Page 1

Junction Box Kit

INSTALLATION INSTRUCTIONS

for Replacement Speed/Temperature Insert

Models: B44V, B66VL, B744V, B744VC, B744VL, B744VLC

WARNING: Always wear safety goggles and a dust

mask when installing to avoid personal injury.

CAUTION: High Voltage Charge

The depth transducer may be storing a high voltage

charge. Accidental discharge could destroy the speed

sensor.

IMPORTANT: Read the instructions completely

17-033-02 rev. 07 12/14/10

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

Applications

• These instructions are for a replacement speed/temperature

insert only. Installing a new insert will NOT solve problems with

depth sounding or fish finding.

• Determine which instructions to follow, either A or B, by looking

at your multisensor. If your multisensor has one cable, follow

instructions A on page 2. If your multisensor has two cables—

one from the depth transducer and one from the speed/

temperature insert—follow instructions B on page 3.

• If these instructions are followed carefully:

• The connections will not corrode

• The strain relief grommets will be water resistant and provide

excellent cable retention.

Before Installing

1. Be sure your new speed/temperature insert is the correct

replacement. Compare the length of the new insert with the

original insert (ignore the cable). If the new insert is more than

3mm (1/8") longer or shorter than the original insert, return it. To

obtain the correct insert, see “ Replacement Parts” on the back

of your multisensor’s owner’s guide.

2. Check the multisensor’s connector at the echosounder for

corrosion. If the connector’s pins are corroded, clean them.

Then test the multisensor to see if the problem has been

corrected.

3. Check the speed and temperature functions of the new insert.

Connect it to the echosounder and spin the paddlewheel.

Check for a reading of several knots. Check for the approximate

air temperature. If there is no reading(s), check the connection

and repeat the test. If there is still no reading(s) or it is

inaccurate, return the product to your place of purchase.

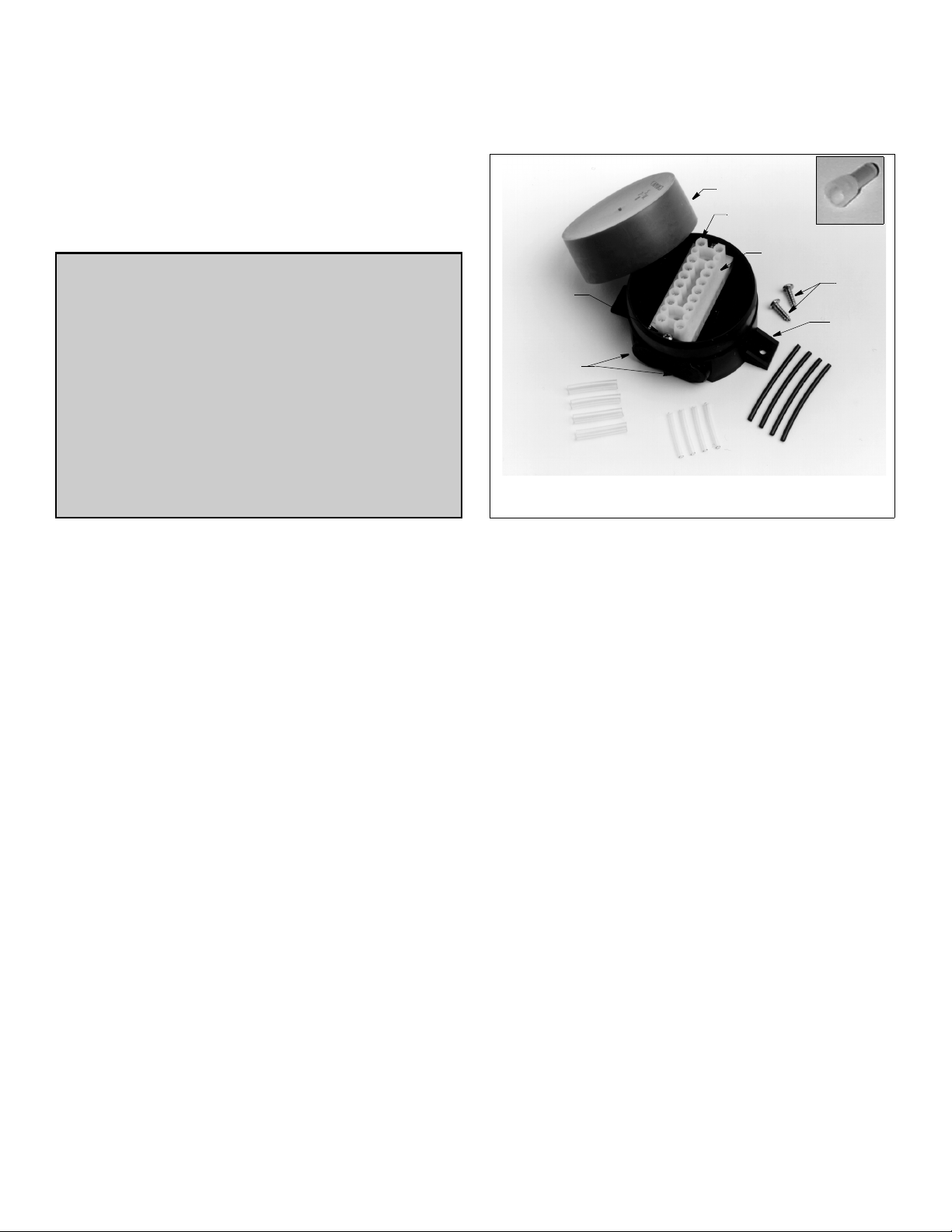

cap

terminal

block

screw (2)

grommet (4)

large diameter

sleeving

terminal screw

(16)

terminal block

mounting screws

small diameter

sleeving

Figure 1. Junction box and contents

Copyright © 2002, 2009 Airmar Techno logy Corp.

connector

mounting

screws

tab (2)

black sleeving

Tools & Materials

Safety goggles

Dust mask

Pencil

Drill

Drill bit: 3mm or 1/8"

Screwdrivers: Phillips and blade

Box-cutter knife (zip-cable installation)

Cutting pliers

Masking tape

Marker

Wire strippers

Alcohol

Crimping pliers (nine or ten-wire cables)

Anti-fouling paint (water-based) (mandatory in salt water)

Silicone lubricant or petroleum jelly

Mounting Location

1. Remove the red cap from the junction box and set the contents

aside (see Figure 1).

2. Select a convenient dry mounting location along the

multisensor’s cable route, preferably 1– 1.5 m (3–5') from the

multisensor but no more than 3m (10').

3. Position the junction box so the grommets are easily accessible

to the cable. Mark the location of the mounting holes.

4. At the marked location, drill two 3mm or 1/8" holes

approximately 10mm (3/8") deep. Do not fasten the junction

box in place at this time.

Page 2

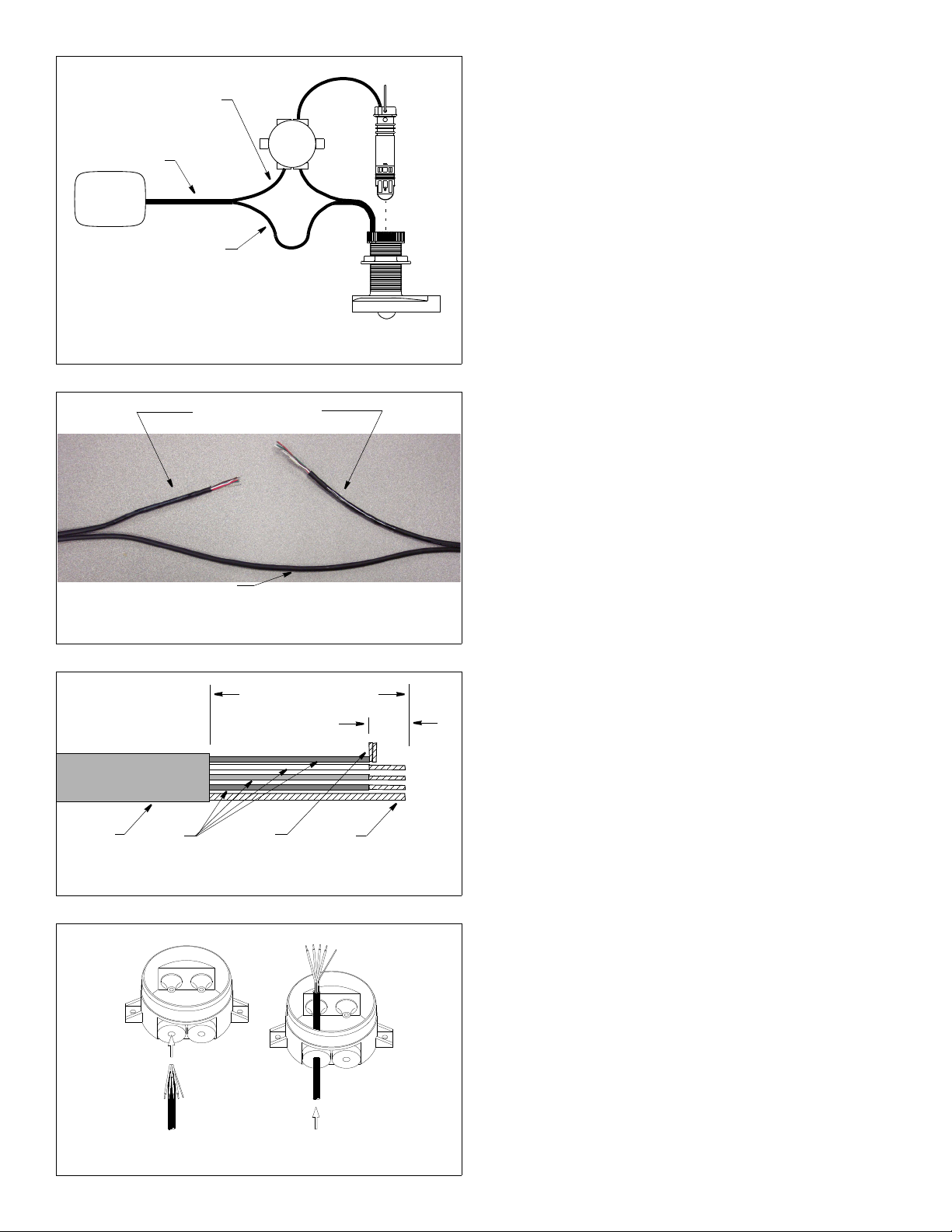

speed/temp half of zip-cable

Figure 4. Preparing the cables

cable

jacket

AIRMAR TRANSDUCER CABLE C344

colored

wires

bare

wire

folded

stripped end

Copyright © 2002, 2009 Airmar Techno logy Corp.

(contains red, green, brown,

echosounder

(printed half)

white, and bare wires)

zip-cable

depth-transducer

half of zip-cable

Figure 2. Splicing a zip-cable multisensor

Copyright © 2002, 2009 Airmar Tec hnology Corp.

zip-cable that is labeled

“Airmar Transducer Cable”

Cut the half of the

Preparing the Cables

C

3-5

5-75-7

insert

BA

multisensor

A. One Cable (Zip-cable) Multisensor

CAUTION: Do not cut the depth-transducer half of the zip-cable.

CAUTION: Do not puncture unused grommets.

1. Disconnect the multisensor from the echosounder.

2. On the junction box, use a small Phillips screwdriver to

puncture the center of both grommets marked 5-7 and one

grommet marked 3-5 (see Figure 2).

3. The multisensor’s cable is actually two separate cables joined

together. This type of cable is called zip-cable. Near the

mounting location of the junction box, separate the two halves of

the zip-cable. Carefully cut them apart with a box-cutter knife for

a distance of 0.5m (18"). Start at the junction box location and

move toward the sounder. Cut only the insulation between the

halves. DO NOT cut into the cables and expose the wires inside.

4. After you have separated the zip-cable, notice that one of the

halves is printed with the words “Airmar Transducer Cable” (see

Figure 3). The printed half of the zip-cable contains the speed

and temperature functions. Cut only the speed/temperature

half of the cable near the junction box. The wires inside will

be red and green. DO NOT cut the depth-transducer half of the

cable.

Figure 3. Cutting the speed/temperature half of a zip-cable

Figure 5. Pushing a cable through a grommet

2

Do not cut the

unmarked half

Copyright © 2002, 2009 Airmar Techn ology Corp.

remove outer jacket and foil shielding

5 -7

5 -7

Copyright © 2002, 2009 Airmar Tech nology Corp.

6cm (2 1/2")

5 -7

5 -7

13mm

(1/2")

NOTE: If the wires inside the cut-half of the cable are blue,

black, and orange, you have cut the depth-transducer side by

mistake. Now cut the speed/temp half of the zip-cable. Because

the depth-transducer cable has been cut, you will need to splice

it back together (see Figure 9). Puncture the center of the

remaining 3-5 grommet. Prepare the cut ends of the depthtransducer cable (see Figure 10). If you have a nine or ten wire

cable, use crimping pliers and the crimp connectors supplied.

Also use silicone lubricant or petroleum jelly to ease sliding

through the grommets.

5. Label the cables as follows with tape and a marker (see Figure 2).

• Cable A—cable to echosounder

• Cable B—cable to multisensor

• Cable C—new speed/temp insert cable

6. Cables A and B—Strip 6cm (2-1/2") of the outer jacket and foil

shield from the cut ends (see Figure 4).

7. Cable A—Strip 13mm (1/2") of insulation from the end of each

colored wire.

8. Cable B—Only the bare wire will be used. Cut-off all the colored

wires.

9. Bend the stripped wires of each cable back against its cable

jacket (see Figure 5). Apply alcohol to the cut end of each cable

jacket to ease sliding. (Do not use any other lubricant to ease

sliding. It will interfere with sealing the grommets.) Push about

20cm (8") of each cable through the appropriate grommet until

all the wires are inside the junction box (see Figure 2). Bend the

wires back to their original position (see Figure 5).

10.Slide a black sleeve over each bare wire and position it against

the cable jacket. For ease in holding the sleeves in place and

connecting to the terminals, fold the stripped ends of each wire

in half. Twist the ends and bend them 90

° (see Figure 4).

11.Go to “Connecting & Testing” on page 3 and follow the

instructions.

Page 3

B. Two-cable Multisensor

CAUTION: Do not cut the depth-transducer cable.

CAUTION: Do not puncture unused grommets.

speed/temp

cable

3-53-5

insert

1. Disconnect the multisensor from the echosounder.

2. On the junction box, use a small Phillips screwdriver to

puncture the center of both 5-7 grommets only (see Figure 6).

3. Near the marked location for the junction box, cut the cable

leading to the speed/temp insert ONLY. Do not cut the depth

transducer cable.

4. Strip 6cm (2-1/2") of the outer jacket and foil shield from the

cable ends (see Figure 4).

5. Strip 13mm (1/2") of insulation from the end of each colored wire.

6. Bend the stripped wires of each cable back against its cable

jacket (see Figure 5). Apply alcohol to the cut end of each cable

jacket to ease sliding. (Do not use any other lubricant to ease

sliding. It will interfere with sealing the grommets.) Push about

20cm (8") of each cable through a grommet until all the wires

are inside the junction box (see Figure 6). Bend the wires back

to their original position (see Figure 5).

7. Slide a black sleeve over each bare wire and position it against

the cable jacket. For ease in holding the sleeves in place and

connecting to the terminals, fold the stripped ends of each wire

in half. Twist the ends and bend them 90

° (see Figure 4).

Connecting & Testing

echosounder

depth

transducer

cable

Figure 6. Splicing a two-cable multisensor

Copyright © 2002, 2009 Airmar Techno logy Corp.

red

green

white

brown

terminals

A

bare wire

with black

sleeve

echosounder

Figure 7. Connecting a zip-cable multisensor

Copyright © 2002, 2009, 2010 Airmar Technology Corp.

B

multisensor

multisensor

red

green

white

brown

C

bare wire

with black

sleeve

speed/temp

insert

CAUTION: Make certain there are no bare wires, frayed strands,

or loose ends to cause shorting.

CAUTION: Zip-cable multisensor—If the depth-transducer half

of the cable (with the blue, black, orange, and bare wires) has

been cut, re-connect it FIRST before connecting the new speed/

temp insert (see Figure 11 on page 4).

1. Insert the stripped end of a colored wire from the echosounder

cable A into the first square opening in the side of the terminal

block (see Figure 7 or 8). Tighten the terminal screw until the

wire is held firmly. Connect each wire in turn including the bare

wire.

2. Connect each matching colored wire and bare wire from the

new speed/temp insert (cable C) to the corresponding terminal.

Zip-cable multisensor—Twist the bare wire from cable B and

the bare wire from cable C together. Connect the twisted pair of

bare wires to the terminal (see Figure 7). This shields the depth

transducer from acoustic noise.

3. Visually inspect all the wires. Make certain the sleeving

completely covers any bare wire(s). There should be no frayed

strands or loose ends to cause shorting. If any bare wire is

visible, shorten the stripped end and reconnect it to the terminal.

4. Connect the cable to the echosounder and turn it ON.

5. Check for the approximate air temperature.

6. Spin the new paddlewheel and look for a speed reading.

NOTE: If the new insert does not work properly, the wiring may

be incorrect. Return to step 1 and recheck your wiring.

terminals

white

bare wire

with sleeve

red

red

white

bare wire

with sleeve

AC

brown

green

echosounder

Figure 8. Connecting a two-cable multisensor

speed/temp half of zip-cable

(contains red, green, brown,

white, and bare wires)

Copyright © 2002, 2010 Airmar Technology Corp.

(printed half)

3-5 3-5

A

5-7 5-7

brown

green

C

speed/ temp

insert

insert

B

echosounder

depth-transducer

half of zip-cable

(contains blue, black,

orange, and bare wires)

DE

multisensor

Figure 9. Splicing both halves of a zip-cable

Copyright © 2002, 2009 Airmar Techno logy Corp.

3

Page 4

Closing & Mounting

1. Apply alcohol to each cable jacket inside the junction box to ease

sliding. Grasp each cable from outside the box and pull until only

25mm (1") of the cable jacket is left inside. This will invert the

grommets to seal the junction box.

2. Arrange the wires neatly inside the junction box.

3. Place the terminal block inside the junction box. Secure the

ends with the terminal block screws provided (see Figure 1).

4. Close the box using the red cap. Expel the excess air inside the

junction box by placing a thumb on the center of the red cap

and applying pressure for 30 seconds.

5. Screw the junction box to the selected mounting surface using

the two #6 x 1/2" (13mm) screws provided.

Anti-fouling Paint

Aquatic growth can accumulate rapidly on the speed / temp insert

reducing its performance within weeks. Surfaces exposed to salt

water must be coated with anti-fouling paint. Use water-based

anti-fouling paint only. Never use ketone based paint since

ketones can attack many types of plastic. Paint the following

surfaces:

• Exposed end of the insert

• Outside wall of the insert below the lower O-ring

• Paddlewheel cavity

• Paddlewheel

Installing the Speed Temperature Insert

WARNING: Different speed/ temperature inserts are attached to

the multisensor in different ways. See your multisensor’s owner’s

guide for more details.

WARNING: O-ring must be intact and well lubricated to make a

watertight seal.

black

bare wire with

black sleeve

shielded pair

with clear

sleeve

echosounder

speed/ temp

red

green

white

bare wire with

black sleeve

remove outer jacket and foil shielding

6cm (2 1/2")

13mm

(1/2")

Figure 10. Preparing the cut ends of the

depth-transducer half of a zip-cable

Copyright © 2002, 2009 Airmar Tec hnology Corp.

CAUTION: Reconnect the

depth transducer before

connecting the new

speed/ temp insert

terminals

D

depth

A

B

multisensor

remove

insulation

bare

wire

blueblue

black

bare wire with

black sleeve

shielded pair

with clear

sleeve

E

depth

multisensor

speed/ temp

insert

C

red

green

white

brownbrown

bare wire with

black sleeve

WARNING: Always attach the safety wire to prevent the insert

from backing out in the unlikely event that the cap nut and/or

insert nut fails or is screwed on incorrectly.

1. Check the O-rings on the new insert (replace if necessary) and

lubricate them with silicone lubricant or petroleum jelly.

2. Remove the failed speed/temperature insert from the housing.

If desired, save it for replacement parts. The paddlewheel and

shaft may be usable.

3. Slide the new insert into the valve assembly with the arrows on

the top pointing forward until it is fully seated.

• Insert nut—Use a twisting motion until the keys fit into the

notches. (The insert fits one way only.) Screw the insert nut

in place and hand-tighten only. Do not over tighten.

• Safety chain or Strap assembly—Reattach the safety

chain/strap assembly to the cable. Slide the retaining pin

through the holes and secure it with the safety ring(s).

4. Reattach the safety wire.

®

AIRMAR

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

TECHNOLOGY CORPORATION

4

Copyright © 2002 - 2010 All rights reserved.

Figure 11. Reconnecting a depth transducer and

connecting new speed/temp insert

Copyright © 2002, 2010 Airmar Techn ology Corp.

Parts

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco Tel: 803-693-0777

(USA) Fax: 803-693-0477

email: sales@gemeco.com

Airmar EMEA Tel: +33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: +33.(0)2.23.52.06.49

email: sales@airmar-emea.com

www.airmar.com

Loading...

Loading...