Page 1

INSTALLATION INSTRUCTIONSOWNER’S GUIDE &

In-Hull, 2-3kW

Transducer

Models: R199, R299, R399

R111LH, R111LM, R599LH, R599LM

U.S. Patent No. 7,369,458. UK Patent No. 2 414 077. U.S. Patent Pending

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING: Always wear safety goggles and a dust

mask when installing.

17-467-01 rev.06 01/12/13

CAUTION: The fiberglass hull below the transducer

must be solid. The transducer will not transmit through

coring material such as foam or balsa wood.

CAUTION: CHIRP transducer—Do not install in the

engine compartment or other hot place. The

transducer may fail if the temperature of the liquid in

the tank exceeds 60° C (140° F).

CAUTION: CHIRP transducer—Always operate the

transducer in liquid. Operating in air will allow the

transducer to overheat resulting in failure.

CAUTION: Never pull, carry, or hold the transducer by

the cable. This may sever internal connections.

CAUTION: Never use solvents. Cleaners, fuel, sealant,

paint, and other products may contain solvents that can

damage plastic parts, especially the transducer’s face.

IMPORTANT: Please read the instructions

completely before proceeding with the installation.

These instructions supersede any other instructions in

your instrument manual if they differ.

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

Applications

• Fiberglass hulls only

• Recommended for high-speed boats

• Accommodates a deadrise angle up to: (see Figure 1)

12° on the long side of the tank

22° on the short side of the tank

• Operates at tank fill-liquid temperatures up to 60° C (140° F)

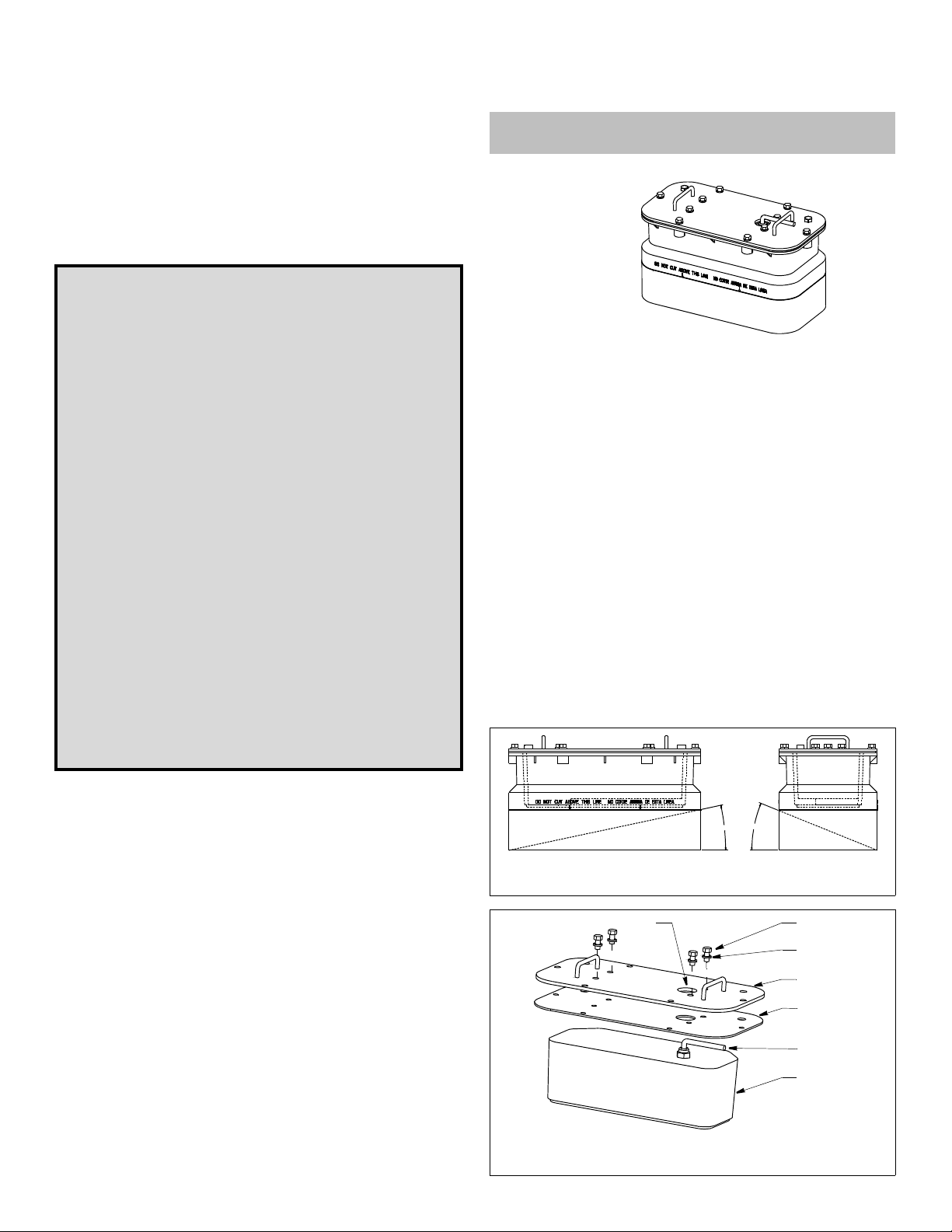

Assembling the Transducer

1. Remove the paper backing from the adhesive side of the gasket.

With the adhesive side facing the plate, align the holes and

edges of the gasket with the under side of the plate (see

Figure 2). Press the gasket firmly into place.

2. Thread the cable through the cable hole in the gasket and plate.

3. Rest the plate on the transducer with the gasket side down and

align the mounting holes. Fasten the plate to the transducer.

Use four of the hex-head bolts and lock washers supplied.

Tighten using a torque wrench with a force not exceeding

85 in-lb. Do not over tighten the bolts.

4. Thread the cable under the handle as seen in the drawing above.

Tools & Materials

Safety goggles

Dust mask

Torque wrench

Rope

Detergent (some installations)

Weak solvent (such as alcohol)

Disk sander (some installations)

Thin sealable plastic bag (some installations)

Cable ties (some installations)

Water-based lubricant (such as K-Y

Carpenter’s level

Pencil

Saw

Scissors

Sand paper: 80 grit

Bonding material (see www.airmar.com for additional brands):

Fiberglass resin: Bondo 401

or Marine-Tex epoxy putty (14 oz. pack)

or 3M™ Marine Adhesive/Sealant 5200

Propylene glycol (non-toxic anti-freeze / coolant)

Funnel

Grommet(s) (some installations)

®

jelly) (some installations)

West Marine #1937762

22°

12°

Figure 1. Maximum cutting angle

Copyright © 2006 Airmar Technology Corp.

cable

hole

Figure 2. Assembling the transducer (R299/R399 shown)

Copyright © 2006 Airmar Technol ogy Corp.

9/16" bolt (4)

lock

washer (4)

plate

gasket

(adhesive

side up)

cable

transducer

Page 2

outboard and I/O

displacement hull

planing hulls

pressure waves

150- 300 mm

(6-12")

inboard

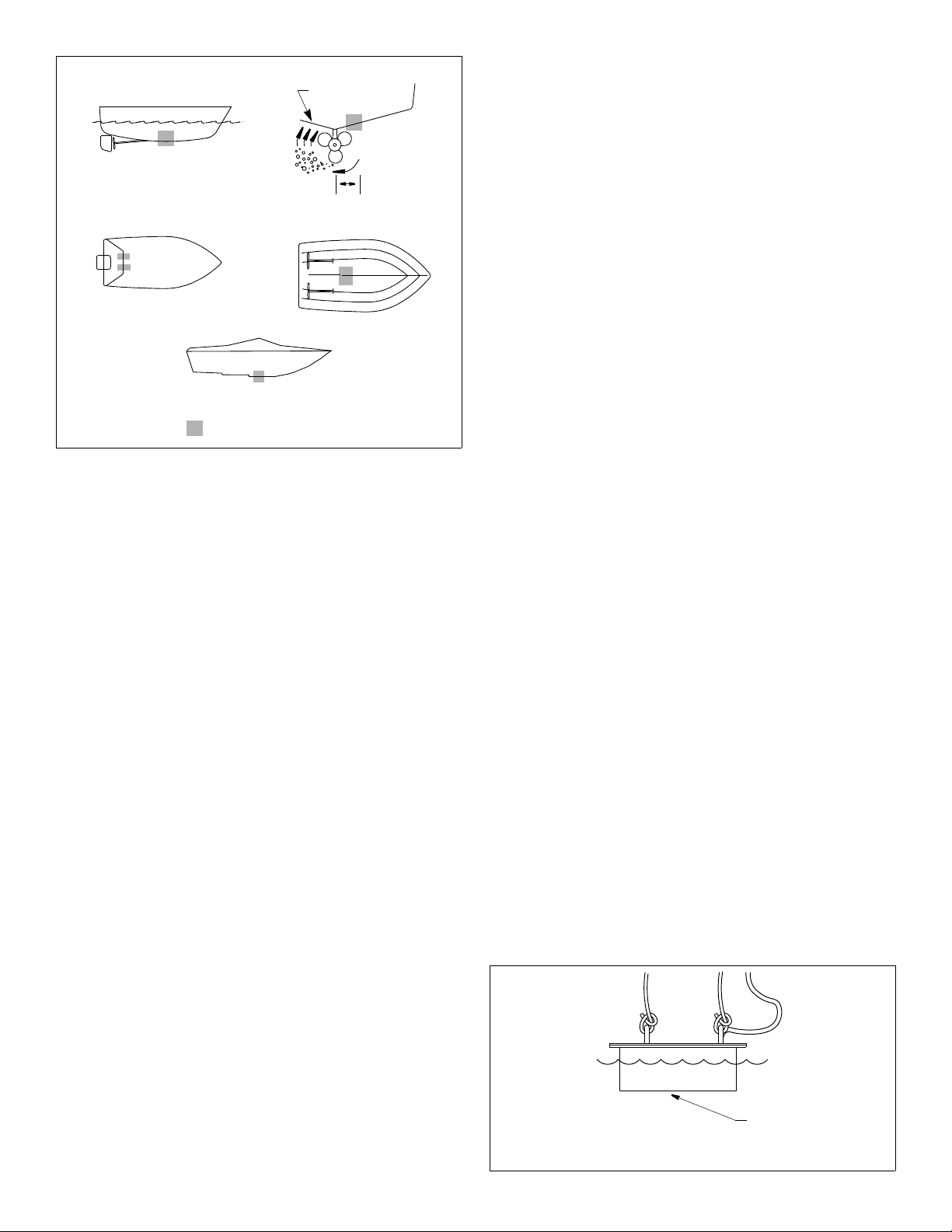

Boat Types (see Figure 3)

• Displacement hull powerboats—Locate amidships near the

centerline. The starboard side of the hull where the propeller

blades are moving downward is preferred.

• Planing hull powerboats—Mount well aft, on or near the

centerline, and well inboard of the first set of lifting strakes to

ensure that the transducer will be in contact with the water at

high speeds. The starboard side of the hull where the propeller

blades are moving downward is preferred.

Outboard and I/O—Mount just forward of the engine(s).

Inboard—Mount well ahead of the propeller(s) and shaft(s).

Stepped hull—Mount just ahead of the first step.

Testing the Selected Mounting Location

Establishing a Performance Baseline

stepped hull

Figure 3.

Best location for the transducer

Copyright © 2006 Airmar Technology Corp.

Mounting Location

About Fiberglass Hulls

Since the hull absorbs acoustic energy, transmitting through the

hull reduces the transducer’s performance. Fiberglass hulls are

often cored in places for added strength or to reduce weight. These

cored areas contain balsa wood or structural foam which are poor

sound conductors. Do not locate the transducer over coring.

Choose a Location

• Where the fiberglass is solid (no air bubbles are trapped in the

fiberglass resin) and where no coring, flotation material, or dead

air space is sandwiched between the inside skin and outer skin

of the hull.

• Where the hull below the transducer will be in contact with the

water at all times.

• Where the water flowing under the hull is smoothest with a minimum of bubbles and turbulence (especially at high speeds). Do

not mount the transducer near water intake or discharge openings; or behind strakes, fittings, or hull irregularities.

• Where the transducer beam will not be blocked by the keel or

propeller shaft(s).

• Away from interference caused by power and radiation sources

such as: the propeller(s) and shaft(s), other machinery, other

echosounders, and other cables. The lower the noise level, the

higher the echosounder gain setting that can be used.

The results of this test are used as a basis of comparison to

determine the best in-hull location for the transducer.

1. Take the boat to the maximum depth in which you will be

operating the echosounder. If deep water is not available, find a

location with at least 30m (100').

2. Connect the transducer to the echosounder.

3. Tie a rope securely around the handles of the transducer (see

Figure 4). Lower it over the side of the boat until the active face

is fully submerged and parallel to the water surface.

4. Observe the echosounder’s performance and the depth reading.

Testing the Location

While the boat is at the same site (depth of water), test the

transducer inside the hull at the mounting location. Use one of the

test methods below:

A.If the transducer will be located near the stern and the boat

has a minimum deadrise angle—Clean away any build-up of

dirt and/or grease using detergent or a weak solvent such as

alcohol. Place the transducer against the hull and allow bilge

water to cover the surface where they touch (see Figure 5-A).

B.For a moderate deadrise angle—If the hull surface is not

smooth, grind it with a disc sander. Place the transducer inside

a thin plastic bag. Partially fill the bag with water and close it

tightly with a cable tie. Wet the surface of the hull and press the

active face of the transducer against it through the bag (see

Figure 5-B).

• Where the deadrise angle does not exceed either 12° on the

long side of the tank or 22° on the short side of the tank.

• Where there is space inside the vessel for the size of the tank

and removing the transducer.

• CHIRP transducer—Mount in a cool well-ventilated area away

from the engine to avoid overheating the liquid inside the tank.

2

active face

Figure 4. Establishing a performance baseline

Copyright © 2006 Airmar Technolog y Corp.

Page 3

AB C

Figure 5. Testing the transducer at the selected location

Copyright © 2006 Airmar Technolo gy Corp.

C.For any location—If the hull surface is not smooth, grind it with

a disc sander. Coat the active face of the transducer with a

®

water-based lubricant (such as K-Y

jelly). With a twisting

motion, press the face firmly against the hull (see Figure 5-C).

After testing, wipe away all traces of the lubricant from the

transducer’s face.

Observe the echosounder’s performance and compare it to the

baseline. Look for a stable depth reading that is similar to the

baseline. Compare the thickness and intensity of the bottom

trace.

If the performance is close to the baseline, this is a good mounting

location. Remember, some energy is lost transmitting through the

hull. If the test reading differs markedly from the baseline, you will

need to find another location to install the transducer.

NOTE: If there is no reading or it is erratic, the transducer may be

positioned over coring which is absorbing the acoustic energy.

Choose another location. If no other location is available, check

with the boat manufacturer to be certain coring is present.

Installation

Marking & Cutting

CAUTION: For optimal performance, the transducer must be

installed so the beam will be aimed straight down. This is

accomplished by cutting the tank to match the deadrise angle of

the hull.

1. When you are satisfied that the selected mounting location is

optimal, place the tank up-side-down on the hull (see Figure 6).

NOTE: The tank can be placed with either a short side or long

side parallel to the centerline of the boat.

2. Holding a carpenter’s level even with the lower corner of one of

the sides to be cut, draw a level line on the tank. Repeat this

process on the opposite side of the tank. Connect these two

lines to form the SHORTEST side of the tank. Be sure the lines

are level, as they will be the cutting guidelines.

3. Before cutting the tank, be sure the TALLEST side will be

closest to the centerline (keel) of the boat after the tank is

installed. And be sure to observe the “Do not cut above this

line” mark.

Using a saw, cut the three sides of the tank along the guidelines

drawn. It may be necessary to further shape the tank to the hull

to ensure a liquid-tight bond.

4. The tank is provided with a cork liner to reduce sound echoes.

After the tank has been cut, wrap the cork liner around the

inside of the tank (see Figure 7). Butt the sides of the liner along

the center of the tallest side. Trace the bottom edge of the tank

onto the liner.

NOTE: There may be a gap between the butted edges which

will not affect performance.

CAUTION: Do not mark or cut the tank in the space labeled

“Do not cut above this line.”

Draw a level line

starting at the

lower corner.

Do not mark

below this line.

top

of tank

Figure 6. Marking the cutting guidelines

Copyright © 2006 Airmar Technolog y Corp. Copyright © 2006 - 2011 Airmar Technology Corp.

carpenter’s

level

hull

5. Remove the cork liner from the tank. Use scissors to cut the

liner along the line drawn.

possible

gap

trace bottom

edge of tank

onto cork liner

Figure 7. Fitting the cork liner (22° angle shown)

3

Page 4

Bonding the Tank

CAUTION: The tank must be liquid-tight. To ensure a tight bond,

the hull surface under and around the tank must be smooth, free

of paint or any other finish, clean, and dry.

1. To ensure a tight bond, remove any paint or other hull finish. If

the surface is rough, use a disk sander to smooth an area slightly

larger than the tank. Clean any dust, grease, or oil from the hull

surface with a weak solvent, such as alcohol. Dry the effected

area.

2. Use 80 grit sand paper to sand the outside and inside of the

tank up 50mm (2") above the bottom edge. Remove the dust

with a weak solvent, such as alcohol. Dry the effected area.

3. Use an approved bonding material (see Tools & Materials on

page 1). Glass the tank to the hull with fiberglass resin, using

standard fiberglass technique. Alternatively, apply a generous

bead of marine putty/ sealant to the bottom edge of the tank

following the manufacturer’s instructions (see Figure 8). Press

the tank firmly in place. Apply a second bead around the inside of

the tank. And apply a third bead around the outside of the tank.

4. Allow the bonding material to cure. The seal must be liquid-tight.

Installing the Transducer

CAUTION: Do not use sealant or adhesive on the gasket. To do

so may break the tank when the transducer is removed.

CAUTION: Do not over tighten the bolts to avoid cracking the tank.

1. After the bonding material has cured, insert the cork liner into the

tank (see Figure 8). Butt the edges along the center of the tallest

side. Note, there may be a gap, but this will not affect

performance.

2. Following the manufacturer’s directions for use, pour propylene

glycol into the tank until it covers the exposed hull.

3. Before installing the transducer, wipe it clean of any lubricant

that was used in testing the location.

4. Grasp the transducer by the handles and lower it into the tank.

There is no fore or aft to the transducer; it fits either way.

5. Attach the transducer to the tank. Use the six remaining 9/16"

hex-head bolts and six lock washers supplied. Tighten using a

torque wrench with a force not exceeding 85 in-lb. Do not over

tighten.

6. Top-off the propylene glycol in the tank. However, allow a small

air space to accommodate expansion with temperature

changes. Using a funnel, pour the fill-liquid through one of the

fill/vent holes until the tank is full. The second hole will act as a

vent. Plug both holes with the vent plugs supplied.

Cable Routing & Connecting

CAUTION: If the transducer came with a connector, do not

remove it to ease cable routing. If the cable must be cut and

spliced, use Airmar’s splash-proof Junction Box No. 33-035 and

follow the instructions supplied. Removing the water-proof

connector or cutting the cable, except when using a water-tight

junction box, will void the transducer warranty.

fill/ vent plug (2)

gasket

transducer

fiberglass

in place

or apply

three beads

of marine

putty/ sealant

hull

propylene glycol

(non-toxic antifreeze/ coolant)

cork liner

Figure 8. Cross section of installed transducer

1. Route the cable to the echosounder being careful not to tear the

cable jacket when passing it through the bulkhead(s) and other

parts of the boat. Use grommets to prevent chafing. To reduce

electrical interference, separate the transducer cable from other

electrical wiring and the engine(s). Coil any excess cable and

secure it in place with cable ties to prevent damage.

2. Refer to your echosounder owner’s manual to connect the

transducer to the instrument.

Copyright © 2006 Airmar Technolog y Corp.

Operation

Monitor the transducer ID line for the internal temperature of the

fill liquid within the tank. The transducer may fail if the fill-liquid

reaches temperatures above 60° C (140° F).

Replacement Transducer & Parts

The information needed to order a replacement Airmar transducer

is printed on the cable tag. Do not remove this tag. When ordering,

specify the part number, date, and frequency in kHz. For convenient reference, record this information at the top of page one.

Lost, broken, or worn parts should be replaced immediately.

In-Hull Mounting Kit 33-453-01

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco (USA) Tel: 803-693-0777

Fax: 803-693-0477

email: sales@gemeco.com

Airmar EMEA Tel: 33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: 33.(0)2.23.52.06.49

Email: sales@airmar-emea.com

®

AIRMAR

TECHNOLOGY CORPORATION

4

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com

Copyright © 2003 - 2013 All rights reserved.

Loading...

Loading...