Air-Shields TI500, TI500-1, TI500-1E, TI500-1C User manual

SERVICE MANUAL

Transport

Incubator

From Hill-Rom Air-Shields

Product No. TI500/TI500-1/TI500-1E/TI500-1C

For Parts or Technical Assistance |

man188rc |

USA (800) 445-3720 Canada (800) 267-2337 |

67 990 11-11 |

International: Contact your distributor. |

|

Transport Incubator

Service Manual

Revisions

Revision Letter |

Pages Affected |

Date |

|

|

|

Original Issue |

|

February, 1999 |

|

|

|

A |

v, 1-4, 3-3, 3-5, 4-3, 4-4, |

October, 1999 |

|

6-1A, 6-3, 6-9, 6-39 |

|

B |

Front cover, Warranty, A, |

December, 1999 |

|

B, 5-2 |

|

C |

All |

January, 2002 |

|

|

|

man188rc (67 990 11-11)

Transport Incubator Service Manual (man188rc) |

Page i |

Revisions

© 2002 by Hill-Rom Services, Inc. ALL RIGHTS RESERVED.

No part of this text shall be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information or retrieval system without written permission from

Hill-Rom Services, Inc. (Hill-Rom).

The information in this manual is confidential and may not be disclosed to third parties without the prior written consent of Hill-Rom.

Fourth Edition

First Printing 1999

Printed in the USA

Air-Shields® is a registered trademark of Hill-Rom Services, Inc.

Bio-Tek® is a registered trademark of Bio-Tek Instruments, Inc.

Critter Covers® is a registered trademark of Hill-Rom Services, Inc.

FERNO® is a registered trademark of Ferno-Washington, Inc.

Fluke® is a registered trademark of Fluke Corporation.

Globe-Trotter™ is a trademark of Hill-Rom Services, Inc.

Hill-Rom Air-Shields™ is a trademark of Hill-Rom Services, Inc.

Hill-Rom® is a registered trademark of Hill-Rom Services, Inc.

Kleenaseptic® is a registered trademark of Predicted Environments, Inc. Loctite® is a registered trademark of Loctite Corporation.

Molykote® is a registered trademark of Alpha Molykote Corporation. Nylok® is a registered trademark of Nylok Fastener Corporation. Oilite® is a registered trademark of Beemer Precision, Incorporated.

Plastite® is a registered trademark of Research Engineering & Manufacturing, Inc.

Plexiglas® is a registered trademark of Rohm and Haas Company.

Page ii |

Transport Incubator Service Manual (man188rc) |

Revisions

Teflon® is a registered trademark of E. I. du Pont and de Nemours and Company.

Tektronix™ is a trademark of Tektronix, Inc.

Transzorb® is a registered trademark of General Semiconductor, Inc.

Variac® is a registered trademark of General Radio Company.

Velcro® is a registered trademark of Velcro Industries, BV (a Dutch corporation).

The information contained in this manual is subject to change without notice. Hill-Rom makes no commitment to update or keep current, the information contained in this manual.

The only product warranty intended by Hill-Rom is the express, written warranty accompanying the bill of sale to the original purchaser. Hill-Rom makes no other warranty, express or implied, and in particular, makes no warranty of merchantability or fitness for a particular purpose.

Additional copies of this manual can be obtained from Hill-Rom.

To order additional copies of this manual, call (800) 445-3720, and place a parts order for part number man188rc (67 990 11-11).

Transport Incubator Service Manual (man188rc) |

Page iii |

Revisions

NOTES:

Page iv |

Transport Incubator Service Manual (man188rc) |

Table of Contents

Chapter 1: Introduction

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 2: Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 3: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 4: Removal, Replacement, and Adjustment Procedures . . . . . . . . . . . 1 - 3

Chapter 5: Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 6: General Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 7: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Technical Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Operating Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Temperature Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Adjustable Stand Assembly (Accessory) . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Environmental Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Electrical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Regulations, Standards, and Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Model Identification and Series Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

Transport Incubator Service Manual (man188rc) |

Page v |

Table of Contents

Warning and Caution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 20

Chapter 2: Troubleshooting Procedures

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Initial Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Function Checks and General Operation Checkout . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Mechanical Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Final Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 13

Power Distribution Does Not Operate Properly . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 14

The Auto-Test Function Does Not Operate Properly . . . . . . . . . . . . . . . . . . . . . . 2 - 20

The Air Temperature Display Does Not Function Properly. . . . . . . . . . . . . . . . . 2 - 21

The Sensor Alarm Does Not Activate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 22

The Baby Temperature Alarm Does Not Function Properly . . . . . . . . . . . . . . . . 2 - 23

The Power Failure Alarm Does Not Function Properly . . . . . . . . . . . . . . . . . . . . 2 - 24

The Set Temp Indicator Does Not Function Properly . . . . . . . . . . . . . . . . . . . . . 2 - 25

The High Temperature Alarm Does Not Function Properly . . . . . . . . . . . . . . . . 2 - 26

Chapter 3: Theory of Operation

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Detailed Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Input Power Circuit Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Power Source Priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Battery Charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Heater Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Switching Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Fault Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Exam Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Feed-Through Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Controller P.C. Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Power On/Off Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Skin Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Air-Temperature-Monitoring Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

Page vi |

Transport Incubator Service Manual (man188rc) |

Table of Contents

Setpoint Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

Air-Temperature-Controlling Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 19

Clock and Timing Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Alarm Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 26

Auto-Test Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 27

Chapter 4: Removal, Replacement, and Adjustment Procedures

Control Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Power Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Battery Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Heater Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 17

Controller P.C. Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

Transport Incubator Service Manual (man188rc) |

Page vii |

Table of Contents

Power P.C. Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 21 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 21 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 21

Chapter 5: Parts List

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3 Service Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5 Exchange Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7 In-Warranty Exchanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7 Out-of-Warranty Exchanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7 Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8 Transport Incubator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10 Base Assembly with Handrail—P/N 67 502 70 . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14 Replacement Outer Hood Assembly—P/N 67 506 70-R and 67 908 60 . . . . . . . 5 - 20 Control Panel Assembly—P/N 67 503 70-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 24 Power Chassis Assembly—P/N 67 407 70-R and 67 407 80-R . . . . . . . . . . . . . . 5 - 26 Battery Tray Assembly—P/N 67 504 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 30 Battery Tray Cable Assembly—P/N 67 504 30 . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 32 Heater Assembly—P/N 67 502 55-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 33 Incandescent Lamp Assembly—P/N 67 505 70 . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 34 Model HLS-101 Adjustable Stand—P/N 67 090 72 (Accessory) . . . . . . . . . . . . 5 - 36 IV Pole Assembly—P/N 67 091 80 (Accessory) . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 40

Accessory Shelf Kit—P/N 67 503 30 and 67 515 00/01/02/03/04/05 and Mount (Accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 42

Controller P.C. Board Assembly (PCB1)—P/N 67 509 71 . . . . . . . . . . . . . . . . . 5 - 46 Power P.C. Board Assembly (PCB2)—P/N 67 508 70 . . . . . . . . . . . . . . . . . . . . 5 - 54

Chapter 6: General Procedures

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3 Steam Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4 Cleaning Hard to Clean Spots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4 Disinfecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4 Disassembly, Cleaning, and Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Page viii |

Transport Incubator Service Manual (man188rc) |

Table of Contents

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

Component Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

P.C. Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

Lubrication Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 14

Preventive Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 15

Preventive Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 23

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 24

Tool and Supply Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 30

Chapter 7: Accessories

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Transport Incubator Service Manual (man188rc) |

Page ix |

Table of Contents

NOTES:

Page x |

Transport Incubator Service Manual (man188rc) |

1

Chapter 1 Introduction

Chapter Contents

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 2: Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 3: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 4: Removal, Replacement, and Adjustment Procedures . . . . . . . . . . . 1 - 3

Chapter 5: Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 6: General Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 7: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Technical Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Operating Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Temperature Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Adjustable Stand Assembly (Accessory) . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Environmental Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Electrical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Transport Incubator Service Manual (man188rc) |

Page 1 - 1 |

Chapter 1: Introduction

Regulations, Standards, and Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Model Identification and Series Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

Warning and Caution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 20

Page 1 - 2 |

Transport Incubator Service Manual (man188rc) |

Purpose |

1 |

Chapter 1: Introduction |

Purpose

This manual provides requirements for the Transport Incubator normal operation and maintenance. It also includes parts lists (in chapter 5) for ordering replacement components.

Audience

This manual is intended for use by only facility-authorized personnel. Failure to observe this restriction can result in severe injury to people and serious damage to equipment.

Organization

This manual contains seven chapters.

Chapter 1: Introduction

In addition to a brief description of this service manual, chapter 1 also provides a product overview.

Chapter 2: Troubleshooting Procedures

Repair analysis procedures are contained in this chapter. Use these procedures to gather information, identify the maintenance need, and verify the effectiveness of the repair.

Chapter 3: Theory of Operation

This chapter describes the application of the mechanical, electrical, and hydraulic systems employed in this product.

Chapter 4: Removal, Replacement, and Adjustment

Procedures

Chapter 4 contains the detailed maintenance procedures determined necessary in chapter 2.

Transport Incubator Service Manual (man188rc) |

Page 1 - 3 |

Organization

Chapter 1: Introduction

Chapter 5: Parts List

This chapter contains the warranty, part-ordering procedure, and illustrated parts lists.

Chapter 6: General Procedures

Cleaning, preventive maintenance, and other general procedures are described in this chapter.

Chapter 7: Accessories

A list of additional products, that can be used in conjunction with the Transport Incubator, is available in chapter 7. Installation procedures for these accessories are also included.

Page 1 - 4 |

Transport Incubator Service Manual (man188rc) |

Typographical Conventions |

1 |

Chapter 1: Introduction |

Typographical Conventions

This manual contains different typefaces and icons designed to improve readability and increase understanding of its content. Note the following examples:

•Standard text—used for regular information.

•Boldface text—emphasizes a word or phrase.

•NOTE:—sets apart special information or important instruction clarification.

•The symbol below highlights a WARNING or CAUTION:

Figure 1-1. Warning and Caution

–A WARNING identifies situations or actions that may affect patient or user safety. Disregarding a warning could result in patient or user injury.

–A CAUTION points out special procedures or precautions that personnel must follow to avoid equipment damage.

•The symbol below highlights a CAUGHT HAZARD WARNING:

Figure 1-2. Caught Hazard Warning

•The symbol below highlights a CHEMICAL HAZARD WARNING:

Figure 1-3. Chemical Hazard Warning

•The symbol below highlights an ELECTRICAL SHOCK HAZARD WARNING:

Figure 1-4. Electrical Shock Hazard Warning

Transport Incubator Service Manual (man188rc) |

Page 1 - 5 |

Typographical Conventions

Chapter 1: Introduction

The Transport Incubator contains different icons designed to increase understanding. Note the following examples:

•The symbol below indicates “Attention, consult accompanying documents:”

Figure 1-5. Attention, Consult Accompanying Documents

•The symbol below indicates “Type B equipment with an F-type isolated (floating) applied part:”

Figure 1-6. Type B Equipment with an F-Type Isolated (Floating) Applied Part

• The symbol below indicates the Battery indicator:

Figure 1-7. Battery Indicator

•The symbol below indicates the Set Temperature Down arrow key:

Figure 1-8. Set Temperature Down Arrow Key

•The symbol below indicates the Set Temperature Up arrow key:

Figure 1-9. Set Temperature Up Arrow Key

•The symbol below indicates the Silence/Reset key:

Figure 1-10. Silence/Reset Key

Page 1 - 6 |

Transport Incubator Service Manual (man188rc) |

Technical Definitions |

1 |

Chapter 1: Introduction |

Technical Definitions

This manual contains different technical terms. For the technical definitions of these terms, see table 1-1 on page 1-7.

Table 1-1. Technical Definitions

Term |

Definition |

|

|

Setpoint |

The temperature of the incubator selected for |

|

operation during use. |

Incubator temperature |

The air temperature at a point 10 cm (4") above |

|

and centered over the mattress surface. |

Temperature |

The condition reached when the average incubator |

equilibrium |

temperature does not vary more than 0.2°C over a |

|

period of one hour. |

Temperature overshoot |

The amount by which the incubator’s temperature |

|

exceeds the average incubator temperature at |

|

temperature equilibrium when the setpoint changes |

|

from 30°C (86°F) to 34°C (93°F). |

Temperature rise time |

The time required for the incubator’s temperature |

|

to rise to 34°C (93°F) from an ambient of 23°C |

|

(73°F) with a 36°C (97°F) setpoint. |

Temperature uniformity |

The amount by which the average temperature at |

|

each of the four points 10 cm (4") above the |

|

mattress surface differs from the average incubator |

|

temperature at temperature equilibrium. The four |

|

points are the centers of the four areas formed by |

|

lines dividing the width and length of the mattress |

|

surface evenly. |

Temperature variability |

The variability of the incubator’s temperature |

|

observed over a 1 hour period after temperature |

|

equilibrium is reached. |

Transport Incubator Service Manual (man188rc) |

Page 1 - 7 |

Introduction

Chapter 1: Introduction

Introduction

Overview

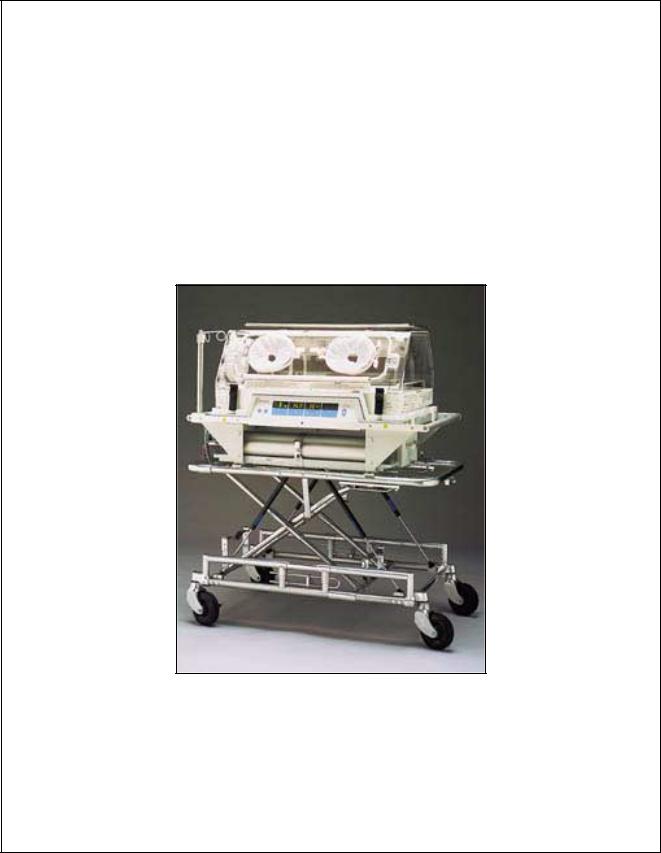

The Transport Incubator is for transport of high risk, premature, low birthweight or critically ill newborns. It provides a means to control air temperature and oxygen concentrations, and adds relative humidity. A double-walled hood provides full visibility and an effective thermal and sound barrier from the environment. Arm ports and door panels provide front and head access, and the mattress tray slides out of the head end for additional access. Tubing access grommets are on both sides of the front access panel and at the left-hand, head end panel. An observation lamp is also included.

The Transport Incubator operates from either a sineor square-wave AC power source. In addition, it can operate from an external 12V DC or 28V DC source or integral 12V batteries. The batteries automatically charge whenever the unit is connected to an AC voltage source and the main Power switch is set to the ON-1 position. A comprehensive visual and audible alarm system is included with a test function to verify proper alarm operation. A Battery indicator is also provided.

Operating Precautions

For additional operating precautions for the Transport Incubator and its accessories, refer to the Transport Incubator (Model TI500) User Manual

(usr038).

Features

Temperature Control

A temperature sensor, located in the recirculation air path, and a proportional control circuit, which determines the heater output to maintain the desired incubator temperature, regulate the incubator temperature. The relative amount of heat provided is indicated by the number of Heater indicators lit on the control panel. The incubator temperature can be maintained at 38.0°C (100.4°F) as selected by the temperature controls on the control panel. The temperature, as sensed by a sensor located within the housing, is compared with the setpoint. Control circuitry uses the information from this sensor to proportion the heater output to maintain the setpoint. The temperature appears on the front panel’s Temperature display.

Page 1 - 8 |

Transport Incubator Service Manual (man188rc) |

Introduction |

1 |

Chapter 1: Introduction |

The initial setpoint is 36.0°C (96.8°F) ± 0.1°C. The incubator heats to this temperature unless the setting is changed. To change the setpoint to a prescribed temperature, use the Set Temp controls on the control panel. An additional sensor within the housing serves as a backup to limit the incubator’s maximum air temperature to 38.9°C (102.0°F) ± 0.5°C. At this limit, the High Temp alarm activates, and the heater shuts off.

Alarms

Each time the unit turns on, it automatically activates a test sequence to verify that the visual display and the audible alarm function. Each of the following six alarms has an indicator on the display and an audible alarm.

High Temperature Alarm

When the incubator temperature is ≥38.9°C (102.0°F), a sensor located below the deck sounds this alarm. A flashing High Temp indicator and an audible tone indicate a High Temp alarm. Internally, the heater turns off. To silence this alarm for 5 minutes, press the Silence/Reset key.

Sensor Alarm

Circuitry monitors the air temperature sensor and the air display sensor for shortor open-circuits or skin temperature probe shorts. A flashing Sensor indicator and an intermittent audible tone indicate a Sensor alarm. This alarm resets itself.

High Heater Temperature Alarm

A flashing Heater Temp indicator and an intermittent audible tone indicate that the heater temperature exceeds 77.0°C (170.6°F). When this occurs, the heater and Heater indicators turn off. To silence this alarm for 5 minutes, press the Silence/Reset key.

Airflow Alarm

A flashing Air Flow indicator and an intermittent audible alarm indicate that the fan impeller is not rotating or is missing. When this occurs, the heater and Heater indicators turn off. To silence this alarm for 5 minutes, press the

Silence/Reset key.

Low DC Alarm

A flashing Low DC indicator and an intermittent audible alarm indicate that the incubator’s DC power source is below the minimum specification value.

Transport Incubator Service Manual (man188rc) |

Page 1 - 9 |

Introduction

Chapter 1: Introduction

Power Failure Alarm

A separate internal battery powers the Power Failure alarm. If AC power is lost and no external DC power source or internal battery is present, the Power Fail indicator lights, and a continuous tone sounds. If the power source switches from an AC power source or a DC power source to an internal battery, the Power Fail indicator lights, and an intermittent tone sounds. To reset this alarm, press the Silence/Reset key.

Adjustable Stand Assembly (Accessory)

The adjustable stand assembly provides a convenient means of moving the Transport Incubator. Each adjustable stand assembly adjusts to different height positions and locks into the litter bar of an ambulance, such as a FERNO®1 Model 175 Series Cot Fastener System.

1. FERNO® is a registered trademark of Ferno-Washington, Inc.

Page 1 - 10 |

Transport Incubator Service Manual (man188rc) |

Specifications |

1 |

Chapter 1: Introduction |

Specifications

Physical Description

For Transport Incubator physical specifications, see table 1-2 on page 1-11.

Table 1-2. Physical Specifications

Feature |

Dimension |

|

|

Length (with accessory adjustable stand |

102 cm (40") |

assembly) |

|

Width (with accessory adjustable stand |

56.5 cm (22.2") |

assembly) |

|

Height (Model TI500 with accessory |

81.3 cm (32.0") to 111.8 cm |

adjustable stand assembly) |

(44.0") |

Height (Model TI500-1/1E/1C with |

85.73 cm (33¾") to 116.2 cm |

accessory adjustable stand assembly) |

(45¾") |

Weight (including accessory adjustable |

72 kg (159 lb) |

stand assembly and one battery) |

|

Battery tray weight with one battery |

10.4 kg (22.9 lb) |

|

|

Battery tray weight with two batteries |

19.4 kg (42.8 lb) |

|

|

Temperature setpoint range |

21.5°C (70.7°F) ± 1.5°C (2.7°F) |

|

to 38.0°C (100.4°F) in 0.1°C |

|

(0.2°F) increments |

Temperature rise time |

30 minutes |

Temperature variability |

≤ 1.0°C (1.8°F) |

Temperature overshoot |

≤ 2.0°C (3.6°F) |

Temperature uniformity |

≤ 1.0°C (1.8°F) |

Correlation of the displayed incubator |

≤ 1.0°C (1.8°F) |

temperature to the actual incubator |

|

temperature at temperature equilibrium |

|

Correlation of the displayed incubator |

≤ 1.5°C (2.7°F) |

temperature to the setpoint at temperature |

|

equilibrium (20°C to 30°C ambients) |

|

Correlation of the displayed incubator |

≤ 2.0°C (3.6°F) |

temperature to the setpoint at temperature |

|

equilibrium (10°C to 20°C ambients) |

|

Transport Incubator Service Manual (man188rc) |

Page 1 - 11 |

Specifications

Chapter 1: Introduction

Feature |

Dimension |

|

|

Observation light |

376.7 lx (35.0 fc) at 10 cm (4") |

|

above the center of the mattress |

Oxygen concentration range |

From 21% to at least 58% |

|

|

Carbon dioxide (CO2) level within the |

< 0.5% when a 4% mixture of |

hood |

CO2 in the air is delivered at |

|

750 ml/min at 10 cm (4") above |

|

the center of the mattress |

Noise level within the hood environment |

< 60 dBa with ambient noise of |

|

≤ 50 dBa |

Environmental Description

For Transport Incubator environmental specifications, see table 1-3 on page 1- 12.

Table 1-3. Environmental Specifications

Feature |

Dimension |

|

|

Operating temperature |

Maintained at a differential of |

|

25°C between the ambient |

|

temperature and the setpoint for |

|

90 minutes per battery |

Normal operating temperature range |

10°C (50°F) to 30°C (86°F) |

Limited operating temperature range |

0°C (32°F) to 40°C (104°F) |

Relative humidity (RH) operating range |

0% to 95%, non-condensing |

Altitude operating range (non-pressurized |

Sea level to 3 km (9843 ft) |

ambient atmosphere) |

|

Altitude operating range (pressurized |

Sea level to 12 km (39370 ft) |

ambient atmosphere) |

|

Altitude shipment range |

Sea level to 12 km (39370 ft) |

|

|

Page 1 - 12 |

Transport Incubator Service Manual (man188rc) |

Specifications |

1 |

Chapter 1: Introduction |

Electrical Description

For Transport Incubator electrical specifications, see table 1-4 on page 1-13.

Table 1-4. Electrical Specifications

Feature |

Dimension |

|

|

AC external power requirements |

100V/120V, 50/60/400 Hz, |

(100V/120V model only) |

270 W maximum, sineor |

|

square-wave |

AC external power requirements |

220V/240V, 50/60/400 Hz, |

(220V/240V and CE mark models only) |

270 W maximum, sineor |

|

square-wave |

DC external power requirements |

11V to 13V, 200 W maximum |

(100V/120V model only) |

or 26V to 30V, 200 W |

|

maximum typical aircraft |

|

voltages |

Internal battery type |

Gel-type, vented, rechargeable |

|

|

Internal battery voltage |

12V DC nominal |

|

|

Internal battery quantity |

One (or two, with the accessory |

|

second battery option) |

Internal battery capacity |

24 ampere hours per battery |

|

|

Internal battery charge time (from full |

10 hours per battery |

discharge) |

|

Internal battery life expectancy |

200 complete charge/discharge |

|

cycles |

Chassis current leakage (100V/120V |

≤ 300 µA |

model only) |

|

Chassis current leakage (220V/240V and |

≤ 500 µA |

CE mark models only) |

|

Regulations, Standards, and Codes

The Transport Incubator is classified as International Electrotechnical

Commission (IEC) Class 1, internally-powered equipment.

Transport Incubator Service Manual (man188rc) |

Page 1 - 13 |

Model Identification and Series Changes

Chapter 1: Introduction

Model Identification and Series Changes

For Transport Incubator model identification and series changes, see table 1-5 on page 1-14.

Table 1-5. Model Identification and Series Changes

Model Number |

Description |

|

|

TI500 Series 00 |

Transport Incubator original design |

TI500 Series 01 |

Transport Incubator with increased spacing |

|

between the control P.C. board and its chassis |

TI500 Series 02 |

Transport Incubator with the resistor changed to |

|

the monitor motor circuit on the control P.C. board |

TI500-1/1E/1C Series |

220V/240V Transport Incubator original design |

00 |

|

For Transport Incubator power chassis assembly model identification and series changes, see table 1-6 on page 1-14.

Table 1-6. Chassis Assembly Model Identification and Series Changes

Model Number |

Description |

|

|

TI500P-1/1E Series 00 |

Power chassis assembly original design |

TI500P-1/1E Series 01 |

Power chassis assembly with reduced patient |

|

current leakage |

TI500P-1/1E Series 02 |

Power chassis assembly with added trickle charge |

|

circuitry on the power P.C. board assembly |

Page 1 - 14 |

Transport Incubator Service Manual (man188rc) |

Safety Tips |

1 |

Chapter 1: Introduction |

Safety Tips

WARNING:

Only facility-authorized personnel should troubleshoot the Transport

Incubator. Troubleshooting by unauthorized personnel could result in personal injury or equipment damage.

WARNING:

During removal and replacement, support the battery tray, and avoid pinch points. Failure to do so could result in personal injury or equipment damage.

WARNING:

Follow the product manufacturer’s instructions. Failure to do so could result in personal injury or equipment damage.

WARNING:

When performing cleaning and maintenance procedures, ensure that the oxygen supply to the incubator is turned off and that the incubator is disconnected from the oxygen supply. A fire and explosion hazard exists when cleaning and maintaining the incubator in an oxygenenriched environment.

WARNING:

The heater fins may be hot enough to burn. Do not touch the heater fins until the unit has cooled for at least 30 minutes.

WARNING:

A dirty air intake filter may affect the oxygen concentrations or cause carbon dioxide build-up. Check the air intake filter on a routine basis, and change it at least every 3 months. Failure to do so could result in infant injury.

WARNING:

Follow the product manufacturer’s instructions. Failure to do so could result in infant injury or equipment damage.

Transport Incubator Service Manual (man188rc) |

Page 1 - 15 |

Safety Tips

Chapter 1: Introduction

WARNING:

After cleaning, install the impeller on the motor shaft. Failure to do so could cause the heater to overheat and become disabled. If the impeller is installed incorrectly, oxygen and temperature could be adversely affected. Ensure that the impeller turns freely after installation.

WARNING:

Only facility-authorized personnel should perform preventive maintenance on the Transport Incubator. Preventive maintenance performed by unauthorized personnel could result in personal injury or equipment damage.

WARNING:

To prevent personal injury, keep fingers clear of moving parts.

WARNING:

Two people should always handle the Transport Incubator. Failure to do so could result in personal injury or equipment damage.

WARNING:

To ensure incubator stability, fully support the weight of the incubator until the height adjustment latch firmly locks in the desired position.

Failure to do so could result in personal injury or equipment damage.

WARNING:

If the gas is released rapidly due to damage or another cause, compressed gas cylinders, such as oxygen cylinders, can become hazardous projectiles. To prevent movement or damage from shock or impact to the adjustable stand assembly or incubator, securely fasten the cylinders and tighten the clamp screw as required.

WARNING:

If not all indicators display or the alarm does not sound briefly at the end of the Auto-Test cycle, do not use the incubator. Infant injury or equipment damage could occur.

Page 1 - 16 |

Transport Incubator Service Manual (man188rc) |

Safety Tips |

1 |

Chapter 1: Introduction |

WARNING:

To prevent accidental opening of the access panel, fully engage the access panel latch. Failure to do so could result in infant injury or equipment damage.

SHOCK HAZARD:

To prevent damage to the equipment, remove all power from the unit.

Failure to do so could result in personal injury or equipment damage.

SHOCK HAZARD:

Unplug the unit from its power source. Failure to do so could result in personal injury or equipment damage.

SHOCK HAZARD:

To disconnect the batteries from the incubator, loosen the battery compartment fastening knob, and slide the compartment out approximately 5 cm (2"). Failure to do so could result in personal injury or equipment damage.

SHOCK HAZARD:

Do not expose the unit to excessive moisture. Personal injury or equipment damage could occur.

SHOCK HAZARD:

Before use, check the continuity of the ground between the chassis and the AC plug grounding pin. Failure to do so could result in infant injury or equipment damage.

SHOCK HAZARD:

To ensure grounding reliability, plug the AC power cord only into a properly grounded, three-wire, hospital-grade or hospital-use outlet of the proper voltage and frequency. Do not use extension cords.

Personal injury or equipment damage could occur.

Transport Incubator Service Manual (man188rc) |

Page 1 - 17 |

Safety Tips

Chapter 1: Introduction

SHOCK HAZARD:

For adequate external DC voltage, do not use a cigarette lighter as the terminal point. Ensure that the ambulance wiring leading to the terminal point is at least 10 gauge and as short as possible. Failure to do so could result in infant injury or equipment damage.

SHOCK HAZARD:

Ensure that the building power source is compatible with the electrical specifications shown on the unit. For proper grounding reliability, plug the power cord only into a properly-marked, hospital-grade receptacle. Do not use extension cords. If any doubt exists as to the grounding connection, do not operate the equipment. Infant injury or equipment damage could occur.

CAUTION:

When installing the impeller, do not place excessive axial force on the motor shaft. Damage to the motor bearing could occur.

CAUTION:

Do not use harsh cleaners, solvents, or detergents. Equipment damage could occur.

CAUTION:

Do not use alcohol, acetone, or any organic solvents for cleaning. They could craze the clear acrylic hood.

CAUTION:

Do not expose the hood assembly to direct radiation from germicidal lamps. Ultraviolet radiation from these sources could crack gaskets, fade paint, and craze the clear acrylic hood.

CAUTION:

To avoid damage to the air temperature probe, exercise care when lowering the upper shell onto the lower shell.

CAUTION:

To prevent component damage, ensure that your hands are clean, and

Page 1 - 18 |

Transport Incubator Service Manual (man188rc) |

Loading...

Loading...