HS-GS216

Y,YH

SERVICE MANUAL

STEREO

CASSETTE PLAYER

BASIC TAPE MECHANISM : 8ZM-3 P2N

S/M Code No. 09-012-439-0N1

DATA

SPECIFICATIONS

Maximum output: 4 mW + 4 mW (EIAJ 16 ohms)<Y>

Load impedance<Y>: 16 - 80 ohms

Power source: DC 3V using two R6 (size AA) batteries

Maximum outside dimensions:

Weight Approx. 130g (4.6 oz) excluding batteries

Design and specifications are subject to change without notice.

5 mW + 5 mW (EIAJ 32 ohms)<YH>

AC house current using an optional AC adaptor Aiwa AC-D302

111.3 (W) x 83 (H) x 29.4 (D) mm

(4 1/2 x 3 3/8 x 1 3/

(excluding projecting parts and controls)

in.)

16

ACCESSORIES / PACKAGE LIST

PART NO.

NO.

1 8B-HG9-902 -010 IB,(ECC)F GS216<YH>

1 8B-HG9-906-010 IB,(EDPHNC)F GS216<Y>

1 8B-HG9-905-010 IB,(EGFSI)F GS216<Y>

2 87-B30-255-010 HEADPHONE,HP-M007B(S)

3 8Z-HRB-050-210 CLIP,BELT ASSY

DESCRIPTIONREF. NO. KANRI

2

ELECTRICAL MAIN PARTS LIST 1 / 1

REF. NO.

IC

87-A20-461-040 C-IC,MM1336DF

TRANSISTOR

87-026-264-080 C-TR,RN1411

89-327-125-080 CHIP TR,2SC2712GR

DIODE

87-A40-630-040 C-DIODE,RB411D

87-020-027-080 CHIP-DIODE 1SS184

MAIN C.B

C101 87-010-178-080 CHIP CAP 1000P-50

C102 87-010-178-080 CHIP CAP 1000P-50

C103 87-010-213-080 C-CAP,S 0.015-50 B

C104 87-010-213-080 C-CAP,S 0.015-50 B

C105 87-010-499-040 CAP,E 22-6.3 GAS

C106 87-010-499-040 CAP,E 22-6.3 GAS

C111 87-010-182-080 C-CAP,S 2200P-50 B

C112 87-010-182-080 C-CAP,S 2200P-50 B

C119 87-010-503-040 CAP,E 220-4 GAS

C120 87-016-350-040 CAP,E 470-4 MA GAS

C121 87-010-805-080 CAP, S 1-16

C122 87-010-178-080 CHIP CAP 1000P-50KB

C123 87-010-494-040 CAP,E 1-50 GAS

C124 87-010-596-080 CAP, S 0.047-16

C125 87-010-499-040 CAP,E 22-6.3 GAS

C126 87-010-503-040 CAP,E 220-4 GAS

C127 87-010-197-080 CAP, CHIP 0.01 DM

C128 87-010-196-080 CHIP CAPACITOR,0.1-25

C230 87-010-196-080 CHIP CAPACITOR,0.1-25

C301 87-010-196-080 CHIP CAPACITOR,0.1-25

C302 87-010-196-080 CHIP CAPACITOR,0.1-25

C303 87-016-087-080 C-CAP,S 0.47-16F

C304 87-016-087-080 C-CAP,S 0.47-16F

C305 87-010-186-080 CAP,CHIP 4700P

C306 87-010-186-080 CAP,CHIP 4700P

C307 87-010-186-080 CAP,CHIP 4700P

C308 87-010-186-080 CAP,CHIP 4700P

C309 87-010-193-080 CHIP CAPACITOR,0.033

C310 87-010-193-080 CHIP CAPACITOR,0.033

C311 87-010-805-080 CAP, S 1-16

PART NO. DESCRIPTIONREF. NO.

KANRI

NO.

DESCRIPTION

PART NO.

C312 87-010-805-080 CAP, S 1-16

C313 87-010-805-080 CAP, S 1-16

C321 87-A10-952-080 C-CAP,TN 22-4 M A MCM

C322 87-010-596-080 CHIP CAPACITOR,0.047-16KR

C403 87-010-197-080 CAP, CHIP 0.01 DM

C404 87-010-197-080 CAP, CHIP 0.01 DM

C405 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C406 87-012-141-080 CHIP-CAPACITOR,0.22-16F

C407 87-010-805-080 CAP, S 1-16

C408 87-010-805-080 CAP, S 1-16

C409 87-010-195-080 C-CAP,S 0.068-25 F

C410 87-010-195-080 C-CAP,S 0.068-25 F

C411 87-010-188-080 CAP,CHIP 6800P

C412 87-010-188-080 CAP,CHIP 6800P

C413 87-010-198-080 CAP, CHIP 0.022

C414 87-010-198-080 CAP, CHIP 0.022

C415 87-010-501-040 E/CAP GAS 47-4

C417 87-010-198-080 CAP, CHIP 0.022

C418 87-010-198-080 CAP, CHIP 0.022

C420 87-010-805-080 CAP, S 1-16

C421 87-010-805-080 CAP, S 1-16

C701 87-012-157-080 C-CAP,S 330P-50 CH

C702 87-012-157-080 C-CAP,S 330P-50 CH

C703 87-010-196-080 CHIP CAPACITOR,0.1-25

C704 87-010-197-080 CAP, CHIP 0.01 DM

C705 87-010-197-080 CAP, CHIP 0.01 DM

C706 87-012-141-080 CHIP-CAPACITOR,0.22-16F

J101 87-A61-124-110 JACK,DC DIA2.75 BLK TC

J102 85-HRL-623-010 JACK,3.5 ST BLK

S101 87-A91-077-010 SW,LEAF

S102 8Z-HRB-607-010 SW,SL 2-2-2 SSZZ-S-502(S)

S301 87-A90-917-010 C-SW,SL 1-1-2 SS-350-B12W-C-L

S401 87-A91-285-110 C-SW,SL 1-1-4 SS-350-B14B-C-L

SFR101 87-024-050-010 SFR,1K V VZ066H1

TH101 87-026-256-090 THERMISTOR, HT-100

VR101 87-A90-818-010 VR,RTRY 20KCX2H XV0102G

KANRI

NO.

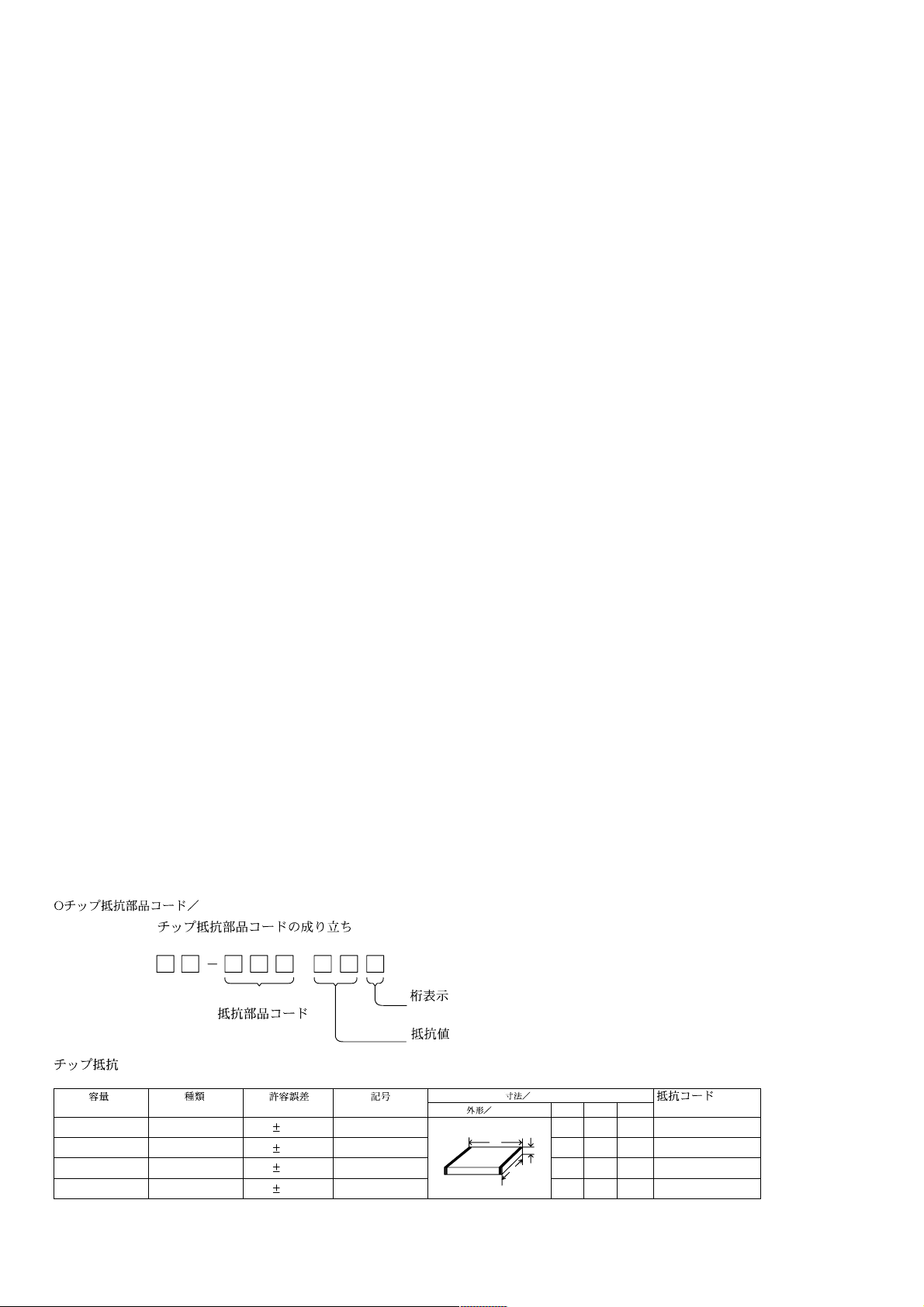

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

3

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

TRANSISTOR ILLUSTRATION

C

B

E

2SC2712

RN1411

4

WIRING

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

5

R

S

T

U

SCHEMATIC DIAGRAM

REV

6

ADJUSTMENT

1. Tape Speed Adjustment

Settings : Test tape : TTA 100

(Tape center)

Test point : Phones Jack (J102)

Adjustment location : SFR101

Tape selector : NORM

Volume : Non clip

(MAX 10 dB down)

Method : Play back the test tape and adjust SFR101 so that the

frequency becomes 3000 Hz ± 10 Hz. Then confirm

WOW is less than 0.50%.

2. GOVERNER Check

Perform the STOP > PLAY and REVERSE operations

(or PAUSE ON > OFF) after the motor is replaced. When the tape

starts running smooth, this adjustment is not necessary. If wow is

conspicuous at the beginning of the tape-run, perform this adjustment

following the procedures below.

1) Solder resistor pattern (C) of the MOTOR AND

GOVERNOR MATCHING ADJ. resistor group.

2) Set the tape speed (using speed adjustment SFR101).

3) Restrict the motor rotation by hand (or turn PAUSE ON).

4) Remove your hand and listen to the beginning of the

tape-run.

5) When the rise of tape running is smooth, no more

adjustment is necessary.

If wow continues for 1 to 2 seconds at the rise time, change

the combined resistance according to procedure 2 and check

that the tape starts running smooth.

6) Solder the resistor pattern according to the table below

Pattern

Step (1)

Step (2)

Step (3)

(NOTE : = 2.7 ohm, = 4.7 ohm, = 10 ohm)

7) Finally re-check the tape speed.

Low

resistance

Open

Open

Open

A

A

Medium

resistance

Open Open

Solder

B

B

High

resistance

SolderOpen

Open

C

C

Caution : Cool the patterns down to normal temperature

after soldering. If the pattern remains heated,

the gorvernor circuit does not operate normally.

7

MECHANICAL EXPLODED VIEW 1 / 1

8ZM-3 P2N

6

2

1

3

B

5

4

PWB

C

14

B

B

D

7

10

8

12

11

9

13

8

MECHANICAL PARTS LIST 1 / 1

REF. NO.

1 8B-HG6-007-010 LID,CASS P EG<Y>

1 8B-HG9-004-010 LID,CASS<YH>

2 8Z-HRB-217-110 SPR-T,CASS

3 8Z-HRB-002-010 WINDOW,CASS

4 8Z-HRB-208-010 BAT-CONTACT,P

5 8B-HRC-203-010 BAT-CONTACT,M

6 8Z-HG9-201-110 HLDR,HP JACK

7 8B-HG9-001-010 CABI,REAR EG<Y>

7 8B-HG9-003-010 CABI,REAR<YH>

8 8B-HG6-201-010 RACK,MSP

9 8B-HG6-202-010 GEAR,MSP

10 8B-HG6-005-010 PLATE,IND MSP

11 8B-HG6-004-010 KNOB,SL DOLBY

12 8B-HG6-003-010 KNOB,SL MSP

13 8B-HG6-002-010 PANEL,MSP

14 8Z-HRB-005-110 LID,BAT SIL

A 87-B10-048-010 VT2+1.4-3 (3) CR HL

B 87-B10-196-010 VT2+1.4-4 BLK (3) HL

C 87-264-527-310 V 1.7-3 SCREW

D 87-067-384-010 SCREWVT1.4-3.5HL

PART NO. DESCRIPTIONREF. NO.

KANRI

NO.

DESCRIPTION

PART NO.

KANRI

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange GM Metallic Green

YM Metallic Yellow DM Metallic Orange PT Transparent Pink

LA Aqua Blue GL Light Green HT Transparent Gray

9

TAPE MECHANISM EXPLODED VIEW 1 / 1

32

38

W-P1.16-2.8-0.4

25

23

26

30

24

21

27

28

29

31

19

20

33

29

22

17

36

34

18

16

35

41

37

40

44

47

46

43

48

49

42

39

50

51

52

11

45

12

10

A

9

7

6

A

7

8

A

13

15

14

1

5

3

53

54

55

56

57

2

10

4

TAPE MECHANISM PARTS LIST 1 / 1

REF. NO.

1 8Z-HRB-003-210 FRAME,CENTER GRY

2 8Z-HRB-207-110 SPR-P,CASS

3 88-ZM3-253-210 SPR-C,BT L

4 88-ZM3-274-010 GEAR,REEL A

5 8Z-HRB-014-110 KNOB,SL OPEN

6 8Z-HRB-204-110 LEVER,EJECT

7 8Z-HRB-216-110 CAP, EJECT

8 8Z-HRB-205-110 SPR-T,EJECT

9 8Z-HRB-215-010 SHAFT,ASSY

10 87-A91-379-010 MOT,BCY3B-13

11 88-ZM3-236-010 PULLEY,MOT S

12 88-ZM3-263-210 BELT,S

13 88-ZM3-243-010 SPR-T,PLAY BACK

14 8Z-HRB-206-010 PLATE,EJECT

15 88-ZM3-217-210 ARM,PINCH L

16 88-ZM3-241-110 SPR-T,PINCH L

17 88-ZM3-003-110 LEVER,REW

18 88-ZM3-246-110 SPR-T,FF REW

19 87-A80-115-010 F-CABLE,5P P2

20 87-A91-019-010 HEAD ASSY,PH 8ZM-3

21 88-ZM3-211-010 LEVER,DIR

22 88-ZM3-001-110 LEVER,PLAY

23 88-ZM3-213-310 LEVER,T-UP

24 88-ZM3-225-110 GEAR,PLAY

25 88-ZM3-224-210 GEAR,TRANSMIT

26 88-ZM3-002-110 LEVER,FF

27 88-ZM3-242-210 SPR-T,PINCH R

28 88-ZM3-242-210 ARM,PINCH R

29 88-ZM3-271-010 ROLLER ASSY,PINCH

30 88-ZM3-220-110 BTN,MODE SEL

31 88-ZM3-267-010 SHAFT,PULLEY TWIN

32 88-ZM3-234-010 PULLEY,BELT TWIN

33 88-ZM3-212-110 LEVER,LOCK

34 88-ZM3-245-110 SPR-T,LOCK

35 88-ZM3-201-410 CHAS ASSY,OUTSERT P

36 88-ZM3-216-110 LEVER,SW

37 88-ZM3-221-110 GEAR,AUTO

38 09-001-453-010 FLY-WHL ASSY,R S

39 88-ZM3-280-010 FLY-WHL ASSY,L2

40 88-ZM3-248-010 SPR-T,AUTO CHOOSE

41 88-ZM3-215-110 LEVER,AUTO KICK

42 88-ZM3-262-010 BELT,L

43 88-ZM3-244-010 SPR-T,DIR

44 88-ZM3-219-010 BTN,DIR KNOB

45 8A-HRH-203-010 HLDR,DC JACK

46 88-ZM3-226-010 GEAR,IDLE

47 88-ZM3-004-210 LEVER,STOP

48 88-ZM3-255-210 SPR-C,STOP

49 88-ZM3-214-110 LEVER,AUTO FIND

50 88-ZM3-238-010 CAP,SLIP

51 88-ZM3-252-010 SPR-C,SHIFT

52 88-ZM3-251-310 SPR-C,SLIP

53 88-ZM3-222-110 GEAR,SLIP FAST

54 88-ZM3-269-110 FELT,SLIP

55 88-ZM3-237-110 CLR,SLIP

56 88-ZM3-247-010 SPR-T,AUTO FIND

57 88-ZM3-223-010 GEAR,SLIP SLOW

58 8A-HRH-203-010 HLDR,DC JACK

A 87-067-384-010 SCREWVT1.4-3.5HL

PART NO. DESCRIPTIONREF. NO.

KANRI

NO.

DESCRIPTION

PART NO.

KANRI

NO.

11

211, IKENOHATA 1CHOME, TAITO-KU, TOKYO 110, JAPAN TEL:03 (3827) 3111

Printed in Singapore9630472 0251431

Loading...

Loading...