Air-Shields C400QT, C450QT User manual

DE

1

3

ETTE

S

C400

®

|NFANT

QT

AND

INCUBATORS

C450

OT

e

PRELIMINARY

SERVICE

Air-ShieldsW/

vær

MANUAL

The

product

year

from

Ail

consumable

Calibrations

During

customer.

This

This

for

from

“The

least

Testing

cians

the

warranty

1.

N

RO

warranty

incidental

breach

Accreditation

annually

Compliance

through

being

the

warranty

There

Damage

The

customer

The

customer

Sale

or

is

or

of

thereafter.

our

described

date

of

shipment

and

disposable

are

considered

period

will

be

no

is

rendered

to

service

in

lieu

consequential

warranty.

Manual

Product

void

the

unit

fails

uses

is

performed

of

all

for

To

Program

Service

in

this

frorn

normal

any

defective

labor

charge

and

is

incurred

to

maintain

any

parts,

other

warranties,

damages

Hospitals

comply

during

LIMITED

WARRANTY

manual

Air-Shields,

products

Air-Shields

by

with

the

Group

is

warranted

Hatboro,

are

guaranteed

maintenance

parts

other

than

for

replacing

cannot

as

a

result

of

the

unit

in

a

accessories,

a

non-certified

expressed

including

requires

this

standard,

warranty

and

loss

each

period.

authorized

against

with

the

to

and

are

not

those

listed

the

parts

within

be

held

liabie

mishandling.

proper

or

manner.

fittings

of

piece

we

not

service/dealer

or

implied,

use,

property

of

equipment

recommend

This

service

dealers.

defects

be

in

following

free

from

included

above

the

for

conditions

specified

agency.

and

Air—Shields

damage,

to

that

can

materials

exceptions.

defects

in

the

1

year

will

be

replaced

continental

resuitant

or

sold

by

shall

or

personal

be

tested

prior

you

participate

be

performed

or

workmanship

upon

shipment

warranty.”

at

no

charge

U.S.

therefrom

Air-Shields.

in

no

event

injury

to

initial

in

our

Accreditation

by

certified

for

one

only.

to

the

if:

be

liable

resulting

use

and

techni-

at

Please

Since

improvements

the

rear

on

shown

THIS

MODIFICATIONS

TO

CANNOT

OPERATION

OR

check

Air-Shields

printed

each

MAINTAIN

MODIFICATION.

of

the

page

on

MANUAL

manuals.

manual

the

ASSUME

OF THIS

NOTE

Some

parts

used

this

manual.

function

of

This

the

PLEASE

the A page

conducts a continuous

are

sometimes

or

of

text

right.

CONTAINS

SHOULD

YOUR

in

sometimes

equipment.

for

change

incorporated

When

this

under

separate

is

indicated

PROPRIETARY

BE

WARRANTY

RESPONSIBILITY

EQUIPMENT

ON

your

REPLACEMENT

equipment

occurs

Order

information.

product

occurs,

by a vertical

PERFORMED

changed

cover

AND

FOR ANY

WHICH

may

be

due

to

the part

listed

READ

improvement

into

equipment

material

in

the

form

bar

in

the

INFORMATION.

ONLY

TO

AVOID

CONDITIONS

MAY

RESULT

different

difficulty

in

than

in

the

program,

before

is

provided

of a change

margin

BY

CREATING

parts

Parts

next

REPAIRS

QUALIFIED

FROM

those

which

procurement,

List.

circuit

they

can

be

on

separate

package.

to

the

SAFETY

AFFECTING

UNAUTHORIZED

Changed

changed

AND

SERVICE

PARTS

appear

but

and

component

incorporated

sheets

material

material,

AUTHORIZED

PERSONNEL

HAZARDS.

THE

PROPER

REPAIR

in

the

Parts

does

not

alter

into

at

the

WE

List

the

as

of

For

optimal

Service

required

tory—authonzed

AT.

1

23456789

123456789

NO.

Group

maintenance

68

performance,

instrumentation

Air—Shields’

Air-Shields

994

50-A

product

specialists

by

calling

330

800-523-2404.

distributor

Jacksonville

service

for

SERVICE

should

be

are

located

Customers

service.

Road,

performed

throughout

outside

Hatboro,

only

the

V

by

qualified

United

the

U.S.

service

States

should

personnel.

and

are

contact

Vickers

medical

PA

19040

Printed

Product

dispatched

their

local

in

USA

for

fac-

10/94

NOTE:

ALSO

SEE

PAGE

2.

LIST

OF

EFFECTIVE

PAGES

THERE

ARE

NO

MODIFICATIONS

AVAILABLE.

PAGE

Front

Cover

Inside

Front

1

と

AandB

ithrough

1

των

2-1

through

St

through

4-1

through

5-1

through

6-1

through

7-4

through

NO.

....................,..........

Cover

..........................

......................,...........

ον ον

ενω

..............................

.

...................,...........

...................,......,....

...............................

...................,......,....

ε

ον

ω

νε

νεο

νε εν

νε

εννοω

CHANGE

ρε ε ο ο ο

νέων

NO.

0

O

0

(O

k

0

0

νο

0

(O

eee

ων

0

[

0

D..............,....,......,....,.2.

0

ενω

ωρών

ων

ее

εννοω

κε

нение

eres

εοωω

ων

εν εν ν εν

εως

DATE

nseene

vnnne

ών

νο

νο

кинзьния

εν νε

OF

10/94

10/94

10/94

10/94

10/94

10/94

10/94

10/94

10/94

10/94

10/94

10/94

10/94

ISSUE

ee

σος,

-

—Ct1w1w1r

———L>Ò>>>ETEI=——-—-——=-r=<-—-=—<-5"!#F8

NeNNN!II

——_

8

TECHNICAL

Control

by

Incubator

face.

Steady

not

Temperature

perature

Temperature

Temperature

above

dition.

mattress

Zone. A plane

lines

that

Temperature

vary

more

during

the

mattress

The

surface.

Temperature.

DEFINITIONS

divide

the

than

0.2

Overshoot.

Steady

Rise

Time.

Uniformity.

surface

four

points

ISOLETTEs

TABLE

10

cm

width

Air

Condition.

°C

over a period

The

Temperature

The

The

are

the

OF

above

the

and

length

temperature

The

amount

time

required

amount

differs

from

centers

of

DEFINITIONS

mattress

of

condition

of

by

Condition,

by

the

four

Infant

with

the

mattress

at a point

reached

one

hour.

which

Incubator

for

the

which

the

average

quadrants

AND

an

area

surface.

10

cm

(4

in.)

when

Temperature

resulting

Incubator

average

Incubator

temperature

formed

Incubator

SYMBOLS

defined

from a change

Temperature

by

by

the

above

and

the

average

exceeds

Temperature

at

lines

that

center

centered

tncubator

in

to

each

at

divide

of

four

quadrants

over

the

Temperature

average

temperature.

rise

of

four

Steady

the

Incubator

11

°C.

points

Temperature

width

and

formed

mattress

does

Tem-

10

cm

(4

Con-

length

of

sur-

in.)

the

(This

page

is

intentionally

lett

blank.)

Temperature

Temperature

Variation.

during

Steady

The

difference

Temperature

between

Condition.

the

Incubator

Temperature

and

the

Average

Incubator

C400/C450

GENERAL

INFORMATION

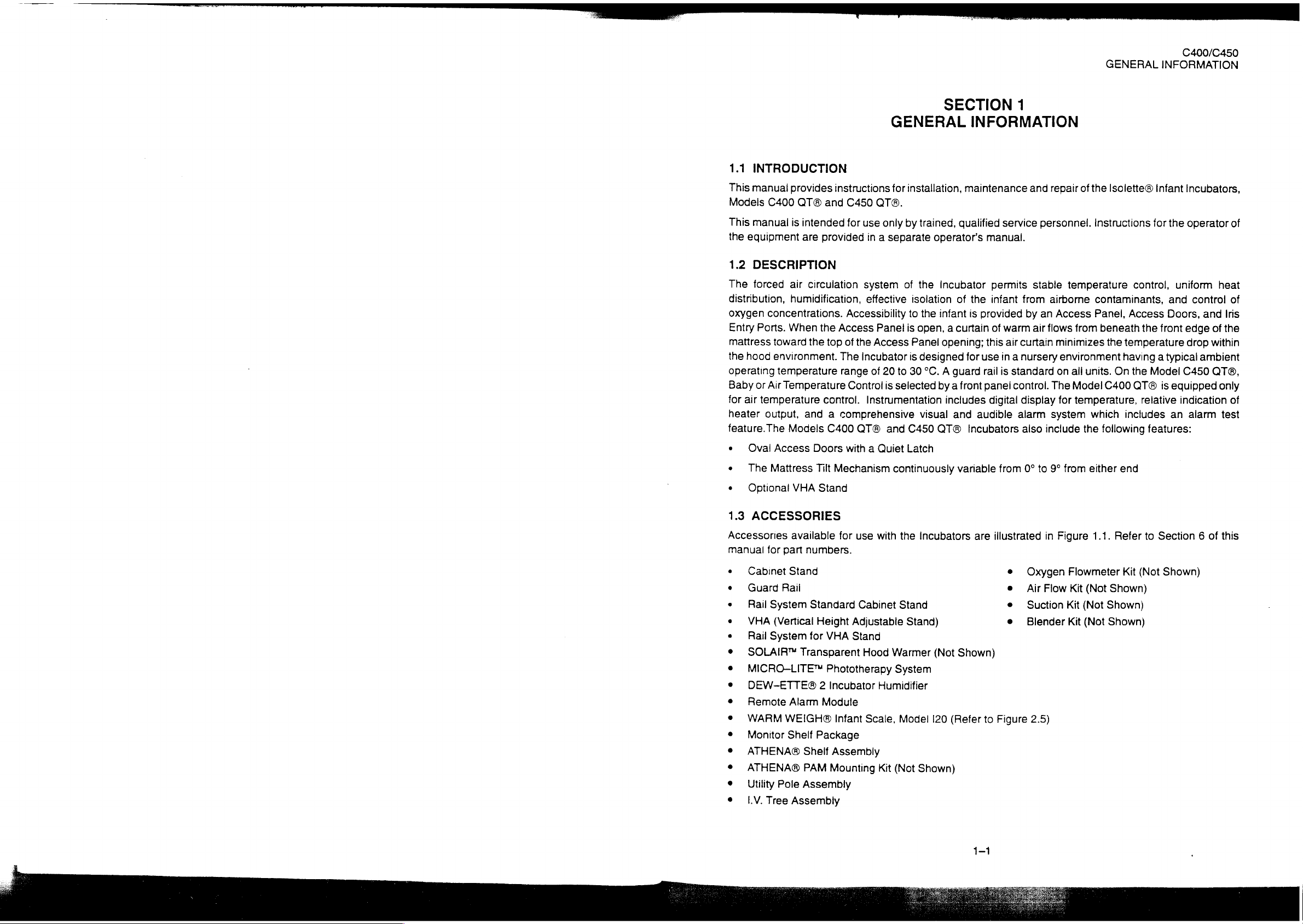

1.1

INTRODUCTION

This

manual

Models

This

manual

the

equipment

1.2

DESCRIPTION

The

forced

distribution,

oxygen

Entry

Ports.

mattress

the

hood

operating

Baby

or

for

air

heater

feature.

provides

C400

is

air

humidification,

concentrations.

When

toward

environment.

temperature

Air

Temperature

temperature

output,

The

Models

GENERAL

instructions

QT®

and

C450

intended

are

for

provided

circulation

Accessibility

the

Access

the

top

of

the

The

range

Control

control.

and a comprehensive

C400

QT®

for

QT®.

use

only

in a separate

system

effective

Panel

Access

Incubator

of

20

is

Instrumentation

and

SECTION

installation,

by

trained,

operator's

of

the

Incubator

isolation

to

the

infant

is

open, a curtain

Panel

opening;

is

designed

to

30

°C. A guard

seiected

visual

C450

by a front

includes

QT®

INFORMATION

maintenance

qualified

of

is

for

and

Incubators

manual.

permits

the

infant

provided

of

this

use

rail

panei

digital

audible

service

warm

air

in a nursery

is

standard

control.

1

and

personnel.

stable

from

by an

air

curtain

display

alarm

also

include

repair

of

temperature

airborne

Access

flows

from

minimizes

environment

on

all

units.

The

Model

for

temperature,

system

the

the

Isolette®

Instructions

for

control,

contaminants,

Panel,

which

Access

beneath

the

C400

the

temperature

having a typical

On

the

QT®

relative

includes

following

features:

Model

Infant

the

uniform

and

Doors,

front

edge

C450

is

equipped

indication

an

Incubators,

operator

of

heat

control

drop

and

Iris

of

the

within

ambient

of

QT®,

only

of

alarm

test

»

Oval

Access

e

The

Mattress

‧

Optional

1.3

ACCESSORIES

Accessories

manual

+

+

e

+

*

9

e

e

e

©

e

e

9

e

e

for

part

Cabinet

Guard

Rail

VHA

Rail

Rail

System

(Vertical

System

SOLAIR™

MICRO-LITE™

DEW-ETTE®

Remote

WARM

Monitor

ATHENA®

ATHENA®

Utility

Pole

LV.

Tree

Doors

Tilt

VHA

Stand

available

numbers.

Stand

Standard

Height

for

VHA

Transparent

Phototherapy

2

Alarm

WEIGH

Shelf

Module

Package

Shelf

PAM

Assembly

Assembly

with a Quiet

Mechanism

for

use

Cabinet

Adjustable

Stand

Hood

Incubator

Infant

Scale,

Assembly

Mounting

Latch

continuously

with

the

Incubators

Stand

Stand)

Warmer

System

Humidifier

Model

Kit

(Not

Shown)

(Not

120

variable

are

Shown)

(Refer

to

from

0°

to

9°

illustrated

e

e

e

e

Figure

in

Oxygen

Air

Flow

Suction

Blender

2.5)

from

either

Figure

Flowmeter

Kit

(Not

Kit

(Not

Kit

(Not

1.1.

Shown)

Shown)

Shown)

end

Refer

Kit

to

Section 6 of

(Not

Shown)

this

C400/C450

GENERAL

Monitor

INFORMATION

Sheif

|

Kk 一 一 一 一

=-

fx

a

一 一 一 一

DEW-ETTE®

Micro—Lite™

E

2

,

Humidifier

Phototherapy

Remote

IV

Tree

Alarm

2

Utility

[ren]

11

Pole,

|

|

i

C400/C450

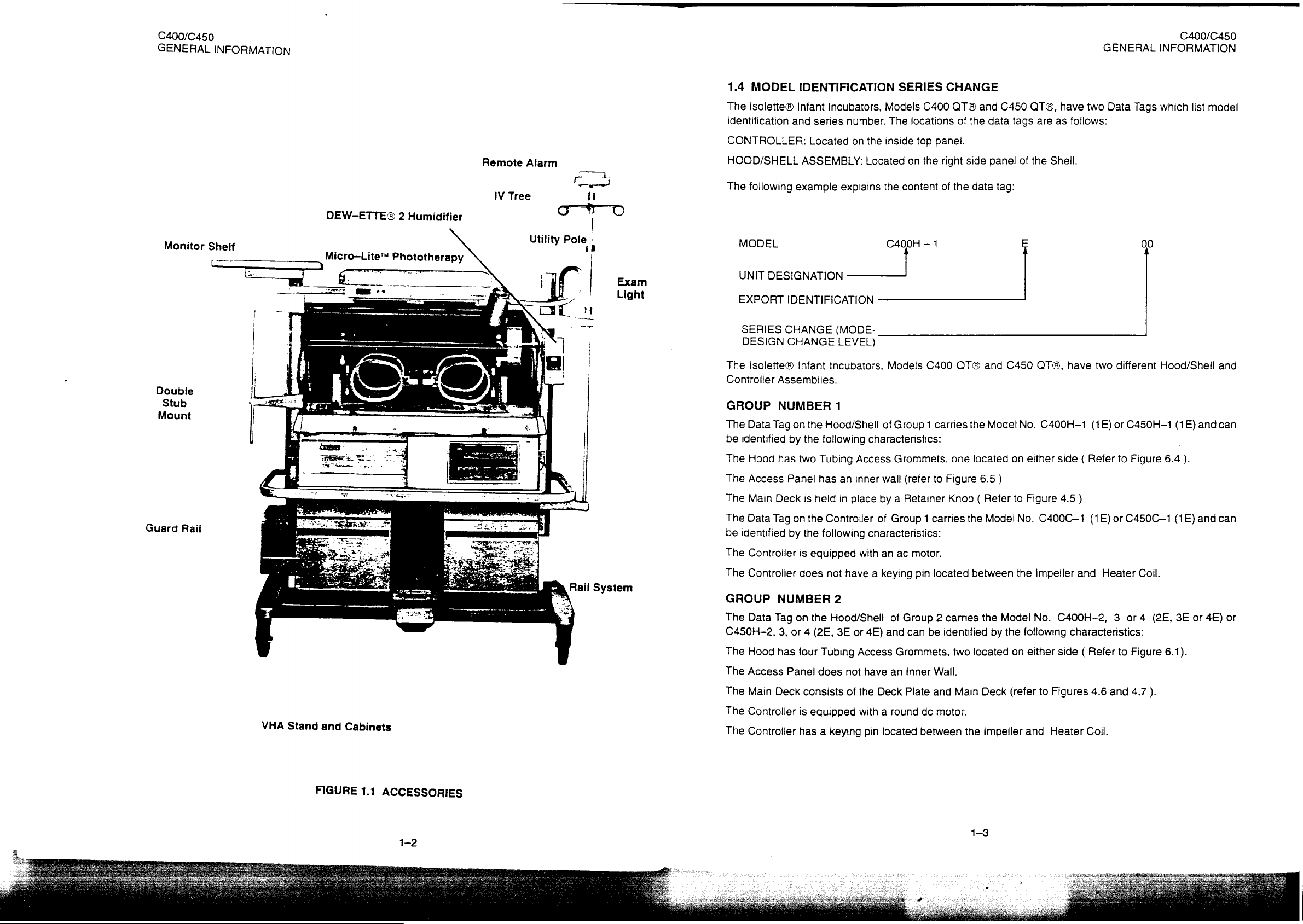

1.4

MODEL

The

Isolette®

identification

CONTROLLER:

and

HOOD/SHELL

IDENTIFICATION

Infant

Incubators,

series

Located

ASSEMBLY:

number.

on

the

Located

SERIES

Models

The

locations

inside

on

C400

top

the

CHANGE

ATA

of

panei.

right

and

the

side

C450

data

panel

tags

of

OTA,

are

the

have

as

follows:

Sheil.

GENERAL

two

Data

INFORMATION

Tags

which

list

model

그.

The

following

|

MODEL

example

explains

the

content

C400H - 1

of

the

data

tag:

00

|

UNIT

Exam

Light

DESIGNATION

EXPORT

SERIES

DESIGN

IDENTIFICATION

CHANGE

CHANGE

_

(MODE-

LEVEL)

|]

Double

Stub

Mount

Guard

Rail

ο

LA

Rail

System

The

Isolette®

Controller

GROUP

The

Data

be

identified

The

Hood

The

Access

The

Main

The

Data

be

identified

The

Controller

The

Controller

GROUP

The

Data

C450H-2,

The

Hood

The

Access

Infant

Assemblies.

NUMBER

Tag

on

the

by

the

has

two

Tubing

Panel

has

Deck

is

held

Tag

on

the

by

the

is

equipped

does

NUMBER

Tag

on

the

3,

or 4 (2E,

has

four

Panel

does

Incubators,

1

Hood/Shell

following

Access

an

inner

in

place

Controller

following

with

not

have a keying

2

Hood/Shell

3E

or

4E)

Tubing

Access

not

have

Models

of

characteristics:

C400

Group 1 carries

Grommets,

wall

(refer

to

by a Retainer

of

Group 1 carries

characteristics:

an

ac

motor.

pin

located

of

Group 2 carries

and

can

be

Grommets,

an

Inner

Wall.

OTA

and

the

Model

one

located

Figure

6.5

Knob ( Refer

the

Model

between

the

identified

two

by

located

C450 QT®,

No.

on

either

)

to

Figure

No.

the

impeller

Model

the

following

on

either

No.

have

two

different

C400H—1

side { Refer

C400C-—1

4.5

)

(1E)

and

(1E)

Heater

or

C450H—1

to

Figure

or

C450C—1

C400H-2, 3 or 4 (2E,

characteristics:

side ( Refer

to

Figure

Hood/Sheil

Coil.

(1E)

6.4

).

(1E)

3E

6.1).

and

and

or

4E)

and

can

can

or

VHA

Stand

and

Cabinets

FIGURE

1.1

ACCESSORIES

The

Main

The

Controller

The

Controller

Deck

consists

is

equipped

has a keying

of

the

Deck

with a round

pin

located

Plate

de

between

and

motor.

Main

the

Deck

(refer

impeller

and

to

Figures

Heater

4.6

and

Coil.

4.7

).

a

TAB

SERIES

C400/C450

GENERAL

TABLE

S

ERIES

00

TABLE

SERIES

00

00

LE

1.2

NO.

1.3

NO.

INFORMATION

1.

oe

SERIES

3,3E,4,

NO.

SERIES

SERIES

CHANGE

AND

DESCRIPTION

Original

CHANG

DESCRIPTION

Original

CHANGE-CONTROLLER

DESCRIPTION

Original

9

-

HOOD/SHELL

4E.

MODELS

Design

E-CONTROLLER

Design

Desi

sign

—

C450H-1,

AND

2E

ASSEMBLY,

AND

2E

ASSEMBLY,

1E,

ITEMS/ASSEMBLIES

ASSEMBLY,

ITEMS/ASSEMBLIES

ITEMS/ASSEMBLIES

MODELS

2,

2E,

MODELS

MODELS

3,3E,

None

—

None

—

None

—

C400H-1,

4,

ANDGE

AFFECTED

C400C-1,

AFFECTED

C450C-1,

AFFECT;

ED

1E,

1E,

1E,

©

2,

2

2

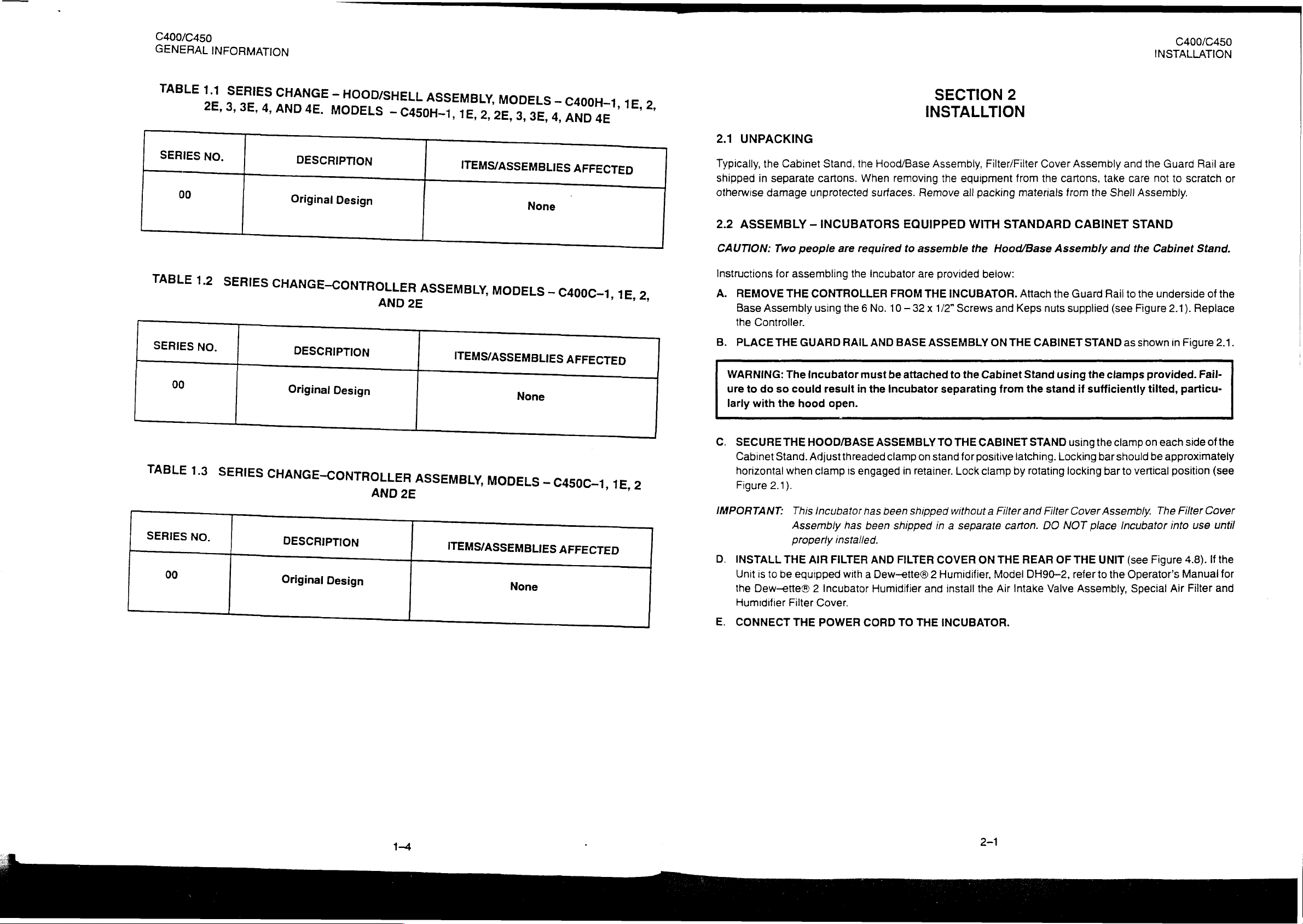

UNPACKING

2.1

Typically,

shipped

otherwise

2.2

CAUTION:

Instructions

A.

B.

WARNING:

ure

larly

C.

IMPORTANT:

D.

E.

the

in

damage

ASSEMBLY

REMOVE

Base

Assembly

the

Controller.

PLACE

to

do

with

SECURE

Cabinet

horizontal

Figure

INSTALL

Unit

is

to

Dew-ette®

the

Humidifier

CONNECT

Cabinet

separate

Two

for

THE

THE

The

so

the

THE

Stand. Adjust

when

2.1).

THE

be

Filter

Stand,

cartons.

unprotected

—

INCUBATORS

people

assembling

CONTROLLER

using

GUARD

incubator must

could

result

hood

HOOD/BASE

clamp

This

Incubator

Assembly

Properly

AIR

equipped

Incubator

2

Cover.

THE

POWER

the

When

are

required

the

the

6

RAIL

in

open.

threaded

1s

engaged

has

installed

FILTER

with

Hood/Base

removing

surfaces.

Incubator

FROM

No.

10

AND

BASE

be

the

Incubator

ASSEMBLY

clamp

has

been

been

shipped

AND

FILTER

a

Dew—ette®

Humidifier

CORD

TO

SECTION

INSTALLTION

Assembly,

equipment

the

packing

Remove

EQUIPPED

to

assemble

are

THE

—

32 x 1/2”

ASSEMBLY

attached

on

in

retainer.

shipped

2

and

THE

all

WITH

the

provided

INCUBATOR.

Screws

to

the

Cabinet

separating

TO

THE

CABINET

stand

for

positive

Lock

clamp

without a Filter

in a separate

COVER

Humidifier,

INCUBATOR.

install

ON

the

2

Filter/Filter

STANDARD

Hood/Base

below:

and

ON

from

carton.

THE

Model

Air

Cover

the

from

materials

Attach

Keps

nuts

THE

CABINET

Stand

the

STAND

latching.

by

rotating

and

Filter

DO

REAR

DH90—2,

Intake

stand

Assembly

cartons,

from

CABINET

Assembly

the

Guard

supplied

using

using

Locking

locking

Cover

NOT

OF

THE

refer

Valve

and

care

take

Shell

the

and

Rail

to

(see

STAND

the

if

sufficiently

place

Assembly,

as

clamps

the

clamp

bar

should

bar

to

Assembly.

Incubator

UNIT

(see

to

the

Operator's

C400/C450

INSTALLATION

the

Guard

to

not

Assembly.

STAND

the

Cabinet

the

underside

Figure

vertical

Special

2.1).

shown

in

provided.

tilted,

on

each

be

approximately

position

The

into

Figure

Air

Figure

particu-

Filter

Manual

Rail

scratch

Stand.

of

Replace

2.1.

Fail-

side

of

(see

Cover

use

until

4.8).

If

:

and

Filter

are

or

the

the

the

for

1-4

C400/C450

INSTALLATION

Screw,

Nut,

10 — 32 x 1/2”

Keps,

10 — 32

(6)

(6)

ie

iii.

99

99

042

107

01

36

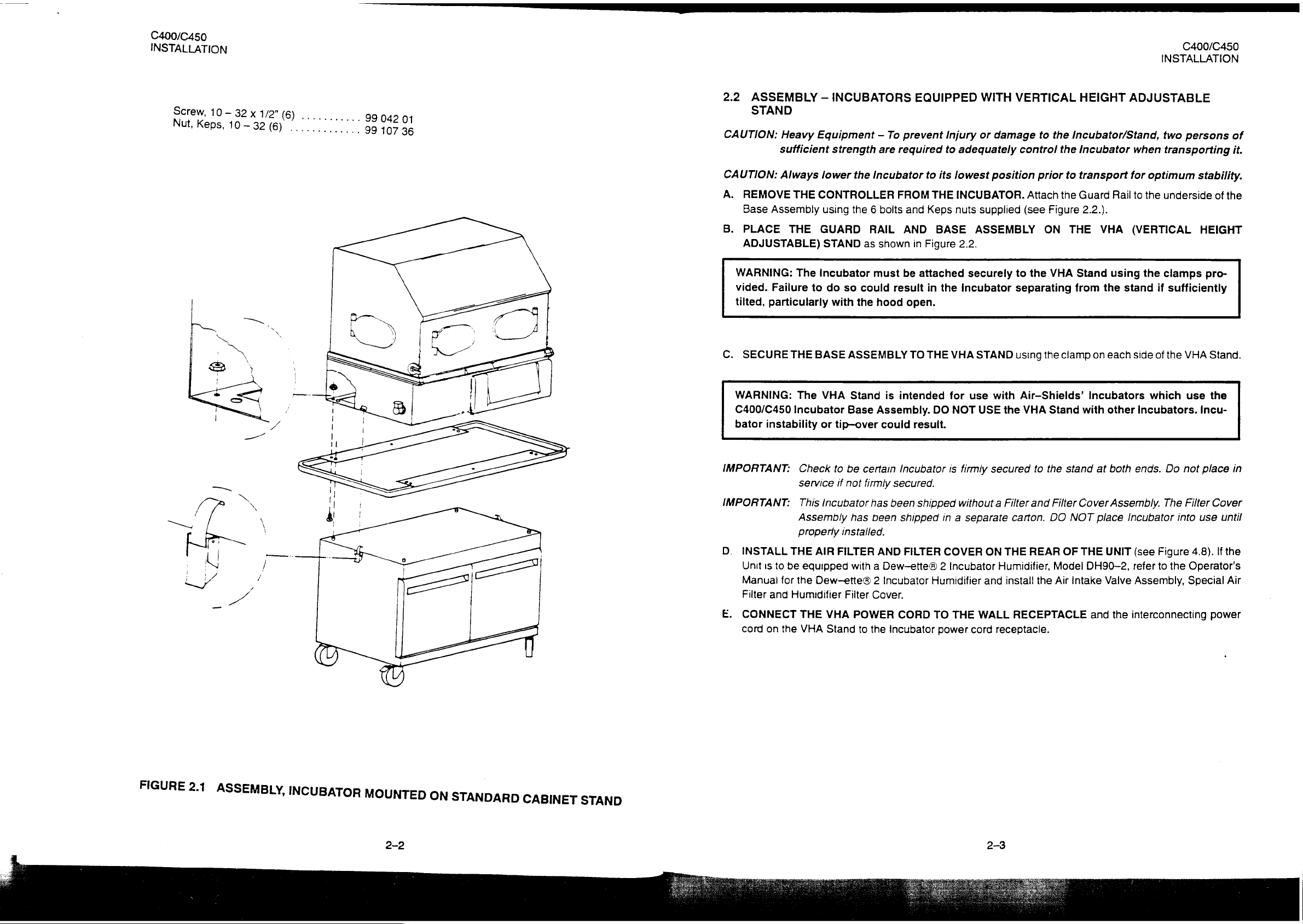

2.2

ASSEMBLY

STAND

CAUTION:

CAUTION:

A.

REMOVE

Base

B.

PLACE

ADJUSTABLE)

WARNING:

vided.

tilted,

—

Heavy

sufficient

Always

Assembly

Failure

particularly

Equipment - To

lower

THE

CONTROLLER

using

THE

GUARD

STAND

The

Incubator

to

do

INCUBATORS

strength

so

with

are

the

Incubator

the 6 bolts

RAIL

as

shown

must

could

the

hood

EQUIPPED

prevent

required

to

FROM

and

Keps

AND

in

Figure

be

attached

result

in

open.

Injury

to

its

lowest

THE

INCUBATOR.

nuts

BASE

the

WITH

or

damage

adequately

position

supplied

ASSEMBLY

2.2.

securely

incubator

VERTICAL

to

the

control

(see

to

separating

prior

Attach

Figure

ON

the

VHA

the

HEIGHT

Incubator/Stand,

incubator

to

transport

the

Guard

2.2.).

THE

Stand

from

ADJUSTABLE

Rail

VHA

using

the

stand

when

for

to

(VERTICAL

C400/C450

INSTALLATION

two

persons

transporting

optimum

the

underside

the

clamps

if

sufficiently

of

it.

stability.

of

the

HEIGHT

pro-

C.

SECURE

WARNING:

C400/C450

bator

instability

IMPORTANT:

IMPORTANT:

D.

INSTALL

Unit

is

Manual

Filter

and

E.

CONNECT

cord

on

THE

The

Incubator

Check

service

This

Assembly

properly

THE

to

be

equipped

for

the

Humidifier

THE

the

VHA

BASE

ASSEMBLY

VHA

Stand

Base

Assembly.

or

tip-over

to

be

certain

if

not

firmly

incubator

AIR

FILTER

Dew—ette® 2 Incubator

VHA

Stand

has

has

been

installed.

with a Dew—ette® 2 Incubator

Filter

Cover.

POWER

to

the

is

intended

could

Incubator

secured.

been

shipped

AND

FILTER

CORD

Incubator

TO

result.

shipped

THE

VHA

for

DO

NOT

is

firmly

without a Filter

in a

separate

COVER

Humidifier

TO

THE

power

STAND

use

USE

and

WALL

cord

with

secured

ON

using

the

Air-Shields’

the

VHA

to

and

carton.

THE

REAR

Humidifier,

install

the

RECEPTACLE

receptacle.

clamp

Stand

the

stand

Filter

DO

OF

Model

Air

on

incubators

with

at

Cover

NOT

place

THE

DH90—2,

Intake

and

each

side

other

Incubators.

both

ends.

Assembly.

Incubator

UNIT

(see

refer

Valve

Assembly,

the

interconnecting

of

the

which

Do

The

Figure

to

the

VHA

Stand.

use

the

Incu-

not

place

Filter

Cover

into

use

4.8).

Operator's

Special

power

in

until

If

the

Air

FIGURE

2.1

ASSEMBLY,

INCUBATOR

MOUNTED

2-2

ON

STANDARD

CABINET

STAND

2-3

C400/C450

INSTALLATION

Screw,

Nut,

10

Keps

—

10

-32

”

(6)

32 x 1/2”

(6)

Mala

Ls

99

99

042

107

01

36

2.3

WARM

For

more

information,

IMPORTANT:

A.

OPEN

B.

REMOVE

IMPORTANT:

WEIGH®

The

Test

FRONT

THE

Use

inaccurate

refer

Load

Cell

and

Calibration

ACCESS

MATTRESS

the

mattress

INFANT

to

the

must

PANEL

from

provided

readings

SCALE,

I20/W30

be

Instructions

due

Operator's

unlocked

of

the

the

Incubator

with the

to

interference

MODEL

Manual.

before

Incubator.

for

the

scale.

operating

(refer

120

(ACCESSORY)

the

procedure.

to

Figure

Use

of

the

with the

surrounding

scale.

Refer

2.3).

C400/C450

walls.

to

the

QT®

400/C450

C

INSTALLATION

120/W30

mattress

Installation,

may

cause

FIGURE

2.2

ASSEMBLY,

INCUBATOR

MOUNTED

ON

VHA

CABINET

STAND

C.

INSTALL

FIGURE

THE

WEIGHING

FIGURE

2.4

2.3

MATTRESS

PLATFORM

WEIGHING

REMOVED

in

the

incubator

PLATFORM

FROM

Mattress

INSTALLED

THE

Tray

IN

INCUBATOR

(Figure

MATTRESS

2.4).

Make

TRAY

sure

it

is

level.

C400/C450

INSTALLATION

D.

PLAC

E

E.

INSERT

THE

THE

MATTRESS

CABLE

INTO

TRAY

THE

AND

HOOD

MATTRESS

ACCESS

PROVIDED

GROMMET

on

the

(Figure

DS

Weighing

2.5).

Platform

(Figure

2.5).

CAUTION:

HEAVY

EQUIPMENT

transporting,

Incubator.

two

-

persons

To

prevent

of

injury

sufficient

or

damage

strength

are

to

the

required

INSTALLATION

Incubator/Stand,

to

adequately

C400/C450

when

control

the

2.4

The

disassembly

A.

GENERAL

operational

|

CHEC

approximately

lifted

lowered

IMPO

ATANT.

B.

BEFOR

ae

failure

Depress

C.

CONN

Standar

|

ncubator

VHA

omen

Stand

FIGURE

over

to

in

alarm

the

2.5

MATTRESS

OPERATION

checkout

for

cleaning

>

cables,

floor.

: ; i

wor

persons

the

event

m

nala

circuit

POWER

aber

is

mounted

receptacle

or

ard

cannes

door

,

Do

not

minimum

a

La

and

switch

Stana

on

to

should

manto

silis

use

are

required

is

caster

THE

nd

and

ensures

CO

.

a

VHA

р

prevent

TRAY

AND

FUNCTIONAL

b

dee

e

performed

(Standard

Own

on

each

or

elevat

or

Incubator

approximately

falls

INCUBATOR

that

a

second

Stand

until

to

perform

out.

the

Power

the

rechargeable

time

i

directly

(Option).

accidental

i |

AND

thresholds.

Fail

AC

MATTRESS

CHECKOUT

before

caster.

loose

70

to

to

POWER

disconnection

the

i

Cabinet

A

loose

This

casters

this

check

pounds.

the

indicator

.

power

should

battery

silence

to

the

the

Incubator

CORD

The

incubator

Inc

Stand

i

A

source,

i

ubator

Only)

caster

could

are

replaced.

—

one

block

must

light.

at

that

alarm.

to

the

Power

ог

damage

ON

WEIGHING

PROCEDURE

is

is

first

fi

by

may

fall

result

i

to

lift.

one

be

used

depress

This

powers

powers

when

the

VHA

cord

when

placed

lifting

each

out

in

Incubator

to

check

t

the

POWER

tests

th

the

the

circuit

incubator

Stand

ac

should

the

PLATFORM

into

i

use

end

duri

ator

tipping

tippi

the

switch;

circulo

fa

is

uit

is

in

i

is

power

be

connected

Incubator

and

of

the

i

over

reg

casters.

i

i

ond

Socci

mounted

outlet

is

after

any

incubator

we

over

wanes

Lifting

sec

ᾗ

MM

the

power

ower

iti

condition

ona

when

the

to

the

raised

or

CAUTION:

D.

CHECK

portion

left

operates

WARNING:

losing

Always

THE

of

the

portion

smoothly

Always

balance.

of

VHA

VHA

the

lower

STAND

Stand

VHA

and

place

the

Incubator

ADJUSTMENT.

Up/Down

Stand

Up/Down

readjust

one

hand

Switch

to

desired

on

to

its

to

Switch

the

Incubator

lowest

Turn

on

raise

the

to

iower

height.

position

the

Main

stand

to

the

stand

for

support

prior

Power

the

maximum

to

when

to

transport

Switch.

the

minimum

adjusting

for

Use

foot

height.

height.

optimum

to

depress

Depress

Verify

height

stability.

the

and

the

to

prevent

hold

stand

right

the

E.

DEPRESS

performs a 5-second

Indicators

not

occur,

IMPORTANT:

F.

SETTHE

full

heater

NOTE:

G.

Allow

CHECK

slowly

shown

i

light,

or

SET

the

HOOD

tilt

the

in

Figure

THE

the

digital

This

test

TEMP

output.

unit

HINGE

Hood

2.6.

POWER

self-test;

audible

display

should

°C

to

operate

back

SWITCH.

alarm

is

missing a segment(s),

be

performed

DISPLAY

while

AND

LATCH

until

the

The

all

Alarms

is

pulsed,

TO

33.0°C.

continuing

OPERATION

Hood

Latch

switch

should

Indicators

and

each

on a daily

All

five

the

operational

engages.

light.

light,

digital

the

unit

basis.

Heater

for

proper

Close

When

all

Mode

display

requires

initially

Indicators

shows

ail

Service.

Power % Indicators

checkout.

positioning.

the

Hood

Using

by

releasing

turned

light,

eights.

should

the

on,

all

Heater

If

any

Hood

the

the

Controller

Power

function

light,

indicating

Lift

Hood

does

handle,

Latch

as

%

CAUTION:

The

following

ON.

Male

enon

receptacle.

sure

en

CAUTIONS

that

the

power

Do

the

right

not

should

ildi

building

side

of

cord

only

use

extension

be

observed

power

the

Incubator

to

a

source

properly

cords.

when

the

2—6

is

compatible

and

VHA

marked

Incubator

Stand.

3-wire

is

mounted

with

the

electrical

For

proper

hospital-

°

on

grounding

grace

a

VHA

specifications

reliability,

)

or

hospilabuse

Stand.

;

FIGURE

2.6

HOOD

RELEASE

2-7

OPERATION

НЕ

C400/C450

INSTALLATION

H.

CHECK

shown

should

open

lation

I.

CK

CHECK

ACCESS

in

Figure

create

position

s

continued

IRIS

ENTRY

PANEL

2.7:

the

a

noticeable

(hanging

ov

PORTS.

DETENT.

Air

Curtain

“drag”

straight

Rotate

Cover

during

down).

both

shouid

initial

movement

latch/releases

rise

Slightly

of

as

the

:

nwaraly

the

Access

panel.

and

Panel

Pivot

open

the

the

opens,

Access

Access

and

panel

Panel

the

detents

to

the

full

-

LA

the

a

iri

iris

shoul

uld

open

and

close

as

FIGURE

ooo

.

2.7

ne

Rotate

ACCESS

the

outer

rin

g

PANEL

of

each

OPERATION

i

iris

Port;

as

K.

CHECKACCESS

should

Door

L.

CHECK

clockwise

counierciookwise

MATTRESS

swing

until

|

DOOR

it

stops.

untilitstops.

LATCH.

Close

open.

FIGURE

ELEVATORS.

The

ili

the

right

The

Press

the

doors

2.9

ACCESS

Rotate

end

of

the

mattress

door

check

and

the

mattress

should

release

for

DOOR

right

should

be

level.

of

each

proper

OPERATION

mattress

be

Repeat

Access

latching

tilt

mechanism

at a 9

degree

the

procedure

Door

and

(Figure

us

handle

angle.

using

C400/C450

INSTALLATION

2.9).

Each

(Figure

Rotate

|

the

the

left

A

mess

2.10)

handle

mattress

J.

CHECK

engaged.

ACCESS

Both

FIGURE

PANEL

latches

must

WARNING:

IMPORTANT:

NOTE:

These

Trendelenburg

use

during

are

raised.

i

>

2.8

LATCHES

be

fully

ela

CHECK

by

closing

engaged

THE

to

IRIS

the

Access

avoid

し

SEs

ENTRY

Panel

accidental

>

PORTS

and

rotating

opening

of

the

both

latches

Access

until fully

Panel.

Do

not

attempt

Be

sure

that

tightened

Elevators

magnitication

all

the

to

ensure

are

provided

position.

to

raise

thumb

Mattress

Do

not

X-ray

the

Hood

screws

that

Tray

to

permit

elevate

procedures.

the

both

when

the

secure

stability.

infant

ends

of

Never

the

to

the

leave

mattress

Mattress

be

positioned

mattress

the

is

raised.

Tilt

in

at

the

infant

Mechanism

the

Trendelenburg

same

time

unattended

to

the

except

while

Deck

or

for

both

are

fully

Reverse

possible

elevators

2-8

FIGURE

2.10

MATTRESS

2-9

TILT

HANDLES

O

C400/C450

INSTALLATION

M.

CHECKMATTRESS

Mattress

WARNING:

Dioxide

months.

d

Peer

O.

CHECK

Oxygen

indicated

Tray;

A

build-up.

to

Parra

AIR/OXYGEN

Input

on

dirty

graph

Valve,

the

Filter

TRAY

b

y

make

sure

NI

Be

it

i

S

Sliding

properly

it

out

to

supported

the

tully

to

extended

provide

position

a

firm

as

infant

RUE

Air

The

5.

then

FIGURE

Intake

filter

must

as

shown

for

additional

SYSTEM

monitoring

Cover

Za

2.11

Microfilter

be

check

in

Figure

instructions.

by

introducin

levels

Assembly.

MATTRESS

ma

y

affect

ed

on

2.12.

inspect

19

8

within

tl)

τπτ

TRAY

oxygen

a

routine

the

microfilter:

Carefully

hood

to

de

στ

OPERATION

concentrations

basis

and

changed

if

visibly

measured

verify

that

8

they

Ipm

shown

platform.

and/or

at

dirty,

of

oxygen

reach

the

in

Figure

cause

least

every

it

should

into

predicted

2.11.

Carbon

three

be

replaced.

the

optional

level

Leanon

as

Q.

CHECK

receptacle.

Indicators

Display

R.

CHECK

PROBE

sensor

Silence/Reset

$.

CHECK

Temp

Change

to

36.0

T.

CHECK

visual

indicators

operation

U.

CHECK

Remove

POWER

Flow

should

proceeding.

V.

CHECK

With

the

seconds.

should

If

the

39.5 + 0.5

Press

inside

to

cancel

W.

CHECK

checked

and

qualified

X.

CHECKOUT

be

used, place

to

be

AUXILIARY

When

illuminated

remains

BABY

Receptacle

to

control

BABY

°C

Display

the

Set

°C.

PATIENT

alarms

should

should

after

AIR

FLOW

the fan

switch

indicator

go

out.

HIGH

should

Reinstall

TEMPERATURE

Keypad

The

Baby

show

the

Set

Temp

°C,

the

the

Keypad

of

the

Incubator.

the

High

THE

OXYGEN

once

every

service

IS

it

used,

it

may

PROBE.

the Air

within

MODE

air

Temperature

will

typically

0.5

CONTROL*

and

select

temperature

Key.

SET

TEMP

to

37.5

°C;

Temp

°C

Display

PROBE

ALARM.”

activate,

all

go

off.

When

the

Silence/Reset

ALARM.

impeller

to

on

and

from

wait

flash, a pulsating

the

is

locked,

Temperature

current

Alarm

High

Lock

When

Temp

Incubator

actuates,

Temp

key

Alarm.

INPUT

four

months

personnel.

COMPLETE.

in

Air

Mode

be

shut

off.

Insert

the

Auxiliary

°C

be

reduced

°C

of

Set

Temp

OF

OPERATION.

Baby

Mode

Control.

above

ALARM.*

the

Set

to

Allow

Temp

34.0

center

Incubator

Indicator

°C;

the

Disconnect

the

Baby

Temperature

the

Patient

Key

Set

the

the

fan

for

the

fan

impeller

ALARM.

simultaneously

*C

temperature

press

indicator

to

exit

the

the

Incubator temperature

VALVE

and

replaced

Disconnect

Control

Probe

is

pressed.

POWER

motor

end

of

audible

and

Position

press

Display

the

Silence/Reset

should

High

Temperature

FILTER.

and

and

leave

Probe

Display

to

no

°C

Display

mattress.

current

the

is

switch

shaft

and

the

Auto—Test

alarm

restore

probe

and

should

and

come

The

if

the

store

the

the

incubator

connector

has

stabilized,

more

than

two.

for

15

Connect

Set

the

Set

If

the

Temperature

should

Patient

alarm

°C

Display

be

on.

should

Probe

reconnected,

to

off.

Remove

reinstall

cycle

should

the

begin

sound,

Incubator

end

of

hold

the

show

[

to

rise.

the

>37

.

]

Key.

on

and

the

test

mode.

falls

below

Oxygen

ends

are

gray

Auxiliary

and

running

into

the

Check

minutes

the

Patient

Temp

°C

Set

Temp

to

stabilize

cancel.

from

should

the

Incubator

the

the

Controller

(5

seconds).

and

to

normal

auxiliary

°C

Key

and

the

When

audible

Return

39.0°C,

input

Valve

or

black.

Patient

until

the

AUXILIARY

number

that

the

after

stabilization.

Probe

Display

alarm

at

Return

the

receptacle.

blank,

and

should

Controller

in

Within 5 minutes,

all

Heater

operating

probe

and

the

Air

Temperature

incubator

alarm

should

the

press

the

Filter

Refer

Probes.

ready

for

C400/C450

INSTALLATION

AIR

PROBE

of

Heater

Air

Temperature

plug

to

36.0

actuates,

36.0

the

the

Heater

from

the

Incubator.

to

the

°C.

Locate

depress

°C.

Set

set

temperature

The

audible

return

the

Incubator.

Power

PATIENT

the

Set

and

Power

to

normal

Set

the

Power % Indicators

condition

outside

Up

the

Arrow

temperature

before

Incubator.

Key

for

°C

Display

reaches

sound.

auxiliary

Silence/Reset

Cartridge

to

the

if

use.

Service

the

Incubator

if

it

probe

should

Manual

is

not

to

Key

is

going

%

°C

the

the

%

the

Air

3

the

be

to

P.

CHECKA

warm

warming

the

patient

When

|

ate

up

|

up,

the

S

within

っ

he

suspend

probe

An

|

pa

Set

typically

the

on

the

Temperature

center

be

0.5

°C

of

FIGURE

cite

Auxiliary

of

So

reduced

Set

Temp

ay

the

re

Probe

Splay

2.12

κ,

setting

throu

m

attress

to

no

°C

Display

FILTER

(33.0

gh

surface;

has

stabilized,

more

than

for

COVER

With

i

°C);

the

e;

two.

15

2-10

all

access

it

should

hole

i

in

do

not

,

the

Check

minutes

REMOVAL

openings

take

the

top

connect

number

that

after

less

of

the

the

of

the

closed,

than

Incub

probe

Heater

Air

allow

one

h

plugs

prob

ος

Power

Temperature

stabilization.

CH

to

ο

the

Whil

the

the

Incubator

iti

and

postion

iti

receptacies.

σσ

μα,

%

ndic

Indi

°C

Display

to

”

“Model

C450

QT®

only.

2-11

V

O

NÍ

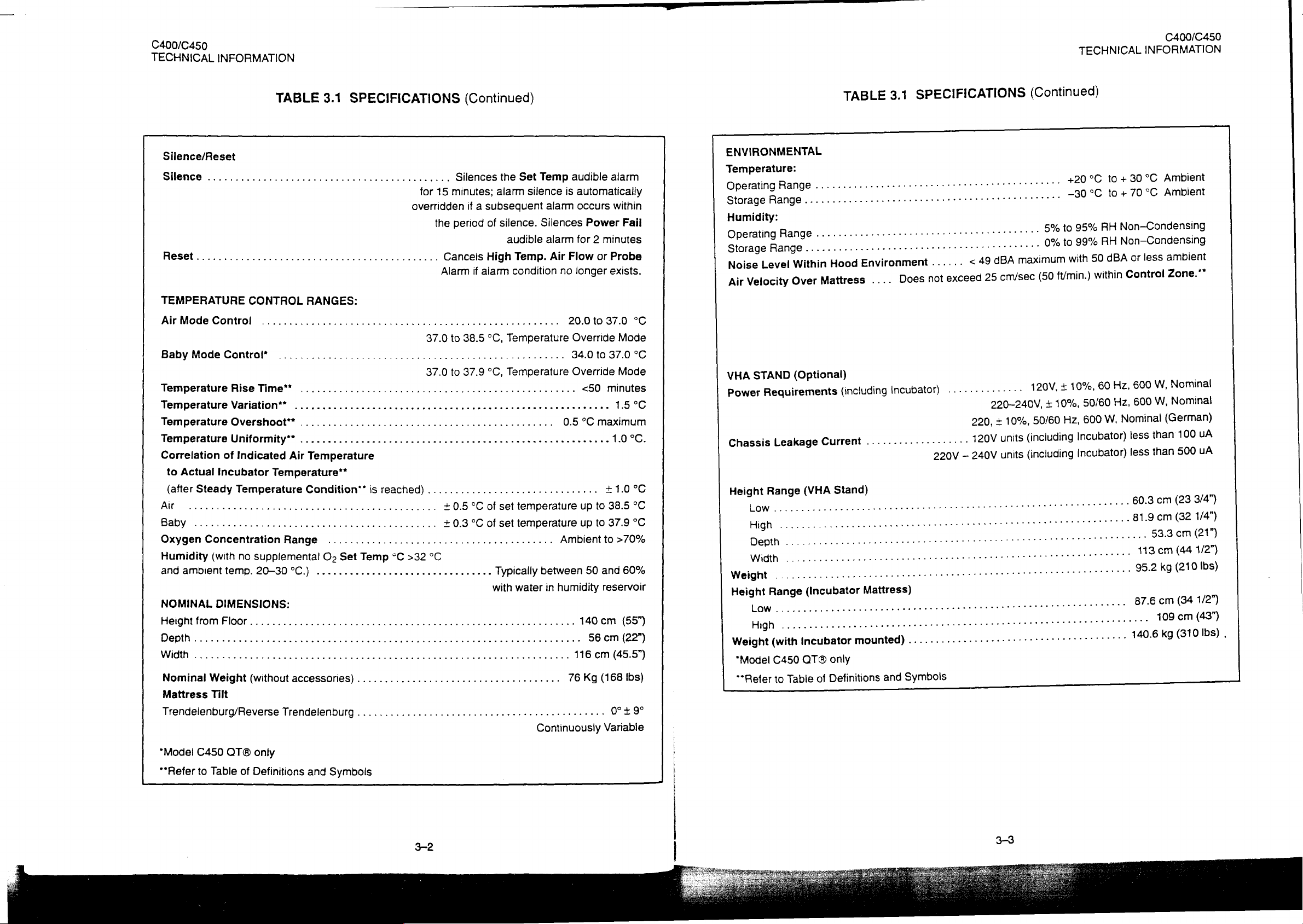

C400/C450

INSTALLATION

3.1

SPECIFICATIONS

Specifications

notice.

within

variability,

skin

Open

the

incubator,

the

temperature.

POWER

Models

Models

Models

Models

for

the

Incubators

Access

correlation

REQUIREMENTS:

C400-1

C400-1E

C400—1E

C400-1E

Doors

which

QT®

QT®

OTA

QT®

TECHNICAL

are

or

Panel

can

alter

of

the

Incubator

TABLE

and

C450-1

and

C450-1E

and

C450—1E

and

C450-1E

provided

or

the

the

air

temperature

QT®

QT®

QT®

QT®

SECTION

INFORMATION

in

Table

1.1.

use

of

infant

flow

pattern,

reading

3.1

SPECIFICATIONS

..........

...220-240V + 10%,

German

........

3

All

specifications

seats,

head

may

affect

to

120V + 10%,

...

220V + 10%,

100V + 10%,

hoods

temperature

center

mattress

50/60

50/60

50/60

TECHNICAL

are

subject

or

other

eguipment

uniformity,

temperature

Hz,

500 W Maximum

Hz,

500 W Maximum

50

Hz,

500 W Maximum

Hz,

500 W Maximum

C400/C450

INFORMATION

to

change

or

supplies

temperature

and

without

infant

(This

page

is

intentionally

left

blank.)

Chassis

ALARMS:

Air

Probe

High

Set

Power

System

“Model

Leakage

FIOw

....................................

...............................,.........

Temp

(High

Temp

(Set

Fail

Fail

C450

Current

Temperature).

Temperature)

(Power

(System

QT®

Failure

Failure)

only

...............................

Activated

Activated

Temperature

Temperature

operating

the

temperature

.....................

..............

Alarm)

............................

..............................

to

the

Activates

in

Baby*

incubator

probe

if

Mode-Baby

In

Air

Mode-Air

fails or

disconnected

.100

uA

or

500

uA

or

by

fan

failure

by a defective

or

Auxiliary

is

disconnected

in

Baby*

Mode.

open-circuited

sensed

Activates

Baby”

below

if

Incubator

or

Air

Temperature

from

set

temperature

Temperature + 1.0 + 0.8

Temperature + 1.5 + 0.5

Activates

the

power

from

internal

less

100/120V

less

220 — 240V

or a short-circuited

Air

Flow

probe

Air,

Baby*

probe

or

if

the

Baby”

from

unit

when

Also

activated

Air

Flow

deck

is

greater

30 °C

Temperature

exceeds

malfunction,

if

cord

the

wall

39.5 + 0.5

—

—

primary

is

by

probe

when

to

31

fluctuates

as

follows:

1.0

+0.3

2.5

+0.5

power

accidentally

receptacle.

refer

to

Service.

units

units

High

an

than

°C.

°C.

°C

°C

°С

°C

unit

2-12

3-1

C40

TECHNICAL

Silence/Reset

Silence

Reset......................................1..

TEMPERATURE

Air

Mode

Baby

Temperature

Temperature

Temperature

Temperature

Correlation

to

Actual

(after

Ar

Baby

Oxygen

Humidity

and

ambient

NOMINAL

Height

Depth

Width

Nominal

Mattress

Trendelenburg/ReverseTrendelenburg.............................

INFORMATION

SPECIFICATIONS

TABLE

............................................

CONTROL

Control

Mode

Control*

of

Incubator

Steady

..................

............................................

Concentration

(with

temp.

DIMENSIONS:

ffrom

Floor

Weight

Tilt

.........................

......,...........................,..,,,....,....2.

Rise

Time"

Variation**

Overshoot**

Uniformity”

Indicated

Temperature

no

supplemental

20-30

(without

Air

Temperature**

Range

°C.)

3.1

RANGES:

.................

......................

.................

.....................

Temperature

Condition”

eee

.........................................

O2

................................

неее

accessories)

is

reached)

Set

Temp

°C

enaz

.....................................

Silences

for

15

minutes;

overridden

the

period

Cancels

Alarm

иене

37.0

to

38.5

37.0

to

37.9

<... < 0000

<..

<<

000000

............................... + 1.0

ον

..

+0.5

0.3

>32

°C

eus

eds

(Continued)

Set

the

alarm

silence

if a subsequent

of

silence.

audible

High

Temp.

if

alarm

condition

няни

нения

°C,

Temperature

°C,

Temperature

a

iie

ee

°C

of

set

temperature

°C

of

set

temperature

Typically

with

water

eee

eue

seen

00.00

audible

Temp

is

automatically

alarm

occurs

Silences

alarm

Air

o n

between

in

Continuously

Power

for 2 minutes

Flow

no

longer

20.0

Override

34.0

Override

<50

K K 0

0.5

°C

up

up

to

Ambient

50

humidity

아이다

140

56

116

76

Kg

or

to

to

maximum

ων

to

ст

alarm

within

Fail

Probe

exists.

37.0

°C

Mode

37.0

°C

Mode

minutes

1.5

°C

1.0

°C.

°C

38.5

°C

37.9

°C

to

>70%

and

60%

reservoir

cm

(55)

ст

(22")

(45.5”)

(168

Ibs)

0° + 9°

Variable

TABLE

ENVIRONMENTAL

Temperature:

Operating

StorageRange.........................

Humidity:

Operating

Storage

Noise

Air

VHA

Power

Chassis

Height

Weight

Weight

"Model

**Refer

Range

Range

Range

Level

Velocity

STAND

Requirements

Leakage

Range

.....................

High

(with

C450

to

..........................:.

..........................:.

..............................

Within

Over

(Optional)

Table

Hood

Mattress

(including

Current

(VHA

Stand)

eee

cece

Incubator

OTA

only

Definitions

of

mounted)

3.1

Environment

....

incubator)

...................

entree

eee

and

SPECIFICATIONS

0...

......

exceed

not

Does

....

220ν

-

eeeeeeeree

ei

eens

...........

Symbols

25

eres

220-240V,

+

220,

120V

240V

(Continued)

cnvsec

120V,

10%,

(including

units

(including

units

5%

0%

ft/min.)

(50

10%,

+

50/60

TECHNICAL

°C

+20

~30°C

95%

to

99%

to

within

10%,

+

50/60

600

Hz,

Incubator)

Incubator)

INFORMATION

+30°C

to

to+70°C

Non-Condensing

RH

Non-Condensing

RH

Control

600

Hz,

60

600

Hz,

Nominal

W,

less

less

60.3

81.9

87.6

C400/C450

Ambient

Ambient

Zone.**

Nominal

W,

Nominal

W,

(German)

100

than

500

than

cm

(23

cm

(32

53.3

cm

cm

(34

109

cm

uA

uA

3/4”)

1/4”)

(21”)

1/2”)

(43)

“Model

**Refer

C450

to

Table

QT®

only

of

Definitions

and

Symbols

C400/C450

TECHNICAL

3.2

THEORY

3.2.1

This

block

3.2.2

The

circulation

is

Supplemental

displaces a portion

of

flowmeter

flow

oxygen

restriction

GENERAL

section

diagram

OVERALL

control

drawn

room

exceeds 8 Ipm, a valve

INFORMATION

OF

contains a functional

of

the

of

temperature,

system

through

air

is

setting,

concentration

is

as

the

oxygen,

controlled

achieved.

OPERATION

Controller

FUNCTIONAL

shown

air

of

room

predictable

intake

which

air

by

the

can

in

within

be

description

is

shown

DESCRIPTION

humidity,

Figures

filter

may

be

to

maintain

impeller/filter

oxygen

the

achieved

in

and

oxygen

3.1

and

by

means

introduced

the

concentrations

oxygen

without

and

detailed

Figure

total

characteristics

3.3.

concentration

3.2. A controlled

of

the

through

gas

inlet

housing

excessive

theory

motor-driven

the

Oxygen

intake

(inciuding

and

within

is

oxygen

of

is

amount

impelier

the

the

Incubator

activated

operation

achieved

of

room

Input

Valve

oxygen)

amount

can

to

restrict

flow.

At

of

by

on

at

of

oxygen

12

the

equipment. A system

means

air

the

on

the

35

be

attained.

air

ipm

of

the

(approximately

Controller.

airintake

lpm.

Since

is

controlled

When

intake

so

maximum

forced

35

filter

cover,

the

amount

by

oxygen

that

higher

air

intake

air

Ipm)

the

desired,

It

probe

receptacle

disconnected,

auxiliary

Inthe

infant’s

the

homeostatic

an

suspended

is

on

probe

Mode

Air

ability

auxiliary

side

the

the

but

becomes

Control

establish

to

control,

may

temperature

air

above

the

of

backup

the

operation,

of

not

probe

mattress

the

Incubator.

sensor

controlling

and

be

within

the

maintain

to

able

can

through

When

the

element

infant’s

own

its

maintain

used

be

weighing

the

plugged

primary

for

temperature

temperature.

a

in,

temperature

air

the

stable

temperature

scale

primary

probe

a

be

Asmail

the

function

infant,

at

control

to

the

temperaiure.

will

一

TECHNICAL

Incubator

and

hole

temperature

air

remains

or

desired

the

air

plugged

connected.

the

of

with

one

C400/C450

INFORMATION

temperature.

a

into

control

temperature

air

underdeveloped

level.

probe

Thus,

This

special

is

the

and

In

addition

a

much

past

reservoir

and

Figures

the

temperature

the

Access

upward

temperature

3.2.3

The

temperature

C400

In

either

desired

Power % Indicators

power

indication

temperature.

to

greater

the

air

flow

for

humidification.

all

the

air

3.1

and

slot

in

the

control

Panel

past

TEMPERATURE

Model

C450

QT®

Incubator

mode

temperature,

required

of

the

drawing

flow

sensor

enters

3.2.

left

end

of

the

opening

in

the

QT®

as

the

of

operation,

to

maintain a given

degree

Each

fresh,

filtered

than

that

of

and

around

When

the

infant

compartment

After

circulating

of

the

main

thermistor

the

Hood

(Figures

Incubator.

CONTROL

Incubator

controlling

provides

the

and

the

relative

on

the

front

of

the

infant s dependency

mode

of

operation

air

into

the

fresh

the

heater

the

Access

within

deck,

and a high

is

open.

the

3.1

and

temperature

parameter;

onty

Air

heater

output

amount

panel.

Changes

temperature.

is

the

incubator,

gas

inflow.

with a predetermined

Panel

up

through

the

infant

past

the

air

temperature

Air

Curtain

3.2)

creating a warm

the

desired

Mode

Control.

is

proportional

of

heat

During

described

the

The

of

the

the

compartment,

temperature

Cover

is

regulated

mode

being

in

the

number

Baby

upon

the

below.

impeller

total

flow

Hood

is

siot

at

the

the

sensing

alarm

thermistor,

is

raised

air

using

is

selected

to

the

provided

of

lamps

Mode

temperature

provides

of

portion

closed,

right

curtain

amount

is

Control,

for

the

fresh

plus

recirculated

being

directed

the

Air

Curtain

end

of

the

air

is

then

recirculated

probe

which

and

back

permitting a portion

which

minimizes

either

Incubator

by a front

of

heat

indicated

illuminated

the

of

its

environment

required

by

the

Modei

internal

main

panel

indicate

recirculation

air

over

the

Cover

deck

as

down

encapsulates

to

the

impeller.

of

the

the

air

or

infant's

key.

to

maintain

number

C450

to

of

the

provides

maintain

is

directed

humidity

is

closed

shown

through

the

When

air

to

drop

The

Model

lit

Heater

amount

at

air

flow

in

air

skin

the

of

an

body

in

AIR

CONTROL

temperature

indicated

located

supplied

temperature

°C

temperature

by

below

to

Display. A second

can

the

deck

the

at

the

to

between

MODE

be

maintained

Set

Temp

and

heater

Set

Temp

sensor

(MODELS

°C

compared

control

39 °C

circuitry

°C

Display

within

and

C400

from

20.0

Display

with

the

setting.

the

40

°C:

QT®

to

37.0

setting.

Set

TempºC

which

air

proportions

Actual

temperature

at

this

temperature,

and

°C

The

C450

QT®).

(20.0

to

Incubator

Display

the

air

temperature

probe

an

in

38.5

°C

air

temperature

setting.

heater

is

serves

alarm

as a backup

is

this

mode

Temperature

is

The

information

output

displayed

to

maintain

by

activated,

of

operation,

Override

monitored

from

Incubator

the

Air

Temperature

to

limit

the

the

heater

the

Mode)

by a probe

this

probe

Incubator

is

shut

off.

air

as

is

air

AIR

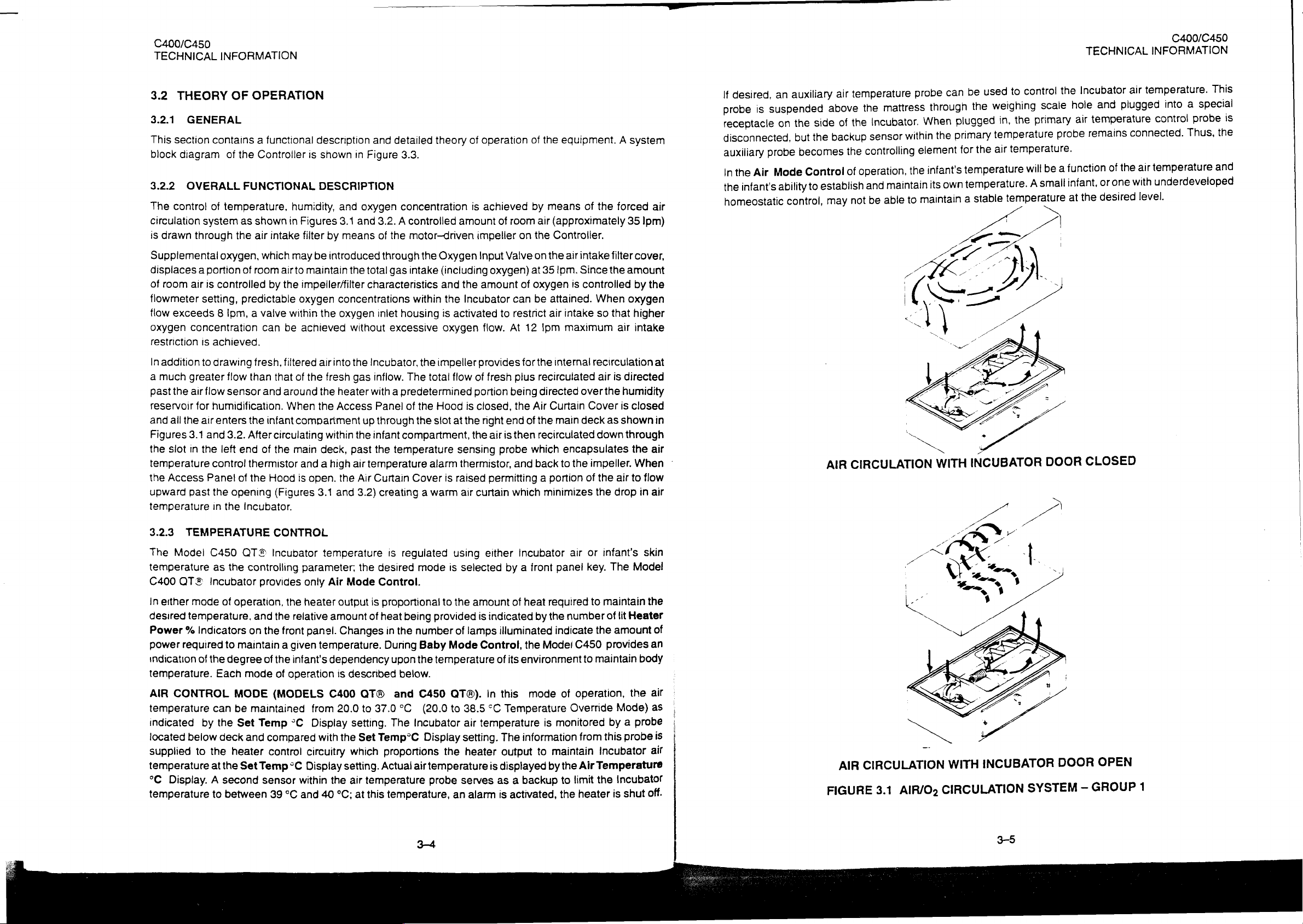

FIGURE

CIRCULATION

AIR/O2

3.1

WITH

INCUBATOR

CIRCULATION

DOOR

SYSTEM

GROUP

—

OPEN

1

C400/C450

TECHNICAL

INFORMATION

AIR

CIRCULATION

WITH

INCUBATOR

DOOR

CLOSED

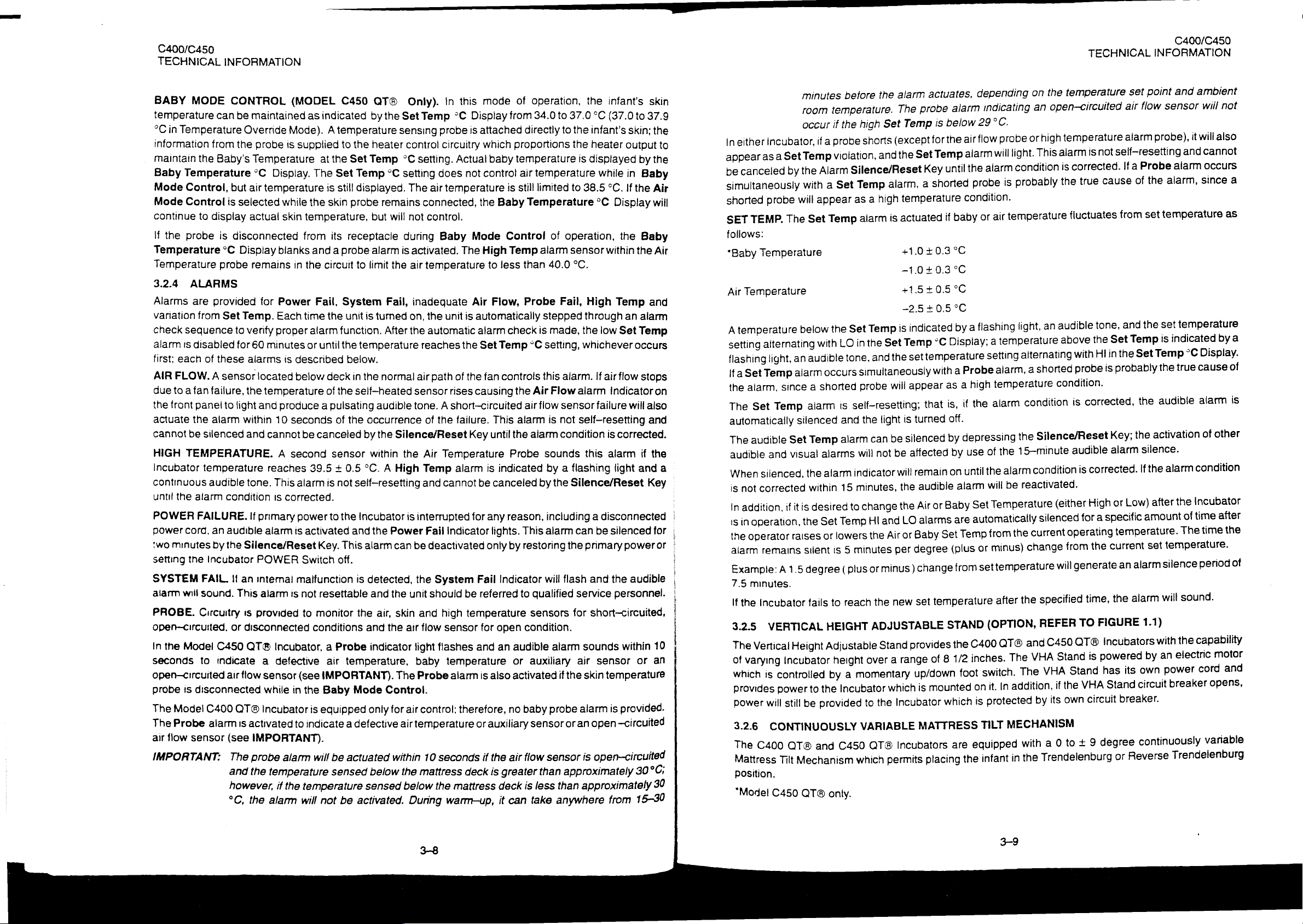

INdINO

Xnv

390Hd

MO

HIV

ag0Hd

HIv

>

01409

390

Hd

C400/C450

ヨ

ヨ

Odd

NIS

TECHNICAL

INFORMATION

VIVO

~

dN3L

OHVOS

9х1

AVIdSIG/NIVW

dXH

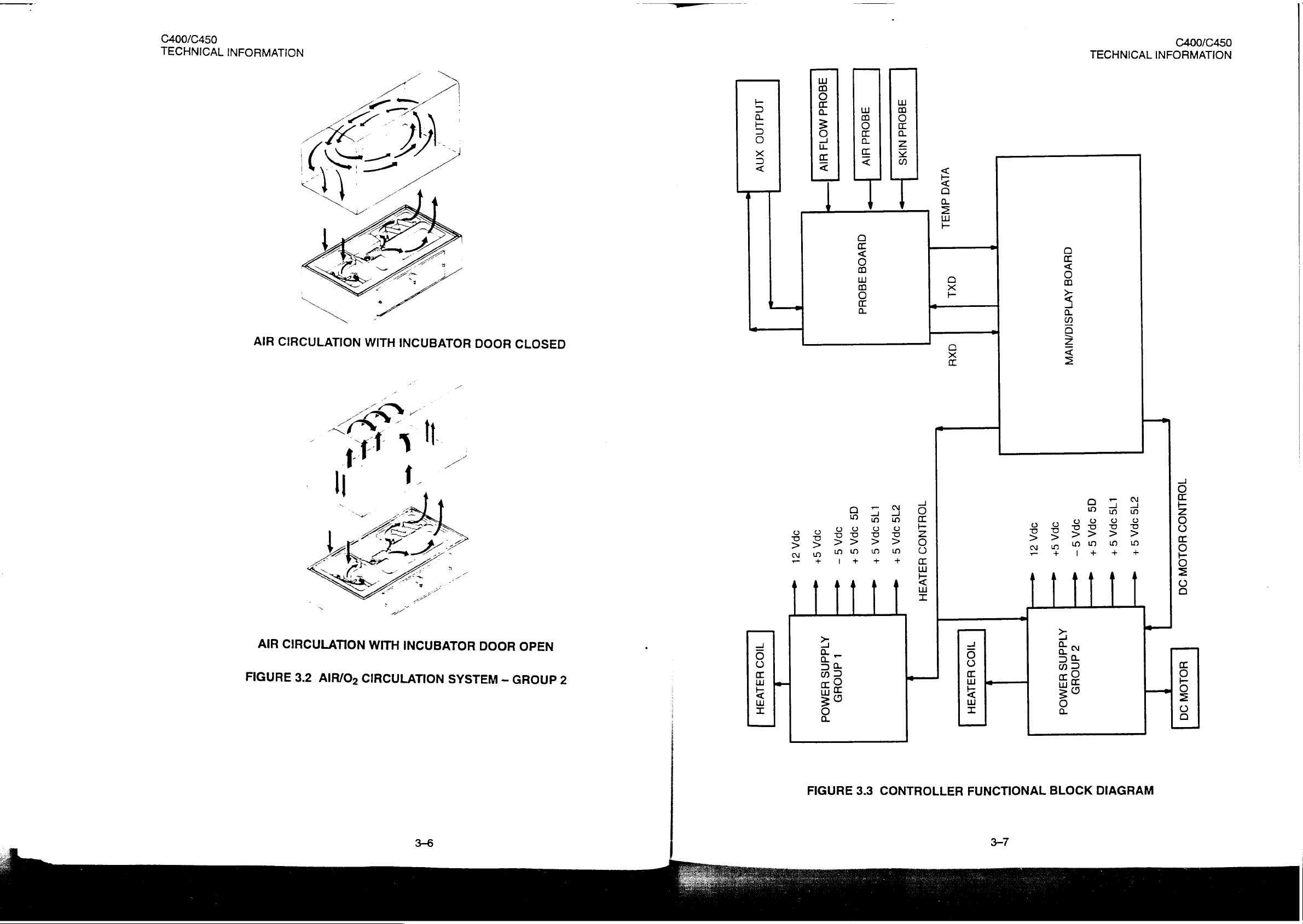

AIR

FIGURE

CIRCULATION

3.2

AIR/O;

WITH

CIRCULATION

INCUBATOR

DOOR

SYSTEM

—

GROUP

OPEN

2

1OHLNO9

ZISOPAG+

LISOPAG+

JOHLNOD

OS

PAS

9PPAS—

5

OPA

PAST

ZL

«e

=

1109

431V3H

AlddnS

HAMOd

+

«=

t

dnNOYD

IS

LISOPAG+

DAS

+

a

H31V3H

7109

HJIVAH

OPA

OPA

St

SL

«e

——

GS

5PA

DPA

S+

S-

«----

——

KIdafiS

<

dnOHD

HIMOd

am

«=

HOLON

90

HOLOW

9

=

o

똑

o

:

©

0

る

©

ul

©

-

已

0

©

>

o

2

N

<

2

〇

O

m

=

ン

<

o

=

=

C400/C450

TECHNICAL

INFORMATION

TECHNICAL

C400/C450

INFORMATION

3.2.7.

The

QUIET

C400

QT®

mechanism

simultaneously.

3.2.8

The

SWIVEL

C400

QT®

post-mounted

or

one

of

each.

with

a

metal

3.3

DETAILED

3.3.1

POWER

GENERAL

The

Power

voitage

+12 and

CR1

Regulator

The

display

This

raw

current.

load

HEATER

The

HEATER

optocoupler

U7

is

regulators

—5

and

capacitors

U2

DC

CONTROL

then

applied

Board

VDC

LED

U7.

LATCH

and

of

these

doors

SHELVES,

and

swivel

These

or

see-through

CIRCUIT

SUPPLY

supplies

U1

are

produced

C9

delivers

and

digital

is

then

regulated

is

controlled

This

optocoupler

to

power

ACCESS

C450

QT®

îs

designed

CABINETS

C450

QT®

shelves.

Modules

(acrylic)

DESCRIPTION

all

necessary

through

(+12)

+5V

to

circuitry

down

by

U7

triac

DOORS

Incubators

Standard

The

VHA

may

also

door,

U6.

Transformer

by

center-tapped

and

C10

the

analog

are

to

and

Q2.

(MOC3041)

Q2

which

such

that

AND

Cabinet

Stand

be

equipped

or

voltages

(-5).

Circuitry.

powered

5V

by

U3,

Logic

has

in

turn

are

equipped

the

doors

DRAWERS

Stand

may

be

equipped

with

no

door

at

to

the

T1

has

secondary

Rectified

from

second

U4,

and

level

SSR

a

triac

switches

with

quiet

may

be

(ACCESSORIES)

or

VHA

Stand

with

fold-down

all.

Controller.

a

dual

DC

All

primary

windings

is

then

windings

US.

Three

CTRL

signal

output

with

a

power

to

latching

opened

one

Side