Page 1

A

ALLPRO

A

P

S

/O

ANUAL

Page 2

2

Manifold Filter Parts List

Upper & Lower Seats

Fluid Pump

20

21

Lo-Boy Machine Parts List

22

Hi-Boy Machine Parts List

23

24

Electrical System Drawing - 5/6 Series

28

TABLE OF CONTENTS

LP Series Speci cations

2

Flushing

How to Flush

Pressure Relief Procedure

Daily Maintenance

Electric Motor Maintenance

Field Troubleshooting

Packing Replacement

Electrical Board Calibration

25

Electrical Troubleshooting - 5/6 Series

27

Replacement of Electrical Components

29

www.airlessco.com email: techsupport@airlessco.com

©

2006, All rights reserved.

Page 3

INTRODUCTION

Tip Size

Weight

41 lbs.

All Service Procedures to be performed by an Authorized Airlessco Service Center ONLY.

WARNING

- Alerts user to avoid or correct conditions that could cause bodily injury.

- Alerts user to avoid or correct conditions that could cause damage to or de struc tion of equipment.

- Alerts users to steps or procedures that are essential to proper equipment repair and maintenance.

- Identi es essential procedures or extra information.

Your new Airlessco or ALLPRO airless paint sprayer is designed to meet the

demands of the professional painting contractor as well as the homeowner.

The famous Airlessco slow-stroking stainless steel piston pump delivers

Triple-Life packing system is externally adjustable, extending packing life

reducing heat. The motor is fan cooled and totally enclosed to reduce brush

wear and to prevent the ignition of paint fumes in the motor.

65 lbs.

Page 4

2

SAFETY WARNINGS

standards have been adopted under the

standards, particularly the General Standards,

should be consulted.

DO NOT USE HALOGENATED SOLVENTS IN THIS SYSTEM.

The prime valve, and most airless guns have aluminum parts and may explode. Clean ing agents, coatings, paints or adhesives

may contain halogenated hydrocarbon solvents. DON'T TAKE CHANCES! Consult your material suppliers to be sure. Some of

the most common of these solvents are: Carbontetrachloride, Chlorobenzene, Dichloroethane, Dichloroethyl Ether,

Ethylbromide, Ethylchloride, Tethrachloethane. Alternate valves and guns are available if you need to use these solvents.

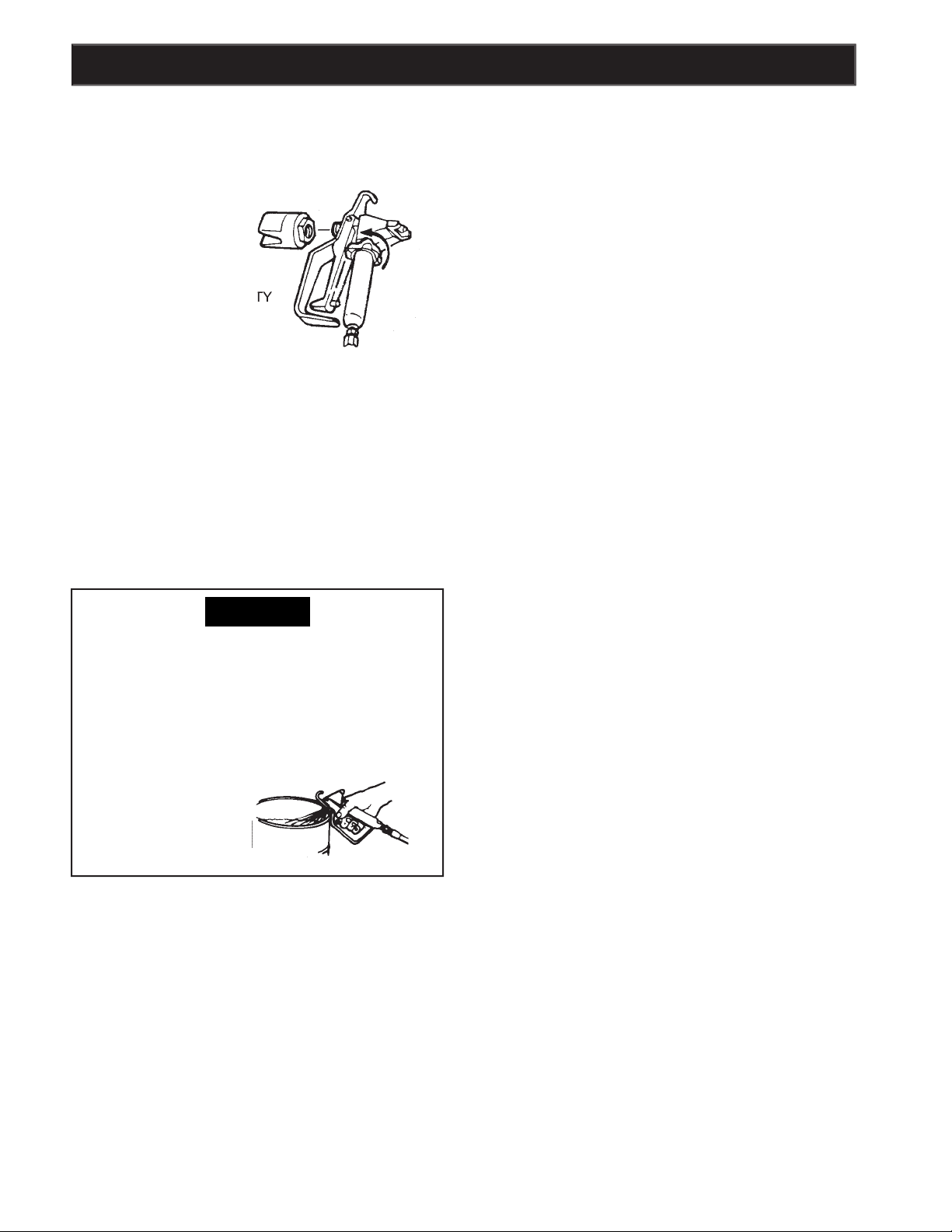

Airless Spray Wounds

Airless Spray Wounds

If any uid appears to penetrate your skin, get

EMERGENCY MEDICAL CARE AT ONCE.

DO NOT TREAT AS A

Tell the doctor exactly what uid was injected

injury.

It is important to treat the injury sur gi cal ly as

toxicity.

Toxicity is a concern with some ex ot ic coatings injected

directly into the blood stream. Con sul ta tion with a plastic surgeon

or re con struc tive hand sur geon may be advisable.

NEVER

alter equipment in any manner.

NEVER

smoke while in spraying area.

NEVER

spray highly ammable materials.

NEVER

use around children.

NEVER

allow another person to use sprayer unless

he is thoroughly instructed on its safe use and

given this operators manual to read.

ALWAYS

wear a spray mask, gloves and protective

eye wear while spraying.

ALWAYS

ensure re extinquishing equipment is

readily available and properly maintained

Fluids under high pressure from spray or leaks can

penetrate the skin and cause ex treme ly serious injury,

including the need for amputation.

NEVER

point the spray gun at anyone or any part of

the body.

NEVER

put your hand or ngers over the spray tip. Do

not use a rag or any other materials over your ngers.

Paint will penetrate through these materials & into the hand.

NEVER

try to stop or de ect leaks with your hand or body.

ALWAYS

have the tip guard in place when spraying.

ALWAYS

lock the gun trigger when you stop spraying.

ALWAYS

remove tip from the gun to clean it.

NEVER

try to "blow back" paint, this is not an air spray

ALWAYS

follow the

PRESSURE RELIEF

PRO CE DURE

before cleaning or re mov ing the spray tip or servicing any

Be sure the equipment safety devices are operating prop er ly

before each use.

Tighten all of the uid connections before each use.

\

If any uid appears to penetrate your skin, get

EMER GEN CY

Go to an emergency room immediately.

Tell the doctor you suspect an injection injury.

Tell him what kind of material you were spraying with

and have him

read NOTE TO PHYSICIAN above.

INJECTION HAZARD

GENERAL PRECAUTIONS

Page 5

SAFETY WARNINGS

Keep the spraying area free from obstructions.

Make sure the spraying area has good ventilation

to safely remove vapors and mists.

NEVER

keep ammable material in spraying area.

NEVER

The spraying area must be at least 20 ft. away from

ALWAYS

po si tion when not in use & before servicing or cleaning.

NEVER

remove or modify any part of the gun.

ALWAYS

REMOVE THE SPRAY TIP when cleaning.

Flush unit at the LOWEST POSSIBLE PRESSURE.

ALWAYS

check operation of all gun safety devices

before each use.

Be very careful when removing the spray tip or hose

from the gun. A plugged line will con tain uid un der

pressure. If the tip or line is plugged, follow the

PRES SURE RE

LIEF PRO CE DURE

ALWAYS

have the tip guard in place on the spray

gun while spraying. The tip guard alerts you to the

injection hazard and helps prevent accidentally

placing your n gers or any part of your body close

to the spray tip.

Use extreme caution when cleaning or changing

gage the gun safety latch immediately. ALWAYS

follow the

PRES

and then remove the spray tip to clean it.

NEVER

wipe off build up around the spray tip.

ALWAYS

remove tip guard & tip to clean AFTER

pump is turned off and the pressure is relieved by

fol low ing the

PRESSURE RELIEF PROCEDURE.

Hazardous uid or toxic fumes can cause serious in ju ry

or death if splashed in eyes or on skin, inhaled or

manufacturer, local, state & national guidelines.

ALWAYS

wear protective eyewear, gloves,

clothing and respirator as recommended by uid

man u fac tur er.

Tighten all of the uid connections securely before each

use. High pressure uid can dislodge a loose coupling or

allow high pressure spray to be emitted from the coupling

and result in an injection injury or serious bodily injury.

Only use hoses with a spring guard. The spring guard

helps protect the hose from kinks or other damage which

could result in hose rupture and cause an injection injury.

NEVER

use a damaged hose, which can result in hose

failure or rupture and cause an injection injury or other

check entire hose for cuts, leaks, abrasions, bulging of the

cover, or damage or movement of couplings. If any of

these conditions exist, replace the hose immediately.

NEVER

use tape or any device to try to mend the hose as

it cannot contain the high pressure uid. NEVER

ATTEMPT TO RECOUPLE THE HOSE. A high pressure

hose is not recoupleable.

Ground the spr

ayer & other components in the system to

reduce the risk of static sparking, re or explosion which

can result in serious bodily injury and property damage.

For detailed instructions on how to ground, check your

local electrical code.

ALWAYS

ensure switch is in OFF position before

plugging unit in.

Always Ground All of These Components:

each equipped with an undamaged three-prong plug, into a

properly grounded outlet. DO NOT USE AN ADAPTER.

Use only a 3 wire extension cord that has a 3 blade

grounding plug, and a 3 slot receptacle that will accept

the plug on the product. Make sure your extension cord is

in good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your product will

draw. (

Note

the cor rect size to use depending on cord length and name

plate ampere rating. If in doubt, use the next heavi er gauge.

The smaller the gauge num ber, the heavi er the cord.)

2. Fluid hose

3. Spray gun or dispensing valve

through connection to a properly grounded u id hose and

pump.

4. Object being sprayed

5. All solvent pails

used when ushing.

Once each week, check electrical resistance of hose (when

using multiple hose assemblies, check overall resistance.)

Overall (end to end) resistance of unpressurized hose must

not exceed 29 megohms (max.) for any coupled length or

combination of hose lengths. If hose exceeds these limits,

replace it im me di ate ly.

length to assure electrical continuity.

ALWAYS INSPECT SPRAYING AREA

SPRAY GUN SAFETY

HOSES

GROUNDING

TIP GUARD

SPRAY TIP SAFETY

TOXIC FLUID HAZARD

Page 6

4

SAFETY WARNINGS

Always Follow Recommended Pressure

ALWAYS

use approved high pressure ttings and

re place ment parts.

ALWAYS

ensure re extinquishing equip ment is readi ly

avail able and properly maintained.

When spraying with ammable liquids, the unit must be located a minimum of 25 feet away from the spraying area in a

well ventilated area. Ventilation must be suf cient enough to prevent the accumulation of vapors.

2.

To eliminate electrostatic discharge, ground the spray unit, paint bucket & spraying object. See GROUNDING. Use only

high pressure airless hoses approved for 3000 psi which is conductive.

3.

Remove the spray tip before ushing. Hold the metal part of the gun rmly to the side of a metal pail & use the lowest

possible uid pressure during ush ing.

4.

Never use high pressure in the cleaning process.

USE MINIMUM PRESSURE.

5.

Do not smoke in spraying/cleaning area.

5 - 6

6 - 8

8 - 10

25

400

8

6

6

30086

6

6

250

8

8

6

20088

8

50

50066

4

Keep clear of moving parts when starting or operating the

amputation by moving parts or burns on hot parts. Pre cau tion

is the best in sur ance against an accident. When starting the

motor, maintain a safe distance from moving parts of the equip-

ment. Before adjusting or ser vic ing any mechanical part of the

This sprayer operates at 3000 psi (205 bar). Al ways be

work ing pres sure of at least 3000 psi to avoid rup ture

which can result in serious bodily injury in clud ing

in jec tion and prop er ty damage.

NEVER

leave a pressurized sprayer un at tend ed to avoid

ac ci den tal operation of it, which could result in serious

bodily in ju ry.

ALWAYS

follow the PRESSURE RE LIEF PRO CE DURE

whenever you stop spraying and before ad just ing,

re mov ing or repairing any part of the sprayer.

NEVER

alter or modify any part of the equipment to

avoid possible component rupture which could result in

NEVER

use weak, damaged, or non-conductive paint

hose. Do not allow kinking or crushing of hoses or

al low it to vibrate against rough, sharp or hot surfaces.

Before each use, check your hoses for damage and wear

and ensure all of the uid connections are secure.

ALWAYS

replace any damaged hose.

NEVER

use tape

or any device to mend the hose.

NEVER

attempt to stop any leakage in the line or

t tings with your hand or any part of the body. Turn off

the unit and release pressure by following PRES SURE

RELIEF PROCEDURE.

ALWAYS

be sure all of the equipment & objects being

paint bucket and object being sprayed. See the ground ing

Reduce the risk of injection injury, static sparking or

ALWAYS

follow the PRESSURE RELIEF PRO CE DURE.

ALWAYS

remove the spray tip before ushing. Hold

the metal part of the gun rmly to the side of a metal pail

& use the lowest possible uid pressure during ush ing.

NEVER

use cleaning solvents with ash points below

ether, gasoline, naptha. Consult your supplier to be sure.

NEVER

Use only conductive fluid hoses for airless ap pli ca tions.

Be sure the gun is grounded through the hose con nec tions.

Check ground continuity in hose & equipment. Overall

exceed 29 megohms for any coupled length or com bi na tion

of hose length. Use only high pressure airless hoses with

Vapors created when spraying can be ignited by sparks.

To reduce the risk of re, always locate the sprayer at

least 20 feet (6 m.) away from spray area. Do not plug in

or unplug any electrical cords in the spray area. Doing so

can cause sparks which can ignite any vapors still in the

air. Follow the coating & solvent man u fac tur ers safety

warnings and precautions.

VOLTAGE

AMPERAGE

KEEP CLEAR OF MOVING PARTS

AVOID COMPONENT RUPTURE

PREVENT STATIC SPARKING FIRE/EXPLOSIONS

FLUSHING

WHEN SPRAYING & CLEANING WITH FLAMMABLE PAINTS AND THINNERS

Page 7

Your sprayer was factory tested in an oil solution which

was left in the pump.

Before using oil-base paint,

ush

with mineral spirits only.

Before using water-base paint

ush with mineral spirits, followed by soapy water, then a

clean water ush.

2. Changing Colors

2. Changing Colors

Flush with a compatible solvent such as mineral spirits or

water.

Flush with soapy water, then mineral spirits

4. Changing from oil-base to

4. Changing from oil-base to

water-base paint.

water-base paint.

Flush with mineral spirits, followed by soapy water, then a

clean water ush

FLUSHING

Always relieve pressure (See pressure relief

procedure on page 10) prior to storage or when

machine is unattended.

Flush with mineral spirits. Ensure that

there is no pressure in the unit, then close the prime/

pressure relief valve.

Water-base Paint:

Flush with water, then mineral spirits.

For longer term storage use a 50/50 mixture of mineral

for storage.

Before using water-base paint,

ush with soapy

water and then a clean water ush.

When using oil-base paint,

ush out the mineral

(Prime/PR Valve)

Used to relieve pressure from gun, hose & tip and to prime

the unit when in OPEN position.

when there is a wider gap

between valve handle and

cam body).

When valve is in the CLOSED

position, there is only a very

When closed the system is

pressurized

Used to adjust pressure. Turn clockwise (CW) to increase

pressure and coun ter clock wise (CCW) to decrease pres-

TOGGLE

SWITCH

HOW TO FLUSH

Page 8

Be sure the gun safety latch is engaged and there

is no spray tip in the gun. Refer to page 14 on how

to lock the safety latch and the gun's safety features.

FIGURE 4

2

empty metal pail to ll the pump and hoses.

3.

Place the suction tube into the pail.

4.

Turn the Prime/Pressure Relief (PR) Valve to the

5.

Point the gun into the metal pail and hold a metal

part of the gun rmly against the pail. Refer to Figure 5.

METAL TO METAL

6.

Disengage the gun safety latch and squeeze the

gun trigger. Turn the ON-OFF Toggle Switch to the

Knob (Figure 2) clockwise to increase pressure just

enough to start the pump.

7.

Turn the Prime/PR Valve to the PRESSURE

ushed through the pump, hoses and gun. Allow the

unit to operate until clean solvent comes from the gun.

8.

Release the trigger and engage the gun safety

latch.

9.

Whenever you shut off the sprayer, follow the

"PRESSURE RELIEF PROCEDURE".

HOW TO FLUSH (continued)

Page 9

Remove the plastic cap plug from the outlet tee

and screw a conductive or grounded 3000 psi

airless spray hose onto uid outlet.

b.

Connect an airless spray gun to the other end of

the hose.

c.

Do not use steel braided airless hose. Use nylon

braided airless hose only.

Be sure the electrical service is 120 VAC, 15 amp

minimum, and that the outlet you use is properly

grounded.

generator with voltage regulation must be used.

4. Grounding

4. Grounding

2. Fill the packing nut/wet cup with

2. Fill the packing nut/wet cup with

As per "Flushing Procedure" in this manual.

safety warning section of this manual.

SETTING UP

Page 10

2. Prepare the material

2. Prepare the material

Prepare the material according to the material

manufacturer's recommendations.

b.

Place the suction tube into the material

container.

Prime/PR Valve must be "OPEN" in the priming

position.

b.

When you have ensured that the gun safety latch is

engaged, attach tip and safety guard.

c.

Turn the ON-OFF Toggle Switch to the

"ON" position.

Turn Pressure Control Knob clockwise to prime

the pump.

After the pump is primed, turn Prime/PR Valve to

the "Closed" position.

f.

Turn Pressure Control Knob to the desired spray

pressure. Optional LCD displays pressure.

g.

Disengage the gun safety latch and you are

ready to spray.

is used to adjust

pressure. Turn clockwise (CW) to increase pressure and

coun ter clock wise (CCW) to decrease pressure

TOGGLE

SWITCH

is used to

prime pump and to relieve pressure from gun, hose and tip.

Prime/Pressure Relief Valve

(Prime/PR Valve)

Used to relieve pressure from gun, hose & tip and to prime

the unit when in the OPEN position. (It is in open position

when there is a wider gap

between valve handle and

cam body)

When in the CLOSED

position, there is only a very

When closed the system is

pressurized. Handle as a loaded rearm!

STARTING UPSTARTING UP

Page 11

4. Adjusting the pressure

4. Adjusting the pressure

Turn the Pressure Control Knob Clockwise to

increase pressure and counterclockwise to decrease

pres sure.

b.

Always use the lowest pressure necessary to

completely atomize the material.

c.

If more coverage is needed, use a larger tip rather

than increasing the pressure.

Check the spray pattern. The tip size and angle

determines the pattern width and ow rate.

Always point the gun toward the ground

Whenever you stop spraying, even for a short break,

follow the "Pressure Relief Procedure".

b.

Clean the tip & gun as recommended it the spray gun

instruction manual.

c.

Flush the sprayer at the end of each work day, if the

material you are spraying is water-based, or if it could

harden in the sprayer overnight. See "Flushing". Use a

compatible solvent to ush, then ll the pump and hoses

with an oil based solvent such as mineral spirits.

For long term shutdown or storage, refer to the

STARTING UP

Avoiding Tip Clogs

Avoiding Tip Clogs

There is an easy way to keep the outside of the

tip clean from material build up:

lock the gun and submerge it into a small bucket

Page 12

To avoid possible serious body injury, always follow this procedure whenever the sprayer

spraying, or when you are instructed to relieve the pressure.

Engage the gun safety latch. Refer to the separate

instruction manual provided with your gun on its

4.

Turn Prime/Pressure Relief Valve (PR Valve) to the

open

open

body when in open position. In the closed position there is

only a very slight gap.

.

2.

Turn the unit off & unplug it from the electrical outlet.

3.

Disengage the gun safety latch and trigger the gun

to relieve residual uid pressure.

Hold metal part of the gun in

5.

Re-engage gun safety latch and

close Prime/Pressure Relief Valve.

splashing into the bucket while relieving pressure during Step 4.

Service Center.

PRESSURE RELIEF PROCEDURE

Keep the displacement pump packing nut/wet cup lubricated with Airlessco TSO (Throat Seal Oil) at all times. The

TSO helps protect the rod and the packings.

2.

Inspect the packing nut daily. Your pump has a patented Triple Life Packing System.

Packing life will be extended a

minimum of three times if the following "Packing Adjustment" procedure is followed:

not any tighter. Overtightening will damage the packings and reduce the packing life.

DAILY MAINTENANCE

Page 13

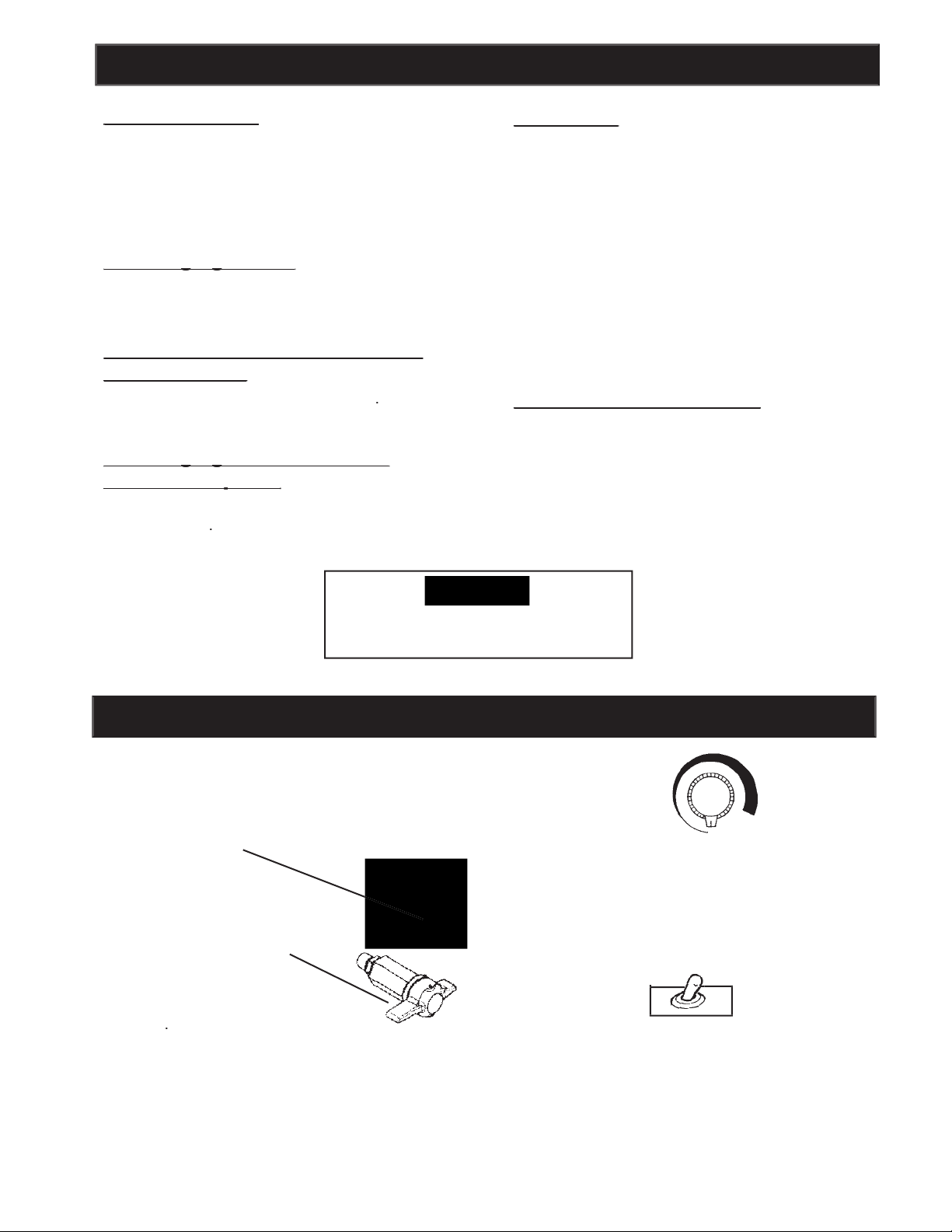

SPRAY GUN OPERATION

Tip Guard

Trig ger

Attach spray gun to airless unit and tighten t tings se cure ly.

or trigger lock)

The gun safety latch should always be set when the gun is

not being triggered.

Read all warnings and safety precautions sup plied with the

Be sure pressure relief procedure is followed before

2.

Lock gun safety latch.

3.

Insert REV-TIP™ cylinder into the REV-GUARD™

4.

5.

Insert O-Ring gasket on metal seat so it ts in the grooves.

Finger tighten REV-GUARD™ retaining nut onto the gun.

7.

Turn guard in the desired position.

8.

O-Ring Gasket

Reverse to

Guard Housing Assembly

TO REMOVE CLOGS FROM SPRAY TIP

Lock gun safety latch.

2.

Turn REV-TIP™ handle 180 de grees.

3.

Disengage trigger lock & trigger gun into pail.

4.

If the REV-TIP™ handle appears locked (resists

turning), loosen the retaining nut. The handle will

now turn easily.

5.

Engage gun safety latch & return handle to the

Immediately after the work is nished, ush the gun out with

a solvent. Brush pins with solvent and oil them lightly so

they will not collect dried paint.

To clean the lter, use a brush dipped in an appropri-

ate solvent. Change or clean lters at least once a day.

four hours of operation.

Gun Safety

Gun Safety

hose by following the "Pressure Relief Procedure." Secure

gun with the safety latch, take off guard, take out the tip,

use a needle or sharp pointed instrument to clean the tip.

The tungsten carbide is brittle and can chip.)

Part # 561-026

Part # 561-029

Part # 561-XXX

G Thread 7/8" 561-002

F Thread 11/16" 561-001

Page 14

Problem Cause Correction

Tip worn beyond use

Thin or Spotty Coverage (Holidays)

Thin Coverage in Center of Pattern

Tip size larger than pump specs

Tip ori ce partialy clogged

Tip damaged

surface

Valve seat and/or ball in gun head

damaged or worn

assembly

Tip Clogs Continually

Thouroughly strain paint before use

Thouroughly strain paint before use

*See “Tip Selection Guide” in this

Page 15

During use, especially with latex paint, high pres sure will

cause the ori ce to grow larger. This de stroys the pattern.

Replace tips before they become excessively worn. Worn

tips waste paint, cause overspray, make cut ting-in dif cult,

and decreases sprayer per formance.

Two tips having the same tip size, but different pat tern widths

will deliver the same amount of paint over a dif fer ent area

width makes it easy to spray in tight places

Thickness of the paint coat per stroke is de ter mined by spray

tip "fan width", rate of the spray gun move ment, and distance

to surface.

SPRAY TIP SELECTION

SPRAY TIP REPLACEMENT

SPRAY TIP SELECTION

minute can be sprayed through the tip. Do not use a tip

larger than the max i mum pump ow rate or capacity the

in gallons per minute (GPM).

and job needs. For light viscosities (thin paints), use a

larger tip size.

(water @ 2000psi, 138 bar)

(latex paint @ 2000psi,

*Pump will support tip worn to next larger size.

Water Flow Rate

2.15

2.54

2.96

3.90

4.98

6.17

6.81

Paint Flow Rate

(gal./min.)

2.20

2.50

3.33

4.24

5.26

5.83

Pump Minimum

2.0

2.2

Output

2.3

2.8

3.3

3.8

5.7

8.2

4-6

209

211

213

215

217

219

221

223

225

229

6-8

307

309

311

313

315

317

319

321

323

325

327

335

8-10

203-254

409

411

413

415

419

423

425

427

431

254-305

511

513

515

517

519

521

523

525

527

531

535

305-356

611

613

615

617

619

621

623

625

627

631

635

639

641

356-406

406-457

815

819

821

831

20-24

508-610

W23

W25

C = Coarse

Wood

Stain, Sealer

Wood

Vinyl, Acrylic, Latex

vinyl,oil-base

alkyd

Ceiling

Structural Steel

.

029

Orifice Size

Inches

4-6

212

214

6-8

312

314

8-10

203-254

Double Orifice

design for lower pressure airless

spraying when you need finer atomization for a smoother

finish on interior trim, cabinetry, shutters, and doors.

TM

REV-TIP

for Painting 561-XXX

SPRAY PAINTING TIP - ORIFICE SIZE

NEW

WIDE PATTERN

►

)

(

Inches

NEW!

REV-TIP

Page 16

ELECTRIC MOTOR MAINTENANCE

This motor is supplied with prelubricated ball bearings, lubricated for life of bearing.

2.

-

These need periodic inspection and replacement as wear indicates. Brushes for the Leeson motor

Motor (LP400/460) PN 331-778 have an initial length of 13/16" and must be replaced when worn to 1/4".

3.

TO CHANGE THE BRUSHES,

follow the procedures below:

Unplug the machine.

b.

Remove brush access plates at the rear of the motor.

c.

Loosen the screw holding the brush terminal and remove the brush lead.

Push the brush retainer clip in and remove.

Remove the worn brushes (one on each side of motor).

f.

Install new brushes in reverse order and replace plates.

properly.

46 *7

* LP690 & 810E come equipped with ttings

MANIFOLD FILTER - PN 111-200-99

FIGURE 10 PARTS LIST

ITEM # PART # DESCRIPTION

Page 17

FIELD TROUBLESHOOTING

Airleak due to:

below suction seat

assembly

Pressure set too low

Turn up pressure

Filter(s) are clogged

Clean or replace gun lter, inlet

lter and/or manifold lter

Outlet Valve fouled/worn

Prime/Pressure Relief valve

Clean or replace primve valve

bypassing

Packings and/or piston worn

Tighten packing nut

Repack unit

Blown spray tip

Replace spray tip

Packings and/or piston worn

Repack unit

Upper Seat worn

Replace upper seat

Blown fuse

Replace fuse

(pn. 331-256) - 4 Series

20A SlowBlow

(pn. 331-328) - 5&6 Series

Electrical failure

4 Series & 5-6 Series

Page 18

SERVICING THE FLUID PUMP

331-209

331-236

Fluid Pump Removal - Refer to Figure 11

1. Follow the Pressure Relief Procedure page 10.

2. Flush the material you are spraying out of the machine.

3. Remove the connecting rod shield (331-11

4. Move the piston rod (331-093) to its lowest position by

cycling pump slowly or by rotating the motor fan.

5. Disconnect the sensor (331-294-99) by holding it in

place with a 7/8” wrench and unscrewing the swivel

connector (100-003) with an 11/16” wrench.

DO NOT TURN THE SENSOR.

6. Remove the retaining ring (331-062) from the

connecting rod (331-038) and slide the sleeve (331-117)

down revealing the connecting rod pin (331-065).

7. Remove the suction tube assembly from the uid pump

by unscrewing the suction nut (331-034) with

the packing adjustment tool.

8. Using a 1/2” wrench unscrew the two bolts (100-318)

from the cover assembly 331-234). The uid pump

(331-209) will be hanging loosely at this point.

9. Remove the connecting rod pin (331-065) out of the

connecting rod (331-038), allowing the removal of the

uid pump (331-209) from the machine.

1).

Fluid Pump Reinstallation -

Refer to Figure 11 & 14

1. Loosen the packing nut and ensure that the piston rod

(331-093) is in its upper position in the uid pump

body. Slip the sleeve (331-117) & the

retaining ring (331-062) over the piston rod.

2. Push the piston rod up into the connecting rod (331-

038) & align the holes. Insert the connecting rod pin

(331-065) through the connecting rod & piston. Slip

the sleeve over the connecting rod pin and insert the

retaining ring into the groove on the connecting rod.

3. Push the two bolts (100-318) through the tube spacers

(331-074) & screw them into the cover assembly (331-

234). Using a 1/2” wrench, tighten the two bolts evenly

(alternating between them) until you reach 20 ft-lbs.

4. Reassemble the lower suction valve assembly by

placing the suction seat assembly: O-ring (106-011),

suction ball (331-030) and suction ball guide (331-029)

in the suction nut (331-034) and screw onto the uid

pump body.

5. Reconnect the sensor (331-294-99) to the uid pump

body. Hold the sensor with a 7/8” wrench while

tightening the swivel connector (100-003) with an

11/16” wrench.

DO NOT TURN THE SENSOR.

6. Start the machine and operate slowly to check the

piston rod for binding. Adjust the two bolts, holding the

uid pump body to the cover assembly, if necessary.

This will eliminate any binding.

7. Tighten the packing nut counter clockwise until

resistance is felt against the Belleville Springs, then go

3/4 of a turn more. Put ve drops of Airlessco Throat

Seal Oil into the packing nut.

8. Run the machine at full pressure for several minutes.

Release the pressure by following the Pressure Relief

Procedure & readjust the packing nut per step 7 above.

9. Install the connecting rod shield (331-111) so that the

small hole is in the upper right hand corner.

Page 19

GEAR AND PUMP ASSEMBLY

Do not operate

Servicing Gear Box Assembly

Servicing Gear Box Assembly

Remove uid pump as per "Fluid Pump Disconnect"

procedures.

2.

Remove frame from the gearbox by loosening the four

mounting screws.

3.

Refer to Figure 12. Separate cover assembly from box

by removing bolts from front of cover & back of box &

4.

Lay unit on its back and disassemble gearbox.

5.

Inspect bearings, Crosshead Assembly, Gearcrank & sleeve

bearing inside cover assembly for wear/damage. Replace

worn/damaged parts.

If gear grease needs replacing, replace with gear grease

7.

Part No. 105-331 BLUE XS™ ADVANCED RTV

8.

Reassemble in reverse order.

Can be ordered separately, but is included

with Motor Ass'y (Part No. 331-490, 331-068)

331-038

331-040

331-046

331-047

331-061

331-062

331-065

331-074

Tube Spacer (2)

331-088

331-111

331-117

331-209

331-234

331-236

331-406

331-407

331-408

331-061

Sleeve Bearing

331-103

Washers (2)

331-197

Screws (2)

prior to inserting into cover assembly.

2

FIGURE 10 PARTS LIST

ITEM # PART # DESCRIPTION

Page 20

Servicing the Piston Rod - Outlet Valve

331-196

331-195

Disconnect the Fluid Pump.

-Low Boy/Carry

331-292-Hi Boy

Suction Nut

331-034

2. Place piston holder (331-195) in a vise. Slide piston into

the holder & lock in place with a 3/8” dowel (331-196).

3. Use a 1/4” allen wrench to unscrew the outlet seat retainer

(331-314) from the piston.

4. Remove the outlet seat (331-026), O-ring (331-100) and

outlet ball (331-027).

5. Inspect outlet ball & seat for wear. Replace as necessary.

6. While piston is still locked in the holder, install parts

back into the piston in the following order:

ball, outlet seat and O-ring

Before reinstalling the outlet seat retainer, apply two drops of

Loctite No. 242 (blue) on the threads & torque to 20 ft-lbs.

* Available in LP tool kit PN 188-397

Servicing the Suction Assembly

Refer to Figure 14

1. Unthread and remove suction nut from the

2. Remove suction seat (331-409), O-ring (106-011), suction ball

(331-030) and suction retainer (331-029).

3. Clean all parts and inspect them for wear or damage, replacing

parts as needed.

4. Clean inside of the

5. Reassemble lower suction valve assembly by placing the

suction seat (331-409), O-ring (106-011), suction ball (331-030)

& suction ball guide (331-029) in the suction nut (331-034) &

screw onto uid pump body.

uid pump body.

uid pump body.

Page 21

of the leather packings (331-306) & place onto the male gland in

the following order with the inverted side down :

Follow step 2 above with your packings inverted side up.

Take the upper male gland (331-022) & place it rounded side up.

Take three upper polyethylene packings (331-023) & two leather

packings (331-307) & assemble with inverted side down ,

Unscrew & remove the packing nut (331-037).

2.

Push the piston rod (331-708) down through the packings

& out of the pump.

3.

Now push the packing removal tool (187-249) up through

the pump & remove from the top bringing packings, spacer

& springs along with it, leaving fluid body (331-011) empty.

Clean inside of fluid body (331-011).

5.

Disassemble all parts & clean for reassembly. Discard any

old packings.

6.

Lubricate leather packing in lightweight oil for 10 minutes

prior to reassembly.

Disassembly of the Outlet Vavle - Figure 13

Packing Replacement Procedures

Fluid Pump Removal - Refer to Figure 11

1. Follow the Pressure Relief Procedure above.

2. Flush material you are spraying out of the machine.

3. Remove the connecting rod shield (331-11

4. Move the piston rod (331-093) to its lowest position by

cycling pump slowly or by rotating the motor fan.

5. Disconnect the sensor (331-294-99) by holding it in place

with a 7/8” wrench & unscrewing the swivel connector

(100-003) with an 11/16” wrench.

DO NOT TURN THE SENSOR.

6. Remove the retaining ring (331-062) from the connecting

rod (331-038) and slide the sleeve (331-117) down

revealing the rod pin (331-065).

7. Remove the suction tube assembly from the uid pump

(331-708) by unscrewing the suction nut (331-034) with the

packing adjustment tool.

8. Using a 1/2” wrench unscrew the two bolts (100-318) from

the cover assembly 331-234). The uid pump (331-209)

will be hanging loosely at this point.

9. Remove the connecting rod pin (331-065) out of the

connecting rod (331-038), allowing the removal of the uid

pump (331-209) from the machine.

1. Place piston holder (331-195) in a vise. Slide piston into

the holder & lock in place with a 3/8” dowel.

2. Use a 1/4” allen wrench to unscrew the outlet seat retainer

(331-026) from the piston.

3. Remove the outlet seat (331-026), O-ring (331-100) and

outlet ball (331-027).

4. Inspect outlet ball & seat for wear. Replace as necessary

5. While piston is still locked in the holder, install parts back

into the piston in the following order:

ball, outlet seat and O-ring

Be

fore reinstalling the outlet seat support, apply two drops of Loctite

No. 242 (blue) on the threads & torque to 20 ft-lbs.

1).

.

REASSEMBLY - Figure 15 & 16

1. Take lower male gland (331-014) & place it down on

the at side.

2. Take three of the lower polyethylene packings (331-016) & two

polyethylene, leather, polyethylene, leather, polyethylene.

3. Take the female adaptor (331-305), which is inverted on both

sides, & place it on top of your assembled lower packings.

4.

5. Take the second lower male gland and place it on top of your

assembled packings with the rounded side down.

6. Take assembled glands & packings (13 pieces) & slide on to the

lower half of the piston.

7. Take the spacer (331-018) & slide over the top of the piston (it

doesn’t matter which direction it sits), falling onto lower packings.

8. Take three Belleville Springs (331-025) & slide over the top of

the piston in the following order:

* First spring, curve facing down

* Second spring, curve facing up

* Third spring, curve facing down

9.

10.

on to the male gland in the following order:

polyethylene, leather, polyethylene, leather, polyethylene.

11. Take upper female gland (331-021) & place on top of the assembled

upper packings with the inverted side down.

12. Take assembled upper glands & packings (7 pieces) & slide on

over the top of the piston, making sure inverted sides are down.

13. Take the packing holder (331-019) & replace the white O-ring

(106-009) & the black O-ring (106-010) with new ones from the

packing kit.

14. Slide the packing holder over the top of the upper packings

so they t inside.

15. Lubricate inside of the uid pump body & the outside of the

packings with a light weight oil.

16. Slide completed assembly into uid pump body (331-011).

*

To keep packings secured in correct position, hold the pump body

upside down & push the completed assembly upwards into the pump

body. Once placed inside, tilt pump body back up to keep all pieces in.

17. Tighten packing nut (331-037) onto the top of the uid pump

body & tighten until you feel slight resistance against the

Belleville Springs (331-025). Using the Packing Adjustment Tool

(189-211), tighten another 3/4 of a turn.

Fluid Pump Reinstallation - Figure 11 & 14

1. Loosen packing nut & ensure that the piston rod (331-093) is in

its upper position in the uid pump body (331-209). Slip the

sleeve (331-117) & the retaining ring (331-062) over the piston rod.

2. Push piston rod up into the connecting rod (331-038) & align the

holes. Insert the connecting rod pin (331-065) through the

connecting rod & piston. Slip the sleeve up over the connecting

rod pin & insert retaining ring into the groove on the connecting rod.

(

(

(

Page 22

Packing Replacement Procedures (Continued)

3. Push the two bolts (100-318) through the tube spacers

(331-074) & screw into the cover assembly (331-234).

Using a 1/2” wrench, tighten the two bolts evenly

(alternating between them) until you reach 20 ft-lbs.

4. Reassemble lower suction valve assembly by placing

the suction seat (331-409) O-ring (106-011), suction

ball (331-030) and suction ball guide (331-029) in the

suction nut (331-034) & screw onto the fl uid pump body.

5. Reconnect the sensor (331-294-99) to the fl uid pump

body. Hold sensor with a 7/8” wrench while tightening

the swivel connector (100-003) with an 11/16” wrench.

DO NOT TURN THE SENSOR.

6. Start the machine & operate slowly to check the piston

rod for binding. Adjust the bolts, holding the fl uid

pump body to the cover assembly, if necessary. This

will eliminate any binding.

7. Tighten packing nut counter clockwise until resistance

is felt against the Belleville Springs, then go 3/4 of a

turn more. Put fi ve drops of Airlessco Throat Seal Oil

into the packing nut.

8. Run the machine at full pressure for several minutes.

Release the pressure by following the Pressure Relief

Procedure & readjust the packing nut per step 7 above.

9. Install the connecting rod shield (331-111) so that the

small hole is in the upper right hand corner.

FIGURE 15

Viton O-Ring

*

106-010

PTFE O-Ring

*

*

106-010

*

*

*

*

*

*

*

†

†

*

†

*

Swivel

Connector

100-003

†

†

*

*

*

*

FIGURE 16

Included in Packing Kit

*

PN #331-210

† Included in Piston Replacement

PN #331-093

331-093

Low Boy/Carry

331-292 Hi Boy

Suction Nut

331-034

Assy

20

Page 23

21

CARRY FRAME MODELS

Tube Spacer (2)

Terminal Box

Page 24

22

LO-BOY MODELS

Wheel 10” (2)

Tube Spacer (2)

Terminal Box

331-074

331-315-99,

331-396-99,

331-068, 331-490, 331-069, 331-426

301-405

331-476

Page 25

23

HI-BOY MODELS

Wheel 10” (2)

Tube Spacer (2)

Terminal Box

331-490

FIGURE 19

Page 26

24

SUCTION ASSEMBLIES

- LoBoy & Carry Frames

- HiBoy Frame

4

6

2

(inc. strainer)

6

ITEM # PART # DESCRIPTION

O-Ring PTFE

FIGURE 21 PARTS LIST

ITEM # PART # DESCRIPTION

Page 27

25

the following calibrations must be per formed.

Place prime/pressure relief valve in the prime (open) position.

2.

3.

Remove the screws and lower the pressure control assembly.

4.

Ensure the jumper is on the "P-ZR" terminal.

Note:

pres ent ly in the unit, remove jumper from single terminal P-ZR and place on both terminals P-ZR. When Zero

5.

Turn machine "ON" and ensure it is not cycling.

If the yellow zero light on the electrical board is ON, use an insulated screwdriver to turn the "ZERO" trimpot

zero trimpot CW until "0000" is displayed.

7.

If the yellow light is OFF, turn the "Zero" trimpot clockwise, just until the light comes on and stop. Con rm

NOTE: If the yellow light remains constantly "ON", or "OFF" during this calibration, the sensor

is defective and should be replaced.

IMPORTANT:When calibration is complete, move jumper from both "PZ-R" terminals to single terminal

2. PRESSURE CALIBRATION

2.

Attach a 50', 1/4" airless hose, airless gun with 0.017 tip and a 5000 psi glycerin lled pressure gauge to the pump.

3.

Place the suction tube into a bucket of Coro-chek and water.

4.

Turn prime/pressure relief valve to the prime (open) position.

5.

Turn pressure control knob clockwise until machine starts to prime.

Place the prime/pressure relief valve in the pressure (closed) position.

7.

While watching pressure gauge, slowly adjust the pressure trimpot (clockwise to increase and counterclockwise

to decrease) until the maximum static pressure is 3000 psi, with the pressure control knob fully clockwise.

Trigger the gun several times to ensure pressure returns to 3000 psi.

this calibration.

2.

Turn pressure control knob up until system pressure is above 2500 psi (as indicated on glycerin lled pressure

gauge) and the ma chine is not cycling.

3.

Use an insulated screwdriver to adjust the Set trimpot. Turn trimpot CCW until it clicks, then adjust to match

pressure against pressure gauge reading.

4.

Move the pressure control knob to different settings and trigger the gun several times to ensure that the LCD

ELECTRICAL BOARD CALIBRATION

Page 28

26

ELECTRICAL BOARD CALIBRATION (CONTINUED)

4. PHASE LIMIT TRIMPOT CALIBRATION

Attach a 50', 1/4" airless hose, airless gun with .017 tip and a 5000 psi glycerin lled pressure gauge to the

pump.

2.

Place the suction tube into a bucket of Pump Conditioner and water.

3.

Turn pump ON and turn up pressure control until the machine starts to prime.

4.

Place the prime/pressure relief valve in the pressure (closed) position.

5.

Pressurize pump to 600 psi.

Trigger the gun several times noting the deadband (the amount of pressure drop before the pump rebuilds to

7.

If deadband is greater than 100 psi, adjust the low pressure voltage trimpot so that the deadband is less than

guidelines and may vary slightly from pump to pump.

8.

Reattach Pressure Control Assembly being careful not to pinch wires.

which are the closest to the "S2" connection. Also on the Revision E is a

Page 29

27

TROUBLESHOOTING - Machine does not start

STEPS (SEE FIGURE 22)

STEPS (SEE FIGURE 22)

STEP 1:

After making sure that the machine is plugged into the wall, verify that the

on-off switch is in the ON position and that the pressure control knob is turned all the

way to the right (clockwise for maximum pressure).

STEP 2:

Using your multi-meter, test the fuse for continuity or replace with a new

fuse. If the fuse reads good, move on to step three.

STEP 4:

Locate the L1 and L2 terminals on the board, and then using your multi-me-

ter check to make sure you have 110 volts AC across the two terminals (the cord wires

will still be attached). If there is no voltage at these leads, there is no power getting

to the machine. Check your power source (outlet, circuit breaker, extension cord, and

power cord). If you have AC voltage at the L1 and L2 terminals, go to step 5.

STEP 3:

Using a Phillips Head screwdriver, remove the four screws holding the

pressure control assembly. Locate the light on the board indicating there is power (it

will be red or green). If light is OFF proceed to step four. If light is ON go to step six.

Thermal Overload

Sensor

STEP 5:

Disconnect the two red motor leads (S1 & S2) and test for continuity between

them. No continuity means that the thermal coupler has opened due to excessive motor

heat. If the motor is still hot to the touch, allow it to cool and then retest. If the motor

is cool and there is not continuity on the red leads, contact your local Leeson repair

facility to repair/replace the thermal coupler. Continuity shows that the motor's thermal

coupler has not tripped. Proceed to step six.

STEP 6:

If everything checks out in steps one through ve and the power indicating

light is still out, replace the pressure control assembly.

STEP 7:

Remove the motor brush covers and turn the machine on. Set the potentiome-

ter (POT) at maximum pressure and check for DC voltage across both brush terminals.

You should read greater than 80 volts DC. IF YOU DO NOT HAVE DC VOLTAGE

GO TO STEP EIGHT. If you have DC voltage, turn the machine off and unplug it from

the wall. Check to make sure that the brushes are making good contact with the arma-

ture. Replace the brushes if they are less than 3/8" long. If the brushes are good, replace

the motor.

STEP 8:

Plug another sensor into the board and perform the zero calibration proce-

dure. If the machine starts to run, the sensor was bad. If there is no replacement sensor

available, use a multi-meter to test the resistance across the red and black wires of the

usually reads no continuity (open). If the sensor passes all the tests move to step nine.

STEP 9:

Plug another potentiometer (POT) into the control board. If the machine

lead (with the machine turned off) from the control board and test the resistance be-

tween the red and black wires (be sure to test at the plug). The resistance should read

between 8-12k ohms if it is outside of this range replace the POT.

STEP 10:

If you do not have DC voltage at the motor brushes and all of the compo-

nents check out ne in steps eight and nine, replace the pressure control assembly.

Page 30

28

ELECTRICAL SYSTEM

FIGURE 22

Jumper

Toggle Switch

Page 31

29

Unplug machine's power cord.

2.

Remove four screws from heatsink housing.

3.

Disconnect all leads from pressure control assembly.

4.

Reassemble in reverse order.

Remove the 4 screws heat sink and lower the pressure control assembly.

2.

Disconnect swivel from sensor by holding sensor with 7/8" wrench and loos en ing swivel with 11/16" wrench.

3.

Disconnect sensor lead from the board. Carefully pull sensor lead out of the terminal box and remove sensor.

4.

Reassemble in reverse order.

Lower pressure control assembly as described above.

2.

Disconnect potentiometer lead from pressure control assembly.

3.

Use a 1/16" allen wrench, loosen set screw in the potentiometer knob (Fig. 22,) and remove knob and spacer.

4.

Using a 1/2" wrench or deep socket, remove the nut from the potentiometer shaft assembly.

5.

Pull entire potentiometer assembly out of terminal box.

6.

Replace in reverse order.

Lower pressure control assembly as described above.

2.

Unscrew the four nuts (6/32") (Fig. 23, Item 5) and remove

LCD Display assembly (Fig. 23, Item 6).

3.

If unable to loosen the four nuts, hold them and unscrew

the four screws (Fig. 23, Item 1). Then remove the

LCD Display Assembly. If the display is removed in this

manner, the mylar label (Fig. 23, Item 2) must be replaced.

4.

Reassemble in reverse order, while making sure

that the four spacers (Fig. 23, Item 4) and the four

washers (Fig. 23, Item 7) are in place.

Tighten the four nuts handtight and seal with blue loctite.

DO NOT overtighten the nuts as this will damage the display.

Lower the pressure control assembly as described above.

2.

Disconnect the two wires on the switch.

3.

Use a 9/16" wrench to loosen the nut on the toggle switch shaft.

4.

Reassemble in reverse order.

Lower pressure control assembly as described above.

2.

Disconnect the two wires on the holder.

3.

Remove holder cover and fuse.

4.

Use 11/16" wrench to remove the nut from the holder shaft.

5.

Reassemble in reverse order.

REPLACEMENT OF ELECTRICAL COMPONENTS

4

6

Window

Washer (4)

ITEM # PART # DESCRIPTION

Always unplug the electrical cord before servicing machine.

FIGURE 24 PARTS LIST

Page 32

from gun and system!

Turn clockwise to increase

to decrease pressure.

STEP

Read safety rules! Read & understand all

warnings & safety rules before operating

equipment. Know how to lock the gun trigger

safety lock before operating the equipment.

Stir paint and if necessary strain paint using

a paint strainer bag to remove lumps.

STEP

Check gun/hose connections to make sure

they are tight.

cal outlet. Extension cord must be 3 wire, 12

gauge. Do not coil cord.

STEP

3A.

3B.

Turn the Prime-Pressure Relief Valve to

open position

open position

(wide gap between handle &

Turn toggle switch ON, and adjust to low

STEP

Wait about one minute until uid comes out

of the return tube (smaller diameter tube).

4B.

Turn the Prime-Pressure Relief Valve to

closed position.

closed position.

(slight gap between handle

and body)

CAUTION: THE UNIT IS NOW

STEP

Leave the Prime-Pressure Relief Valve

fully closed and very carefully unlock the guns

trigger safety lock.

5A.

Aim the gun 12” from test surface card-

Turn thepressure control knob clockwise to

enough to atomize the paint & give a full

5B.

Always keep the gun perpendicular to

the surface. Move the gun at a steady rate.

5C.

Overlap half the width of each paint stroke.

STEP

6A.

Release pressure when you stop spraying

& before servicing gun or machine or before

changing or cleaning gun tip by:

Lock the gun trigger safety.

2.

Turn toggle switch to OFF position and

3.

Release gun safety lock and trigger

gun to relieve residual pressure.

Turn Prime/PR Valve to open position.

5.

Relock gun safety latch.

6B.

Submerge gun in water (if using latex)

or thinner (oil-base) to prevent paint from

drying in the gun nozzle.

& tip and to prime the unit when in OPEN

When in the CLOSED position, there is

only a very slight gap between handle

& body. When the relief valve is

closed

the system is pressurized.

Handle as a

loaded rearm!

ON/OFF Toggle Switch

Turns the unit ON and OFF.

LP Series Electric Paint Sprayer

Always use low pressure in the cleaning process.

Always remove spray tip before cleaning–

AFTER

following the Pressure Relief Procedure!

TOOLS & EQUIPMENT NEEDED:

TOOLS & EQUIPMENT NEEDED:

Soft bristle brush, clean-up rags.

2.

8” crescent wrench for removing

gun tip & lter in gun handle.

3.

water if using latex, or mineral

spirits if using oil-based. (Second

STEP

gun and place in mineral spirits or water.

STEP

the bucket out through the return tube.

2B.

Wipe excess paint from suction tube.

2C.

of water or mineral spirits.

STEP

carefully.

3A.

Turn the Prime/PR Valve to the closed

IMPORTANT: Never use high

pressure for cleaning!

3B.

Trigger gun into paint bucket to allow

3C.

and trigger gun using VERY LOW

to metal contact for 3-4 minutes until

STEP

gun handle. Clean with water or mineral

spirits and soft brush and reassemble

suction and gun lter only.

STEP

5A.

with 1

gal. of water or prepared mineral spirits

and put suction tube into pail. Prime

Trigger gun to ll the hose & gun.

for storage. DO NOT DIS CHARGE. Turn

5B.

5C.

gun with spray tip and tip guard. After

you have disconnected sprayer from

electrical power, turn Prime/PR Valve to

the closed position for storage.

5.

Storage solution of Pump Conditioner

OR compatible paint thinner if using

oil-based paint.

Quick Reference Guide

OPERATION

CLEAN ING

Loading...

Loading...