Page 1

D33

English

SERVICE MANUAL

VIDEO MECHANISM

TYPE

P2 LRN106A

P4 LRN133A

S/M Code No. 09-99B-336-8N2

DATA

Page 2

TABLE OF CONTENTS

REMOVING CASSETTE MANUALLY ............................. 3

DECK MECHANISM PARTS LOCATIONS

Top View............................................................................ 4

Bottom View ...................................................................... 4

DECK MECHANISM DISASSEMBLY

1. Drum Assembly........................................................... 5

2. Plate Assembly Top..................................................... 7

3. Holder Assembly CST................................................. 7

4. Guide CST .................................................................. 7

5. Bracket Side (L)/Bracket Assembly Door.................... 7

6. Arm Assembly F/L ....................................................... 7

7. Lever Assembly S/W................................................... 7

8. Arm Assembly Cleaner................................................ 8

9. Head F/E ..................................................................... 8

10. Base Assembly A/C Head ........................................... 8

11. Brake Assembly S ....................................................... 9

12. Brake Assembly T ....................................................... 9

DECK MECHANISM ADJUSTMENT

Tools and Fixtures for service ......................................... 16

1. Mechanism Alignment Position Check........................ 17

2. Preparation for Adjustment ......................................... 18

3. Checking Torque ......................................................... 18

4. Guide Roller Height Adjustment.................................. 19

4-1. Preliminary Adjustment .......................................... 19

4-2. Precise Adjustment ................................................ 19

5. Audio/Control (A/C) Head Adjustment......................... 20

5-1. Preliminary Adjustment .......................................... 20

5-2. Confirm that the Tape Path smoothly between

the Take-up Guide and Pinch Roller ..................... 21

5-3. Precise Adjustment (Azimuth Adjustment)............. 21

6. X-Value Adjustment..................................................... 21

7. Adjustment after Replacing Drum Assembly

(Video Heads) ............................................................. 22

8. Check the Tape Travel after Reassembling

13. Arm Assembly Tension................................................ 9

14. Reel S & Reel T .......................................................... 9

15. Support CST ............................................................. 10

16. Base Assembly P4 .................................................... 10

17. Opener Lid ................................................................ 10

18. Arm Assembly T/up ................................................... 10

19. Arm Assembly Pinch ................................................. 10

20. Belt Capstan/Motor Capstan ..................................... 11

21.Clutch Assembly D33 ................................................. 11

22. Lever F/R .................................................................. 11

23. Gear Assembly H-Up/D or Gear Assembly Up/D...... 11

24. Bracket Assembly Jog............................................... 12

25. Guide Rack F/L, Gear Rack F/L................................ 12

26. Brake Assembly Capstan.......................................... 12

27. Gear Drive/Gear Cam/Gear Connector .................... 13

28. Bracket Assembly L/D motor..................................... 13

29. Gear Sector............................................................... 14

Deck Mechanism......................................................... 22

8-1. Checking Audio and RF Locking Time

during Playback and after CUE or REV ................ 22

8-2. Check for Tape Curling or Jamming....................... 22

MAINTENANCE/INSPECTION PROCEDURE

1. Check before starting Repairs .................................... 23

2. Required Maintenance ................................................ 24

3. Scheduled Maintenance ............................................. 24

4. Supplies Required for Inspection and Maintenance ... 24

5. Maintenance Procedure.............................................. 24

5-1. Cleaning................................................................. 24

5-2. Greasing ................................................................ 25

MECHANISM TROUBLESHOOTING GUIDE

1. Deck Mechanism ........................................................ 26

2. Front Loading Mechanism .......................................... 29

MECHANISM EXPLODED VIEW 1/3 ............................. 32

MECHANISM MAIN PARTS LIST 1/3 ............................ 33

30. Base Tension/Plate Slider/Lever Tension .................. 14

31. Gear Assembly P3/Gear Assembly P2 ..................... 15

32. Base Assembly P3/Base Assembly P2 ..................... 15

33. Arm Assembly Idler Jog or Arm assembly Idler......... 15

MECHANISM EXPLODED VIEW 2/3 ............................. 34

MECHANISM MAIN PARTS LIST 2/3 ............................ 35

MECHANISM EXPLODED VIEW 3/3 ............................. 36

MECHANISM MAIN PARTS LIST 3/3 ............................ 37

2

Page 3

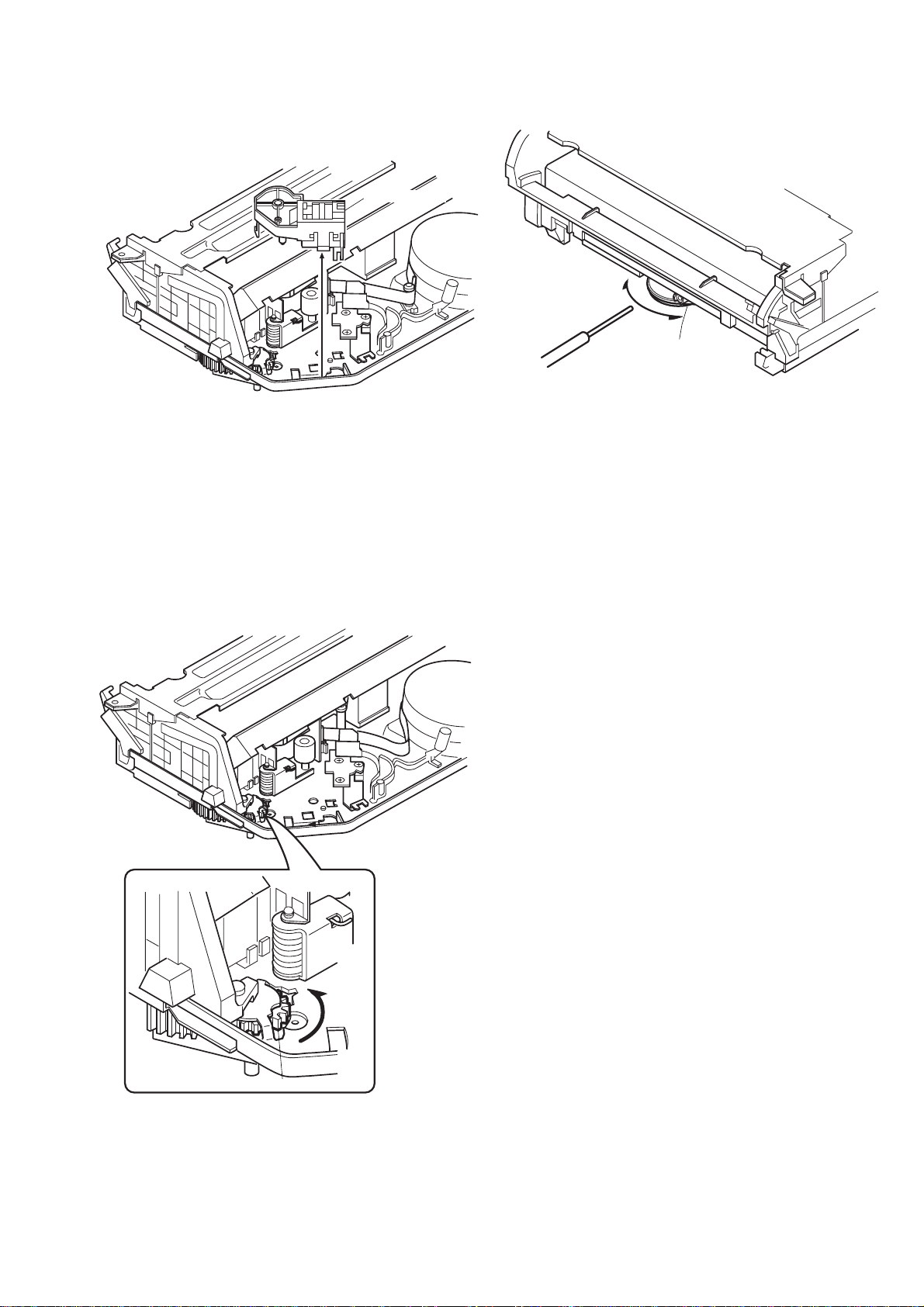

REMOVING CASSETTE MANUALLY

Capstan belt

Fine rod, etc.

1. Remove the loading motor.

Fig. 1

3. Turn the capstan belt to take up slack tape.

Loading motor

Fig. 3

2. Turn the gear connect in the direction of the arrow

with you finger to perform unsledding.

4. Turn the gear connect in the direction of the arrow

with you finger to perform unloading.

Gear connect

Fig. 2

3

Page 4

4

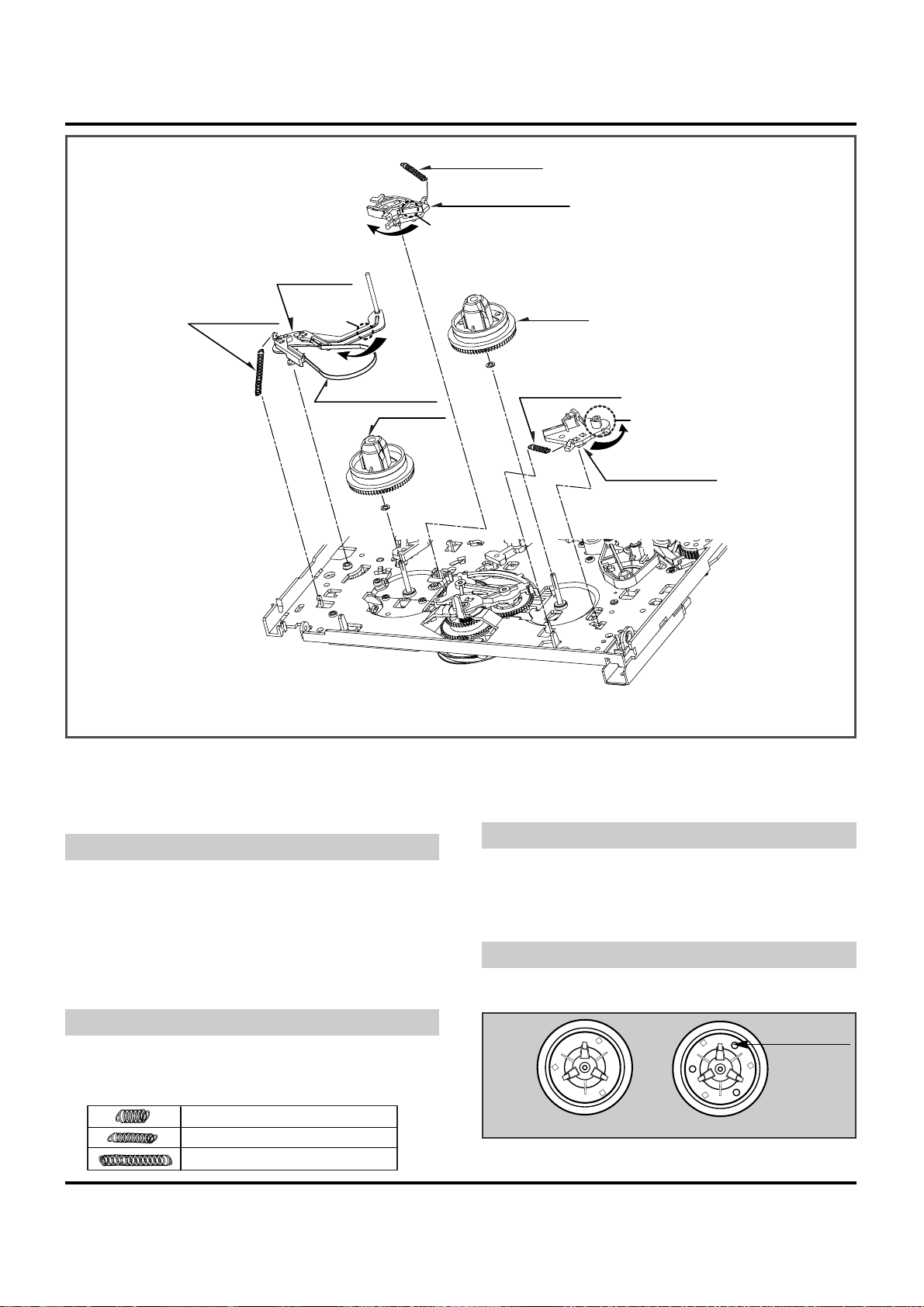

DECK MECHANISM PARTS LOCATIONS

Bracket Side 'L' 5

Plate Assembly 2

Top

Lever Assembly 8

S/W

4 Guide CST

3 Holder Assembly CST

Opener Door

6 Bracket

Assembly Door

7 Arm Assembly F/L

• Top View

• Bottom View

Motor Capstan 23

Gear Connector 33

Gear Cam 32

Brake Assembly 30

Capstan

Belt Capstan 22

Gear Drive 31

Guide Rack F/L 28

Gear Rack F/L 29

Clutch Assembly D33 24

Lever F/R 25

26 Gear Assembly H-Up/D

39 Gear Assembly P3

40 Gear Assembly P2

36 Base Tension

35 Gear Sector

38 Lever Tension

37 Plate Slider

27 Bracket Assembly

Jog

NOTE : When reassembly perform the

procedure in the reverse order.

1) When reassembling, confirm Mechanism and Mode

Switch Alignment Position (Pefer to Page 17)

2) When disassembling, the Parts for Starting No. Should

be removed first.

1 Drum Assembly 3 Screws , Cap FPC A-1

2 Plate Assembly Top Two Hooks A-2

2 3 Holder Assembly CST Chassis Hole A-2

4 Guide CST 2 Hooks A-2

2,3,4 5 Bracket Side (L) 1 Screw A-2

2,3,4 6 Bracket Assembly Door 1 Screw A-2

2,3,4,5,6 7 Arm Assembly F/L Chassis Hole A-2

2,3,4,5 8 Lever Assembly S/W Chassis Hole A-2

9 Arm Assembly Cleaner Chassis Embossing A-3

10 Head F/E 2 Hooks A-3

11 Base Assembly A/C Head 1 Screw A-3

12 Brake Assembly S Chassis Hole A-4

2,3 13 Brake Assembly T Chassis Hole A-4

2,3,12, 14 Arm Assembly T ension Chassis Hole A-4

2,3,12,14 15 Reel S Chassis Shaft A-4

2,3,13 16 Reel T Chassis Shaft A-4

17 Support CST Chassis Embossing A-5

18 Base Assembly P4 Chassis Embossing A-5

19 Opener Lid Chassis Embossing A-5

19 20 Arm Assembly T/Up Chassis Embossing A-5

19 21 Arm Assembly Pinch Chassis Shaft A-5

Starting

No.

Pracedure

Part

Fixing Type

Fig-

ure

22 Belt Capstan A-6

22 23 Motor Capstan 3 Screws A-6

24 Clutch Assembly D33 1 Washer A-6

22,24 25 Lever F/R 1 Hook A-6

22,24 26 Gear Assembly H-Up/D 2 W ashers A-6

27 Bracket Assembly Jog 1 Screw A-7

28 Guide Rack F/L 1Screw A-7

28 29 Gear Rack F/L A-7

28, 29 30 Brake Assembly Capstan Chassis Shaft A-7

28, 29 31 Gear Drive 1 Washer A-8

28, 29, 30 32 Gear Cam Chassis Shaft A-8

28, 29, 30, 31

33 Gear Connector Chassis Shaft A-8

34 Bracket Assembly L/D Motor 3 Hooks A-8

35 Gear Sector 3 Washers A-9

36 BaseT ension 1 Screw A-9

22, 24, 25, 27

37 Plate Slider Chassis Shaft A-9

28, 29, 31, 35

36

22, 24, 25, 27

28, 29, 31, 35

38 Lever T ension Chassis Hole A-9

36

35 39 Gear Assembly P3 2 Hooks A-10

35, 39 40 Gear Assembly P2 2 Hooks A-10

35, 39, 40 41 Base Assembly P3 Chassis Hole A-10

35, 39, 40, 41

42 Base Assembly P2 Chassis Hole A-10

1, 2 43 Arm Assembly Idler Jog 1 Hook A-10

Starting

No.

Pracedure

Part

Fixing Type

Fig-

ure

Head F/E 10

Drum Assembly 1

Support CST 17

Base Assembly P2 42

Brake Spring S

Brake Assembly S 12

Arm Assembly 14

Tension

Band Assembly

Tension

Reel S 15

Lever

Assembly S/W 8

9 Arm Assembly Cleaner

34 Bracket Assembly

L/D Motor

11 Base Assembly

21 Arm Assembly Pinch

20 Arm Assembly T/Up

A/C Head

19 Opener Lid

18 Base Assembly P4

41 Base Assembly P3

43 Arm Assembly

ldler Jog

16 Reel T

13 Brake Assembly T

Brake Spring T

Page 5

5

DECK MECHANISM DISASSEMBLY

Cap FPC

Holder FPC

(only for 4HD-Hi-Fi Models)

Drum Sub Assembly

Rotor

H1

(S1)

(S1)

(S1)

(S2)

(S3)

(S3)

(S2)

Drum Motor

Stator

or or

Optional Parts

Drum FPC

Holder FPC

(only for 2HD Models)

Holder FPC

(only for 4HD-Mono Models)

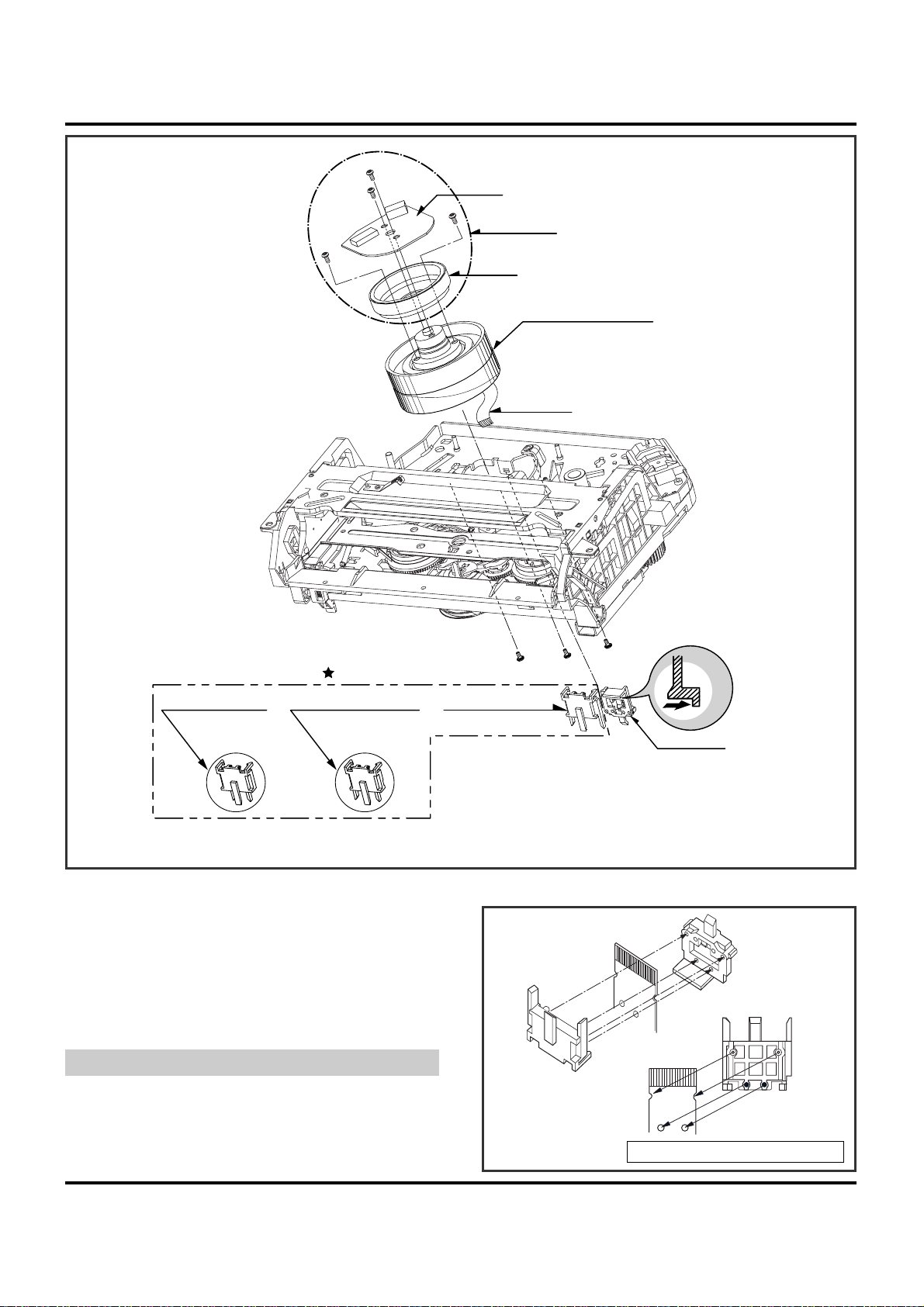

1. Drum Assembly (Fig. A-1-1)

1) Unhook the (H1) on the back side of the Chassis and

separate the Cap FPC.

2) Remove three Screws (S1) and lift up the Drum

Assembly.

3) Remove two Screws (S2) and Separate the Stator of

Drum Motor.

4) Remove two Screws (S3) and Separate the Rotor of

Drum Motor from the Drum Sub Assembly.

(1) When reassembling Cap FPC, two Holes of Drum FPC

are inserted to the two Bosses of Holder FPC correctly.

(Refer to Fig. B-1)

Fig. A-1

NOTE

(Fig. A-1-1)

(Fig. A-1-1)

(Fig. B-1)

Holder FPC

Drum FPC

Cap FPC

Figure in the opposite direction

Page 6

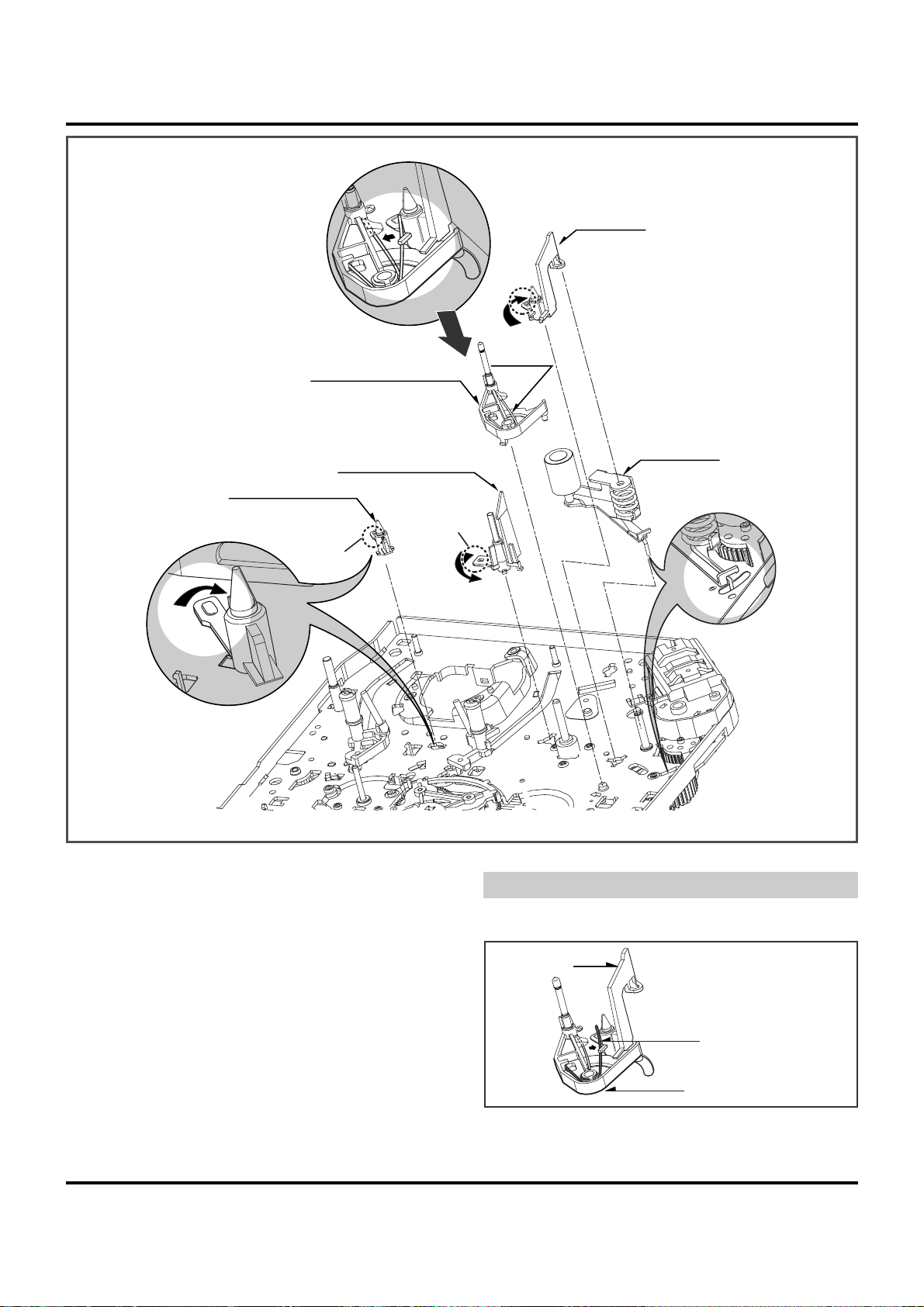

DECK MECHANISM DISASSEMBLY

H1

H3

(S1)

(S2)

(H5)

Gear Rack F/L Groove

Arm F/L

(A)

Lever Stopper (L)

Bracket Side (L)

Bracket

Assembly Door

Lever Stopper (R)

(B)

H2

H4

Lever Assembly S/W

Guide CST

Arm Assembly F/L

Holder Assembly CST

Plate Assembly Top

Groove

Fig. A-2

6

(Fig. A-2-1)

(Fig. A-2-2)

(Fig. A-2-6)

(Fig. A-2-7)

(Fig. A-2-5)

(Fig. A-2-3)

(Fig. A-2-4)

Page 7

7

DECK MECHANISM DISASSEMBLY

2. Plate Assembly Top (Fig. A-2-1)

1) Unhook the (H1) and separate the Left Side.

2) Unhook the (H2) and lift up the Plate Assembly Top.

(1) When reassembling, confirm (A),(B) Part of the Plate

Assembly Top is inserted to the (L),(R) Grooves of the

Bracket Side(L) and Bracket Assembly Door.

3. Holder Assembly CST (Fig.A-2-2)

1) Push the Lever Stopper(L),(R) in the direction of the

arrows (A), (B), and move the Holder Assembly CST.

2) Push the Bracket Assembly Door to the right and lift up

the Holder Assembly CSTalong the Guide Groove of the

Bracket Assembly Door.

4. Guide CST (Fig.A-2-3)

1) Push two Hooks(H3),(H4) in the direction of the arrow

and separate the left side.

2) Unhook (H5),(H6) as above No.1) and disassemble the

Guide CST in the direction of the arrow.

5. Bracket Side(L) (Fig. A-2-4)/

Bracket Assembly Door (Fig.A-2-5)

1) Remove the Screw (S1) and disassemble the Bracket

Side(L) in the front.

2) Remove the Screw (S2) and disassemble the Bracket

Assembly Door in the front.

6. Arm Assembly F/L (Fig. A-2-6)

1) Push the Arm Assembly F/L to the left and lift up it.

(1) When reassembling, confirm that the Gear(A) of the Arm

F/L and the Gear(B) of the Gear Rack F/L are assembled

as below.

7. Lever Assembly S/W (Fig. A-2-7)

1) Hook the Spring Lever S/W on (H5).

2) Lift up the left side of the Lever S/W from the Groove(A)

of the Chassis.

(1) Place the Spring Lever S/W of the above (No.1) as

original position.

NOTE

Plate Assembly Top

Bracket Side (L)

Bracket Assembly Door

Lever Stopper (L)

Lever Stopper (R)

Holder Assembly CST

(A)

(B)

Bracket Side (L)

Bracket Assembly Door

(H3)

(H4)

NOTE

Gear (B)

Gear (A)

NOTE

(H5)

Spring

Lever S/W

(H5)

Spring

Lever S/W

(H5)

(H5)

Page 8

DECK MECHANISM DISASSEMBLY

Arm Assembly

Cleaner

Head F/E

Base Assembly A/C Head

(S1)

(A)

(H1)

Fig. A-3

8

8. Arm Assembly Cleaner(Fig. A-3-1)

1) Break away the (A) part shown above Fig. A-3-1 from the

Embossing of the Chassis in the clockwise direction and

lift up the Arm Assembly Cleaner.

9. Head F/E (Fig. A-3-2)

1) Unhook the two Hooks (H1) on the back side of the

Chassis and lift up the Head F/E.

10. Base Assembly A/C Head (Fig. A-3-3)

1) Remove the Screw (S1) and lift up the Base Assembly

A/C Head.

(Fig. A-3-1)

(Fig. A-3-3)

(Fig. A-3-2)

Page 9

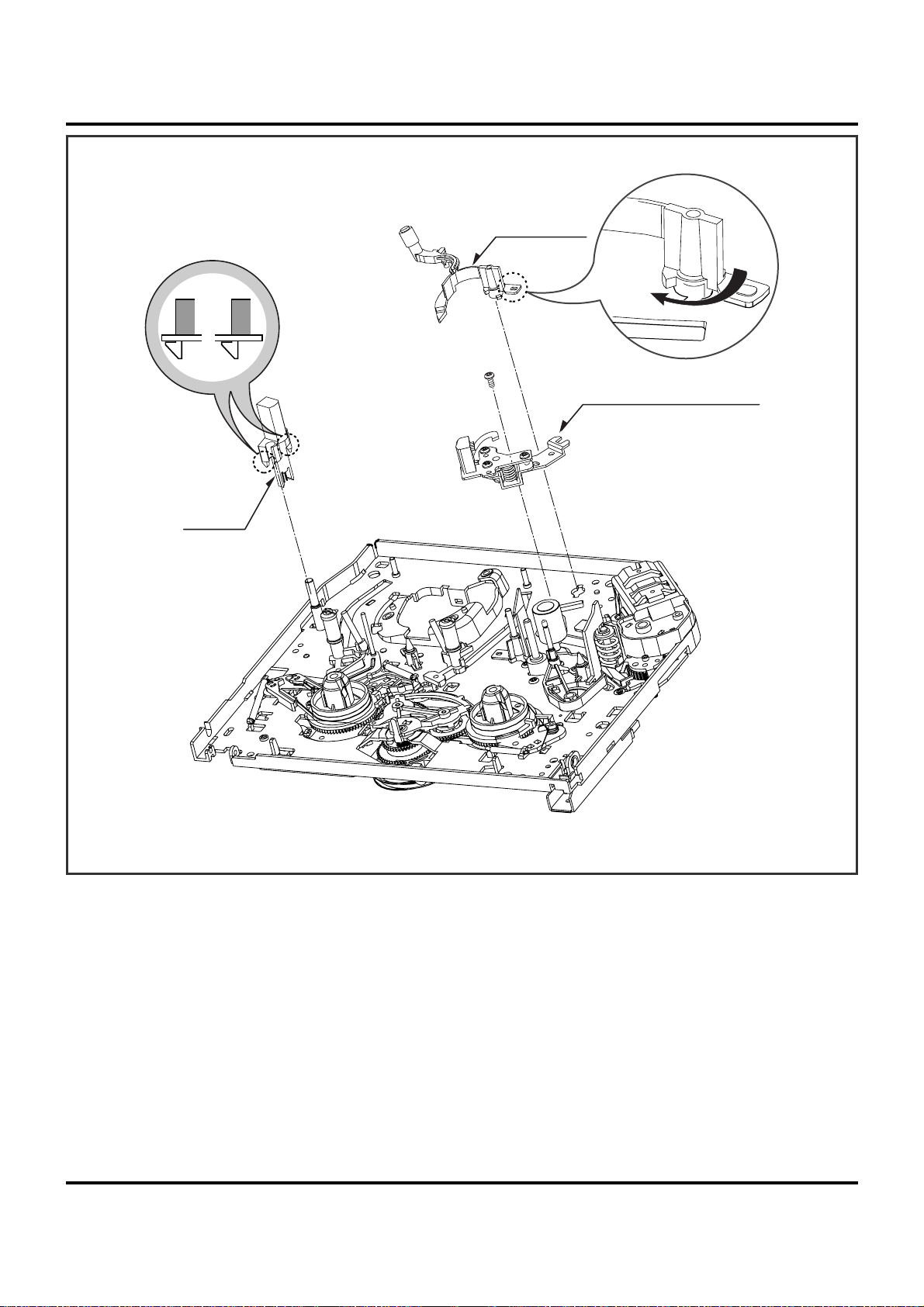

DECK MECHANISM DISASSEMBLY

Reel T

Reel S

Arm Assembly

Tension

Spring T Brake

Brake Assembly T

Band

Assembly

Tension

Brake Assembly S

Spring S Brake

Spring Tension

B

(A)

(C)

Fig. A-4

9

11. Brake Assembly S (Fig. A-4-1)

1) Remove the Spring S Brake.

2) Hold the (A) part shown above Fig. A-4-1 and turn to the

clockwise direction, and then lift up the Brake Assembly S.

(1) When reassembling, be careful not to change the Spring

with below No.12.(Refer to Fig. B-2).

12. Brake Assembly T (Fig. A-4-2)

1) Remove the Spring T Brake.

2) Hold the (B) part shown above Fig. A-4-2 and turn to the

counterclockwise direction, and then lift up the Brake

Assembly T.

(1) When reassembling, be careful not to change the Spring

with above No.11.(Refer to Fig. B-2).

13. Arm Assembly Tension (Fig. A-4-3)

1) Remove the Spring Tension.

2) Hold the (C) part shown above Fig. A-4-3 and turn to the clockwise direction, and then lift up the Arm Assembly Tension.

(1) When reassembling, be careful not to change the Spring

with above No.11,12.(Refer to Fig. B-2).

14. Reel S (Fig. A-4-4) & Reel T (Fig. A-4-5)

1) Lift up the Reel S and Reel T.

(1) When reassembling, be careful not to change the Reel S

and Reel T each other.

(2) Confirm two Slide Washers under the Reel S and Reel T.

NOTE

Spring T Brake

Spring S Brake

Spring Tension

NOTE

(Difference for Springs)

Color (Black)

Three Holes

Reel S

Reel T

(Fig. B-2)

NOTE

NOTE

(Fig. A-4-1)

(Fig. A-4-5)

(Fig. A-4-3)

(Fig. A-4-4)

(Fig. A-4-2)

Page 10

DECK MECHANISM DISASSEMBLY

Arm

Assembly

Pinch

Opener Lid

Base Assembly P4

Support CST

Arm Assembly T/up

(A)

(B)

(C)

(D)

Spring

Arm T/Up

Fig. A-5

10

15. Support CST (Fig. A-5-1)

1) Break away the (A) part shown above Fig. A-5-1 from the

Embossing of the Chassis in the clockwise direction, and

lift up the Support CST.

16. Base Assembly P4 (Fig. A-5-2)

1) Break away the (B) part shown above Fig. A-5-2 from the

Embossing of the Chassis in the counterclockwise direction and lift up the Base Assembly P4.

17. Opener Lid (Fig. A-5-3)

1) Hook the Spring Arm T/up on the Split digged under the

Arm Assembly T/up.(Refer to Fig.A-5-4(D)).

2) Break away the (C) Part of the Opener Lid from the

Embossing of the Chassis in the Clockwise direction and

lift up the Opener Lid.

18. Arm Assembly T/up (Fig. A-5-4)

1) Confirm that the Spring Arm T/up is placed as above

(No.17.1).

2) Lift up the Arm Assembly T/up.

(1) When reassembling, unhook the Spring Arm T/up Shown

above (No.17.1) to the original position.

19. Arm Assembly Pinch (Fig. A-5-5)

1) Lift up the Arm Assembly Pinch.

NOTE

Opener Lid

Spring Arm T/up

Arm Assembly T/up

(Fig. A-5-3)

(Fig. A-5-4)

(Fig. A-5-1)

(Fig. A-5-2)

(Fig. A-5-5)

Page 11

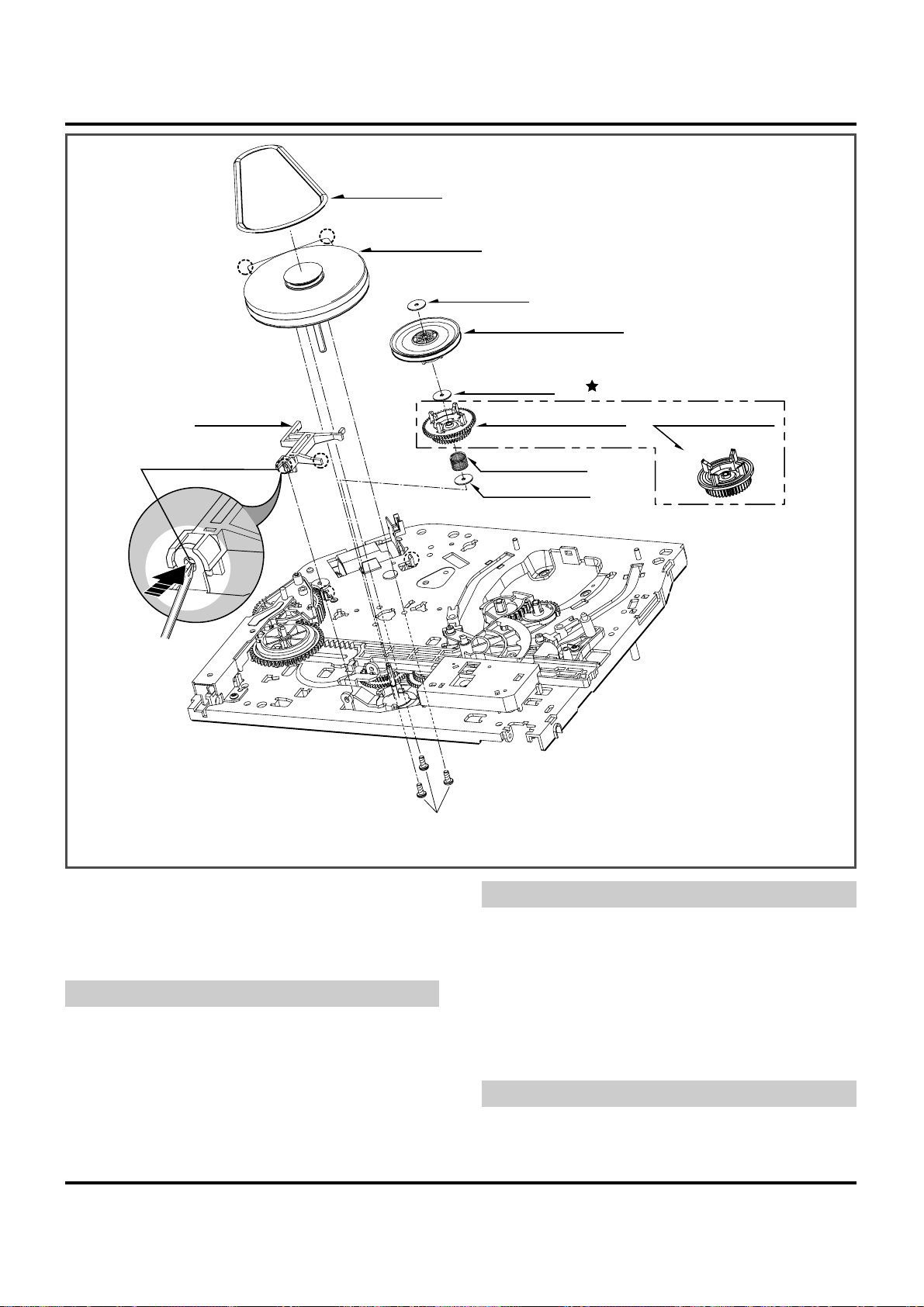

DECK MECHANISM DISASSEMBLY

Belt Capstan

Motor Capstan

Clutch Assembly D33

Washer(W1)

Washer(W2)

Spring Up/D

Slide Washer

Gear Assembly H-Up/D or

Lever F/R

(S1)

Hook(H1)

(A)

(C)

(A')

(B')

(B)

Gear Assembly Up/D

(For Normal Models)(For Hi-Rewind Models)

Optional Parts

Fig. A-6

11

20. Belt Capstan (Fig. A-6-1)/

Motor Capstan (Fig. A-6-2)

1) Remove the Belt Capstan.

2) Remove three Screws(S1) on the back side of the

Chassis and lift up the Motor Capstan.

(1) When reassembling, Confirm the (A), (B) parts of Motor

Capstan is located to the (A'), (B') of the Chassis.

21. Clutch Assembly D33 (Fig. A-6-3)

1) Remove the Washer(W1) and lift up the Clutch Assembly

D33.

22. Lever F/R (Fig. A-6-4)

1) Unhook the (H1) shown above Fig. A-6-4 and lift up the

Lever F/R.

(1) When reassembling, move the (C) part of the Lever F/R up

and down, then confirm if it is returned to original position.

23. Gear Assembly H-Up/D or Gear

Assembly Up/D (Fig. A-6-5)

1) Remove the Washer(W2) and lift up the Gear Assembly

H-up/D.

2) Remove the Spring Up/D.

3) Remove the Slide Washer.

(1) Gear Assembly H-Up/D is for Hi-Rewind Models.

(2) Gear Assembly Up/D is for Normal Models except Hi-Rewind

Models.

NOTE

NOTE

(Fig. A-6-1)

(Fig. A-6-2)

(Fig. A-6-3)

(Fig. A-6-5)

(Fig. A-6-4)

NOTE

Page 12

DECK MECHANISM DISASSEMBLY

Bracket Assembly Jog

(S1)

Brake

Assembly Capstan

Guide Rack F/L

Gear Rack F/L

(S2)

Hole (B)

Brake

Assembly Capstan

Hole (A)

(H2)

(H1)

Spring Capstan

Gear Cam

Gear Cam

Hole (A)+(B)

Fig. A-7

12

24. Bracket Assembly Jog (Fig. A-7-1)

1) Remove the Screw(S1) and lift up the Bracket Assembly

Jog.

25. Guide Rack F/L (Fig. A-7-2)/

Gear Rack F/L (Fig. A-7-3)

1) Remove the Screw(S2) and lift up the Guide Rack F/L.

2) Lift up the Gear Rack F/L.

26. Brake Assembly Capstan (Fig. A-7-4)

1) Hook the Spring Capstan on the Hook(H1).

2) Unhook the Hook(H2) and lift up the Brake Assembly

Capstan.(Refer to Fig. to the right)

(1) When reassembling, confirm that the Hole(A) of the

Brake Assembly Capstan is aligned to the Hole(B) of the

Gear Cam.

(Refer to above Fig. A-7-4).

NOTE

Hook(H2)

Hook(H2)

(Fig. A-7-4)

(Fig. A-7-1)

(Fig. A-7-2)

(Fig. A-7-3)

Page 13

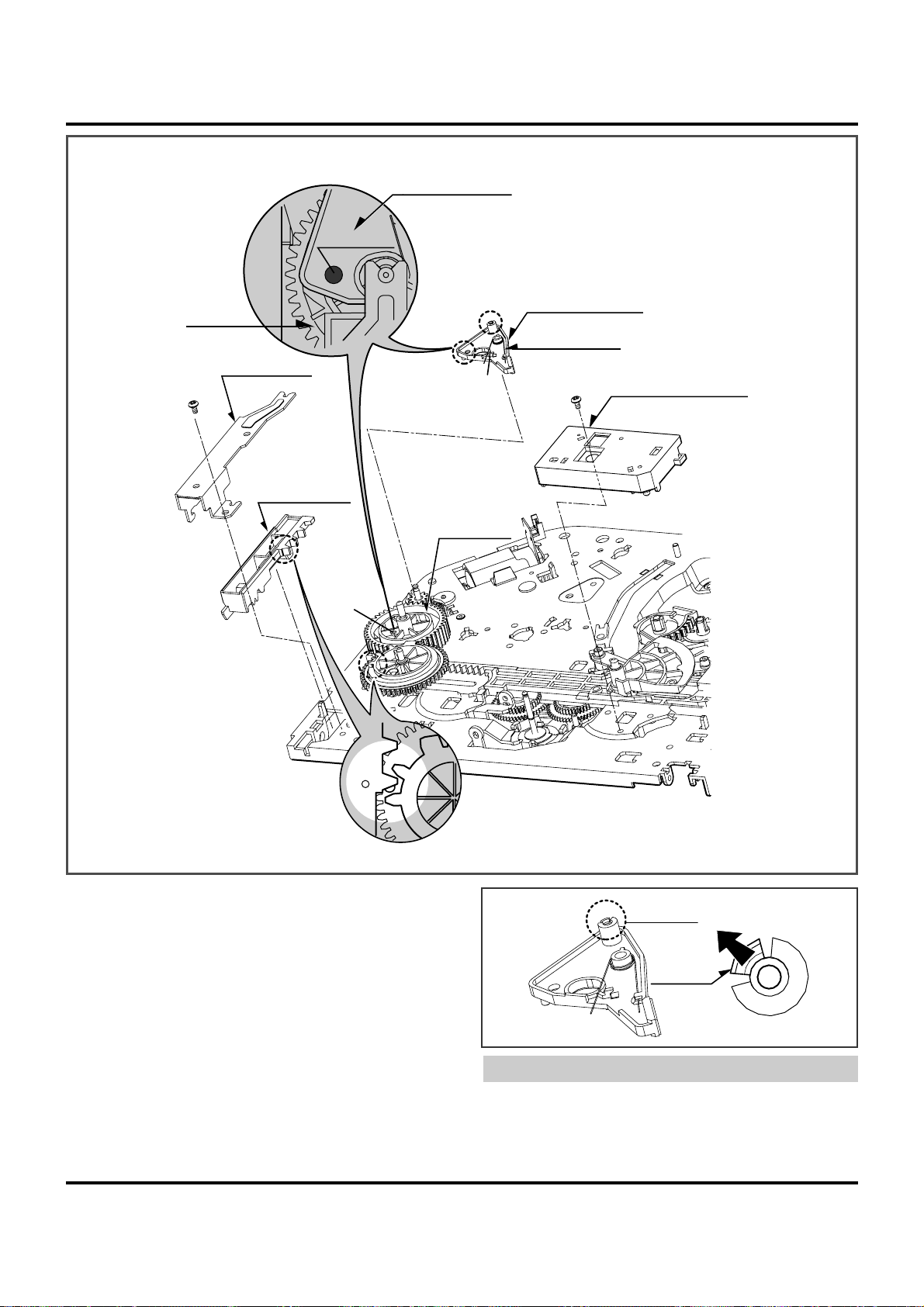

DECK MECHANISM DISASSEMBLY

H1

H2

Gear Drive

Gear Cam

Gear Connector

Bracket Assembly

L/D Motor

Washer (W1)

Gear Connector

Hole(A')+(A)

Hole(B')+(B)

Chassis

Gear Cam

Hole(B)

Hole(B')

Hole(A)

Hole(A')

Fig. A-8

13

27. Gear Drive (Fig. A-8-1)/

Gear Cam (Fig. A-8-2)/

Gear Connector (Fig. A-8-3)

1) Remove the Washer(W1) and lift up the Gear Drive.

2) Lift up the Gear Cam.

3) Lift up the Gear Connector.

(1) When reassembling, confirm that the Hole (A) of the

Gear Connector is aligned to the Hole (A') of the Chassis

(Fig. A-8-3).

(2) When reassembling, confirm that the Hole (B) of the

Gear Cam is aligned to the Hole (B') of the Chassis (Fig.

A-8-2).

(3) When reassembling, confirm that the (C) part of the Gear

Cam is aligned to the (D) part of the Gear Drive as shown

Fig. B-3

28. Bracket Assembly L/D Motor (Fig. A-8-4)

1) Unhook the three Hooks(H1),(H2) and push down the

Bracket Assembly L/D Motor.

NOTE

Gear Cam (C)

Gear Drive (D)

Hook (H1), (H2)

Chassis

(Fig. B-3)

(Fig. A-8-1)

(Fig. A-8-2)

(Fig. A-8-3)

(Fig. A-8-4)

Page 14

DECK MECHANISM DISASSEMBLY

Base Tension

Gear Sector

( S1)

Washer

Plate Slider

(A)

Lever Tension

(W1)

Fig. A-9

14

29. Gear Sector (Fig. A-9-1)

1) Remove the Washer(W1) and lift up the Gear Sector.

30. Base Tension (Fig. A-9-2)/

Plate Slider (Fig. A-9-3)/

Lever Tension (Fig. A-9-4)

1) Remove the Screw(S1) and lift up the Base Tension.

2) Lift up the Plate Slider.

3) Hold the (A) Part of the Lever Tension and turn to the

counterclockwise direction, and then lift up the Lever

Tension.

(1) When reassembling, turn the Lever Tension to the clock-

wise direction in maximum.

NOTE

(Fig. A-9-1)

(Fig. A-9-2)

(Fig. A-9-4)

(Fig. A-9-3)

Page 15

DECK MECHANISM DISASSEMBLY

Gear Assembly P3

Gear Assembly P2

Arm Assembly Idler Jog Arm Assembly Idler or

(For 2HD Models) (For 4HD Models)

Base Assembly P3

Base Assembly P2

Chassis

H1

H2

(A)

(B)

(H3)

Gear Assembly P3

Gear Assembly P2

(A)

(B)

Optional Parts

Fig. A-10

15

31. Gear Assembly P3 (Fig. A-10-1)/

Gear Assembly P2 (Fig. A-10-2)

1) Unhook the two Hooks(H1) and lift up the Gear Assembly P3.

2) Unhook the two Hooks(H2) and lift up the Gear Assembly P2.

32. Base Assembly P3 (Fig. A-10-3)/

Base Assembly P2 (Fig. A-10-4)

1) Move the Base Assembly P3 in the direction of the arrow of the

Chassis Hole(A) and push down the Base Assembly P3.

2) Move the Base Assembly P2 in the direction of the arrow of the

Chassis Hole(B) and push down the Base Assembly P2.

33. Arm Assembly Idler Jog or Arm Assembly

Idler (Fig. A-10-5)

1) Unhook the Hook(H3) and push down the Arm Assembly Idler

Jog.

1) Arm Assembly Idler Jog is for 4HD Models.

2) Arm Assembly Idler is for 2HD Models.

1) When reassembling, confirm that the (A) Part of the Gear

Assembly P3 is aligned to the (B) Part of the Gear Assembly P2

as shown below.

NOTE

NOTE

Gear Assembly P3

Gear Assembly P2

(A)

(B)

(Fig. A-10-1)

(Fig. A-10-2)

(Fig. A-10-4)

(Fig. A-10-3)

(Fig. A-10-5)

(Unloading Condition)

Page 16

DECK MECHANISM ADJUSTMENT

16

• Tools and Fixtures for Service

1. Cassette Torque meter

1. SRK-VHT-303(Not SVC part)

4. Torque gauge adaptor

5. Post height adjusting driver

Parts No:

SV-TGO-030-000 (SMALL)

SV-TGO-020-000 (LARGE)

6. + Type driver (ø 5)

2. Alignment tape

(See figure below)

3. Torque gauge

3. 600g.Cm A TG

SRK

VIDEO

CASSE

TTE

TORQUE

M

ETER

VHT-303

S

R

K

-

V

H

T

-

S

S

R

K

-

V

H

T

-

T

3

0

0

25

0

200

1

50

50

0

3

0

0

25

0

20

0

1

50

50

0

10

0

ALIGNMENT TAPES FOR ADJUSTMENT

Derivation No.

Mechanism

Adjustment ltems

FM Envelope

A

PAL

SP/LP

2/4 Head

TTV-P2L

B

PAL

SP

2 Head

TTV-P2

C

NTSC

SP/LP/EP

2/4 Head

TTV-N1

(TTN-N12)

D

NTSC

SP

2 Head

TTV-N2

Slantness

Height

Azimuth

A commercially available tape

A/C

Head

TTV-P1

(TTV-P1L)

TTV-P2

TTV-P2

(TTV-P2L)

TTV-N1

(TTV-N12)

TTV-N2

TTV-N2

TTV-P1

TTV-P2

TTV-P2

TTV-N1

(TTV-N12)

(TTV-N1E)

TTV-N2

TTV-N2

TTV-N2E

TTV-N12

A commercially available tape

SRK-VHT-303

RG Post lnclination

Tape Back Tension

The numbers in ( ) parenthesis can be used as the substiture.

X-value

Page 17

Purpose:To determine if the Mechanism is in the correct position, when a Tape is ejected.

DECK MECHANISM ADJUSTMENT

17

1.Mechanism Alignment Position Check

1) Turn the Power S/W on and eject the Cassette by pressing the Eject Button.

2) Remove the Top Cover and Plate Assembly Top, visually check if the Gear Cam Hole is aligned with the

Chassis Hole as below Fig. C-2.

3) IF not, rotate the Shaft of the Loading Motor to either

Clockwise or Counterclockwise until the Alignment is

as below Fig. C-2.

4) Remove the Screw which fixes the Deck Mechanism

and Main Frame and confirm if the Gear Cam is aligned

with the Gear Drive as below Fig. C-1(A).

5) Confirm if the Mode S/W on the Main P.C.Board is

aligned as below Fig. C-1(B).

6) Remount the Deck Mechanism on the Main P.C.Board

and check each operation.

Mode S/W

Gear Cam

Gear Drive

(A)

(B)

Test Equipment/ Fixture

• Blank tape

Test Conditions (Mechanism

Condition)

• Eject Mode (with Cassette ejected)

Check Point

• Mechanism and Mode Switch Position

Fig. C-1

Fig. C-2

CHECK DIAGRAM

BOTTOM VIEW

TOP VIEW

Gear Cam (o) and Gear Drive (o) groove alignment

L/D Motor Assembly

Gear Cam

Gear Cam Hole

Chassis Hole

Page 18

18

Purpose: To insure smooth Transport of the Tape during each Mode of Operation.

If the T ape Transport is abnormal, then check the Torque as indicated by the chart below .

DECK MECHANISM ADJUSTMENT

2. Preparation for Adjustment (To set the

Deck Mechanism to the Loading state

without inserting a Cassette Tape).

1) Unplug the Power Cord from the AC Outlet.

2) Disassemble the Top Cover and Plate Assembly Top.

3) Plug the Power Cord into the AC Outlet.

4) Turn the Power S/W on and push the Lever Stopper (L),(R)

of the Holder Assembly CSTto the back for Loading the

Cassette without Tape.

Cover the Holes of the End Sensors at the both sides of the

Bracket Side(L) and Bracket Assembly Door to prevent a

light leak.

Then The Deck Mechanism drives to the Stop Mode.

In this case, The Deck Mechanism can accept inputs of

each mode, however the Rewind and Review Operation

can not be performed for more than a few seconds

because the Take-up Reel Table is in the Stop State and

can not be detected the Reel Pulses.

3. Checking Torque

The Values are measured by using a Torque Gauge and

Torque Gauge Adaptor with the Torque Gauge affixed.

The Torque reading to measure occurs when the Tape

abruptly changes direction from Fast Forward of Rewind

Mode, when quick bracking is applied to both Reels.

SRK

V

ID

E

O

C

A

S

S

E

T

T

E

T

O

R

Q

U

E

M

E

T

E

R

V

H

T

-3

0

3

S

R

K

-

V

H

T

-

S

S

R

K

-

V

H

T

-

T

300

250

200

150

50

0

300

250

200

150

50

0

100

Test Equipment/ Fixture

• Torque Gauge(600g/cm ATG)

• Torque Gauge Adaptor

• Cassette Torque Meter

SRK-VHT-303

Checking Method

• Perform each Deck Mechanism Mode without

inserting a Cassette Tape(Refer to above No.2

Preparation for Adjustment).

• Read the Measurement of the Take-up or Supply

Reels on the Cassette Torque Meter(Fig. C-3-2).

• Attach the Torque Gauge Adaptor to the Torque

Gauge and then read the Value of it(Fig. C-3-1).

NOTE:

Fig. C-3-2

Fig. C-3-1

Torque Gauge

Torque Gauge

Adaptor

Reel Table

Item

Fast Forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Mode

Fast Forward

Rewind

Play

Review

Test Equipment

Cassette Torque Gauge

Cassette Torque Gauge

Cassette Torque Meter

Cassette Torque Meter

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

More than 400g/cm

More than 400g/cm

75~115g/cm

130~200g/m

Measurement Reel

Measurement Values

Test Conditions (Mechanism

Condition)

• Play (FF) or Review (REW) Mode

NOTE:

• Cassette Torque Meter (SRK-VHT-303)

• Torque Gauge (600g.cm ATG)

Page 19

DECK MECHANISM ADJUSTMENT

19

4.Guide Roller Height Adjustment

Adjustment Procedure

1) Confirm if the Tape runs along the Tape Guide Line of the

Lower Drum.

2) If the Tape runs the Bottom of the Guide Line, turn the Guide

Roller Height Adjustment Screw to Clockwise direction.

3) If it runs the Top, turn to Counterclockwise direction.

4) Adjust the Height of the Guide Roller to be guided to the Guide

Line of the Lower Drum from the Starting and Ending Point of

the Drum.

Purpose: To regulate the Height of the Tape so that the Bottom of the Tape runs along the

Tape Guide Line on the Lower Drum.

Test Equipment/ Fixture

• Post Height Adjusting Driver

Test Conditions (Mechanism Condition)

• Play or Review Mode

Adjustment Point

• Guide Roller Height Adjustment

screws on the Supply and Take-Up

Guide Rollers.

Fig. C-4-1

Upper Flange

Guide Roller

Retaining Screw

Guide Roller Height

Adjustment screw

ADJUSTMENT DIAGRAM

Test Equipment/Fixture

• Oscilloscope

• Alignment T ape

• Post Height Adjusting

Driver

Test Equipment Connection Points

• CH-1:PB RF Envelope

• CH-2:NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Point

• RF Envelope Output

Point

Test Conditions VCR(VCP) State

• Play an Alignment Tape

Adjustment Point

• Guide Roller Height

Adjustment Screws

Fig. C-4-2

Fig. C-4-3

P3 POST

ADJUSTMENT

P2 POST

ADJUSTMENT

Turn the Roller Guide Height

Adjustment Screw slightly

to flatten the waveform.

Tracking control at center

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Turn(Move) the tracking

control to both directions

4-1. Preliminary Adjustment

4-2. Precise Adjustment

Adjustment Procedure

1) Play an Alignment Tape after connecting the Probe of the

Oscilloscope to the RF Envelope Output Test Point and

Head Switching Output Test Point.

2) Tracking Control(in PB Mode) : Center Position(When

this Adjustment is performed after the Drum Assembly

has been replaced, set the Tracking Control so that the

RF Output is Maximum).

3) Height Adjustment Screw : Flatten the RF Waveform.

(Fig. C-4-2)

4) Turn(Move) the Tracking Control(in PB Mode)

Clockwise and Counterclockwise.(Fig. C-4-3)

5) Check that any Drop of RF Output is uniform at the

Start and End of the Waveform.

If the adjustment is excessive or insufficient the tape

will jam or fold.

NOTE

Waveform Diagrams

Connection Diagram

Page 20

20

DECK MECHANISM ADJUSTMENT

5. Audio/Control (A/C) Head Adjustment

Purpose: To insure that the Tape passes accurately over the Audio and Control Tracks in exact

Alignment in both the Record and Playback Modes.

Test Equipment/ Fixture

• Blank Tape

• Screw Driver(+) Type 5mm

• Play the blank tape

Test Conditions (Mechanism Condition)

Adjustment Point

• Tilt Adjustment Screw(C)

• Height Adjustment Screw(B)

• Azimuth Adjustment Screw(A)

Fig. C-5-1

A/C Head Base

Fig. C-5-2

Height Adjustment

Screw(B)

Tilt Adjustment

Screw(C)

Azimuth Adjustment

Screw(A)

X-Value Adjustment

Hole

Fixed Screw

Fig. C-5-3

A/C Head

Tape

Tape

0.2~0.25mm

P4

5-1. Preliminary Adjustment (Height and Tilt Adjustment)

Perform the Preliminary Adjustment, when there is no Audio Output Signal with the Alignment Tape.

1) Initially adjust the Base Assembly A/C Head as shown

Fig. C-5-1 by using the Height Adjustment Screw(B).

2) Play a Blank Tape and observe if the Tape passes accurately over the A/C Head without Tape Curling or

Folding.

3) If Folding or Curling is occured then adjust the Tilt

Adjustment Screw(C) while the Tape is running to

resemble Fig. C-5-3.

4) Reconfirm the Tape Path after Playback about 4~5 seconds.

Ideal A/C head height occurs, when the tape runs

between 0.2~0.25mm above the bottom edge of the A/C

head core.

NOTE

Adjustment Procedure/Diagrams

A/C Head Assembly

-0.05

10.9

Page 21

Purpose: To obtain compatibility with other VCR(VCP) Models.

DECK MECHANISM ADJUSTMENT

21

5-2. Confirm that the Tape passes smoothly

between the Take-up Guide and Pinch

Roller(using a Mirror or the naked eye).

1) Afetr completing Step 5-1.(Preliminary Adjustment),

check that the Tape passes around the Take-up Guide

and Pinch Roller without Folding or Curling at the Top or

Bottom.

(1) If Folding or Curling is observed at the Bottom of

the Take-up Guide then slowly turn the Tilt

Adjustment Screw(C) in the Clockwise directioin.

(2) If Folding or Curling is observed at the Top of it then

slowly turn the Tilt Adjustment Screw(C) in the

Counterclockwise direction.

Check the RF Envelope after adjusting the A/C Head, if

the RF Waveform differs from Fig. C-5-4, performs

Precise Adjustment to flat the RF Waveform.

Test Equipment/ Fixture

• Oscilloscope

• Alignment Tape(SP)

• Screw Driver(+) Type 5mm

Connection Point

• Audio output jack

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

1KHz, 7KHz Sections

Adjustment Point

• Azimuth Adjustment Screw(A)

• Height Adjustment Screw(B)

1) Connect the Probe of the Oscilloscope to Audio Output

Jack.

2) Alternately adjust the Azimuth Adjustment Screw(A) and

the Tilt Adjustment Screw(C) for Maximum Output of the

1Khz and 7Khz segments, while maintaining the flattest

Envelope differential between the two Frequencies.

Adjustment Procedure

5-3. Precise Adjustment (Azimuth adjustment)

6. X-Value Adjustment

Fig. C-5-4

1KHZ

• Oscilloscope

• Alignment tape(SP only)

• Screw Driver(+) Type 5mm

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Swithching Output

Test Point

• RF Envelope Output Test

Point

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

Adjustment PointConnection PointTest Equipment/ Fixture

Adjustment Procedure

1) Insert the alignment tape, and press the + or - manual

tracking (channel) button once while "AUTO TRACKING"

is flashing on the screen to release auto tracking, and then

center the tracking.

2) Run the tape long enough for tracking to complete one

cycle.

3) Loosen the fixing screw, and move the A/C head base

assembly in the direction shown in the diagram, to find the

center of the peak so that the maximum envelope is available.

With this method, the 31-µm head can trace on the centerof 58-µm track.

4) Tighten the A/C head base assembly fixing screw.

7KHZ

A:Maximum

B:Maximum

Left

Right

Groove at the

Base A/C

Height Adjustment Screw(B)

Tilt Adjustment Screw(C)

Azimuth Adjustment

Screw(A)

X-Value Adjustment Hole

Fixed Screw

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST POINT

Connection Diagram

Adjustment Diagram

NOTE:

CH-1

CH-2

Page 22

Purpose: To correct for shift in the Roller Guide and X value after replacing the Drum.

8-2.Check for tape curling or jamming

Test Equipment/ Fixture

• T-160 Tape

• T-120 Tape

Specification

• Be sure there is no tape jamming or curling

at the begining, middle or end of the tape.

VCR(VCP) State

•

Run the CUE, REV play mode at the

beginning and the end of the tape.

Test Conditions (Mecanism Condition)

1) Confirm that the tape runs smoothly around the roller

guides, drum and A/C head assemblies while abruptly

changing operating modes from Play to CUE or REV.

This is to be checked at the begining, middle and end

sections of the cassette.

2) Confirm that the tape passes over the A/C head assembly as indicated by proper audio reproduction and proper tape counter performance.

Checking Procedure

DECK MECHANISM ADJUSTMENT

22

7. Adjustment after Replacing Drum Assembly (Video Heads)

T est Equipment/ Fixture

• Oscilloscope

• Alignment tapes

• Blank Tape

• Post Height Adjusting Driver

• Screw Driver(+) Type 5mm

Connection Point

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Swithching Output

Test Point

• RF Envelope Output Test Point

Test Conditions

(Mechanism Condition)

• Play the blank tape

• Play an alignment tape

Adjustment Points

• Guide Roller Precise

Adjustment

• Switching Point

• Tracking Preset

• X-Value

Checking/Adjustment Procedure

Play a blank tape and check for tape curling or creasing around

the roller guide. If there is a problem then follow the procedure

4. "Guide Roller Height" and 5. "Audio Control(A/C) Head

Adjustment".

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Connection Diagram

Waveform

V1/V MAX ≤0.7

V2/V MAX ≤0.8

RF ENVELOPE OUTPUT

Fig. C-7

8. Check the Tape Travel after Reassembling Deck Assembly.

8-1.Check Audio and RF Locking Time during playback and after CUE or REV (FF/REW)

Test Equipment/ Fixture

• Oscilloscope

• Alignment tapes(with 6H

3kHz Color Bar Signal)

• Stop Watch

Specification

• RF Locking Time: Less than 5 sec.

• Audio Locking Time:Less than

10sec

Test Equipment

Connection Points

• CH-1: PB RF Envelope

• CH-2: Audio Output

• RF Envelope Output Point

• Audio Ouptut Jack

Test Conditions

(Mecanism Condition)

• Play an alignment tape

(with 6H 3kHz Color Bar

Signal)

Checking Procedure

Play an alignment tape then change the operating mode to

CUE or REV and confirm if the unit meets the above listed

specifications.

1) CUE is fast forward mode (FF)

2) REV is the rewind mode (REW)

3) Referenced to the Play mode

NOTES:

V1

V

V2

CH1 CH2

Connection Points

Page 23

MAINTENANCE/INSPECTION PROCEDURE

23

(4) F/E Head

(3) P1 Post

(6) Drum Assembly

(Video Head)

(5) Base

Assembly P2

(2) Tension Post

(1) Supply Reel

(7) Base Assembly P3

The following faults can be remedied by cleaning and oiling.

Check the needed lubrication and the conditions of cleanliness in the unit.

Check with the customer to find out how often the unit is

used, and then determine that the unit is ready for inspection

and maintenance. Check the following parts.

1 Check before starting repairs

Phenomenon Inspection

Replacement

Color beats Dirt on full-erase head

o

Poor S/N, no color

Dirt on video head

Vertical or

Horizontal jitter

Dirt on Audio/control head

Dirt on pinch roller

If locations marked with o do not operate normally after cleaning, check for wear and replace.

See the EXPLODED VIEWS at the end of this manual as well

as the above illustrations See the Greasing (Page 25) for the

sections to be lubricated and greased.

NOTE

o

o

o

o

Dirt on video head

Dirt on tape transport system

Low volume,

Sound distorted

Tape does not run.

Tape is slack

o

In Review and

Unloading (off mode),

the Tape is rolled up

loosely.

Clutch Ass’y S27

Torque reduced

Cleaning Drum and

transport system

Fig. C-9-3

(8) A/C Head

(9) P4 Post

(11) Pinch Roller

(12) T ake-up Guide Post

(10) Capstan Shaft

(13) T ake-up Reel

* No. (1)~(13) Indicates the Tape Path to be traveled from Supply Reel to Take-up Reel.

Fig. C-9-1 Top VIEW

Fig. C-9-2 BOTTOM VIEW

F/E Head

Video Head

A/C Head

Pinch Roller

Belt Capston

Clutch

Assembly D33

Fig. C-9-3 Tape Transport System

Page 24

24

MAINTENANCE/INSPECTION PROCEDURE

The recording density of a VCR(VCP) is much higher than

that of an audio tape recorder. VCR(VCP) components must

be very precise, at tolerances of 1/1000mm, to ensure compatiblity with other VCRs. If any of these components are

worn or dirty, the symptoms will be the same as if the part is

defective. To ensure a good picture, periodic inspection and

maintenance, including replacement of worn out parts and

lubrication, is necessary.

Schedules for maintenance and inspection are not fixed

because they vary greatly according to the way in which the

customer uses the VCR(VCP), and the environment in which

the VCR(VCP) is used.

But, in general home use, a good picture will be maintained

if inspection and maintenance is made every 1,000 hours.

The table below shows the relation between time used and

inspection period.

Table 1

(1) Grease : Kanto G-311G (Blue) or equivalent

(2) Isopropyl Alcohol or equivalent

(3) Cleaning Patches

(4) Grease : Kanto G-381(Yellow) : Used only for Reel S and

Reel T

(1) Cleaning video head

First use a cleaning tape. If the dirt on the head is too

stubborn to remove by tape, use the cleaning patch.

Coat the cleaning patch with Isopropyl Alcohol. Touch

the cleaning patch to the head tip and gently turn the

head(rotating cylinder) right and left.

(Do not move the cleaning patch vertically. Make sure

that only the buckskin on the cleaning patch comes into

contact with the head. Otherwise, the head may be

damaged.)

Thoroughly dry the head. Then run the test tape. If

lsopropyl Alcohol remains on the video head, the

tape may be damaged when it comes into contact

with the head surface.

(2) Clean the tape transport system and drive system, etc,

by wiping with a cleaning patch wetted with Isporopyl

Alcohol.

1 It is the tape transport system which comes into contact

with the running tape. The drive system consists of those

parts which moves the tape.

2 Make sure that during cleaning you do not touch the tape

transport system with the tip of a screw driver and no that

force is that would cause deforming or damage applied to

the system.

2.Required Maintenance

3.Scheduled Maintenance

5) Maintenance Procedure

5-1) Cleaning

NOTES:

About 1

year

One hour

Two hours

Three hours

When

inspection is

necessary

Average

hours used

per day

About 18

months

About 3

years

4.Supplies Required for Inspection and

Maintence

Fig. C-9-4

Drum

(Rotating Cylinder)

Head Tip

Coat With Isopropyl Alcohol

Touch this section of cleaning

patch to the head tip and gently

turn the Drum (Rotating Cylinder)

Cleaning Patch

Page 25

MAINTENANCE/INSPECTION PROCEDURE

25

(1) Greasing guidelines

Apply grease, with a cleaning patch. Do not use excess

grease. It may come into contact with the tape transport

or drive system. Wipe any excess and clean with clean

ing patch wetted in Isopropyl Alcohol.

(2) Periodic greasing

Grease specified locations every 5,000 hours.

5-2) Greasing

NOTE:Greasing Points

3

2

1

4

5

6

9

7

8

1)Loading Path Inside & Top side

2)Base Tension Boss inside Hole

3)Arm Assembly F/L "U" Groove

4)Arm Take-up Rubbing Section

5)L/D Motor Worm Wheel Part

6)Shaft

7)Arm Assembly F/L of Buming

Inside Hole

8)Reel S, TShaft (G381:Yellow)

9)Brake T Groove

Gear Assembly Up/D

Gear Drive

Gear Sector

Gear Cam

Press

Cam Part

Cam Part

Gear Part

Stopper Part

Bracket Side (L)

Bracket Assembly Door

1

4

5

76

3

2

1) Loading Path Inside & Top side

2) Shaft

3) Gear Rack F/L Moving Section

4) Shaft

5) Lever Tension Groove

6) Clutch Assembly D33 Shaft

7) Brake "S" Rubbing Section

Chassis (Top)

Chassis (Bottom)

Guide Rack F/L Gear Rack F/L

Side

Bottom

inside

Bottom

Cam &

Gear Part

Plate Slider (Top)

Plate Slider (Bottom)

Cam Part

Cam Part

Gear Part

Guide Rail

Page 26

MECHANISM TROUBLESHOOTING GUIDE

26

Auto REW doesn't work.

Is the output of END sensor

of supply side "H"?

“H”: more than 3.5V

“L”: less than 0.7V~1V

Is the voltage across IR LED

between 0.8~1.5V?

Replace LED.

Is the Vcc. voltage of End

sensor 5V?

Check the syscon power.

Replace End sensor.

Check syscon circuit.

YES

YES

YES

NO

NO

NO

1.Deck Mechanism

A.

NO

NO

NO

No F/R modes.

Is the present mode,

F/R Mode?

Is the mode SW assembled

correctly (refer to Page 17.)

Is the normal voltage supplied to

the Capstan Motor Vcc1, Vcc2.?

Does terminal voltage(Vctl) of

Capstan Motor supply side

more than 4V?

Check Servo, Power Circuits.

Replace the Capstan Motor.

Does the Capstan Motor rotate?

Do the T/Up, Supply Reel rotate?

Check syscon circuit.

YES

YES

YES

YES

YES

YES

B.

YES

Page 27

MECHANISM TROUBLESHOOTING GUIDE

27

AUTO STOP.

(PLAY/CUE/REV)

Are there T/up and supply reel

pulses.

In Play/Cue/Rev is the pinch

roller in contact with the capstan

shaft.

Replace Reel Sensor.

Is the output of DFG, DPG OK?

Check aligment positions (page 17)

Check spring Pinch.

Replace Drum Motor.

Check Servo, Syscon.

Check the Syscon, µ-COM.

No cassette loading.

Insert the cassette.

Check Cassette Carry Assembly.

Is there variation for F/L S/W

Output?

(In Tape with REC Tab

“L”→“H”→“L”)

(In Tape without REC Tab

“L”→“H”→“L”→“H”)

Does the F/L S/W work normally?

Does the lever S/W work

normally.

Check Syscon Circuit.

Check Syscon Circuit.

Replace F/L S/W.

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

YES

C.

D.

Page 28

MECHANISM TROUBLESHOOTING GUIDE

28

In PB mode Tape Presence

not sensed.

Is the Pinch Roller attached

to the Capstan Motor Shaft?

Check Alignment positions

(page 17)

Does the T/Up

Reel turn?

Replace the Belt.

Is the Belt ok?

Does the Drum

Motor turn?

Are there DPG,

DFG Pulses?

Are the T/Up Supply Reel Sensors

ok?

Check Syscon,

Circuit.

Check Syscon,

Circuit.

Check Servo, Syscon.

Does the Capstan Motor turn?

Is the terminal voltage

of the Drum Motor

more than 2.3V?

Replace the

Drum Motor.

Is the Vcc voltage of the Drum

Motor normal?

Check the clutch and the Idler

Assembly.

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

Is the terminal voltage of Capstan

Motor supplied more than 4V?

Replace the

Capstan Motor.

Is the Voltage supplied to the Capstan

Motor Vcc1,Vcc2 each?

YES

YES

YES

Check Servo,

Power.

NO

NO

NO

E.

Page 29

MECHANISM TROUBLESHOOTING GUIDE

29

Cassette cannot be inserted.

Does the Lever Switch work?

Is the Lever Switch Spring

damaged or omitted?

Does the F/L switch work

normally?

Replace or add the

Lever Switch Spring.

Is the Vcc of Main P.C.Board

5V?

YES

YES

Check syscon circuit.

YES

Check power circuit.

NO

Is the voltage between cassette

switch and GND on Main

P.C.Board 5V?

YES

Is there a short circuit between cassette

switch and GND on main P.C.Board?

Remove the short circuit part or

Replace the main P.C.Board.

NO

Check Mode switch location and

syscon circuit.

Replace F/L Switch.

YES

NO

YES

NO

NO

Replace F/L Switch.

NO

2. Front Loading Mechanism

A.

Page 30

MECHANISM TROUBLESHOOTING GUIDE

30

NO

Cassette will not eject.

Does the L/D motor rotate in reverse?

Check L/D Motor or Drive IC.

Replace lever Switch.

Does the Lever Switch work?

YES

NO

NO

Does the Arm Assembly F/L work normally?

YES

NO

Does the Opener Door work?

YES

Replace Arm Assembly F/L.

Replace the Opener Door.

B.

Page 31

MECHANISM TROUBLESHOOTING GUIDE

31

Cassette will not load.

Does the CST insert?

Does the opener Lid work?

Is the opener Door assembled correctly?

Replace the Opener Lid.

Replace the Arm Assembly F/L.

Check the power of L/D Motor.

Is the Holder Assembly Cassette

assembled correctly?

Replace the Rear Rack F/L.

Does the Gear Rack F/L work?

Does the Opener Door work?

Does the Arm Assembly F/L work?

Does the L/D Motor work?

Does the Holder Assembly Cassette

move the Arm Assembly F/L?

Replace the Front Loading

Mechanism Assembly .

YES

YES

YES

YES

NO

NO

NO

YES

NO

YES

NO

YES

NO

C.

Page 32

MECHANISM EXPLODED XIEW 1/3

15

14

ARM CLEANER

19

17

20

21

22

27

28

25

26

24

1

2

P4 ONLY

P2 ONLY

3

BASS ASSY

P2

6

7

5

12

13

16

4

9

8

10

11

18

23

A

A

A

C

D

B

B

B

D

CAP. A CLEANER

ROLLER CLEANER

2

32

Page 33

MECHANISM MAIN PARTS LIST 1/3

REF. NO PART NO. KANRI DESCRIPTION

1 S1-41R-000-2A0 CHASSIS ASSY

2 S2-61R-000-9A0 ARM ASSY IDLER-J<P4>

2 S2-61R-000-8A0 ARM ASSY IDLER-J<P2>

3 S4-08R-000-1A0 REEL S

4 S2-61R-000-4A0 ARM ASSY TENSION

5 S9-70R-005-2A0 SPRING TENSION

6 S7-70R-000-4A0 BAND ASSY TENSION(MECH)

7 S5-238-33B-000 HEAD FE D33

8 S4-21R-000-3A0 BRAKE ASSY S

9 S9-70R-005-4A0 SPRING SB

10 S9-80R-001-0A0 SUPPORTER CST

11 S0-41R-000-7A0 BASE ASSY P4

12 S0-06R-001-4A0 CAP,FPC

13 S9-30R-010-7A0 HOLDER FPC<P4>

13 S9-30R-010-6A0 HOLDER FPC<P2>

14 S7-23R-010-1B0 DRUM ASSY SUB D33 2HD<P2>

14 S7-23R-010-2D0 DRUM ASSY SUB D33 4HD<P4>

15 S6-80R-B00-04A MOTOR(MECH)

16 S0-41R-000-5A0 BASE ASSY A/C HEAD

17 S2-61R-000-3A0 ARM ASSY CLEANER

18 S0-41R-000-4A0 BASE ASSY P3

19 S2-61R-001-1A0 ARM ASSY PINCH

20 S8-10R-005-3A0 BRACKET L/D MOTOR

21 S6-81R-000-7A0 MOTOR ASSY L/D

22 S4-70R-002-5A0 GEAR WHEEL

23 S8-70R-000-1A0 OPENER LID

24 S4-08R-000-2A0 REEL T

25 S9-70R-005-3A0 SPRING TB

26 S4-21R-000-4A0 BRAKE ASSY T

27 S9-70R-004-3A0 SPRING T/UP

28 S2-60R-001-1A0 ARM T/UP

29 S0-41R-000-3A0 BASE ASSY P2

A 87-261-071-410 PAN HEAD SCREW 2.6-4

B 87-261-094-410 PAN HEAD SCREW 3-6

C 87-741-095-410 SCREW,PAN HEAD 3.0-8.0

D S3-540-01B-000 WASHER,P.S 3.1-6-0.5

NO.

33

Page 34

MECHANISM EXPLODED VIEW 2/3

7

8

15

16

LEVER

SLOW

18

GEAR JOG

19

20

1

12

10

6

5

4

14

11

17

P4 ONLY

9

BRAKE

CAPSTAN

13

2

3

B

D

C

C

A

B

B

D

BRACKET JOG

LEVER JOG

ARM JOG

GEAR P3

SPRING L/D

LEVER P3

GEAR P2

SPRING L/D

LEVER P2

34

Page 35

MECHANISM MAIN PARTS LIST 2/3

REF. NO PART NO. KANRI DESCRIPTION

1 S9-70R-005-1A0 SPRING UP/D

2 S4-70R-004-4A0 GEAR ASSY UP/D

3 S2-65R-000-2A0 CLUTCH ASSY

4 S5-10R-002-5A0 LEVER F/R

5 S4-70R-003-7A0 GEAR RACK F/L

6 S9-74R-001-8A0 GUIDE RACK F/L

7 S4-00R-000-5A0 BELT CAPSTAN

8 S6-80R-A00-03A MOTOR CAPSTAN(MECH)

9 S9-70R-005-9A0 SPRING CAPSTAN

10 S4-70R-003-3A0 GEAR DRIVE

11 S4-70R-003-6B0 GEAR CONNECT

12 S4-70R-003-2A0 GEAR CAM

13 S4-70R-003-4A0 GEAR SECTOR

14 S3-00R-015-7A0 PLATE SLIDER

15 S4-70R-002-8A0 GEAR ASSY P3

16 S4-70R-002-6A0 GEAR ASSY P2

17 S8-11R-001-2A0 BRACKET ASSY JOG<P4>

18 S9-70R-004-9A0 SPRING JOG<P4>

19 S0-40R-001-8A0 BASE TENSION

20 S5-10R-002-2A0 LEVER TENSION

A SA-PF0-262-218 SCREW,PAN HEAD 2.6-6.8

B 87-261-094-410 PAN HEAD SCREW 3-6

C SW-ZZR-000-4B0 WASHER STOPPER

D SW-ZZR-000-4A0 WASHER STOPPER

NO.

35

Page 36

MECHANISM EXPLODED VIEW 3/3

4

5

8

7

3

HOLDER

SIDE(L)

HOLDER

SIDE(R)

HOLDER CST

LEVER

STOPPER(L)

LEVER

STOPPER(R)

BODY F/L

6

SPRING

F/L(L)

SPRING

F/L(R)

ARM

F/L(L)

ARM

F/L(R)

2

1

B

A

A

B

BRACKET

SIDE(R)

OPENER

DOOR

36

Page 37

MECHANISM MAIN PARTS LIST 3/3

REF. NO PART NO. KANRI DESCRIPTION

1 S5-10R-002-0A0 LEVER SWITCH

2 S9-70R-005-0A0 SPRING SWITCH

3 S8-10R-005-6A0 BRACKET SIDE(L)

4 S3-01R-002-9A0 PLATE ASSY TOP

5 S9-31R-001-5A0 HOLDER ASSY CST

6 S9-74R-001-9A0 GUIDE CST

7 S8-11R-001-4A0 BRACKET ASSY DOOR

8 S2-61R-001-0A0 ARM ASSY F/L

A 87-841-034-210 SCREW PAN HEAD 2.0-5.0

B 87-261-094-410 PAN HEAD SCREW 3-6

NO.

37

Page 38

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110-8710, JAPAN TEL:03 (3827) 3111

931261

Printed in Singapore

Loading...

Loading...