Page 1

Operation/Repair/Parts

3A1187E

Airless Paint Sprayer

For application of architectural paints and coatings. For professional use only.

Airlessco - GS6250 (24F575), (16M532)

3000 psi (20.7 MPa, 207 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Related Manuals

Gun Manual

312363

Model 24F575

Model 16M532 3A0413

312364

312365

EN

ti15986a

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and

can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with

any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Airlessco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure

before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3000 psi. Use Airlessco replacement parts or accessories that are

rated a minimum of 3000 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

2 3A1187E

Page 3

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Airlessco.

• Do not use the hose as a strength member to pull or lift the equipment.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death.

• Do not operate in an enclosed area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

3A1187E 3

Page 4

Warnings

WARNING

WARNINGWARNINGWARNING

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 3A1187E

Page 5

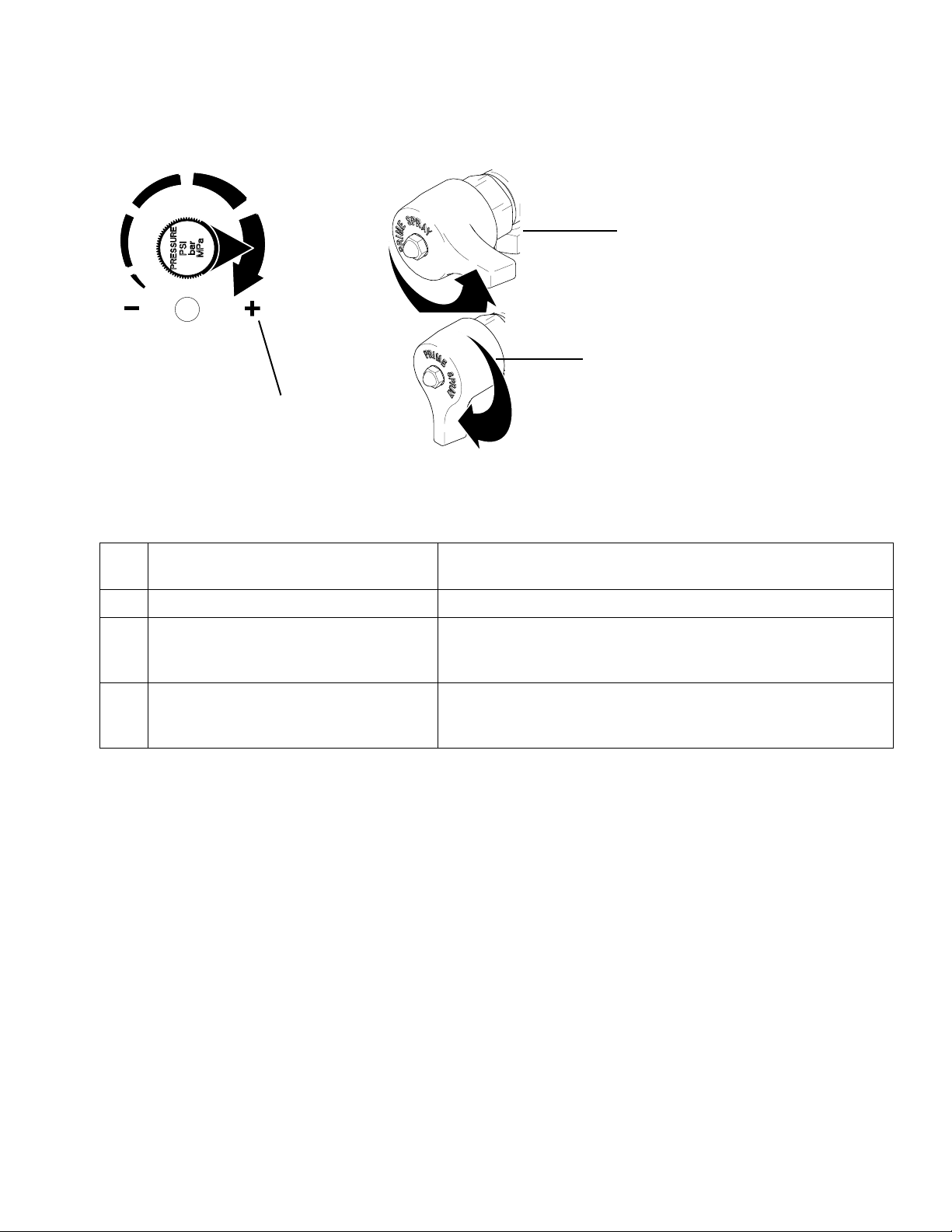

Component Identification

Component Identification

C

PRIME

ti14792a

PRESSURE

A

NOTE: The valve handle can move both clockwise and counter clockwise and can face different directions.

ti16292a

B

ti16293a

A Pressure Control Knob Adjusts pressure. Turn clockwise to increase pressure and

counterclockwise to decrease pressure.

Prime/Pressure (PR) Relief Valve Primes pump and relieves pressure from gun, hose and tip.

B Prime/Pressure (PR) Relief Valve Open

Position

Relieves pressure from gun, hose and tip and primes the unit

when in the open position. It is in the Open position when there

is a wider gap between valve handle and cam body.

C Prime/Pressure (PR) Relief Valve

Closed Position

Pressurizes system when closed. It is in the Closed position

when there is only a slight gap between handle and body. Turn

to the closed position to spray.

3A1187E 5

Page 6

Operation

Operation

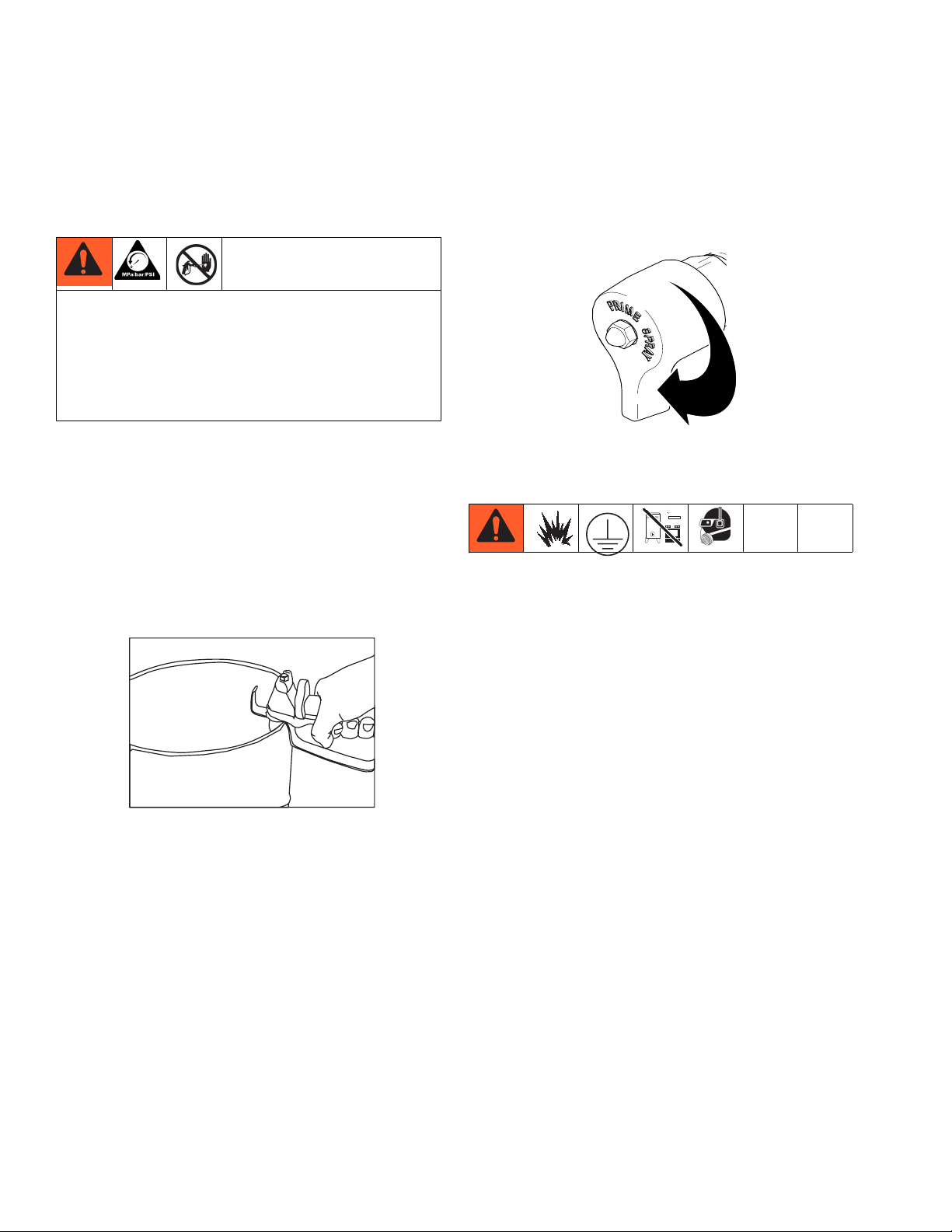

Pressure Relief Procedure

To reduce risk of injury, follow this pressure relief procedure whenever you see this symbol throughout this

manual, Also, perform this procedure whenever you:

•Stop spraying

• Check or repair any part of this system

• Install or clean spray nozzle

1. Engage the gun trigger lock. Refer to the separate

instruction manual provided with gun for safety features and how to engage the trigger lock.

2. Turn the unit off.

3. Disengage the gun trigger lock and trigger the gun

to relieve residual fluid pressure.

Hold metal part of the gun in contact with

grounded metal pail. Use minimum pressure.

NOTE: If you suspect that pressure hasn’t been relieved

due to damaged Prime/Pressure Relief Valve, or other

reason, slowly loosen the tip nut or hose coupling.

ti16293a

Setup

Grounding

Always ground the following components:

ti15989a

4. Turn Prime/Pressure Relief Valve (PR Valve) to the

open (priming) position to relieve residual pressure.

5. Re-engage gun trigger lock and close Prime/Pressure Relief Valve.

If the spray tip or hose is clogged, follow Steps 1

through 5 above. Expect paint to splash into the

bucket while relieving pressure during Step 4.

• Sprayer - Connect a ground wire and clamp (supplied) to a true earth ground.

• Fluid Hose - Use only grounded hoses.

• Spray Gun of Dispensing Valve - Grounding is

obtained through connection to a properly grounded

fluid hose and pump.

• Object being sprayed - According to local code.

Connect the hose and gun

1. Remove the plastic cap plug from the outlet and

screw a conductive or grounded 3000 psi spray

hose onto fluid outlet.

2. Connect an airless spray gun to the other end of the

hose. Do not install spray tip.

NOTE: Do not use thread sealer on swivel unions as

they are made to self seal.

NOTE: The 6’ whip hose should always be 3/8”.

6 3A1187E

Page 7

Operation

Fill the Packing Nut/Wet Cup

1. Fill the Packing Nut/Wet Cup 1/3 full with Airlessco

Throat Seal Oil (TSO).

ti15987a

Check the Engine Oil Level

1. Unscrew the oil fill plug. The dipstick is attached to

the plug.

2. Without threading the plug into place, check to be

sure the oil is up to the top mark of the dipstick.

3. If oil is needed, refer to engine manual.

Fill the Fuel Tank

1. Close the fuel shutoff valve.

2. Use only clean, fresh, well-known brands of

unleaded regular grade gasoline.

• When changing from oil based material to water

base material, flush with mineral spirits solvent (also

called white spirit), followed by soapy water, then a

clean water flush.

• When flushing with solvents, ground pail and gun.

• Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

Flushing

• To reduce the risk of static sparking, which can

cause fire or explosion. Always hold a metal part of

the gun firmly against the metal pail when flushing.

This also reduces splashing.

• Always remove the spray tip before flushing.

• Only metal pails, which are conductive, should be

used as solvent pails when flushing.

1. Make sure the gun trigger lock in engaged and there

is no spray tip in the gun. Refer to the separate

instruction manual provided with gun for safety features and how to engage the trigger lock.

3. Remove the fuel cap and fill tank. Be sure the air

vent in the fill cap is not plugged so fuel can flow to

the carburetor, then replace the cap.

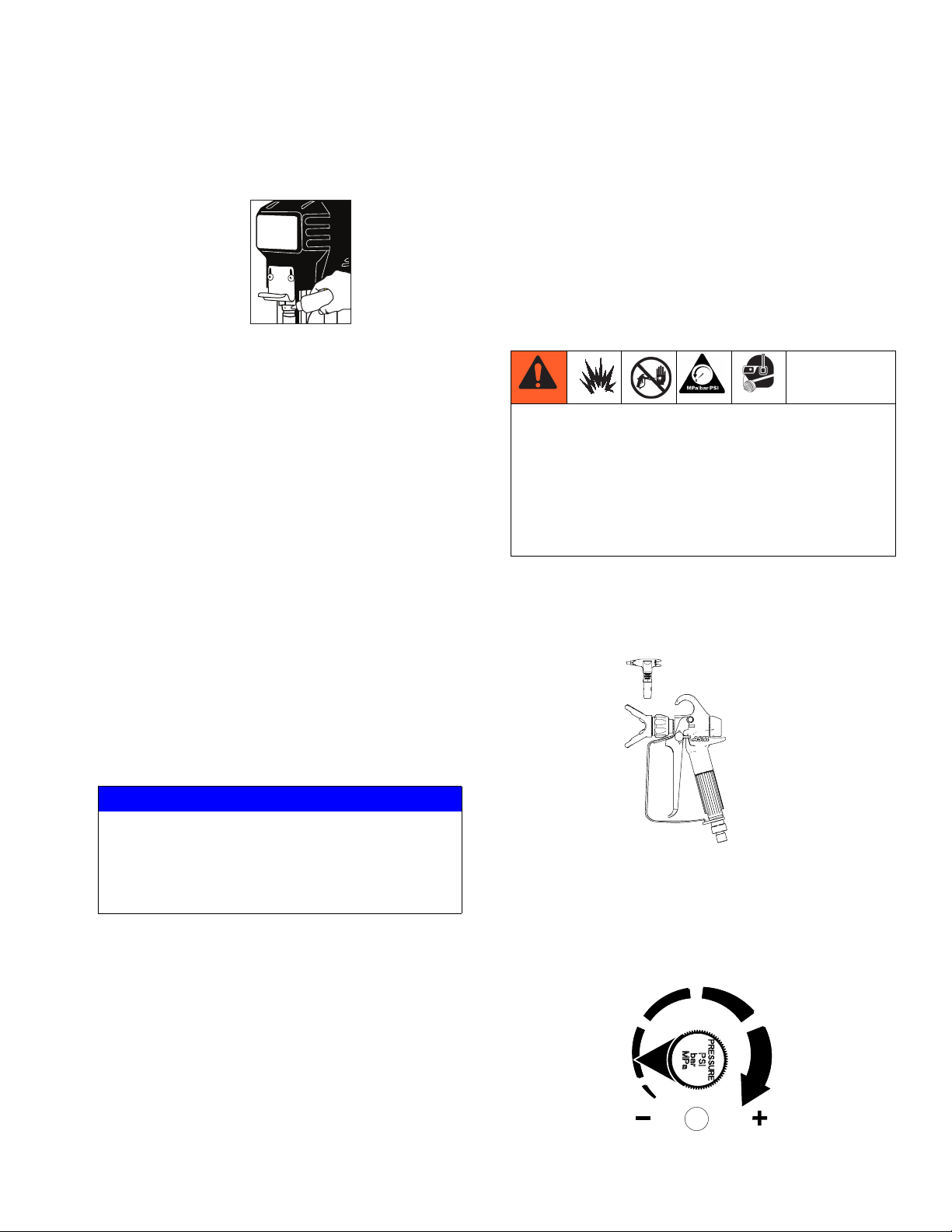

Prime and Flush Storage Fluid

NOTICE

The equipment was tested with lightweight oil,

which is left in the fluid passages to protect parts.

To avoid contaminating your fluid with oil, flush the

equipment with a compatible solvent before using

the equipment for the first time.

Before beginning a new spraying project you need to

prime the sprayer and flush the storage fluid out of the

sprayer.

Oil- or Water-based Materials

• When changing from water-based material to oil

based material, flush with soapy water and then

mineral spirits solvent (also called white spirit).

ti16028a

2. Pour enough clean, compatible solvent into a large,

empty metal pail to fill the pump and hoses.

3. Place the suction tube into the pail or place the pail

under the pump.

4. Turn Pressure Control Knob to low.

PRIME

HIGH PRESSURE

ti17939a

PRESSURE

3A1187E 7

Page 8

Operation

5. Open the prime valve to the open - “Priming Position”. This will allow an easy start.

Open

(Priming and

Pressure Relief)

ti16293a

6. Turn the engine ON/OFF switch to ON.

7. Move the choke toward the closed position.

8. Move the throttle lever slightly to the left.

9. Turn the fuel valve ON. Pull the start rope. Pull the

engine over against compression stroke and then let

the rope rewind slowly into the starter. Pull firmly

and rapidly to start the engine. Do NOT drop the

rope. Hold on to the handle while rewinding, or the

rope may rewind improperly and jam the assembly.

If the engine does not start, open the choke a little

more. If the engine floods, open the choke all the

way and continue cranking.

12. Disengage the gun trigger lock and squeeze the gun

trigger. At the same time, slowly turn the pressure

control knob clockwise, just enough to move liquid

at low pressure.

13. Allow the pump to operate until clean solvent comes

from the gun.

14. Release the trigger and engage the gun trigger lock.

15. If you are going to start spraying, place the pump or

suction tube into the supply container. Release the

gun trigger lock and trigger the gun into another

empty, metal container, holding a metal part of the

gun firmly against the metal pail, forcing the solvent

from the pump and hose. When paint starts coming

from gun, turn pressure control knob to minimum

pressure, place prime valve in prime (open) position

and engage the gun trigger lock.

16. If you are going to store the sprayer, remove the

suction tube or pump from the solvent pail, force the

solvent from the pump and hose. Engage the gun

trigger lock. See Storage, 10.

17. Whenever shutting down the sprayer, follow Pres-

sure Relief Procedure, page 6.

Throttle Lever

Choke Lever

Fuel Valve

ti14793a

10. After the engine is warm, gradually close the choke,

raise the RPM of engine slightly by moving throttle

to the left. Close the prime valve.

Closed

(Pressure)

ti15988a

11. Point the gun into the metal pail and hold a metal

part of the gun firmly against the pail. Maintain firm

metal to metal contact between gun and container.

NOTICE

To prevent damage and freezing during storage,

never leave water in the fluid pump

Startup

1. Prepare the material according to the material manufacturer’s recommendations.

2. Place pump or suction tube into the material container.

3. Start the sprayer.

a. Prime Valve must be “OPEN” in the priming

position.

b. Pressure Control Knob must be in low pres-

sure.

c. Turn the engine ON/OFF switch to ON.

d. Move the choke toward the closed position.

e. Move the throttle lever slightly to the left.

f. Turn the fuel valve ON. Pull the start rope. Pull

ti10312a

the engine over against compression stroke

and then let the rope rewind slowly into the

8 3A1187E

Page 9

Operation

starter. Pull firmly and rapidly to start the

engine. Do NOT drop the rope. Hold on to the

handle while rewinding, or the rope may

rewind improperly and jam the assembly. If the

engine does not start, open the choke a little

more. If the engine floods, open the choke all

the way and continue cranking.

g. After the engine is warm, gradually close the

choke, raise the RPM of engine slightly by

moving throttle to the left. Close the prime

valve.

h. Point the gun into the metal pail and hold a

metal part of the gun firmly against the pail.

Maintain firm metal to metal contact between

gun and container.

i. Disengage the gun trigger lock and squeeze

the gun trigger. At the same time, slowly turn

the pressure control knob clockwise, just

enough to move liquid at low pressure.

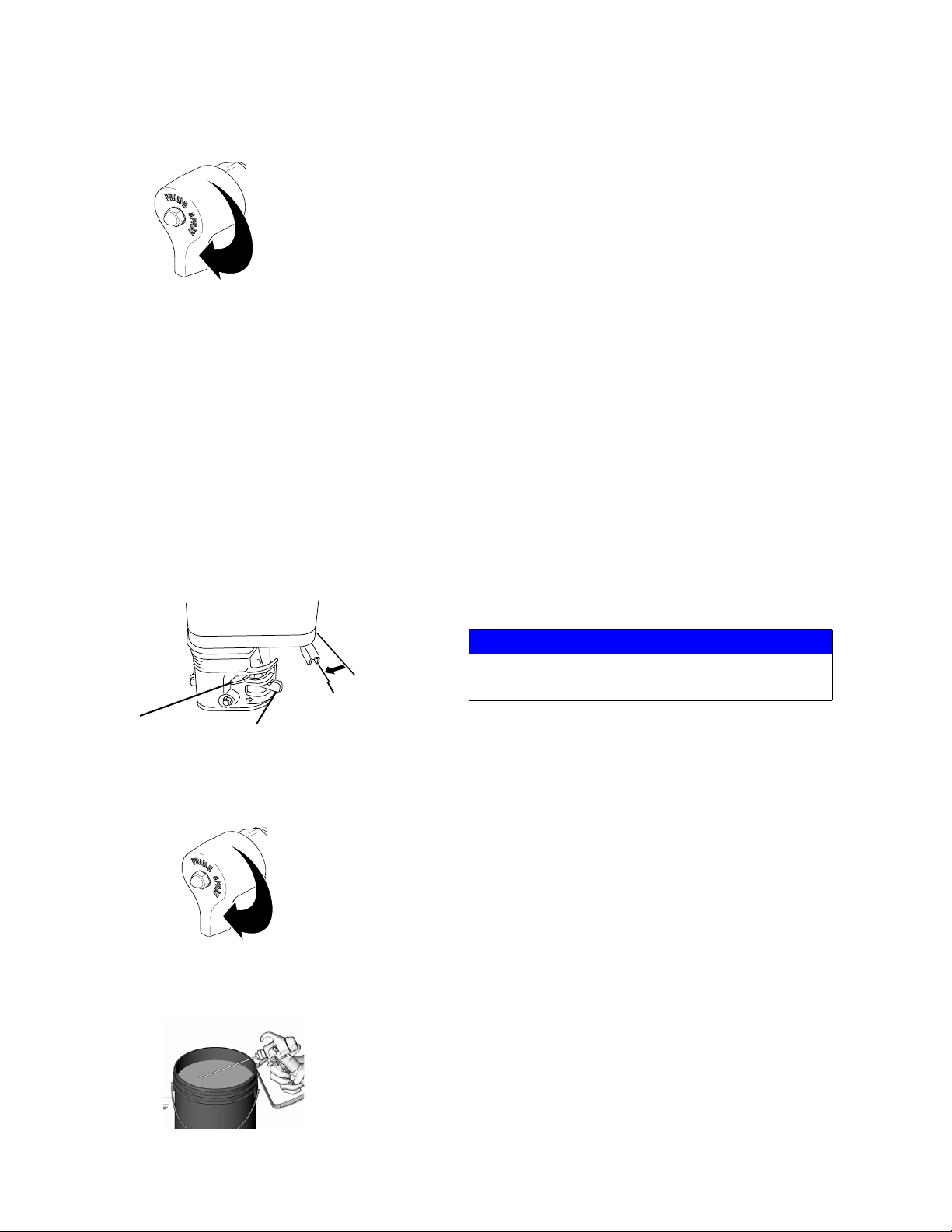

4. Prime the pump.

NOTICE

Adjust the Pressure

• To reduce the risk of injection, never hold your

hand, body, fingers or hand in a rag in front of the

spray tip when cleaning or checking for a cleared

tip. Always point the gun toward the ground or into

a waste container when checking to see if the tip is

cleared or when using a self cleaning tip.

• To stop the unit in an emergency, turn the engine

off. Then relieve the fluid pressure in the pump and

hose. See Pressure Relief Procedure, page 6

When adjusting the pressure, turn the Pressure Control

Knob clockwise to increase pressure and counterclockwise to decrease pressure. Always use the lowest pressure necessary to completely atomize the material. If

more coverage is needed, use a larger tip rather than

increasing the pressure. Check the spray pattern. The

tip size and angle determines the pattern width and flow

rate.

Do not start engine without fluid pump having

enough fluid so that it can be primed. Running fluid

pump dry will decrease life of the pumps packings.

a. Allow pump to operate until paint comes from

gun.

b. Release the trigger and engage the gun trig-

ger lock.

c. Turn Prime Valve OPEN to the prime position

ensuring the pressure is released from the

system.

d. Turn Pressure Control Knob to minimum pres-

sure.

e. Install spray tip onto gun.

f. Close the prime valve to the pressure position.

g. Turn the pressure control knob to desired

spray pressure.

h. Disengage the gun safety lock and you are

ready to start spraying.

NOTE: If you spray into the paint bucket, always use the

lowest spray pressure and maintain firm metal to metal

contact between gun and container.

NOTICE

NOTE: Operating the sprayer at higher pressure than

needed wastes material, causes early tip wear, and

shortens sprayer life.

Shutdown

1. Relieve Pressure, page 6.

2. Clean the tip and gun as recommended in the separate Gun Manual supplied with the gun.

3. If spraying water-based material or a material that

could harden in the sprayer overnight, flush the

sprayer after use. See Flushing, page 7.

NOTE: To stop the unit in an emergency, turn the engine

off. Then relieve the fluid pressure in the pump and

hose. See Pressure Relief Procedure, page 6

3A1187E 9

Page 10

Operation

Storage

Short Term

1. Flush sprayer with compatible solvent before storing, then fill the pump and hoses with an oil based

solvent such as mineral spirits solvent (also called

white spirit) or Graco or Airlessco Pump Armor.

• For oil base paint: flush with mineral spirits sol-

vent (also called white spirit)

• For water-base paint: flush with water, then min-

eral spirits solvent (also called white spirit) and

leave the pump, hose and gun filled with mineral

spirits solvent (also called white spirit).

Long Term

For longer storage, use Graco or Airlessco Pump Armor.

Shut off sprayer, Relieve Pressure, page 6, and make

sure prime valve is left open.

Start Up After Storage

Before using water-base paint, flush sprayer with soapy

water and then a clean water flush. When using oil-base

paint, flush out the mineral spirits solvent (also called

white spirit) with the material to be sprayed.

NOTE: Always store unit indoors.

10 3A1187E

Page 11

Maintenance

Maintenance

Daily Maintenance

Keep displacement pump packing nut/wet cup lubricated with Airlessco Throat Seal Oil at all times. The

TSO helps protect the packings and rod. Inspect the

packing nut daily. If seepage of paint into the packing nut

and/or movement of the piston upward is found (while

not spraying), the packing nut should be tightened just

enough to stop leakage. Overtightening will damage the

packings and reduce the packing life.

Cleaning a Clogged Tip

1. Relieve Pressure, page 6.

2. Clean the front of the tip frequently (with toothbrush

only) during the day to keep material from building

up and clogging the tip.

3. To clean and clear a tip if it clogs, refer to the separate instruction manual received with your gun and

nozzle.

Regular Maintenance

1. Always stop the pump at the bottom of its stroke

when you take a break or at the end of the day. This

helps keep material from drying on the rod, damaging the packings.

2. Keep the displacement pump packing nut/wet cup

1/3 full of Airlessco Throat Seal Oil (TSO) at all

times. The TSO helps protect the packings and rod.

3. Lubricate Connecting Rod Pin every 3 months.

Oil and Lubrication Instructions

Bleed (Weep Hole)

Sealed

Bearing

1 oz. SAE 30W Oil semi-annually

4. Clean a clogged standard flat tip only after the tip is

removed from the gun.

Reducing Clutch Wear

1. The first 50 feet of airless spray hose should be 3/8”,

the larger diameter works as a pulsation damper

and saves unnecessary cycling the clutch. A minimum of 100 feet of hose should be used.

2. Adjust the Engine Speed and Pump Pressure. First

set the throttle lever to the maximum RPM setting

(fully left). Trigger the gun onto a test paper to check

the spray pattern and atomization. Adjust the Pressure Control Knob until you get a good pattern.

Reduce RPM of engine to support pressure without

laboring engines.

Oil impregnated sleeve - dip in

hot 10W oil when removed

Fill plug- unit has grease in gearbox from factory

and will not require changing. (Grease - PN

301178)

ti15992a

Servicing the Fluid Pump

Fluid Pump Disconnect

1. Flush the material you are spraying, if possible.

2. Relieve Pressure, page 6. Stop the pump in the

middle of down stroke.

3. Remove the suction tube and fluid hose (if so

equipped) from the fluid pump.

4. Remove the connecting rod shield from the pump.

3A1187E 11

Page 12

Maintenance

5. Remove two retaining rings (4) and slip the sleeve of

the coupling down and remove both coupling

halves. This will disconnect fluid pump from the connecting rod.

6. Using a 7/8” box wrench disconnect the high pressure fluid line from the pump.

7. Using a 9/16” wrench, unscrew the two tie rod locknuts (10).

8. Pull the pump off the tie rods.

1

2

3

55

44

6

12

13

2. Insert one of the retaining rings through the packing

nut and rest the sleeve on top of it.

ti15995a

ti15996a

3. Connect the connecting rod with the fluid pump by

installing the coupling halves. Slide sleeve over the

coupling halves and secure with retaining ring.

ti15997a

4. Remove the retaining ring from the packing nut and

insert into coupling halves.

8

9

11

10

ti15993a

5. Secure the fluid pump housing to the tie rods and

ti15998a

screw locknuts with washers on loosely.

Fluid Pump Reinstall

1. Loosen the packing nut and extend piston rod to

fully up position.

6. Tighten the tie rod locknuts evenly to 30 ft. lb.

NOTE: After all the rod locknuts are tight, the alignment

of both rods should allow easy assembly and disassembly of the coupling. If any binding, loosen and retighten

all the rod locknuts to improve the alignment. Misalignment causes premature wear of seal and packings.

7. Tighten packing nut clockwise until resistance

against the packings can be felt. Turn it one full turn

more.

ti15994a

12 3A1187E

Page 13

Maintenance

8. Start the pump and operate it slowly (at low engine

speed) to check the piston rod for binding. Adjust tie

rod lock nuts if necessary to eliminate binding.

9. Prime the unit and run at maximum pressure for

several minutes, then release the pressure and

repeat step 7.

10. Fill the wet cup (packing nut) with five drops of TSO

(Throat Seal Oil).

Servicing the Inlet and Outlet Valves

Disassembly of the Outlet Valve

1. Using the rod collar tool (189211), screw the suction

nut (7), containing intake seat support, off of the

fluid body.

2. Remove the inlet seat (4), O-ring, inlet ball (3) and

inlet retainer (2) with O-ring.

3. Clean all parts and inspect them for wear and damage, replacing parts as needed. Old O-rings should

be replaced with new ones.

NOTE: Inlet Seat (867574) is reversible.

4. Clean inside of fluid body.

5. Reassemble the valve and screw it onto the fluid

body if no further service is needed.

1

2

Servicing the Outlet Valve

1. Complete all steps of the Fluid Pump Disconnect,

page 11.

2. Screw the suction nut off the pump and remove inlet

valve assembly.

3. Using the rod collar tool, loosen the packing nut and

push the piston (13) down and out of the fluid body.

4. Place piston holder (866058) in a vise. Slide piston

(13) into holder and lock in place with a 1/4” pin

(867166).

5. Clean all parts and inspect them carefully for wear

or damage. Inspect the outside of the piston rod for

scoring or wear. Replace these parts if needed. A

worn piston rod will cause premature wear of packings.

6. Using 3/8” allen wrench to unscrew retainer (8) from

piston (13).

7. Remove outlet seat (9), O-ring, outlet ball (11) and

outlet retainer (12).

8. Inspect outlet ball (11) and seat for wear. Replace

as required.

NOTE: Outlet Seat (867575) is reversible.

9. Install parts back into piston rod. Place two drops of

loctite No. 242 (blue) on threads of the retainer (8)

before assembling and torque to 20 ft-lbs.

8

9

10

11

12

3

4

5

6

7

ti15999a

3A1187E 13

13

867166

866058

ti16000a

Page 14

Maintenance

Packing Replacement Procedures

Disassembly of the Fluid Pump

1. Unscrew and remove the packing nut.

2. Push the piston rod down through the packings and

out of the pump.

3. Now push the packing removal tool up through the

pump and remove the top bringing the packings,

spacer and springs along with it, leaving the fluid

body empty.

NOTE: Make sure all packings and glands have been

removed from the fluid pump.

4. Clean inside of fluid body.

5. Disassemble all parts and clean for reassembly. Discard any old packings. Save the metal upper glands.

Replace metal lower glands with new metal glands

from the packing kit.

NOTE: If the old packing had a metal gland, discard and

replace with a new plastic one from packing kit.

6. Lubricate leather packing in lightweight oil for 10

minutes prior to reassembly.

7. Unscrew and remove the packing nut.

8. Push the piston rod down through the packings and

out of the pump.

9. Now push the packing removal tool up through the

pump and remove from the top bringing the packings, spacer and springs along with it, leaving fluid

body empty.

NOTE: Make sure all old packings and glands have

been removed from fluid pump.

Reassembly of the Fluid Pump

1. Take the lower metal male gland and place it down

on the flat side.

2. Take three of the lower polyethylene V-packings and

tow of the leather V-packings and place onto the

male gland, with the inverted side down, in the following order:

• Polyethylene

• Leather

• Polyethylene

• Leather

• Polyethylene

3. Take the female adaptor, which is inverted on both

sides, and place it on top of the assembled lower

packings.

4. Follow step 2 above, but with the packings inverted

side up.

5. Take the second lower male gland and place it on

top of the assembled packings with the rounded

side down.

6. Take the assembled glands and packings (13 pieces

all together) and slide on to the lower half of the piston.

7. Take the spacer and slide over the top of the piston

(it doesn’t matter which direction it sits).

8. Take the three Belleville Springs and slide over the

top of the piston in the following order:

• First spring, curve facing down

• Second spring, curve facing up

• Third spring, curve facing down

9. Take the upper male gland and place it rounded side

up.

10. Take the three upper polyethylene V-packings and

two leather packings and assemble with the inverted

side down on to the male gland in the following

order:

• Polyethylene

• Leather

• Polyethylene

• Leather

• Polyethylene

14 3A1187E

Page 15

Maintenance

11. Take the upper female gland and place on top of the

assembled upper packings with the inverted side

down.

12. Take the assembled upper glands and packings (7

pieces) and slide over the top of the piston, making

sure the inverted sides are facing down.

13. Take the V-packing holder and replace the white

O-ring and the black O-ring with new ones form the

packing kit.

14. Slide the V-packing holder over the top of the upper

packings so they fit inside.

15. Lubricate the inside of the fluid pump body and the

outside of the packings with a lightweight oil.

16. Slide the completed assembly into the fluid pump

body.

NOTE: To keep packings secured in the correct position,

hold the pump body upside down and push the completed assembly upwards into the pump body. Once

placed inside, tilt the pump body back up to keep all

pieces.

17. Thread the packing nut into the top of the fluid body

and tighten hand tight.

Replacement of Electrical Control Board

1. Remove electrical cover.

2. Disconnect sensor lead from Electrical Board.

3. Disconnect two clutch leads on Electrical Board

from leads on clutch.

4. Using a 1/16” allen, loosen set screw in Pressure

Control Knob and remove knob.

5. Using a 1/2” nutdriver or 1/2” deep socket, remove

nut from pressure control shaft. This will allow

removal of electrical control board from frame.

6. Replace Electrical Board Assembly in reverse order.

Adjust pressure. See Pressure Calibration of the

Electrical Control Board, page 15.

Pressure Calibration of the Electrical Control Board

1. Turn “Pressure Calibration” Trimpot adjustment on

electrical control board in the counter clockwise

direction at least 15 revolutions.

18. Take the suction retainer and replace the black

O-ring with a new one from the packing kit. Replace

the suction ball with the new one from the kit into the

suction retainer. Place the suction seat into the flat

side of the ball guide, over the suction ball. Now

place the white O-ring into the groove around the

suction seat.

19. Take the completed suction valve assembly and

place it into the bottom of the fluid body, with the

rounded side fitting inside.

20. Take the suction seat support and place the flat side

down on the suction valve assembly (threads will be

facing upwards).

21. Thread the suction nut, over the suction seat support.

22. Tighten the packing nut (utilizing the packing nut

adjustment tool) clockwise one full turn.

2. Connect 5000 psi glycerine pressure gauge on outlet of pump between fluid pump and airless hose to

monitor Fluid Pump Pressure.

3. Start engine and run at maximum RPM. Turn prime

Valve to open (Prime) position. Turn Pressure Control Knob to maximum position (fully clockwise).

4. Using an insulated screwdriver adjust “Pressure

Calibration” Trimpot by turning clockwise until the

clutch engages. When the clutch engages the pump

will commence Priming. When pump is primed, turn

the Prime Valve to the Closed (Pressure) Position.

NOTE: The pump will begin to pressurize and the clutch

will disengage at a low pressure. Continue turning the

trimpot clockwise to increase pressure 3000 psi.

5. Trigger gun. The pressure should drop approximately 350-400 psi, the clutch will engage and build

pressure to 3000 psi and disengage. Trigger gun

several times to ensure proper pressure setting.

6. Turn Pressure Control Knob to minimum position.

The clutch should disengage and pump stop moving.

3A1187E 15

Page 16

Maintenance

7. Secure leads with tie strap. 8. Replace cover on unit. Ensure the leads are not

pinched or damaged in the process of replacing

covers.

SENSOR

PRESSURE

CALIBRATION

4

TRIMPOT

BLACK

3

TO ENGINE

BLACK

GREEN

BLUE

BLUE

BLACK

BLACK

TO CLUTCH

1

2

ti16006a

16 3A1187E

Page 17

Clutch Replacement

Removing the Clutch

Clutch Replacement

Refer to the following parts diagrams: Belt Tensioning,

Clutch Assembly, and Power Unit Assembly

1. Remove the gear box cover (Power Unit Assembly,

item 1) by disconnecting fluid hose to the manifold

filter by unscrewing the four allen head bolts (Power

Unit Assembly, item 36).

2. Disconnect the Fluid Pump, page 11.

3. Pull off the spacer tubes (Power Unit Assembly, item

30) and drop the sleeve bearing down and off. Slide

the connecting rod off the gear box.

4. Remove the top cover (Power Unit Assembly, item

2) by unscrewing the 6 mounting screws. Be careful

not to lose the 6 matching grommets.

5. Remove the bottom cover (Power Unit Assembly,

item 14) by unscrewing the 2 bolts and nuts.

6. Remove the splash cover (Power Unit Assembly,

item 12) from the clutch brackets and spacer tubes.

7. Disconnect the two clutch from the electrical control

board leads and clutch the spring (Clutch Assembly,

item 9) from the spacer tube.

8. Loosen (do not remove completely) the block tensioner’s set screws (Belt Tensioning, item 6) to

detension the belt.

9. Loosen (do not remove) the four plate bolts.

10. Pull the cog belt loose from the engine shaft god

pulley and let hang loose on the clutch cog pulley.

14. Hold coupling screw, with 13/16” wrench, then with

5/16” allen wrench, screw differential screw out of

coupling screw and gearbox shaft.

15. Remove the coupling screw from the clutch bore.

NOTE: After extended use the coupling screw can hang

up inside of the clutch bore. Tapping on the side of the

coupling screw and/or the use of the lightweight oil or

break free product can ease the removal process. In

extreme cases, screw the differential screw large thread

size in, then place a washer and nut on the small thread

side. This allows pulling or prying on the coupling screw

in order to remove it.

16. The clutch and other components can now be slid

off the gear box shaft.

Inspecting the Clutch

1. Inspect clutch and belt, replace as necessary.

Installing the Clutch

Refer to the following parts diagrams: Belt Tensioning,

Clutch Assembly, and Power Unit Assembly

1. With gearbox held in a vice vertically as previously

described, place first spacer, and bearing, onto

gearbox shaft. See Clutch Assembly, page 27

2. Inspect snap rings (2), into recesses of cog pulley

portion of clutch. Place cog pulley portion of clutch

with cog belt attached onto shaft.

11. Remove the two vertical bracket screws. (Power

Unit Assembly, item 20)

12. Remove the four horizontal screws throughout the

gearbox plate (Belt Tensioning, item 5) and lift the

gear box off the machine.

13. Place gearbox in vice by gripping the flat part of the

drive crank allowing the clutch assembly to face up.

Use caution and not allow gearbox to swing and

damage casting against vice.

3A1187E 17

3. Place second spacer, into cog pulley portion of

clutch. This spacer will rest on the first bearing,

installed.

4. Insert second bearing, on top of upper snap ring.

5. Lay removable spacer on top of last bearing. If the

clutch air gap is larger than .024”, do not use removable spacer. Put spacer over removable spacer, if

used, and top bearing.

6. Place coil portion of clutch down onto cog pulley

portion of clutch and center on gearbox shaft.

Page 18

Clutch Replacement

7. Screw differential screw, into coupling screw and nut

until 1/16” is showing. See Clutch Assembly, page

27

8. Push coupling nut assembly, into clutch assembly

until it comes to a positive stop. (Differential screw

comes into contact with the threaded gearbox

shaft.)

9. With 13/16” wrench on coupling screw and 5/16”

allen wrench in differential screw, simultaneously

with both wrenches screw coupling nut assembly

into gearbox shaft by turning clockwise until a positive stop is reached.

10. Hold coupling nut assembly and tighten differential

screw to 30 ft.-lbs. This will expand the coupling

assembly, thereby holding the clutch assembly to

gearbox shaft. Turn clutch observing clutch gap.

The pulley should turn freely with a gap of .012 to

.024” between the two clutch faces. If the gap is

greater than .024, remove the removable spacer.

Reassemble and check gap for proper clearance.

11. Place cog belt over cog pulley portion of clutch. Set

gearbox and clutch assembly on the support brackets (Power unit Assembly, Ref. 25 & 26), screw in

the two vertical bracket screws (Power unit Assembly, Ref. 20) and start the four horizontal screws

throughout the gearbox plate (Belt Tensioning, Ref.

25 & 26) and into the back of the gearbox.

Belt Tensioning

Refer to the following parts diagrams: Belt Tensioning,

Suction Assembly, and Power Unit Assembly

1. Slightly loosen the two horizontal screws (Power

unit Assembly, Ref. 19-22) that connect the top and

bottom supports (Power unit Assembly, Ref. 24 &

25).

2. Evenly tighten set screws (Belt Tensioning, Ref. 6)

until flush with tip of block tensioner (Belt Tensioning, Ref. 7). Check tension on cog belt by pressing

hard with thumb. Proper tensioning should allow for

approximately 1/8”. If belt is too loose, tighten set

crews further.

3. Once belt tension is correct tighten down the four

horizontal screws that go through the gearbox plate

(Power Unit Assembly, Ref. 8) and into the back of

the gearbox. Also tighten the two horizontal screws

(Power Unit Assembly, Ref. 19-20) that connect the

top and bottom supports (Suction Assembly, Ref. 24

& 25). Reconfirm that the belt deflection is still 1/8”.

4. Reassembly connections, covers and fluid pump in

reverse order as described in steps 1-7 of Removing

Clutch instructions, page 17.

12. Slide cog belt over engine pulley.

18 3A1187E

Page 19

Troubleshooting

General

Problem Cause Solution

There is spitting from the gun. The fluid supply is low or empty. Refill the supply container.

Troubleshooting

Air entrapped in the fluid pump

or hose.

Paint leaks into the wet cup The packing nut/wet cup is

loose.

The upper packings are worn or

damaged.

Worn Piston Rod. Replace Piston Rod.

The engine operates, but the

paint pump doesn’t cycle.

The engine and displacement

pump operates, but paint

pressure is too low or none.

The displacement pump operates, but the output is too low

on the downstroke or both

strokes.

The pressure setting is too low. Increase the pressure.

The clutch is not engaged. See Electrical Troubleshooting.

The displacement pump is

seized.

The pressure setting is too low. Increase the pressure.

The tip or gun filter is clogged. Remove the tip and/or filter and clean them.

The tip is worn. Replace tip.

The fluid displacement pump

filter is clogged.

There is a large pressure drop

in the fluid hose.

The inlet valve ball is not seating properly.

Check for loose connections on the siphon

assembly, tighten, then reprime pump.

Tighten just enough to stop leakage.

Replace the packings. See Packing Replace-

ment Procedures, page 14.

Service the pump. See Packing Replace-

ment Procedures, page 14.

Clean the filter.

Use a larger diameter hose.

Service the Inlet Valve, page.

The displacement pump operates, but the output is too low

on the upstroke.

3A1187E 19

The outlet valve ball is not seating properly.

The lower packings are worn or

damaged.

Service the Outlet Valve, page 13.

Replace the Packings, page 14.

Page 20

Troubleshooting

Electrical

Problem Cause Solution

Clutch does not engage Pressure Control Knob Ensure the pressure control knob is in the maxi-

mum clockwise position.

Poor Electrical Connection Remove the clutch and electrical box covers.

Check all electrical connections between the

engine magneto, sensor, control board and

clutch for loose connections or damaged leads.

Magneto Disconnect the two leads from the control board

(blue) and the clutch assembly (black). Using a

multimeter, with the engine at maximum RPM,

pressure control knob in the maximum position

and the prime valve open (priming) position, test

the DC voltage across the boards lead (blue).

This voltage must be 13-14 VDC. If the readings

are correct, the board, sensor and magneto are

functioning. See Clutch Assembly.

When the DC voltage from the board is not

13-14 VDC, disconnect the control board lead

(black) from the engine magneto lead (pink),

located on the side of the engine. With the

engine at maximum RPM (3600), pressure control knob in maximum clockwise position and

prime valve open (priming), read the AC voltage

from the magneto lead to the sprayer frame. The

reading should be 19-24 VAC. If outside this

range, replace the magneto. If the magneto is

producing proper voltage, see Defective Sen-

sor.

Defective Sensor Test the sensor by reading the resistance

between the red and black wires. The resistance

runs between 1.5 - 3K ohms. A defective sensor

usually shows no resistance (open). If the reading is outside standards, replace the sensor.

An alternative method of testing the sensor is to

plug a new sensor into the board to see if the

clutch will engage. When using this method,

ensure prime/pressure valve is in the prime

position because the sensor plugged into

the board in not measuring pressure in the

fluid section.

20 3A1187E

Page 21

Problem Cause Solution

Clutch Assembly Measure resistance between the clutch leads

(black). This value must be 10-16 ohms. If this

reading is out of specifications, the clutch is

defective and must be replaced.

If the clutch resistance readings are correct,

check spacing between the clutch field and

plate. The gap should be .012” to .024”. If the

gap is greater than .024 the gap is too wide and

the spacer should be removed from the clutch

assembly. If the clutch still does not engage,

replace the clutch assembly. See Clutch

Replacement, page 17.

Electrical Control Board If the magneto and sensor are functioning,

replace the electrical control board.

Airless Spray Gun

Troubleshooting

Problem Cause Solution

Coarse spray Low pressure Increase the pressure

Excessive fogging (overspray) High pressure Reduce the pressure to satisfactory pattern dis-

tribution.

Material too thin Use less thinner

Pattern too wide Spray angle too large Use smaller spray angle tip

Pattern too narrow Spray angle too small Use larger spray angle tip (if coverage is OK, try

tip in same tip group)

Too much material Nozzle too large Use smaller nozzle

Material too thin

Pressure too high Reduce pressure

Too little material Nozzle too small Use next larger nozzle

Material too thick

Thin distribution in center of

pattern “horns”

Thick skin on work Material too viscous Thin cautiously

Worn tip Change to new tip

Wrong tip Use nozzle with narrow spray angle

Application too heavy Reduce pressure and/or use tip in next smaller

tip size

Coating fails to close and

smooth over

Spray pattern irregular,

deflected

Craters or pock marks, bubbles on work

3A1187E 21

Material too viscous Thin cautiously

Orifice clogged Clean carefully

Tip damaged Replace with new tip

Solvent balance Use 1 to 3% “short solvents remainder “long”

solvents (this is most likely to happen with material of low viscosity, lacquers, etc.)

Page 22

Troubleshooting

Problem Cause Solution

Clogged screens Extraneous material in paint Clean screen

Course pigments Use coarse screen if orifice size allows.

Poorly milled pigments (paint

pigments coagulate)

Test the Pattern

Good, Full

Use courser screen, larger orifice tips. Obtain

ball milled paint. If thinner had been added, test

to see if a cover screen. Incompatible drop

placed on top of paint mixes or flattens out on

the paint mixture and thinners on the surface. If

not, try different thinner in fresh batch of paint.

Spotty Pattern,

Increase Pressure

ti15991a

22 3A1187E

Page 23

Parts

Fluid Pump

14

2

3

55

44

12

Parts

1

Ref. Part Description Qty.

1 866143 GEARBOX 1” 1

2 301320 COVER 1

3 301046 ROD END 1

4 867468 RETAINING RING 1

5 866074 COUPLING SET 1

6 866069 RETAINING SLEEVE 1

7 301467 FRONT SHIELD 1

8 866267 SL PAINT PUMP ASSEMBLY 2

9 866241 SUCTION NUT 1

10 140051 NUT 2

11 140035 LOCK WASHER 2

12 301059 SPACER 2

13 867641 STUD 2

14 16F587 LABEL, FRONT 1

6

13

8

9

11

10

ti15993a

3A1187E 23

Page 24

Parts

Inlet Valve

1

2

Outlet Valve

3

Ref. Part Description Qty.

1 556562 BLACK O-RING 1

4

2 866306 INLET RETAINER 1

3 101822 INLET BALL 1

5

4 867574 INLET SEAT 1

5 867390 WHITE O-RING 1

6 866400 SUCTION FITTING 1

7 866241 SUCTION NUT 1

6

7

ti15999a

8

9

10

11

12

13

Ref. Part Description Qty.

8* 866274 RETAINER 1

9 867575 OUTLET SEAT 1

10 104319 WHITE O-RING 1

11 867047 OUTLET BALL 1

12* 866307 OUTLET RETAINER 1

13* 187330 PISTON 1

* Included in Item No. 13

ti16000a

24 3A1187E

Page 25

Manifold Filter (865627)

1

Parts

2

3

1 867145 BASE 1

2 301356 SPRING 1

3 867377 O-RING 1

4 867214 FILTER 60 MESH 1

5 867647 SUPPORT 1

6 867077 BASE 1

Ref. Part Description Qty.

4

7 301309 HOSE 1

8 557391 PLUG 3/8” 2

9 867311 NIPPLE 3/8”M x 1/4”M 1

10 867420 PLUG 1/4” 1

5

6

7

9

8

1010

3A1187E 25

ti16005a

Page 26

Parts

Packing Replacement

Ref. Part Description Qty.

1* 187330 PISTON,2.00 STROKE, SL 1

2 866056 SCREW,COLLAR 1

3 866295 BODY,PUMP,MACHINING 1

4 866362 SPACER,TUBE 1

5*+ 104319 PACKING,O-RING 1

6*+ 866307 RETAINER,BALL,.3125,SL 1

7+ 867047 BALL,.3125, GR25, PISTON 1

8 867575 SEAT,UPPER,T.C. 1

9* 866274 PLUG,3/4-20 1

10 866306 RETAINER,SUCTION 1

11+ 101822 BALL, INTAKE 1

12 866400 SUPPORT,SUCTION SEAT 1

13 867574 SEAT,T.C. 1

14+ 867390 O-RING,5-677, PTFE 1

15+ 556562 O-RING,-121 VITON-A 75 DURO 1

16 866241 NUT,SUCTION 1

17+ 867689 PACKING,VEE,LEATHER 4

18+ 866018 ADAPTER,MALE, SHORT 2

19+ 867693 PACKING,V-PACKING(1.500/1.125) 6

20+ 866100 ADAPTER,DOUBLE, FEMALE 1

21 867083 SPRING,BELLEVILLE 3

22 866011 ADAPTER,MALE 1

23+ 867688 PACKING,VEE,LEATHER 2

24+ 867608 PACKNG,SEAL,1.187/.810,UHWPE 3

25 866010 ADAPTER,FEMALE 1

26 866426 HOLDER,V PACKING 1

27+ 867378 O-RING,2-126, PTFE 1

28+ 107083 PACKING,O-RING 1

These parts are included in Repair Kit 866267

* These parts are included in Repair Kit 866269

+ These parts are included in Packing Kit 865672

2

28

27

26

25

2423242324

22

212121

4

3

6

7

9

15

11

18

1917191719

20

1917191719

18

1

5

8

14

10

13

12

16

ti16002a

26 3A1187E

Page 27

Clutch Replacement

6

7

9

5

4

3

2

1

Parts

Ref. Part Description Qty.

1 301284 CLUTCH REPLACEMENT 1

2 301231 COG BELT 1

3 305088 SCREW 1

4 867602 SHOULDER SCREW 1

5 111800 SCREW FLANGED 4

8

6 867581 SET SCREW 2

7 301534 BLOCK TENSIONER 1

10

8 301208 GEARBOX 1

9 305045 PLATE 1

10 305046 SPACER TUBE 1

ti16007a

Clutch Replacement (866054)

10

7

9

21

8

55

66

33

44

ti16008a

Ref. Part Description Qty. Ref. Part Description Qty.

1 866322 DIFFERENTIAL SCREW 1 6 867464 RETAINING RING 2

2 866234 COUPLING NUT ASSEMBLY 1 7 301413 REMOVABLE SPACER 1

3 CLUTCH 1 8 301412 SPACER 1

4 301037 BEARING 2 9 136068 SPRING 1

5 301274 SPACER 2 10 301316 RUBBER EDGE 1

3A1187E 27

Page 28

Parts

Engine Assembly

4

1

2

3

5

7

6

98

ti16009a

Ref. Part Description Qty. Ref. Part Description Qty.

1 114530 HONDA ENGINE 1 6 565007 SCREW 4

2 305012 ADAPTOR 1 7 866337 SHEAVE ASSEMBLY 1

3 109031 SCREW 4 8 301229 THRUST PLATE 1

4 866212 KEY 1 9 867771 SCREW 1

5 555326 SET SCREW 1

Frame Assembly

Ref. Part Description Qty.

1 867770 FRAME 1

2 301202 MOTOR BRACKET 1

3 301165 WHEEL 2

4 136126 SCREW 4

1

2

10

4

5

6

8

12

11

3

5 140029 WASHER 12

6 867325 NUT 4

7 331048 RUBBER BOOT 2

8 305039 SPACER 2

9 143029 SET COLLAR 2

10 110637 SCREW 2

11 866084 CUP 1

12 116969 NUT 2

342473▲ LABEL, WARNING (NOT SHOWN) 1

342506▲ LABEL, WARNING (NOT SHOWN) 1

9

7

ti16011a

▲ Additional warning labels are available at no cost.

28 3A1187E

Page 29

Power Unit Assembly

Parts

4

3

2

11

39

40

37

3

36

19

7

35

6

5

20

20

1

38

12

13

20

15

16

26

2121

17

212521

18

23

2323

ti16010a

Ref. Part Description Qty. Ref. Part Description Qty.

1 301320 GEARBOX COVER 1 24 100450 SCREW 2

2 301531 TOP COVER 1 25 301299 BOTTOM SUPPORT 1

3 301135 GROMMET 6 26 301232 TOP SUPPORT 1

4 301337 SCREW 2 27 301173 RETURN BRACKET 1

5 301047 SLEEVE BEARING 1 28 867641 STUD 2

6 301333 CONNECTION ROD 1 29 140035 WASHER 2

7 301446 GEARBOX 1 30 140051 NUT 2

8 305045 GEARBOX MOUNTING PLATE 1 31 301059 SPACER 2

9 305064 MANIFOLD HOLDER 1 32 866069 COUPLING SET COVER 1

10 305012 ADAPTER 1 33 866074 COUPLING SET 1

11 114530 HONDA ENGINE 1 34 867468 RETAINING RING 2

12 301529 SPLASH COVER 1 35 301467 SHIELD 1

13 305046 TUBE SPACER 4 36 867505 SCREW 4

14 109031 SCREW 2 37 121112 SCREW 4

15 305067 BOTTOM COVER 1 38 305140 MANIFOLD FILTER BRACKET 1

16 102547 SCREW 2 39 867529 SCREW 2

17 305047 STUD 4 40 301105 HOOK 1

18 140044 NUT 8 * 866149 GROUNDING ASSEMBLY 1

19 331294 SENSOR 1 342473▲ LABEL, WARNING (NOT SHOWN) 1

20 867528 SCREW 4 342506▲ LABEL, WARNING (NOT SHOWN) 1

21 140029 WASHER 10

22 867301 WASHER 4

23 867325 NUT 2 ▲ Additional warning labels are available at no cost.

3A1187E 29

Page 30

Parts

Suction Assembly (301594)

6

4

2

2

3

5

1

ti16012a

Ref. Part Description Qty. Ref. Part Description Qty.

1 866020 ELBOW 1 4 15F149 TUBE 1

2 867446 PUNCH CLAMP 2 5 187147 INLET FILTER 1

3 866388 HOSE 54” 1 6 15F513 GASKET, PAIL 1

Paint System Assembly

9

10

11

8

7

6

5

12

14

3

2

13

See Packing Replacement Procedures

5

9

16

15

1

17

ti16003a

Ref. Part Description Qty. Ref. Part Description Qty.

1 GUN 9 867183 ELBOW

289316 24F575 1 10 301253 MANIFOLD 1

24E382 16M532 1 11 867325 NUT 2

2 HOSE 12 102547 BOLT 2

HSE3850 3/8” x 50’ (24F575) 1 13 867188 ELBOW 1

865675 3/8” x 50’ (16M532) 1 14 867400 HOSE, PAINT 3/8” x 21”’ 1

3 867309 NIPPLE 1 15 867660 TEE 1

5 867311 NIPPLE 1 16 865719 PRIME VALVE 1

6 557391 PLUG 1 17 248217 HOSE DRAIN 1

7 865627 MANIFOLD FILTER ASSY 1 15F514 GASKET, PAIL 1

8 301309 HOSE 1 16D431 GROMMET 1

867759 CONNECTOR, MALE, 3/8” x 1/8” 1

255439 HOSE 3/8” x 3’ (24F575) 1

30 3A1187E

Page 31

Technical Data

Technical Data

Maximum working pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 psi (20.7 MPa, 207 bar)

Maximum delivery gpm (lpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.70 (6.4)

Maximum tip size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .041 with one gun, .029 with two guns

Fluid outlet npsm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 in.

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . zinc and nickel-plated carbon steel, nylon, stain-

less steel, PTFE, acetal, leather, UHMWPE,

aluminum, tungsten carbide

3A1187E 31

Page 32

Airlessco Standard Warranty

Airlessco warrants all equipment referenced in this document which is manufactured by Airlessco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Airlessco, Airlessco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Airlessco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Airlessco’s

written recommendations.

This warranty does not cover, and Airlessco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Airlessco component parts. Nor shall Airlessco be liable for malfunction, damage or wear caused by the incompatibility of Airlessco equipment

with structures, accessories, equipment or materials not supplied by Airlessco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Airlessco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Airlessco distributor for verification

of the claimed defect. If the claimed defect is verified, Airlessco will repair or replace free of charge any defective parts. The equipment will be

returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship,

repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Airlessco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

AIRLESSCO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY Airlessco. These items sold, but not manufactured by Airlessco (such as electric motors, switches, hose, etc.), are subject

to the warranty, if any, of their manufacturer. Airlessco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Airlessco be liable for indirect, incidental, special or consequential damages resulting from Airlessco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of

warranty, the negligence of Airlessco, or otherwise.

FOR AIRLESSCO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

TO PLACE AN ORDER OR FOR SERVICE, contact your Airlessco distributor,

or call 1–800–223-8213 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Airlessco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English. MM 3A1187

Airlessco, 3501 N. 4th Avenue, Sioux Falls, SD 57104

Copyright 2010, Graco Inc. is registered to ISO 9001

www.airlessco.com

Revised 02/2012

Loading...

Loading...