Page 1

I

$nUEEillAilljAL

PAHT$LilSTru

AKAI

MG'.'ELGlX-?3cltrI

ALScl

STEFIEC'

APÍ'LICAEILE TtrI McltrlEL

TAPE

trIEG}<

GX-E3cl

Page 2

I

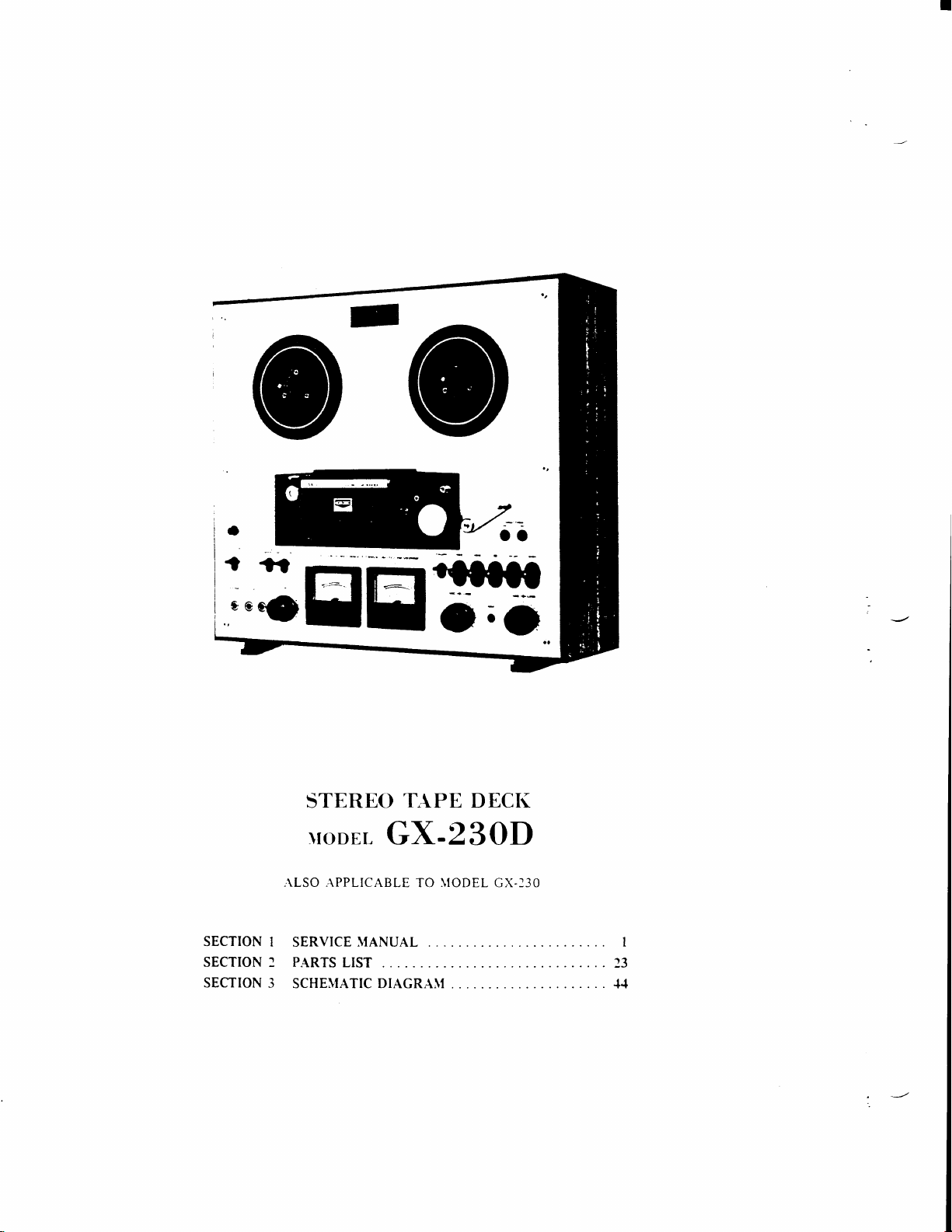

STtrREO

}IODEL

,\LSO .\PPLICABLE

SECTION

SECTION ] PARTS

SECTION 3

I

SERVICE

SCHEMATICDIAGRA}Í

TAPE DECI(

GX.23OD

MANUAL

LIST

TO

\IODEL

....

GX.]30

I

23

.tl

Page 3

I

I

SPECIFICATIONS

II.

DIS\I\NTLING

III.

.\RR-\,NGENÍENT

IV.

}fECHANISNÍ

I. .\DJUST}f

]. BRAKE

3.

.\DJUST\ÍENT

.I.

.\DJUSTIvÍENT

.i.

.\DJUST}IENT

6. HEIGHT

:

.\DJUST}IENT

8.

.{DJUST}IENT

9.

.\DJUSTillENT

10. .\DJUST\Í

\.

HEAD

VI.

.\}IPLIFIER

I PO\\'ER

:.

T\PE

3

RECORDING.

VII.

D.C.

RESISTANCE

VIII.

CLASSIFICATION

I. P C. BOARD

]

CO\IPOSITE

SEtrIVICE

OF

OF TÍAIN

ADJUSTIIIENT

ENT

TENSION

.\DJUSTMENT

ENT

.\CTIVATOR

.\DJUST\ÍENT

SYSTEM

SUPPLY

SPEED

ADJUSTNÍENT

PLAYBAC]K

OF VARIOUS

INTERCIIANGE,\BILITY

VIEWS

SECTION

TABLE

UNIT

PARTS

OF PINCH \\'HEEL

ADJUST\IENT

OF

REEL

TABLE

oF

CAPSTAN

OF

II,IPEDANCE

OF

TENSION

OF

RECORDING

oF FF

oF

PLAY

POSITION

ADJUSTI\IENT

VOLTAGE

OF VARIOUS

OF

\{oToR

ROLLER

OF

TAPE

ARN{

SLIDE

MICRoSwITCH

\ilcRoswtrcH

ADJUST},ÍENT

.

AMPLIFIER

COILS

P.C.

('O\IPONE\TS

I

MAI\ITJAL

OF

CONTE\TS

PRESSURE

HEIGHT

SHAFT LooSE

SHAFT LOOSE

GUIDE

BOARDS

ON TENSION

\f ICROSWITCH

SWITCH

(SW.-s)

(sw-r

.\DJUST\IENT

CIIART

(SW-IO)

.\CTUAToR

¡nd

PL.\Y

SW-9

SW-il

PLAY

,

.{RM

POSITION

TI\ÍING...

PoSITION

r

. .

l

-t

6

7

7

¡l

9

9

t0

l0

il

ll

t2

lz

¡3

l5

t5

t5

l6

l7

l7

l7

l8

[:r.i

i'r:lc.idJusin]cnts.

(;E\ER.\L

OPER.\

ntc.lsLlnng ntetltods. lnd

f IN(; I'RINCIPI-ES .\\D

opc:-,l:^ltg

,\I)JL'S

f\IENTS

prlltelDic's.

rcfer lt.r

Page 4

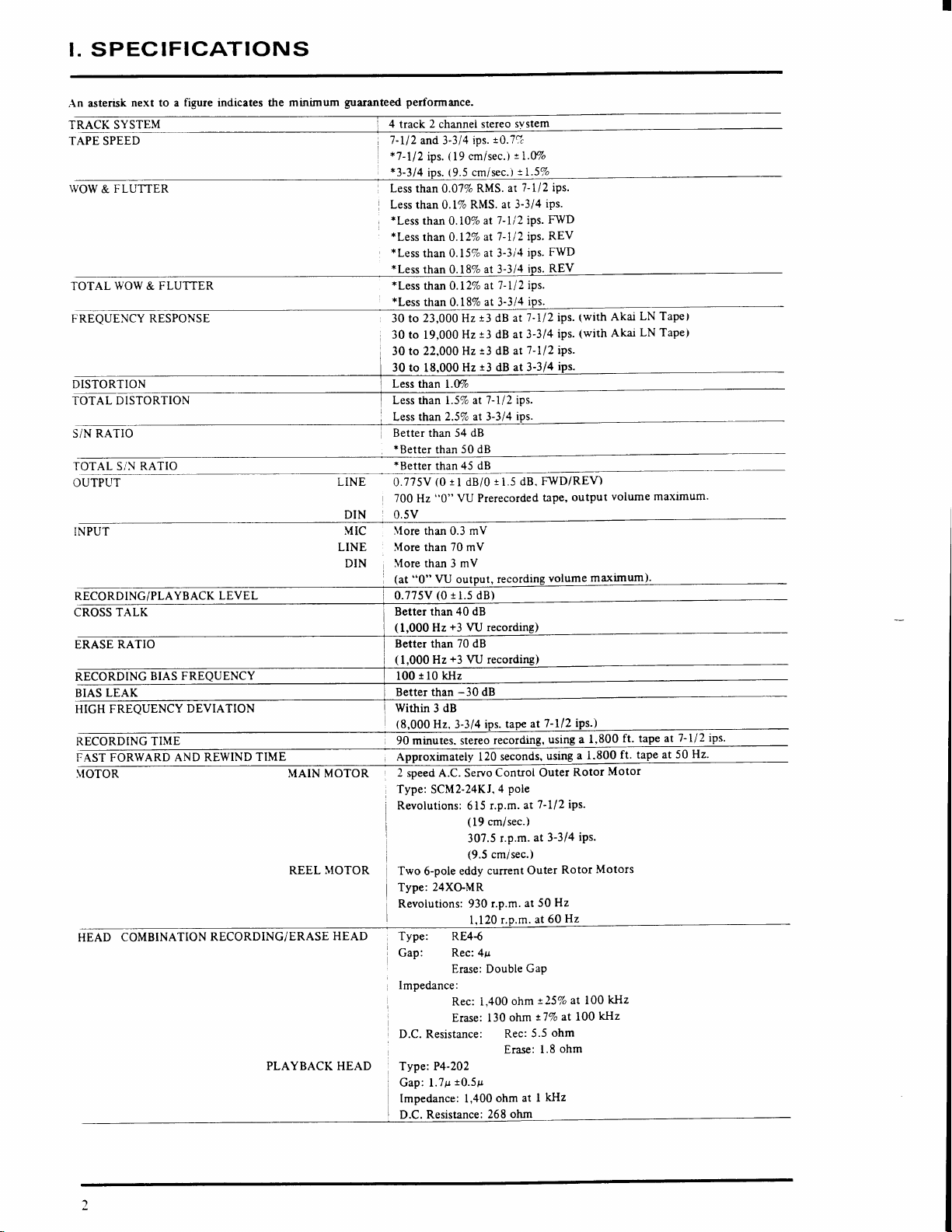

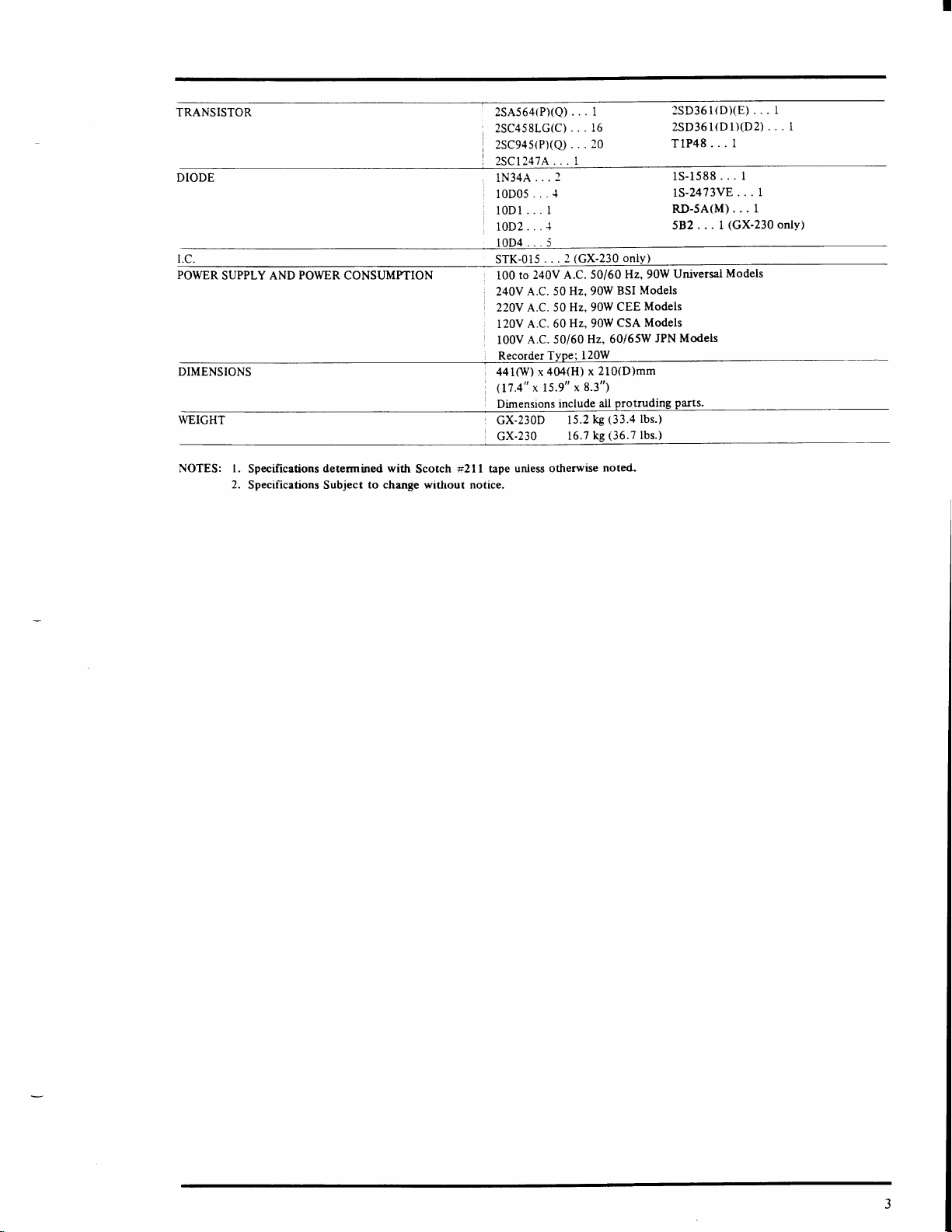

I. SPECIFICATIONS

I

An astersk

TRACK SYSTEM

next to a

figure

TAPE SPEED

WOW & FLUTTER

WOW & FLUTTER

TOTAL

FREQUENCY

DISTORTION

TOTAL DISTORTION

SiN RATIO

TOTAL S/N

RESPONSE

RATIO

OUTPUT

INPUT

RECORDING/PLAYBACK

TALK

CROSS

ERASE RATIO

FREQUENCY

RECORDING

BTAS

HIGH FREQUENCY

RECORDING

FAST FORWARD

\IOTOR

HEAD

BIAS

LEAK

DEVIATION

TIME

AND REWIND

COMBINATION

indicates the

LEVEL

RECORDING/ERASE

minimum

TIME

MAIN MOTOR

}IOTOR

REEL

PLAYBACK HEAD

guaranteed

i 4 track 2 channei

LINE

DIN

MIC

LINE

DIN

HEAD

performance.

svstem

stereo

7-ll2

and 3-314

*'l-ll2

ips.

*3-3l4

ips.

Less than 0.07%

Less

than 0.i%

*Less

than 0.l0Vo at

*Less

than 0.I2%

*

Less

than 0.15%

*Less

than 0.l8Vo

*Less

than 0J2%

*Less

than

23,000 Hz

30 to

30 to

19,000

22.000 Hz

30 to

to

30

18.000

Less

than 1.07o

Less than 1.5% at

Less than

Better than 54 dB

*Better

*Better

0.775V

700 Hz

25% at 3-314

than 50

than 45

(0

"0"

x0.7%

ips.

(19

(9.5

0.I8%

Hz

Hz

t

dB/O t 1.5

I

VU Prerecorded

xl.Mo

crn/sec.)

cml

at

RMS.

3-3/4

RMS. at

7-Il2 iPs.

at'l-ll2

at 3-3

at 3-3/4

7-ll2 ips.

at

at 3-314

t3

at

dB

t3

dB at

t3

dB at

t3

at3-314

dB

7-ll2 ips.

i

dB

dB

4 ips.

dB.

0.5v

\f

than

ore

More

More than 3 mV

(at

"0"

0.775V

Better than 40 dB

(1,000

Better than 70 dB

(1,000

100 t 10

Better

Within 3 dB

(8,000

90

minutes.

Approxrmately 120 seconds,

2

speed

Type:

Revolutions: 6 l5

Two

Type:

Revolutions: 930

| 1,120

Type: RE4-6

Gap:

lmpedance:

D.C.

Type: P4-202

Gap: 1.7¡r

Impedance: 1,400

D.C. Resistance:

mV

0.3

70

than

mV

VU

output,

(0

t

dB)

1.5

+3

VU

Hz

+3

VU recording)

Hz

kHz

-30

than

Hz.

SCM2-24K1,4

6-pole

24XGMR

Resistance:

dB

ipt.

3-314

stereo

A.C. Servo

(19

307.5

(9.5

eddy current

Rec:

4¡¡

Erase: Double

Rec: i,400

Erase: 130

t0.51

recording

recordi

ta

recording,

Conuol

pole

r.p.m.

cm/sec.)

r.p.m.

cmisec.)

r.p.m.

r.p.m.

ohmt25%

ohm

Rec:

Erase:

at

ohm

ohm

268

7-ll2iPs.

ips.

FWD

REV

ips.

FWD

REV

iPs.

ips.

ips.

7-ll2

ips.

3-314

7-ll2 ips.

i

FWD/REV)

output

tape,

volume

using

a 1.800

using

Rotor

Outer

ips.

7'Ll2

at

at 3-314

Rotor

Outer

Hz

50

at

Hz

60

at

GaP

at 100

t7% at lO0kÍlz

ohm

5.5

ohm

1.8

kHz

I

Akai

lwith

(with

Akai

volume maximum'

maximum),

ft. tape

a 1,800

ft. tape

Motor

iPs.

Motors

kHz

LN Tapel

LN Tape)

7-ll2 ips'

at

¿1!9

FIz.

Page 5

I

TRANSISTOR

2SA564(PXQ)

2SC4s8LG(C)...16

2SC945(PXO.

2SC1247A...

DIODE

1N34A...2

10D05...4

... I

toDl

10D2...+

10D4...5

STK-015

POWER

SUPPLY AND POWER CONSUMPTION 100

to

A.C. 50

240V

A.C. 50

220V

A.C. 60H2,90W

l20V

A.C. 50/60

100V

RecorderTvoe:

DIMENSIONS 441(W) x

(l'7.4"x15.9"x8.3")

Dimensions

GX-230D

cX-230

NOTES: l.

Specificaüons determined

2.

Specifications Subject

with

Scotch #2ll

to change without notice.

tape

unless otherwise

.. . i

. .

I

(GX-230

. . .2

240V A.C.

Hz, 90W

Hz. 90W

l20W

404(H)

include

15.2

16.7

20

only)

Hz, 90W

50/60

BSI

CEE

CSA

60/65W

Hz.

210(D)mm

x

ail

(33.4

ks

(36.7

ks

noted.

2SD361(DXE)...1

2SD361(DlXD2)...1

.

TlP48.

15-1588...

. 1

1

ls-2473VE...

RD-sA(M)...1

582...1(GX-230only)

Universal

Models

Models

Models

Models

JPN Models

lbs.)

lbs.)

r

Page 6

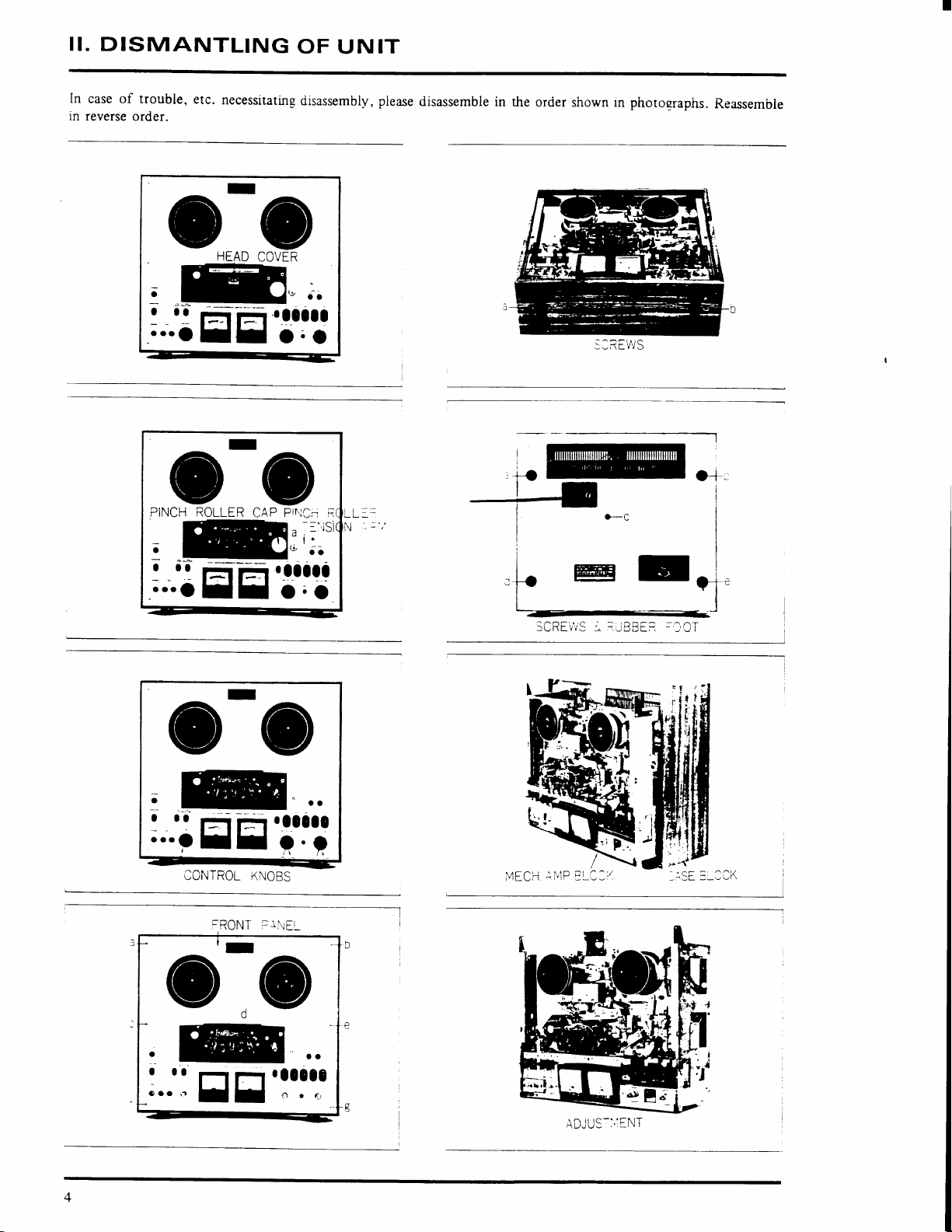

II.

DISMANTLING

In

case of

in

reverse

trouble,

order.

etc.

necessitating

HEAD

COVER

OF

UNIT

ciisassembly, piease

disassemble

in

the order

shown rn

photoeraphs.

I

Reassemble

':

:

---oII

Ft t=t

o

NCH

ROLLPI

ER

CAP

rftsf

O-O

¡

ffiE

SCREv'jS

:^

iuBBER

-,tlOT

i

CONTROL

KNOBS

-RONT

F]\EL

OO

D

gt,

-l

I

I

ADJU-S-:'If

NT

Page 7

T

]CNNECTION

{ffi

¡

PLUGS

-tl

q"ffi

_.¿J*i

:?.i

-

:-f--¡'-

:.RE\,VS

-

AfvlP

BLOCK

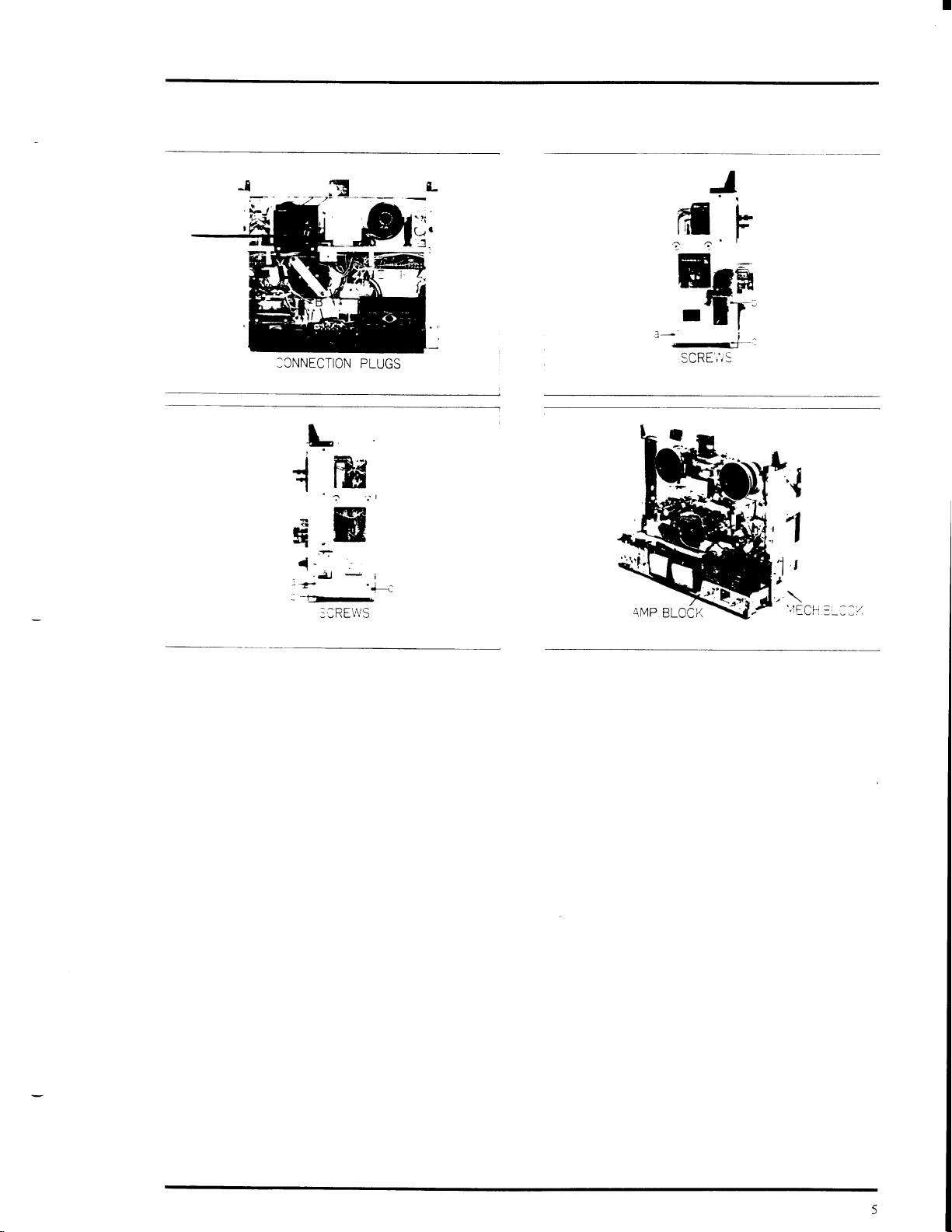

Page 8

I

ARRANGEMENTOF

III.

MAIN PARTS

-

GFi,

rlf

-

g-

E

,'tt'=

3

---

.1t--

t#-=

-ñ'

,r'6

FAST

s

2

:ssiMELY

HEAO

BLOCK

ELOCK

S iV'9

SUTTCN

't ó

:

TENSICN

KEY

a

"¿¡U5E

RIGHT REEL MOTOR

:ERVO :CNTROL

3OARD

:t

VAIN MOTCR

?EC,

BOARD

i5c. a[4P

-'¡sc.

I

SOARD

MY- 2C36

^v c,¡/ ?

iF

SW5

SW,

MY-2044

r-:-'6

lt'1

EC.

oc,

/B

1-

!

I

REEL

LEFT

POWER

POWER

30ARD

MOTOR

TRANSFORMER

PC.

S"PPLY

'lY-

2037

tü

P

C

Page 9

T

IV.

MECHANISM

FIXATION

ADJUSTMENT

SOLENOI

D

SCREWS

-BRAKE

LEVER B

BRAKE LEVER

_-l8Oo-.

SCREW

SCREW

CAPSTAN

A-

-

C

SHAFT

@

O5mm

X

SPRING

-J

sw-4

''AT

STOP

F iq,2

ENT

I. ADJUSTNÍ

SURE

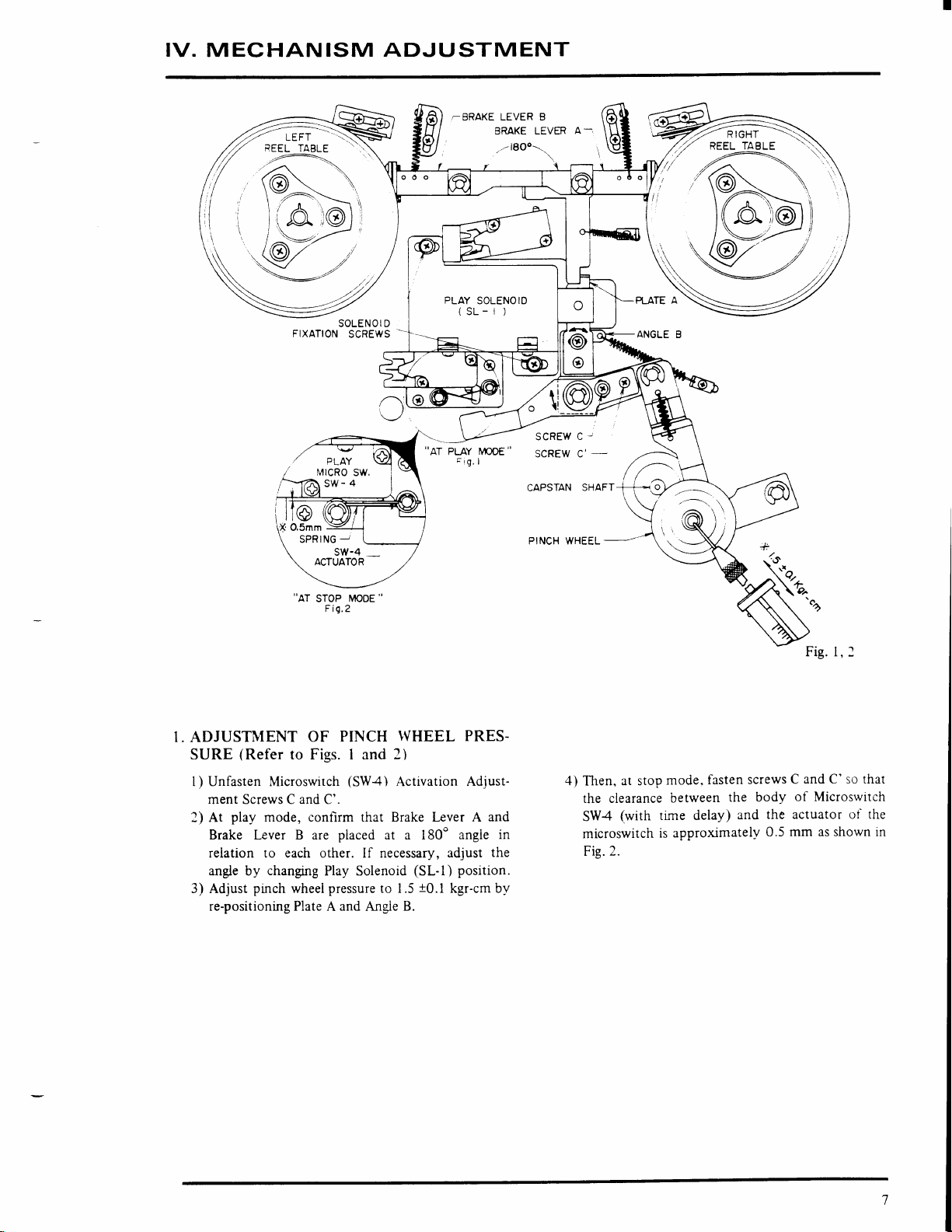

I ) Unfasten Microswitch

2)

3) Adjust

(Refer

ment Screws C and C'.

play

At

Brake

Lever

relation to each other. If necessary, adjust

angle by

prnch

re-positioning Plate A and

OF

to Figs. I and

mode,

confirm

B are

changrng

wheel

Play

pressure

"

MOOE

PINCH

1VHEEL PRES-

2)

(SW4)

placed

Activation

that Brake Lever A

at a 180"

Solenoid

to

1.5

B.

Angie

Adjust-

and

in

angle

the

(SL-l) position.

t0.l

kgr-cm by

PINCH WHEEL

4)

Then,

the clearance

SW4

microswitch

Fig. 2.

at stop

(with

fasten

mode.

between

time delay)

approximately

is

the body

and C' so that

C

screws

of Microswitch

the actuator of the

and

mm as shown in

0.5

Page 10

SOmm-

I

BRAKE

BRAKE

ERAKE DRUM

A

v

BAND SUSPENSION

BAND .

METAL

X Confirm thot

coírpl€loly

boih ore

soporoted

Fig.3

METAL

Fig.4

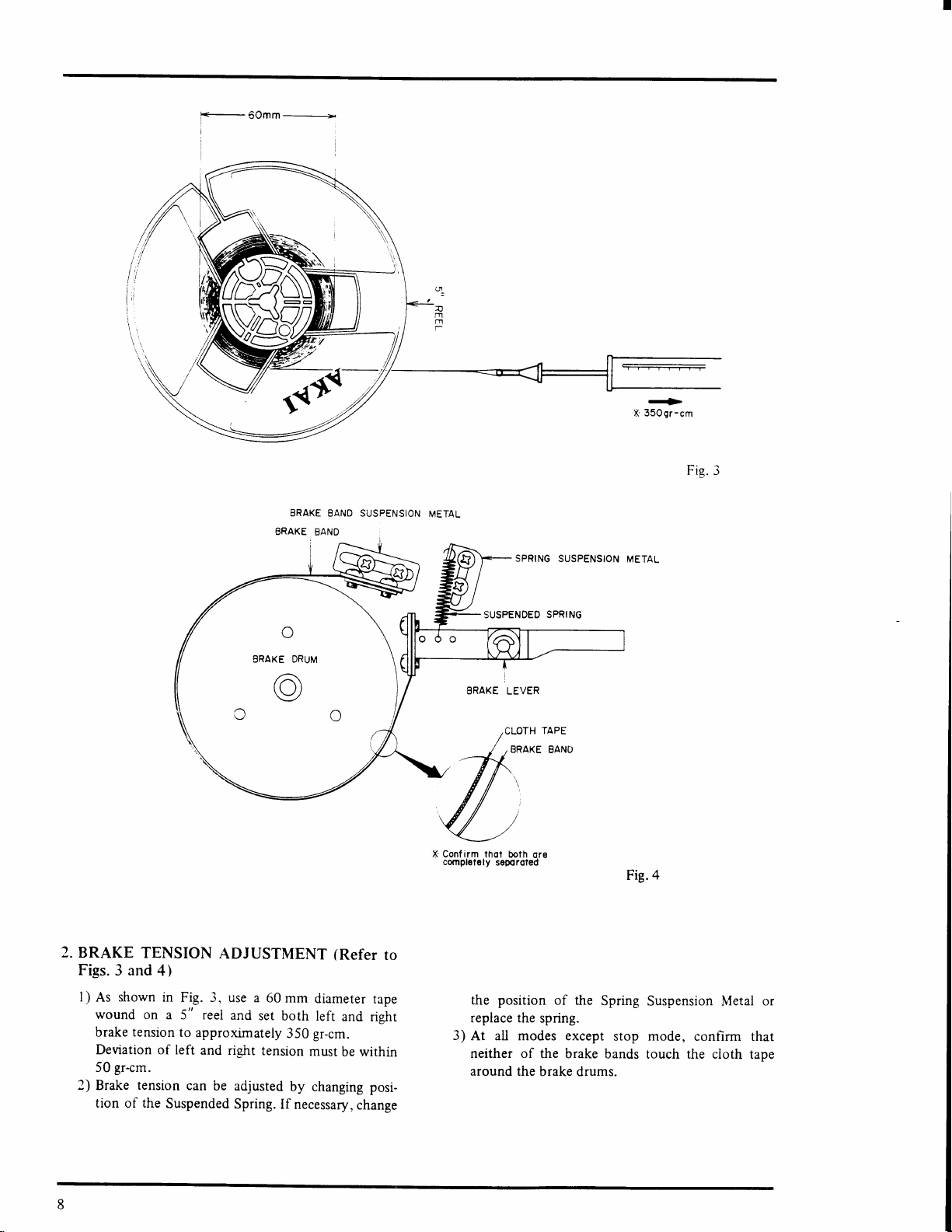

2.

BRAKE

Figs.

l)

As

wound on

brake tension

Deviation of

50

2)

Brake

tion

TENSION

3 and

shown

gr-cm.

tension

the

of

4)

in

Fig. 3, use

a 5" reel

to

approximately

left

and right

can

Suspended

ADJUSTMENT

a

60mm

and

set

tension

be adjusted

Spring.

diameter

both

left

350 gr-cm.

must

by changing posi-

If necessary,

(Refer

tape

and

right

be within

change

to

the position

replace the

3)

At all modes except

neither of

around the

of the

spring.

the brake

brake drums.

Spring

Suspension Metal or

stop mode, confirm

bands touch the cloth

that

tape

Page 11

T

ñEEL

IAELE-

MAIN

tt

t;

/

MOTOR-

-

IHRUST SUPPORT

ANGLE

REEL TABLE

,I

F|XATION

SCREWS

Fig.

5

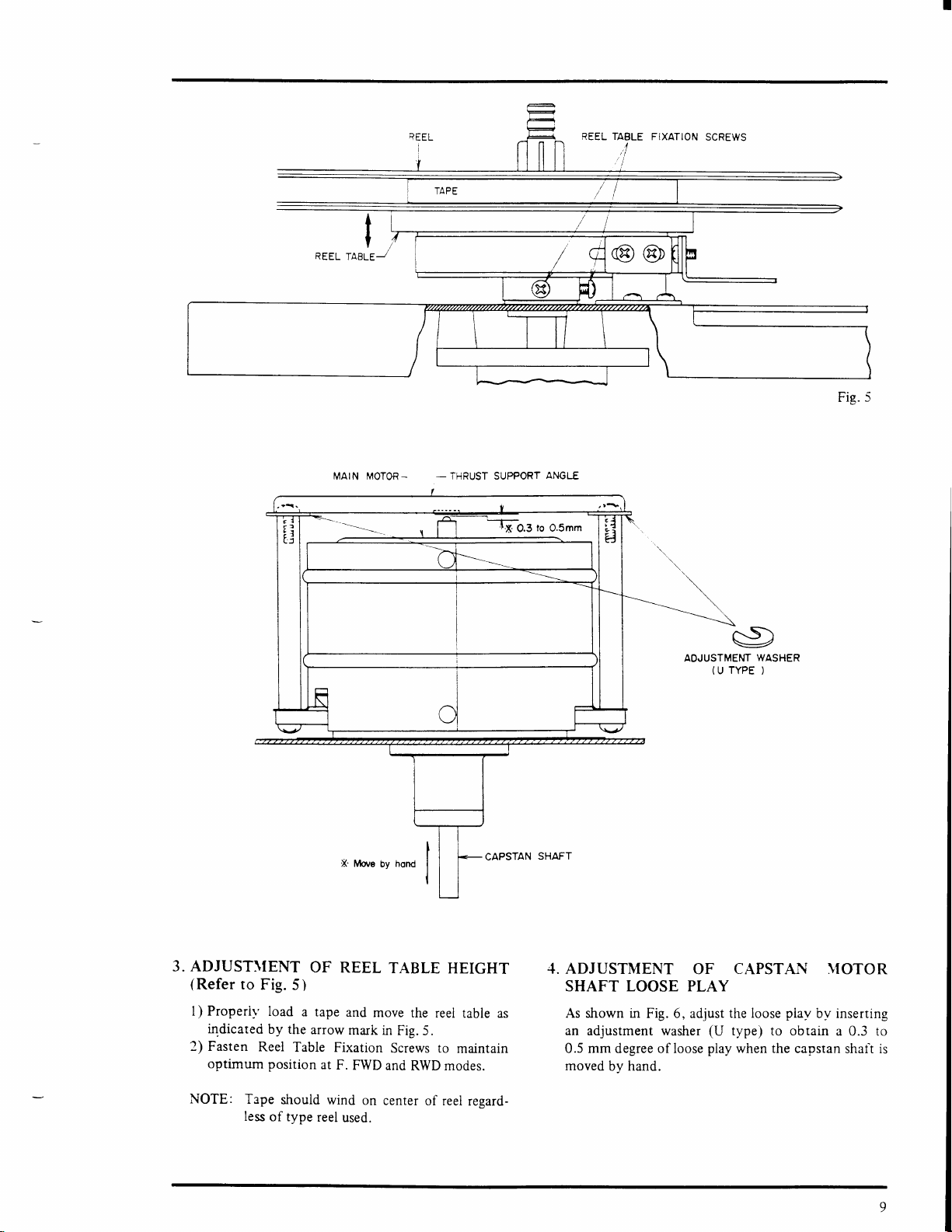

3.ADJUST}ÍENT

(Refer

I ) Properil'

2) Fasten

NOTE:

to

Fig.

5)

load

indicared

optimum position

by the

Reel

Tape

less

Table Fixation

should

of type

OF

a tape

arrow

at

wind

reel

REEL

and

ma¡k in

F.

FWD

on

used.

TABLE

move

Fig.

Screws to

and

center

HEIGHT

the

reei table as

5.

maintain

RWD modes.

of reel

resard-

4.

ADJUSTMENT

SHAFT

As shown in

an

0.5 mm degree of loose

moved

LOOSE PLAY

Fig. 6, adjust

adjustment washer

hand.

by

CAPSTAN MOTOR

OF

the loose

(U

type) to obtain

play

when the capstan

piav

by inserting

a 0.3 to

shaft is

Page 12

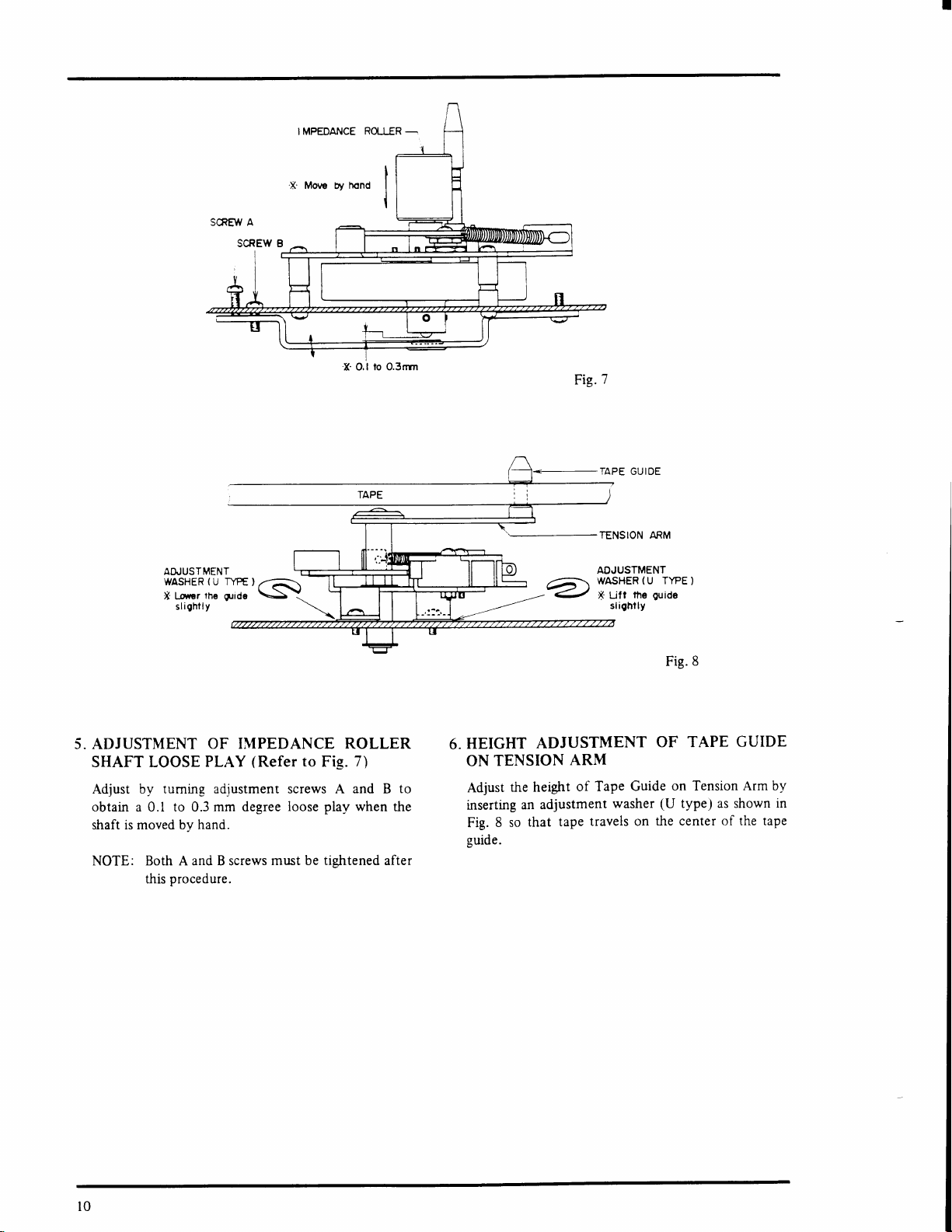

X'O.l

to O.3nm

Fig.

t

7

,

A&JUSTMENT

lfl':,i:

slightly

5. ADJUSTMENT

SHAFT LOOSE

tuming adjustment screws A and B

Adjust

obtain a 0.1 to 0.3

shaft is moved bv

NOTE: Both A and B screws

by

this

procedure.

lT'a

OF IMPEDANCE ROLLER

PLAY

mm degree loose

hand.

\

(Refer

to

must be tiehtened after

Fig.

play

7)

when the

l=__1_IAPE

'i--'i

HEIGHT

6.

ON

to

Adjust

inserting

Fig.

euide.

ADJUSTMENT

TENSION

the height

adjustment

an

tape

that

8 so

ARM

of Tape

GUTDE

t

TENSION ARM

ADJUSTMENT

WASHER(U

fh€

X'L¡ff

slighl ly

Guide

washer

travels on

TYPE)

gu¡do

8

Fig.

OF TAPE

on Tension

(U

the center

type)

as shown

GUIDE

Arm by

in

of the tape

l0

Page 13

Switch Potñi

mtcroswt?cñ

for

I

REC. PUSH

lncluding

X

o I lowonce

EUTTON

bock

SLIDE SWITCH

.ICTIVATOR

lhls

X Bend

INTERLOCK

i-y¡6pg

Port

(TENSION

ANGLE

r

SWTTCH

SW,

SWITCH SLIOER

SLIDE

SWg

)

Fig.9

SPR I NG

x.Just

contocls

Fig.

SACK

l0

PART

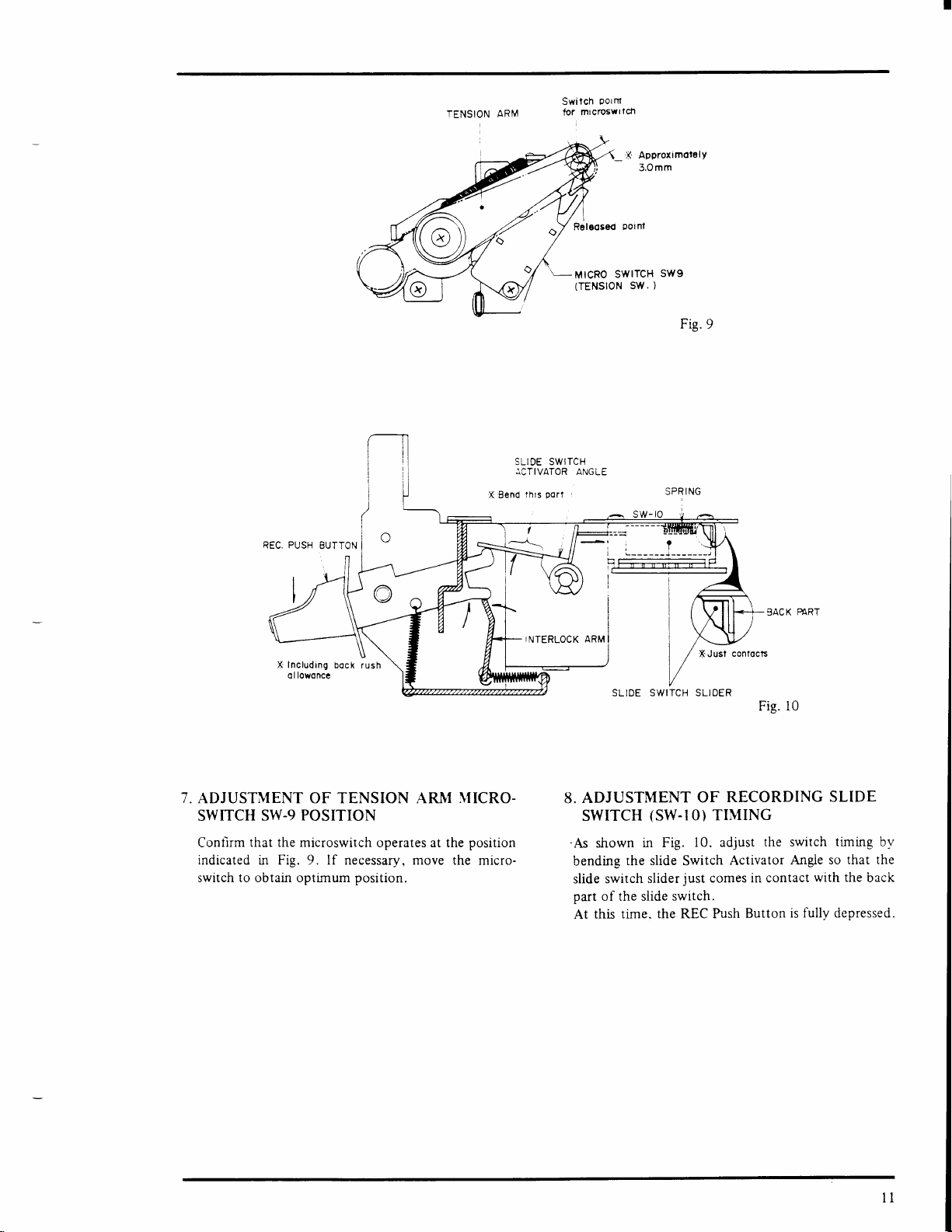

7.

ADJUSTMENT

SWTTCH

Cont'irm

SW-g POSITION

that the microswitch

OF

indicated in Fig. 9. If

switch to obtain optimum

TENSION ARM

operates at the

necessary,

position.

move the

MICRO-

position

micro-

ADJUSTMENT

8.

the

switch

(SW.IO)

in Fig.

slide

slider

the REC Push

SWITCH

'fu

strown

bending

slide

part

of the slide

this time.

At

OF

10. adjust

Switch

just

switch.

RECORDING SLIDE

TIMING

the switch

so that the

Activator

comes

Angie

in contact

is fully

Button

with the

depressed.

timing by

back

ll

Page 14

F E

MICRO

(sw-5)

SWITCH

SWITCH

I

LEVER

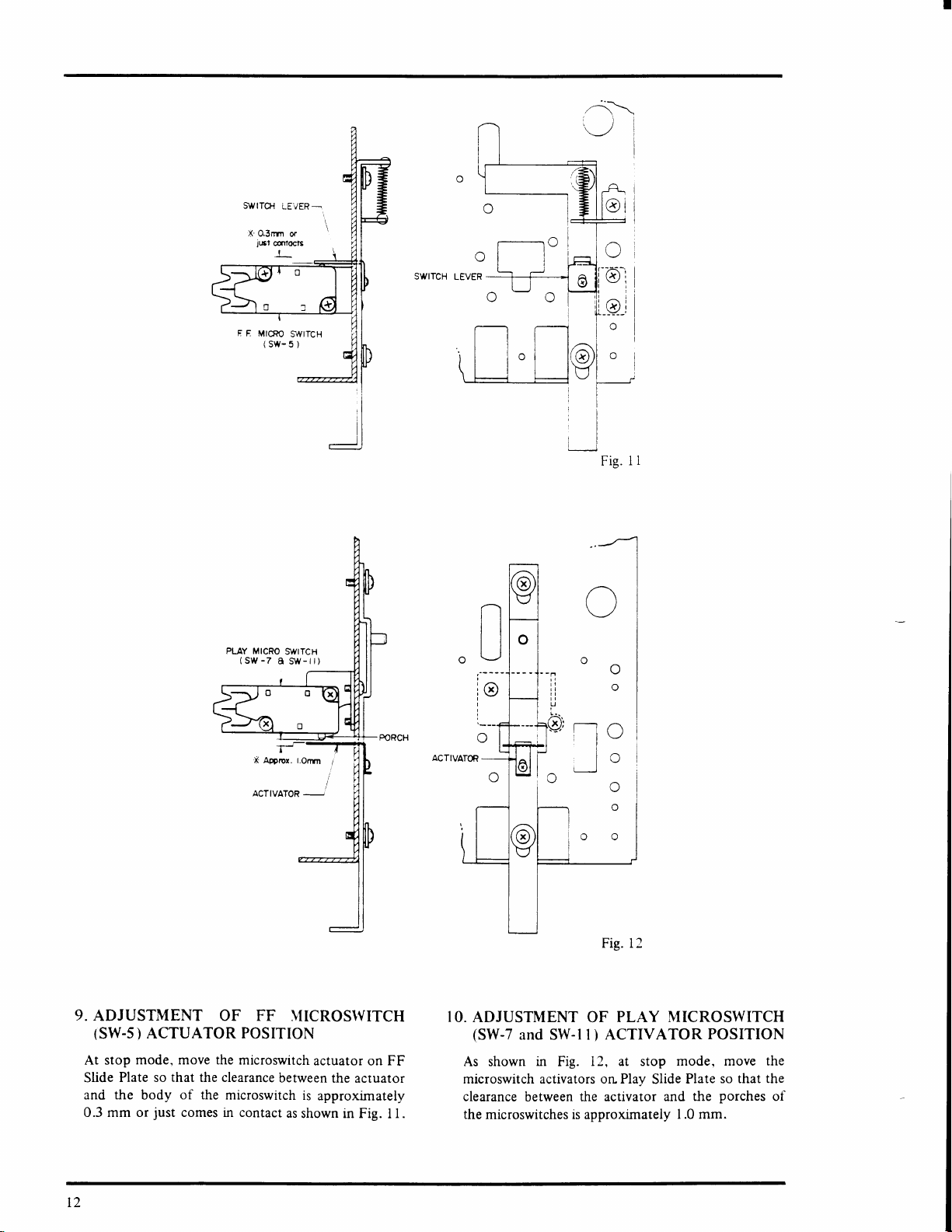

9.

ADJUSTMENT OF FF

(SW.s

At stop

Slide

and

0.3 mm or

ACTUATOR POSITION

)

mode.

Plate so

the

body

just

the

move

that

the clearance

of the

comes in contact

T2

}ÍTCROSIVITCH

microswitch

between

microswitch

as

actuator

the acruator

is

approximately

shown in Fig. I l.

on

FF

I

O. ADJUSTMENT OF PLAY

(SW-7

and SW-l I ) ACTIVATOR

As shown

microswitch activators on Play

clearance

the

microswitches

in

between the

12, at stop

Fig.

activator and

is approximately

MICROSWITCH

POSITION

mode, move the

so that the

Plate

Slide

porches

the

1.0 mm.

of

Page 15

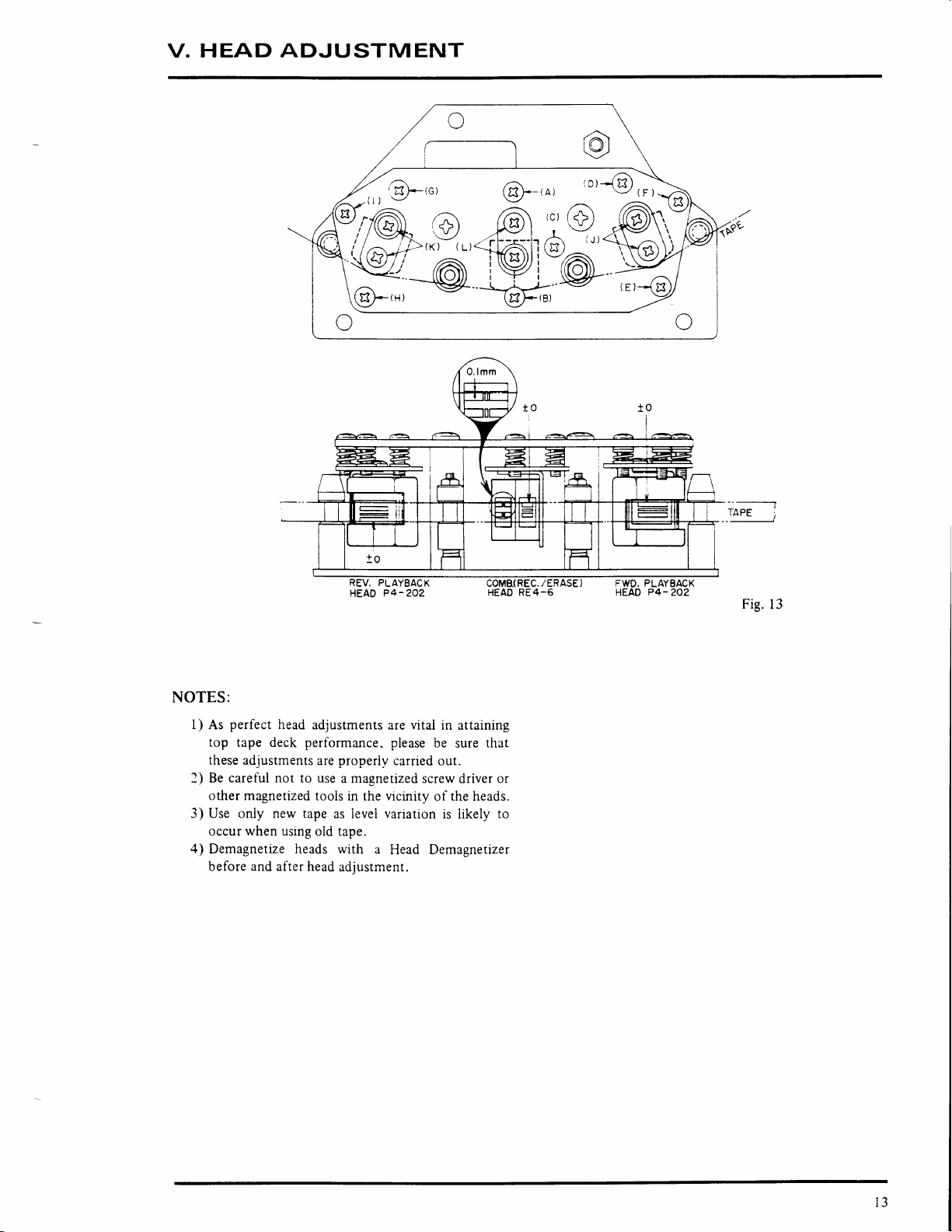

V.

HEAD

ADJUSTMENT

'@*'o'

REV. PLAYBACK

P4-2O2

HEAO

@,o,

,0,@,r,-

COMB(REC./ERASE)

HEAD RE4-6 HEAD

FWD.

PLAYBACK

P4-2O2

q

Fig.

l3

NOTES:

perfect

I

As

)

top

these adjustments

Be careful not

2)

other magnetized

3) Use only new tape

occur when using

4)

Demagnetize heads

before and after head

head

tape deck

adjustmenrs

perforrnance.

properiy

are

use

to

a magnetized screw

tools

in the

as level

old tape.

with

adjusrment.

vitai

are

piease

carried out.

vicinity

variation

a

Head Demagnetizer

in

attaining

be

sure

driver

of the heads.

is likely

that

or

to

13

Page 16

A.ljustment

Item

Test

Suppiv

Taoe

Signal

Adjustment

Point

Remarks

Combination

Height

Adjustment

[rWD

Plavback

Heieht

.{,diustment

REV

Plavback

Height

Adjusrment

IrWD Plavback

Azimuth

FWD

REV

Azrmuth

REV

Azrmuth

Alignment

Adiustment

Plavback

Gap Alignment

Adiustment

Plrvback

Alignment

.\djustment

Plavback

Gap Alignment

Adjustment

Combination

Alignment

Adjustment

Head

Head

Head

Head

Head

Head

Head

Head

I

Scotch

optionai

optionai

optlonal

8.000

Hz.

3-3l4

ips

test

taDe

8,000

Hz.

3-3/4

ips

test

tape

8,000

Hz.

3-3/4

ips

test

taDe

8,000

Hz,

3-314

ips

test

tape

;211

15,000

-20

dBm

Hz

tape

REV

REV

(AX

B)(C)

(DXEXF)

(GXHXI)

(F)

(K)

Upper

edge of ch.

upper edge

height.

Upper edge of ch. t

upper edge

height.

Lower edge

lower edge of the tape

heieht.

Maximum output.

|

I

I

I

Adjust head

no change

is

applied to the

Ilaximum

Adjust

no change

is

applied to the supply reei

Maximum

of the tape are the

of the tape

ch. i

of

gap

in output

output. both

gap

head

in output

output.

I

head core

head core

head core

both

surface

level

suopiy

surtace

level

both

are the

the same

are

channels.

so

that

when

side.

reel

channels

so

that

when

side.

channeis.

and the

same

and

the

same

and the

there is

tension

there is

tension

Combination

NOTE:

Gap

Alignment

Adjustment

Set

tape

Head

speed

Scotch

to 7-l/2

=21I

15,000

-20

dBm

ips.

when

tape

Hz

making

ali alignment

(L)

adjustments.

gap

Adjust head

no

change in

is applied to the supply

surface

output level when

so that there

tension

side.

reel

is

L4

Page 17

AMPLIFIER

VI.

SYSTEM

ADJUSTMENT

1. POWER SUPPLY

J

,-l

-|,l,*¡i

=-lI

ILr-

r'¡r!!

1:)

G"'/-

|||||||ry.I-I:l

O'

I

ffiffR

ilt

IGT

_i

VOLTAGE

F

|

_

.at lK8

,:CJUST TO

ADJUSTMENT

24V

Fig. 14

TAPE

2.

|

VR I IOKE

gcm

SPEED

/3cc.

ADJUST}IENT

ffi

t

3e

l''-

@t."

',r..fi

i9

cm/s!c

95cm'/s¿c:

I

Fis. l5

Adjustment Item

Power

Voltase

Supply

Adiustment

7-ll2

ips.

Tape

Speed

Adjustment

3-3/4

ips.

Tape Speed

Adjustment

Test Tape

1.000 Hz. 7-Il2 ips

test tape

i,000 Hz. 7-ll2

test

ips.

tape

I

I

Mode

STOP

FWD

P.B.\

FWD

p.¡.

VR2 30

kB 500

Result

24.0V

xlj%

Hz

I

i

I

Terminal

Supply P.C. Boa¡d

Tape

Tape

Rema¡ks

Po*"t

@,

Speed 7-ll2 ips.

Speed 3-3/4

ips.

r5

Page 18

3. RECORDING.

PLAYBACK AMPLIFIER ADJUSTMENT

,R

I vR3

SOKB

a ^

v¿)

*/

23mH

LI

2KE 2K8

V)

'/R3b

,a,a

"lU

VRrb

3CKB

<-/

A

.9

_t¡

3OP

.V

_^(h

iOP

VR2D

20K8

^

w

Adjustment

Playback

Adjustment

VU

Meter

Adjustment

Recording Level

Adiustment

Frequency

Adjustment

Bias

Adiustrnent

NOTES:

l.

Tape

2. Tape

3.

Output

4.

Nerv

5.

The

indicates

Item

Level

Sensitivity

Response

Leak

Speed

I

at 7-Il2

Selector at LOW

volume

maximum.

test

tape

should be used.

letter

b following

"right

channel".

Test Tape

Supply

700

Hz, 7-Il2 ips.

tvv

700

ftz, t-Ll¿ tps.

Hz.7-l12 i

"O"

VIJ

Scotch

1,000

recording

Scotch

1,000

Hz, 10,000 Hz

-20

dBm

(19

ips.

NOISE.

an

adjústment

Signal

test

tape

test tape

#21 I tape.

"O" \rU

Hz

#21 I tape,

recordins

cm/sec.)

p¿uts

Mode

FWD

P.B.

FWD

REC

REC

number

Adjustment

Point

VRl

vR32kB

i

i

vR2

c25

tt23mH

I

50

20

80P

KB

kB

Result

rl.0

0

(0.77sv)

tl.5

0

(0.77sv)

1,000 Hz

10.000 Hz

Less than

-30

w

dB

dB

to

flat

within 0

rsverse

Monitor

Readjust

following bias

With

Monitor

SOURCE

and

Rema¡ks

t1.5

playback

Switch at

SOURCE

recording

adjustment

Switch

Positions.

dB

at

at

level

TAPE

r6

Page 19

VII.

D.C.

RESISTANCE

VARIOUS

OF

COILS

Plav Solenoid

Shut-Off

Output Transformer

Oscillator Coil

Plavback Head

Rec.;Erase Head

NOTE:

Resistance

Part

\fain Motor

Reel

Motor

Solenoid

Relay

Relay

phone

Head

Combination

values

shown

Desisnation

SCM2.]4KJ

]4XO-MR

1660

0730

MY44-US-ADA DC24V

N16-53sS

in this chart

are averase

THT3

THTl

MTS.2

oT-204

P4-202

RE4ó

values.

D.C.

Resistance

Between

Between

Between

BLU-RED

YLW-GRN

Pick-up Coil

BLU-RED

635

Between YLW-GRN

685

ohm

tlj%

15

ohm

650

ohm

980

ohm

Primary 565

Secondarv

Be¡reenl-3

Between4-

Between7-9

Erase

ohm

0.95

ohm

0.3ohm

6 0.7ohm

%+<ffi

168

ohm

Rec.5.5 ohm

1.8

ohm

100

180

ohm

74

166

!15%

xIS%

ohm

ohm

otun

ohm

VIII. CLASSIFICATION

P.C. BOARD TNTERCHANGEABILITY

I.

P.C. Board

Relay

P.C. Board

Servo

OSC. and

NOTE:

Control

Power Suppiy

REC. SW.

Transistor

Equalizer

Lamp P.C.

Recording

Playback

Main

Asterisk

mark indicates "not

P.C. Board

P.C.

Board

P.C. Board

P.C. Board

P.C. Board

Board

Amp. P.C. Board

Amp. P.C. Board

Amp. P.C. Board

interchanseable"

VARIOUS

OF

CHART

GX-230D

MY{008 MY{008

MY-2036

MY-2037 MY-2037

MY-204 MY-2044

MY-2054

I4

MY.5O

A.B

MY-501s

MY-5016

MY-5017* MY-s017*

GX-230

MY-2036

MY-2054

MY.sOI4A.B

MY-501s

MY-50r6

MS-5024

P.C.

BOARDS

t7

Page 20

2. COMPOSITE VIEWS

1.

OSC. and

Recording

OF

COMPONENTS

Amp.

P.C. Board

-

i

:

a

:

O4y-5016)

*-;*;;ri-

.:-::=:=tb1

p

Fl

I ¿

ó

a

I

¿_ ¿

.Fi.,*r

i

É+

-1

ú

;,,¡

¡ril.¿'t

;i

ffi#;r3*.

éuÉl¡l

O a a ar-ra a -.¡

t

? t''f

r-

lt f

fl

,t',-

'

¿

g3l"¿.r;.

'

ir

!-

;.

ry,$::

E-qti

-a

?

'

¡

r

. : ¿

:*lc:sl* :*!r'

ffi{,l#$Lifi

*.;a

r,

i-

.*l.t¡Fxql

?

"-*'I'"'l

ul

¿,

+]

-¡'¿

J

¡

,: ' *,".*q \

b

*

I'

,"

€¡r"E"F*rT

s;Ss{Elj

ffi

Q

e .*lffii].¿.g

|

-l¡b+J

¿ . . i,] I

ff

;l¡lN"i;,

:i'..'

fi

É

It'rll''r*

t*,\

#,*.F*+'t+

r:isli.ffidt*],

r'**riirffffffi

tffifu-

i#tht5$,5+"*{f;

i;

i';llr:

ii

11 t

i?

?.

á;,BJ

Íl

3,

$.tElE"n"!ñEK;'ie

F' F'

¡*qf

ü;;;i9;;¡i;i'.s

;

t;!-1,?',,f''

ffifi#*Fffi

'!:Í

s|st

*1,"

;¡

llfl¿',

t

r- a

t

i

ó:

*J

{,:

lff11

S.*r,t;a.,

;

i

'l

t,'

9k'-"

.&I

d¡-.

A

ffi¡gKñl

g

Nf¡ftq .€$fntq-i

l8

Page 21

l. Plavback

.{mp.

P.C.

Board

(MY'5017).

<7

G-@

;L+GdC/

rr¿Élt'

I

= Yó

i;q

-:>

'ortt&*

€/do

t Er" Sfnffil

'71'.I

á

:.'á

.*

i- =+'.='lf

'i.*r.I-q$i

l¡'.-Tpt*f"

$

3l

s&i

.i:

ii

,

-

f

:

=

f3

ar

:

I

t

á

t I rii

¡,,

.ll

I

,I

!

4

I

I

I

ÉfiF:

iE:

\-b

i

\cl

rl-

='l

19

Page 22

3.

Power

Supply

¡

i

-

-

O

I

O

a)

,D

r

m

-

-

c

-D

z

m

ar

o

I

-

x

z

a)

a

€

ó

P.C.

-

6

5

a

=

::

O

G

_-

;c

:t

>c

z*

<€

ri

(MY-1037)

Board

{r

!

a.-

-=

:

;

ñ - ¡r

;i=--

j_==.

¡ i

?i:2

=r.;

-,"'."i

=l;{=*

=i:ñ-rs;;3ia:

N

=

=

aa

á

'b

oI

<

¡

i=¡:

;!ñ

O

c

;

i

=

;

_:

I

f=

AKAg

33i7

ie

,t

|

!

=

-

"

: ?

:

tl

í:

.

:3

q#

ffinffi

6

nmk

Ei- t

t

I

i

"¡a

Ét

-?

-

q:

i¿

:-

¡=

;3

=E

ó[

I

nEDzv*r

ll

I

till

:

-

llll

rrtl

m

-

g3

-t

<:

n

o;

n

t)<

zo

C

a)

-lo

O-

8

Dm

!D'

q,

<o

N<

cl

k\'

AO

'@o

r<

\s,

li

I

i

m

ñ

6:,

I

z

é

I

a-

c,

;

e,>

O

=

x

€<

-c

T

;

¡

x

c)

D

lÉ

:

=

C

=i

:

N

¡

C

iu

o)

¡

{:

f

-:

REC

!Ai\¡P

lND. I

¡ROM

MATEi

ll ll xll

:r ll

tl

=ll >il

>ti

9ll üt.

ilr

F.ll

dll

lll

N-LOCK

J9

11

i¡

!ñ

I

-=

=:

a

-'t

¡{

Sfr

;

Éo

r=

-c

ffi*f

F

¡¡¡

t.

F

6roro

@olP

C¡

F

o=!

,

ño>

r

i

:

9

ü¡;

o

z

.

a

20

atffi

'S¿sTT

tNC.2.

o

¡"

Page 23

-<.

Servo t

-:itroi

Board

P.C.

ieoM

colL

AKAI

o o

(IfY-1036)

PtcK

,P -.:

¡rcfoR

oF VAIN

O

my-2o3ó

-^

-'LECTOR

sc-r2H

fAoE

QpÉqñ

-'

' " '--

swlz

I

PO\,VER

,FROM

lPc,

¡ rol/ rall4

\a/\:/ €7

)

TO

BASE

FROM POtfER

PC.

FROM POWER

SUPPLY

MY-2037

soaRD

TRANSISTOR TRI

SUPPLY

MY-2037

80AR0

IRA¡ISFORi¡ER

^

t.9

o

ro

rRANsrsToR

FROM TRANSISTOR

lRr

coLLECfoR

fRI

EMITTER

6.

Equalizer

3f----'

...[I

EEC.

'."-ta6

8.

Transistor

P C. Board

lo

a o,

ao

aa

-'l

if

1¡5

{HT

¡

'?:ar

,3.

PC.

AMP

,.1(e

7

v'-::

':

AMP

; ,,rv-5¡i-

3:JO

'ROM

P C. Board

SERVO

P

c. BoARD MY-2o36

(MY-5014

+,4

i

la.,

¡

fltr

qATG€

'l

o

l.l

r0l

ino'o'

.,

l¡.,

Str

iAP€

SEL€CfORI

MY=sETFTA-

\.--

r"-ñffcto

I

zl

ÉpOV

SOARD

;i

v.r-¡ore

PC

P8 AMP

¡-.,i

!

(MY-1054)

CONTROL

A.

2" csr

REC.

AMP PC.

iz)

SOARD

@@@

B)

t)

SCARD

7.

REC. SW. P.C. Board

;l

É.

z

FZ

\(n

ñz

z(n

I

F)"

o

U

o

F

Fd

P=

z

3@3

l¡-=J

i n z ,i

Fooú

=ñ¡Fc

(r>-

->dR

toz^

693É

o-H

Fa

1

¡¡J

(MY.1044)

E

I!v

F

;=

'(

z

?¿

F

ñO

o-F

F

2l

Page 24

9.

Main Amp. P.C.

Board

(MS-5024)

I

:<

F

tn

i

I

I

I

)

10. Relay P.C.

Board

il tl

il tl

5-3

F>

eñ

óro

Pg

(MY-0008)

¡41

?

=üi

o<

(JG

¡¡J

>\

9r¿

{l

rtnn

OUTPUT 6Rcl,no

l¡J

-

at

(L

l¡J

l¿l

lrJ

=

l!

'

J

litl

tt tl

tl

il

GÚ)

olo

F\

(Jx

{€ OUTPUT

o

es

UJ

@

(9

)

E

a

T

:

F

(L

;L

s(h

o

gx

OY

lr^

=ü=

Y;

L

t!=

:ll

ll=

Qll

ll'

>t

ll

I

stl

H

i

llF

nF r,

ll!l

ltlPUT

o

G

ro@

tsS

sR

UI

=;

8=

>P

&E

<x

.r(t

oB

11

,.--

-l

(R.

HEAD

CII.)

(R.

CH.)

FROM FOWARD P8. HEAD

TO

ML.{-TI PLIJG

FROM REVERSE PB.

P8

Page 25

SECTION

2

PAFITS

CONTENTS

TABLE

Frg. I

Fig. 2 R-EEL

Fig. 3

Fig. 4 OPERATION

Fig. 5

Frg. ó

FE. 7 TENSION ARM/DIRJCTION

Frg. 8 MECH. ASSEMBLY

Frg. 9

Fig.

Frg. 1l

Fig. 12 SERVO

Fis. 13

Fig. 14

Fig. 15

Fig 16 AMP. ASSEMBLY

Fig. 17

INDEX

HEAD BLOCK

MOTOR/REEL

MAIN MOTOR BLOCK

PINCH ROLLER

IMPEDANCE ROLLER

POWER

REC.,

l0

PB. P.c. BOARD

EQ. P.c. BOARD

POWER

MAIN AMP.

FINAL ASSEMBLY

SLJPPLY

P.C. BOARD

OSC.

P.C. BOARD

SLJPPLY

(M95024)

OF

TABLE

BITOCK

PLLJNGER/QUCK

BLOCK

BLOCK

BLOCK

(MY-5016)

(MY-5017)

(MY-s036)

(MY-s014)

P.c. BOARD

BLOCK

BITOCK

BLOCK

LIST

BLOCK

BLOCK

Sw.

BITOCK

BIJOCK

BLocK

(MY'2037)

BLOCK.

Sw.

BLOCK

. . .

BLOCK

24

25

26

27

. .

29

30

30

3l

33

35

36

37

38

38

39

39

4l

42

23

Page 26

FIG.

1 HEAD

BLOCK

_WhenorderingpaÍs.pleasedescribePartsNumber.SerialNumber.andModelNumberindetail.-

24

Page 27

FIG. 2 REEL MOTOR/REEL TABLE

BLOCK

=_1

'--ib

Sche¡ratrc

Ref.

rarts

No.

No.

r-2Ex HZ583l'76

r-29 25411816

l-30 MHó25094

zs3ó9900

1-31

r-32 EA625138

-33

I

l-34x

-35

l

l-3ó

EOE

EP62 I

EDó24903

E2625r21

25422016

l-37x EA382713

t-38 MHó25083

g

l-39 2W416698

Description

RE4-ó Terminal

pan

Screw,

Relay

Screw,

Relay

Relay MTS-2

Silicon

Relay Shield

Screw.

Head Connector

Double

Nut M4

head 2x3

Prop

pan

head 3x8.

P.C.

Board

Diode

pan

head

Side Screw

Plate

IS24?3

3xS

P.C.

w/washer

Board

Prop

\o.

T$'-0035

\fY-0005

\{Y-0008

t;-2-26

15-3-28

\fY-0007

RDAS

\fY-0001

^.

(J

tY

I

.,

2

2

I

I

I

I

2

I

I

I

HEAD

$::'

1- l x 8H622 585

l-2

l-3

l4

-5

l

I

I-7

I

l-9 2G466312 Angle Adjust

i-lO 2W273835

l-l

r-12 2W2739

I - I 3

l-14

I - I 5 2G4663

l-ló

l-17

l-lE

1-19

I

1-2 I Z360A411

l-22

r-23

l-24x

1-25 ZS2Ol508

t-26

I-77

BLOCK

Parts

No.

Head Block Comp.

H2626E37

H2626848

MSó25072 Tape Guide

ZS4I4O44

-ó

ZS4l32O

MH578957 Tape

-E

HZS327IO Tape Guide B

I MH529233

H2532132 CH Retaining Base

256085l2

HZS32165

ZG3O33OO

HAó25105

HA625

-20

H2627

ZW4l3256

HPs3óSOl

EA4632Oó Terminal

HA532743 CH Angle A

HR55ó582 REC./ERASE

Head Base A

Head Base B

Screw. countersunk head

I Screw,

Nut M3

Head

14 Spring Washer M4

Screw,

12

Angle Adjust

PH

Retaining

Angle Adjust

Head

I l6 Head

Head

546

Screw,

Washer

PB. HEAD P4-202

Screw,

D escription

pan

Guide

Base

pan

Angle A

Angle

Shield

pan

(SPC)

P.C. Board A

pan

4xE

head

Prop

Spring

Prop

B

3xl3

head

pring

S

Base

Spring

B

3x4

head

D3.ax7.8x0.5t

head 2x4

HEAD

E

E

B

RE4.6

4x8

t'n.l.f"''

vYl

nY-0001

MY-0002

MY-0003

TD0003

TW-0006

890018

ri}00l7

TW-0008

BS-ml8

TW-0010

RD55

MY-0006

It Y-0006

MY-0010

RDA36 4

TW-0009 I

e'tv

Block

Block

(Supply)

A

3x3

head

(Take-u

head

4x

lO

head

BLOCK

Block

Comp.

Comp.

Comp.

P¡

2.3x I O

3x

1.4

Plate

t"1""''

lO

e',,

\IRK-D.|\IS,

\fc.ItY

KD.KF.IIY I

\D.KF.IlY

Rt>2i2

iR-102

3 R-108

3R-109

3R-139

6-l-9 I

KD20l7

\fR-216

\fR-216

KD20l8

\tR-269

)rR-218

\tR-260

\fR-217

\fY-1016

ItR-210

IIR-213

11R-212

}fR-21{

\D1076

6-l-t

\rR-102

I

I

I

I

I

I

I

I

I

I

I

2

2

I

I

I

I

2

2

t

I

z

.1

2

2

I

I

REEL

$::'

2-t BM3l474l

2-2x

2-3x

2-4

2-S MT2

2-6 MS342000

I

6

2

3

I

I

2

6

3

2

4

I

2-7

2-8 MT291663

2-9 2W270088

2-ro MT391225

2-rr MT495606

2-l2x MT495617

2-r3 MT405268

2-l4x 2W273718

2-l5x 2S425981

2-r6 MT4368ó0

2-r1

2-18 2G3r1496

2-t9

2-20

2-2t

2-22 25403222

2-23

2-24 ML3r4916

2-25 MT314987

2-26

2-27 M23r5000

2-24

2-30 MH317373

t

I

2

I

5

2

2

2

4

2

4

9

MOTOR/REEL

Parts

No.

8R398430

8R398441

MT488l4?

5 5420

ZG2SS633

MT3l?48s

MR317507

255t6644

25424056

MBó25566

M23t4998

MG540s5l

2-29 2W290283

Reel Motor

Supply Reel Table

Take-up

Reel Table

Reel Retainer

Reel

Reel Spring

3R'O'Ring 2.9x1.65M

'E'Ring

Reel Table

Brake

Brake

Reel Table

Earth Lug

Screw, binding

Brake

U Metal Fitting

Felt Tension

Counter

Screw,

Screw,

Screw. countersunk

Counter

Brake

Brake

Brake Band

Brake

Brake

'U'Ring

Brake

TABLE

Description

(24XO-2)

Reel Table

Disk B. RD

Shaft

l.9M

Rubber

(R) A (Take-up)

Drum

(L)

Drum

Spacer

M3

Cloth Comp.

Spring

Pulley

countersunk

pan

head

D88.4x

Belt

A

Lever

Band

Retaining

Support

Band

Spring

2.85M

Prop

Lever

25

Page 28

FIG. 3 MAIN

\IOTOR BLOCK

MAIN

Ref.

No.

3-lx

3-2 2W591543

3-3 2W605ó98

34 2W591622

3-5 SK597633

3-6 BZó00300

3-1 MV3ó88Eó

3-8

3-9 M2591644

3-lo M2597690

3-l I

MOTOR

Parts No.

BMóoo298

M2597666

MS59?65 5

254r3234

3-12

2W603786

3-13

ZtN6O3191

3-l4x

3-l5x 2W603764

3- I 6x ZWóO3??

MZ62SS71

3-17

Main

Thrust

Thfust

Felt

Cap

Detector

Steel Ball

Motor

Thrust

Ball

Thrust

Screw,

Adjust.

Adjust.

Adjust.

.{.djust.

5

Motof

BLOCK

Description

Motor

Washer

washer

Washer

Gear

Shield

Angle

Holder

Holding

pan

Washer

Washer

Washer

Washer

Shield

(SCM2-24KJ)

A

B

Block Comp.

D3

Plate

Prop

4xl2

head

(U)

(U)

(U)

(U)

plate

Block

ComP.

l3x0.2t

D4x

l3xo.5t

D4x

l.2t

D4x l3x

D4xl3xl.6t

t"1;"'e',,

iü'MY

I

h'J'i009

I

hJ_i0m

I

P-i022

I

I

KJ'7023

I

KJ.MY.TE-l

I

u-7026

I

KJ-7021

I

KJ-7029

I

2

U-70?J

4

2

2

2

\ty-10{i

é

26

?--"

I

t0

9

1,2

Page 29

FIG.

OPERATION

4a

BLOCK

N,N:::

oo'

¡o'

af'

27

Page 30

FIG. 4b OPERATION

BLOCK

OPERATION BLOCK

Parts

$::'

4-l

x 82622484

4-2

4-3

44

4-5

4-6

4-7

4-8

4-9

4-lO

4-l

4-12

4-

I 3 M2625656

4-14

4-15

4-16

4-r1

No.

MZ6268SO

MZ62S6|2

2G568934

MS62560l Lever Guide,

M2625678

MZó25ó80 Slider Plate B

Zr¡,I21OlOl

ZG62S33I Wind Spring

MSó25623 Button Shaft

I MLó25645 Record Lever

ML62

5634

25422076

2G625667

M2625746

ML625724

4-18 2W290283

4-19

MZ62S735

4-20

8P494425

4-2t

MH494414

4-22

2W2700E8

4-23

M2625757

4-24x

ED224526

4-25

25592378

4-26

ES62l9 l I

4-27x

ER589566

4-28

EAó l 5082

4-29

ET3987l l

4-30

8C220994

4-31

ER212883

4-32

ESó21933

4-33

EC2sO88s

4-34 E2623818

Description

Operation

Button

Plate

Lock

Spring

Lock

Plate

Slider

'E'Ring

Operat Lever

Shaft Angle

Screw,

Operat Lever

Operat

REC. SW. Lever

'U'Ring

Operat

Plunger

Pin

Joint

'E'Ring

Joint

Silicon D¡ode

Screw,

Lever SW. I-U2OO2

Spark

Quencher

Type)0.

REC. SW.

Transistor

Elect./C. 1O¡¡F

Carbon/R.

Push

SW.

O.OlpF(K)

Mylar

Pin For V Connector.

Block Comp.

Bracket

w/pin

A

3M

pan

head

Spring

Plate

Side

2.85M

Side Plate

Solenoid

l.9M

lODl

pan

head

I 20fl 25OWV

l¡r+

P.C.

Board

2SC94

25WV

RDI/4

UEG-ó3808

w/Base

C

3x5

B,

w/sw.

A

O?3OTHT

2.6x3

(DIP

U/L

5(QX R)

(Vert.

4.?k(J)

(Stop.

SOWV

RTB-1.54

Shaft

I

Tvpe)

Type)

(Vert.

Tvpe)

t"i;t''

MY

MY-2mt

MY-20üt

cF30n

MY-m02

MY-2009

MY-mt0

6-l

MY-1023

MY-200{

MY-206

MY-206

MY-20f7

MY-20ü

MY-2016

MY-20{

6-l-l

MY-2015

4t-l-tE

cGl206

6-l{

MY-mt7

r5-2-ll

25-t-21

{t-l-60

MY-20s

{5-l-t5

24-t2-9

J)-ltFt

25-5-t50

2{-l-t

32-l-61

o't"

-9

Ref.

No.

I

4-35

I

I

2

I

I

I

a

25432843

4-36

SBó2ó9ó2

4-37

58ó26973

4-3E

5862ó984 Operat

4-39

58ó26995 Operat

Pa¡ts

No.

Screw,

Operat

Operat

head

Pan

Button

Button

Button

Button

Description

2.6x4

(Red)

I

(Yellow)

2

(Green)

3

(White)

a

t":,;"''

MY-6012

MY-6012

MY-6012

MY-6012

o',,

)

I

2

I

I

2

I

I

I

1

)

I

I

28

Page 31

FIG. 5 PINCH

ROLLER PLUNGER/QUICK

SW.

BLOCK

PINCH

Ref.

No.

5-lx

S-2 M2625768

5-3 EPs?3658 Plunger Solenoid

54x

5-5

5-6

S-7

5-8 ZW2?0o88

5-9 ML625386 Plunger

5-lO 2W555693 Washer

5-t I ML625397

5-12

5-13

5-14

5-r5 T¡1416698 Nut M4

5-16

5-17

5-18

5-19

5-20

ROLLER PLUNGER/QUICK

Parts

No.

PINCH ROLLER PLI.INGER BLOCK

82622596

ED224550

25422076

MZ62S17O Plunger Plate

MH5339 13

M2625421 Pinch

MS625432 Pinch

2W213914

M2625443 Pinch

ZW27O/.34

MZ62S4S4 Pinch

2W334ó53

2G625465

Description

Pinch

Plunger

Silicon Diode

Screw.

Connecting

'E'

Ring

Quick

Spring Washer M4

'E'

Ring 5M 6-l-9

'E'

Ring

Pinch Roller Spring

Pluncer

Roller

Bracket

pan

head 3x5

Pin

l.9M

Lever,

D3.2x8xo.5t

SW. Lever

Roller

A¡m

Roller Shaft

Roller Plate

Plate

Roller

?M

l66OTHT-3

lOD4

w/pin

A

B

Block

Comp.

B

SW. BI-OCK

t"*:,;"'Q'r,

MY-mlg

TW-ml0

6-F9

My-lgtJ

My-1030

My-1032

My-1033

MY{03{

MY-1035

6-1{

My-ttso

I

I

|

l

7

I

I 5-28

2

t

2

l

l

I

I

I

I

3

I

I

I

MY

MY-mlE

{{-l-66

{5-2-16

Ref.

Parts No. Description

No.

SW. BLOCK

QUICK

lx

8,5622620

5-2

s-22

s-23

5-24

5-25

5-26

s-27

5-29

5-30

5-31

s-32

s-¡¡

s-¡+

5-35

s-lo

s-¡z

5-38

s-¡g

s¿o

541

s42

EZ62SlEl

8S562465

25483502

MH528513

MH527635

Ztr273756

ZGS292Ir

2W259738

mI2lOlO

M2529391

62200l

TV,l

ZW622012

ZW21OO88

MS625184

MZ582O3O

ZGS8O168

MPó2504E

ZW260OlO

SK63l

?vV621876

ZG6O832I

I

326

Quick

Quick

Micro

Screw,

SW.

SW. Pipe

Nut M3

SW.

Washer

Quick

Washer D3.l

Washer

SW. Block

Table,

SW.

SW. K-1

pan

head

Pin

Spring

(PolYslider)

'E'Ring

3M

Plate

x I 3xO.5t

D3.lx5x0.2t

'E'Ring

l.9M

Roüer

Hanger

(PBP)

Roller

pan

A¡m

H, LC

D6.lxlOxO.lt

Cap C

head

Pinch

Spring

Spoke Spring

Pinch Rolle¡

Washer

Pinch

Washer Dó.2xl3xlt

Screw,

Comp.

w/ProP

3xl3

x?xO.2

D4.l

Shaft

3xó' w/washer

i:ieortrc,-r.r,

\o.

5t

Y

VY

MY-2020

25-l-26

r-D1055

NDl051

)¡D1053

6-l-9

){D1063

6'l-9

MY-1006

TDlolE

Tp2o?7

LC-321

MS-6020

rr

I

I

1

2

I

I

I

29

Page 32

FIG. 6 IMPEDANCE

ROLLER

BLOCK

IMPEDANCE

Parts

*::'

Glx BIóOO355

6-2

ó-3 MZSg7Oll

64 MV597082

ó-5 MZ6O61|2

6-6

6-i 25499331

ó-8 EZ6O6lOl

6-9 M2591137

ó-lO MS59?148

ó-l

6-12 MZS97|12

ó-f 3 MZ597ISO

ó.f 4 SE597lól

ó-15 ZW6OlO75

ó-ló

6-17

ó-rE

6-19 ZS2OI

6-20 MI59?183

6-21

6-22

6-23x

6-24x

6-25

6-26

6-21x

6-28

6-29

ó-30

6-3 I

No.

ZWóO3990

M2597O93

r ZW6O4OI2

2W273633 Earth Lug

25484828 Screw.

ZG646O2O Z Nm

l50 Screw,

25593196 Set Screw,

I

M

M2597126

2W649618

ZlMzTOlOl

MVs378ó2

2,5422016

MH625162 Z

M2596823 Thrust

t 5 Impedance

R59?

Z]NS932l2 Washer

25421806

ROLLER

Impedance

Metal

Impedance

Sensing

Stopper

Metal Case,

Screw,

Insulator

Sensing Arm

Sensing

Washer D4.3xl

Sensing

Sensing

Insulated

Washer D4.lx?xo.lt

Flywheel

Roller

Washer D4xlOxlt

'E'Ring

Steel Baü D4

Screw,

Block

Screw,

BLOCK

Description

Roller Block Comp.

Nut

Base

Metal KJ-20?¡

Shaft

Rubber

w/metal

pan

head

Collar

Shaft

(Lower)

Post

(Upper)

Post

Collar S

M2.3

binding head

Spring

truss head

hexason

Roller,

Plate

3M

pan

head

Prop

Plate

DExlt

pan

head

t"-:,;"'Q'r,

KJ.MY

6-3-9

A-nn

KJ

2.3xS

(L) KJ-m39

lxO.lt

2.3x25

(black)

3x6

socket

(Flat/p.)

3xó

w/shaft

3x5

3x8

KJ-mo

KJ-mn

KJ-m6

K¡-Al

KJ'20{0

KJ-2¡3t

K¡-439

MY-2059

KJ'20{l

KJ-m$ I

KJ-m35

6-l- 9

MY-tofl

KJ-tm{

t

I

I

)

I

3

I

I

I

3

I

I

I

I

I

I

I

I

I

2

l

I

I

I

3

3

I

I

3

FIG. 7

BLOCK

-€

------E-

i

TENSION

@l

ARM/DIRECTION

sw.

TENSION

S:fl

No.

7-lx 82622618 Tension

1-2

7-3 MS625825 Tension

74

7-S M2627265 Tension

7-6 MZSlOlgl

7-1 ZWóO10?5

?-8 2W419646

7-9 ZIN2TOIOL

7-lO ZG6|491O Tension

7-ll 85562465 Micro

7-12

7-13 Zlff273756

1-l4x

7-t5 MZ6l498l Di¡ection

7-16 M2316822 Insulator Coüar

7-17

7-r8 ZW3ló8OO Earth Lug

7-19 25464692

7-2O 2W273688

7-21

7-22 ML614992 Di¡ection Lever

7-23

1-24 Z3417216 Screw,

7-25

7-26 SBóf

7-21

7-2E 2W535094 Decorative

1-29 ZS2OO395 Screw. countersunk

7-3O

ARM/DIRECTION

Parts

No. Description

TENSION ARM

MZó25803 Tension Arm Table,

MSól5014

2,5422965 Screw,

DIRECTION

8S622642

HZS42O92 Insulated

ZW5ó3218

ML6l5003 Di¡ection Lever B

2G317177

4428

ME5804ó5

ZS422016 Screw,

BLOCK

A¡m Block Comp.

Shaft

SW. Cam,

Rubber.

D4.lx7xo.lt

(SPC)

Da.5x9.8xO.5t

3M

Spring

SW.

K-l

pan

head

A

Tension Shaft B

wcight

Cushion

Washer

Washer

'E'Ring

Nut M3

SW. BLOCK

Direction

Screw, binding head

Nut

Washe¡

Pull

Power

Tension Arm,

SW. Block Comp.

SW.

Washer

M2.6

M2.3

(Bake)

pan

head

Spring

Button B

Washer

pan

head

Table

D3.2xlOxlt

w/guide B

SW. BLOCK

w/metal

w/counter

RD

3xl5

B

2.3xó

A

3x4

3x6

head

3x5

r.ri;,'.

MY

vY-nn

\{Y-m2{

MY-2032

MY-n25

RD?7E

6-l{

MY-á}6

A--t-ü

MY

$l-ñn

MR.U5

MC-(P13

MY-A¡2t

MY.AA

MR{7

A5-ll2l

TD2019

TV-nn

e,,,

I

I

I

2

I

I

I

a

I

30

Page 33

FIG. 8

\¡OO)rr

-:-.a-)ll

rli

irl

l

1

ri

MECH.

I

ASSEMB

3l

Page 34

\ÍECH.

$::'

8-l

8-2

E-3x

84

8-5x

8-ó

8-7x

8-Ex

8-9

E-10

8-l I

8-r2x

88-14

8-15

8-16

8-l?

E-lE

8-19

8-20

8-2 I

8-22

8-23

3-24

3-2

8-26

E-21

8-28

8-29x

8-30

8-31

8-32

8-33

8-34

8-35

8-36

E-3?

8-3E

8-39

840

841

842

843

E44

ASSEMBLY

Parts

YIZ627l42

!fH625l40

ZS4

l32Ol Screw,

\{H581927

2W213756

\f

2625l5l

ZW4 lóó98 Nut

l\{H6251ó2

25422076

MH625173

\12625498

2W273156

l 3 MHó2

MH317373

ML39ó8lO

ML314976

ML62S2O6

2W29O283

MT3l49E?

M2314998

l\f

Z3l50O

Z3411216

!\12397080

\f

23l4óOS Spring

5 ZG54O55I

If

2582030 Spring

ZG62S2|7

ZG3lll14

ER589566

M2625228

MLó25230

25432843

2W625241

ZS42l80ó

MZ62S3O7 Spring

N12625252

2G625263

M2625214

ML625285

ML625296 Wind

MZó253rE

M

ZB l0l9 l

ZG456IE6

M2625342

No.

5

l9

5

BLOCK

Description

ir{ech.

Frame

Head

Shifter

Nut M3

Shifter

Z Block Prop

Screw,

Lever Prop

SW.

Nut

Brake Lever Prop

Brake

Brake Lever

Brake

Brake

'U'Ring

Brake Band

Brake

Brake Band

Sc¡ew,

Spring

Brake Spring

Lever Spring

Reset

Spark

Type)

FF Plate

SW.

Screw,

Graduated

Screw,

Play Plate,

SW. Spring

RWD Plate

Play

Brake Plate,

C ushion

Lock Leve¡

Shifter Plate.

Prop

Base

pan

hed

Guide Post

Lever Post

M4

pan

head

Post

M3

Lever Prop

B

Lever

A

Lever

C

2.85M

Band Retaining Plate

Support

pan

head

Rack

Rack, MR

Hanger

Lever Spring

Quencher

O.l¡¡+

Lever

pan

head

Washer

pan

hed 3xE

Rack

w/pin

Lever, w/pin

w/pin

Lever,

w/pin

R ubber.

Spring

w/pin

4x8

3x5

3x4

(Dip

U/L

l2Of¿ 250WV

2.6x4

RD

hcnat

Sc

\o.

yY-1001

\tY-1002

TD-1off

MY-1003

\fY-100{

\fY-1005

MY-t039

MY-1007

MR-102

KD.IO3E

MR-210

MY-1008

6- l-l

vR-2t3

MR-212

\tR-21{

KD

\fR-10{

\D

iD10l8

\tY-1010

ED2l9

{ l- l-60

vY-l0ll

vY-1012

!{Y-1013

vY-1020

MY-t0l{

MY-10t5

MY-t0t6

MY-1017

MY-10t9

MY-1021

RDz?t

cc-llt9

\tY-102{

r

c

Q'tY

-1010

1076

Ref.

No.

8-45 ZW58O I

846

847 ZG535lO5 Tension Arm

848x M

849

8-50 M2625364 Connecting

8-51

8-52x ZG58O?ó8

8-53 MZ6255OO

8-54 ftI27OO88

8-55 MZ625Sll Reverse

8-5ó HZ3l5O9O Reverse Guide

8-57

8-58 EZ62SS22 SW. Angle A

8-59

E-óO 254835O2 Screw,

8-61 MCó21E87 Counter

8-62

8-63 ER376435 Spark

8-64

8-ó5 ECS2O626

8-óó EZ62SS33

8-67 ES573478 Micro SW. K-3

8-ó8

8-ó9 E2625544 Power SW.

8-7Ox

E-?l

8-?2x

8-?3

8-74x EC565896

8-75

8-76

8-77

8-78

8-79

&EO M86255óó Counter Belt D88.4x1.4

E-Elx

8-82 EJ25

8-83

8-E4

Parts

No.

Guide

73

2W420682

23 14673 Reel

\f

L625353

ZG62S37S

2,5344463

ES57345ó

M2625487 Counter Base

ES5624ó5

2S608264 Screw,

EAó264 I I

ES4?9395

ES62l l7E Push SW.

EC55l

58614428

25325495

MZ62SSSS Speed SW. Table

ESó21898

25432614

8J20598ó Cramp Terminal

EJ255l l5 Lug Plate

ERs54556 Cement/R. 5W

Washer

Shifter Lever,

Play Spring

Spoke Spring

Quick

'E'Ring

Set Screw, hexagon

Micro SW. K-2

Micro

MP/C.

SW. Angle B

Power

Push

Ceramic/C. NB82l

l60

Ceramic/C. DPóóOO

0.0lpF(P) l.4kwv

Power

Tapping

Slide

Screw,

Lug

5O93

Motor Shield MR-123

SW. TV-3

SW.

Plate

Descriptron

Washer

(Nylon)

D4.2x9x0.5t

Spring

wlpin 2

Plate

Plate

l.9M

Guide Table.

pan

Quencher

SW. K-l

(3+l)¡rFx2

pan

SW.

Button B

pan

3xl3

head

MP-49O-21

U/L

O.lr¡tl2Ol¿ 25oWV

(Lug

3x25

head

Table

P.C.

Board

JHs

S-J4ló2

o.olpF(Z)

Screw #2

SSC342B

3x3

head

2-SD

VB

I L I

VB2L2

39Í-l(K)

(Wire-wound

socket

2sowv

Type

(CEE)

YZ

YM

3x6

w/prop

(cup/p.)

Uni/D.)

l.4kwv

(JPN,

4x6

AC

cAS)

Type)

t'o*llt't

Tll055

T\{-207E

yY-1025

VY-1026

uy-t0?7

¡¡,Zi77

My-1010

6{-9

\{y-10{l

RDZZ5

uY-10r2

25-t-30

9-l-3E

$Y-1038

1ll-35

2s-l-26 I

2{-}7{

yY-10r3

25-r-31

$Y-l0s

vY-105{

?s-5-62

zttl{5

2{-5-55

2{-5-5E

.{5-5021

t{Y-10{5

25-3-t09

yY-10{6

32-l-E

33-{-l

{-3

33-

::-i6-3

e'tt

I

I

3

8

I

I

2

I

I

2

.,

I

I

t

I

2

I

I

I

I

I

I

I

I 5

I

I

I

32

Page 35

FIG. 9

POWER

SUPPLY BLOCK

-q

ts*' [Á

\ \ n,,s

33

Page 36

POWER SUPPLY

BLOCK

Parts

$:1'

9-l Nlz6270r1

9-2

9-3x

9-4x

9-5x

9-6

9-7

9-E

e-9

9-lo

9-l

9-t2

9-l 3 ZS32s49s

9-r4x

9-l5x

9-l6x

9-l7x

9-lE

9-l9x

9-2Ox

9-2lx

9-22x

9-23x

9-24x

9-2Sx E2623231

9-26x

9-27x

9-2A

9-29x MZ62SESB

9-3Ox

9-3r

9-32

9-33

9-34 8T621786

9-35

9-36

9-31

9-38x

9-39x

9-4Ox

94lx

942

943x

9-44x

9-45x

946x

941x

94Ex

949

9-5Ox

9-5lx

9-52x

9-5

v-i4x

9-55x

9-5óx

9-57x

9-5Ex

9-59x

No.

8T621922

8T621944

8T621988

l99O

BTó2

M2627636

254240s6

82486611

zw4l3l88

Ec364858

I ER36s0ló

EC593?63

8D224512

EC4Ol58O

2W562416

Z)N2738O2

ER5?5ó40

E2632068

MZ6l5lO4

EJ328364

TY'1272122

2W56O231

Z\t1393164

M2623913

E2624O47

M262686r

M2647133

EJ233370

ZS4Er724

8A62807s

ZS42l80ó

W.t273156

2,5422076

25462925

82614586

2S379350

2,5455207

EF563?03

EF5ó3?03

EFSó3681

EF511631

EFó02550

EF6O|942

EF624543

EJ63l94s

E7246936

8W374E94

EW524845

3x EWS I ó600

EWó04585

8J205986

85479395

ESó21

178

EJ297O6ó

EJ3?3634

Discription

Power

Chassis MY-20R

Power

Power

Power

Power

Trans. Shield

Screw,

Trans. Reinforcement

Nut

M4

Elect. 330¡¡F

Carbon/R.

!{P/C.

Tapping Screw

Silicon

Elect.

Earth

Toothed

Cement/R.

Jack

SP

Jack

I'lic.

Toothed

E

Jack Nut

Washer

Mech.

Mech.

Cord Retainer

VS

Table

VS

Table B

VS

Base C

Socket

ISO

Screw,

Transistor

Transistor

Screw,

Nut

lv{3

Screw,

Tapping

Fuse

ISO Screw,

Tapping Screw

Fuse

Fuse 2A 2sOV

Fuse lA 25OV

Fuse ULMF6IM

Fuse

Fuse

Fuse ULMFólM

Strain

Strain Reüef

U/L

AC Cord

Power

Power

Cramp

Push

Push

Mate-N-Lock

SocketContact

MYT-I

Trans.

Trans. MYT-lA

Trans. MYT-l I

MYT-12

Trans.

Plate

pan

head 4x

lóOWV

RD l/4 220k(J)

3.5+ 1.5,¡F

(Lug

d2 3x6

Diode

582

22OO¡¡F

SOWV

(Lue

(230)

Lug M3

Washer

Lock

H(20+20)

B(43+220+

Silk Plate

Jack 2PMJ3

Table

2.A' 25OV

l.25AT 2sov

(SEMKO)

AC

SW. TV-3

SW. S-J4162

(230)

Bracket

Lock Washer

D9.3xl3xO.5t

(23O)

(SUP)

D9. I x I l.7xO.2

Harness

Harness

MY-2

A

(CSA,

(JPN)

S-lEOtO

truss

P.C.

Board

P48

T I

pan

head 3x8

pan

head 3x5

Screw

r¡2

MY

pan

#2

(JPN)

(JPN)

Relief SR4N-4

SR-óW-1

Cord 3M

(J)

2.5M

VM-OOóS

Cord

Cord

BSI

Terminal 2-SD

JHs

Plug

l4EO3O4_O

(230)

(JPN,

(CEE)

l0

Plate

(Lug

(Insu.

I SoWV

Type

(230)

Type)

M3

(230)

(230)

M9

(JPN,

CSA.

CEE)

(Volt.

Selector)

3x6

head

(BR)

ax8

head 3x6

(BR)

3x5

25OV

lA

(CEE)

630MAT

25OV

2A

(WG'

(CEE)

(JPN,

(CEE)

Housing

óIIlS-l

CSA)

TYPe)

Type)

Uni/D.)

l 80)K

(csA)

(CEE)

(csA)

3

(230)

B

AC

(230)

(230)

(230)

5t

(230)

CEE)

core)

CSA)

3P

(230)

"t:,;"''

38-{-3t{

18-{-315

3E-{-3r6

J8-{-3lz

My-20S3

LF-S2?

24-ltrsf

21-9-8E

{5-2-20

21.1tr11

35-1ts5a

MY-2056

MY-m{7

3l-2-n

?s-6-Ar

26-6-2n

2-1-at

MY-A30

MY-20S

MY-2030

{tr2-3

MY-205{

{5-t-197

MY-A{3

391-f)

39.1-50

3$t-50

39-t-{5

39t-53

39-¡-i3

3e-t-{s

Z-I-tg

2-7-8

26'3-19

26-3-31

26-3-Zt

26-3-3?

32-l-E

2s-s-62

2s-s-lls

s2_l-s

52-t-l

e'r,

(23O)

(CEE)

9P

CAS)

CSA)

(CEE)

(CEE)

CSA)

t".:;"'Q',,

3l-{-ls

I{Y-m55

3A-7{5

2s-3-66

MY'm56

vY-20{0

vY-2-{l

MY-m12

33-2-16

33-2-17

l3-2-1S

33-2-{9

vY-?o{s

vy-mrO

I

t

I

I

9

I

I

I

I

I

I

a

a

I

Ref.

Parts

No.

9óOx

9-ól M26294r4

9-62x

I

9-ó3x 2W273881

I

9-64x

I

955x ZS4l32Ol

.,

946x

2

947 ES4794Es

a

9óEx

9ó9x

9-?0 EZ6l 505

9-1r E26l50óO

I

I

I

I

I

2

I

4

t

I

I

I

I

,,

I

I

I

I

1

4

2

4

4

2

4

9-12

9-?3x

9-14x

9-75x

9-76x

9-17x

9-78x

9-?9x EAó 15093

9-EOx 8A614632

l8

No.

EJ364915

M2259233

2W273892

2W416698

?8

ZS414l

SMó4?245

EZ6rSOlr

EJ3OO5O8

EÍ313634

EAó24521

EA624532

E4624554

EA624565

8

Description

\f

ulti-Jack

Reinforcement Bracket

Wire

Earth

Toothed

Screw.

Nut M4

Slide

Screw, truss head

Cycle

P.C.

P.C. Board

P.C. Board Holder C

Mate-N-Lock Plug Housing

SocketContact6lll5-l 52-l-l

Fuse P.C. Board MY-l-A

Fuse

Fuse

Fuse

Fuse

Fuse

10P

PBOI-lOS-2482G

Band C

Board

(CEE)

M4

Lug

Lock

pan

head

(CEE)

S-l

SW.

Name Plate

Holder A

Holder

P.C.

Board

P.C.

Board

P.C.

Board MY-2-B

P.C.

Boa¡d

Washer M4

ax8

3x5,

B

MY-t-B

MY-2-A

MY--

P.C. Board MY-2

(CEE)

w/washer

I4EO274-O 52-l-7

(JPN,

(JPN,

(JPN,

(CEE)

34

Page 37

FIG.

REC. OSC.

IO

P.C. BOARD

i

¡

-l

¡l

tl

.a

I

(MY-50I6)

:a

BLOCK

tl

.É

REC..

Symbol

No.

lO-lx

lO-TRlto4

1O-TR5to?

lo-Ll

to-L2

ro-vRl

10-vR2

lo-R39

10-R40

r0{1

lo-c2

lo{3

lo{4

l0{5

o-c6,7

l

o-c8

l

OSC.

Parts

8462272r

ET52340s

ET4?8001

EO32l2s4

8O3833ó5

EVó22078

8V522791

ERsl50?O

ER426892

EC290520

E.C220618

EC4328

EC290s20

EC220364

EC39956s

EC3200s

P.C.

No.

l 0

BOARD

Description

Rec., Osc.

Transistor

Transistor

Ferri lnductor

OSC.

Double

Semi-fixed/Vol.

Metal

Solid/R. RCI/2

Capacitor,

vFM lOOPF(J) 5OWV

Elect.

Elect.

VFM IOOPF(J) sOWV

Elect. 100¡¡F 6.3WV

VFM

Elect. lOuF l6WV

l

(MY.sOI6)

P.C.

2SC45

2SC94 5(PXQ)

Coil OT-204

Vol.

Oxide

Vertical Type

4?¡rF

lO¡rF l6WV NL

22PF(J) sOWV

Comp.

Board

8 LG(C)

FLTH 5.6MH(J)

V24L5DPHN

Film/R.

2sWV

V8K4-l

2W

2.4k(J)

A5Okx2

l

soo(K)

BLOCK

Q'tv

20 kB

soWv

5OWV

SOWV

2sOwV

sowv

ttt.:totttt

e'r,,

l

2

2

)

)

2

2

2

2

2

a

)

2

2

2

2

2

I

')

I

Symbol

No.

I

8

4

2

lO-C9

ro-cro

lO-Cl

lO-Cl2

I

1O-Cr

2

)

I

I

2

,,

,,

2

2

4

lO-C14

lo-cls

lO-C16

lO-Cl?

lO-Cl8

lo-Cl9

lO-C2O

lO-C2l

lO-C22

lO-C23

1O-C24

I O-C25

lo-C26

,,

ro-C21,28

lO-C29

I

3

Pa¡ts

No.

8C32911r

EC3712r2

EC32OOSI

8C22O678

EC329111

EC399s6s

EC29O52O

EC379|1O

EC32OO5l

8C32911r

EC389496

EC22OlSl

EC320O5l

F;C22O994

EC405898

EC25084l

EC558202

8C55823s

EC25O84l

EC45OO55

Resistor

Carbon

Description

Elect.4?¡rF

VFM

Elect.

Elect.4?PF

Elect.

vFM 22PF(J)

VFM I0OPF(J)

Mvlar

Elect.

Elect'

Mvlar

Elect.

Elect.

Elect.

Stvrol4?0PF(J)

Mvlar

Trimmer

Stvrol

Mvlar

Elect.

6.3WV

4?PF(J)

lóWV

t0¡¡F

2swl/

4?gF ó.3WV

0.1¡¡F(J)

l6WV

lO¡¡F

4?PF 6.3WV

0.068t¡F(J)

lOO¡rF

lóWV

l0¡¡F

25WV

10PF

o.0lpF(J)

TM-8OA

l8ooPF(J)

o.0l¡,rF(J)

2sWV

1¡¡F

Omitted

sOW\/

5OWV

5OW1/

SOWV

2sWV

35

Page 38

Frc.

I I

p.B.

.Rlb

-ib

R6b

;R

1b

-R2b

-?

3b

*?,1h

-^¡

p.C.

BOARD (My-s017)

BLocK

ri

,i¡

PB.

P.C.

Symbol

No.

1l-lx

Il-2x

I l-TRlto4

l l-TR5.6

I t-Dl

l l-D2

l

l-Ll

l

l-Tl

rr-vRl

l l-vR2

l l-vR3

l{l

I

l l-c2

l l-c3

l

l-c4

l

l-c5

l

l-c6

l

l-c7

l l-c8

l

l-c9,10

l l-cl

I

l l-cl2

l

l-ct3

I l-cr4

l

l-c

l5

BOARD

Parts

No.

8A622732

BA622743

ET523405

ET47800

ED5?04?s

E.Dzt9464

EO49ó3ór

8T517274

EV464220

EV622967

EV4ó4196

EC22067E

EC4328 I O

8C290520

EC46?

EC290s20

8C32971r

EC3200s

8C38948s

EC2506E3

EC220678

EC329Es0

EC4328lO

E,C32977r

EC 399

r

l 33

I

56 5

(}ÍY.5OI7)

Description

PB.

P.C.

Board

PB.

P.C.

Boa¡d

Transistor

Transistor

Zener

Germanium

Inductor

Headphone

Semi-fixed/Vol.

2-axial

Semi-fixed/Vol.

C:pacitor,

Elect.4?¡¡F

Elect.

vFM

VFM

vru

Elect. 47¡rF

Elect.

Mylar

Mylar

Elect. 47pF

vFM

Elect.

Elect. 47pF

VFM

2SC45

2SC94s(pXe)

Diode WZ-O7S

Diode lN34A

óO7OGE

Trans.

2-throw/Vol.

Vertical

2sWV

lO¡¡F

l6WV

looPF(J)

68PF(J)

looPF(J)

6.3WV

lOr¡F

l6WV

O.o l8r¿F(J)

O.OO22¡¡F(J)

2sWV

22OPF(J)

lO¡¡F

lóWV

6.3WV

22PF(J)

BLOCK

Comp.

(MY-so

Comp.

(MY-so

8LG(C)

23

N

V8K4-l

(Friction

V8K4-l

Type

NL

sowv

sOWV

sowv

S0WV

SoWV

sOWV

NL

(230D)

I

?)

I

7)

MH(J)

l6-5355

S0

50

kAx2

Type)

2kB

(2

30)

kB

Q'ty

Symbol

No.

l l{16

I

I l{17

l l{18

I

I l{19

8

l

4

2

2

2

)

't

I

l{20

l

l{21

rtc22

l

l{23

Parts

No.

Description

E,C290520

EC32OO5l

VFM

Elect.

EC22O364 Elect.

EC45OO5s

EC32OO5l

Elect. lsF

Elect. lOpF

EC45O527 Elect.

E,C329771

Elect.

8C368256 Elect.

Ca¡bon Resistor

Omitted

TOOPF(J)

lO¡¡F

IOO¡¡F

soWV

l6WV

ó.3WV

2sWV

l6WV

4.7¡,rF

2sWV

4?r¡F

6.3WV

0.47uF 2sWV

Scbc¡¡trc

)to.

Q'tY

1

)

)

t

1

1

a

t

2

2

2

)

2

,)

2

2

)

4

J

2

2

2

1

36

Page 39

FIG.

1)

SERVO P.C.

BOARD

(MY-20361

BLOCK

SERVO

slmbol

l2-lx

l2-TRl.2

l2-TR3.4

2-TR5

t

l2-TR6

l2-TR7

l2-TRE

l2-TH

I

l2-D

I

l2-D2to5

l2-vRl

l2-vR2

r2-2

r2-3

124

r2-s

12-6

r2-7

l2-R20

l2{l

124.2

l2-c3

r2{4

r2-cs

L2-C6

t2-c7

l2-c8

124.9

l2-cl0

l2{l

l

r2-cr2

r21r3

P.C.

BOARD

parts

No. Description

8A622574

ET4?8001

ET399846

ET5 38

I s4

ET39984ó

ETó2386?

ET47800I

ED59335

EDss?447

ED224548

Ev62l9s5

EV62r966

ZS42l EOó

2W273156

EZ6tsO47

2s422016

EZó

I

5060

EZ6r

sol

ER593346

Ec2sr29l

Ec2str22

EC250s82

EC331828

EC2sr

r22

EC2505E2

Ec311793

EC557166

EC45005

EC3200sl

Ec220l5l

Ec250885

EC34673s

(MY-2036)

Servo P.C.

(MY-2036)

Transistor 2SC945(PXQ)

Transistor 2SC945(Q)

Transistor 2SA5ó4(QXR)

T¡ansistor 2SC945(Q)

Transistor

Transistor

7

Thermister 34D2

Silicon

Silicon

Semi-ñxed/Vol.

Semi-fixed/Vol.

Screw,

Nut

Heat-sink

Screw,

P.C.

r

P.C.

Cement/R. 2W 330A(K)

(Wire-wound

Capacitor, Vertical

Mylar o.l¡¡F(K)

Mylar o.027pF(K)

Mylar

Elect.

Mylar

ylar

l\f

Mylar

Solid

Elect. l¡rF

5

Elect.

Elect.