Aiwa TV-FA2500 Service Manual

TV-FA2500

SH, SHA

SERVICE MANUAL

COLOR TELEVISION

• This Service Manual is the “Revision Publishing” and replaces “Simple Manual”

of TV-FA2500 <SH>, (S/M Code No. 09-009-437-6T1) and TV-FA2500 <SHA>,

(S/M Code No. 09-009-437-6T2).

S/M Code No. 09-00A-437-6R1

REVISION

DATA

TABLE OF CONTENT

SPECIFICATIONS ................................................................................................................................................................3

ACCESSORIES / PACKAGE LIST ...................................................................................................................................... 3

NOTICES BEFORE REPAIRING........................................................................................................................................ 4

DISASSEMBLY INSTRUCTIONS.................................................................................................................................. 5 ~ 9

ELECTRICAL MAIN PARTS LIST ........................................................................................................................... 10 ~ 13

TRANSISTOR ILLUSTRATION ......................................................................................................................................... 14

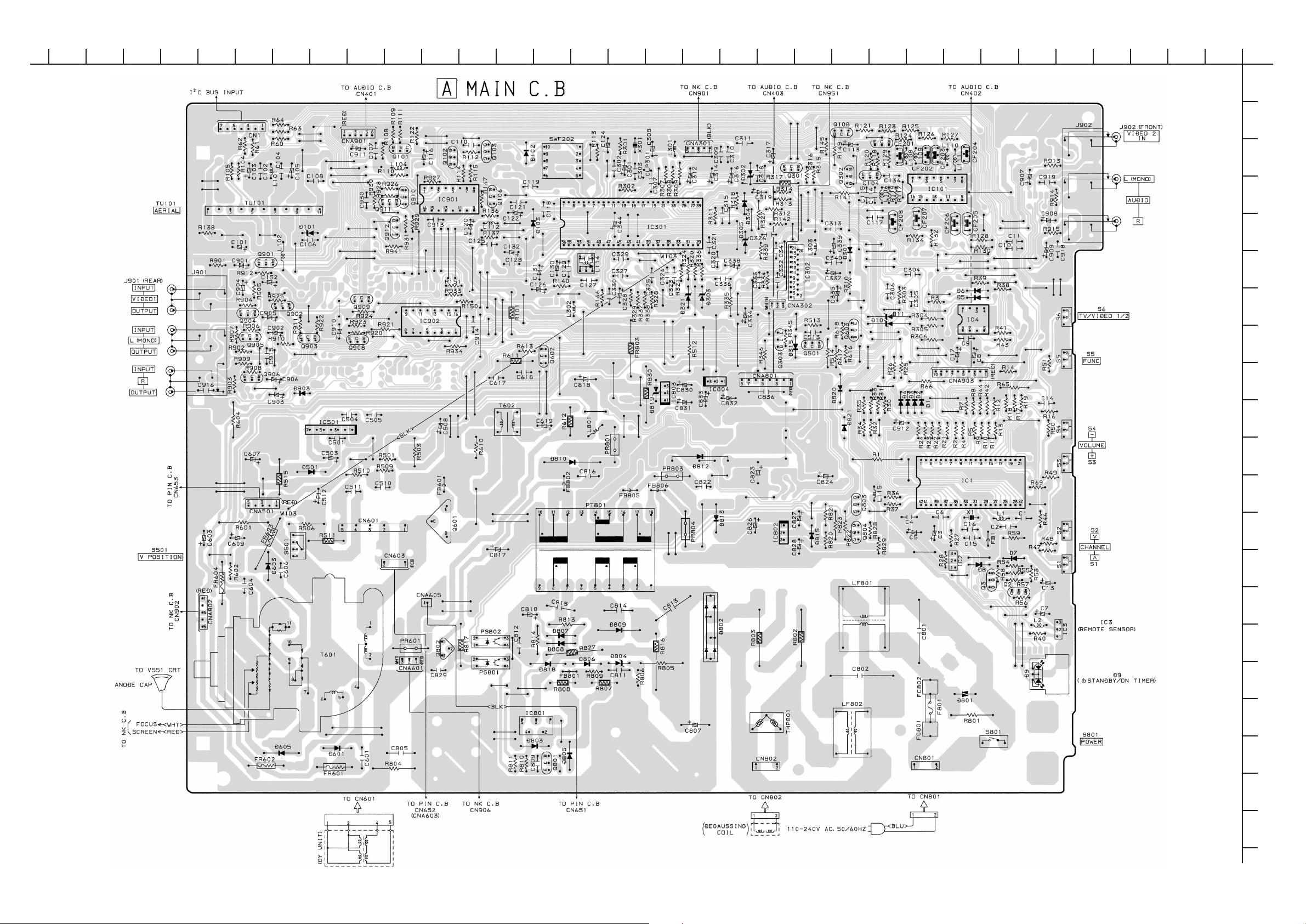

WIRING – 1 (MAIN) ........................................................................................................................................................... 15

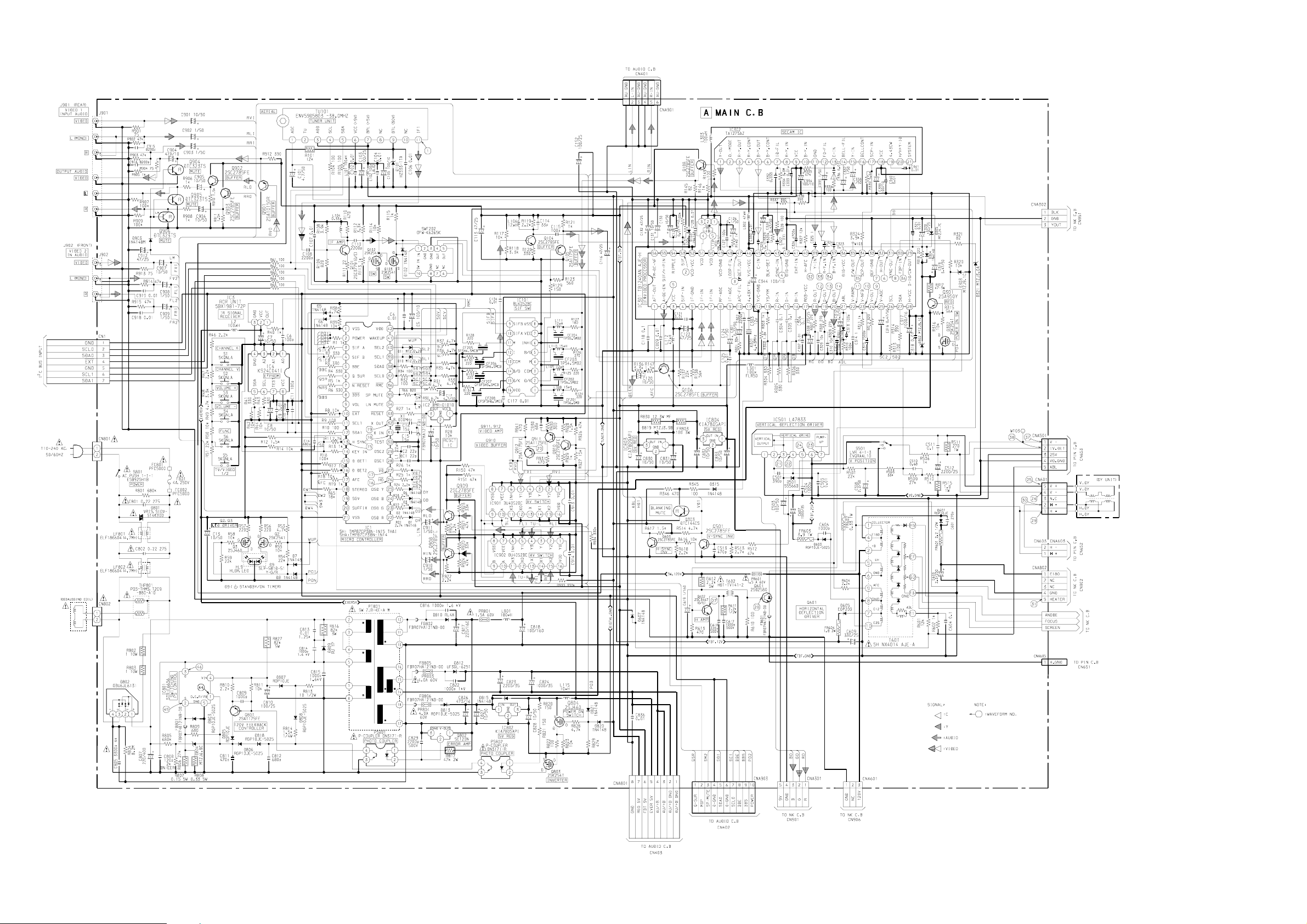

SCHEMATIC DIAGRAM – 1 (MAIN)................................................................................................................................. 16

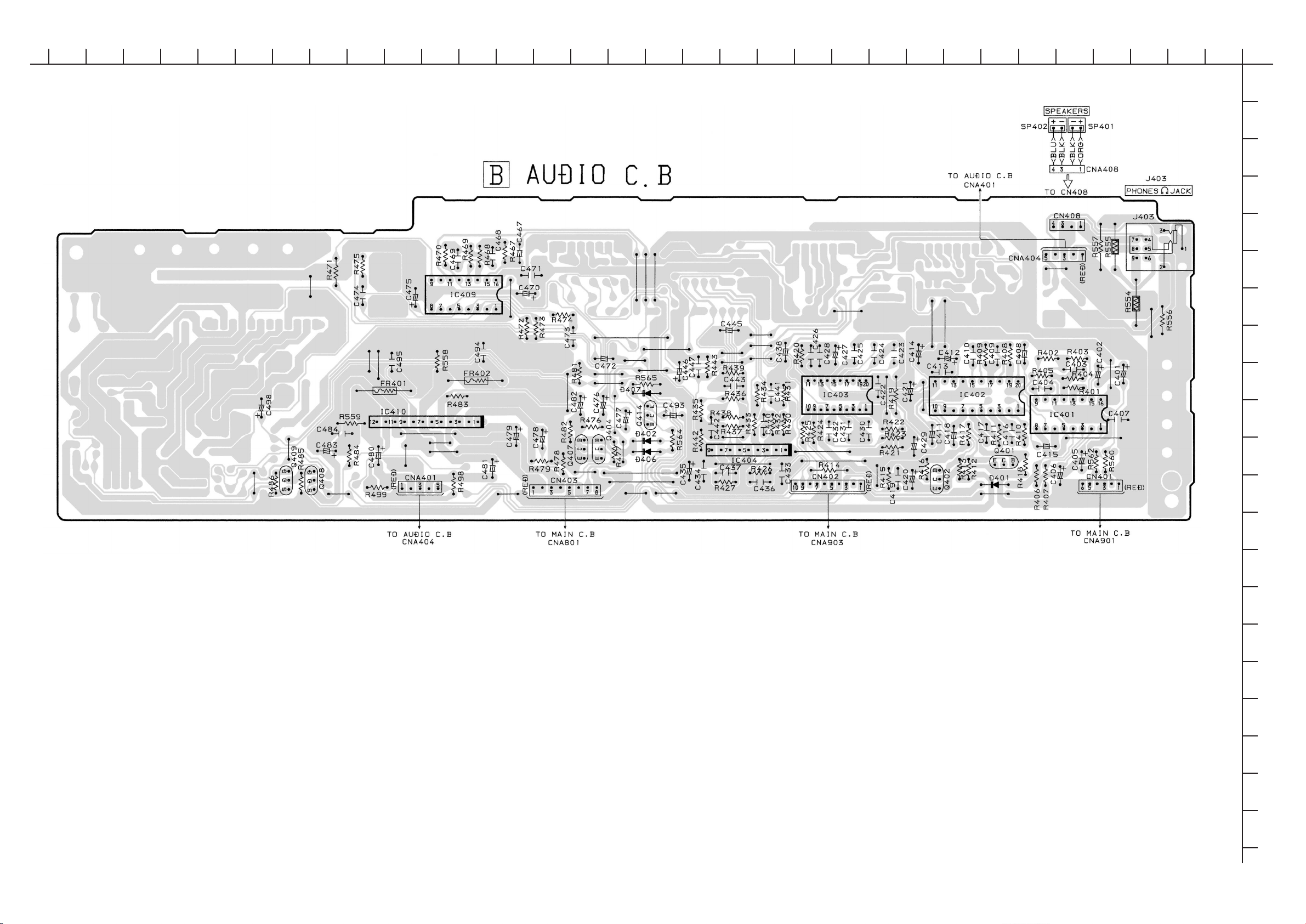

WIRING – 2 (AUDIO : SH) ................................................................................................................................................. 17

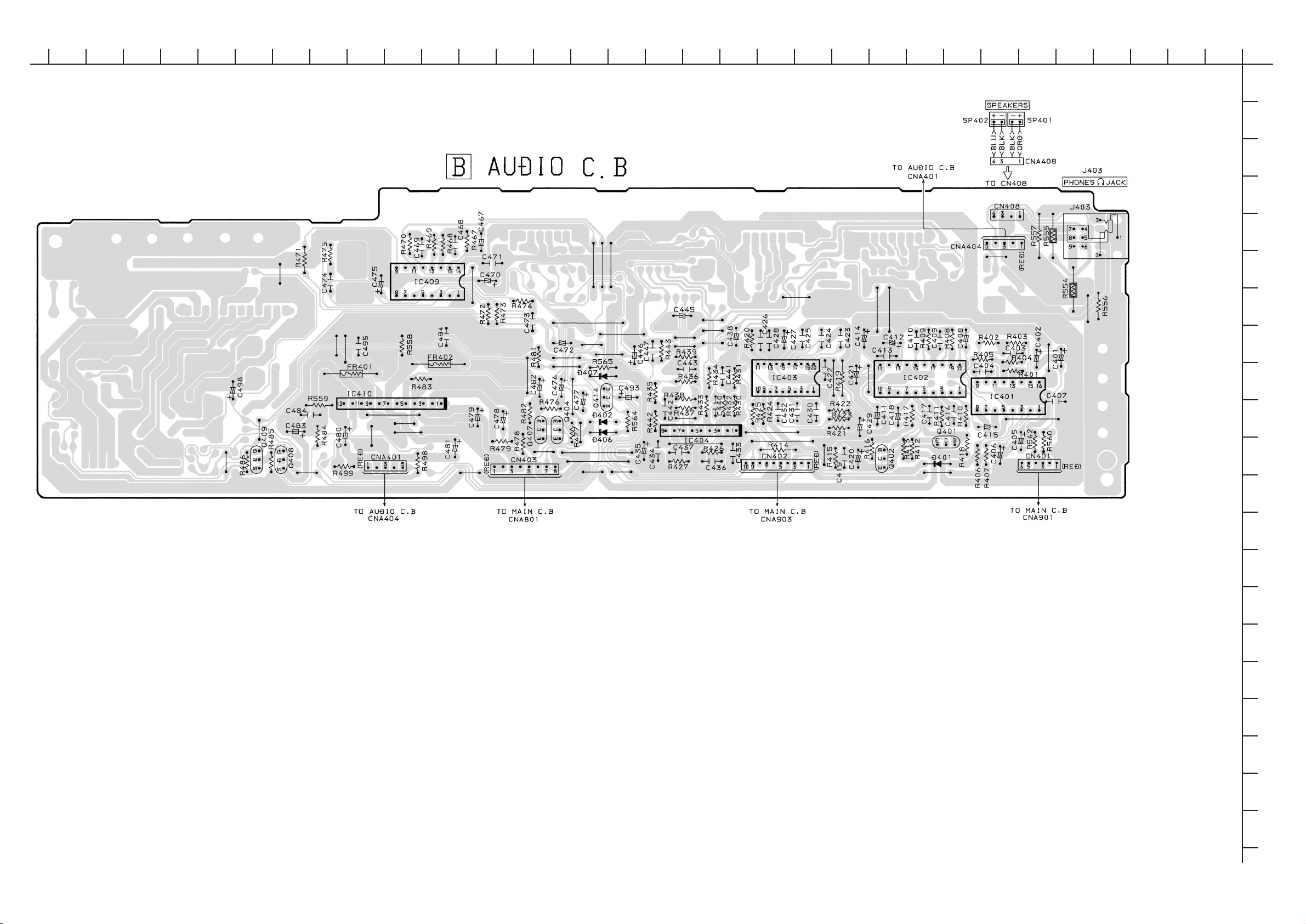

WIRING – 3 (AUDIO : SHA)............................................................................................................................................... 18

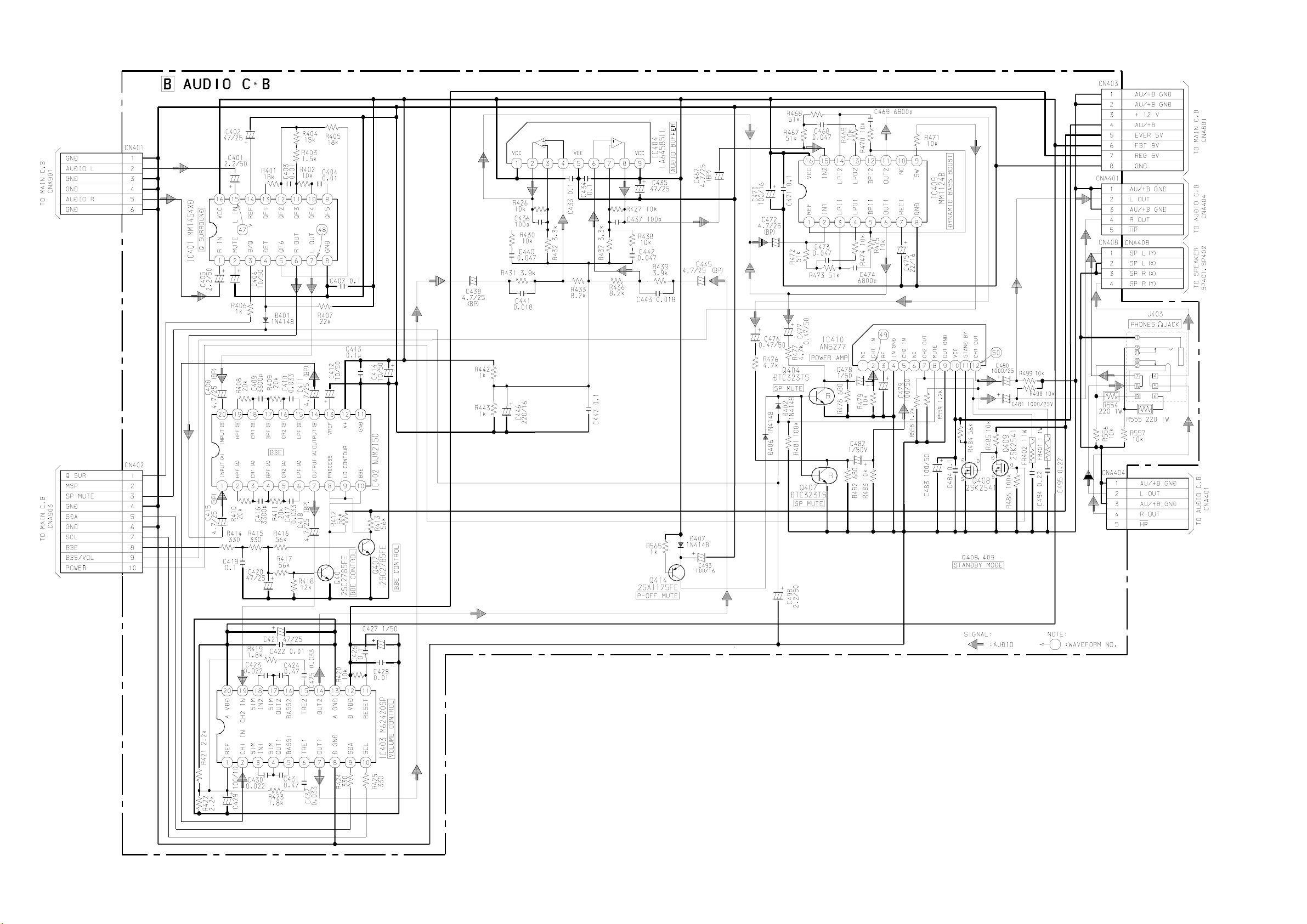

SCHEMATIC DIAGRAM – 2 (AUDIO : SH, SHA) ............................................................................................................. 19

WIRING – 4 (NK : SH) ....................................................................................................................................................... 20

WIRING – 5 (NK : SHA) ..................................................................................................................................................... 21

SCHEMATIC DIAGRAM – 3 (NK : SH, SHA) ................................................................................................................... 22

WIRING – 6 (PIN : SH) ...................................................................................................................................................... 23

WIRING – 7 (PIN : SHA) .................................................................................................................................................... 24

SCHEMATIC DIAGRAM – 4 (PIN : SH, SHA) .................................................................................................................. 25

IC BLOCK DIAGRAM.................................................................................................................................................26 ~ 27

IC DESCRIPTION ......................................................................................................................................................28 ~ 31

WAVEFORM ...............................................................................................................................................................32 ~ 38

VOLTAGE CHART..................................................................................................................................................... 39 ~ 43

ADJUSTMENT ............................................................................................................................................................44 ~ 58

MECHANICAL EXPLODED VIEW 1 / 1........................................................................................................................... 59

MECHANICAL PARTS LIST 1 / 1 .................................................................................................................................... 60

– 2 –

SPECIFICATIONS

Tuner System Frequency synthesized tuner

TV System PAL (B/G, H, I, D/K)

Channel Coverage VHF: E2 to E12, R1 to R12

Program Memory 100 TV stations

Antenna Input 75 ohms, unbalanced

Picture Tube 25"

Screen Size 478 (W) X 359 (H) mm (187/8 X 141/4 in.)

Video Input /Output 1 Vp-p 75 ohms

Audio Input -8 dBs., more than 33 k ohms

Audio Output -8 dBs., less than 2.2 k ohms

Speaker 60 X 120 mm (23/8 X 43/4 in.)

Operating Voltage 110 - 240 V AC, 50/60 Hz

Power Consumption 125 W (Standby mode: 13 W)

Phones Jack Stereo-mini jack

Operating Temperature 5 °C – 40 °C

Operating Humidity 35 % – 80 %

Dimensions 690 (W) X 506 (H) X 485 (D) mm

Weight 32.5 kg (71.5 lbs.)

• Design and specifications are subject to change without

notice.

SECAM (B/G, I, D/K, K1)

NTSC(M)

UHF: 21 to 69

CATV: S1 to S41

598 mm (diagonal) (235/8 in.)

10 W + 10 W (10 % Harmonic distortion)

(271/4 x 20 x 19 1/8 in.)

ACCESSORIES / PACKAGE LIST

REF. NO. DESCRIPTIONPART NO.

1 8A-JEK-902-010 IB,SH (ECAPR) FA2100/2500-M

2 8A-JEA-951-010 RC UNIT,RC-ZVT25

KANRI

NO.

– 3 –

NOTICES BEFORE REPAIRING

To make the best use of this equipment, make sure to

obey the following items when repairing (or mending).

1. Do not damage or melt the tunicate of the leading

wire on the AC1 side, including the power supply

cord.

2. Do not soil or stain the letters on the spec.

inscription plates, notice labels, fuse labels, etc.

3. When repairing the part extracted from the

conducted side of the board pattern, fix it firmly

with applying bond to the pattern and the part.

4. Restore the following items after repairing.

1) Conditions of soldering of the wires (especially,

the distance on the AC1 side).

2) Conditions of wiring, bundling of wires, etc.

3) Types of the wries.

4) Attachment conditions of all types of the insulation.

5. After repairing, always measure the insulation

resistance and perform the voltage-withstand test

(See Fig-1).

1) The insulation resistance must be 6 MΩ to 10 MΩ

when applying

2) In the voltage withstand test, apply 3 kV for 1 min

and check that the GO lamp lights.

500V per second.

Insulation resistance: 6 MΩ to 10 MΩ (500 V/s)

Voltage-withstand: 3 kV for 1 min

Safety checker (Model 7110, etc.)

Earth cable

AC cable

Connect the earth cable

to the outside metal part

terminal.

Fig-1

* Breaking current set to 10 mA.

* Connect the safety checker as shown in Fig-1,

then measure the resistance and perform the test.

* Do not touch the equipment during testing.

* For details of the safety checker, refer to the supplied

Operation manual.

When servicing and checking on the TV, note the followings.

1. Keep the notices.

As for the places which need special attentions, they

are indicated with labels or seals on the cabinet,

chassis and parts. Make sure to keep the indications

and notices in the operation manual.

2. Avoid an electric shock.

There is a high voltage part inside. Avoid an electric

shock while the electric current is flowing.

3. Use the designated parts.

The parts in this equipment have the specific

characteristics of incombustibility and withstand voltage

for safety.

Therefore, use a part which has the same character

as the replaced part. Especially as to the important

parts for safety which is indicated in the circuit

diagram or the table of parts with a mark, the

designated parts must be used.

4. Put parts and wires in the original position after

assembling or wiring.

There are parts which use the insulation material such

as a tube or tape for safety, or which are assembled so

that these parts do not make contact with the printed

!

board. The inside wiring is designed not to get close to

the pyrogenic parts and high voltage parts. Therefore,

put these parts in the original positions.

5. Take care of the cathode-ray tube.

By setting an explosion-proof cathode-ray tube in this

equipment, safety is secured against implosion.

However, when removing it or servicing from the

back, it gives out shock that is dangerous. Take

enough care to deal with it.

6. Avoid an X-ray.

Safety is secured against an X-ray by giving

considerations to the cathode-ray tube and the high

voltage peripheral circuit, etc. Therefore, when

repairing the high voltage peripheral circuit, use the

designated parts and do not change the circuit.

Repairing, except indicates, causes rising of high

voltage, and the cathode-ray tube emits an X-ray.

7. Perform a safety check after servicing.

Confirm that the screws, parts and wiring which were

removed in order to service are put in the original

positions, or whether there are deteriorated portions

around the places serviced.

!

Safety Components Symbol

This symbol is given to important parts which serve to maintain the safety of the product, and which

are made to confirm to special Safety Specifications.

Therefore, when replacing a component with this symbol make absolutely sure that you use a

designated part.

– 4 –

Anode cap

CRT GND

Hook

CRT

CRT GND

Grip

DISASSEMBLY INSTRUCTIONS

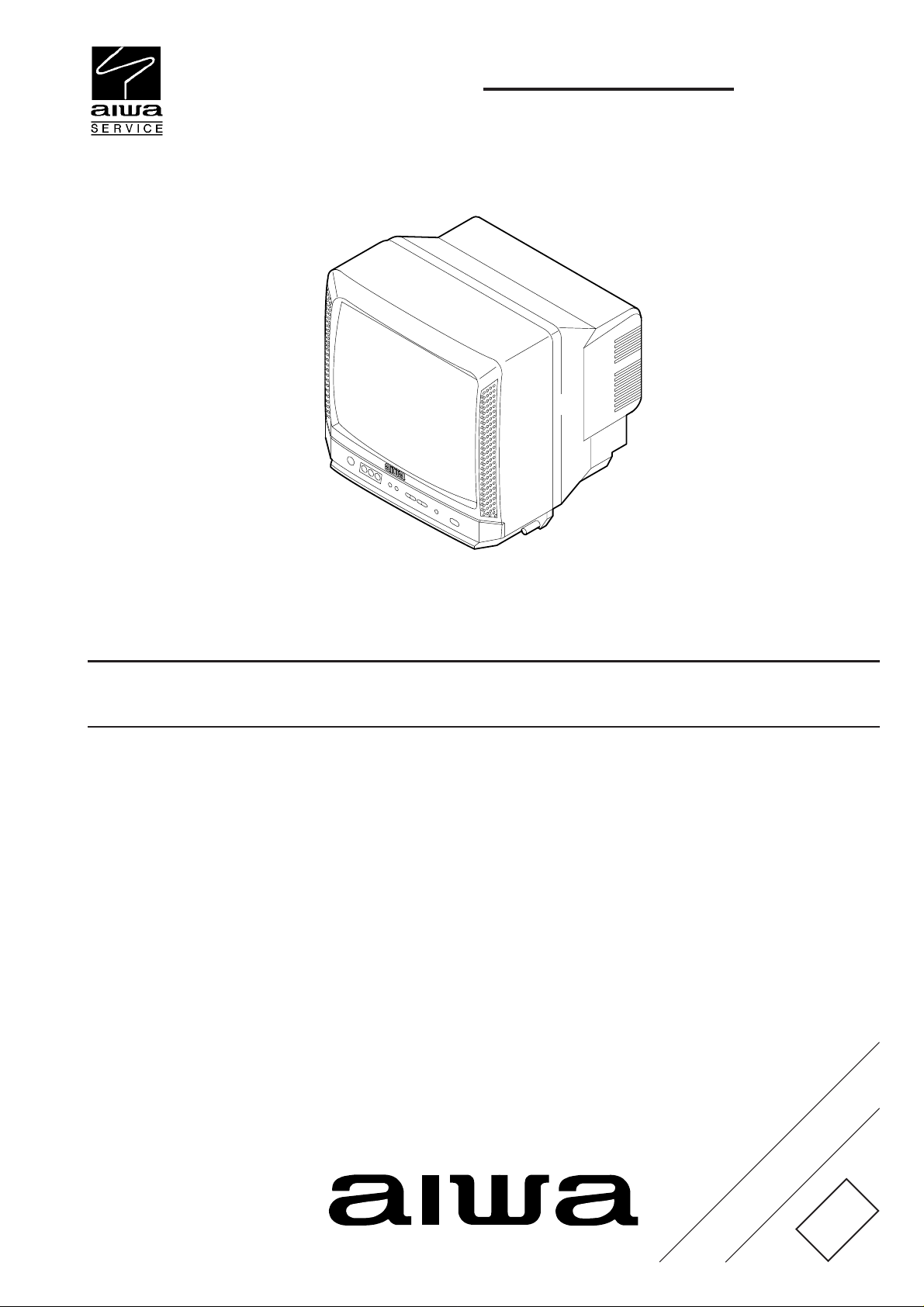

1. REAR CABINET REMOVAL

(1) Remove eight screws 1, then remove the rear cabinet in

the direction of the arrow.

(See Figure1-1)

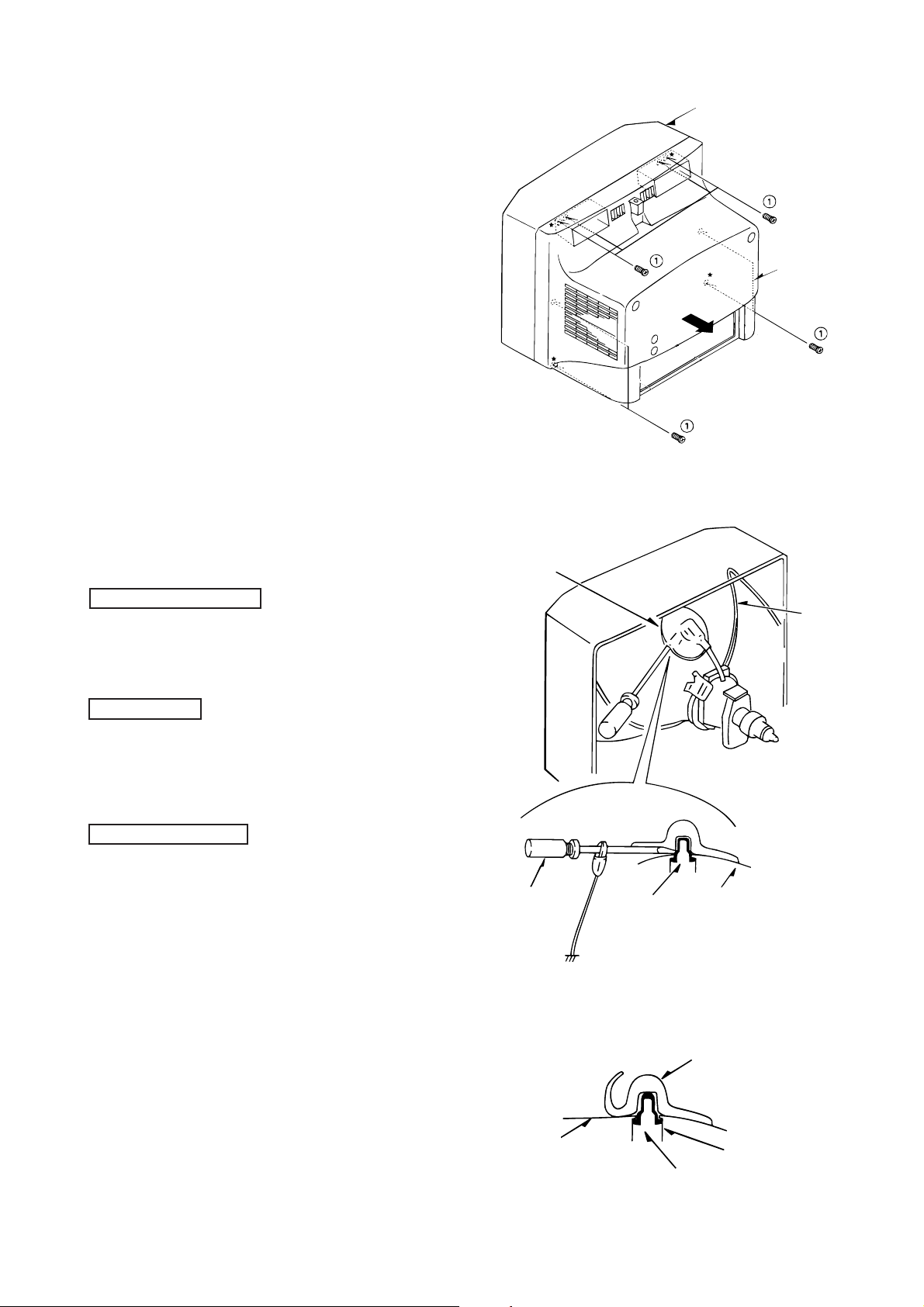

2. HIGH-VOLTAGE CAP (ANODE CAP) REMOVAL

Front cabinet

Rear cabinet

Figure 1-1

2-1. Cautions before Removing

Discharge the anode voltage

(1) The anode voltage is not discharged completely from the

CRT of this unit even after the power is turned off. Be

sure to discharge the residual anode voltage before

removing the anode cap.

Do not use pliers

(2) Do not use pliers, etc. to remove the anode cap. If you

used pliers and bent the hook to remove the cap, the spring

characteristics of the hook could be lost, and when

reinstalled, the cap would come off from the CRT anode

button easily, causing an accident.

Do not turn the anode cap

(3) If the anode cap is turned in the direction of its

circumference, the hook is likely to come off.

Figure 2-1

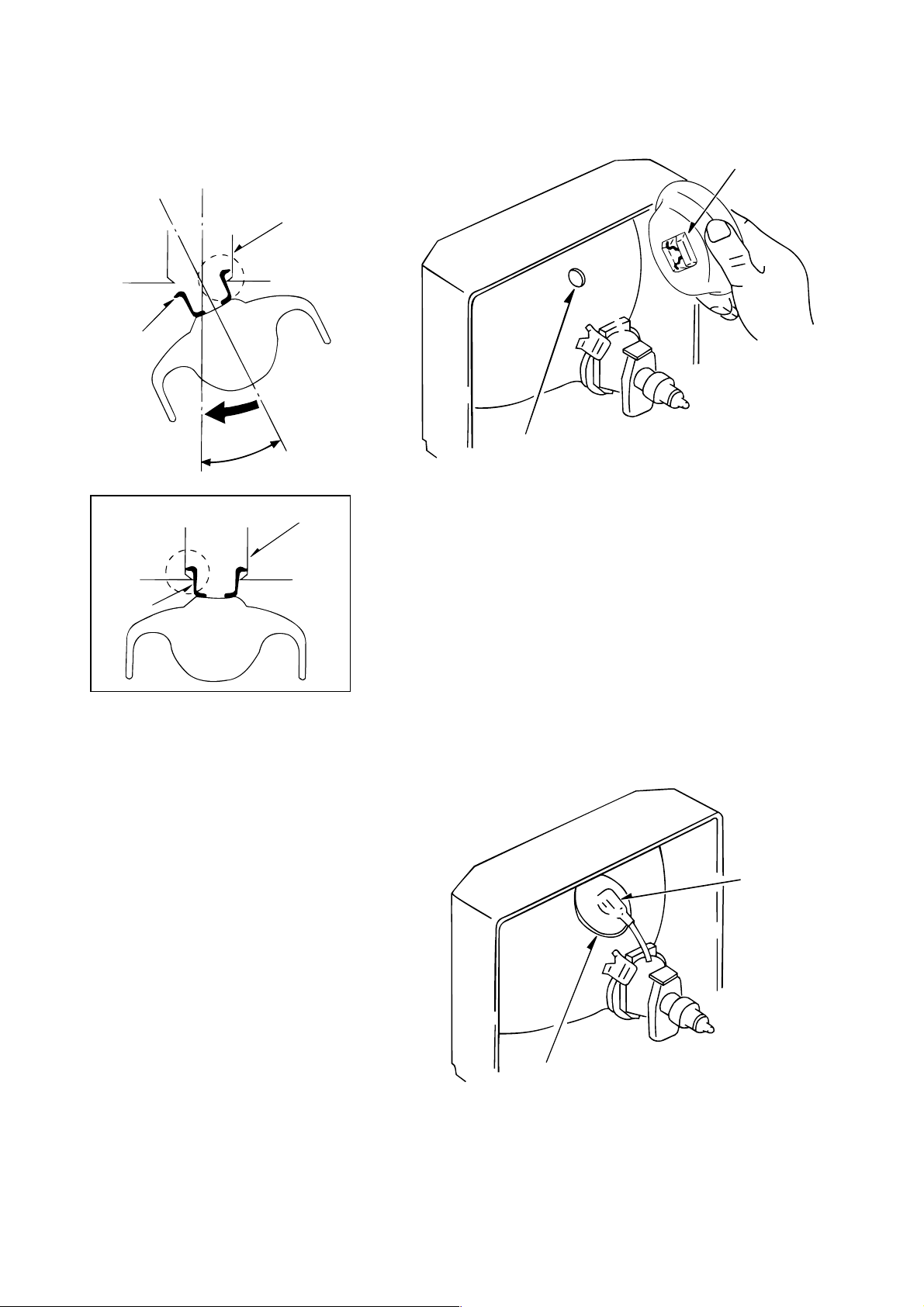

2-2. Anode Cap Removal

Discharge the anode voltage. (See Figure 2-1)

(1) Connect a flat-bladed screwdriver to the CRT GND via

an alligator clip.

(2) Use a tester to check the end of the screwdriver and ground

of the TV for continuity.

(3) Touch the hook with the end of the screwdriver.

Caution : Be careful not to damage the anode cap.

(4) Turn over the anode cap.

Caution : Be careful not to damage the anode cap.

– 5 –

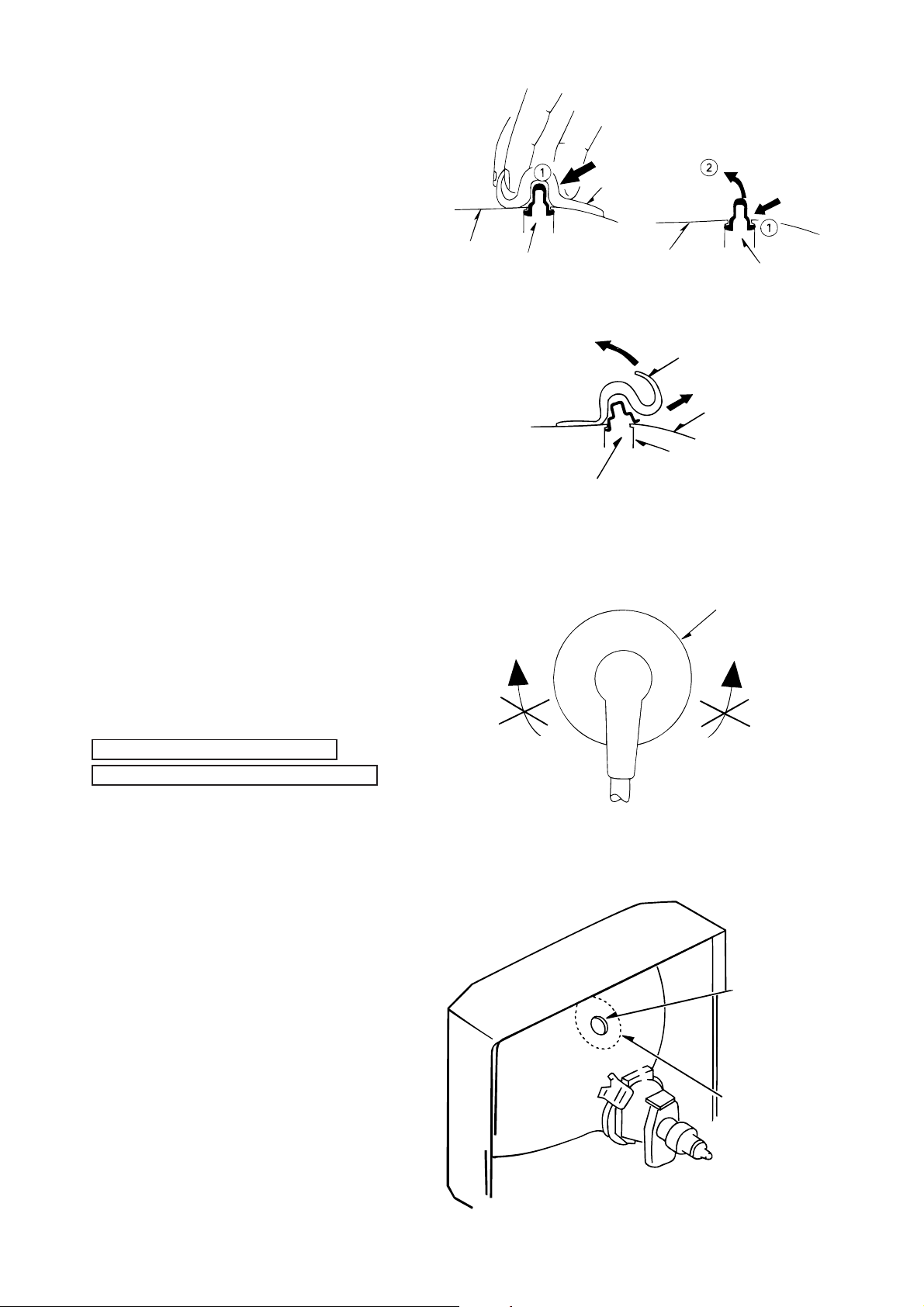

CRT

Anode cap

Anode button

Hook

Figure 2-2

(5) Push the anode cap with your thumb in the direction of

arrow 1 as shown in the figure, then lift the cap in the

direction of arrow 2 to release the hook on one side.

(See Figure 2-3)

Anode cap

(6) Turn over the anode cap on the side where the hook was

released and pull out the cap in the direction opposite to

that on which the cap was pushed. (See Figure 2-4)

Caution : Do not pull out the anode cap straight up.

: Do not pull the cap forcibly. After removing

the cap, check that the hook is not deformed.

3. ANODE CAP REINSTALLATION

Observe the cautions carefully so that no accident occurs

due to a defect in installing the anode cap and so it does

not come off.

CRT

Hook

Left

CRT

Hook

Figure 2-3

Anode cap

CRT

Anode button

Hook

Figure 2-4

Anode cap

Right

3-1. Caution before Reinstalling

Never turn the anode cap after installing it

Never re-use the hook when it has been deformed

(1) If the anode cap is turned after it is installed, it may come

off. Therefore, arrange the high-voltage cable before

attaching the anode cap. (See Figure 3-1)

(2) If you have attached the anode cap before arranging the

high-voltage cable, arrange the cable carefully so the cap

does not turn.

3-2. Anode cap reinstallation

(1) Use a clean cloth moistened slightly with alcohol to clean

the installation section. (See Figure 3-2)

Caution : Check that the installation section is free from

dust, foreign matter, etc.

(2) Coat the anode cap installation circumference with an

appropriate amount of the specified silicone grease (KS650N).

Caution : Be careful that silicone grease does not enter

the anode button.

Figure 3-1

Anode button

Installation

section

– 6 –

Figure 3-2

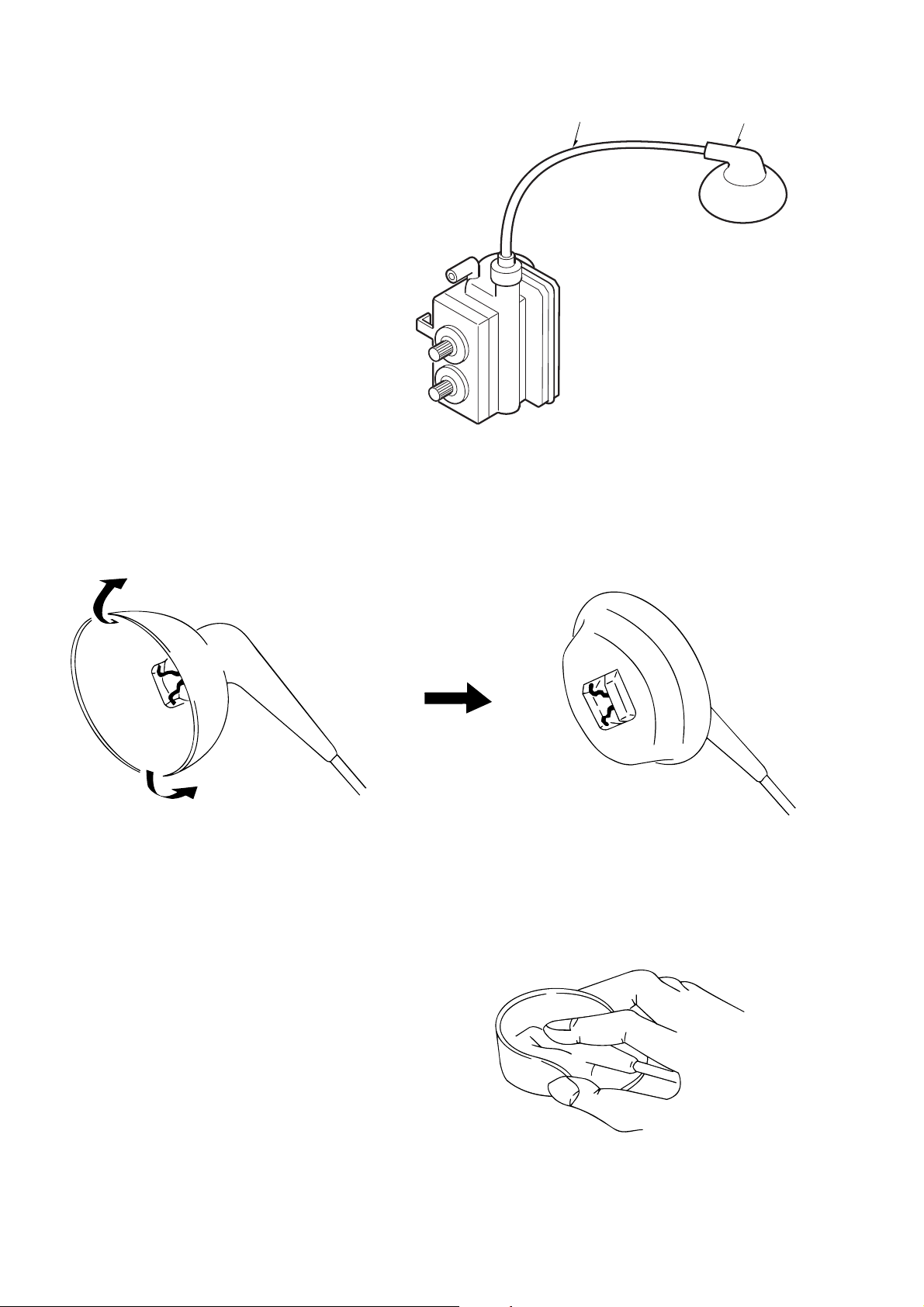

(3) Eliminate twisting, etc. of the high-voltage cable and

arrange it so that no twisting occurs. (See Figure 3-3)

Caution : If the cable is not arranged correctly , the anode

cap could turn and cause an installation defect.

(4) Turn over the rubber cap symmetrically on the left and

right. (See Figure 3-4)

Caution : Take great care not to damage the anode cap.

High-voltage cable

Anode cap

Figure 3-3

(5) Fit your forefinger over the projection at the center of the

cap and hold the cap between your thumb and middle

finger. (See Figure 3-5)

Figure 3-4

Figure 3-5

– 7 –

(6) Apply the hook on one side to the anode button as shown

Hook

Anode button

on the figure. (See Figure 3-6)

Caution : Check that the hook is held securely.

(7) Apply the hook on the other side to the anode button as

shown in Figure 3-7.

Anode button

Hook

30°

Anode button

Hook

Figure 3-7

(8) Pull the anode cap slightly with the rubber cap turned

over and visually check that the hook is engaged securely.

(9) Release your hand from the rubber cap of the anode cap.

Caution : Cover the anode cap so that it does not lift.

(10) Hold the skirt of the andoe cap slightly to improve the

close contact between the cap and CRT.

(11) Check that the anode cap is in close contact with the CRT .

(See Figure 3-8)

Figure 3-6

Anode button

Skirt

Figure 3-8

– 8 –

4. NK C.B. (PWB, NK) REMOVAL

(1) Disconnect CN903 (CRT GND).

(2) Disconnect CN901, CN902

(3) Remove the NK C.B. in the direction of arrow 1.

(See Figure 4-1)

5. MAIN C.B (PWB, MAIN) REMOVAL

(1) Remove connector (CN408).

(2) Remove connector (CN801).

(3) Remove connector (CN802).

(4) Pull out the MAIN C.B. in the direction of the arrow 2

(See Figure 4-1).

CN801

(Power Cord)

CN802

(Degauss

cord)

NK C.B

CN901

CN902

CN903

Front cabinet

AUDIO C.B

MAIN C.B

CN408

(Speakers)

Figure 4-1

– 9 –

ELECTRICAL MAIN PARTS LIST

REF. NO. DESCRIPTIONPART NO.

NO.

IC

87-A21-433-010 IC,KS24C041I

87-017-804--010 IC,BU4052BC

87-A21-723-010 IC,TB1240AN AJE-H

87-A21-166-010 IC,TA1275AZ

87-A21-259-010 IC,MM1454XD

87-A21-345-010 IC,NJM2150

87-A20-312-010 IC,M62420SP

87-A21-299-010 IC,LA6458SLL

87-A21-169-010 IC,MM1124B

87-A21-283-010 IC,AN5277

87-A21-456-010 IC,LA7833

87-070-417-010 IC,NJM4558 DD

87-A21-344-010 IC,STR-F6656

87-A21-787-010 IC,KIA7805API

87-A21-788-010 IC,KIA7809API

8A-JEE-652-010 IC,TMP87CP38N-1N15 THAI<SH>

8A-JEE-651-010 IC,TMP87CP38N-1N14<SHA>

87-A21-133-080 IC,BMR-0101D

87-A91-538-010 RCR UNIT,SBX1981-72P

87-A21-457-010 IC,SE120N

TRANSISTOR

87-A30-090-080 FET,2SK2541

87-A30-091-080 FET,2SJ460

89-337-794-580 TR,2SC3779 D/E

87-A30-066-080 TR,2SA1175FE

87-A30-065-080 TR,2SC2785FE

89-109-504-080 TR,2SA950

87-026-218-080 TR,DTC144ES (0.2W)

87-A30-121-080 TR,DTC 323 TS

87-A30-366-010 TR,2SD2580

89-334-674-580 TR,2SC3467 D/E

87-A30-363-010 TR,2SD2531

89-110-155-080 TR,2SA1015GR

87-A30-344-010 TR,2SC5147D

89-347-930-010 TR,2SC4793

89-118-370-010 TR,2SA1837

87-026-462-080 TR,2SC1740SRS

87-026-463-080 TR,2SA933SRS

89-407-742-080 TR,2SD774

DIODE

87-070-345-080 DIODE,IN4148

87-A40-347-080 ZENER,MTZJ2.2B

87-070-444-080 ZENER,HZS33-1TA

87-A40-235-080 ZENER,MTZJ9.1C

87-A40-350-080 ZENER,MTZJ 4.7C

87-070-092-080 DIODE,S5566B

87-A40-286-080 DIODE,RGP10JE-5025

87-A40-794-080 DIODE,EGP20G

87-A40-735-090 DIODE,ERC06-15

87-017-593-090 DIODE,RGP15J

87-017-654-060 DIODE,GBU6J

87-A40-509-080 ZENER,MTZJ6.8C

87-A40-450-090 DIODE,RU 1P

87-A40-850-090 DIODE,RL4A

87-A40-354-090 DIODE,UF3GL-6251

87-A40-611-080 ZENER,MTZJ3.9B

87-A40-736-080 DIODE,IN4148(SEM)

87-017-650-080 DIODE,1SS119

87-A40-503-080 ZENER,MTZJ39B

87-A40-574-080 ZENER,MTZJ3.0A

MAIN C.B

C1 87-A11-073-080 CAP, TC U 22P-50 J CH

C2 87-A11-073-080 CAP, TC U 22P-50 J CH

REF. NO. DESCRIPTIONPART NO.KANRI

C3 87-010-405-080 CAP, ELECT 10-50V

C4 87-018-134-080 CAPACITOR,TC-U 0.01-16

C5 87-010-263-080 CAP, ELECT 100-10V

C6 87-018-119-080 CAP, CER 100P-50V

C7 87-010-405-080 CAP, ELECT 10-50V

C8 87-010-405-080 CAP, ELECT 10-50V

C9 87-018-134-080 CAPACITOR,TC-U 0.01-16

C10 87-018-119-080 CAP, CER 100P-50V

C11 87-018-119-080 CAP, CER 100P-50V

C13 87-010-405-080 CAP, ELECT 10-50V

C14 87-018-129-080 CAP, CER 680P-50V

C15 87-018-149-080 CAP, TC-U 15P-50 CH

C16 87-018-149-080 CAP, TC-U 15P-50 CH

C17 87-010-404-080 CAP, ELECT 4.7-50V

C101 87-010-404-080 CAP, ELECT 4.7-50V

C102 87-018-134-080 CAPACITOR,TC-U 0.01-16

C103 87-010-384-080 CAP, ELECT 100-25V

C104 87-018-134-080 CAPACITOR,TC-U 0.01-16

C105 87-010-263-080 CAP, ELECT 100-10V

C106 87-A11-132-080 CAP, TC U 0.01-50 K B UP050

C107 87-018-134-080 CAPACITOR,TC-U 0.01-16

C108 87-018-132-080 CAP, CER 2200P-16V

C110 87-018-132-080 CAP, CER 2200P-16V

C113 87-010-260-080 CAP, ELECT 47-25V

C114 87-018-113-080 CAP, TC U 33P-50 J SL UP050

C115 87-018-119-080 CAP, TC U 100P-50 K B UP050

C116 87-010-260-080 CAP, ELECT 47-25V

C117 87-018-134-080 CAPACITOR,TC-U 0.01-16

C120 87-010-405-080 CAP, ELECT 10-50M 11L SME

C121 87-018-134-080 CAPACITOR,TC-U 0.01-16

C122 87-010-260-080 CAP, ELECT 47-25V

C124 87-010-401-080 CAP, ELECT 1-50V

C125 87-018-134-080 CAPACITOR,TC-U 0.01-16

C126 87-010-544-080 CAP, ELECT 0.1-50V

C127 87-018-119-080 CAP, CER 100P-50V

C128 87-018-134-080 CAPACITOR,TC-U 0.01-16

C129 87-018-134-080 CAPACITOR,TC-U 0.01-16

C130 87-010-405-080 CAP, ELECT 10-50V

C131 87-010-405-080 CAP, ELECT 10-50V

C132 87-010-260-080 CAP, ELECT 47-25V

C134 87-018-134-080 CAP, TC U 0.01-16 N Y UP050

C152 87-010-384-080 CAP, ELECT 100-25V

C301 87-010-545-080 CAP, ELECT 0.22-50V

C302 87-018-132-080 CAP, CER 2200P-16V

C303 87-018-148-080 CAP, TC-U 12P-50 CH

C307 87-018-134-080 CAPACITOR,TC-U 0.01-16

C308 87-010-385-080 CAP, E 220-25 M SME

C309 87-018-147-080 CAP, TC-U 10P-50 CH

C310 87-018-147-080 CAP, TC-U 10P-50 CH

C311 87-018-147-080 CAP, TC-U 10P-50 CH

C312 87-010-404-080 CAP, ELECT 4.7-50V

C313 87-018-119-080 CAP, CER 100P-50V

C315 87-018-196-080 CAP, CER 1500P-16V

C316 87-010-400-080 CAP, ELECT 0.47-50V

C317 87-010-237-080 CAP, ELECT 1000-16 M SME

C318 87-018-134-080 CAPACITOR,TC-U 0.01-16

C319 87-010-400-080 CAP, ELECT 0.47-50V

C320 87-010-384-080 CAP, ELECT 100-25V

C321 87-018-134-080 CAPACITOR,TC-U 0.01-16

C323 87-A11-148-080 CAP, TC U 0.1-50 Z F

C324 87-A11-148-080 CAP, TC U 0.1-50 Z F

C328 87-010-400-080 CAP, ELECT 0.47-50V

C330 87-018-134-080 CAPACITOR,TC-U 0.01-16

C333 87-018-134-080 CAPACITOR,TC-U 0.01-16

C334 87-010-263-080 CAP, ELECT 100-10V

C335 87-010-401-080 CAP, ELECT 1-50V

C336 87-018-134-080 CAPACITOR,TC-U 0.01-16

C337 87-010-401-080 CAP, ELECT 1-50V

C338 87-010-401-080 CAP, ELECT 1-50V

C339 87-010-263-080 CAP, ELECT 100-10V

KANRI

NO.

– 10 –

REF. NO. DESCRIPTIONPART NO.

NO.

C340 87-018-134-080 CAPACITOR,TC-U 0.01-16

C341 87-018-134-080 CAPACITOR,TC-U 0.01-16

C344 87-010-263-080 CAP, ELECT 100-10V

C501 87-018-126-080 CAP,TC-U 390P-50 B

C503 87-010-247-080 CAP, ELECT 100-50V

C508 87-010-402-080 CAP, ELECT 2.2-50V

C511 87-A11-245-080 CAP,M/P 0.1-100 J TF-ECQV

C512 87-A10-011-090 CAP,E 2200-25 SMG

C513 87-018-127-080 CAP, CER 470P-50V

C601 87-A10-406-010 CAP,CER 270P-2K K BN DE

C603 87-A10-052-080 CAP,E 2.2-250

C606 87-016-515-080 CAP,CER 1000P-1K B

C607 87-010-397-090 CAP,E 1000-35 SME

C609 87-010-386-080 CAP,E330-25 SME

C616 87-018-132-080 CAP, CER 2200P-16V

C617 87-010-976-080 CAP,CER 1000P-500 B

C618 87-010-974-080 CAP,CER 220P-500 B

C619 87-016-215-080 CAP,E 1-160 M TWSS

C801 87-A10-688-090 CAP,M/P 0.22-275 K (B81133)

!

C802 87-A10-688-090 CAP,M/P 0.22-275 K (B81133)

!

!

C805 87-A10-517-010 CAP,CER 3300P-4K M E KX

C807 87-A10-646-090 CAP,E 220-400 SMH (25.4*40)

C808 87-A11-825-080 CAP,CER 120P-2K J SL

C809 87-018-131-080 CAP, CER 1000P-50V

C810 87-010-384-080 CAP, ELECT 100-25V

C811 87-018-127-080 CAP, CER 470P-50V

C812 87-018-129-080 CAP, CER 680P-50V

C813 87-A10-626-090 CAP,M/P 0.01-1250 J

C814 87-A11-779-090 CAP,M/P 1000P-1.6K J ECWH(VB)

C815 87-A11-779-090 CAP,M/P 1000P-1.6K J ECWH(VB)

C816 87-A11-260-090 CAP,M/P 1000P-1.6K H ECWH(VR)

C817 87-A10-731-090 CAP,E 220-160 M KMF

C818 87-A12-051-090 CAP,E 100-160 M SK

C822 87-A10-832-080 CAP,CER 1000P-1K K R

C823 87-016-051-090 CAP,E 2200-35 SMG

C824 87-010-397-090 CAP,E 1000-35 SME

C826 87-010-235-080 CAP,E 470-16 SME

C827 87-010-405-080 CAP, ELECT 10-50V

C828 87-010-405-080 CAP, ELECT 10-50V

C829 87-A10-469-080 CAP,CER 2200P-500 K B DD10

C830 87-010-405-080 CAP, ELECT 10-50V

C831 87-010-405-080 CAP, ELECT 10-50V

C832 87-010-405-080 CAP, ELECT 10-50V

C833 87-010-405-080 CAP, ELECT 10-50V

C836 87-018-134-080 CAPACITOR,TC-U 0.01-16

C901 87-010-405-080 CAP, ELECT 10-50V

C902 87-010-401-080 CAP, ELECT 1-50V

C903 87-010-401-080 CAP, ELECT 1-50V

C904 87-010-221-080 CAP, ELECT 470-10V

C905 87-010-405-080 CAP, ELECT 10-50V

C906 87-010-405-080 CAP, ELECT 10-50V

C907 87-010-405-080 CAP, ELECT 10-50V

C908 87-010-401-080 CAP, ELECT 1-50V

C909 87-010-401-080 CAP, ELECT 1-50V

C910 87-010-401-080 CAP, ELECT 1-50V

C911 87-010-401-080 CAP, ELECT 1-50V

C912 87-010-260-080 CAP, ELECT 47-25V

C913 87-018-134-080 CAPACITOR,TC-U 0.01-16

C914 87-018-134-080 CAPACITOR,TC-U 0.01-16

C915 87-018-203-080 TC,U 8200P-16 N Y UP050

C916 87-018-203-080 TC,U 8200P-16 N Y UP050

C918 87-018-134-080 CAPACITOR,TC-U 0.01-16

C919 87-018-134-080 CAPACITOR,TC-U 0.01-16

C930 87-018-117-080 CAP,TC U 68P-50 J SL UP050

CF201 87-A90-224-080 FLTR, TPS6.0MB

CF202 87-008-578-080 FLTR,TPS6.5MB2

CF203 84-LB3-626-080 FLTR,TPS4.5MB2

CF204 87-008-577-080 FLTR,TPS5.5MB2

CF205 87-008-574-080 FLTR,SFSH4.5MCB

CF206 87-A90-223-080 FLTR,SFSH6.0MCB

REF. NO. DESCRIPTIONPART NO.KANRI

KANRI

NO.

CF207 87-008-575-080 FLTR,CFSFSH5.5MCB

CF208 87-008-576-080 FLTR,CFSFSH6.5MCB

CN1 87-A60-446-010 CONN,7P V TID-X

CN601 87-099-762-010 CONN,5P TBL-P V BOSS

CN603 87-A60-003-010 CONN,2P V TBL-P BOSS

!

CN801 87-A61-045-010 CONN,2P V THL-P

!

CN802 82-481-649-010 PLUG,2P MINI(*)

CNA301 84-LB2-631-010 CONN ASSY,5P TN-4

CNA302 8A-JEE-641-010 CONN ASSY,3P 2.0MM TV-NK

CNA501 8A-JEA-660-010 CONN ASSY,5P MAIN-PIN

CNA601 8A-JEE-640-010 CONN ASSY,3P 2.5MM 120V-NK

CNA603 8A-JEH-660-010 CONN ASSY,2P MAIN-PIN

CNA605 8A-JEH-661-010 CONN ASSY,1P BLK MAIN-PIN

CNA801 8Z-JB9-663-010 CONN ASSY,8P V AU PW 200

CNA802 8Z-JB4-658-010 CONN ASSY,5P MAIN-NK 20'/21'

CNA901 8Z-JB9-662-010 CONN ASSY,6P V AU L/R 300

CNA903 8Z-JB9-661-010 CONN ASSY,10P MAIN-AUDIO

D801 87-A91-641-010 VRIS,SI0V-S14K300

!

D9 87-A40-422-010 LED,SLP-581D-51 Y-G/R

F801 87-035-458-010 FUSE,4A 250V T W/C

!

FB1 87-003-320-080 F-BEAD,FBR07HA121NB-00

FB601 87-003-320-080 F-BEAD,FBR07HA121NB-00

FB801 87-003-320-080 F-BEAD,FBR07HA121NB-00

FB802 87-003-320-080 F-BEAD,FBR07HA121NB-00

FB805 87-003-320-080 F-BEAD,FBR07HA121NB-00

FB806 87-003-320-080 F-BEAD,FBR07HA121NB-00

FC801 87-033-213-080 FUSE, CLAMP PFC5000

!

!

FC802 87-033-213-080 FUSE, CLAMP PFC5000

FR601 87-A00-063-060 RES,FUSE 2.2-1/2W J R-TYPE

FR602 87-A00-652-090 RES,FUSE 0.33-1W J RF 1SL12.5

FR603 87-A00-052-060 RES,FUSE 3.9-1W J R-TYPE

FR604 87-A00-057-060 RES,FUSE 1.8-2W J R-TYPE

FR803 87-A00-247-090 RES,M/F 100-3W J RSF(S)

HL9 84-LB3-216-010 HLDR,LED

J901 87-A60-324-110 JACK,PIN 6P Y-W-R W/SW

J902 87-A61-435-010 JACK,PIN 3P WHT YKC21-5734A

L1 87-003-147-080 COIL, 22UH

L2 87-003-152-080 COIL, 100UH

L101 87-005-444-080 COIL 100UH,K

L102 87-003-152-080 COIL, 100UH

L104 87-003-106-080 COIL,0.33UH K LAL02

L106 87-003-282-080 COIL,12UH J LAL02

L108 87-003-146-080 COIL,15UH J LAL02

L109 87-003-282-080 COIL,12UH J LAL02

L110 87-003-146-080 COIL,15UH J LAL02

L111 87-003-282-080 COIL,12UH J LAL02

L112 87-005-440-080 COIL,47UH K FLR50

L114 87-A50-530-010 COIL,VCO38.0MHZ

L115 87-005-473-080 COIL,10UH J FLR50

L301 87-005-444-080 COIL 100UH,K FLR50

L302 87-005-481-080 COIL,47UH J FLR50

L303 87-005-444-080 COIL 100UH,K FLR50

L801 87-A50-641-010 COIL,180UH RCH110

!

LF801 8A-JEE-610-010 FLTR,LINE ELF18D604 (4.7MH)

!

LF802 8A-JEE-610-010 FLTR,LINE ELF18D604 (4.7MH)

PR601 87-A90-090-080 PROTECTOR,1.5A 491SERIES 60V

!

PR801 87-A90-090-080 PROTECTOR,1.5A 491SERIES 60V

!

PR803 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

!

PR804 87-A90-094-080 PROTECTOR,4A 491SERIES 60V

!

PS801 87-A91-407-010 P-COUPLER,ON3171-R

PS802 87-A91-407-010 P-COUPLER,ON3171-R

!

!

PT801 8Z-JB9-621-010 PT,SW ZJB-KE-A M

R101 87-A00-164-090 RES,M/F 12K-2W J RSF(S)

R317 87-A00-308-090 RES,M/F 47-3W J RSF(S)

R511 87-A00-653-090 RES,M/F 270-1W J RSF(S)

R515 87-A00-143-090 RES,M/F 1.0-1W J RSF(S)

R612 87-A00-225-090 RES,M/F 2.2K-5W J RSV5

R802 87-A00-552-010 RES,CEM 1.0-10W J MPC722

R803 87-A00-552-010 RES,CEM 1.0-10W J MPC722

R804 87-A00-543-080 RES,SD 8.2M-1W J RCR60

– 11 –

REF. NO. DESCRIPTIONPART NO.

NO.

R807 87-A00-639-090 RES,CEM 0.15-5W K BPR

R808 87-A00-573-090 RES,CEM 0.33-5W J MPC71

R816 87-A00-170-090 RES,M/F 82K-3W J RSF(S)

R817 87-A00-223-090 RES,M/F 47K-2W J RSF(S)

R827 87-A00-673-090 RES,M/F 82K-5W J RSS5L30

R830 87-A00-102-090 RES,M/F 12-3W J

S1 87-A91-525-080 SW,TACT SKQNLA

S2 87-A91-525-080 SW,TACT SKQNLA

S3 87-A91-525-080 SW,TACT SKQNLA

S4 87-A91-525-080 SW,TACT SKQNLA

S5 87-A91-525-080 SW,TACT SKQNLA

S6 87-A91-525-080 SW,TACT SKQNLA

S501 87-A90-567-010 SW,LVR 4-1-3 EVQRAAL10

S801 87-A91-410-010 SW,AC PUSH 1-1-1 ESB92SH1B

!

SWF202 87-A90-670-010 FLTR,SAW OFW-K6265K

!

T601 8A-JEA-606-010 FBT,SH NX4014 AJE-A

!

T602 85-JT2-653-010 PT,HDT-TV141-2

!

THP801 87-A91-405-010 POS-THMS,T209-B80-A10

TU101 87-A91-495-010 TU UNIT, ENV59D58G3-38.0MHZ

X1 87-030-300-080 VIB,XTAL 8.00MHZ

X301 87-A70-054-080 VIB,XTAL 4.43MHZ AQC-1018

AUDIO C.B

C401 87-010-402-080 CAP, ELECT 2.2-50V

C402 87-010-260-080 CAP, ELECT 47-25V

C403 87-018-134-080 CAPACITOR,TC-U 0.01-16

C405 87-010-402-080 CAP, ELECT 2.2-50V

C406 87-010-405-080 CAP, ELECT 10-50V

C407 87-A11-148-080 CAP,TC U 0.1-50 Z F

C408 87-010-367-080 CAP,E 4.7-25 BP

C411 87-010-367-080 CAP,E 4.7-25 BP

C412 87-010-405-080 CAP, ELECT 10-50V

C413 87-A11-148-080 CAP,TC U 0.1-50 Z F

C414 87-010-405-080 CAP, ELECT 10-50V

C415 87-010-367-080 CAP,E 4.7-25 BP

C418 87-010-367-080 CAP,E 4.7-25 BP

C419 87-A11-148-080 CAP,TC U 0.1-50 Z F

C420 87-010-260-080 CAP, ELECT 47-25V

C421 87-010-260-080 CAP, ELECT 47-25V

C422 87-018-134-080 CAPACITOR,TC-U 0.01-16

C426 87-A11-148-080 CAP,TC U 0.1-50 Z F

C427 87-010-401-080 CAP, ELECT 1-50V

C428 87-018-134-080 CAPACITOR,TC-U 0.01-16

C429 87-010-263-080 CAP, ELECT 100-10V

C433 87-A11-148-080 CAP,TC U 0.1-50 Z F

C434 87-A11-148-080 CAP,TC U 0.1-50 Z F

C435 87-010-260-080 CAP, ELECT 47-25V

C436 87-018-119-080 CAP, CER 100P-50V

C437 87-018-119-080 CAP, CER 100P-50V

C438 87-010-367-080 CAP,E 4.7-25 BP

C440 87-A11-147-080 CAP,TC U 0.047-50 Z F

C442 87-A11-147-080 CAP,TC U 0.047-50 Z F

C445 87-010-367-080 CAP,E 4.7-25 BP

C446 87-010-101-080 CAP, ELECT 220-16

C447 87-A11-148-080 CAP,TC U 0.1-50 Z F

C467 87-010-367-080 CAP,E 4.7-25 BP

C470 87-010-112-080 CAP, ELECT 100-16V

C471 87-A11-148-080 CAP,TC U 0.1-50 Z F

C472 87-010-367-080 CAP,E 4.7-25 BP

C475 87-010-379-080 CAP, ELECT 22-16V

C476 87-010-400-080 CAP, ELECT 0.47-50V

C477 87-010-400-080 CAP, ELECT 0.47-50V

C478 87-010-401-080 CAP, ELECT 1-50V

C479 87-010-247-080 CAP, ELECT 100-50V

C480 87-010-388-080 CAP ELECT 1000-25V SME

C481 87-010-388-080 CAP ELECT 1000-25V SME

C482 87-010-401-080 CAP, ELECT 1-50V

C483 87-010-247-080 CAP, ELECT 100-50V

REF. NO. DESCRIPTIONPART NO.KANRI

KANRI

NO.

C484 87-A11-148-080 CAP,TC U 0.1-50 Z F

C493 87-010-112-080 CAP, ELECT 100-16V

C498 87-010-402-080 CAP, ELECT 2.2-50V

CN401 87-A60-623-010 CONN,6P V 2MM JMT

CN402 87-A60-627-010 CONN,10P V 2MM JMT

CN403 87-A60-447-010 CONN,8P V TID-X

CN408 87-A60-457-010 CONN,4P V TID-X

CNA401 8A-JEH-664-010 CONN ASSY,5P AUDIO-AUDIO

CNA408 8Z-JE5-640-010 CONN ASSY,4P SP-25

FR401 87-A00-084-090 RES,FUSE 1-1W J

FR402 87-A00-084-090 RES,FUSE 1-1W J

J403 87-A61-275-010 JACK,3.5 BLK ST 2 SW P

L651 87-A50-607-080 COIL,3.9MH J LHL 10

R401 87-025-381-080 RES,M/F 18K-1/6W F

R402 87-025-424-080 RES,M/F 10K 1/6W F

R404 87-025-380-080 RES,M/F 15K-1/6W F

R405 87-025-381-080 RES,M/F 18K-1/6W F

R554 87-A00-070-090 RES,M/F 220-1W J

R555 87-A00-070-090 RES,M/F 220-1W J

R652 87-A00-537-090 RES,M/F 100-5W J RSV5

NK C.B

C901 87-010-405-080 CAP, ELECT 10-50V

C902 87-010-968-080 CAP,CER 680P-2K K B

C903 87-010-405-080 CAP, ELECT 10-50V

C906 87-010-400-080 CAP, ELECT 0.47-50V

C907 87-010-235-080 CAP,E 470-16 SME

C908 87-018-129-080 CAP, TC U 680P-50 K B UP050

C909 87-018-129-080 CAP, TC U 680P-50 K B UP050

C910 87-018-129-080 CAP, TC U 680P-50 K B UP050

C911 87-A11-106-080 CAP, TC U 560P-50 J CH

C912 87-A11-106-080 CAP, TC U 560P-50 J CH

C913 87-A11-106-080 CAP, TC U 560P-50 J CH

C914 87-A10-052-080 CAP,E 2.2-250

C915 87-010-260-080 CAP, ELECT 47-25V

C916 87-018-134-080 CAPACITOR,TC-U 0.01-16

C917 87-010-970-090 CAP,CER 4700P-2K B F

C951 87-010-381-080 CAP, E 330-16 M SME

C952 87-018-114-080 CAP,TC U 39P-50 J SL

C954 87-010-405-080 CAP, E 10-50 M 11L SME

C955 87-010-405-080 CAP, E 10-50 M 11L SME

C956 87-010-405-080 CAP, E 10-50 M 11L SME

C958 87-018-117-080 CAP,TC U 68P-50 J SL

C959 87-A10-050-010 CAP,CER 4700P-500 K

C960 87-010-221-080 CAP,E 470-10 M SME

C961 87-010-965-080 CAP,E 33-160 M L SME

C962 87-A12-010-080 CAP,M/P 0.047-250 J ECQE2

C963 87-A12-352-080 CAP,M 1000P-100 J CP

C964 87-A12-352-080 CAP,M 1000P-100 J CP

C965 87-010-963-080 CAP,E 2.2-160 M 11L SME

C966 87-A12-014-080 CAP,M/P 0.1-250 J ECQE2

C967 87-A12-372-080 CAP,M 0.047-100 J CP

C968 87-010-221-080 CAP,E 470-10 M SME

C981 87-018-120-080 CAP,TC U 120P-50 K B

C982 87-018-134-080 CAP,TC U 0.01-16 NY

CN901 87-049-590-010 CONN,5P 8283 V WHT

CN902 87-A60-444-010 CONN,5P V TID-X

CN903 87-A61-126-080 MALE, 1P TP42097

CN904 87-A61-060-080 CONN,1P V RED TP00706

CN906 87-A60-456-010 CONN,3P V TID-X

CN951 87-A60-620-010 CONN,3P V 2MM JMT

CN952 87-A60-455-010 CONN,2P V TID-X

CNA952 8A-JE7-620-010 CONN ASSY,2P VM-NK

CON903 8A-JEF-607-010 CONN ASSY,1P CRT-GND

DL981 87-A91-598-010 DELAY LINE,350NS EQFK5-MT

L901 87-005-614-080 COIL 100UH LAV35 J

L902 87-005-614-080 COIL 100UH LAV35 J

L903 87-005-614-080 COIL 100UH LAV35 J

– 12 –

REF. NO. DESCRIPTIONPART NO.

NO.

L904 87-005-608-080 COIL,33UH J LAV35

L951 87-005-482-080 COIL,56UH J FLR50

L952 87-005-481-080 COIL,47UH J FLR50

L981 87-003-146-080 COIL,15UH J LAL02

R901 87-A00-242-090 RES,M/F 8.2K-3W J RS

R902 87-A00-242-090 RES,M/F 8.2K-3W J RS

R903 87-A00-242-090 RES,M/F 8.2K-3W J RS

R968 87-022-382-090 RES,M/F 120-2W J

R969 87-A00-638-080 RES,M/F 47-1/2W J SPR

R970 87-A00-634-080 RES,M/F 2.7-1/4W J SPR

R971 87-A00-636-080 RES,M/F 560-1/4W J SPR

R973 87-A00-637-080 RES,M/F 1K-1/4W J SPR

R974 87-022-556-090 RES,M/O 180-3W J

R976 87-A00-636-080 RES,M/F 560-1/4W J SPR

R977 87-A00-634-080 RES,M/F 2.7-1/4W J SPR

R978 87-A00-635-080 RES,M/F 47-1/4W J SPR

SO901 8A-JE7-670-010 SOCKET,CRT 11P HPS1521

PIN C.B

C651 87-A12-320-090 CAP,M/P 0.013-1.6K H ECWH(VB)

C652 87-A11-999-090 CAP,M/P 0.012-800 H ECWH(V)

C653 87-012-392-090 CAP,CER 1200P-2K K BNDE

C654 87-A10-833-090 CAP,CER 1000P-2K K R

C655 87-A11-278-090 CAP,M/P 0.47-250 J ECWF(SR)

REF. NO. DESCRIPTIONPART NO.KANRI

C658 87-016-217-080 CAP,E 4.7-160

C659 87-010-976-080 CAP,CER 1000P-500 B

C660 87-018-131-080 CAP, CER 1000P-50V

C661 87-010-405-080 CAP, ELECT 10-50V

C662 87-010-405-080 CAP, ELECT 10-50V

C663 87-010-395-080 CAP,E 330-35 SME

C665 87-A11-124-080 CAP,TC U 2200P-50 K B

CN651 87-A61-126-080 MALE, 1P TP42097

CN652 87-A60-003-010 CONN,2P V TBL-P BOSS

CN653 87-A60-444-010 CONN,5P V TID-X

CNA603 8A-JEH-660-010 CONN,ASSY 2P MAIN-PIN

L652 8Z-JE5-621-010 COIL,HLC ZJE-5

L653 87-005-757-010 COIL,3.3MH

R653 87-A00-629-090 RES,M/F 5.6-1W J RSF(S)

SFR651 87-024-434-080 SFR,22K RH063EC

SFR652 87-024-429-080 SFR,1K RH063EC

SFR653 87-024-436-080 SFR 47K H RH063MC

KANRI

NO.

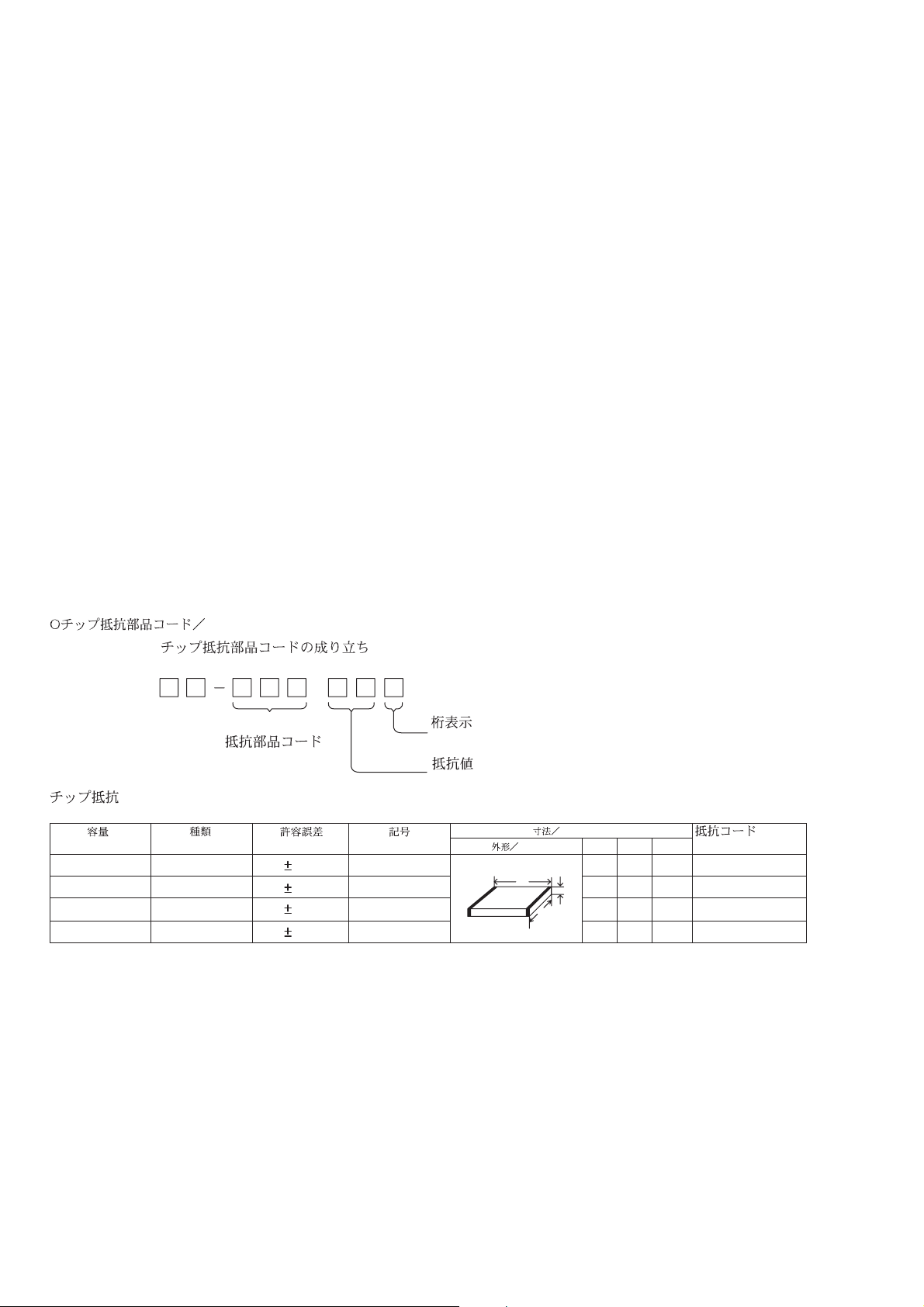

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

– 13 –

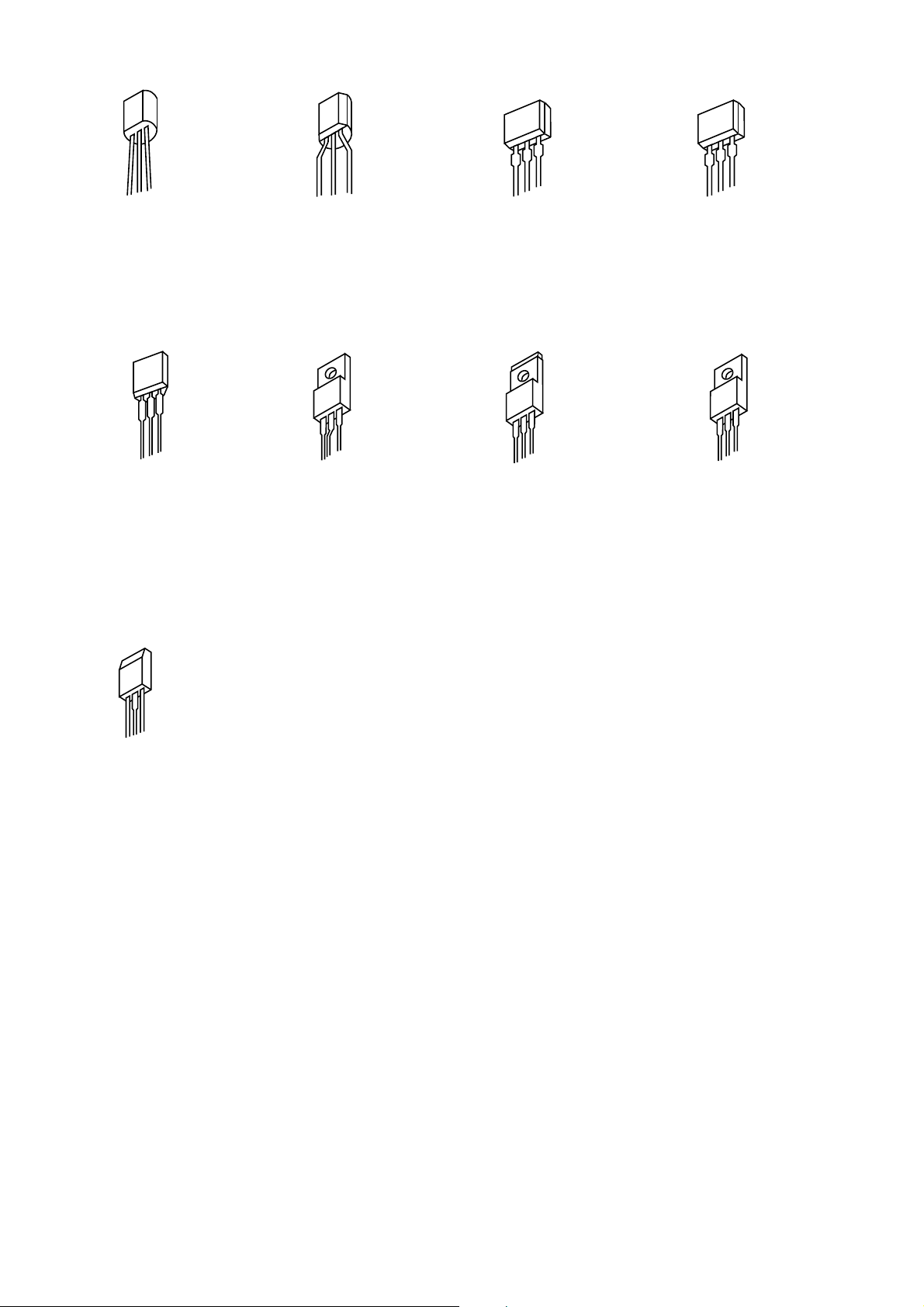

TRANSISTOR ILLUSTRATION

E C B B E C

2SC3467D/E

2SC3779D/E 2SJ460

2SA1015GR

E C B

2SC1740SRS

B C E

2SD2580

DTC144ES

2SA933SRS

2SA1175FE

E C B S D G

2SA950

2SC2785FE

2SK2541

DTC323TS

B C E

2SD2531

2SC5147D

2SC4793

2SA1837

B C E

E C B

2SD774

– 14 –

WIRING – 1 (MAIN)

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 15 –

R

S

T

U

SCHEMATIC DIAGRAM – 1 (MAIN)

– 16 –

WIRING – 2 (AUDIO : SH)

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 17 –

R

S

T

U

WIRING – 3 (AUDIO : SHA)

101112131415161718192021222324

1234567892526272829303132

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

– 18 –

R

S

T

U

SCHEMATIC DIAGRAM – 2 (AUDIO : SH,SHA)

– 19 –

Loading...

Loading...