Page 1

Operation/Repair/Parts

LP 400/500/600/700

Mustang 5100/8100

3A1185H

Airless Paint Sprayer

For application of architectural paints and coatings. For professional use only. Not

approved for use in European explosive atmosphere locations.

3000 psi (20.7 MPa, 207 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual. Save these instructions.

For model information, see page 2.

Related Manuals

Gun Manual

312363 - English

312364 - Spanish

312365 - French

EN

Page 2

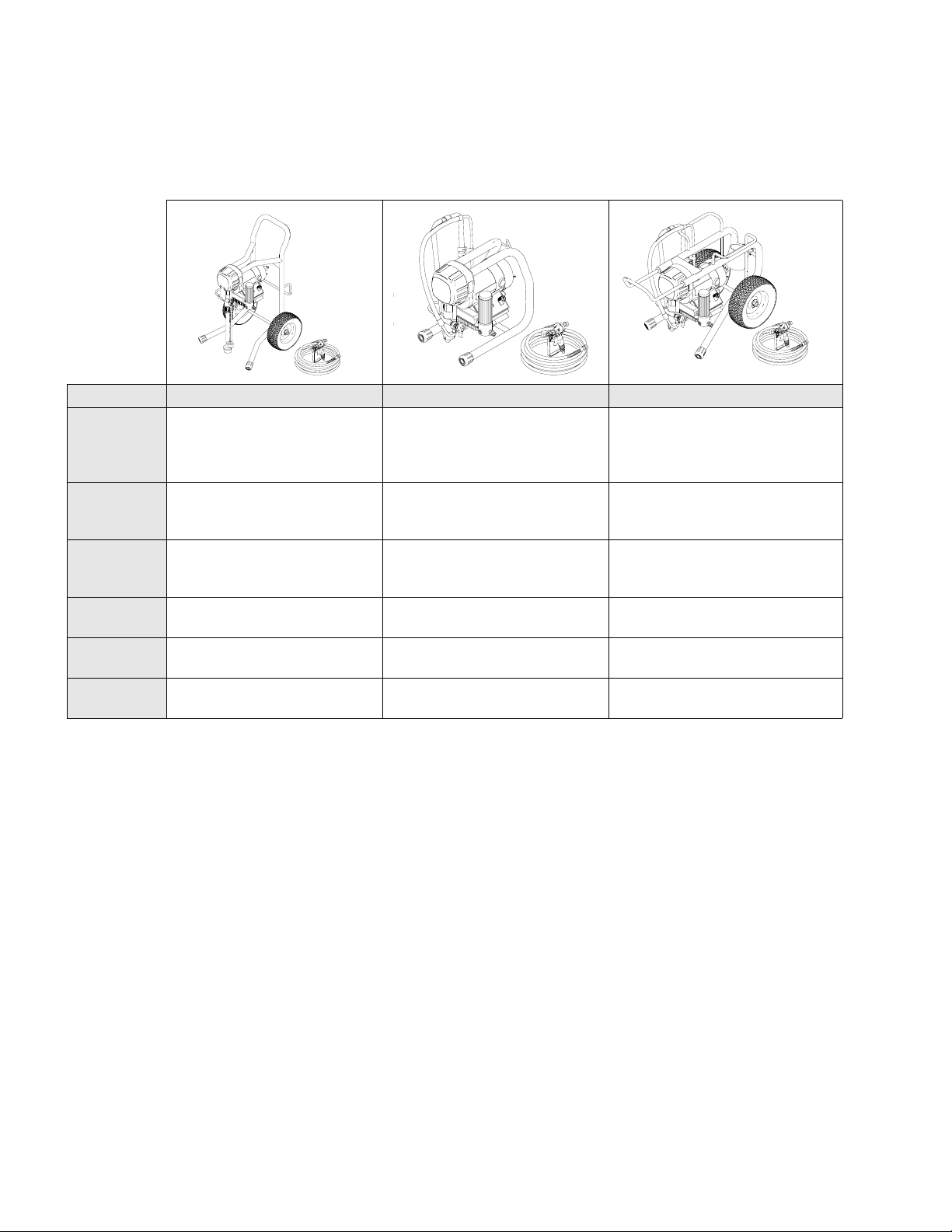

Models

Models

ti16112a

ti16111a

Vac HiBoy Stand LoBoy

120V

North America

240V

Europe

110V

UK

230V

Australia

230V Asia 17M002 LP600 - Series A 17M000 LP400 - Series A

230V CN 17M005 LP600 - Series A 17M003 LP400 - Series A

24F568 LP500 - Series B

24F571 LP600 - Series B

24F581 Mustang 5100 - Series B

24F583 Mustang 8100 - Series B

16M373 LP500 - Series A

16M374 LP600 - Series A

16M375 LP700 - Series A

16M380 LP500 - Series A

16M381 LP600 - Series A

16M382 LP700 - Series A

16M393 LP600 - Series A 16M389 LP400 - Series B

24F567 LP500 - Series C

24F579 Mustang 5100 - Series C

16M371 LP400 - Series A

16M372 LP500 - Series A

16M378 LP400 - Series A

16M379 LP500 - Series A

16M390 LP500 - Series B

17M001 LP500 - Series A

17M004 LP500 - Series A

ti16113a

24F569 LP500 - Series C

24F570 LP600 - Series C

16M391 LP500 - Series B

16M392 LP600 - Series B

2 3A1185H

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

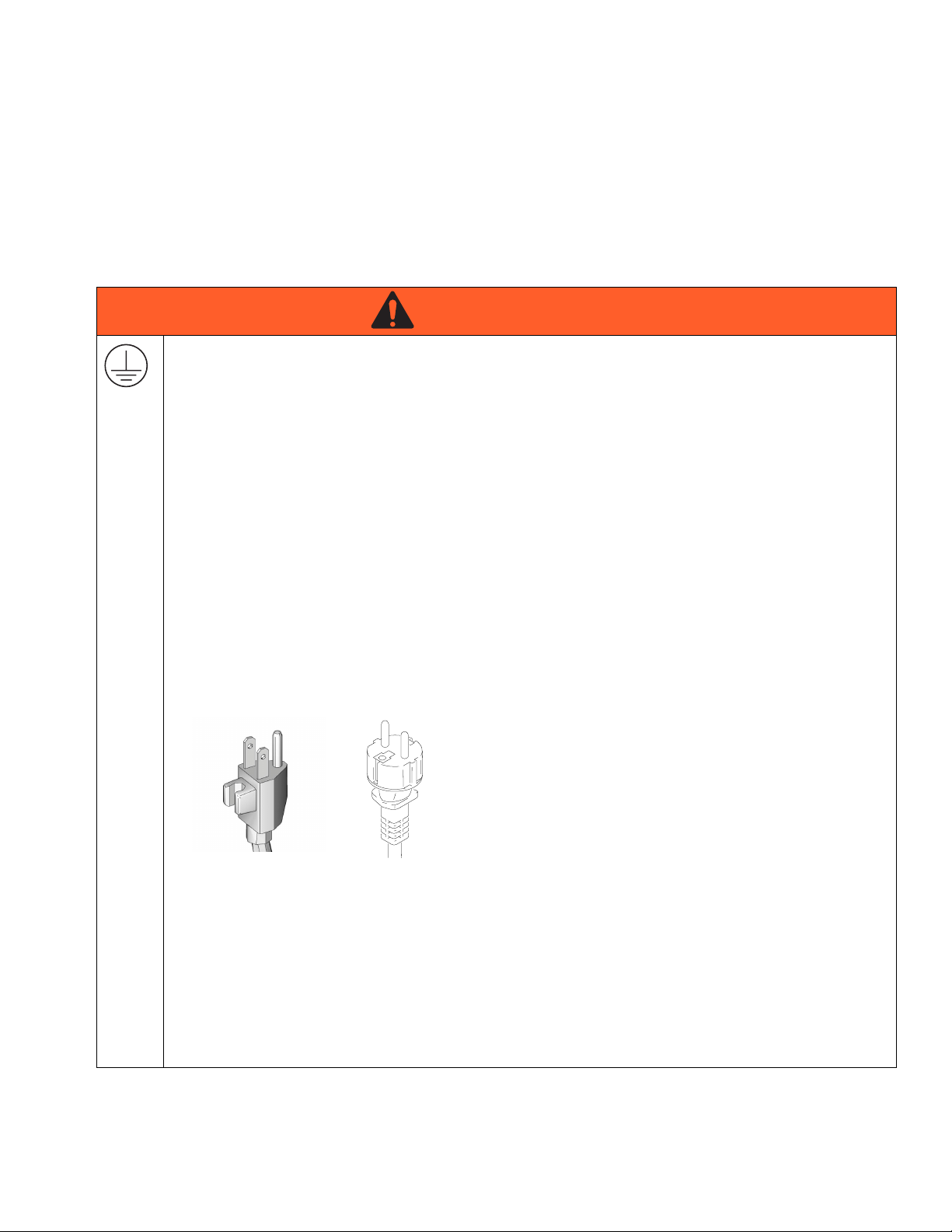

WARNING

WARNINGWARNINGWARNING

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to either

flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a

qualified electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding plug similar to the plug

illustrated in the figure below.

120V US

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that

accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

(2.5 mm

• An undersized cord results in a drop in line voltage and loss of power and overheating.

2

) minimum to carry the current that the product draws.

230V

3A1185H 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity

creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray

system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall

be properly grounded to protect against static discharge and sparks. Use Airlessco conductive or

grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep pump

assembly in a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents

manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or

cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

4 3A1185H

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with

any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Airlessco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure, page 8 for turning off the unit and relieving the

pressure before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure, page 8 for turning off the unit.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3000 psi. Use Airlessco replacement parts or accessories that are

rated a minimum of 3000 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure, page 8 for turning off the unit.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Airlessco.

• Do not use the hose as a strength member to pull or lift the equipment.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

3A1185H 5

Page 6

Warnings

WARNING

WARNINGWARNINGWARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure, page 8 and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

6 3A1185H

Page 7

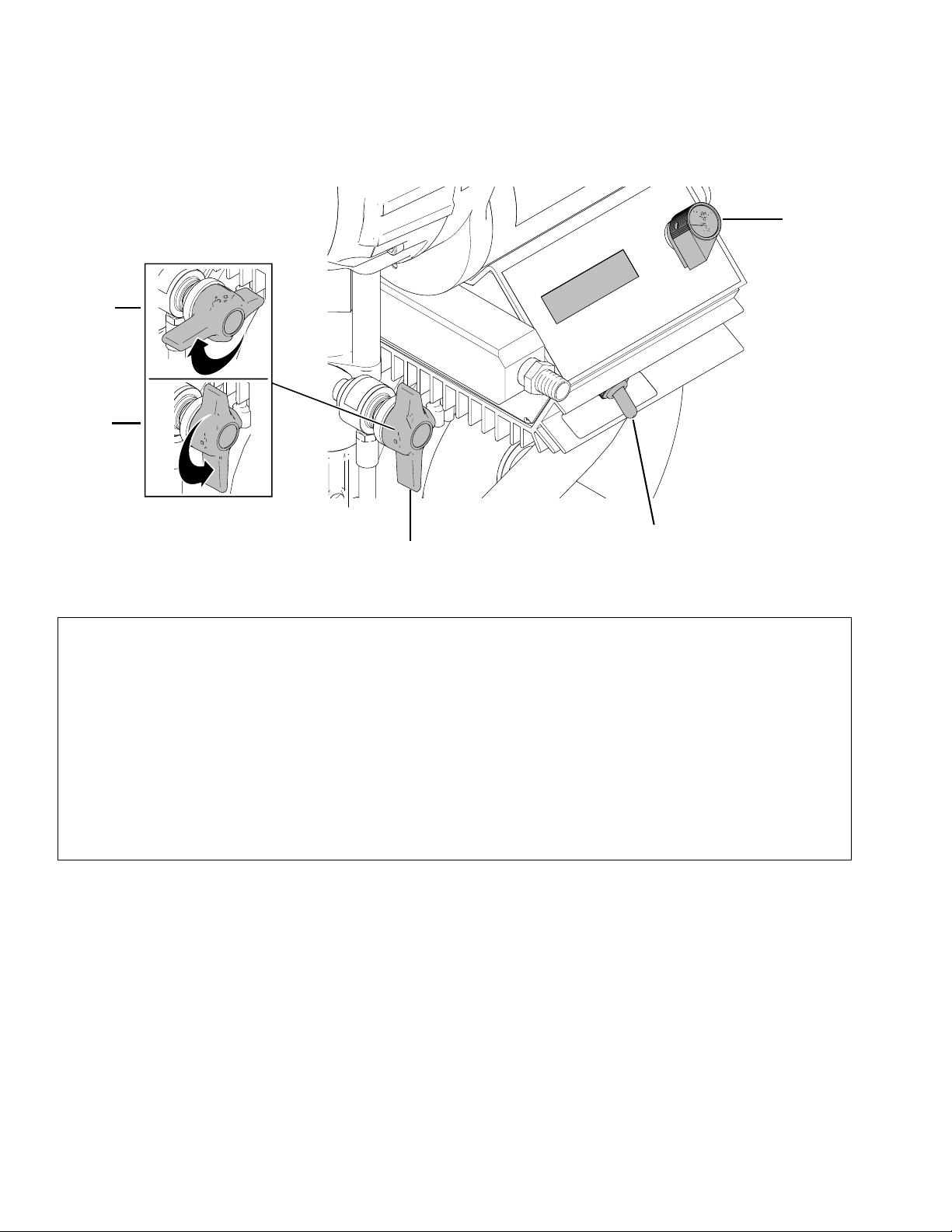

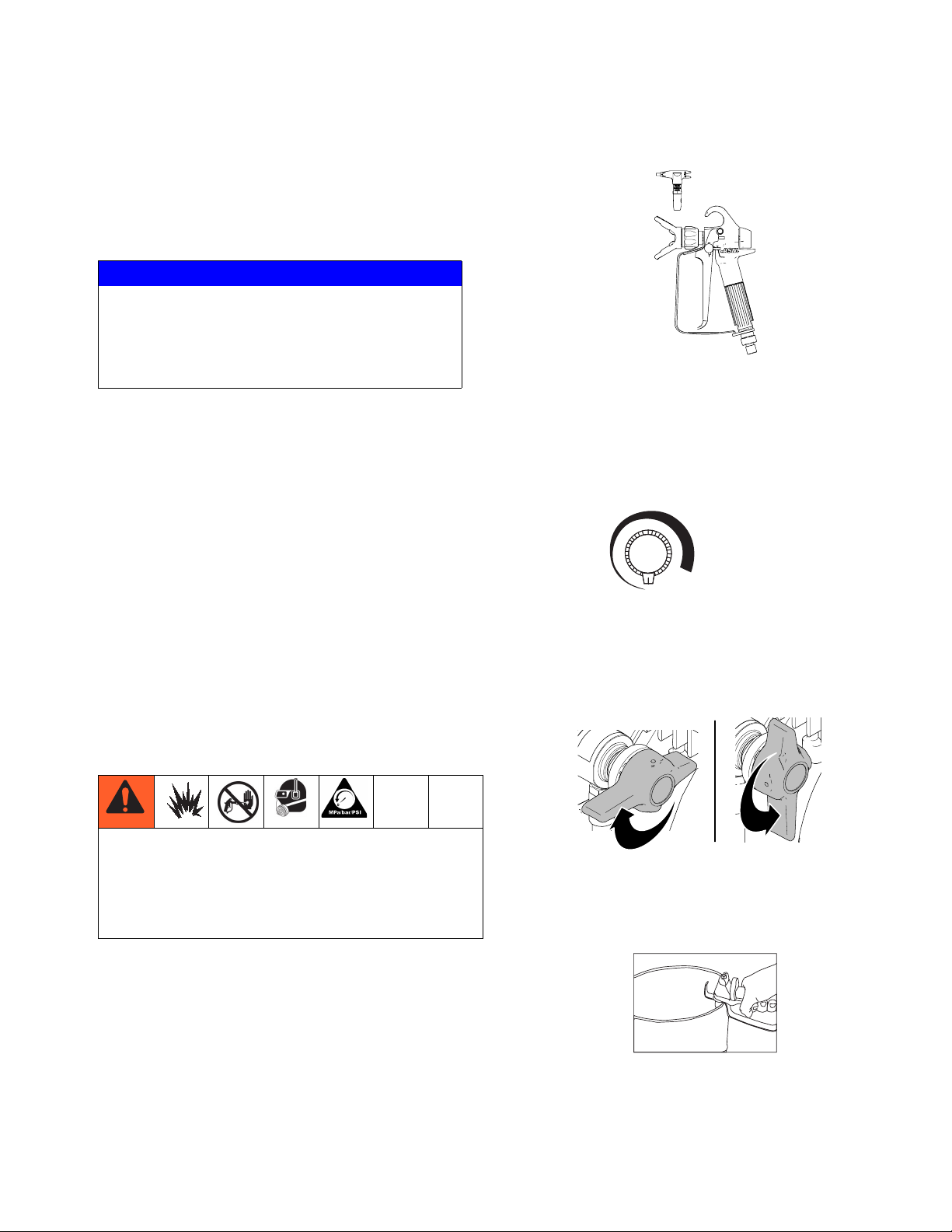

Component Identification

E

D

Component Identification

B

ti17301a

A

C

A Power switch Turns sprayer ON and OFF

B Pressure Control Knob Adjusts pressure. Turn clockwise to increase pressure and

counterclockwise to decrease pressure.

C Prime/Pressure Relief Valve Primes pump and relieves pressure from gun, hose and tip.

D Prime/Pressure Relief Valve Open

Position

E Prime/Pressure Relief Valve Closed

Position

Relieves pressure from gun, hose and tip and primes the unit

when in the open position. Valve is in open position when there

is a wider gap between valve handle and cam body.

Refer to Pressure Relief Procedure page 8.

Pressurizes system when closed. Valve is in closed position

when there is a slight gap between valve handle and cam body.

3A1185H 7

Page 8

Operation

Operation

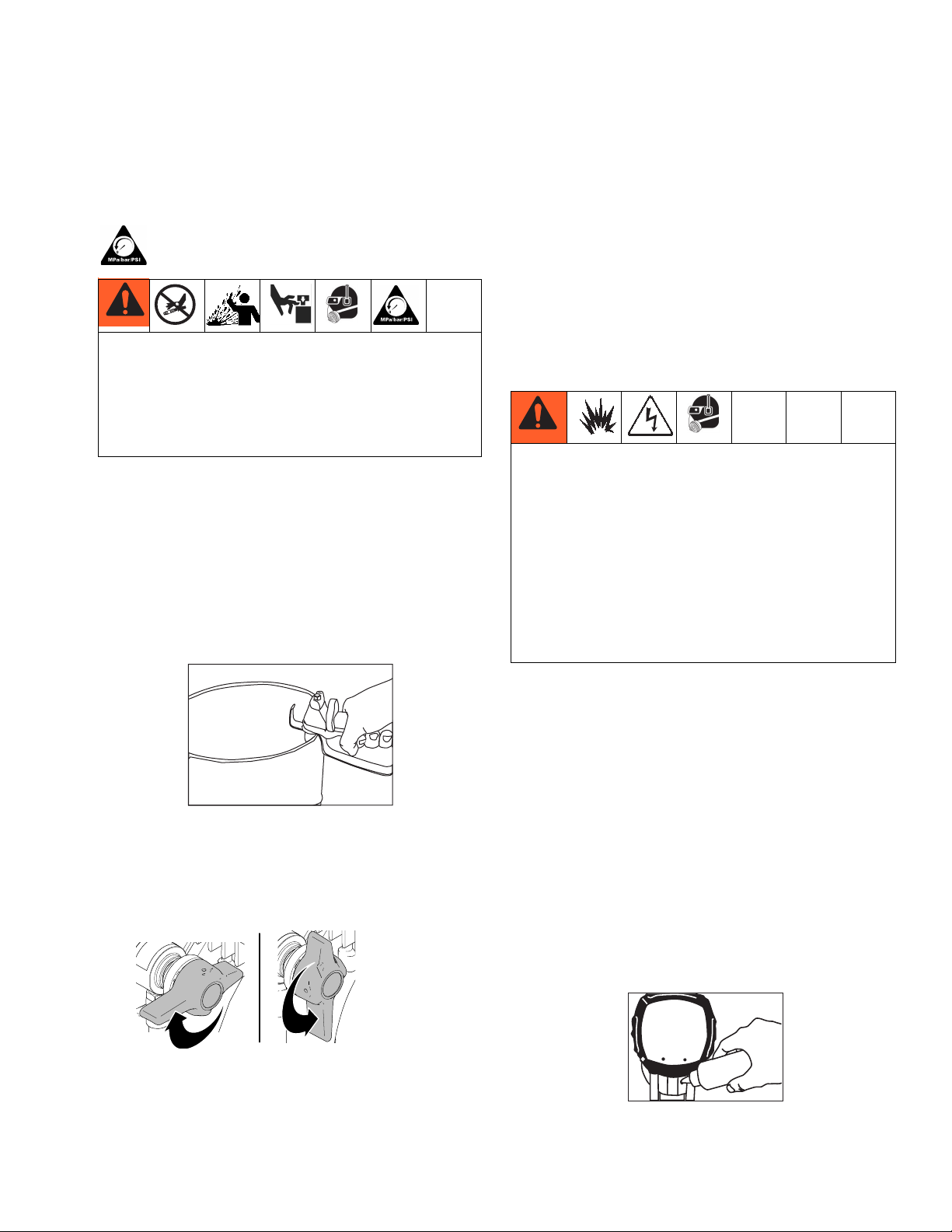

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Engage the gun trigger lock. Refer to the separate

instruction manual provided with gun for safety features and how to engage the trigger lock.

2. Turn the unit off.

3. Disengage the gun trigger lock and trigger the gun

to relieve residual fluid pressure.

Hold metal part of the gun in contact with

grounded metal pail. Use minimum pressure.

If the spray tip or hose is clogged, follow Steps 1

through 4 above. Expect paint to splash into the

bucket while relieving pressure during Step 3.

NOTE: If you suspect that pressure hasn’t been relieved

due to damaged Prime/Pressure Relief Valve, or other

reason, slowly loosen the tip nut or hose coupling to

relieve pressure.

Setup

• To reduce the risk of static sparking, fire or

explosion which can result in serious bodily injury

and property damage. Always ground the sprayer

and system components and the object being

sprayed, as instructed in the safety warning

section of this manual.

• Ensure proper electrical service and amperage

and that the outlet is properly grounded.

• For generator power, a minimum 7000 watt

generator with a voltage regulation must be used.

ti15989a

4. Re-engage gun trigger lock and turn Prime/Pressure Relief Valve (PR Valve) to the open (priming)

position to relieve residual pressure.

Closed

(Pressure)

There will be a wider gap between valve handle

and cam body when in open position. In the

closed position there is only a very slight gap.

NOTE: The valve handle can move both clockwise and

counter clockwise and can face different directions.

(Priming and Pressure Relief)

Open

ti17403a

Connect the hose and gun

1. Remove the plastic cap plug from the outlet and

screw a conductive or grounded 3000 psi spray

hose onto fluid outlet.

2. Connect an airless spray gun to the other end of the

hose. Do not install spray tip.

NOTE: Do not use thread sealer on swivel unions as

they are made to self seal.

Fill the Packing Nut/Wet Cup

1. Remove guard and cap.

2. Fill the Packing Nut/Wet Cup with 5 drops of Airlessco Throat Seal Oil (TSO) or Packing Seal fluid.

ti16049a

8 3A1185H

Page 9

Operation

Flush the Sprayer

1. Flush the sprayer. See Flushing Procedure on

page 9.

Prime and Flush Storage Fluid

NOTICE

The equipment was tested with lightweight oil,

which is left in the fluid passages to protect parts.

To avoid contaminating your fluid with oil, flush the

equipment with a compatible solvent before using

the equipment for the first time.

Before beginning a new spraying project you need to

prime the sprayer and flush the storage fluid out of the

sprayer.

Oil- or Water-based Materials

• When changing from water-based material to oil

based material, flush with soapy water and then

mineral spirits.

• When changing from oil based material to water

base material, flush with mineral spirits, followed by

soapy water, then a clean water flush.

• When flushing with solvents, ground pail and gun.

• Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

instruction manual provided with gun for safety features and how to engage the trigger lock.

ti16028a

2. Pour enough clean, compatible solvent into a large,

empty metal pail to fill the pump and hoses.

3. Place the suction tube into the pail or place the pail

under the pump.

4. Turn Pressure Control Knob to low.

High Pressure

ti16048a

5. Open the prime/pressure relief valve to the open “Priming Position”. This will allow an easy start.

Closed

(Pressure)

(Priming and Pressure Relief)

Open

Flushing

ti17403a

• To reduce the risk of static sparking, which can

cause fire or explosion, always hold a metal part of

the gun firmly against the metal pail when flushing.

This also reduces splashing.

• Always remove the spray tip before flushing.

1. Make sure the gun trigger lock is engaged and there

is no spray tip in the gun. Refer to the separate

3A1185H 9

6. Turn the engine ON/OFF switch to ON.

7. Point the gun into the metal pail and hold a metal

part of the gun firmly against the pail. Maintain firm

metal to metal contact between gun and container.

ti15989a

8. Disengage the gun trigger lock and squeeze the

trigger. At the same time, slowly turn the pressure

Page 10

Operation

control knob clockwise, just enough to move liquid

at low pressure.

9. Allow the pump to operate until clean solvent comes

from the gun.

10. Release the trigger and engage the gun trigger lock.

11. If you are going to start spraying, place the pump or

suction tube into the supply container. Release the

gun trigger lock and trigger the gun into another

empty, metal container, holding a metal part of the

gun firmly against the metal pail, forcing the solvent

from the pump and hose. When paint starts coming

from gun, turn pressure control knob to minimum

pressure, place prime/pressure relief valve in prime

(open) position and engage the gun trigger lock.

12. If you are going to store the sprayer, remove the

suction tube or pump from the solvent pail, force the

solvent from the pump and hose. Engage the gun

trigger lock. See Storage, page 11.

13. Whenever shutting down the sprayer, follow Pres-

sure Relief Procedure, page 8.

NOTICE

To prevent damage and freezing during storage,

never leave water in the fluid pump

Startup

Adjusting the Pressure

• To reduce the risk of injection, never hold your

hand, body, fingers or hand in a rag in front of the

spray tip when cleaning or checking for a cleared

tip. Always point the gun toward the ground or into

a waste container when checking to see if the tip is

cleared or when using a self cleaning tip.

• When you spray into the paint bucket, always use

the lowest spray pressure and maintain firm metal

to metal contact between the gun and container.

• To stop the unit in an emergency, turn the engine

off. Then relieve the fluid pressure in the pump and

hose. See Pressure Relief Procedure, page 8

When adjusting the pressure, turn the Pressure Control

Knob clockwise to increase pressure and counterclockwise to decrease pressure. Always use the lowest pressure necessary to completely atomize the material. If

more coverage is needed, use a larger tip rather than

increasing the pressure.

NOTE: Operating the sprayer at higher pressure than

needed wastes material, causes early tip wear, and

shortens sprayer life.

1. Prepare the material according to the material manufacturer’s recommendations.

2. Place the suction tube into the material container.

3. Start the sprayer.

a. Prime/PR Valve must be “OPEN” in the prim-

ing position.

b. After ensuring the gun trigger lock is engaged,

attach tip and safety guard.

c. Turn the engine ON/OFF switch to the “ON”

position.

d. Turn the Pressure Control Knob clockwise to

prime the pump.

e. After the pump is primed, turn the Prime/PR

Valve to the “CLOSED” position.

f. Turn Pressure Control Knob to the desired

spray pressure.

g. Disengage the gun trigger lock to begin spray-

ing.

NOTE: Check the spray pattern. The tip size and angle

determines the pattern width and flow rate.

10 3A1185H

Page 11

Maintenance

Shutdown

1. Relieve Pressure, page 8.

2. Clean the tip and gun as recommended in the separate Gun Manual supplied with the gun.

3. If spraying water-based material or a material that

could harden in the sprayer overnight, flush the

sprayer after use. See Flushing, page 9.

Storage

Short Term

1. Flush sprayer with compatible solvent before storing, then fill the pump and hoses with an oil based

solvent such as mineral spirits.

• For oil base paint: flush with mineral spirits

• For water-base paint: flush with water, then min-

eral spirits and leave the pump, hose and gun

filled with mineral spirits.

Long Term

For longer storage, use Graco Pump Armor or mineral

spirits. Shut off sprayer, Relieve Pressure, page 8, and

make sure prime/pressure relief valve is left open.

Electric Motor Maintenance

Lubrication

The motor is supplied with pre-lubricated ball bearings,

lubricated for the life of the bearing.

Motor Brushes

Motor brushes need periodic inspection and replacement as wear indicates. Standard brushes have an initial length of 1” and should be replaced when they are

worn to a length of 1/2”. Brush wear is greatly influenced

by individual application and it is recommended that

brush wear be checked at early intervals of operation in

order to determine future required inspection.

To change the brushes:

1. Unplug the machine.

2. Remove the cover over the motor, if applicable.

3. Open the two covers at the rear of the motor.

4. Disconnect the brush wire.

5. Pull out the wire.

6. Push the brush retainer clip in and withdraw.

7. Remove the worn brushes.

Start Up After Storage

Before using water-base paint, flush sprayer with soapy

water and then a clean water flush. When using oil-base

paint, flush out the mineral spirits with the material to be

sprayed.

NOTE: Always store unit indoors.

Maintenance

Daily Maintenance

1. Keep the displacement pump packing nut/wet cup

lubricated with Airlessco TSO (Throat Seal Oil) at all

times. The TSO helps protect the rod and packings.

2. Inspect the packing nut daily. If seepage of paint

into the packing nut and/or movement of the piston

upward is found (while not spraying), the packing

nut should be tightened just enough to stop leakage.

Overtightening will damage the packings and

reduce the packing life.

8. Install new brushes in the reverse order.

To increase brush life, new brushes (Part #331780)

need to have a run in period. After changing brushes,

set the machine for spraying. With a bucket of Pump

Conditioner and water, a 50’ 1/4” airless hose, airless

gun and tip on unit, open the prime/pressure relief valve

and switch on. The pump will now prime. With pump

running in the prime mode, turn the pressure control

knob to high pressure. (The pump has to cycle fast with

no pressure in the pump). Run the pump for 20 minutes

and the brushes will be run in.

Brush Kit

331780

ti16051a

3A1185H 11

Page 12

Maintenance

Servicing the Fluid Pump

Fluid Pump Disconnect

1. Relieve Pressure, page 8.

2. Flush the material you are spraying out of the

machine.

3. Remove the connecting rod shield (12).

4. Move the piston rod (10) to its lowest position by

cycling pump slowly.

5. Turn off the motor and disconnect power from unit.

6. Disconnect fluid tube (17) from pump body.

7. Remove the retaining ring (4) from the connecting

rod (2) and slide the sleeve (3) down revealing the

connecting rod pin (1).

8. Remove the suction tube assembly from the fluid

pump (9) by unscrewing the suction nut (7) with the

packing adjustment tool. (865008).

9. Using a 1/2” wrench, unscrew the two bolts (8) from

the cover assembly (14). The fluid pump (9) will be

hanging loosely at this point.

5. Reconnect the Fluid Tube (17) to the fluid pump

body.

6. Start the machine and operate slowly to check the

piston rod (10) for binding. Adjust the two bolts (8),

holding the fluid pump body to the cover assembly,

if necessary. This will eliminate any binding.

7. Tighten packing nut clockwise until resistance is felt

against the Belleville Springs, go 3/4 of a turn more.

Put five drops of Airlessco Throat Seal Oil in the

packing nut.

8. Run the machine at full pressure for several minutes. Release the pressure by following the Pres-

sure Relief Procedure, page 8, and readjust the

packing nut per step 7 above.

9. Install the connection rod shield (12) so the small

hole is in the upper right hand corner.

14

10. Remove the connecting rod pin (1) out of the connecting rod (2), allowing the removal of the fluid

pump (9) from the machine.

Fluid Pump Reinstall

1. Loosen the packing nut and ensure that the piston

rod (10) is in its upper position in the fluid pump

body, snap cap onto packing nut and slip the sleeve

(3) and the retaining ring (4) over the piston rod

(10).

2. Push the piston rod (10) up into the connecting rod

(2) and align the holes. Insert the connecting rod pin

(1) through the connecting rod (2) and piston. Slip

the sleeve (3) up over the connecting rod pin (1) and

insert the retaining ring (4) into the groove on the

connecting rod (2).

3. Push the two bolts (8) through the tube spacers (11)

and screw them into the cover assembly. Using a

1/2” wrench, tighten the two bolts (8) evenly (alternating between them) until you reach 20 ft-lbs

(27.12 N.m).

4. Reassemble lower suction valve assembly by placing the suction seat, O-ring, suction ball and suction

ball guide in the suction nut (7) and screw onto fluid

pump body.

17

2

1

12

3

11

4

5

10

9

7

8

ti16053b

12 3A1185H

Page 13

Maintenance

Servicing the Inlet Valve- Hi-Boy

1. Un-thread and remove suction nut from the fluid

pump body (8).

2. Remove suction seat (12), O-ring (11), suction ball

(10), and ball guide (9).

3. Clean all parts and inspect them for wear or damage, replacing parts as needed.

4. Clean inside of the fluid pump body (8).

5. Reassemble lower suction valve assembly by placing the suction seat (12), O-ring (11), suction ball

(10) and suction ball guide (9) in the suction nut (13)

and screw onto fluid pump body (8).

8

159

160

157

158

9

10

11

12

13

ti16115b

Servicing the Inlet Valve- Lo-Boy

1. Un-thread and remove suction nut from the fluid

pump body (8).

3. Push the piston rod down through the packings and

out of the pump.

4. Now push the packing removal tool up through the

pump and remove from the top bringing packings,

spacer and springs along with it, leaving fluid body

empty.

Make sure all old packings and glands have been

removed from fluid pump.

5. Clean inside of fluid body.

6. Disassemble all parts and clean for reassembly.

Discard any old packings.

7. Lubricate leather packing in lightweight oil for 10

minutes prior to reassembly.

Reassembly of the Fluid Pump

1. Place lower male gland(1) down on the flat side.

2. Take three of the lower polyethylene packings (2)

and two of the leather packings (23) and place onto

the male gland (1), with the inverted side down, in

the following order:

• Polyethylene

• Leather

• Polyethylene

• Leather

• Polyethylene

3. Take the female adaptor (3), which is inverted on

both sides, and place it on top of your assembled

lower packings.

2. Remove O-ring (158), suction seat assembly (157),

O-ring (159) and backup (160).

3. Clean all parts and inside fluid body (8).

4. Reassemble inlet valve with O-ring (159), backup

ring (160) and O-ring (158).

5. Tighten suction nut using packing adjustment tool

(865008).

4. Follow step 2 with your packings inverted side up.

5. Take the second lower male gland (1) and place it

on top of your assembled packings with rounded

side down.

6. Take assembled glands and packings (13 pieces)

and slide onto the lower half of the piston (14).

7. Take the spacer (15) and slide over the top of the

piston (14).

Packing Replacement Procedures

Disassembly of the Fluid Pump

8. Take three spring washers (16) and slide over the

top of the piston (14) in the following order:

• First spring - curve facing up

• Second spring - curve facing down

• Third spring - curve facing up

1. Disconnect the Fluid Pump, page 12.

9. Take the upper male gland (17) and place it

2. Unscrew and remove the packing nut, with wet cup

rounded side up.

cap.

3A1185H 13

Page 14

Maintenance

10. Take three upper polyethylene packings (18) and

two leather packings (22) and assemble with

inverted side down, on to the male gland (17) in the

following order:

• Polyethylene

• Leather

• Polyethylene

• Leather

• Polyethylene

11. Take upper female gland (19) and place on top of

assembled upper packings with the inverted side

down.

12. Take assembled upper glands and packings (7

pieces) and slide on over the top of the piston (14),

making sure inverted sides are down.

13. Take the packing holder (20) and replace the white

O-ring (24) and the black O-ring (25) with new ones

from the packing kit.

14. Slide the packing holder (20) over the top fo the

upper packings so they fit inside.

15. Lubricate inside of the fluid pump body (4) and the

outside of the packings with a light weight oil.

16. Slide assembly into fluid pump body.

NOTE: To keep packings secured in correct position,

hold the pump body upside down and push the completed assembly upwards into the pump body. Once

placed inside, tilt pump body back up to keep all pieces

in.

18. Reinstall Fluid Pump, page 12.

26

21

20

25

24

19

181818

17

161616

15

14

13

11

12

10

23232323

2222

5

6

7

8

9

1

2

22

3

222

1

4

159

160

157

158

17. Tighten packing nut (21) onto the top of the fluid

pump body and tighten until you feel slight resistance against the Belleville Springs (16). Using the

ti16056b

Packing Adjustment Tool, tighten another 3/4 of a

turn.

14 3A1185H

Page 15

Maintenance

Gear and Pump Assembly

Servicing Gear box Assembly

1. Remove fluid pump. See Fluid Pump Disconnect,

page 12.

2. Remove frame from the gearbox by loosening the

four mounting screws.

3. Separate cover assembly (13) from box by removing bolts (1) from front of cover and back of box and

shoulder bolts (2) from front of cover and back of

box.

4. Lay unit on its back and disassemble gearbox.

5. Inspect bearings (14, 17), Crosshead Assembly

(15), Gearcrank (16) and sleeve bearing (10) inside

cover assembly (15) for wear/damage. Replace

worn/damaged parts.

6. If gear grease needs replacing, replace with gear

grease (Part No. 114819).

7. Clean mating surfaces of cover and box thoroughly.

Apply Loctite

bell.

8. Reassemble in reverse order.

®

518 on half the bottom surface of end

Replacement of Electrical Components

Always unplug the electrical cord before servicing the

machine.

NOTE: Anytime the pressure control assembly, sensor,

or both are replaced, perform the calibrations.

Pressure Control Assembly (Electrical

Control Board)

1. Unplug machine’s power cord.

2. Remove six screws heatsink housing.

3. Disconnect all leads from pressure control assembly.

4. Reassemble in reverse order.

NOTICE

Unit will not operate if wires are disconnected or

pinched. Upon reassembly, ensure all wires are

connected and not pinched.

1

2

17

16

13

2

1

12

14

11

15

10

8

4

5

6

ti22326a

Sensor

1. Remove the four screws, heatsink, and lower the

pressure control assembly.

2. Disconnect sensor lead from the board.

3. Unscrew sensor by holding sensor with 3/4” wrench.

4. Reassemble in reverse order.

NOTICE

Unit will not operate if wires are disconnected or

pinched. Upon reassembly, ensure all wires are

connected and not pinched.

Potentiometer

1. Lower pressure control assembly as described

above.

2. Disconnect potentiometer lead from pressure control assembly.

3. Use a 1/16” allen wrench, loosen set screw in the

poteniometer knob and remove knob and spacer.

4. Using a 1/2” wrench or deep socket, remove the nut

from the potentiometer shaft assembly.

3A1185H 15

Page 16

Maintenance

5. Pull entire potentiometer assembly out of the terminal box.

6. Replace in reverse order.

NOTICE

Unit will not operate if wires are disconnected or

pinched. Upon reassembly, ensure all wires are

connected and not pinched.

On-Off Toggle Switch

1. Lower the pressure control assembly as described

above.

2. Disconnect the two wires on the toggle switch.

3. Use a 9/16” wrench to loosen the nut on the toggle

switch shaft.

4. Reassemble in reverse order.

NOTICE

Unit will not operate if wires are disconnected or

pinched. Upon reassembly, ensure all wires are

connected and not pinched.

Liquid Crystal Display (LCD)

1. Lower pressure control assembly as described

above.

2. Unscrew the two nuts (M3) and remove LCD Display assembly.

3. If unable to loosen the two nuts, hold them and

unscrew the two screws. Then remove the LCD Display Assembly.

4. Reassemble in reverse order, while making sure

that the two spacers and the two washers are in

place. Tighten the two nuts handtight and seal with

blue loctite. Do not overtighten the nuts as this will

damage the display.

NOTICE

Unit will not operate if wires are disconnected or

pinched. Upon reassembly, ensure all wires are

connected and not pinched.

16 3A1185H

Page 17

Troubleshooting

Problem Cause Solution

Unit doesn’t prime Airleak due to loose suction nut Tighten suction nut.

Airleak due to worn o-rings Replace o-ring (108526) on suction seat and

o-ring (867370) below suction seat.

Troubleshooting

Airleak due to hole in suction

hose

Stuck or fouled balls Service inlet and outlet valves.

Unit primes but has poor or no

pressure

Unit does not maintain good

spraying pressure

Unit does not run Blown fuse Replace fuse 20A Slow Blow (331328).

Machine does not start Control Settings Make sure machine is plugged into the wall.

Pressure set too low Turn up pressure.

Filter(s) are clogged Clean or replace gun filter, inlet filter, and/or

Outlet valve fouled/worn. Service outlet valve.

Prime/pressure relief valve

bypassing

Packings and/or piston worn Tighten packing nut, repack unit.

Blown spray tip Replace spray tip.

Packings and/or pistons worn Repack unit.

Upper seat worn Replace upper seat.

Replace suction hose.

manifold filter.

Clean or replace prime/pressure relief valve

(866428).

Verify the on-off switch is in the ON position

and the pressure control knob is turned all the

way to the right (clockwise for maximum pressure).

Pressure Control Assembly

(Board)

3A1185H 17

If the power indicating light is still out after

checking the control settings and power

source, replace the pressure control assembly.

Page 18

Troubleshooting

Problem Cause Solution

Motor Remove the motor brush covers and turn the

machine ON. Set the potentiometer (POT) at

maximum pressure and check for DC voltage

across both brush terminals. It should read

greater than 80 volts DC.

If you have DC voltage, turn the machine off

and unplug it from the wall. Check to make

sure the brushes are making good contact

with the armature. Replace the brushes if they

are less than 1/2” long. If the brushes are

good, replace the motor.

If you do not have DC voltage, see Sensor.

Sensor Plug another sensor board into the board and

perform the zero calibration procedure. If the

machine starts to run, the sensor is bad. If

there is no replacement sensor available, use

a multi-meter to test the resistance across the

red and black wires of the sensor (be sure to

test the plug). You should read 1.5 - 3.5k

ohms. A faulty sensor usually reads no continuity (open).

Pressure Control Knob (Potentiometer)

If the sensor passes all the tests, see Pressure Control Knob (Potentiometer).

Plug another potentiometer (POT) into the

control board. If the machine starts, the old

POT is bad.

When a replacement POT is not available,

remove the POT lead (with the machine

turned off) from the control board and test the

resistance between the red and black wires

(be sure to test at the plug). The resistance

should read between 8-12k ohms. If it is outside of this range replace the POT.

If there is DC voltage at the motor brushes

and the sensor and pressure control knob are

functioning, replace the pressure control

assembly.

18 3A1185H

Page 19

Pressure Control Repair

Motor Control Board Diagnostics

Relieve pressure and unplug sprayer before

servicing control board. See Pressure Relief

Procedure, page 8.

NOTE: Keep a new transducer on hand to use for test.

NOTICE

Do not allow sprayer to develop fluid pressure without transducer installed. Leave prime/pressure

relief valve open if test transducer is used.

LED

BLINKS

SPRAYER OPERATION INDICATES WHAT TO DO

Troubleshooting

1. For sprayers with digital display, see Digital Display Messages, page 20

2. Remove four screws and cover.

3. Turn ON/OFF switch ON.

4. Observe LED operation and reference following

table:

Once Sprayer runs Normal operation Do nothing

Two times

repeatedly

Three times

repeatedly

Four times

repeatedly

Five times

repeatedly

Six times

repeatedly

Sprayer shuts down and

LED continues to blink two

times repeatedly

Sprayer shuts down and

LED continues to blink four

times repeatedly.

Sprayer shuts down and

LED continues to blink four

times repeatedly.

Sprayer does not start or

shuts down and LED continues to blink five times

repeatedly

Sprayer shuts down and

LED blinks six times

repeatedly

Run away pressure. Pressure

greater than 4500 psi (310 bar,

31 MPa) or damaged pressure

transducer.

Pressure transducer is faulty or

missing

Line voltage is too high Check for voltage supply prob-

Motor fault Check for locked rotor, shorted

Motor is too hot or there is a

fault in the motor thermal

device

Replace motor control board or

pressure transducer.

Check transducer connection.

Open prime/pressure relief valve.

Substitute new transducer for

transducer in sprayer. If sprayer

runs, replace transducer.

lems

wiring or disconnected motor.

Repair or replace failed parts.

Allow sprayer to cool. If sprayer

runs correctly when cool, check

motor fan function and air flow.

Keep sprayer in cool location. If

sprayer does not run when cool

and continues to blink 6 times,

replace motor.

Eight times

repeatedly

3A1185H 19

Sprayer stops or does not

run

High input voltage Check power source for correct

voltage

Page 20

Troubleshooting

Digital Display Messages (Series B)

No display does not mean that sprayer is not

pressurized. Relieve pressure before repair. See

Pressure Relief Procedure, page 8

DISPLAY SPRAYER OPERATION INDICATION ACTION

No Display Sprayer stops. Power is

not applied. Sprayer may

be pressurized.

Sprayer is pressurized.

Power is applied. (Pressure varies with tip size

and pressure control setting.)

Sprayer may continue to

run. Power is applied.

Sprayer stops. Power is

applied.

Sprayer stops. Power is

applied.

Sprayer does not start or

stops. Power is applied.

Loss of power Check power source. Relieve

pressure before repair or disassembly.

Normal operation Spray

Pressure greater than 4500 psi

(310 bar, 31 MPa) or pressure

transducer faulty

Pressure transducer faulty, bad

connection or broken wire.

Line voltage too high Check for voltage supply problem

Motor fault / High Current Check for locked rotor, shorted

Replace pressure control board or

pressure transducer

Check transducer connection.

Open prime/pressure relief valve.

Substitute new transducer for

transducer in sprayer. If sprayer

runs, replace transducer.

wiring or disconnected motor,

frozen or stuck pump. Repair or

replace failed parts.

Sprayer stops. Power is

applied.

Sprayer stops or does not

run.

Power is applied. Pressure less than 200 psi (14

20 3A1185H

Motor is too hot Allow sprayer to cool. If sprayer

runs correctly when cool, check

motor fan function and air flow.

Keep sprayer in cool location. If

sprayer does not run when cool

and continues to blink 6 times,

replace motor.

Low input voltage Check power source for correct

voltage.

Increase pressure if desired.

bar, 1.4 MPa)

Prime/pressure relief valve may

be open.

Page 21

Parts

Manifold Filter (866480)

Mustang 8100, LP600/700 HiBoy, LP600 LoBoy

1

2

3

5

6

4

Parts

Ref. Part Description Qty

1 867145 COVER 1

2 301356 SPRING 1

3 867377 O-RING 1

4 867214 FILTER 60 MESH 1

5 867647 SUPPORT 1

6 867077 BASE 1

7 867420 PLUG 2

9 867309 NIPPLE 3/8”M x 1/4”M 1

10 557391 PLUG 1/4” 1

9

Inlet Valve

159

160

157

158

ti16115b

7107

ti16052a

Ref. Part Description Qty

8 331011 FLUID PUMP BODY 1

9 331029 SUCTION BALL GUIDE 1

8

10 331030 SUCTION BALL 1

11 108526 O-RING 1

9

10

11

12 331292 SUCTION SEAT (HI-BOY) 1

13 331034 SUCTION NUT 1

157‡ SUCTION SEAT ASSY

1

(LO-BOY/STAND)

12

158*‡ O-RING 1

159*‡ O-RING 1

13

160*‡ RING,BACKUP 1

* Included in O-Ring Kit 16W484

‡ Included in Kit 331051.

3A1185H 21

Page 22

Parts

Stand Frame Parts Diagram

199

102

107

197

100

101

106

105

Ref. Part Description Qty

100 16F551 FASTENER,THREAD,EXTERNAL 4

101 GUN

289316 500,2 FINGER,ASM, LP500

(120V/230V)

289283 MODEL MUSTANG 5100 1

24E514 SPRAY, 009, (230/240V & 110V) 1

102 140040 WASHER .392X.198X.045 .ZN 2

105 331048 RUBBER BOOT 2

106 331143 FRAME WELD LP CARRY 1

107 331342 SCREW,10-24 X.50 PH PN HD 2

188

Ref. Part Description Qty

188 HOSE 1/4” x 50

HSE1450 (120V/230V) 1

1

865674 (230/240V & 110V) 1

197 867622 SPRING,CLAMP PLATED 1

199 867477 NUT, RIVNUT 10-24 2

16F574 LABEL, FRONT, LP500 (not shown) 1

16F735 LABEL, FRONT, MUSTANG 5100

(not shown)

16F735 LABEL, FRONT, MUSTANG 5100

(not shown)

16H948 LABEL, FRONT, LP400 (not shown) 1

ti17479a

1

1

22 3A1185H

Page 23

LoBoy Frame Parts Diagram

101

Parts

105

102

108

199

104

111

Ref. Part Description Qty

100 867488 SCREW #6X.25 SLFTAP PH HD 2

101 867551 SCREW 6-32X1.25 PH PN HD

(120V/230V)

102 867329 NUT 6-32 X .109 TOP LOCK 2

103 GUN

289316 500,2 FINGER,ASM, (120V) 1

24E514 SPRAY, 009 (230/240V & 110V)

104 143029 COLLAR,SCREW,SET (SPECIAL

ID)

105 15B870 CUP,SUCTION/DRAIN 1

108 305039 SPACER,3/4 ID .50 LG PVC 2

109 331048 RUBBER BOOT 2

110 331103 WASHER .562 .250 .060 .ST 4

111 331171 FRAME WELD- LP-LB 1

184 866476 HANDLE,LB,SUBASSEMBLY

(Includes 184a, 184b, 184c, 184d)

189

110

100

184

103

109

187

ti17480a

Ref. Part Description Qty

184a 331174 HANDLE 1

184b 331222 PIN 2

2

184c 331175 SPACER 2

184d 331176 BUSHING 2

187 HOSE 1/4” X 50’

HSE1450 (120V) 1

865674 (230/240V & 110V) 1

189 121112 SCREW,CAP, SOCKET HEAD 4

2

199 867736 WHEEL-10” OD X3.5’W 150LB 2

16F574 LABEL, LP500 FRONT (not shown) 1

16F575 LABEL, LP600 FRONT (not shown) 1

16F576 LABEL, RIGHT, LP600 (not shown) 1

16F577 LABEL, LEFT, LP600 (not shown)

16K914 LABEL, RIGHT, LP500 (not shown)

1

16K915 LABEL, LEFT, LP500 (not shown)

3A1185H 23

Page 24

Parts

Hi-Boy Parts Diagram

2

3

1

78

77

7

Ref.Part Description Qty

1 MOTOR

331490 .5HP, 110V: LP500 HIBOY/STAND,

LP400 STAND

331491 1HP, 110V: LP600/700 HIBOY,

120V: LP500/600 & MUSTANG

5100/8100

331492 .5HP, 230V: LP500 LOBOY, 240V:

LP500 HIBOY, 230/240V:

LP400/500 STAND

331493 1HP, 230V:LP600 LOBOY,

230/240V: LP600/700 HIBOY

2 331273 FRAME,LP540 HD 1

3 16F551 FASTENER,THREAD,EXTERNAL 4

4 866356 SPACER,SPACER .75 LG PVC 2

5 867736 WHEEL,10” X 3.5” 2

6 143029 COLLAR,SCREW,SET (SPECIAL

ID)

7 331048 BOOT,RUBBER BOOT 2

77 HOSE 1/4X50’

HSE1450 (120V/230V) 1

865674 (230/240V & 110V) 1

78 GUN

4

5

6

ti17483a

Ref.Part Description Qty

289316 500,2 FINGER,ASM, LP500

1

(120V/230V)

289283 MODEL MUSTANG 5100 1

1

24E514 SPRAY, 009 (230/240V & 110V) 1

16F574 LABEL, FRONT, LP500 (not shown)

1

16F575 LABEL, FRONT, LP600 (not shown)

16F576 LABEL, RIGHT, LP600 (not shown)

1

16F577 LABEL, LEFT, LP600 (not shown)

16F735 LABEL, FRONT, MUSTANG 5100

(not shown)

16F737 LABEL, RIGHT, MUSTANG 8100

(not shown)

16F736 LABEL, FRONT, MUSTANG 8100

(not shown)

2

16F738 LABEL, LEFT, MUSTANG 8100

(not shown)

16K914 LABEL, RIGHT, LP500 (not shown)

16K915 LABEL, LEFT, LP500 (not shown)

16H949 LABEL, FRONT, LP700 (not shown)

16H950 LABEL, RIGHT, LP700 (not shown)

16H951 LABEL, LEFT, LP700 (not shown)

1

24 3A1185H

Page 25

Control Parts Diagram

9

19

22

23

21

98

33

103

Parts

20

30

110

26

25

27

76

96

92

96

92

97

100

95

101

94

102

34

Ref. Part Description Qty

9 867800 BOX,TERMINAL BOX WELDMENT 1

19 117281 SPACER,#6 X .312 2

20* 867816 SCREW,MACH,PHILLIPS FLAT HD 2

21* DISPLAY,LCD 1

22* 867731 WASHER,PLAIN-1/8IN.IDX5/16IN.OD2

23* 867817 NUT,HEX 2

25 256219 POTENTIOMETR,ASSEMBLY 1

26 867804 LABEL,CONTROL,LP 1

27* 867798 DISPLAY,WINDOW 1

30 116167 KNOB,POTENTIMETER 1

33* 867965 CONTROL,BOARD, 110V/120V 1

867966 CONTROL,BOARD, 230V/240V bar 1

867967 CONTROL,BOARD, 230V/240V psi 1

34 331342 SCREW,MACH,PANHEAD 4

76 866049 CABLE,ASSY 9” LG 1

92* 100272 WASHER,LOCK 6

94 342513 LABEL,LABEL OFF-ON 1

95* HEAT SINK,MACHINED LP 1

ti17482a

Ref. Part Description Qty

96* SCREW,MACH,PHILLIPS PAN HD 6

97* SPACER,CONTROL BOARD 6

98* CONNECTOR,ELECTRICAL

MOTOR

100 331296 GUARD,SPLASH 2

101* 301083 SWITCH,TOGGLE 1

102* 301150 BOOT,RUBBER,BLACK 1

103* 867797 GASKET,COVER LP 1

110 15C973 GASKET 1

* 867822 CONTROL BOARD KIT (110/120V)

867823 CONTROL BOARD KIT (230/240V)

KIT, Upgrade from old control board

to new control board

867826 With display (110/120V)

867827 With display (230/240V)

867828 Without display (110/120V)

867829 Without display (230/240V)

1

3A1185H 25

Page 26

Parts

Motor and Drive Parts Diagram

35a

35e

35b

35c

35d

ti17841a

37

39

36

121

120

48

1

47

56

55

17

16

46

41

48

57

58

45

60

66

35

40

43

44

50

42

112

51

49

14

52

16

53

13

11

15

72

54

72

47

70

8

9

12

10

1818

13

32

31

213

34

63

159

160

59

157

158

156

ti17840d

61

26 3A1185H

Page 27

Drive Parts

Parts

Ref. Part Description Qty

1 MOTOR

331490 0.5HP, 110V: LP500 HIBOY/STAND,

LP400 STAND

331491 1HP, 110V: LP600/700 HIBOY, 120V;

LP500/600 & MUSTANG 5100/8100

331492 0.5 HP, 230V: LP500 LOBOY, 240V:

LP500 HIBOY, 230/240V: LP400/500

STAND

331493 1HP, 230V; LP600 LOBOY, 230/240V:

LP600/700 HIBOY

1a 331785 FAN 1

1b 331786 FAN COVER 1

1c 331787 BOLT 1

8 867243 GASKET,SEAL 1

9 867800 BOX,TERMINAL BOX WELDMENT 1

10 15V909 SCREW,M8X12 2

11 867813 MANIFOLD 1

12 100020 WASHER,LOCK 4

14 243222 KIT, REPAIR, TRANSDUCER 1

15 867309 FITTING (UNITS WITHOUT FILTER) 1

867311 FITTING, (UNITS WITH FILTER) 1

17 331364 TUBE, ASSY 3-1/4” 1

867892 TUBE, ASSY 2-1/4” 1

18 331185 VALVE,STRAIN RELIEF 2

31 116969 NUT. LOCK 1

32 POWER CORD

331163 (120V) 1

867427 (230V) 1

301101 (240V) 1

118046 (110V) 1

34 331342 SCREW,MACH,PANHEAD 9

35 866477 COVER,FRONT,ASSEMBLY (Includes

35a, 35b, 35c)

35a 331046 BEARING 1

35b 331061 SLEEVE BEARING 1

35c 331103 WASHER 2

35d 331197 SCREW 2

35e 331234 COVER, BARE 1

36 331047 BEARING,BALL 1

37 GEAR,CRANK

331406 .21 (LP400) 1

331407 .26 ASSY (MUSTANG 5100, LP500) 1

331593 (LP600 -230/240V & 110V) 1

331590 (MUSTANG 8100, LP600 - 120V &

230V LP700)

39 331038 YOKE,CROSSHEAD ASSY 1

40 331074 SPACER 2.691 LONG 2

41 866482 PUMP,PAINT,ASSY 1

42 866082 PIN,CROSS PIN .375 1

43 331117 SLEEVE 1

1

1

1

1

Ref. Part Description Qty

44 331062 SPRING,RET. SPRING 1

45 867539 SCREW,5/16-18 X3.75 HX HD 2

46 331111 COVER - GUARD 1

47 866338 SCREW, SHOULDER 2

48 107445 SCREW, CAP 2

49 557391 PLUG 1

50* 865013 ADAPTER, VALVE

51* 239913 VALVE, DRAIN

52* 867102 CAM, PRIMING VALVE

53* 867263 HANDLE, PRIMING VALVE

54* 867404 PIN, GROOVED

55 331336 HOOK,PAIL HIBOY 1

56 113783 SCREW,MACH,PNH HIBOY 2

57 331029 RETAINER,PUMP 1

58 331030 BALL .500 GR100 ...SS 440 1

59++ TUBE,SUCTION,SUBASSEMBLY 1

60 108526 PACKING,O-RING 1

61++ STRAINER, HIBOY 1

187651 STRAINER, STAND & LOBOY 1

63 301348 BYPASS LINE ASSY 1

66 342467 LABEL FRONT LP AIRLESSCO 1

70 342524 LABEL- PRIME/SPRAY 1

72 LABEL - WARNING 1

195793 LABEL - (120V) 1

195792 LABEL - (230V) 1

16G596 LABEL - (240V, 110V) 1

112 111457 O-RING 1

120 331178 TRIM EDGE 2

121 331795 COVER (LP600/8100 & LP700) 1

156 331051 KIT SUCTION SEAT ASSY 1

213 866480 KIT,FILTER W/FITTINGS (MUSTANG

1

* Included in 866428 Valve Relief Kit

++ Included in 331284 Hi-Boy Suction Assy

5100/8100, LP500/600/700 HIBOY,

LP600 LOBOY, LP500 STAND

110/120V)

Additional warning labels are available at no cost.

Older machines use tube with approximately 2-1/4”

center to center distance. Newer machines use wider

spaced tube with approximately 3-1/4” center to center

distance. Measure connection points to order correct

part.

1

1

3A1185H 27

Page 28

Parts

Packing Replacement

Ref. Part Description Qty

1* 331014 MALE GLAND 2

2* 331016 PACKING POLYETHYLENE 6

3* 331308 FEMALE ADAPTOR 1

4 331011 FLUID PUMP BODY 1

5 331029 SUCTION BALL GUIDE 1

6* 331030 SUCTION BALL 1

7* 108526 O-RING 1

8 331292 SUCTION SEAT (HI-BOY) 1

331051 SUCTION SEAT (LO-BOY) 1

9 331034 SUCTION NUT 1

10+ 331314 OUTLET SEAT RETAINER 1

11+ 331026 OUTLET SEAT 1

12+* 111457 O-RING 1

13+* 331027 OUTLET BALL 1

14+ PISTON 1

15* 331018 SPACER 1

16* 331025 WASHER, SPRING 3

17* 331022 MALE GLAND 1

18* 331023 PACKING POLYETHYLENE 3

19* 331021 FEMALE GLAND 1

20 331019 PACKING HOLDER 1

21 331037 PACKING NUT 1

22* 331307 PACKING LEATHER 2

23* 331306 PACKING LEATHER 4

24* 107313 WHITE O-RING 1

25* 108771 BLACK O-RING 1

26 180656 PLUG, BUTTON 1

157** SEAT,SUCTION SEAT 1

158**‡ PACKING, O-RING 1

159**‡ PACKING, O-RING 1

160**‡ RING, BACKUP 1

* 331210 PACKING KIT

+ 331093 PISTON ASSEMBLY

** Included in 331051

‡ Included in O-Ring Kit 16W484

26

21

20

25

24

19

181818

17

161616

15

14

13

11

12

10

2222

23232323

1

2

22

3

222

1

4

5

6

7

8

9

159

160

157

158

ti16056b

28 3A1185H

Page 29

Gearbox Sleeve Bearing Replacement

1 2

Suction Assemblies

Parts

Ref. Part Description Qty

1 331061 SLEEVE BEARING 1

2 331103 WASHER 2

3 331197 SCREW 2

NOTE: When replacing item (1), cover outside of

sleeve with 6 drops of Loctite 246 prior to inserting into

ti16059a

3

cover assembly.

Lo-Boy and Carry Chassis (865717)

1

7

4

6

2

ti16062a

Ref. Part Description Qty

1 331290 SUCTION HOSE ASSEMBLY 1

2 187651 INLET STRAINER 1

4* DRAIN HOSE 1

5* 241920 THREADED DEFLECTOR 1

6* 867759 MALE CONNECTOR 1

7* 276888 DRAIN LINE CLIP 1

* Sold in Kit 865721

5

Hi-Boy Chassis (331284)

2

3

1

4

5

ti16061a

Ref. Part Description Qty

1 301348 BYPASS HOSE ASSEMBLY 1

2 331034 SUCTION NUT 1

3 331292 SUCTION SEAT ASSEMBLY 1

4 331400 INLET TUBE 1

5 187190 INLET STRAINER 1

3A1185H 29

Page 30

Parts

Electrical System

120V

230V

ON/OFF

Switch

Power Plug

1

from Motor

Black

3

Black

Black (-)

Green

Black (+)

White

2 x Red

Power

Plug

7

Black

6

5

ti2471b

1

3

from Motor

ON/OFF

switch

Black/White

Green/Yellow

Black/Brown

White/Blue

Black

5

2 x Red

7

6

ti22758a

Ref. Part Description Qty Ref. Part Description Qty

1 POWER CORD 1 3 301083 TOGGLE SWITCH 1

331163 (120V) 1 5 PRESSURE CONTROL ASSEMBLY 1

867427 (230V) 1 6 243222 KIT, REPAIR TRANSDUCER 1

301101 (240V) 1 7 256219 POTENTIOMETER 1

118046 (110V) 1 8 15T069 LABEL,WARNING (120V) 1

15H087 LABEL,WARNING (230V)

Additional warning labels are available at no cost.

30 3A1185H

Page 31

Electrical Components

Parts

1

4

6

3

7

5

2

ti16066a

Ref. Part Description Qty Ref. Part Description Qty

1 867816 SCREW 2 5 867817 NUT 2

2 867804 LABEL, PRESSURE CONTROL 1 6 867731 WASHER 2

3 867798 WINDOW 1 7 LCD DISPLAY (PSI) 1

4 117281 SPACER 2 867821 LCD DISPLAY Kit (PSI)

1

Includes 1, 3, 4, 5, 6, 7

3A1185H 31

Page 32

Technical Data

Technical Data

LP400/500/600/700, Mustang 5100/8100

US Metric

Power requirements 120V AC, 60 hz, 11A, 1 phase

230V AC, 50/60 hz, 7.5A, 1 phase

Generator required 3000 w minimum

Maximum working pressure 3000 psi 21 MPa, 207 bar

Maximum delivery

LP400 0.46 gpm 1.75 lpm

LP500 0.54 gpm 2.0 lpm

LP600 (International) 0.66 gpm 2.5 lpm

LP700 0.74 gpm 2.8 lpm

LP600 (North America) 0.85 gpm 3.2 lpm

Maximum tip size

LP400 0.021

LP500 0.023

LP600 (International) 0.025

LP700 0.027

LP600 (North America) 0.027

Fluid outlet npsm 1/4 inch

Noise (dBa)

Sound pressure 80 dBa

Wetted parts zinc and nickel-plated carbon steel, nylon, stainless

steel, PTFE, acetal, leather, UHMWPE, aluminum,

tungsten carbide

Notes

Sound pressure measure at 3.1 feet (1 meter) from equipment.

32 3A1185H

Page 33

Notes

Notes

3A1185H 33

Page 34

Airlessco Standard Warranty

Airlessco warrants all equipment referenced in this document which is manufactured by Airlessco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Airlessco, Airlessco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Airlessco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Airlessco’s

written recommendations.

This warranty does not cover, and Airlessco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Airlessco component parts. Nor shall Airlessco be liable for malfunction, damage or wear caused by the incompatibility of Airlessco

equipment with structures, accessories, equipment or materials not supplied by Airlessco, or the improper design, manufacture, installation,

operation or maintenance of structures, accessories, equipment or materials not supplied by Airlessco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Airlessco distributor for verification

of the claimed defect. If the claimed defect is verified, Airlessco will repair or replace free of charge any defective parts. The equipment will be

returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship,

repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Airlessco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

AIRLESSCO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY Airlessco. These items sold, but not manufactured by Airlessco (such as electric motors, switches, hose, etc.), are subject

to the warranty, if any, of their manufacturer. Airlessco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Airlessco be liable for indirect, incidental, special or consequential damages resulting from Airlessco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of

warranty, the negligence of Airlessco, or otherwise.

FOR AIRLESSCO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées

TO PLACE AN ORDER OR FOR SERVICE, contact your Airlessco distributor,

or call 1–800–223-8213 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Airlessco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original Instructions. This manual contains English. MM 3A1185

AIRLESSCO • 3501 N. 4th AVENUE • SIOUX FALLS, SD 57104 • USA

Copyright 2010, Airlessco. All Airlessco manufacturing locations are registered to ISO 9001.

Revised January 2014

Loading...

Loading...