Page 1

I R S T R E A M

A

1 9 9 7

R A I N

G

O N D I T I O N I N G

C

Y S T E M S

S

DRYER OPERATION

A N D S E R V I C E M A N U A L

PNEG-339

1100 SERIES SINGLE FAN

PORTABLE DRYER

MODELS

1

Page 2

2

Page 3

1100 SERIES DRYER OPERATION AND SERVICE

TABLE OF CONTENTS

Warranty.......................................................................................................................4

Safety First...................................................................................................................5

Safety Alert Decals.......................................................................................................6

Safety Precautions.......................................................................................................7

Dryer Control Panel Featuring The Electronic Monitoring Control System.......................8

Safety Circuit Shutdown Messages......................................................................13

Dryer Pre Start Checks...............................................................................................14

Pre Season Inspection..........................................................................................14

Dryer Start Up...................................................................................................................18

Continuous Flow And Continuous Batch Start Up Procedure..............................18

Continuous Flow Metering Roll Settings...............................................................19

Continuous Batch Metering Roll And Timer Settings................................................22

1100 Series Dryer Service Guide.....................................................................................23

Seasonal Inspection And Service.........................................................................24

Suggested Lubricants..........................................................................................25

Fan Propellor Removal And Installation...............................................................26

Fan Motor Removal And Installation....................................................................27

Heater Parts Removal And Installation................................................................28

Metering Roll Servicing........................................................................................29

How To Determine A Metering Roll Problem........................................................30

Wiring Diagrams...................................................................................................31

Trouble Analysis Procedure...................................................................................41

Quick Reference Guide........................................................................................46

Notes...................................................................................................................47

3

Page 4

WARRANTY

THE GSI GROUP, INC. ("GSI") WARRANTS ALL PRODUCTS MANUFACTURED BY GSI TO BE FREE OF

DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND CONDITIONS FOR A PERIOD OF TWENTY-FOUR MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER OF SUCH PRODUCTS. GSI'S ONLY OBLIGATION IS, AND PURCHASER'S SOLE REMEDY SHALL BE FOR GSI, TO REPAIR OR REPLACE, AT GSI'S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI'S SOLE JUDGMENT,

CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI'S FACTORY WILL BE PURCHASER'S RESPONSIBILITY. EXPENSES

INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION

FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY OF

ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH (i) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR

SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR

RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR BENEFITS.

PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED ABOVE, WHICH

SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY OR ON BEHALF

OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS WHICH

CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE PRODUCT NOT

SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS

ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO RESEARCH AND COMPLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION.

4

Page 5

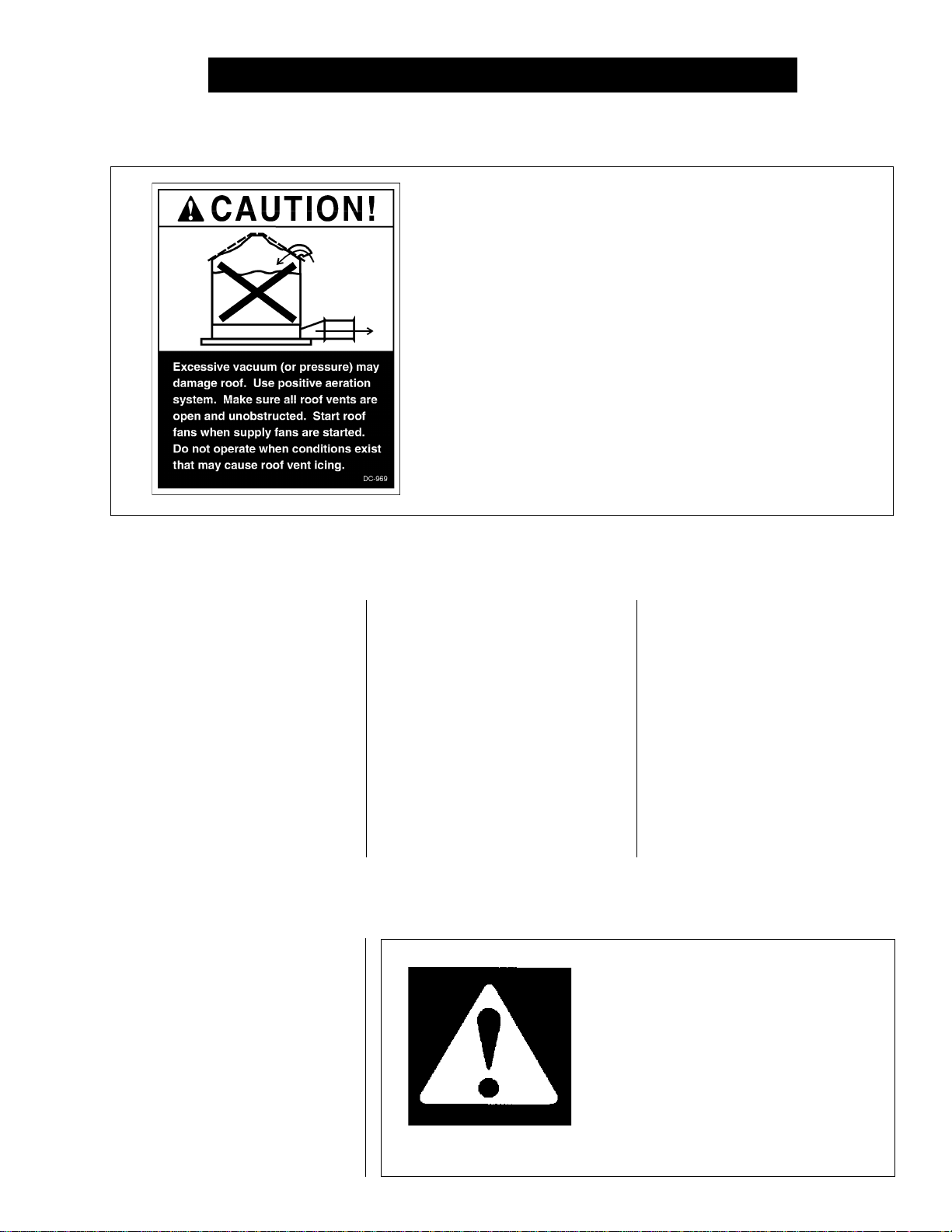

ROOF WARNING, OPERATION & SAFETY

ROOF DAMAGE WARNING AND DISCLAIMER

GSI DOES NOT WARRANT ANY ROOF DAMAGE CAUSED

BY EXCESSIVE VACUUM OR INTERNAL PRESSURE FROM

FANS OR OTHER AIR MOVING SYSTEMS. ADEQUATE

VENTILATION AND/OR "MAKEUP AIR" DEVICES SHOULD

BE PROVIDED FOR ALL POWERED AIR HANDLING SYSTEMS. GSI DOES NOT RECOMMEND THE USE OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE ROOF DAMAGE CAN RESULT FROM ANY BLOCKAGE OF AIR PASSAGES. RUNNING FANS DURING HIGH HUMIDITY/COLD

WEATHER CONDITIONS CAN CAUSE AIR EXHAUST OR

INTAKE PORTS TO FREEZE.

Thank you for choosing a GSI/

Airstream product. It is designed

to give excellent performance

and service for many years.

This manual describes the

operation and service for all standard 1100 Series one fan grain

dryers. These models are available for liquid propane or natural gas fuel supply, with either

single phase 230

The symbol shown is used to call

your attention to instructions concerning your personal safety. Watch

for this symbol; it points out important safety precautions. It means

"ATTENTION", "WARNING", "CAUTION", and "DANGER". Read the

message and be cautious to the

possibility of personal injury or

death.

DRYER OPERATION

volt, or three phase 220 or 440

volt electrical power.

The principal concern of the GSI

Group, Inc. ("GSI") is your safety and

the safety of others associated with

grain handling equipment. This

manual is written to help you understand safe operating procedures,

and some of the problems that may

be encountered by the operator or

other personnel.

SAFETY ALERT SYMBOL

WARNING! BE ALERT!

Personnel operating or working around

electric fans should read this manual.

This manual must be delivered with the

equipment to its owner. Failure to read

this manual and its safety instructions is

a misuse of the equipment.

As owner and/or operator, it is

your responsibility to know what

requirements, hazards and precautions exist, and to inform all

personnel associated with the

equipment, or who are in the dryer

area. Avoid any alterations to the

equipment. Such alterations may

produce a very dangerous situation, where serious injury or death

may occur.

5

Page 6

SAFETY ALERT DECALS

Three decals displayed on all Airstream Dryers. Belt drives, chain driven meter rolls

and combustible fuels must be treated with caution.

6

Page 7

SAFETY PRECAUTIONS

1. Read and understand the operating manual before trying to operate the

dryer.

2. Never operate the dryer while the guards are removed.

3. Power supply should be OFF for service of electrical components.

Use CAUTION in checking voltage or other procedures requiring power

to be ON.

4. Check for gas leaks at all gas pipe connections. If any leaks are

detected, do not operate dryer. Shut down and repair before further operation.

5. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

6. Set pressure regulator to avoid excessive gas pressure applied to

burner during ignition and

operating procedures. Do not exceed maxi

ing temperature.

7. Keep the dryer clean. Do not allow fine material to accumulate in

the plenum chamber.

8.

Keep auger drive belts tight

when burner is in operation. See chart for

mum recommended dry-

enough to prevent slippage.

USE CAUTION

IN THE OPERATION

OF THIS EQUIPMENT

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature of

a grain dryer having a gas burner,

high voltage electrical equipment

and high speed rotating parts, does

present a hazard to personnel,

which can not be completely safeguarded against, without interfering

with efficient operation and reasonable access to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary conveyors, which may start without

warning when the dryer is operating

on automatic control.

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

9. Use CAUTION in working around high speed fans, gas burners,

augers and auxiliary conveyors which START AUTOMATICALLY.

10. Do not operate in any area where combustible material will be drawn into

the fan.

11. Before attempting to remove and reinstall any propellor, make certain

to read the recommended procedure listed within the servicing section

of the manual.

12. Be certain that capacities of auxiliary conveyors are matched to dryer

auger capacities.

13. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

READ THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE

OUTSIDE OF THE DRYER

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommendations within this manual, and

make it a practice to regularly inspect the operation of the unit for any

developing problems or unsafe conditions.

Take special note of the safety

precautions listed above before attempting to operate the dryer.

7

Page 8

DRYER CONTROL PANEL

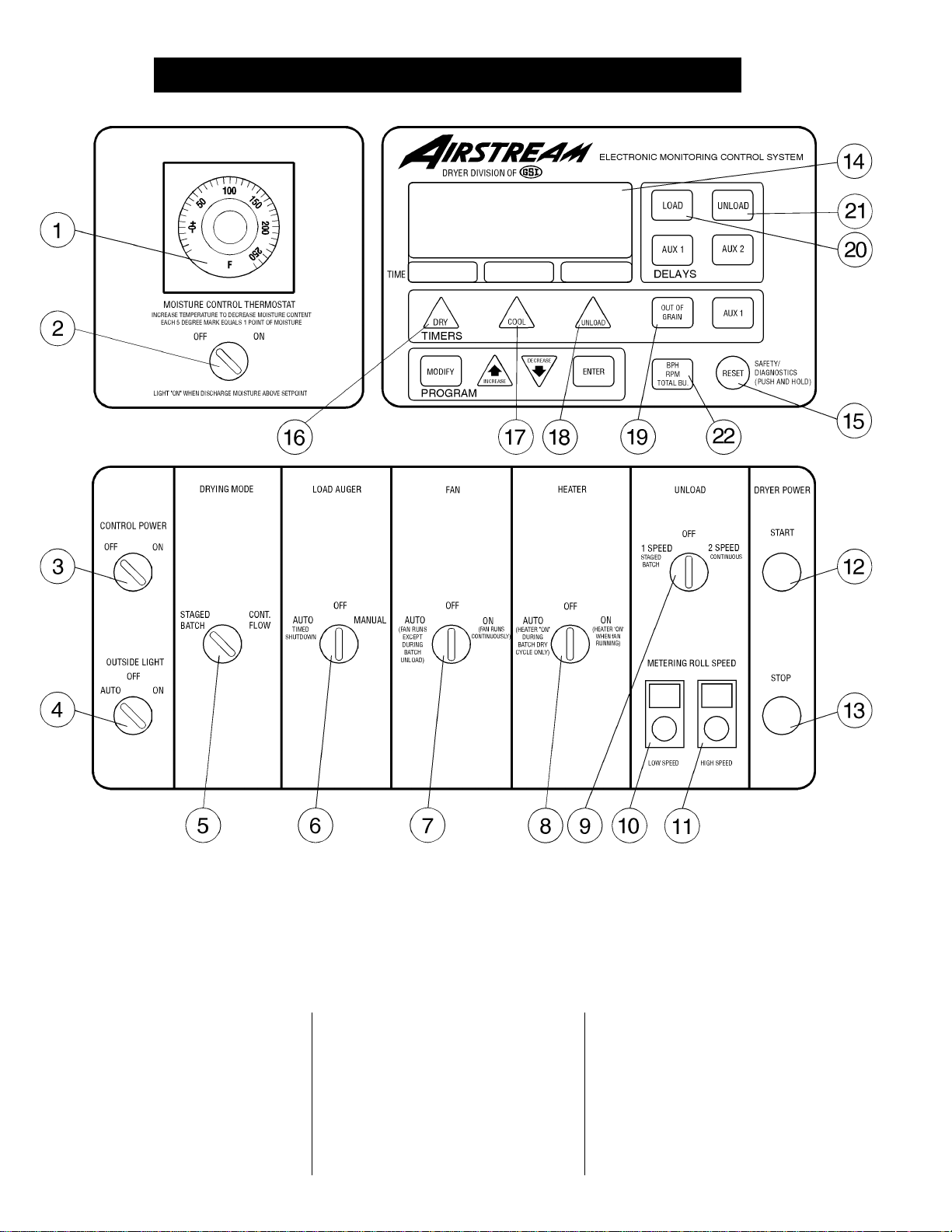

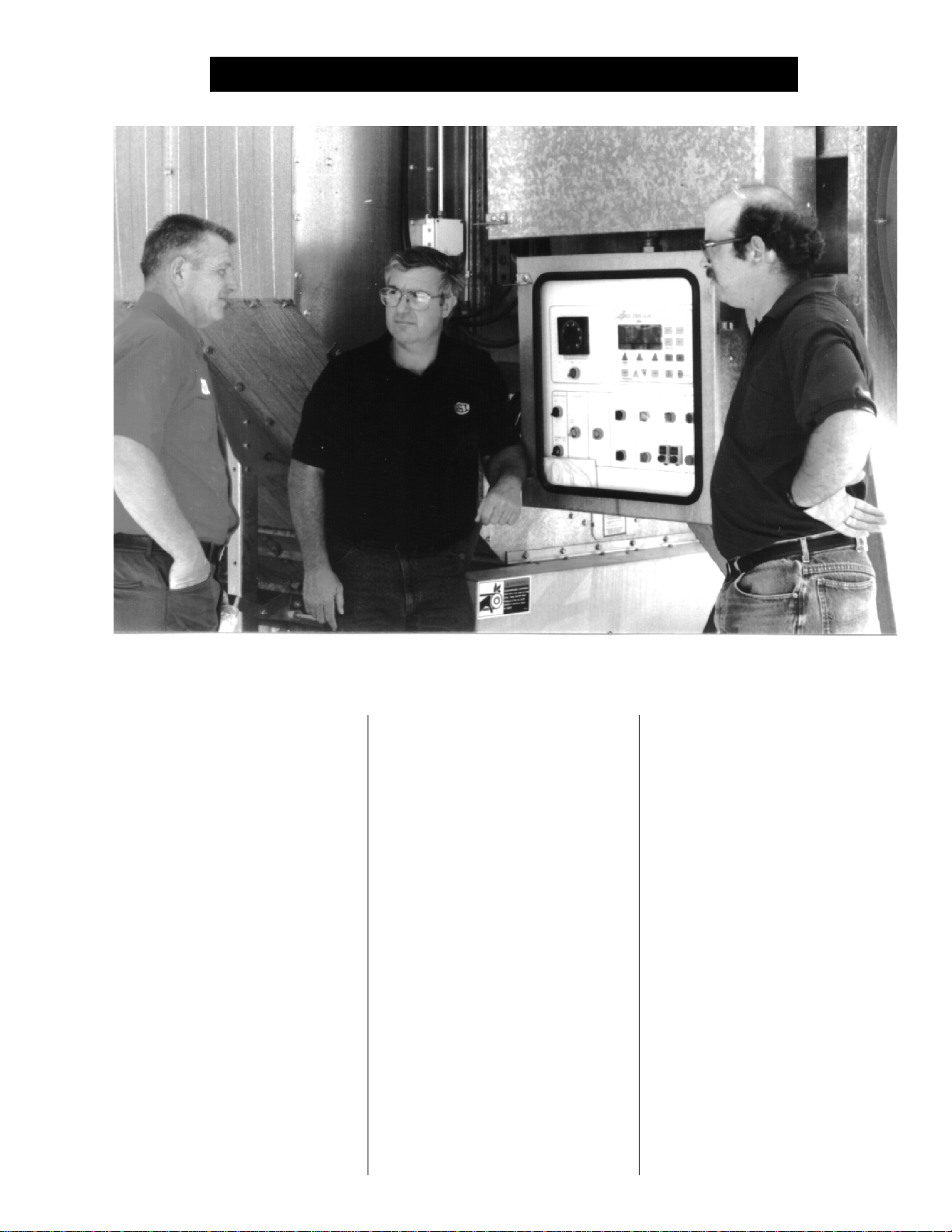

Figure 1: The grain dryer control panel with the Electronic Monitoring Control System in the upper right panel.

DRYER CONTROL PANEL FEATURING

THE ELECTRONIC MONITORING CONTROL SYSTEM

The control panel provides easy access to gauges and controls, and the

ILLUMINATED SWITCHES are a

quick reference for every operating

function. The patent pending Elec-

tronic Monitoring Control System

is computerized and gives instant

8

information about dryer operation.

MOISTURE CONTROL

THERMOSTAT (1)

This electronic thermostat controls the moisture level of discharged grain by sensing grain

column temperature.

MOISTURE CONTROL

SWITCH (2)

This switch turns the power ON or

OFF to the moisture control ther-

mostat. It lights up when the grain

column temperature is below the

thermostat set point.

Page 9

DRYER CONTROL PANEL

CONTROL POWER

SWITCH (3)

The power to the Electronic Monitoring Control System is turned

ON or OFF with this switch.

OUTSIDE LIGHT (4)

The dryer service light is turned

ON or OFF here. It also may be

set on AUTO, which turns the light

on while the dryer is running, and

off if a shutdown occurs.

DRYING MODE SWITCH (5)

This is used to select STAGED

BATCH or CONTINUOUS FLOW

drying. The switch will light only after the Electronic Monitoring Con-

trol System has been turned ON,

the safety circuit is okay and the

RESET button has been pressed.

LOAD AUGER SWITCH (6)

This is used to select the operation of the load auger. In both the

AUTO and MANUAL position the

load auger will operate if the dryer

is low on grain, and will automatically shut off when the dryer is full.

In the AUTO position only, the

dryer will shut down after a predetermined period of time set on the

OUT OF GRAIN TIMER, or if grain

flow is interrupted to the dryer. The

switch will light whenever the load

auger is operating.

Note: When this switch is set

to AUTO or MANUAL it also controls the operation of any auxiliary

load equipment being utilized,

such as an auxiliary auger or conveyor.

FAN SWITCH (7)

The fan is turned ON or OFF with

this switch. The ON position operates the fan continuously during

STAGED BATCH and CONTINUOUS FLOW modes. The AUTO position operates the fan in STAGED

BATCH during the dry and cool

cycle. The switch will light up whenever the airflow switch is sensing

airflow and the dryer is full of grain.

HEATER SWITCH (8)

This switch is used to turn the

burner ON or OFF. The AUTO position operates the burner in

STAGED BATCH during the dry

cycle. The ON position will operate

the burner only when the fan is running. The switch will light up when

the flame sensor detects the flame.

UNLOAD SWITCH (9)

The UNLOAD switch turns the metering rolls and discharge auger

ON or OFF, and selects the operation of the metering rolls.

• In the 2 SPEED position if the

MOISTURE CONTROL switch is

ON, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED will alternate between the

HIGH speed metering roll potentiometer setting and the LOW

speed metering roll potentiometer

setting depending on the control

signal from the MOISTURE CONTROL THERMOSTAT. The dis-

charge auger will operate continuously.

• In the 1 SPEED position, if the

MOISTURE CONTROL switch is

ON, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED will operate at the HIGH

speed metering roll potentiometer

setting or turn OFF depending on

the control signal from the MOISTURE CONTROL THERMOSTAT. The discharge auger will

operate whenever the metering

rolls are operating.

• In both the 1 SPEED or the 2

SPEED position, if the MOISTURE CONTROL THERMOSTAT

is OFF, and the DRYING MODE

switch is turned to CONTINUOUS

FLOW, the METERING ROLL

SPEED can be manually controlled by adjusting the HIGH

speed metering roll potentiometer.

The discharge auger will operate

continuously.

• If the DRYING MODE switch is

turned to STAGED BATCH, the

UNLOAD switch should be set to

the 1 SPEED position. The dis-

charge auger and metering rolls

will only operate during the unload

cycle of the staged batch operation, and the METERING ROLL

SPEED is adjusted using the

HIGH speed metering roll potentiometer.

Note: When this switch is set to

AUTO or MANUAL it also controls

the operation of any auxiliary load

equipment being utilized, such as

an auxiliary auger or conveyor.

9

Page 10

DRYER CONTROL PANEL

LOW SPEED METERING

ROLL POTENTIOMETER (10)

This is used to adjust the LOW

speed of the metering roll when the

2 SPEED and MOISTURE CONTROL THERMOSTAT are in use.

HIGH SPEED METERING

ROLL POTENTIOMETER (11)

This is used to:

• Set the HIGH speed of the meter-

ing roll when the 2 SPEED automatic moisture control feature of

the dryer is utilized.

• Set the speed of the metering

rolls when the 1 SPEED auto-

matic moisture control feature of

the dryer is utilized.

• Set the speed of the metering

rolls during continuous flow operation when the moisture control

is not used.

• Set the rate of grain discharge from

the dryer during the unload cycle of

staged batch dryer operation.

DRYER POWER

START SWITCH (12)

This switch starts and operates the

dryer based on switch settings. If

other switch settings are in the OFF

position, individual dryer compo-

nents can be operated by turning the

DRYING MODE switch to CONTINUOUS FLOW, pressing the

DRYER POWER START button and

then turning ON the desired dryer

component.

DRYER POWER

STOP SWITCH (13)

This switch stops all dryer functions. If an automatic dryer shutdown occurs, first determine and

correct the cause of the shutdown.

Then, press the DRYER POWER

STOP button to reset the dryer before restarting.

10

The Airstream Dryer Control Panel.

Page 11

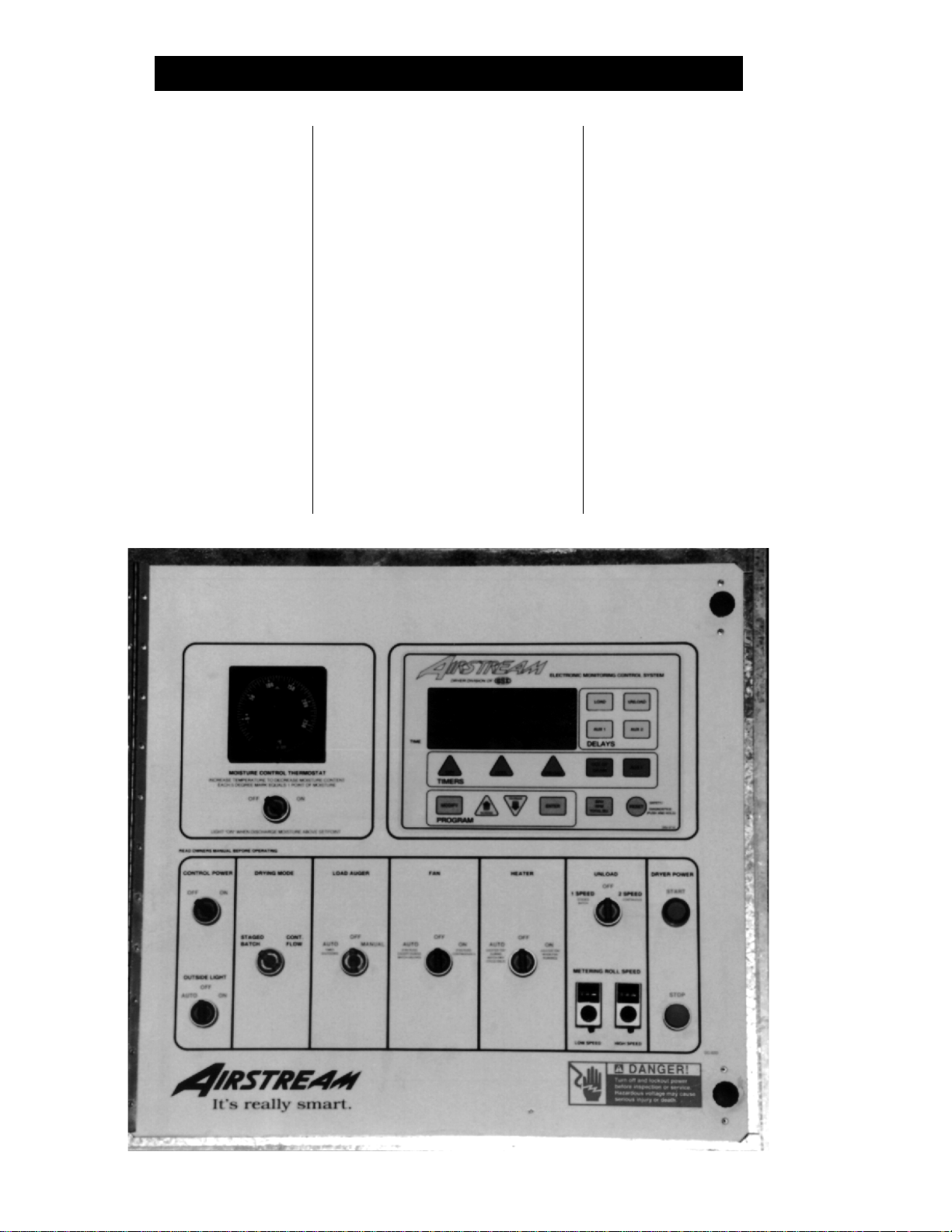

DRYER CONTROL PANEL

ELECTRONIC

MONITORING CONTROL

SYSTEM (14)

The Electronic Monitoring Control

System (Figure 2) controls all tim-

ing functions and safety circuit

checks. It is designed to simplify

dryer operation by providing printed

messages and warnings on its liquid crystal display (LCD).

TURNING ON THE

ELECTRONIC

MONITORING CONTROL

SYSTEM USING THE

RESET BUTTON (15)

Turn the CONTROL POWER switch

to ON. The monitor will display a

copyright message and model number, total running time in hours and

minutes and the current time and

date. To activate the controller press

the RESET button.

SETTING THE DRY (16),

COOL (17) AND UNLOAD

(18) BATCH TIMERS

These switches are used to set the

cycle times in the STAGED BATCH

DRYING MODE only. The DRYING

MODE switch must be in the

STAGED BATCH position. The current settings on these three TIMERS

are displayed directly above each

TIMER button. To change the setting of these TIMERS follow these

instructions:

1. Press the DRY, COOL or UNLOAD TIMER button.

2. Press the MODIFY button.

3. Press the INCREASE or DECREASE button to adjust the

settings.

4. Press the ENTER button.

During operation the remaining

time on each TIMER is displayed on

the screen. If the power goes out or

if the dryer is stopped, these times

are saved by the controller. When

the dryer is restarted the TIMERS

will continue timing down. The TIMERS will return to their initial settings

by pressing the RESET button.

SETTING THE OUT OF

GRAIN TIMER (19)

If the dryer runs out of grain while

the LOAD AUGER switch is in the

AUTO position, the OUT OF GRAIN

TIMER automatically shuts OFF the

dryer after the period of time preset

on the TIMER. When pressed, the

display will show the amount of time

left on the TIMER and the percentage of time the last load expended.

A second screen will appear showing the TIMER'S setting and will allow the operator to modify it as described for setting the BATCH TIMERS.

Figure 2: The Airtream Electronic Monitoring Control System

11

Page 12

DRYER CONTROL PANEL

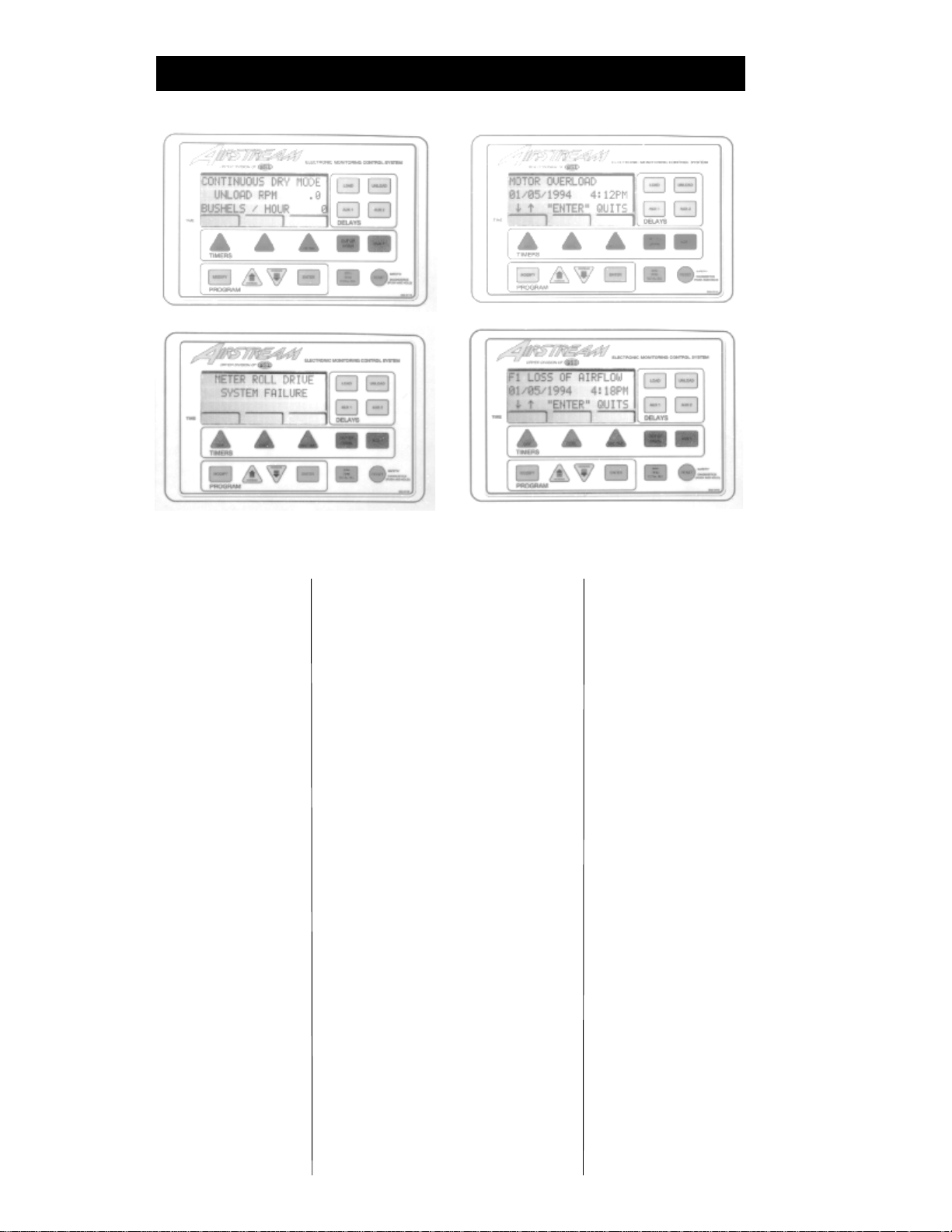

The Airstream Electronic Monitoring Control System showing different LCD displays.

SETTING THE LOAD (20)

AND UNLOAD (21) DELAYS

The LOAD DELAY is used to delay

the starting of the load auger when

the dryer is unloading to prevent the

load auger from starting and stopping. The UNLOAD DELAY is used

to control the amount of time the un-

load auger runs after the metering

rolls stop to allow for auger

cleanout. Both the LOAD and UNLOAD DELAYS are set using the

same procedure as the TIMERS.

The AUX1 and AUX 2 DELAYS are

presently not being used.

UTILIZING THE

BUSHEL COUNTER (22)

When operating the dryer the LCD

display will show the DRYER MODE

OF OPERATION on the first line, the

BUSHELS PER HOUR or the METERING ROLL RPM on the second

line and the TOTAL BUSHELS dried

on the third line. By pressing the

BPH/RPM/TOTAL BU button the

second line will alternate between

the METERING ROLL RPM's or the

BUSHEL PER HOUR rate. The TOTAL BUSHELS DRIED reading is

the total since the bushel counter

was last reset. To reset the

BUSHEL COUNTER, press and

hold the RESET button for five seconds. Press the ENTER button

through the date and time settings

and then follow the instructions displayed on the LCD for resetting the

counter.

In the STAGED BATCH DRYING MODE the first line of the LCD

display tells which TIMER is being

used, and the second line switches

between TOTAL BATCHES, UNLOAD RPM or TOTAL BUSHELS.

The third line indicates TOTAL DRY

TIME and the fourth line is TIME

REMAINING on the TIMERS.

DRYER SAFETY CIRCUIT

The Electronic Monitoring Control

System continuously checks all

safety circuits on the dryer, and will

automatically shut the dryer down

should a problem occur. The cause

of the dryer shutdown will be displayed on the LCD display, and a

beeper will sound on the controller.

To restart the dryer after a safety

shutdown, first correct the reason for

the shutdown, and then press the

DRYER POWER STOP button to reset the circuit. Press the START

button.

The Electronic Monitoring

Control System stores in its

memory the time, date and cause for

the last 25 dryer safety shutdowns.

To review this information hold the

RESET button in for five seconds.

The procedure for reviewing the

safety circuit shutdown log will be

displayed on the LCD display.

12

Page 13

DRYER CONTROL PANEL

SAFETY CIRCUIT SHUTDOWN MESSAGES

BURNER VAPOR HIGH

TEMPERATURE

The LP gas vapor temperature sensor located in the gas pipe train

downstream from the vaporizer, has

opened indicating that the vaporizor

is running too hot and must be readjusted. This sensor is set at 200°F

and automatically resets itself when

cool.

BURNER WARNING FLAME

NOT DETECTED

The flame sensor has failed to detect a burner flame indicating that the

burner has failed to light, there is a

problem with the flame sensing circuitry or the dryer is not getting

burner fuel.

FAN HOUSING HIGH

TEMPERATURE

The temperature high limit located

on the fan/burner housing has

opened, indicating an over temperature condition has occurred towards

the rear of the fan/heater housing.

This control is set at 200°F and must

be manually reset.

GRAIN DISCHARGE

WARNING

The lid on the grain discharge box

has opened, indicating that grain is

not being taken away fast enough

at the discharge box.

LOWER ADJUSTABLE

GRAIN HIGH

TEMPERATURE

An over temperature condition has

occurred in the right side (left and

right as viewed from behind the

dryer) grain column causing the

control to shut down the dryer. This

control is set at 210°F and automatically resets itself when cool.

LOWER FIXED GRAIN

HIGH TEMPERATURE

An over temperature condition has

occurred in the left side (left and

right as viewed from behind the

dryer) grain column causing the

control to shutdown the dryer. This

control is set at 210°F and automatically resets itself when cool.

MOTOR OVERLOAD

One of the thermal overloads on

either the fan, load, unload or aux-

iliary motors has opened, indicating an overcurrent condition. The

overloads must be manually reset.

OUT OF GRAIN

WARNING/UNLOAD

CLEANOUT

The dryer has run low on grain, and

the OUT OF GRAIN TIMER has

timed out, shutting the dryer down.

The unload auger will clean out the

dryer if in continuous flow operation.

METERING ROLL DRIVE

SYSTEM FAILURE

The metering roll drive system has

failed to turn. A broken chain or

jammed metering roll is a possibility.

RIGHT METERING ROLL

FAILURE

The right (as viewed from behind the

dryer) metering roll has stopped turning, or the sensor has been damaged.

LEFT METERING ROLL

FAILURE

The left (as viewed from behind the

dryer) metering roll has stopped turn-

ing, or the sensor has been damaged.

12 VOLT POWER

SUPPLY WARNING

The right circuit breaker on the input/output board has tripped.

AUXILIARY SAFETY

SHUTDOWN

A shutdown has occurred due to an

auxiliary installed safety feature.

BURNER SHUTDOWN

LOSS OF AIRFLOW

The contacts in the air switch have

opened due to insufficient airflow for

the burner to operate.

FAN FAILURE

NO AIRFLOW

The contacts in the air switch have

opened due to the fan not turning, or

the air switch may need adjustment.

L1 VOLTAGE LOST

The left circuit breaker located on

the input/output board of the Elec-

tronic Monitoring Control System

has tripped, or one of the hardware

timers has shut down the dryer.

PLENUM HIGH

TEMPERATURE

An over temperature condition has

occurred inside the dryer plenum.

This control is a 300°F limit and automatically resets itself when cool.

FAN CANNOT START

CHECK AIR SWITCH

The air switch contacts have closed

prior to the fan starting, indicating a

freewheeling blade or improper setting of the air switch.

13

Page 14

Before the dryer is filled, thoroughly

inspect the unit and check the operation of the dryer as follows.

INSPECT THE METERING

ROLLS

Open all metering roll access

doors and inspect each compart-

ment for any bolts, nuts or other foreign material, that may cause possible jamming of the metering rolls.

BEFORE ATTEMPTING TO

OPERATE THE DRYER MAKE

DRYER PRE START CHECKS

PRE SEASON INSPECTION

The Maxon safety shut off valve.

SURE ALL SAFETY SHIELDS

ARE IN PLACE, ALL BOTTOM

CLEANOUT AND REAR

ACCESS DOORS ARE CLOSED

AND ALL PERSONNEL ARE

CLEAR OF THE DRYER

SET CONTROL SWITCHES

Moisture Control Switch-ON

Moisture Control Thermostat-MAXI-

MUM TEMPERATURE

Load Switch-OFF

Unload Switch-OFF

Fan Switch-OFF

Burner Switch-OFF

Out of Grain Timer-8 MINUTE

Load Delay-30 SECONDS

Unload Delay-30 SECONDS

Metering Roll Speed-LOW AND

HIGH SPEED SETTINGS PUT

ON ZERO

Dry Timer-60 MINUTE

Cool timer-20 MINUTE

Unload timer-10 SECONDS

Mode Switch-CONTINUOUS FLOW

14

ELECTRICAL POWER

Turn ON the electrical power supply to the dryer, set all circuit breakers to ON, including the safety disconnect handle mounted on front

of the dryer's power panel.

CONTROL POWER

SWITCH

Turn the CONTROL POWER switch

to ON. The switch will light up. A

copyright message, model number,

total running time in hours and minutes, current date and time will appear. At this point the controller will

lock out all other dryer functions.

Once the date and time appear,

press RESET and the dryer will perform its safety circuit check. If a fault

is found, the cause will be displayed

on the LCD. If all are found safe, the

controller will supply power to the

electronic fuel shut- off valve (if

so equipped) and the DRYING

MODE switch will light up, indicating

that the dryer is ready to be started.

POWER START BUTTON

Push the DRYER START button,

and all the selector switches on the

control panel will be activated.

FUEL CHECK

If using LP gas, make sure the tank

has plenty of fuel and that the tank

does not have a regulator mounted

to it. If using natural gas, make sure

an adequate supply is available.

If using LP gas, slowly OPEN

the main fuel supply valve at the

tank. If using natural, gas turn ON

the valve along the supply line.

Then, OPEN the electronic shut off

valve (Maxon valve), if so equipped,

or OPEN the manual shut off valve

on the dryer to allow fuel flow to the

dryer. Inspect all gas lines and con-

nections for possible leaks.

Any gas leaks need to be

fixed immediately!

Page 15

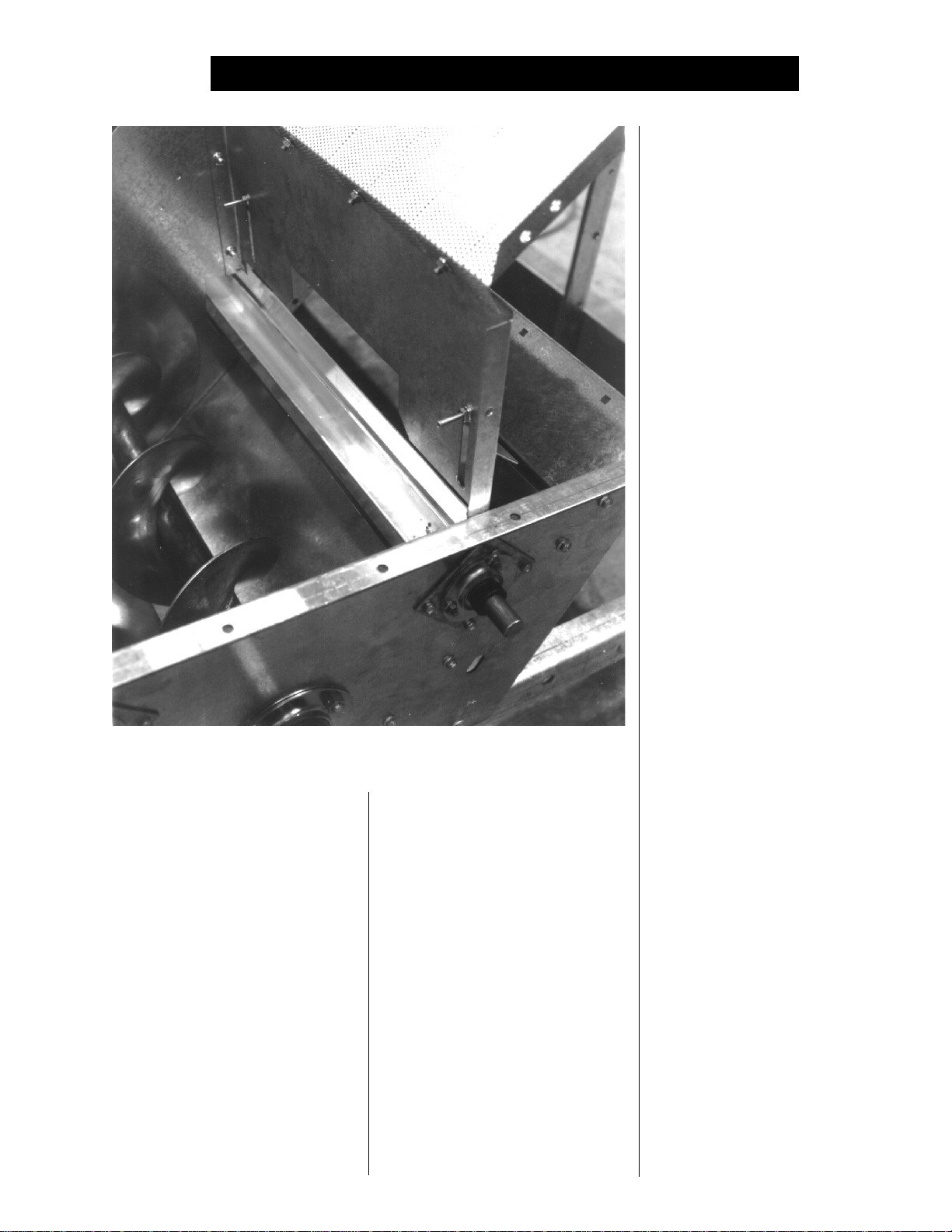

The metering roll access area.

LOAD AUGER

With the grain supply SHUT OFF,

quickly bump the LOAD AUGER

switch to MANUAL, and see if the

load auger rotates clockwise as

viewed from the drive end, or counterclockwise if the dryer is a front

load model. If the wet grain supply

auxiliary is wired to the dryer it

should also rotate in the correct direction at this time. Turn the LOAD

AUGER switch to the AUTO position. The top auger and wet grain

supply auxiliary should run for one

minute, and then the dryer will shut

down leaving the safety shutdown

DRYER PRE START CHECKS

message (out of grain warning) displayed. Press the DRYER POWER

STOP button to reset the panel, then

press the START button.

ONE SPEED OPERATION

To check 1 speed operation place

the UNLOAD switch in the 1 SPEED

setting. Turn up the HIGH SPEED

METERING ROLL DIAL until the

metering rolls start rotating. The

bottom auger should rotate coun-

terclockwise as viewed from the

drive end. The metering roll drive

motor should rotate clockwise as

viewed from the drive end of the

gear box. If the dry grain take away

auxiliary is wired to the dryer, it

should start and rotate in the proper

direction.

MOISTURE CONTROL

THERMOSTAT

To check the MOISTURE CONTROL THERMOSTAT leave the

UNLOADING switch on 1 SPEED,

and slowly turn down the MOISTURE CONTROL THERMOSTAT.

As the setting is decreased, the indicator light should come on and the

metering rolls should stop operating. The bottom auger will stop after the 30 second clean out delay,

providing that the dryer is still being

held by the MOISTURE CONTROL

THERMOSTAT. Rotate the MOISTURE CONTROL THERMOSTAT

up to its maximum setting. The light

should go off, and the metering

rolls should restart along with the

bottom auger if it has stopped.

To check 2 SPEED operation

move the switch to the 2 SPEED position, set LOW speed on 200 and

HIGH speed on 600. Slowly turn the

thermostat until the MOISTURE

CONTROL switch light comes ON.

The METERING ROLL SPEED is

now controlled by the LOW speed

dial. Turning the THERMOSTAT the

other way until the light goes out now

leaves the metering rolls controlled

by the HIGH SPEED DIAL.

METERING ROLL

OPERATION

To check the metering roll operation

turn either the LOW speed or HIGH

speed knob clockwise, and the ME-

15

Page 16

DRYER PRE START CHECKS

TERING ROLL SPEED should increase. Turning either knob counterclockwise will decrease the

speed. Make sure the drive chain

tension is properly adjusted and all

sections of the metering rolls rotate. Turn the UNLOAD switch OFF

after these checks are complete.

The bottom auger will continue to

run for 30 seconds after the switch

is turned OFF to allow for cleanout.

FAN SWITCH

Bump the FAN switch and observe

the fan rotation. The fan should run

counterclockwise. Sometimes on

three phase models all motors will

run backwards. They can easily be

reversed by interchanging the two

of three power supply wires. Reverse the two outside wires, L1 and

L3, and leave the middle one in the

same position.

Note: If the dryer is empty, the

burner will not operate. The fans

cannot create enough static pressure to engage the air switch. You

will receive a loss of airflow message.

ignite after a short purge delay of approximately 10 seconds. Gas pressure should be shown on the gauge.

At this time adjust the BURNER

HIGH-LOW FIRE THERMOSTAT to

200°F, causing the burner to operate on high-fire. The thermostat is

located on the front left side of the

dryer. Observe the gas pressure on

gauge, and turn the thermostat to

its MINIMUM SETTING, causing the

burner to cycle into low-fire. As the

burner thermostat is turned down

the gas pressure should also show

a noticeable drop, indicating that the

high-fire solenoid is closed and the

burner is being supplied with less

gas through the low-fire control

valve. At this time set the high-

fire and low-fire pressure settings.

Use the PRESSURE REGULATOR

for high-fire and the BALL VALVE

for low-fire. The thermostat should

cycle between high and low, approximately 4 to 5 times per minute.

Approximate settings should be:

LP Gas High-Fire 6-15 lbs.

Low-Fire 2-6 lbs.

Natural Gas High-Fire 6-10 lbs.

Low-Fire 1-3 lbs.

If the burner remains on high-

fire and does not cycle, INCREASE

the regulator setting on the propane

models, or the supply valve on the

natural gas models in order to reach

the thermostat setting. If the

burner remains in low-fire and does

not cycle, slightly DECREASE gas

7

5

BURNER SAFETY

To check the burner safety function,

first make sure the main GAS

VALVE is OFF. Turn the FAN switch

ON and allow the fan to start. Then,

turn the HEATER switch ON. The

dryer will shut down after 20 seconds.

The safety message, "Burner 1 warning flame not detected" will appear.

BURNER TEST FIRE

START the fan, and then turn the

HEATER switch to ON. Turn ON the

fuel supply, and the burner should

16

3

4

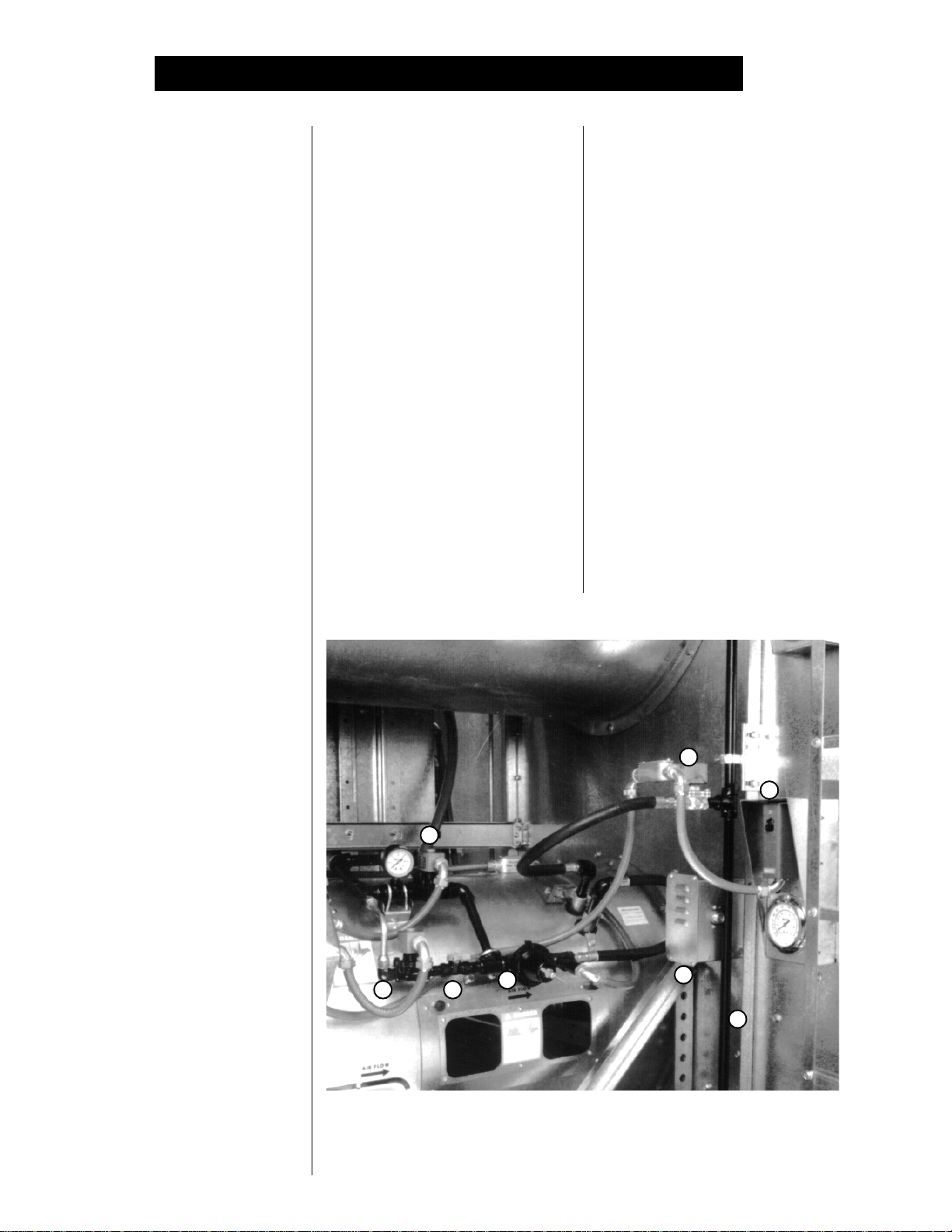

The dryer fan and heater controls featuring: 1-pressure regulator, 2-low-fire

control valve, 3-high pressure solenoid, 4-low pressure solenoid, 5-high-

low fire thermostat (assembly includes thermometer), 6-fuel supply line, 7-

LP solenoid or supply ball valve(NG) and 8-air pressure switch.

2

1

8

6

Page 17

DRYER PRE START CHECKS

All dryer functions should be checked before operation each season.

pressure with the LOW-FIRE CONTROL VALVE. If the gas pressure

is decreased too much a popping or

fluttering sound will be heard. Also,

anytime the high pressure side is

adjusted the low pressure side

needs to be checked.

STAGED BATCH CHECK

To check the staged batch operation, turn the CONTROL POWER

switch to the ON position. Press the

RESET button, OPEN the main

FUEL SUPPLY VALVE at the tank

on an LP dryer or valve in the fuel

supply line on a natural gas dryer.

Turn the DRYING MODE switch to

the STAGED BATCH position.Turn

ON the electric SHUT OFF

VALVE to allow fuel flow to the

dryer, if so equipped. Turn the

LOAD switch to AUTO and UNLOAD switch to 1 SPEED. Push

the DRYER POWER START button and the controller will sequentially start all dryer components in

their proper order. If any switches

are not in their correct position for

staged batch operation, the dryer

will indicate improper switch position, and will not start until the

switches are in the proper position.

After starting, all batch timers will

time down in sequence. When the

unload cycle is complete the timers will automatically reset to their

original settings, and start the dry

timer again.

DRYER SHUTDOWN

To shutdown the dryer, first CLOSE

the FUEL SUPPLY VALVE at the

tank or valve along the fuel line. If

the burner is operating, let the dryer

run out of fuel, and it will shutdown

automatically due to loss of flame.

CLOSE the FUEL VALVE at the

dryer, and press the DRYER

POWER STOP button. Turn OFF

the safety disconnect handle on

the front of the power box, and turn

OFF the main POWER to the dryer.

EMERGENCY

In case of emergency push the dryer

POWER STOP button. The fan,

burner and all augers will stop immediately.

17

Page 18

DRYER START UP

CONTINUOUS FLOW AND CONTINUOUS BATCH START UP PROCEDURE

At the beginning of each harvest and

before filling the dryer with grain

make sure to inspect the dryer for

rodent damage, proper belt and

chain tension and missing or damaged safety shields. Test operate

the dryer using the prestart check

procedures located on pages 14-17.

1. Before attempting to operate the

dryer make sure that all safety

shields are in place, all plenum

bottom closure panel doors

are closed, all rear access

doors are closed and all per-

sonnel are clear of the grain

dryer and grain handling machinery.

2. Turn all SELECTOR switches

on the control panel to the OFF

position.

3. Turn ON the electric POWER

supply to the dryer, and move

the safety disconnect handle

mounted on the dryer's upper

power box to ON.

4. Turn the CONTROL POWER

switch to ON. The switch will

light up. A copyright message,

model number, total running

time in hours and minutes, current date and time will appear.

At this point the controller will

lock out all other dryer functions.

Once the date and time appear,

press RESET, and the dryer will

perform its safety circuit checks.

If a fault is found the cause will

18

be displayed on the LCD. If all

are found safe the controller will

allow the electronic FUEL SHUT

OFF valve to be manually

OPENED (if so equipped), and

the DRYING MODE switch will

light up, indicating that the dryer

is ready to be started.

5. Move the LOAD AUGER switch

to MANUAL, and push the dryer

POWER START switch. The

top auger will immediately start,

and the LOAD AUGER switch

will light up. If additional grain

handling equipment is wired to

the dryer it will also start immediately.

6. When the dryer is full of grain

the top auger will stop auto-

matically, and any grain handling equipment wired to the

dryer will also stop.

CONTINUOUS FLOW

OPERATION

1. Turn the CONTROL POWER

switch to ON.

2. After the date and time appear

on screen, press the RESET

button.

3. Push the dryer POWER START

switch.

4. OPEN the main FUEL SUPPLY

VALVE on the tank if using LP

gas, or OPEN the FUEL SUP

PLY LINE if using natural gas.

Turn ON the electric SHUTOFF,

Maxon valve (if so equipped), or

OPEN the manual SHUTOFF

valve to allow fuel flow to the

dryer.

5. Turn the DRYING MODE switch

to CONTINUOUS FLOW.

6. The dryer should already be

filled with grain. Turn the

LOAD AUGER switch to the

AUTO position. In both the auto

and manual positions the dryer

grain level switch will automatically keep the dryer full of grain.

In the auto position the dryer will

shut down after a preset time

period on the out of grain timer.

7. Turn the FAN switch to ON. The

fan will start, and the switch will

light up when airflow is detected.

8. Start the burner by turning the

HEATER switch to ON. After

purging for approximately 10

seconds the burner will fire, and

the heater switch will light up.

This indicates that the flame

sensing circuit is sensing burner

flame. For information concerning burner adjustment see the

pre start section of this manual.

9. Operate the heaters to dry grain

for 6-7 minutes per point of

moisture to be removed with the

plenum temperature set at

180°F. Example: Shelled corn

starts with 25% moisture and

Page 19

DRYER START UP

the final moisture content is to

be 15% (10% removal). Using

the all heat dryeration process,

the estimated drying time is 60

minutes (10 x 6).

10. While operating the dryer adjust

the METERING ROLL dials to

the recommended settings. See

the chart on page 00.

11. To move grain through the dryer

turn the MOISTURE CONTROL

switch to ON. The switch will

light up.

Note: When the UNLOAD switch is

in the 2 SPEED position, and the

MOISTURE CONTROL THERMOSTAT switch is OFF, the speed of

the metering rolls can be manually

adjusted by turning the HIGH

SPEED METERING ROLL dial.

Turning the dial clockwise will INCREASE the grain discharge rate,

counterclockwise will DECREASE

the discharge rate. (The numbers on

the speed dials indicate the percentage of full speed.)

12. At the end of the start-up period, start the flow of grain out

of the dryer. Turn the UNLOAD

switch to the 2 SPEED position. The bottom auger and

metering roll will immediately

start, and the unload switch will

light. If additional grain handling equipment is utilizing the

unload auxiliary overload supplied with the dryer, this equipment will also immediately

start.

13. To shut the dryer down, CLOSE

the FUEL SUPPLY VALVE at

the fuel tank or fuel source. Let

the dryer run until the fuel supply lines drain, and the dryer

automatically shuts down due to

loss of flame. CLOSE the FUEL

valve at the dryer. Press the

DRYER POWER STOP button.

Turn OFF the dryer's SAFETY

DISCONNECT handle. Turn

OFF the MAIN POWER supply

to the dryer.

14. In case of emergency push the

dryer STOP button. The fan,

burner and all augers will stop

immediately.

Note: The Electronic Monitoring

Control System can be used to automatically start the dryer. Place all

the control panel SELECTOR

switches in the PROPER POSITION, and OPEN the electric FUEL

SHUT OFF valve before PRESSING

the DRYER POWER START button.

The controller will start all dryer components in their proper order.

STAGED BATCH

OPERATION

1. Turn the CONTROL POWER

switch to ON.

2. Make sure the DRYING MODE

switch is turned to STAGED BATCH.

3. After the date and time appear,

PRESS the RESET button.

4. OPEN the main FUEL SUPPLY

VALVE on the tank if using LP

gas or the valve in the FUEL

SUPPLY LINE if using natural

gas. Turn ON the ELECTRIC

SHUT OFF, Maxon valve (if so

equipped), or OPEN the manual

SHUT OFF valve to allow fuel

flow to the dryer.

5. The dryer should already be

filled with grain. Turn the LOAD

AUGER switch to AUTO. In both

the auto and manual position,

the grain level switch will automatically keep the dryer full of

grain. In the auto position, the

dryer will shut down after the

preset time period on the OUT

OF GRAIN TIMER, or if the

grain flow to the dryer is interrupted.

6. Turn the FAN switch to AUTO.

The fan will start, and the switch

will light up when airflow is detected.

7. Start the burner by turning the

HEATER switch to AUTO. After purging for approximately

10 seconds the burner will fire,

and the heater switch will light

up indicating that the flame

sensing circuit is sensing

burner flame. For information

concerning burner adjustment

see the pre start section of this

manual.

8. To properly set the correct dry,

cool and unload time for various

moisture content grains. See the

chart on page 00.

19

Page 20

DRYER START UP

9. If the dryer is being operated in

all heat, turn the FAN switch to

ON. In this position the fan will

run continuously during the dry,

cool and unload stages of the

staged batch operation. If the

dryer is being operated in the

dry and cool mode, the preferred

position for the FAN switch is the

ON position, so the fan will run

continuously. If desired, the fan

can be turned off during the unload cycle of the dry-cool-unload

sequence by turning the FAN

switch to AUTO.

10. If the dryer is being operated in

all heat, turn the HEATER

switch to ON. The burner will

operate whenever the fan is

operating. If the dryer is being

used in dry and cool, turn the

HEATER switch to AUTO and

the burner will automatically

shutdown during the cooling and

unloading cycles.

11. Turn the UNLOAD switch to the

1 SPEED position. The bottom

auger and metering rolls will

start automatically during the

unload cycle of the dry-coolunload mode, along with any

grain handling equipment that

is wired to the dryer. The

speed at which the metering

rolls operate during the unload

cycle is adjusted by using the

HIGH SPEED METERING roll

dial. Turning the dial clockwise

will INCREASE the grain discharge rate, and counterclock

wise will DECREASE the discharge rate.

12. To control the length of the dry

cycle using only the dry time

setting programmed into the

system, turn the MOISTURE

CONTROL setting to OFF. To

use the automatic moisture control so that the dry time is determined, not only by the dry time

setting, but also by the moisture

content of the drying grain, turn

the MOISTURE CONTROL

switch to ON.

13. To start the drying operation

push the dryer POWER START

button. The controller will start

all the dryer components in their

proper order. If any of the selected switches are improperly

positioned for staged batch drying, the display will indicate the

proper switch position, and will

not allow the dryer to operate

until the position of the switch is

corrected.

14. To shutdown the dryer, CLOSE

the FUEL SUPPLY valve at the

fuel tank or fuel source. If the

burner is operating, let the dryer

run out of fuel causing an automatic shutdown due to a loss of

flame. CLOSE the FUEL VALVE

at the dryer, and press the dryer

POWER STOP button. Turn

OFF the dryer's main CIRCUIT

BREAKER located on the front

of the power panel. Turn OFF

the MAIN main POWER SUPPLY to the dryer.

15. In case of an emergency press

the dryer POWER STOP button.

The burner, fan and all augers

will stop immediately.

FAN & HEATER SWITCH SETTINGS

Fan Setting

Auto

Auto

On

On

At the end of the dry cycle in staged batch, the fans and heaters will continue running if in the Auto-Auto setting, until the preset tempera-

20

Heater Setting

Auto

On

On

Auto

Fans stay on during dry and cool

Fans stay on during dry and cool

ture on the moisture control thermostat is reached.

Fan Function

cycle only

cycle only

Fans are on continuously

Fans are on continuously

Heater Function

Burners stay on during dry timer cycle

only

Burners stay on during dry and cool

Burners are on continuously

Burners shut down at the end of the

dry cycle

Page 21

DRYER START UP

1100 SERIES BATCH TIMER SETTINGS

Initial

Moisture

17%

18%

19%

20%

21%

22%

23%

24%

25%

26%

27%

Moisture

Removed

2 pts.

3 pts.

4 pts.

5 pts.

6 pts.

7 pts.

8 pts.

9 pts.

10 pts.

11 pts.

12 pts.

Full Heat

Fan & Burner Switches on Manual

Approx.

Dry Time

16 min.

21 min.

26 min

31.5 min.

37 min.

41.5 min.

47 min.

51 min.

54 min.

58 min.

62 min.

Dry

6 min.

11 min.

16 min

21.5 min.

27 min.

31.5 min.

37 min.

47 min.

44 min.

48 min.

52 min.

Cool

0

0

0

0

0

0

0

0

0

0

0

Unload*

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

Dry & Cool

Fans on Manual Burners on Auto

Approx.

Dry Time

18 min.

24 min.

30 min

35 min.

40 min.

45 min.

50 min.

55 min.

60 min.

65 min.

70 min.

Dry

18 min.

24 min.

30 min

35 min.

40 min.

45 min.

50 min.

55 min.

60 min.

65 min.

70 min.

Cool

18 min.

18 min.

18 min

18 min.

18 min.

18 min.

18 min.

18 min.

18 min.

18 min.

18 min.

Unload*

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

28%

29%

30%

31%

32%

33%

34%

35%

These are approximate starting points.

*Set unload metering roll high speed setting to 999. If unload equipment cannot adequately keep up, lower the speed

setting and add time to the unload timer setting to completely unload the batch. In full heat mode, the time added to the

unload timer will need to be substracted from the dry timer. If fan is on auto and does not run during unload, set cool timer

to 25 minutes.

New unload time calculation = present unload time new dial setting

13 pts.

14 pts.

15 pts.

16 pts.

17 pts.

18 pts.

19 pts.

20 pts.

66.5 min.

71.5 min.

76 min.

81 min.

86 min.

91 min.

96 min.

100 min.

Example

13.75 = 11 ÷ 800

56.5 min.

61.5 min.

66 min.

71 min.

76 min.

81 min.

86 min.

90 min.

1000

0

0

0

0

0

0

0

0

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

1000

75 min.

80 min.

85 min.

90 min.

95 min.

100 min.

105 min.

110 min.

75 min.

80 min.

85 min.

90 min.

95 min.

100 min.

105 min.

110 min.

18 min.

18 min.

18 min.

18 min.

18 min.

18 min.

18 min.

18 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

10 min.

21

Page 22

QUICK START UP PROCEDURE

Standard electrical safety practices

and codes should be used when

working with a dryer. Refer to the

National Electric Code Standard

Handbook by the National Fire Protection Association. A qualified elec-

trician should make all wiring installations.

ALWAYS DISCONNECT

AND LOCK OUT POWER

BEFORE WORKING ON OR

AROUND DRYER

FULL START UP CHECK

This start up procedure assumes the following:

1. That you have read and understand the dryer operation and service

manual.

2. That you have taken special note of all safety precautions.

3. That all safety shields are in place.

4. That all metering roll access doors have been opened and all foreign

objects have been removed.

5. That you have done a pre start up check out.

6. That all motors have been checked for proper rotation.

7. That all heaters have been test fired.

8. That the fuel has been turned ON at the tank.

9. That the electric power has been turned ON.

10. That the main DISCONNECT switch on the dryer is ON.

11. That you have wet grain in the wet holding bin.

12. That you know the incoming grain moisture.

13. That you have the dry grain take away equipment in place.

14. That you have the grain going to the proper bin.

15. That all SWITCHES have been set to the OFF position.

16. That the load mercury switch box is installed with the side stamped

up, in the up position.

FILLING THE DRYER

1. Turn the green CONTROL POWER switch to ON. It should light up, go

through 4 screens and end with the time and date.

2. Turn the DRYING MODE switch to CONTINUOUS FLOW.

3. Push the RESET on the computer key pad to activate the computer.

4. Make sure the UNLOAD switch is in the OFF position.

5. Push the DRYER POWER start switch, it should light up.

6. Turn the LOAD AUGER switch to the MANUAL position to fill the dryer.

The load auger should start and run until the dryer is full, then shut off

automatically. (If the switch is set to the auto position the dryer will

shut down each time the out of grain timer times out, and will have to be

restarted.)

7. When the dryer has filled, turn the LOAD AUGER switch to the AUTO

position.

22

Page 23

QUICK START UP PROCEDURE

STARTING THE DRYER

This start up procedure is for a cold start on wet grain for continuous flow

operation.

1. Set the MAXON or FAST ACTION HAND VALVE on the incoming fuel

line to the ON position.

2. Make sure the MOISTURE CONTROL switch is in the OFF position.

3. Turn the FAN switch (or switches if a multi-fan dryer) to the ON position. The light in the switch should light when the fan comes up to

about half speed.

4. Adjust the PLENUM AIR PRESSURE switch if necessary. Use a flat

blade screwdriver counterclockwise to make it more sensitive (taking

less pressure to activate it), or clockwise for the opposite effect.

5. Turn the HEATER switch (or switches if a multi-fan dryer) to the ON

position. The heater will purge for about 10 seconds then ignite. The

light in the heater switch will come on during ignition and will stay on if

the heater ignites. If the heater does not ignite, the light will go out after

trial for ignition and the dryer will shut down, indicating that it did not

light. If this happens check gas supply, and all valves in the fuel line to

make sure they are on.

ADJUSTING THE TEMPERATURE

1. Set the HIGH-LOW FIRE PLENUM THERMOSTAT on the left side of

the dryer to the drying temperature that you want to run (180° to 200°).

On multiple module dryers set the plenum chambers 30° to 60° apart.

Hottest at the top, most cool at the bottom.

2. On LP gas models adjust the PRESSURE REGULATOR (high fire) on

the burner fuel line, so that burner will reach the thermostat setting

and switch to (low fire) (pressures may be required up to 25 lbs.). Natural gas does not have a regulator, but uses a LARGE BALL VALVE

close to the vertical supply line for adjustment (pressures may be required up to 18 lbs.).

On LP gas models adjust the small RED HANDLED BALL VALVE

(low fire) so that the burner maintains flame then switches back to (high

fire). Natural gas has a BALL VALVE close to the burner control box,

for low fire adjustment.

3. Adjust the burner pressure so that the burners cycles 4 times per

minute (approx. 10 sec. on high--approx. 5 sec. on low). When on

high fire increasing the pressure with the PRESSURE REGULATOR

DECREASES the time spent on high fire. When on low fire increasing

the low fire pressure with the RED BALL VALVE INCREASES the time

spent on low fire.

4. On LP gas models adjust the VAPORIZER so the fuel pipes going to

How much gas pressure do I

use? See step number two in

the Adjusting The Temperature

section.

How often should my burner

cycle? See step number three

in the Adjusting The Temperature

section.

23

Page 24

QUICK START UP PROCEDURE

the burner from the regulator are warm to the touch (not hot and cold).

The vaporizer can be adjusted two ways:

•Loosen the bolt in the hinging mechanism and swing it to a

hotter or cooler position, or

•Loosen the two bolts in the hinge pipe and slide the vaporizer

in or out to a cooler or hotter position.

Either one or both methods may have to be used to get the vaporizer to

the proper temperature. Natural gas does not use a vaporizer.

FULL HEAT-CONTINUOUS FLOW OPERATION

How often do I make speed

adjustment? See step number

ten in the Full Heat-Continuous

Flow Operation section.

1. Check the Continuous Flow Metering Roll Settings-Full Heat on page

25. Pick the line that has your initial starting moisture. These are the

settings we will be referring to during this start up procedure.

2. Make sure the UNLOAD switch is OFF.

3. Make sure the MOISTURE CONTROL switch is OFF.

4. Run the fan(s) and heater(s) for about 10% longer than the approxi-

mate drying time required for the moisture you are trying to dry.

5. Example: 10% removal would be about 54 minutes, 15% removal would

be about 76 minutes and 20% removal would be about 100 minutes.

Add 10 minutes to insure that the grain is dry.

6. After the time in step 4 turn the UNLOAD to 1 SPEED and set the

METERING ROLL SPEED, HIGH SPEED potentiometer to the setting

for 1 SPEED operation. Grain should begin to run at this time. Run time

for this is about 10% longer than the approximate drying time required

for the moisture you are trying to dry, as shown in the example #5 above.

This allows the moisture in the dryer to reach an even gradient top to

bottom without having any highs or lows in it. It will, however, overdry

some of the corn a little.

7. Increase the drying temperature to 190° for single fans or for multiple

fan dryers set the heat chambers 30° to 60° apart. Hottest at the top,

most cool at the bottom.

8. DO NOT TRY TO ADJUST THE DRYER FOR MOISTURE DURING

THIS PROCESS OR YOU WILL ESTABLISH HIGH AND LOW

SWINGS IN THE MOISTURE CONTROL. IT WILL TAKE SEVERAL

HOURS TO WORK ITSELF OUT.

9. After the run time in step 6 you are ready to set up the moisture control.

Now turn the MOISTURE CONTROL to the ON position. Set the temperature to about 100°.

10. Turn the UNLOAD to 2 SPEED. Set the METERING ROLL SPEED,

LOW SPEED and HIGH SPEED potentiometer to the settings listed for

them. Let the dryer run on these settings as shown in the example #5

before trying to adjust moisture or meter roll settings. These settings

24

Page 25

QUICK START UP PROCEDURE

will not have your grain moisture adjusted exactly where you want it, but

will be a good place to start initially. A little different moisture at the

bottom of the storage bin is not usually a problem as long as you have

full floor aeration.

11. After the run time in step 10 you are ready to adjust the moisture control,and the meter roll speeds if required. Each time you make an

adjustment to the moisture control, it will take the approximate time shown

in example #5 to see the results.

1100 SERIES CONTINUOUS FLOW METERING ROLL SETTINGS

Full Heat

Initial

Moisture

Moisture

Removed

Approx.

Dry Time

1 Speed

2 Speed

Low

2 Speed

High

17%

18%

19%

20%

21%

22%

23%

24%

25%

26%

27%

28%

29%

30%

2 pts.

3 pts.

4 pts.

5 pts.

6 pts.

7 pts.

8 pts.

9 pts.

10 pts.

11 pts.

12 pts.

13 pts.

14 pts.

15 pts.

16 min.

21 min.

26 min

31.5 min.

37 min.

41.5 min.

47 min.

51 min.

54 min.

58 min.

62 min.

66.5 min.

71.5 min.

76 min.

625

476

385

317

270

241

213

196

185

172

161

150

140

132

317

270

241

213

196

185

172

161

150

140

132

123

116

110

875

775

675

575

476

385

317

270

241

213

196

185

172

161

31%

32%

33%

34%

35%

These are approximate starting points.

16 pts.

17 pts.

18 pts.

19 pts.

20 pts.

81 min.

86 min.

91 min.

96 min.

100 min.

123

116

110

104

100

104

100

096

087

082

150

140

132

123

116

25

Page 26

QUICK START UP PROCEDURE

ADJUSTING THE MOISTURE CONTROL

How do I set my moisture

control? See step number one

in the Adjusting The Moisture

Control section.

1. Each 5° on the MOISTURE CONTROL changes the output moisture by

about 1%. Example: 100° is set, producing 16% corn out, however,

17% corn out is needed. Reduce the MOISTURE CONTROL temperature by 5° to 95°. This should change the moisture out to about 17%. To

make the corn come out dryer, raise the temperature on the MOISTURE

CONTROL.

2. There are 4 sensors that are averaged together for sensing MOISTURE CONTROL temperature, 1 on each side of the dryer in the front,

and 1 on each side of the dryer in the back. They are located about

1

⁄3 of the way up the grain column from the bottom, and in from the

side about 4 inches.

3. The small lights behind the temperatures on the MOISTURE CONTROL indicate the temperature of the grain at this sample point.

4. The 2 lights in the center are green, the lights to the right or to the left of

these are red.

5. When the grain temperature has the dryer cycling HIGH and LOW speed

on the green lights the moisture setting is being maintained correctly.

6. Set the METERING ROLL SPEED in relation to the small red lights

behind the temperatures on the MOISTURE CONTROL.

7. Red lights to the left indicate that the grain at the sample point is too

cool or wetter than desired. With this condition turn the LOW SPEED

left potentiometer to a lower number. This will slow down the metering

rolls and dry the grain longer, warming it up.

8. Red lights to the right indicate that the grain at the sample point is too

hot or dryer than desired. With this condition turn the HIGH SPEED

right potentiometer to a higher number. This will speed up the metering

rolls and remove the grain quicker, cooling it down.

9. If the MOISTURE CONTROL switches to LOW and only stays on low

for a minute or two and switches back to HIGH, speed up the LOW

SPEED left potentiometer. It is set too slow.

10. If the MOISTURE CONTROL switches to HIGH and only stays on high

for a minute or two and switches back to LOW, slow down the HIGH

SPEED right potentiometer. It is set too fast.

11. The MOISTURE CONTROL should stay on HIGH about 50% of the

time and on LOW about 50%, give or take 25%. There is a broad range

that will work. It should be switching low to high and back to maintain

the desired moisture. A control that does not switch, will not maintain

an evenly dried grain moisture, when the incoming wet grain moisture

is varying.

12. When adjusting the metering roll speeds it is better not to change the

speed more than 20 points at a time.

26

Page 27

QUICK START UP PROCEDURE

27

Page 28

1100 SERIES SERVICE GUIDE

28

Page 29

SERVICE

SEASONAL INSPECTION AND SERVICE

The dryer is made of weather resistant material, and is designed to require a minimum of service. However,

each season we recommend the following items be checked before the

unit is used, and any damaged or

questionable parts replaced. These

checks will help eliminate possible

failures, and assure dependable operation of the equipment.

1. SHUTOFF electrical power.

OPEN power box and control

box, and inspect for moisture,

rodent damage or accumulated

foreign material. Remove any

foreign material present. Inspect

and tighten any loose terminal

connections. Replace any damaged or deteriorated wiring.

2. CHECK propellor for freedom

of rotation and uniform tip clearance. It should also be inspected for dirt and grain dust,

especially inside the hub. Any

additional weight can seriously

effect the balance, and result inharmful vibrations and a short

bearing life.

3. CHECK propellor for free play.

Any side play is an indication of

defective motor bearings,

which should be replaced to prevent a complete motor failure.

Make sure motor mount bolts

are tight.

4. Motor bearings should be LU-

BRICATED periodically, depending on operating conditions. Under normal usage it is

desirable to have the motor

cleaned, checked and bearings

repacked by an authorized service station every two to three

seasons. If the unit is operated

continuously through most of the

year, this service should be per-

formed each year.

Note: If on site bearing relubrication

is to be performed, see lubrication

instructions for ball bearing motors.

To keep motor bearings properly lubricated, and dispel any accumulation of moisture within the windings,

the fan and auger motors should

be operated for 15 to 30 minutes

each month.

LUBE PROCEDURES

If the motor is equipped with an

alemite fitting, CLEAN the tip of the

fitting and apply grease gun. Use 1

or 2 full strokes on motors in NEMA

215 frame and smaller. Use 2 to 3

strokes on NEMA 254 through

NEMA 365 frame. Use 3 to 4 strokes

on NEMA 404 frames and larger.

On motors equipped with slot-

ted head grease screw, remove

screw and apply grease tube to hole.

Insert 2 to 3 inch length of grease

string into each hole on motors in

NEMA frame and smaller. Insert 3

to 5 inch length on larger motors. On

motors having grease drain plugs,

remove plug and operate motor for

20 minutes before replacing drain

plug.

LUBRICATION INSTRUCTIONS FOR BALL BEARING MOTORS

SUGGESTED LUBRICATION INTERVALS*

Hours of Service per Year

5000

Continuous Normal Applications

Seasonal Service (motor is idle for 6

months or more)

Continuous high ambient temperatures, dirty or moist locations, high

vibrations or when shaft end gets hot

* The bearings have been lubricated at the factory, thus no lubrication should be added before start up.

H. P. Range

1/8 to 7 1/2

10 to 40

50 to 150

1/8 to 7 1/2

10 to 40

50 to 150

All

1/8 to 40

50 to 150

Suggested Lube Interval

5 years

3 years

1 year

1 year

3 years

9 months

1 year-beginning of season

6 months

3 months

29

Page 30

SERVICE

SUGGESTED LUBRICANTS

Insulation Class

A & B

A & B

F & H

Consistency

Medium

Medium

Medium

Note: All of the auger and metering roll bearings are lifetime lubri-

cated and do not require service

relubrication.

1. Remove and CLEAN the gas

line strainers. Make certain gas

valves are CLOSED and that

gas is purged from the system

before attempting disassembly.

2. Inspect the collector plate (at

the top of the burner casting)

and the burner cup for any ac-

cumulation of foreign material.

CLEAN if required. Foreign material in the burner cup or casting will not burn out and will impair burner operation.

3. If required, inspect ignitor plug

and CLEAN the electrodes.

Use an ignition point file to remove

Type

Polyurea

Polyurea

Polyurea

carbon and rust between the

electrode surfaces. Ignitor gap

should be about 1/8 inch.

4. Inspect flame sensor for pos-

sible damage or poor connections. Flame sensor wire must

be in good condition.

5. Inspect and manually ROTATE

the top auger paddle assem-

bly. The paddle unit must rotate

freely without any indication of

sticking or binding.

6. Inspect the top auger and bot-

tom auger drive lines for proper

adjustment and condition. Readjust line tension as required.

Note: All of the auger and meter-

ing roll bearings are lifetime lubricated and do not require service

relubrication.

1

3

Grease

Shell Dolium R

Shell Dolium R

Shell Dolium R

Frame Type

215T & Smaller

254 & Larger

7. OPERATE dryer clean out levers, and CHECK clean-out

hatch mechanism for proper op-

eration. With hatch open, inspect and remove any accumulation of dirt, fines and foreign

material from the bottom au-

ger trough area.

Note: Do not allow high moisture

material to collect within the trough

area. It may adversely affect metal

parts.

8. Inspect entire dryer for loose,

worn or damaged parts. Include

CHECK of auger flighting, me-

tering rolls and other internal

parts. CHECK that temperature

sensors within air plenum chamber are secured within insulated

clamps, and do not chafe on

other metal parts.

9. Make sure all dryer guards and

warning decals are securely installed. Guards should not interfere with moving parts. If guards

or warning decals are missing,

contact your dealer for a free replacement.

All

4

2

Remove the Blue Burn Optimizer Cone. Inspect 1-collector plate, 2-burner

cup, 3-ignitor plug and electrodes and 4-flame sensor on the heater.

30

10. TEST FIRE the dryer several

weeks ahead of the drying season. CHECK for possible gas

leaks. (See page 16 for burner

test fire.)

Page 31

SERVICE

FAN PROPELLOR REMOVAL AND INSTALLATION

The fan propellor is secured to the

motor shaft by the use of a taperlock bushing, motor shaft key and

three cap screws.

CAUTION: Although the taper-lock

method of retaining the propellor

onto the motor shaft is simple, it is

essential that the following points be

read carefully and fully understood.

Improper installation can cause a

loose flying propellor, and result in

serious injury or death.

THREADED BUSHING

HOLES

The threaded holes within the bushing are provided for disassembly

purposes only. Do not attempt to use

these holes for reassembly. They

will not allow the parts to lock onto

the shaft thereby causing a hazardous operating condition.

CLEARANCE HOLES

When reassembling parts, the cap

screws must be installed through

the untapped clearance holes as

shown. This will cause the propellor

to be pulled forward onto the ta-

pered bushing, thus locking the

parts securely onto the motor shaft.

When fan servicing requires removal and installation of the

propellor, make sure the propellor

is removed and reinstalled properly.

Key

2. REMOVE the three cap screws

from the clearance holes in the

taper-lock bushing.

3. INSTALL two grade 5 cap

screws into the threaded holes

in bushing. TURN caps by hand

until they bottom against the

front surface of the propellor.

4. BLOCK propellor to prevent it

from turning, and gradually TURN

the cap screws (up to 1/4 turn

at a time) until the propellor

breaks loose from the bushing

and motor shaft. Carefully REMOVE bushing and propellor.

With the propellor free from the

bushing, a wheel can be used

to PULL the bushing off of the

motor shaft. REATTACH bush-

Capscrews installed

through threaded

holes of bushing

Fan Hub

Split Taper Bushing

Fan blade

installation

ing onto propellor to prevent the

loss of parts.

Note: During manufacture the

propellor and bushing on the 26" and

28" solid aluminum blades are balanced together, and are marked with

two small dots to identify their original alignment position. CHECK the

bushing and propellor to make

sure they have alignment marks.

MARK the alignment of the propellor

and bushing, if necessary.

Crowley blades have a keyway

to prevent any misalignment of the

propellor and bushing. Alignment

marks are on the back of the fan hub

assembly. To replace one of the

blade fins, alignment would be necessary, however, this is not recommended. In most cases, the complete propellor should be changed.

Capscrews installed

through threaded

holes of bushing

Fan Hub

1. LOCK OUT the fan power

supply, and REMOVE the fan

guard and the venturi, as required on some models.

Split Taper Bushing

Fan blade

removal

31

Page 32

SERVICE

FAN MOTOR REMOVAL AND INSTALLATION

In the event of motor failure, remove

the motor as described, and take it

to the nearest service station. An

authorized service station is the only

place that can provide possible motor warranty. Motor service and re-

pair at other places will be at owners expense.

If the service station determines

motor failure is caused by faulty material or workmanship within the

warranty period, repair will be covered under the warranty. Motor failure caused by external sources will

result in a charge to the owner for

repair.

1. Make certain power is SHUT-

OFF and locked out. REMOVE

fan guard and propellor.

2. REMOVE cover from fan/heater

control box, and DISCONNECT

the motor lead wires from

within the box.

Note: Tag or otherwise identify wires

for ease of reassembly.

3. REMOVE motor mount bolts.

If there are shims between the

motor and its base, note their

location so they can be properly

installed during reassembly.

4. DISCONNECT the upper end of

the motor conduit, and care-

fully PULL the wires through the

hole in the fan/heater housing.

REMOVE motor from the fan/

heater unit with the conduit still

attached. If motor requires ser-

vice, take it to an authorized ser-

vice station.

5. To reinstall motor, SLIDE onto

motor base plate and REPLACE

shims (if required) between mo-

tor base and plate. REINSTALL

motor mount bolts and washer.

Do not fully tighten at this time.

6. REINSTALL conduit and wires

through hole in fan/heater

housing and carefully CONNECT all electrical wiring.

7. ADJUST position of motor.

Temporarily MOUNT fan blade

on motor shaft. ROTATE fan

blade by hand, making the necessary adjustments, so the tip

clearance between blade and

housing is uniform. If required,

REMOVE the fan blade and

fully TIGHTEN all four motor

mount bolts.

Note: Make sure to INSTALL and

TIGHTEN the propellor in accordance with previous instructions.

32

The position of the fan motor provides easy access for service.

Page 33

SERVICE

HEATER PARTS REMOVAL AND INSTALLATION

Most heater parts can be removed