Page 1

INSTALLATION INSTRUCTIONSOWNER’S GUIDE &

Sealcast

™

and Cast Resin Transducers

Models: M42, M155, M163, M172, M177, R155

IMPORTANT : Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

CAUTION : NEVER USE SOLVENTS!

Cleaners, fuel, paint, sealants, and other products may

contain strong solvents, such as acetone, which attack

many plastics greatly reducing their strength.

17-011 rev. 05 10/05

Mounting Location

Carefully study the hull to determine the best mounting location.

•Away from the propeller(s) and shaft(s), other machinery, and

other echosounders to minimize the effect of noise on the

echosounder display. The lower the noise level, the higher the

gain setting that can be used.

• On the side of the hull where the propeller(s) blades are moving

downward. The upward motion of blades generates pressure

waves and pushes bubbles up against the hull. By mounting on

the downward side, the hull shades the transducer from this

effect (see Figure 1).

• Where the transducer beam will be unobstructed by the keel or

propeller shaft(s).

• Where there is a minimum deadrise angle.

• Where there is adequate headroom inside the vessel for the

height of the stuffing tube and tightening the nuts.

• Locate the transducer about 1/3 aft LWL. Generally, this

provides the best compromise between obtaining aeration-free

water away from the bow and minimizing propeller noise (see

Figure 2).

Caution : Do not mount in an area of turbulence or bubbles:

Near water intake or discharge openings,

Behind strakes, fittings, or hull irregularities.

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

M155

Stuffing Tube

Choosing the Stuffing Tube

Warning: A stuffing tube is required for all installations.

Caution : The stuffing tube must be compatible with the hull material

The stuffing tube seals the hull forming a water-tight conduit for

the cable. Choose a stuffing tube based on the hull material and

diameter of the transducer cable. Airmar stuffing tubes are

available from your marine dealer (see table below).

Fiberglass hull —The stuffing tube

fiberglass, not in coring.

Aluminum hull —Use a stainless steel stuffing tube.

bronze stuffing tube as electrolytic corrosion will occur.

Stuffing Tube

Material

bronze

stainless steel

steel weld to steel hull up to 0.5” D 38mm (1-1/2") 33-818

a. Requires the tube to be isolated from the hull with non-electrically conductive spacers.

Hull Material Cable Diameter

fiberglass

wood

fiberglass, wood

steel, aluminum

a

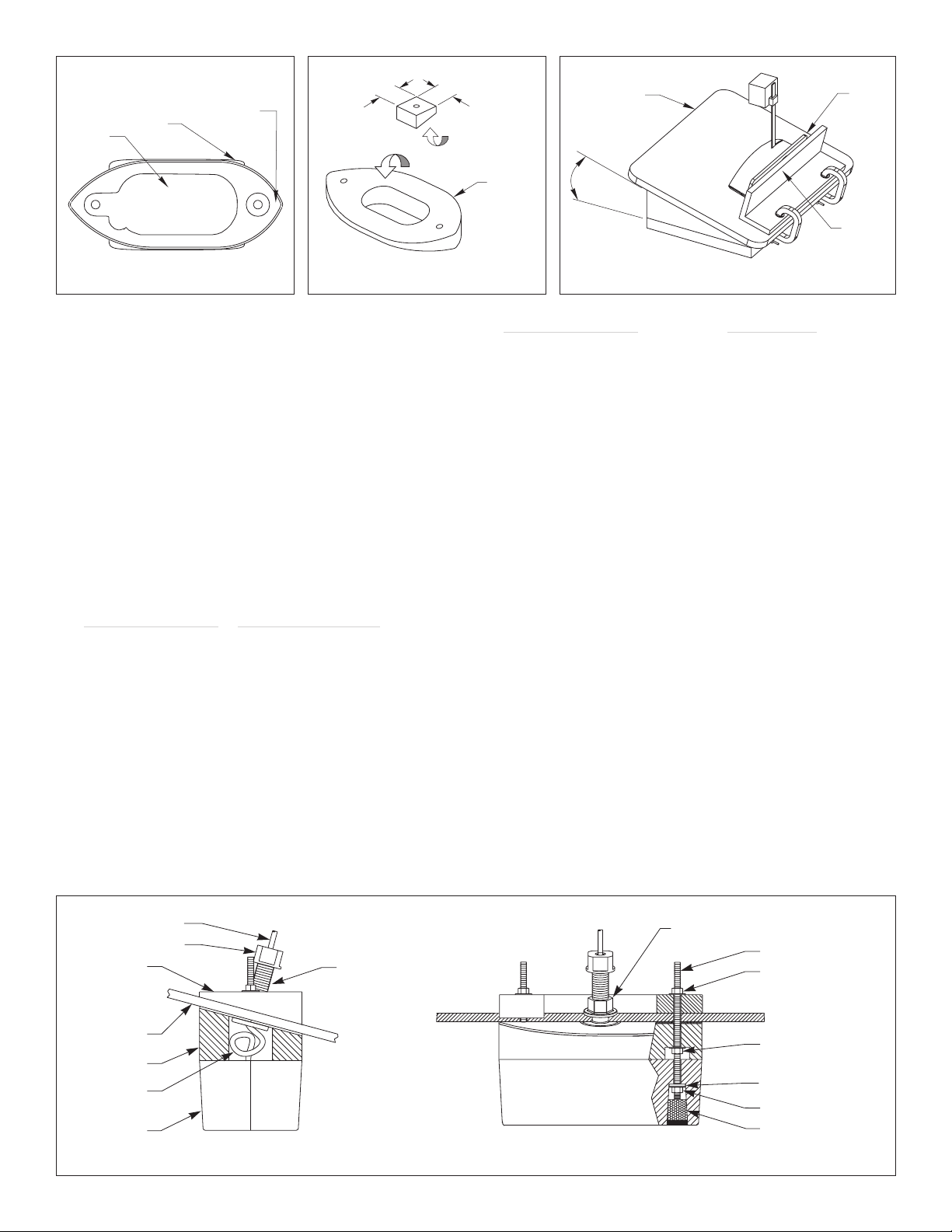

Installing the Stuffing Tube

After determining the best mounting location, install the stuffing tube.

Follow the installation instructions that came with the stuffing tube.

must

be installed in solid

Never

use a

Hull Hole

Diameter

up to 0.47” D 44mm (1-3/4") 33-511-01

up to 0.47” D 26mm (1") 33-819

Airmar

Part No.

Tr ansom View

pressure waves

aeration, cavitation, and turbulence

slope of hull

deadrise angle

parallel to waterline

fairing

- corrects for the deadrise angle

of the hull, so the transducer

beams shoots straight down

- mounts the transducer deeper

in the water for clean flow

over the transducer’s face

Figure 1. Mounting location and deadrise angle

AIRMAR

®

1/3 aft

LWL

(Load Waterline Length)

AIRMAR

®

Figure 2. Mounting location on displacement hull

Page 2

▲

AIRMAR

®

cutting

cavity

guide

Figure 3. Airmar fairing

Bow

➣

arrow points

toward bow

backing block (2)

77mm (3")

deadrise shape

deadrise shape

fairing

Figure 4. Fabricating a fairing

and backing blocks

Fairing

Nearly all vessels have some deadrise angle at the transducer’s

mounting location. If the transducer is mounted directly to the hull,

the sound beam will be tilted off the vertical at the same angle as

the deadrise. If the deadrise angle at the mounting location

exceeds 10 ° a fairing is strongly recommended (see Figure 1).

•Orients the sound beam straight down by mounting the

transducer parallel to the water surface.

• Mounts the transducer deeper in the water for clean flow over

the transducer’s face.

AIRMAR Polymer Fairing

Made of a high impact polymer with an integrated cutting guide,

the Airmar fairing is easy to cut with a band saw and shape with

hand tools (see Figure 3). The fairing also has a center cavity for

the stuffing tube and cable service loop.

Model (see cab

M155, R155, M172 33-147

M177 33-145

Fabricating a Fairing & Backing Blocks

A fairing is usually constructed of an oily wood such as mahogany

or teak. Shape the fairing to match the outline of the transducer

(see Figure 4). Cut a 75mm x 150mm (3" x 6") hole in the center

of the fairing for the stuffing tube and the cable service loop. Place

the transducer over the fairing and using the transducer as a

guide, drill two holes for the threaded rods.Backing blocks are

mounted inside the hull to provide a level surface for tightening the

nuts that hold the threaded rods. They are fabricated to match the

interior deadrise angle. Drill a hole through the center of each

backing block.

le tag) Airmar Fairing Part No.

➣

®

band saw

table

deadrise

angle

AIRMAR

77mm (3")

blunt

end

Bow

Figure 5. Cutting an Airmar fairing

Model (see cab

le tag) Hole Diameter

M42 13mm or 1/2"

M163 10mm or 3/8"

Cutting the Fairing

Warning : The fairing must be installed parallel to the keel to

ensure proper boat handling and water flow over the transducer.

1. The stuffing tube will be centered in the cavity of the fairing (see

Figures 3, 4 & 6). Measure the deadrise angle of the hull at the

stuffing tube using an angle finder or a digital level (see Figure 1).

2. Tilt the band saw table to the measured angle and secure the

cutting fence (see Figure 5).

Caution : The arrow will be pointing forward toward the bow

after the fairing is installed (see Figure 3).

M177 —This fairing is symmetrical.

3. Place the fairing on the table so the cutting guide rests against

the fence. The arrow will be pointing toward you for installation

on the port side and away from you for installation on the

starboard side of the boat (see Figure 5).

fairing on the band saw so the angle cut matches the intended

side of the hull and not the mirror image.

Warning : Always wear safety goggles and a dust mask.

4. Recheck steps 1 through 3; then cut the fairing.

5. Center the stuffing tube in the cavity of the fairing.

fairing is parallel to the keel (centerline). Shape the fairing to the

hull as precisely as possible with a rasp or power tool.

6. The remaining section of the fairing with the cutting guide will

be used as the backing block inside the hull. It will provide a

level surface for tightening the nuts on the threaded rods.

Be sure

to orient the

Be sure

AIRMAR

cutting

guide

fence

the

®

backing block

service loop

transducer

2

cable

compression nut

hull

fairing

cable

forward view

stuffing

tube

Figure 6. Threaded stem stuffing tube installation

Bow

➣

backing block

fairing

transducer

—stainless steel stuffing tube shown

flanged nut

or

nut & washer

threaded rod (2)

nut (2) & washer (2)

nut (2) & washer (2)

rubbery washer (2)

nut (2) & washer (2)

plug (2)

AIRMAR

®

Page 3

Installing the Fairing & Transducer

M172 —Follow separate installation instructions on page 3.

Warning: The fairing must be installed parallel to the keel to

ensure proper boat handling and water flow over the transducer.

1. Locate the hole for the forward threaded rod (see Figures 3 & 6).

Hold the fairing against the hull,

points forward toward the bow

inside the cavity. With the fairing parallel to the centerline of

the boat (keel) , use the

Drill the 11mm or 7/16" diameter hole through the hull for the

threaded rod.

2. Temporarily fasten the fairing to the hull with one of the

threaded rods. With the fairing parallel to the centerline of

the boat (keel) , use the

the 11mm or 7/16" diameter hole through the hull for the

remaining threaded rod.

3. Remove the temporary threaded rod. Clean and sand the area

around the holes, inside and outside, to ensure that the marine

sealant will adhere properly. Remove any petroleum residue with

a mild household detergent or a weak solvent such as alcohol.

Metal hull —Remove all burrs with a file and sandpaper

Welded steel stuffing tube

seal the cable inside the stuffing tube before the transducer and

fairing are attached to the hull. Follow the instructions that came

with your stuffing tube.

4. Apply a 2mm (1/16") thick layer of marine sealant to the surface

of the fairing that will contact the hull (see Figures 6 & 7).

5. Apply a 2mm (1/16") thick layer of marine sealant to each

threaded rod. The marine sealant will seal the hull and hold the

nuts securely in place. Screw a nut and slide a stainless steel

washer onto each threaded rod. Position the nuts a distance

from the rod ends equal to dimension “A”. Slide the threaded

rods through the fairing.

Do not drill the second hole at this time.

forward

aft

Note : The rods will extend above and below the fairing

6. Place the fairing against the hull, pushing the threaded rods

through the hull. With a person stationed inside the vessel,

position the backing block on the rods. Secure each rod with a

stainless steel washer and nut (see Figure 8). Tighten the nuts

with a torque wrench using a force not exceeding 7 N-m (5 ft.-lb.).

Aluminum hull —

prevent electrolytic corrosion.

Be sure

Caution : Never pull, carry, or hold the transducer by its cable as

this may sever internal connections.

7. Thread the transducer cable through the cavity in the fairing and

the stuffing tube to the inside of the hull. Apply a 2mm (1/16")

thick layer of marine sealant to the surface of the transducer that

will contact the fairing. Push the transducer onto the threaded

rods (see Figures 6 & 7).

8. Mount the transducer to the fairing by sliding a rubbery washer

and stainless steel washer onto each threaded rod and

securing them with a nut. Tighten the nuts with a torque wrench

using a force not exceeding 12 N-m (10 ft.-lb.).

Note : The rods should extend a minimum of 3 threads beyond

the nut after it is tightened. Be sure there is marine sealant on

the exposed threads.

9. Plug the mounting holes to minimize turbulence on the surface

of the transducer. Cut the foam plugs to length so that each

plug will be recessed 5mm (3/16") below the surface of the

housing. Push the foam plugs into the holes. Use marine

sealant to fill each recess

10.Remove excess sealant on the outside of the hull and the

fairing to ensure smooth water flow over the transducer.

being sure the arrow/blunt end

and the stuffing tube is centered

hole in the fairing as a guide.

hole in the fairing as a guide. Drill

with

conduit only —It is easier to

.

the rods are isolated from the hull to

FLUSH

with the transducer’s surface.

model dimension “A”

M155 28kHz 54mm (2.13")

M155 38kHz 45mm (1.75")

R155 45mm (1.75")

M177 86mm (3.38")

dimension “A”

Figure 7. Marine sealant

—detail shown

AIRMAR

marine

sealant

Sealing & Routing the Cable

To form a watertight seal inside the stuffing tube, follow the

installation instructions that came with your stuffing tube.

Route the cable to the echosounder

cable jacket when passing it through the bulkhead and other parts of

the boat. To reduce electrical interference separate the transducer

cable from other electrical wiring and the engine. Refer to your

echosounder owners manual to connect the cable to the instrument.

being careful

not to tear the

Checking for Leaks

Warning : Never install a transducer and leave the boat in the

water unchecked for several days.

When the boat is placed in the water, immediately check around

the stuffing tube and the rods that fasten the transducer to the hull

for leaks. Note that very small leaks may not be readily observed. It

is best not to leave the boat in the water unattended for more than 3

hours before checking it again. If there is a small leak, there may be

considerable bilge water accumulation after 24 hours.If a leak is

observed around the stuffing tube, tighten the compression nut

another quarter turn and see if the leakage stops. If there is a leak

around the threaded rods or the outside of the stuffing tube, repeat

the installation and sealing procedures immediately .

Maintenance & Replacement

Antifouling Paint

Surfaces exposed to salt water

paint. Use water-based antifouling paint only.

based antifouling paint, since ketones can attack many plastics

possibly damaging the transducer.

Cleaning

Aquatic growth can accumulate rapidly on the transducer’s face,

reducing its performance within weeks. Clean it using a ScotchBrite® scour pad and mild household detergent,

avoid making scratches. In severe cases, lightly wet sand the

surface with fine grade wet/dry paper.

Replacement

Contact your marine dealer or echosounder manufacturer to

obtain parts.The information needed to order a replacement Airmar

transducer is printed on the cable tag.

ordering, specify the part number, date, and frequency in kHz. For

convenient reference, record this information on the top of page one.

must

be coated with antifouling

Never

being careful

Do not

remove this tag. When

use ketone

to

®

3

Page 4

marine

sealant

®

transducer

housing

AIRMAR

Figure 8. M172 installation in resin housing

Installing the M172

M172 in Resin Housing with Fairing

1. After the stuffing tube is installed following the instructions that

came with it, apply a 2mm (1/16") thick layer of marine sealant to

each threaded rod. Secure each rod with a nut. The rods should

extend a minimum of 3 threads beyond the nut. Slide a stainless

steel washer and rubbery washer onto each rod (see Figure 8).

2. Insert the transducer into the housing and place the clamp bar

on top. Slide the threaded rods up through the housing and

clamp bar. Secure the assembly in place with a stainless steel

washer and nut. Tighten the nuts with a torque wrench using a

force not exceeding 12 N-m (10 ft.-lb.).

3. Slide the fairing onto the threaded rods. Position it against the

transducer assembly.

Caution : Never pull, carry, or hold the transducer by its cable as

this may sever internal connections.

4. Thread the transducer cable through the stuffing tube to the

inside of the hull. Allow a service loop in the cavity of the fairing

so there is no tension applied to the cable.

5. Apply a 2mm (1/16") thick layer of marine sealant to the surface

of the fairing that will contact the hull.

AIRMAR

threaded

rod (2)

nut (2) and

washer (2)

backing

block

hull

fairing

clamp

nut (2)

rubbery

washer (2),

nut (2) and

washer (2)

plug (2)

hull

tank

nut (2)

clamp bar

(shortened)

screw (2)

plate

bolt (4)

transducer

weld

Figure 9. M172 tank mount

6. Place the entire assembly against the hull, pushing the rods

through the hull. With a person stationed inside the vessel,

position the backing block on the rods. Secure each rod with a

stainless steel washer and nut. Tighten the nuts with a torque

wrench using a force not exceeding 7 N-m (5 ft.-lb.).

7. Plug the mounting holes to minimize turbulence on the surface

of the transducer.Cut the foam plugs to length so that, each

plug will be recessed 5mm (3/16") below the surface of the

housing. Push the foam plugs into the holes. Use marine

sealant to fill each recess flush with the transducer’s surface.

8. Remove excess marine sealant on the outside of the hull and

fairing to ensure smooth water flow over the transducer.

9. Follow the instructions that came with your stuffing tube to seal

the cable.

10.Check for leaks (see “Checking for Leaks” on page 3).

M172 Tank Mount

11.It is recommended that the clamp bar be shortened and redrilled to accommodate two bolts. They will secure the

transducer to threaded stand-offs that are welded to the floor of

the tank (see Figure 9). Check for leaks (see “Checking for

Leaks” on page 3).

®

®

AIRMAR

TECHNOLOGY CORPORATION

4

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

■

Copyright © 2005 Airmar Technology Corp. All rights reserved.

www.airmar.com

Loading...

Loading...