Air King LIN34M, LIN40M, LIN46M, LIN58M Operating Manual

IMPORTANT INSTRUCTIONS -

OPERATING MANUAL

Models: LIN34M, LIN40M,

LIN46M, LIN58M

Outdoor Kitchen

Powered Liner

READ AND SAVE THESE INSTRUCTIONS

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE PRODUCT DESCRIBED.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

GENERAL SAFETY INFORMATION

When using electrical appliances, basic precautions

should always be followed to reduce the risk of fire,

electric shock and injury to person, including the following:

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK

AND INJURY TO PERSON, OBSERVE THE FOLLOWING:

a) Use this unit only in the manner intended by the manufacturer.If you

have questions, contact the manufacturer.

b) Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service panel.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK

AND INJURY TO PERSON, OBSERVE THE FOLLOWING:

a) Installation work and electrical wiring must be done by qualified

person(s) in accordance with all applicable codes and standards,

including fire-related construction.

b) Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment to

prevent back drafting. Follow the heating equipment manufacturer’s

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA) and the American

Society for Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

CAUTION: TO REDUCE THE RISK OF FIRE AND TO PROPERLY

EXHAUST AIR, BE SURE TO DUCT AIR OUTSIDE - DO NOT VENT

EXHAUST AIR INTO SPACES WITHIN WALLS OR CEILINGS OR INTO

ATTICS, CRAWL SPACES, OR GARAGES.

d) Ducted fans must always be vented to the outdoors.

e) This unit must be grounded.

f) To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power unit.

g) Read all instructions before installing or using exhaust fan.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, DO

NOT USE THIS FAN WITH ANY SOLID-STATE SPEED CONTROL DEVICE.

WARNING: TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

flambéing food (ie. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan filter.

d) Use proper pan size. Always use cookware appropriate for

the size of the surface element.

WARNING: TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:

a) SMOTHER FLAMES with a close-fitting lid, cookie sheet, or

metal tray, then turn off burner. BE CAREFUL TO PREVENT

BURNS. If the flames do not go out immediately, EVACUATE

AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - You may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels -

a violent steam explosion will result.

d) Use an extinguisher ONLY if:

I. You know you have a Class ABC extinguisher, and you

already know how to operate it.

II. The fire is small and contained in the area where it started.

III. The fire department is being called.

IV. You can fight the fire with your back to an exit.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCTWORK.

SAVE THESE INSTRUCTIONS

6728024M New 8-10 1 of 8

www.airkinglimited.com

INSTALLATION INSTRUCTIONS

CAUTION:

BEFORE STARTING INSTALLATION.

NOTE: Outdoor Kitchen Professional Range Hoods are approved for use in covered

outdoor kitchens only. Proper duct adapters, ducting, chimneys, roof/wall caps, etc.

must be utilized as called out in the following instructions. Do not install the hood in an

uncovered area directly exposed to the elements.

MAKE SURE POWER IS SWITCHED OFF AT SERVICE PANEL

SECTION 1

Preparing the Insert

1. Unpack hood from the carton and confirm that all pieces are present. In addition to

the range hood you should have:

12 - Screws (46", 58" models - 14)

2 - Halogen Bulbs (58" models - 4)

1 - Duct Adapter

1 - Grease Trough

2 - Grease Baffles (46", 58" models - 3)

1 - Instruction/Safety Sheet

NOTE: Some hoods may be shipped with a protective plastic adhered to the underside

of the unit. It is recommended to leave this in place during installation to protect it from

scratching. Remove when the installation is complete.

NOTE: If additional support is required, install a 2" x .75" strip of wood (34" wide) between

the back of the canopy (rear wall) and the hood. When installing the wood strip to the

back of the canopy, locate studs in the wall to support the weight of the canopy. Center

the wood strip 11.5" from the bottom of the canopy and attach the strip to at least two

studs in the rear wall (do not fasten the strip to drywall only). Lift unit up into position so

that the bottom flanges are in solid contact with the bottom of the canopy or cabinet. Using

wood screws and washers (not included) secure the hood to the wood strip through the

two keyholes in the back of the hood. Using the included wood mounting screws, secure

the unit to the canopy or cabinet by driving the screws through the holes (Figure 3).

OPTIONAL ADDITIONAL SUPPORT

Canopy

Wood

Mounting

Washer

Strip

Screws

Flange

Figure 3

SECTION 4

Ducting

SECTION 2

Preparing the Area

CAUTION: MAKE SURE POWER IS SWITCHED OFF AT SERVICE PANEL

BEFORE STARTING INSTALLATION.

CAUTION: WHEN CUTTING OR DRILLING INTO WALL DO NOT DAMAGE

ELECTRICAL WIRING AND OTHER HIDDEN UTILITIES.

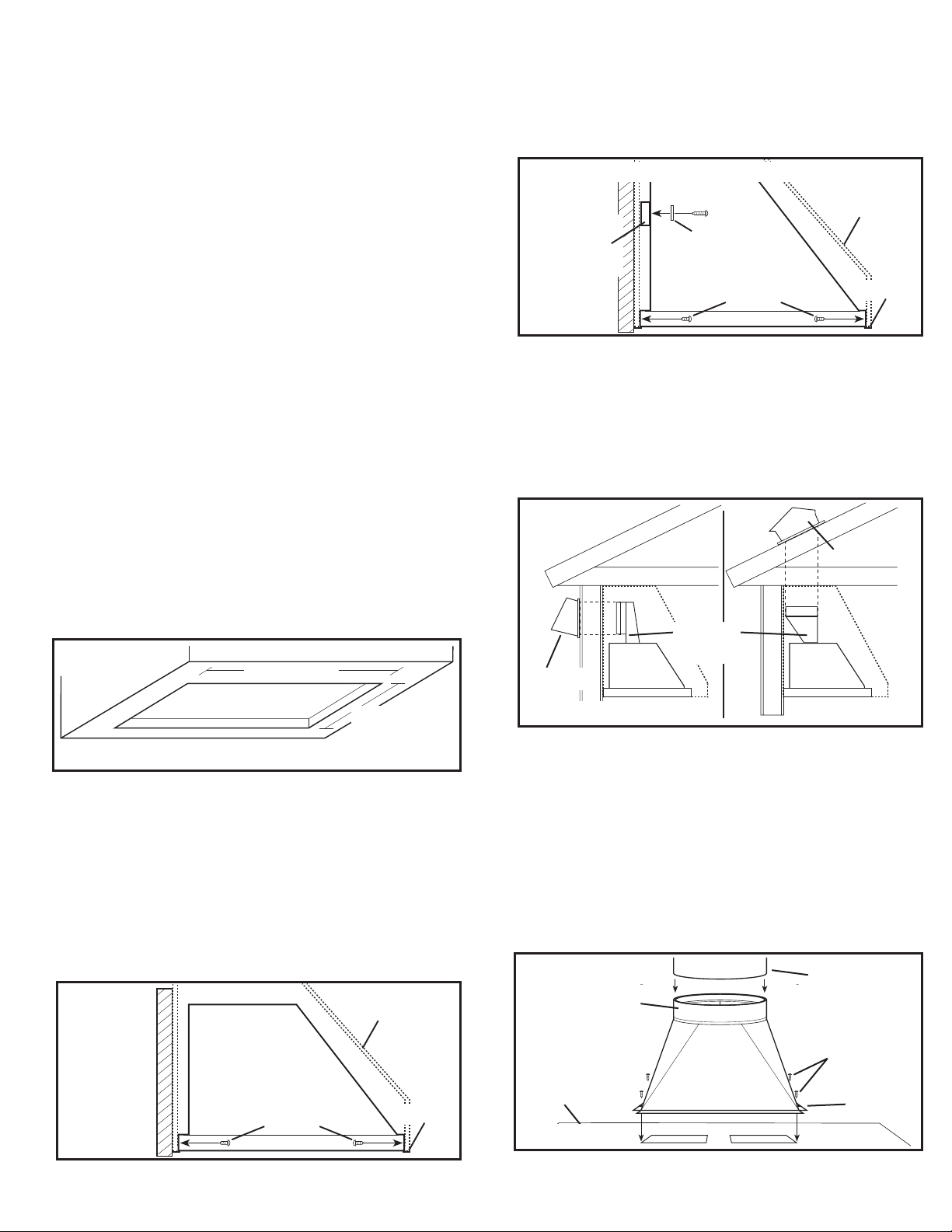

1. Cut an appropriately sized hole for the cabinet or canopy the liner will be mounted

into (Figure 1):

Model LIN34M: 34.5" x 19.375"

Model LIN40M: 40.5" x 19.375"

Model LIN46M: 46.5" x 22.625"

Model LIN58M: 58.5" x 22.625"

34.5"/40.5"/

46.5"/58.5"

19.375"

22.625"

Figure 1

NOTE: The hood must be mounted a minimum of 24" and a maximum of 36" from the

cooking surface.

SECTION 3

Mounting the Liner

CAUTION: DUE TO THE WEIGHT AND BULK OF THE UNIT, IT IS RECOMMENDED

THAT THREE PEOPLE ARE PRESENT DURING INSTALLATION TO LIFT, HOLD, AND SECURE

THE UNIT IN PLACE.

1. Lift unit up into position so that the bottom flanges are in solid contact with the bottom

of the canopy or cabinet. Using the included wood mounting screws, secure the unit

to the canopy or cabinet by driving the screws through the holes (Figure 2).

CAUTION: ALL DUCTING MUST COMPLY WITH LOCAL AND NATIONAL

BUILDING CODES.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

1. Determine the type of ducting you will require (Figure 4).

Horizontal

Roof Cap

Outlet

Adapter

Wall Cap

Figure 4

NOTE: For models using the B600 blower (LIN34, LIN40), a minimum of 6” diameter

outlet adapter & ducting is required to achieve the proper air flow. The B1125 (LIN46,

LIN58) requires a minimum 10” diameter adapter and ducting.

NOTE: When the duct termination is similar to that shown in Figure 4 (passing through

the wall to which the hood is mounted) the installation requires special consideration.

Depending upon where the wall studs are located, it may be necessary to cut one

or more of the wall studs and install a header and footer to transfer the load to the

adjacent studs. Additional studs may need to be framed into the opening to attach dry

wall or secure the hood. If this is your situation Air King recommends that you hire a

professional and comply with all applicable codes.

2. Install the proper sized outlet adapter to the hood by matching up the four holes on

the flange of the adapter to the four corresponding holes on the hood and secure

in place with the provided screws. Ensure an airtight seal around the adapter by

securing all connections with ducting tape (Figure 5).

Vertical

Ducting

Canopy

Outlet Adapter

Screws

Hood

Screws

Figure 2

6728024M New 8-10 2 of 8

Flange

Figure 5

www.airkinglimited.com

Flange

3 When there is access to the top of the unit, connect the ducting to the duct collar

and secure in place using tape to seal all joints (Figure 5).

4. When there is no access to the top of the hood, carefully pull down the metal duct

through the custom hood base hole. Slide this duct over the duct collar. Make sure

the adapter/damper assembly enters the ducting. Seal the connection with duct tape.

3. Install the baffle filters by inserting the top of the filter into the top channel of the

hood, then slide the bottom of the filter into the bottom channel. The filters have a

top and a bottom. The bottom of the filter will have small drain holes. These holes

must be facing down towards the grease trough to be effective (Figure 9).

SECTION 5

Wiring

CAUTION: ALL ELECTRICAL CONNECTIONS MUST BE MADE IN

ACCORDANCE WITH LOCAL CODES, ORDINANCES, OR NATIONAL ELECTRICAL

CODE. IF YOU ARE UNFAMILIAR WITH METHODS OF INSTALLING ELECTRICAL

WIRING, SECURE THE SERVICES OF A QUALIFIED ELECTRICIAN.

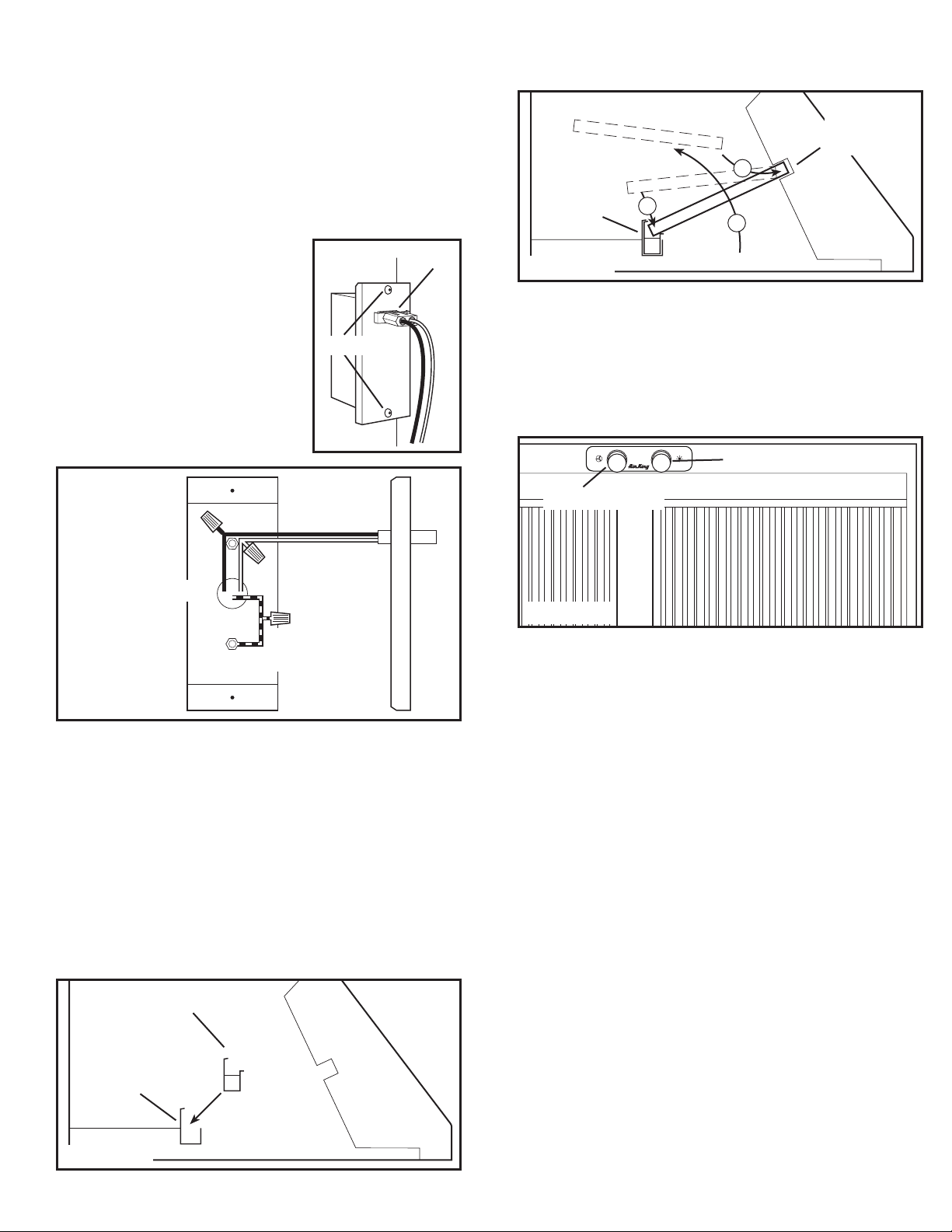

1. Remove the two wire compartment cover screws

to gain access into the wire compartment (Figure

6). Connect the white wire from the range hood to

the white wire from the supply, and the black wire

from the range hood to the black wire of the supply.

Connect the ground wire from the home (green or

bare) to the ground wire (green) from the hood. Use

approved methods for all connections (Figure 7).

2. Replace the wire compartment cover and tighten

screws. Make sure all wiring is securely contained

within the wire compartment. If the quick connect

wire connector was removed from the receptacle,

replace. The connector will only fit one way into

the receptacle (Figure 6).

Supply from house

Ground

(Green or Bare)

Wire Connector

Screws

Figure 6

Hot (Black)

Neutral

(White)

Top

Channel

2

Bottom

Channel

3

1

Figure 9

SECTION 8

Operation

Controls

Your Range Hood is equipped with two rotary switches with one controlling the lighting

and the other controlling the exhaust fan blower. The light switch has three positions,

High, Low, and Off. The fan switch has four positions, Off, High, Medium, and Low

(Figure 10).

Light Switch

Blower Switch

Figure 10

SECTION 9

Maintenance

Figure 7

SECTION 6

Installing the Blower

1. Refer to the instructions included with the specific blower you have chosen for

installation.

SECTION 7

Finishing the Installation

1. Install the proper lighting for your specific unit:

Halogen Lamps: Use PAR16, 45W maximum lamps. Install by inserting lamp into

socket and turning clockwise until lamp is firmly seated. DO NOT over tighten.

2. If the included removable grease trough is not already installed within the hood,

insert into the rear inside channel of the hood. Make sure the taller side of the

trough is facing towards the back of the hood (Figure 8).

Grease Trough

Channel

Figure 8

CAUTION: MAKE SURE POWER IS SWITCHED OFF AT SERVICE PANEL

BEFORE SERVICING THE UNIT.

Grease Baffles

Included with your range hood are stainless steel grease baffles along with a grease

trough that should be washed at least once a month. The baffles and trough are dishwasher

safe and should be washed in a mild soap or detergent. Reverse the instruction in

SECTION 8 Finishing the Installation, to remove baffles and trough. If the grease baffles

become damaged, replace with Air King Model PHGB1 Grease Baffles.

CAUTION: ALLOW BULB TO COOL BEFORE REPLACING.

Changing the Lamps

Remove the lamp by turning slightly counter-clockwise and pulling out of the socket.

Replace with a PAR16 45W maximum Halogen lamp.

Fuse

To replace the fuse, turn the fuse cap located next to the wire connector counter

clockwise and pull out. Replace with the proper fuse specific to your blower. Reinstall

the fuse back into the hood.

Cleaning

CAUTION: DO NOT USE GASOLINE, BENZINE, THINNER, HARSH CLEANSERS,

ETC., AS THEY MAY DAMAGE THE RANGE HOOD.

1. Clean your power unit with a mild detergent, such as dishwashing liquid, and dry with

a soft cloth. NEVER USE ANY ABRASIVE PADS OR SCOURING POWDERS. Completely

dry before restoring power. NEVER IMMERSE ELECTRICAL PARTS IN WATER.

2. The fan assembly can be vacuumed when build up (dirt, lint, etc.) accumulates

over time. The fan is permanently lubricated and does not require oiling.

6728024M New 8-10 3 of 8

www.airkinglimited.com

Loading...

Loading...