Page 1

AKAI CT-2159 U

General Information

Also Covers CT-2159UT

Recommended Safety Parts

Item Part No. Description

C901 026-473212-21 METALLIZED POLY CAP. 0.047MFD AC250V 20%

C902 026-474271-2A METAL POLY CAP. 0.47UF 275VAC +1-10%

C914 123-222467-41 CERAMIC CAPACITOR 0.0022 MFD 400V +-20%

F901 082-223150-23 BFUSE 3.15A 250V 5 X 20MM TIME LAG HBC

L902 001-190005-95 LINE FILTER ELF18DG15 (39MH) TECHCON

R401 013-688305-85 FLAME PROOF FUSING RES. 0.68 OHM 1W +-5%

R402 013-688205-82 FLAME PROOF FUSING RES. 0.68 OHM 1/2W 5%

R425 013-688305-85 FLAME PROOF FUSING RES. 0.68 OHM 1W +-5%

R426 013-688305-85 FLAME PROOF FUSING RES. 0.68 OHM 1W ±-5%

R427 013-688305-85 FLAME PROOF FUSING RES. 0.68 OHM 1W +-5%

R434 013-688305-85 FLAME PROOF FUSING RES. 0.68 OHM 1W +-5%

R507 013-229305-82 FLAME PROOF FUSING RES. 2.2 OHM 1W 5%

R901 013-479605-54 CEMENT RES. 4.7 OHM 5W 5%

R914 013-338405-85 FLAME PROOF FUSING RES. 0.33 OHM 2W +-5%

R916A 013-825305-92 HIGH VOLTAGE RESISTOR 8.2M OHM 1W S%

RLY401 006-210012-02 RELAY 12V VS 12MB 12VDC TV-5 TAKAMISAWA

S901 046-100006-00 POWER SWITCH ME-7 DPST 70063-300 PREH

TH901 014-212322-01 PTC THERMISTOR 2322 622 96211

31 071-440254-00 100” VDE APPROVAL W/PLUG

(A51EBV13X01)

R439 013-828305-85 FLAME PROOF FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20/21 PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRAMSFORMER EI-41 BCK-4002WH SANGOIANG

CRT SOCKET 061-520001-08 CRT SOCKET GZS10-2-102G “HUAYANG” CRT SOCKET

R507 A 013-129305-82 FLAME PROOF FUSING RESISTOR 1.2 OHM 1W 5%

(A51EAL155X01)

R439 013-828305-85 FLAME PROOF FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20”/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRAMSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-520001-08 CRT SOCKET GZS10-2-102G “HUAYANG” CRT SOCKET

R507 013-399305-85 FLAME PROOF FUSING RESISTOR 3.9 OHM 1W 5%

(54SX503Y22-OC01)

R439 013-828305-85 FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20/21’ PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRANSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-540007-01 CRT SOCKET GZS8-17 FIRST EAGLE CRT SOCKET

R507 013-399305-85 FLAME PROOF FUSING RESISTOR 3.9 OHM 1W 5% (KOA)

(A51AEZ90X01)

R439 013-828305-85 FLAME PROOF FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20”/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRAMSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-520001-08 CRT SOCKET GZS10-2-102G “HUAYANG” CRT SOCKET

R507 013-229305-82 FLAME PROOF FUSING RESISTOR 2.2 OHM 1W 5%

(A51AGP90X24)

R439 013-828305-85 FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20”/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRANSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-540007-01 CRT SOCKET GZS8-17 FIRST EAGLE CRT SOCKET

R507 013-479305-82 FLAME PROOF FUSING RESISTOR 4.7 OHM 1W 5% (KOA)

(A51AGP90X13)

R439 013-828305-85 FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRANSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-540007-01 CRT SOCKET GZS8-17 FIRST EAGLE CRT SOCKET

R507 013-479305-82 FLAME PROOF FUSING RESISTOR 4.7 OHM 1W 5% (KOA)

(A51AGP90X26)

R439 013-828305-85 FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20”/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRANSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-540007-01 CRT SOCKET GZS8-17 FIRST EAGLE CRT SOCKET

R507 013-479305-82 FLAME PROOF FUSING RESISTOR 4.7 OHM 1W 5% (KOA)

(A51JSW90X10)

R439 013-828305-85 FLAME PROOF FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20”/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRAMSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-540007-01 CRT SOCKET GZS8-17 FIRST EAGLE CRT SOCKET

R507 013-399305-85 FLAME PROOF FUSING RESISTOR 3.9 OHM 1W 5%

(A51EER11X46)

R439 013-828305-85 FLAME PROOF FUSING RESISTOR 0.82 OHM 5% 1W

T402 101-220009-04 20/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRAMSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-520001-08 CRT SOCKET GZS8-17 FIRST EAGLE CRT SOCKET

R507 013-159305-82 FLAME PROOF FUSING RESISTOR 1.5 OHM 1W 5%

(A51KQK69X01)

R439 013-918305-82 FLAME PROOF FUSING RESISTOR 0.91 OHM 5% 1W

T402 101-220009-04 20”/21” PAL FLYBACK FCM-21A004 SAMSUNG

T901 001-418721-94 TRANSFORMER EI-41 BCK-4002WH SANGQIANG

CRT SOCKET 061-520001-08 CRT SOCKET GZS10-2-102G “HUAYANG” CRT SOCKET

R507 013-229305-82 FLAME PROOF FUSING RESISTOR 2.2 OHM 1W 5%

102-321001-10 VIDEO COLOR

(CORN DEVICES)

102-321001-17 PHILIPS

(CORN DEVICES)

102-321001-13 CAl HONG

102-321003-19 CHUNG HWA

(CORN DEVICES)

102-321004-19 CHUNG HWA

102-321002-19 CHUNG HWA

102-321005-19 CHUNG HWA

102-321001-12 ORION

(CORN DEVICES)

102-321004-16 SAMSUNG

(CORN DEVICES)

102-321003-16 SAMSUNG

(CORN DEVICES)

Alignments

I. Before Adjustment and Maintenance

A. Don’t short any two soldering points or

connect any component while TV set is power

on.

B. Pull out power plug before maintenance.

C. In order to ensure safety all components

replaced should be identical with originals.

(For further details, refer to the component

name and component No. in PARTS LIST.)

D. Must warm up for 30 minutes or more and

degauss CRT thoroughly with demagnetiser

before alignment.

II. Equipment for Adjustments

a. Pattern Generator (PHILIPS PM 5518)

b. Digital Voltmeter (Inner Resistance ≥ 10MΩ)

c. High Voltage Meter

d. Demagnetiser

e. DC Regulated Power Supply

f. Oscilloscope

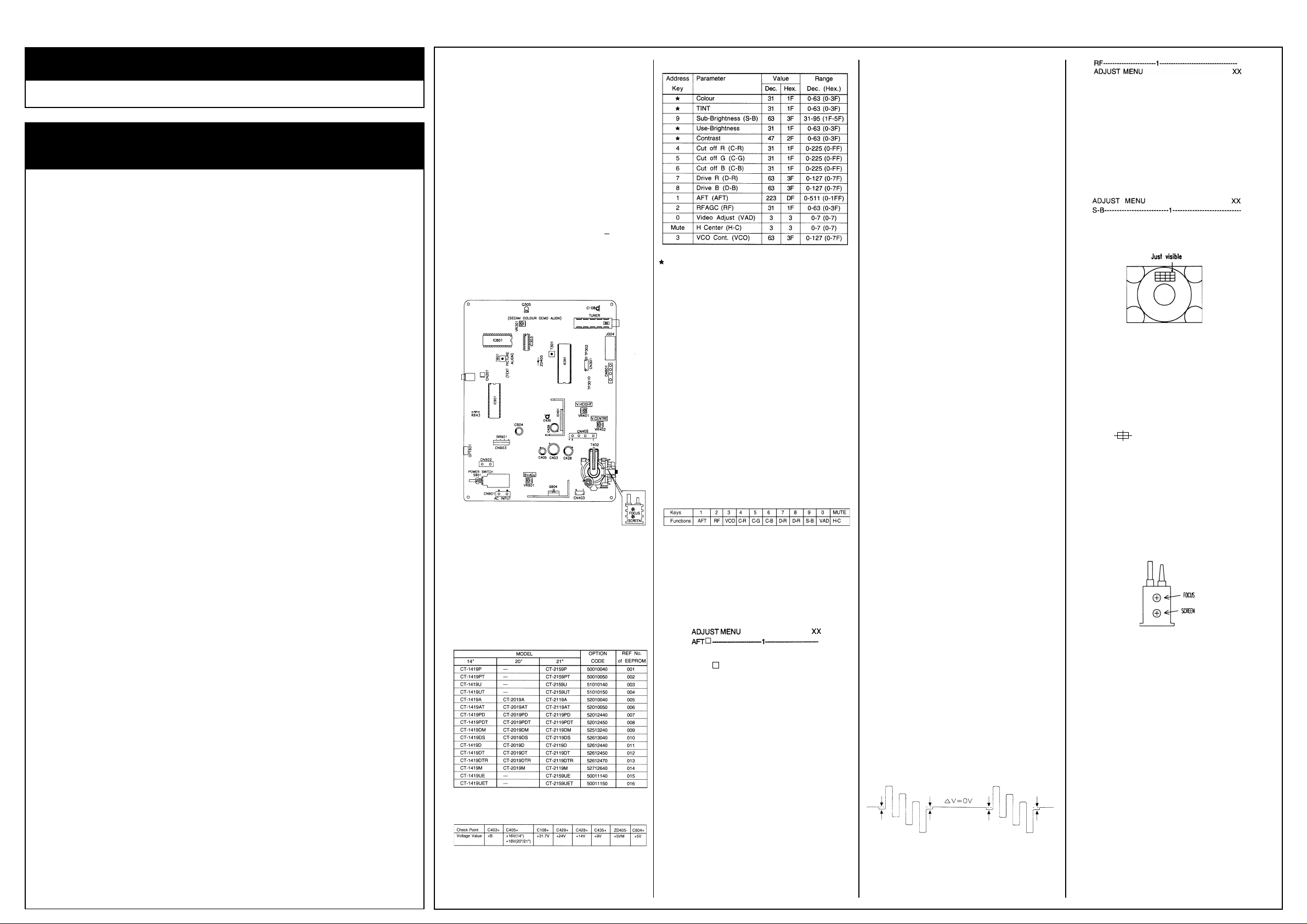

III. ADJUSTMENT LOCATION

IV. SETUP EEPROM (IC602)

A. OPTION (W/INITIATE CHANNEL) LIST FOR

AKAI 1-CHIP MODEL

In order to maintain the option code. The IC602

EEPROM is absoletely necessary to replace

with the following item according Mto the

destination, when the IC602 EEPROM in the

Main PCB is replace for any reason. When

placing an order tor EEPROM be sure to list the

option code and Ref No. of EEPROM which is

required for ordering instead of part number.

B. Check each pairs of power supply and if

normal then go on to do following alignment

C. Press key NORMAL on REMOTE HANDSET

to set each analogue (Brightness, Contrast

Colour and Tint) value at normal position.

D DATA SETTING

These settings are able to set by ‘normal

adjustment (Colour, Brightness and Contrast)

Engaging the TEST MODE or ADJUST MENU.

To set the CTV to test mode (adjust menu), turn

on the power switch while press and holding

volume “+” and “-” buttons on the front cabinet.

The “ADJUST MENU” is indicated with each

parameter on the screen.

To disengage the “TEST MODE” (ADJUST

MENU), turn off the power switch or press the

power key on the hand set.

Pressing the above address key can select the

corresponding parameter. The parameter value

can be changed by pressing volume “+” and “-”

keys.

V. Method to enter into ADJUST MENU

A. Turn off the Main Power Switch, then keep

down Volume Buttons “UP” and “DOWN” on

the Main PCB Simultaneously and turn on the

Main Power Switch again “ADJUST MENU”

will be displayed on the screen.

B. Corresponding Functions of keys on RE-

MOTE HANDSET

VI. Adjustment of AFC

A. Preparation Procedure

1. Set digital voltmeter at DC, then connect its

probes to terminal of R643 and GND.

2. Enter into ADJUST MENU.

B. Adjustment Step

1. Press key “1’ on REMOTE HANDSET,

following will be displayed on the screen:

2. Press key “-” on REMOTE HANDSET, to

make digit following AFT to be 0, the “XX”

at right on the first line to be “00”, then power

off (Exit from ADJUST MENU).

3. Receive Broadcasting TV signal. Press the

“MENU” key on the handset then select

“MANUAL TUNE” (press “RED” colour key)

and press “-” or “+” key, until get the best

picture and sound, and press “GREEN” key to

memorize.

4. Enter into ADJUST MENU again, repeat step 1.

5. Press key “+” on REMOTE HANDSET

continuously until the DC voltage on digital

voltmeter rise to 2.5 ± 0.1V slowly after

jumping down.

6. Exit from ADJUST MENU.

VII. +B voltage Alignment

A. Preparation Procedure.

1. Receive standard colour bar signal.

2. Press key “NORMAL” on remote handset to

set analogue values at normal position.

3. Connect digital voltmeter between (+) of C403

and GND.

4.

MODEL CRT +B

CT-1419xx 102-314000-13 +110V

CT-2019xx 102-320001-19 +115V

CT-2119xx 102-321004-19 +110V

CT-2159xx 102-321001-10 +110V

NOTE: Other CRT, +B see the CRT conversion.

B.Adjustment Step

Adjust VR901 to make the read-out on the

Voltmeter to be +B ± 0.25V.

VIII. Adjustment for White Balance

A. Preparation Procedure.

1. Receive Black-White pattern RF signal.

2. Press key “NORMAL” to set Contrast,

Brightness at normal position.

3. Switch off then switch on again immediately

to enter ADJUST MENU.

B.Adjustment Step

1. Press keys “4”; “5”; “6”; “7”; “8”; “9” on

REMOTE HANDSET separately.

Set C-R, C-G, C-B, (CUT OFF R/G/B) at “1F”;

Set D-R, D-B (DRIVE RIB) at “3F”;

Set S-B (SUB-BRIGHTNESS) at “3F”.

2. Short TP301 to TP302 with jumper wire.

3. Adjust knob “SCREEN” on the FBT, until just

begin to see a horizontal line (which is red or

green or blue).

4. If the horizontal line is red, then press key “+”

or “-” to change the C-G, C-B to make the

horizontal line to become white. In the same

way, if appeared horizontal line is green or

blue, should change the values of C-R, C-B

or C-R, C-G correspondingly. At last the

horizontal line should become white.

5. Remove the jumper wire which from TP301 to

TP302, then adjust values of D-R, D-B to

make bright area of Black White pattern

become normal white.

6. Repeat above step 2, 3, 4, 5, until both bright

area and area meet white balance.

7. Power off to exit from ADJUST MENU.

IX. TV video signal amplitude Adjustment

(VAD)

A. Preparation procedure

1. Receive standard colour bar RF signal.

2. Connect the probe of oscilloscope to the

emitter of Q305 and GND.

3. Switch off, then enter into ADJUST MENU.

B. Method of Adjustment

1. Press key “0” on REMOTE HANDSET and

following be displayed on screen:

2. Press key “+” or “-” on REMOTE HANDSET

to change value of VAD to make the amplitude of video signal on oscilloscope to be

2Vp-p ± 5%.

3. Power off to exit.

X. SECAM Colour Demodulator Alignment.

(FOR M/D/DT/DTR/DS)

1. Turn TV SET to AV mode.

2. Input SECAM (-BG/DK) COLOUR BAR

signal.

3. Connect the Oscilloscope’s probe to PIN. 10

of IC303 (AN5637) and GND.

4. Adjust VR301 to obtain the waveform as in

Fig 1.

Fig. 1

XI. Adjustment of RF AGC

1. Receive RF signal (62 ± 3dBuV).

2. Enter into ADJUST MENU.

3. Press key “2” on REMOTE HANDSET, and

following will be displayed on the screen:

4. Press key “+” or “-” on REMOTE HANDSET

change the value of RF AGC until snow noise

on the screen just disappeared.

5. Exit from ADJUST MENU

XII. Adjust of Sub-brightness

1. Receive Moonscape Pattern.

2. Press key “NORMAL” on REMOTE HANDSET to set Brightness and Contrast at normal.

3. Enter into ADJUST MENU.

4. Press key “9” on REMOTE HANDSET, the

display on screen will be:

5. Press key “+” or “-” on REMOTE HANDSET

to change the value of S-B until eight and half

of portions indicated in Fig.2 is just visible.

Fig. 2

XIII. Teletext picture Alignment. (FOR PT/UT/

UET/AT/PDT/DT MODELS)

1. Receive a pattern with teletext signal.

2. Select a teletext page.

3. Connect DC voltage meter to IC801 PIN 28

and GND.

4. Adjust T801 to obtain 2.5 ± 0.1V.

XIV. Adjust for Horizontal Centre (H-C) and VHIGHNESS & V-CENTER

1. Receive pattern signal.

2. Enter then change the value of “H-C” to make

the centre of picture to be on top of the center

of screen.

3. Adjust VR401 to get a normal picture.

4. Adjust VR402 to get a get V-CENTER picture.

XV. Adjust for FOCUS

1. Press key “NORMAL” on remote handset to

set brightness and contrast both at normal

position.

2. Adjust knob “FOCUS” on FBT to make the

picture on the screen to be the most distinct.

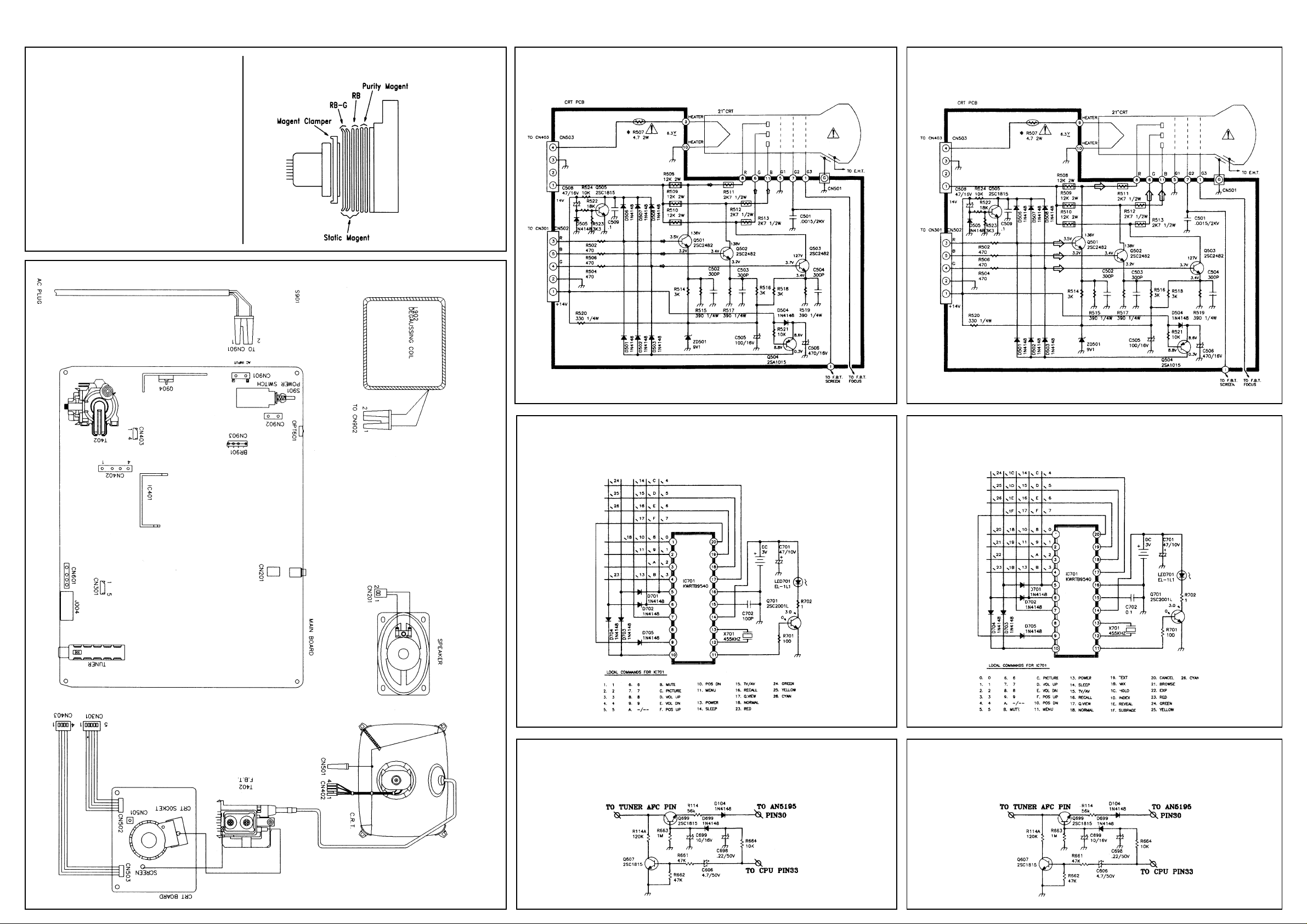

XVI. COLOUR PURITY ADJUSTMENT

(See Fig.3)

BEFORE ANY ADJUSTMENTS DESCRIBED

BELOW ARE ATTEMPTED, V-HIGH, B+

VOLTAGE AND FOCUSING ADJUSTMENT

MUST BE COMPLETED.

1. Place the TV receiver facing NORTH or

SOUTH.

2. Plug in TV receiver and turn it on.

3. Operate the TV receiver over 30 minutes.

4. Fully degauss the TV receiver by using and

external degaussing coil.

5. Receive a crosshatch pattern and adjust the

static convergence control roughly.

6. Loosen the clamp screw of the deflection

yoke and pull the deflection yoke towards you.

7. Enter into ADJUST MENU. Set the values of

C-R, C-G, C-B to “00”.

8. Adjust the purity magnets so that green field

is obtained at the center of the screen.

9. Slowly push the deflection yoke toward cone

of CRT and set it where a uniform green field

is obtained.

10.Tighten the clamp screw of the deflection

yoke.

11.After COLOUR PURITY ADJUSTMENT, you

must adjust the WHITE BALANCE again.

Page 2

AKAI CT-2159 U

Alignments Cont’d

XVII. CONVERGENCE ADJUSTMENT

(See Fig.3)

1. Receive a dotted pattern.

2. Unfix the convergence magnet damper and

align red with blue dots at the center of the

screen by rotating (RB) static convergence

magnets.

3. Align Red/Blue with green dots at the center

of the screen by rotating (RB-G) static

convergence magnet.

4. Fix the convergence magnets by turning the

damper.

5. Remove the deflection yoke wedges and

slightly tilt the deflection yoke horizontally and

vertically to obtain the good overall convergence.

6. Fix the deflection yoke by wedges.

7. If purity error is found, follow “PURITY

ADJUSTMENT” instructions.

Fig.3

CRT (CT-2159U) Diagram

CRT (CT-2159UT) Diagram

Remote Control (CT-2159U) Diagram

Remote Control (CT-2159UT) Diagram

Wiring Diagram

AFT Board (CT-2159U) Diagram

AFT Board (CT-2159UT) Diagram

Page 3

AKAI CT-2159 U

Main (CT-2159U) Diagram

Page 4

AKAI CT-2159 U

Main (CT-2159UT) Diagram

Loading...

Loading...