VCT-1000

Vertical Contact Toaster

owner’s manual

Manufacturing Numbers:

9210700, 9210702, 9210704, 9210705, 9210706,

9210708, 9210709, 9210710, 9210711, 9210712,

9210714, 9210716, 9210720, 9210722, 9210727

www.ajantunes.com

P/N 1010807 Rev. K 07/14

CONTENTS

GENERAL 2

Warranty

Information 2

Service/Technical

Assistance 2

Important Safety

Information 3

Warnings 3

Specications 4

Installation 5

Unpacking 5

Assembling the Unit 5

Equipment Setup 6

Operating

Instructions 6

Safety Features 6

Hi-Limit Reset Button 6

Conveyor interlock Safety switch 6

Maintenance 7

Daily 7

Replacing the Black and Silver Release

Sheet (Every 4–6 weeks) 7

Replacing the Optional Belt Wraps (Every

3–6 months) 7

Checking the Conveyor Belt Chains 8

Checking the Roller Tensioners

(every 3–6 months) 9

TROUBLESHOOTING 10

Wiring Diagram 12

Replacement Parts 13

Parts Identication 13

Mechanical Butter Wheel Kit (P/N

7000298) Requires Professional Installation. 18

Mechanical Butter Wheel Kit

(model 7000238) 18

Notes 19

Limited Warranty 20

GENERAL

This manual provides the safety, installation,

and operating procedures for your toaster.

Please read all of the information contained

in this manual prior to installing and operating the toaster.

Your toaster is manufactured from the nest materials available and is assembled

to Roundup’s strict quality standards. This

toaster was tested at the factory to ensure

dependable trouble-free operation.

WARRANTY

INFORMATION

Please read the full text of the Limited Warranty in this manual.

If the unit arrives damaged, contact the

carrier immediately and le a damage claim

with them. Save all packing materials when

ling a claim. Freight damage claims are the

responsibility of the purchaser and are not

covered under warranty.

The warranty does not extend to:

y Damages caused in shipment or dam-

age as result of improper use.

y Installation of electrical service.

y Normal maintenance as outlined in

this manual.

y Malfunction resulting from improper

maintenance.

y Damage caused by abuse or careless

handling.

y Damage from moisture into electrical

components.

Damage from tampering with, removal of,

or changing any preset control or safety

device.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your system,

contact A.J. Antunes & Co. at 1-630-7841000, or toll free in the United States at

1-800-253-2991.

Fill in the information in the next column

and have it handy when calling for assistance. The serial number is on the specication plate located on the system.

Purchased From

Date of Purchase

Model Number

Serial Number

Mfg. Number

Use only genuine Roundup replacement

parts in this unit. Use of replacement parts

other than those supplied by the manufacturer will void the warranty. Your Authorized

Service Agency has been factory trained

and has a complete supply of parts for this

unit.

Visit www. ajantunes.com or contact the

factory at 1-630-784-1000 to locate your

nearest Authorized Service Agency.

Refer to the service agency directory

packaged with your manual and ll in the

information below.

IMPORTANT

A.J. Antunes & Co. reserves the right to

change specications and product de-

sign without notice. Such revisions do not

entitle the buyer to corresponding changes,

improvements, additions or replacements

for previously purchased equipment.

IMPORTANT

Keep these instructions for future refer-

ence. If the unit changes ownership, be sure

this manual accompanies the equipment.

Authorized Service Agency

Name

Phone Number

Address

2

P/N 1010807 Rev.K 07/14

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

y Read all instructions before using

equipment.

y For your safety, the equipment is fur-

nished with a properly grounded cord

connector. Do not attempt to defeat

the grounded connector.

y Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

y Do not operate this equipment if it

has a damaged cord or plug, if it is

not working properly, or if it has been

damaged or dropped.

y This equipment should be serviced

by qualied personnel only. Contact

your nearest Authorized Service

Agency for adjustment or repair.

y Do not block or cover any openings

on the unit.

y Do not immerse cord or plug in water.

y Keep cord away from heated surfaces.

y Do not allow cord to hang over edge

of table or counter.

y Turn the power o, unplug the power

cord, and allow unit to cool down

before performing any service or

maintenance on the unit.

y The procedures in this manual may

include the use of chemical products.

See Hazard Communication Standard

manual for the appropriated Material

Safety Data Sheets (MSDS).

y The equipment should be grounded

according to local electrical codes to

prevent the possibility of electrical

shock. It requires a grounded recep-

tacle with separate electrical lines,

protected by fuses or circuit breaker

of the proper rating.

y All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

y Do not clean this appliance with a

water jet.

WARNINGS

Be advised of the following warnings when

operating and performing maintenance on

this unit.

y If the supply cord is damaged, it must

be replaced by the manufacturer or

its service agent or a similarly qualied person in order to avoid a hazard.

y Do not modify the power supply cord

plug. If it does not t the outlet, have

a proper outlet installed by a qualied

electrician.

y Do not use an extension cord with

this appliance.

y Electrical ground is required on this

appliance.

y Check with a qualied electrician

if you are unsure if the appliance is

properly grounded.

y If a chemical cleaner is used, be sure

it is safe to use on cast aluminum.

Observe all precautions and warnings

on product label.

y Inspection, testing, and repair of

electrical equipment should only

be performed by qualied service

personnel.

y This equipment is to be installed to

comply with the basic plumbing code

of the Building Ocials and Code Administrators, Inc. (BOCA) and the Food

Service Sanitation Manual of the Food

and Drug Administration (FDA).

y To ensure proper steaming character-

istics, some calcium/mineral deposits

must be present on the generator surface. If, during cleaning, the

surface does become free of calcium/

mineral deposits, add plain tap water

to the surface and allow it to boil o.

This may have to be repeated several

times to ensure proper steaming

characteristics by creating a thin layer

of deposits on the surface.

y Do not use a sanitizing solution or

abrasive materials. The use of these

may cause damage to the stainless

steel nish.

y Chlorides or phosphates in clean-

ing agents (e.g. bleach, sanitizers,

degreasers or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of

metal surface nish, pits, voids, holes,

or cracks. This damage is permanent

and not covered by warranty.

The following tips are recommended for

maintenance of your stainless steel equipment:

y Always use soft, damp cloth for clean-

ing, rinse with clear water and wipe

dry. When required, always rub in

direction of metal polish lines.

y Routine cleaning should be done

daily with soap, ammonia detergent,

and water.

y Stains and spots should be sponged

using a vinegar solution.

y Finger marks and smears should be

rubbed o using soap and water.

y Hard water spots should be removed

using a vinegar solution.

P/N 1010807 Rev. K 07/14

3

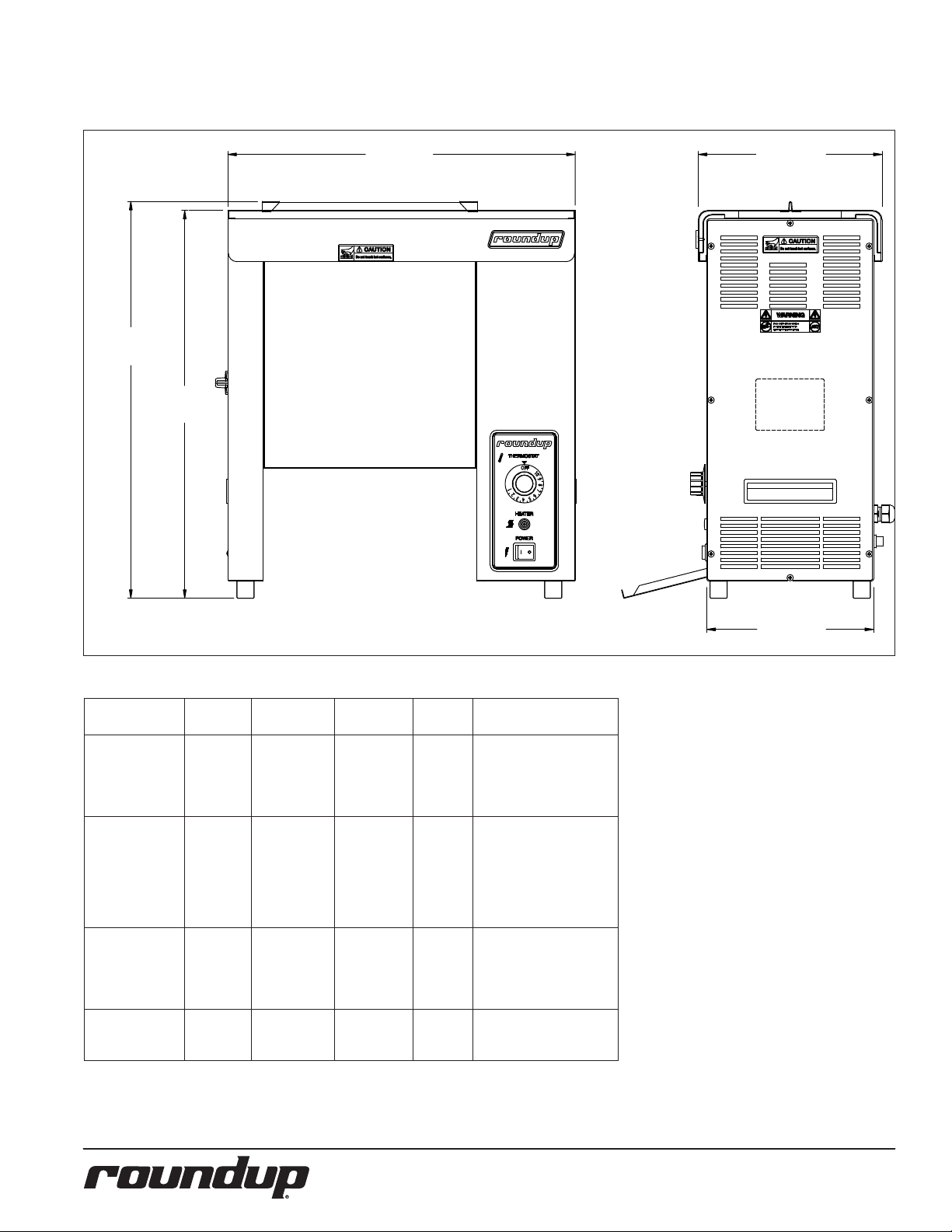

SPECIFICATIONS

23-7/32”

(590.0 mm)

22-11/16”

(576.2 mm)

20-5/16”

(516.0 mm)

10-3/4”

(237.1 mm)

Model &

Mfg. No.

VCT-1000CF

9210700

9210706

9210716

9210722

VCT-1000CV

9210702

9210708

9210709

9210714

9210720

9210727

VCT-1000HI

9210704

9210705

9210710

9210711

VCT-1000HC

9210712

Volts Watts Amp. Hertz Description

120 1800 15.0 60

208/240 2600/3455 12.5/14.4 60

208/240 2600/3455 12.5/14.4 50

220/240 1775/2125 8.07/8.85 50

5-15P, 15 Amp.,

120 VAC, Non-locking

(Assembly Only)

6-20P, 20 Amp.,

250 VAC, Non-locking

(Assembly Only)

IEC-309, 16 Amp.,

250 VAC, Pin & Sleeve

(Assembly Only)

CEE 7/7, 16 Amp.,

250 VAC

(Assembly Only)

9-3/4”

(248.0 mm)

4

P/N 1010807 Rev.K 07/14

INSTALLATION

Unpacking

1. Remove unit and all packing materi-

als from shipping carton.

2. Open the large box. It should

contain:

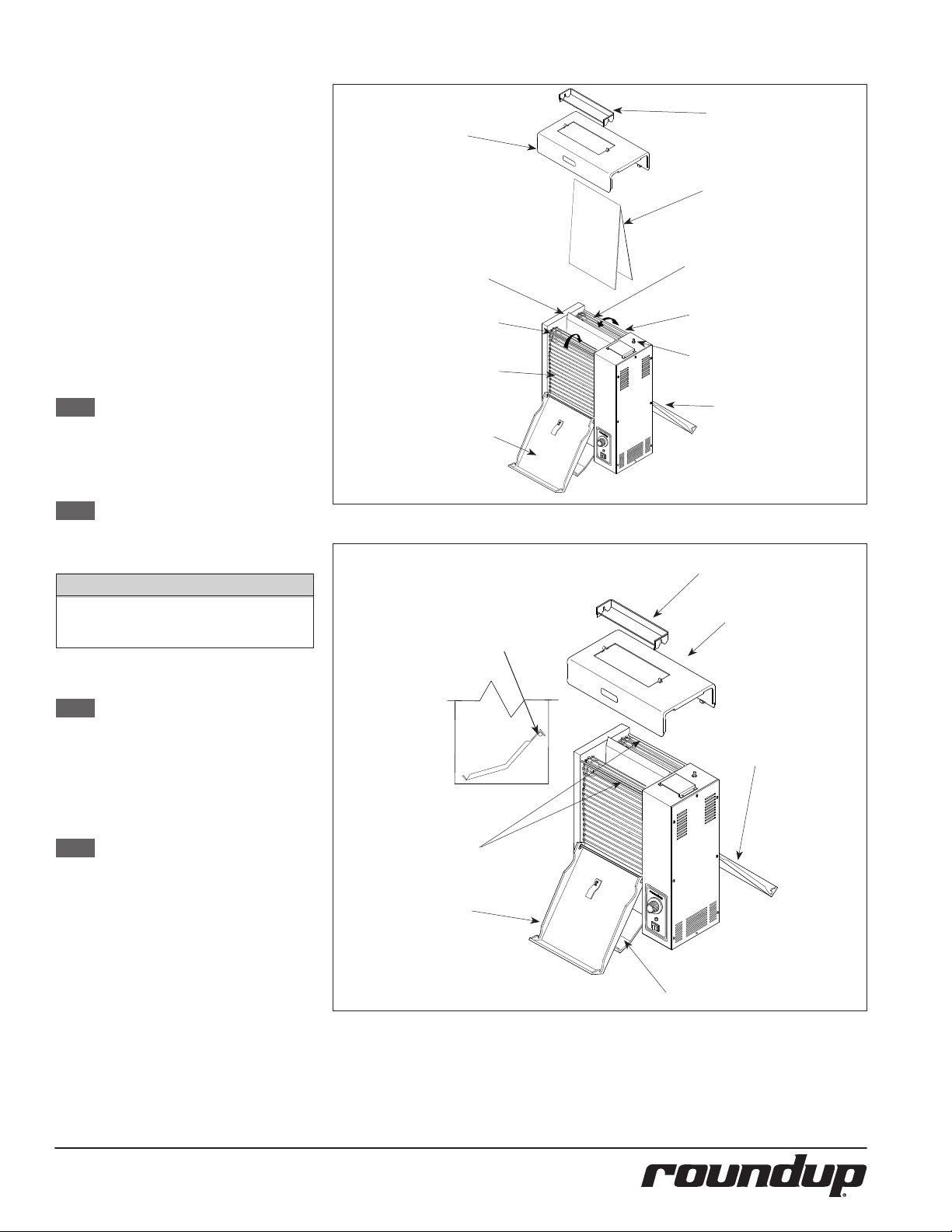

• Bun Feeder (Figure 1)

• Bun Chute (Figure 2)

• Two Release Sheets (Figure 1)

• Authorized Service Agency Directory

• Owner’s Manual

3. Remove all packing materials and

protective coverings from the unit

and parts.

NOTE: If any parts are missing or dam-

aged, contact Antunes Technical

Service IMMEDIATELY at 1-877392-7854.

Assembling the Unit

NOTE: The factory has pre-installed a

Release Sheet over the Platen

(Figure 1). Verify that it is properly in place before proceeding.

CAUTION

Failure to use Release Sheets may

result in damage to the unit and

loss of warranty coverage.

HEAT

SHIELD

PLATEN

YELLOW

SUPPORT ROD FRONT

FRONT CONVEYOR

BELT CHAIN

CONVEYOR

COVER ASSY. REAR

HOOK BUN CHUTE

OVER REAR BOTTOM

CONVEYOR COVER

YELLOW SUPPORT ROD

CONVEYOR INTER

SHOWN WITHOUT OPTIONAL

ROLLER TENSIONERS AND BELT

Figure 1. Toaster and Accessories

BUN FEEDER

BUN FEEDER

RELEASE

SHEET

REAR CON

VEYOR BELT

CHAIN

YELLOW SUPPORT

ROD REAR

LOCK SWITCH

CONVEYOR

COVER ASSY.

REAR

WRAPS.

HEAT SHIELD

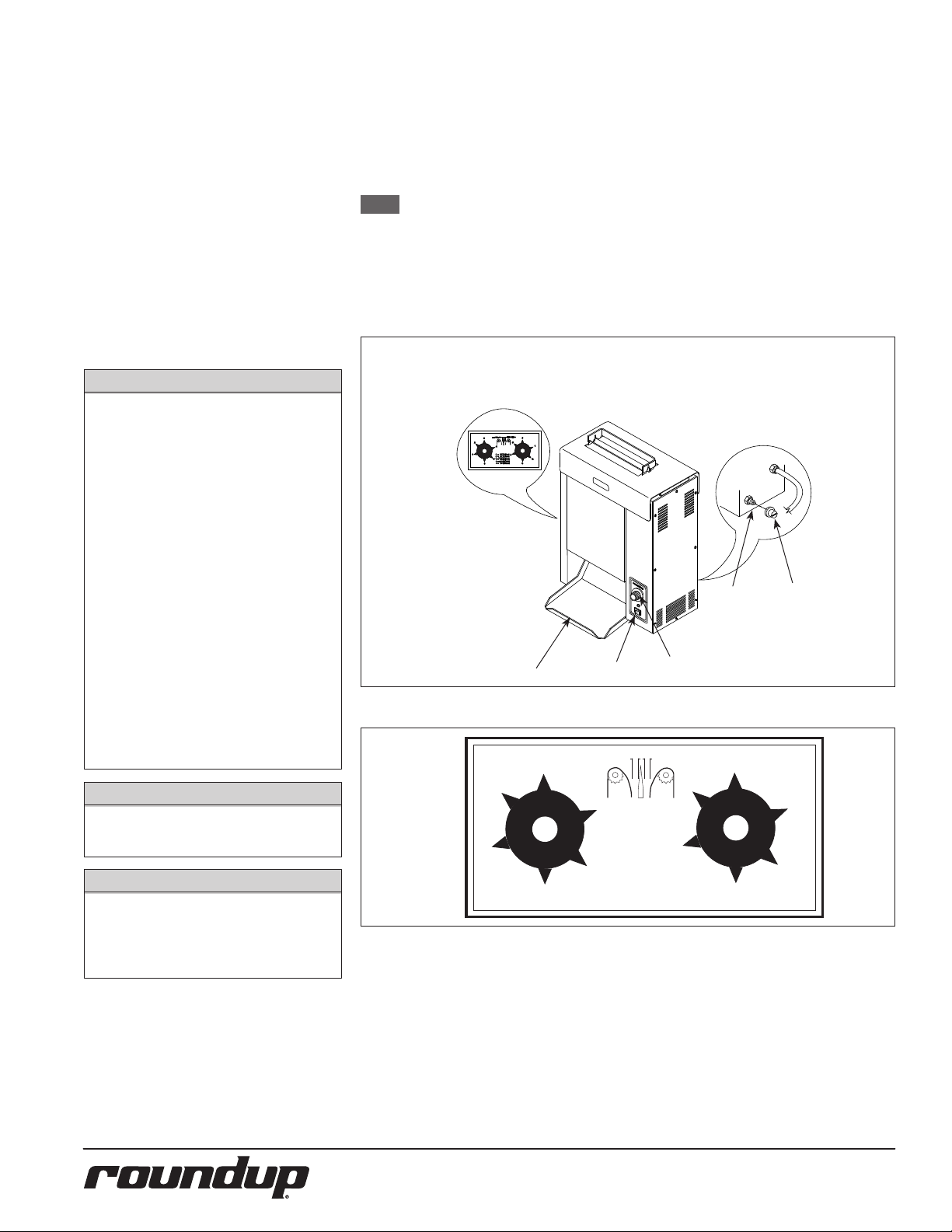

1. Install the Bun Feeder (Figure 1) and

Bun Chute (Figure 2).

NOTE: Make sure Heat Shield As-

sembly is properly seated and

engages the Conveyor Interlock

Safety Switch (see Figure 1). The

conveyors will not rotate unless

the Heat Shield is in place and

correctly engages the Conveyor

Interlock Safety Switch.

NOTE: Check the Release Sheet to make

sure it is not caught in the conveyor. Additional Release Sheets

can be purchased through your

Authorized Service Agency under

P/N 7000249 (3-pack) or 7000250

(10-pack).

YELLOW SUP

PORT ROD

CONVEYOR

COVER ASSY.

FRONT

SHOWN WITHOUT OPTIONAL

ROLLER TENSIONERS AND BELT

WRAPS.

Figure 2. Installing Bun Chute

BUN CHUTE

CONVEYOR

COVER ASSY.

REAR

P/N 1010807 Rev. K 07/14

5

Equipment Setup

1

2

3

4

5

1 = 1/2"(12.7mm)

2 = 5/8"(15.9mm)

4 = 3/4"(19.1mm)

5 =13/16"(20.6mm)

6 = 7/8"(22.2mm)

THICKNESS

THICKNESS

1

2

3

4

5

6

6

3 =11/16"(17.5mm)

1

2

3

4

5

1 = 1/2"(12.7mm)

2 = 5/8"(15.9mm)

4 = 3/4"(19.1mm)

5 =13/16"(20.6mm)

6 = 7/8"(22.2mm)

THICKNESS

THICKNESS

1

2

3

4

5

6

6

3 =11/16"(17.5mm)

When placing the toaster into service, pay

attention to the following guidelines.

y Make sure power to the unit is o and

the toaster is at room temperature.

y Do NOT block or cover any openings

on the unit.

y Do NOT immerse cord or plug in

water.

y Keep cord away from heated surfaces.

y Do NOT allow cord to hang over edge

of table or counter.

y Connect the unit to the power supply.

Refer to the specication plate for the

proper voltage.

WARNING

ELECTRICAL SHOCK HAZARD. Failure

to follow the instructions in this manual

could result in serious injury or death.

• Electrical ground is required on this

appliance.

• Do NOT modify the power supply cord

plug. If it does not t the outlet, have

a proper outlet installed by a qualied

electrician.

• Do NOT use an extension cord with

this appliance.

• The toaster should be grounded ac-

cording to local electrical codes to prevent the possibility of electrical shock.

It requires a grounded receptacle with

separate electrical lines, protected by

fuses or circuit breaker of the proper

rating.

• Check with a qualied electrician

if you are unsure if the appliance is

properly grounded.

OPERATING

INSTRUCTIONS

1. Set the Bun Thickness Compression

Knobs (Figure 7) to the desired settings.

NOTE: After initial run of 4-6 buns,

adjust controls according to the

desired nished product.

2. Turn the power on (Figure 6).

3. Turn the temperature control to 10

and allow the unit to warm up for 30

minutes.

BUN THICKNESS ADJUSTMENT

CONTROLS

SEE FIGURE 7

BUN LANDING AREA

Figure 6. Toaster Controls

POWER SWITCH

4. Drop buns into toaster. Cut sides

of heel and crown must face each

other.

5. Toasted product will drop into the

bun landing area (Figure 6).

6. Test at least 4 buns before putting

toaster into service. Turn temperature control to lower setting for

lighter toasting or to higher setting

for darker toasting.

7. Turn the power o when nished

toasting and

follow the daily cleaning procedures.

HILIMIT RESET

RESET

BUTTON

TEMPERATURE CONTROL

PROTECTIVE

CAP

CAUTION

All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

CAUTION

Bread may burn. Therefore toasters must

not be used near or below curtains or other

combustible walls and materials. Failure

to maintain safe operating distances may

cause discoloration or combustion.

SAFETY FEATURES

Hi-Limit Reset Button

A Hi-Limit Control turns o electrical power

to the heater if the unit overheats. To reset

this control, allow 10-15 minutes for the unit

to cool down, Remove the Protective Cap,

and fully press the Reset Button

located at the rear of the unit (Figure 6).

Figure 7. Bun Thickness Compression Knobs

If the unit requires continuous resetting,

contact your Authorized Service Agency.

Conveyor interlock Safety switch

A Conveyor Interlock Safety Switch is

located on top of the unit under the Heat

Shield (Figure 1). The Conveyor Belt Chains

will not rotate unless the Heat Shield is in

place and activating the Conveyor Interlock

Safety Switch properly.

6

P/N 1010807 Rev.K 07/14

Loading...

Loading...