TM

T LN

80000343 Issue 1 04/15

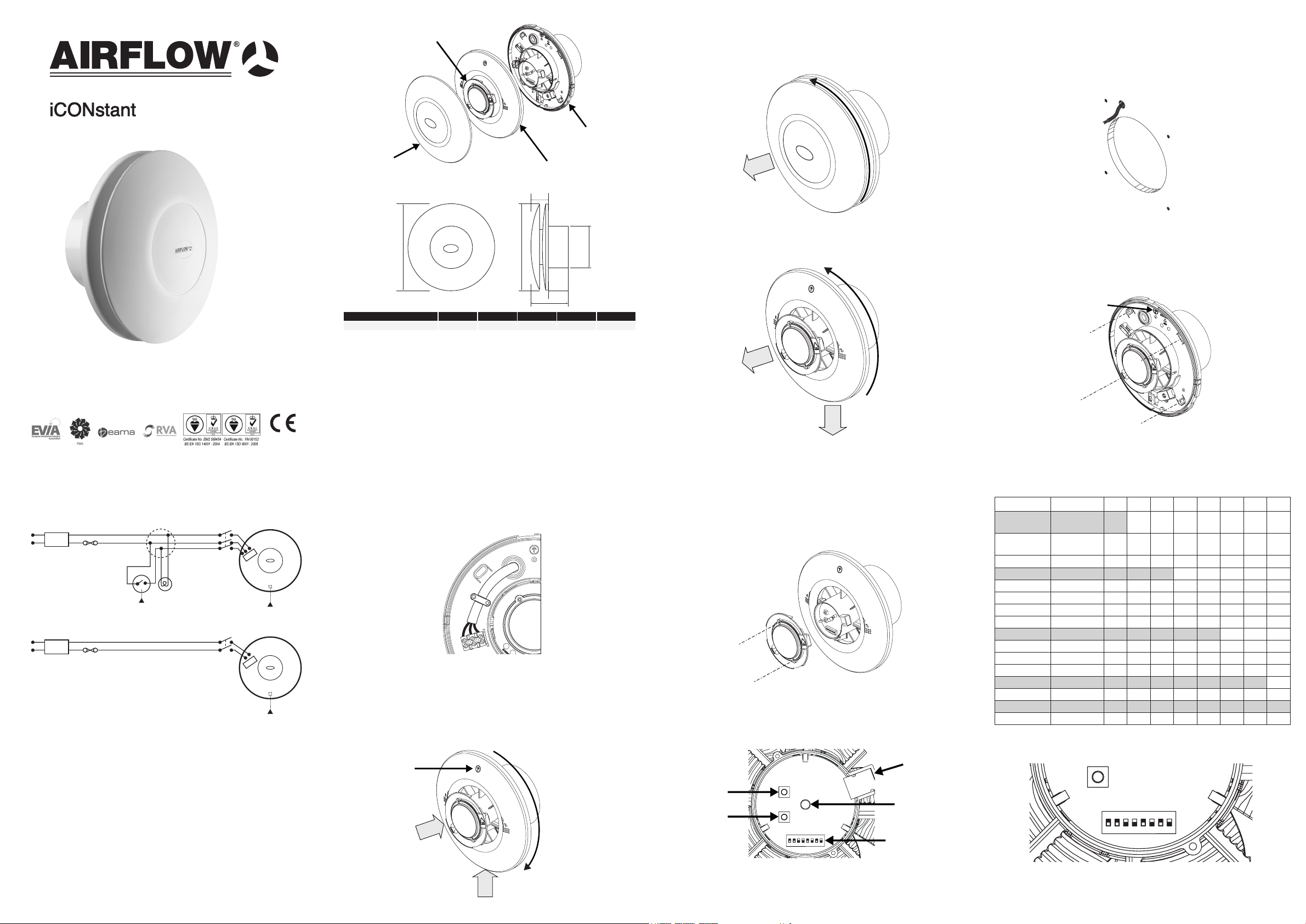

Fan overview

Installation Prepare wall or ceiling

Continuous Ventilation

Installation and Operating Guide

iCONstant T - 72687117

iCONstant HT - 72687118

Electronics Cover

Main Body

Front Cover

Fan Dimensions

A

Model A B C D E

iCONstant 197 120 70 100 50

Back Plate Cover

E

A

C

B

D

The iCONstant range consists of timer and humidity/timer

variants. They are designed for use in any wet room. Trickle

ows rates of 6, 8 or 13 l/s can be activated on installation.

Boost ow rates are selected by pull cord, external switch

or humidity sensor (HT model only). The iCONstant range is

IPX5 rated and suitable for use in Zone 1 of a wet room.

Page 2 of 16

Remove front cover.

1. Twist anticlockwise and 2. Lift away.

1

2

Remove back plate cover.

1. Remove screw at base of back plate cover.

2. Twist back plate cover anticlockwise.

3. Lift away.

2

3

1

Page 3 of 16

Using the template provided, mark and drill a spigot hole to

suit 100mm diameter rigid ducting. Make provision for the

electrical supply cable. Fit wall plugs provided.

Mount fan into the spigot hole ensuring cable is fed through

the cable grommet provided. Position alignment arrow

vertically. Fix to wall or ceiling with the 4 screws provided.

Alignment arrow

Page 4 of 16

Electrical Installation

3 AMP

3 AMP

N - Neutral

L - Live

T - Tigger

N - Neutral

L - Live

3 POLE FAN

ISOLATOR

L

N

LS

2 POLE FAN

ISOLATOR

TLN

TLN

For control with

external switching

N

RCD

L

SWITCHED FUSE

For control with no

external switching

N

RCD

L

SWITCHED FUSE

All electrical installation to be carried out by an approved

electrician in accordance with Part “P” U.K. Building

Regulations and to the latest IEEE standards, or the

appropriate regulations in the country of installation.

iCONstant fans require a 90-264V 50/60Hz supply, it is

double insulated so therefore does not require an earth.

Fans installed in Zone 1 or Zone 2 must be at least IPX4

(splash proof) rated. Additionally, fans installed in Zone 1

must be SELV (Safety Extra Low Voltage) or IPX5 (jet proof)

rated. The iCONstant range is IPX5 rated and suitable for

use in Zone 1.

Secure supply wires into the terminal block. L—Live,

N-Neutral and T—switched live (optional). Secure AC mains

cable to main body of fan with cable clamp supplied.

Fit back plate cover.

1. Locate back plate cover on to main body assembly.

2. Twist back plate cover clockwise until locked. (Arrow

should be in the 12 o’clock position).

3. Secure back plate cover with xing screw.

Alignment Arrow

2

1

3

Page 6 of 16Page 5 of 16

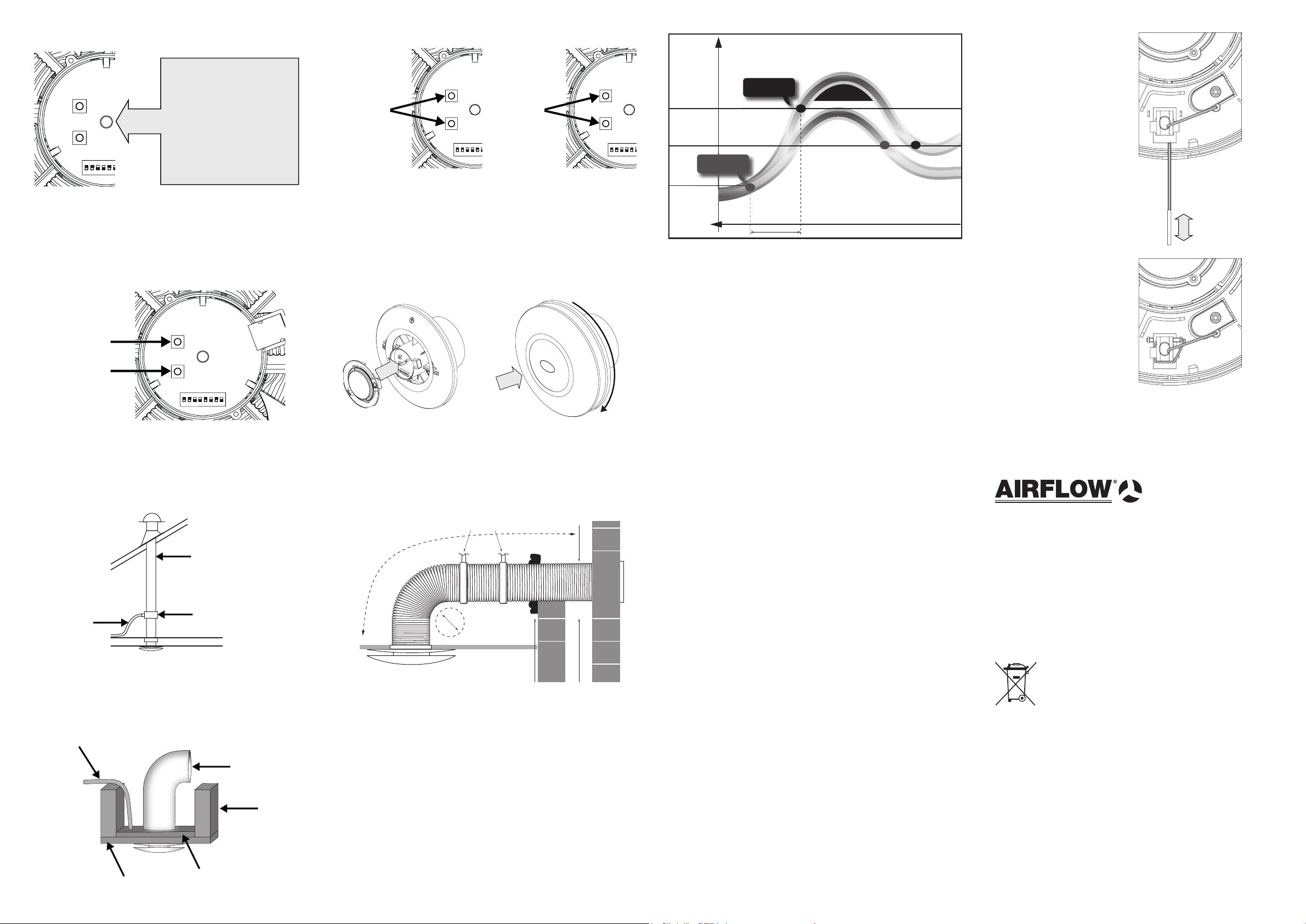

Access to the electronics Dip switch functions

Remove electronics cover.

1. Undo the 2 xing screws,

2. Lift off electronics cover.

Description of electronic controls.

Increase airow

Decrease airow

ON

OFF

Page 7 of 16

Humidity sensor

(HT model only)

Info LED

Function

Dip Switches

Function 1 2 3 4 5 6 7 8

Delayed

start

Delayed

start

Timer 2 mins

Timer 15 mins

Timer 30 mins

Timer 45 mins

Humidity 50-60%

Humidity 60-70%

Humidity 70-80%

Humidity 80-90%

Flow rate

Flow rate

Flow rate

Flow rate

Flow sensor

Flow sensor

0 seconds

2 minutes

OFF OFF OFF

6 L/s OFF ON

8 L/s ON OFF

13 L/s ON ON

ON ON

OFF OFF

Dip Switch factory settings highlighted above.

OFF

ON

OFF OFF

OFF ON

ON OFF

ON ON

OFF OFF

OFF ON

ON OFF

ON ON

ON

OFF

Page 8 of 16

Store new ow rate

Restore selected dip switch

ow rate

Humidity function (HT model only) Boost activationStart up diagnostic sequence

On connection to the

power supply the fan

will run a diagnostic

sequence. This is

indicated by the LED

ON

OFF

ashing 6 times. The fan

will automatically start.

Commissioning adjustment

To adjust the airow rate on commissioning, press top button

to increase ow rate, press bottom button to decrease ow

rate.

Increase airow

Decrease airow

ON

OFF

Press & hold

both for 5

seconds.

LED will

ash

once for

conrmation

ON

OFF

Press & hold

both for 10

seconds.

LED will

ash

twice for

conrmation

ON

OFF

Fit electronics cover and secure with the 2 xing screws.

Check the fan is running. If the LED is on permanently check

installation for impeller obstructions and resolve. Replace

the front cover and twist clockwise to secure.

Page 10 of 16Page 9 of 16

RELATIVE HUMIDITY

Upper Limit - Fan On

Fan Off

iCONstant

HT On

Conventional

Humidity On

iCONstant

Pre-Start

Phase

Mould/

Condensation

will occur

TIME

Automatic Humidity Control with a progressive increase in

humidity—the fan will boost when the pre-set value (factory

setting 70-80% RH) is reached. However, when the sensor

detects a rapid increase in humidity the fan will boost

automatically before the pre-set value has been reached so

that preventive ventilation commences. The fan reverts to

trickle automatically when the humidity is reduced to 10%

below the set point. Note: It is possible that a high level

of humidity is present within the room for a longer period

of time due to generally high humidity in the ambient air

(summertime) or a build up of high humidity over several

hours (steam rooms/sauna etc.)

Page 11 of 16

Pull Cord or switched live

activation increases the

trickle ow rate to boost

for the selected timer

period.

From 6 l/s trickle to 8 l/s

From 8 l/s trickle to 13 l/s

From 13 l/s trickle to 20 l/s

Pull cord storage

Wrap and store around

stowaway mechanism

if not required

Delayed start

The delayed start function of the fan to its’ boost function is

only activated by a remote switch and not by the pull cord.

Page 12 of 16

Good practice guide MaintenanceInstallation with exible ducting

Installation in the ceiling.

Flexible

ducting supports

Minimum radius =

the diameter of

flexible ducting used

Page 14 of 16Page 13 of 16

110mm diameter

plastic pipe

outlet drain to

the outside

To avoid the back ow of condensation into the fan in the

ceiling installations it is good practice to t a condensation

trap (optional—Airow Part 51978301) to the vertical outlet

duct of the fan.

possible cable routing

duct

joist

plywood

ceiling

Maximum length of

flexible ducting

Airflow

Where exible ducting is used the diameter must be

maintained and it is good ventilation practice that the

ducting is extended to 90% of its possible length in order to

maintain the best possible airow. Ensure that exible duct

connections are not over tightened to the fan outlet spigot.

To avoid reduced air ow rigid ducting should be used

(see airow.com). The fan and ducting should be installed

in accordance with the requirements of the Domestic

Ventilation Compliance Guide, part of the

Building Regulations.

Sealant

Slope to outside

Cavity

SAFETY FIRST: ALWAYS ISOLATE THE FAN UNIT FROM THE

POWER SUPPLY BEFORE REMOVING THE COVERS. When

installed according to these instructions the iCONstant is completely

safe. The materials used do not constitute a hazard.

Cleaning

The external housing of the fan can be wiped with a damp cloth.

Do not use household cleaners containing abrasives. Note: Always

isolate the fan when cleaning. Never clean any parts of the fan

assembly by immersing in water or using a dishwasher.

Warranty

Applicable to units installed and used in the United Kingdom.

Airow guarantees the iCONstant for 3 YEARS from date of

purchase against faulty material or workmanship. Warranty only

covers the fan, not the re-installation of the fan if required. In the

event of any defective parts being found, Airow Developments Ltd

reserve the right to repair or at our discretion replace without charge

provided that the unit:

1. Has been installed and used in accordance with the tting and

wiring instructions supplied with each unit.

2. Has not been connected to an unsuitable electrical supply.

3. Has not been subjected to misuse, neglect or damage.

4. Has not been modied or repaired by any person not authorised

by Airow Developments Ltd.

5. Has been installed in accordance with latest Building Regulations

and IEEE wiring regulations by a recognised competent installer.

Page 15 of 16

Warranty cont’d

Airow Developments Ltd shall not be liable for any loss, injury

or other consequential damage, in the event of a failure of the

equipment or arising from, or in connection with, the equipment

excepting only that nothing in this condition shall be construed as to

exclude or restrict liability for negligence.

This warranty does not in any way affect any statutory or other

consumer rights.

Disposal

Do not dispose of with household waste.

Please recycle where facilities exist.

Check with your local authority for recycling advice.

UK Head-Ofce

AIRFLOW DEVELOPMENTS Limited

Aidelle House, Lancaster Road

Cressex Business Park

High Wycombe

Buckinghamshire

HP12 3QP

United Kingdom

Tel: +4(0) 1494 525252

Fax: +4(0) 1494 461073

Email: info@airow.com

Web: airow.com

AIRFLOW DEVELOPMENTS Limited reserve the right in the interest of continuous development to alter any or all

specications without prior notice.

Czech Republic

AIRFLOW LUFTTECHNIK GmbH

o.s. Praha

Hostýnská 520

108 00 Praha 10

Malešice

Czech Republic

Tel: +42(0) 2 7477 2230

Fax: +42(0) 2 7477 2370

Email: info@airow.cz

Web: airow.cz

Page 16 of 16

Germany

AIRFLOW LUFTTECHNIK GmbH

Postfach 1208

D-53349 Rheinback

Germany

Tel: +49(0) 222 69205 0

Fax: +49(0) 222 69205 11

Email: info@airow.de

Web: airow.de

Loading...

Loading...