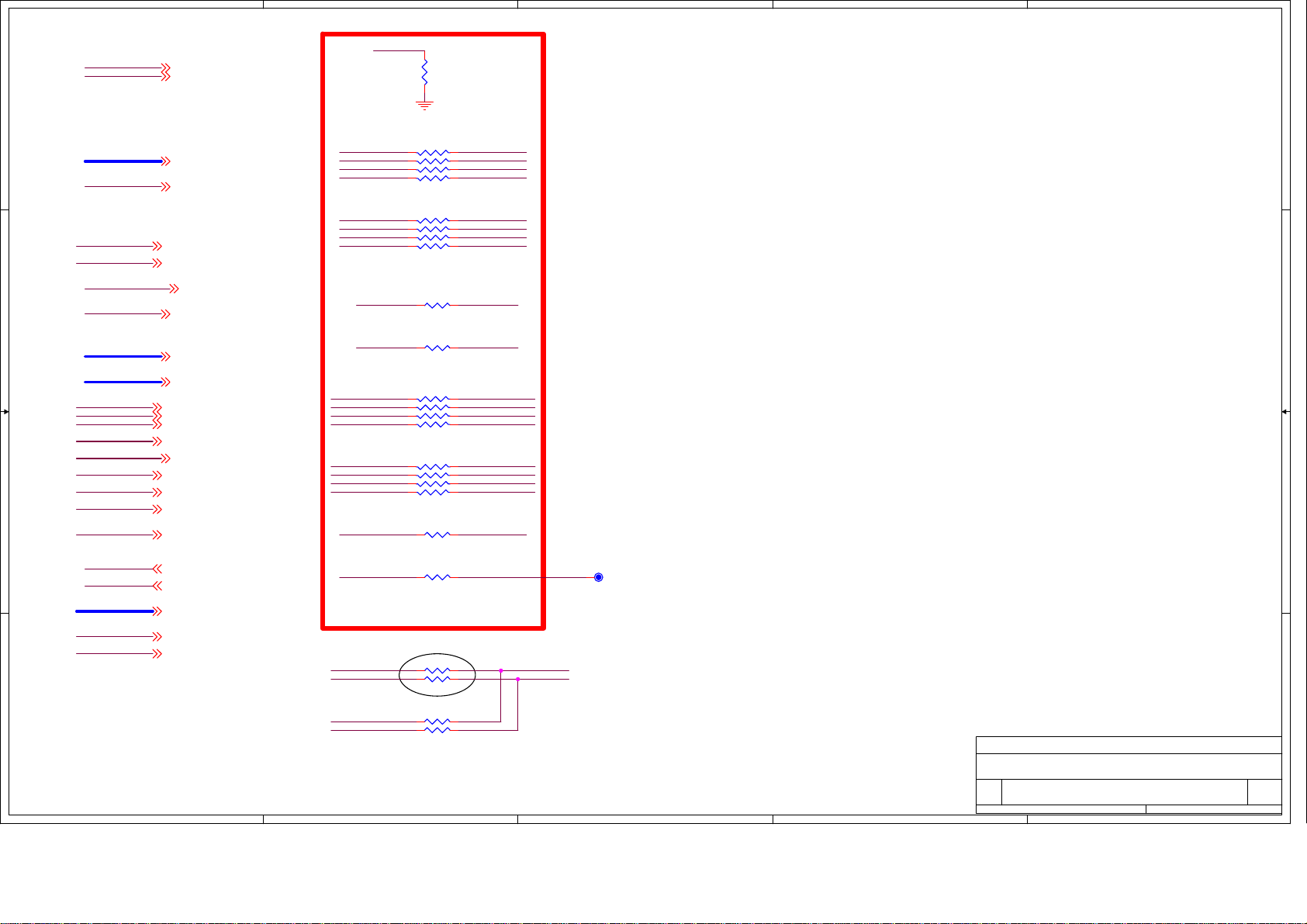

Page 13

A

MT8205P1V3.2

MT8205E (PBGA388) LCDTV BOARD 4 LAYERS

1. INDEX

4 4

2. LDO

3. MT8205E PBGA388

B

C

D

E

Rev DateP#History

V0.1 2004/11/29

V0.2 1. 2.5V use 5VSB conversion. All 0402 change to 0603

1.FIRST VERSION

2. LED_RED/GRN CIRCUIT CHANGE

3. Change Power on/off circuit(ORO7 CTRL PIN)

4. WM8776 DVDD Needed

5. Del the Si9936 LVDS Parts

6. Del DVI&AD9883 PARTS

2005/03/09

4. MT8205 ANALOG DECOUPLING

5. MT8205 DIGITAL DECOUPLING

6. ICE I/F

7. DDR MEMORY & FLASH

8. DVI INPUT

9. AD9883

10. VGA IN & PC AUDIO IN

11. VIDEO IN & TUNER I/O

J24

12. AUDIO / VIDEO IN CIRCUIT

13. WM8776 AUDIO CODEC

3 3

2 2

1 1

14. LVDS / CRT / TTL OUT

15 BACK LIGHT / KEYPAD

16. READER CARD I/F

HOLE/GND

H1

9

9

8

8

7

7

6

6

9

9

8

8

7

7

6

6

9

8

7

6

9

8

7

6

2

2

3

3

4

4

5

5

1

1

HOLE/GND

H2

2

2

3

3

4

4

5

5

1

1

HOLE/GND

H3

9

8

7

6

9

8

7

6

2

2

3

3

4

4

5

5

1

1

HOLE/GND

H4

2

2

3

3

4

4

5

5

1

1

H5

9

9

8

8

7

7

6

6

1

H6

9

9

8

8

7

7

6

6

1

UP3_0 BLACKLIGHT ON/OFF

MUTE<-->UP1_5

HOLE/GND

2

2

3

3

4

4

5

5

1

HOLE/GND

2

2

3

3

4

4

5

5

1

P5

CONNECTOR DB9

1

6

2

7

3

8

4

9

5

RxD

TxD

RS-232

R51

10k

RSRXD

RSTXD

C1 0.1uF

C3 0.1uF

C6 0.1uF

C7 0.1uF

DIP8/P2.0

TO Power BD

24V

INVERTER_PWR

PWR_GND

DV33A

R52

J2

10k

1

2

3

4

4x1 W/HOUSING

DIP4/W/H/P2.0

U6

13

R1IN

8

R2IN

11

T1IN

10

T2IN

1

C+

3

C1-

4

C2+

5

C2-

2

V+

6

V-

MAX232A

R1OUT

R2OUT

T1OUT

T2OUT

12

9

14

7

5VSB

16

VCC

GND

C8

0.1uF

15

VCC

1

2

3

4

5

6

7

8

TXD

RXD

J108

1

2

3

4

5

6

8x1 W/HOUSING

DIP8/W/H/P2.54

TXD

RXD

+12V

J6

5

4

3

2

1

5x1 W/HOUSING

DIP5/W/H/P2.0

SYS_PWR

5VSB

+12V

5VSB

+

CB75

0.1uF

+

5VSB

5VSB

3 2

CE16

220uF/16v

C220UF16V/D6H11

CE93

220uF/16v

C220UF16V/D6H11

SYSTEM EEPROM

1

2

3

4 5

R359

10k

Q14

1

SOT23/SMD

2N3904

L14

FB

BEAD/SMD/0805

U13

NC

NC

NC

GND SDA

EEPROM 24C16

SOP8/SMD

ORO7 High :POWER OFF

ORO7 LOW :POWER ON

R364

ORO7

4.7k

For Tuner

CE17

+

47uF/16v

8

VCC

7

WP

SCL

SCL

6

SDA

5VSB

R53

10k

TUNER_12V

CB11

0.1uF

R54

10k

FOR Tuner

TXD

RXD

SCL

SDA

+12V

TUNER_12V

ORO7

MUTE

TXD 3

RXD 3

SCL 6,9,11,13

SDA 6,9,11,13

+12V 2

TUNER_12V 11

ORO7 3

UP1_5 6

Title

AUIO IN/OUT GND ANALOG INPUT GND

A

B

DIGITAL GND

C

D

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

C

Date: Sheet of

INDEX

E

116Tuesday, May 10, 2005

V0.1

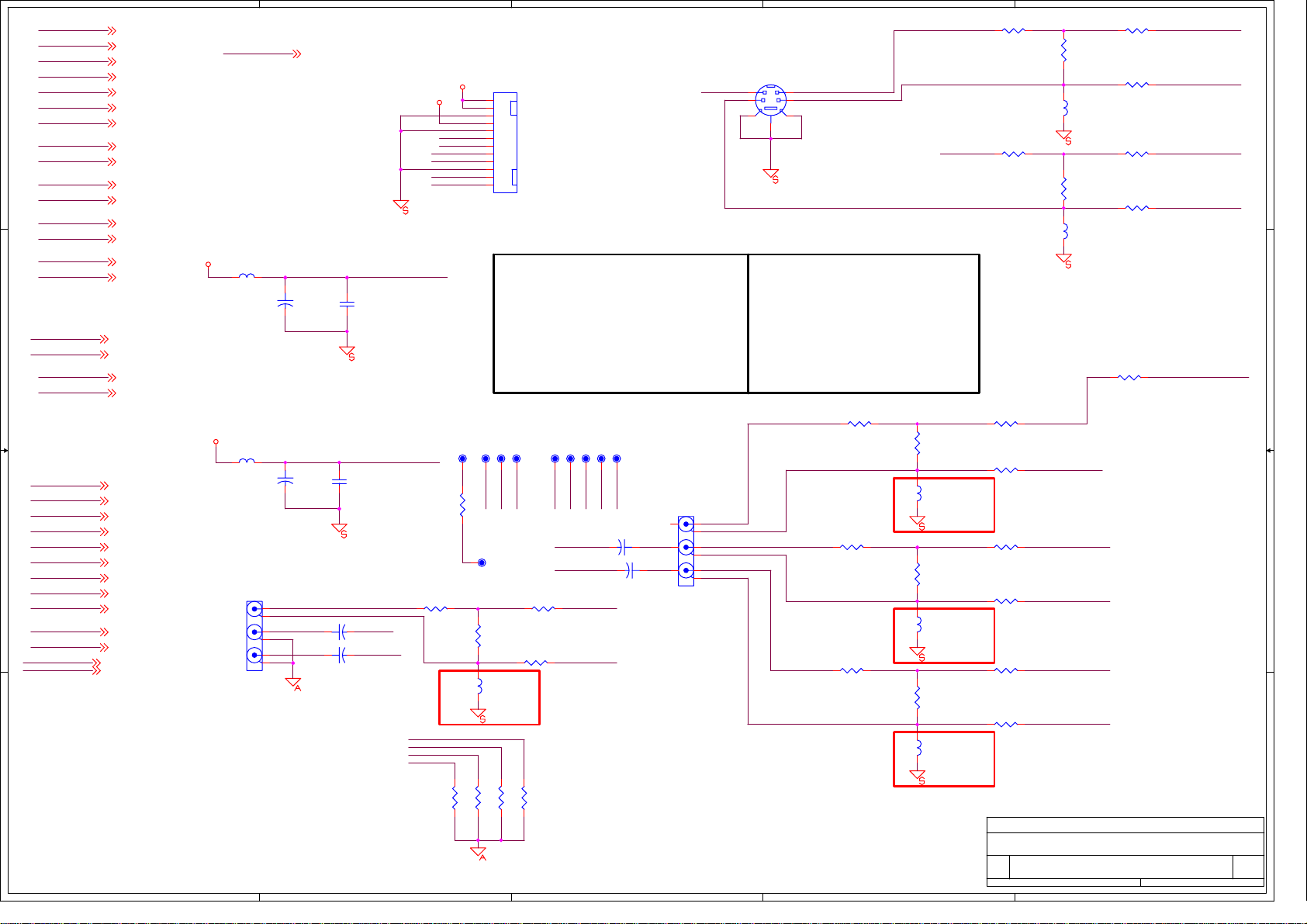

Page 14

A

B

C

D

E

Power ON alive source

Vout

4 4

VCC

+

CE4

220uF/16v

CB4

0.1uF

U1

OUTIN

SOT223/SMD

ADJ/GND

CM1117-3.3V

1

23

L8

FB

BEAD/SMD/0805

+

CE5

220uF/16v

DV33

CB5

0.1uF

DV33

5VSB

CE6

220uF/16v

U35

M1117-3.3V

+

CB200

0.1uF

OUTIN

SOT223/SMD

ADJ/GND

1

23

CE118

+

220uF/16v

BEAD/SMD/0805

CB201

0.1uF

L7

FB

DV33A

ADJ/GND

U5

ADJ/GND

U3

CM1117-3.3V

1

23

OUTIN

3 3

SOT223/SMD

L11

FB

BEAD/SMD/0805

+

CE10

220uF/16v

C5

10uF/10v

1.25x(1+180/110)=3.3V

AV33

CB6

0.1uF

AV33

+

CE11

100uF/16v

CB7

0.1uF

CM1117-1.8V

OUTIN

SOT223/SMD

1

23

+

CE12

220uF/16v

1.25x(1+300/680)=1.8V

L6

FB

BEAD/SMD/0805

CB8

0.1uF

Vout

DV18A

DV33A

DV18A

5VSB

+

+

CE128

220uF/16v

2 2

VCC

+

CE8

100uF/16v

C100UF16V/D6H11

5V ==> +12v

L107

R3 0

FB

R0805/SMD

R5

10

R0805/SMD

L9

12

CHOKE-100uH L18W10H18

L/CHOKE/DIP/1810

U2

SOIC8

8

DRC

7

Ipk

6

VCC

AZ34063A-PWM

L10

+12V

D2

DIODE SMD

1N4148/SMD

R6

13k

C2

CE7

+

1

SWC

2

SWE

3

TC

45

GNDCII

C4

100pF

100uF/16v

270pF

R8

1.5k

R325

FB

0

+12V

+

CE107

100uF/25v/NC

CE129

220uF/16v

CB212

0.1uF

CB213

0.1uF

CB214

0.1uF

CB215

3300pF

CB216

3300pF

CB217

3300pF

1 1

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

C

A

B

C

D

Date: Sheet of

LDO

216Tuesday, May 10, 2005

E

V0.1

Page 15

A

XTALI

XTALO

ANALOGVDD

4 4

ADCVDD

APLLVDD

VPLLVDD

ADCPLLVDD1

ADCPLLVDD

AUXTOP

AUXBOTTOM

REXTA

APLL_CAP

PWM2VREF

ADCVDD0

3 3

AVCM

VOCM

VICM

VREFP4

VREFN4

DACFS

DACVREF

DACVDD

LVDDA

2 2

IR

1 1

XTALI 4

XTALO 4

ANALOGVDD 4

ADCVDD 4

APLLVDD 4

VPLLVDD 4

ADCPLLVDD1 4

ADCPLLVDD 4

AUXTOP 4

AUXBOTTOM 4

REXTA 4

APLL_CAP 4

PWM2VREF 4

ADCVDD0 4

AVCM 4

VOCM 4

VICM 4

VREFP4 4

VREFN4 4

DACFS 4

DACVREF 4

DACVDD 4

LVDDA 4

IR 15

DV33A

GND

DV18A

GND

U7

ADCVDD0

ADCVDD0

MPX1

MPX2

GND

VREFP4

VREFN4

GND

ADCVDD

PWM2VREF

AUXTOP

AUXBOTTOM

GND

VPLLVDD

VPLLVDD

GND

GND

REXTA

VPLLVDD

LVDDA

AP7

AN7

CLK2+

CLK2GND

AP6

AN6

AP5

AN5

LVDDA

AP4

AN4

AP3

AN3

GND

CLK1+

CLK1AP2

AN2

LVDDA

AP1

AN1

AP0

AN0

GND

DACVDD

DACVREF

DACFS

GND

SVM

DACVDD

GND

DACVDD

G

GND

B

R

VSYNC

HSYNC

OBO7

OBO6

OBO5

AC18

L11

M12

M11

N12

N11

AC9

P11

AA1

AA2

AA3

AA4

AB1

AB2

AB3

AB4

AC1

AC2

AC3

AC4

R11

AD1

AD2

AD3

AD4

AE1

C3

D3

C1

C2

D1

D2

F2

D4

E1

E2

E3

E4

F1

F4

F3

G3

J3

G4

H3

K3

K4

J4

H4

L3

G2

G1

H2

H1

J2

J1

K2

K1

L4

L2

L1

M2

M1

N2

N1

P2

P1

M3

R2

R1

T2

T1

N3

M4

N4

T4

P3

R3

P4

U4

R4

U3

V4

T3

U1

U2

V1

V2

V3

W1

W2

W3

W4

Y1

Y3

Y4

VFEVDD1

ADCVDD4

SIF

AF

ADCVSS4

REFP4

REFN4

ADCVSS

ADIN4

ADIN3

ADIN2

ADIN1

ADIN0

ADCVDD

PWM2VREF

AUXVTOP

AUXVBOTTOM

VPLLVSS

VPLLVDD

DLLVDD

DLLVSS

BGVSS

REXTA

BGVDD

LVDDA

A7P

A7N

CLK2P

CLK2N

LVSSA

A6P

A6N

A5P

A5N

LVDDB

A4P

A4N

A3P

A3N

LVSSB

CLK1P

CLK1N

A2P

A2N

LVDDC

A1P

A1N

A0P

A0N

LVSSC

DACVDDC

VREF

FS

DACVSSC

SVM

DACVDDB

DACVSSB

DACVDDA

G

DACVSSA

B

R

DE

VSYNCO

HSYNCO

VCLK

EBO7

EBO6

EBO5

EBO4

DVDD3I

EBO3

EBO2

EBO1

EBO0

EGO7

DVSS18

EGO6

EGO5

EGO4

EGO3

EGO2

EGO1

EGO0

ERO7

ERO6

ERO5

DVDD18

ERO4

ERO3

ERO2

DVSS3

ERO1

ERO0

OBO7

OBO6

OBO5

GND

AVCM

L12

AVCM

VFEVSS1

OBO4

OBO3

AE2

AF1

OBO3

OBO4

ADCVDD0

CVBS2+

CVBS2-

CVBS2P

CVBS2N

ADCVDD0

OBO1

OBO0

OBO2

AE3

AF3

AF2Y2AF4

OBO1

OBO2

OBO0

CVBS1+

CVBS1-

CVBS1N

OGO7

AE4

OGO6

OGO7

CVBS0-

CVBS1P

CVBS0N

OGO5

OGO6

AC5

OGO5

CVBS0+

GND

CVBS0P

DVSS18

T11

AD5

OGO4

GND

REFP0

REFN0

ADCVSS0

OGO4

OGO3

OGO2

AE5

AF5

OGO2

OGO3

SC-

ADCVDD0

ADCVDD1

OGO1

AC6

AD9

OGO1

DV33A

SC+

SCP

SCN

DVDD3

OGO0

AD6

OGO0

SY-

AE6

ORO7

SY+

SYN

ORO7

ORO6

AF6

GND

M13A6B6A5B5C5A4B4L13A3B3A2B2A1B1C4D5

SYP

ORO6

AC7

ORO5

REFP1

ADCVSS1

ORO4

ORO5

AD18

AD7

ORO4

DV18A

B

VOCM

ADCVDD0

REFN1

VFEVDD0

DVDD18

ORO3

AE7

AF7

ORO2

ORO3

GND

VOCM

ORO2

AC8

ORO1

VICM

ADCVDD0

C7A7N13B7D7C6D6

VICM

VFEVSS0

ADCVDD2

ORO1

ORO0

HIGHA7

AD8

AF8

ORO0

F_A15

GND

BN

BLUE+

A13

BP

GND

D12

C10

REFP3

ADCVSS3

VGAVSYNC#

VGAHSYNC#

C14

C13

C12

REFN3

VSYNC

N14

DVSS

HSYNC

DV18A

D14

DVDD

CB+

CB-

CR-

CR+

A8B8A9B9C8

CRP

CBN

CRN

GREEN-

GREEN+

BLUE-

VGASOG

ADCVDD0

RED+

RED-

GND

Y+

Y-

SOY

B13

D13

A12

B12

A11

B11D8C11

D11C9D9

D10

A10

B10

YP

YN

CBP

SOY

REFP2

REFN2

ADCVSS2

MON0

MON1

ADCVDD3

RP

GP

RN

GN

SOG

MT8205

HIGHA6

HIGHA5

HIGHA4

HIGHA3

HIGHA1

HIGHA0

AD0

AD1

DVDD18

AD2

AD3

AD4

DVSS3

AD7

AD5

IOA0

IOA3

IOA4

IOA5

IOA6

IOA7

DVSS18

HIGHA2

AE9

AF9

AE10

AF10

AD11

AF12

AE15

P12

AC11

F_A8

F_A9

F_A10

F_A12

F_A13

F_D0

F_A11

F_A14

GND

AD15

F_D1

AD6

AC19

AC15

AF16

AE16

R12

AF17

AD16

AD17

AC16

F_D3

F_D6

F_D5

F_D7

F_D4

F_D2

DV18A

IOA0

GND

AD14

IOA1

A16

IOA1

IOA2

AF14

AF13

AE13

AD13

AC13

AE8

AE14

F_A16

IOA7

IOA6

IOA3

IOA5

IOA4

IOA2

ADCPLLVDD

GND

ADCPLLVDD1

GND

M14

C15

D15

L14

ADCPLLVDD

ADCPLLVSS1

ADCPLLVDD1

DVDD3I

A17

IOA18

AC10

AC17

AE12

AD12

F_A17

F_A19

F_A18

DV33A

ANALOGVDD

GND

B14

D16

L15

TESTP

SYSPLLVSS

SYSPLLVDD

ADCPLLVSS

IOA20

DVSS18

IOA21

IOA19

AE11

T12

AF11

F_A20

F_A21

GND

C

XTALO

ANALOGVDD

A14

B15

C16

XTALO

TESTN

XTALVDD

IOALE

IOOE#

IOWR#

AE17

AF15

AC12

F_OE#

IOWR#

XTALI

A15

XTALI

IOCS#

AC14

IOCE#

APLL_CAP

GND

A16

M15

XTALVSS

WR#

AF18

AE18

GND

D18

APLL_CAP

RD#

AD10

DV33A

ANALOGVDD

APLLVDD

C17

D17

APLLVSS

APLLVDD

INT0#

DVDD3

AE19

AF19

8205UP1_2

GND

C18

DMPLLVDD

UP12

AF20

8205UP1_3

VI0

B16

VI0

DMPLLVSS

UP13

UP14

AE20

8205UP1_4

VI1

A17

AD19

DV18A

D

DV33A

DV33A

HWSCL 6

HWSDA 6

TXD 1

RXD 1

IOA[0..7] 6

8205UP3_4 6

8205UP3_5 6

R365

47k

R18

10k

+

CE21

10uF/25v

GND

GND

DV18A

VI8

VI6

VI4

VI5

VI3

VI7

VI2

B17

VI1

DVDD18

AD20

8205UP1_5

VI9

VI13

VI12

VI14

VI15

VI11

VI10

M16

A21

D21

C21

B20

L16

A20

D20

C20

B19

A19

E23

D19

C19

B18

A18

VI9

VI8

VI7

VI6

VI5

VI4

VI3

VI2

DVDD18

UP30

PRST#

UP34

UP17

UP15

UP31

DVSS18

UP16

AE21

AC21

AD22

AF21

AD21

P13

AC20

8205UP3_0

8205UP3_1

8205UP1_7

8205UP1_6

8205UP3_4

URST#

GND

AC22

8205UP3_5

VI15

VI14

VI13

VI12

VI11

VI10

DVSS3

UP35

PWM0

FCICMD

FCICLK

FCIDAT

GPIO0

AE24

AF24

AC23

AD23

AE22

AF22

AF23

AE23

IR

PWM0

PWM1

FCLK

FCMD

RxD

FDAT

GPIO

VI17

VI16

B21

VI16

DVSS18

RXDIRPWM1

TXD

AD24

TxD

GND

C22

R13

VI18

D22

VI18

VI17

ICE

DVSS3

AC24

ICE

VI19

A22

AF25

HWSCL

VI19

SCL

VI20

VI21

B22

VI20

SDA

AE25

VGASCL

HWSDA

VI22

D23

C23

VI21

SCL0

AF26

AE26

VGASDA

VI23

DVIODCK

B23

A23

VI23

VI22

VCLK_DVI

VSYNC_DVI

HSYNC_DVI

AOSDATA0

AOSDATA1

AOSDATA2

AOSDATA3

SDA0

SDA1

SCL1

AB24

AB23

DVISDA

DVISCL

DE_DVI

DVDD18

DVDD3I

AOBCK

AOLRCK

AOMCLK

DVSS3

DQ24

DQ25

DQ26

DVDD2

DQ27

DQ28

DVSS2

DQ29

DVDD2

DQ30

DQ31

DQS3

DQM1

DVSS18

DQS2

DQ23

DQ22

DVSS2

DQ21

DQ20

DVDD18

DQ19

DVDD2

DQ18

DQ17

DQ16

DVSS2

DVSS18

RA11

DVDD2

RCLK

RCLKB

DVSS2

RA10

DVDD2I

DVDD18

RCS#

RAS#

DVSS2

CAS#

RWE#

DQ10

DVDD2

DQ11

DVSS18

DQ12

DQ13

DVSS2

DQ14

DQ15

DQS1

AVSS18

AVDD18

RVREF

DVSS18

DQM0

DQS0

DVDD2

DVSS2

DVDD2

LIN

RA4

RA5

RA6

RA7

RA8

RA9

CKE

RA3

RA2

RA1

RA0

BA1

BA0

DQ8

DQ9

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

C24

D24

A24

Y24

A25

A26

B26

F23

B25

B24

C26

C25

E24

N15

G26

G25

F26

F24

F25

E26

N16

E25

G24

D26

D25

H25

H26

P14

J25

J26

K25

P16

K26

L25

AA24

L26

H24

M25

M26

N25

J23

R16

J24

K23

K24

L23

R14

L24

M23

N26

H23

P26

P25

P15

M24

N23

N24

R26

P24

P23

U23

AA23

R24

R23

T24

R15

T23

U24

W26

V25

V26

V23

U25

T13

U26

T25

T15

T26

R25

W25

W23

Y23

G23

T16

Y26

Y25

AA26

V24

AA25

AB26

T14

AB25

AC26

W24

AC25

AD26

AD25

BGA388/SOCKET

MT8205

DVIDE

DVIVSYNC

DVIHSYNC

AOSDATA0

AOSDATA1

AOSDATA2

AOSDATA3

DOUT

DACBCLK

DACLRC

DACMCLK

A_DQ24

A_DQ25

A_DQ26

A_DQ27

A_DQ28

A_DQ29

A_DQ30

A_DQ31

A_DQS3

A_DQM1

A_DQS2

A_DQ23

A_DQ22

A_DQ21

A_DQ20

A_DQ19

A_DQ18

A_DQ17

A_DQ16

A_RA4

A_RA5

A_RA6

A_RA7

A_RA8

A_RA9

A_RA11

A_CKE

A_CLK

A_CLK#

A_RA3

A_RA2

A_RA1

A_RA0

A_RA10

A_BA1

A_BA0

A_CS#

A_RAS#

A_CAS#

A_WE#

A_DQ8

A_DQ9

A_DQ10

A_DQ11

A_DQ12

A_DQ13

A_DQ14

A_DQ15

A_DQS1

VREF

A_DQM0

A_DQS0

A_DQ7

A_DQ6

A_DQ5

A_DQ4

A_DQ3

A_DQ2

A_DQ1

A_DQ0

DV18A

DV33A

SDV25

SDV25

DV18A

SDV25

SDV25

SDV25

DV18A

SDV25

DV18A

SDV25

SDV25

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

D5

1N4148/SMD

URST#

SW1

123

1=3 2=4

SW4P/DIP/FLAT

GND

DACBCLK

HWSCL

HWSDA

TXD

RXD

IOA[0..7]

8205UP3_4

8205UP3_5

4

E

VI[0..23]

DVIODCK

DVIDE

DVIHSYNC

DVIVSYNC

DVISCL

DVISDA

URST#

A_DQS[0..3]

A_RA[0..11]

A_BA[0..1]

A_DQM[0..1]

A_DQ[0..31]

A_CLK

A_CLK#

A_CKE

A_CS#

A_RAS#

A_CAS#

A_WE#

SDV25

VREF

IOWR#

IOCE#

FCLK

FCMD

FDAT

8205UP1_[2..7]

F_A[8..21]

F_D[0..7]

F_OE#

8205UP3_0

8205UP3_1

ICE

MPX1

MPX2

ORO[0..7]

OGO[0..7]

OBO[0..7]

VSYNC

HSYNC

VGASDA

VGASCL

RED+

REDGREEN+

GREENBLUE+

BLUE-

VGASOG

VGAHSYNC#

VGAVSYNC#

CVBS0+

CVBS0SY+

SYSC+

SCY+

YCB+

CBCR+

CR-

AP[0..7]

AN[0..7]

CLK1+

CLK1CLK2+

CLK2-

SCL

SDA

DACBCLK

DACMCLK

DACLRC

AOSDATA3

DOUT

AOSDATA0

AOSDATA1

AOSDATA2

SOY

CVBS1+

CVBS1CVBS2+

CVBS2SVM

R

G

B

GPIO

PWM0

PWM1

VI[0..23] 9

DVIODCK 8,9

DVIDE 8,9

DVIHSYNC 8,9

DVIVSYNC 8,9

DVISCL 8

DVISDA 8

URST# 6,15

A_DQS[0..3] 7

A_RA[0..11] 7

A_BA[0..1] 7

A_DQM[0..1] 7

A_DQ[0..31] 7

A_CLK 7

A_CLK# 7

A_CKE 7

A_CS# 7

A_RAS# 7

A_CAS# 7

A_WE# 7

SDV25 7

VREF 7

IOWR# 6

IOCE# 6

FCLK 16

FCMD 16

FDAT 16

8205UP1_[2..7] 6

F_A[8..21] 6,7

F_D[0..7] 6,7

F_OE# 7

8205UP3_0 6

8205UP3_1 6

ICE 6

MPX1 12

MPX2 12

ORO[0..7] 11,13,16

OGO[0..7] 8,11

OBO[0..7] 15

VSYNC 14

HSYNC 14

VGASDA 10

VGASCL 10

RED+ 12

RED- 12

GREEN+ 12

GREEN- 12

BLUE+ 12

BLUE- 12

VGASOG 12

VGAHSYNC# 10

VGAVSYNC# 10

CVBS0+ 12

CVBS0- 12

SY+ 12

SY- 12

SC+ 12

SC- 12

Y+ 12

Y- 12

CB+ 12

CB- 12

CR+ 12

CR- 12

AP[0..7] 14

AN[0..7] 14

CLK1+ 14

CLK1- 14

CLK2+ 14

CLK2- 14

SCL 1,6,9,11,13

SDA 1,6,9,11,13

DACBCLK 6,13

DACMCLK 13

DACLRC 13

AOSDATA3 6,13

DOUT 13

AOSDATA0 6,13

AOSDATA1 6,13

AOSDATA2 6,13

SOY 11

CVBS1+ 12

CVBS1- 12

CVBS2+ 12

CVBS2- 12

SVM 14

R14

G14

B14

GPIO 14

PWM0 13

PWM1 13

DV33A DV18A

DV33A

A

DV18A

B

C

D

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

C

Date: Sheet of

MT5205BGA388

316Tuesday, May 10, 2005

E

V0.1

Page 16

A

B

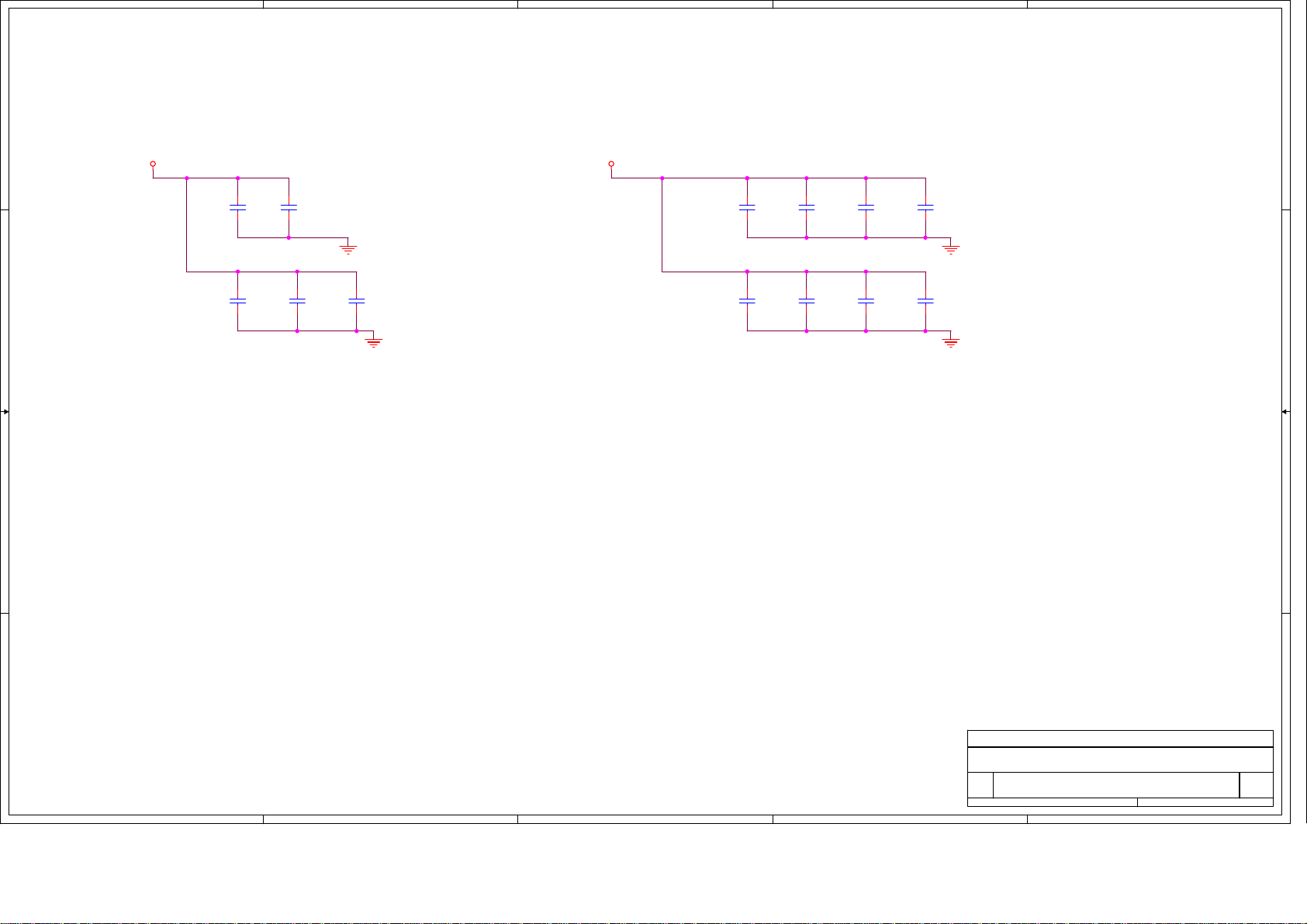

MT8205 ANALOG DECOUPLING

C

D

E

CE30

+

47uF/16v

CB41

0.1uF

GND

APLL_CAP

L37

FB

PWM2VREF

C11

33pF

GND

R20

100k

Y1

27MHz

C20

1500pF

C0603/SMD

C28

4.7uF

C0603/SMD

+

CE32

47uF/16v

GND

XTALOXTALI

C12

33pF

CB24

0.1uF

C0603/SMD

CB28

0.1uF

C0603/SMD

CB30

0.1uF

C0603/SMD

D

GND

LVDDA

GND

LVDDA

GND

ADCVDD

CB42

0.1uF

C0603/SMD

GND

CB47

0.1uF

C0603/SMD

GND

DV33A

L19

FB

BEAD/SMD/0603

C15

0.1uF

AV33

AV33

C25

0.1uF

DV18A

L30

FB

BEAD/SMD/0603

LVDDA

L17

FB

BEAD/SMD/0603

R22

33

+

CE78

47uF/16v

R23

33

+

CE31

47uF/16v

REXTA

L38 FB

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

C

Date: Sheet of

C9

4.7uF

C0603/SMD

C14

4.7uF

C0603/SMD

C17

4.7uF

+

CE25

22uF/25v

C0603/SMD

C19

4.7uF

C0603/SMD

C21

4.7uF

+

CE26

22uF/25v

C0603/SMD

C22

4.7uF

C0603/SMD

C24

4.7uF

C0603/SMD

C26

4.7uF

C0603/SMD

C27

4.7uF

C0603/SMD

R27

3.3k

R31

50

R34

50

MT8205 DECOUPOMG--ANALOG

ADCPLLVDD1DV18A

CB14

0.1uF

C0603/SMD

GND

DEL

ANALOGVDD

CB16

0.1uF

C0603/SMD

GND

ADCPLLVDD

CB19

0.1uF

C0603/SMD

GND

ANALOGVDD

CB21

0.1uF

C0603/SMD

GND

APLLVDD

CB22

0.1uF

C0603/SMD

GND

ANALOGVDD

CB23

0.1uF

C0603/SMD

GND

VPLLVDD

CB29

0.1uF

C0603/SMD

GND

VPLLVDD

CB31

0.1uF

C0603/SMD

GND

VPLLVDD

CB32

0.1uF

C0603/SMD

GND

GND

TP3

AUXTOP

AUXBOTTOM

E

TP4

416Tuesday, May 10, 2005

V0.1

DACVREF

DACFS

ADCPLLVDD1

4 4

ADCPLLVDD

APLLVDD

ANALOGVDD

VPLLVDD

LVDDA

ADCVDD

DACVDD

AVCM

VOCM

VICM

3 3

VREFP4

VREFN4

ADCVDD0

PWM2VREF

AUXTOP

AUXBOTTOM

REXTA

APLL_CAP

XTALI

XTALO

2 2

1 1

DACVREF 3

DACFS 3

ADCPLLVDD1 3

ADCPLLVDD 3

APLLVDD 3

ANALOGVDD 3

VPLLVDD 3

LVDDA 3

ADCVDD 3

DACVDD 3

AVCM 3

VOCM 3

VICM 3

VREFP4 3

VREFN4 3

ADCVDD0 3

PWM2VREF 3

AUXTOP 3

AUXBOTTOM 3

REXTA 3

APLL_CAP 3

XTALI 3

XTALO 3

AV33

AV33

CE23

+

10uF/25v

Note for Fix or Adj Regulator

VCC

+

CE27

100uF/16v

AZ1117

Fix regulator

Adj regulator

ADC_VDD

ADC_VDD

A

L32

FB

BEAD/SMD/0805

CB27

0.1uF

Rdown

0 ohm

180 1%

U8

CB17

0.1uF

CM1117-3.3V

OUTIN

SOT223/SMD

Rup

OFF

110 1%

L18

FB

BEAD/SMD/0603

FOR ADCVDD

ADJ/GND

1

23

L28

FB

BEAD/SMD/0805

1.25x(1+Rdown/Rup)

1.25x(1+180/110)=3.3V

ADCVDD0

CB34

0.1uF

C0603/SMD

GND

ADCVDD0

CB38

0.1uF

C0603/SMD

GND

ADCVDD0

CB39

0.1uF

C0603/SMD

GND

ADCVDD0

CB45

0.1uF

C0603/SMD

GND

ADCVDD0

CB48

0.1uF

C0603/SMD

GND

ADCVDD0

CB52

0.1uF

C0603/SMD

GND

ADCVDD0

CB54

0.1uF

C0603/SMD

GND

B

FOR DACVDD

CE24

+

10uF/25v

Vout

+

+

CE28

220uF/16v

CE29

10uF/25v

DACVREF

C13

4.7uF

C0603/SMD

C16

4.7uF

C0603/SMD

C18

4.7uF

C0603/SMD

CB25

0.1uF

C10

0.1uF/NC

C0603/SMD

GND

CB15

0.1uF

C0603/SMD

GND

CB18

0.1uF

C0603/SMD

GND

CB20

0.1uF

C0603/SMD

GND

CB26

0.1uF

DACVDD

DACVDD

DACVDD

ADC_VDD

DACFS

R21

560

GND

ADC_VDD

AV33

L29

AV33 LVDDA

FB

BEAD/SMD/0603

C23

GND

AVCM

CB36

4.7uF

C0603/SMD

GND

VOCM

CB44

0.1uF

C0603/SMD

GND

VICM

CB50

0.1uF

C0603/SMD

GND

VREFP4

CB58

4.7uF

C

C0603/SMD

VREFN4

0.1uF

ADCVDD0

CB56

4.7uF

C0603/SMD

GND

CB60

4.7uF

C0603/SMD

Page 17

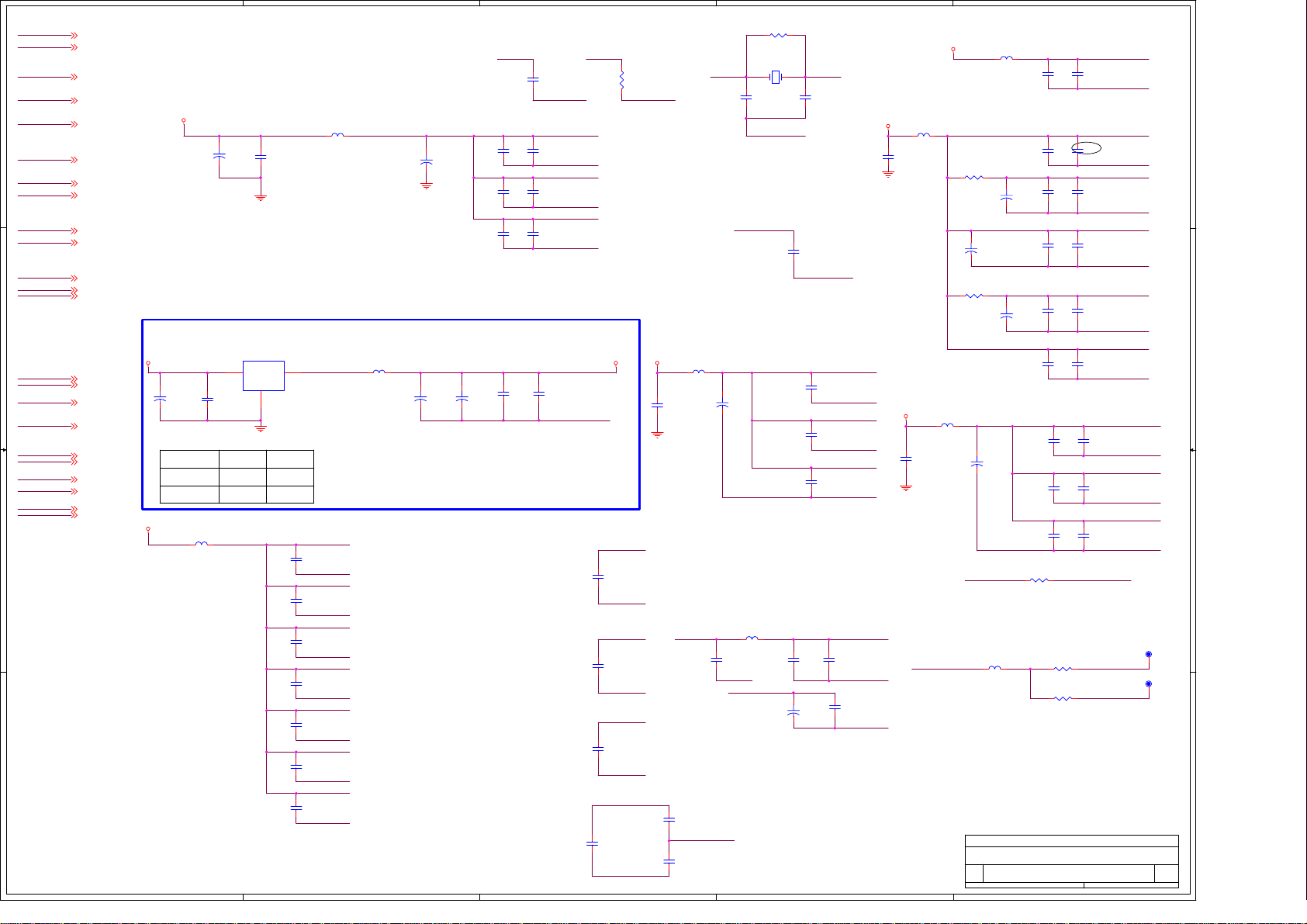

A

B

C

D

E

MT8205 DIGITAL POWER & DECOUPLING

4 4

DV33A

DV18A

DV18A

0603 PUT ON NEARLY BGA

CB61

0.1uF

3 3

CB68

0.1uF

C0603/SMD

2 2

CB62

0.1uF

C29

0.01uF

C0603/SMD

C30

3300pF

C0603/SMD

0603 PUT ON NEARLY BGA

0603 PUT ON NEARLY BGA

CB69

0.1uF

C0603/SMD

C31

3300pF

C0603/SMD

CB70

0.1uF

C0603/SMD

C32

3300pF

C0603/SMD

CB71

0.1uF

C0603/SMD

C33

3300pF

C0603/SMD

CB72

0.1uF

C0603/SMD

C34

3300pF

C0603/SMD

1 1

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

B

Date: Sheet of

A

B

C

D

MT8205 DECOUPOMG--DIGITAL

516Tuesday, May 10, 2005

E

V0.1

Page 18

A

B

C

D

E

4 4

3 3

2 2

1 1

SCL

SDA

IOA[0..7]

ICE

IOWR#

IOCE#

PWR#

PCE#

A[0..7]

F_A[8..21]

UP1_2

UP1_6

UP1_3

UP3_1

UP1_4

UP1_5

UP3_0

HWSCL

HWSDA

8205UP3_0

8205UP3_1

8205UP1_[2..7]

8205UP3_4

8205UP3_5

SCL 1,9,11,13

SDA 1,9,11,13

IOA[0..7] 3

ICE 3

IOWR# 3

IOCE# 3

PCE# 7

A[0..7] 7

F_A[8..21] 3,7

UP1_2 15

UP1_6 11

UP1_3 11

UP3_1 15

UP1_4 1

UP1_5 1

UP3_0 1

HWSCL 3

HWSDA 3

8205UP3_0 3

8205UP3_1 3

8205UP1_[2..7] 3

8205UP3_4 3

8205UP3_5 3

A

PWR# 7

UP3_4 FOR S/W SCL

UP3_5 FOR S/W SDA

REMOVE WHEN USE ICE MODE

UP3_5

UP3_4

ICE

R311

1k

IOA0

IOA1

IOA2

IOA3

RN38

7 8

5 6

3 4

1 2

A0

A1

A2

A3

0x4

IOA4

IOA5

IOA6

IOA7 A7

RN39

7 8

5 6

3 4

1 2

A4

A5

A6

0x4

IOWR# PWR#

R314

0

IOCE# PCE#

R315

0

8205UP3_0

8205UP3_1

8205UP3_4

8205UP3_5

RN40

7 8

5 6

3 4

1 2

UP3_0

UP3_1

UP3_4

UP3_5

0x4

8205UP1_2

8205UP1_3

8205UP1_4

8205UP1_5

RN41

7 8

5 6

3 4

1 2

UP1_2

UP1_3

UP1_4

UP1_5 MUTE

0x4

8205UP1_6 UP1_6

R313

0

8205UP1_7 UP1_7

HWSDA

HWSCL

R312

0

DEL

R300 R

R301 R

R302 0

R303 0

B

SDA

SCL

TP28

TEST POINT DIP1.0

TP/DIP/D1.0

C

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

B

D

Date: Sheet of

MT8205 DECOUPOMG--DIGITAL

616Tuesday, May 10, 2005

E

V0.1

Page 19

A

B

C

D

E

+

A1

A2

A3

A4

A5

A6

A7

F_A8

F_A9

F_A10

F_A11

F_A12

F_A13

F_A14

F_A15

F_A16

F_A17

F_A18

F_A20

F_A21

CB80

0.1uF

CB88

0.1uF

CB96

0.1uF

CE34

220uF/16v

CB107

0.1uF

CB115

0.1uF

C49

3300pF

CB126

0.1uF

C42

3300pF

U14

25

A0

24

A1

23

A2

22

A3

21

A4

20

A5

19

A6

18

A7

8

A8

7

A9

6

A10

5

A11

4

A12

3

A13

2

A14

1

A15

48

A16

17 13

A17 NC

15

RY/BY

WP/ACC

9

A19

10

A20

26

CE

TSOP 48 pin

28

OE

12

RESET

MX29LV160BT

CB81

0.1uF

CB89

0.1uF

CB97

0.1uF

C43

3300pF

CB108

0.1uF

DEL

0402 PUT ON NEARLY BGA

CB116

0.1uF

C50

3300pF

CB127

0.1uF

F_D0

29

D0

F_D1

31

D1

F_D2

33

D2

F_D3

35

D3

F_D4

38

D4

F_D5

40

D5

F_D6

42

D6

F_D7

44

D7

30

D8

32

D9

34

D10

36

D11

39

D12

41

D13

43

D14

A0

45

D15

F_A19

16

A18

14

47

BYTE

37

VCC

2711

GND1WE

46

GND2

CB82

CB83

0.1uF

0.1uF

CB91

CB90

0.1uF

0.1uF

CB98

CB99

0.1uF

0.1uF

C44

3300pF

CB110

CB109

0.1uF

0.1uF

CB118

CB117

0.1uF

0.1uF

C0603/SMD

C51

C52

3300pF

3300pF

CB129

CB128

0.1uF

0.1uF

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

C

Date: Sheet of

DV33A

FLASHVCC

CB84

0.1uF

CB92

0.1uF

CB100

0.1uF

C45

3300pF

CB111

0.1uF

CB119

0.1uF

C0603/SMD

C53

3300pF

CB130

0.1uF

DDR MEMORY&FLASH

C46

3300pF

R55

10k

CB85

0.1uF

CB93

0.1uF

CB101

0.1uF

CB112

0.1uF

CB120

0.1uF

C0603/SMD

C54

3300pF

C0603/SMD

CB131

0.1uF

DV33A 5VSB

R56

0

CB77

0.1uF

C47

3300pF

CB113

0.1uF

CB121

0.1uF

C0603/SMD

E

R57

R

CB102

0.1uF

C55

3300pF

C0603/SMD

CB124

0.1uF

716Tuesday, May 10, 2005

CB103

0.1uF

V0.1

CB104

0.1uF

RN2

A_RA3

7 8

A_RA2

5 6

A_RA1

3 4

A_RA0

1 2

RN4

A_RA4

4 4

VREF

VREF

A_DQS[0..3] 3

A_RA[0..11] 3

A_BA[0..1] 3

A_DQM[0..1] 3

A_DQ[0..31] 3

A_CLK 3

A_CLK# 3

A_CKE 3

A_CS# 3

A_RAS# 3

A_CAS# 3

A_WE# 3

SDV25 3

VREF 3

PWR# 6

PCE# 6

A[0..7] 6

F_D[0..7] 3,6

F_OE# 3

F_A[8..21] 3,6

CB132

CB133

VREF DECOUPLING

0.1uF

CB137

0.1uF

0.1uF

CB138

0.1uF

A

VREF

VREF

A_DQS[0..3]

A_RA[0..11]

A_BA[0..1]

A_DQM[0..1]

A_DQ[0..31]

A_CLK

A_CLK#

A_CKE

A_CS#

A_RAS#

A_CAS#

A_WE#

SDV25

VREF

3 3

RWR#

PCE#

A[0..7]

F_D[0..7]

F_OE#

F_A[8..21]

2 2

1 1

7 8

A_RA5

5 6

A_RA6

3 4

A_RA7

1 2

RN6

A_RA8

7 8

A_RA9

5 6

A_RA11

3 4

1 2

R59 22

A_RA10

RN8

A_DQ0

7 8

A_DQ1

5 6

A_DQ2

3 4

A_DQ3

1 2

RN10

A_DQ4

7 8

A_DQ5

5 6

A_DQ6

3 4

A_DQ7

1 2

RN11

A_DQ8

7 8

A_DQ9

5 6

A_DQ10

3 4

A_DQ11

1 2

RN13

A_DQ12

7 8

A_DQ13

5 6

A_DQ14

3 4

A_DQ15

1 2

RN16

A_DQ16

7 8

A_DQ17

5 6

A_DQ18

3 4

A_DQ19

1 2

RN17

A_DQ20

7 8

A_DQ21

5 6

A_DQ22

3 4

A_DQ23

1 2

RN19

A_DQ24

7 8

A_DQ25

5 6

A_DQ26

3 4

A_DQ27

1 2

RN21

A_DQ28

7 8

A_DQ29

5 6

A_DQ30

3 4

A_DQ31

1 2

Change to 47 ohm

A_DQS0

R61 47

A_DQS1

R62 47

A_DQS2

R63 47

R64 47

A_DQS3

A_CS#

7 8

A_RAS#

5 6

A_CAS#

3 4

A_WE#

1 2

A_BA1

R66 22

A_BA0

R68 22

R71 22

A_DQM0

A_DQM1

R73 22

R75 22

A_CKE

R77 22

A_CLK

A_CLK#

R79 22

CB134

CB135

0.1uF

0.1uF

CB139

CB140

0.1uF

0.1uF

RN25

D_RA3

D_RA2

D_RA1

D_RA0

22x4

D_RA4

D_RA5

D_RA6

D_RA7

22x4

D_RA8

D_RA9

D_RA11

22x4

D_RA10

D_DQ0

D_DQ1

D_DQ2

D_DQ3

47x4

D_DQ4

D_DQ5

D_DQ6

D_DQ7

47x4

D_DQ8

D_DQ9

D_DQ10

D_DQ11

47x4

D_DQ12

D_DQ13

D_DQ14

D_DQ15

47x4

D_DQ16

D_DQ17

D_DQ18

D_DQ19

47x4

D_DQ20

D_DQ21

D_DQ22

D_DQ23

47x4

D_DQ24

D_DQ25

D_DQ26

D_DQ27

47x4

D_DQ28

D_DQ29

D_DQ30

D_DQ31

47x4

D_DQS0

D_DQS1

D_DQS2

D_DQS3

D_CS#

D_RAS#

D_CAS#

D_WE#

22x4

D_BA1

D_BA0

D_DQM0

D_DQM1

D_CKE

D_CLK

D_CLK#

SDV25

SDV25

CB136

0.1uF

CB141

0.1uF

SDV25 SDV25

D_DQ0

D_DQ1

D_DQ2

D_DQ3

D_DQ4

D_DQ5

D_DQ6

D_DQ7

D_DQS0

D_DQM0

D_WE#

D_CAS#

D_RAS#

D_CS#

D_BA0

D_BA1

D_RA10

D_RA0

D_RA1

D_RA2

D_RA3

SDV25 SDV25

D_DQ16

D_DQ17

D_DQ18

D_DQ19

D_DQ20

D_DQ21

D_DQ22

D_DQ23

D_DQS2

D_DQM1

D_WE#

D_CAS#

D_RAS#

D_CS#

D_BA0

D_BA1

D_RA10

D_RA0

D_RA1

D_RA2

D_RA3

D1V25

D1V25

CB122

0.1uF

3

VREF

CB123

0.1uF

U4 CM1117-2.5V

IN

B

SOT223/SMD

5VSB

+

TP10

CE41

220uF/16v

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

+

CE36

220uF/16v

2

OUT

U15

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

NC

VDDQ

LDQS

NC

VDD

DNU

LDM

WE

CAS

RAS

CS

NC

BA0

BA1

A10/AP

A0

A1

8M x 16

A2

A3

VDD

M13L128168 8Mx16-6

U16

1

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

NC

15

VDDQ

16

LDQS

17

NC

18

VDD

19

DNU

20

LDM

21

WE

22

CAS

23

RAS

24

CS

25

NC

26

BA0

27

BA1

28

A10/AP

29

A0

30

A1

31

A2

32

A3

33

VDD

M13L128168 8Mx16-6/NC FOR ENTRY

R69 4.7k

1

2

3

4 5

IC LP2996 DDR Termination SOP8

ADJ/GND

1

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VDDQ

DQ8

NC

VSSQ

UDQS

NC

VREF

VSS

UDM

CK

CK

CKE

NC

A12

A11

DDR

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

VDDQ

VSSQ

UDQS

VREF

8M x 16

DDR

U17

GND

SD

VSENSE

VREF VDDQ

CE37

+

220uF/16v

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

A9

39

A8

38

A7

37

A6

36

A5

35

A4

34

66

VSS

65

64

63

62

61

60

59

58

57

56

DQ9

55

54

DQ8

53

NC

52

51

50

NC

49

48

VSS

47

UDM

46

CK

45

CK

44

CKE

43

NC

42

A12

41

A11

40

A9

39

A8

38

A7

37

A6

36

A5

35

A4

34

VSS

8

VTT

7

PVIN

6

AVIN

+

D_DQ15

D_DQ14

D_DQ13

D_DQ12

D_DQ11

D_DQ10

D_DQ9

D_DQ8

D_DQS1

D_DQM0

D_CLK#

D_CLK

D_CKE

D_RA11

D_RA9

D_RA8

D_RA7

D_RA6

D_RA5

D_RA4

CE38

220uF/16v

D_DQ31

D_DQ30

D_DQ29

D_DQ28

D_DQ27

D_DQ26

D_DQ25

D_DQ24

D_DQS3

D_DQM1

D_CLK#

D_CLK

D_CKE

D_RA11

D_RA9

D_RA8

D_RA7

D_RA6

D_RA5

D_RA4

+

VREF

SDV25

VREF

CE35

47uF/16v

+

CE39

220uF/16v

+

CB76

0.1uF

CB105

0.1uF

CE40

220uF/16v

SDV25

D1V25

RN3

D_RA0

7 8

D_RA1

5 6

D_RA2

3 4

D_RA3

1 2

75x4

RN5

D_RA4

D_RA5

D_RA6

D_RA7

D_RA11

D_RA9

D_RA8

D_RA10

D_DQ0

D_DQ1

D_DQ2

D_DQ3

D_DQ4

D_DQ5

D_DQ6

D_DQ7

D_DQ8

D_DQ9

D_DQ10

D_DQ11

RN15

D_DQ12

D_DQ13

D_DQ14

D_DQ15

RN18

D_DQ16

D_DQ17

D_DQ18

D_DQ19

RN20

D_DQ20

D_DQ21

D_DQ22

D_DQ23

RN22

D_DQ27

D_DQ26

D_DQ25

D_DQ24

RN23

D_DQ31

D_DQ30

D_DQ29

D_DQ28

D_RAS#

D_CS#

D_BA0

D_BA1

D_DQS2

D_DQS3

D_CAS#

D_WE#

D_DQM1

D_DQS1

D_DQS0

D_DQM0

C

75x4

RN7

75x4

R60 75

RN9

7 8

5 6

3 4

1 2

75x4

RN12

7 8

5 6

3 4

1 2

75x4

RN14

7 8

5 6

3 4

1 2

75x4

7 8

5 6

3 4

1 2

75x4

75x4

75x4

1 2

3 4

5 6

7 8

75x4

1 2

3 4

5 6

7 8

75x4

RN24

7 8

5 6

3 4

1 2

75x4

R65 75

R67 75

R70 75

R72 75

R74 75

R76 75

R78 75

R80 75

SDV25

78

56

34

12

12

34

56

78

NEW ADD

12

34

56

78

12

34

56

78

D1V25

SDV25

DV33A

R58

10k

D1V25

CB78

0.1uF

D1V25

CB86

0.1uF

D1V25

CB94

0.1uF

D1V25

+

CE33

270uF/16v OS-CON/NC

C270UF16V/D10H12

SDV25

D1V25

C40

3300pF

PWR#

D

SDV25

CB79

0.1uF

CB87

0.1uF

CB95

0.1uF

SDV25

CB106

0.1uF

SDV25

CB114

0.1uF

C48

3300pF

CB125

0.1uF

DV33A

C41

3300pF

PCE#

F_OE#

Page 20

A

B

C

D

E

VCC

4 4

VGA_PLUGPWR

D19

VGA_PLUGPWR VGA_PLUGPWRVGA_PWR

CB157

0.1uF

U22

1

NC

2

NC

3

NC

4 5

GND SDA

EEPROM 24C02

VCC

SCL

WP

VGA_PLUGPWR

8

7

6

VGASCL

VGASDA

GND

R115

10k

R116

10k

DIODE SMD

1N4148/SMD

D6

DIODE SMD

1N4148/SMD

VGA_IN_L

VGA_IN_R

VGA_IN_L 13

VGA_IN_R 13

P4

3 3

PHONEJACK STEREO

PHONEJACK/DIP

VGASDA

R110 100

VGASCL

R111 100

2 2

11

VGA_SDA

12

13

VSYNC#

1 1

A

VGA_SCL

14

15

P6

1617

1

6

2

7

3

8

4

9

5

10

VGA_SDA

VGA_SCL

D-SUB15 FEMALE

DSUB15/DIP/F

VGA_PWR

B

K1K2K3K4K5

RED

RED_GND

GREEN

GRN_GND

BLUEHSYNC#

BLU_GND

R

1

2

3

L

4

G

VGA_R

VGA_L

VSYNC# VSYNC_VGA

HSYNC#

+

CE100 10uF/25v

+

CE101 10uF/25v

L98

FB

BEAD/SMD/0603

L99

FB

BEAD/SMD/0603

C

R323 10k

R324 10k

R298

2.2k

R299

2.2k

C157

5pF

C158

5pF

VGA_IN_R

VGA_IN_L

HSYNC_VGA

VGASDA

VGASCL

HSYNC_VGA

VSYNC_VGA

RED_GND

GRN_GND

BLU_GND

RED

GREEN

BLUE

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

B

VGA IN&PC AUDIO IN

Date: Sheet of

D

VGASDA 3

VGASCL 3

VGAHSYNC# 3

VGAVSYNC# 3

RED_GND 12

GRN_GND 12

BLU_GND 12

RED 12

GREEN 12

BLUE 12

V0.1

10 16Tuesday, May 10, 2005

E

Page 21

A

B

C

D

E

CVBS0---TUNER1

CVBS1---FRONT BD AV_IN

CVBS2---AV BD (AV/S-V) IN

R40

0

R44

0

R30 0

R33 0

R36 0

R19 0

R25 0

R28 0

Title

LCD TV - MediaTek MT8205 Solution

Size Doc Number Rev

A3

Date: Sheet of

R41 0

R42

75

R43 0

FB6

0

R45 0

R46

75

R47 0

FB5

0

R17

0

Y

Y_GND

CB

CB_GND

CR

CR_GND

VIDEO IN & TUNER IO

SY

SY_GND

SC

SC_GND

SOY1

11 16Tuesday, May 10, 2005

E

V0.1

R32

75

R37

75

R26

75

FB2

FB3

FB4

SY_IN

SC_IN

0

0

0

Y

Y_GND

4 4

3 3

2 2

1 1

CB

CB_GND

CR

CR_GND

SOY

SY

SY_GND

SC

SC_GND

TV

TV_GND

CVBS1

CVBS1_GND

SIF1_OUT

AF1_OUT

SCL

SDA

OGO0

OGO1

OGO2

OGO3

OGO4

OGO5

OGO6

ORO6

ORO7

S1_AV1_L

S1_AV1_R

YPBPR1_L

YPBPR1_R

Y12

Y_GND 12

CB 12

CB_GND 12

CR 12

CR_GND 12

SOY 3

SY 12

SY_GND 12

SC 12

SC_GND 12

CVBS0 12

CVBS0_GND 12

CVBS1 12

CVBS1_GND 12

SIF1_OUT 12

AF1_OUT 12

SCL 1,6,9,13

SDA 1,6,9,13

OGO0 3

OGO1 3

OGO2 3

OGO3 3

OGO4 3

OGO5 3

OGO6 3

ORO6 3

ORO7 3

S1_AV1_L 11

S1_AV1_R 11

YPBPR1_L 11

YPBPR1_R 11

A

VCC

TUNER_12V

TUNER_12V

L102

FB

L103

FB

P1

RCA1X3

RCA3/6P/DIP

AV , TUNER I/O

TUNER_12V 1

TU_12V

TV_GND

R1

S1_AV1_R

S1_AV1_L

YPBPR1_R

YPBPR1_L

TV

R11

0

18

TU VCC FOR TUNER POWER USE

TU_VCC

CB197

0.1uF

TU_12V

CB198

0.1uF

S1_AV1_L

S1_AV1_R

+

+

B

1

2

3

4

5

6

CE97

+

1000uF/16v

+

CE98

1000uF/16v

CE9

10uF/25v

CE13

10uF/25v

TU_VCC

SDA

SCL

SIF1_OUT

AF1_OUT

R39

100K

J4

1

2

3

4

5

6

7

8

9

10

11

12

CON12

DIP12/P2.0

OGO3 FOR AV SWITCH IO-1

ORO7 FOR TUNER SIF SELECT SWITCH IO-1

OGO0 FOR TUNER SIF SELECT SWITCH IO-2

OGO1 FOR TUNER BOARD PAL/NTSC SWITCH

ORO6 FOR AUDIO 1st SWITCH IO-1

OGO5 FOR AUDIO 1st SWITCH IO-2

OGO6 FOR AUDIO 2nd SWITCH IO-1

OGO2 FOR AUDIO 2nd SWITCH IO-2

OGO4 FOR AUDIO 2nd SWITCH IO-2

TP6

TP7

TP8

TP9

TP20

TP21

TP24

TP25

ORO6HP_SENSE

ORO7

OGO0

OGO1

OGO2

OGO3

OGO4

OGO5

CE14

TP5

R15

56

R16 0

FB1

0

R38

100K

R7 0

R48

R49

100K

100K

YPBPR1_L

YPBPR1_R

CVBS1AV1_IN

CVBS1_GND

10uF/25v

CE15

10uF/25v

C

TP27

OGO6

YPBPR

+

P2

2

5

8

RCA1X3

RCA5/9P/Y

+

SC_IN

RESERVER

1

3

6

4

9

7

JP1

CON\SVHS

2

1

7

6

SY_IN

3

4

5

UP1_2 FOR POWER ON/OFF

ORO7 FOR SYS_PWR

R29

0

R35

0

R24

0

D

Page 22

A

B

C

D

E

VGASOG

RED+

RED-

4 4

GREEN+

GREEN-

BLUE+

BLUE-

CB+

CBCR+

CRY+

Y-

SY+

SY-

SC+

SC-

CVBS0+

CVBS0-

3 3

CVBS1+

CVBS1-

CVBS2+

CVBS2-

MPX1

MPX2

Y

Y_GND

CB

CB_GND

CR

CR_GND

SOY

2 2

SY

SY_GND

SC

SC_GND

CVBS0

CVBS0_GND

CVBS1

CVBS1_GND

CVBS2

CVBS2_GND

SIF1_OUT

AF1_OUT

RED

1 1

GREEN

BLUE

RED_GND

GRN_GND

BLU_GND

VGASOG 3

RED+ 3

RED- 3

GREEN+ 3

GREEN- 3

BLUE+ 3

BLUE- 3

CB+ 3

CB- 3

CR+ 3

CR- 3

Y+ 3

Y- 3

SY+ 3

SY- 3

SC+ 3

SC- 3

CVBS0+ 3

CVBS0- 3

CVBS1+ 3

CVBS1- 3

CVBS2+ 3

CVBS2- 3

OUTPUT

MPX1 3

MPX2 3

Y11

Y_GND 11

CB 11

CB_GND 11

CR 11

CR_GND 11

SOY 3,11

SY 11

SY_GND 11

SC 11

SC_GND 11

CVBS0 11

CVBS0_GND 11

CVBS1 11

CVBS1_GND 11

CVBS2 11

CVBS2_GND 11

SIF1_OUT 11

AF1_OUT 11

RED 10

GREEN 10

BLUE 10

INPUT

RED_GND 10

GRN_GND 10

BLU_GND 10

R168

NC

R172

NC

R163

NC

R348

22

R349

0

R350

22

R351

0

R352

22

R353

0

R166 0

CVBS0_GND

R170 0

CVBS1_GND

R162 0

CVBS2_GND

FROM Tuner

SIF1_OUT

AF Path

AF1_OUT

A

R176 0

R333 39k

B

R344 0

C106

15pF/NC

R332 39k

C160

15pF

C165

15pF/NC

C161

15pF

C168

330pF

C169

330pF

C170

330pF

CE116

47uF/16v /NC

C104

47nF

C166

47nF/NC

CE62

47uF/16v

C94

C96

C98

C100

C89

C92

CVBS0+CVBS0

47nF

CVBS0-

47nF

CVBS1+CVBS1

47nF

CVBS1-

47nF

CVBS2+CVBS2

47nF

CVBS2-

47nF

+

MPX1

+

MPX2

C

RED RED_IN

RED_GND

GREEN GREEN_IN

GRN_GND

BLUE

BLU_GND

CB

CB_GND

CR

CR_GND

L55

FB

BEAD/SMD/0603

L57

FB

BEAD/SMD/0603

L59

FB

BEAD/SMD/0603

Y

Y_GND

SY

SY_GND

SC

SC_GND

R160 0

R164 0

R167 0

R171 0

R174 0

D

R179

75

L104

FB

R186

75

GRN_GND

L106

FB

BLUE_IN

R195

75

L105

FB

R161

NC

R165

NC

R169

NC

R173

NC

R175

NC

R178 100

R180 100

R183 0

R185 100

R187 100

R338

100

R339

100

R340

100

R341

100

R342

100

R343

100

R354

22

R355

0

R356

22

R357

0

R191 100

R199 100

C88

Y+

47nF

C162

30pF

C90

Y-

47nF

C91

CB+

47nF

C163

10pF

C93

CB-

47nF

C95

CR+

47nF

C164

10pF

C97

CR-

47nF

C99

SY+

47nF

C171

330pF

C101

SY-

47nF

C102

SC+

47nF

C172

330pF

C103

SC-

47nF

C105

RED+

47nF

C107

5pF

C108

RED-

C109

4.7nF

Title

Size Doc Number Rev

C

Date: Sheet of

47nF

VGASOG

C111

GREEN+

47nF

C112

5pF

C113

GREEN-

47nF

C114

BLUE+

47nF

C115

5pF

C116

BLUE-

LCD TV - MediaTek MT8205 Solution

47nF

AUDIO/VIDEO IN CIRCUIT

E

12 16Tuesday, May 10, 2005

V0.1

Page 23

A

B

C

D

E

Del Parts

VCC

L61

R219 5k

AIN5R

NC

R220 5k

AINVGL

AINOPL

AINOPR

36

35

34

33

32

31

30

29

28

HPGND

HPVDD

27

26

25

HPVDD

WMVREFP

3738394041424344454647

AGND

AINVGR

HPOUTR

NC

24

FB

HPVDD