Page 1

HV-FX5200

LE

SERVICE MANUAL

STEREO VIDEO CASSETTE RECORDER

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

(S/M Code No. 09-996-332-8T1).

BASIC TAPE MECHANISM : D-33

S/M Code No. 09-996-332-8R1

REVISION

DATA

Page 2

TABLE OF CONTENTS

SPECIFICATIONS ............................................................ 3

ACCESSORIES LIST ....................................................... 3

DISASSEMBLY INSTRUCTIONS..................................... 4

SERVICE POSITION ........................................................ 5

VCR TEST TAPE INTERCHANGEABILITY TABLE ........ 6

ELECTRICAL MAIN PARTS LIST.............................. 7 ~ 9

TRANSISTOR ILLUSTRATION........................................ 9

WIRE HARNESS DIAGRAM .......................................... 10

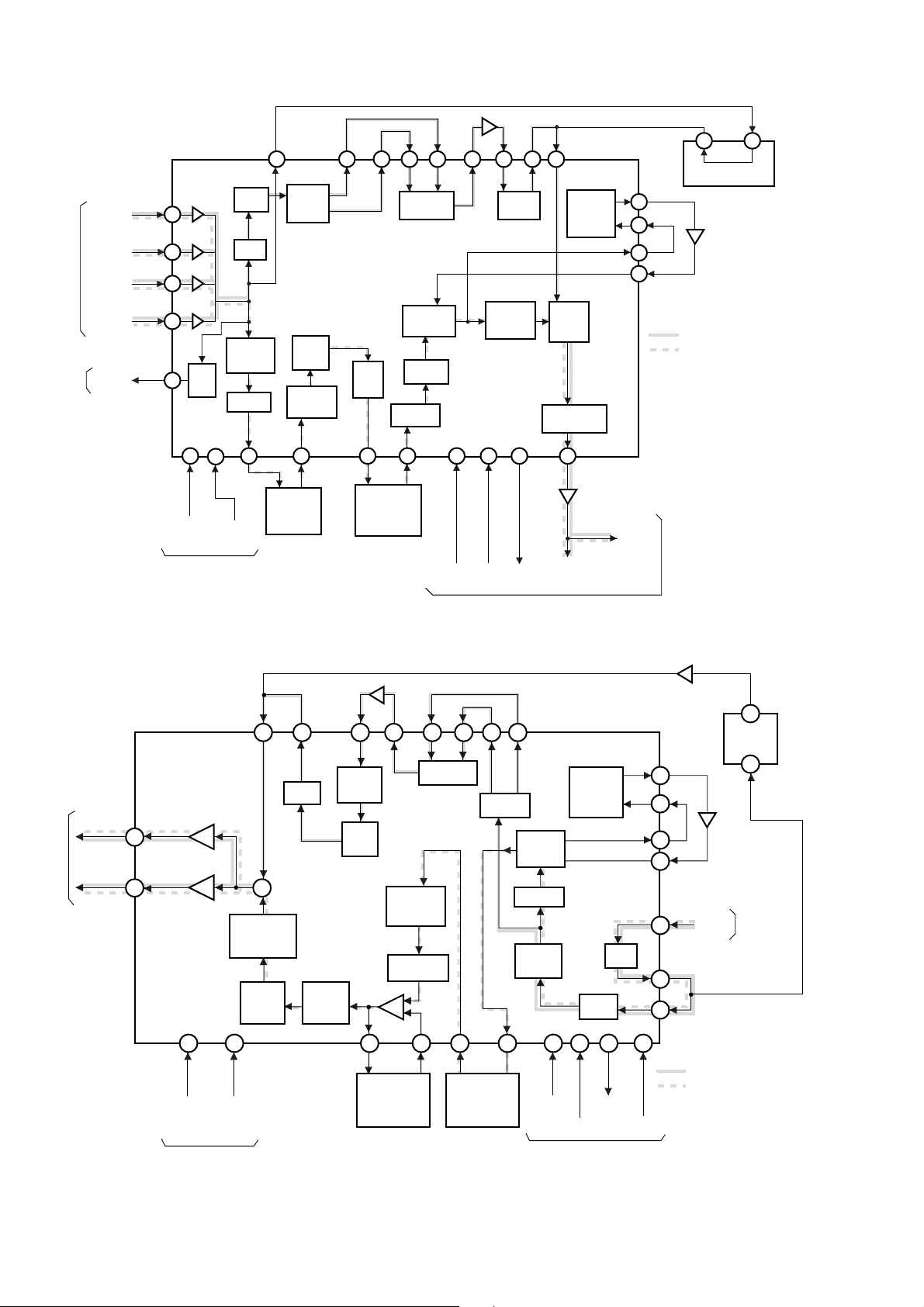

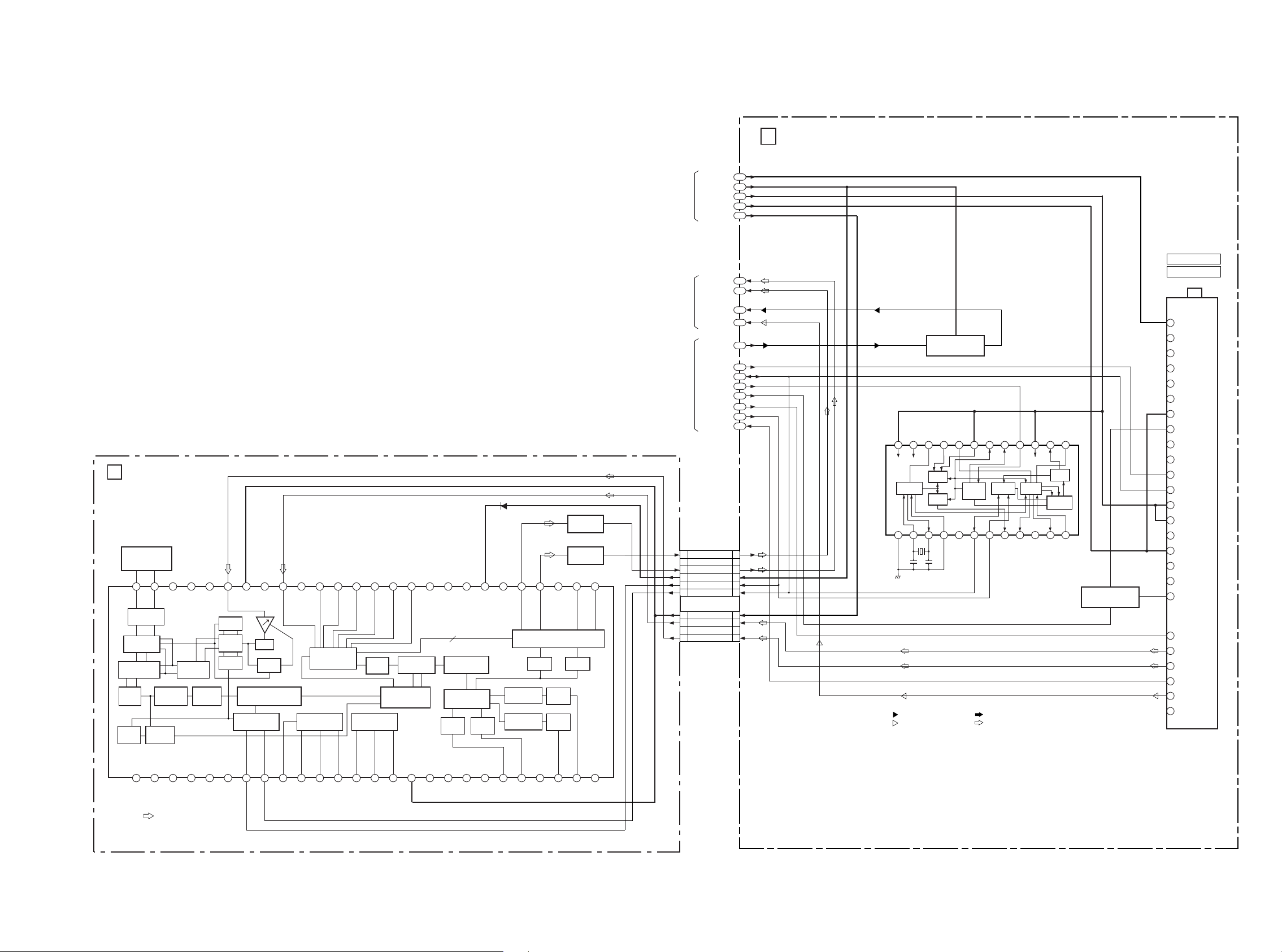

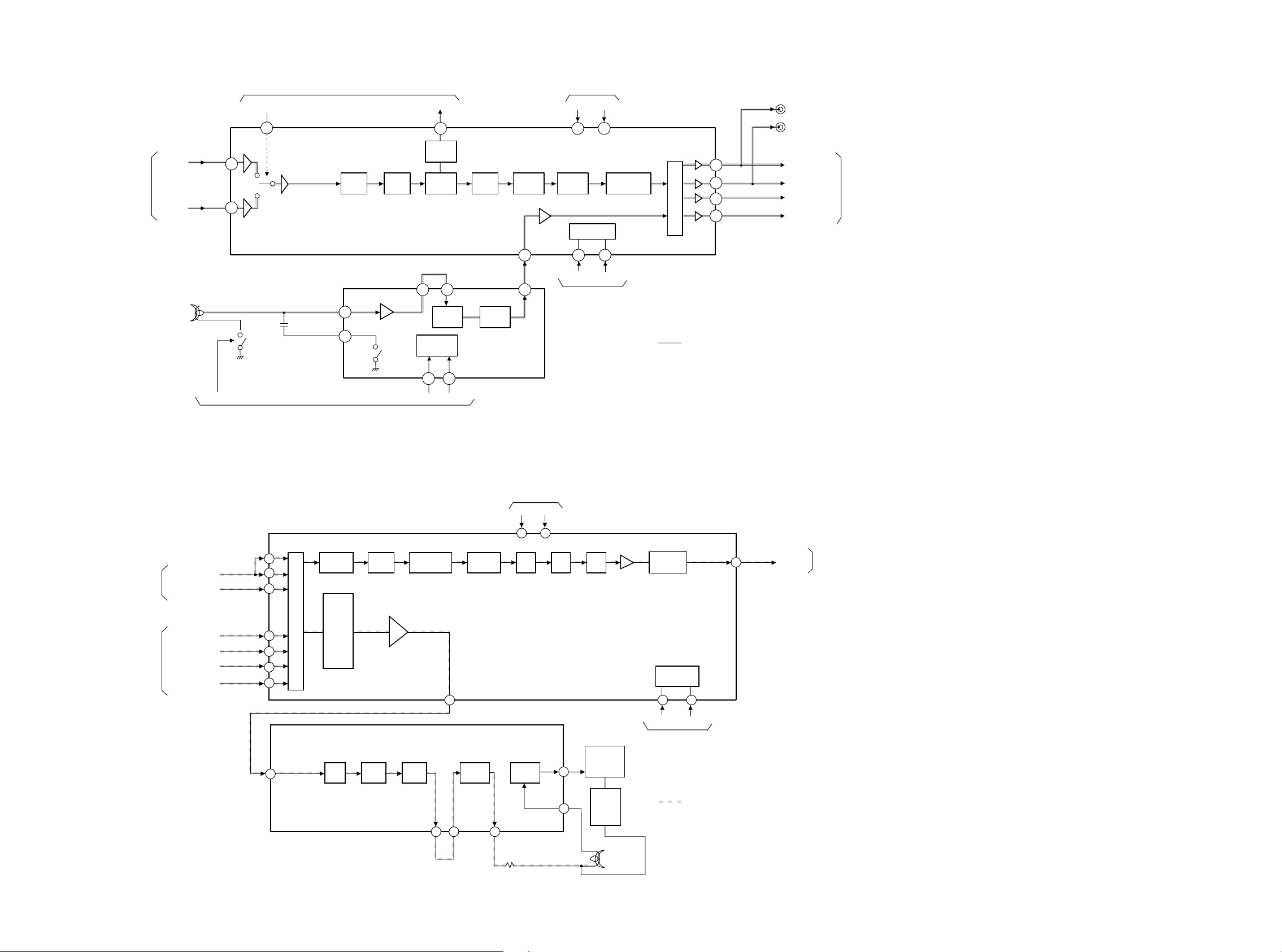

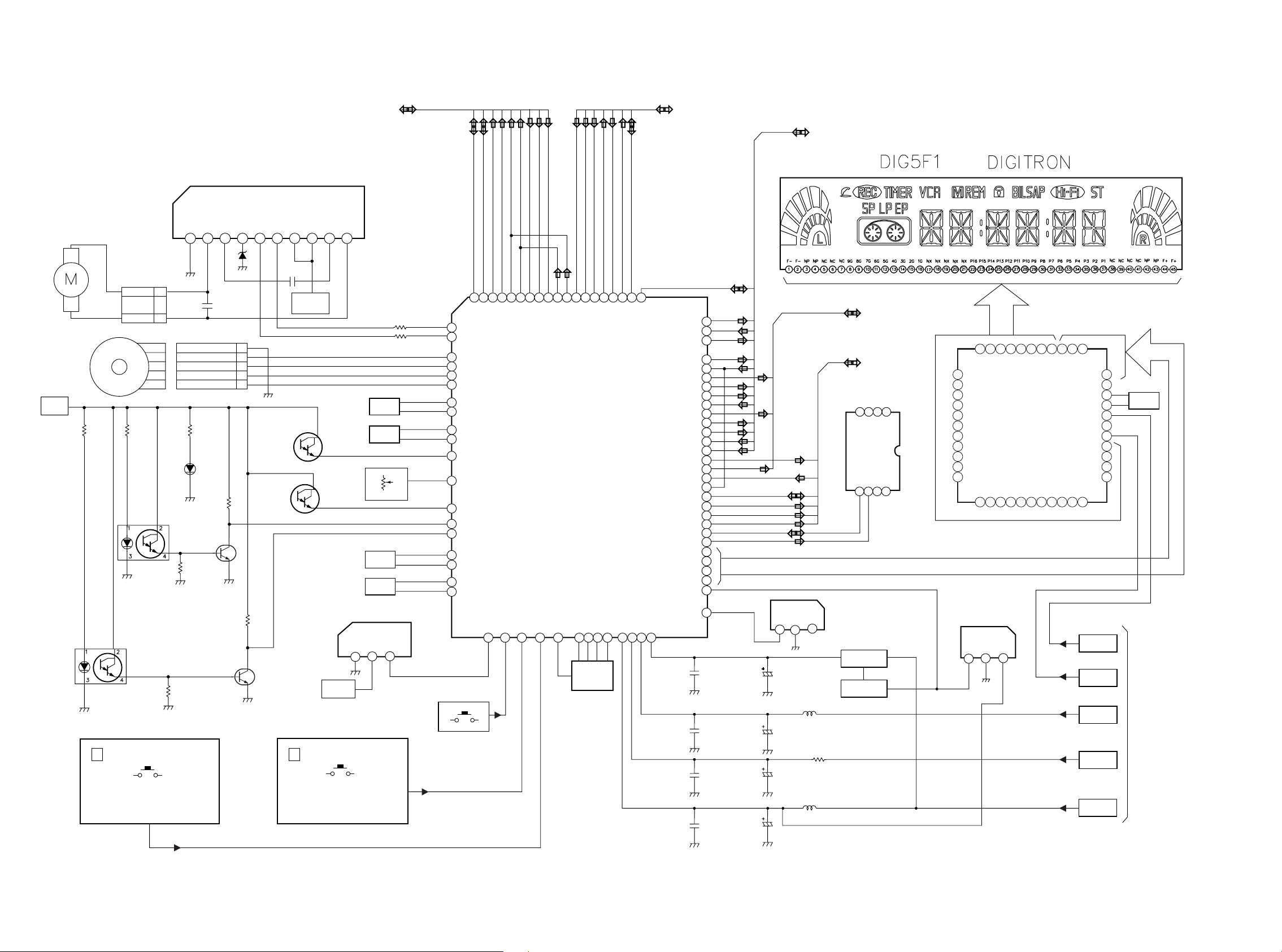

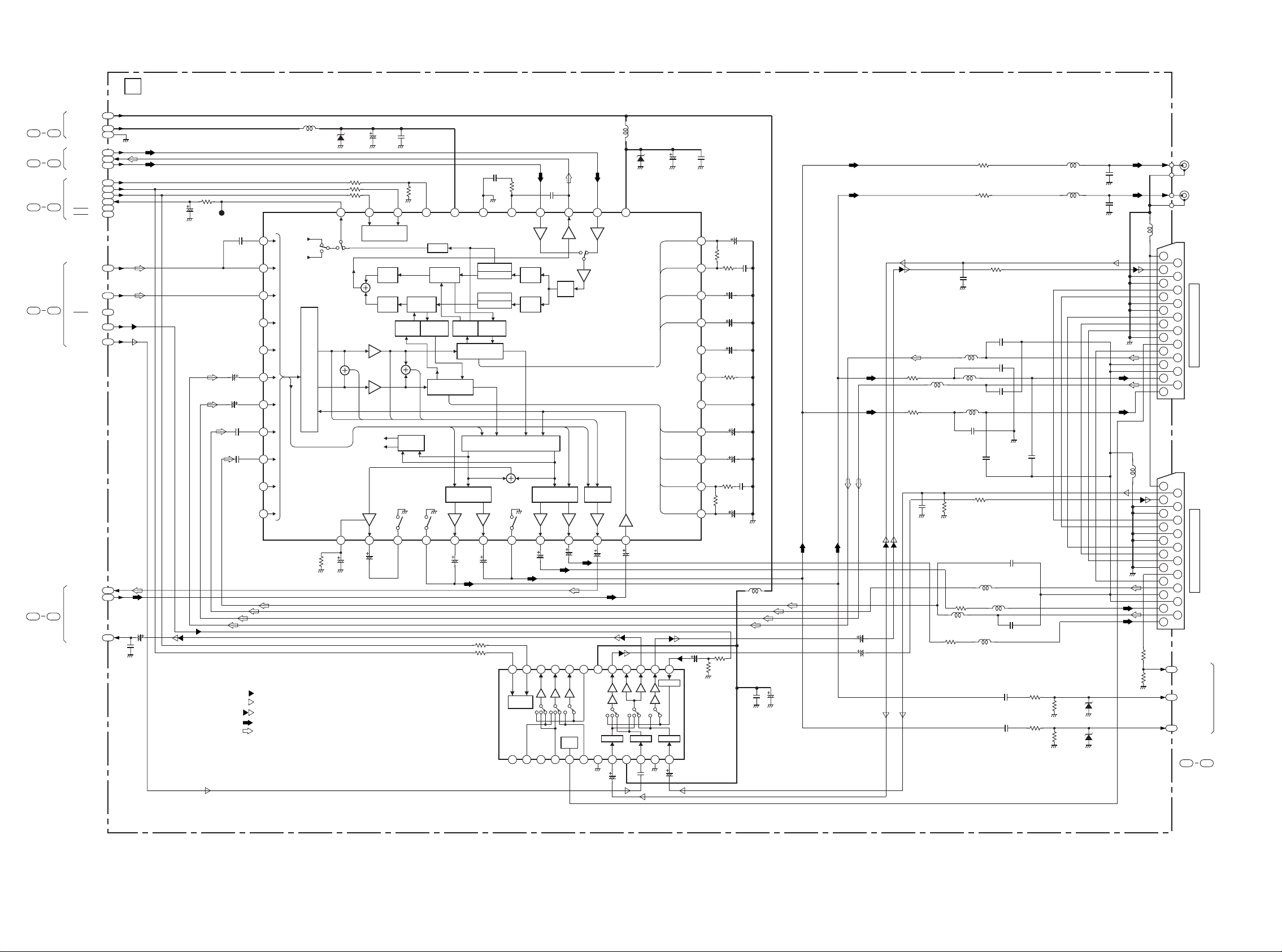

BLOCK DIAGRAM ................................................. 11 ~ 20

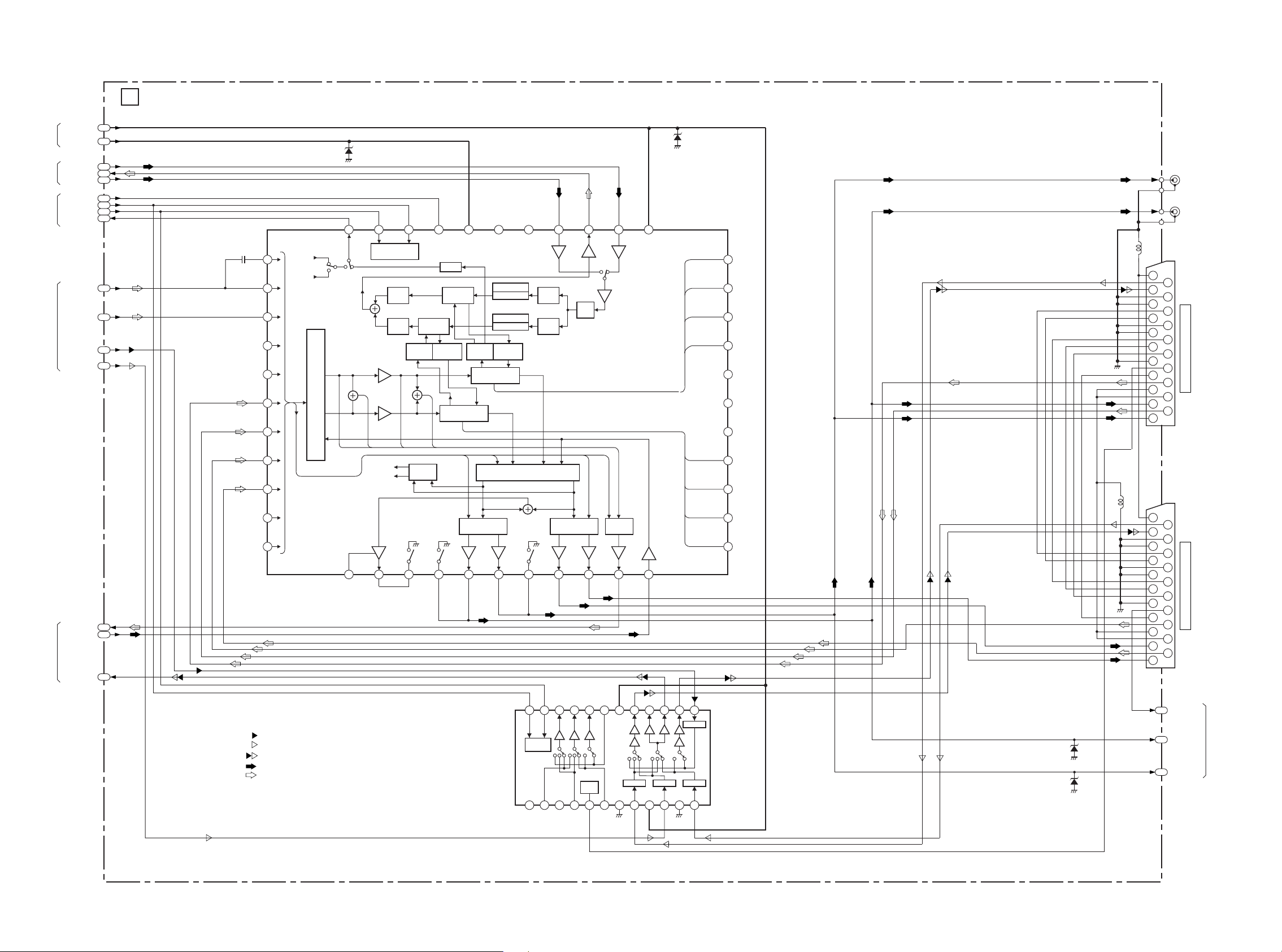

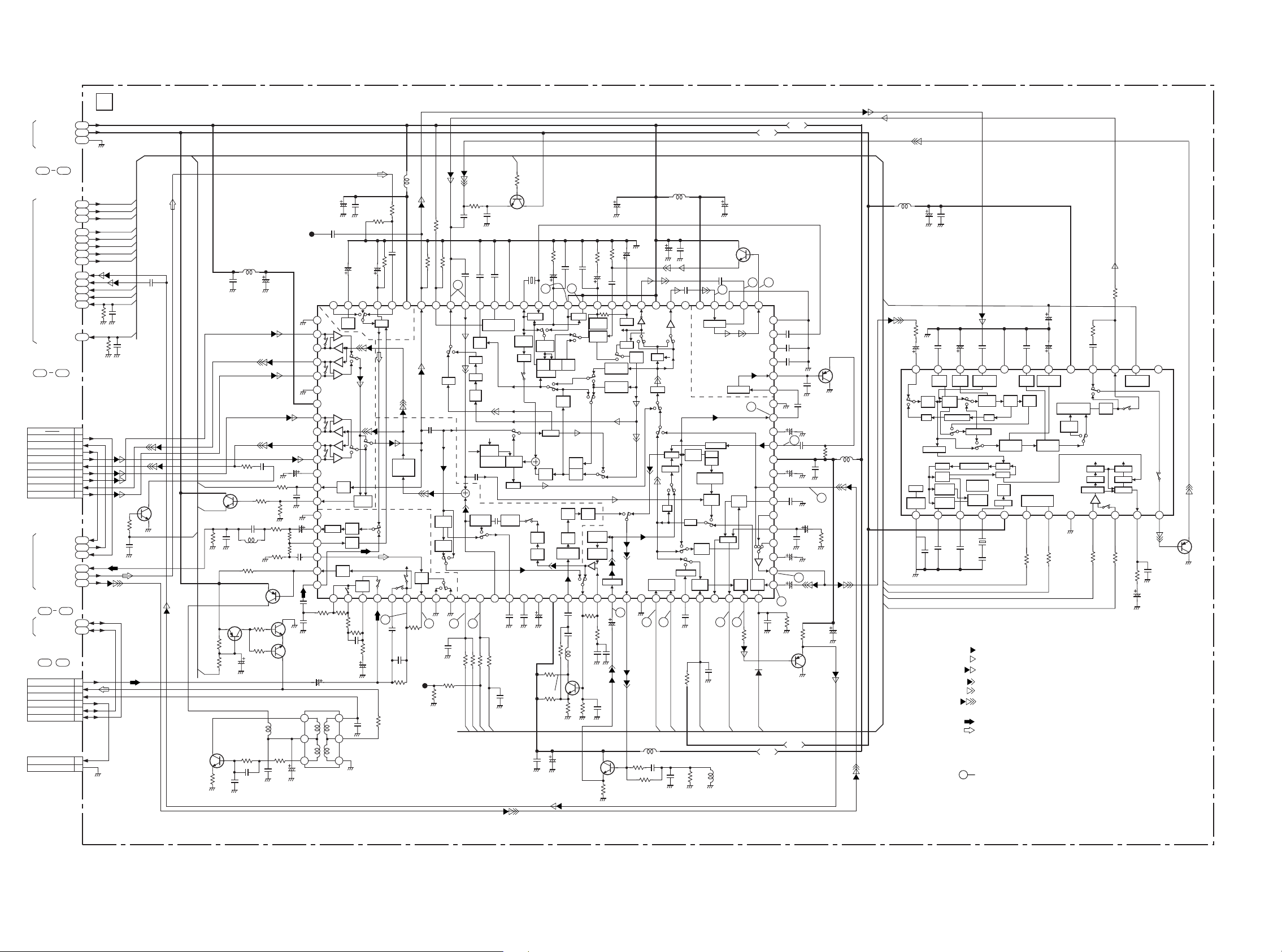

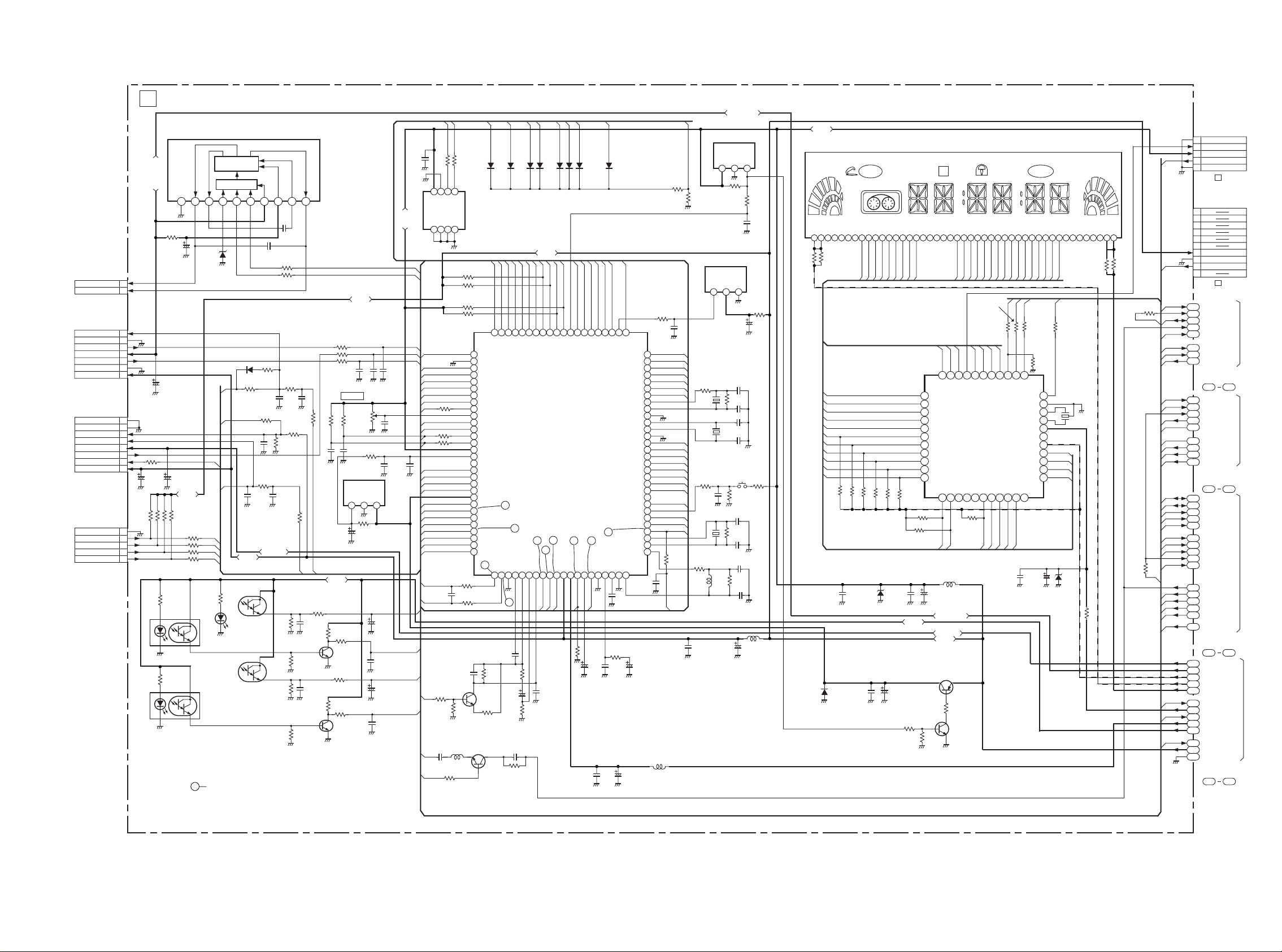

SCHEMATIC DIAGRAM

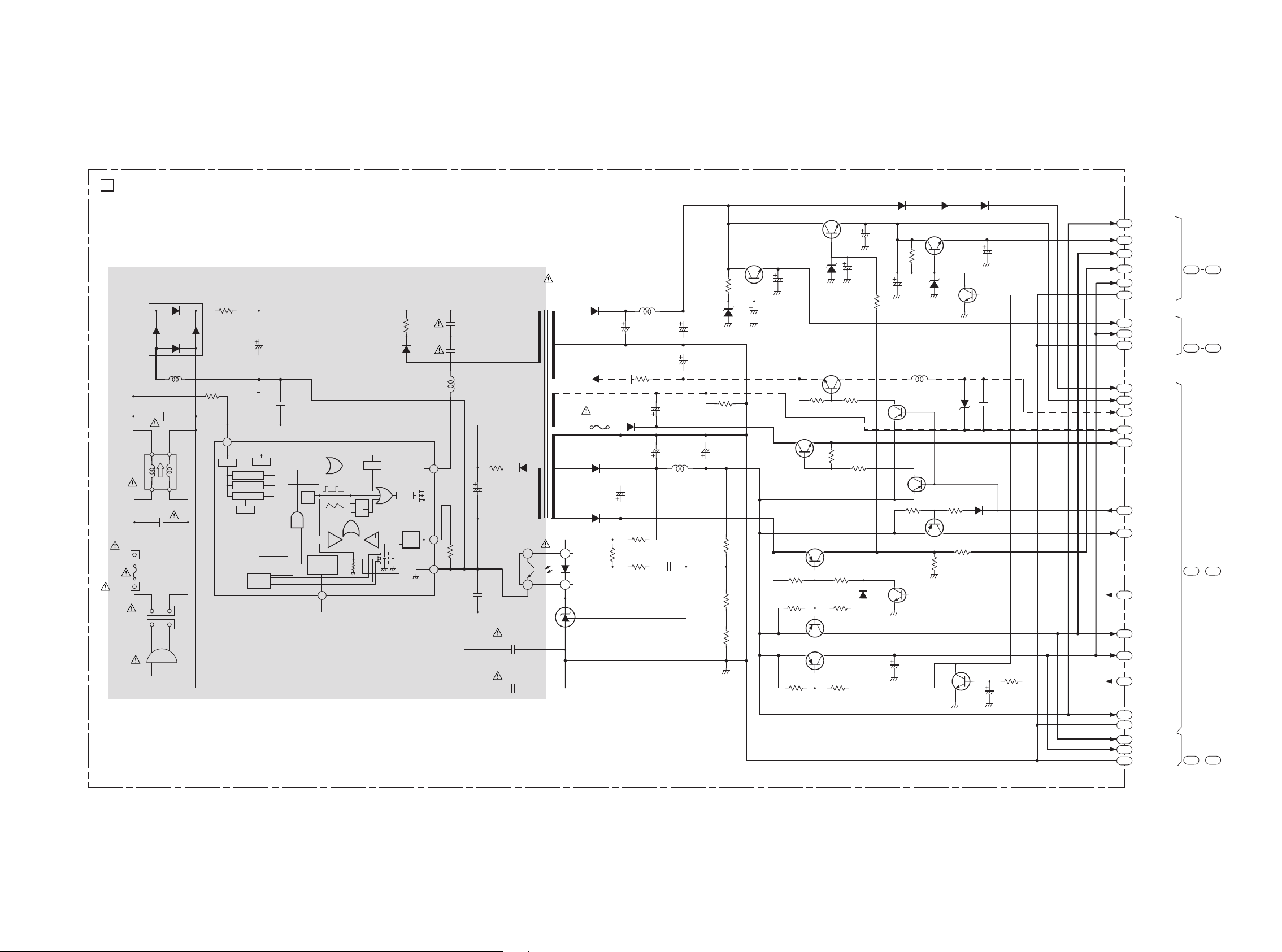

1. POWER SECTION.............................................. 21 ~ 22

2. AUDIO/VIDEO SECTION.................................... 23 ~ 24

3. SYSTEM CONTROL/SERVO/OSD SECTION) .. 27 ~ 28

4. Hi-Fi/SCART SECTION ...................................... 29 ~ 30

5. TUNER/IF SECTION........................................... 31 ~ 32

6. NICAM SECTION................................................ 33 ~ 34

7. FRONT-1 C.B.............................................................. 37

8. FRONT-2 C.B.............................................................. 37

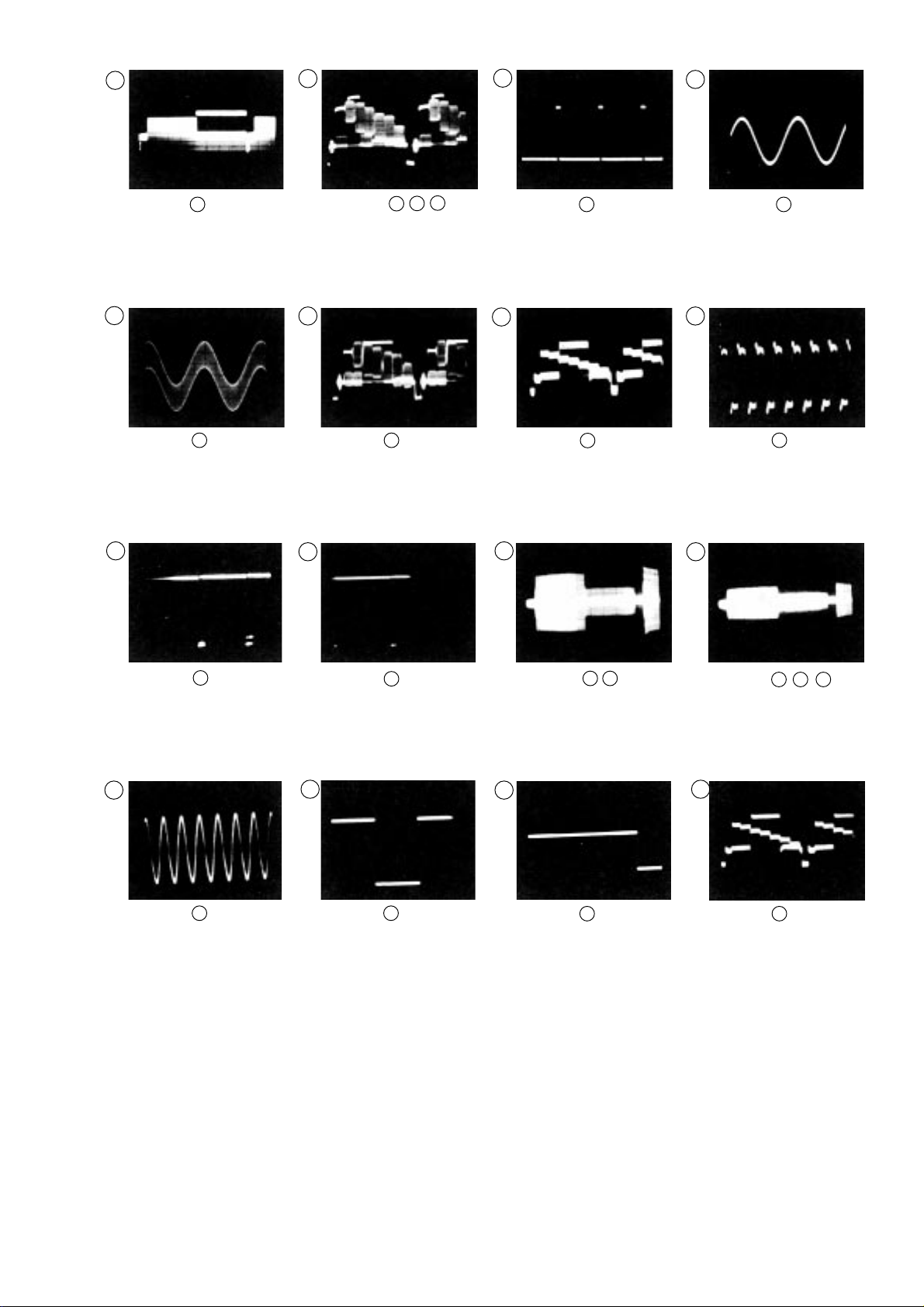

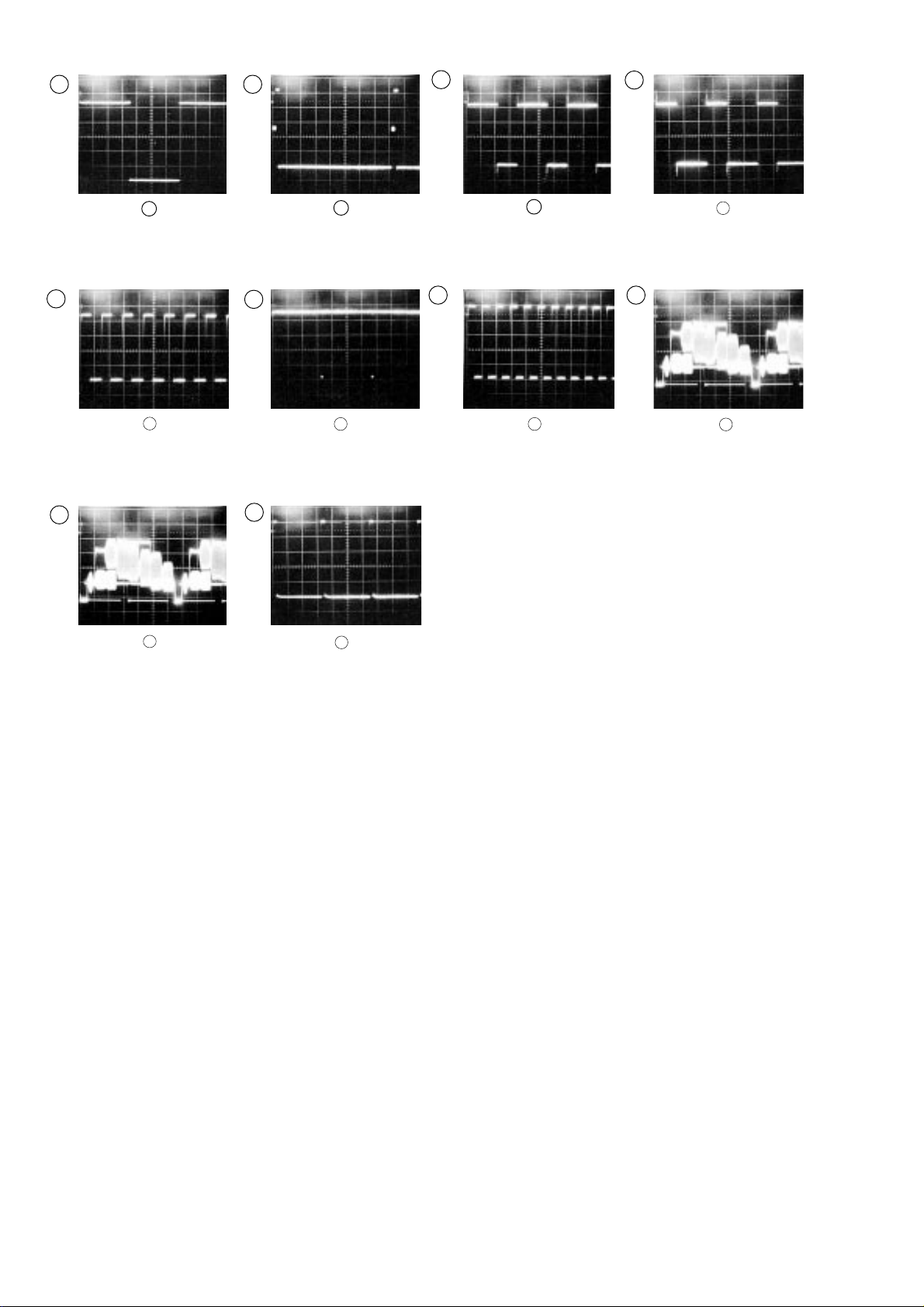

WAVEFORM

1. VIDEO SECTION ........................................................ 25

2. SERVO/OSD SECTION.............................................. 26

3. TUNER/IF SECTION................................................... 32

4. NICAM SECTION........................................................ 34

WIRING

1. MAIN C.B SECTION ........................................... 35 ~ 36

2. FRONT 1 C.B SECTION............................................. 38

3. FRONT 2 C.B SECTION............................................. 38

IC DESCRIPTION ................................................... 40 ~ 45

ADJUSTMENT........................................................ 46 ~ 47

MECHANICAL EXPLODED VIEW 1/1 ........................... 48

MECHANICAL PARTS LIST 1/1 ................................... 49

MECHANISM EXPLODED VIEW 1/3, 2/3, 3/3 ..... 50,52,54

MECHANISM PARTS LIST 1/3, 2/3, 3/3 .............. 51,53,55

DECK MECHANISM PARTS LOCATIONS

Top View.......................................................................... 56

Bottom View .................................................................... 56

DECK MECHANISM DISASSEMBLY

1. Drum Assembly......................................................... 57

2. Plate Assembly Top................................................... 59

3. Holder Assembly CST............................................... 59

4. Guide CST ................................................................ 59

5. Bracket Side (L)/Bracket Assembly Door.................. 59

6. Arm Assembly F/L ..................................................... 59

7. Lever Assembly S/W................................................. 59

8. Arm Assembly Cleaner.............................................. 60

9. Head F/E ................................................................... 60

10. Base Assembly A/C Head ......................................... 60

11. Brake Assembly S ..................................................... 61

12. Brake Assembly T ..................................................... 61

13. Arm Assembly Tension.............................................. 61

14. Reel S & Reel T ........................................................ 61

15. Support CST ............................................................. 62

16. Base Assembly P4.................................................... 62

17. Opener Lid ................................................................ 62

18. Arm Assembly T/up ................................................... 62

19. Arm Assembly Pinch ................................................. 62

20. Belt Capstan/Motor Capstan ..................................... 63

21.Clutch Assembly D33 ................................................. 63

22. Lever F/R .................................................................. 63

23. Gear Assembly H-Up/D or Gear Assembly Up/D...... 63

24. Bracket Assembly Jog............................................... 64

25. Guide Rack F/L, Gear Rack F/L................................ 64

26. Brake Assembly Capstan.......................................... 64

27. Gear Drive/Gear Cam/Gear Connector .................... 65

28. Bracket Assembly L/D motor..................................... 65

29. Gear Sector............................................................... 66

30. Base Tension/Plate Slider/Lever Tension .................. 66

31. Gear Assembly P3/Gear Assembly P2 ..................... 67

32. Base Assembly P3/Base Assembly P2 ..................... 67

33. Arm Assembly Idler Jog or Arm assembly Idler......... 67

DECK MECHANISM ADJUSTMENT

Tools and Fixtures for service ......................................... 68

1. Mechanism Alignment Position Check........................ 69

2. Preparation for Adjustment ......................................... 70

3. Checking Torque ......................................................... 70

4. Guide Roller Height Adjustment.................................. 71

4-1. Preliminary Adjustment .......................................... 71

4-2. Precise Adjustment ................................................ 71

5. Audio/Control (A/C) Head Adjustment......................... 72

5-1. Preliminary Adjustment .......................................... 72

5-2. Confirm that the Tape Path smoothly between

the Take-up Guide and Pinch Roller ..................... 73

5-3. Precise Adjustment (Azimuth Adjustment)............. 73

6. X-Value Adjustment..................................................... 73

7. Adjustment after Replacing Drum Assembly

(Video Heads) ............................................................. 74

8. Check the Tape Travel after Reassembling

Deck Mechanism......................................................... 74

8-1. Checking Audio and RF Locking Time

during Playback and after CUE or REV ................ 74

8-2. Check for Tape Curling or Jamming....................... 74

MAINTENANCE/INSPECTION PROCEDURE

1. Check before starting Repairs .................................... 75

2. Required Maintenance ................................................ 76

3. Scheduled Maintenance ............................................. 76

4. Supplies Required for Inspection and Maintenance ... 76

5. Maintenance Procedure.............................................. 76

5-1. Cleaning................................................................. 76

5-2. Greasing ................................................................ 77

MECHANISM TROUBLESHOOTING GUIDE

1. Deck Mechanism ........................................................ 78

2. Front Loading Mechanism .......................................... 81

2

Page 3

SPECIFICATIONS

Video recording system Rotary 2 head helical scanning system

Video head Double azimuth 4 heads

Tuner system Frequency synthesized tuner

TV system B/G, L/L’ SECAM, B/G PAL

Video signal system SECAM/MESECAM/PAL color signal,

625 lines, 50 fields

Usable cssettes VHS video cassettes

Recording/playback time PAL/SECAM/MESECAM

SP: 4 hours 20 minutes max. with

E-260 tape.

LP: 8 hours 40 minutes max. with

E-260 tape

NTSC (Playback only)

SP: 3 hours max. with T-180 tape

LP: 6 hours max. with T-180 tape

EP: 9 hours max. with T-180 tape

Tape speed PAL/SECAM/MESECAM

SP: 23.39 mm/sec.

LP: 11.69 mm/sec.]

NTSC (Playback only)

SP: 33.35 mm/sec.

LP: 16.67 mm/sec.

EP: 11.12 mm/sec.

Rewind time: Approx. 3 min. with E-180 tspe

Channel coverage VHF-low: C02 to C04, C13 to C20

(SECAM), S01 to S07

VHF-high: C05 to C12, S08 to S41

UHF: C21 to C71

Video input 0.5 - 2.0 Vp-p, 75 ohm, unbalanced

Video output 1.0 Vp-p, 75 ohm, unbalanced

Horizontal resolution 240 lines

Video S/N 43 dB (SP)

Audio track 3 tracks (Hi-Fi sound 2 tracks,

Normal sound 1 track)

Audio input SCART: -8 dBs, 22 k ohm

Audio output SCART: -8 dBs, less than 2.2 k ohm

Hi-Fi frequency response 20 Hz - 20 kHz

Hi-Fi dynamic range More than 80 dB

Hi-Fi wow & flutter Less than 0.01%(nominal)

Operating temperature: 5 °C to 40 °C

Power requirements 200 - 240 V AC, 50 Hz

Power consumption 20 watts

TYPE 3.5 watts (power save mode.)

Dimensions 360 (W) x 278 (D) x 95 (H) mm

(141/4 x 11 x 33/4 in.)

Weight Approx. 3.3 kg (7.26 lbs.)

• Design and specifications are subject to change without notice.

ACCESSORIES LIST

REF. NO PART NO. KANRI DESCRIPTION

1 S8-35R-P00-36B INSTRUCTION ASSY(FX52OOLE)

2 S7-11R-1P0-16A REMOTE CONTROLLER ASSY

3 S5-640-18B-000 PLUG ASSY PHONO CORD

4 S8-610-33B-000 CABLE SET ASSY

5 S8-610-45F-000 CABLE,COAXIAL 1.2M/M

6 S8-615-05R-000 CABLE ASSY

NO.

3

Page 4

DISASSEMBLY INSTRUCTIONS

1. Top Case Removal

1) Remove 4 screws holding the top case.

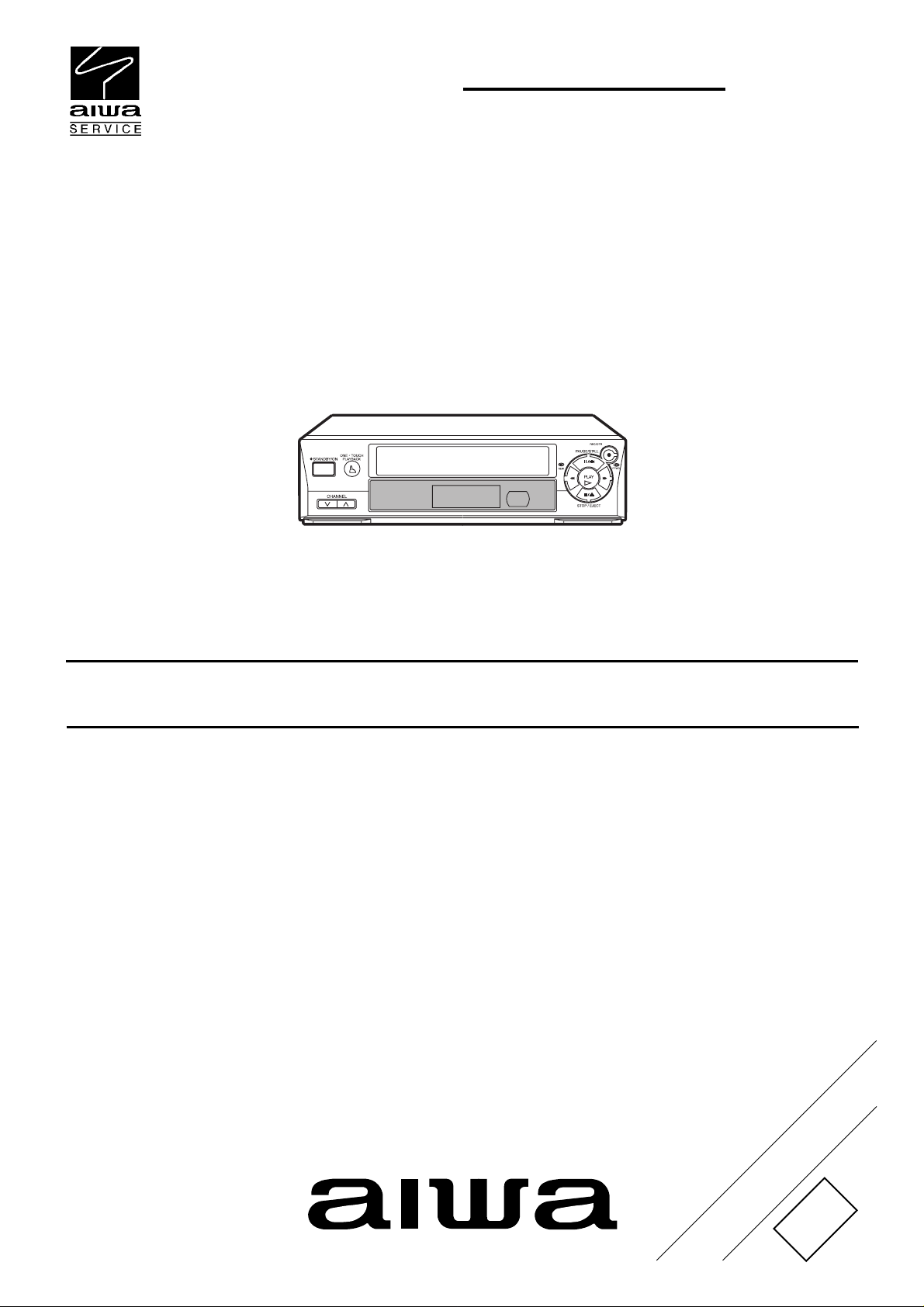

2. Panel Front Removal (see Fig. 1)

1) Release 7 tabs, and then remove the panel front.

4. Mechanism Removal (see Fig. 3)

1) Disconnect the drum FF cable from the connector

(PMD01) on the Main C.B.

2) Disconnect the ACE head FF cable from the connector

(P3D02) on the Main C.B.

3) Remove 6 screws (A).

PMD01

FF CABLE

P3D02

A

PANEL

FRONT

TAB

Fig. 1

3. Front-1 C.B. and Front-2 C.B. Removal (see Fig. 2)

1) Release 2 tabs, and then remove front-1 C.B. from the

connector (PKM02) in the direction of arrow (1).

2) Release the tab, and then remove front-2 C.B. from the

connector (PKM01) in the direction of arrow (2).

TAB

(1)

PKM01

TAB

Front-2 C,B

MAIN C,B

Front-1 C,B

(2)

FF CABLE

A

A

Fig. 3

5. Main C.B. Removal (see Fig. 4)

1) Remove 2 screws (B) holding the panel assy , distri-butor.

2) Release 5 tabs, and then simultaneously lift the panel assembly, distributor and Main C.B. to remove them.

B

TAB

TAB

PANEL ASSY,

DISTRIBUTOR

TAB

TAB

TAB

Fig. 2

TAB

PKM02

MAIN C,B

Fig. 4

4

Page 5

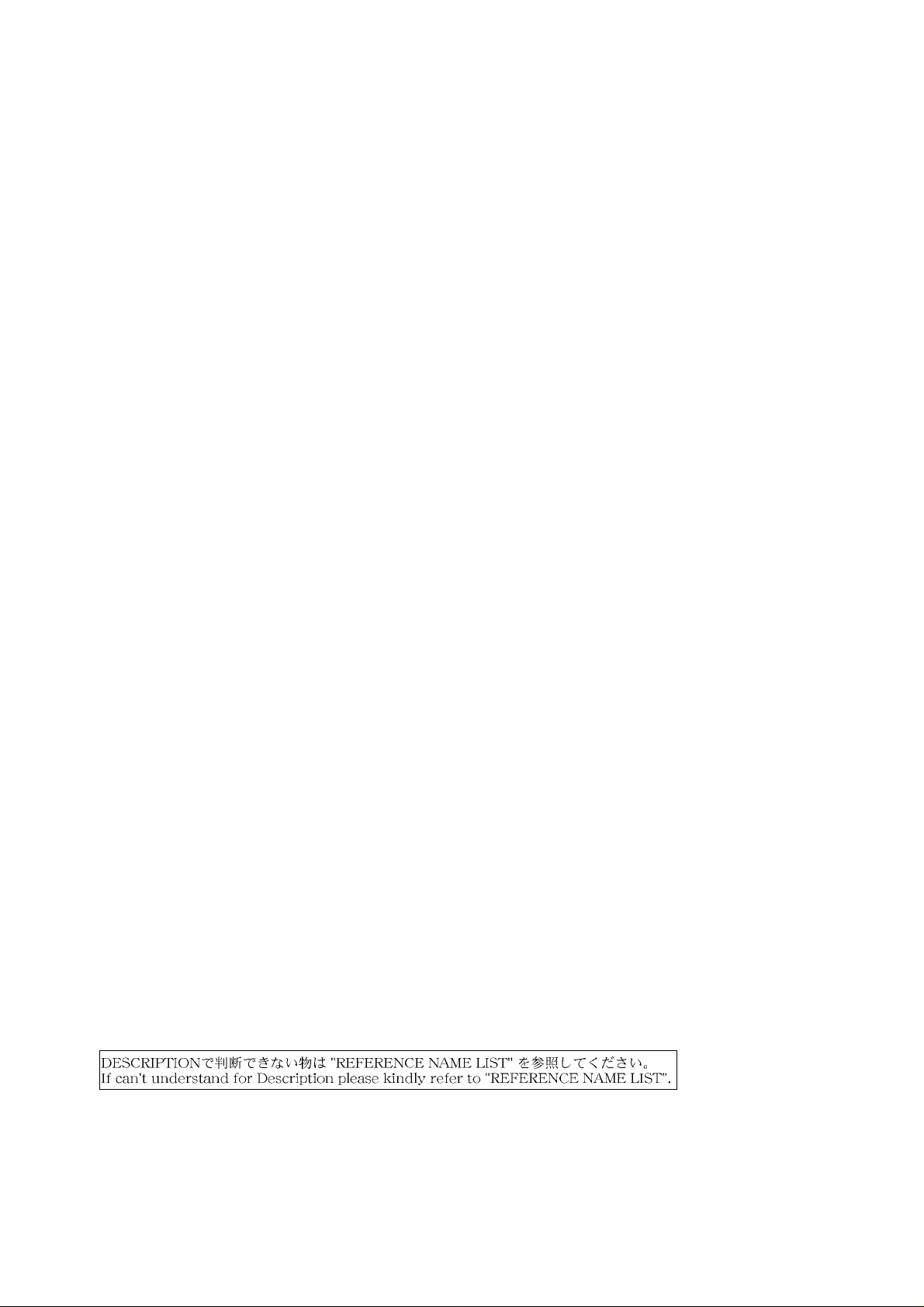

SERVICE POSITION

MAIN C.B

D33 MECHANISM

SPACER

60mm

MAIN C.B

D33

MECHA

SPACER

REAR PANEL

Use a spacer with a diameter of 10-15 mm,

and of any shape (round, square, etc.).

Caution: The spacer must be of insulated

material, of a size that does not hinder

the mechanism loading.

Side view

To set the mechanism to the service position in active status:

Insert a spacer as shown below: The service position can be set in the stable status without any defective contact.

Location

Install spacers at locations (A) and (B).

A

D33 Mechanism Top View

CYLINDER

B

HEAD CLEANER

5

Page 6

VCR TEST TAPE INTERCHANGEABILITY TABLE

There are two types of the new allgnment tape CH-1B (for NTSC) and CH-2 (for PAL). On each tape four signals (1)-(4)

are recorded for the times and in the order shown below.

(1) : 8min. → (2) : 2min. → (3) : 5min. → (4) : 5min.

The TTV-MP1 (for M-PAL), TTV-MS1 (for MESECAM) and TTV-S1 (for SECAM) allgnment tapes have the same

contents as the previous tapes.

Method

NTSC

Now in use TYPE

Model Contents *1

TTV-N1

TTV-NS1

TTV-N1E

TTV-NS6E

TTV-N2

TTV-N12

(SCV-1998)

TTV-N6

(TTV-N06T)

TTV-N7A

NTSC, Color bar,

1 kHz, SP

NTSC, Color bar,

1 kHz, SP

NTSC, Color bar,

1 kHz, EP

NTSC, Color bar,

No sound, EP

NTSC, Stairsteps,

7 kHz, SP

NTSC, Color bar,

1 kHz, SP

NTSC, Mono scope,

7 kHz, SP

NTSC, Stairsteps,

1 kHz, SP, HiFi 400 Hz

New TYPE

Model Contents *1

CH-1B(2)

CH-1B(4)

*2

CH-1B(1)

CH-1B(4)

CH-1B(3)

NTSC, Stairsteps,

1 kHz, SP

No Changed.

NTSC, Color bar,

1 kHz, EP

No Changed.

NTSC, Stairsteps,

7 kHz, SP

NTSC, Color bar,

1 kHz, EP

No Changed.

NTSC, Color bar,

No sound SP,

HiFi 400 Hz

Application

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

For S-VHS (SQPB) check

Switching position ADJ.

For S-VHS (SQPB) check

Head ACE Azimuth ADJ.

FM Envelope ADJ.

X-V alue ADJ.

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

Switching position ADJ.

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

Switching position. (LP Model)

FM Envelope ADJ. (LP Model)

X-Value ADJ. (LP Model)

HEAD ACE Azimuth ADJ.

FM Envelope ADJ. (SP Model)

X-Value ADJ. (SP Model)

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

FM Filter ADJ.

PAL

TTV-P1

TTV-P1L

TTV-P2

TTV-P6

(TTV-N06T)

TTV-P7

TTV-P16

PAL, Color bar,

1 kHz, SP

PAL, Color bar,

1 kHz, LP

PAL, Stairsteps,

6 kHz, SP

PAL, Monoscope,

6 kHz, SP

PAL, Stairsteps,

1 kHz, SP,

HiFi 1 kHz

PAL, Color bar,

400 Hz,

SP, HiFi 1 kHz

CH-2 (2)

* 3

CH-2 (4)

CH-2 (1)

CH-2 (3)

PAL, Stairsteps,

1 kHz, SP

PAL, Color bar,

1 kHz, LP

PAL, Stairsteps,

6 kHz, SP

No Changed.

PAL, Color bar,

No sound

SP, HiFi400 Hz

No Changed.

* 1. Described in the order of color format. video signal. linear audio. tape speed and Hi-Fi audio.

* 2. Use CH-1B (1)-(3) with models used exclusively in the SP mode.

* 3. Use CH-2 (3) and (4) when it is necessary to observe the chroma signal.

6

Page 7

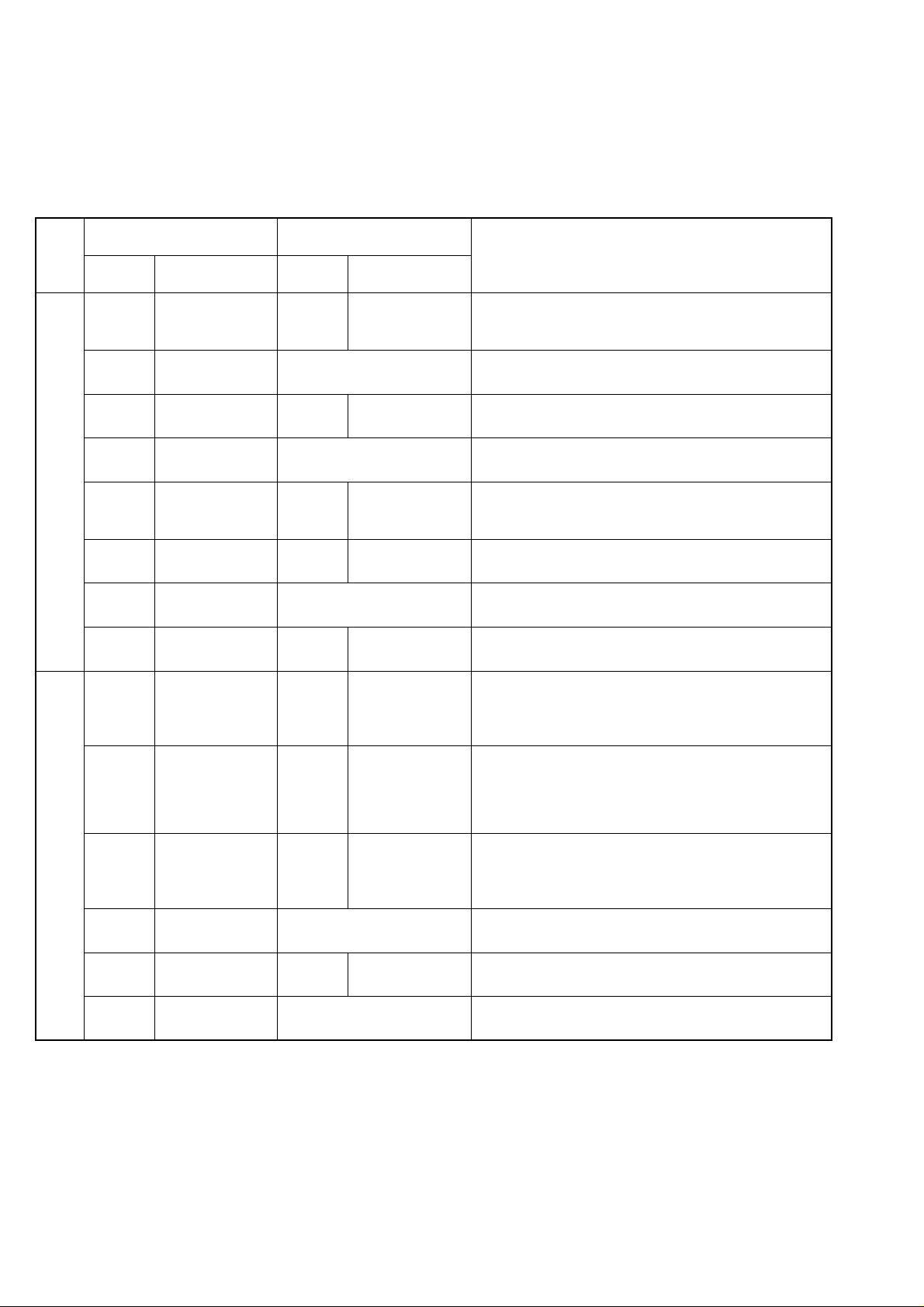

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

SI-SS4-310-00A IC,KA431AZ

SI-SK6-153-00A IC,STR-G6153T 5P

! S2-309-024-040 SENSOR LTV-817B PHOTO COU

! S6-570-62B-000 SENSOR PC123Y

SI-KE4-310-00A IC,KIA431 3P

SI-TO1-238-00A IC,TA1238N

SI-SA7-159-10A IC,LA71591M

SI-GS3-977-57B IC,GMS3977RAA57F

SI-HI3-977-17A IC,HD3977RC17F

SI-SS3-082-00A IC,KA3082

SI-AL2-416-00B IC,AT24C16-10PC

SI-SS7-531-00A IC,KA7531Z

SI-KE7-031-00A IC,KIA7031P

SI-SS7-542-00A IC,KA7542Z

87-001-196-010 IC,KIA7042P

87-A20-281-010 IC,MN12510

87-A21-261-010 IC,MSP3417D

SI-SA7-479-30A IC,LC74793

SI-PH9-605-00A IC,TDA9605H

SI-RH7-635-00A IC,BH7635S

TRANSISTOR

ST-R31-990-9AF TR,KTC3199-BL

ST-R10-300-9AE TR,KRC103M

ST-R32-030-9AA TR,KTC3203-Y

S7-A30-293-010 TR,KTC2804-Y

ST-R31-980-9AC TR,KTC3198-TP-BL

S3-1KR-A10-3M0 TR,KRA103M-TP

ST-R70-900-9AE TR,KSA709C-Y

ST-R12-680-9BA TR,KTA1268-BL

ST-R12-730-9AA TR,KTA1273-TP-Y

SK-RC1-01M-000 TR,KRC101M

ST-R12-670-9AC TR,KTA1267-GR

DIODE

SD-D01-000-9AC DIODE,EU01W

87-020-465-080 DIODE,1SS133

87-017-011-080 DIODE,IN4003A

83-NEG-677-080 DIODE,MTZ5.6B

87-070-173-010 DIODE,S1WBA60

SD-D01-000-9CA DIODE,EG01CW

87-A40-284-080 DIODE,ERA22-10

87-020-215-010 DIODE,ERC81-004L22

SD-R18-020-9AA DIODE,ERA18-02KFRB

87-070-112-060 DIODE,RU4YX-LF

87-A40-345-080 ZENER,MTZ10-C

SM-TZ6-8CT-000 ZENER,MTZ6.8C

83-NEG-678-080 ZENER,MTZ6.2B

87-002-743-080 ZENER,MTZ33B

SD-Z51-000-9HA ZENER,MTZ5.1B 0.5W

SD-Z13-000-9AA ZENER,MTZ13A

MAIN C.B

!C101 S6-240-88F-000 CAP,0.1UF-275V

!C102 S6-240-88F-000 CAP,0.1UF-275V

C103 S0-2TF-H68-0M0 CAP,E 68U-400V

!C105 87-016-375-010 CAP,0.01UF-630V

!C106 S6-240-87B-000 CAP,100P-1KV

C109 87-010-982-040 CAP,E 33UF-25V

!C112 87-012-379-010 CAP,3300PF-400V

!C113 SA-1B3-0KH-2M0 CAP,220PF-400V

C115 87-010-408-040 CAP,E 47UF-50V

C116 87-010-237-910 CAP,E 1000UF-16V

C117 87-016-577-080 CAP,E 470UF-16V

C118 87-010-248-080 CAP,E 220-10V

NO.

REF. NO PART NO. KANRI DESCRIPTION

C119 87-010-408-040 CAP,E 47UF-50V

C120 87-010-387-010 CAP,E 470UF-25V KME

C121 87-010-387-080 CAP,E 470UF-25V

C123 87-010-078-080 CAP,E 47M-6.3V

C124 87-010-552-040 CAP,E 22-16V

C151 87-015-698-080 CAP,E 4.7-50V

C152 87-015-698-080 CAP,E 4.7-50V

C153 87-015-698-080 CAP,E 4.7-50V

C156 87-015-681-080 CAP,E 10-16V

C157 87-015-681-080 CAP,E 10-16V

C159 87-015-681-080 CAP,E 10-16V

C201 87-010-402-040 CAP,E 2.2-50V

C203 87-010-400-080 CAP,E 0.47-50V

C206 87-010-400-080 CAP,E 0.47-50V

C208 87-015-681-080 CAP,E 10-16V

C210 87-010-078-080 CAP,E 47M-6.3V

C213 87-010-402-040 CAP,E 2.2-50V

C303 87-015-695-080 CAP,E 1.0-50V

C304 87-016-088-040 CAP,E 220-6.3V

C310 87-015-698-080 CAP,E 4.7-50V

C315 87-015-681-080 CAP,E 10-16V

C316 87-015-681-080 CAP,E 10-16V

C318 87-010-402-040 CAP,E 2.2-50V

C320 SC-N10-50K-948 CAP,1UF-50V

C322 87-010-078-080 CAP,E 47M-6.3V

C323 87-010-078-080 CAP,E 47M-6.3V

C325 SC-N10-50K-948 CAP,1UF-50V

C326 87-015-681-080 CAP,E 10-16V

C327 SC-N10-50K-948 CAP,1UF-50V

C331 87-016-088-040 CAP,E 220-6.3V

C334 87-016-088-040 CAP,E 220-6.3V

C337 87-015-698-080 CAP,E 4.7-50V

C339 87-015-698-080 CAP,E 4.7-50V

C346 87-016-088-040 CAP,E 220-6.3V

C348 87-015-695-080 CAP,E 1.0-50V

C354 87-016-088-040 CAP,E 220-6.3V

C358 87-015-695-080 CAP,E 1.0-50V

C401 87-010-078-080 CAP,E 47M-6.3V

C405 87-015-681-080 CAP,E 10-16V

C406 87-015-681-080 CAP,E 10-16V

C415 87-010-552-040 CAP,E 22-16V

C420 87-010-408-040 CAP,E 47UF-50V

C423 87-015-698-080 CAP,E 4.7-50V

C466 87-010-403-040 CAP,E 3.3-50V

C4A1 87-010-552-040 CAP,E 22-16V

C500 87-016-455-080 CAP,E 470UF-6.3V

C502 87-010-078-080 CAP,E 47M-6.3V

C504 87-016-088-040 CAP,E 220-6.3V

C505 87-010-078-080 CAP,E 47M-6.3V

C524 87-010-265-080 CAP,E 33-16V

C525 87-015-684-080 CAP,E 47-16V

C526 87-016-130-080 CAP,47-25V

C530 87-015-681-080 CAP,E 10-16V

C534 87-015-698-080 CAP,E 4.7-50V

C535 87-015-698-080 CAP,E 4.7-50V

C541 87-015-698-080 CAP,E 4.7-50V

C546 87-015-684-080 CAP,E 47-16V

C561 87-010-078-080 CAP,E 47M-6.3V

C588 87-015-698-080 CAP,E 4.7-50V

C5F7 87-010-078-080 CAP,E 47M-6.3V

C5F8 87-010-078-080 CAP,E 47M-6.3V

C701 87-015-698-080 CAP,E 4.7-50V

C702 87-015-681-080 CAP,E 10-16V

C703 87-015-681-080 CAP,E 10-16V

C704 87-010-078-080 CAP,E 47M-6.3V

C706 87-016-577-080 CAP,E 470UF-16V

C7S1 87-010-265-080 CAP,E 33-16V

C7V1 87-015-684-080 CAP,E 47-16V

C7V2 SC-N10-50K-948 CAP,1UF-50V

C7V6 87-015-698-080 CAP,E 4.7-50V

NO.

7

Page 8

REF. NO PART NO. KANRI DESCRIPTION

C7V7 87-015-695-080 CAP,E 1.0-50V

C7V8 87-015-695-080 CAP,E 1.0-50V

C806 87-015-698-080 CAP,E 4.7-50V

C807 87-015-698-080 CAP,E 4.7-50V

C810 87-015-681-080 CAP,E 10-16V

C811 87-015-681-080 CAP,E 10-16V

C813 87-015-681-080 CAP,E 10-16V

C814 87-015-681-080 CAP,E 10-16V

C815 87-015-681-080 CAP,E 10-16V

C816 87-015-681-080 CAP,E 10-16V

C817 87-015-681-080 CAP,E 10-16V

C818 87-015-698-080 CAP,E 4.7-50V

C819 87-015-681-080 CAP,E 10-16V

C821 87-015-684-080 CAP,E 47-16V

C822 87-015-681-080 CAP,E 10-16V

C823 87-015-681-080 CAP,E 10-16V

C824 87-015-681-080 CAP,E 10-16V

C825 87-015-684-080 CAP,E 47-16V

C827 87-015-681-080 CAP,E 10-16V

C828 87-015-684-080 CAP,E 47-16V

C832 87-010-078-080 CAP,E 47M-6.3V

C835 87-010-400-080 CAP,E 0.47-50V

C902 87-016-577-080 CAP,E 470UF-16V

C912 87-016-577-080 CAP,E 470UF-16V

C941 87-015-681-080 CAP,E 10-16V

C942 87-010-132-080 CAP,E 1.0-50V

C948 87-015-681-080 CAP,E 10-16V

C950 87-015-681-080 CAP,E 10-16V

C951 87-015-684-080 CAP,E 47-16V

CS501 S6-00R-DB0-04B SW SPPB62042 5V

CS501 S6-00R-DB0-04C SW,MPU10252MLB4 MIC

DIG5F1 S3-02R-1N0-03A DH 9MT168GK

DIG5F1 S3-02R-2N0-03A DH SVV09MM14

ES501 S9-31R-001-6A0 SENSOR END

ES502 S9-31R-001-6A0 SENSOR END

!F101 S5-850-11T-000 FUSE,1600MA 250V

!F101 S5-850-11C-000 FUSE,T 1.6A 250V

!F103 87-001-196-010 ICP-N10 T104

!FH01 S5-860-08B-000 FUSE CLUMP

!FH02 S5-860-08B-000 FUSE CLUMP

JK901 S6-20R-M00-02A JACK 42P

JK902 S5-720-36H-000 JK BJP

!L102 S6-161-45H-000 FILTER SHT LFS2020V4-04350

!L102 S6-161-45J-000 FL BUJEON V-04350

L103 S6-330-88G-000 COIL,CHOCK TP 5MM

L104 S6-330-88G-000 COIL,CHOCK TP 5MM

L105 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L201 87-003-282-080 COIL,12 2.3-3.4-5

L301 87-005-196-080 COIL,10UH

L302 87-003-286-080 COIL,56 2.3-3.4-5

L303 87-003-148-080 INDUCTOR,33

L304 87-005-696-080 COIL,100UH

L307 87-005-696-080 COIL,100UH

L309 87-005-696-080 COIL,100UH

L401 87-003-145-080 INDUCTOR,8.2

L402 87-003-129-080 INDUCTOR,6800

L405 87-005-196-080 COIL,10UH

L502 87-005-696-080 COIL,100UH

L505 87-005-696-080 COIL,100UH

L506 87-005-686-080 COIL,15UH

L507 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L5S1 87-003-148-080 INDUCTOR,33

L701 87-005-696-080 COIL,100UH

L702 87-005-196-080 COIL,10UH

L703 87-005-196-080 COIL,10UH

L704 87-003-145-080 INDUCTOR,8.2

L7V1 87-005-696-080 COIL,100UH

L801 87-005-696-080 COIL,100UH

L802 87-005-696-080 COIL,100UH

L901 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

NO.

REF. NO PART NO. KANRI DESCRIPTION

L902 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L904 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L905 S6-360-04C-000 COIL,BFS3550R2FD8

L906 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L907 S6-360-04C-000 COIL,BFS3550R2FD8

L911 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L912 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L914 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L916 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L924 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L926 87-003-152-080 INDUCTOR,100M 2.3-3.4-5

L941 87-005-696-080 COIL,100UH

LD501 S9-31R-001-7A0 LED

MS501 S6-00R-PY0-01B SW,MMS00420ZMBO MIC

P3D01 S5-612-34Y-000 CONN,6P

P3D02 S6-30R-5S0-08E CONN,6P

P3D03 S5-612-51B-000 CONN,2P

PM701 S6-724-43B-000 CONN,6P

PM702 S5-618-43J-000 CONN,9P

PMC01 S6-30R-2P0-05C CONN,8P

PMD01 S5-612-34V-000 CONN,7P

PMK01 S6-724-34B-000 CONN,5P

PMK02 S5-618-43J-000 CONN,10P

PML01 S6-30R-2S0-11A CONN,2P

PML01 S6-30R-2S0-11A CONN,2P

!PW101 S5-612-92B-000 CONN,2P

R101 S6-140-07R-000 RES,2.7-2W

R102 SR-S10-03K-619 RES,100K-2W

R109 SR-S03-50K-619 RES,0.35-2W

R/C5F1 S7-12R-293-8GA REMOCON RECEIVER

RS501 S5-00R-AB0-02A SENSOR GP1S566

RS502 S5-00R-AB0-02A SENSOR GP1S566

!T101 S6-420-23M-000 TRANS EER2828

TL401 S6-330-32K-000 COIL,OSC BIAS 1CHIP 5V

TU701 S7-00R-P3L-02A TUNER TADC-S003D LGC&N BG SECA

VR501 S6-130-32W-000 SFR,RH0638CJ5R(220K)

X201 S2-02R-142-8BE X’TAL,4.286230MHZ

X201 S2-02R-142-8AC X’TAL,4.286M 16PF

X301 S2-02R-144-3AD X’TAL,4.433709M

X301 S2-02R-144-3AC X’TAL,4.433709M

X301 S2-02R-144-3AE X’TAL,4.433709MHZ 15PPM

X501 S2-02R-310-01F X’TAL,10.0000

X501 S2-02R-310-01E X’TAL,10.0000MHZ

X502 S5-290-01B-000 X’TAL,32.768KHZ

X502 S5-290-01K-000 X’TAL,32.768KHZ

X503 S2-02R-317-71F X’TAL,17.7344

X503 S2-02R-317-71E X’TAL,17.734476MHZ

X5F1 S6-180-10B-000 X’TAL,4MHZ

X7V1 S2-02R-317-71F X’TAL,17.7344

X7V1 S2-02R-317-71E X’TAL,17.734476MHZ

NICAM C.B

C752 87-015-684-080 CAP,E 47-16V

C753 87-015-684-080 CAP,E 47-16V

C760 87-015-684-080 CAP,E 47-16V

C761 87-010-403-040 CAP,E 3.3-50V

C763 87-015-681-080 CAP,E 10-16V

C765 87-015-684-080 CAP,E 47-16V

C773 87-015-681-080 CAP,E 10-16V

C774 87-015-681-080 CAP,E 10-16V

C775 87-015-681-080 CAP,E 10-16V

C776 87-015-681-080 CAP,E 10-16V

L752 87-005-696-080 COIL,100UH

L753 87-005-696-080 COIL,100UH

L754 87-003-129-080 INDUCTOR,6800

L755 87-003-129-080 INDUCTOR,6800

P7M51 S5-618-48D-000 CONN,6P

P7M52 S5-618-48F-000 CONN,9P

X751 S5-290-219-000 X’TAL 18.432MHZ

NO.

8

Page 9

REF. NO PART NO. KANRI DESCRIPTION

FRONT-1 C.B

PMK02 S5-618-44J-000 CONN,10P

SW5A1 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A2 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A3 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A4 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A5 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A6 S5-562-82C-000 SW,SKQNQED ALPS 5MM

FRONT-2 C.B

LD5A1 SD-L53-110-0AA LED,SG5311(GRN)

PMK01 S5-610-36D-000 CONN,5P

SW5A0 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A7 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A8 S5-562-82C-000 SW,SKQNQED ALPS 5MM

SW5A9 S5-562-82C-000 SW,SKQNQED ALPS 5MM

NO.

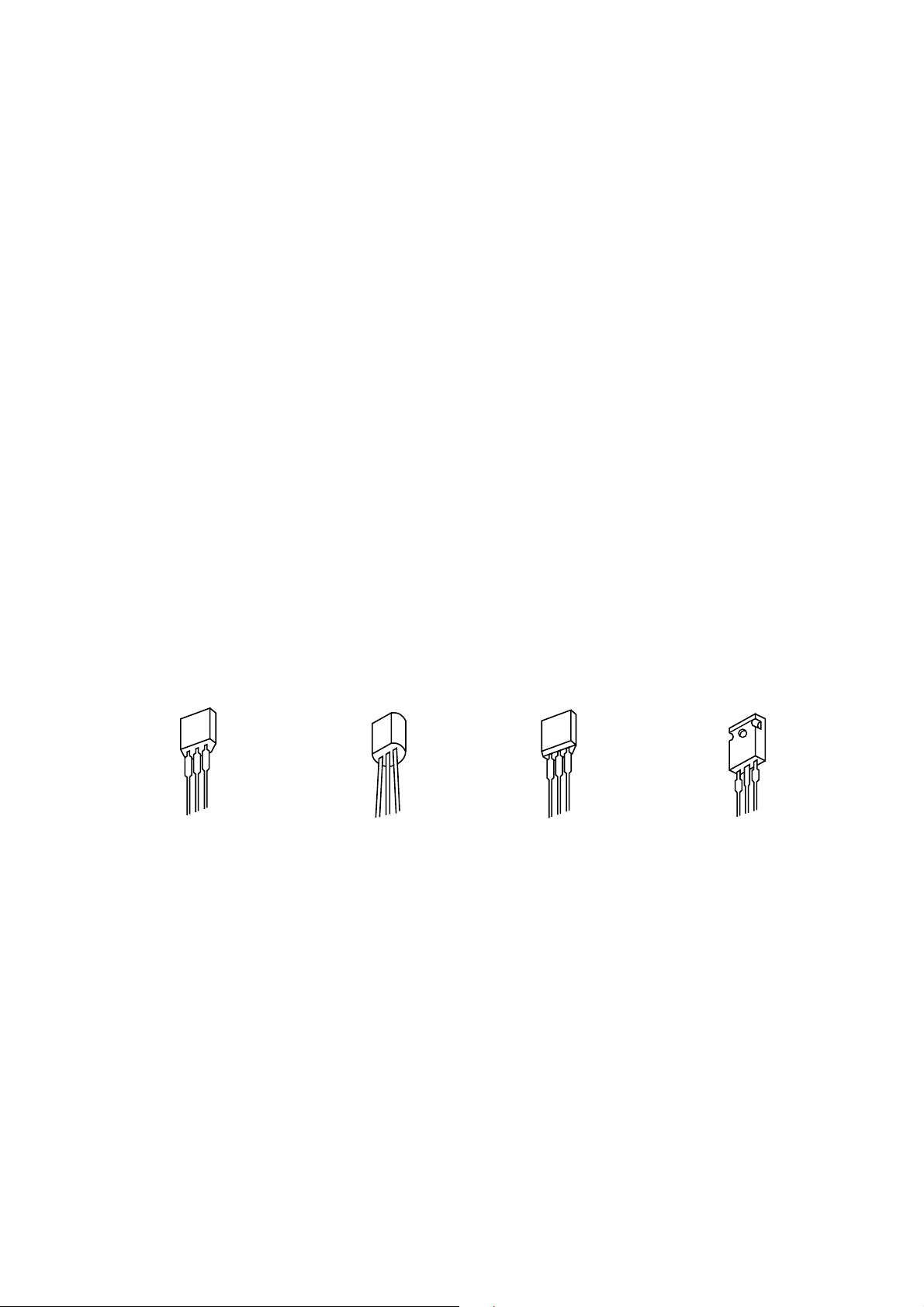

TRANSISTOR ILLUSTRATION

E C B

KRA103M

KRC101M

KRC103M

KTA1267

KTC3198

KTC3199

E C B

KSA709

KTA1268

KTC3203

E C B

E C B

KTA1273 KTC2804

9

Page 10

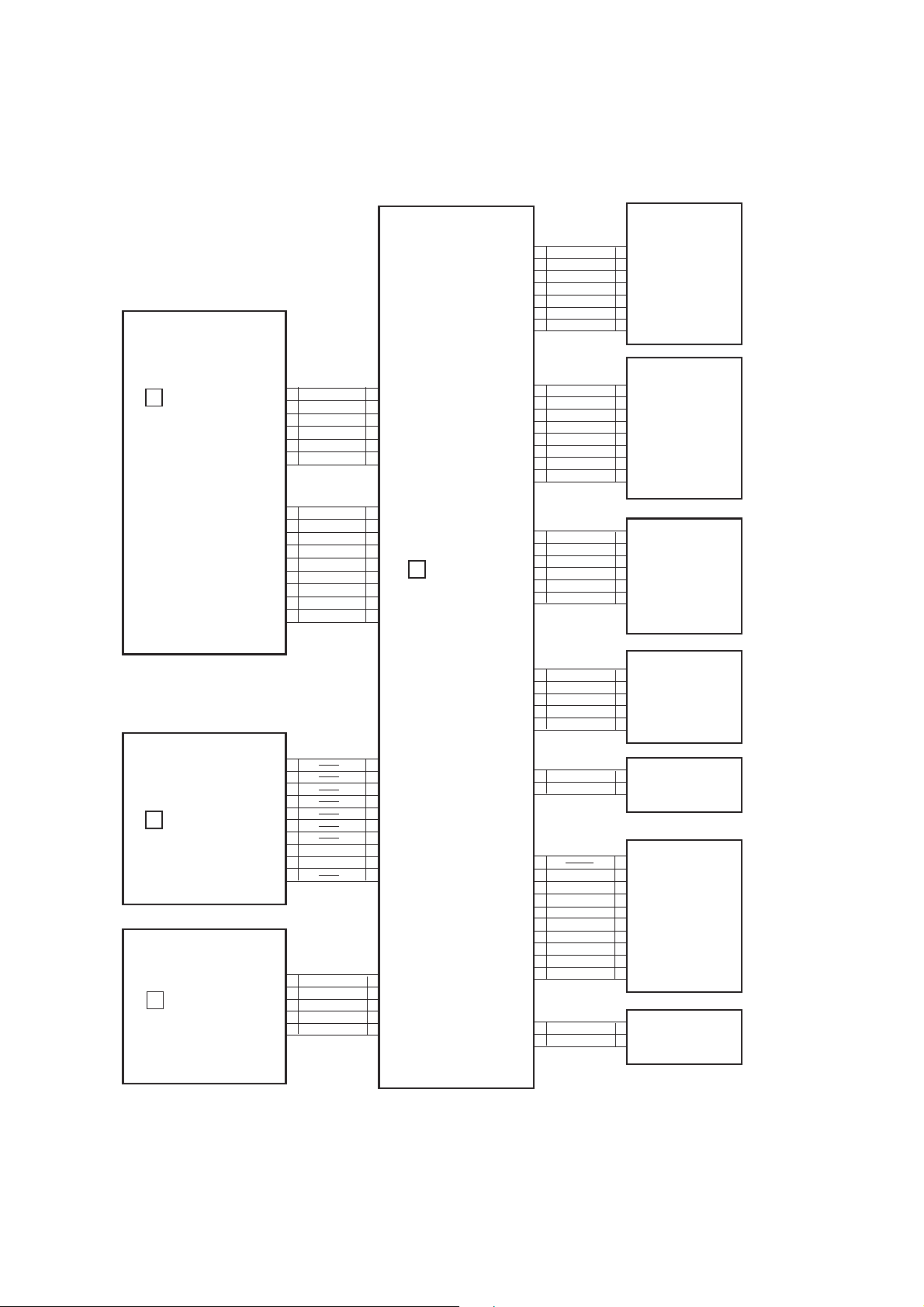

WIRE HARNESS DIAGRAM

B NICAM C.B

P7M51 PM701

5V

MONO AUDIO

GND

SIF

GND

GND

P7M52 PM702

1

GND

2

GND

3

GND

4

TU AUDIO (R)

5

GND

6

TU AUDIO (L)

7

9V

8

IIC CLOCK

9

IIC DATA

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

A MAIN C.B

PMD01 PMD01

D.CTL

1

M.GND

2

DFG

3

12V

4

PG

5

GND

6

5.3V

7

PMC01 PCM01

GND

1

MOTOR GND

2

I-LIMIT

3

CAP CTL

4

12V

5

CFG

6

CAP REV "L"

7

5.3V

8

P3D02 P3D02

CTL(+)

1

CTL(-)

2

A/E(-)

3

A/E(+)

4

A.REC

5

A.PB

6

MS501

GND

1

MODE S1

2

MODE S2

3

MODE S3

4

MODE S4

5

1

2

LOWER

3

4

DRUM

5

6

7

1

2

3

4

CAPSTAN

5

MOTOR

6

7

8

1

2

3

ACE

4

HEAD

5

6

1

2

MS501

3

MODE SW

4

5

C FRONT1 C.B

D FRONT2 C.B

PKM02 PMK02

1

2

3

4

5

6

7

8

GND

9

KEY RTN0

10

PKM01 PMK01

GND

1

OTB "H"

2

5.3VA

3

GND

4

KEY RTN1

5

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

P3D03 PD303

12GND

FULLERASE12

P3D01 P3D01

1

2

Hi-Fi A PB

3

Hi-Fi REC

4

Hi-Fi B PB

5

SP A PB

6

SP REC

7

SP B PB

8

LP A PB

9

LP REC

10

LP B PB

PML01 PML01

12LD(+)

LD(-)12

FULL ERASE

HEAD

1

2

3

4

CYL.

5

HEADS

6

7

8

9

10

LOADING

MOTOR

10

Page 11

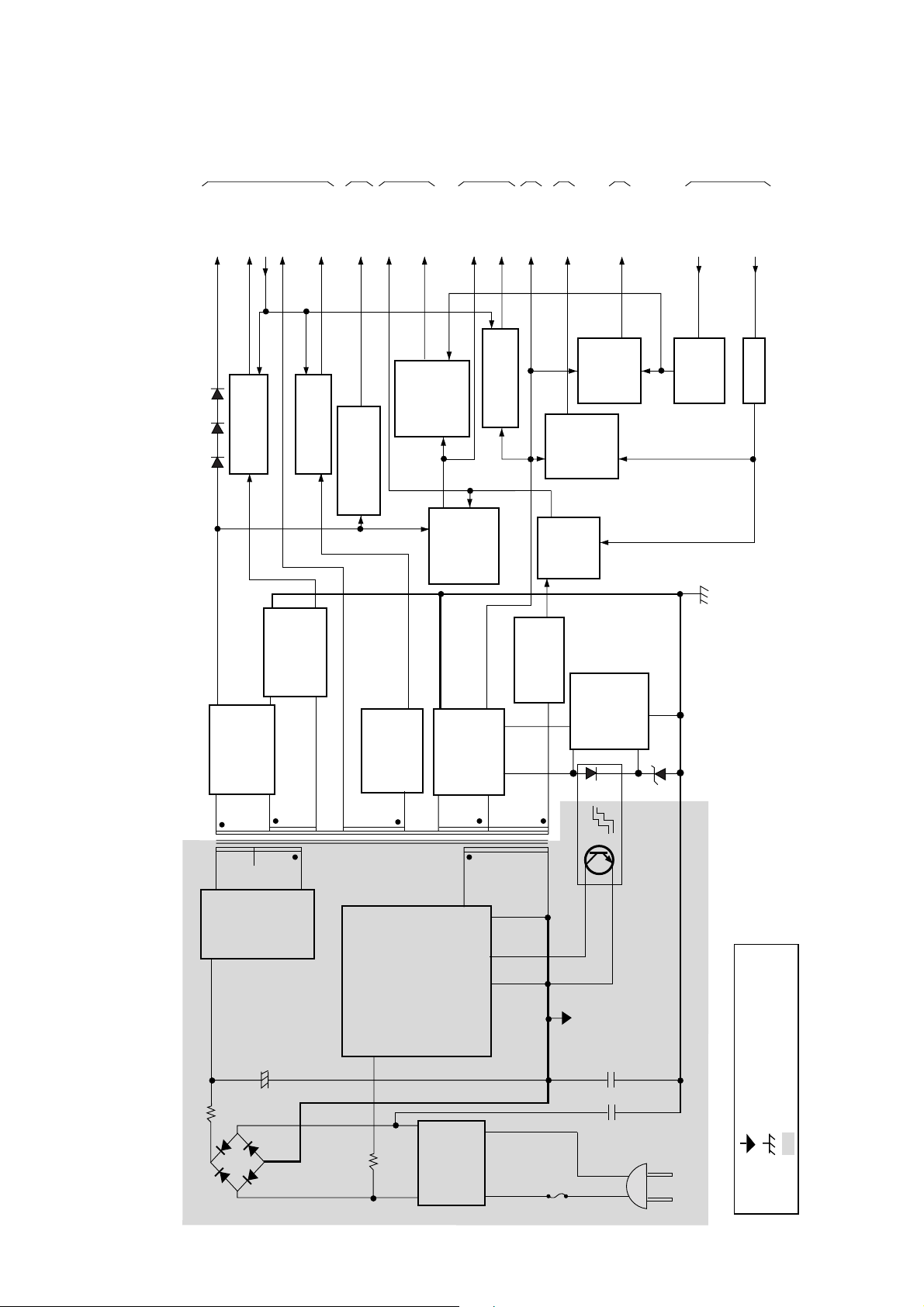

BLOCK DIAGRAM-1 (POWER SECTION)

FROM/TO

SYSCON/SERVO

SECTION

TO

Hi-Fi SECTION

TO

TUNER/IF

SECTION

TO

SYSCON/SERVO

SECTIONTOSYSCON/SERVO,

TUNER/IF SECTION

TO

SYSCON/SERVO,

TUNER/IF,AUDIO/VIDEO

SECTIONTOSYSCON/SERVO,

TUNER/IF,AUDIO/VIDEO,

Hi-Fi SECTION

FROM

SYSCON/SERVO

SECTION

12.5VA

D152 D154 D155

FD(-)

-27VA

STAND-BY "H"

-27VG S/W BLK

(Q154,R164,R165,Q155)

FD(+) REG BLK

(D108, C119)

RECTIFIER

& SMOOTHING

33V

12VA

FD(+)

9V REG.

(Q156,Q157,R166,R167)

12VA REG.

BLOCK

(Q151,R151, ZD151, C151)

9V

BLOCK

(Q152,R152,

Q165,C153,

12VT REG.

12V(DRUM)

ZD152)

BLOCK

(Q153,C152

R171, ZD153)

5.3VA

5VG

5VG SW BLK

(Q164,R169,R170)

36V S/W

RECTIFIER

& SMOOTHING

5VT

BLOCK

5VT SW

BLOCK

(Q158,R154,

(D105, C115)

5V

BLOCK

(Q159, R158,

R159)

5V S/W

(Q162, R161,

R162)

R155)

P.CTL"H"

(Q161)

PWR CTL

BLOCK

FROM µ-COM

Q160

RECTIFIER

& SMOOTHING

9

T101

6

TRANSFORMER

SNUBBER

R101

1

4

2

BD101

(D109, C120,

L104,C121)

10

(D102,R104,

BLOCK

C103

+

3

11

4

C105,C106)

(D107, F103,

C118)

RECTIFIER

& SMOOTHING

7

8

DRIVE & S/W BLOCK

OVER CURRENT LIMIT

BLOCK

R102

LINE FILTER

(D106, C116,

RECTIFIER

(IC101,R109,C111,

BLOCK

L103,C117)

& SMOOTHING

12

2

D104,R103,C109)

C102)

(C101,L102,

FEED-BACK

BLOCK

(R116,R117,R118

R119,R120,R121

C114)

1

13

13

1

4

HOT GND

F101

IC103

2

IC102

3

C112

Hot Circuit

Symbol denotes DC chassis ground.

C113

WH

(BL)

BK

PW101

(BR)

NOTES: Symbol denotes AC ground.

11

Page 12

BLOCK DIAGRAM-2 (VIDEO SECTION)

PB MODE

5974 57 54 52 51 61 72 71

MAIN

CONV

IC301

LA71591M

VIDEO/AUDIO

PROCESSOR

FM

DEM

DOUBLE

LIMIT

SUB

LPF

LP 'A' PB

LP 'B' PB

SP 'B' PB

FROM

CYL.HEADS

SP 'A' PB

V. ENV

TO

SYSCON/SERVO

SECTION

82

85

88

91

ENV.

93

DET

10 18 17 21 20 23 24 28 29

ACC

C LPF

PB FM

AGC

PB EQ

11

Q304

C. COMB LPF

YNR

LPF

CLAMP

NL

DE EMP

Y

DELAY

Y/C

MIX

60dB AMP

46

45

43

41

15 21

IC201 TA1238N

Q303

:PB CHROMA SIGNAL

:PB Y SIGNAL

REC MODE

LP REC

SP REC

TO

CYL.HEADS

COLOR

ROTARY

FROM

SYSCON/SERVO

SECTION

IC 301

LA71591M

VIDEO/AODIO

PROCESSOR

84

90

V.H S/W

PB

PEAKING

Q301

MAIN

DE-EMPH

Q302

Q304

71 72 61 51 52 54 57 59

C. COMB

BPF

COMB

AMP

CCD

LPF

+

DETAIL

ENH

REC FM

EQ

NL EMPH

FM

MOD

W/D

CLIP

CLOCK DATA C SYNC

FROM/TO

SYSCON/SERVO

SECTION

BPF1

YNR

Y-LPF

FBC

Y/C

VIDEO

Q305

Y

DELAY

AGC

V. OUT

VPS

S/W

46

45

43

41

38

32

31

Q201

Q303

V. IN 1

12

IC201

TA1238N

24

FROM

Hi-Fi

SECTION

COLOR

V. H S/W

ROTARY

FROM

SYSCON/SERVO

SECTION

MAIN

EMPH

R308,R309,

C309,C363

12

2120

MAIN

DE-EMPH

Q302

CLOCK

DATA

FROM/TO

SYSCON/SERVO

SECTION

3028242319181110

:REC CHROMA SIGNAL

:REC Y SIGNAL

C. SYNC

REC 'H'

Page 13

BLOCK DIAGRAM-3 (TUNER/IF, NICAM, A2 SECTION)

4

6

7

8

9

4

6

7

8

9

TU AUDIO(R)

TU AUDIO(L)

9V

IIC CLOCK

IIC DATA

1

2

4

1

2

4

5V

MONO AUDIO

SIF

123456789101112

24 23 22 21 20 19 18 17 16 15 14 13

1

25

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

BB

NC

AUDIO

SDA

4MB

SCL

VIDEO

MD TU

RF AGC

NC

AS

SCL

SDA

B+

B+

NC

TU

TP

IF

SW 1

SW 2

AUDIO

SIF

AFT

VIDEO

1B

2B

3B

4B

5B

1E

2E

4E

5E

1H

2H

3H

4H

5H

6H

7H

8H

5.3VA

9V

5VT

33VT

5V

TU AUDIO(L)

TU AUDIO(R)

VIDEO

TU VIDEO

OSD VIDEO

IIC CLOCK

IIC DATA

TU SECVL "H"

IIC CLOCK

AFT

VIDEO(VPS)

TU SEC "H"

To

POWER

SECTION

To

Hi_Fi

SECTION

To

SYSCON/

SERVO

SECTION

PM701P7M51

PM702P7M52

C7V3 C7V4

X7V1

17.734476MHz

IC7V1

LC74793

VPS

Timing

Generator

V.Sync

Sep.

Sync

Detect

Sync Sep/

Data

Sucer

IIC BUS

Interface

AFC

(VCO)

Data

Latch

Data

Acousition

VDD2

VDD1 RST

VSS1

NC VSS2

A MAIN(TUNER/IF SECTION)C.B

:REC AUDIO SIGNAL

:PB AUDIO SIGNAL

:REC VIDEO SIGNAL

:PB VIDEO SIGNAL

TU701

ANTENA IN

ANTENA OUT

SECAM AGC

CONTROL

Q7S1

SECAM AGC

CONTROL

Q701

52 51 50 49 48 47 46 45 44 43 42 41 39 38 37 36 35 34 33 32 31 30 29 272840

1

NC

AUD CLK

C CTL 1

C CTL 0

ADR SEL

STANDBYQ

IIC CLK

IIC DATA

IIS CL

IIS WS

IIS DA OUT

IIS DA IN

ADR DA

ADR WS

ADR CLK

DVSSUP

DGND

IIS DA IN2

NC

RESETQ

DACA R

DACA L

VREF2

DACM R

DACM L

DACM SUB

SC2 OUT R

SC2 OUT L

VREF1

SC1 OUT R

SC1 OUT L

CAPL A

A8VSUP

CAPL M

AGND

AGNDC

SC3 IN L

SC3 IN R

SC2 IN L

SC2 IN R

SC1 IN L

SC1 IN R

VREF TOP

MONO IN

AGND

AVSUP

ANA IN1

ANA IN-

ANA IN2

TESTEN

IN

OUT

2 3 4 5 6 7 8 9 101112 1415161718192021222324 262513

PILOT

DETFMBLOCK

IIC BUS

INTERFACE

DEINTERLEAVING

NICAM DECODING

FRAME

SYNC

DQPSK

DECODER

PD

IIS1 BUS

INTERFACE

IIS2 BUS

INTERFACE

DECIMATION SHAPING

FILTER

GEN2

MIXER

GEN1

A/D

LEVEL

CTL

TIMING

RECOVERY

AUDIO

PLL

INPUT

SELECT

A/D

7-LINE

I/P

SELECT

DEEMPHASIS

S-BUS

INTERFACE

MATRIX

DAC

VOL

DAC

VOL

DAC

VOL

OVERSAM

FILTER

DAC

VOL

OVERSAM

FILTER

DAC

DAC

OUTPUT SELECT

D751

X751

18.432MHz

IC751IC751

MSP3415DMSP3415D

NICAM,A2NICAM,A2

B NAICAM C.B

:REC AUDIO SIGNAL

FILTER

FILTER

1413

Page 14

BLOCK DIAGRAM-4 (Hi-Fi/SCART SECTION)

A MAIN(Hi-Fi SECTION)C.B

1A

To

POWER

SECTION

To

A/V

SECTION

To

SYSCON/

SERVO

SECTION

To

TUNER/IF

SECTION

To

A/V

SECTION

12VA

5V

HF A PB

HF REC

HF B PB

A.H/SW

IIC DATA

IIC CLOCK

A.ENV.

TU AUDIO(L)

TU AUDIO(R)

VIDEO

TU VIDEO

AUDIO IN 1

MONO AUDIO

VIDEO IN 1

2A

1G

2G

3G

1J

2J

3J

4J

C801

1

1E

2E

4E

5E

5G

4G

6G

2

3

4

5

6

7

8

9

10

11

DCL

DCR

ZD801

44 34

INPUT

SELECT

43 42 41

2

I C

HF

LPF

HF

LPF

DCL

DCR

12 2213 14

A.H/SW VCCH GNDH

PLL 1.7M

CCO

NOISE

SUPPR.

PEAK

HOLD

40 39 38 37 36 35

DOC

NOISE

SUPPR.

NOISE

REDUCTION

LINE

SELECT

LEVEL DET.

HF LIMITER

LEVEL DET.

HF LIMITER

AUDIO

CLIPPER

OUTPUT

SELECT

1.3M

BPF

1.7M

BPF

DEC.

SELECT

HF

AGC

PLL 1.3M

CCO

AUDIO

CLIPPER

NOISE

REDUCTION

15 16 17 18 19 20 21

NORMAL

SELECT

IC801

TDA9605H

VHS Hi-Fi AUDIOVHS Hi-Fi AUDIO

PROCESSORPROCESSOR

VCC

ZD802

Vref

Lref

GND

JK902

AUDIO

OUT(R)

AUDIO

OUT(L)

C827

10/16

33

R822

C826

33K

R821

2.7K

C825

47/16

C824

10/16

C823

10/16

R820

R819

2.7K

R818

33K

39K

C822

10/16

C821

47/16

C819

10/16

6800P

C820

6800P

32

31

30

29

28

27

26

25

24

23

L907

L905

BEAD

BEAD

JK901

SCART1

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

5

3

1

42

40

38

36

34

32

30

28

26

24

22

AV1 IN/OUT (TV)

6

4

2

JK901

SCART2

41

39

37

35

33

31

29

27

AV2 IN (DECODER)

25

23

:PB VIDEO SIGNAL

:REC VIDEO SIGNAL

: VIDEO SIGNAL

:PB AUDIO SIGNAL

:REC AUDIO SIGNAL

IC901

BH7635S

13 24

14 15 16 17 18 19

IC-BUS

CONT.

5V

REG

12 1

11109876

20 22 2321

VCC

CLAMP CLAMP CLAMP

GND

VCC

532

4

CLAMP

GND

7J

C+ DET "H"

8J

9J

LV MT "L"

LV MT "R"

To

SYSCON/

SERVO

SECTION

ZD805

ZD806

1615

Page 15

BLOCK DIAGRAM-5 (Hi-Fi PB SECTION)

FROM

CYL.HEADS

HI-FI A

HI-FI B

AUDIO

REC/PB

HEAD

REC"H"

HI-FI S/W 25

AMP

35

37

AMP

41

AMP

IC801

TDA9605H

VHS Hi-Fi AUDIO

PROCESSOR

Q402

Q403

Q404

FROM/TO

SYSCON/SERVO

SECTION

HF

AGC

4

5

FROM

SYSCON/SERVO

SECTION

BPF

(L,R)

LP/EP

A.ENV

44 40 34

LEVEL

DET

HP

LIMITER

100

LINE

AMP

SERIAL

SERIAL

DECODER

DECOEDR

PLL

MUTE

SWITCH

NOISE

961

AUDIO

IC301

LA71591M

VIDEO/AUDIO

PROCESSOR

24

23

CLK

DATA

FROM

POWER

SECTION

5V 12VA

2

I C

CLOCK

434222

REDUCTION

LPF

DATA

FROM

SYSCON/SERVO

SECTION

NOISE

OUT SELECT

16

17

19

20

:PB AUDIO SIGNAL

JK902

A.OUT L

A.OUT R

EU1 A.OUT L

EU1 A.OUT R

EU2 A.OUT L

EU2 A.OUT R

TO

SCART 1,

SCART 2

BLOCK DIAGRAM-6 (Hi-Fi REC SECTION)

FROM

TUNER/IF

SECTION

FROM

SCART 1,

SCART 2

TU A.IN L

TU A.IN R

EU1A.IN L

EU1A.IN R

EU2A.IN L

EU2A.IN R

IC301

LA71591M

VIDEO/AUDIO

PROCESSOR

1

2

3

6

7

8

9

76

VOLUME

INPUT SELECT

EE

SELECT

NOMAL

ALC

IC801

TDA9605H

VHS Hi-Fi AUDIO

PROCESSOR

AUIDO

LPF

LINE

AMP

NOISE

REDUCTION

MUTE

98

AUIDO

CLIPPER

REC

AMP

FROM

POWER

SECTION

5V 12VA

40 34

CCO MIX

AUTO

BIAS

796

HF

LPF

99

6

CONTROL

Q401

BIAS

OSC

TL401

Q405

AUDIO

REC,PB

HEAD

CURRENT

AMP

2

I C

434221

DATA

CLOCK

FROM

SYSCON/SERVO

SECTION

:PB AUDIO SIGNAL

36

HF REC

TO

CYL.HEAD

1817

Page 16

BLOCK DIAGRAM-6 (SYSTEM CONTROL SECTION)

L/D MOTOR

MODE SW

5V

IN 1

67

ES502

END

IN 2

C528

(DRUM)

RC5F1

KA3082

VCC 1

VCC 2

89

12V

17.734MHz

P 2

10MHZ

32.768KHZ

VR501

PG ADJ

X503

R553

PML01

R555

RS502

SUP.REEL

GND

12345

1LD +

2LD -

MS501

GND

MODE S1

MODE S2

MODE S3

MODE S4

R550

LD501

DECK IR LED

Q515

R558

OUT 1

C529

R559

IC502

P 1

ZD501

1

2

3

4

5

R

V ret

ES501

T-UP END

R560

REMOCON

SENSOR

5.3VA

RS501

T-UP REEL

Q514

R

R556

D FRONT 2 C.B C FRONT 1 C.B

10

X501

X502

L506

R518

C518

C519

GND

FROM/TO DECK

FROM/TO

Hi-Fi

SECTION

FROM/TO

AUDIO/

VIDEO

SECTION

OUT 2

78

CFG

DPG

CAP ADJ

DRUM ADJ

IC501

HD3977

KEY RTN 0

CTL.GAIN ADJ

A.ENV

LEVEL METER 'L'

LEVEL METER 'R'

CTL1

CTL2

CTL3

34

CTL.

GAIN

ADJ

Q5A1

IIC CLK

A. H/SW

IIC DATA

C+ DET 'H'

S4/ FLD DATA OUT

CTL CONT.

Vcc(OSD)

Vcc(A/D)

15

90

IIC DATA

IIC CLK

S5/ FLD DATA IN

Vcc(SERVO)

V.ENV

V. H/SW

A.MUTE "H"

C.SYNC(NOR)

PWR CTL 'H'

REC 'H'

DV.SYNC

SECAM DET "H"

TIMER "H"

C.ROTARY

H AMP SW

COMP. IN

CVout

STAND-BY 'H'

C.SYNC(INV)

IIC DATA

IIC CLK

TU SEC "H"

TU SEC VL "H"

IIC DATA

IIC CLK

S7/ FLD ENV

S6/ FLD CLK

PWR FA

RESE

Vcc(SYS)

CVin

AFT

C501C506 C521C503

FROM/TO

91

12

24

62

54

60

79

27

6

66

28

29

30

43

45

88

9

87

81

90

63

18

91

90

94

97

96

95

89

16

C500C505

OUT

3

RESET

2

GND

VCC

1

POWER

SECTION

FROM/TO

TUNER/IF

SECTION

1234

IC503

AT24C16

EEPROM

5678

IC504

KIA703P

Q503

33 32 31 30 29 28 27 26 25 24 23

P3P2P1

34 P4

P5

35

P6

36

P7

37

P8

38

39

P9

P10

40

P11

41

P12

42

P13

43

44

P14

P15

1

234567891011

SHUTTLE4

SHUTTLE3

POWER LED

IC5F1

MN12510

LED DRIVE

P16NCNCG1G2G3G4

IC505

KIA7042P

VCC

GND

OUT

RESET

1

23

DATA OUT

SHUTTLE2

SHUTTLE1

CLK

ENA

DATA IN

VSS

OSC2

OSC1

VDD

VPP

G5

5VG

-27VG

G9

G8

G7

G6

22

21

20

19

18

17

16

15

14

13

12

X5F1 4MHz

OSC

Q501

L505

C561C554

R503

5V

5VT

FROM

POWER

SECTION

OSC

OSC

OSC

OSC

VCC

R526

R525

V OUT

321

31 32 61 78 26 25 38 39 40 80 81 11 23 21 90 91

CTL-

CTL+

19

LD(-)

LD(+)

20

MODE SW1

77

76

MODE SW2

75

MODE SW3

MODE SW4

74

72

OSC1

73

OSC2

70

X-TAL1

X-TAL2

69

END SENSOR

3

PG ADJ

10

1

T-UP SENSOR

5

SUPPLY REEL

T-UP REEL

4

4fsc out

52

4fsc in

53

51

DOSC OUT

DOSC IN

50

82 57 14 13 55 35 36 37 42 41 22

CS501

CST&REC SW

DFG

I - LIMIT

CAP PWM

DRUM PWM

CAP REV "H"

SYSCON/SERVO

PROCESS

R/C

CST SW 'H'

KEY RTN 1

REC P/STILL REW

FF PLAY STOP

CH-UP CH DOWN

ONE-TOUCH POWER

PLAYBACK

L502

5.3VA

2019

Page 17

SCHEMATIC DIAGRAM-1(POWER SECTION)

A MAIN(POWER SECTION)C.B

FH02

FH01

PW101

L102

33m

C101

F101

T1.6A/250V

POWER CORD

BD101

S1WBA60

BC101

BEAD CORE

C102

0.1

0.1

R101

2.7 2W

R102

100K 2W

5

Slort

VCC

Reg1(9.4V)

Reg2(7.2V)

Reg3(7.2V)

TSD

IC101

G-6153T

OVP

Counter

C103

68/400

C122

0.022

OSC

FB OCP

Mirror

FB Curent

Detector

FB

4

HOT CIRCUIT

Latch

S

RQ

D102

ERA22-10

EG01CW

Drive

R104

DROIN

Buffer

Amp.

56K

2W

GND

OCP

1

2

3

R109

0.35 2W

C105

0.01/630

C106

100P/1K

BC102

BEAD

R103

8.2

C109

33/25

IC102

PC123Y

or

LTB-8178

C111

0.022

T101

EER2828

4

D104

EU01W

2

1

41

IC103

KA431AZ

or

KIA431

C112

3300P

C113

220P

96

10

11

8

7

12

13

15

23

D109

RU4YXLF

D108

EU01W

F103

ICP-N10

D106

ERC81-004L

D105

EU01W

R117

2.2K

4.7 1/4W

D107

ERA18

C115

47/50

R116

R118

L104

22MH

C120

470/25

FR02

330

1K

C118

220/10

C116

1000/16

L103

22MH

C114

0.047

ZD151

MTZ13A

C121

470/25

C119

47/50

R151

1.2K

470/16

R119

3.3K

1%

R120

2.7K

1%

R121

180

R114

100K

C117

Q151

KTC3203Y

C151

4.7/50

Q153

KTC2804Y

C157

10/16

ZD153

MTZ13A

Q154

KTC3198BL

R164

12K

Q156

KTC3203Y

Q158

KTA1268BL or KSA709CY

R154

1K

R161

270

R158

270

R165

R166

2.2K

R155

27K

R162

330

Q162

KTA1273Y

Q159

KTA1273Y

R159

330

C152

4.7/50

R171

3.9K

12K

R167

2.2K

D151

1SS133

C159

10/16

KRC101M

D152

1N4003A

C153

4.7/50

Q155

KRA103M

R

KRA103M

R169

R

Q160

C123

47/6.3

R152

1.2K

ZD152

MTZ10C

L105

100M

Q157

R

1K

Q164

KTA1273Y

R156

10K

Q161

KTC3199BL

D154

1N4003A

KTC3203Y

ZD104

MTZ5.6B

Q152

R170

1K

R157

R

1K

D155

1N4003A

Q165

KRC101M

D153

T/W

C156

10/16

C155

0.1

C124

22/16

R172

12K

1B

2B

3B

4B

5B

6B

1A

2A

3A

1C

12.3V(CAP)

12V(DRUM)

2C

3C

4C

-21VG(F-)

5C

-15VG(F+)

6C

STAND-BY "H"

7C

8C

TIMER "H"

9C

10C

11C

PWR CTL "H"

12C

13C

1D

2D

3D

5.3VA

9V

5VT

33VT

5V

GND

12VA

5V

GND

-27VG

5VG

5VT

5V

5.3VA

GND

5VT

5V

GND

To

TUNER/IF

SECTION

1B 6B

To

Hi-Fi

SECTION

1A 3A

To

SYSCON/

SERVO

SECTION

1C 13C

To

A/V

SECTION

1D 3D

2221

Page 18

SCHEMATIC DIAGRAM-2 (AUDIO/VIDEO SECTION)

A MAIN(AUDIO/VIDEO SECTION)C.B

5VT

1D

5V

2D

GND

3D

To

POWER

SECTION

3D1D

REC "H"

H.AMP SW

C.ROTARY

A.MUTE "H"

V.H/SW

IIC DATA

IIC CLOCK

DV.SYNC

VIDEO(VPS)

VIDEO(Y/C)

SEC DET "H"

C.SYNC

COMP OUT

V.ENV

To

SYSCON/

SERVO

SECTION

16F3F

P3D01

Hi-Fi A PB

Hi-Fi REC

Hi-Fi B PB

SP A PB

SP REC

SP B PB

LP A PB

LP REC

LP B PB

To

CYL.HEADS

HF B PB

HF REC

HF A PB

MONO A.OUT

AUDIO IN1

VIDEO IN1

To

Hi-Fi

SECTION

CTL(-)

CTL(+)

To

SYSCON/

SERVO

SECTION

,

P3D02

AUDIO PB

AUDIO REC

A/E (+)

A/E (-)

CTL (-)

CTL (+)

To

CTL/AUDIO

HEADS

P3D03

F/E

GND

To

FULL

ERASE

HEAD

2.2K

R337

18K

79

29

28

62

24

91

90

27

6

54

30

C3A1

0.022

12

C367

0.022

Q3A2

KTC3199BL

R3A3

1K

C375

0.1

C320

1

REC "H"

79

Q405

KTC3203Y

R421

12 V.ENV

30

COMP.OUT

KTC3199BL

R431

4.7K

R410

10K

79

REC "H"

C419

2.2

Q3A1

C431

0.01

KTA1267GR

Q402

KTA1267GR

R411

22K

0.01

C373

R350

470

R420

L307

100uH

0.1

C408

0.015

L402

6800u

R407

22K

Q401

C4A1

22/16

1K

C418

0.015

C350

0.1

R333 560

R3A2

47K

R3B1

4.7K

R424 270

KTC3199BL

R408

2.2K

R409

4.7K

C346

220/6.3

C348

R403

6.8K

R404

270

R406

2.7K

Q403

L405

10uH

R419

47

C424

0.1

1/50

C302

0.1

C410

0.1

C412

KTC3199BL

0.1

3F

4F

5F

6F

7F

8F

9F

10F

11F

12F

13F

14F

15F

R3A1

16F

1

2

3

4

5

6

7

8

9

10

3G

2G

1G

4G

5G

6G

6G1G

1F

2F

2F1F

6

5

4

3

2

1

2

1

RF TP

IC301

LA71591M

VIDEO/AUDIO

PROCESSOR

0

81

H.A

GND

0

82

0

83

0.7

84

0.7

85

0

H.A

86

GND

5.0

H.A

87

GND

1.9(4.8)

88

0

89

1.9(0)

90

1.9(4.8)

91

0.2

REC

92

FM AGC2

DET

4.2(0)

93

0(0.3)

94

0

A.GND

95

2.3

96

C466

0

3.3/50

97

2.4(1.6)

98

4.9

(4.1)

99

2.4(3.3)

100

R412

1.8K

C413

0.01

Q404

C423

4.7/50

TL401

BIAS COIL

1

2

3

C420

47/50

C401

47/6.3

C355

0.01

C406

10/16

2.4

(1.9)

80 5179 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52

ENV

DET

MUTE

Vref

2.3V

1 30

2.4 2.4 2.5 2.4 0.1

R413

8.2K

6

5

4

79

REC "H"

R222

470

C218

0.1

C343

C344

0.047

0.022

2.0

(2.9)

SECAM DET

PAL M DET

KIL

DET

BPF

NAP

KIL

B.D.

320/321FH

VCO

SUB

CONV

BALANCE

REC FM

AGC1

R

P

FM

PROCESSING

RFSW/

HASW IN

REC

5.1

(2.7)

R303 18K

R304 10K

R340 18K

28 C.ROTARY

24 V.H/SW

29 H.AMP SW

1K

Q202

KTC3199BL

0.01

C342

C-GND

MAIN

CONV

BPF2

REC

FM EQ

S-FM IN

FM AGC

DET

1.5

0.1

C301

C371

0.022

4.43MHz

PILOT

P

R

R

P

8.2K

R322

X301

1/50

C358

8

(1.4)

2.73.800.6

REC

VXO2 VXO1

APC

DET

NTSC-M

PHASE

BG

ALT

D.E.

REC

REC

APC

APC

ID DET

C-LPF

B-UP

AMP

S-VHS:OPEN

FM

MOD

W/D

CLIP

BAL/TCI

Y-VCC

ACC DET

1.9

2.3 5.1

(1.5)

1/50

C303

C3B1

0.033

R306

330

4.3(3.8)

R341

(1.7)

2.7K

C305

0.1

C341

0.022

C340

13

2.1

P

R

REC

AFC

BEFORE

R

AFTER

P

REC

BGA

AGC

DET

ACC

SUB

LPF

FM

DEM

DOUBLE

LIM

P

3.0

(0.2)

0.01

C306

27P

C307

R305 1.2K

L302 56M

1.2

5.6K

R349

R307

330

C304

220/6.3

0.033

R

V/I

CON

1.9

(2.5)

1.8(2.3)

KTC3199

C339

DETAIL

EMPHA

R

C334

220/6.3

1.5K

R326

R321

4.7/50

320FH

VXO

COMB

AMP

NON CORR

MES

CORRE

BEFORE

P

R

ENH

NL

CLAMP

(2.5)

1.1

R308

2.7K

R309

C363

39P

Q301

BL

C353

Q302

KTC3199BL

5.1

1.3

(1.9)

2.7K

To

SEC

DET

PB BGA

PB BGA

AFTER

P

P

R

3.0

820

C309

330P

22P

(2.5)

R310

1K

C337

C338

0.022

SLD

D.E.

CCD

LPF

R

P

2.2

(2.5)

1

C310

4.7/50

R312

2.2

1.8K

R311

4.7K

8.2M

2.3V

L401

C402

0.022

R430

47K

R425

3.9K

0.1

ALC

C403

R402 2.2M

A-VCC

R301

1.8

(0)

5.02.402.42.5

C405

10/16

Vref

5.6K

R323

R324 10K

11

R

P

KIL

R201

C220

0.022

2.53.23.4

RF

HEAD AMP

PROCESSING

VXO

PB FM

AGC

PB FM

EQ

R490

47K

XO

PB EQ

THROUGH

LP/EP

A-MUTE/

C+ROT

R302 10K

62 A.MUTE

REC

FM

AGC2

COMP

OUT

R

LINE

AMP

ALC

DET

AMP

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

R414

C414

0.01

PB/EE

EQ

12K

C421

0.022

R415

330K

R416

C415

P

150

22/16

AUDIO

SIGNAL

PROCESSING

Vref

PB/EE

REC:EP/LP

PB:EP

EQ

AMP

2.4 2.4 0 0 1.0 1.7

(2.4)

5

C416

R417

2200P

1K

C417

1200P

V.H/SW TP

R418

R491

27K

12K

R422

560

SP

4 15 14

C368

1000P

4.7/50

Y-GND

0

C-MAIN

Cn-CTL

COMP

IN

9

L301

10uH

C-VCC

BPF1

P

DECODER

C311

180P

L309

100uH

C354

220/6.3

C332 0.01

3.4

5.03.33.43.43.55.05.0

NTSC:H

C-DELAY

Cn-CTL

D.E.

R

Y/C SEP

IN

R

Y.N . R

Y.LPF

R

P

1/2

RR

P

RR

P

B.B

CLAMP

SERIAL

4.9 4.9 0

R335

18K

90 IIC CLOCK

91 IIC DATA

C312

22P

C369

0.022

C335

0.1

(0.5)

P

DEEMP

P

PB-C

FBC

0.2

CCD

VCC

PROCESSING

NL

PIC-CTL

SYNC

SEP

Chara

INS

0.1 0.3 0.3

27 DV.SYNC

R313

470

C331

220/6.3

Q304

KTC3199BL

C336 0.01

12

C COMB

CCD

LC89981/82

DELAY

CLAMP

N.C1

N.C2

ANR

PB-Y

Y/C

MIX

P

R

H-PLL

3 610

C370

180P

L303

33M

5.0

1.3

CCD

GND

Y DELAY

54 C.SYNC

DELAYED

SIGNAL

SYNC

DET

60dB

AMP

PB

CTLEQTC1

1.9

2.602.65.1

16

EE

AGC

1.7

(2)

R316

5V

1212

1.9

50

49

48

47

46

45

44

43

VCA

42

DET

41

40

ALWAYS

5V

REG

39

38

SYNC

37

DET

36

AFC

35

DET

34

AGC

TC2

33

32

31

1.1

(4.4)

C314

150

1.7(0.6)

D301

1SS131

79 REC "H"

5VT

0

0.9

2.2

9.5

1.6

1.5

(2.3)

0

2.1

2.8(3.1)

3.0

5.1

4.1

2.2

47/6.3

1.6

(4.7)

1.8

(3.3)

1.3

(3.4)

1.8

(3.3)

1.9(1.3)

1.5(2.3)

2.9

2

0.1

C326

10/16

C322

C316

10/16

C315

10/16

5VT

C330

C329

C328

0.047

C313

100P

7

R317

82K

5V

0.01

0.01

C325

C319

0.1

0.1

C318

2.2/50

2

C327

C317

0.01

KTA1267GR

1.6

1

R318

R325

1K

2.4

Q305

KTA1267

0

4.7K

C324

2

GR

0.1

Q303

(2.2)

0

R319

1K

2.6

L304

100UH

C323

47/6.3

L201

12M

C210

47/6.3

6 SECAM DET "H"

R213

100

C208

10/16

C209

0.022

C207

0.047

C206

0.47

C205

0.01

C204

0.047

C201

22/50

C203

0.47/50

R211

1.5K

C211

0.022

24 1323 22 21 20 19 18 17 16 15 14

ACC

BPF

4.3M

ACC1

BPF

2.2M BPF

X 2 X 2

SW2

LIMITER

LP

ADJ

TRICK

AFC

ID-DET

MAIN

PHASE

ID-DET

ADJ

BELL

ADJ

SW3

REC

PB

QUAD DET

PRE-BPF

REC

PB

1.1M BPF

REC

PB

SYSTEM

SW

IDENT

1.1M

4.3/1.1

BELL

SW4

Anti Ball

EP

DAC

1/4

C/D

XVCO

1.1/4.3

ACC

DET

L/M 1/4

IIC BUS

Anti Bell

ADJ

ACC2

PAL/NTSC

SECAM

SYNC

COMORESS

SYNC

GATE

PB

REC

SW5

V C/D

V SEP

SLICER

SW7

ATT

TRICK

1 12234567891011

X201

4.286MHz

C215

C216

0.1

91 IIC DATA

90 IIC CLOCK

54 C.SYNC

27 DV.SYNC

0.1

C217 0.1

C214

15P

:PB Y SIGNAL

:PB CHROMA SIGNAL

R209

100

R206

100

R2101KR205

:PB VIDEO SIGNAL

:REC Y SIGNAL

:REC CHROMA SIGNAL

:REC VIDEO SIGNAL

:PB AUDIO SIGNAL

:REC AUDIO SIGNAL

ONE VOLTAGE:PB OR REC MODE

*

TWO VOLTAGES:PB AND (REC) MODE

: WAVEFORMS No.

R212

100

SW6

V C/D

VCO

AFC

1K

R204

C213

2.2/50

PB

1K

PROCESSOR

SYSTEM

SW

REC

IC201

TA1238N

L-SECAM

CHRONA

SW8

C212

0.033

Q201

KTA1267GR

2423

Page 19

WAVEFORM-1 (VIDEO SECTION)

1

IC301 Pin

PBmode

500mvp-p

5

IC301 Pin

REC mode

2.2Vp-p

2

20

IC301 Pin

38 , 32 , 31

Video in

1Vp-p

6

6

IC301 Pin

29

PB mode

2.1 Vp-p

3

IC301 Pin

PB/REC mode

4.2Vp-p

7

IC301 Pin

PB mode

400mVp-p

4

28

IC301 Pin

7

REC mode

1.4Vp-p

8

41

IC301 Pin

64

PB mode

600mVp-p

9

IC301 Pin

PB/REC mode

5Vp-p

13

IC301 Pin

PB mode

600mVp-p

10

23

IC301 Pin

24

PB/REC mode

5Vp-p

14

63

IC301 Pin

71

PB mode

3.2Vp-p

11

IC301 Pin

REC mode

340mVp-p

15

IC301 Pin

PB mode

1.8Vp-p

71, 72

10

12

IC301 Pin

PB mode

300mVp-p

16

IC301 Pin

PB mode

400mVp-p

51 , 52 , 54

43

25

Page 20

WAVEFORM-2 (SERVO/OSD SECTION)

1 2

IC501 Pin

24

1V/5mS

REC/PB mdes

(V.H/SW)

5

IC501 Pin

38

1V/1mS

REC/PB mode

(DFG)

9

IC501 Pin

1V/2mS

QUE/REV modes

(D.V-SYNC)

6

IC501 Pin

1V/10µS

REC/PB modes

(DPG)

10

3

27

IC501 Pin

31

1V/10mS

REC mode

(CTL+)

4

IC501Pin

1V/10mS

REC mode

(CTL–)

32

87

39

IC501 Pin

1V/1mS

REC/PB modes

(CFG)

40

IC501 Pin

43

100mV/10µS

EE/PB modes

(V-IN)

IC501 Pin

45

500mV/10µS

EE/PB modes

(V-OUT)

IC501Pin

54

1V/20µS

EE/PB modes

(C-SYNC)

26

Page 21

SCHEMATIC DIAGRAM-3 (SYSCON/SERVO SECTION)

PML01

LD+

LD-

To

LOADING

MOTOR

PMD01

D.CTL

M.GND

DFG

12V

PG

GND

5.1V

To

LOWER

DRUM C.B

PDM01

PMC01

GND

MOTOR GND

I.LIMIT

CAP.CONTROL

12V

CFG

CAP.REV "L"

5.1V

To

CAPSTAN

MOTOR C.B

PCM01

MS501

GND

MODE S1

MODE S2

MODE S3

MODE S4

To

MODE SW

A MAIN(SYSCON/SERVO SECTION)C.B

IC502

KA3082

MOTOR DRIVE

MOTOR DRIVE

MOTOR DET

2345678910

C528

C522

0.01

C529

R535

470K

C545

0.1

R521

3.3K

0.01

R526

0.1

5.6K

R525

5.6K

R563

10K

C544

0.047

R579

56K

R528

10K

R523

15K

ZD501

MTZ6.8C

D509

1SS133

R569

1M

81

78

61

R546

5.6K

80

77

76

75

74

5.1V

R550

220

21

DECK IR LED

4

21

LD501

ES501

ST5811-A,B

T-UP END

ES502

ST5811-A,B

SUP END

4

ONE VOLTAGE:PB OR REC MODE

TWO VOLTAGES:PB AND (REC) MODE

C543

2200P

12V(CAP)

5.3

R557

27K

5.3

R556

22K

R564

27K

R558

22K

C551

0.033

R547

12K

25

26

R5C5

1K

C536

0.01

R560

4.7K

5.1

C537

0.01

R559

4.7K

5.1

: WAVEFORMS No.

R506 1K

R522 1K

R512 1K

C574

1000P

PG ADJ

R5E8 10K

R5E7 10K

C557 0.01

C502

47/6.3

5V

R5B3

1K

5.3

Q514

R

KRC103M

0

R5C7

1K

R5B4

1K

5.3

Q515

R

KRC103M

0

5.3VA

C567

3900P

VR501

220KB

C556

0.01

IC504

KIA7031P or

KA75312

RESET

RESET

GND

3

0

R531

10K

R5C9

10K

12

5.3

C534

4.7/50

C581

0.01

C535

4.7/50

C582

1

2

1

2

3

4

5

6

7

1

2

3

4

5

6

7

R505 1K

8

1

2

3

4

5

C546

47/16

C525

47/16

R575 4.7K

12V(DRUM)

GND

1

0 0.5 0.8 3 1.8 1.8 12.2 12.2 0.9 0.5

R524

6.8 1W

C530

10/16

C526

47/25

5.3VA

R576 4.7K

R577 4.7K

R578 4.7K

R5C1 1K

R5C2 1K

R5C3 1K

R5C4 1K

R553

220

3

RS501

GP1S566

R555

220

3

RS502

GP1S566

*

VCC

0.01

C575

1000P

C509

0.022

C507

0.1

C508

0.1

1

C516

0.022

5.3VA

19

20

38

40

39

4

3

5

5.304.6(5.2)

8765

VCC

GND

1

000

1

3

4

5

6

7

8

9

R507 1K

11

12

R543 100

13

14

15

R5B5 100

18

19

20

21

23

24

25

26

27

28

29

30

31

C533

1000P

32

R5A1

68K

55

R5A2

120K

C5S1

43P

45

56

9190

100

R502

4.6(5.2)

CLK

GND

DATA

GND

GND

GND

234

0

R545 2.2K

R586 2.2K

R510 2.2K

R508 3.3K

0.1(0)

0.2(2.3)

2.3(4.2)

5.0(0)

R561

560

C527

180P

KTC3199BL

L5S1

33M

R5S2

6.8K

100

R501

IC503

AT24C16

EEPROM

0.4

1

0

2

3

0

4

0

5

5.1

6

4.5

7

4.5

8

1.6

9

3.5

10

11

12

5.1

13

0

14

5.3

15

5.0

16

0

17

5.2

18

0

19

20

0

21

5.3

22

2.5

23

2.5

24

2.7

25

2.4

26

0

27

2.5

28

0

29

0

30

2.9(2.3)

R562

560

2.2

Q5A1

Q5S2

KTC3199BL

99

97

94

93

86

85

DJ02 1SS133

DJ04 1SS133

DJ06 1SS133

DJ07 1SS133

DJ09 1SS133

DJ010 1SS133

DJ011 1SS13384DJ014 1SS133

5.3VA

100

99 9897 96 95 94 93 92 91 90 8788 86 85 84 83 81

000

4.8(0)

4.9

0(4.9)

4.900

4.8

4.8

100

99 9897 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81

S1

S3

S2

T-UP SENSOR

VSS(A/D)

END SENSOR

T-UP REEL

SUPPLY REEL

SEC DET "H"

LEVEL METER "L"

LEVEL METER "R"

AFT

PG ADJ

A.ENV

V.ENV

KEY RTM 0

KEY RTM 1

VCC(A/D)

RESET

NC

TU SECAM VL "H"

LD (-)

LD (+)

C+ DET "H"

VCC(SYS)

A.H/SW

V.H/SW

CAP.PWM

DRUM PWM

D.V-SYNC

C.ROTARY

H.AMP SW

COMP.IN

3

CTL+

31

S6/FLD CLK

S5/FLD DATA IN

S4/FLD DATA OUT

HD3977RC17F or

GMS3977RAA57F

SYSCON/SERVO

1

2

5

CTL-

VSS(SERVO)

CTL1

CTL2

CTL3

32 3334 35 36 37 38 39 40 41 42 43 44 45

0

0.1

2.2

2.2

2.3

2.2

4

C564

330P

R568

R527

680K

560

C524

33/16

R5A3

56K

R519

27K

C5S2

0.022

R5S3

330

4.304.60000

S9

S8

IIC CLK

IIC DATA

S7/FLD ENA

PWR FAIL

STAND BY "H"(3W LED)

IC501

PROCESS

7

89

6

CTL OUT

DFG

DPG

CFG

VCC(SERVO)

VCC(OSD)

CV IN

2.2

4.4

2.5

5.202.6

38 39 40 43 45

R513

100K

C596

0.022

C503

0.1

1.3

65

G1G2G3

CAP ACCEL "H"

C.SYNC(INV)

OPT RTN(CTL MON)

CTL GAIN ADJ

10

4fsc out/2fsc out

VREF(OSD)

CV OUT

CHAR BIAS

AFC LPF

46 47 48 49 50

0

2.602.0

R567

820

C588

4.7/50

C513

5.1

1.2

G4

R/C

ADJ

DRUM

REC "H"

I-LIMIT

MODE SW1

MODE SW2

MODE SW3

MODE SW4

OSC2

OSC1

VSS(SYS)

X-TAL1

X-TAL2

TEST "H"

TIMER "H"

TSS "L"

16:9 "H"

TU SEC "H"

A.MUTE "H"

CAP.REV "H"

PWR CTL "H"

OSD"H"

C-SYNC "H"

SCART "H"

SEC/MEC "H"

C.SYNC

4fsc in/2fsc in

D OSC

IN

AFC OSC

VSS(OSD)

D OSC

0

1.2

C512

180P

0.1

C504

220/6.3

OUT

C589

150P

C541

4.7/50

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

R511

1K

C542

680P

2.7

0

3.1

5.0

5.4

0

5.4

2.5

2.5

0

0.8

1.5

0

0

0.1(0.2)

5.1

0

0

0

5.0(0)

4.9(4.5)

0

0

5.1

0

5.1

0(0.4)

2.3

2.4

1.2(0)

87

L507

100M

67

R581

R5B1

68K

1K

(REMOCON SENSOR)

80

79

78

77

76

R515

75

270

74

73

72

67

66

65

64

63

62

R5C6

1K

61

60

C552

0.01

58

56

55

54

17.734MHz

R509

10K

R518

560

C521

0.022

12V(DRUM)

IC505

KIA7042P or KA7542Z

VCC

GND

1

32

0

5.3

R504

1K

RC5F1

V OUT

GND

VCC

3

12

0

C5F7

47/6.3

R534

1M

X501

10MHz

X502

32.768KHz

CS501

CST/REC.SW

R548

100K

R589

1M

X503

R517

L506

1M

15uH

C561

L505

47/6.3

100uH

RESET

R570

4.7K

C520

1000P

R5H2

330

C570

18P

C571

18P

C515

15P

C514

18P

R544

4.7K

C576

14P

C577

14P

C519

39P

C518

33P

5.3VA

9MT168GK or SVV09MM14 (DISPLAY)

REC TIMER

SP LPLEP

F-F-NPNPNCNCNC9G8G7G6G5G4G3G2G1GNXNXNXNXNX

1

234567 1718192021

R5F0

R5F1

10

C532

0.022

D502

1SS133

10

34

35

36

37

38

39

40

41

42

43

44

R5G0 27K

81591410131112121013914815716

R5G1 27K

R5G2 27K

R5G3 27K

R5G4 27K

ZD503

MTZ6.2B

C501

0.1

R5G5 27K

C506

0.022

C500

470/6.3

R5G6 27K

R5G7 27K

5V

R583

10K

R529

10K

DIG5F1

VCR M REM BILSAP Hi-Fi ST

P16

P15

P14

P13

P12

P11

2222312444254326422741284029393038313732363335343435333632373138 39 40 41 42 43 44

6

33 32 31 30 29 28 27 26

33 32 31 30 29 28 27 26 25 24 23

P3P2P1

34

P4

P5

35

P6

36

P7

37

P8

38

39

P9

P10

40

DISPLAY DRIVE

P11

41

P12

42

P13

43

44

P14

P15

P16NCNCG1G2G3G4

1

2345678910

R5H0

12 768910

L502

100uH

C505

47/6.3

12V(DRUM)

12V(CAP)

5.3VA

Q503

KTA1267

5.3

5.4

3.6

R542

2.2K

Q501

KTC3199BL

P10P9P8P7P6P5P4P3P2P1NCNCNCNCNPNPF+

R5F6

1K

9796 95 94

R5F5

1K

R5F7

1K

R5F8

CLK

ENA

DATA IN

VSS

DATA OUT

SHUTTLE4

SHUTTLE3

SHUTTLE2

SHUTTLE1

POWER LED

IC5F1

MN12510

G5

OSC2

OSC1

VDD

VPP

11

G9

G8

G7

G6

27K

C5F8

C5F4

47/6.3

0.1

27K

22

21