Aiwa TV-SX2177, TV-SA2157 Service Manual

TV-SA2157

SHR

TV-SX2177

SHR

SERVICE MANUAL

COLOR TELEVISION

• This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

of TV-SA2157<SHR>, (S/M Code No. 09-005-434-9T1) and TV-SX2177<SHR>,

(S/M Code No. 09-005-434-8T1).

• This Service Manual does not include “DISASSEMBLY INSTRUCTIONS”

and “ADJUSTMENT”. These items will be issued in the next supplement.

S/M Code No. 09-008-434-8R1

REVISION

DATA

SPECIFICATIONS

Tuner System Frequency synthesized tuner

TV System PAL (B/G, H, I, D, K)

Channel Coverage VHF: E2 to E12, R1 to R12

Program Memory 100 TV stations

Antenna Input 75 ohms, unbalanced

Picture Tube 21"

Screen Size 406 (W) X 305 (H) mm (16 X 121/8 in.)

Video Input /Output 1 Vp-p 75 ohms

Audio Input -8dBs., more than 33 k ohms

Audio Output -8dBs., less than 2.2 k ohms

Speaker Main: 60 X 120 mm (2) (23/8 X 43/4 in.)

Operatiing Voltage 110 - 240 V AC, 50/60 Hz

Power Consumption TV-SX2177: 95 W (Standby mode: 13.5 W)

Phone Jack Stereo-mini jack

Operating Temperature 5°C – 40°C

Operating Humidity 35% – 80%

Dimensions 610 (W) X 440 (H) X 485 (D) mm

Weight TV-SX2177: 24.4 kg (53.68 lbs.)

SECAM (B/G, I, D/K, K1)

NTSC(M)

UHF: 21 to 69

CATV: S1 to S41

508 mm (diagonal) (20 in.)

Woofer: ø 80 mm (2)

(ø 31/4 in.) (TV-SX2177 only)

TV-SA2157: 93 W (Standby mode: 13.5 W)

(241/8 x 173/8 x 19 1/8in.)

TV-SA2157: 21.4 kg (47.08 lbs.)

• Design and specifications are subject to change without

notice.

ACCESSORIES / PACKAGE LIST

REF. NO. DESCRIPTIONPART NO.

1 8A-JBB-901-010 IB,SH (E/CH/A/P)SX2177, SA2157

2 8A-JBB-950-010 RC UNIT,RC-AVT05

3 86-LB3-610-010 ANT ASSY,TV 5 SEC.(PAL)

KANRI

NO.

– 2 –

NOTICES BEFORE REPAIRING

To make the best use of this equipment, make sure to

obey the following items when repairing (or mending).

1. Do not damage or melt the tunicate of the leading

wire on the AC1 side, including the power supply

cord.

2. Do not soil or stain the letters on the spec.

inscription plates, notice labels, fuse labels, etc.

3. When repairing the part extracted from the

conducted side of the board pattern, fix it firmly

with applying bond to the pattern and the part.

4. Restore the following items after repairing.

1) Conditions of soldering of the wires (especially,

the distance on the AC1 side).

2) Conditions of wiring, bundling of wires, etc.

3) Types of the wries.

4) Attachment conditions of all types of the insulation.

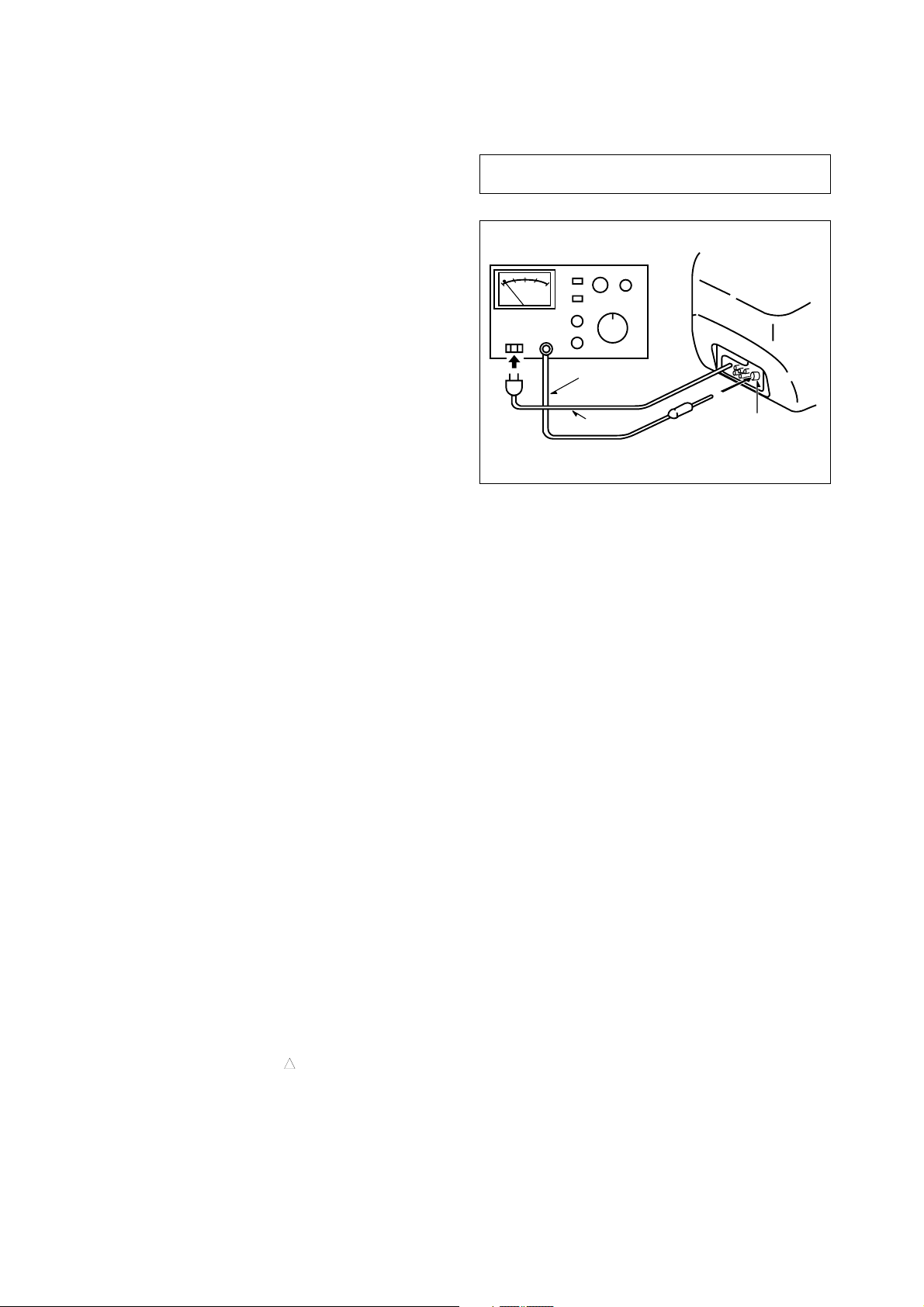

5. After repairing, always measure the insulation

resistance and perform the voltage-withstand test

(See Fig-1).

1) The insulation resistance must be 6.0 ~ 10 MΩ

when applying

2) In the voltage withstand test, apply 3 kV for 1 min

and check that the GO lamp lights.

500V per second.

Insulation resistance: 6.0 ~ 10 MΩ (500 V/s)

Voltage-withstand: 3 kV for 1 min

Safety checker (Model 7110, etc.)

Earth cable

AC cable

Connect the earth cable

to the outside metal part

terminal.

Fig-1

* Breaking current set to 10 mA.

* Connect the safety checker as shown in Fig-1,

then measure the resistance and perform the test.

* Do not touch the equipment during testing.

* For details of the safety checker, refer to the supplied

Operation manual.

When servicing and checking on the TV, note the followings.

1. Keep the notices.

As for the places which need special attentions, they

are indicated with labels or seals on the cabinet,

chassis and parts. Make sure to keep the indications

and notices in the operation manual.

2. Avoid an electric shock.

There is a high voltage part inside. Avoid an electric

shock while the electric current is flowing.

3. Use the designated parts.

The parts in this equipment have the specific

characteristics of incombustibility and withstand voltage

for safety.

Therefore, use a part which has the same character

as the replaced part. Especially as to the important

parts for safety which is indicated in the circuit

diagram or the table of parts with a mark, the

designated parts must be used.

4. Put parts and wires in the original position after

assembling or wiring.

There are parts which use the insulation material such

as a tube or tape for safety, or which are assembled so

that these parts do not make contact with the printed

!

board. The inside wiring is designed not to get close to

the pyrogenic parts and high voltage parts. Therefore,

put these parts in the original positions.

5. Take care of the cathode-ray tube.

By setting an explosion-proof cathode-ray tube in this

equipment, safety is secured against implosion.

However, when removing it or servicing from the

back, it gives out shock that is dangerous. Take

enough care to deal with it.

6. Avoid an X-ray.

Safety is secured against an X-ray by giving

considerations to the cathode-ray tube and the high

voltage peripheral circuit, etc. Therefore, when

repairing the high voltage peripheral circuit, use the

designated parts and do not change the circuit.

Repairing, except indicates, causes rising of high

voltage, and the cathode-ray tube emits an X-ray.

7. Perform a safety check after servicing.

Confirm that the screws, parts and wiring which were

removed in order to service are put in the original

positions, or whether there are deteriorated portions

around the places serviced.

– 3 –

ELETRICAL MAIN PARTS LIST

REF. NO. DESCRIPTIONPART NO.

NO.

IC

8A-JEE-651-010 IC,TMP87CP38N-1N14

87-A21-133-080 IC,BMR-0101D

87-A91-538-010 RCR UNIT,SBX1981-72P

87-A21-433-010 IC,KS24C041I

87-027-666-010 IC,TC4052BP

87-A21-723-010 IC,TB1240AN AJE-H

87-A21-166-010 IC,TA1275AZ

87-A21-259-010 IC,MM1454XD

87-A21-345-010 IC,NJM2150

87-A20-312-010 IC,M62420SP

87-A21-299-010 IC,LB6458SLL

87-027-656-010 IC,TC4066BP<2177>

87-A21-346-010 IC,M5222L<2177>

87-A21-169-010 IC,MM1124B<2157>

87-A21-283-010 IC,AN5277

87-070-237-010 IC,LA7832

87-A21-261-010 IC,MSP3417D

87-A21-287-010 IC,SAA5261PS/222<2177>

87-A21-062-010 IC,M24C02-BN6<2177>

87-A21-344-010 IC,STR-F6656

87-020-903-010 IC,NJM7805FA

87-A20-389-010 IC,NJM7809FA

TRANSISTOR

87-A30-090-080 FET,2SK2541

87-A30-091-080 FET,2SJ460

89-337-794-580 TR,2SC3779 D/E

87-A30-066-080 TR,2SA1175FE

87-A30-065-080 TR,2SC2785FE

89-109-504-080 TR,2SA950

87-026-218-080 TR,DTC144ES (0.2W)

87-A30-121-080 TR,DTC 323 TS

87-A30-005-010 TR,2SC2688M/L

87-A30-366-010 TR,2SD2580

89-334-674-580 TR,2SC3467 D/E

89-324-122-080 TR,2SC2412K

87-A30-041-110 TR,SE115N

89-110-155-080 TR,2SA1015(0.4W)

DIODE

87-070-345-080 DIODE,IN4148

87-A40-347-080 ZENER,MTZJ2.2B

87-070-444-080 ZENER,HZS33-1

87-A40-235-080 ZENER,MTZJ9.1C

87-A40-350-080 ZENER,MTZJ 4.7C

87-070-092-080 DIODE,S5566B

87-A40-286-080 DIODE,RGP10JE-5025

87-A40-794-080 DIODE,EGP20G

87-A91-768-010 VRIS,S14K275

87-017-654-060 DIODE,GBU6J

87-A40-509-080 ZENER,MTZJ6.8C

87-A40-856-080 DIODE,UF4007

87-A40-850-090 DIODE,RL4A

87-A40-354-090 DIODE,UF3GL-6251

87-A40-611-080 ZENER,MTZJ3.9B

MAIN C.B

C1 87-018-151-080 CAP, CERA-SOL SS 20P CH

C2 87-A11-073-080 CAP,TC U 22P-50 J CH

C3 87-010-405-080 CAP, ELECT 10-50V

C4 87-018-134-080 CAPACITOR,TC-U 0.01-16

C5 87-010-263-080 CAP, ELECT 100-10V

C6 87-018-119-080 CAP, CER 100P-50V

C7 87-010-405-080 CAP, ELECT 10-50V

C8 87-010-405-080 CAP, ELECT 10-50V

C9 87-018-134-080 CAPACITOR,TC-U 0.01-16

REF. NO. DESCRIPTIONPART NO.KANRI

C10 87-018-119-080 CAP, CER 100P-50V

C11 87-018-119-080 CAP, CER 100P-50V

C13 87-010-405-080 CAP, ELECT 10-50V

C14 87-018-129-080 CAP, CER 680P-50V

C15 87-018-149-080 CAP,TC-U 15P-50 CH

C16 87-018-149-080 CAP,TC-U 15P-50 CH

C17 87-010-404-080 CAP, ELECT 4.7-50V

C101 87-010-404-080 CAP, ELECT 4.7-50V

C102 87-018-134-080 CAPACITOR,TC-U 0.01-16

C103 87-010-384-080 CAP, ELECT 100-25V

C104 87-018-134-080 CAPACITOR,TC-U 0.01-16

C105 87-010-263-080 CAP, ELECT 100-10V

C106 87-A10-207-080 CAP,TCS 0.01-50KBUP050

C107 87-018-134-080 CAPACITOR,TC-U 0.01-16

C108 87-018-132-080 CAP, CER 2200P-16V

C110 87-018-132-080 CAP, CER 2200P-16V

C111 87-018-132-080 CAP, CER 2200P-16V

C113 87-010-260-080 CAP, ELECT 47-25V

C116 87-010-260-080 CAP, ELECT 47-25V

C117 87-018-134-080 CAPACITOR,TC-U 0.01-16

C121 87-018-134-080 CAPACITOR,TC-U 0.01-16

C122 87-010-260-080 CAP, ELECT 47-25V

C123 87-018-134-080 CAPACITOR,TC-U 0.01-16

C124 87-010-401-080 CAP, ELECT 1-50V

C125 87-018-134-080 CAPACITOR,TC-U 0.01-16

C126 87-010-544-080 CAP, ELECT 0.1-50V

C127 87-018-119-080 CAP, CER 100P-50V

C128 87-018-134-080 CAPACITOR,TC-U 0.01-16

C129 87-018-134-080 CAPACITOR,TC-U 0.01-16

C130 87-010-405-080 CAP, ELECT 10-50V

C131 87-010-405-080 CAP, ELECT 10-50V

C132 87-010-260-080 CAP, ELECT 47-25V

C137 87-010-384-080 CAP, ELECT 100-25V

C301 87-010-545-080 CAP, ELECT 0.22-50V

C302 87-018-132-080 CAP, CER 2200P-16V

C303 87-018-148-080 CAP,TC-U 12P-50 CH

C307 87-018-134-080 CAPACITOR,TC-U 0.01-16

C308 87-010-385-080 CAP, ELECT 220-25V

C309 87-018-147-080 CAP,TC-U 10P-50 CH

C310 87-018-147-080 CAP,TC-U 10P-50 CH

C311 87-018-147-080 CAP,TC-U 10P-50 CH

C312 87-010-404-080 CAP, ELECT 4.7-50V

C313 87-018-119-080 CAP, CER 100P-50V

C314 87-010-401-080 CAP, ELECT 1-50V

C315 87-018-196-080 CAP, CER 1500P-16V

C316 87-010-400-080 CAP, ELECT 0.47-50V

C317 87-015-997-010 CAP, ELECT 2200UF-16V

C318 87-018-134-080 CAPACITOR,TC-U 0.01-16

C319 87-010-400-080 CAP, ELECT 0.47-50V

C320 87-010-384-080 CAP, ELECT 100-25V

C321 87-018-134-080 CAPACITOR,TC-U 0.01-16

C323 87-018-209-080 CAP, CER 0.1-50V

C324 87-018-209-080 CAP, CER 0.1-50V

C328 87-010-400-080 CAP, ELECT 0.47-50V

C330 87-018-134-080 CAPACITOR,TC-U 0.01-16

C333 87-018-134-080 CAPACITOR,TC-U 0.01-16

C334 87-010-263-080 CAP, ELECT 100-10V

C335 87-010-401-080 CAP, ELECT 1-50V

C336 87-018-134-080 CAPACITOR,TC-U 0.01-16

C337 87-010-401-080 CAP, ELECT 1-50V

C338 87-010-401-080 CAP, ELECT 1-50V

C339 87-010-263-080 CAP, ELECT 100-10V

C340 87-018-134-080 CAPACITOR,TC-U 0.01-16

C341 87-018-134-080 CAPACITOR,TC-U 0.01-16

C344 87-010-263-080 CAP, ELECT 100-10V<2177>

C501 87-018-195-080 CAP, CER 1200P-16V

C502 87-018-115-080 CAP, CER 47P-50V

C503 87-010-247-080 CAP, ELECT 100-50V

C509 87-010-405-080 CAP, ELECT 10-50V

C512 87-A10-011-090 CAP,E 2200-25 SMG

KANRI

NO.

– 4 –

REF. NO. DESCRIPTIONPART NO.

NO.

C513 87-018-127-080 CAP, CER 470P-50V

C601 87-A10-406-090 CAP,CER 270P-2K K BN DE

C603 87-A12-023-080 CAP,E 10-250 M SME

C606 87-016-515-080 CAP,CER 1000P-1K B

C607 87-010-397-090 CAP,E 1000-35 SME

C609 87-010-386-080 CAP,E330-25 SME

C610 87-016-217-080 CAP,E 4.7-160

C611 87-016-481-010 CAP,M/P 0.47-200 J DHS

C612 87-016-220-090 CAP,E 47-160 M TWSS

C613 87-A10-967-090 CAP,M/P 5600P-1.25K H DKRG

C615 87-012-406-090 CAP,CER 2200P-2K K BN DE

C616 87-018-132-080 CAP, CER 2200P-16V

!

C617 87-010-976-080 CAP,CER 1000P-500 B

!

C618 87-010-974-080 CAP,CER 220P-500 B

!

C801 87-A10-688-090 CAP,M/P 0.22-275 K (B81133)

!

C802 87-A10-688-090 CAP,M/P 0.22-275 K (B81133)

!

C805 87-012-370-010 CAP,CER 3300P-250NS

C807 87-A10-646-090 CAP,E 220-400 SMH (25.4*40)

C808 87-010-977-090 CAP,CER 680P-2K BN

C809 87-018-131-080 CAP, CER 1000P-50V

C810 87-010-384-080 CAP, ELECT 100-25V

C811 87-018-127-080 CAP, CER 470P-50V

C812 87-018-129-080 CAP, CER 680P-50V

C813 87-A10-626-090 CAP,M/P 0.1-1.25K J

C814 87-A10-862-010 CAP,CER 680P-2K K R LONG

C815 87-A11-779-090 CAP,M/P 1000P-1.6K J ECWH(VB)

C816 87-A10-859-090 CAP,CER 390P-2K K R

C817 87-A10-731-090 CAP,E 220-160 M KMF

C818 87-016-221-090 CAP,E 100-160 M TWSS

C819 87-A10-832-080 CAP,CER 1000P-1K K R<2177>

C820 87-010-398-090 CAP,E 2200-35V<2177>

C821 87-010-397-090 CAP,E 1000-35 SME<2177>

C822 87-A10-832-080 CAP,CER 1000P-1K K R

C823 87-010-398-090 CAP,E 2200-35V

C824 87-010-397-090 CAP,E 1000-35 SME

C826 87-010-235-080 CAP,E 470-16 SME

C827 87-010-405-080 CAP, ELECT 10-50V

C828 87-010-405-080 CAP, ELECT 10-50V

C829 87-A10-469-080 CAP,CER 2200P-500 K B DD10

C830 87-010-405-080 CAP, ELECT 10-50V

C831 87-010-405-080 CAP, ELECT 10-50V

C832 87-010-405-080 CAP, ELECT 10-50V

C833 87-010-405-080 CAP, ELECT 10-50V

C834 87-010-382-080 CAP, ELECT 22-25V

C835 87-010-384-080 CAP, ELECT 100-25V

C901 87-010-405-080 CAP, ELECT 10-50V

C902 87-010-071-080 CAP, ELECT 1-50V

C903 87-010-071-080 CAP, ELECT 1-50V

C904 87-010-221-080 CAP, ELECT 470-10V

C905 87-010-498-080 CAP,E 10-16 M 5L SRE

C906 87-010-498-080 CAP,E 10-16 GAS

C907 87-010-405-080 CAP, ELECT 10-50V

C908 87-010-401-080 CAP, ELECT 1-50V

C909 87-010-401-080 CAP, ELECT 1-50V

C910 87-010-071-080 CAP, ELECT 1-50V

C911 87-010-401-080 CAP, ELECT 1-50V

C912 87-010-260-080 CAP, ELECT 47-25V

C913 87-018-134-080 CAPACITOR,TC-U 0.01-16

C914 87-018-134-080 CAPACITOR,TC-U 0.01-16

C915 87-018-133-080 CAPACITOR,CER 4700P-16V

C916 87-018-133-080 CAPACITOR,CER 4700P-16V

CF201 87-A90-224-080 FLTR, TPS6.0MB

CF202 87-008-578-080 FLTR,TPS6.5MB2

CF203 84-LB3-626-080 FLTR,TPS4.5MB2

CF204 87-008-577-080 FLTR,TPS5.5MB2

CF205 87-008-574-080 FLTR,SFSH4.5MCB

CN1 87-099-407-010 CONN,7P EH V WHT

CN2 87-A60-734-010 CONN,8P JL-BT

CN3 87-A60-731-010 CONN,5P JL-BT

CN101 87-A60-734-010 CONN,8P JL-BT

REF. NO. DESCRIPTIONPART NO.KANRI

KANRI

NO.

CN102 87-A60-732-010 CONN,6P JL-BT

CN601 87-099-675-010 CONN,5P V V

!

CN801 87-099-674-010 CONN,2P VA V

!

CN802 82-481-649-010 PLUG,2P MINI(*)

CN901 87-049-469-010 CONN,4P V

CNA301 84-LB2-631-010 CONN ASSY,5P TN-4

CNA801 8Z-JB9-663-010 CONN ASSY,8P V AU PW 200

CNA802 8Z-JB4-658-010 CONN ASSY,5P MAIN-NK 20'/21'

CNA803 8Z-JB3-661-010 CONN ASSY,4P V WF PW 340<2177>

CNA900 8Z-JBX-602-010 CONN ASSY,4P SP 205-0.5

CNA901 8Z-JB9-662-010 CONN ASSY,6P V AU L/R 300

CNA902 8Z-JB4-660-010 CONN ASSY,5P 401-401 AUDIO

CNA903 8Z-JB9-661-010 CONN ASSY,10P MAIN-AUDIO

D9 87-A40-422-010 LED,SLP-581D-51 Y-G/R

!

F801 87-035-458-010 FUSE,4A 250V T W/C<2177>

FB1 87-003-320-080 F-BEAD,FBR07HA121NB

FB501 87-003-320-080 F-BEAD,FBR07HA121NB

FB601 87-003-320-080 F-BEAD,FBR07HA121NB

FB801 87-003-320-080 F-BEAD,FBR07HA121NB

FB802 87-003-320-080 F-BEAD,FBR07HA121NB

FB804 87-003-320-080 F-BEAD,FBR07HA121NB<2177>

FB805 87-003-320-080 F-BEAD,FBR07HA121NB

FB806 87-003-320-080 F-BEAD,FBR07HA121NB

!

FC801 87-033-213-080 CLAMP, FUSE

!

FC802 87-033-213-080 CLAMP, FUSE

FR601 87-A00-063-060 RES,FUSE 2.2-1/2W J R-TYPE

FR602 87-A00-057-060 RES,FUSE 1.8-2W J R-TYPE

FR603 87-029-150-090 RES,FUSE 3.9-2W J

FR604 87-A00-643-060 RES,FUSE 1-2W J R-TYPE

FR606 87-A00-049-060 RES,FUSE 2.2K-1/2WJ R-TYPE

FR803 87-A00-672-090 RES,M/F 68-3W J RSS3L20

HL9 84-LB3-216-010 HLDR,LED

J901 87-A60-324-110 JACK,PIN 6P Y-W-R W/SW

J902 87-A61-435-010 JACK,PIN 3P WHT YKC21-5734 A

J903 87-A61-196-010 JACK,3.5 BLK ST 3 SW HSJ0944

JW807 87-018-134-080 CAPACITOR,TC-U 0.01-16

L1 87-005-688-080 COIL,22UH

L2 87-003-152-080 COIL, 100UH

L101 87-005-444-080 COIL 100UH,K

L102 87-003-152-080 COIL, 100UH

L104 87-003-106-080 COIL,0.33UH

L108 87-003-146-080 COIL,15UH LAL02

L109 87-003-282-080 COIL,12UH

L110 87-003-146-080 COIL,15UH LAL02

L111 87-003-282-080 COIL,12UH

L112 87-003-149-080 COIL,47UH

L113 87-003-098-080 COIL,2.2UH

L114 87-A50-530-010 COIL,VCO38.0MHZ

L301 87-005-444-080 COIL 100UH,K

L302 87-005-474-080 COLL,12UH J FLR50

L303 87-005-444-080 COIL 100UH,K

L601 87-A50-040-010 COIL,2.2MH

L602 8Z-JBE-606-010 COIL,LINEARITY SH5L8409

L801 87-A50-170-010 COIL,390UH RCH106

!

LF801 87-JB8-651-010 FLTR,LINE SS24H-K15070

!

PR801 87-A90-090-080 PROTECTOR,1.5A 491SERIES 60V

!

PR802 87-A90-094-080 PROTECTOR,4A 491SERIES 60V<2177>

!

PR803 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

PR804 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

PS801 87-A91-407-010 P-COUPLER,ON3171-R

!

PS802 87-A91-407-010 P-COUPLER,ON3171-R

!

PT801 8Z-JBA-621-010 PT,SW ZJB-KE-7 M

R101 87-A00-164-090 RES,M/F 12K-2W J RSF(S)

R317 87-A00-308-090 RES,M/F 47-3W J RSF(S)

R506 87-025-119-090 RES,M/F 560-1W J

R511 87-025-119-090 RES,M/F 560-1W J

R608 87-A00-721-090 RES,M/F 12-7W J RSV7

R612 87-A00-225-090 RES,M/F 2.2K-5W J RSV5

R619 87-A00-200-090 RES,M/F 100-2W J RSF(S)

R802 87-A00-552-010 RES,CEM 1.0-10W J MPC722

– 5 –

REF. NO. DESCRIPTIONPART NO.

NO.

R803 87-A00-552-010 RES,CEM 1.0-10W J MPC722

R804 87-A00-543-080 RES,SD 8.2M-1W J RCR60

R807 87-A00-639-090 RES,CEM 0.15-5W K BPR

R808 87-A00-573-090 RES,CEM 0.33-5W J MPC71

R816 87-A00-170-090 RES,M/F 82K-3W J RSF(S)

R817 87-A00-223-090 RES,M/F 47K-2W J RSF(S)

R827 87-A00-673-090 RES,M/F 82K-5W J RSS5L30

R830 87-A00-077-090 RES,M/F 8.2-3W J

R936 87-A00-070-090 RES,M/F 220-1W J

R937 87-A00-070-090 RES,M/F 220-1W J

S1 87-A90-712-080 SW,TACT EVQ11L07K

S2 87-A90-712-080 SW,TACT EVQ11L07K

S3 87-A90-712-080 SW,TACT EVQ11L07K

S4 87-A90-712-080 SW,TACT EVQ11L07K

S5 87-A90-712-080 SW,TACT EVQ11L07K

S6 87-A90-712-080 SW,TACT EVQ11L07K

S501 87-A90-567-010 SW,LVR 4-1-3 EVQRAAL10

!

S801 87-A91-410-010 SW,AC PUSH 1-1-1 ESB92SH1B

SWF201 87-A91-515-010 FLTR,SAW TSB5388P

SWF202 87-A91-556-010 FLTR,SAW TSF6364U

!

T601 8Z-JBR-605-010 FBT, HFT3607(SAN)21-C

T602 84-LB3-651-010 TRANS,HD MS-101N

!

!

THP801 87-A91-405-010 POS-THMS,T209-B80-A10

TU101 87-A91-495-010 TU UNIT, ENV59D58G3-38.0MHZ

X1 87-030-300-080 VIB,XTAL 8.00MHZ

X301 87-A70-054-080 VIB,XTAL 4.43MHZ AQC-1018

AUDIO C.B

C401 87-010-402-080 CAP, ELECT 2.2-50V

C402 87-010-260-080 CAP, ELECT 47-25V

C403 87-018-134-080 CAPACITOR,TC-U 0.01-16

C405 87-010-402-080 CAP, ELECT 2.2-50V

C406 87-010-405-080 CAP, ELECT 10-50V

C407 87-A11-148-080 CAP,TC U 0.1-50 Z F

C408 87-010-367-080 CAP,E 4.7-25 BP

C411 87-010-367-080 CAP,E 4.7-25 BP

C412 87-010-405-080 CAP, ELECT 10-50V

C413 87-A11-148-080 CAP,TC U 0.1-50 Z F

C414 87-010-405-080 CAP, ELECT 10-50V

C415 87-010-367-080 CAP,E 4.7-25 BP

C418 87-010-367-080 CAP,E 4.7-25 BP

C419 87-A11-148-080 CAP,TC U 0.1-50 Z F

C420 87-010-260-080 CAP, ELECT 47-25V

C421 87-010-260-080 CAP, ELECT 47-25V

C422 87-018-134-080 CAPACITOR,TC-U 0.01-16

C426 87-A11-148-080 CAP,TC U 0.1-50 Z F

C427 87-010-401-080 CAP, ELECT 1-50V

C428 87-018-134-080 CAPACITOR,TC-U 0.01-16

C429 87-010-263-080 CAP, ELECT 100-10V

C433 87-A11-148-080 CAP,TC U 0.1-50 Z F

C434 87-A11-148-080 CAP,TC U 0.1-50 Z F

C435 87-010-260-080 CAP, ELECT 47-25V

C436 87-018-119-080 CAP,TC V 100P-50 K B UP050<2157>

C437 87-018-119-080 CAP,TC V 100P-50 K B UP050<2157>

C438 87-010-367-080 CAP,E 4.7-25 M BP SP<2157>

C445 87-010-367-080 CAP,E 4.7-25 M BP SP<2157>

C446 87-010-101-080 CAP, ELECT 220-16

C447 87-A11-148-080 CAP,TC U 0.1-50 Z F

C448 87-010-260-080 CAP, ELECT 47-25V<2177>

C449 87-A11-148-080 CAP,TC U 0.1-50 Z F<2177>

C450 87-010-367-080 CAP,E 4.7-25 BP<2177>

C451 87-018-134-080 CAPACITOR,TC-U 0.01-16<2177>

C452 87-A11-148-080 CAP,TC U 0.1-50 Z F<2177>

C454 87-010-101-080 CAP, ELECT 220-16<2177>

C455 87-A11-148-080 CAP,TC U 0.1-50 Z F<2177>

C459 87-A11-148-080 CAP,TC U 0.1-50 Z F<2177>

C460 87-010-260-080 CAP, ELECT 47-25V<2177>

C461 87-010-367-080 CAP,E 4.7-25 BP<2177>

REF. NO. DESCRIPTIONPART NO.KANRI

KANRI

NO.

C462 87-010-382-080 CAP, ELECT 22-25V<2177>

C463 87-010-402-080 CAP, ELECT 2.2-50V<2177>

C464 87-010-401-080 CAP, ELECT 1-50V<2177>

C465 87-A11-148-080 CAP,TC U 0.1-50 Z F<2177>

C466 87-010-260-080 CAP, ELECT 47-25V<2177>

C467 87-010-367-080 CAP,E 4.7-25 M BP SP<2157>

C470 87-010-112-080 CAP,E 100-16 M 11L SME<2157>

C471 87-A11-148-080 CAP, TC U 0.1-50 Z F<2157>

C472 87-010-367-080 CAP,E 4.7-25 M BP SP<2157>

C475 87-010-379-080 CAP,E 22-16 M 11L SME<2157>

C476 87-010-404-080 CAP, ELECT 4.7-50V

C477 87-010-404-080 CAP, ELECT 4.7-50V

C478 87-010-405-080 CAP, E 10-50 M 11L SME<2157>

C478 87-010-401-080 CAP, ELECT 1-50V<2177>

C479 87-010-247-080 CAP, ELECT 100-50V

C480 87-010-388-080 CAP ELECT 1000-25V SME

C481 87-010-388-080 CAP ELECT 1000-25V SME

C482 87-010-405-080 CAP, E 10-50 M 11L SME<2157>

C482 87-010-401-080 CAP, ELECT 1-50V<2177>

C483 87-010-247-080 CAP, ELECT 100-50V

C484 87-A11-148-080 CAP,TC U 0.1-50 Z F

C485 87-010-247-080 CAP, ELECT 100-50V<2177>

C486 87-010-388-080 CAP ELECT 1000-25V SME<2177>

C487 87-010-388-080 CAP ELECT 1000-25V SME<2177>

C488 87-010-405-080 CAP, ELECT 10-50V<2177>

C489 87-010-405-080 CAP, ELECT 10-50V<2177>

C490 87-010-405-080 CAP, ELECT 10-50V<2177>

C491 87-A11-148-080 CAP,TC U 0.1-50 Z F<2177>

C492 87-010-411-090 CAP,E 1000-50 M SME<2177>

C493 87-010-112-080 CAP, E 100-16 M 11L SME<2157>

C493 87-010-260-080 CAP, ELECT 47-25V<2177>

C498 87-010-402-080 CAP, E 2.2-50 M 11L SME<2157>

C498 87-010-260-080 CAP, ELECT 47-25V<2177>

CN401 87-009-034-010 CONN,6P PH V

CN402 87-009-038-010 CONN,10P PH

CN403 87-099-408-010 CONN,8P EH V WHT

CN404 87-009-195-010 CONN,5P B5BEH

CN405 87-099-043-010 CONN 2P EH<2177>

CN406 87-099-043-010 CONN 2P EH<2177>

CN407 87-049-469-010 CONN,4P V<2177>

CNA405 8Z-JB3-602-010 CONN ASSY,2P SP-750<2177>

CNA406 8Z-JB3-601-010 CONN ASSY,2P SP-850<2177>

FR996 87-A00-084-090 RES,FUSE 1-1W J

FR997 87-A00-084-090 RES,FUSE 1-1W J

R401 87-025-381-080 RES,M/F 18K-1/6W F

R402 87-025-424-080 RES,M/F 10K-1/6W F

R404 87-025-380-080 RES,M/F 15K-1/6W F

R405 87-025-381-080 RES,M/F 18K-1/6W F

SP401 8Z-JB4-620-010 SPKR,6*12 8OHM 10W<2177>

SP402 8Z-JB4-620-010 SPKR,6*12 8OHM 10W<2177>

SP403 8A-JBF-621-010 SPKR,8 8OHM 10W<2177>

SP404 8A-JBF-621-010 SPKR,8 8OHM 10W<2177>

NICAM C.B

C701 87-010-318-080 C-CAP,S 47P-50 CH

C702 87-010-318-080 C-CAP,S 47P-50 CH

C703 87-010-145-080 C-CAP,S 1P-50 CH

C704 87-010-145-080 C-CAP,S 1P-50 CH

C705 87-010-553-080 CAP,E 47-16

C706 87-010-197-080 CAP, CHIP 0.01 DM

C707 87-010-197-080 CAP, CHIP 0.01 DM

C708 87-010-496-080 CAP,E 3.3-50 5L

C709 87-010-197-080 CAP, CHIP 0.01 DM

C710 87-010-197-080 CAP, CHIP 0.01 DM

C714 87-010-555-080 CAP,E 100-10 GAS

C715 87-010-197-080 CAP, CHIP 0.01 DM

C716 87-010-316-080 C-CAP,S 33P-50 CH

C719 87-010-498-080 CAP,E 10-16 GAS

C720 87-012-157-080 C-CAP,S 330P-50 CH

– 6 –

REF. NO. DESCRIPTIONPART NO.

NO.

C723 87-010-498-080 CAP,E 10-16 GAS

C724 87-010-494-080 CAP ELECT GAS 1-50

C725 87-010-197-080 CAP, CHIP 0.01 DM

C726 87-010-197-080 CAP, CHIP 0.01 DM

C727 87-010-497-080 CAP,E 4.7-35 5L

C728 87-010-197-080 CAP, CHIP 0.01 DM

C729 87-010-555-080 CAP,E 100-10 GAS

C730 87-010-321-080 CHIP CAPACITOR,82P-50

C731 87-012-140-080 CAP 470P-50

C732 87-010-189-080 C-CAP,S 8200P-50 B

C733 87-010-183-080 C-CAP,S 2700P-50 B

C734 87-012-142-080 CAP, S 0.33-16

C737 87-010-552-080 CAP,E 22-16 GAS

C739 87-012-157-080 C-CAP,S 330P-50 CH

C740 87-010-318-080 C-CAP,S 47P-50 CH

C741 87-012-140-080 CAP 470P-50

C742 87-010-189-080 C-CAP,S 8200P-50 B

C743 87-010-183-080 C-CAP,S 2700P-50 B

C744 87-012-142-080 CAP, S 0.33-16

C745 87-012-157-080 C-CAP,S 330P-50 CH

C748 87-012-154-080 C-CAP,S 150P-50 CH

CN701 87-A60-722-010 CONN,8P JL-R

CN702 87-A60-720-010 CONN,6P JL-R

L701 87-005-461-080 COIL,1UH J FLR50

L702 87-005-461-080 COIL,1UH J FLR50

L703 87-005-473-080 COIL,10UH J FLR50

L705 87-005-473-080 COIL,10UH J FLR50

L707 87-005-473-080 COIL,10UH J FLR50

L708 87-005-485-080 COIL,100UH J FLR50

X701 87-A70-199-080 VIB,XTAL 18.432MHZ

REF. NO. DESCRIPTIONPART NO.KANRI

C756 87-010-553-080 CAP,E 47-16 M 5L SRE<2177>

C757 87-010-196-080 CHIP CAPACITOR,0.1-25<2177>

C758 87-010-313-080 CAP, CHIP 18P-50<2177>

C759 87-010-313-080 CAP, CHIP 18P-50<2177>

C760 87-010-495-080 CAP,E2.2-50<2177>

CN750 87-A60-722-010 CONN,8P JL-R<2177>

CN751 87-A60-719-010 CONN,5P JL-R<2177>

L751 87-005-481-080 COIL,47UH J FLR50<2177>

X751 83-JU3-667-080 VIB,XTAL 12.0M<2177>

NICAM C.B

!

C551 87-010-976-080 CAP,CER 1000P-500 B

!

C552 87-012-397-010 CAP,CER 1000P-2K BN

C553 87-018-127-080 CAP, CER 470P-50V

C554 87-018-127-080 CAP, CER 470P-50V

C555 87-018-128-080 CAP, TC U 560P-50 K B UP050

C556 87-010-405-080 CAP, ELECT 10-50V

C557 87-010-405-080 CAP, ELECT 10-50V

CN551 87-009-195-010 CONN,5P B5BEH

CN552 87-049-590-010 CONN,5P 8283 V WHT

CN553 87-A61-112-080 CONN,1P V BLU TP00704

CN554 87-A61-060-080 CONN,1P V RED TP00706

L551 87-005-444-080 COIL 100UH,K<2177>

R551 87-A00-165-090 RES,M/F 15K-2W J RSF(S)

R552 87-A00-165-090 RES,M/F 15K-2W J RSF(S)

R553 87-A00-165-090 RES,M/F 15K-2W J RSF(S)

SO551 8Z-JB4-670-010 SOCKET,CRT 9P CVT3327 1603

V551 86-LB2-602-010 CRT,A51KST94X01(VM)<2177>

!

KANRI

NO.

TEXT C.B

C751 87-010-196-080 CHIP CAPACITOR,0.1-25<2177>

C752 87-010-196-080 CHIP CAPACITOR,0.1-25<2177>

C753 87-010-196-080 CHIP CAPACITOR,0.1-25<2177>

C754 87-010-197-080 CAP, CHIP 0.01 DM<2177>

C755 87-010-555-080 CAP,E 100-10 GAS<2177>

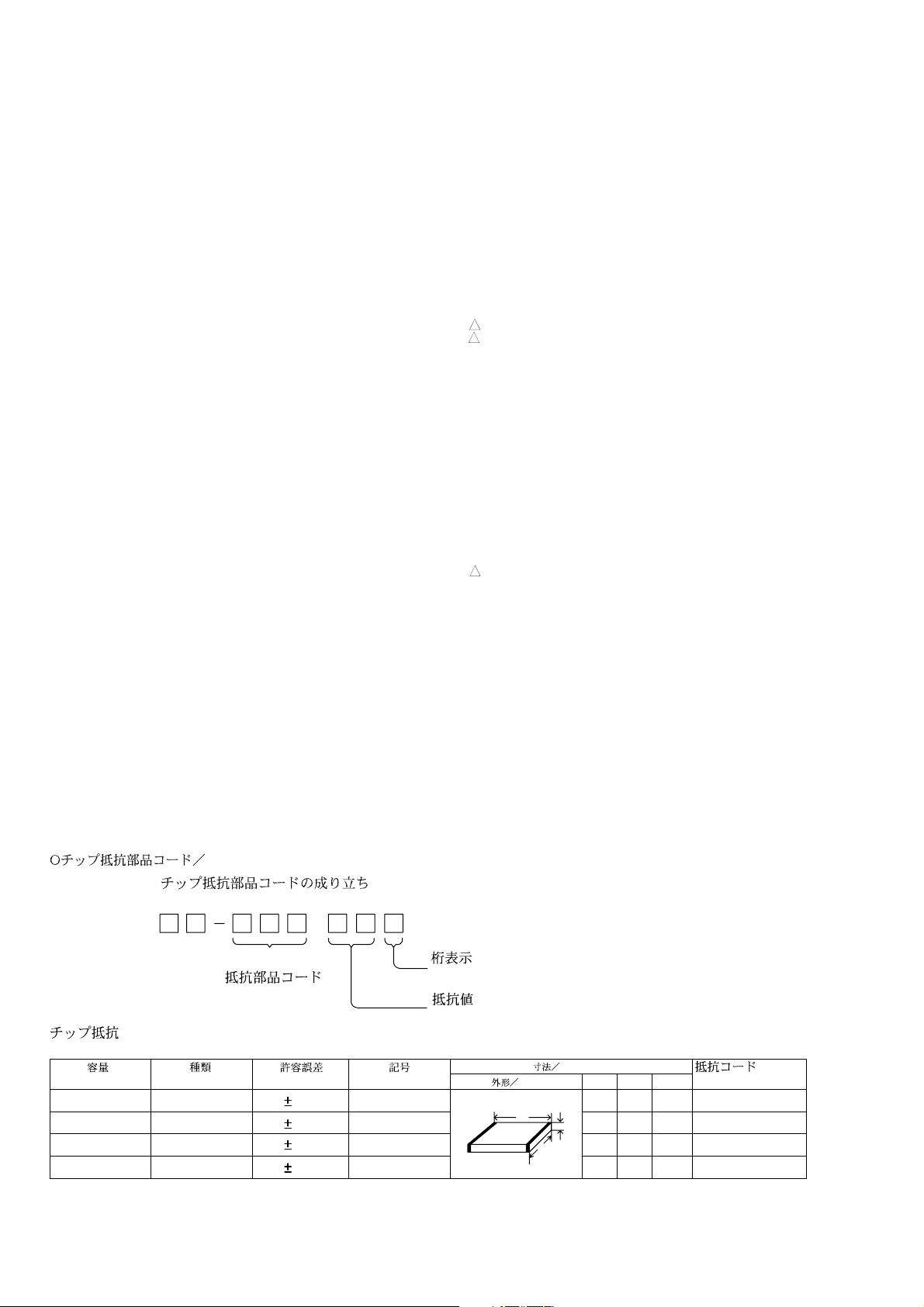

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

Figure

Value of resistor

CJ

CJ

CJ

Form

L

W

Dimensions (mm)

LW t

1.0 0.5 0.35 104

t

1.6 0.8 0.45

2 1.25 0.45

1.6

0.55

3.2

Resistor Code

108

118

128

: A

: A

– 7 –

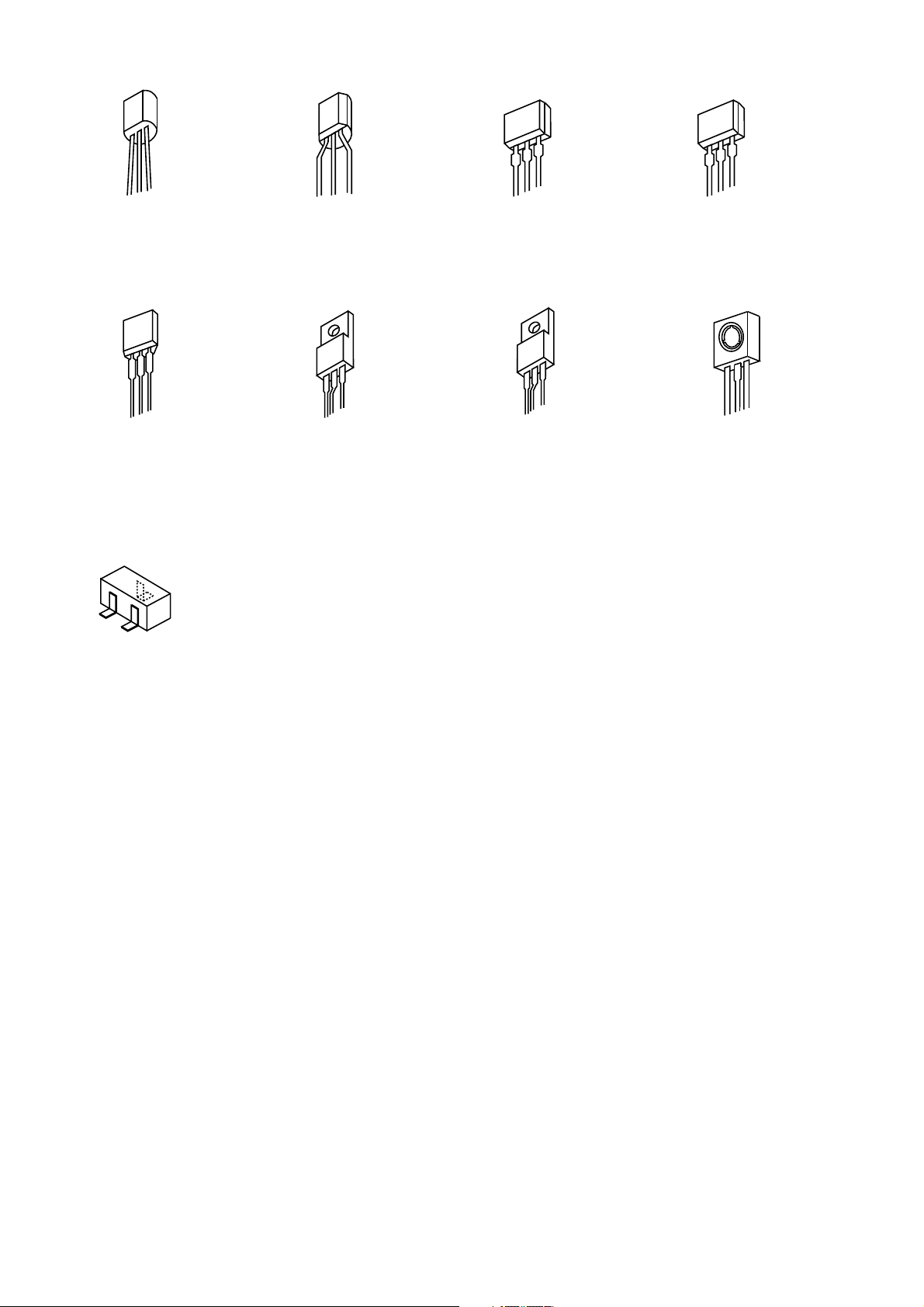

TRANSISTOR ILLUSTRATION

E C B B E C

2SC3467D/E

2SA1015GR

E C B

DTC144ES

2SA1175FE

C

B

E

E C B S D G

2SC3779D/E 2SJ460

2SA950

2SC2785FE

2SK2541

DTC323TS

B C E

2SD2580

1 2 3

SE115N

E C B

2SC2688

2SC2412K

– 8 –

WIRING - 1 (MAIN)

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 9 –

R

S

T

U

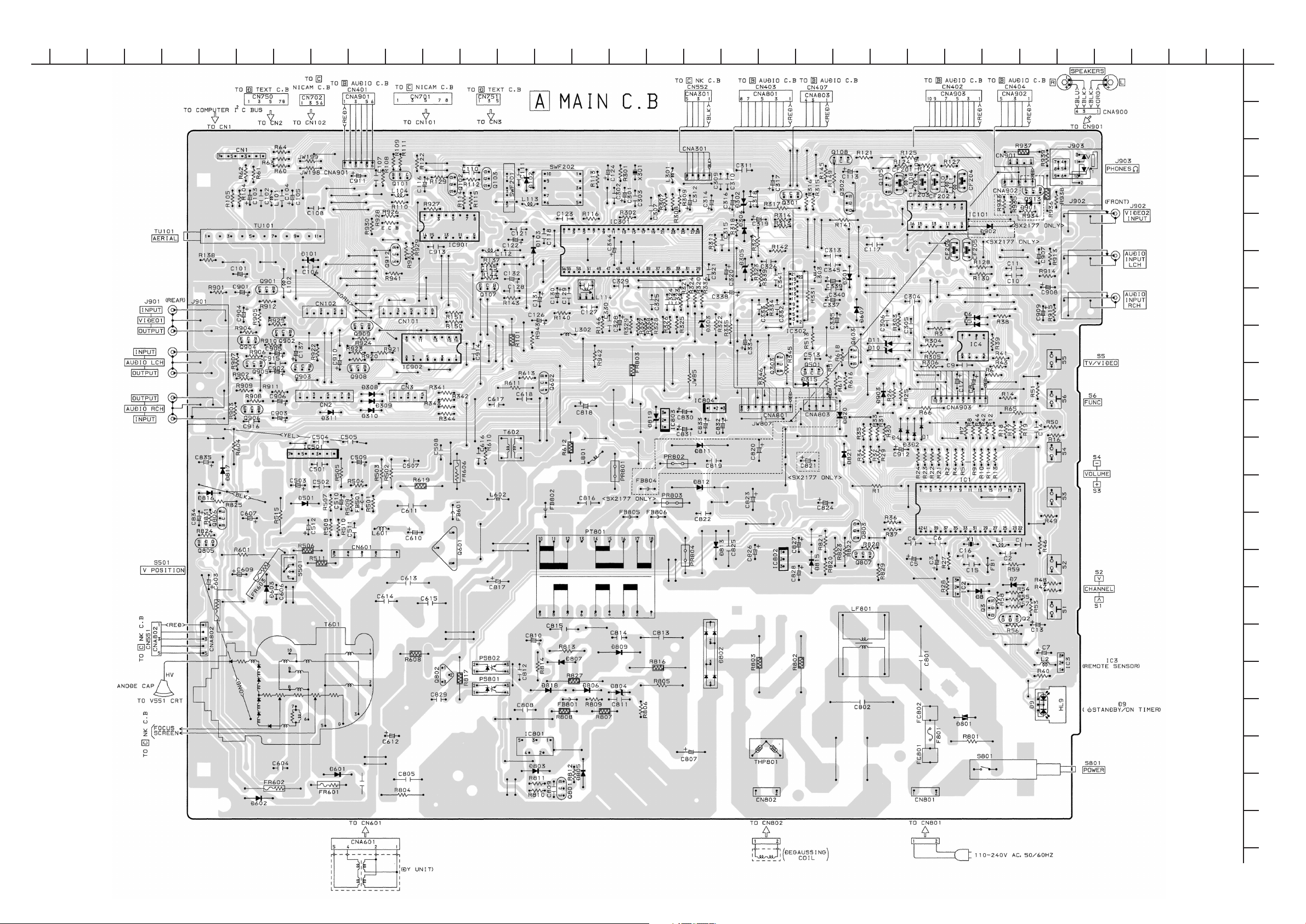

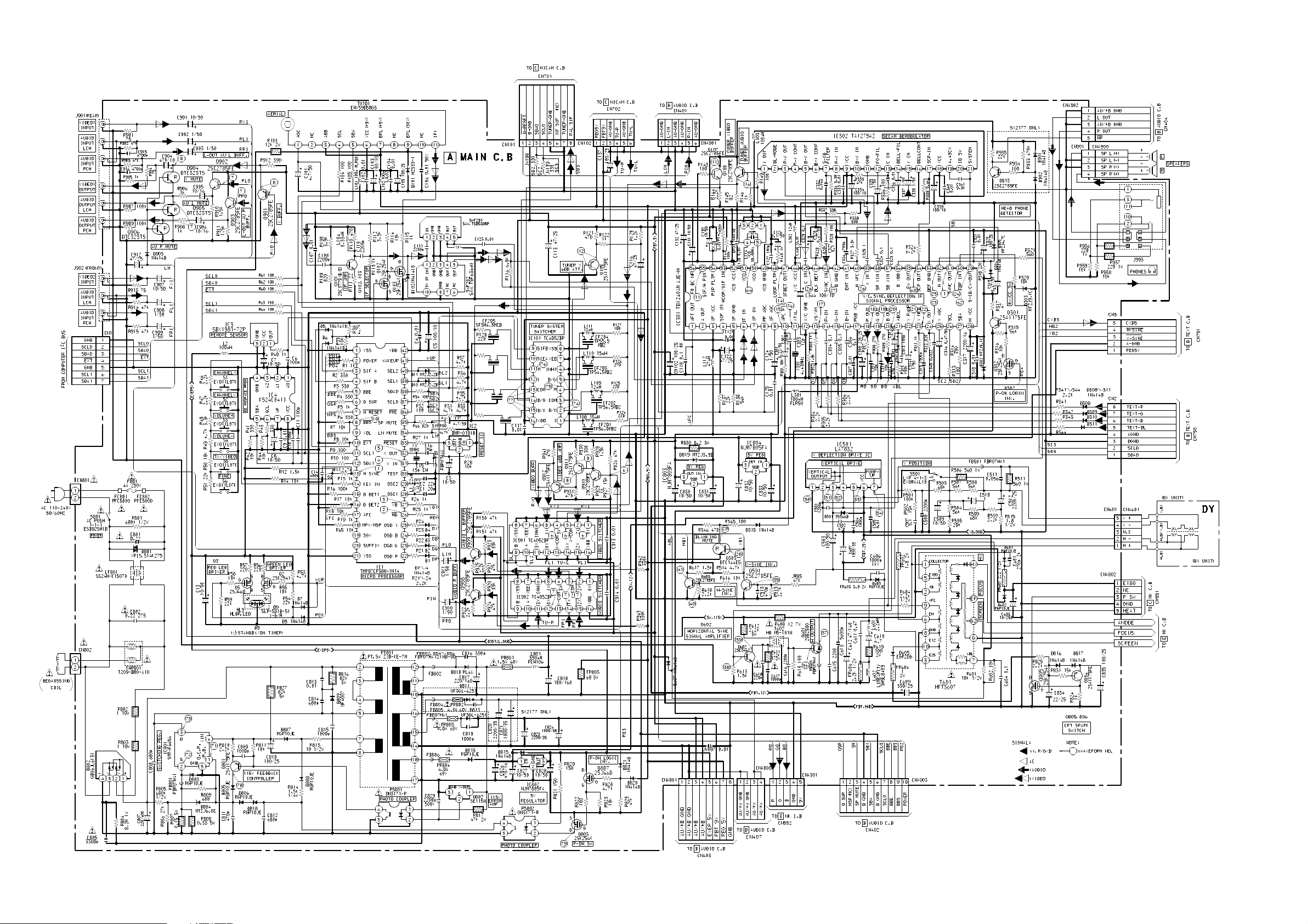

SCHEMATIC DIAGRAM - 1 (MAIN)

– 10 –

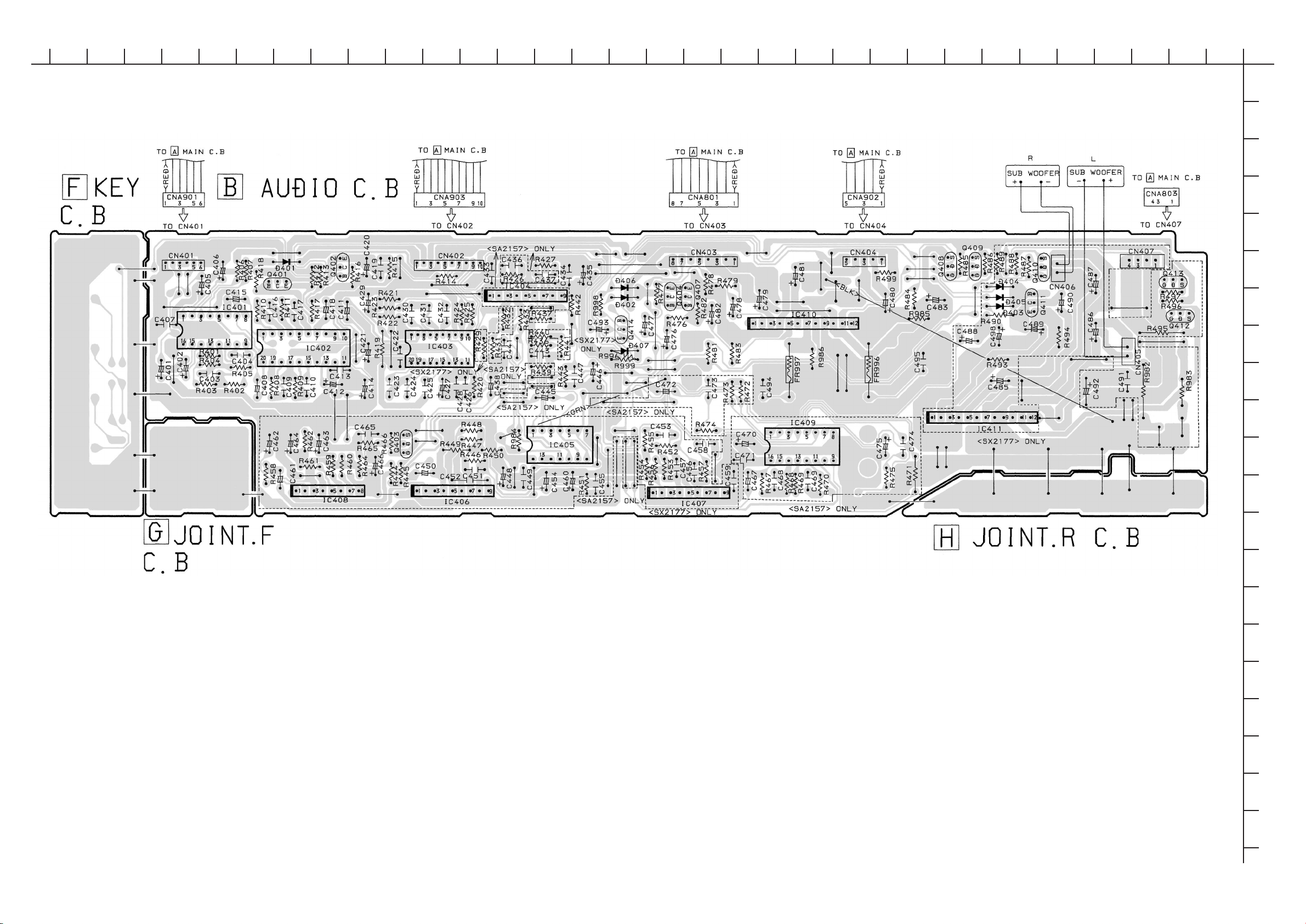

WIRING - 2 (AUDIO / KEY / JOINT.F / JOINT.R)

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 11 –

R

S

T

U

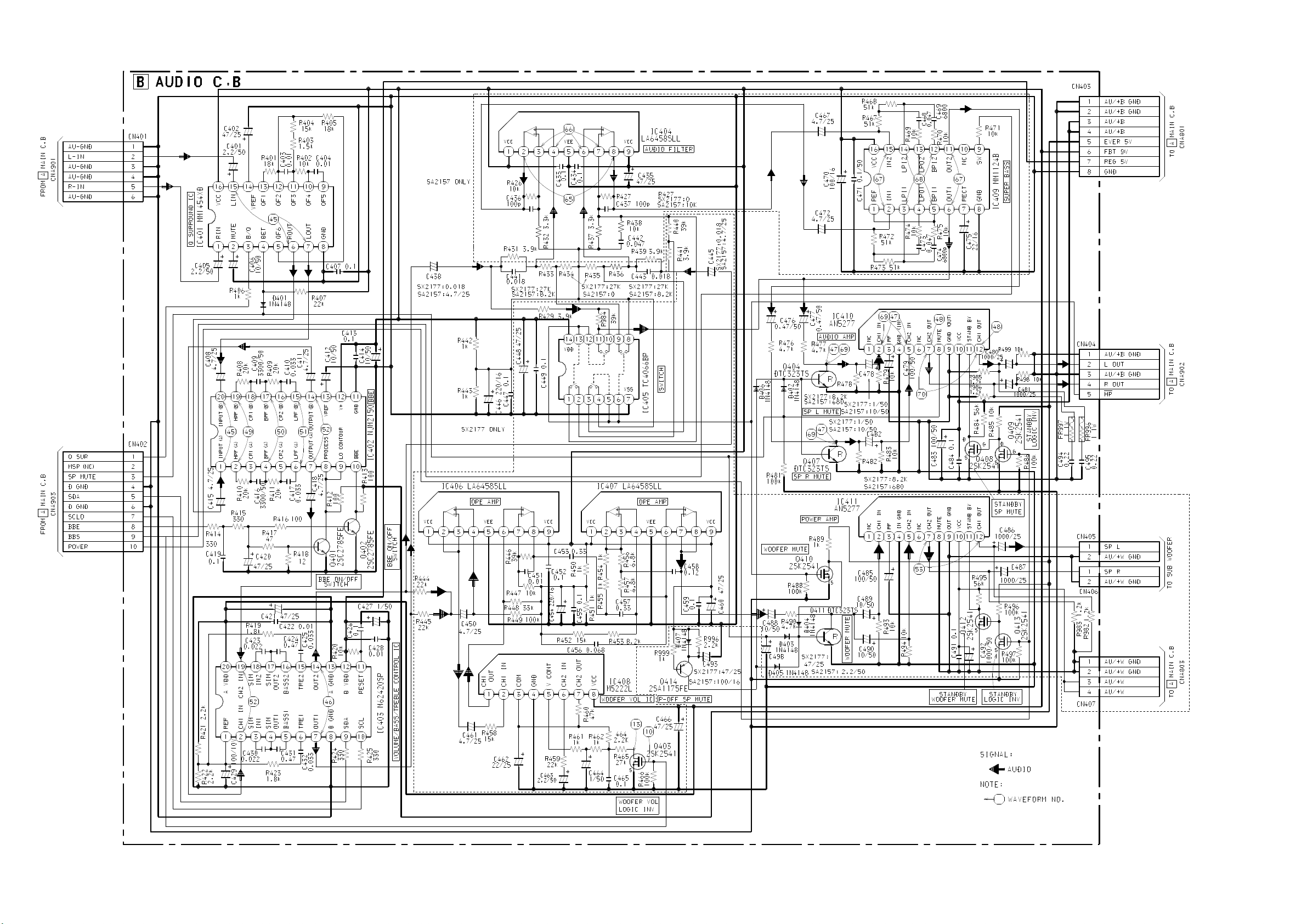

SCHEMATIC DIAGRAM - 2 (AUDIO)

– 12 –

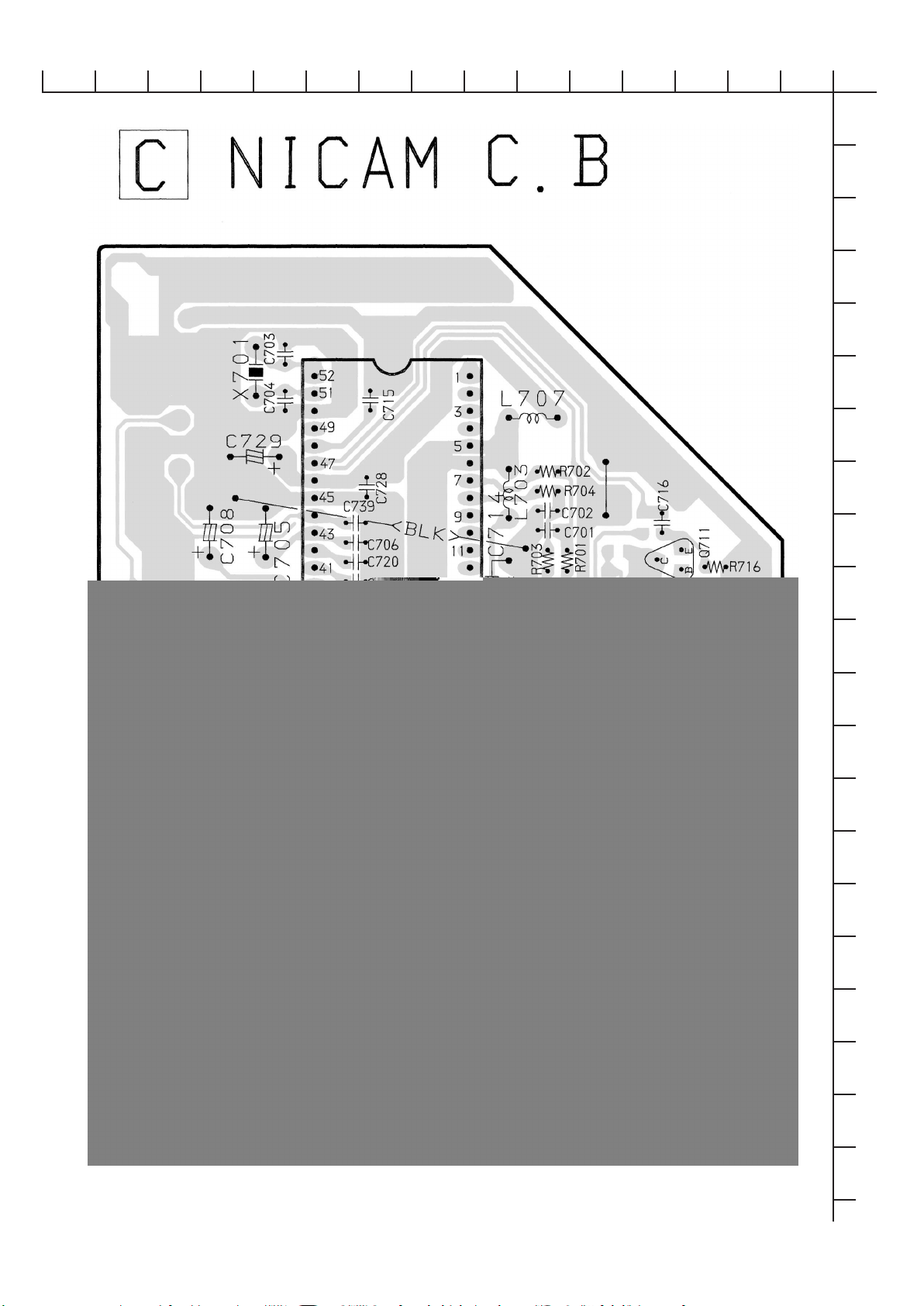

WIRING – 3 (NICAM)

123456789101112131415

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 13 –

R

S

T

U

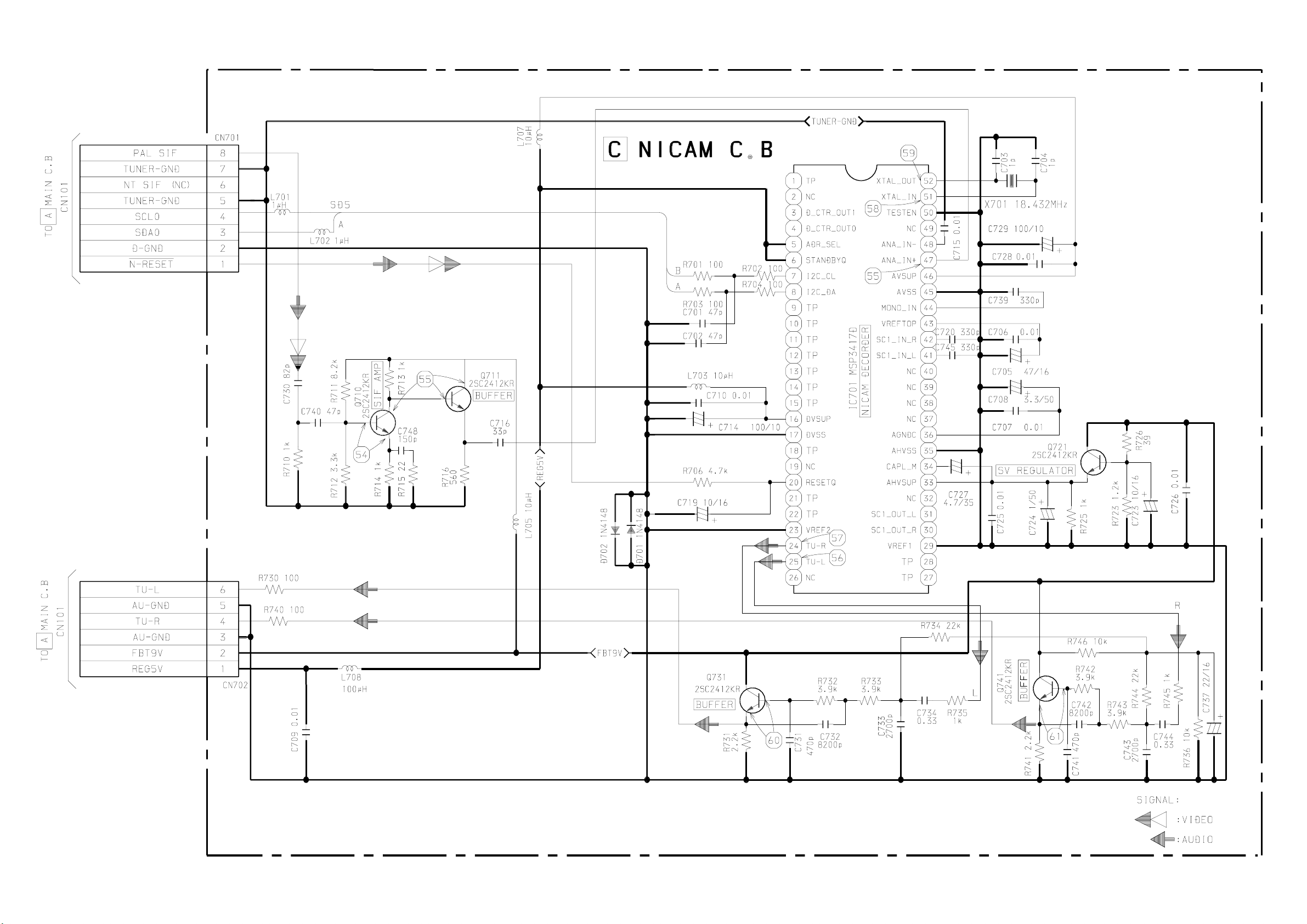

SCHEMATIC DIAGRAM - 3 (NICAM)

14

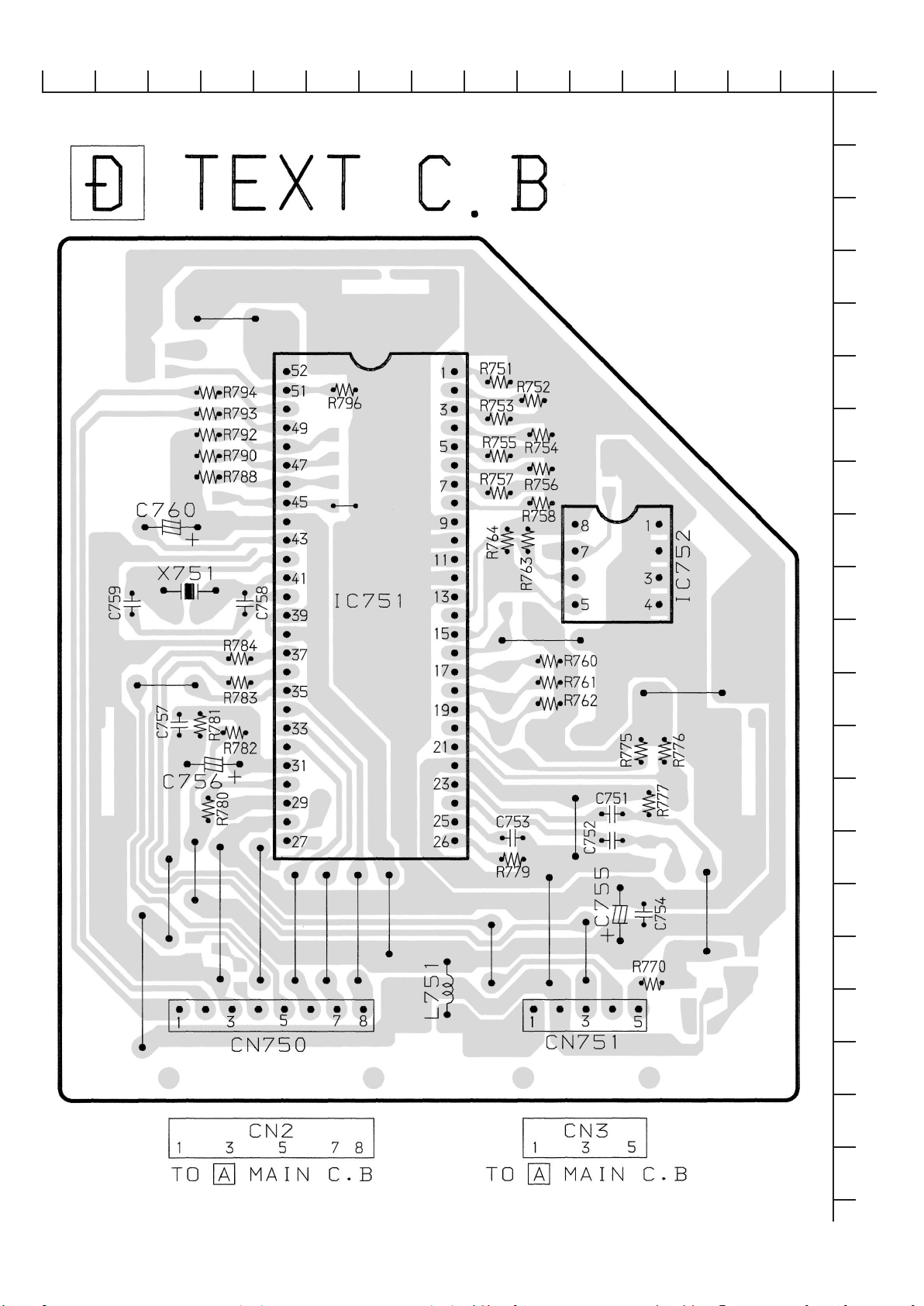

WIRING – 4 (TEXT)

123456789101112131415

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 15 –

R

S

T

U

Loading...

Loading...