HRS-100, HRS-200 Filter system for

the optimization of drinking water

Installation and Operation Manual

HRS-100, HRS-200 Sistema de filtro

para la optimización de aqua otable

Manuel de instalación y operación

2

17

US

ES

The installation and operation manual provides the necessary information for an efficient and

safe operation/handling of the filter system VIZION HRS-100, HRS-200 (addressed in this

manual as the filter system). The installation and operation manual is part of the filter system and

has to be stored close to the filter system. The accessibility must be possible for any person at

any time operating the filter system.

Each person handling and operating the filter system has to read and understand the installation

and operation manual completely.

Job safety is based on the safety instructions and guidelines given in this installation and

operation manual. Furthermore, state and local regulations according to safety and accident

prevention have to be applied.

It is not possible to file a claim because of the Figures and Drawings shown in this manual.

They are shown for the principal understanding and they may vary from the real application.

All instructions, guidelines and data in this manual are given under consideration of the

actual regulations and requirements, state of the art, as well as, our experience in the field of

water filtration and technology.

Manufacturer:

BWT water + more GmbH

Walter-Simmer-Straße 4

A-5310 Mondsee

www.bwt-wam.com

Distributed by:

A.J. Antunes & Co.

180 Kehoe Blvd.

Carol Stream, IL 60188

USA

Toll Free Number: (800) 253-2991

www.ajantunes.com

Antunes Equipment Manufacturing

(Suzhou) Co., Ltd.

2 # Building North,

89 Songshan Road,

ShiShan Industrial Complex Park,

New District

Suzhou Jiangsu 215129

China

+86 (512) 68413637

www.ajantunes.com

307036-A 131121CT

HRS-100, HRS-200 Sistema de filtro

para a otimização da água potável

Manual de Instalação e Operação

HRS-100, HRS-200 Système de filtrage

pour l‘amélioration de l‘eau potable

Manuel d‘installation et de service

Please read this manual carefully

before starting the installation

Lea este manual atentamente

antes de comenzar la instalación

Leia este manual com atenção

antes de iniciar a instalação

Lisez attentivement ce manuel

avant de commencer l‘installation

Tested and Certified by NSF

International against NSF/ANSI

Standard 42 for the reduction

of chlorine, taste and odor.

34

51

PT

FR

The liability of the manufacturer does not include claims caused by:

disregarding instructions given in the installation and operation manual

misusage of the filter system

inappropriate or wrong installation

inappropriate operation

unauthorized modifications of the system

technical changes

usage of non certified parts

Copyright by A.J. Antunes & Co. All rights are reserved.

Duplication (in whole or in parts) and distribution to third parties are prohibited in any case

unless there is a written agreement with the manufacturer.

Acting against this agreement may lead to a claim of compensation.

Tested and Certified by NSF International against NSF/ANSI Standard 42 for the

reduction of chlorine, taste and odor. Visit www.nsf.org for claims associated with

products that are NSF listed.

The VIZION HRS Water Filter System is used to remove carbonate hardness (temporary hardness/

alkalinity)* from drinking water to prevent lime scale deposits in downstream appliances.

Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system. Use cold water in drinking water quality. All of the

materials used are approved and safe for contact with drinking water.

* Not performance tested and certified by NSF

1011255 Rev. A 12/13

5351_EEBA Vizion HRS-100 + HRS-200_UMSCHLAG.indd 1 05.12.13 09:11

Fig. 1

A

1× = 1 °KH

10 ml

Content

2

E

1

3

B A

C

F

B

C

D

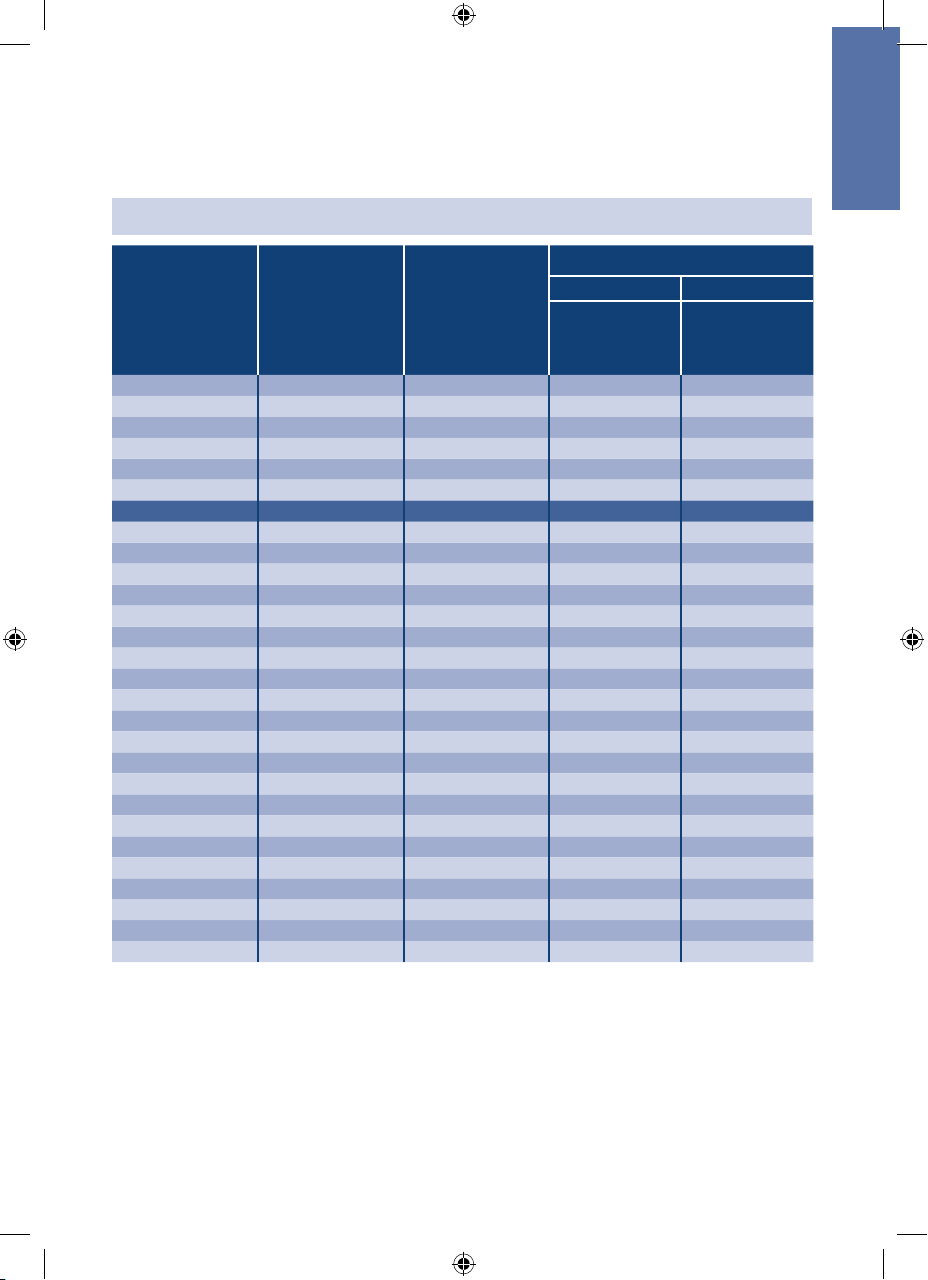

1. Scope of Delivery ........................................................................................................... 3

1.1 Installation Set .............................................................................................................3

1.2 Replacement Cartridge ................................................................................................ 3

2. Technical Data ................................................................................................................3

2.1 Dimensions and Weights .............................................................................................3

2.2 Operation Conditions ..................................................................................................4

3. General Information .......................................................................................................4

3.2 Symbol Explanation ..................................................................................................... 4

3.2 Information about this Installation and Operation Manual.............................................4

3.3 Limited Warranty and Liability ......................................................................................4

3.4 Responsibility of the Costumer ....................................................................................5

4. Filter Function ................................................................................................................5

4.1 Assigned Use ..............................................................................................................5

4.2 Construction ...............................................................................................................5

5. Operation and Safety Instructions ............................................................................... 6

5.1 Intended Use ............................................................................................................... 6

5.2 Qualified Staff ..............................................................................................................7

5.3 Operation after a Shut Down ....................................................................................... 7

5.4 Replacement Interval ................................................................................................... 7

5.5 Disposal ....................................................................................................................... 7

6. Filter installation ............................................................................................................. 7

6.1 Water Quality ...............................................................................................................7

6.2 Pressure ......................................................................................................................8

6.3 Material Selection ........................................................................................................8

6.4 Unpacking the Filter ..................................................................................................... 8

6.5 Mounting of the Filter Head and Wall bracket ..............................................................8

6.5.1 Mounting the Wall bracket ..................................................................................8

6.5.2 Mounting the Filter Head ..................................................................................... 9

6.6 Installing a Water Meter ...............................................................................................9

6.7 Determination of the Filter Capacity and the Blend Setting .......................................... 9

6.8 Filter Cartridge Installation

6.8.1 Rinse/Purge with the Device .............................................................................10

6.8.2 Rinse/Purge with a Rinsing Tap ........................................................................10

6.8.3 Rinse/Purge by Using the Outlet or Water Disposal Hose

6.9 Filter Cartridge Replacement ..................................................................................... 11

7. Service and Maintenance ...........................................................................................11

8. Trouble Shooting .......................................................................................................... 12

9. Order Numbers .............................................................................................................12

10. Capacities and Blend Setting .....................................................................................13

10.1 Application - Capacity .............................................................................................13

10.1.1 Hot Beverage Machines with steam generator .............................................13

10.1.2 Cold and Hot Beverage Machines without steam generator

[max. temperature 203°F(95°C)] ...................................................................14

10.1.3 Combi-Steamer/Oven, Blend “1” ..................................................................15

10.1.4 Combi-Steamer/Oven, Blend “0” .................................................................. 16

10.2 Chlorine Reduction ..................................................................................................16

10.3 Capacity based on Chlorine Reduction ...................................................................16

..........................................................................................10

.................................11

D

5351_EEBA Vizion HRS-100 + HRS-200_UMSCHLAG.indd 2 05.12.13 09:11

E

F

US

1 Scope of Delivery

1.1 Installation Set

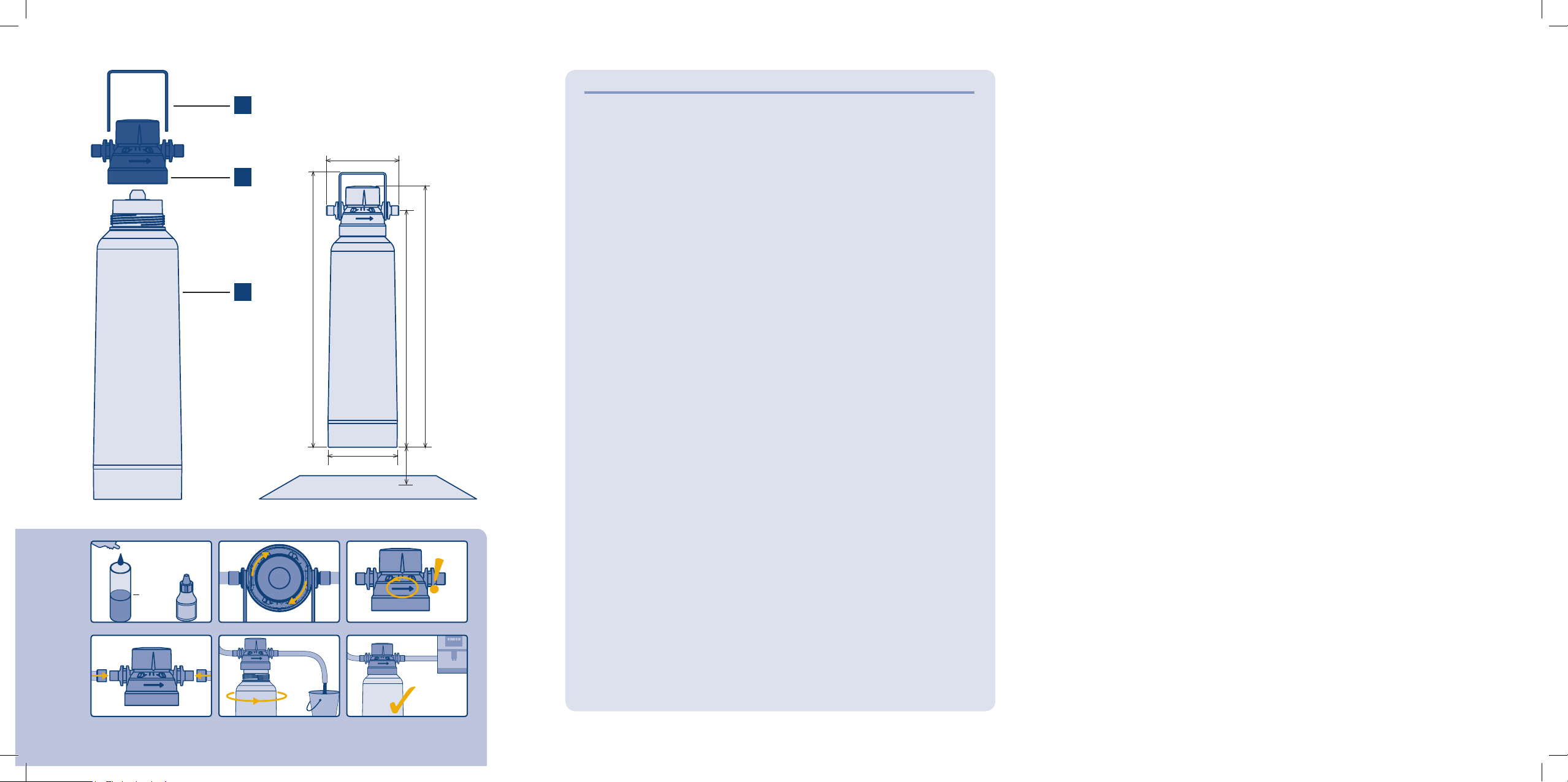

The installation set consists of the following parts (see Fig. 1):

Filter head (1) with female thread for the connection to the filter cartridge. The head is fitting to

different VIZION HRS filter cartridge sizes. An integrated shut-off and two non return valve (inlet

and outlet) are installed in the filter head

Wall bracket (2) to mount the filter cartridge

Filter cartridge (HRS-100 and HRS-200) (3) with hygienic cap and male thread as counterpart to

the filter head (1)

Installation and Operating Manual

For hygienic reasons all parts are wrapped in a protection foil.

1.2 Replacement Cartridge

The replacement package includes a VIZION HRS filter cartridge with a protection/hygienic cap (3)

wrapped in a protection foil including the installation and operation manual.

2 Technical Data

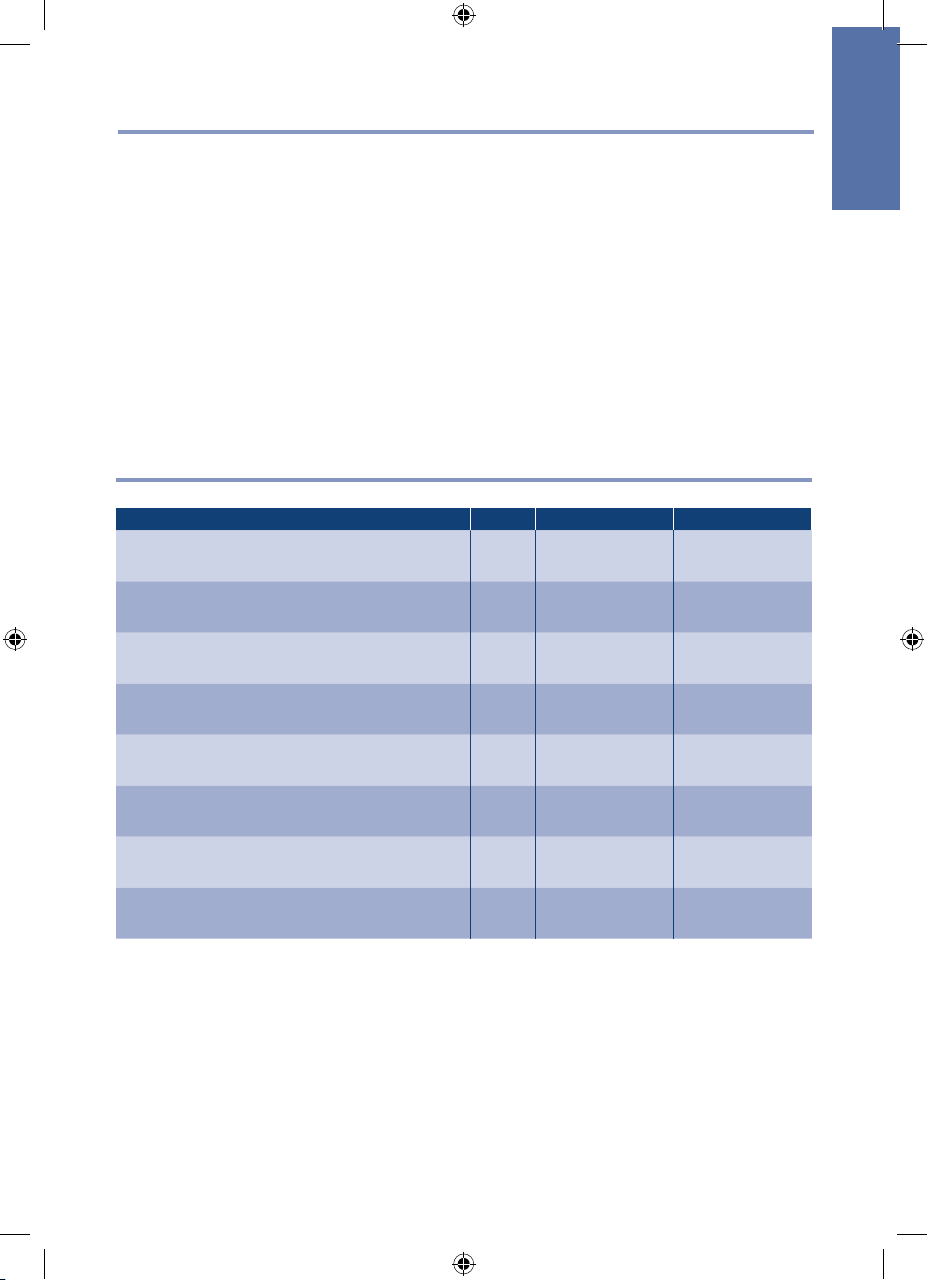

2.1 Dimensions and Weights

VIZION HRS 100 200

Total height without wall mounting bracket (A)

Total height with wall monuting bracket (B)

Height to centre of connection (C)

Distance required for service (D)

Installation length (E)

Filter cartridge Ø (F)

Filter cartridge weight, cartridge dry appr.

Inch

Inch

(mm)

Inch

Inch

(mm)

Inch

Inch

(mm)

Inch

Inch

(mm)

Inch

Inch

(mm)

Inch

Inch

(mm)

lb

(kg)

19.30-19.69

5

– 19

19

/16

(490 – 500)

20.87

20

(530)

17.72

17

(450)

2.56

2

(65)

4.93

15

4

(125)

5.71

11

5

(145)

8.38

(3.8)

11

/16

7

/8

11

/16

9

/16

/16

/16

22.44-22.83

7

22

– 22

/16

(570 – 580)

23,62

23

(600)

20.47

7

20

(520)

2.56

2

(65)

4.93

15

4

(125)

7.28

1

7

(185)

16.53

(7.5)

13

/16

5

/8

/16

9

/16

/16

/4

3

Filter cartridge weight, wet appr.

lb

(kg)

13.23

(6.0)

24.25

(11.0)

US

4

2.2 Operation Conditions

VIZION HRS 100 200

Inlet/Outlet fittings 3/8” BSP male

Nominal flow rate

Working pressure, min-max

Required water pressure inlet psi (bar)

Pressure drop at 8 US gallons/h (0.5 Litres/min)

Pressure drop at 16 US gallons/h (1 Litres/min)

Pressure drop at 48 US gallons/h (3 Litres/min)

Water temperature, min-max. °F (°C)

Ambient temperature, min-max. °F (°C)

Transportation and storage ambient temperature,

min-max

Operation/Installation position

(1)

Blend setting „2“, including a 59.06 (59 1/16) inch (1.5 m) hose DN8 mounted on inlet and outlet

(1)

(1)

(1)

US gallons/d (L/d)

US/gallons/min (L/min)

psi (bar)

psi

(bar)

psi

(bar)

psi

(bar)

°F (°C)

720 (2.725)

0.5 (1.9)

29 – 116 (2 – 8)

>17.4 (>1.2)

1.5

(0.10)

2.2

(0.15)

7.3

(0.50)

+39 to +86 (+4 to +30)

+39 to +100 (+4 to +38)

-4 to +100 (-20 to +38)

horizontal or vertical

3 General Information

3.1 Symbol Explanation

Use and Safety Precautions are marked by symbols and they start with the appropriate signal word

to express their importance.

Please follow the given instructions and warnings to avoid risk of health and damage of property

2.9

(0.20)

4.4

(0.30)

8.7

(0.60)

I WARNING!

… Indicates a possible dangerous situation which may cause risk of health

I CAUTION!

… Indicates a possible dangerous situation which may cause damage of property

Recommendations

NOTE!

… Additional information for an efficient and optimal operation

3.2 Information about this Installation and Operation Manual

This installation and operation manual provides the necessary information for the correct installation

and operation of the filter system.

Please make sure that the installation complies with applicable state and local regulations for the

operation, installation and for the disposal of used filters as well.

Each person handling and operating the filter system has to read and understand the installation and

operation manual completely.

3.3 Limited Warranty and Liability

The Manufacturer warrants, to the original purchaser/consumer, all equipment that it manufacture’s

to be free from defects in materials and workmanship for a period of 2 years from the date of

purchase. This warranty is subject to exclusions and limitations.

US

All recommendations and data in this manual are given under consideration of the actual regulations

and requirements, state of the art, as well as, our experience in the field of water filtration and

technology.

5

This warranty does not include primary and secondary damage caused by:

disregarding instructions given in the installation and operation manual

misusage of the filter system

inappropriate or wrong installation

inappropriate operation

unauthorized modifications of the system

technical changes

usage of non certified parts

3.4 Responsibility of the Consumer

The installation and operation manual must be stored close to the filter system, accessibility must

be available at any time

Operation of the filter system should only be carried out under technically correct and safe conditions

Comply according to the instructions given in this installation and operation manual

4 Filter Function

4.1 Assigned Use

The VIZION HRS filter system is designed exclusively for the intended purpose described in this manual:

VIZION HRS filter Cartridges are used for the decarbonization of cold water fulfilling the legal

requirements for drinking water.

Lime* and carbonate hardness* are reduced. The devices connected to the filter system, mainly

equipment used in gastronomy (e.g. coffee machine, espresso machine, hot-/coldwater machine,

steamer, combi steamer, ice machine), are protected against lime scale.

Furthermore, substances responsible for taste and odor (e.g. chlorine), are removed.

Particles* are also removed by the filter system.

I Risks of misusage!

Any other use than the intended use outlined in this manual for the VIZION HRS filter system is strictly

prohibited by the manufacturer and does exclude any and ALL liabilities and warranty of the manufacturer

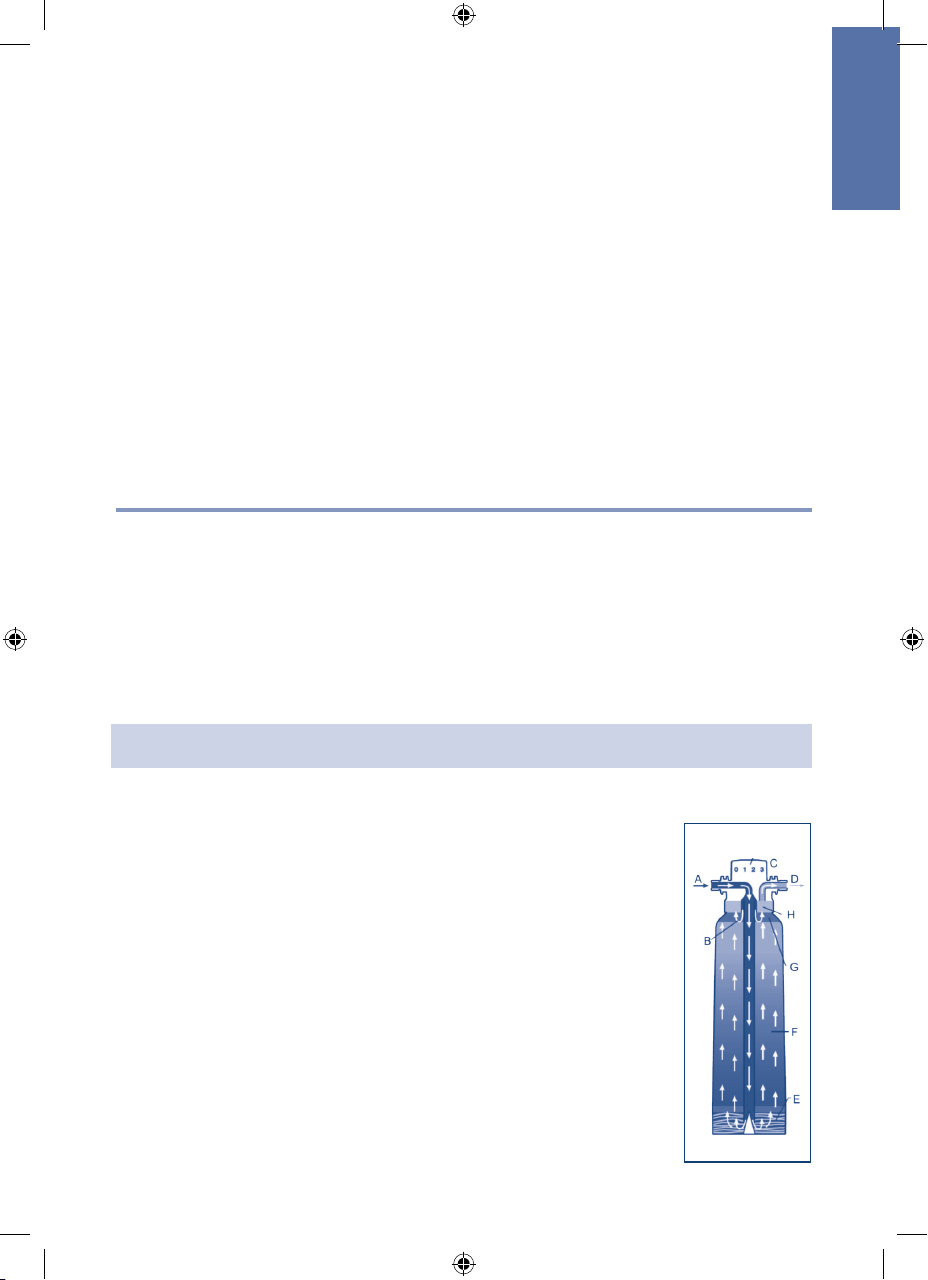

4.2 Construction

Flow diagram (Fig.2).The tap water is entering the filter cartridge (A). In section

(E) particles are removed by a pre filter and substances responsible for taste and

odor (e.g. chlorine) are removed by activated carbon. Afterwards the

decarbonisation is done by ion exchange in section (F). Finally, the water is

treated by activated carbon (G) and particles are removed by a filter (H).

Within the filter system there is an integrated blend unit (B). With this unit the

system is capable doing a part decarbonisation means a defined amount of tap

water can blend without decarbonization but this proportion of water must also

pass the activated carbon (G) and particle filter (H). In section (D) both flow rates

(decarbonisation and blend) are mixed together.

F

A Inlet tap water

B Blend water

C Blend setting on the filter head

D Outlet filtered water

Pre - Filtration (particles, activated carbon)

E

* Not performance tested and certified by NSF

Decarbonisation based on ion

exchange

G Filtration with activated carbon;

including blend water

H particle filtration; including blend

water

Fig. 2

US

6

5 Operation and Safety Instructions

This section is an overview about all important safety and operational aspects for a safe and

satisfying operation. Nevertheless, there are always some risks which have to be considered in case

of a misusage or inappropriate handling.

The warranty only applies if the given instructions in this manual are completely fulfilled.

5.1 Intended Use

The filter system is designed for the decarbonization of cold water fulfilling the legal requirements for

drinking water, removal of flavour influence substances and particles within the water.

The filter system must only be used for the above mentioned purposes.

Any other usage of this filter system is not recommended and voids ALL warranties.

I WARNING!

f Only operate the filter system with cold water of drinking quality. If the water quality is poor

(not reaching the criteria for drinking water) there is a risk of health caused by microorganism,

pathogenic germs, high concentration of heavy metals or organic impurities.

f For the protection of the drinking water, maintenance and any other work on the filter system

must be carried out under consideration of the applicable state and local regulations

f If there is the necessity, given by the authorities or operator of the water supply system, to boil

the water because of bacteria it is also necessary to boil the filtered water. If the requirement of

boiling the water isn’t necessary anymore, the filter cartridge has to be replaced and the system

including the connections and hoses have to be cleaned carefully otherwise there may still be

health risk.

f Included in the filter system is a non return valve (approved according DIN EN 13959).

If the filter system is used for devices requiring a special safety unit, the appropriate safety unit

has to be additionally installed.

f Before any maintenance work on the water supply system is performed the filter system must be

disconnected completely from the water supply system. The water system has to be rinsed and

sanitized before reconnecting the filter system.

f Before starting any work disconnect all power supplies of any devices connected to the system

(unplug).

I CAUTION!

f Inappropriate installation can cause damage of property. State and local regulations must be

applied as well as hygienic requirements and technical standards for the protection of the drinking

water.

f Unauthorized modifications or technical changes are prohibited.

f The warranty is only applicable, if the system is installed correctly and in accordance to state and

local regulations.

f A valve (shut-off valve) should be installed on the inlet of the filter system (not included in the scope

of delivery)

f Only use flat seals. Compression and barrel gaskets may damage the filter head and the warranty

isn’t applicable in this case.

f For the connection of the filter system appropriate hoses according DVGW 543 or NSF 42/53 have

to be used.

f If the product was stored below freezing point, then before the filter is installed it should be stored

unwrapped for 24 hours under installation conditions.

f Don’t install the filter close to a heat source or open fireplace.

f The system should not come in contact with chemicals, dissolvers and vaporous dissolvers

f The place of installation must be protected against freezing and any direct or indirect sun light.

US

NOTE!

f The non return valve is approved according DIN EN 13959 and affixed in the filter head

f Devices with boilers or water tanks such as coffee machines, etc... have to be cleaned, rinsed

and sanitized before operating the filter system to ensure the protection.

f In general for immunocompromised people and for babies it is recommended to boil the water

before use. This should be done for filtered and unfiltered water.

f For the protection against microbiological growth the filter contains a small amount of silver

(„bacteriostatic“).* Therefore, there might be a harmless release of silver in concentrations below

the recommendations of the World Health Organisation (WHO). The term “bacteriostatic”

indicates that the system limits the passage or growth of bacteria that may already exist in the

incoming water.* It does not mean that the water leaving the system is safer to drink than the

water entering the system.

f Do not use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system

5.2 Qualified Staff

Only authorized, instructed and specially trained personnel (professional plumber) are allowed to

install, start up and maintain the filter system

Authorized Personnel

Are to have the Instructions about the assigned tasks and possible risks in case of misuse

Professional

Professionals who are able to install, start up and maintain the filter system, because of their

training, experience and knowledge of applicable guidelines and codes

5.3 Operation after a Shut Down

The inlet valve (shut-off valve) has to be closed in case of a shut down.

If the shut down was more than two days (weekend, holiday….) the filter system has to be rinsed

with 1.1 – 1.3 gallons (4 – 5 liters) of water before use.

After a shut down period of more than 4 weeks the filter cartridge has to be replaced

7

5.4 Replacement Interval

The cartridge has to be replaced if:

f the capacity (see chapter 10) is reached

f at least every 12 months after installation

f if there was a shut down longer than 4 weeks

5.5 Disposal

Used filter cartridges, all other parts and the wrapping foil must be disposed according the local

rules. To protect the environment, recycling is recommended and appreciated.

6 Filter installation

6.1 Water Quality

The filter system must be operated with cold water fulfilling the legal requirements for drinking water.

I WARNING!

Risks of misusage!

In any case of usage against the intended use e.g. poor water quality (not reaching the criteria for

drinking water) there is a risk of health.

* Not performance tested and certified by NSF

US

8

6.2 Pressure

I CAUTION!

If the nominal pressure is above 116 psi (8 bar) a pressure reduction/reducer has to be installed in

front of the filter system.

NOTE!

f The implementation of a pressure reducer might have an influence on the water flow.

f The inlet pressure of the filter system should be higher than 17.4 psi (1.2 bar)

6.3 Material Selection

Please take under consideration that decarbonized water contains free carbonic acid.

I CAUTION!

VIZION recommends, not installing copper pipes and no galvanized or nickel-plated pipes/

connectors between the filter system and device. When choosing the material for parts that come

into contact with water after the filter system it must be considered that, due to the process,

decarbonized water contains free carbon dioxide.

6.4 Unpacking the Filter

After unpacking please check the completeness of the content and inspect the condition of the filter

and parts e.g. damages caused by transport.

I CAUTION!

f Defect or damaged parts have to be replaced with original parts from the manufacturer

f Always ensure a safe and clean working place

f Keep children away from the wrapping material, risk of suffocation!

For the protection of the environment, dispose all the plastic waste properly, complying with local

disposal regulations.

6.5 Mounting of the Filter Head and Wall bracket

6.5.1 Mounting the Wall Bracket

I CAUTION!

f Please check the technical data, operation and safety instruction before installation

f Use only approved and certified plumbing adapters, piping and hoses according DVGW 543 or

NSF 42/53 for the connection of the system

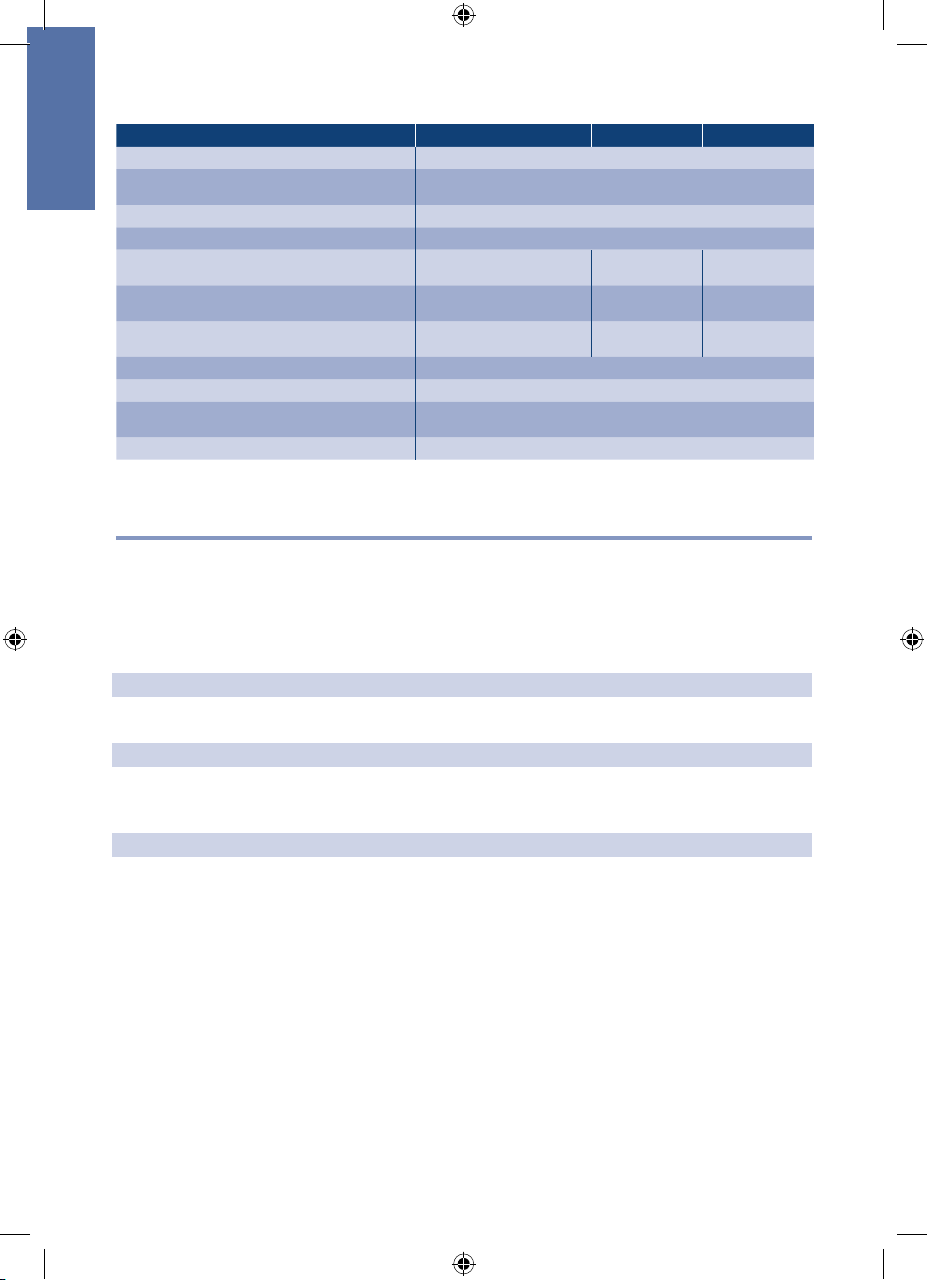

Procedure:

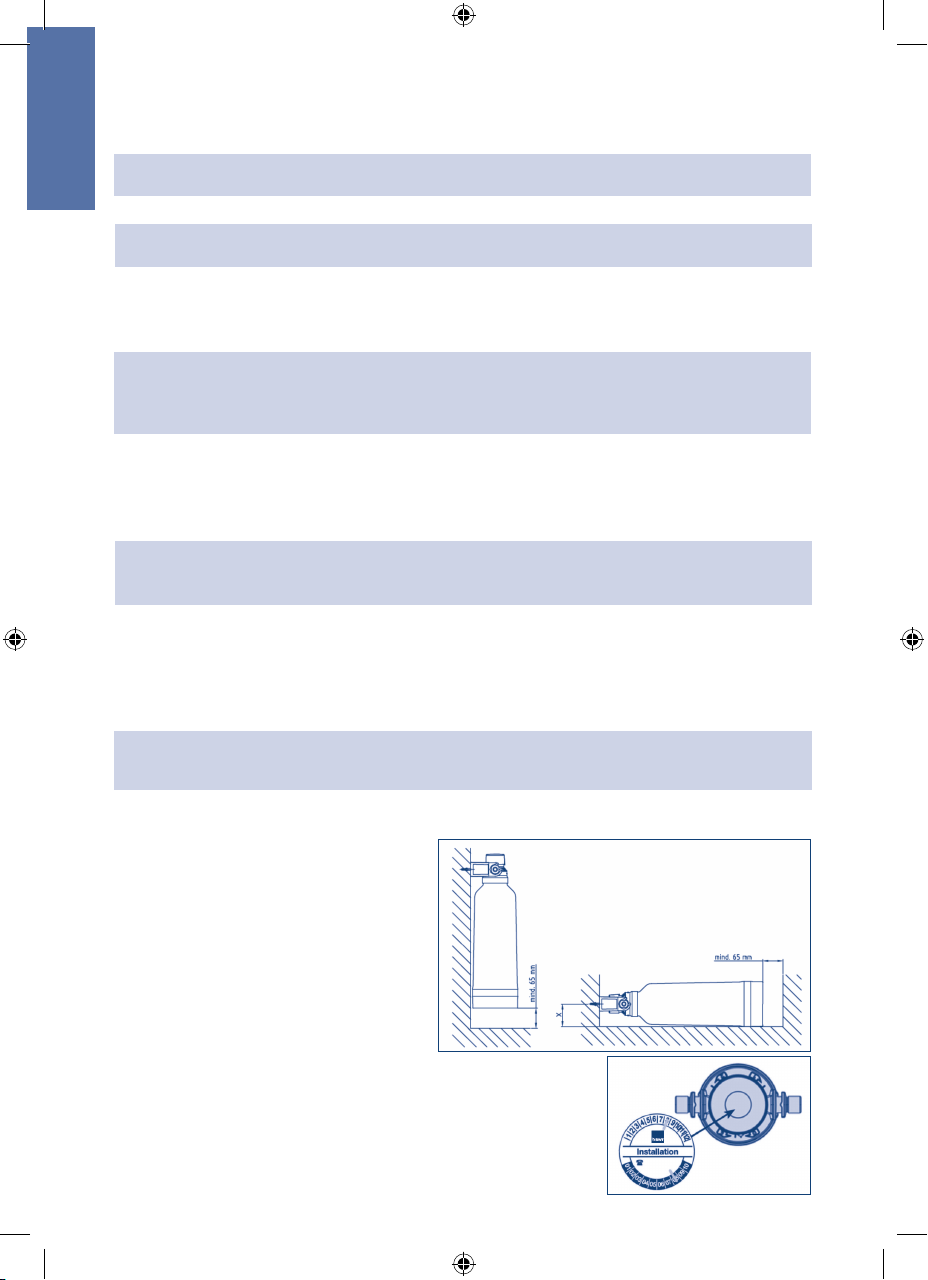

1. The filter system should be installed at

locations where the connection to the

drinking water supply is as simple and as

close as possible.

2. The filter system can be installed and operated

in horizontal and vertical position (see Fig.3)

3. For easy service and replacement of the

cartridge after installation a minimum

clearance/distance of 2.56 (2 9/16) inch

(65 mm) is required at the bottom of the

cartridge and cartridge is required in case

of a vertical installation.

4. The wall bracket has to be adjusted and mounted to allow a

convenient access and replacement of the cartridge.

5. The system has to be mounted on the wall firmly and securely.

6. The installation must be done by a professional and authorized person.

7. Mark the included label with the installation date (month/year) and stick

the label on top of the filter head (see Fig. 4)

A

Fig. 3

B

Fig. 4

US

6.5.2 Mounting the Filter Head

I CAUTION!

f Make sure that the filter head is never left under system pressure without any filter cartridge

f The tightening torque of the fittings (inlet/outlet) must not exceed 15Nm!

NOTE!

f The integrated shut-off in the filter head prevents a water flow without the filter cartridge

f Before removing the filter cartridge the separately installed shut off valve on the filter system inlet

should be closed (not included in the scope of delivery).

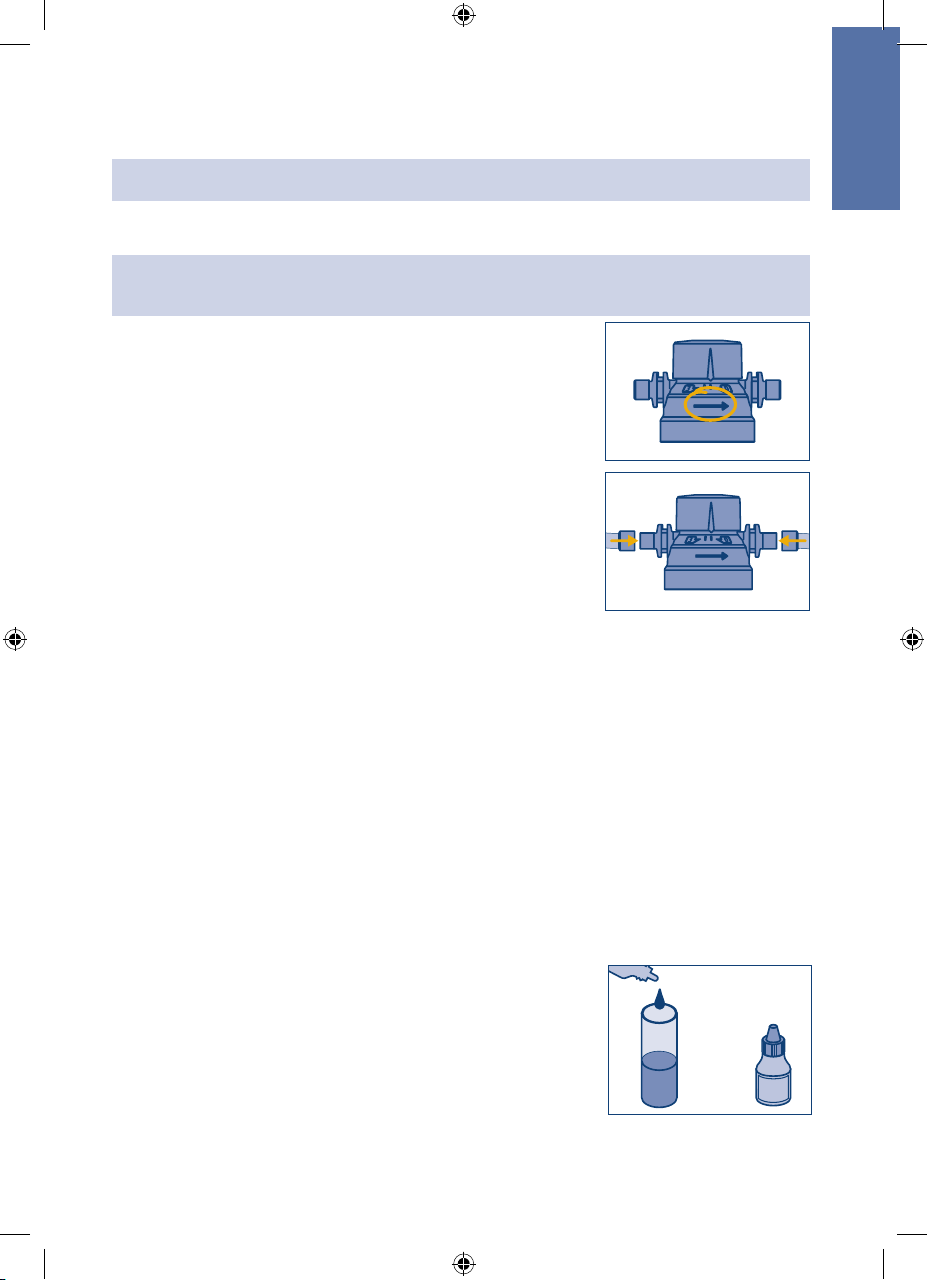

Procedure:

1. Insert the filter head on the wall bracket

2. pay close attention to the correct direction arrow on the filter

head, filter is only to be installed in the directional flow.(see Fig.5)

3. mount and connect the adapters/hoses to the filter head

(consider the bending radius of the hoses) (see Fig.6)

4. connect the inlet to the water supplies inlet/shut-off valve

(shut-off valve not part of the scope of delivery)

5. connect the outlet of the filter system to the

consumer system/device

6. open the inlet valve and check if the system is leak-proof

7. close the inlet valve

9

Fig. 5

6.6 Installing a Water Meter

VIZION recommends the installation of a water meter at the inlet of

the filter cartridge in case the filter system is used for a device without an integrated water meter

(e.g. coffee machine) which indicates the required replacement of the filter cartridge.

With the water meter the actual/remaining capacity of the filter cartridge can be displayed or

calculated at any time.

Procedure:

1. Read the Instruction manual of the water meter

2. Mount the water meter on the filter head (outlet) by considering the flow direction.

Display should be visible. Programming and start up of the water meter according to the

instruction manual provided.

3. Connect all the hoses at the inlet and outlet of the water meter

4. Open the inlet (shut-off valve)

5. Check the installation for leaks

6.7 Determination of the Filter Capacity and the Blend Setting

The blend setting and the filter capacity are based on the carbonate hardness of the drinking water

and the application field of the filter cartridge.

Procedure:

1. The information of carbonate hardness of your drinking water can

either be provided by your water supplier or can be determined by

an analyses (e.g. droplet test, Fig.7)

Based on the determined hardness and application, the blend

setting can be determined according Table 1-4 chapter 8 and the

filter capacity is given in the tables as well.

1× = 1 °KH

10 ml

Fig. 6

Fig. 7

10

US

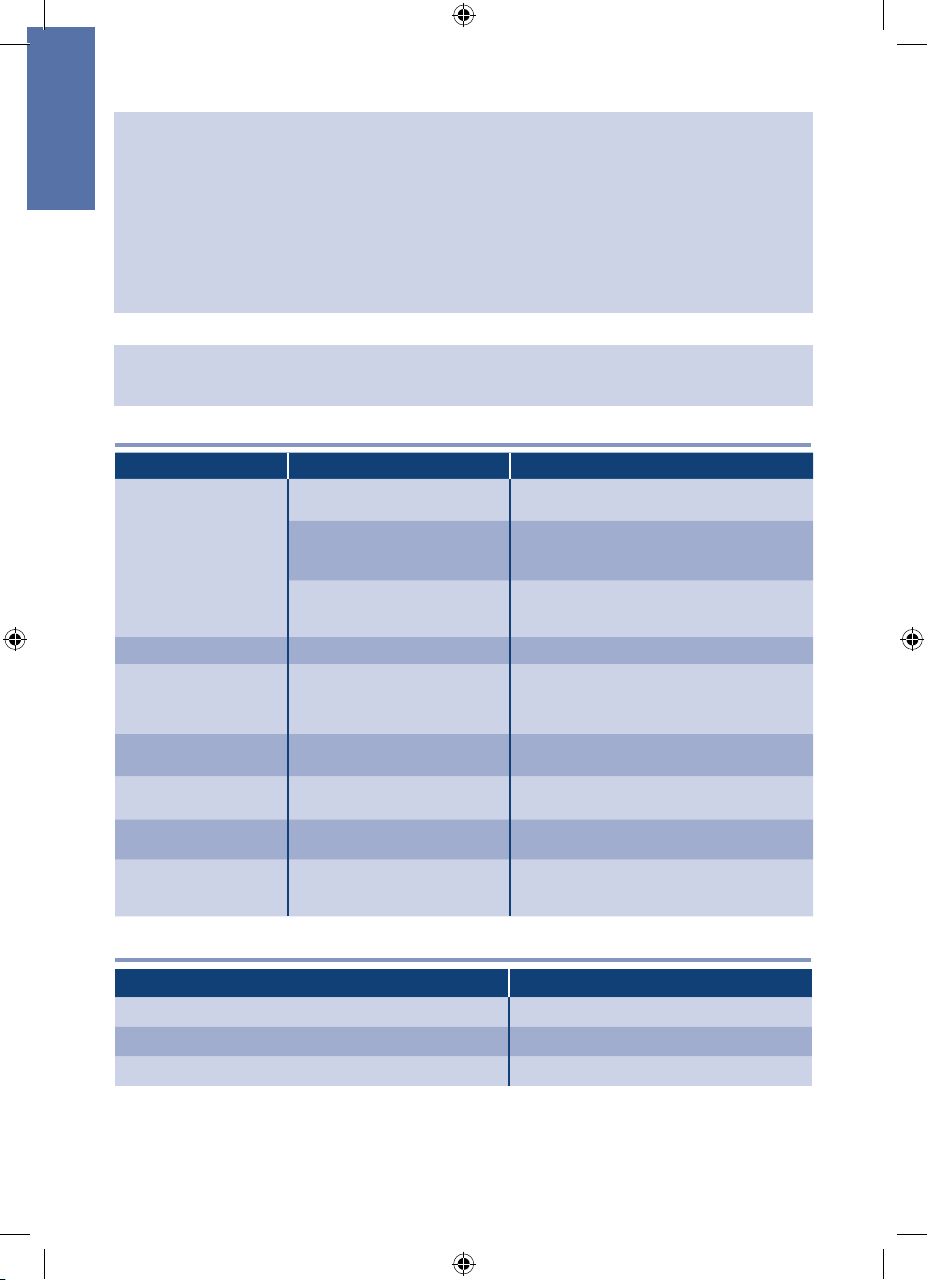

2. There are four possible positions/settings for the blend. The factory

setting of a new filter head is “2”. The blend can be changed easily by

twisting the cap on top of the filter head (see Fig. 8). Turn the cap either clockwise or counter clockwise until the indication is pointing to

the required blend setting where the cap is snapping in.

3. The blend can be fixed by the included seal tag

NOTE!

f Our recommendation is to choose a size of cartridge, where the capacity requires replacemante

every six months, but no longer than 12 months.

f After a shut down period of longer than 4 weeks, the cartridge has to be replaced in any case

6.8 Filter Cartridge Installation

I CAUTION!

f Only use the VIZION HRS filter cartridge in combination with an original VIZION filter head.

f Please avoid any impurities in the filter system, keep the working conditions and filter system clean

Procedure:

1. Unwrap the filter cartridge and remove the hygienic cap.

2. Before installation of the filter cartridge please mark the date of

installation and the date of the replacement on the data plate of

the filter cartridge (see Fig. 9). Optional you can get and add this

information in the service-pass (see Fig. 10) which has to be fixed

on the filter head (e.g. by using a cable clip).

3. To mount the filtercartridge in the filter head turn the cartridge

counter clockwise into the thread of the filter head (see Fig. 11)

4. Open the inlet valve (shut-off valve)

5. The filter system has to be rinsed and flushed (see chapter 6.8.1

to 6.8.3). The necessary rinsing volume is given in the table below:

Fig. 10

Fig. 9

Fig. 8

Required volume of flushing water

VIZION HRS 100 200

Flushing water in US gallons (Liter) 2.4 (9) 3.96 (15)

2

NOTE!

f After a shut down of more than two days the filter system must

be rinsed with a water volume according table 1.

Depending on the installation there are several possibilities to rinse and purge the system:

6.8.1 Rinse/Purge with the Device

If the device (e.g. coffee machine etc…) used after the filter system has the option/function for start

up of filter cartridges, the purge and rinsing process can be done via this device

(e.g. coffee machine). Please read the instruction manual for the device.

1

Fig. 11

NOTE!

f Don’t feed the boiler of the device with the rinsing water!

6.8.2 Rinse/Purge with a Rinsing Tap

VIZION recommends the installation of a rinsing/purging tap after the filter system. Rinsing/Purging

can simply be done by using this tap. Please read the instruction manual of the tap.

US

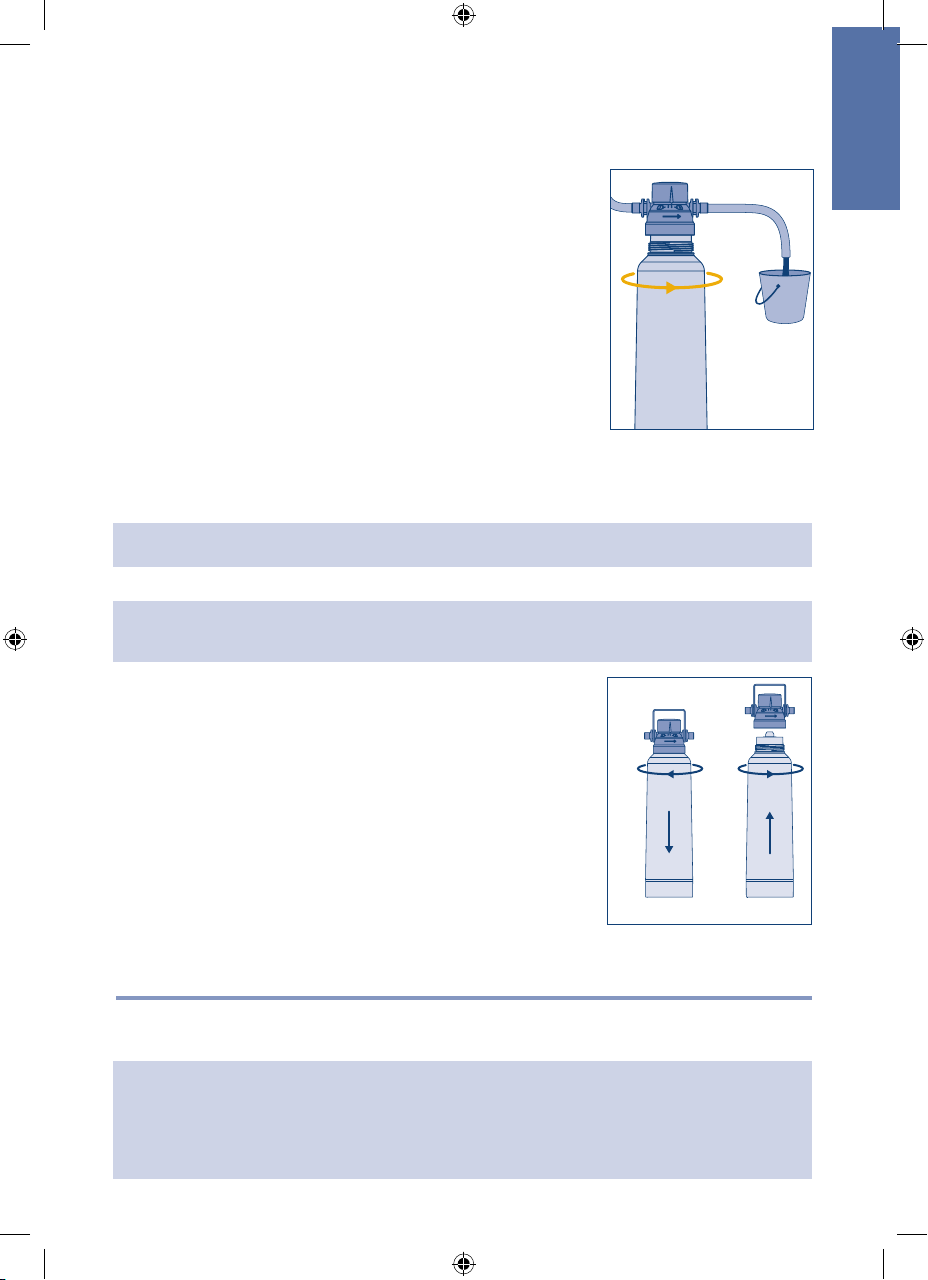

6.8.3 Rinse/Purge by Using the Outlet or Water Disposal Hose

If there is no other possibility the filter system can also be purged/flushed by using the outlet hose/

piping.

Procedure:

1. close the inlet valve (shut-off valve)

2. disconnect the outlet hose/piping of the filter system from the

device (e.g. coffee machine)

3.

Hold/fix the hose in a container, volume approximately 2.6 gallons (10l)

4. Open the inlet valve

5.

Rinse/purge the filter system until the water outlet is clear and free of

air bubbles (see chapter 6.8 for the required volume of rinsing water)

6. Close the inlet valve

7. Connect the hose to the device again

8. Open the inlet valve

9. Check the filter system for leaks

6.9 Filter Cartridge Replacement

Fig. 12

I CAUTION!

f The inlet valve/shut-off vlave (provided by the customer) must be closed before the filter cartridge

is changed/replaced.

NOTE!

f The filter cartridge has to be replaced after 12 months from installation/start up independent of

the remaining capacity.

f After a shut down period of longer than 4 weeks, the filter cartridge has to be replaced.

11

Procedure:

1. Close the inlet valve (shut-off valve)

2. Unscrew and remove the filter cartridge out of the filter head by

turning the cartridge clockwise (see Fig 13). The filter head can

be turned by 90° (horizontal position of the filter cartridge)

to make the replacement easier.

3. Check again the carbonate hardness of the drinking water,

change the blend setting if necessary (see chapter 6.7)

4.

Install the new filter cartridge as described in chapter 6.8 (see Fig. 14)

5. Rinse/purge the filter cartridge as described in chapter 6.8

6. Open the inlet valve

7. Check the filter system for leaks

8. Dispose the used filter cartridge according the local requirements

1

2

Fig. 13 Fig. 14

2

1

7 Service and Maintenance

To ensure a satisfying function every technical device has to be maintained regularly.

I CAUTION!

Drinking water is food therefore, please handle the filter system hygienically. Clean the

Leak-proof check daily

filter system regularly with a wet cleaning rag. Keep everything

clean especially if the filter cartridge has to be replaced. Avoid the

usage of alcohol based cleaners, acidic and strong chemicals

US

12

Checking the hoses/piping regular inspection, hoses/piping should not be squeezed or bent,

replace squeezed/bent hoses/piping

Shut down

Replacement of the

filter cartridge

After a shut down of more than two days the cartridge has to be

rinsed with at least 1.1–1.3 US gallons (4-5 Litres) of water

at least after 12 months independent of the remaining capacity,

also after a shut down of more than 4 weeks

Replacement of the filter head after 5 years

Replacement of the hoses after 5 years

NOTE!

f Note, that the filter has to be changed within the given period and capacity otherwise there is the

risk of health.

f Filter heads and hoses older than 5 years may cause damage of property, change accordingly.

8 Trouble Shooting

ERROR CAUSE ACTION

water supply out of the

filter is stopped

Low flow rate System pressure is too low Check the system pressure (see chapter 6.2)

Integrated shut-off in the

filter head is leaking

(while the filter cartridge

is removed)

Screw connection between the fitting is leaking

Air bubbles System isn’t purged completely Repeat the purging/rinsing process

turbid/white water generation of small bubbles of

Heater, boiler are not enough protected against

lime scale

Water supply in general is

stopped or a valve is close

Filter cartridge is not mounted

properly in the filter head

Wrong mounted filter head Check the flow direction of the water accor-

Particles within the integrated

shut-off

Sealing is defect Check the sealing, if necessary replace the

carbon acid

wrong chosen blend setting, filter

capacity is reached/passed, filter

size is too small

Open and check all the valves

Loosen the filter cartridge by turning the filter

cartridge 180 degree clockwise and tighten the

filter cartridge again (see chapter 6.9)

ding the arrow (see chapter 6.5.2), change the

flow direction if necessary

Rinse the system with installed filter

(see chapter 6.8)

sealing

(see chapter 6.8)

After 5 minutes the turbidity is vanished

completely

Check the hardness blend setting and the

filter capacity, if necessary use the bigger size

of the filter cartridge

9 Order Numbers

Order Number

Filter Head w/ Bracket 2180373

Replacement cartridge VIZION HRS-100

Replacement cartridge VIZION HRS-200

7000966

7000967

US

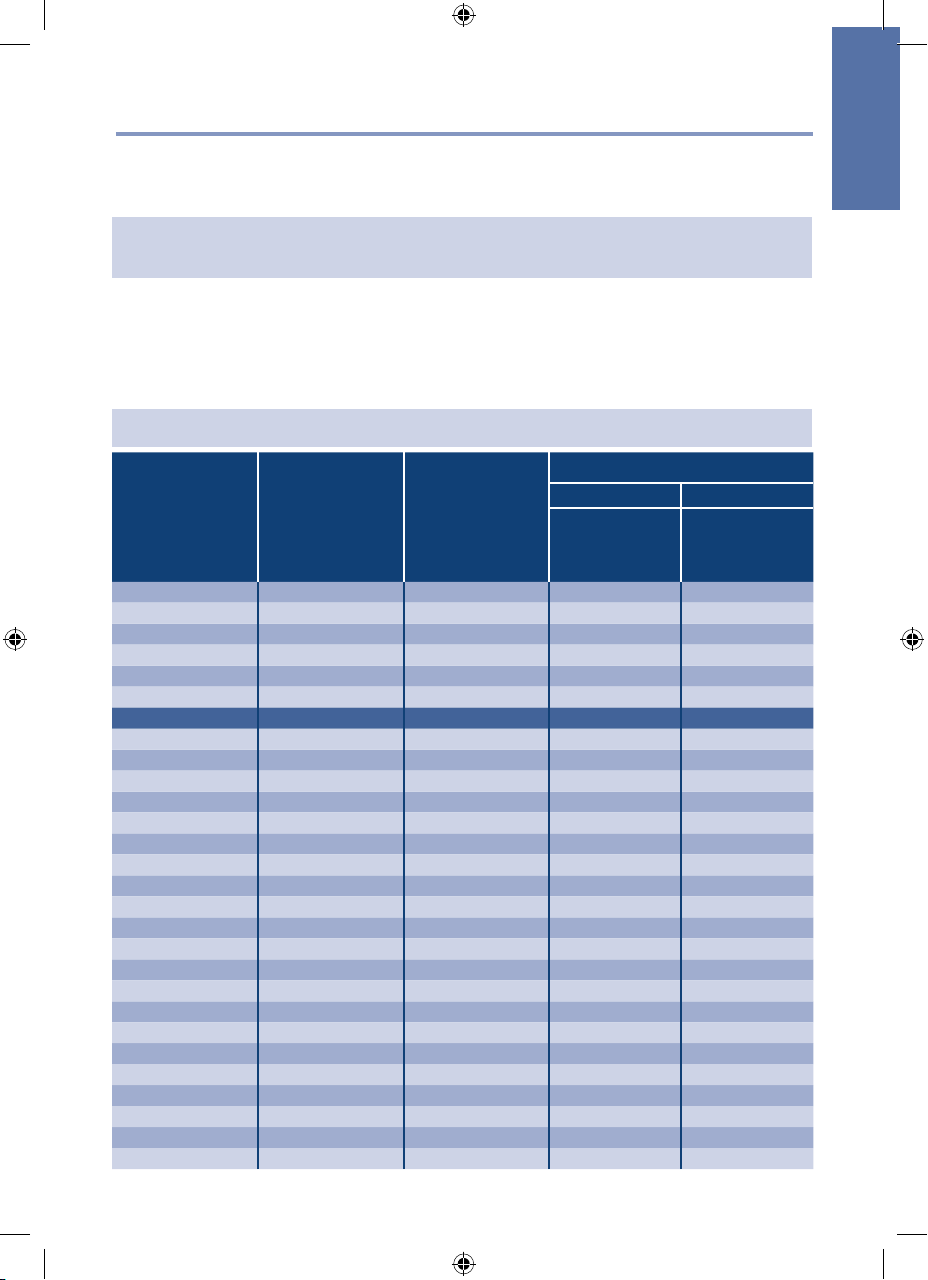

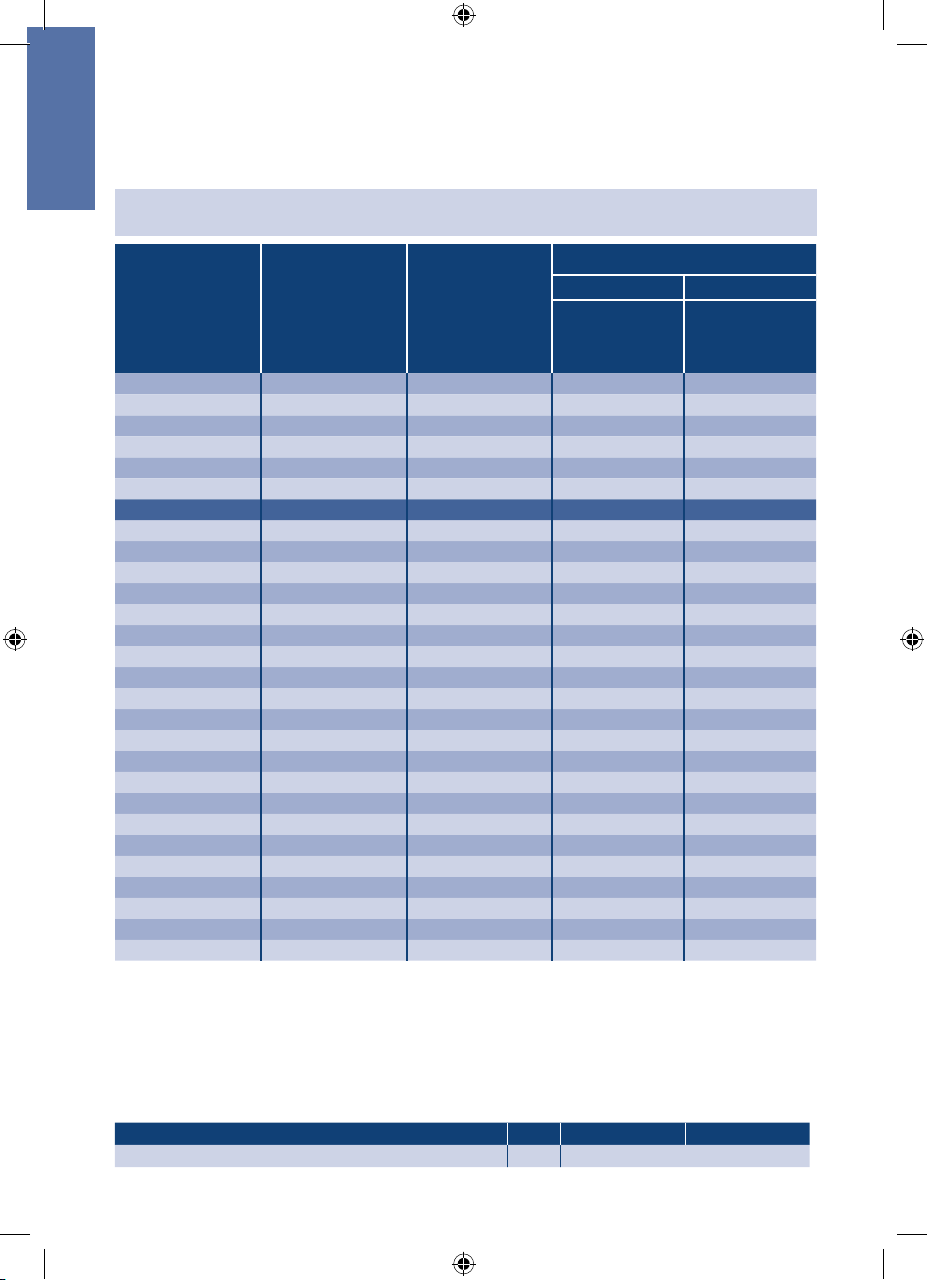

10 Capacities and Blend setting

The following tables show typical capacities and the recommended blend setting depending on the

carbonate hardness (not the Total Hardness) of the water.

NOTE!

f Our recommendation is to choose a size of cartridge, where the capacity requires replacement

every six months, but no longer than 12 months.

f After a shut down period of longer than 4 weeks, the cartridge has to be replaced.

10.1 Application - Capacity

10.1.1 Hot Beverage Machines with steam generator

NOTE!

The actual capacity may vary from the given values provided. Capacity is dependent on the overall

water quality, flow rate, inlet water pressure and the continuity of the flow rate.

ppm

CaCO

3

71 4 3

89 5 3

107 6 3

125 7 3

143 8 3

161 9 3

178 10 3

196 11 2

214 12 2

232 13 2

250 14 2

267 15 2

285 16 1

303 17 1

321 18 1

339 19 1

356 20 1

374 21 1

392 22 1

410 23 1

428 24 1

445 25 1

463 26 1

481 27 1 505 (1,910) 891 (3,372)

499 28 1

517 29 1

534 30 1

> 534 >30 1

Grains

per US gallon

(GPG)

German carbonate

hardness (°dKH)

Blend setting

Filter capacity VIZION HRS

100 200

US

gallons

(Liters)

4,491 (17,000) 7,926 (30,000)

3,593 (13,600) 6,341 (24,000)

2,993 (11,330) 5,284 (20,000)

2,565 (9,710) 4,529 (17,143)

2,246 (8,500) 3,963 (15,000)

1,996 (7,555) 3,523 (13,333)

1,797 (6,800) 3,170 (12,000)

1,464 (5,540) 2,584 (9,781)

1,342 (5,080) 2,369 (8,966)

1,239 (4,690) 2,186 (8,276)

1,151 (4,355) 2,030 (7,685)

1,073 (4,060) 1,895 (7,172)

851 (3,220) 1,503 (5,690)

801 (3,030) 1,415 (5,355)

757 (2,865) 1,336 (5,057)

717 (2,715) 1,266 (4,791)

680 (2,575) 1,203 (4,552)

649 (2,455) 1,145 (4,335)

620 (2,345) 1,093 (4,138)

592 (2,240) 1,046 (3,958)

567 (2,145) 1,002 (3,793)

544 (2,060) 962 (3,641)

523 (1,980) 925 (3,501)

486 (1,840) 859 (3,251)

469 (1,775) 829 (3,139)

454 (1,720) 802 (3,034)

412 (1,560) 729 (2,759)

US

gallons

(Liters)

13

14

US

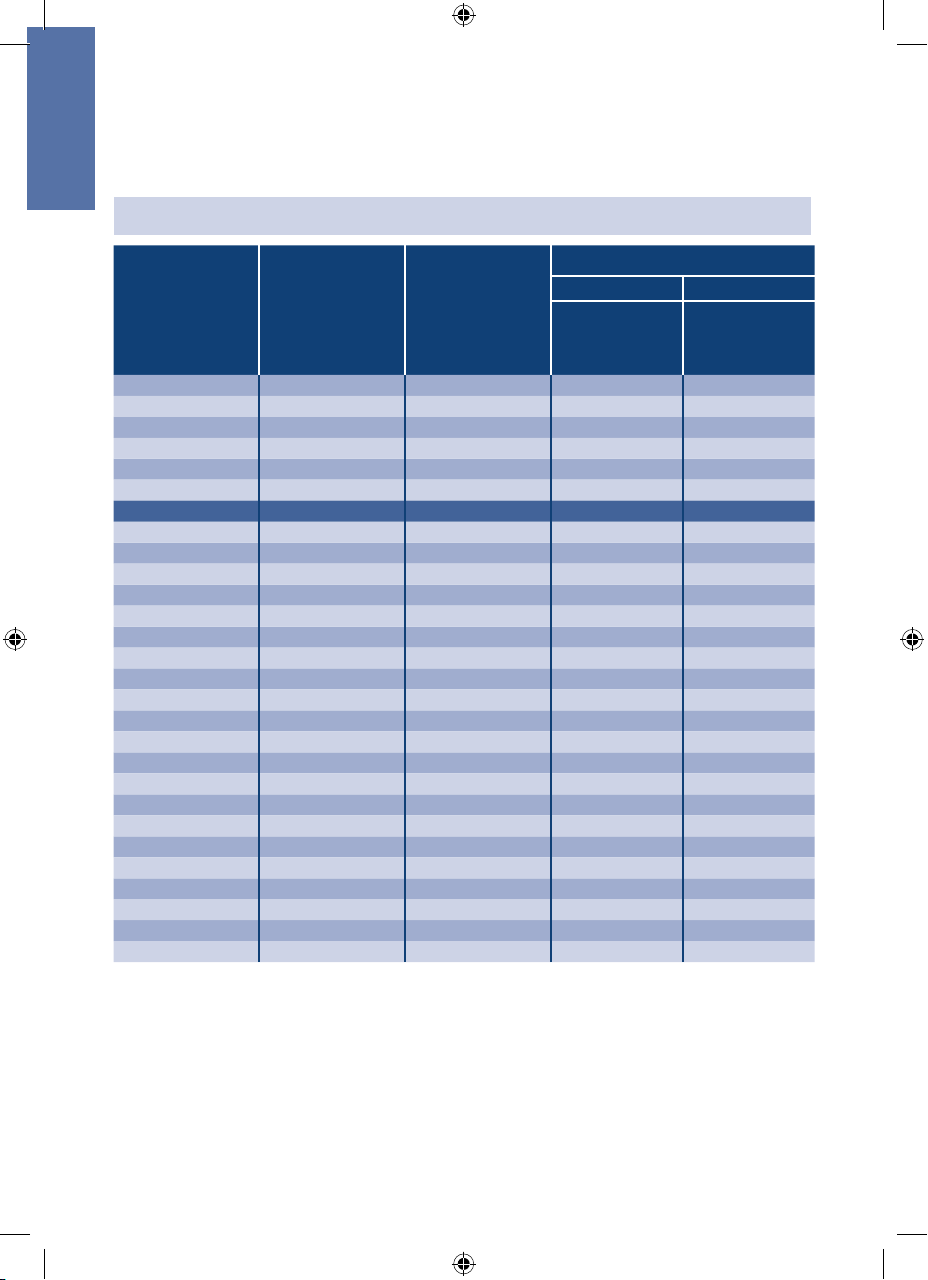

10.1.2 Cold and Hot Beverage Machines without steam generator

[max. temperature 203°F (95°C)]

NOTE!

The actual capacity may vary from the given values provided. Capacity is dependent on the overall

water quality, flow rate, inlet water pressure and the continuity of the flow rate.

ppm

CaCO

3

71 4 3

89 5 3

107 6 3

125 7 3

143 8 3

161 9 3

178 10 3

196 11 3

214 12 3

232 13 3

250 14 3

267 15 3

285 16 3

303 17 3

321 18 3

339 19 3

356 20 3

374 21 3

392 22 3

410 23 3

428 24 3

445 25 2

463 26 2

481 27 2

499 28 2

517 29 2

534 30 2 643 (2,435) 1,137 (4,303)

> 534 >30 2

Grains

per US gallon

(GPG)

German carbonate

hardness (°dKH)

Blend setting

Filter capacity VIZION HRS

100 200

US

gallons

(Liters)

5,390 (20,400) 9,511 (36,000)

4,312 (16,320) 7,609 (28,800)

3,593 (13,600) 6,341 (24,000)

3,079 (11,655) 5,435 (20,571)

2,695 (10,200) 4,756 (18,000)

2,395 (9,065) 4,227 (16,000)

2,156 (8,160) 3,804 (14,400)

1,959 (7,415) 3,459 (13,091)

1,797 (6,800) 3,170 (12,000)

1,658 (6,275) 2,927 (11,077)

1,539 (5,825) 2,717 (10,286)

1,437 (5,440) 2,536 (9,600)

1,347 (5,100) 2,378 (9,000)

1,268 (4,800) 2,238 (8,471)

1,197 (4,530) 2,114 (8,000)

1,135 (4,295) 2,002 (7,579)

1,078 (4,080) 1,902 (7,200)

1,026 (3,885) 1,812 (6,857)

979 (3,705) 1,729 (6,545)

937 (3,545) 1,654 (6,261)

898 (3,400) 1,585 (6,000)

773 (2,925) 1,364 (5,164)

742 (2,810) 1,312 (4,966)

716 (2,710) 1,263 (4,782)

690 (2,610) 1,218 (4,611)

666 (2,520) 1,176 (4,452)

585 (2,215) 1,034 (3,912)

US

gallons

(Liters)

US

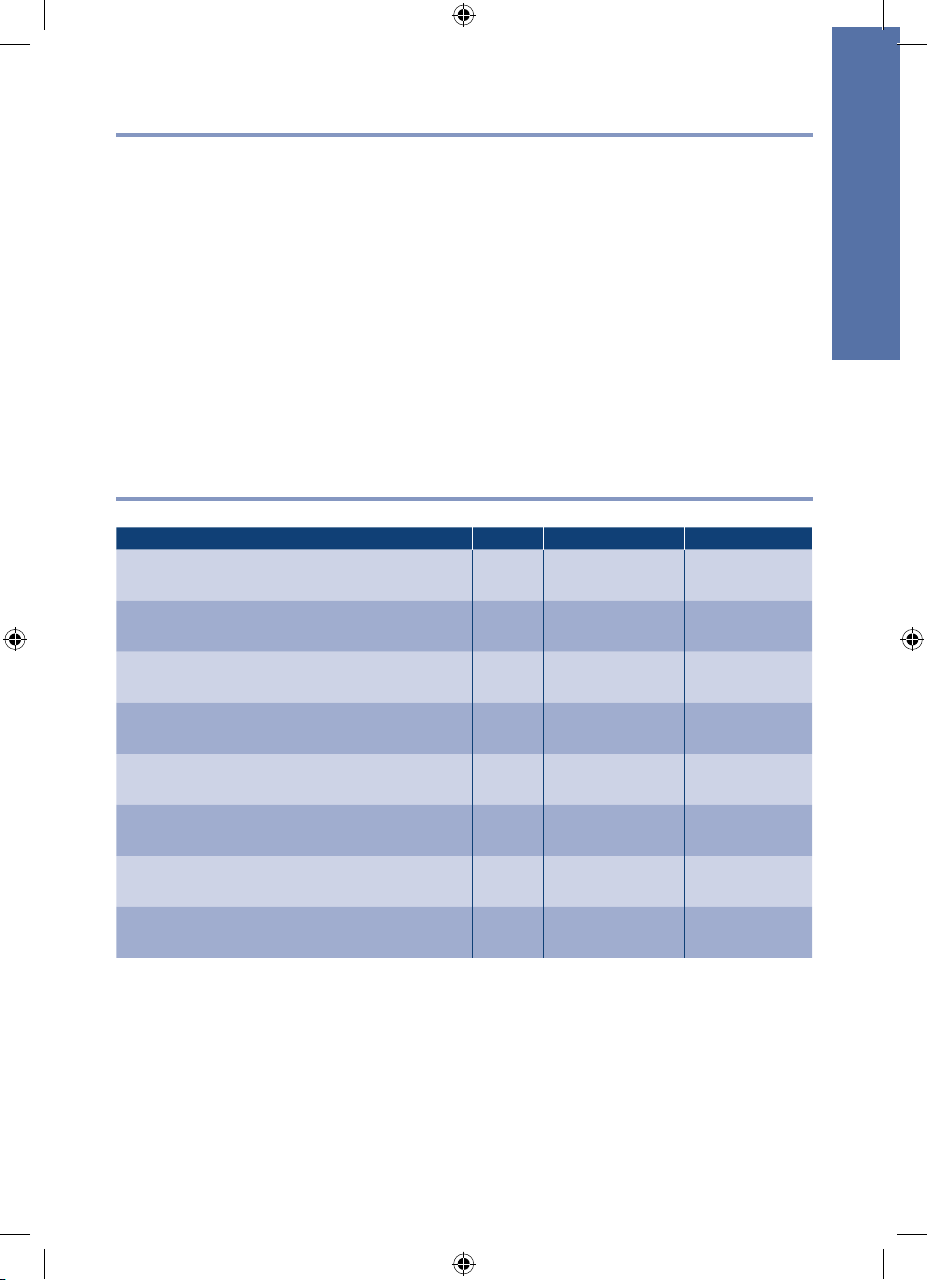

10.1.3 Combi-Steamer or Oven, Blend “1”

15

NOTE!

The actual capacity may vary from the given values provided. Capacity is dependent on the overall

water quality, flow rate, inlet water pressure and the continuity of the flow rate.

ppm

CaCO

3

71 4 1

89 5 1

107 6 1

125 7 1

143 8 1

161 9 1

178 10 1

196 11 1

214 12 1

232 13 1

250 14 1

267 15 1

285 16 1

303 17 1

321 18 1

339 19 1

356 20 1

374 21 1

392 22 1

410 23 1

428 24 1

445 25 1

463 26 1

481 27 1

499 28 1

517 29 1

534 30 1 454 (1,720) 802 (3,034)

> 534 >30 1

Grains

per US gallon

(GPG)

German carbonate

hardness (°dKH)

Blend setting

Filter capacity VIZION HRS

100 200

US

gallons

(Liters)

3,407 (12,895) 6,013 (22,758)

2,725 (10,315) 4,810 (18,206)

2,271 (8,595) 4,008 (15,172)

1,947 (7,370) 3,436 (13,004)

1,703 (6,445) 3,006 (11,379)

1,514 (5,730) 2,672 (10,114)

1,362 (5,155) 2,405 (9,103)

1,239 (4,690) 2,186 (8,275)

1,135 (4,295) 2,004 (7,586)

1,048 (3,965) 1,850 (7,002)

974 (3,685) 1,718 (6,502)

908 (3,435) 1,603 (6,069)

851 (3,220) 1,503 (5,689)

802 (3,035) 1,415 (5,355)

757 (2,865) 1,336 (5,057)

717 (2,715) 1,266 (4,791)

682 (2,580) 1,203 (4,552)

649 (2,455) 1,145 (4,335)

620 (2,345) 1,093 (4,138)

592 (2,240) 1,046 (3,958)

568 (2,150) 1,002 (3,793)

544 (2,060) 962 (3,641)

523 (1,980) 925 (3,501)

505 (1,910) 891 (3,371)

486 (1,840) 859 (3,251)

469 (1,775) 829 (3,139)

412 (1,560) 729 (2,758)

US

gallons

(Liters)

16

US

10.1.4 Combi-Steamer or Oven, Blend “0”

NOTE!

The actual capacity may vary from the given values provided. Capacity is dependent on the overall

water quality, flow rate, inlet water pressure and the continuity of the flow rate.

ppm

CaCO

3

71 4 0

89 5 0

107 6 0

125 7 0

143 8 0

161 9 0

178 10 0

196 11 0

214 12 0

232 13 0

250 14 0

267 15 0

285 16 0

303 17 0

321 18 0

339 19 0

356 20 0

374 21 0

392 22 0

410 23 0

428 24 0

445 25 0

463 26 0

481 27 0

499 28 0

517 29 0

534 30 0

> 534 >30 0

Grains

per US gallon

(GPG)

German carbonate

hardness (°dKH)

Blend setting

Filter capacity VIZION HRS

100 200

US

gallons

(Liters)

3,098 (11,725) 5,466 (20,690)

2,478 (9,380) 4,373 (16,552)

2,065 (7,815) 3,644 (13,793)

1,770 (6,700) 3,124 (11,823)

1,548 (5,860) 2,733 (10,345)

1,376 (5,210) 2,429 (9,196)

1,239 (4,690) 2,186 (8,276)

1,125 (4,260) 1,988 (7,524)

1,032

(3,905)

952 (3,605) 1,682 (6,366)

885 (3,350) 1,562 (5,911)

826 (3,125) 1,458 (5,517)

774 (2,930) 1,367 (5,173)

728 (2,755) 1,286 (4,868)

688 (2,605) 1,215 (4,598)

651 (2,465) 1,151 (4,356)

620 (2,345) 1,093 (4,138)

589 (2,230) 1,041 (3,941)

563 (2,130) 994 (3,762)

538 (2,035) 951 (3,598)

515 (1,950) 911 (3,448)

495 (1,875) 875 (3,310)

476 (1,800) 841 (3,183)

458 (1,735) 810 (3,065)

443 (1,675) 781 (2,956)

427 (1,615) 754 (2,854)

412 (1,560) 729 (2,759)

375 (1,420) 663 (2,508)

1,822

US

gallons

(Liters)

(6,897)

10.2 Chlorine Reduction

The VIZION HRS water filter systems have been tested and certified by NSF International according

to NSF/ANSI 42 for reduction of chlorine.

The concentration of chlorine in water entering the system was reduced to a concentration less than

or equal to the permissible limit for water leaving the system, as specified in NSF/ANSI 42.

While testing was performed under standard laboratory conditions, actual performance of the

system may vary.

VIZION HRS 100 200

Reduction (influent challenge concentration 2.0mg/l) % > 50 %

ES

El manual de instalación y operación ofrece la información necesaria para una operación y manejo seguros del sistema de filtro VIZION HRS-100, HRS-200 (denominado en este manual el sistema de filtro).

El manual de instalación y operación es parte del sistema de filtro y se debe almacenar en un lugar

cercano a él. Debe ser posible el acceso en cualquier momento para cualquier persona que opere

el sistema de filtro. Cada persona que maneje y opere el sistema de filtro tiene que leer y comprender el manual de instalación y operación por completo.

La seguridad en el trabajo se basa en las instrucciones y pautas de seguridad proporcionadas en

este manual de instalación y operación. Además se deberán aplicar las normas estatales y locales

referentes a la seguridad y la prevención de accidentes.

No es posible presentar una queja debido a las Figuras y los Dibujos que aparecen en este manual.

Se muestran para la comprensión principal y pueden diferir de la aplicación real.

Todas las instrucciones, pautas y datos de este manual se dan teniendo en cuenta las normas y requisitos reales, lo más novedoso, así como nuestra experiencia en el campo de filtración y tecnología de agua.

La responsabilidad del fabricante no incluye reclamaciones causadas por:

hacer caso omiso de las instrucciones dadas en el manual de instalación y operación

uso indebido del sistema de filtro

instalación inadecuada o equivocada

operación inadecuada

modificaciones no autorizadas al sistema

cambios técnicos

uso de partes no certificadas

Copyright por A.J. Antunes & Co. Todos los derechos reservados.

La duplicación (en todo o en parte) y la distribución a terceros se prohíben en cualquier caso a menos que exista un acuerdo por escrito con el fabricante.

Actuar en contra de este acuerdo puede ser causa de una demanda de indemnización.

17

Probado y certificado por NSF International contra el estándar 42 NSF/ANSI para

la reducción de cloro, gusto y olor. Visite www.nsf.org para conocer las declaraciones relacionadas con productos con registro NSF.

Visite www.nsf.org en relación con las declaraciones relacionadas con productos con registro NSF.

El Sistema de Filtro de Agua VIZION HRS se usa para eliminar dureza de carbonato (dureza o alcalinidad temporal)* del agua potable para impedir la formación de depósitos de cal en equipos corriente abajo. No use agua no segura desde el punto de vista microbiológico o cuya calidad no se conoce, sin efectuar una adecuada desinfección antes o después de usar el sistema. Use agua fría

con calidad de agua potable. Todos los materiales están aprobados y son seguros para estar en

contacto con agua potable.

* No se hicieron pruebas ni se cuenta con certificación de NSF

ES

18

Índice

1. Material entregado ...............................................................................................................19

1.1 Juego de instalación .........................................................................................................19

1.2 Cartucho de repuesto .......................................................................................................19

2. Datos técnicos ......................................................................................................................19

2.1 Dimensiones y pesos ........................................................................................................ 19

2.2 Condiciones de operación ................................................................................................20

3. Información general .............................................................................................................20

3.1 Explicación de símbolos .................................................................................................... 20

3.2 Información sobre este Manual de instalación y operación ...............................................20

3.3 Garantía limitada y responsabilidad ...................................................................................20

3.4 Responsabilidad del consumidor ...................................................................................... 21

4. Función del filtro ...................................................................................................................21

4.1 Uso asignado ....................................................................................................................21

4.2 Construcción.....................................................................................................................21

5. Instrucciones de operación y seguridad ...........................................................................22

5.1 Uso buscado ....................................................................................................................22

5.2 Personal calificado ............................................................................................................ 23

5.3 Operación después de un paro .........................................................................................23

5.4 Intervalo de reemplazo ......................................................................................................23

5.5 Desecho............................................................................................................................23

6. Instalación de filtro ...............................................................................................................23

6.1 Calidad del agua ............................................................................................................... 23

6.2 Presión ..............................................................................................................................24

6.3 Selección de materiales ....................................................................................................24

6.4 Desempacar el filtro ..........................................................................................................24

6.5 Montaje de la cabeza de filtro y el soporte de pared .........................................................24

6.5.1 Montaje del soporte de pared ..................................................................................24

6.5.2 Montar la cabeza de filtro .........................................................................................25

6.6 Instalación de un medidor de agua ................................................................................... 25

6.7 Determinación de la capacidad del filtro y el ajuste de desviación .....................................25

6.8 Instalación del cartucho de filtro ........................................................................................26

6.8.1 Enjuagar/purgar con el dispositivo ...........................................................................26

6.8.2 Lavar/purgar con una derivación de enjuague .........................................................27

6.8.3 Enjuague/purgue usando la salida o la manguera de desecho de agua ..................27

6.9 Reemplazo del cartucho de filtro .......................................................................................27

7. Servicio y mantenimiento ....................................................................................................28

8. Solución de problemas ........................................................................................................29

9. Números de pedido ..............................................................................................................29

10. Capacidades y ajuste de desviación ..................................................................................30

10.1 Aplicación capacidad ......................................................................................................30

10.1.1 Máquinas de bebidas calientes con generador de vapor ......................................30

10.1.2 Máquinas de bebidas calientes y frías sin generador de vapor

[máx. temp. 203 °F (95 °C)] ..................................................................................32

10.1.3 Horno de vapor combinado o máquina de hielo, desviación “1” ...........................32

10.1.4 Horno de vapor combinado o máquina de hielo, desviación “0” ...........................33

10.2 Reducción de cloro .........................................................................................................33

10.3 Capacidad basada en reducción de cloro .......................................................................33

ES

1 Material entregado

1.1 Juego de instalación

El juego de instalación consiste en las siguientes partes (ver Fig. 1):

Cabeza de filtro (1) con rosca hembra para la conexión al cartucho de filtro. La cabeza se adapta

a diferentes tamaños de cartucho de filtro VIZION HRS. Hay un aqua stop y dos

válvulas de retención (entrada y salida) en la cabeza de filtro

Soporte de pared (2) para montar el cartucho de filtro

Cartucho de filtro (HRS-100, HRS-200) (3) con tapa higiénica y rosca macho como contraparte a

la cabeza de filtro (1)

Instrucciones y manual de instalación y operación

Por razones de higiene todas las partes están envueltas en una hoja protectora.

1.2 Cartucho de repuesto

El paquete de repuesto incluye un cartucho de filtro VIZION HRS con una tapa protectora/higiénica

(3) envuelta en una hoja protectora e incluye el manual de instalación y operación.

2 Datos técnicos

2.1 Dimensiones y pesos

VIZION HRS 100 200

Altura total sin soporte de montaje en pared (A)

Altura total con soporte de montaje de pared (B)

Altura al centro de la conexión (C)

Distancia requerida para el servicio (D)

Longitud de instalación (E)

Ø de cartucho de filtro (F)

Peso de cartucho de filtro, cartucho seco aprox.

Pulg.

Pulg.

(mm)

Pulg.

Pulg.

(mm)

Pulg.

Pulg.

(mm)

Pulg.

Pulg.

(mm)

Pulg.

Pulg.

(mm)

Pulg.

Pulg.

(mm)

lb

(kg)

19.30-19.69

5

19

– 19

/16

(490 – 500)

20.87

20

(530)

17.72

17

(450)

2.56

2

(65)

4.93

15

4

(125)

5.71

11

5

(145)

8.38

(3.8)

22.44-22.83

11

/16

7

/8

11

/16

9

/16

/16

/16

7

22

/16

(570 – 580)

23,62

23

(600)

20.47

20

(520)

2

4

(125)

7

(185)

16.53

– 22

5

/8

7

/16

2.56

9

/16

(65)

4.93

15

/16

7.28

1

/4

(7.5)

13

/16

19

Peso de cartucho de filtro, húmedo aprox. lb

(kg)

13.23

(6.0)

24.25

(11.0)

ES

20

2.2 Condiciones de operación

VIZION HRS 100 200

Conexiones de entrada y salida 3/8” BSP male

Gasto nominal

Presión de trabajo, mín.-máx.

Presión de entrada de agua requerida psi (bar)

Caída de presión a 8 galones U.S./h

(0.5 litros/min.)

Caída de presión a 16 galones U.S./h

(1 litro/min.)

Caída de presión a 48 galones U.S./h

(3 litros/min.)

Temperatura del agua: mín-máx. °F (°C)

Temperatura ambiente: mín-máx. °F (°C)

Temperatura ambiente de transporte y

almacenamiento, mín.-máx.

Posición de operación/instalación

(1)

Ajuste de desviación “2”, incluyendo una manguera de 59.06 (591/16) pulgadas (1.5 m) DN8 montada en entrada y salida

(1)

(1)

(1)

Galones U.S./d (l/d)

Galones U.S./min.

psi (bar)

psi

(bar)

psi

(bar)

psi

(bar)

°F (°C)

720 (2.725)

29 – 116 (2 – 8)

>17.4 (>1.2)

1.5

(0.10)

2.2

(0.15)

7.3

(0.50)

+39 to +86 (+4 to +30)

+39 to +100 (+4 to +38)

-4 to +100 (-20 to +38)

horizontal or vertical

3 Información general

3.1 Explicación de símbolos

Los precauciones de uso y seguridad están marcadas por símbolos y comienzan con la palabra de

señal adecuada para expresar su importancia.

Siga las instrucciones y advertencias dadas para evitar riesgo para la salud y daños materiales.

I ¡ADVERTENCIA!

… Indica una situación posiblemente peligrosa que puede causar riesgo a la salud

0.5 (1.9)

2.9

(0.20)

4.4

(0.30)

8.7

(0.60)

I ¡PRECAUCION!

… Indica una situación posiblemente peligrosa que puede causar daños materiales

Recomendaciones

NOTA

… Información adicional para una operación eficiente y óptima

3.2 Información sobre este Manual de instalación y operación

Este Manual de instalación y operación ofrece la información necesaria para la instalación y operación correctas del sistema de filtro.

Asegúrese de que la instalación cumpla con las normas estatales y locales aplicables para la operación, instalación y también para el desecho de los filtros usados.

Cada persona que maneje y opere el sistema de filtro tiene que leer y comprender el manual de instalación y operación por completo.

3.3 Garantía limitada y responsabilidad

El Fabricante garantiza al comprador o consumidor original, que todo el equipo que fabrica estará libre de defectos en materiales y mano de obra durante un periodo de 2 años a partir de la fecha de

compra. Esta garantía está sujeta a exclusiones y limitaciones.

Todas las recomendaciones y datos de este manual se dan teniendo en cuenta las normas y requisitos reales, lo más novedoso, así como nuestra experiencia en el campo de filtración y tecnología

de agua.

Loading...

Loading...