Air-Shields C400QT, C450QT, CE Service manual

SERVICE

ISOLETTE

MANUAL

Infant

From

Incubator

Hill-Rom

Air-Shields

Products:

For

Paris

USA

Intemational:

Or

(800)

Technical

445-3720

Contact

C400

Canada

ATY/C450

Assisiance

(800)

your

distributor.

AT“

267-2337

and

CE

VERSIONS

man203

The

year

product

from

the

All

consumable

being

date

described

of

shipment

and

disposable

in

this

from

LIMITED

WARRANTY

manual

products

is

Hill-Rom

warranted

Ajir~Shields,

are

guaranteed

against defects

Inc.,

Hatboro,

to

be

free

in

materials

with

from

defects

or

the

following

workmanship

exceptions:

upon

shipment

for

one

only.

Calibrations

During

customer.

This

therefrom

This

event

injury

*The

least

Maintenance

through

the

warranty

There

warranty

if:

1.

Damage

2.

The

3.

The

Inc.

4.

Sale

warranty

be

liable

resulting

Accreditation

annually

our

are

considered

period any

will

be no

is

rendered

to

the

customer

customer

or

service

is in

lieu

for

incidental

from

breach

Manual

thereafter.

Program

Product

Service

labor

void

unit

fails

to

uses

any

is

performed

of

all

other

of

for

To

during

normal

defective

charge

and

Hill-Rom

is

incurred

maintain

parts,

accessories,

by a non-certified

warranties,

or

consequential

warranty.

Hospitals

comply

Group

the

warranty

with

and

maintenance

parts

other

for

replacing

Air-Shields,

as a result

the

unit

in a proper

expressed

damages

requires

this

authorized

each

standard,

period.

and

are

than

those

the

parts within

inc.

of

mishandling.

manner.

or

fittings

service/dealer

or

implied,

including

piece

of

we

recommend

This

service

dealers.

not

included

listed

above

the

cannot

not

equipment

be

specified

agency.

and

loss

of

can

be

in

the 1 year

will

be

continental

held

liable

or

sold

Hill-Rom

use,

property

to

be

tested

that

you

participate

performed

warranty.*

replaced

by

Air-Shields,

at

U.S.

for

conditions

Hill-Rom

damage,

prior

to

by

certified

in

no

charge

resultant

Air-Shields,

Inc.

shall

or

personal

initial

use

and

our

Preventive

technicians

to

the

inno

at

For

Services

quired

and

JAT.

NO.

„123456789

40038

man203

456789

7

optimal

Canada

performance,

representatives

maintenance

should

Hill-

A

HILLENBRAND

330

Jacksonvifle

68

994

50-7

product

are

by

calling

contact

'

USA

their

ROM

service

located

throughout

(800)

local

factory-authorized

INDUSTRY

Road,

Hatboro,

SERVICE

should

445-3720

be

performed

the

United

and

Canada

Hill-Rom

Air-Shields.

PA

19040

only

States

(800)

-

by

qualified

and

267-2337.

Air-Shields,

service

Canada

personnel.

and

are

dispatched

Customers

Inc.

distributor

Printed

Change

Change

Change

Change

Change

Change

Technical

outside

for

in

USA

1

2

3

4

5

6

for re-

the

U.S.

service.

2/95

5/95

10/95

2/96

10/96

12/97

3/99

PLEASE

READ

Please

Since

and

incorporated

separate

package.

to

THIS

MODIFICATIONS

TO

CANNOT

OPERATION

OR

check

Hill-Rom

component

into

sheets

Changed

the

changed

MANUAL

MAINTAIN

ASSUME

OF

MODIFICATION.

NOTE

Some

parts

used

this

manual.

function

for a listing

of

This

the

of

the A page

Air-Shields,

improvements

the

printed

at

the

rear

material

material,

CONTAINS

SHOULD

YOUR

WARRANTY

RESPONSIBILITY

THIS

EQUIPMENT

ON

in

your

equipment

sometimes

equipment.

recommended

for

change

inc.

manuals.

of

on

as

shown

PROPRIETARY

BE

information.

conducts a continuous

are

sometimes

the

manual

each

page

on

the

PERFORMED

AND

WHICH

incorporated

When

this

or

under

of

text

right.

INFORMATION.

ONLY

TO

AVOID

FOR ANY

MAY

is

indicated

CONDITIONS

RESULT

REPLACEMENT

may

be

different

occurs

Order

the

spare

NOTE:

due

to

part

listed

parts.

ALSO

difficulty

in

the

SEE

product

occurs,

separate

BY

QUALIFIED

CREATING

than

those

in

paris

Parts

List.

PAGE

improvement

into

equipment

changed

cover

by a vertical

REPAIRS

FROM

which

procurement,

Refer

2.

material

in

SERVICE

SAFETY

AFFECTING

UNAUTHORIZED

appear

to

Section 6 of

program,

before

the

bar

AND

they

is

provided

form

of a change

in

the

margin

AUTHORIZED

PERSONNEL

HAZARDS,

THE

PROPER

PARTS

in

the

Parts

but

does

not

this

circuit

can

be

on

next

WE

REPAIR

List

alter

the

Manual

of

Change

6

1

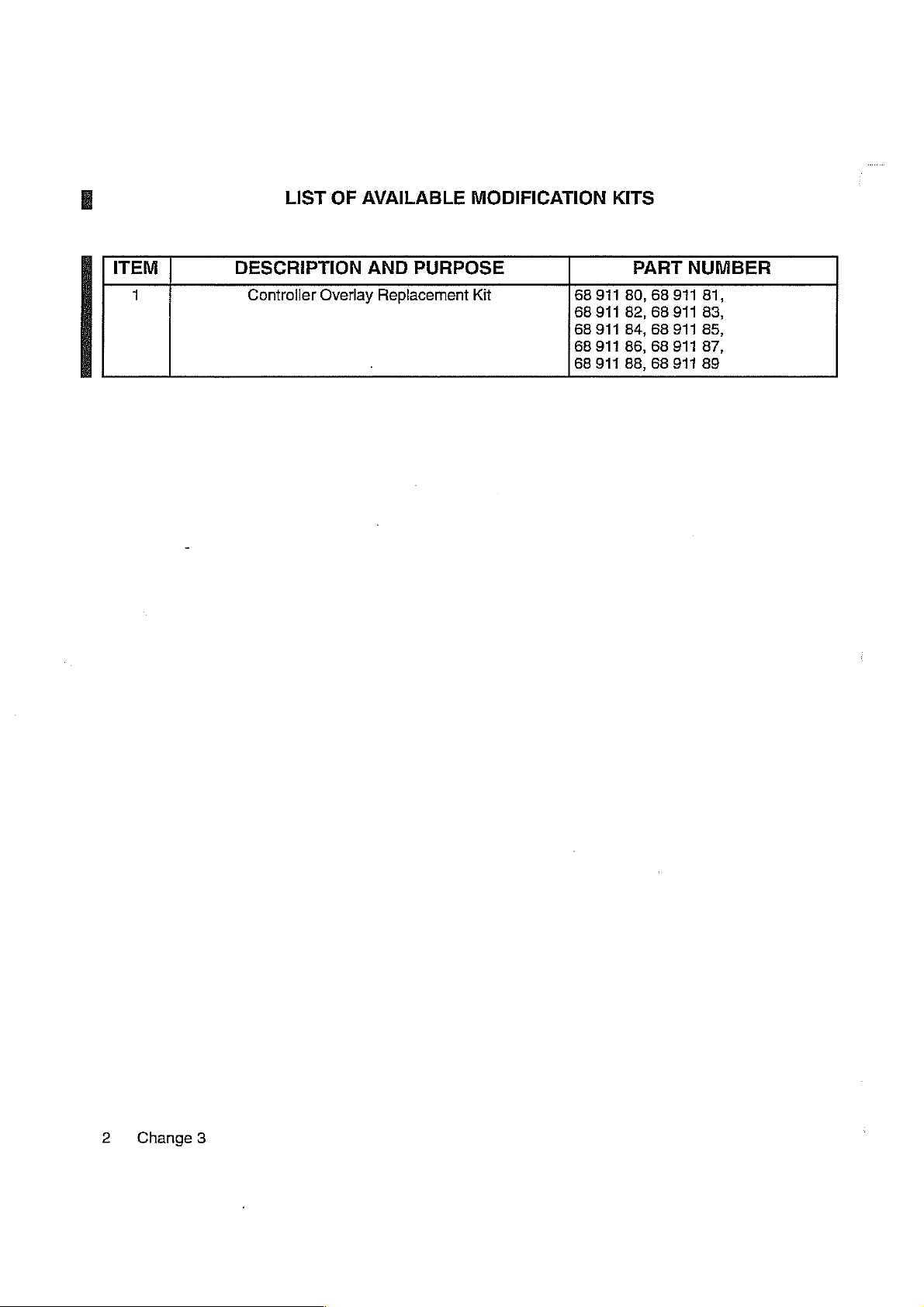

ITEM

LIST

OF

DESCRIPTION

Controller

Overlay

AVAILABLE

AND

PURPOSE

Replacement

MODIFICATION

Kit

68

68

68

68

68

KITS

911

911

911

911

911

PART

80,

68

82,

68

84,

68

86,

68

88,

68

NUMBER

911

81,

911

83,

911

85,

911

87,

917

89

2

Change

3

LIST

OF

EFFECTIVE

PAGES

PAGE

1-1

3-2 and

8-3A

3-4through3-14

4-1

BAT

4-8

NO.

and

1-2

3-3

through

through

aaa

through

..........

..........,..........,.........

4-6

4-12

ee

3-8D

................,........

..........................

..

CHANGE

nee

O...

0

0

2...

eee

NO.

DATE

K κ κε

εον

OF

2/95

2/95

10/95

ISSUE

5-12

5-19

5

5~25

5

through

A

through

through

5-17

5-23

5-26

(Change

6)

A

LIST

OF

EFFECTIVE

PAGES

PAGE

a

6-22

6-26

6-27

6-29

6-32

6

6-34 に に

6-35 1 eee

6—36............

EV

6-38........

¡AN

6

6-41

6-442

6~-483

6-44

6-46

4

6-49

Bcc

NO.

users

through

....,,...,....,...,,...,..........

and

through

44e.

cc

cesser

.......

and6-45

and

through

6-25

6-28

6-37

ear

6-47

6-53

CHANGE

...................,.....

............................ ド に

.........................

ron

rr

rr

rc

rr

rr

..........,..............,..

.............................

.........................

rr

rr

rr

rr

ro

ko

k

NO.

人

0

Dro

0

【

A

e

cesser

0

2......

iie

o

4

0

5

seeesremeteeesss

0

5

0

5

Arena

0

人

cee

tenet

rr

enn

esessnkee

ます

すす

cece

center

ence tent e eens

DATE

まま

まま

en

eee

10/96

아아

다아

12/97

10/95

12/97

10/96

12/97

12/97

10/96

10/96

OF

2/95

5/95

2/96

2/95

5/95

3/99

2/96

2/95

2/95

2/96

2/95

2/95

2/95

ISSUE

B

(Change

6)

TABLE

OF

CONTENTS

SECTION

1

GENERAL

1.1

INTRODUCTION

1.2

DESCRIPTION

1.3

ACCESSORIES

1.4

MODEL

2

INSTALLATION

2.1

UNPACKING

2.2

ASSEMBLY

2.3

ASSEMBLY

2.4

WARM

2.5

GENERAL

3

TECHNICAL

3.1

SPECIFICATIONS,

3.2

THEORY

321

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.2.8

3.3

DETAILED

3.3.1

3.3.2

INFORMATION

IDENTIFICATION

200...

-

INCUBATORS

—

INCUBATORS

WEIGH)

OF

GENERAL.................

OVERALL

TEMPERATURE

ALARMS

VERTICAL

CONTINUOUSLY

QUIET

SWIVEL

POWER

»e

e

в

e

MAIN/DISPLAY

INFANT SCALE,

OPERATION

INFORMATION

OPERATION

FUNCTIONAL

LATCHACCESS

SHELVES,

CIRCUIT

SUPPLY

GENERAL..................

HEATERCONTROL......................

LINE

MOTOR

..........

SERIES

cece

AND

CONTROL

HEIGHT

DESCRIPTION

REFERENCE

ADJUSTABLE

VARIABLE

CABINETS

..........

CONTROLLER

BOARD

000000

CHANGE

EQUIPPED

EQUIPPED

MODEL

FUNCTIONAL

ΡΕΡΟΗΙΡΤΙΟΝ

MATTRESS

DOOHNS

............L

(IEC

K

cere

WITH

WITH

I20

(ACCESSORY)

CHECKOUT

eee

STAND

AND

DRAWERS

CONTROLLERS

a

ии

ина

STANDARD

VERTICAL

e

cece

(OPTION,

TILT

MECHANISM

e

cee

K K K K K

иное R K K K K KR

CABINET

HEIGHT

PROCEDURE

44e

eee

K K P

REFER

(ACCESSORIES)

ene t eet

sisi

ONLY)

sun

esans

eee

ADJUSTABLE

TO

......

nent

K

K

S

K K

K K K

STAND

ーー

...............

トレ

トー

kk

sner k ker r rr

cesser

erer

K

FIGURE

1.1)

STAND

er

enee

sieurs

e ε κε ε κκ ε νοκ κ ον

K

n

トド

ーーー

renen

........

kk

PAGE

k

....

srnge

εως

sans

1-1

2-1

2-1

2-1

2-3

2-5

3-9

KEYPAD

SIGNAL

ALARMS

-…

High

一

SetPOointAIar

—

SystemFail.......................

—

PoewerFall

ー

Probe

—

AirFlow

ADCONVERTER..................

POWER

BATTERY

DISPLAYS

ντ νε

CONDITIONERS

..............

Temperature

Fail

..................

SUPPLY

CHARGER

ωω

εννοω

Alarm . «ων

.........................

MEASUREMENT

εν

eler

εν

εν

νεο ενω

eee

νννννω

2...

εν

εεοώνο

ενω

00

5.el

een

2222.

ενω

iie

이이다

νο νε

εκ ε ενω ν ένο ώ νε

ρω νε εν

οκ

0

0000111

ees

ela

아아아

eee

eee

ο

aerea

ων

ον

마

TABLE

OF

CONTENTS

(Cont.)

SECTION

3.3.3

4

PREVENTIVE

4.1

СЕМЕВАЕ........

4.2

CLEANING

4.2.2

4.3

GAS

STERILIZATION

5

SERVICE

5.1

GENERAL

5.2

CONTROLLER

5.2.1

®

ΑΙΟΡΙΟ

e

REMOTE

e

ACLINEVOLTAGECORRECTİON.............................

e

DC

PROBE BOARD

e

GENERAL

e

SERIAL

e

SKIN

MAINTENANCE

------ᾱ-υᾱ--ἷ,

„....

CLEANING

.......,.,..,,........,

GENERAL.....................

ΑΙΑΗΜ

ALARM

MOTOR

COMMUNICATION

PROBE

....,.,....,.....,...,.4.......44

AND

INCUBATOR

INTERFACE

CONTROL

CALIBRATION

FUNCTIONAL

(GROUP 2 CONTROLLERS

CHECK

ccc

cen

cence

4e

TESTS

eee

K

ee

ONLY)

L

ие

la

...................

K k n

еее

ниче

k

PAGE

3-12

3-13

3-13

3-13

e

5.3

CALIBRATION

5.3.1

5.3.2

5.3.3

5.4.1

5.4.2

5.4.3

PROCEDURE

PROCEDURES

TEST

EQUIPMENT

POWER

LOCATION

本

e

MAIN

LOCATION

*

GENERAL

TEST

ERROR

SUPPLY

OF

PROCEDURE

BOARD

OF

SET-UP............

EQUIPMENT

CODES

(REFER

.............

REQUIRED

(REFER

TEST

POINTS

............

TEST

POINTS

ενω

REQUIRED

..........

TO

FIGURES

AND

TO

FIGURE

AND

ρνων

5.1

ADJUSTMENTS)

5.2

FOR

ADJUSTMENTS)

ων

εως

нения

AND

eee

5.2

FOR

...............................

K

иене

rr

нение

어이

нее

eee e eens

тяеки

тия

5-7

5-7

5-7

TABLE

OF

CONTENTS

(Cont.)

SECTION

5.5.2

5.5.3

5.5.4

5.5.5

5.6

АСТЕАМАТМЕ

5.6.1

5.6.2

5.6.3

5.6.4

6

REPLACEMENT

6.1

GENERAL

6.2

RECOMMENDED

CONTROLLER

e

CONTROLLER

e

MAIN

e © POWER

e

РНРОВЕ

e

DUAL

OXYGEN

VHA

STAND

e

VHASTAND

®

UP/DOWNSWITCH

e

PHASE

REASSEMBLY

OUTER

35.89

39.30

36.00

36.00

COLUMN

ТЕЗТ

°C

BABY

°C

°C

AIR

°C

AIR

PARTS に に に 1 に

..

FRONT

PRINTED

SUPPLY

ВОАНО

AIR

TEMPERATURE

INPUT

HIGH

VALVE

eee

SHIFT

OF

ЕСШРМЕМТ

TEMPERATURE

TEMPERATURE

TEMPERATURE

TEMPERATURE

SPARE

PANEL

FRONT

CIRCUIT

„o

............

FILTER

ACTUATOR

CAPACITOR

INNER

(REFER

PARIS

COLUMN

TO

......

AND

CONTROLLER

PANEL

FIGURE

SIMULATION

SIMULATION

........

BOARD

PROBE

CARTRIDGE

.......................

нение

INTO

5.6)

нение

SIMULATION

SIMULATION

ce

.............

еее»

...........-

.............

GROUP 1 UNITS

GROUP 2 UNITS

ーー

eee

nee

PRINTED

cece

ect

ии

еек

няня

CIRCUIT

eee tee

еее

.....................

......,....,...,.....

неее

κεν

BOARDS

eee

eee e eens

r

sner

cnet

εεεο

ρε

κορν

ян

εν εκ εκ ε εν

te

тнтнни

чину

νεο

PAGE

...

knrer

neeees

ενος

ντε

εν

5-23

5-30

5—30

6-1

6-1

6-3

7

DIAGRAMS

71

GENERAL..................

...........

0000000000000

S K K K R K S K

(Change

2)

K

ο

rer

irere

7-1

7-1

证

LIST

OF

TABLES

(cont.)

TABLE

6.10

MAIN/DISPLAY

6.1

PROBE

6.12

POWER

6.13

POWER

6.14

CABINET

6.15

VHA

STAND

6.16

INNER

6.17

CABINET,

FLOWCHART

5.1

SYSTEM

5.1

SYSTEM

5.2

POWER

5.2

POWER

5.2

POWER

5.3

MAIN

5.3

MAIN

5.3.

MAIN

5.3

MAIN

5.3

MAIN

5.3

MAIN

BOARD,

SUPPLY

SUPPLY

STAND,

ASSEMBLY,

COLUMN

VHA

FAIL

FAIL

SUPPLY

SUPPLY

SUPPLY

BOARD

BOARD

BOARD

BOARD

BOARD

BOARD

BOARD,PARTSLISI

PARTS

BOARD

BOARD

ASSEMBLY,

STAND,

ALARM

ALARM

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

LIST

GROUP1,PARTSLIST...................

GROUP

ASSEMBLY,

PARTSLIST

PARTS

TROUBLESHOOTING

TROUBLESHOOTING

BOARD

BOARD

BOARD

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

PAHTS

«νε

2,

PARTS

LIST

LIST

....................

νωωνωενεννωνων

PARTS

LIST

OF

(Sheet 1 of

(Sheet 6 of

LIST

LIST

........

000000000

FLOWCHARTS

(Sheet10f2)............................

(Sheet 2 of

(Sheet 2 of

(Sheet 3 of

(Sheet 4 of

(Sheet 5 of

κε κ εκ

...................,...........,,.,.

2.0000

2)...................,.........

(Sheet 1 0f

(Sheet 2 of 3)

(Sheet 3 of 3)

6)

6)

6)

6)

6)

6)

eee

εν

ενος

κών

εν

νε

ν κ

ναών

00

ee

ee

0

3)

.........................

.........................

...................,.....

εκ εω

anes

νε

νο

ke

k

ne

PAGE

6-37

εν

6-41

6-43

6-47

6-51

6-54

6-59

PAGE

5-12

5-13

5-14

5-15

5-16

vi

TABLE

OF

DEFINITIONS

AND

SYMBOLS

TECHNICAL.

Control

by lines

Incubator

Zone. A plane

that

Temperature.

face.

Steady

not

Temperature

vary

more

Temperature

perature

during

Temperature

Temperature

above

the

mattress

dition.

mattress

The

four

surface.

Temperature

Temperature

DEFINITIONS

10

cm

divide

the

width

Air

Condition.

than

0.2

°C

Overshoot,

Steady

Rise

Time. The

Uniformity. The

surface

points

are the

Variation.

during

The

Steady

above

the

and

length

temperature

The

condition

over a period

The

amount

Temperature

time

required

amount

differs

from

centers

of

difference

Temperature

mattress

of

the

mattress

at a point

of

one

by

which

Condition,

for

by

which

the

average

four

quadrants

between

Condition.

with

an

10

cm

reached

hour.

Incubator

resulting

the

Incubator

the

average

Incubator

formed

the

Incubator

area

defined

surface.

(4

in.)

above

when

the

Temperature

from a change

Temperature

temperature

Temperature

by

Temperature

by

average

lines

that

the

center

and

centered

Incubator

exceeds

at

each

divide

of

four

over

average

in

temperature.

to

rise

11

of

four

at

Steady

the

width

and

the

quadrants

the

mattress

Temperature

Incubator

°С.

points

10

cm

Temperature

and

length

Average

Incubator

formed

sur-

does

Tem-

(4

in.)

Con-

of

the

vii

NOTE,

IMPORTANT,

CAUTION,

AND

WARNING

NOTE: A Note

or

IMPORTANT:

CAUTION:

WARNING:

inherent

sonal

injury

is

inserted

overlooked. A Note

Similar

A

Caution

can

lead

A

Warning

to

the

operation,

or

death

in

text

to a Note

is

inserted

to

damage

is

inserted

of

the

to

point

may

also

but

used

in

text

or

destruction

cleaning,

operator

out

procedures

be

where

to

in

text

and

or

used

to

clarify

greater

call

attention

of

the

to

call

attention

maintenance

patient.

or

conditions

apparently

emphasis

to a procedure

equipment

to

of

the

which

may

contradictory

is

required.

which,

or

improper

dangerous

equipment

otherwise

or

confusing

if

not

operation.

or

hazardous

which

may

be

misinterpreted

situations.

followed

result

exactly,

conditions

in

per-

SYMBOLS

Attention;

Type B eguipment

isolated

consult

(floating)

accompanying

with

applied

an

F-type

part.

documents.

M

©

Set

Temperature

Set

Temperature

Up

Key

Down

Key

Caution:

Refer

PaP

AC

power.

Protective

©,

Air

»

Mode

Baby

=

Air

Mode

Electric

ice

service

Earth

Control

Mode

Control

Control

shock

t

to

qualified

(ground).

Indicator

Indicator

Selection

hazard.

ified

personne

Key

|.

©

>87º

|

©

©

、

Keypad

Keypad

Lock

Lock

Temperature

Indicator

Temperature

Selection

Silence/Reset

Key

Indicator

Key

Override

Override

Key

Mode

Mode

© @

Baby

Mode

Control

Selection

Key

viii

POWER

De

On/Off

Switch

GENERAL

C400/C450

INFORMATION

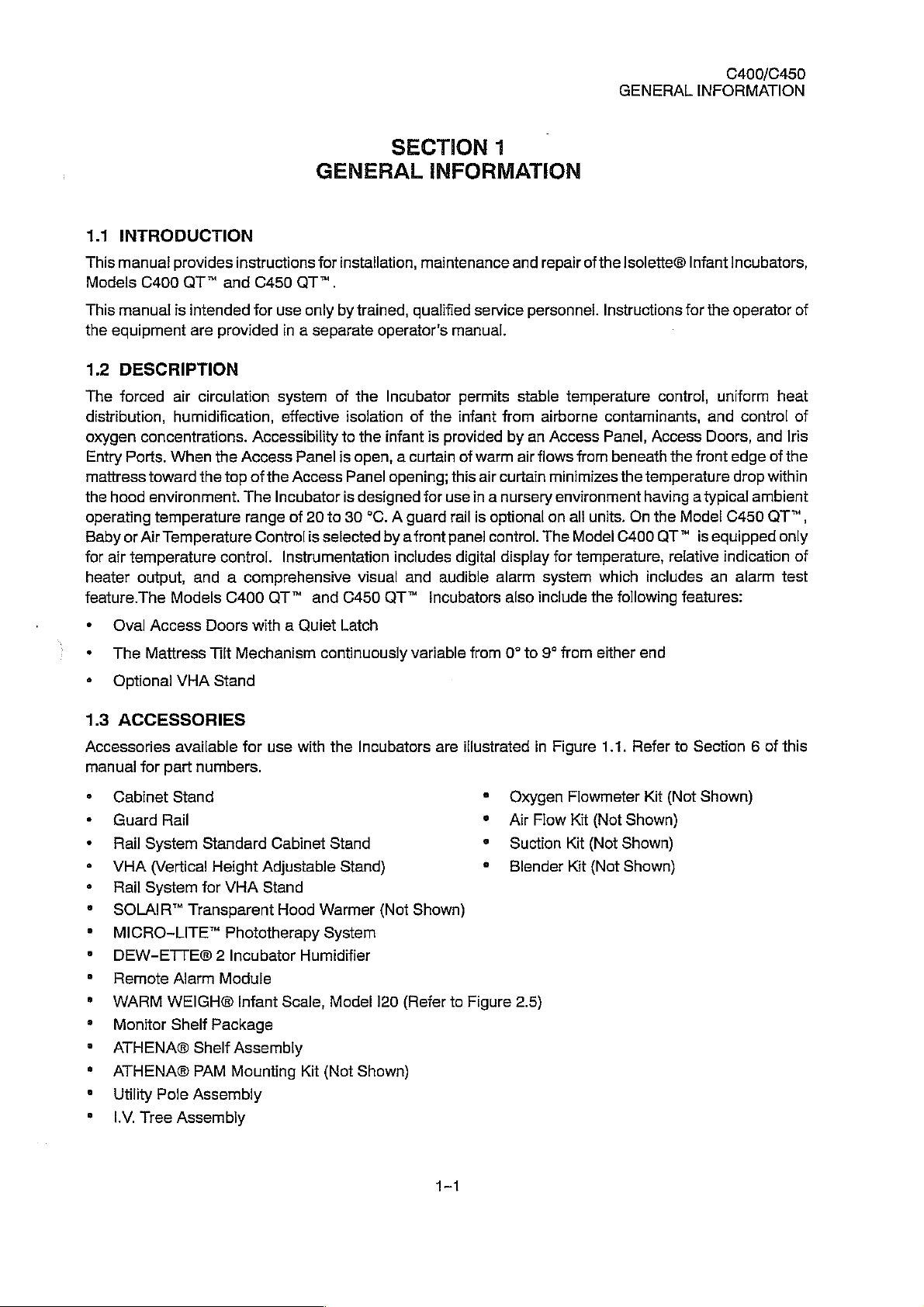

1.1

INTRODUCTION

This

manual

Models

This

manual

the

equipment

1.2

DESCRIPTION

The

forced

distribution,

oxygen

Entry

Ports.

mattress

the

hood

operating

Baby

or

for

air

heater

feature.The

provides

C400

is

air

humidification,

concentrations.

When

toward

environment.

temperature

Air

Temperature

temperature

output,

Models

instructions

QT™

and

C450

QT™.

intended

are

circulation

for

provided

use

only

in a separate

system

effective

Accessibility

the

Access

the top

The

range

control.

and a comprehensive

C400

Panel

of

the

Access

Incubator

of

20

Control

is

Instrumentation

QT™

GENERAL

for

installation,

by

trained,

operator's

of

the

isolation

to

the

is

open, a curtain

Panel

is

designed

to

30

°C. A guard

selected

visual

and

C450

SECTION

INFORMATION

maintenance

qualified

manual.

Incubator

of

the

infant

is

provided

opening;

by a front

includes

QT™

this

for

use

rail

panel

and

audible

Incubators

digital

1

and

service

permits

infant

of

stable

from

by

warm

air

air

curtain

in a nursery

is

optional

control.

display

alarm

also

repair

of

the

personnel.

temperature

airborne

an

Access

flows

from

minimizes

environment

on

all

units.

The Model

for

temperature,

system

include

which

the

Isolette®

Instructions

Infant

for

control,

contaminants,

Panel,

Access

beneath

the

the

front

temperature

having a typical

On

the

Model

C400

QT™

is

relative

includes

following

features:

Incubators,

the

operator

uniform

and

control

Doors,

and

edge

drop

ambient

C450

equipped

indication

an

alarm

of

heat

of

Iris

of

the

within

QT™,

only

of

test

*

Oval

Access

*

The

Mattress

ㆍ

Optional

1.3

ACCESSORIES

Accessories

manual

ㆍ

*

・

*

*

®

>

s

9

9

for

Cabinet

Guard

Rail

System

VHA

(Vertical

Rail

System

SOLAIR™

MICRO-LITE™

DEW-ETTE®

Remote

WARM

+ | Monitor

s

ATHENA®

»

АТНЕМА®

®

Utility

Pole

s

INV.

Tree

Doors

Tilt

VHA

Stand

available

part

numbers.

Stand

Rail

Standard

Height

for

Transparent

2

Alarm

WEİGHG©

Shelf

Package

Shelf

РАМ

Assembly

Assembly

with a Quiet

Mechanism

for

use

Cabinet

Adjustable

VHA

Stand

Hood

Phototherapy

Incubator

Module

Infant

Scale,

Assembly

Mounting

Latch

continuously

with

the

Incubators

Stand

Stand)

Warmer

System

Humidifier

Model

Kit

(Not

Shown)

(Not

120

variable

are

Shown)

(Refer

to

from

0°

to

illustrated

s

Oxygen

©

Air

Flow

s

Suction

e

Blender

Figure

2.5)

9º

from

in

Figure

Flowmeter

Kit

Kit

Kit

either

1.1.

(Not

(Not

Shown)

(Not

Shown)

end

Refer

Kit

Shown)

to

Section 6 of

(Not

Shown)

this

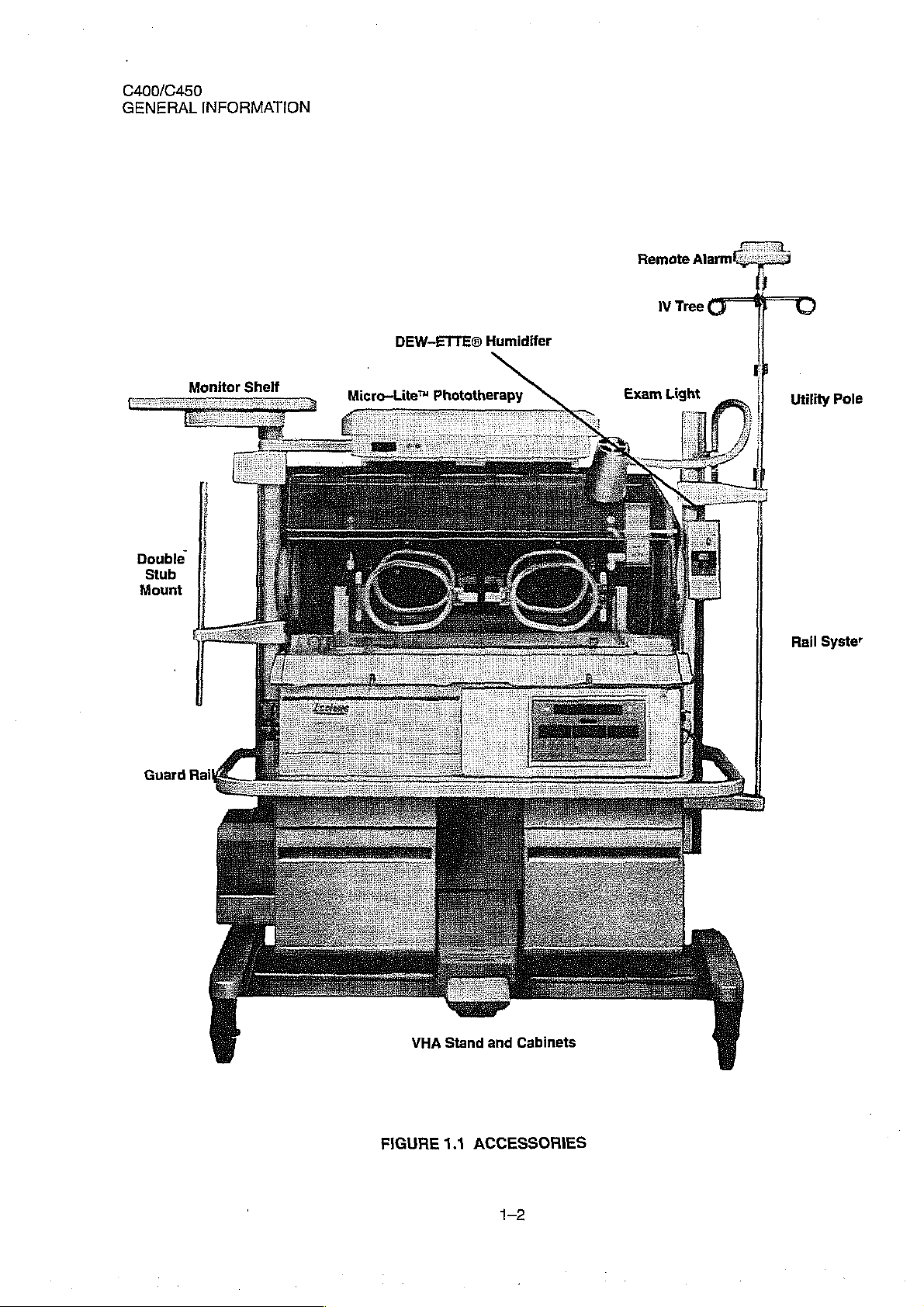

C400/C450

GENERAL

INFORMATION

Double

Stub

Mount

Monitor

Shelf

DEW-ETTE®

Micro--Lite”

Humidifer

Phototherapy

Remote

Exam

W

Tree

Light

Alarmf:

—..

Utility

Pole

Rail

Syste"

Guard

VHA

Stand

FIGURE

1.1

and

Cabinets

ACCESSORIES

1.4

MODEL

The

Isolette®

identification

IDENTIFICATION

Infant

and

Incubators,

series

number.

SERIES

Models

The

locations

C400

CHANGE

QT™

of

the

and

C450

data tags

QT™,

are

have

as

follows:

GENERAL

two

data

INFORMATION

tags

which

0400/0450

list

model

CONTROLLER:

HOOD/SHELL

The

following

MODEL

UNIT

DESIGNATION

EXPORT

SERIES

DESIGN

The

Isolette®

three

Controller

GROUP

The

be

identified

The

The

Data

Hood

Access

NUMBER

Tag

has two

Located

ASSEMBLY:

example

explains

IDENTIFICATION

CHANGE

CHANGE

Infant

(MODE

LEVEL)

Incubators,

Assemblies.

1

on

the

Hood/Shell

by

the

following

Tubing

Panel

has

an

on

the

top

panel

Located

the

on

content

C400H ~ 1

İİ

Models

of

Group 1 carries

characteristics:

Access

Inner

Grommets,

Wall

(refer

of

the

C400

the

Controller.

right

side

of

the

QT™

one

to

Figure

panel

data

tag:

and

the

Model

located

6.5).

of

C450

No.

on

the

Shell.

QT™,

C400H-1

either

have

side

two

(1E)

(Refer

00

different

or

C450H-1

to

Figure

Hood/Shell

(1E)

and

6.4).

and

can

The

The

be

The

The

7

The

GROUP

The

C450H-2,

The

The

The

Π

The

be

The

The

Я

The

Main

Deck

is

held

in

Data

Tag

on

the

Controller

identified

Controller

Controller

Auxiliary

Data

Hood

Access

Main

Data

identified

Controller

Controller has a keying

Auxiliary

by

is

does

Air

NUMBER

Tag

on

3,

or 4 (2E,

has

four

Panel

Deck

Tag

on

by

is

Air

the

following

equipped

not

Probe

2

the

Hood/Shell

3E

Tubing

does

consists

the

Controller

the

following

equipped

Probe

place

by a Retainer

of

Group 1 carries

characteristics:

with

an

ac

have a keying

is a single

or

Access

not

of

the

thermistor

of

Group 2 carries

4E)

and

Grommets,

have

an

Deck

of

Group 2 carries

characteristics:

with a round

pin

located

is a dual

thermistor

motor.

pin

can

be

Inner

Plate

de

between

Knob

the

located

between

probe.

identified

two

located

Wall.

and

Main

the

motor.

the

probe.

(Change

(Refer

Model

the

Model

by

the

Deck

Model

Impeller

3)

to

Figure

No.

C400C-1

the

Impeller

No.

following

on

either

(refer

to

No.

C400C-2

and

4.5).

(1E)

or

C450C-1

and

Heater

Coil.

C400H-2, 3 or 4 (2E,

characteristics:

side

(Refer

to

Figure

Figures

Heater

4.6

(2E)

Coil.

and

or

C450C-2

4.7).

(1E)

3E

6.1).

(2E)

and

or

and

can

4E)

can

or

1-3

C400/C450

GENERAL

INFORMATION

TABLE

SERIES

TABLE

SERIES

00

00

1.1

2E,

NO.

1.2

NO.

SERIES

3,

3E,

SERIES

CHANGE

4,

AND

DESCRIPTION

Original

CHANGE-CONTROLLER

Original

-

HOOD/SHELL

4E.

MODELS

Design

DESCRIPTION

Design

—

C450H-1,

AND

2E

ASSEMBLY,

1E,

ITEMS/ASSEMBLIES

ASSEMBLY,

ITEMS/ASSEMBLIES

2,

2E,

MODELS

3,

3E,

None

MODELS

None

—

C400H-1,

4,

AND

AFFECTED

—

C400C-1,

AFFECTED

4E

1E,

1E,

2,

2,

TABLE

SERIES

00

1.3

NO.

SERIES

CHANGE-CONTROLLER

DESCRIPTION

Original

Design

AND

ASSEMBLY,

2E

MODELS

ITEMS/ASSEMBLIES

None

—

C450C-1,

AFFECTED

1E,

2

14

C400/C450

INSTALLATION

2.1

UNPACKING

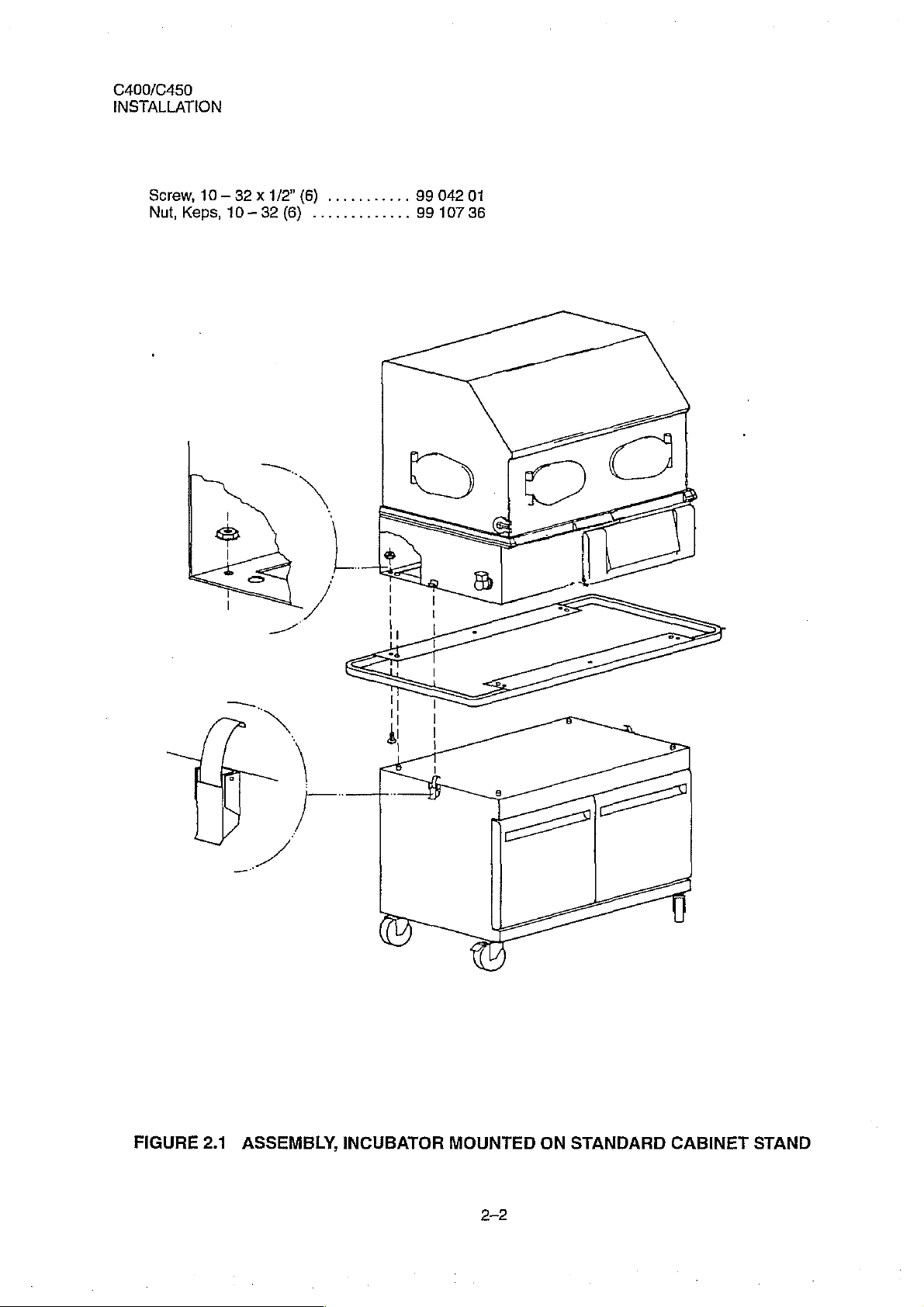

Typically,

shipped

otherwise

2.2

CAUTION:

Instructions

A.

B.

WARNING:

ure

larly

the

in

separate

damage

ASSEMBLY

REMOVE

Base

Assembly

the

Controller.

PLACE

to

do

with

Two

for

THE

Cabinet

unprotected

—

people

assembling

THE

CONTROLLER

GUARD

The

Incubator

so

could

the

hood

Stand,

cartons.

the

When

INCUBATORS

are

required

the

using

the 6 No.

RAIL

result

in

open.

Hood/Base

removing

surfaces.

Incubator

FROM

10—

AND

BASE

must

be

the

Incubator

SECTION

INSTALLATION

Assembly,

the

equipment

Remove

EQUIPPED

to

assemble

are

THE

32 x 1/2”

ASSEMBLY

attached

all

packing

WITH

the

provided

INCUBATOR.

Screws

to

the

separating

2

Filter/Filter

from

materials

STANDARD

Hood/Base

below:

Attach

and

Keps

ON

THE

CABINET

Cabinet

from

Stand

the

Cover

the

cartons,

Assembly

the

nuts

using

stand

Assembly

take

from

the

CABINET

Guard

Rail

supplied

STAND

the

clamps

if

sufficiently

and

care

Shell

and

to

(see

as

the

Guard

not

Assembly.

STAND

the

Cabinet

the

underside

Figure

shown

provided.

tilted,

to

scratch

Stand.

2.1).

Replace

in

Figure

particu-

Rail

of

Fail-

are

or

the

2.1.

C.

SECURE

Cabinet

approximately

position

IMPORTANT:

D.

INSTALL

Unit

is

the

Dew—ette@® 2 Incubator

Humidifier

E.

CONNECT

THE

Stand.

(see

THE

to

be

HOOD/BASE

Adjust

horizontal

Figure

This

Incubator

Assembly

properly

AIR

equipped

Filter

Cover.

THE

POWER

the

when

ASSEMBLY

threaded

clamp

TO

clamp

is

engaged

THE

on

the

in

2.1).

has

been

has

been

installed.

FILTER

AND

shipped

shipped

FILTER

without a Filter

in a separate

COVER

with a Dew-ette® 2 Humidifier,

Humidifier

CORD

TO

and

THE

install

INCUBATOR.

CABINET

stand

retainer.

carton.

ON

THE

Model

the

Air

Intake

STAND

for

positive

Lock

and

DO

REAR

DH90~2,

using

clamp

Filter

Cover

NOT

OF

refer

Valve

the

clamp

latching.

by

rotating

Assembly.

place

THE

UNIT

to

the

Assembly,

on

each

Locking

bar

locking

The

Incubator

(see

Figure

Operator’s

Special

side

should

bar

to

Filter

into

4.8).

Manual

Air

Filter

of

the

vertical

Cover

use

until

lfthe

for

and

be

C400/C450

INSTALLATION

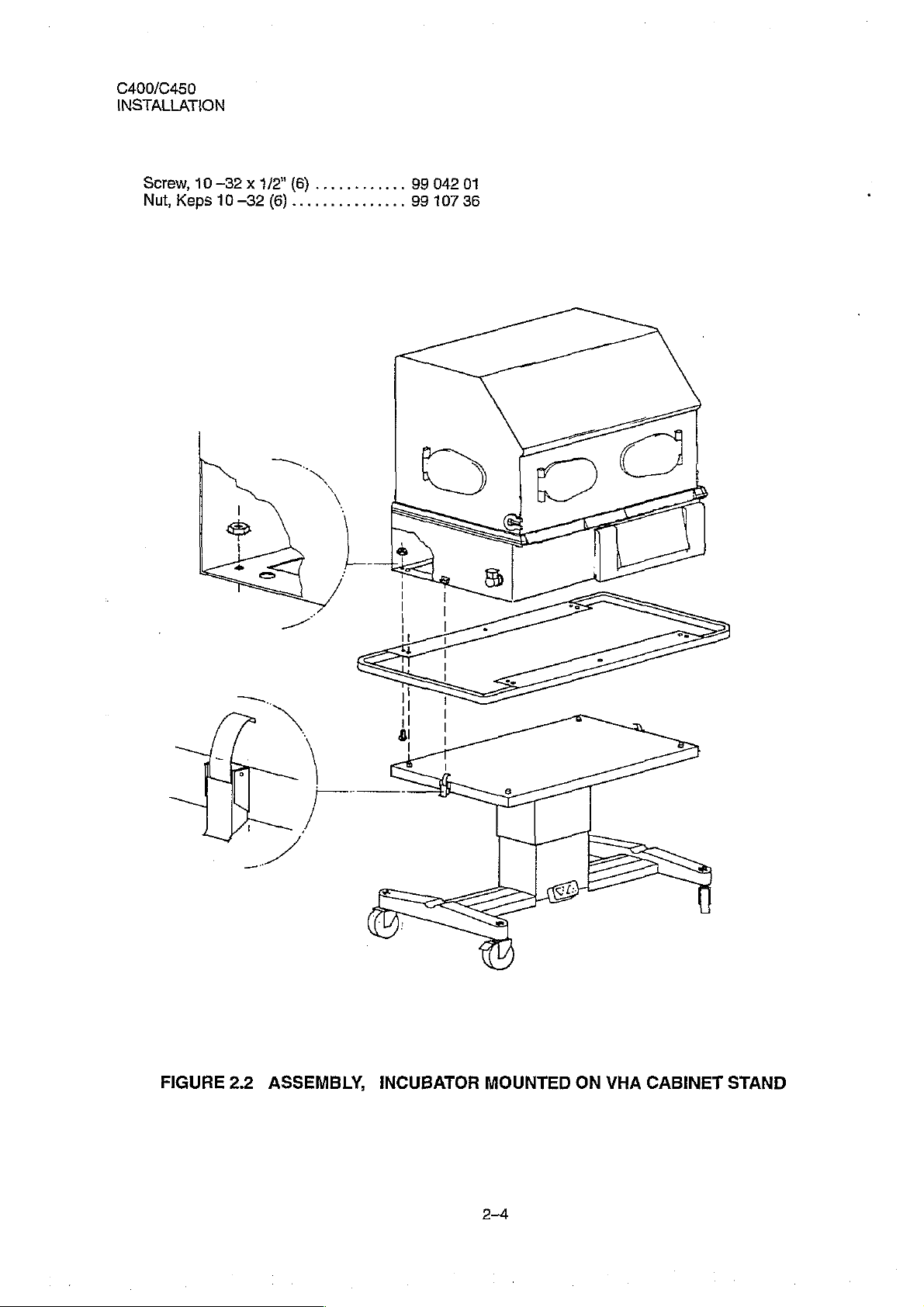

Screw,

Nut,

Keps,

10—

32 x 1/2"

10-32

(6)

...........

(6)

.............

99

99

042

107

01

36

FIGURE

2.1

ASSEMBLY,

INCUBATOR

MOUNTED

2-2

ON

STANDARD

CABINET

STAND

2.3

ASSEMBLY

STAND

-

INCUBATORS

EQUIPPED

WITH

VERTICAL

HEIGHT

C400/C450

INSTALLATION

ADJUSTABLE

CAUTION:

CAUTION:

A.

REMOVE

Base

B.

PLACE

ADJUSTABLE)

WARNING:

vided.

tilted,

C.

SECURE

WARNING:

the

C400/C450

cubator

Heavy

sufficient

Always

Assembly

Failure

particularly

instability

Equipment - To

strength

lower

THE

CONTROLLER

using

THE

GUARD

STAND

The

Incubator

to

do

with

THE

BASE

The

VHA

incubator

the

the 6 bolts

as

so

could

the

ASSEMBLY

Stand

Base

or

tip-over

prevent

are

required

Incubator

FROM

and

RAIL

shown

must

result

hood

is

intended

Assembly.

could

AND

in

be

open.

TO

Injury

to

to

its

THE

Keps

BASE

Figure

attached securely

in

the

THE

for

result.

or

damage

adequately

lowest

nuts

VHA

use

DO

position

INCUBATOR.

supplied

ASSEMBLY

2.2.

Incubator

STAND

with

NOT

USE

Hill-Rom

to

the

control

(see

to

separating

using

the

the

prior

to

Attach

the

Figure

ON

the

VHA

the

clamp

Air-Shields’

VHA

Stand

Incubator/Stand,

Incubator

transport

Guard

2.2).

THE

Stand

from

on

with

when

for

Rail

to

VHA

(VERTICAL

using

the

stand

each

side

Incubators

other

optimum

the

the

two

persons

transporting

stability.

underside

HEIGHT

clamps

if

sufficiently

of

the

Incubators.

pro-

VHA

which

of

it.

of

the

Stand.

use

in-

IMPORTANT:

IMPORTANT:

D.

INSTALL

Unit

is

Manual

Filter

and

E.

CONNECT

cord

on

Check

service

This

Assembly

properly

THE

to

be

equipped

for

the

Humidifier

THE

the

VHA

to

be

certain

if

not

firmly

incubator

has

installed.

AIR

FILTER

with a Dew-ette® 2 Incubator

Dew~ette® 2 Incubator

Filter

VHA

POWER

Stand

to

secured.

has

been

been

AND

Cover.

the

Incubator

Incubator

shipped

shipped

FILTER

CORD

is

firmly

withaut a Filter

in a separate

COVER

Humidifier

TO

THE

WALL

power

cord

(Change

secured

carton,

ON

THE

REAR

Humidifier,

and

install

RECEPTACLE

receptacle.

6)

to

and

the

the

stand

Filter

DO

NOT

OF

Model

Air

at

Cover

place

THE

DH90-2,

Intake

and

bath ends.

Assembly.

Incubator

UNIT

(see

refer

Valve

Assembly,

the

interconnecting

Da

not

The

Filter

into

Figure

to

the

place

in

Cover

use

until

4.8).

If

the

Operator’s

Special

Air

power

C400/C450

INSTALLATION

Screw,

Nut,

Keps

10

-32 x 1/2"

10-32

(6)

............

(6)

...............

99

99

042

107

01

36

FIGURE

2.2

ASSEMBLY,

INCUBATOR

MOUNTED

2-4

ON

VHA

CABINET

STAND

2.4

For

WARM

more

information,

WEIGH®

INFANT

refer

to

the

SCALE,

120/W30

MODEL

Operator's

120

(ACCESSORY)

Manual.

C400/C450

INSTALLATION

IMPORTANT:

A.

OPEN

B.

REMOVE

IMPORTANT:

The

Test

FRONT

THE

Use

inaccurate

Load

Cell

Calibration

and

ACCESS

MATTRESS

the

mattress

readings

must

PANEL

from

provided

be

unlocked

Instructions

of

the

Incubator.

the

Incubator

with

interference

to

due

before

the

for

the

scale.

operating

procedure.

(refer

to

Use

the

with

the

scale.

Figure

2.3).

of

the

C400/C450

surrounding

Refer

walls.

to

QT

the

120/W30

™

mattress

Installation,

may

cause

C.

INSTALL

FIGURE

THE

WEIGHING

FIGURE

2.4

2.3

MATTRESS

PLATFORM

WEIGHING

REMOVED

in

the

Incubator

PLATFORM

FROM

Mattress

INSTALLED

THE

Tray

IN

MATTRESS

INCUBATOR

(Figure

2.4).

Make

TRAY

sure

itis

level.

C400/C450

INSTALLATION

D.

PLACE

E.

INSERT

THE

THE

MATTRESS

CABLE

TRAY

INTO

THE

AND

HOOD

MATTRESS

ACCESS

PROVIDED

GROMMET

on

the

(Figure

Weighing

2.5).

Platform

(Figure

2.5).

FIGURE

2.5

The

disassembiy

A.

IMPORTANT:

6.

C.

GENERAL

operational

CHECK

approximately

lifted

over

lowered

BEFORE

failure

alarm

failure

alarm

Depress

CONNECT

Standard

Incubator

VHA

Stand

lowered.

2.5

OPERATION

checkout

for

cleaning

FOR

LOOSE

2”

and

cables,

to

floor.

Do

Two

persons

weight

the

CONNECTING

the

Cabinet

is

minimum

event a caster

should

circuit

POWER

THE

AC

mounted

receptacle

MATTRESS

should

or

maintenance.

CASTERS

pulling

door

sills

not

use

Incubator

are

required

is

THE

sound

and

and

ensures

switch a second

POWER

Stand.

CONNECT

on a VHA

to

prevent

TRAY

AND

be

performed

AND

FUNCTIONAL

(Standard

down

on

each

or

elevator

thresholds.

until

to

perform

approximately

falls

out.

INCUBATOR

the

Power

that

Fail

the

rechargeable

time

CORD

THE

Stand

directly

AC

(Option).

accidental

MATTRESS

CHECKOUT

before

caster. A loose

loose

70

to

to

the

Incubator

Cabinet Stand

This

casters

this

are

check — one

pounds. A block

the

power

source,

indicator

silence

to

POWER

battery

the

The

should

the

Incubator

CORD

Incubator

disconnection

ON

PROCEDURE

Only)

caster

could

replaced.

must

light.

that

alarm.

to

the

power

or

damage

WEIGHING

is

first

placed

by

lifting

may

fall

result

in

to.lift,

one

be

used

depress

powers

when

This

VHA

cord

the

tests the

the

the

Stand

when

PLATFORM

into

each

end

out

during

Incubator

to

check

to

support

POWER

operation

circuit

is

Incubator

ac

power

should

be

the

incubator

use and

of

the

use

if

Incubator

tipping

the

over

casters.

the

raised

switch;

of

in

good

is

mounted

outlet

connected

is

after

any

Incubator

is

when

Lifting

end

in

the

power

the

power

condition.

on

a

when

the

to

the

raised

or

CAUTION:

The

following

Make

sure

shown

connect

receptacle.

on

the

CAUTIONS

that

the

power

Do

should

the

right

not

building

side

of

the

cord

only

use

extension

be

observed

power

source

Incubator

to a properly

cords.

when

is

and

marked

the

Incubator

2-6

compatible

VHA

Stand.

3-wire

is

mounted

with

the

electrical

For

proper

grounding

hospital-grade

on a VHA

specifications

reliability,

or

hospital-use

Stand.

Loading...

Loading...