Aiwa XR-HG7MD Service Manual

XR-HG7MD

EZ, K

SERVICE MANUAL

MD / CD

STEREO SYSTEM

SYSTEM

XR-HG7MD

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

(S/M Code No. 09-008-349-4T1).

If requiring information about the CD mechanism, see Service Manual of AZG-1

(S/M Code No. 09-001-335-3NE).

If requiring information about the MD mechanism, see Service Manual of AZG-T

(S/M Code No. 09-007-348-1N2).

MD/CD

CASSEIVER

CX-NHG7MD

BASIC TAPE MECHANISM : AZM-1 A1

BASIC CD MECHANISM : AZG-1 SB3RNMD

BASIC MD MECHANISM : AZG-T D

SPEAKER

SX-WNH81

REMOTE

CONTROLLER

RC-ZAS18

S/M Code No. 09-008-349-4R1

REVISION

DATA

SPECIFICATIONS

Main unit CX-NHG7MD

FM tuner section

Tuning range 87.5 MHz to 108 MHz

Usable sensitivity (IHF) 16.8 dBf

Antenna terminal 75 ohms (unbalanced)

AM (MW) tuner section

Tuning range 531 kHz to 1602 kHz (9 kHz step)

530 kHz to 1710 kHz (10 kHz step)

Usable sensitivity 350 µV/m

Antenna Loop antenna

LW tuner section

Tuning range 144 kHz to 290 kHz

Usable sensitivity 1400 µV/m

Antenna Loop antenna

Amplifier section

Mid-high frequency amplifier

Power output Rated: 20 W + 20 W (8 ohms,

T.H.D. 1 %, 1 kHz/DIN 45500)

Reference : 25 W + 25 W (8 ohms,

T.H.D. 10 %, 1 kHz/DIN 45324)

DIN MUSIC POWER:

40 W + 40 W

Total harmonic distortion 0.1 % (10 W, 1 kHz, 8 ohms, DIN

AUDIO)

Low frequency amplifier

Power output Rated: 60 W + 60 W (6 ohms,

T.H.D. 1 %, 130 Hz/DIN 45500)

Reference : 75 W + 75 W (6 ohms,

T.H.D. 10 %, 130 Hz/DIN 45324)

DIN MUSIC POWER:

130 W + 130 W

Total harmonic distortion 0.1 % (30W, 130 Hz, 6 ohms, DIN

AUDIO)

Inputs VIDEO/AUX: 316 mV

DIGITAL IN (OPTICAL)

Outputs SPEAKERS LOW FREQ:

accept speakers of 6 ohms or more

SPEAKERS HIGH FREQ:

accept speakers of 8 ohms or more

SURROUND SPEAKERS:

accept speakers of 8 ohms to 16

ohms

PHONES (stereo jack): accepts

headphones of 32 ohms or more

CD DIGITAL OUT (OPTICAL) jack

Compact disc player section

Laser Semiconductor laser (λ = 780 nm)

D-A converter 1 bit dual

Signal-to-noise ratio 85 dB (1 kHz, 0 dB)

Harmonic distortion 0.05 % (1 kHz, 0 dB)

Wow and flutter Unmeasurable

MD recorder section

Scanningmethod Non-contact optical scanner

(Semiconductor laser application)

Recording system Magnetic polarity modulation

overwrite system

Rotation speed Approx. 400 - 900 rpm (CLV)

Sampling frequency 44.1 kHz

No. of channels Stereo: 2 channels

Monaural: 1 channel

A-D, D-A converter 1-bit

Frequency 20 to 20000 Hz + 0.5 - –1.5 dB

Wow & Flutter Unmeasurable

Cassette deck section

Track format 4 tracks, 2 channels stereo

Frequency response 50 Hz – 15000 Hz

Recording system AC bias

Heads Recording/playback head x 1,

erase head x 1

General

Power requirements 230 V AC, 50 Hz

Power consumption 160 W

Power consumption in standby mode

If the power-economizing mode is

ECO OFF: 22 W

If the power-economizing mode is

ECO ON or ECO AUTO: 0.9 W

Dimensions of main unit 260 x 324 x 394 mm

(W x H x D)

Weight of main unit 11 kg

Speaker system SX-WNH81

Speaker system 3 way, Built-in subwoofer (magnetic

shielded type)

Speaker units Subwoofer: 200 mm cone type

Full range: 120 mm cone type

Super tweeter: 20 mm ceramic type

Impedance 6 ohms/8 ohms

Sensitvity 87 dB/W/m

Dimensions (W x H x D) 240 x 324 x 285 mm

Weight 5.7 kg

ACCESSORIES LIST

REF. NO PART NO. KANRI DESCRIPTION

NO.

1 8A-DB6-915-010 IB,K(E)I<K>

1 8A-DB6-916-010 IB,EZ(9L)I<EZ>

2 8Z-NB5-703-010 RC UNIT,RC-ZAS18

3 87-006-225-010 ANT,LOOP ANT NC2

4 87-A90-118-010 ANT,WIRE FM(Z)

! 5 87-099-811-010 PLUG,ADPTR CONV(K)<K>

• Design and specifications are subject to change without notice.

• The word “BBE” and the “BBE symbol” are trademarks of BBE

Sound, Inc.

• Under license from BBE Sound, Inc.

2

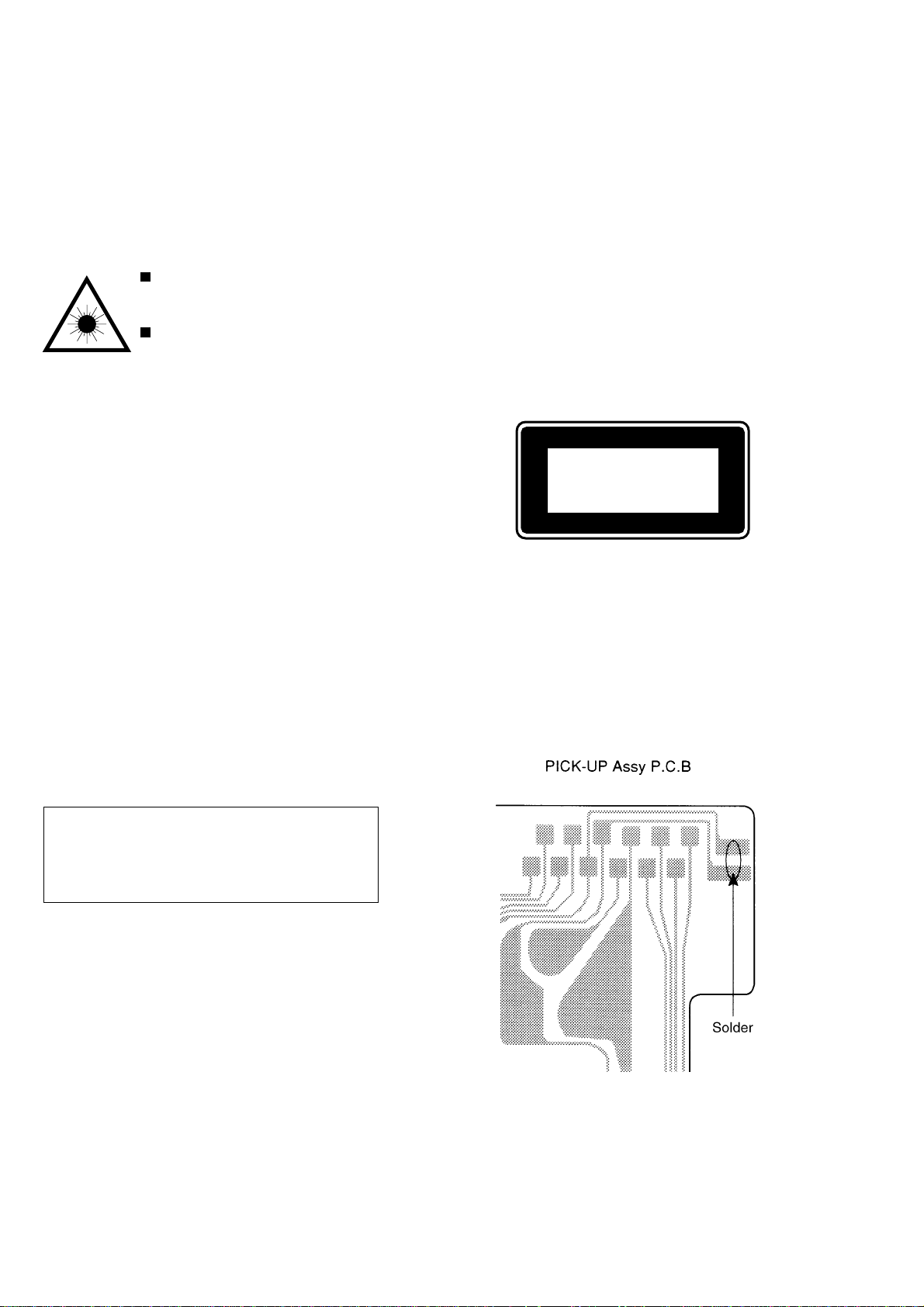

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

CLASS 1

KLASSE 1

LUOKAN 1

KLASS 1

LASER PRODUCT

LASER PRODUKT

LASER LAITE

LASER APPARAT

This set employs laser. Therefore, be sure to follow carefully the

instructions below when servicing.

WARNING!

WHEN SERVICING, DO NOT APPROACH THE LASER EXIT

WITH THE EYE TOO CLOSELY. IN CASE IT IS NECESSARY TO

CONFIRM LASER BEAM EMISSION. BE SURE TO OBSERVE

FROM A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL

PICK-UP BLOCK.

Caution: Invisible laser radiation when

open and interlocks defeated avoid exposure to beam.

Advarsel:Usynling laserståling ved åbning,

når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

VAROITUS!

Laiteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyt-täjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION

L'utilisation de commandes, réglages ou procédures autres que

ceux spécifiés peut entraîner une dangereuse exposition aux

radiations.

ADVARSEL!

Usynlig laserståling ved åbning, når sikkerhedsafbrydereer ude

af funktion. Undgå udsættelse for stråling.

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located on the rear

exterior.

VARNING!

Om apparaten används på annat sätt än vad som specificeras i

denna bruksanvising, kan användaren utsättas för osynling

laserstrålning, som överskrider gränsen för laserklass 1.

Precaution to replace Optical block

(KSS-213F)

Body or clothes electrostatic potential could ruin

laser diode in the optical block. Be sure ground

body and workbench, and use care the clothes

do not touch the diode.

1) After the connection, remove solder shown in

the right figure.

3

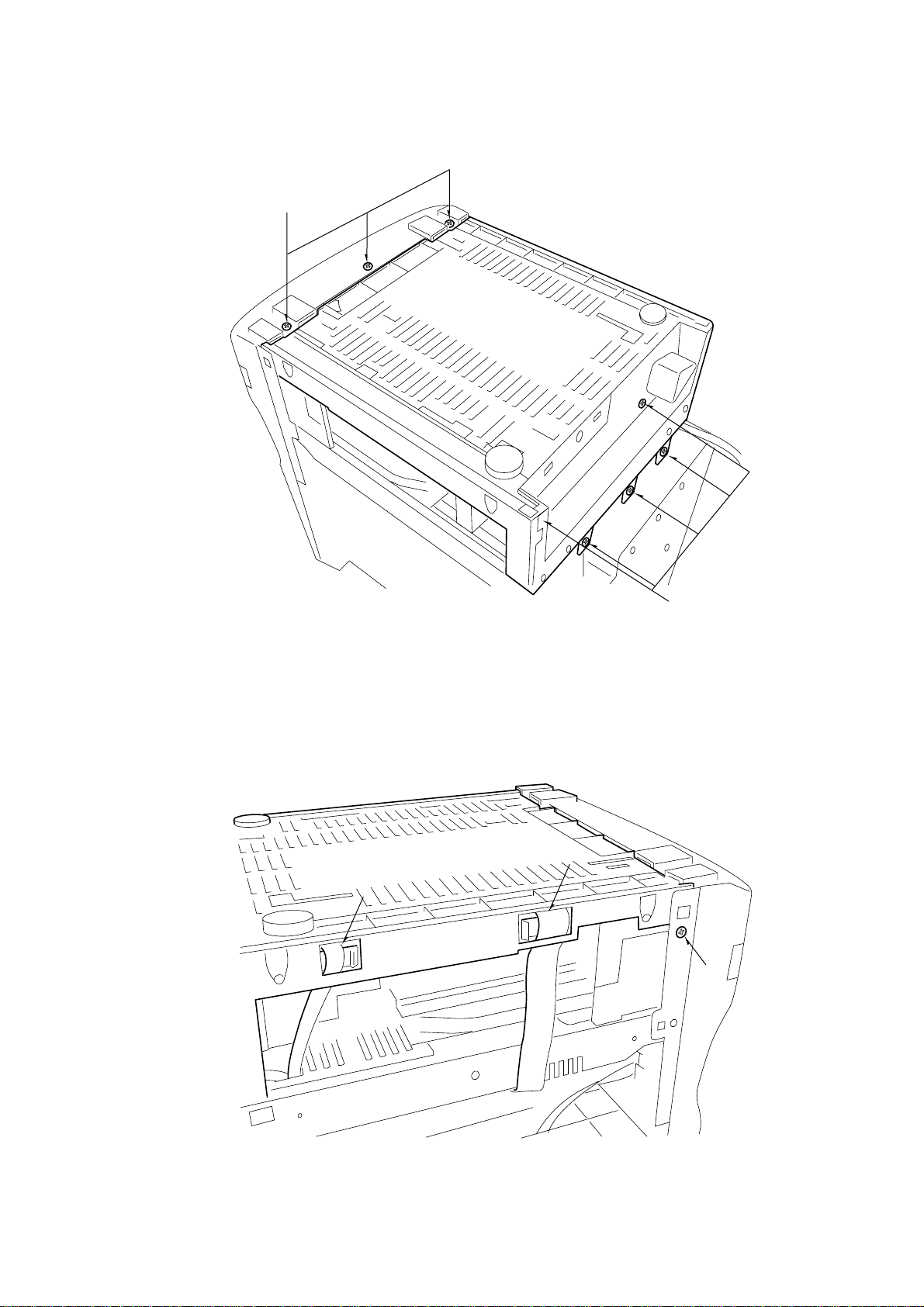

NOTE ON BEFORE STARTING REPAIR

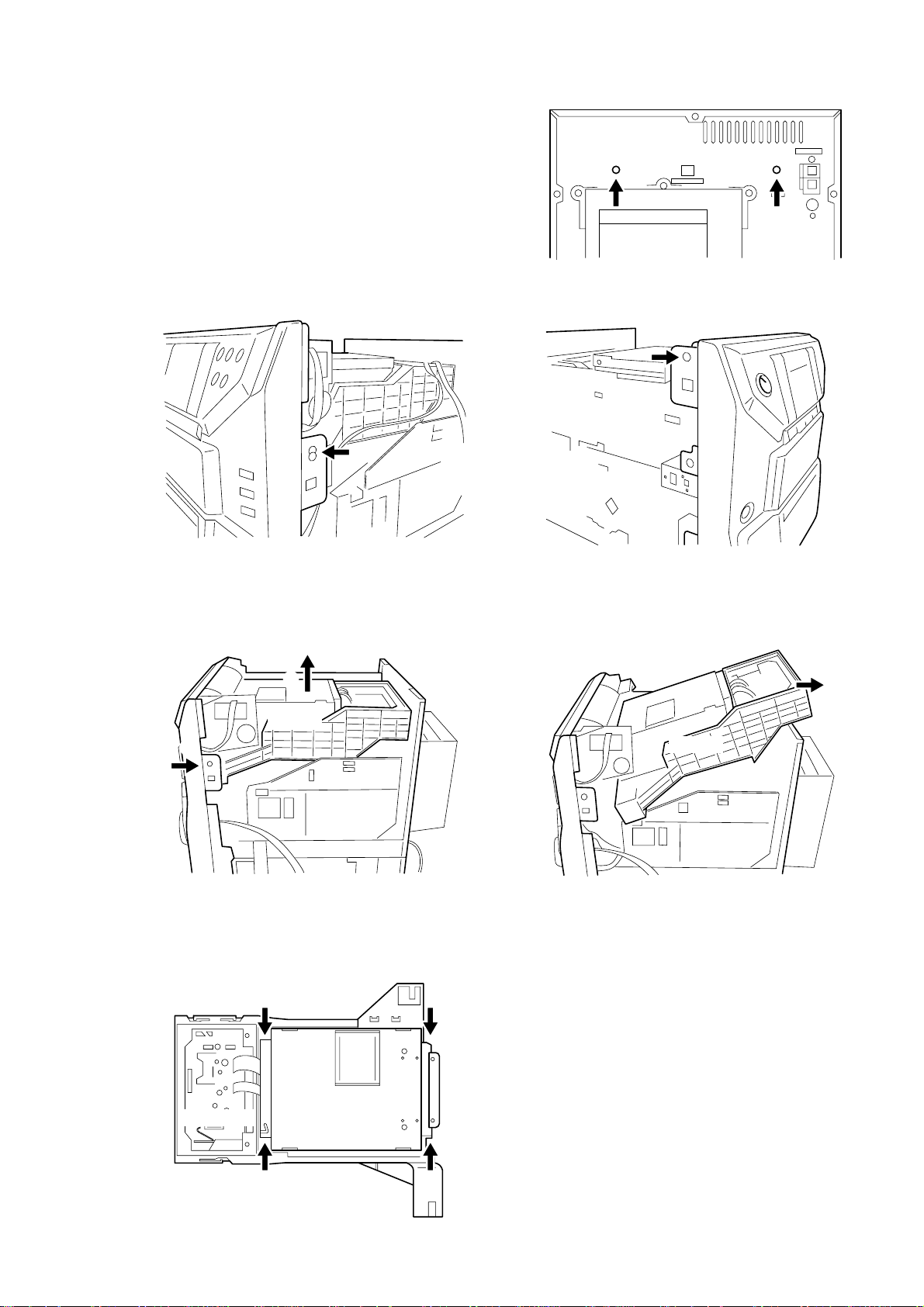

• CD service position

Remove the CABI, STEEL.

Remove the five screws (BVT2+3-10) A.

Turn over the unit and remove the CABI, BOTTOM.

A

A

Remove the two FFCs (13P and 6P) the CD block from the hook of the CABI, BOTTOM.

Loosen the two screws (QT2+3-12) B of the AZG-1 CABI, FR. (The screws are used at the both sides.)

B

4

Remove the hooks in the direction of the arrow. (The hooks are used at the both sides.) Pull the CABI, BOTTOM up to the diagonally

top right and remove it.

HOOK

Lay down the unit and remove the 3ZG-2 mechanism.

Extend the 3ZG-2 mechanism using the respective extension jigs.

Service position

5

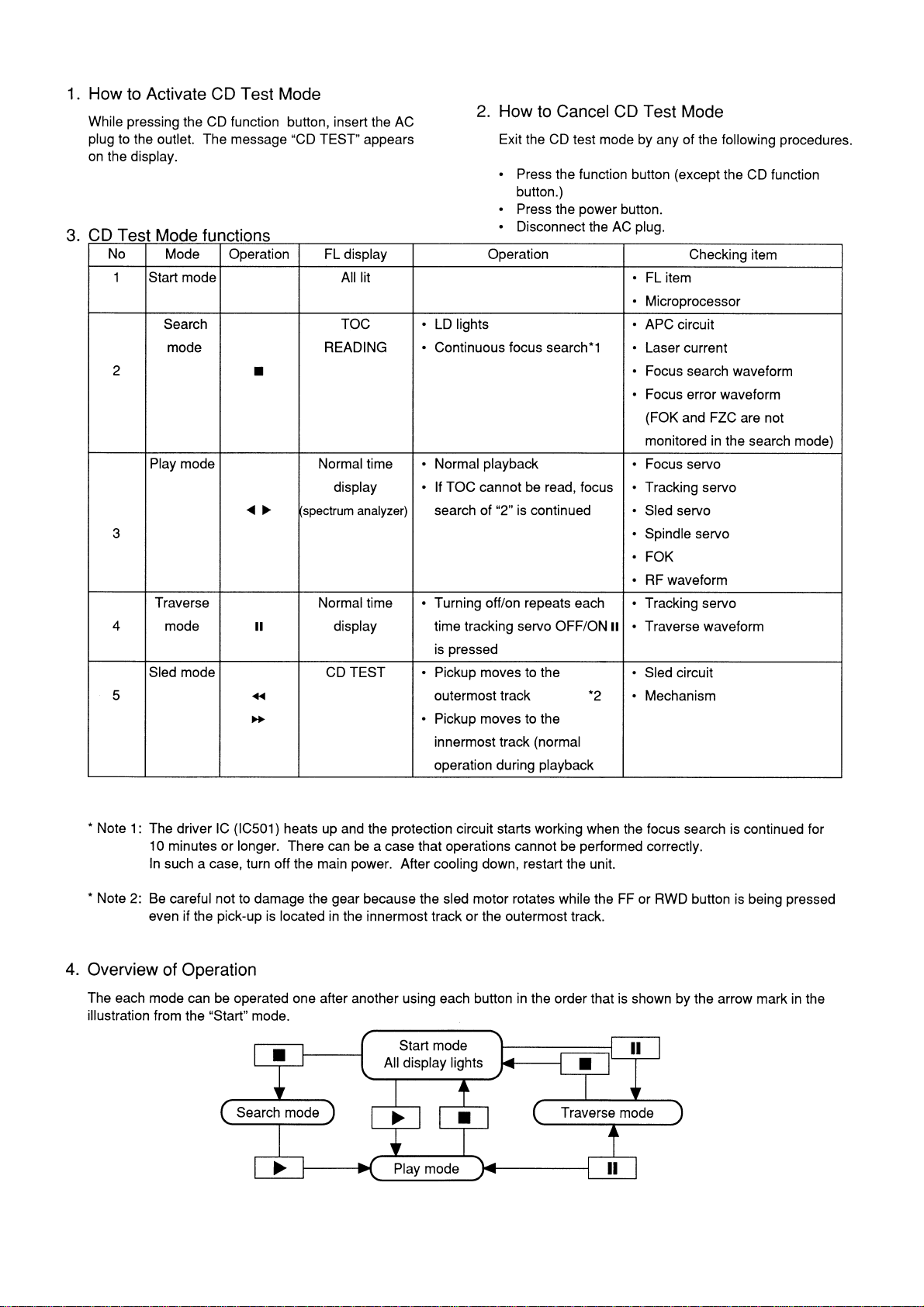

TEST MODE <CD>

6

MD TEST MODE

1. Starting up the MD Test Mode

While pressing the MD function button, insert the AC plug into the outlet.

Notes: 1) Mechanical abnormalities are ignored while the test mode is starting up.

If any abnormality occurs, disconnect the plug immediately.

2) During test mode operation, playback and recording are not possible.

2. Checking the MD Test Mode

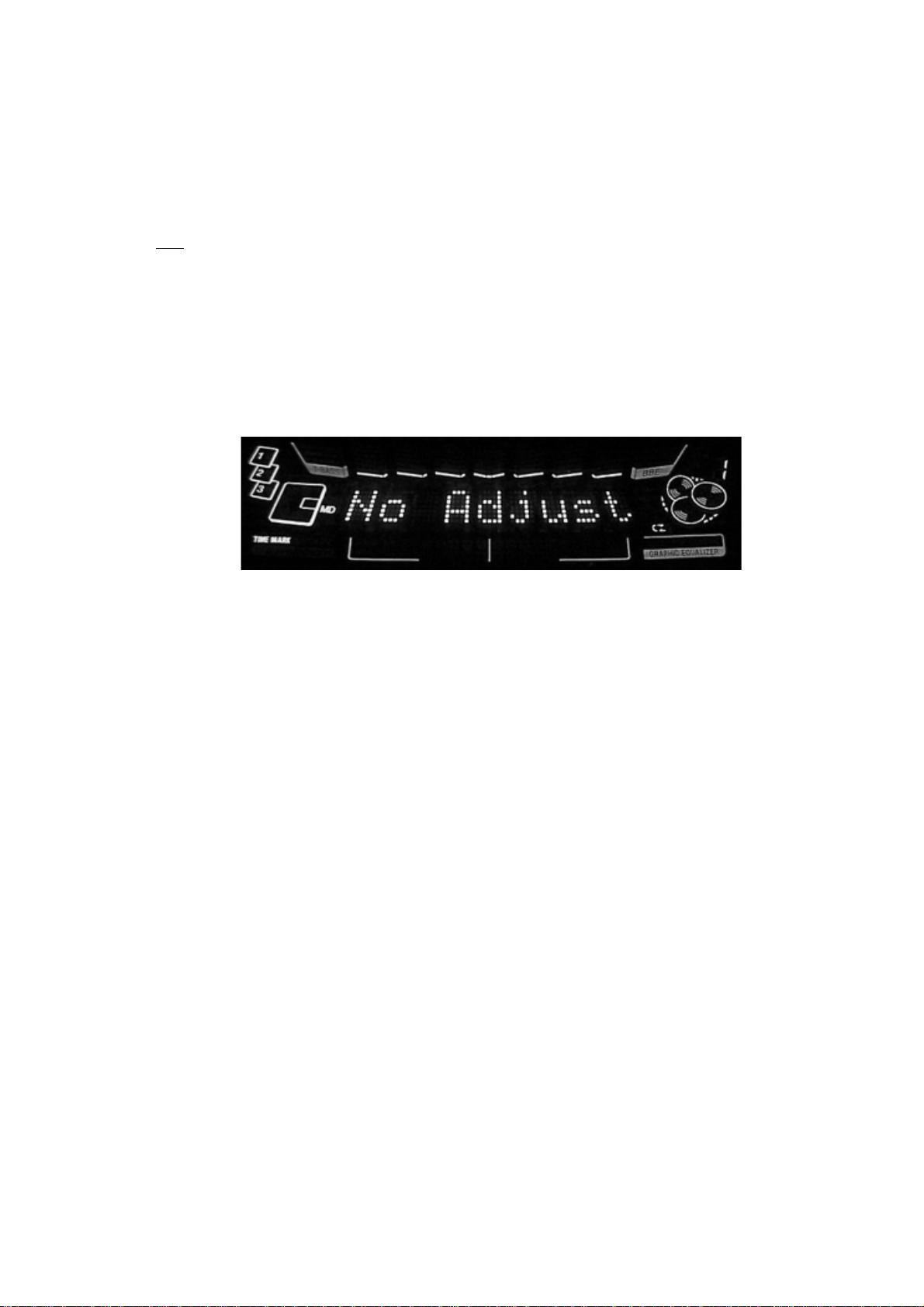

Indication

About five seconds after the test mode starts, characters are displayed as shown below on the display and the test mode becomes

usable.

3. Canceling the MD Test Mode

1) Keep pressing the MD EJECT button to eject the disk.

2) Disconnect the AC plug.

* If the MD test mode is canceled by procedures other than the above, the unit sometimes run incorrectly when the power is turned

on again. If this happens, disconnect the AC plug.

4. Switching to the Servo Standby Mode

After starting up the test mode, press the STOP button to switch to the servo standby mode. (Indication: ALL SVoFF)

Change from the this mode to other modes.

When the STOP button is pressed in each mode, the display returns to “ALL SVoFF”.

4-1. Audio System Output Check

The signal of 1 kHz, -17 dBV (140 mV) can be checked using the MD board AOUTL, AOUTR in the test mode.

5. Checking the Sled Feed Operation

1) Press the CD ™ 1MD REC button to load the mechanism.

2) Press the F.SKIP button in the “ALL SVoFF” state to move the pickup to the outer circumference.

Then “T.SLED fwd” is displayed.

3) Press the B.SKIP button in the “ALL SVoFF” state to move the pickup to the inner circumference.

Then “T.SLED rvs” is displayed. Turn on the INSIDE LIMIT switch to turn on the graphic equalizer “CLASSIC”.

4) After checking, press the B.SKIP button to move the pickup to the innermost circumference (CLASSIC lights) and press the MD

EJECT button to unload the mechanism.

6. Checking the Laser Power

1) Every time the EDIT button is pressed in the “ALL SVoFF” state, the laser power is switched. The display is switched as shown

below.

LA READ LA WRITE

2) After checking, press the STOP button to return the display to “ALL SVoFF”.

LA 1/2

ALL SVoFF

7

7. Checking the Loading Mechanism and OWH

To check the operations of the loading mechanism and OWH, follow the procedure given below.

Method 1: Insert the MO disk into the desired slot of magazines 1 to 3 and press the MD DISC DIRECT PLAY button of the slot.

After loading, confirm that the OWH moves up.

Method 2: Press CD ™ 1MD button in the “ALL SVoFF” state. The mechanism is loaded regardless of whether a disk is inserted.

To load the disk, insert the disk into the slot at the position where the elevator stops.

Every time the CD ™ 1MD REC button or MD EJECT button is pressed during loading, the OWH moves up or down.

CD ™ 1MD .................. The OWH moves down.

MD EJECT button....... The OWH moves up and is unloaded.

Note: Even if the MD DISC DIRECT PLAY button is pressed when a disk is not inserted into the slot, loading is not performed.

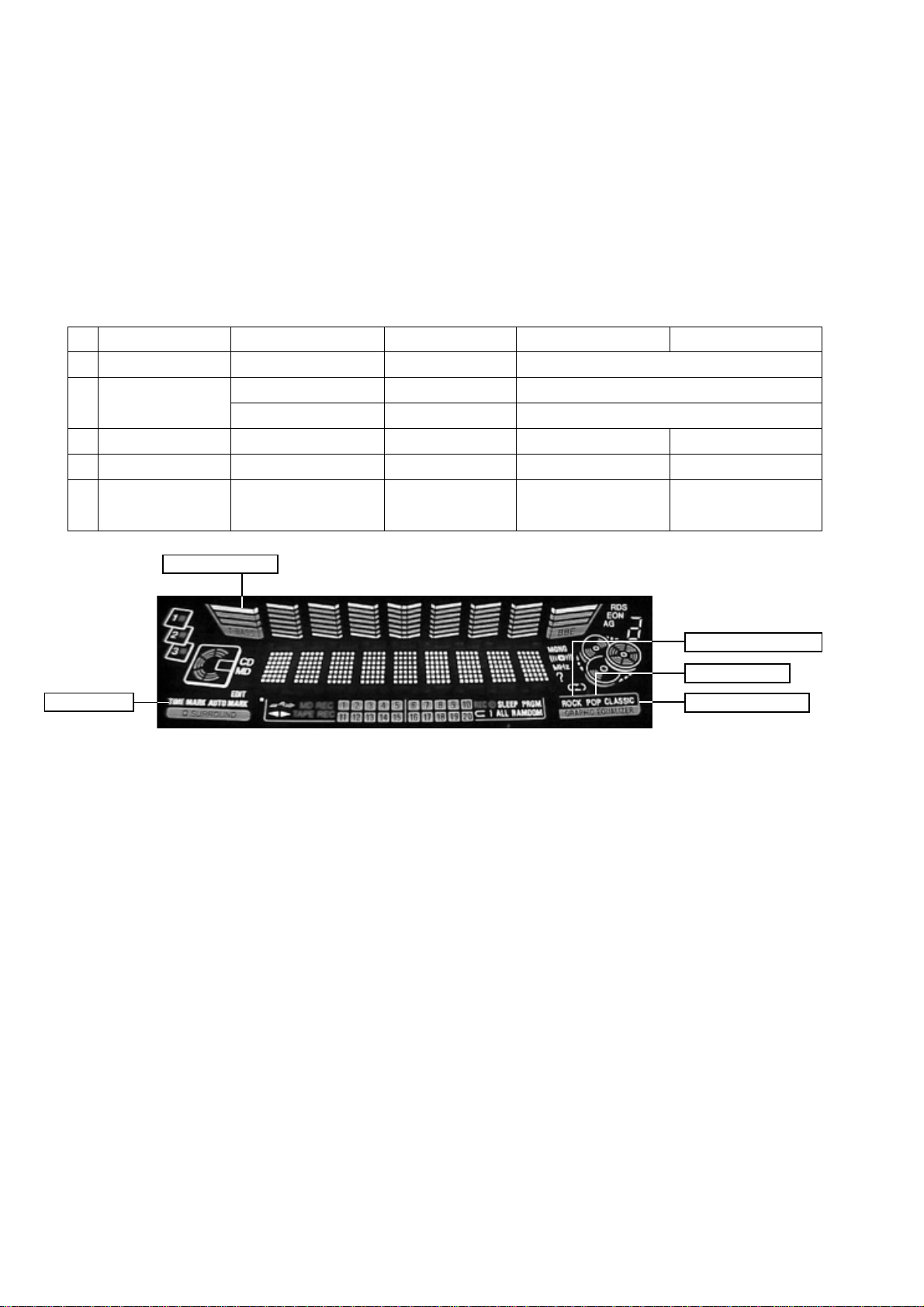

8. Display Indication

The state of the circuits, selected disk and switches can be checked on the display.

Function Display Pict indication During pict on During pict off

1 Laser power LA READ-1/2-WRITE T-BASS Displayed using the three-step level meter

2 Disk type SEL GRV AUTO MARK MO DISC (for recording and playback)

SEL PIT TIME MARK PIT DISC (for playback)

3 REC PROTECT SW ROCK REC is possible REC protect

4 REFLECT SW POP PIT DISC MO DISC

5 INSIDE LIMIT SW CLASSIC SW ON SW OFF

(innermost circumference)

1 LASER POWER

2 DISC TYPE

9. Checking the Servo Operation

9-1. Checking the Focus Search and Spindle Kick 1 (checking the S-curve)

1) When the RANDOM/REPEAT button of the remote control is pressed in the “ALL SVoFF” state, the focus search is

performed. Then “FOCUS CHK” is displayed. These operations are repeated regardless of whether a disk is installed.

Therefore, the S-curve can be checked with the disk inserted.

2) After checking, press the STOP button to return the display to “ALL SVoFF”.

9-2. Checking the Focus Search and Spindle Kick 2

1) When the PLAY button is pressed in the “ALL SVoFF” state without inserting a disk, the search and spindle kick are

performed at the same time. Then “FOCUS SCH” is displayed.

2) After checking, press the STOP button to return the display to “ALL SVoFF”.

9-3. Checking the Focus Servo

1) Insert a disk.

2) Press the MODE button and set the servo mode according to the inserted disk as shown below.

• MO disk ................Indication “SEL GRV” appears and “TIME MARK” lights.

• PIT disk ................ Indication “SEL PIT” appears and “AUTO MARK” lights.

3) Press the PLAY button.

If the focus servo is normal, “FOCUS SRCH” appears and “FOCUS ON!” appears.

4) After checking, press the STOP button to return the display to “ALL SVoFF”.

3 REC PROTECT SW

4 REFLECT SW

5 INSIDE LIMIT SW

9-4. Checking the All Servo ON

1) When the ENTER button is pressed in the “FOCUS ON!” state, the tracking sled servo is turned on and all servos run. If the

servos are all normal, “ALL SV ON” is displayed.

2) After checking, press the STOP button to return the display to “ALL SVoFF”.

8

ELECTRICAL ADJUSTMENT

All the adjustments and checks of the MD block are performed in the test mode.

When “No Adjust” appears on the display, follow sections 1 through 3 to adjust.

1. Temperature Compensation Adjustment

* Normally, do not perform the temperature compensation adjustment.

If the adjustment value is extensively different, perform the adjustment as given below in a suitable environment for measuring

the correct temperature near the unit.

• Test point: Check the test point on the display.

• Tool: Thermometer

1) After the MD test mode starts up, press the STOP button to display “ALL SVoFF”.

2) Press the DISPLAY button to display “TEMP = $**”.

3) Press the PAUSE button to display “T + **C :+ 00”.

4) Put the thermometer near the MD mechanism to measure the room temperature.

5) Check the values of the thermometer and press the B.SKIP button and the F.SKIP button until the value is the same as ** of the

display. Press the ENTER button to store the value.

6) After adjustment, press the STOP button to return the display to “ALL SVoFF”.

* When “No Adjust” is displayed, perform 1) to 3) and press the ENTER button without changing the adjustment value using the

B/F.SKIP button.

2. Laser Power Adjustment

• Test point: Check the display/Pickup laser output

• Tool: Laser power meter (meters that can measure up to 10 mW)

2-1. Playback Laser Power Adjustment

1) Press the EDIT button in the “ALL SVoFF” state to change the display to “LA READ”.

2) Press the PAUSE button once to display “LASER = $**”.

3) Adjust “LASER=$11” using the B.SKIP and F.SKIP buttons and press the ENTER button.

4) Measure the pickup laser output using the laser power meter and check that it is about 0.68mW.

5) After adjustment, press the STOP button to change the display to “ALL SVoFF”.

2-2. Record Laser Power Adjustment

1) Press the EDIT button three times in the “ALL SVoFF” state to change the display to “LA WRITE”.

2) Press the PAUSE button once to display “LASER = $**”.

3) Adjust “LASER=$9F” using the B.SKIP and F.SKIP buttons and press the ENTER button.

4) Measure the pickup laser output using the laser power meter and check that it is about 6.8mW.

5) After adjustment, press the STOP button to return the display to “ALL SVoFF”.

Note: If the laser power exceeds 7.0 mW, the pickup may be damaged.

3. Automatic Sequence Adjustment (EFB/IVR/FOCUS AGC/TRACKING AGC adjustment)

• Test point: Check the test point on the display.

• Test disk: MDW-74, TGYS-1 or equivalent

3-1. Adjusting the MO Disk

1) Load the MDW-74.

2) Press the MODE button to display “SEL GRV”.

3) Press the MD function button to display “AUTO ADJ”. After adjustment, “DONE” is displayed.

(If the adjustment failed, “FAILED” appears.)

4) Then, press the STOP button to return the display to “ALL SVoFF”.

3-2. IVR, EFB, Focus/Tracking/Sled Gain Check of MO Disk

1) Move the pickup to the center of the disk using the B.SKIP button and F.SKIP button.

2) Press the PLAY button to display “FOCUS ON!”.

3) Press the ENTER button to display “ALL SV ON”.

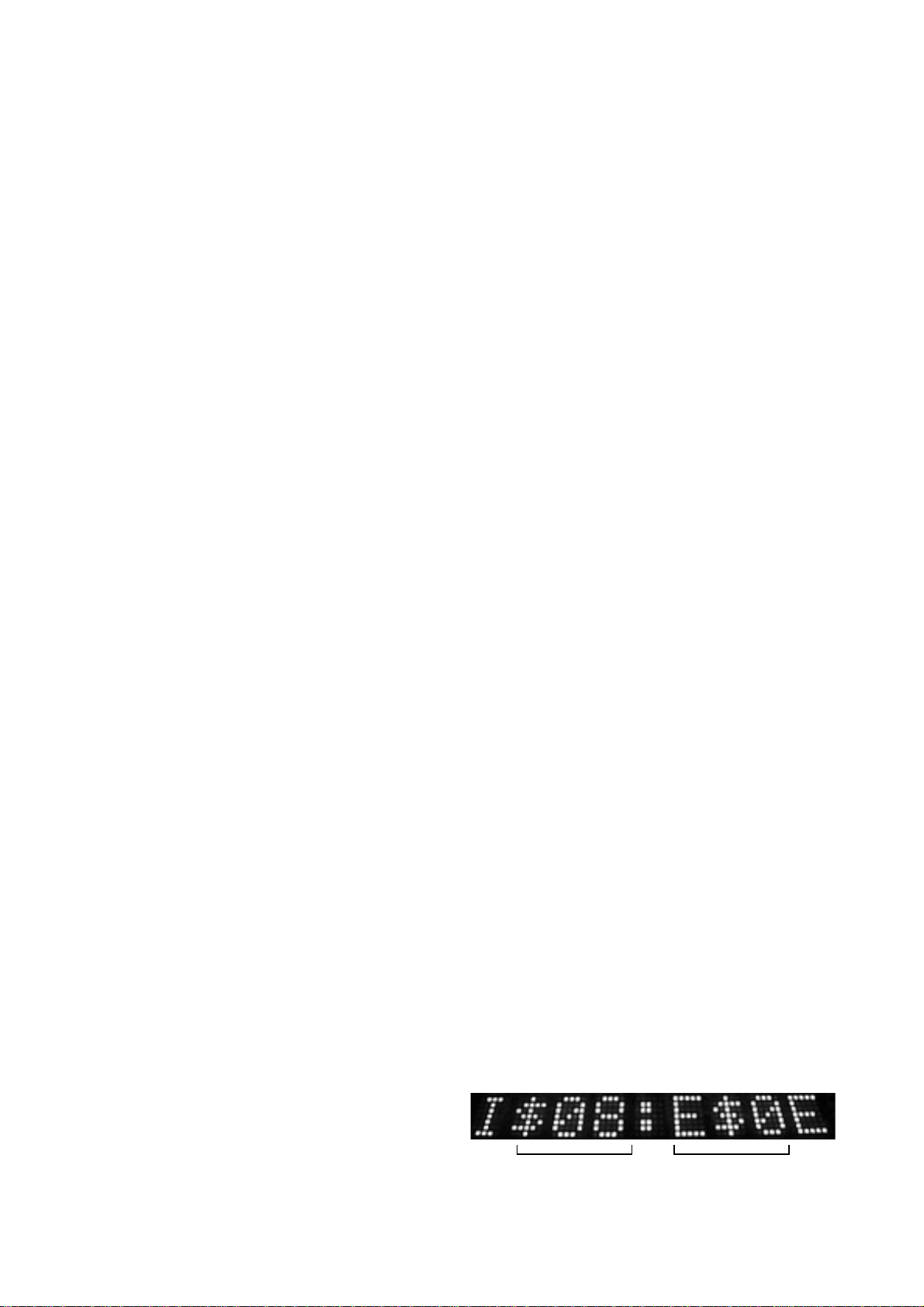

4) Press the STOP button and press the DISPLAY button twice. Confirm that the values of “I$**: E$⁄⁄” are within the range

shown below. (hexadecimal)

I$“**” ..................... 03 to 0A

E$ “⁄⁄” ................. 09 to 15

IVR EFB

9

5) Press the DISPLAY once again.

Confirm that the values of “f**t##s33” are within the range shown below. (hexadecimal)

f “**” ...................... 1A to 40

t “##” ....................... 0C to 30

s “33” .................... 0C to 30

FOCUS GAIN TRACKING GAIN SLED GAIN

6) After adjustment, press the STOP button to return the display to “ALL SVoFF”.

3-3. Adjusting the PIT Disk

1) Insert the TGYS-1.

2) Press the MODE button to display “SEL PIT”.

3) Press the MD function button to display “AUTO ADJ”. After adjustment, “DONE” is displayed. (If the adjustment failed,

“FAILED” appears.)

4) Then, press the STOP button to return the display to “ALL SVoFF”.

3-4. IVR, EFB, Focus/Tracking/Sled Gain Check of PIT Disk

1) Move the pickup to the center of the disk using the B.SKIP button and F.SKIP button.

2) Press the PLAY button to display “FOCUS ON!.

3) Press the ENTER button to display “ALL SV ON”.

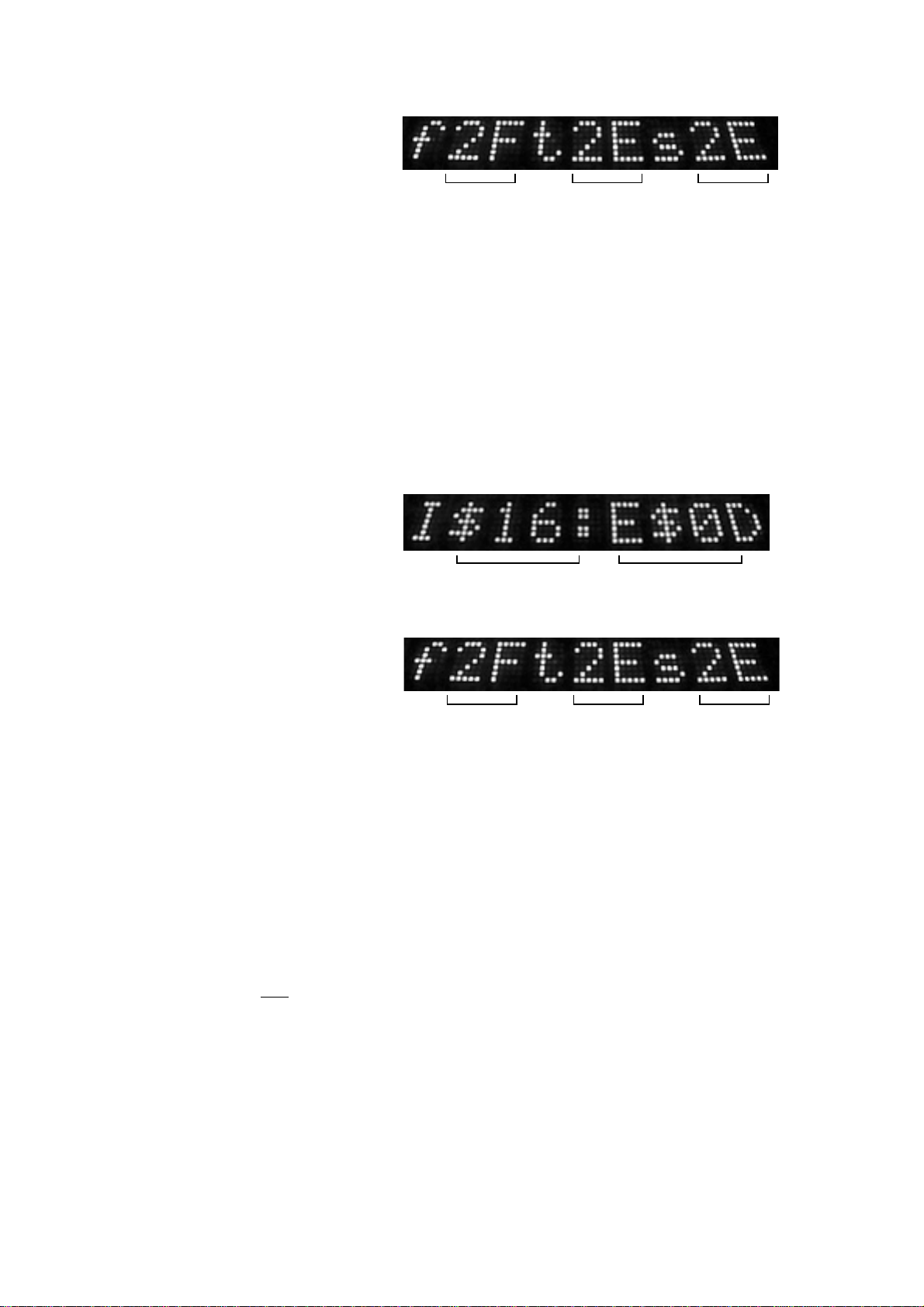

4) Press the STOP button and press the DISPLAY button twice. Confirm that the values of “I$**: E$⁄⁄” are within the range

shown below. (hexadecimal)

I$ “**” .................... 14 to 19

E$ “⁄⁄” ................. 09 to 15

IVR EFB

5) Press the DISPLAY button once again. Confirm that the values of “f**t##s33” are within the range shown below.

(hexadecimal)

f “**” ...................... 1A to 45

t “##” ....................... 0C to 3F

s “33” .................... 0C to 3F

FOCUS GAIN TRACKING GAIN SLED GAIN

6) After adjustment, press the STOP button to return the display to “ALL SVoFF”.

4. Playback Error Rate Check (PIT DISC)

• Test point: Check the test point on the display.

• Test disk: TSYS-1 or equivalent

1) Load the TGYS-1.

2) Move the pickup to the center of the disk using the B.SKIP button and F.SKIP button.

3) Press the MODE (MD) button to display “SEL PIT”.

4) Press the PLAY button to display “FOCUS ON!”.

5) Press the ENTER button to display “ALL SV ON”.

6) Press the DISPLAY button once to confirm that counting of the address indication is stable.

7) Press the DISPLAY button once again to display the playback error rate.

Confirm that the numbers of “

8) After checking, press the STOP button to return the display to “ALL SVoFF”.

****:****” (underlined portion) is “0030” or lower.

10

5. Record/Playback Error Rate Check (MO DISC)

• Test point: Check the test point on the display.

• Test disk: MDW-74

1) Load the MDW-74.

2) Move the pickup to the center of the disk using the B.SKIP button and F.SKIP button.

3) Press the CD function button. Recording starts automatically in cluster 600.

4) After recording for about 15 seconds, press the STOP button.

5) Press the AUX/D-IN function button move the pickup to around cluster 600 and enter the “ALL SV ON” state (the display is in

the state of the address indication). Press the DISPLAY button in or after cluster 600. Then confirm that the values of

“

****:****” (underlined portion) is “0030” or lower.

6) After checking, press the STOP button to return the display to “ALL SVoFF”.

6. How to Initialize the EEP-ROM

Do the following procedure to set the adjustment value of the EEP-ROM to the default (standard value).

1) Press the BBE button.

2) Turn on the power again and confirm that “No Adjust” is displayed.

* Even when “No Adjust” is displayed, MDs can be operated.

Note: When initializing the EEP-ROM, be sure to do 1 to 3 of the MD electrical adjustment.

11

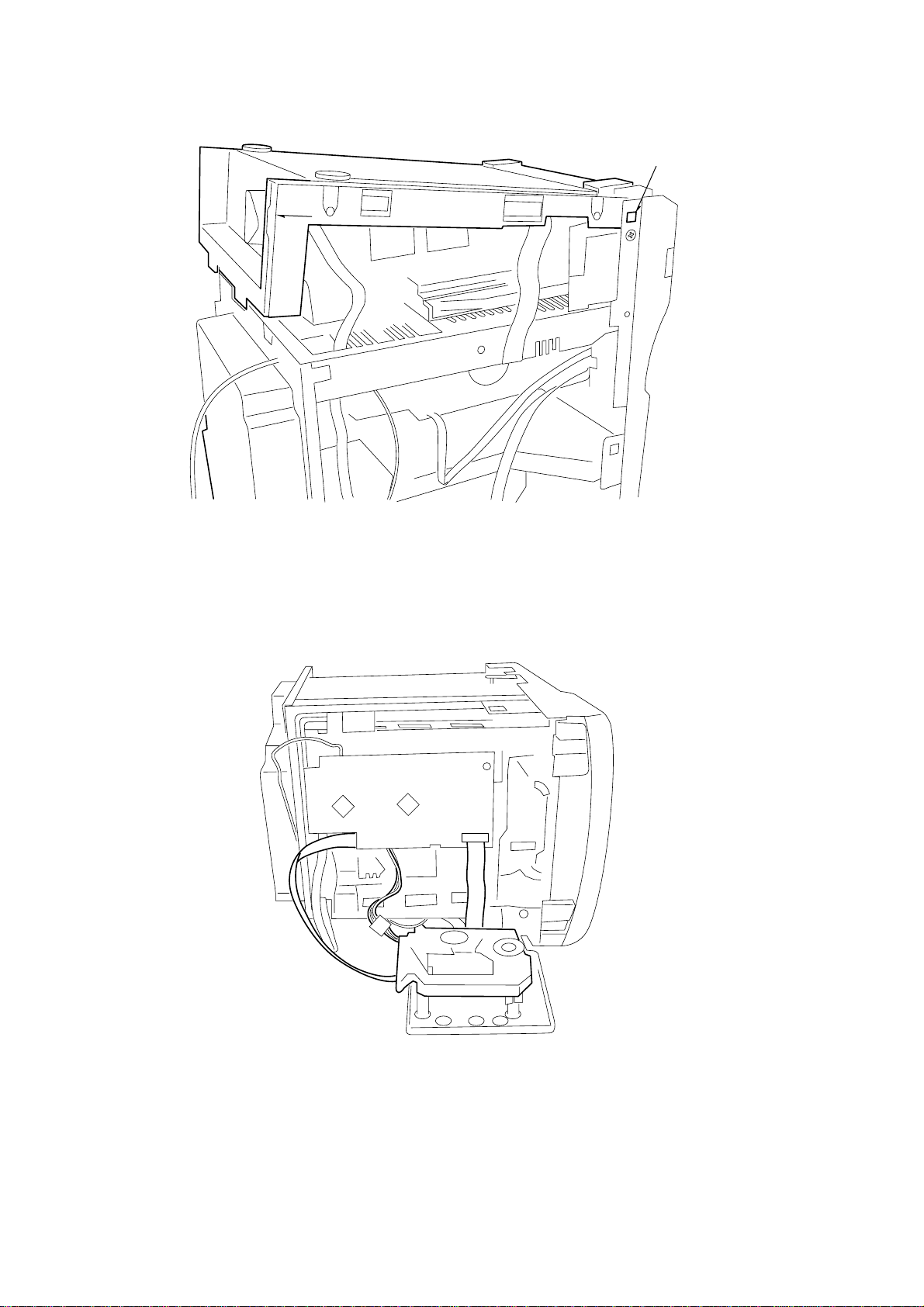

DISASSEMBLY INSTRUCTIONS

DISASSEMBLY INSTRUCTION

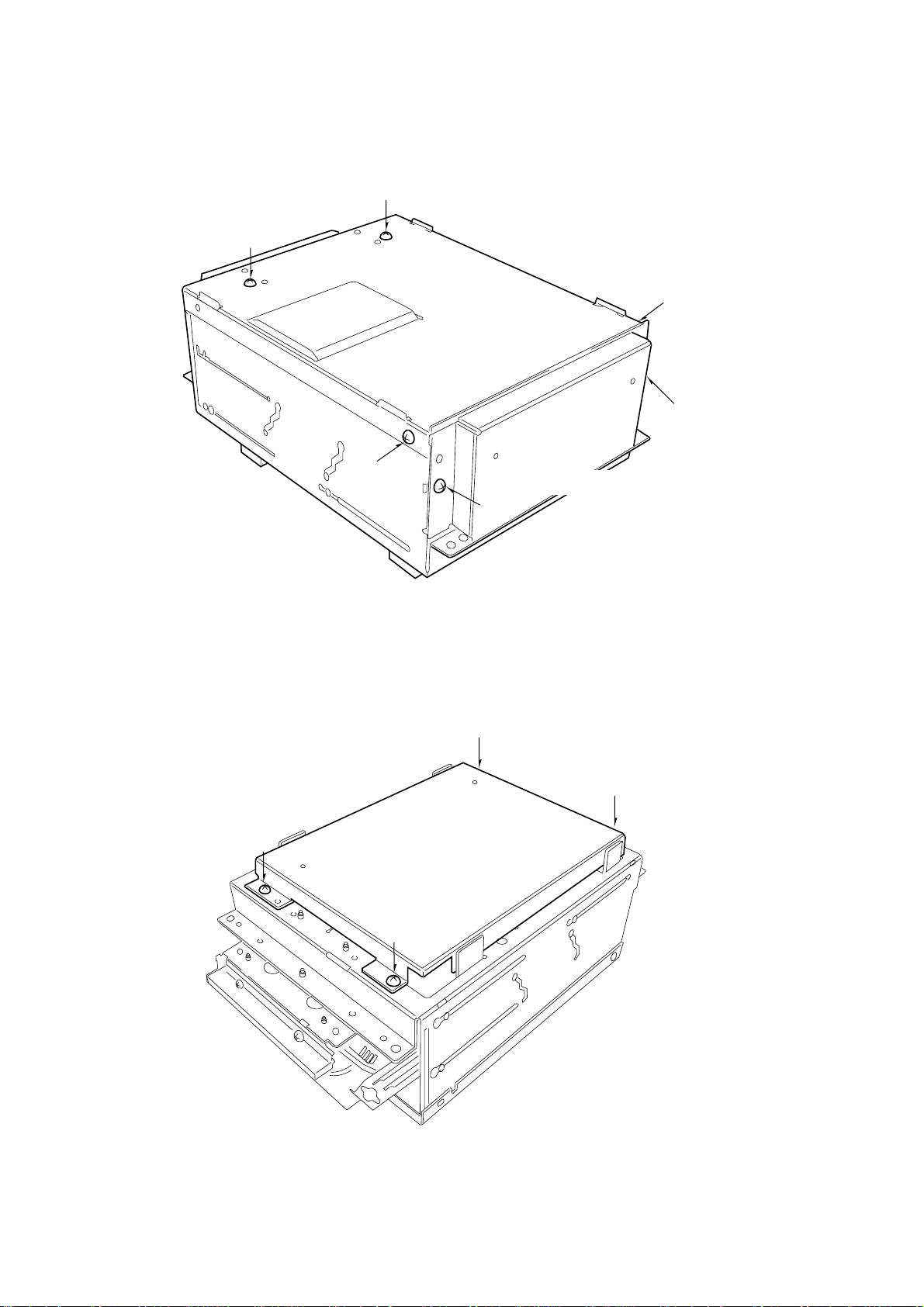

Removing the MD Block

1) Remove the PANEL, REAR in advance.

2) Remove the two screws.

3) Remove the two screws.

PANEL, REAR

4) Release the hook 1 and remove the AZG-26 in the

order of 2™3.

2

AZG-26

1

5) Remove the four screws and remove the AZG-21 from

the HLDR, MD.

3

AZG-26

HLDR, MD

AZG-21

12

Disassembling the MD block

Remove the AZG-21.

1) Remove the two screws (UT2+2.6-6 GLD) D from the PLATE, SHLD REAR. Remove the PLATE, SHLD REAR.

2) Remove the four screws (U+2+2.6-6) E from the PLATE, SHLD TOP. Remove the PLATE, SHLD TOP.

E

E

E

PLATE, SHLD TOP

D

E

PLATE, SHLD REAR

D

3) Remove the four screws (UT2+2.6-6 GLD) F and remove the PLATE, SHLD BOTTOM.

F

F

PLATE, SHLD BOTTOM

F

F

13

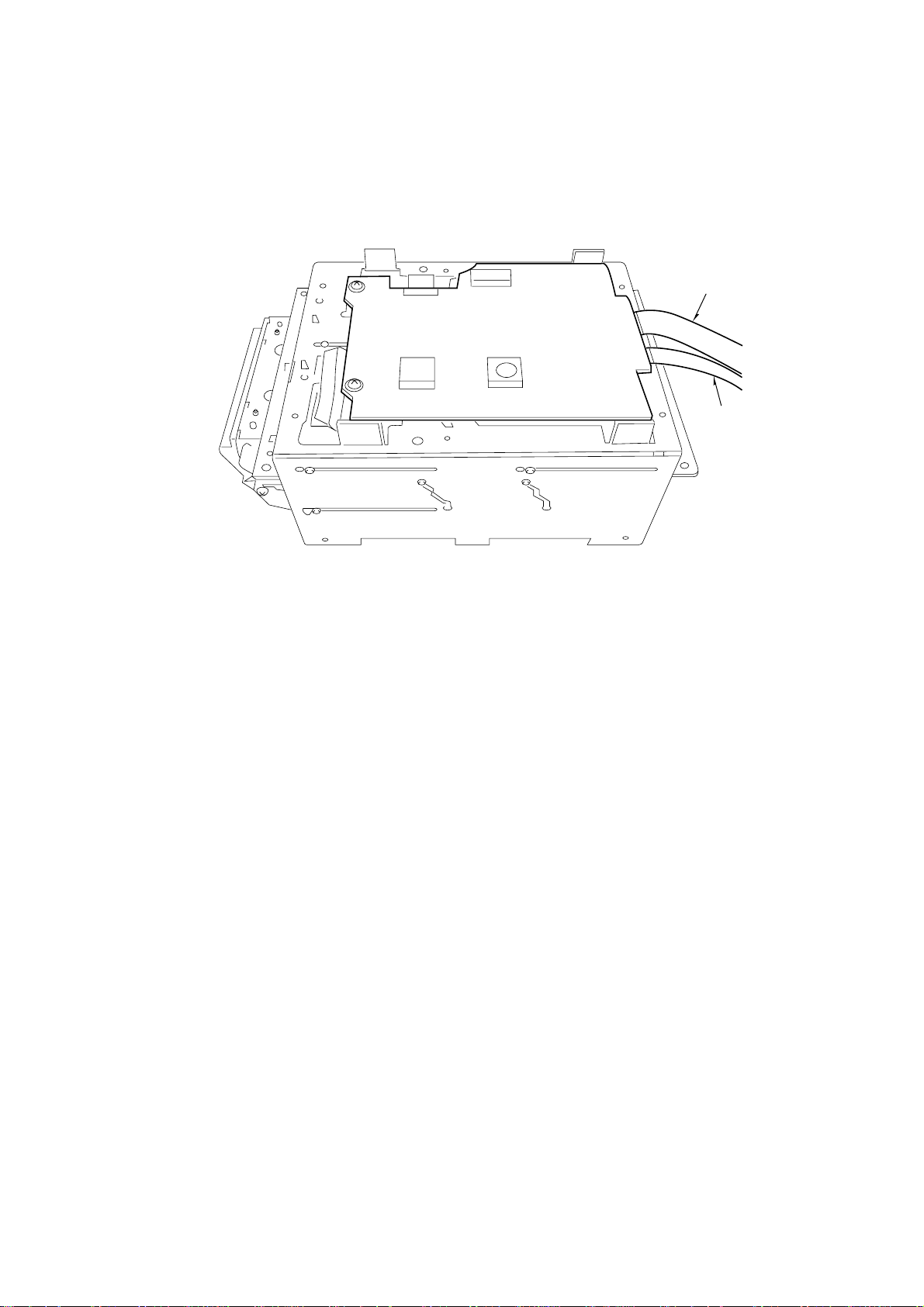

SERVICE POSITION

MD service position

Place the MD block in the service position as follows. Connect the MD block with the interface board using the extension FFC as

shown to place the MD block into the service position.

FFC, 8P-1.0 SV-J00-043-010

FFC, 14P-1.0 SV-J00-044-010

FFC, 14P-1.0

FFC, 8P-1.0

14

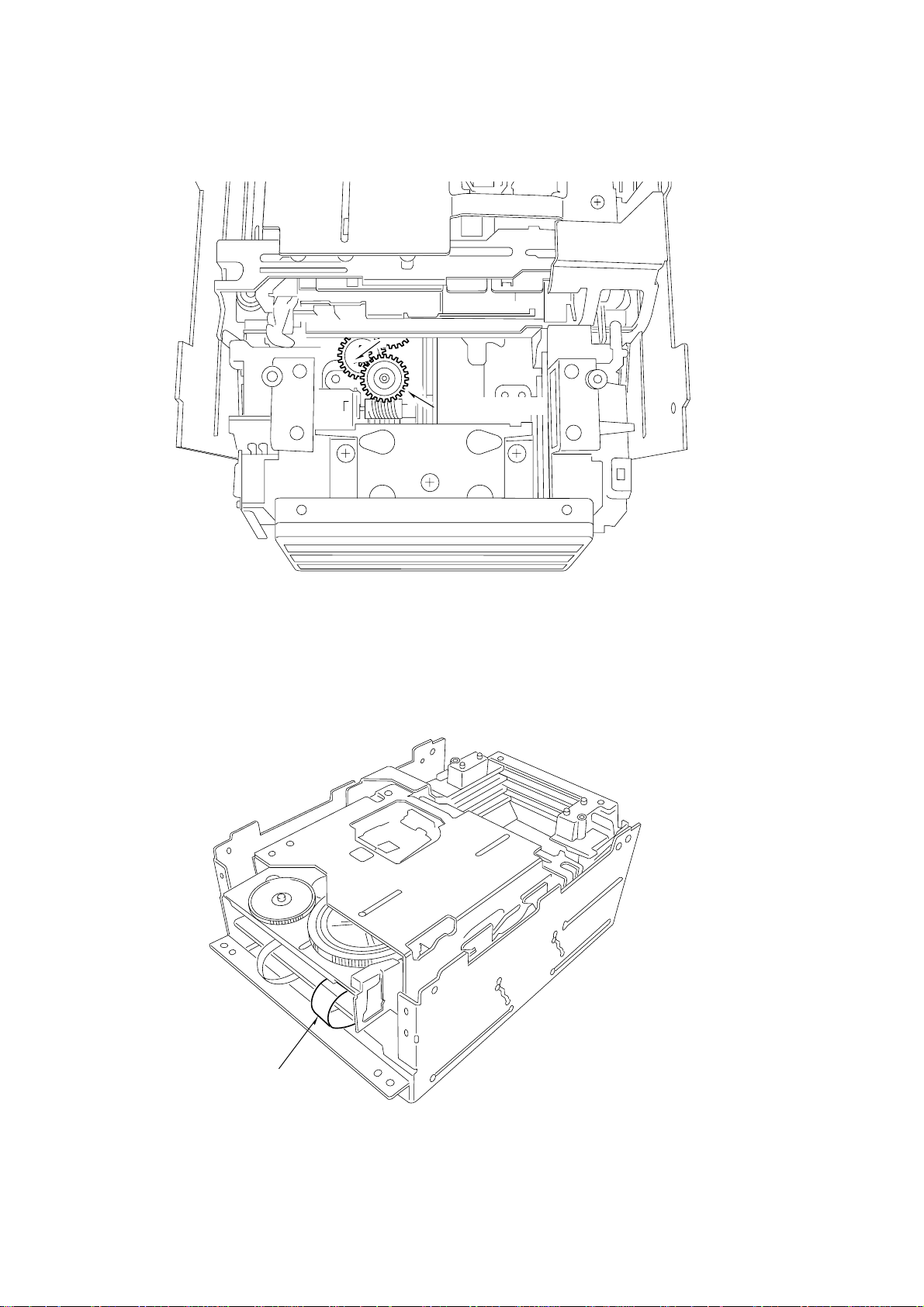

Disassembling the elevator

1) Rotate the WORM-WHL, JT (the gear shown by the arrow below) counterclockwise to move the elevator to the top position.

Note: If the PANEL, SHLD BOTTOM is not removed, the elevator cannot be removed.

WORM-WHL, JT

2) Remove the FF-CABLE, 9P 1.0 from the LOAD C.B.

FF-CABLE, 9P 1.0

15

Loading...

Loading...