Aiwa TV-C1400 Service Manual

TV-C1400

PO

W

E

R

TEXT

C1400

KY EZY KHY

SERVICE MANUAL

COLOR TELEVISION

SIMPLE-2

Apartofcontentsisadequate.

Re-issuing is under request.

S/M Code No. 09-009-352-0N1

DATA

NOTICES BEFORE REPAIRING

To make the best use of this equipment, make sure to

obey the following items when repairing (or mending).

1. Do not damage or melt the tunicate of the leading

wire on the AC1 side, including the power supply

cord.

2. Do not soil or stain the letters on the spec.

inscription plates, notice labels, fuse labels, etc.

3. When repairing the part extracted from the

conducted side of the board pattern, fix it firmly

with applying bond to the pattern and the part.

4. Restore the following items after repairing.

1) Conditions of soldering of the wires (especially,

the distance on the AC1 side).

2) Conditions of wiring, bundling of wires, etc.

3) Types of the wries.

4) Attachment conditions of all types of the insulation.

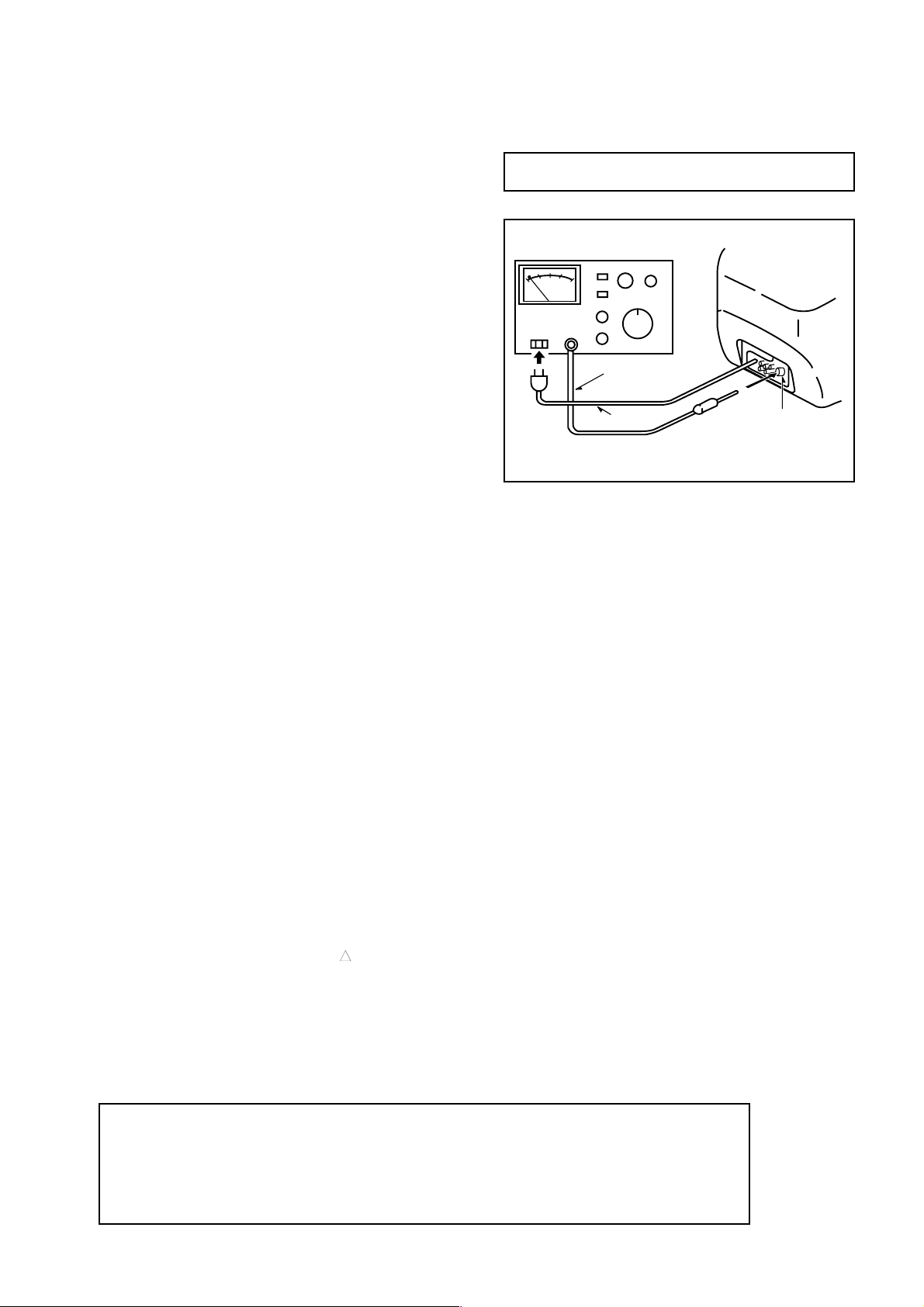

5. After repairing, always measure the insulation

resistance and perform the voltage-withstand test

(See Fig-1).

1) The insulation resistance must be 7.3 MΩ to 10.1 MΩ

when applying

2) In the voltage withstand test, apply 3.0 kV for 1

minute and check that the GO lamp lights.

500V per second.

Insulation resistance: 7.3 MΩ to 10.1 MΩ(500 V/s)

Voltage-withstand: 3.0 kV for 1 minute

Safety checker (Model 7110, etc.)

Earth cable

AC cable

Fig-1

Connect the earth cable

to the outside metal part

terminal.

* Breaking current set to 10 mA.

* Connect the safety checker as shown in Fig-1,

then measure the resistance and perform the test.

* Do not touch the equipment during testing.

* For details of the safety checker, refer to the supplied

Operation manual.

When servicing and checking on the TV, note the followings.

1. Keep the notices

As for the places which need special attentions, they

are indicated with the labels or seals on the cabinet,

chassis and parts. Make sure to keep the indications

and notices in the operation manual.

2. Avoid an electric shock.

There is a high voltage part inside. Avoid an electric

shock while the electric current is flowing.

3. Use the designated parts.

The parts in this equipment have the specific

characters of incombustibility and withstand voltage

for safety.

Therefore, the part which is replaced should be used

the part which has the same character. Especially as

to the important parts for safety which is indicated in

the circuit diagram or the table of parts as a mark,

the designated parts must be used.

4. Put parts and wires in the original position after

assembling or wiring.

There are parts which use the insulation material

such as a tube or tape for safety, or which are

assembled so that these parts do not contact with

the printed board. The inside wiring is designed not

!

to get closer to the pyrogenic parts and high voltage

parts. Therefore, put these parts in the original

positions.

5. Take care of the cathode-ray tube.

By setting an explosion-proof cathode-ray tube is set

in this equipment, safety is secured against

implosion.

However, when removing it or serving from

backward, it is dangerous to give a shock. Take

6. Avoid an X-ray.

Safety is secured against an X-ray by considering

peripheral circuit, etc. Therefore, when repairing the

high voltage peripheral circuit, use the designated

parts and do not change the circuit. Repairing

except indicates causes rising of high voltage, and

the cathode-ray tube emits an X-ray.

7. Perform a safety check after servicing.

Confirm that the screws, parts and wiring which were

removed in order to service are put in the original

positions, or whether there are the portions which are

deteriorated around the places serviced.

enough care to deal with it.

about the cathode-ray tube and the high voltage

!

Safety Components Symbol

This symbol is given to important parts which serve to maintain the safety of the product, and which

are made to confirm to special Safety Specifications.

Therefore, when replacing a component with this symbol make absolutely sure that you use a

designated part.

-2-

SPECIFICATIONS

Tuner system Frequency synthesized tuner

Picture tube 14 in. (34 cm “V”), 90 degree deflection

TV system PAL (B/G, D/K, I), SECAM (D/K, L)

Channel coverage VHF: E2-E12

UHF: E21-E69

CABLE: S1-S41

Antenna input 75 ohms, unbalanced

Video input 1.0 Vp-p, 75 ohms, unbalanced

Video output 1.0 Vp-p, 75 ohms, unbalanced

Audio input -3.8 dBs, 50 kohm

Audio output -3.8 dBs less than 1 kohm

Operating temperature 5°C to 40°C

Power requirements 220-240 V AC, 50 Hz

Power consumption 58 watts

Standby 2 watts

Dimensions 364(W) x 315(H) x 364(D) mm

(143/8 x 121/2 x 143/8 in.)

Weight Approx. 10.5 kg (23.1 lbs.)

• Design and specifications are subject to change without notice.

ACCESSORIES LIST

REF. NO PART NO. KANRI DESCRIPTION

1 8A-JB8-901-010 IB,K (E) -C1400<KY>

1 8A-JB8-903-010 IB,EZ (EGDSI)<EZY>

1 8A-JB8-904-010 IB,KH (E/R/CZ/PO) -C1400<KHY>

2 8A-JB4-610-010 RC UNIT,RC-AVT02

NO.

-3-

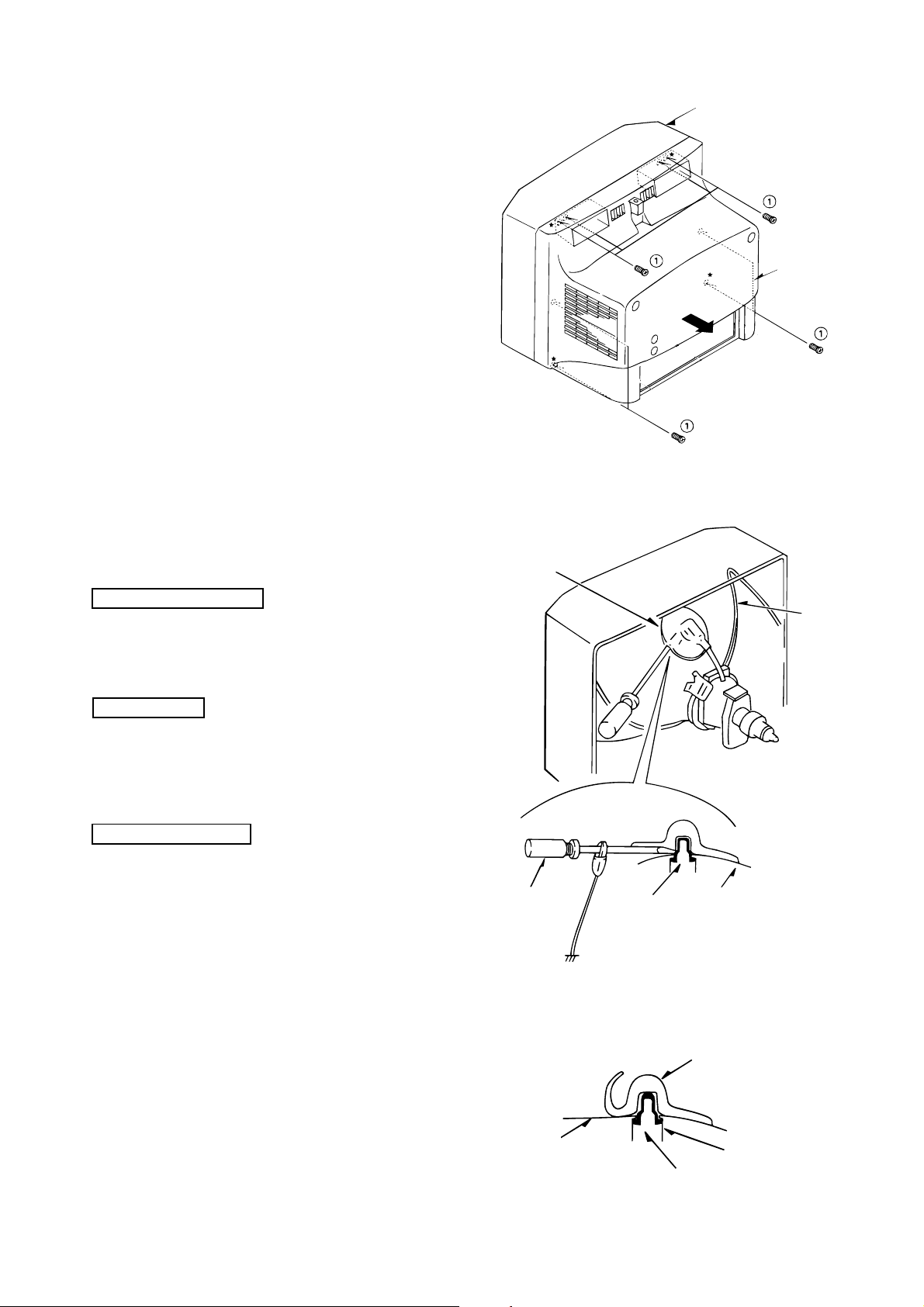

DISASSEMBLY INSTRUCTIONS

1. REAR CABINET REMOVAL

(1) Remove eight screws 1, then remove the rear cabinet in

the direction of the arrow.

(See Figure1-1)

2. HIGH-VOLTAGE CAP (ANODE CAP) REMOVAL

Front cabinet

Rear cabinet

Figure 1-1

2-1. Cautions before Removing

Discharge the anode voltage

(1) The anode voltage is not discharged completely from the

CRT of this unit even after the power is turned off. Be

sure to discharge the residual anode voltage before

removing the anode cap.

Do not use pliers

(2) Do not use pliers, etc. to remove the anode cap. If you

used pliers and bent the hook to remove the cap, the spring

characteristics of the hook could be lost, and when

reinstalled, the cap would come off from the CRT anode

button easily, causing an accident.

Do not turn the anode cap

(3) If the anode cap is turned in the direction of its

circumference, the hook is likely to come off.

2-2. Anode Cap Removal

Anode cap

Grip

CRT GND

Hook

CRT GND

CRT

Figure 2-1

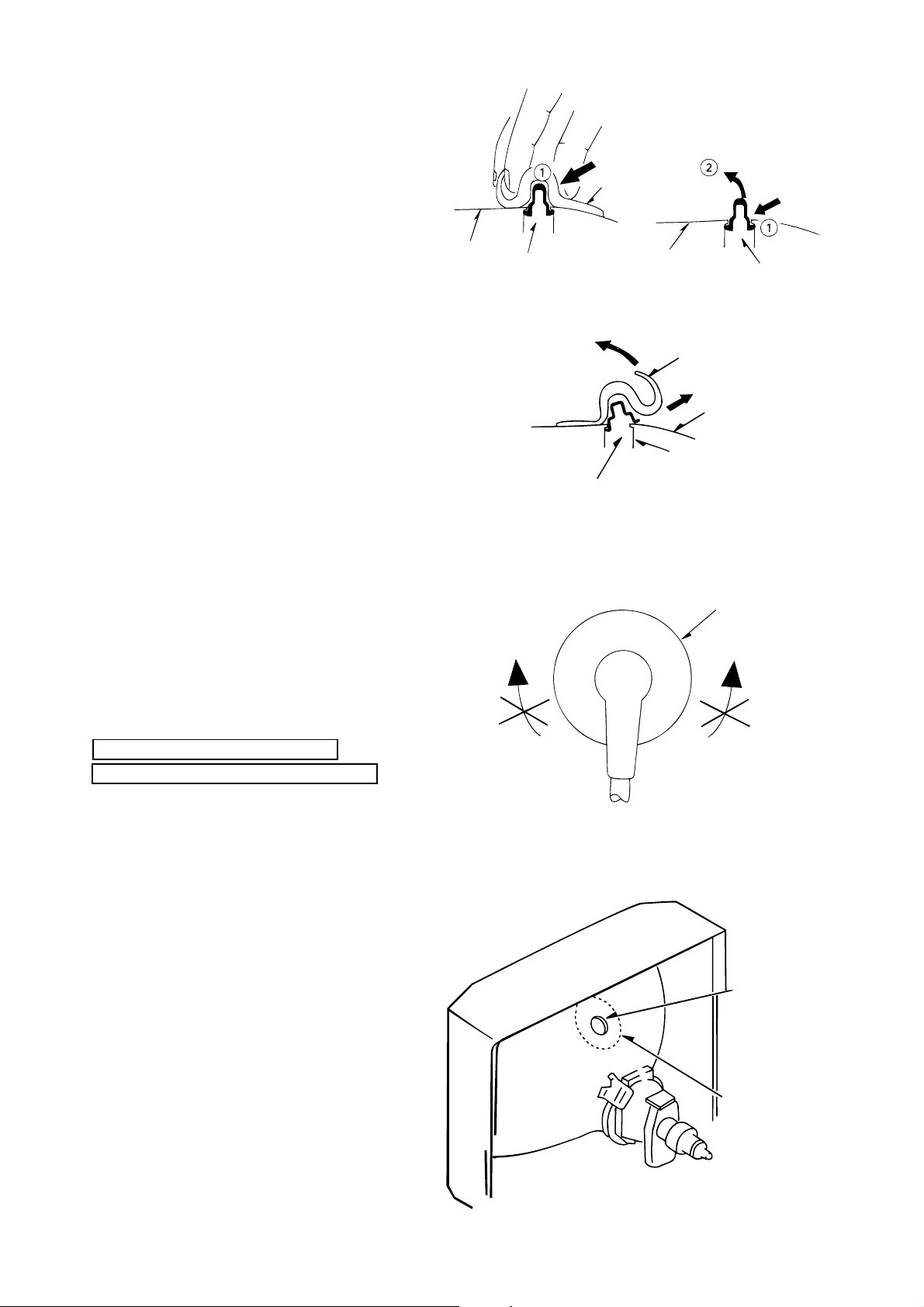

Discharge the anode voltage. (See Figure 2-1)

(1) Connect a flat-bladed screwdriver to the CRT GND via

an alligator clip.

(2) Use a tester to check the end of the screwdriver and ground

of the TV for continuity.

(3) Touch the hook with the end of the screwdriver.

Caution : Be careful not to damage the anode cap.

(4) Turn over the anode cap.

Caution : Be careful not to damage the anode cap.

-4-

CRT

Anode cap

Anode button

Hook

Figure 2-2

(5) Push the anode cap with your thumb in the direction of

arrow 1 as shown in the figure, then lift the cap in the

direction of arrow 2 to release the hook on one side.

(See Figure 2-3)

Anode cap

(6) Turn over the anode cap on the side where the hook was

released and pull out the cap in the direction opposite to

that on which the cap was pushed. (See Figure 2-4)

Caution : Do not pull out the anode cap straight up.

: Do not pull the cap forcibly. After removing

the cap, check that the hook is not deformed.

3. ANODE CAP REINSTALLTION

Observe the cautions carefully so that no accident occurs

due to a defect in installing the anode cap and so it does

not come off.

CRT

Hook

Left

CRT

Hook

Figure 2-3

Anode cap

CRT

Anode button

Hook

Figure 2-4

Anode cap

Right

3-1. Caution before Reinstalling

Never turn the anode cap after installing it

Never re-use the hook when it has been deformed

(1) If the anode cap is turned after it is installed, it may come

off. Therefore, arrange the high-voltage cable before

attaching the anode cap. (See Figure 3-1)

(2) If you have attached the anode cap before arranging the

high-voltage cable, arrange the cable carefully so the cap

does not turn.

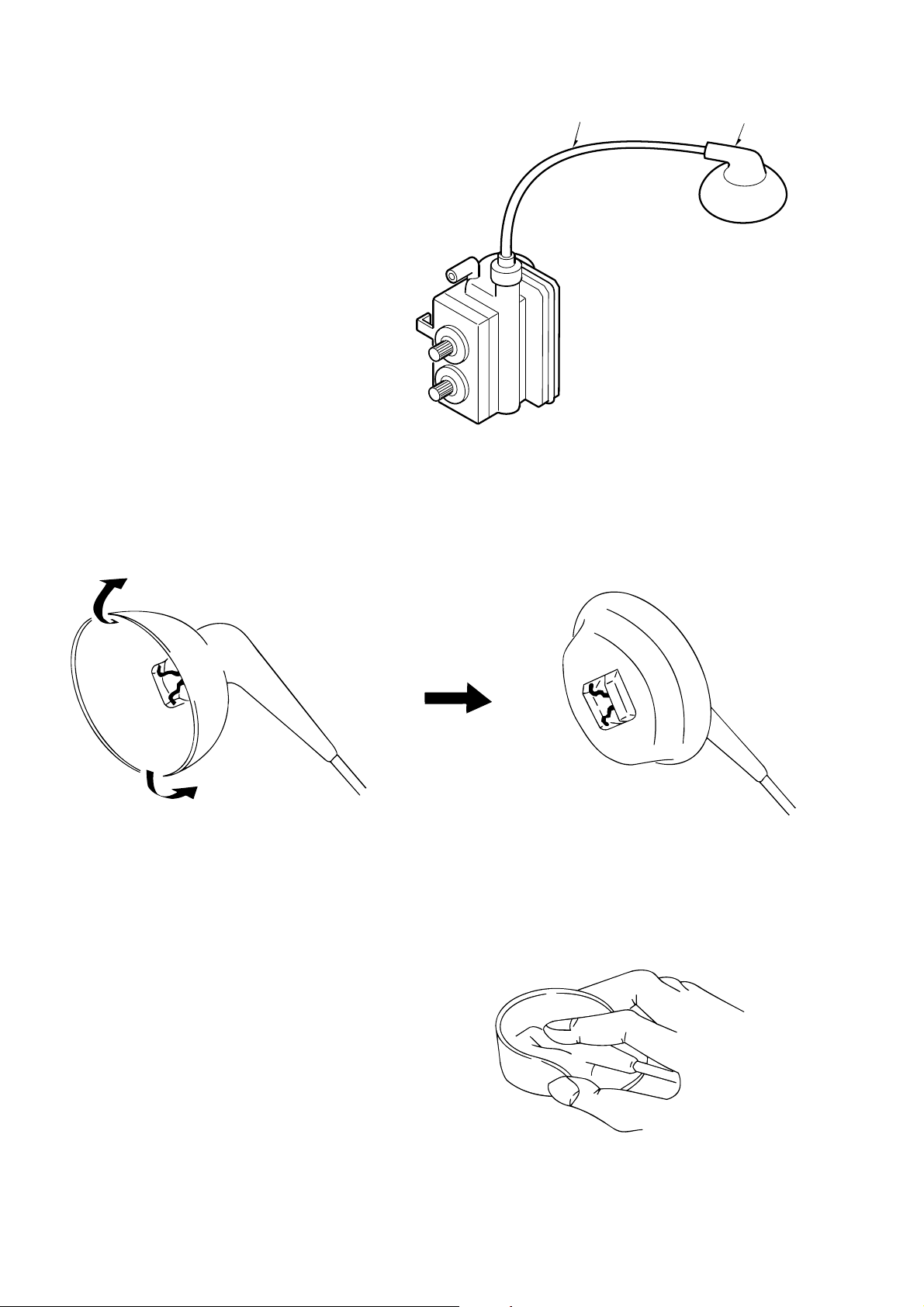

3-2. Anode cap reinstallation

(1) Use a clean cloth moistened slightly with alcohol to clean

the installation section. (See Figure 3-2)

Caution : Check that the installation section is free from

dust, foreign matter, etc.

(2) Coat the anode cap installation circumference with an

appropriate amount of the specified silicone grease (KS650N).

Caution : Be careful that silicone grease does not enter

the anode button.

Figure 3-1

Anode button

Installation

section

-5-

Figure 3-2

(3) Eliminate twisting, etc. of the high-voltage cable and

arrange it so that no twisting occurs. (See Figure 3-3)

Caution : If the cable is not arranged correctly, the anode

cap could turn and cause an installation defect.

(4) Turn over the rubber cap symmetrically on the left and

right. (See Figure 3-4)

Caution : Take great care not to damage the anode cap.

High-voltage cable

Anode cap

Figure 3-3

(5) Fit your forefinger over the projection at the center of the

cap and hold the cap between your thumb and middle

finger. (See Figure 3-5)

Figure 3-4

Figure 3-5

-6-

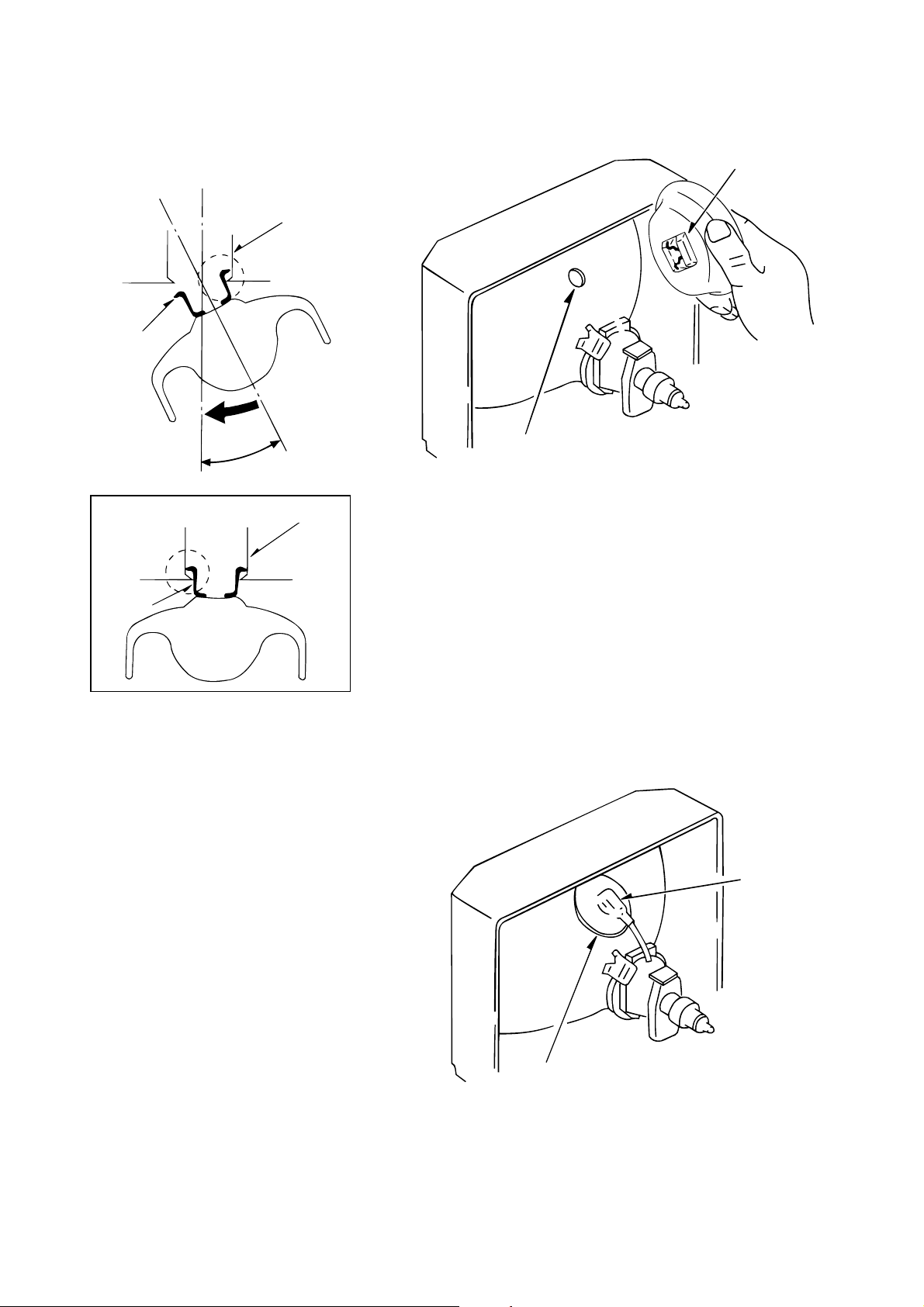

(6) Apply the hook on one side to the anode button as shown

on the figure. (See Figure 3-6)

Caution : Check that the hook is held securely.

(7) Apply the hook on the other side to the anode button as

shown in Figure 3-7.

Anode button

Hook

Hook

Anode button

30°

Anode button

Hook

Figure 3-7

(8) Pull the anode cap slightly with the rubber cap turned

over and visually check that the hook is engaged securely.

(9) Release your hand from the rubber cap of the anode cap.

Caution : Cover the anode cap so that it does not lift.

(10) Hold the skirt of the andoe cap slightly to improve the

close contact between the cap and CRT.

(11) Check that the anode cap is in close contact with the CRT.

(See Figure 3-8)

Figure 3-6

Anode button

-7-

Skirt

Figure 3-8

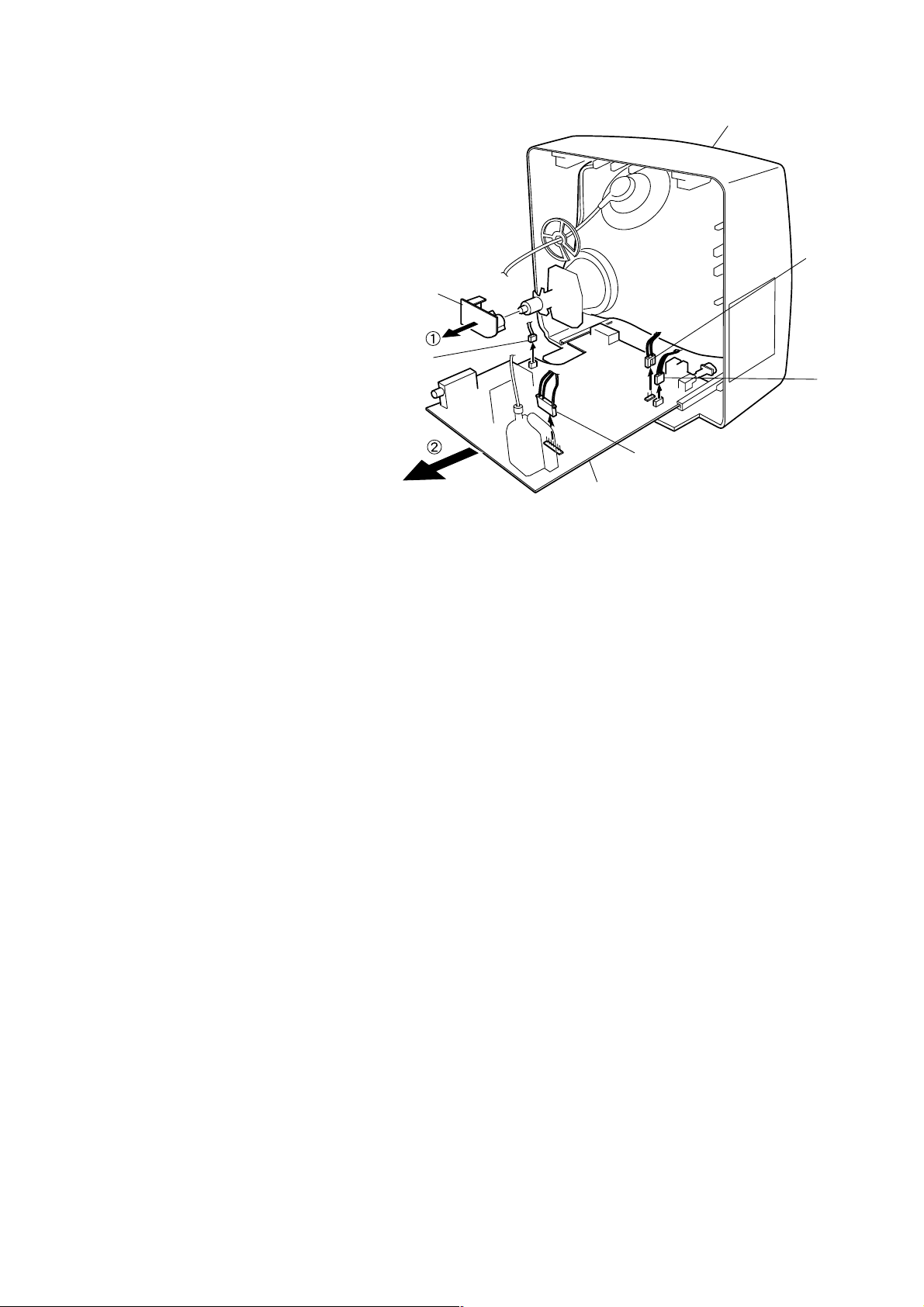

4. NECK C.B. REMOVAL

(1) Remove the NECK C.B. in the direction of arrow 1

(See Figure 4-2).

5. MAIN C.B REMOVAL

(1) Remove connector (P601).

(2) Remove connector (P801).

(3) Remove connector (P802).

(4) Remove connector (P401).

(5) Pull out the MAIN C.B. in the direction of

the arrow 2 (See Figure 4-2).

NECK C.B

P601

(Speakers

Main C.B

P401

Front Cabinet

P802

(Degauss

Cord)

P801

(Power Cord)

-8-

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

SI-AL2-416-00B IC,AT24C16-10PC

S1-DW1-95D-E2Q C-IC,DW92195B7T-DE2

S1-KA7-805-000 IC,KA7805

S1-KRT-300-000 IC,KRT30

S1-STV-223-8DQ C-IC,STV2238D

!!

! S4-850-M04-710 MODULE POWER DPM001T1A

!!

S1-STV-813-100 IC,STV8131

87-JB1-605-010 IC,TDA1771

S1-TDA-610-3Q0 IC,TDA6103Q

S1-TDA-726-7A0 IC,TDA7267A

TRANSISTOR

87-A30-492-080 TR,2SC5343Y

ST-KTC-320-700 TR,KTC3207

87-A30-050-010 TR,2SD2499

ST-R33-300-9DB TR,STA933-Y

!!

! ST-2SK-267-100 TR,2SK2671

!!

ST-KSA-101-3Y0 TR,KSA1013Y

DIODE

87-A40-246-080 DIODE,1N4148

SD-1SS-85T-A00 DIODE,1SS85TA

SD-UZ3-3B0-000 ZENER,UZ-33B

SD-TZX-5V1-B00 ZENER,TZX5V1B

SD-BYW-360-000 DIODE,BYW36

SD-BY2-280-000 DIODE,BY228

SD-TZX-5V6-B00 ZENER,TZX5V6B

SD-UZ3-R9B-000 ZENER,UZ-3.9B

SD-BYW-760-000 DIODE,BYW76

SD-BYW-340-000 DIODE,BYW34

SD-R2M-000-000 ZENER,R2M

SD-LT2-A05-G00 DIODE,LT2A05G

MAIN C.B

C101 87-015-695-010 CAP,E 1MF-50V

C102 87-010-408-040 CAP,E 4.7MF-50V

C103 87-010-285-010 CAP,E 2200MF-16V

C301 87-016-593-080 CAP,E 470MF-35V

C302 SC-CXB-3A4-71K CAP,CER 4700PF-1KV

C303 87-A10-493-080 CAP,E 1000MF-25V

C304 87-016-638-080 CAP,E 22MF-50V

C306 87-010-393-010 CAP,E 100MF-35V

C313 87-015-695-010 CAP,E 1MF-50V

C401 SC-MYE-2D3-64J CAP,M 0.36MF-200V

C402 S0-E7T-B01-0M0 CAP,E 1MF-160V

C404 SC-MYT-3C6-92J CAP,M 6900PF-1.6KV

C406 87-010-976-010 CAP,CER 1000PF-500V

C411 SC-MYN-1J1-05K CAP,M 1MF-63V

C420 87-010-553-080 CAP,E 47MF-16V

C421 87-010-545-080 CAP,E 33MF-250V

C501 87-015-694-080 CAP,E 0.47MF-50V

C502 87-015-695-010 CAP,E 1MF-50V

C503 87-010-553-080 CAP,E 47MF-16V

C504 87-015-696-080 CAP,E 2.2MF-50V

C506 87-015-696-080 CAP,E 2.2MF-50V

C507 87-010-112-040 CAP,E 100MF-16V

C511 87-010-553-080 CAP,E 47MF-16V

C512 87-015-695-010 CAP,E 1MF-50V

C513 87-010-405-040 CAP,E 10MF-50V

C514 87-015-695-010 CAP,E 1MF-50V

C515 87-015-695-010 CAP,E 1MF-50V

C516 87-015-695-010 CAP,E 1MF-50V

C517 87-015-695-010 CAP,E 1MF-50V

C520 87-010-553-080 CAP,E 47MF-16V

C522 87-010-553-080 CAP,E 47MF-16V

NO.

REF. NO PART NO. KANRI DESCRIPTION

C523 87-015-695-010 CAP,E 1MF-50V

C524 87-015-695-010 CAP,E 1MF-50V

C601 87-010-553-080 CAP,E 47MF-16V

C602 87-010-544-080 CAP,E 0.1MF-50V

C606 87-016-126-080 CAP,E 470MF-16V

C611 87-010-553-080 CAP,E 47MF-16V

C620 87-010-405-040 CAP,E 10MF-50V

C702 87-015-695-010 CAP,E 1MF-50V

C703 87-010-553-080 CAP,E 47MF-16V

C704 87-010-237-910 CAP,E 1000MF-16V

C706 87-015-694-080 CAP,E 0.47MF-50V

C801 SC-L1S-C34-74M CAP,0.47MF-275V

C803 SC-CXF-3A4-72Z CAP,CER 4700PF-1KV

C804 SC-CXF-3A4-72Z CAP,CER 4700PF-1KV

C805 87-A10-003-090 CAP,E 100MF-400V

C807 SC-MYU-3C2-22J CAP,M 2200PF-1.6KV

C809 87-A12-170-010 CAP,CER 1000PF-4.0KV

C812 87-A12-170-010 CAP,CER 1000PF-4.0KV

C814 SC-CYR-3A4-71K CAP,CER 470PF-1KV

C815 87-016-249-090 CAP,E 100MF-160V

C818 87-016-249-090 CAP,E 100MF-160V

C819 87-016-299-080 CAP,E 10MF-100V

C820 87-A10-493-080 CAP,E 1000MF-25V

C822 87-010-112-040 CAP,E 100MF-16V

C825 87-016-638-080 CAP,E 22MF-50V

C826 87-010-408-040 CAP,E 4.7MF-50V

C827 87-010-285-010 CAP,E 2200MF-16V

C828 87-010-112-040 CAP,E 100MF-16V

C829 87-010-405-040 CAP,E 10MF-50V

C830 87-016-126-080 CAP,E 470MF-16V

C842 87-016-515-080 CAP,CER 1000PF-1KV

C850 87-010-553-080 CAP,E 47MF-16V

D706 SD-LH2-PR0-000 LED BLOCK LH-2P-R

!!

!F801 S5-FSC-B40-22R FUSE CERA 4A 250V

!!

JS02 S4-859-109-950 JACK PIN BOARD PH-JB-9710A

L101 S5-8N0-000-044 COIL VCO TRF-V010

L301 S5-CPZ-100-K04 COIL PEAKING 10UH 10.5MM

L511 S5-CPZ-100-K02 COIL PEAKING 10UH 3.5MM

L601 S5-CPZ-109-M02 COIL PEAKING 1UH 3.5MM

L602 S5-CPZ-109-M02 COIL PEAKING 1UH 3.5MM

L604 S5-CPZ-109-M02 COIL PEAKING 1UH 3.5MM

L701 S5-CPZ-100-K02 COIL PEAKING 10UH 3.5MM

L702 S5-CPZ-569-K02 COIL PEAKING 5.6UH 3.5MM

L800 S5-8Q0-000-093 COIL DELAY LINE RS208

!!

!L801 S5-PLF-24A-300 FILTER LINE LF-24A3

!!

L802 S5-MC0-000-100 COIL BEAD MD-5

L803 S5-MC0-000-100 COIL BEAD MD-5

L805 S5-8C4-500-079 COIL CHOKE L-45

L806 S5-CPZ-390-K04 COIL PEAKING 39UH 10.5MM

P101 S4-859-231-620 CONN WAFER YW025-03

P401 S4-859-240-020 CONN WAFER YFW500-05

P601 S4-859-231-620 CONN WAFER YW025-03

!!

!P801 S4-859-287-320 CONN WAFER MKS2822

!!

P802 S4-859-242-220 CONN WAFER YFW800-02

P601A S4-850-703-S50 CONN AS YH025

R302 87-022-576-010 RES,R METAL 2.2-2W

R303 87-022-642-090 RES,R METAL 270-2W

R307 SR-N02-B18-1JS RES,R METAL 180-2W

R308 SR-N02-B18-1JS RES,R METAL 180-2W

R309 SR-N02-B18-1JS RES,R METAL 180-2W

R310 SR-N02-B18-1JS RES,R METAL 180-2W

R402 87-025-590-060 RES,R M-OXIDE 15K-2W

!!

!R403 SR-S02-Y43-9JS RES,R M-OXIDE 4.3-2W

!!

R410 SR-N02-B13-2JS RES,METAL 1.3K-2W

R503 SR-N01-B30-0JS RES,METAL 30-1W

!!

!R801 SD-EC1-40M-290 POSISTOR ECPCC140M290

!!

R802 SR-X07-C33-9JF RES,CEM 3.3-7W

R808 SR-S02-Y82-8JS RES,R M-OXIDE 0.82-2W

R819 SR-S02-Y27-8JS RES,R M-OXIDE 0.27-2W

R850 87-A00-618-090 RES,METAL 18-2W

NO.

-9-

Loading...

Loading...