MATERIALS AND TOOLS REQUIRED

AIR COMPRESSOR (5HP OR BETTER)

DIE GRINDER (WITH WAFER THIN DISCS)

PNEUMATIC AIR SHEARS

DRILL

WITH 1/16", 1/8", 3?16" BITS

HAND OR

AIR OR ELECTRIC ROTAR

SIDE CUTTERS

LEVEL

DUCT TA

CENTER PUNCH

MET

COMP

CYLINDER OR BLACK SILICONE

CAULKING GUN

SAFTEY

CONT

2 P

MAGIC MARKER / RAZOR KNIFE

A

IR RIVET

PE

A

L FIL SET

ASS / SCRIBE

GLASSES

ACT CEMENT

A

RT EPOXY (1 PINT)

GUN

Y SANDER

RATICAL HARD TOP INSTALL

NOTE: MAKE SURE YOU READ AND UNDERSTAND ALL INSTRUCTIONS PRIOR

TO STARTING. THIS IS A COMPLEX INSTALL AND SHOULD ONLY BE

PERFORMED BY AN EXPERIECNED PERSON.

1. REMOVE ALL MOULDING FROM THE DOR FRAME AREAS, REAR VIEW

MIRROR, VISORS, SEATS, PLASTIC PANELS, AND HEADLINER. REMOVE UPPER

SEAT BELT ATTACHMENT ON PILLAR. CUT SHOULDER HARNESS BRACKETS

FROM SHOULDER STRAPS. HARNESS IS NO LONGER USED, YOU MUST USE

LAP BELT.

2. INSTALL OPTIONAL (AND RECOMMENDED) CAB REINFORCEMENT KIT.

A. SLIDE CAB STIFFENER DOWN BEHIND DOOR PILLARS. DRILL HOLES IN

2

3

4

5

8

9a

9b

10

11

MOUNTING PLATE AND ATTACH WITH HARDWARE PROVIDED.

B. DRILL 1/16" HOLES THROUGH REAR CAB WALL WITH SHEET METAL

SCREWS THROUGH LARGER HOLES.

3. DETACH HEADLINER AT WINDSHIELD AND LET HANG LOOSE PAST CUT LINE.

NOTE: COMPASS MEASUREMENTS ARE MADE FROM FRONT EDGE OF

WINDSHIELD MOULDING WHERE GLASS MEETS MOULDING (SEE

ILLUSTRATION 3).

4. FRONT ROOF LINE COMPASS MARKING:

A. SET COMPASS AND SCRIBE YOUR LINE STARTING AT CORNER

WINDSHIELD WHERE MOULDING CURVES AWAY.

B. SCRIBE A 2ND LINE 3/8" BEHIND FIRST LINE. THIS REPRESENTS

APPROXIMATE AMOUNT OF MATERIAL TO BE REMOVED FROM ROOF.

5. MAKE SURE TRUCK IN P

PILLAR TRIM. WITH DOOR CLOSED, MEASURE REAR DOOR CUT LINE.

MAINTAIN THIS SAME HEIGHT FOR YOU REAR CAB WALL CUT. MAKE SURE

THAT PLACEMENT IS CONSISTANT FROM ONE SIDE TO OTHER. USING CHALK

LINE OR STRAIGHT EDGE, MARK LINE ACROSS REAR CAB WALL BETWEEN

MARKS. AFTER LINE IS MARKED, USE LEVEL TO DOUBLE CHECK LINE IS

LEVEL IN RELATION TO BACK WIINDOW AND TRUCK BED TOP EDGE.

6. TRANSFER LINE TO INSIDE OF CAB BY DRILLING TWO 1/8" HOLES ON LINE

YOU JUST

HOLES. THIS IS REAR CUT LINE. MARK WITH DUCT TAPE ON EACH SIDE OF

LINE LEAVING A 3/8" LINE REPRESENTING AMOUNT OF METAL TO BE

REMOVED. MARKING REAR PILLAR POST CUT LINES INSIDE AND OUT OF CAB

IS TRICKY, MAKE SURE THEY ARE LEVEL AND EVEN. GET SECOND OPINION.

7. IT IS RECOMMENDED THAT YOU REMOVE YOUR REAR GLASS TO KEEP IT

FROM PITTING OR BREAKING. BE SURE

FOR SAFETY. ALSO, USE SOME SORT OF COVER TO PROTECT THE BED'S

PAINT. MAKE AN ELONGATED HOLE ON REAR CUT LINE WITH DIE GRINDER

FOR AN ENTRY POINT. USE A STRAIGHT BAR OR EDGE TO SERVE AS CUTTING

"FENCE" FOR AIR SHEARS TO INSURE A STRAIGHT LINE. CUT ALL PLACES YOU

CAN REACH ON THAT LINE. GET HELP ON MARKING AND CUTTING SIDE

PILLARS. OPEN DOOR AND START FROM DOOR JAMB WITH HACKSAW

WORKING TOWARD REAR CORNERS. DO NOT CUT ALL THE WAY THROUGH

YET, THIS WILL HELP AVOID PINCHING UNTIL READY TO REMOVE TOP.

8. USING A DIE GRINDER ST

EACH END FOR AIR SHEARS. IT IS SUGGESTED THAT YOU USE AN ADHESIVE

BACK MOLDING AS A "FENCE" TO GUIDE AIR SHEARS. PRECISION IS

IMPORTANT, DO NOT RUSH THIS CUT. CUT TOP OF ROOF FROM END TO END

FOLLOWING PRECISELY ON. MARKS SCRIBED.

9. DOOR FRAME CUT: SEE ROOF CUTTING GUIDE FOR REFERENCE

MEASUREMENTS. BE SURE

MINIMIZE VIBRATION DURING CUTS. USE DIE GRINDER FOR MAKING CUTS.

MAKE SURE ALL RUBBER MOULDINGS AND TRIM ARE REMOVED OR PULLED

ASIDE. MARK AND TAPE FRONT OF DOOR FRAMES, CONTINUING SAME ANGLE

AS ROOF LINE (SEE ILL. 9b), CUT ALONG TAPE GUIDES. CUT REAR DOOR

FRAME AT SAME LEVEL AS REAR PILLAR POST YOU JUST CUT.

NOTE: FOLLOWING STEPS SHOULD ONLY BE DONE AFTER LOWER REAR

CAB WALL IS CUT SO THAT CORNER OF CUTS ARE NOT COMPLETED UNTIL

REMAINING REAR CAB WALL CUTS ARE MADE.

10. OPEN DOORS AND CUT CORNERS THROUGH HEADER WITH HACKSAW ON

SAME LINE AND ANGLE SCRIBED ON ROOF AS USED EARLIER UNTIL YOU

REACH AIR SHEAR CUT. YOU NOW SHOULD BE ABLE TO LIFT OFF ROOF,

UNLESS YOUR TRUCK HAS 2ND LAYER OF METAL. YOU CAN REMOVE ROF

WITHOUT CUTTING THROUGH 2ND LAYER IF YOU USE A LOOSE HACKSAW

BLADE TO SEPARATE SILICOJNE BONDING THOSE LAYERS. NOW YOU CAN

LIFT OFF ROOF. NOW YOU TRIM 2ND LAYER OF METAL USING AIR SHEARS IN

SAME MANNER AS 1ST LAYER.

NOTE: BE SURE TO KEEP SAME ESTABLISHED 90 DEGREE ANGLE TO OP

SLOPE OF ROOF. USE A FLAT SURFACE SUCH AS WODEN BLOCK TO ENSURE

PROPER ANGLE AND AMOUNT TRIMMED.

11. LIFT OFF ROOF AND PLACE ON PROTECTED SURFACE, TRIM ENDS OF ROF

SECTION TO MATCH MATERIAL TRIMMED FROM CENTER (3/8"). AFTER

TRIMMING MATCH ROOF BACK UP TO TRUCK WITH REAR PILLAR CAPS

TEMPORARILY ON, BUT NOT FRONT BOWS, TO ENSURE YOU HAVE NO "HIGH

SPOTS" (LINE UP RAIN GUTTERS).

NOTE: IF YOU DO NOT PROPERLY ACCOMPLISH TRIMMING THE 3/8" METAL

OFF ROOF, YOUR TOP CAN NOT ALIGN CORRECTLY. PAY SPECIAL ATTENTION

TO THE CORNERS AND ANGLES TO MAKE SURE YOU HAVE AT LEAST 1/4"

CLEAR SPACE WITH RAIN GUTTERS IN ALIGNMENT AND WITHOUT FRONT

BOWS ON.

YOU ARE NOW READY TO PREPARE THE ROOF.

ARKED ON LEVEL GROUND. REMOVE ANY SIDE

DREW. MARK A LINE ON INSIDE OF CAB WALL BY LINING UP BTH

TO TAPE AND MASK REAR WINDOW

ART ROOF CUT BY MAKING STARTER SLOT AT

TO GET ASSISTANCE TO HOLD FRAME STEADY TO

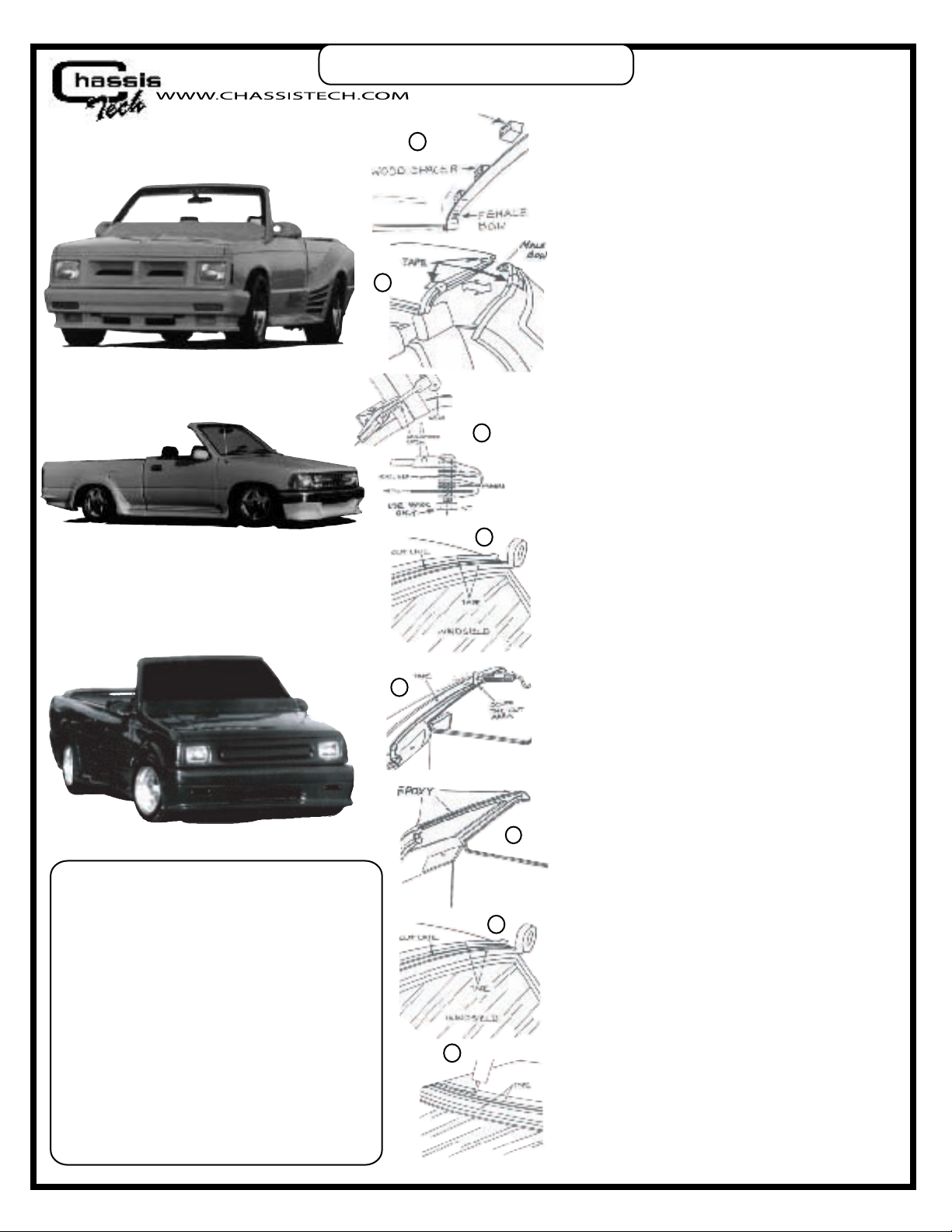

RATICAL HARD TOP INSTALL

22

WINDOW TRIM INSTALLATION

1. INSTALL TRIANGULAR SEAL INSIDE YOUR WINDOW CHANNEL, CUTTING

CORNERS TO 45 DEGREES FOR BEST FIT AND APPEARANCE.

2. REINSTALL ALL ORIGINAL TRIM AROUND INSIDE DOOR AREAS.

NOTE:

FOAM TRIM SUPPLIED IS FOR USE AT YOUR BEST DISCRETION TO

INSURE LEAKPROOF SEAL. PAY SPECIAL ATTENTION AT BOTTOM REAR OF

WINDOWS TO TRIM OR SUPER GLUE AS NEEDED TO AVOID WINDOW FROM

TEARING TRIM WHEN ROLLING UP. MAKE CORRECTIONS AS NECESSARY

FOR BEST FIT.

SEAL KIT INSTALLATION

(FOR FEMALE BOW)

1. MAKE SURE SURFACE IS FREE FROM ALL DIRT AND GREASE. INSTALL TOP

RUBBER SEAL FIRST, CONFORMING TO CURVATURE OF BOW AS

ILLUSTRATED. LEAVE APPROXIMATELY 1/3" HANGING OVER ENDS SO WATER

DOESN'T DRIP INTO CAP AT TOP OF WINDOW.

2. USE SUPER GLUE OR LOCKTITE TO

OTHER TYPE OF ADHESIVE. NOTE THAT BOTTOM SEAL DOES NOT CONFORM

TO CURVATURE FOR EASE OF INSTALLATION.

3. MAKE SURE TO

APPROXIMATELY 1/3" SO WATER WILL FOR A DRIP POINT AT END RATHER

THAN INTO TRUCK.

P

SEAL EXTENDS PAST END OF FEMALE BOW

GLUE IN POSITION. DO NOT

USE ANY

20. PRE-FITTING FEMALE BOW:

REMOVE WOOD SPACERS FROM FEMALE ABS BOW. DO NOT DISCARD! THEY

SERVE AN IMPORTANT ROLE KEEPING SPACE TO PREVENT GAP BETWEEN FEMALE

20

BOW AND ROOF ON TOP SIDE OF VEHICLE. SHIM THESE SPACERS AS NECESSARY

TO ELIMINATE ANY GAP. THEY WILL BE EPOXIED IN PLACE WHEN BONDING ROOF.

21. USING A

ASSISTANT, START AT EITHER END OF ROOF AND FIT FEMALE BOW TO

N

TOP, FITTING LEADING EDGE OF ROOF UNDER UPPER PORTION OF FEMALE BOW.

TEMPORARILY TAPE IN PLACE.

22. TEMPORARILY TAPE IN PLACE MALE PILLAR POST CAPS, MAKING SURE THEY

FIT

PROPERLY. LEAVE UPPER CAB WALL COVER UNTIL BONDING PARTS ON.

YOU A

RE NOW READY TO MAKE A FIT CHECK OF YOUR ROOF

NOTE: DO NOT EPOXY PARTS ON UNTIL YOU HAVE INSTALLED AND SECURED

LATCHES AND ARE SATISFIED WITH FIT.

23. PLACE ROOF ON T

RUCK INSER

TING FEMALE BOW OVER MALE BOW, THEN,

SETTING ROOF IN POSITION BY INTERLOCKING REAR PILLAR POST CAPS. GET

INSIDE VEHICLE AND HOLD LATCHES IN POSITION ON ROOF BEHIND FEMALE BOW.

YOU WILL ATTACH LATCH THROUGH HEADLINER AND PLASTIC TRIM, EXTEND

UPPER LATCH 3/4 OUT, WITH LATCH CLOSED, MAKE SURE LATCH HOOK REACHES

INTO WINDSHIELD HEADER AREA. MARK BOLT HOLE WITH MARKER.

24. REMOVE ROOF A

ND FEMALE BOW

, DRILL 1/4" LATCH BOLT HOLE WHERE

MARKED ON ROOF. INSTALL LATCH USING WASHERS AND BOLT IN EXACTLY SAME

WAY AS ILLUSTRATION.

25. PLACE ROOF IN PLACE AGAIN, THIS TIME TO INSTALL REAR LOWER LATCH.

INSTALL KEEPER FIRST, BUTTING UP TO ABS PLASTIC LOWER PILLAR CAP. THEN

24

INSTALL LATCH PORTION APPROXIMATELY 1 1/2" UP FROM UPPER ABS PILLAR CAP.

IF KEEPER PUSHES IN DURING ATTACHMENT, USE CLAW HAMMER TO LEVERAGE

OUT FOR ALIGNMENT. EXTEND UPPER LATCH 3/4 OUT, WITH LATCH CLOSED, PLACE

KEEPER IN APPROXIMATE LOCATION ON HEADER FOR LATCHING. TO MOUNT IN

PLACE, USE 3/16" RIVETS, THEN LATCH AND ADJUST. (DO NOT OVER TIGHTEN!!)

26. AT T

HIS TIME INSERT WOOD BLOCK UNDER FEMALE BOW AND SHIM TIGHTLY,

THIS WILL

ELIMINATE SPACE BETWEEN ROOF AND FEMALE BOW. TAPE AROUND

ALL PLASTIC CAPS AND BOWS ONCE YOU ARE SATISFIED WITH FIT. THIS WILL BE

26

PERMANENT LOCATION OF ALL PARTS ONCE YOU PERMANENTLY INSTALL THEM.

27. Y

OU CAN NOW PERMANENTLY INSTALL PLASTIC PARTS. FIRST LAY DOWN A

OF TAPE NEXT TO PARTS INDICATING FINISHED FIT LINE. DO NOT REMOVE

STRIP

TAPE UNTIL AFTER BONDING PART ON!! THIS WILL PROTECT PAINT FROM EPOXY

AND GIVE CLEAN FINISHED LOOK. REMOVE ALL ABS PLASTIC FROM TRUCK AND

ROOF. SCUFF AND PREPARE SURFACES, ESPECIALLY IN BOW AREAS. USE A DIE

GRINDER TO SCORE METAL, THIS PROMOTES GOOD ADHESION.

NOTE: READ INSTRUCTIONS ON EPOXY A

ALLOW AMPLE WORKING AND CURING

N

TIME BEFORE PROCEEDING. USING MORE CATALYST WILL SPEED CURE TIME IF

NEEDED. DO NOT USE RIVETS, URETHANE OR SILICONE TO ATTACH, THIS WILL

VOID WARRANTY.

28. PREPA

27

RE ALL SURFACES TO BE BONDED, INCLUDING ABS PLASTIC. MIX AMPLE

OF EPOXY TO COMPLETE JOB. WORK WITH AN ASSISTANT AND APPLY

AMOUNT

EPOXY TO PART AND BODY.

a

) 4 PILLAR POST CAPS

b

) MALE AND FEMALE BOWS

c) UPPER AND LOWER REAR CAB WALL COVERS

DO WINDOW FRAME END CAPS LAST

29. TA

PE MALE BOW IN PLACE, MAKING SURE IT IS FULLY SEATED. WE SUGGEST

YOU USE DUCT

TAPE AND DRAW A PIECE OVER FRONT WINDSHIELD AND ADHERE

,

AFTER COMPLETING INSTALL.

IT TO MIDDLE OF WINDSHIELD INSIDE. FIT FEMALE BOW TO ROOF SECTION AND

WITH AN ASSISTANT, REPLACE AND LATCH ROOF IN PLACE, ON TRUCK. MAKE

28

SPECIAL ATTENTION TO REINSTALL WOOD BLOCKS AND SHIM TIGHTLY IN FEMALE

BOW. THIS WILL DRAW BOW DOWN TIGHTLY TO ROOF SKIN, USE EPOXY TO

SECURE AND TIGHTLY LOCK IN PLACE.

30. REMOVE A

LL

TAPE, PULLING TOWARD YOU AND ACROSS PART. THIS GIVES A

CRISP LINE. VERIFY THAT ALL PARTS ARE IN PROPER POSITIONS AND PUT TRUCK

IN DIRECT SUNLIGHT FOR FASTER CURE TIME. DO NOT REMOVE TOP EARLY!!

29

REMOVE ALL EXCESS EPOXY AND ALL TAPE BEFORE EPOXY SETS UP.

31. Y

OU NOW MUST SEAL EVERYTHING WITH BLACK SILICONE. PUT STRIP OF DUCT

APE DOWN ADJACENT TO ALL ABS PARTS YOU INSTALLED. DRAW A STRIP OF

T

BLACK SILICONE DOWN ENTIRE SEAM AREA. USE FINGER TO COMPRESS SILICONE

INTO CREVICE TO MAKE SMOOTH SEAM. (WET FINGER FOR SMOOTH FINISH.)

32. REMOVE TA

PE IMMEDIA

TELY, PULLING TAPE TOWARD YOU (NOT AWAY) FROM

ABS PART. THIS WILL BE FOR CLEAN CRISP EDGE. PUT SILICONE ON BACK SIDE OF

MALE BOW ENDS AT LEAK POINT. USE SILICONE AT END OF RAIN GUTTER WHERE IT

MEETS MALE BOW.

31

NOTE: OPTIONAL, BUT TO

BACK-FILL CORNERS WITH BONDO. THIS WILL ALSO CREATE GOD INNER SEAL,

FINISH MALE BOW WITH PROFESSIONAL

LOOK YOU CAN

DEPENDING ON YOUR ABILITY TO WORK IT. WINDOW END CAP AND BACK OF MALE

BOW SHOULD BE AS CLOSE AS POSSIBLE WITHOUT INTERFERING WITH OPENING

AND CLOSING OF DOOR. FINISH OFF AND USE FLAT BLACK PAINT TO TOUCH UP.

YOU CAN ALSO CREATE YOUR OWN WATER SEAL AT BACK OF MALE BOW WHERE

END CAPS SEAT BY FILLING BACK OF BOW WITH RTV SILICONE THEN COATING END

CAP WITH GREASE SO PREVENT ITS ADHESION. GENTLY CLOSE DOOR AND LET

SET FOR SEVERAL HOURS, THEN FINISH TRIM.

Loading...

Loading...